Patents

Literature

175results about How to "Fully crystallized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

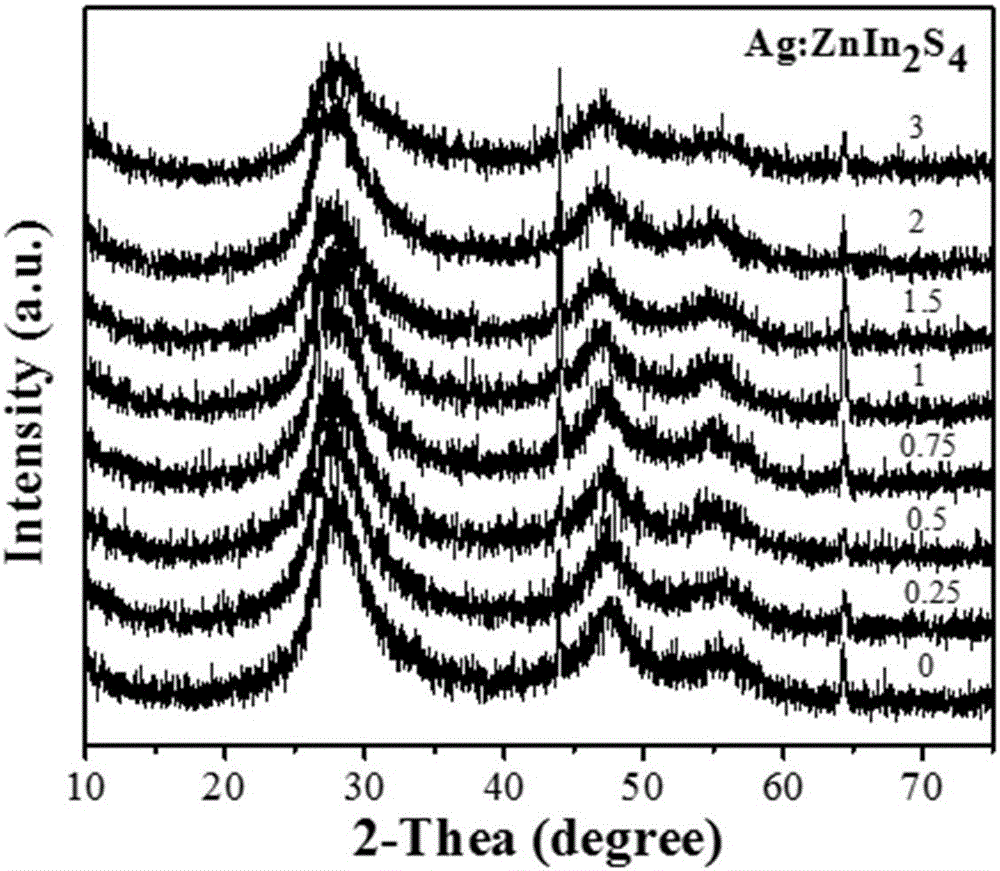

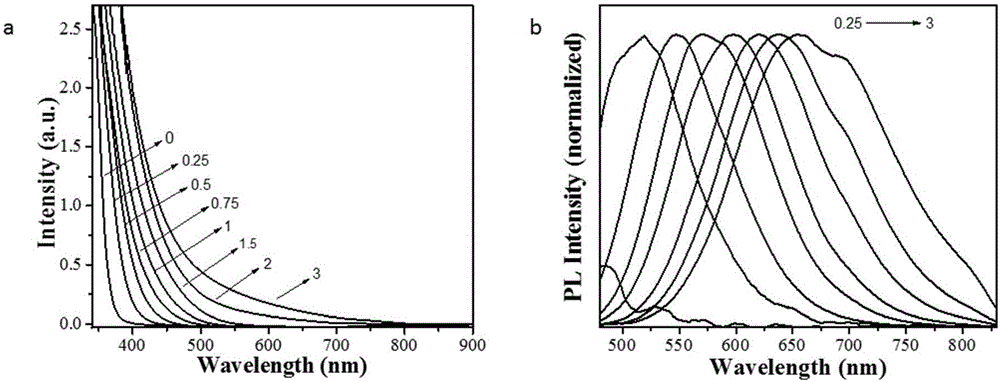

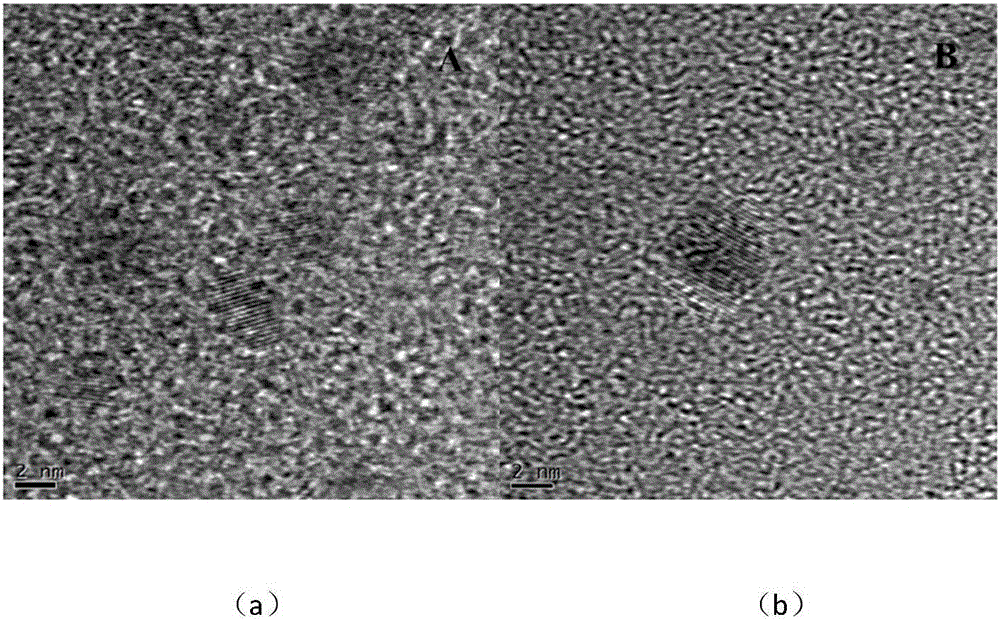

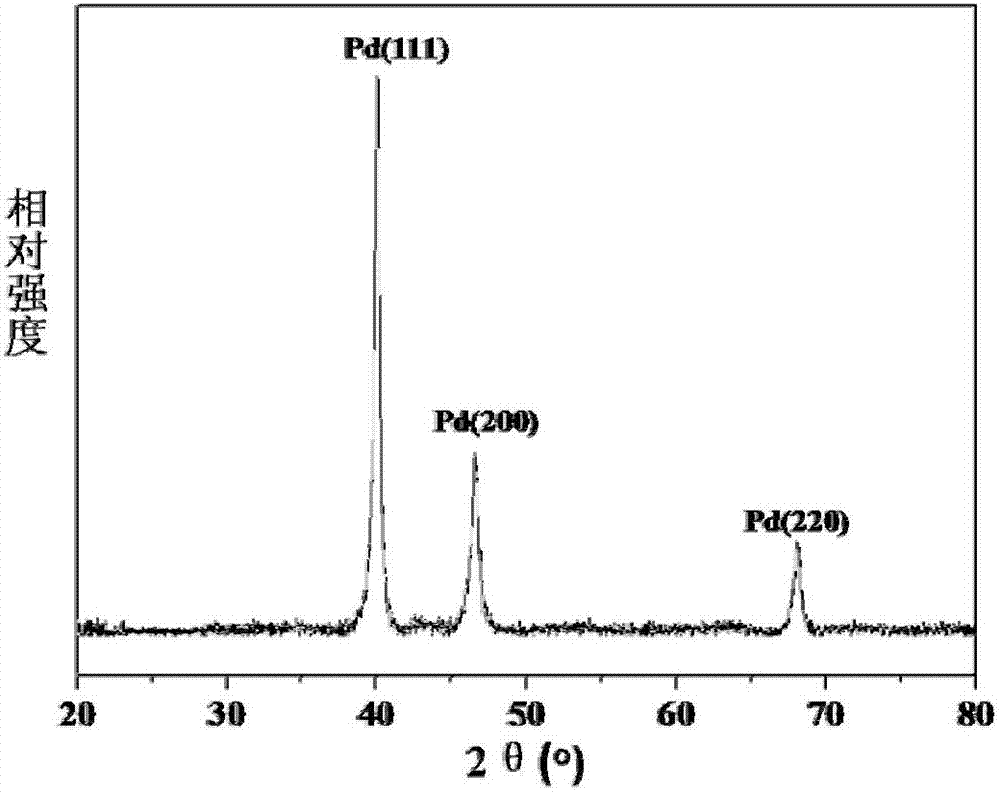

Method for preparing Ag:ZnIn2S4 luminescent quantum dots and photocatalyst

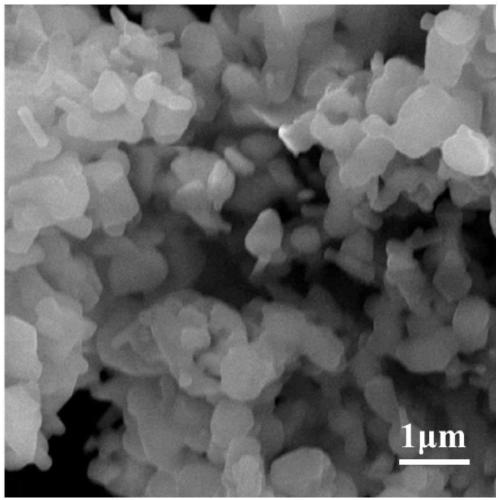

InactiveCN105950140AFully crystallizedGood dispersionMaterial nanotechnologyPhysical/chemical process catalystsFluorescenceZinc Acetate Dihydrate

The invention relates to the field of synthesis of nano-materials and particularly relates to a method for synthesizing a series of Ag:ZnIn2S4 luminescent quantum dots by using a simple and rapid hydrothermal method in one step. Fluorescence is adjustable in the range of 460nm to 830nm, the fluorescent life is relatively long, and the luminescent quantum dots can be applied to water-decomposed hydrogen production under visible light. The method comprises the steps of firstly, mixing and dissolving silver nitrate, indium nitrate, zinc acetate dihydrate and L-cysteine in an aqueous solution, adjusting the pH value of the solution to 8.5 by using NaOH, adding thioacetamide into the solution, carrying out ultrasonic stirring, then, carrying out a hydrothermal reaction for 4 hours at the temperature of 110 DEG C, and carrying out centrifugal drying after the reaction ends, thereby obtaining Ag@ZnIn2S4 nanocrystals of different ratios. Proven by a photocatalytic hydrogen production experiment under the visible light, the prepared composite photocatalyst has good photocatalytic activity.

Owner:JIANGSU UNIV

Extrusion casting method for wrought aluminum alloy lampshade

The invention provides an extrusion casting method for a wrought aluminum alloy lampshade. The extrusion casting method comprises the following steps of S1, preparing an aluminum alloy precursor; S2, adding the aluminum alloy precursor into a smelting furnace, and heating to 690-710 DEG C until the aluminum alloy precursor is completely molten to obtain molten aluminum, introducing nitrogen or mixed inert gas to the molten aluminum by rotary blowing equipment for refining, purifying and skimming; S3, regulating the smelting temperature to 710-730 DEG C, and adding an AlSr alterant to react for 10-30 minutes; and then, regulating the smelting temperature to 700-720 DEG C again, adding an AlTiB grain refiner, uniformly stirring for 5-10 minutes, and next, adding a hexachloroethane refining agent to react, and skimming after ending to obtain refined molten aluminum; S4, pouring the refined molten aluminum into a die cavity, and carrying out extrusion casting to obtain a cast-state casting; and S5, carrying out thermal treatment on the cast-state casting to obtain the wrought aluminum alloy lampshade. The wrought aluminum alloy lampshade prepared by using the extrusion casting method is compact in tissue and high in corrosion resistance, tensile strength and elongation percentage.

Owner:东台城东科技创业园管理有限公司

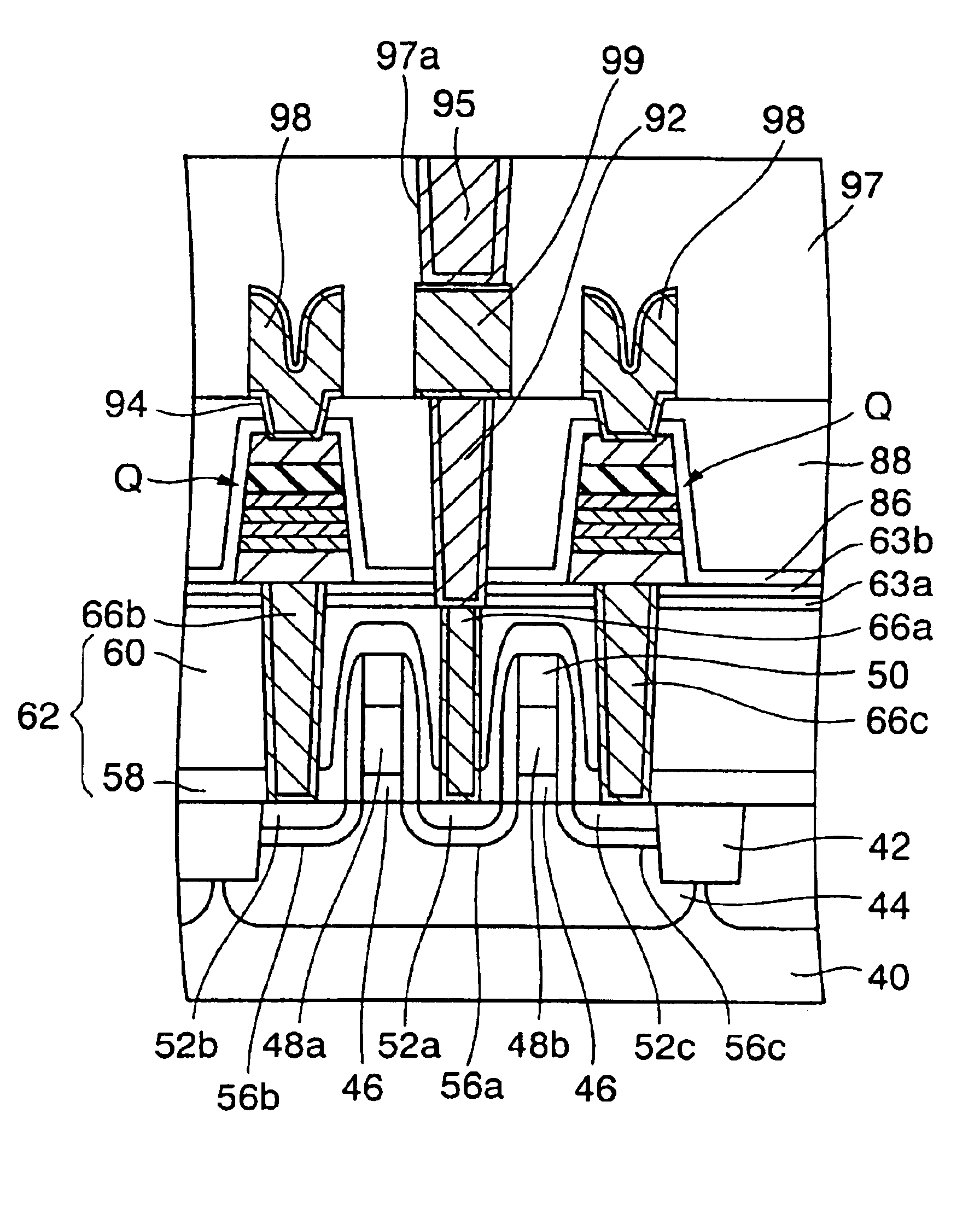

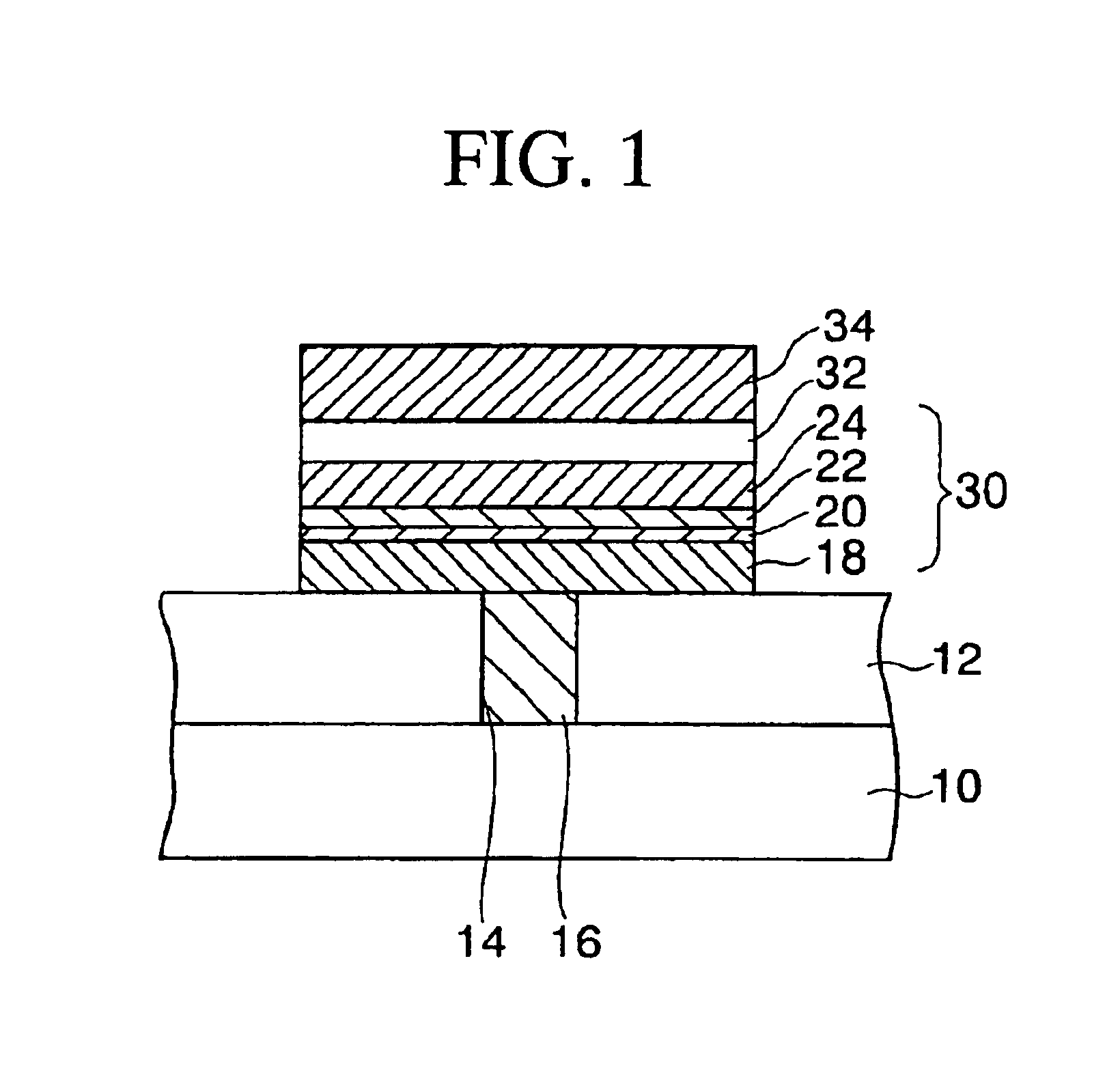

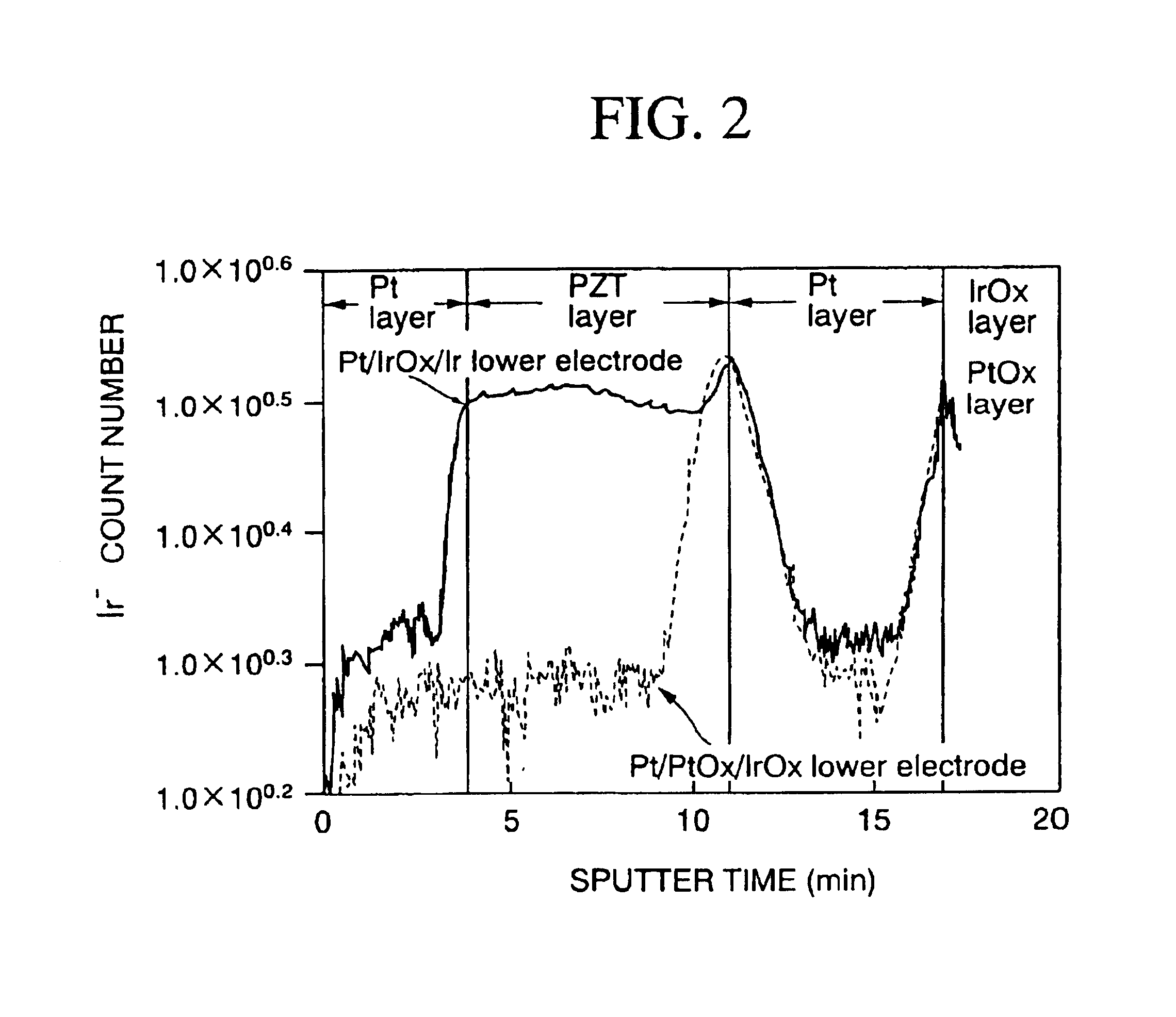

Semiconductor capacitor with diffusion prevention layer

InactiveUS6933156B2Avoid conductionInhibited DiffusionTransistorSemiconductor/solid-state device detailsDielectric layerSemiconductor

A capacitor which has a lower electrode having a structure in which the first conductive layer containing a first metal, a second conductive layer that is formed on the first conductive layer and made of the metal oxide of the second metal different from the first metal, and a third conductive layer that is formed on the second conductive layer and made of a third metal different from the first metal. These layers are formed sequentially. A dielectric layer is formed on the lower electrode, and an upper electrode is formed on the capacitor dielectric layer.

Owner:FUJITSU SEMICON LTD

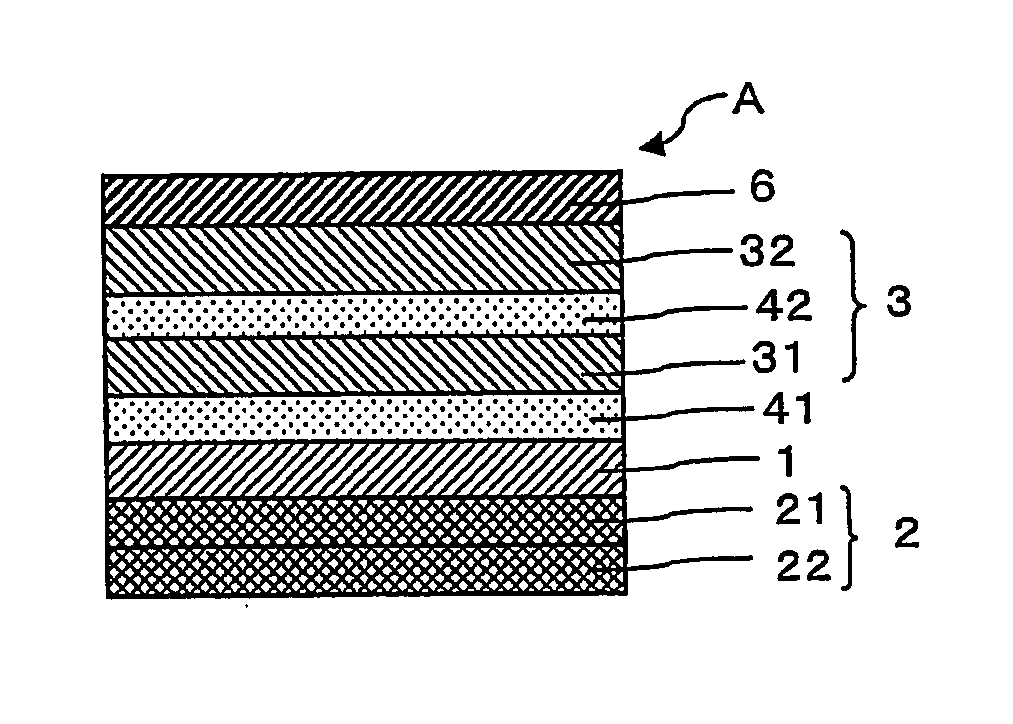

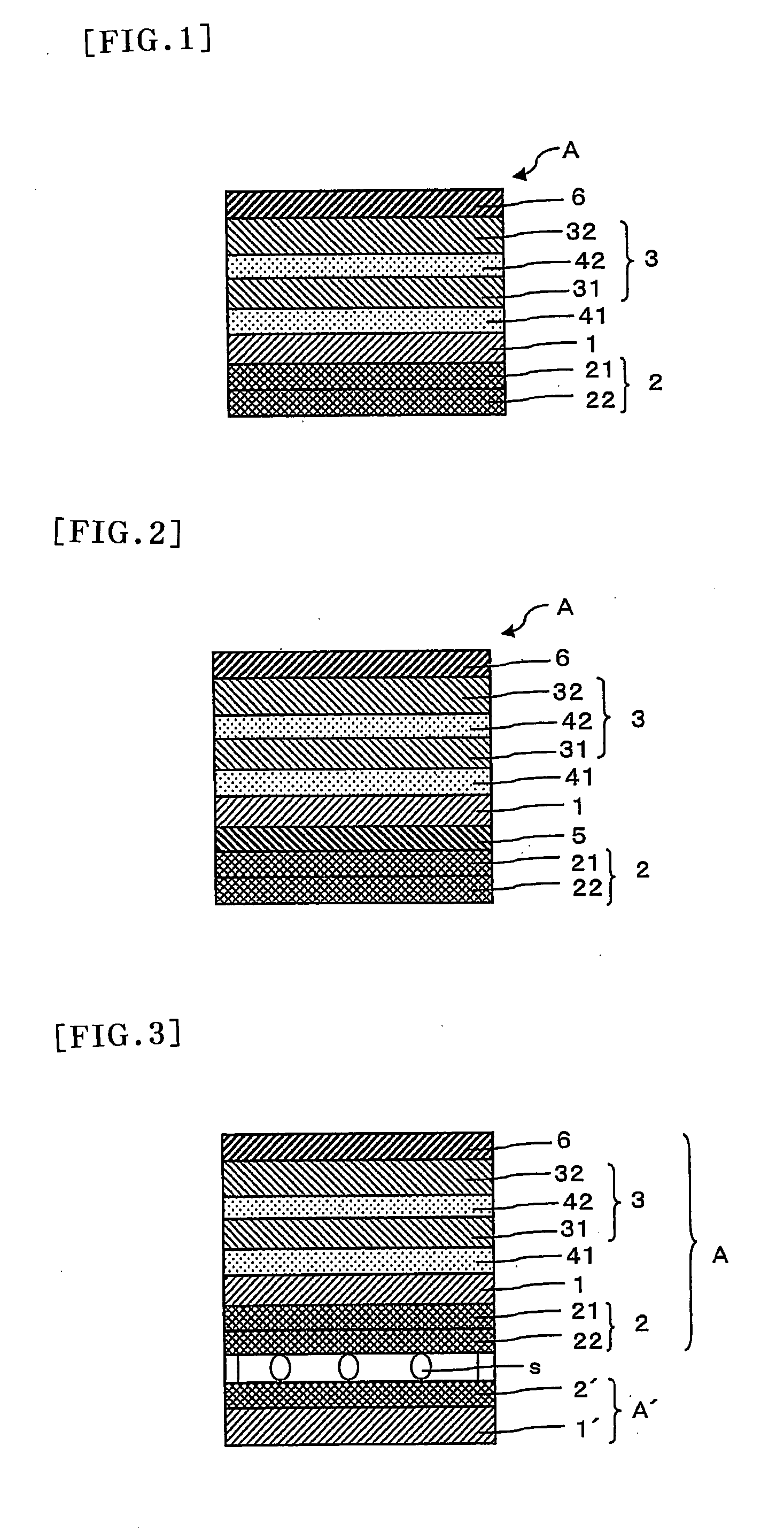

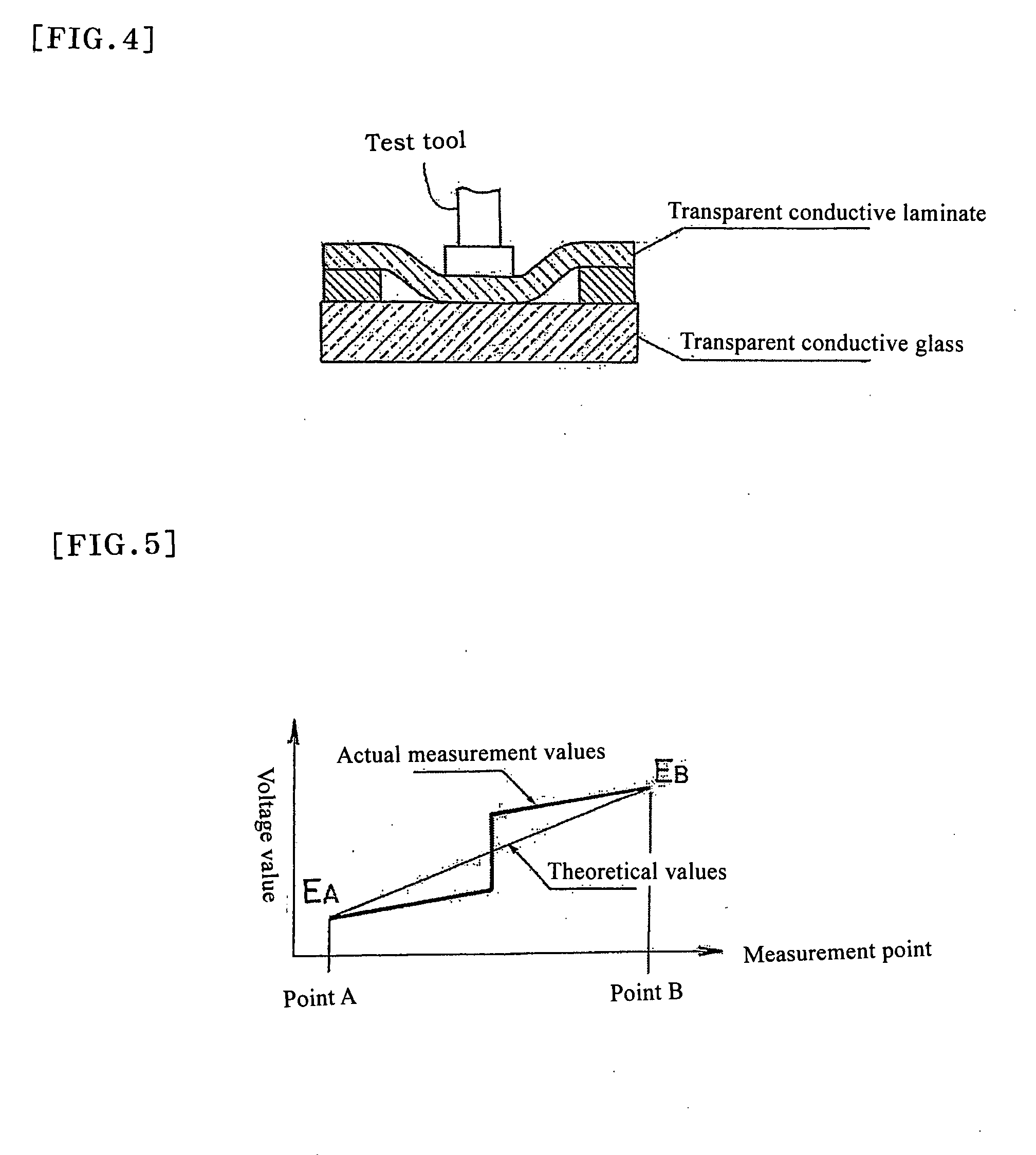

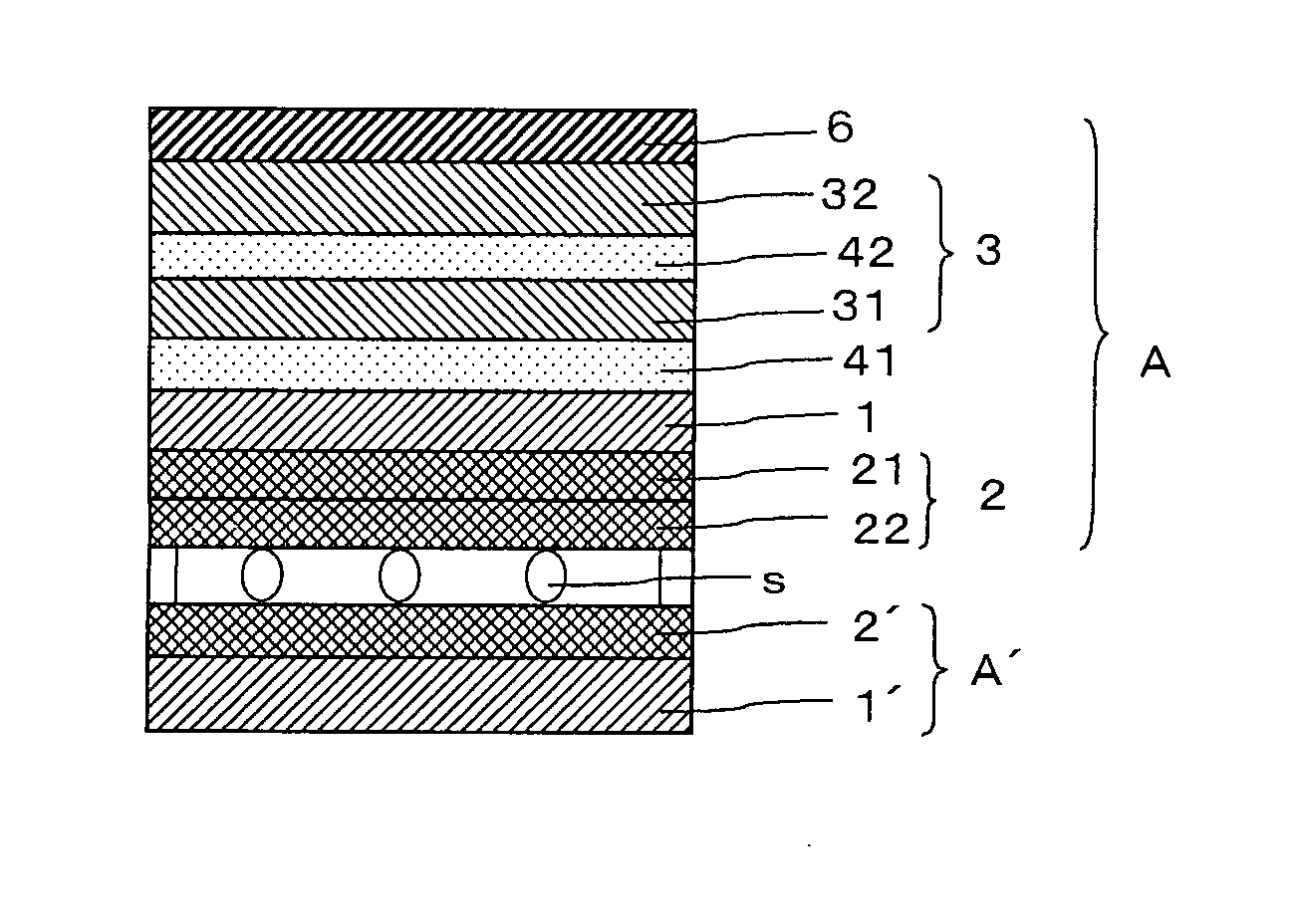

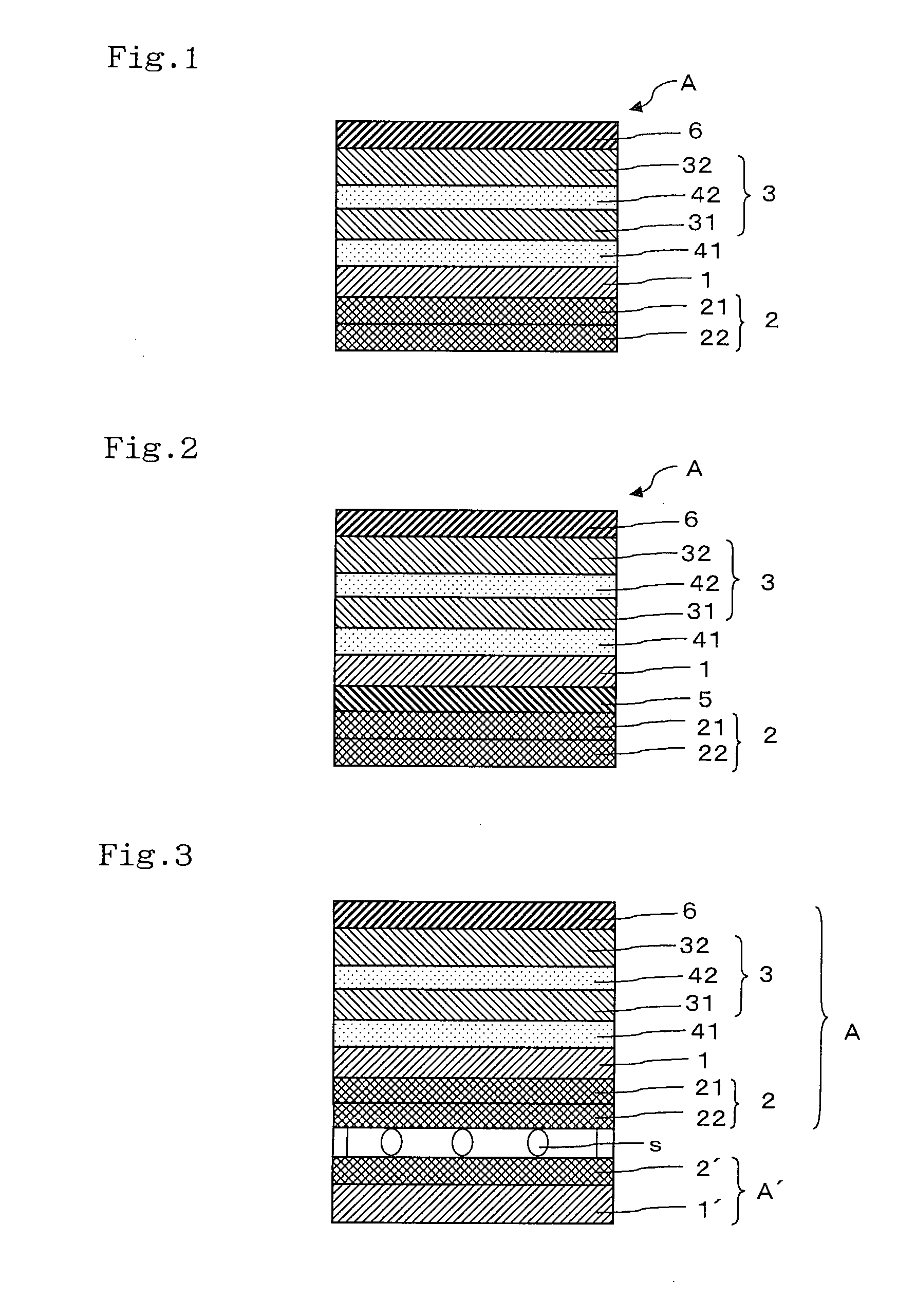

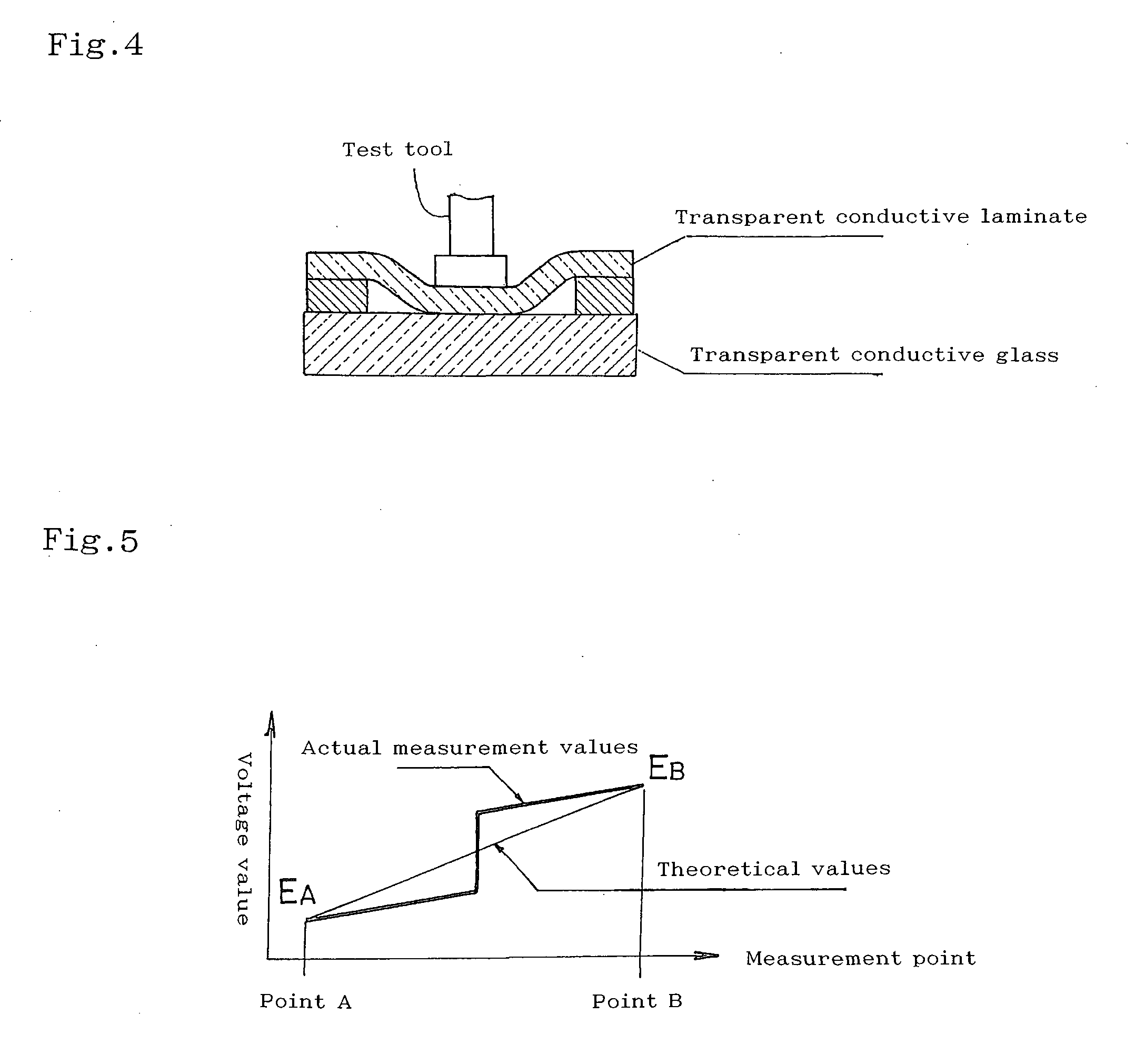

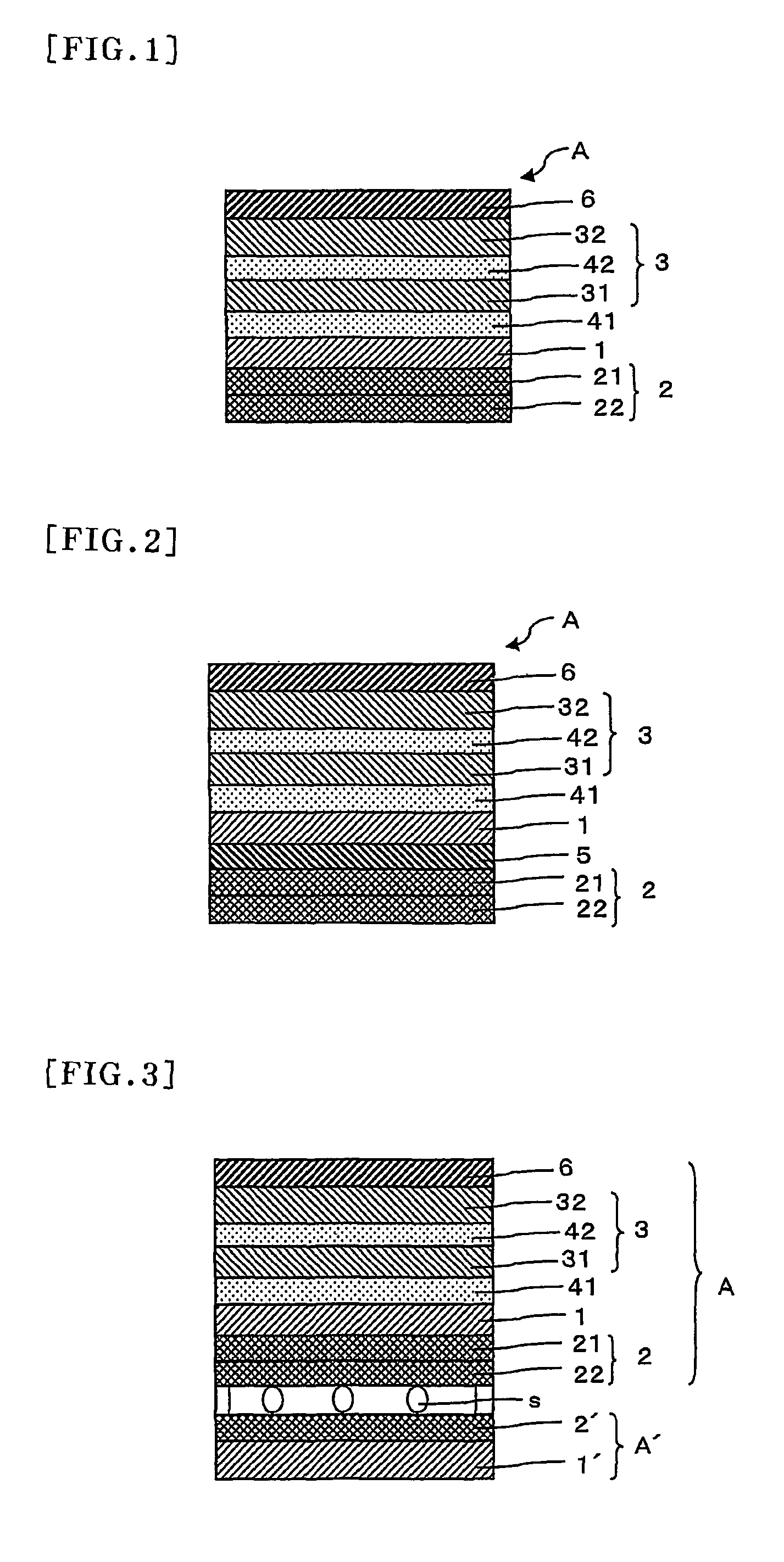

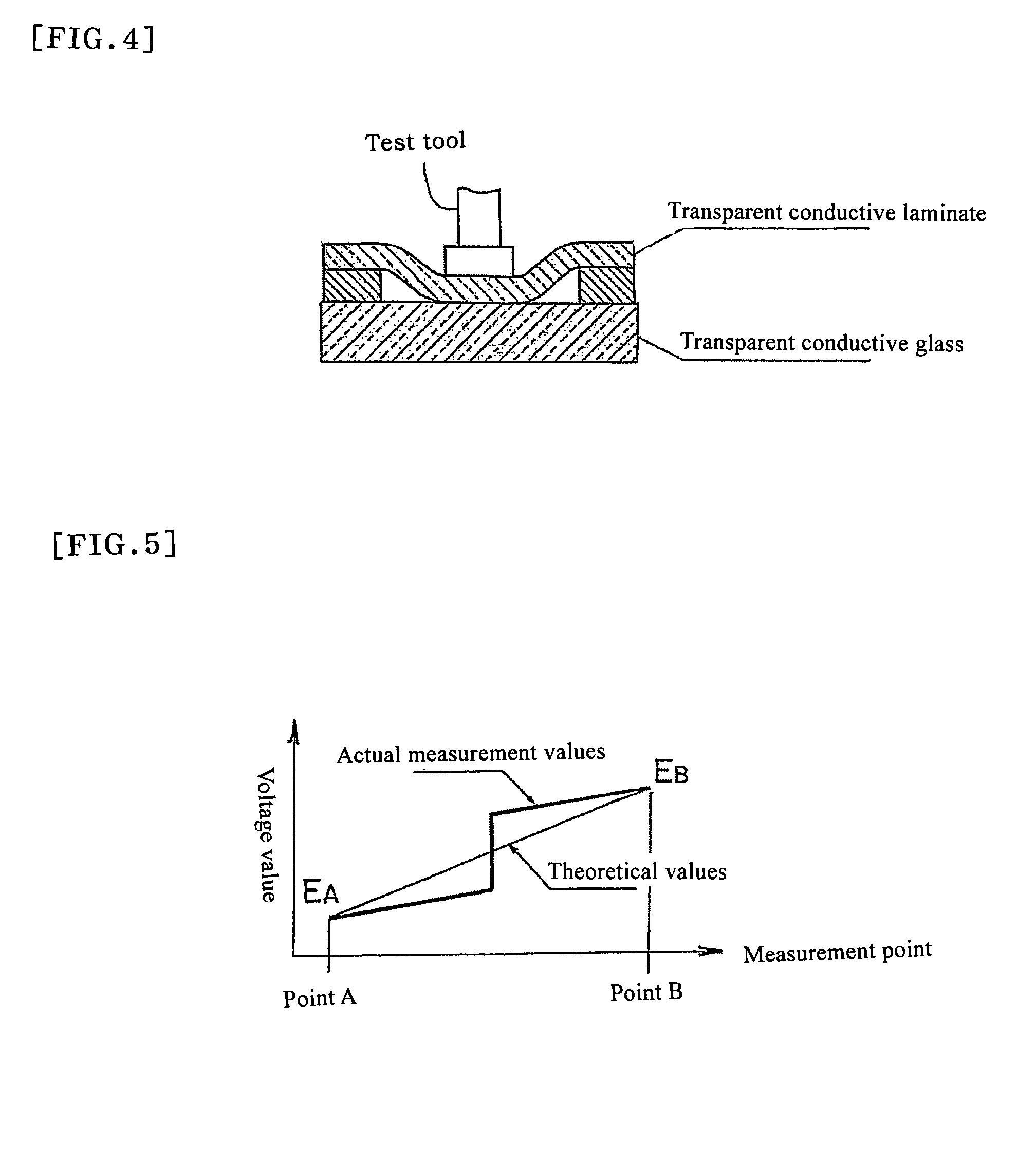

Transparent conductive laminate and touch panel therewith

ActiveUS20080261030A1High reliabilityImproved pressureConductive layers on insulating-supportsSynthetic resin layered productsPressure sensitiveTouch panel

Owner:NITTO DENKO CORP

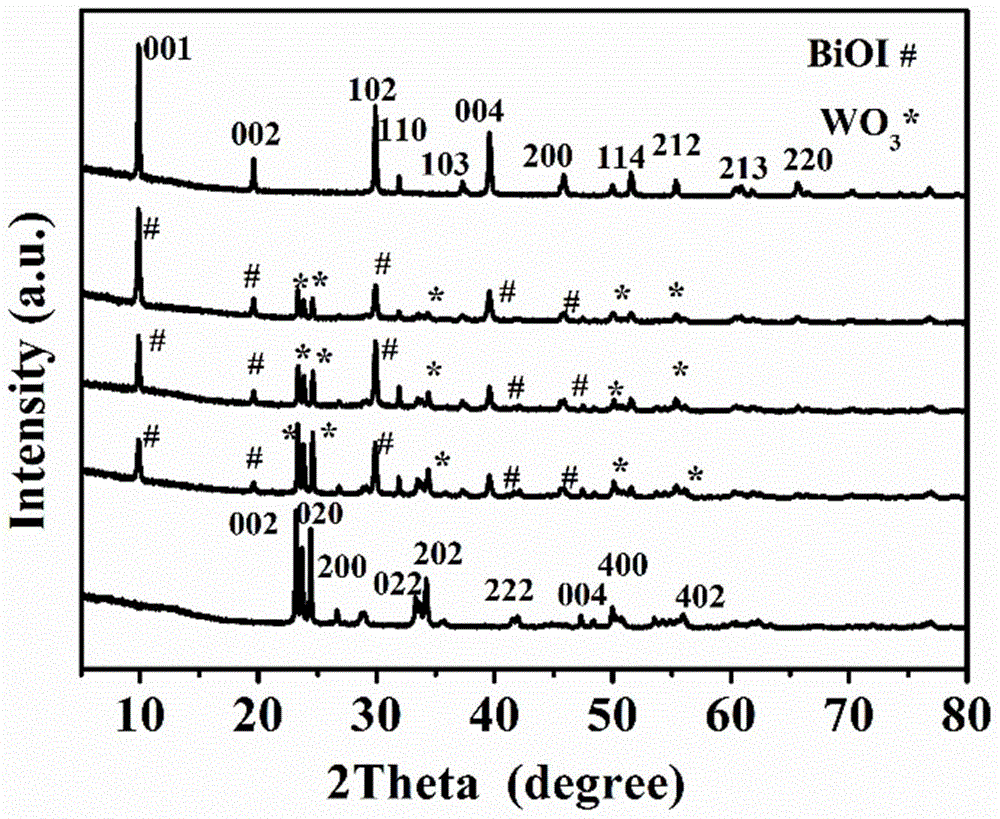

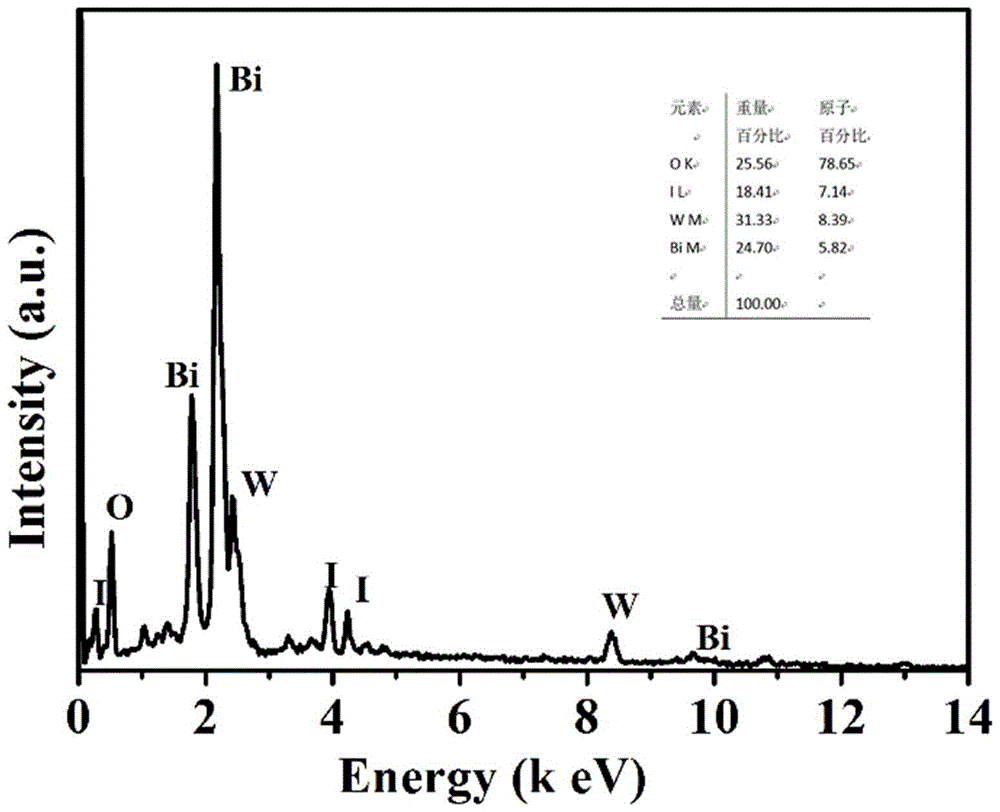

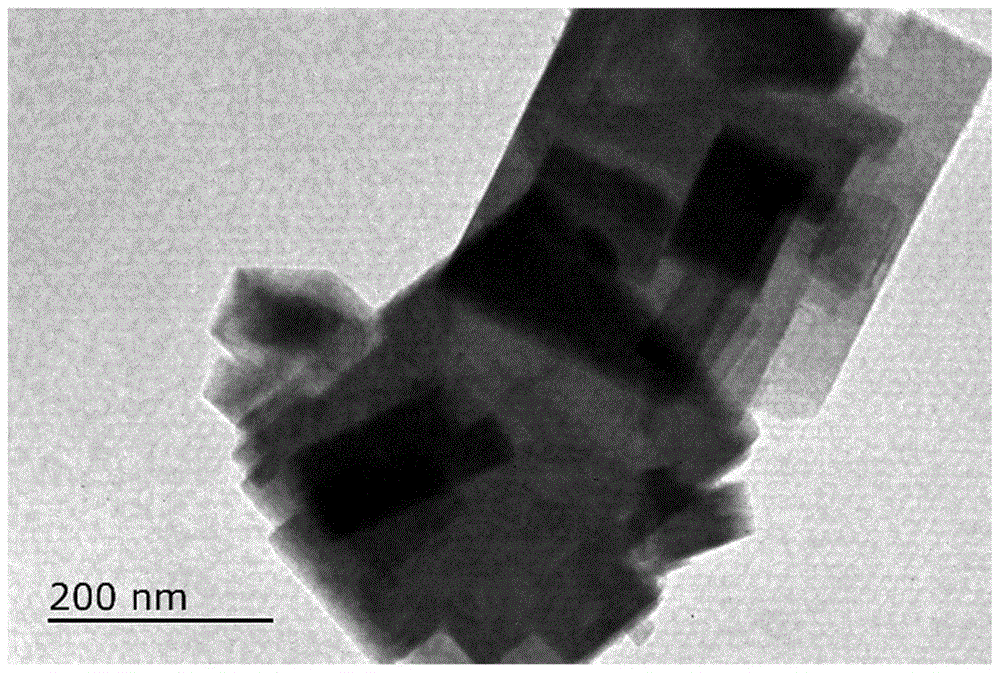

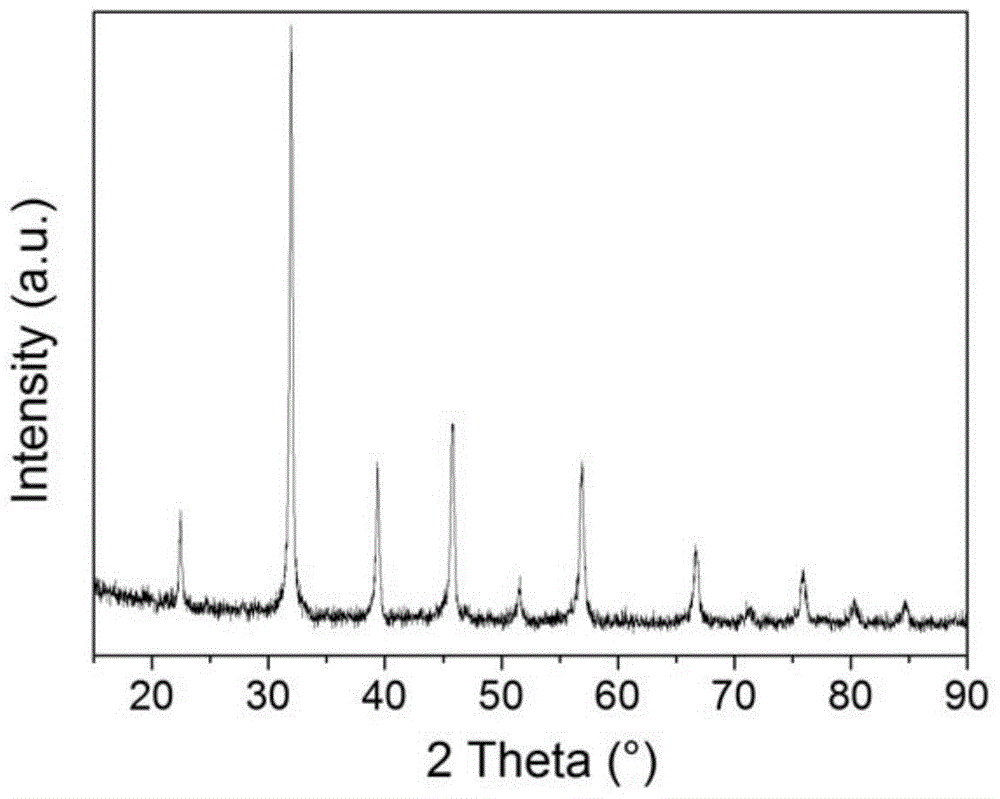

Method for preparing BiOI/WO3 composite heterojunction photocatalyst

InactiveCN105688953AFully crystallizedMorphological rulesPhysical/chemical process catalystsIonPotassium iodine

The invention relates to the technical field of preparation of heterojunction composite photocatalysts, in particular to a method for preparing BiOI / WO 3 A method for heterojunction composite photocatalysts. Disperse tungsten oxide in deionized water, add potassium iodide and bismuth nitrate, stir and mix evenly, filter and wash, and then obtain BiOI / WO 3 Heterojunction composite photocatalysts. The prepared nanocomposite photocatalysts have excellent visible light catalytic activity, especially bismuth nitrate and WO 3 The sample with a molar ratio of 1.0 has the best activity in degrading rhodamine B, and the degradation rate reaches 92% after visible light reaction for 100min, which is higher than that of pure BiOI and WO 3 high degradation activity.

Owner:JIANGSU UNIV

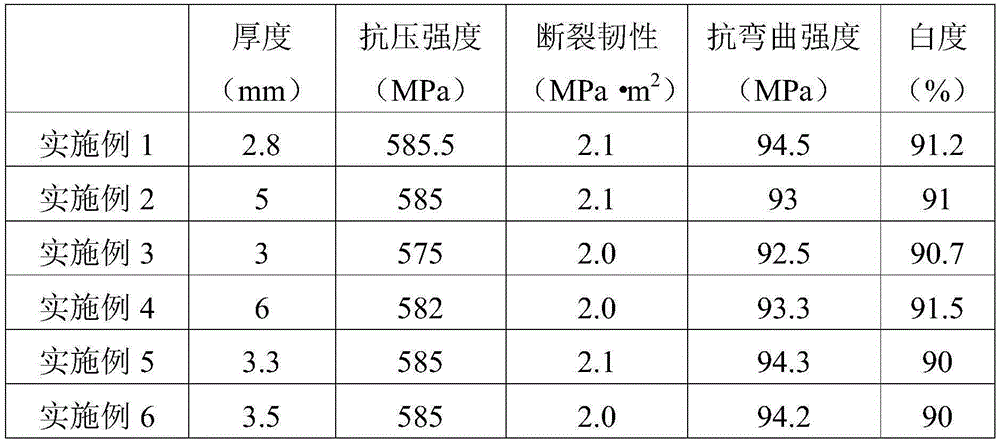

Preparation technology for glass ceramics sheet

ActiveCN105271642AImprove bending abilitySolve technical problems that are easily deformedGlass rolling apparatusFlexural strengthNucleation

The invention discloses a preparation technology for a glass ceramics sheet. The preparation technology includes the steps that 1, SiO2, Al2O3, K2O, Na2O, CaO, MgO, F and a clarifying agent are weighed to obtain batch; 2, the batch is added into a melting furnace, the melting temperature is controlled to be 1510 DEG C-1520 DEG C, and the melted batch is clarified on the stirring condition to generate glass melt; 3, the glass melt enters a three-roll roller press to be rolled and calendered to form a glass plate; 4, the glass plate enters a roller kiln, and a glass ceramics sheet is obtained through primary nucleation, intensified nucleation and crystallization; 5, annealing, cooling, polishing and trimming are carried out on the obtained glass ceramics sheet to obtain the glass ceramics sheet product. The thickness of the glass ceramics sheet prepared through the preparation process according to the component content is 2-10 mm, the technical effect of bending resistance of the sheet in the production technical process is achieved, bending resistance and compressive strength are high, industrialization of the glass ceramics sheet is achieved, and market promotion is easy.

Owner:JIANGXI XINFENG MICROCRYSTALLINE JADE CO LTD

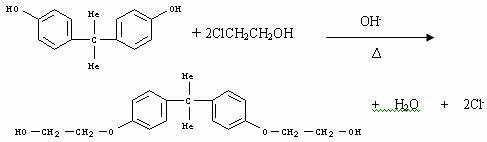

Preparation method of bisphenol A epoxy ethane additive product

ActiveCN102531855AGood reaction selectivityHigh yieldEther preparation from oxiranesMother liquorBisphenol A

The invention discloses a preparation method of a bisphenol A epoxy ethane additive product. The method comprises the following steps of: dissolving 1 mole of bisphenol A and 0.001-0.1 mole of trialkylamine catalyst into 2-10 mole of ether solvent of which the temperature is 80-150 DEG C, and dropwise adding 2.05-2.30 mole of epoxy ethane which can be dissolved into 5-10 mole of n-hexane or n-heptane at the same temperature; and after reacting, slowly cooling to 0-30 DEG C for crystalizing, filtering, washing n-hexane or n-heptane, and performing vacuum drying to obtain 2 mole of bisphenol A-added epoxy ethane product of which the content is over 98 percent. After n-hexane or n-heptane is separated out of a crystalized mother liquor through normal-pressure or reduced-pressure rectification, the crystalized mother liquor can be taken as an ether solvent containing a catalyst for use in a next reacting process. The method has the advantages of high reaction selectivity, high yield, circular usability of the catalyst and suitability for industrial production.

Owner:ZHEJIANG UNIV +1

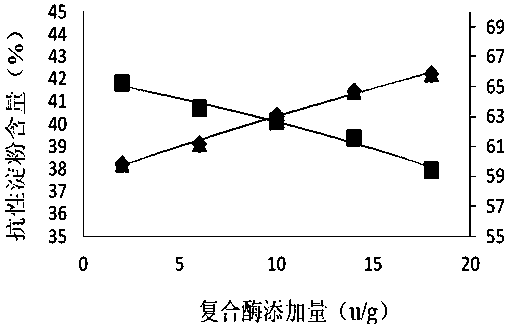

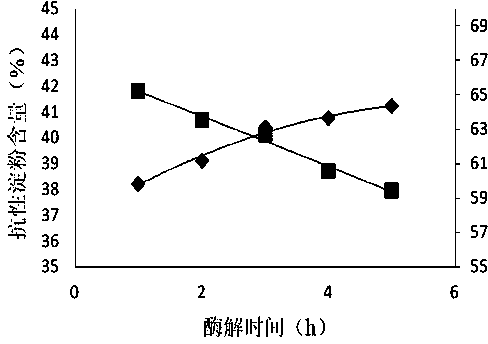

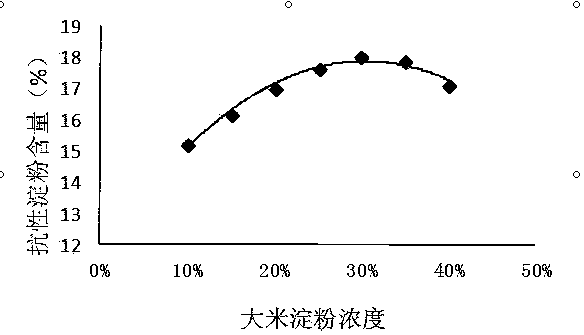

Production method for preparing resistant rice starch

ActiveCN103918872ARealize industrial productionImprove the utilization level of deep processingProtein foodstuffs working-upAmylaseDietary fiber

The invention relates to a production technology of resistant rice starch. A production method for preparing resistant rice starch comprises the following steps: firstly, gelatinizing, debranching and crystallizing the rice starch, and then drying the extracted resistant rice starch to obtain the resistant rice starch; improving the content of amylase in the rice starch by debranching treatment; controlling the concentration of the gelatinized rice starch at 20-50%, the debranching enzyme content at 12-25U / g, the debranching temperature at 45-55 DEG C and the debranching time at 12-20 hours; crystallizing under the condition of 2-12 DEG C after debranching is ended, and then extracting the resistant rice starch, and drying under the condition of 50-70 DEG C. The excessive rice resources such as broken rice and early indica rice can be reasonably utilized, the economic value of the potential resources is increased, and the produced resistant rice starch can overcome the defects of the traditional dietary fibers. By adopting the production method disclosed by the invention, the deep processing utilization level of the rice starch in China can be improved, and the method has important significance on development of grain storage enterprises and rural economy.

Owner:HENAN MINGYE BIOTECH

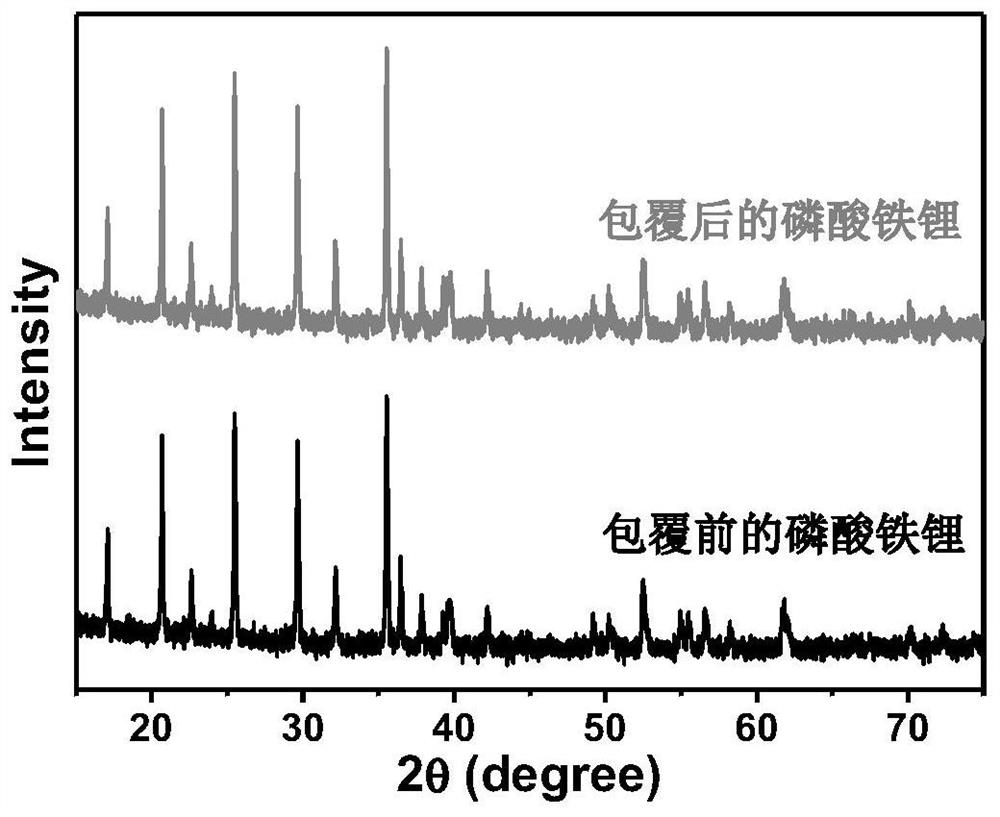

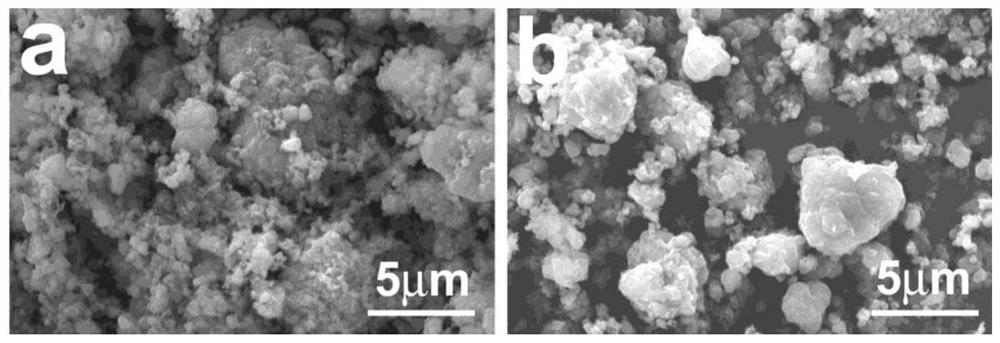

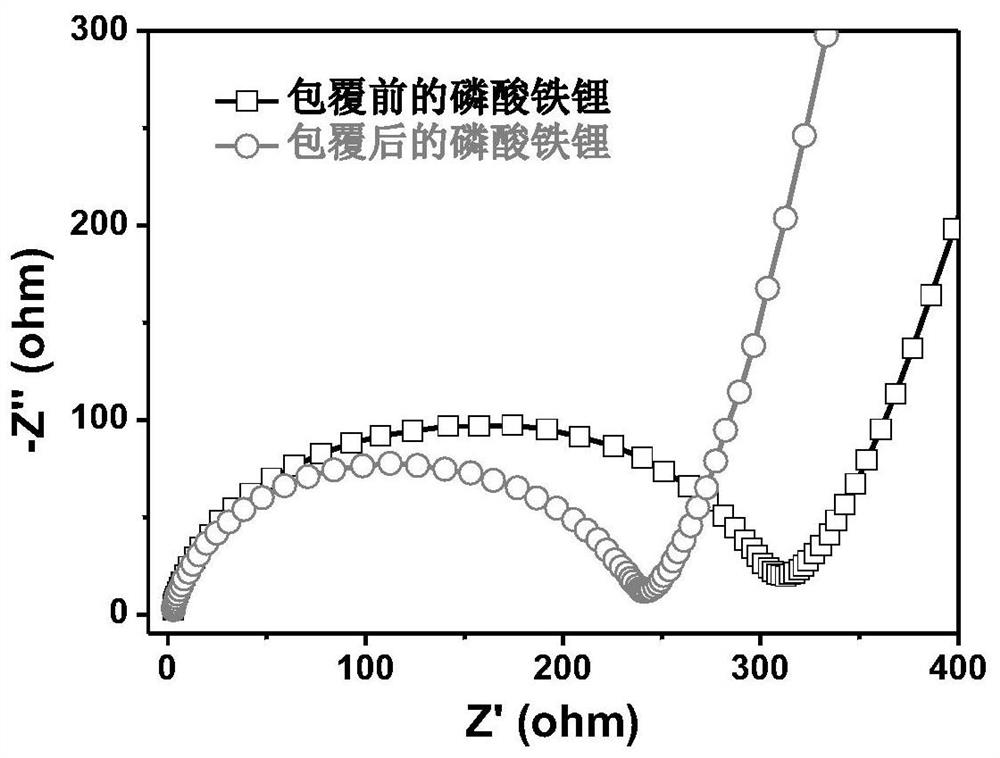

Method for compositely coating lithium battery positive electrode material with tungsten oxide and nitrogen-doped carbon

ActiveCN111900401AImprove conductivityImprove electrochemical stabilityFinal product manufactureCylindrical casing cells/batteryElectronic conductivityPolymerization

The invention belongs to the technical field of manufacturing of lithium battery cathode materials, and specifically relates to a method for compositely coating a lithium battery cathode material withtungsten oxide and nitrogen-doped carbon. A coating layer is formed on the surface of the lithium battery positive electrode material by polymerization of a carbon precursor and precipitation of a tungsten precursor. Curing and bonding of coating layer are realized through a calcining process. According to the present invention, the method has characteristics of low cost, low energy consumption and simple operation, and the lithium battery positive electrode material prepared through the method has characteristics of excellent electronic conductivity and excellent electrochemical stability.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

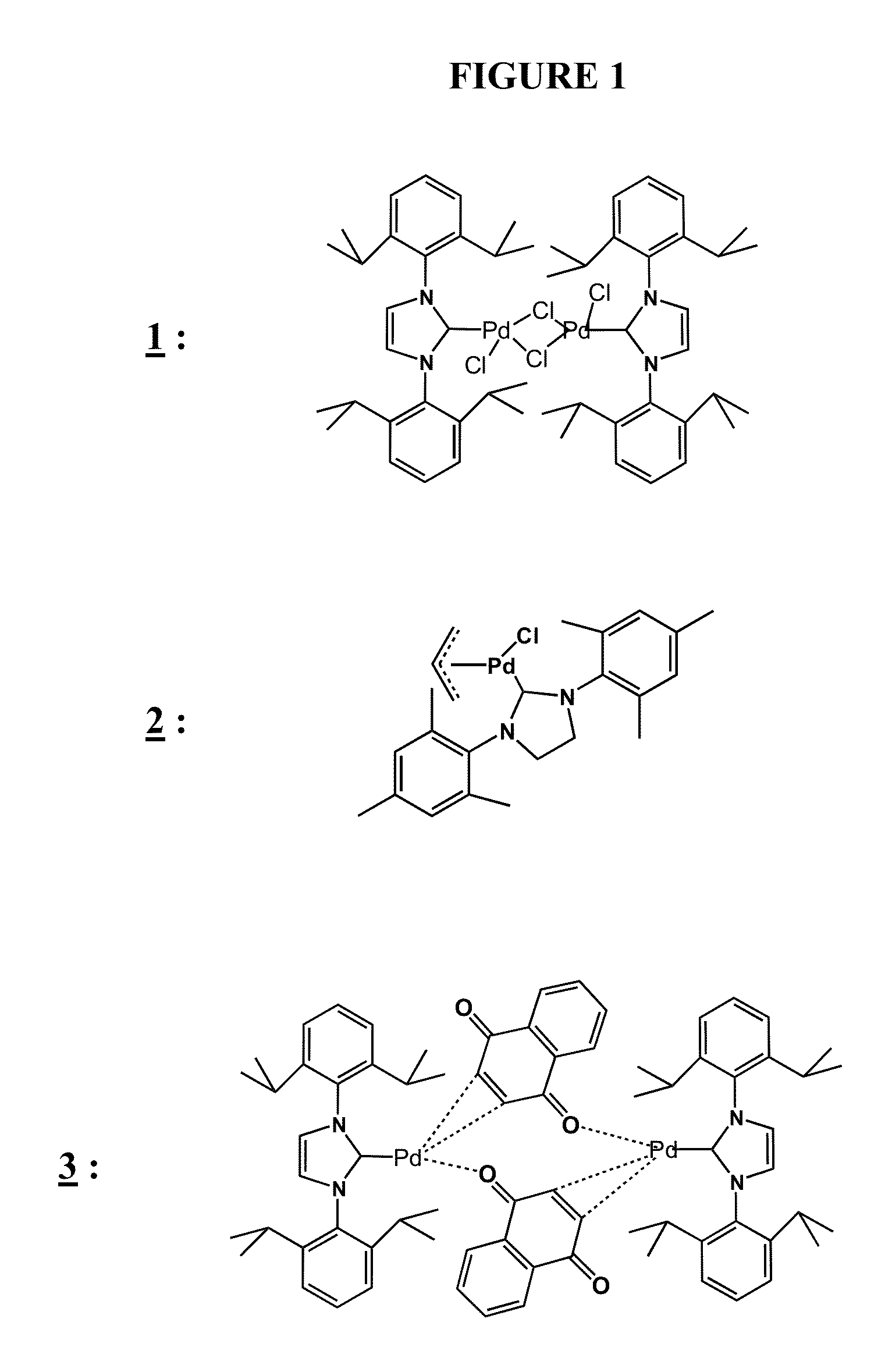

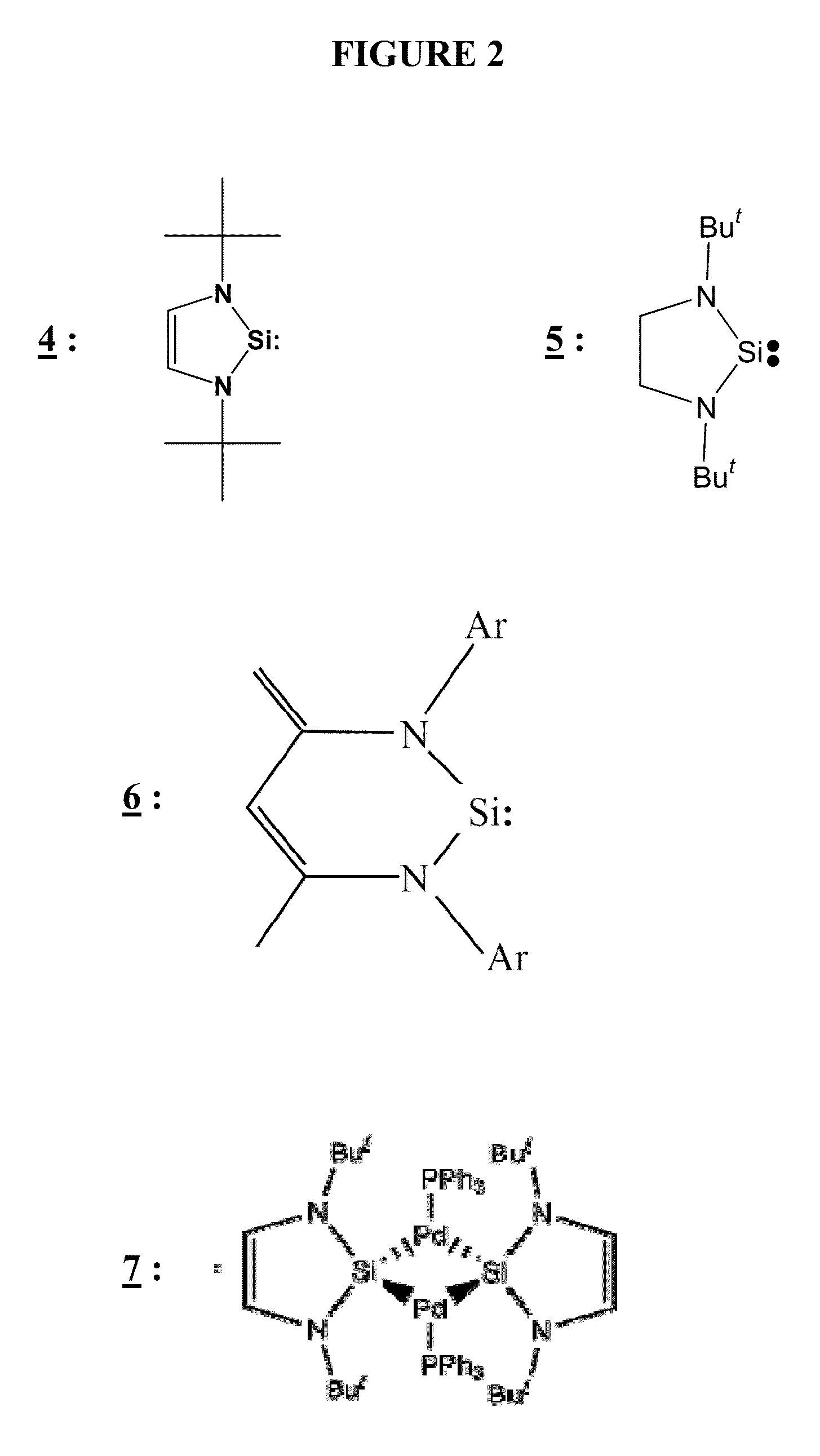

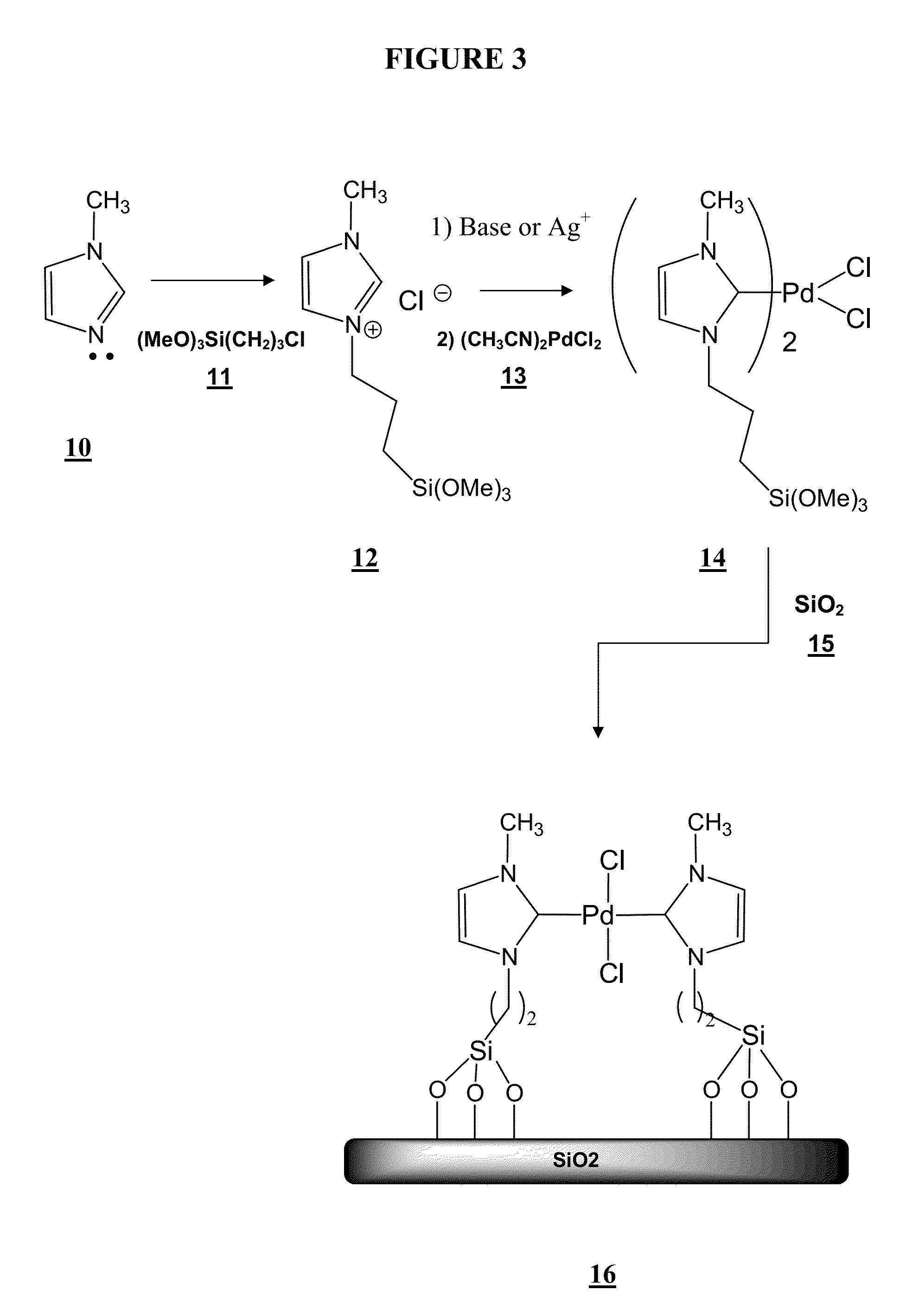

Methods of Polymerizing Silanes and Cyclosilanes Using N-Heterocyclic Carbenes, Metal Complexes Having N-Heterocyclic Carbene Ligands, and Lanthanide Compounds

ActiveUS20130026453A1Reduce hydrogen contentFully crystallizedFinal product manufactureConductive materialCarbeneChemistry

Compositions and methods for controlled polymerization and / or oligomerization of silane (and optionally cyclosilane) compounds, including those of the general formulae SinH2n and SinH2n+2, as well as halosilanes and arylsilanes, to produce soluble polysilanes, polygermanes and / or polysilagermanes having low levels of carbon and metal contaminants, high molecular weights, low volatility, high purity, high solubility and / or high viscosity. The polysilanes, polygermanes and / or polysilagermanes are useful as a precursor to silicon- and / or germanium-containing conductor, semiconductor and dielectric films.

Owner:ENSURGE MICROPOWER ASA

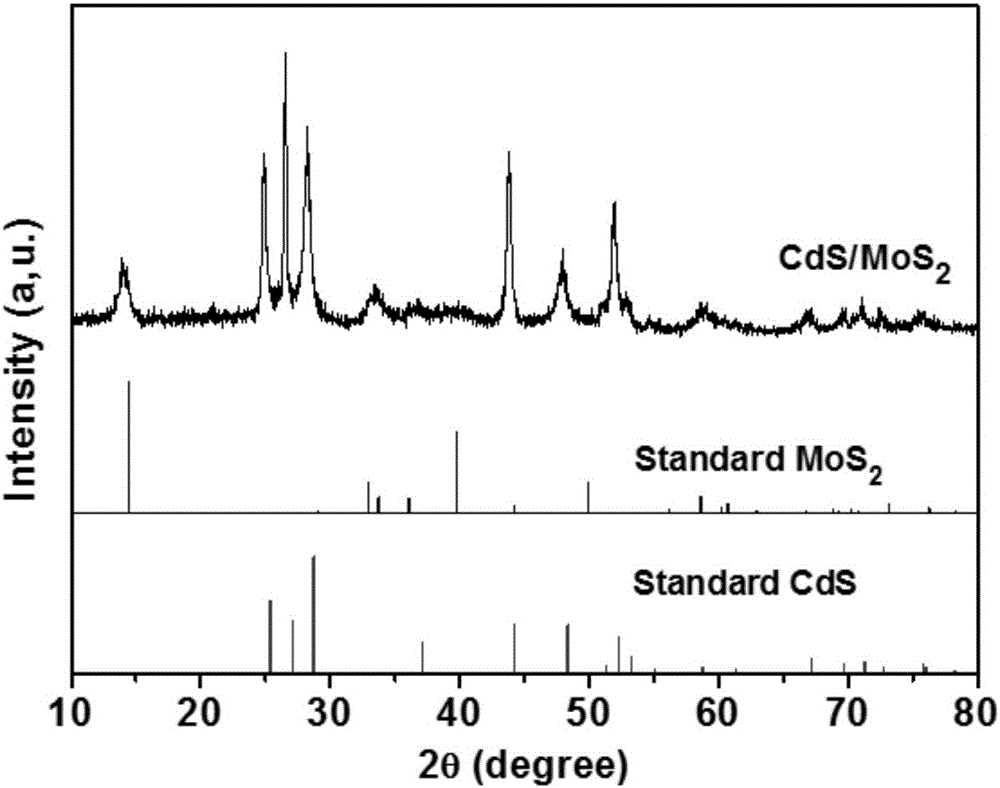

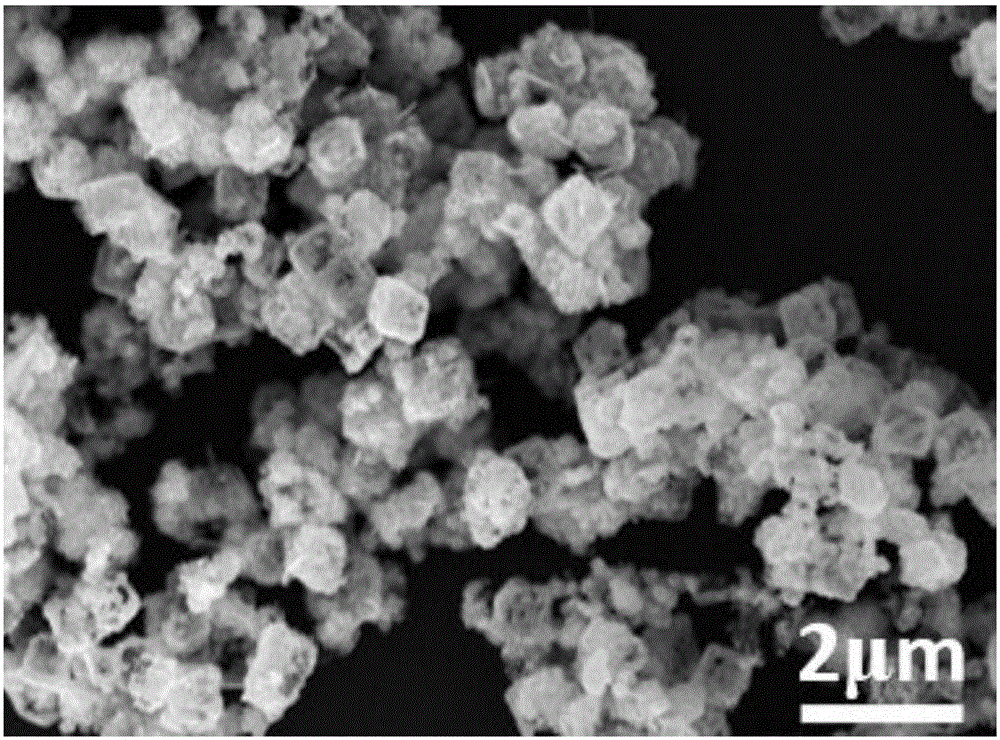

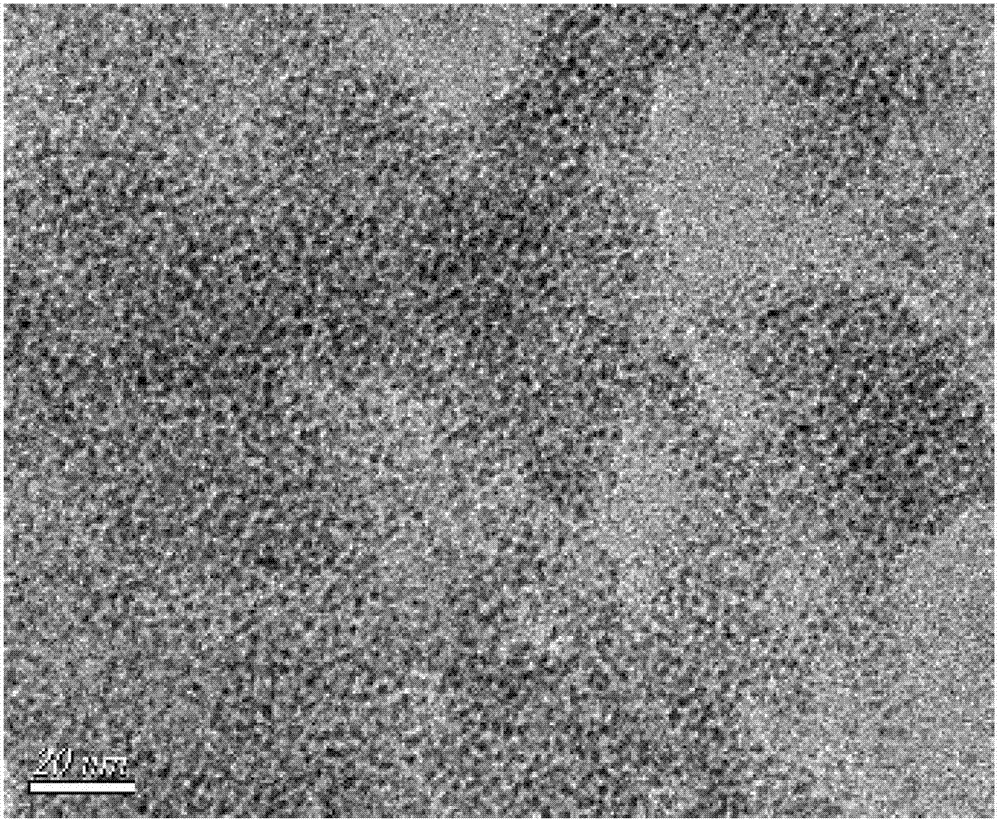

Method for preparing CdS/MoS2 composite hollow-block photocatalyst

InactiveCN106378160AFully crystallizedGood dispersionCatalyst activation/preparationSodium bicarbonateSodium molybdate

The invention relates to the technical field of composite nanomaterials and in particular discloses a method for preparing a CdS / MoS2 composite hollow-block photocatalyst by taking cadmium acetate, sodium bicarbonate, PVP, sodium molybdate and thiourea as raw materials, particularly a method for preparing a component photocatalyst with the advantages of simple preparation process and excellent visible-light catalytic activity of the product. The method comprises the following steps: weighing cadmium acetate and PVP, and dissolving in deionized water according to a mass ratio of 1:10; adding sodium bicarbonate into the mixture, so that the mass ratio of the cadmium acetate to sodium bicarbonate is 1:2; stirring and reacting at room temperature for 2 hours, washing and centrifuging the product after the reaction is completed, thereby obtaining cadmium carbonate; dissolving the cadmium carbonate, sodium molybdate and thiourea in the deionized water according to a mass ratio of (1):(0.15-1.4):(4), mixing and stirring, carrying out a hydrothermal reaction under the condition of 220 DEG C for 24 hours, washing and centrifuging the product after the reaction is completed, and drying, thereby obtaining the CdS / MoS2 composite photocatalyst.

Owner:JIANGSU UNIV

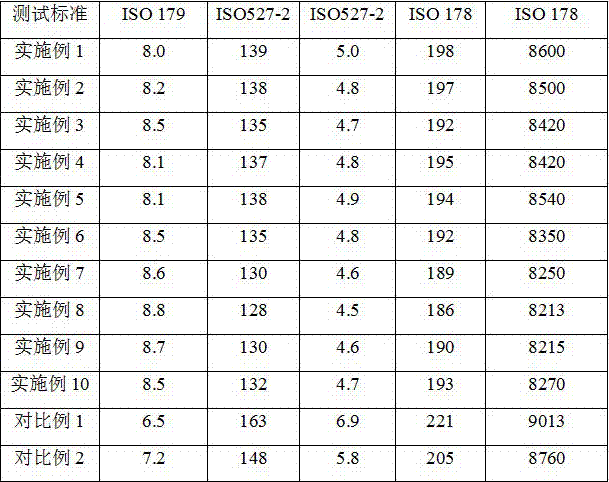

LCP/PBT/PET ternary alloy material and preparation method thereof

InactiveCN107383807AStrong impact resistanceHigh tensile strengthPolytetramethylene terephthalatePolybutylene

The invention relates to the technical field of a high-molecular material, and more specifically relates to a LCP / PBT / PET ternary alloy material and a preparation method thereof. The LCP / PBT / PET ternary alloy material comprises the following raw materials in parts by weight: 10-40 parts of a liquid crystal polymer, 10-40 parts of polybutylene telephthalate, 10-40 parts of polyethylene glycol terephthalate, 5-40 parts of glass fiber, 3-15 parts of a compatilizer, 3-15 parts of a fire retardant, 0.1-0.5 parts of an anti-oxidant, 0.2-2 parts of a lubricant and 1-2 parts of a modifier. The ternary alloy material has the excellent mechanical properties of toughness, impact strength, tensile strength and bending strength, and has the advantages of good fireproof performance, good heat resistance, low water absorption, good size stability, high crystallization efficiency, good moulding performance, good processing performance, low cost, and high usage value.

Owner:广东壹豪新材料科技股份有限公司

Transparent conductive laminate and touch panel therewith

InactiveUS20120012370A1Satisfactory reliabilityPen input durability and surface pressure durabilityConductive layers on insulating-supportsSynthetic resin layered productsHigh humidityEngineering

A transparent conductive laminate comprising a transparent film substrate; a transparent conductive thin film provided on one side of the transparent film substrate; and a transparent base substrate bonded to another side of the transparent film substrate with a transparent pressure-sensitive adhesive layer interposed therebetween. The transparent conductive laminate has satisfactory reliability at high temperature and high humidity for touch panels and also has pen input durability and surface pressure durability.

Owner:NITTO DENKO CORP

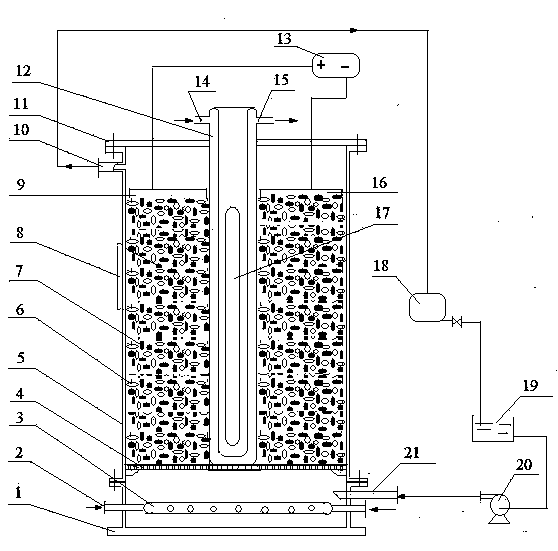

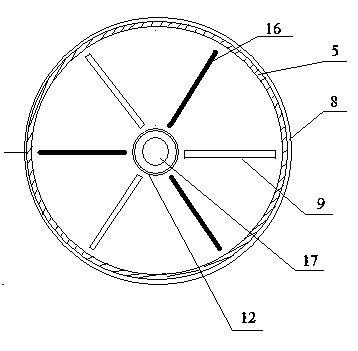

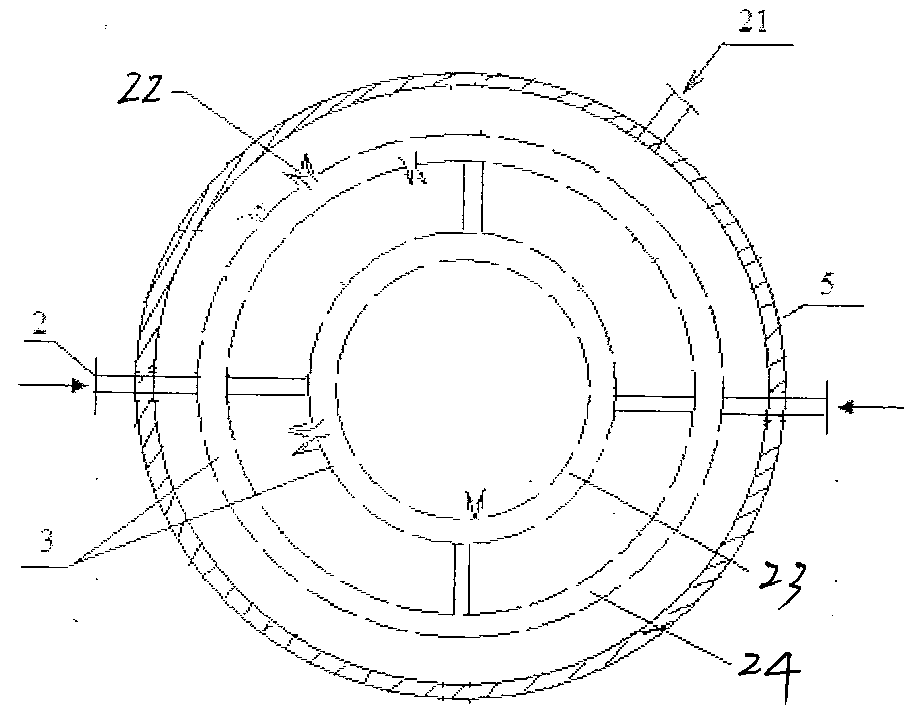

Bipolar packed bed type three-dimensional electrode photo-electricity catalytic reactor

InactiveCN103420452AReasonable structureHigh emissivityWater/sewage treatment by irradiationWater contaminantsGraphiteQuartz

The invention discloses a bipolar packed bed type three-dimensional electrode photo-electricity catalytic reactor. The catalytic reactor comprises a glass cylinder body, wherein a feeding chamber is arranged at the bottom of the glass cylinder body; a cover plate is arranged at the top part of the glass cylinder body; a tin foil reflective layer is coated outside the glass cylinder body; support grid plates are arranged in the cylinder body and above the feeding chamber; a central quartz jacket is positioned at the axle center of the cylinder body; the ultra-violet lamp is built-in; a cooling water inlet and a cooling water outlet are respectively formed in the top end of the quartz jacket; the cooling water is poured to control the temperature; TiO2 / Ti anode and graphite cathode are axially arranged in the cylinder body; photo-electricity particle electrodes and insulating particles are mixedly stacked in the cylinder body to form a particle electrode bed layer; the feeding chamber is arranged at the lower part of the reactor. The catalytic reactor has the advantages of reasonable structure, high light energy and electrical energy utilization ratio, good photo-electricity synergistic effect, and high photo-electricity catalytic oxidation efficiency.

Owner:NANTONG UNIVERSITY

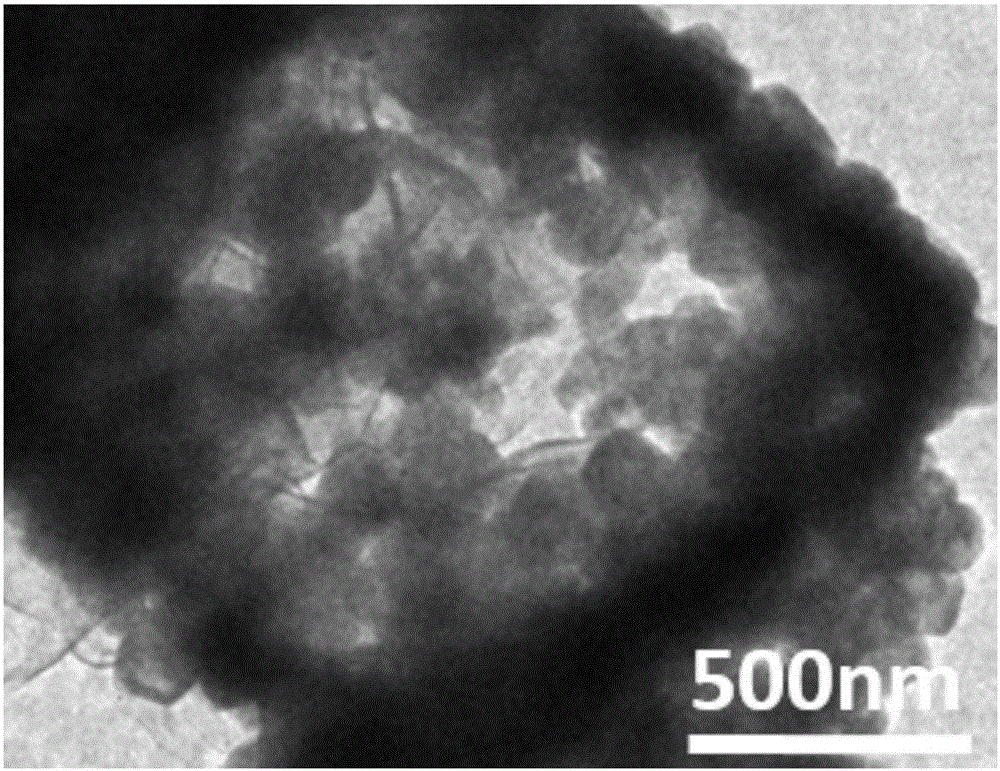

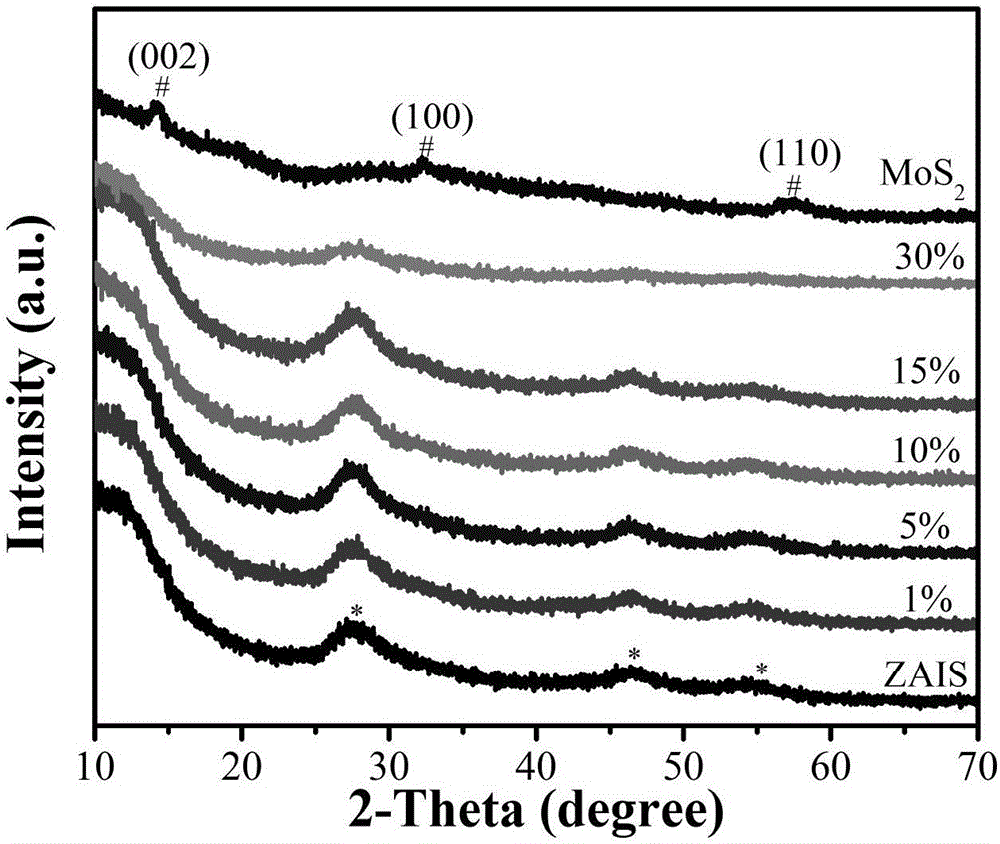

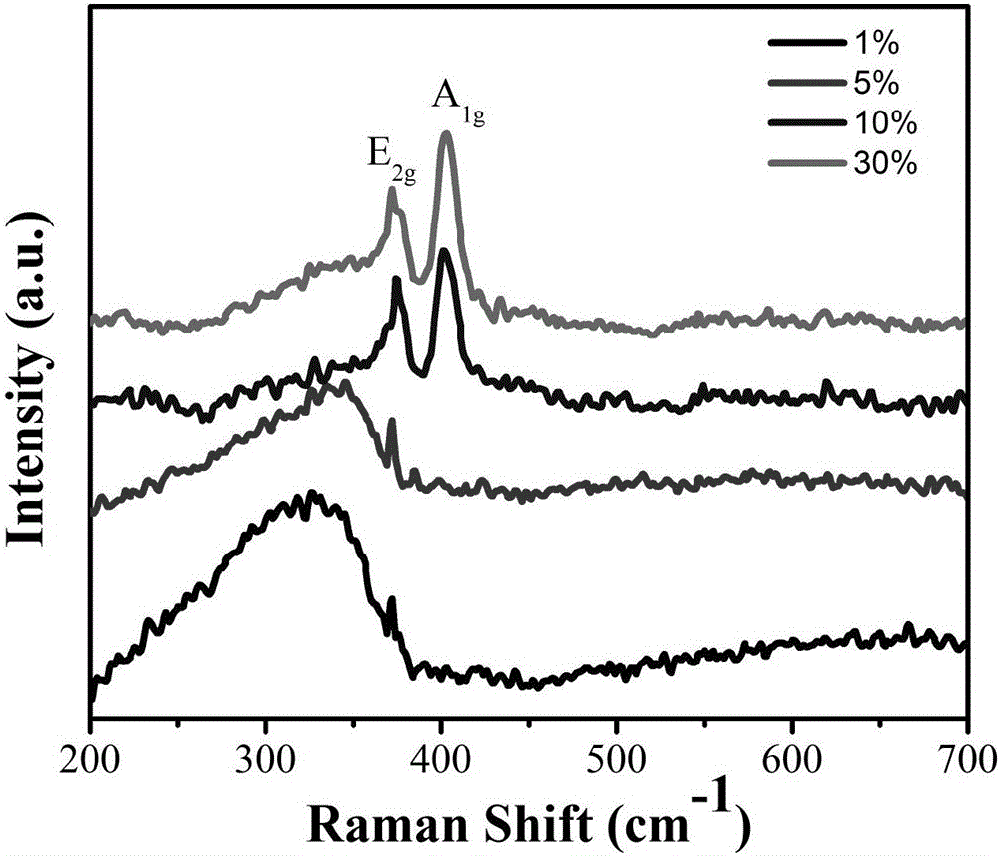

Method for preparing quaternary sulfide quantum dot based heterojunction efficient photocatalyst

ActiveCN105727999AFully crystallizedGood dispersionPhysical/chemical process catalystsHeterojunctionThiourea

The invention relates to I-III-VI group 2 sulfide and particularly relates to an AgIn5S8-ZnS / MoS2 heterojunction composite photocatalyst prepared by utilizing a simple and rapid hydrothermal method. The AgIn5S8-ZnS / MoS2 heterojunction composite photocatalyst can be used for degrading a rhodamine B dye under visible light. The AgIn5S8-ZnS / MoS2 heterojunction composite photocatalyst is prepared by mixing and stirring AgIn5S8-ZnS nano crystals, ammonium molybdate tetrahydrate and thiourea, carrying out a hydrothermal reaction for 8 hours at 200 DEG C, and filtering, washing and drying after the reaction is finished, wherein the mass ratio of the MoS2 to the AgIn5S8-ZnS nano crystals is 1%-30%, and the optimal mass ratio of the photocatalytic performance is 5%. An experiment of degrading rhodamine B (RhB) under the visible light shows that the prepared composite photocatalyst has good photocatalytic activity.

Owner:JIANGSU UNIV

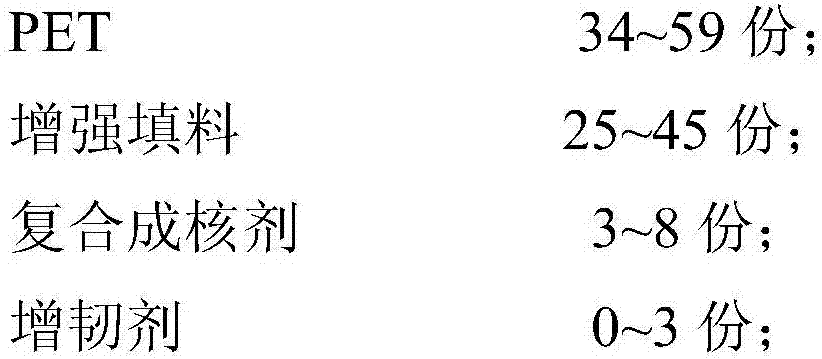

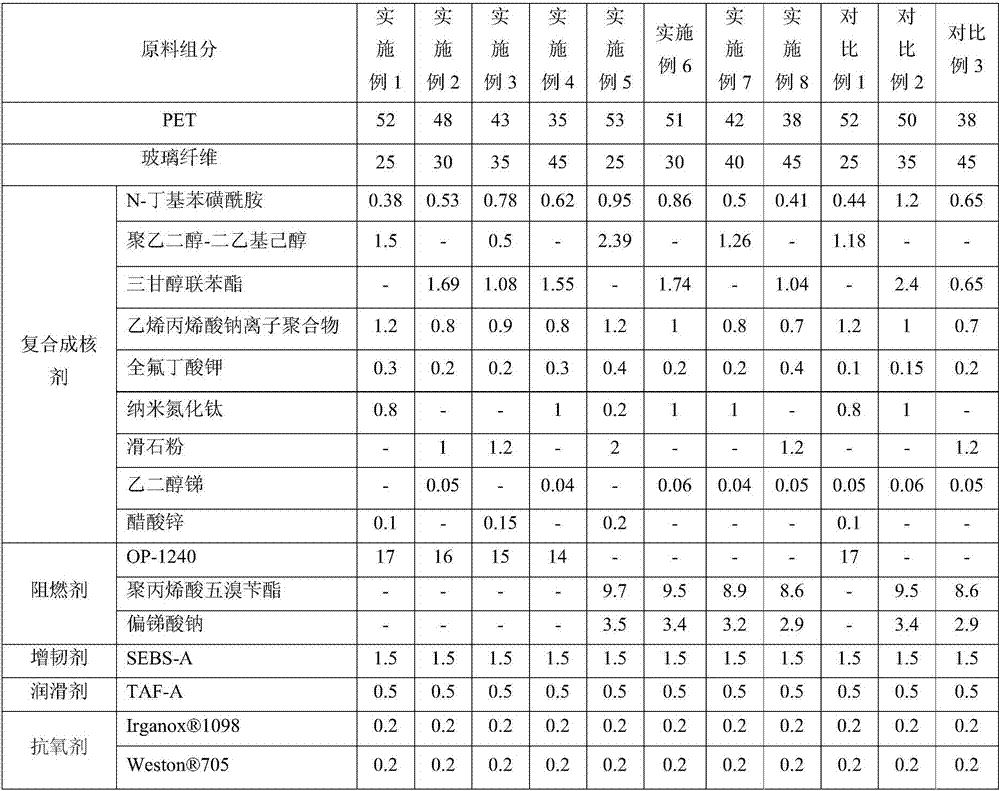

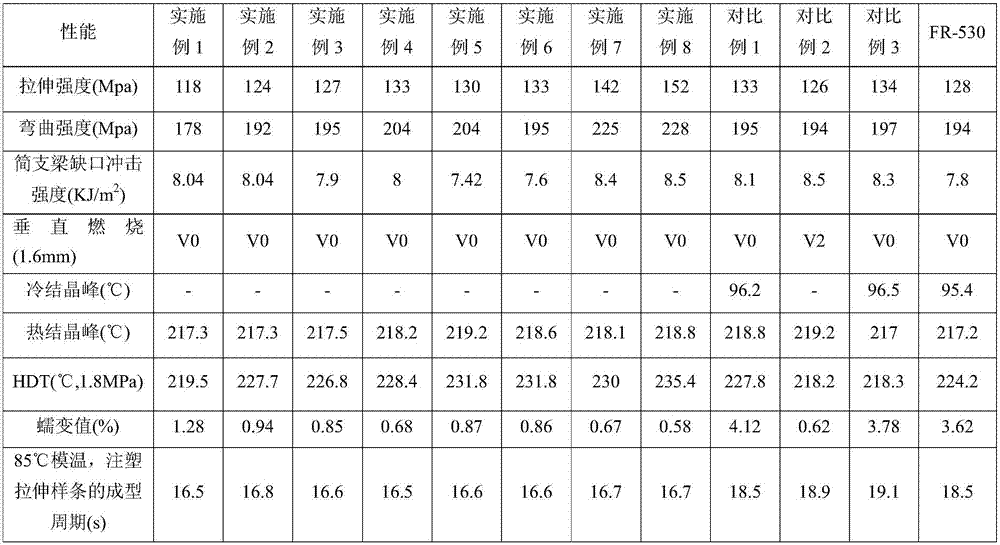

PET composite material

The invention discloses a PET composite material, which comprises the following components in parts by weight: 34 to 55 parts of PET, 25 to 45 parts of enhanced filling material, 3 to 8 parts of composite nucleating agent, and 0 to 3 parts of flexibilizer; wherein the composite nucleating agent comprises a chemical nucleating agent and a plasticizer, the weight ratio of the plasticizer to PET resin is 3.5-7:100, the plasticizer is prepared by compounding a benzsulfamide plasticizer with other plasticizers, other plasticizers can be one or more of polyethylene glycol-diethyl hexyl alcohol, neopentyl glycol diphenyl ester, tribenzyl propylidene ether diethyl hexyl alcohol, and triethylene glycol diphenyl ester, the structural formula of the benzsulfamide plasticizer is represented in the description, and in the structural formula, R represents a branched alkyl group or a straight chain alkyl group. The composite material is injection-moulded at a mould temperature of 85 DEG C, the crystallization is complete, the moulding period is short, and the PET composite material can be used to produce large moulded goods or precision thin-wall moulded goods.

Owner:本松新材料技术(芜湖)有限公司

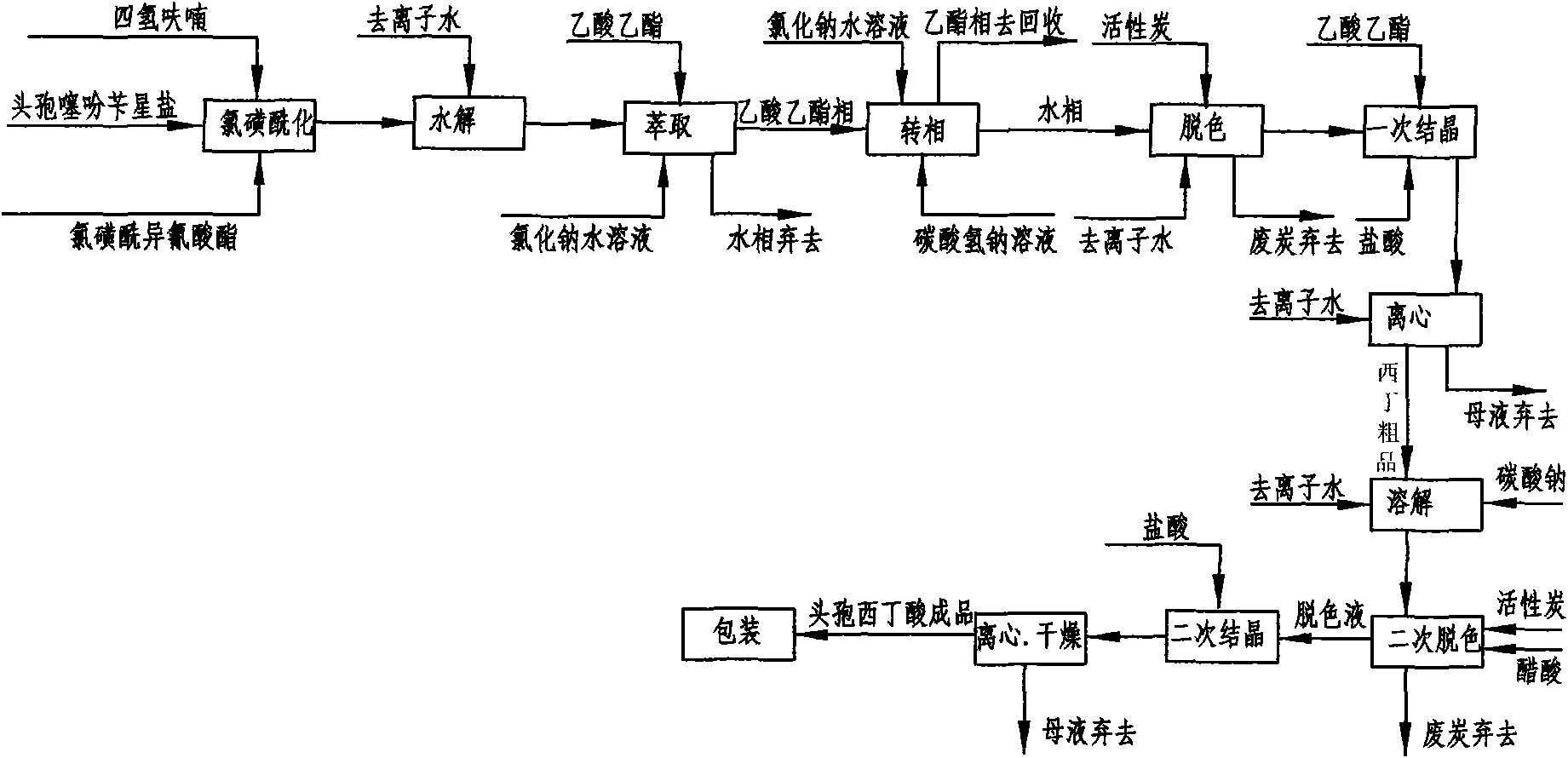

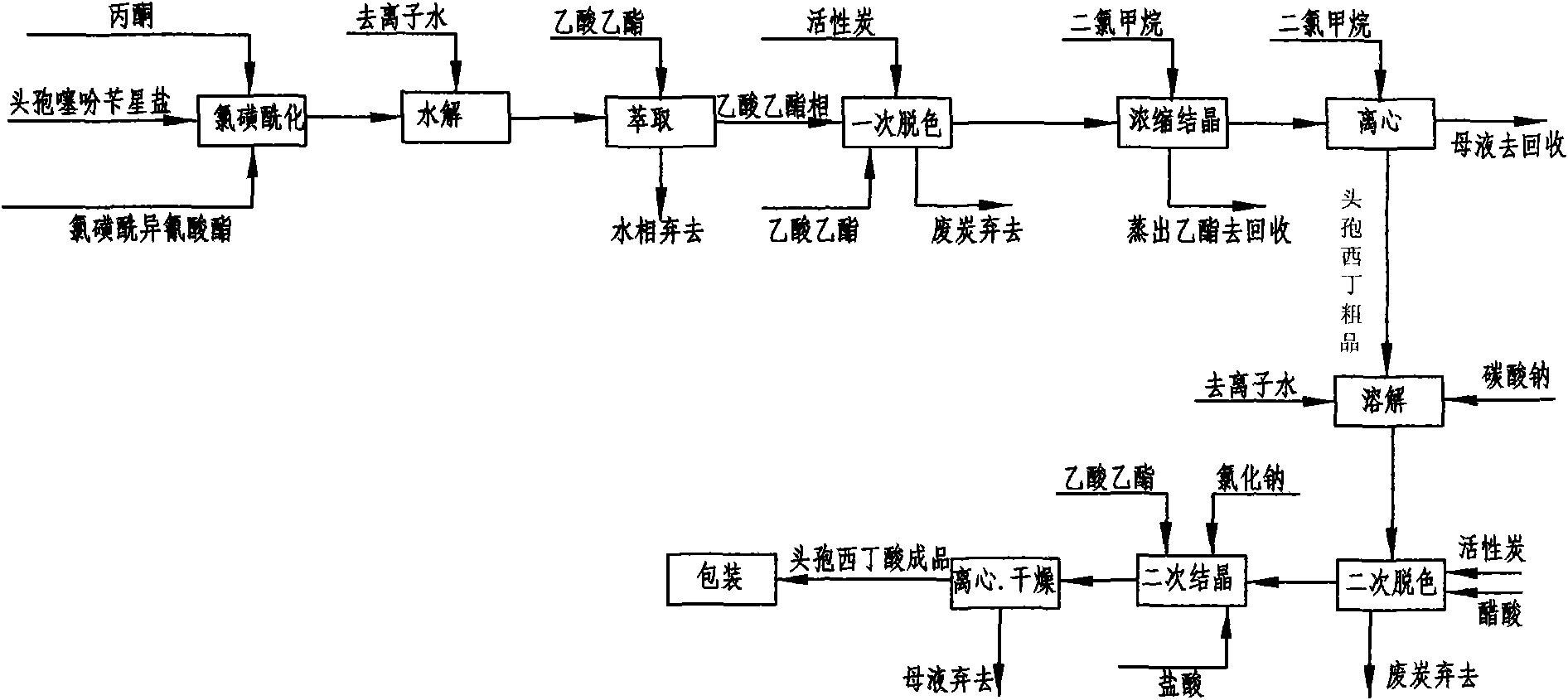

Cefoxitin acid preparation method

The invention discloses a cefoxitin acid preparation method, comprising the following steps: adding 7-alpha-methoxyl-3-deacetylcefalotin benzathine salt in acetone at room temperature, cooling the solution and adding chlorosulfonyl isocyanate to react and then producing the finished product by hydrolysis, extraction, decoloration, concentrated crystallization, filtration, dissolution and secondary crystallization. In the invention, acetone with a consumption of 2.6kg / kg which is easy to recycle is used instead of tetrahydrofuran which is used in the prior art with a consumption of 13kg / kg and the production cost is reduced by 120 Yuan / Kg. In the invention water phase decarburization is changed to organic phase decarburization, thus eliminating the step of phase inversion in the original process and avoiding the yield loss in phase inversion process; water phase crystallization is changed to the crystallization method which adopts organic phase for concentrating and adds dichloromethane for crystallizing so that the crystallization is realized fully, the yield is higher and the total yield of cefoxitin is increased from 58% to 67%. The material cost of the cefoxitin acid can be reduced by 240 Yuan / Kg, the total reduced cost can be about 360 Yuan / Kg and the product prepared by the method has stronger market competitiveness and remarkable economic benefit.

Owner:河北九派制药股份有限公司

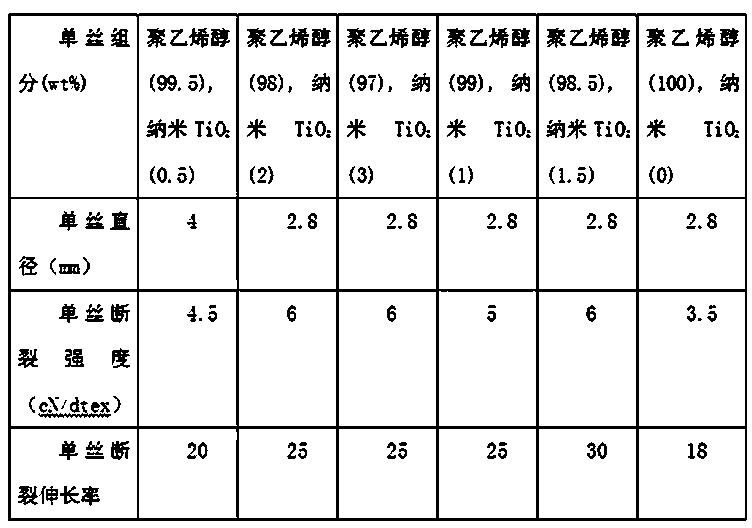

Large-diameter polyvinyl alcohol monofilament and production method thereof

ActiveCN103741249AHigh strengthImprove toughnessMonocomponent synthetic polymer artificial filamentWet spinning methodsPolymer scienceSpinning

The invention discloses a large-diameter polyvinyl alcohol monofilament and a production method thereof. The monofilament comprises 97-99.5 percent by weight of polyvinyl alcohol and 3-0.5 percent by weight of modified nanometer inorganic additives, wherein the monofilament is 0.5-5 millimeters in diameter, 3-6.7 cN / dtex in breaking strength and 15-35 percent in the elongation at break, and the strength and toughness of the product can be improved remarkably by adding the nanometer inorganic additives. The production method mainly comprises the treatment processes of polyvinyl alcohol dissolving, defoaming, wet spinning, stretching, winding and acetalation. Furthermore, a two-step method is adopted in a stretching procedure. In a first stretching step, the stretching rate is low. In a second stretching step, hot air stretching is adopted, and the stretching rate is high, so that the large-diameter polyvinyl alcohol monofilament can be crystallized fully, and the strength of the monofilament is enhanced.

Owner:NANTONG NTEC MONOFILAMENT TECH CO LTD

Preparation method of walnut oil

InactiveCN106665890AImprove qualityGood colorFatty-oils/fats refiningFatty-oils/fats productionWaxOil separation

The invention discloses a preparation method of walnut oil. The preparation method of the walnut oil comprises the following steps: carrying out careful selecting, carrying out washing, carrying out sterilization, carrying out peeling, carrying out pressing, and carrying out ultrasonic extraction. According to the preparation method of the walnut oil, the preparation is carried out at 45 DEG C, and the walnut kernel peel is removed before pressing by using alkaline liquor, so that the qualities and the color of the walnut oil are improved; and ultrasonic extraction is adopted so as to increase yield rate, reduce oil content rate of the oil cakes, balance protein in the walnut oil and the oil cakes so as to ensure protein stability in the oil cakes, and improve wax-oil separation effect. The preparation method of the walnut oil is simple in processes; and the walnut oil which is clear, transparent and bright in color, free of impurities, rich in nutrition and high in oil yield can be prepared without the step of carrying out decoloring by adopting the preparation method.

Owner:迪庆香格里拉舒达有机食品有限公司

Preparation method capable of increasing macropore volume of silicon dioxide carrier

ActiveCN105149012AIncrease the amount addedPore expansion effect is obviousCatalyst carriersCelluloseSilicon dioxide

The invention provides a preparation method capable of increasing the macropore volume of a silicon dioxide carrier. The preparation method comprises steps as follows: components comprising, in parts by mass, 100 parts of silicon dioxide powder with the specific surface area of 60 m<2> / g-250 m<2> / g and 10-30 parts of macromolecule ultrafine powder which basically doesn't have any residues after firing and basically doesn't absorb water to be swollen are sufficiently and uniformly mixed; 80-100 parts of a polymer aqueous solution with certain viscosity and with the mass concentration being 0.1%-0.5% is added, the mixture is sufficiently and uniformly mixed, 40-70 parts of silica sol with the concentration being 20%-30% is added, and the mixture is sufficiently and uniformly mixed and placed in an airtight manner; the average diameter of particles of the silica sol ranges from 10 nm to 30 nm, and the polymer basically doesn't have any residues after calcination and is selected from one of polyacrylamide, cellulose and modified starch; the mixture is kneaded and extruded to form strips, the extruded strips are dried and calcined at the temperature of 600 DEG C-670 DEG C for 2-4 hours, and the silicon dioxide carrier is obtained. According to the silicon dioxide carrier, the volume of macropores with the diameters larger than 100nm is higher than 0.10-0.35ml / g, the silicon dioxide carrier has higher mechanical strength, and the side pressure strength is higher than 150 N / cm.

Owner:山东迅达化工集团有限公司

Method for preparing perovskite nano powder

ActiveCN104477978AEffective size controlAvoid toxicityMaterial nanotechnologyZirconium compoundsReaction temperatureIon

The invention provides a method for preparing ABO3 perovskite nano powder. The method comprises the following steps: dropwisely adding a B-site element source alcohol solution into surfactant / acetic acid-dissolved deionized water to obtain a mixed solution, adding ammonia water into the mixed solution, and reacting the reaction system at constant temperature to obtain a B-site element hydrous oxide gel; and preparing a B-site element hydrous oxide gel dispersion solution, adding an A-site element source into the dispersion solution, and carrying out hydrothermal reaction under normal pressure to obtain the ABO3 perovskite nano powder. The aqueous gel-normal pressure hydrothermal process and raw materials with lower cost are adopted, and the aqueous reaction is utilized to avoid the toxicity of the organic solvent. The pH value, surfactant amount, reaction raw material concentration, reaction time, reaction temperature and other conditions of the system are regulated to effectively control the size of the product, thereby obtaining the well-crystallized monodisperse perovskite powder with the particle size of 15-300nm.

Owner:TSINGHUA UNIV

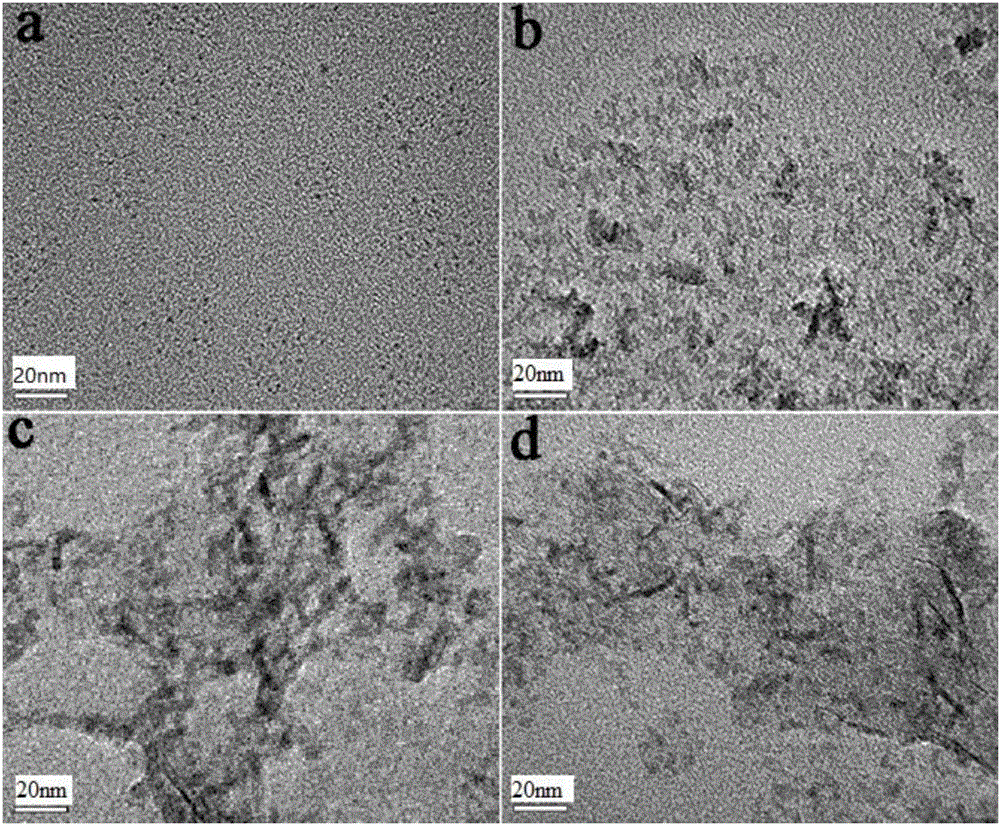

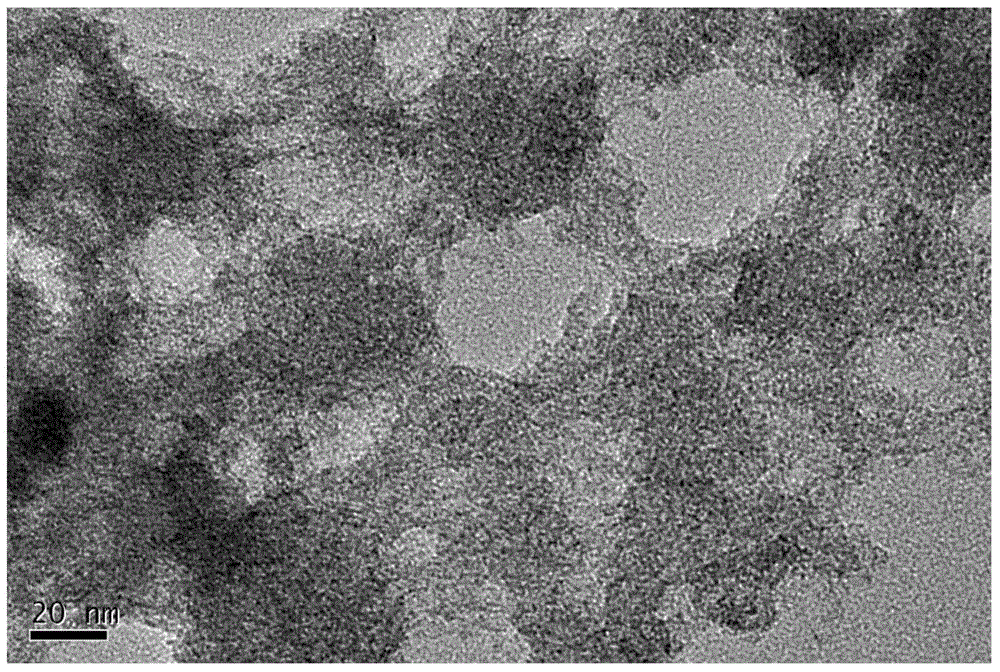

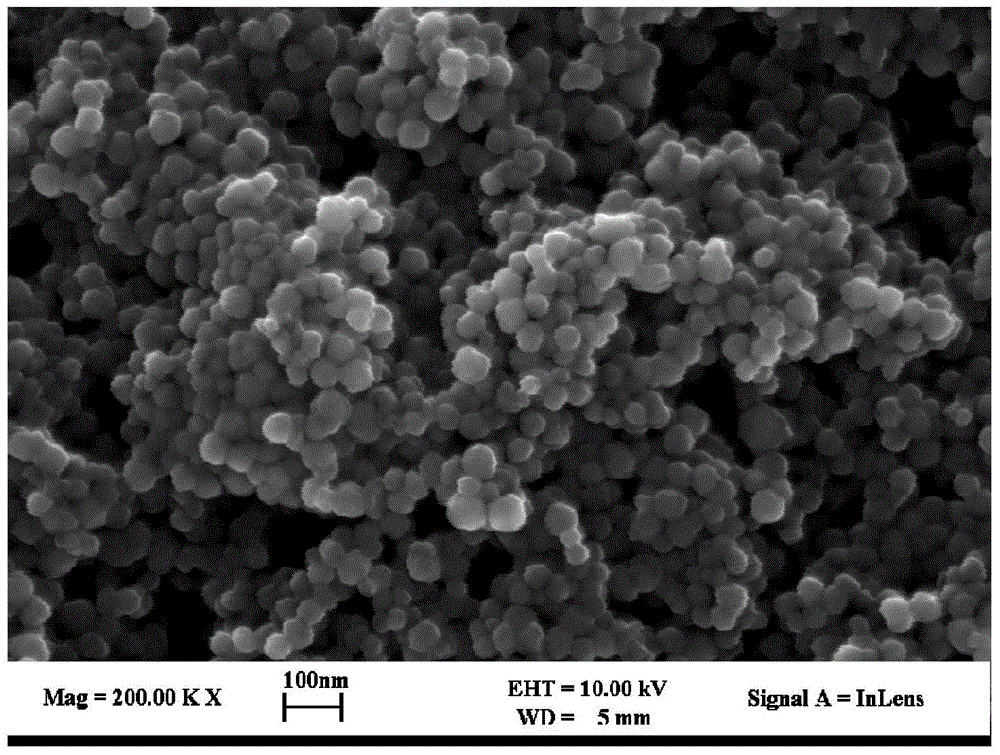

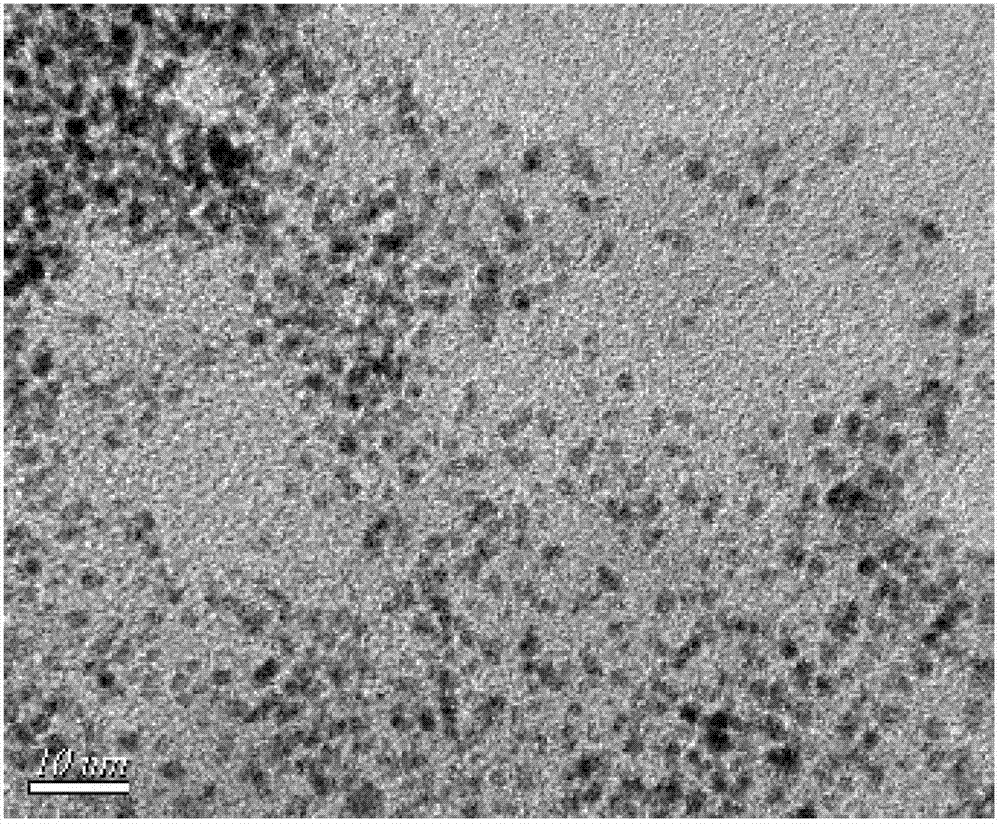

Preparation method for atomic scale precious metal nanoparticle stable colloidal suspension

The invention relates to a preparation method for atomic scale precious metal nanoparticle stable colloidal suspension. The preparation method comprises the steps: using mixed solvent of polyethylene glycol and ethanediol as stabilizing agent, reducing agent and solvent; using precious metal halogen containing acid as metal resource, adjusting system potential of hydrogen (PH) by sodium hydroxide, and obtaining a reaction product after reaction for three minutes in a microwave reactor in temperature of 140 DET C. after the reaction is finished, the produce is naturally cooled to be room temperature, and the obtained product is sucked and filtered by using a number 6 core hopper, absolute ethyl alcohol and deionized water are alternately washed for ten times and then are dispersed in ethanol solution, the dispersion liquid can be laid aside for a long time, and flocculation and agglomeration cannot occur. Reagent used in the preparation method for the atomic scale precious metal nanoparticle stable colloidal suspension is common, synthesizing steps are simple, cost is low, pollution cannot occur, mass production is easy to conduct, and addition of surfactant and additional reducing agent is can not occur. According to synthetic products, partical size is in atomic scale of 1nm, dispersion is uniform and agglomeration phenomenon can nor occur after the products are placed for a long time.

Owner:JIANGSU UNIV

Method for manufacturing heat-resistance polylactic acid water bottle

ActiveCN103831966AHigh dimensional accuracyGood defective rateHollow articlesInjection equipmentInjection molding machine

The invention relates to a method for manufacturing a heat-resistance polylactic acid water bottle, and belongs to the field of polymer materials and processing application thereof. The method comprises the following steps: melting, extruding and granulating polylactic acid and a nucleating agent in a certain ratio by a twin-screw extruder, performing injection molding on the polylactic acid particles by injection equipment to form a bottle preform; heating and insulating the mouth part of the bottle preform in the die before the bottle preform is demolded to sufficiently crystalize. Therefore, the bottle preform is subjected to blow molding by blow molding equipment, the mouth and body parts of the bottle preform can be heated and insulated in the die before demolding, so that the bottle preform can be crystallized sufficiently, and the heat-resistance polylactic acid water bottle can be prepared finally. According to the method, the crystallization efficiency of the polylactic acid can be improved by virtue of the nucleating agent, and dies of injection and blowing two-step molding equipment can be improved, so that the bottle preform can be sufficiently crystallized in the die directly after being molded, and the product is more stable in size. The method enriches the molding process of heat-resistance polylactic acid products, and further expands the application field of polylactic acid, which is an emerging biological environment-friendly raw material.

Owner:HANGZHOU SEEMORE NEW MATERIAL TECH

Transparent conductive laminate and touch panel therewith

InactiveUS8029886B2Satisfactory reliabilityPen input durability and surface pressure durabilityConductive layers on insulating-supportsSynthetic resin layered productsHigh humidityTouch panel

Owner:NITTO DENKO CORP

Production method of sodium citrate

ActiveCN103044239AFully crystallizedShort reaction timeCalcium/strontium/barium carbonatesCarboxylic acid salt preparationSodium bicarbonateCalcium bicarbonate

The invention relates to a production method of sodium citrate. The method comprises the main steps that limestone powder and citric acid fermentation liquor are reacted, filtered and crystallized, and then are conducted to at least one time of neutralization and crystallization, so that calcium hydrogen citrate crystal is continuously and directly obtained; and the calcium hydrogen citrate crystal is reacted with the mixed solution of sodium hydroxide and sodium carbonate, so that sodium citrate and calcium carbonate are obtained. The method increases the content of carbonate in a whole system, reduces the hydrolysis rate of the carbonate, avoids the affect to finished products by calcium bicarbonate, and prevents the calcium ion in the finished products from exceeding standard. Part of sodium in the sodium citrate is provided by ionic membrane caustic soda, and compared with the traditional one-step method for producing sodium citrate, the production method has the advantages that the purity of solution is high, contents of calcium ion, iron ion and chloride ion are low, and return rate of sodium citrate mother liquor is greatly reduced.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

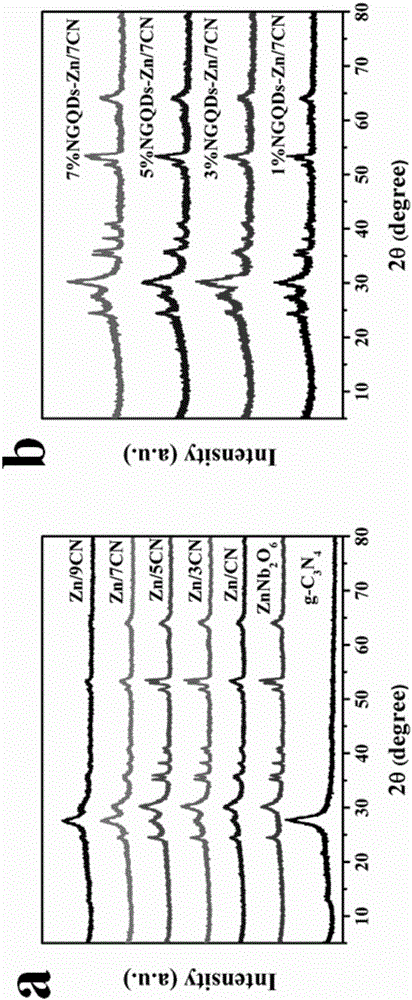

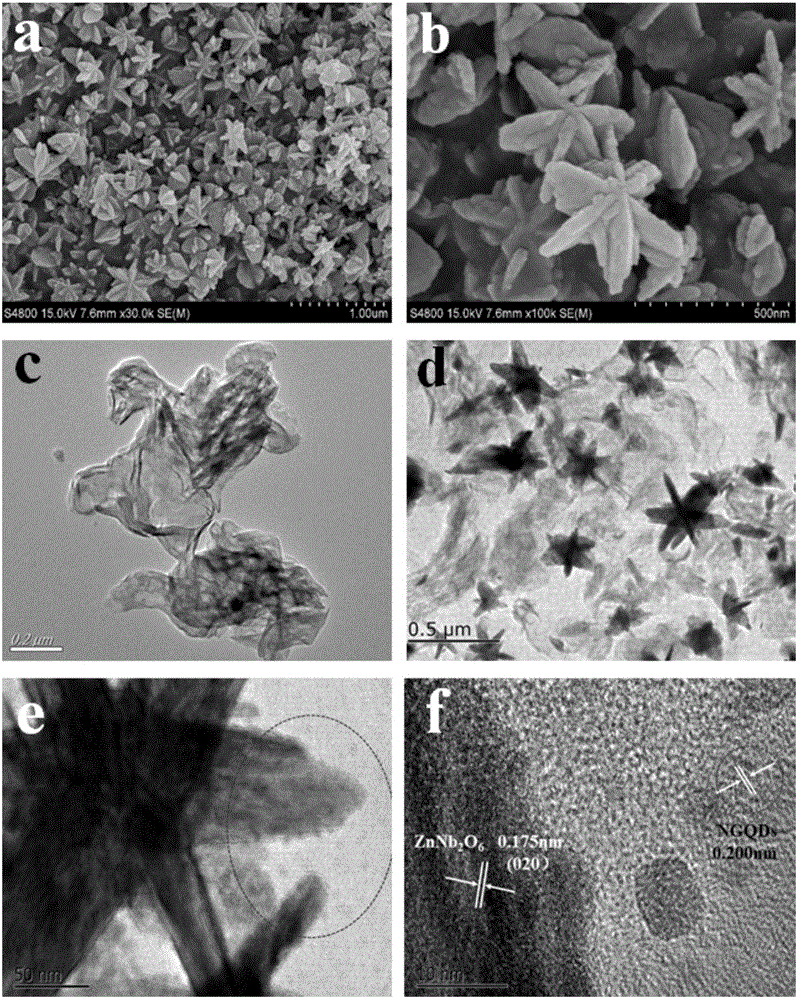

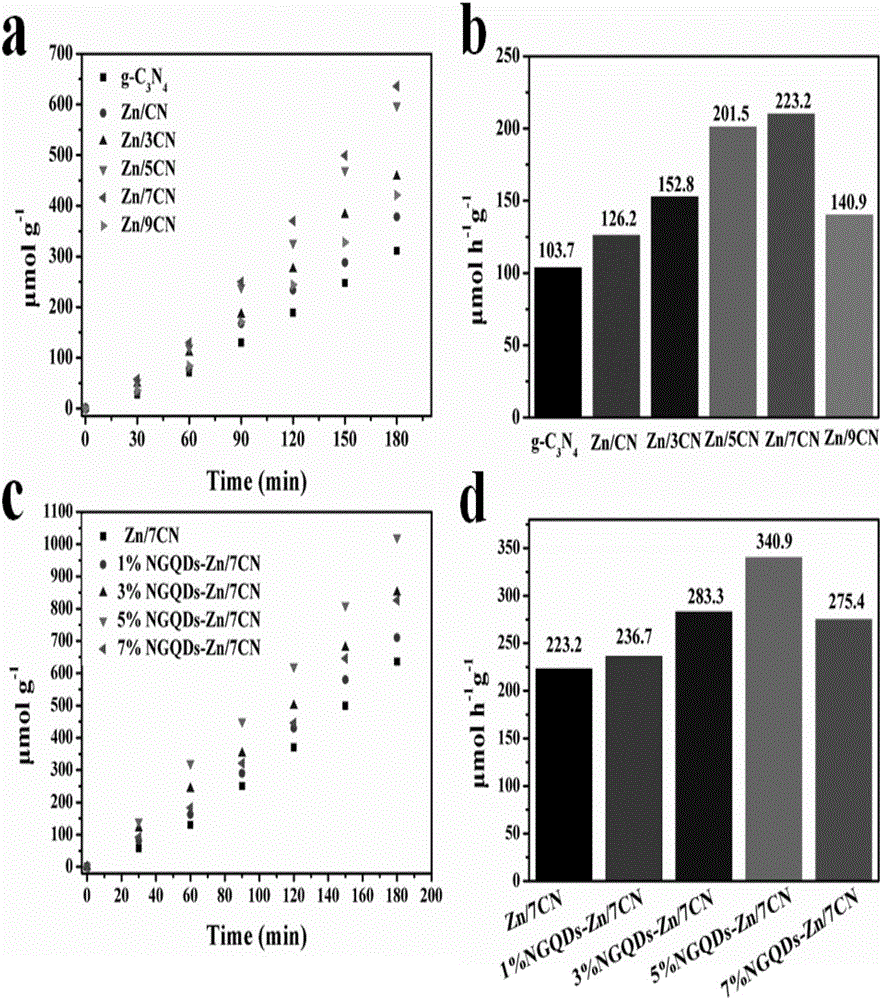

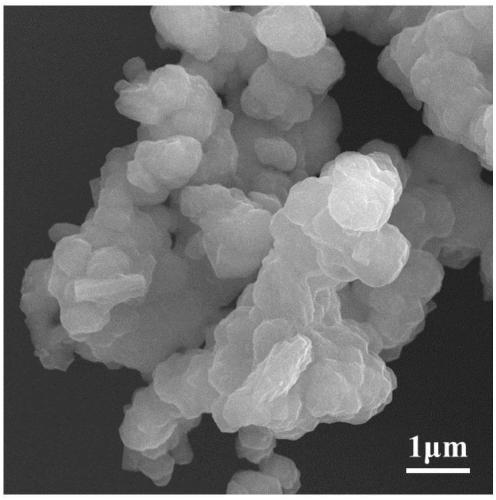

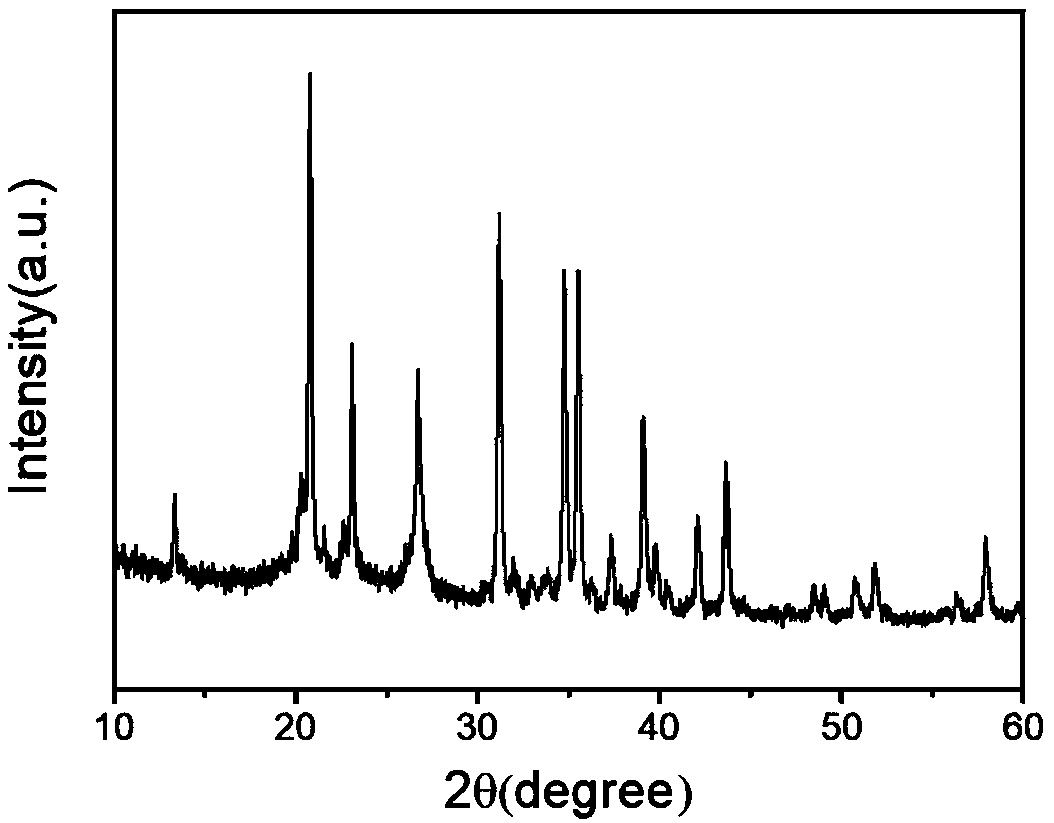

Method for preparing heterojunction photocatalyst

ActiveCN106311307AFully crystallizedMorphological rulesPhysical/chemical process catalystsHydrogen productionUreaChemistry

The invention relates to the technical field of photocatalytic oxidation treatment, particularly relates to a method for preparing an NQGDs-zNnB2O6 / G-C3N4 heterojunction photocatalyst by taking C6H5O7(NH43), Nb2O5, KOH, Zn(NO3).6H2O and urea as raw materials. The method has the advantages that the preparation technology is simple and the cost is low.

Owner:JIANGSU UNIV

Method for extracting iron from modified molten copper slag and preparing ceramic using tailings of modified molten copper slag

PendingCN110453064AReduce the amount addedFully crystallizedMagnetic separationProcess efficiency improvementMetalMagnetic separation

The invention provides a method for extracting iron from modified molten copper slag and preparing ceramic using tailings of modified molten copper slag, and belongs to the technical field of resourceutilization and environmental protection. The method comprises the steps that by taking molten copper slag as a raw material, a modifier containing alkali metal oxide is added in a molten state of the copper slag, or the atmosphere of the molten copper slag is simultaneously controlled in a blowing gas mode, so that an iron-containing phase of the molten copper slag is transformed into magnetitethrough modification, and after magnetic minerals such as the magnetite are fully crystallized and grown up, the modified molten copper slag is cooled; and he cooled copper slag is subject to crushingand magnetic separation treatment to obtain iron fine powder and the tailings; and the tailings containing the alkali metal oxide is utilized as a ceramic raw material to prepare a ceramic material.According to the method for the extracting the iron from the modified molten copper slag and preparing the ceramic using the tailings of the modified molten copper slag, high-temperature heat energy of furnace slag melts the modifier, the composition and the structure of the slag are changed by reasonably controlling the temperature, the additive and the movement behaviors of fluids, so that the valuable components in the slag are recycled, and the separated tailings are used as the raw materials for preparing the ceramic, and a ceramic product is further prepared.

Owner:UNIV OF SCI & TECH BEIJING

Recycling method of acid ammonium salt precipitating vanadium waste water

InactiveCN105525096AFully crystallizedWater contaminantsTreatment involving filtrationChemistrySodium salt

The invention belongs to the field of chemical engineering and metallurgy, and particularly relates to a recycling method of acid ammonium salt precipitating vanadium waste water. The recycling method comprises the following steps that a, the acid ammonium salt precipitating vanadium waste water is added to and is uniformly mixed with a polyoxovanadium sodium solution to form a mixed solution; b, the pH value of the mixed solution is adjusted to 5-6, the mixed solution is subjected to standing crystallization and filtration, a vanadium-containing raw material and new waste water are obtained; c, a reducing agent is added to the new waste water for reduction, after the reduction, alkali is added for neutralization, pressure filtration is carried out, and pressure filtration water and vanadium and chromium residues are obtained; and d, the pressure filtration water is subjected to evaporation and concentration, crystals of sodium salt and ammonium salt and condensation water are obtained. According to the recycling method of the acid ammonium salt precipitating vanadium waste water, after alkaline polyoxovanadium solution is mixed with the acid ammonium salt precipitating vanadium waste water, the pH value is adjusted to 5-6, the solution is crystallized sufficiently, and parts of ammonium and acid in the waste water can be recycled.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Method for preparing equiaxed alpha-phase silicon nitride powder

ActiveCN109608205AUniform particle size distributionUniform particle distributionNitrogen compoundsLiquid ammoniaBoron nitride

The invention discloses a method for preparing equiaxed alpha-phase silicon nitride powder. The method comprises the steps that with silicon tetrachloride and liquid ammonia as raw materials, a silicon imine solid is synthesized under a liquid phase condition, and then the silicon imine solid is thermally decomposed to obtain amorphous silicon nitride; the amorphous silicon nitride and auxiliary additives are treated by a ball milling process for full and uniform mixing; the obtained mixture is put into a graphite or boron nitride crucible, crystallization is carried out for 0-48 hours in an atmosphere sintering furnace under a certain atmosphere condition, and then the equiaxed high-alpha-phase silicon nitride powder with few impurities is obtained. The preparation process of the siliconnitride powder is short in period, the particle morphology of silicon nitride is easy to control, and large-scale industrial production is facilitated.

Owner:浙江英德赛半导体材料股份有限公司

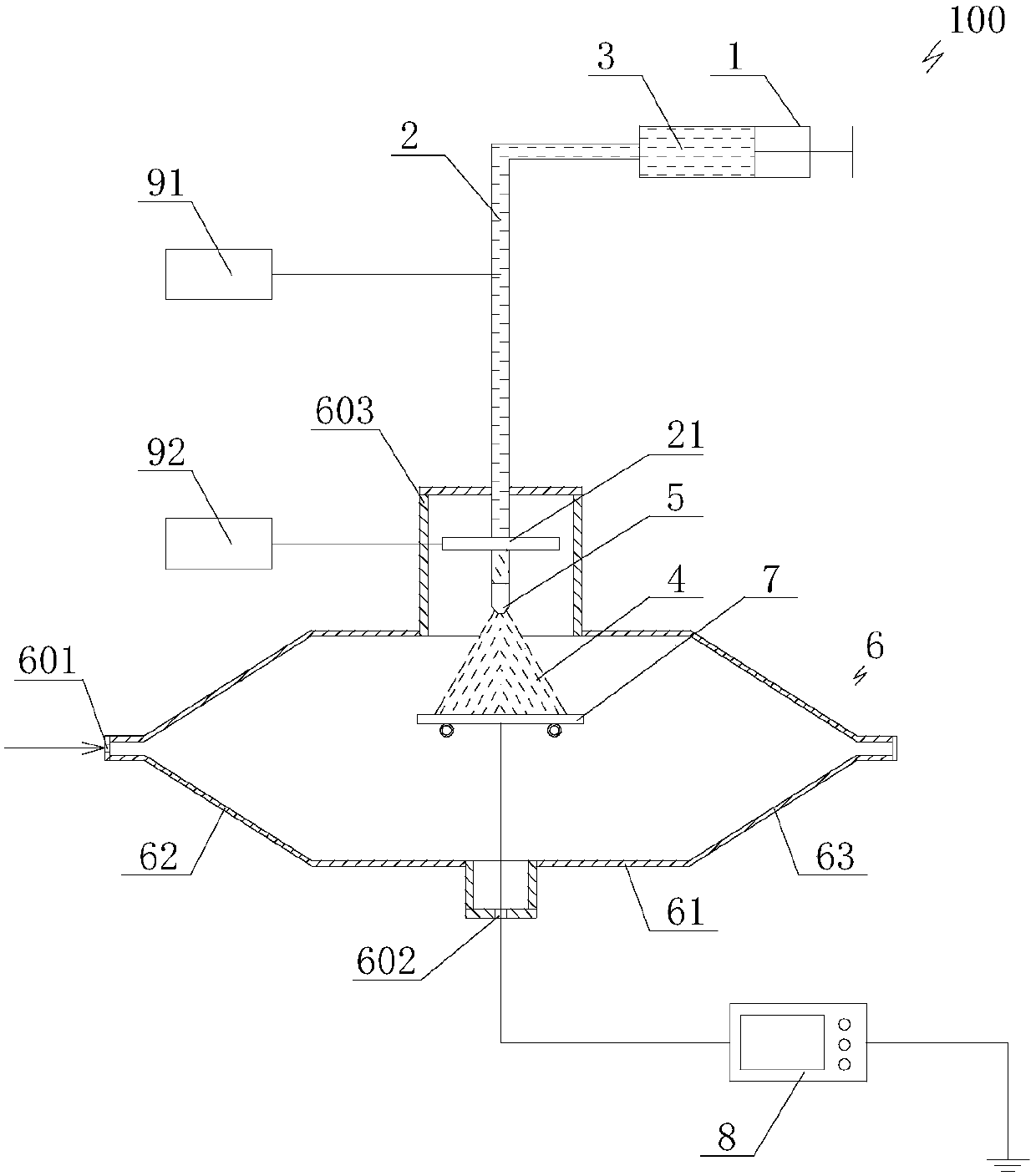

Novel method and device for preparing polymer particles

ActiveCN107715789AAvoid the influence of the preparation processOvercome surface tensionGranulation by liquid drop formationEnergy based chemical/physical/physico-chemical processesPolymer scienceOrganic solvent

The invention relates to a novel method and device for preparing polymer particles. The method includes the following steps that, a conductive organic solvent is pumped into an insulated capillary tube through an injection pump, the capillary tube is sealed and penetrate through a shuttle-shaped pneumatic conveying container which can be sealed, the outlet end of the capillary tube is communicatedwith a nozzle, under the strong electric field effect generated by a high voltage source, the organic solvent is dispersed to form charged droplets, under the traction force effect of electric fieldforce, gravity and flowing gas in the container, the charged droplets are uniformly spread on a grounded collection plate in the shuttle-shaped pneumatic conveying container, and the charged dropletsare grounded through the collection plate so as to remove static electricity, and solid polymer particles are formed. The novel method for preparing the polymer particles is convenient to operate, thedevice for preparing the polymer particles is simple in structure, and the particle size and shape of the obtained products, namely the polymer particles, are uniform, the performance is stable, andthe method and the device are conducive to application and popularization.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com