Method for preparing heterojunction photocatalyst

A photocatalyst and heterojunction technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve undiscovered problems, and achieve regular morphology, complete crystallization, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1NGQDs-BiOI / MnNb 2 o 6 Preparation of p-n junction photocatalyst

[0018] 0.5 g of Nb 2 o 5 Mix with 3.37 g of KOH, add 60 ml of distilled water and react at 200°C for 3 days to obtain the precursor liquid [Nb 6 o 19 ] 8- ; Take 16 milliliters of precursor liquid (containing 0.5mmolNb 5+ ), the pH value of the above solution was adjusted to 7.8 with hydrochloric acid solution, and subsequently, different molar amounts of g-C obtained by calcining urea were added 3 N 4 (0.25, 0.75, 1.25, 1.75 and 2.25mmol) were stirred for 30 minutes before adding 0.25mmol Zn(NO 3 )·6H 2 O (abbreviated as: Zn / CN, Zn / 3CN, Zn / 5CN, Zn / 7CN and Zn / 9CN) and different amounts of NGQDs obtained by pyrolysis of ammonium citrate, where NGQDs with ZnNb 2 o 6 / g -C 3 N 4 The mass ratio of the mass sum is 1:100; 3:100; 5:100 and 7:100 (abbreviated as: 1% NGQDs-ZnNb 2 o 6 / g -C 3 N 4 , 3% NGQDs-ZnNb 2 o 6 / g -C 3 N 4 , 5% NGQDs-ZnNb 2 o 6 / g -C 3 N 4 and 7% NGQDs-Zn...

Embodiment 2

[0019] Embodiment 2NGQDs-ZnNb 2 o 6 / g -C 3 N 4 Characterization Analysis of Heterojunction Photocatalysts

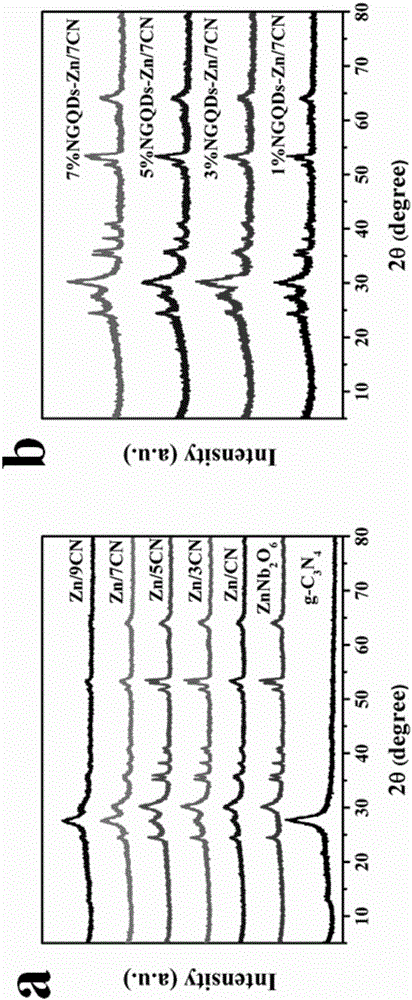

[0020] Such as figure 1 As shown in a, ZnNb 2 o 6 / g -C 3 N 4 Composite samples have both ZnNb 2 o 6 g-C 3 N 4 peak, and g-C 3 N 4 The peak intensity of g-C accompanies 3 N 4 content increases and becomes stronger; as figure 1 b, When NGQDs were introduced into ZnNb 2 o 6 / g -C 3 N 4 On the surface, no diffraction peaks of NGQDs were found, which may be due to the presence of NGQDs in the NGQDs-ZnNb 2 o 6 / g -C 3 N 4 The content in the heterojunction is relatively small, the dispersion is relatively high and the crystallinity is relatively low.

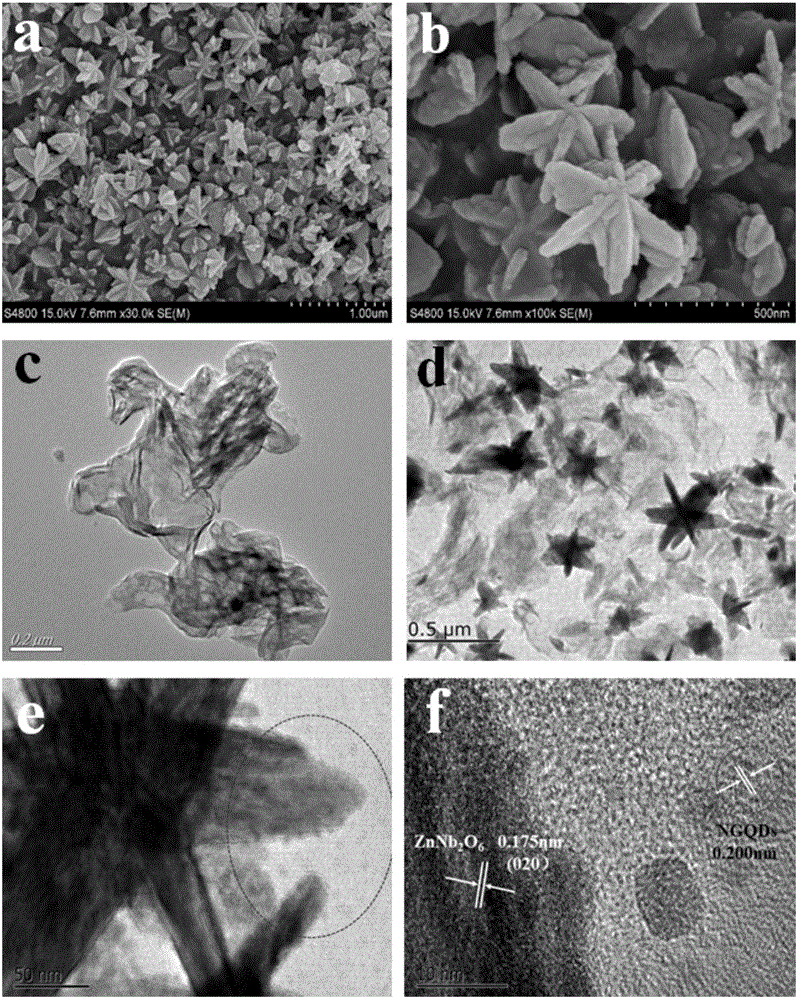

[0021] figure 2 a-b It can be observed that pure ZnNb 2 o 6 presents a large-scale microsphere structure composed of many nanosheets; as figure 2 c, g-C 3 N 4 Presents a sheet-like graphene structure; figure 2 d shows g-C 3 N 4 Nanosheets and 3D flower-like ZnNb 2 o 6 mixed together to form...

Embodiment 3

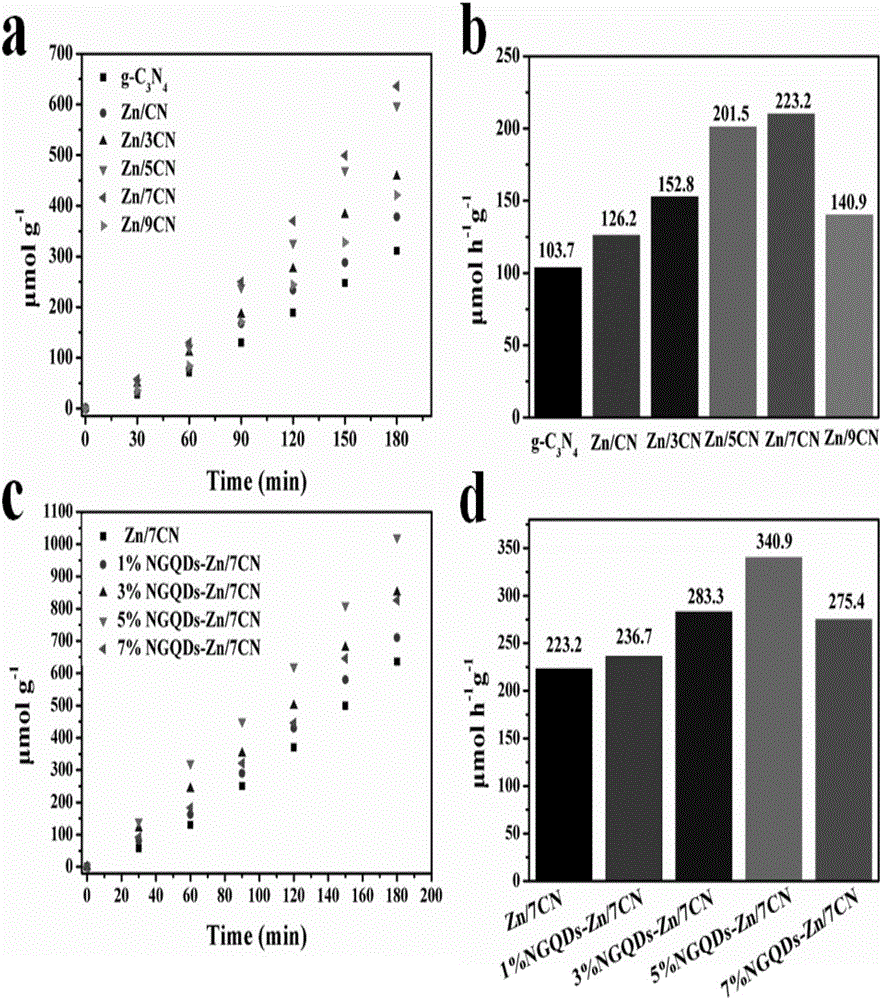

[0022] Embodiment 3NGQDs-ZnNb 2 o 6 / g -C 3 N 4 Visible light catalytic activity experiments of heterojunction photocatalysts

[0023] (1) Deposit cocatalyst (0.6% Pt) nanocrystals onto 50 mg NGQDs-ZnNb by light 2 o 6 / g -C 3 N 4 The surface of the target composite system to enhance its catalytic activity.

[0024] (2) On-line detection of NGQDs-ZnNb under the irradiation of visible light (420-680nm) by photolysis water hydrogen production test platform 2 o 6 / g -C 3 N 4 The photocatalytic hydrogen production efficiency of the target composite system; a closed and transparent device containing an aqueous solution of the target composite system is irradiated with a visible light source with a fixed wavelength (420nm).

[0025] (3) The hydrogen production is detected by gas chromatography every 30 minutes, and the hydrogen production efficiency is calculated.

[0026] (4) by image 3 It can be seen that the prepared NGQDs-ZnNb 2 o 6 / g -C 3 N 4 The catalyst has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com