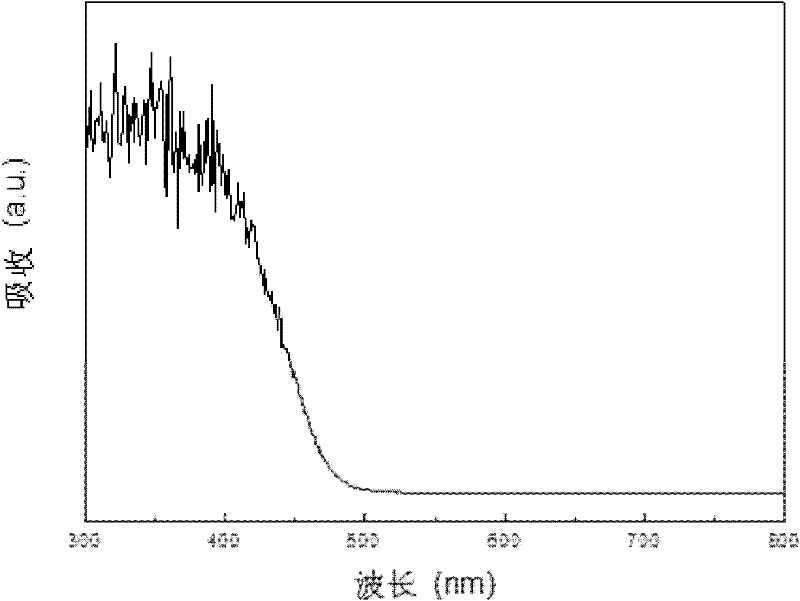

A kind of synthesis method and application of nano zinc cadmium sulfide with visible light catalytic activity

A nano-zinc sulfide, catalytically active technology, applied in cadmium sulfide, chemical instruments and methods, nanotechnology, etc., can solve the problems of long reaction time and high reaction temperature, and achieve the effects of short synthesis time, high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

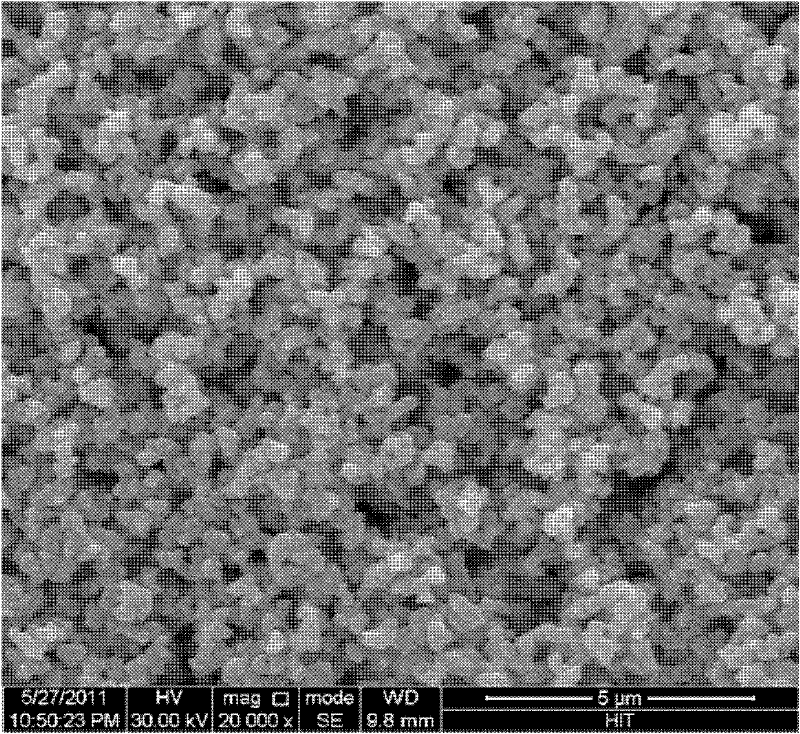

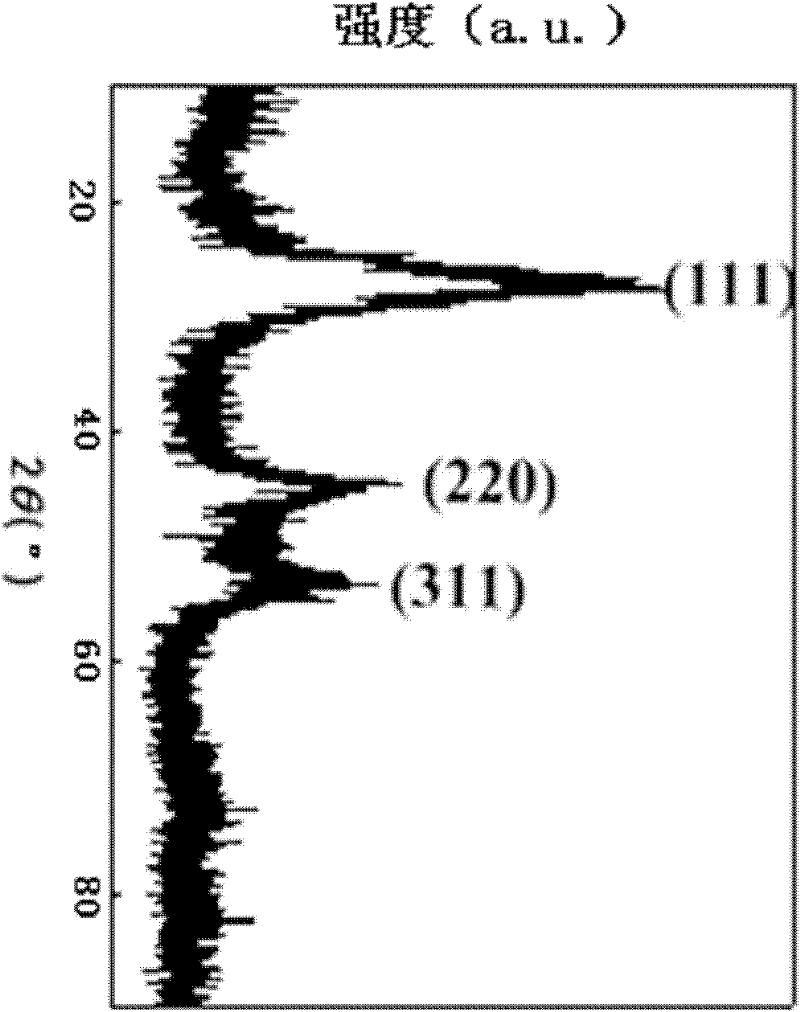

[0014] Specific embodiment one: present embodiment is a kind of synthesis method with visible light catalytic activity nano-zinc cadmium sulfide, it is realized by following steps: 1. Weigh Zn(Ac) 2 2H 2 O, Cd(Ac) 2 2H 2 O, thioacetamide (TAA) and sodium dodecylbenzenesulfonate (SDBS), control Zn(Ac) 2 2H 2 O and Cd(Ac) 2 2H 2 The molar ratio of O is 1:1.5, Zn(Ac) 2 2H 2 The molar ratio of O to thioacetamide is 1:5, Zn(Ac) 2 2H 2 The molar ratio of O to sodium dodecylbenzenesulfonate is 1: 0.023~0.0347; 2. The Zn(Ac) taken in step 1 2 2H 2 O and Cd(Ac) 2 2H 2 Add O into the alcohol solvent, stir and dissolve to obtain solution A, then add the thioacetamide and sodium dodecylbenzenesulfonate weighed in step 1 into the alcohol solvent, stir and dissolve, and then ultrasonically disperse for 5-10 minutes to obtain solution B. Then mix solution A and solution B to obtain a mixed solution; 3. React the mixed solution under normal pressure at 64-66°C and 100-200W for 10...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that the alcohol solvents used in solution A and solution B in step 2 are all ethylene glycol, ethanol, methanol or glycerol. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 3, the mixed solution is reacted under normal pressure at 65°C and 120-180W for 12-16 minutes. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com