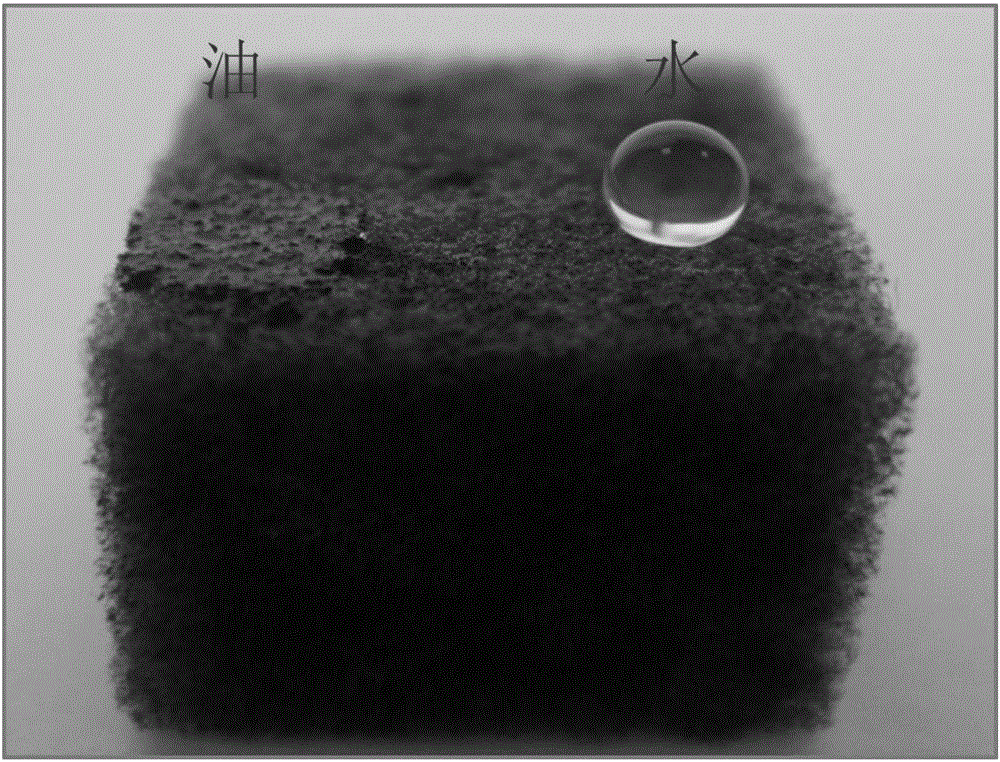

Super-hydrophobic reduced graphene oxide/sponge composite material and preparation method thereof

A composite material and graphene technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of harsh preparation conditions, poor stability, cumbersome process, etc., and achieve simple preparation process, short reaction time, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of superhydrophobic reduced graphene oxide / melamine sponge composite material comprises the following steps:

[0032] 1) Pretreatment of substrate (sponge)

[0033] Soak a melamine sponge (3cm×2cm×2cm) in absolute ethanol solution, ultrasonically clean it, rinse it with water after taking it out, dry it after taking it out, and set aside;

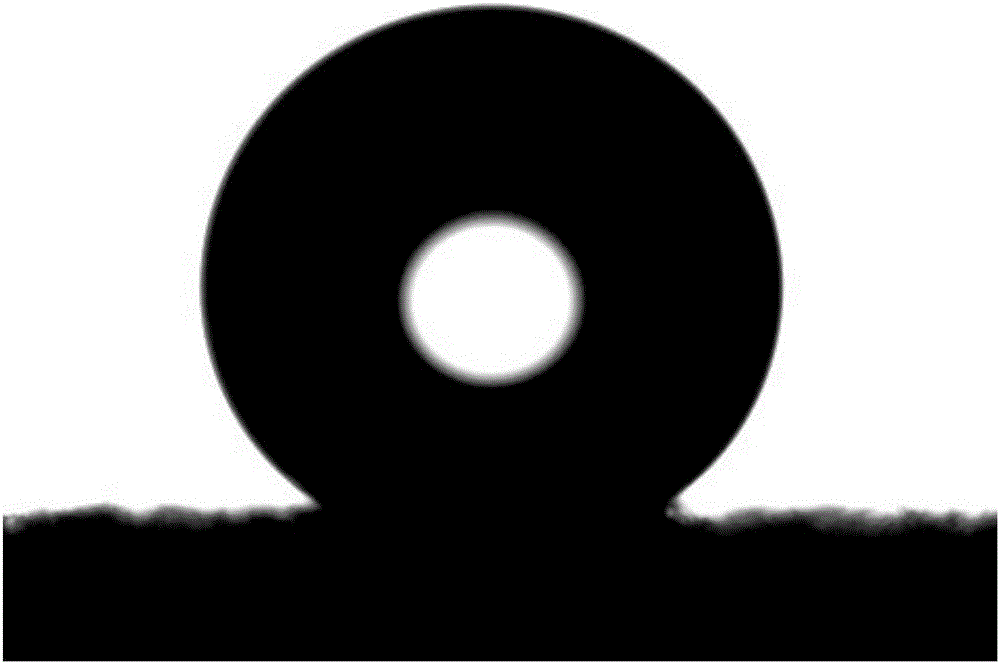

[0034] 2) Preparation of superhydrophobic reduced graphene oxide / melamine sponge composite

[0035] Weigh 100mg of graphite oxide and dissolve it in 50mL of water, and ultrasonically disperse it evenly for 10min to obtain a graphene oxide solution with a concentration of 2.0mg / mL, then add 2.0mL of ethylenediamine, and then pour the above mixed solution into microwave-ultrasonic reaction In the reactor, the microwave power is 400W, the ultrasonic power is 750W, and the solution is boiled and refluxed. After reacting for 40 minutes, the sponge pretreated in step 1) is put into the mixed solution of the reactor,...

Embodiment 2

[0039] The preparation method of superhydrophobic reduced graphene oxide / polyurethane sponge composite material comprises the following steps:

[0040] 1) Pretreatment of substrate (sponge)

[0041] Soak the polyurethane sponge (3cm×2cm×2cm) in anhydrous ethanol solution, clean it ultrasonically, rinse it with water after taking it out, dry it, and set it aside;

[0042] 2) Preparation of superhydrophobic reduced graphene oxide / polyurethane sponge composites

[0043]Weigh 50 mg of graphite oxide and dissolve it in 50 mL of water, and disperse it evenly by ultrasonication for 5 minutes to obtain a graphene oxide solution with a concentration of 1.0 mg / mL, then add 1.0 mL of ethylenediamine, and then pour the above mixed solution into microwave-ultrasonic reaction In the reactor, the microwave power is 300W, the ultrasonic power is 700W, and the solution is boiled and refluxed. After reacting for 30 minutes, the sponge pretreated in step 1) is put into the mixed solution of the...

Embodiment 3

[0046] The preparation method of superhydrophobic reduced graphene oxide / polyester sponge composite material comprises the following steps:

[0047] 1) Pretreatment of substrate (sponge)

[0048] Soak the polyester sponge (3cm×2cm×1cm) in anhydrous ethanol solution, ultrasonically clean it, rinse it with water after taking it out, dry it, and set it aside;

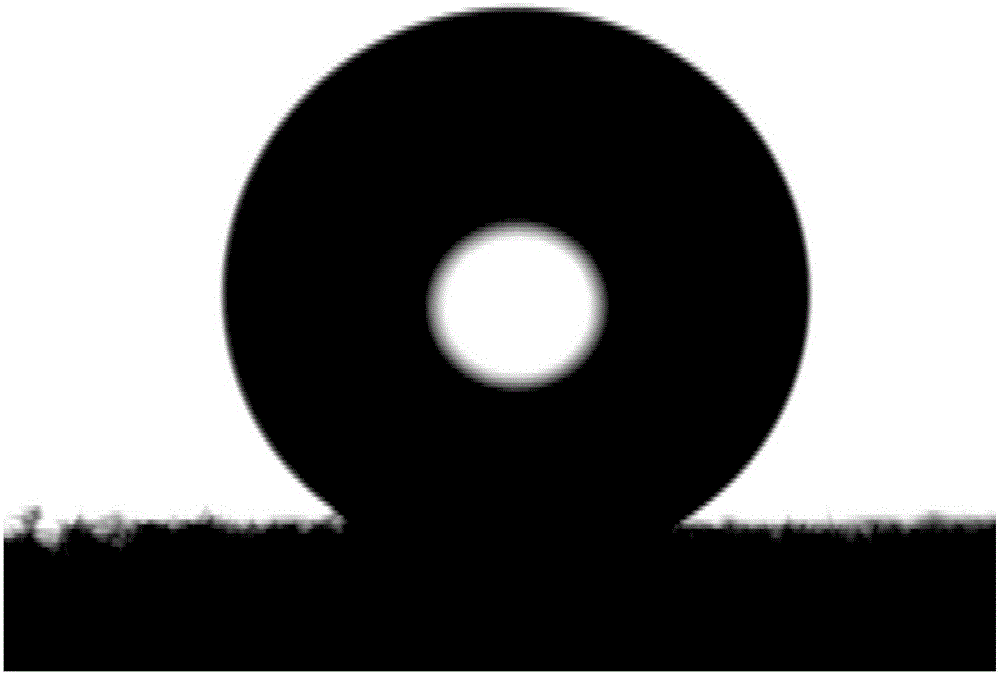

[0049] 2) Preparation of superhydrophobic reduced graphene oxide / polyester sponge composites

[0050] Weigh 150 mg of graphite oxide and dissolve it in 50 mL of water, and disperse it evenly by ultrasonication for 15 minutes to obtain a graphene oxide solution with a concentration of 3.0 mg / mL, then add 3.5 mL of ethylenediamine, and then pour the above mixed solution into microwave-ultrasonic reaction In the reactor, the microwave power is 400W, the ultrasonic power is 900W, and the solution is boiled and refluxed. After reacting for 50 minutes, the sponge pretreated in step 1) is put into the mixed solution of the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com