Method for preparing Ag:ZnIn2S4 luminescent quantum dots and photocatalyst

A luminescent quantum and photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, gallium/indium/thallium compounds, etc., to achieve the effects of short reaction time, excellent photocatalytic activity, and complete crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Ag:ZnIn 2 S 4 Preparation of Luminescent Quantum Dot Photocatalyst

[0021] Mix and dissolve silver nitrate, indium nitrate, zinc acetate dihydrate, and L-cysteine in an aqueous solution, adjust the pH value of the solution to 8.5 with NaOH, add thioacetamide for ultrasonic stirring, and then conduct a hydrothermal reaction at 110 degrees for 4 Hours, after the reaction, through centrifugation and drying, to obtain Ag:ZnIn 2 S 4 Luminescent quantum dots; the addition of zinc acetate dihydrate, indium nitrate and L-cysteine are 1mmol, 2mmol, and 3mmol respectively; the addition of thioacetamide is 3.82mmol; the addition of silver nitrate is: 0.05mmol , 0.1 mmol, 0.15 mmol, 0.2 mmol, 0.3 mmol, 0.4 mmol, 0.6 mmol.

Embodiment 2

[0022] Example 2 Ag:ZnIn 2 S 4 Characterization and Analysis of Luminescent Quantum Dot Photocatalysts

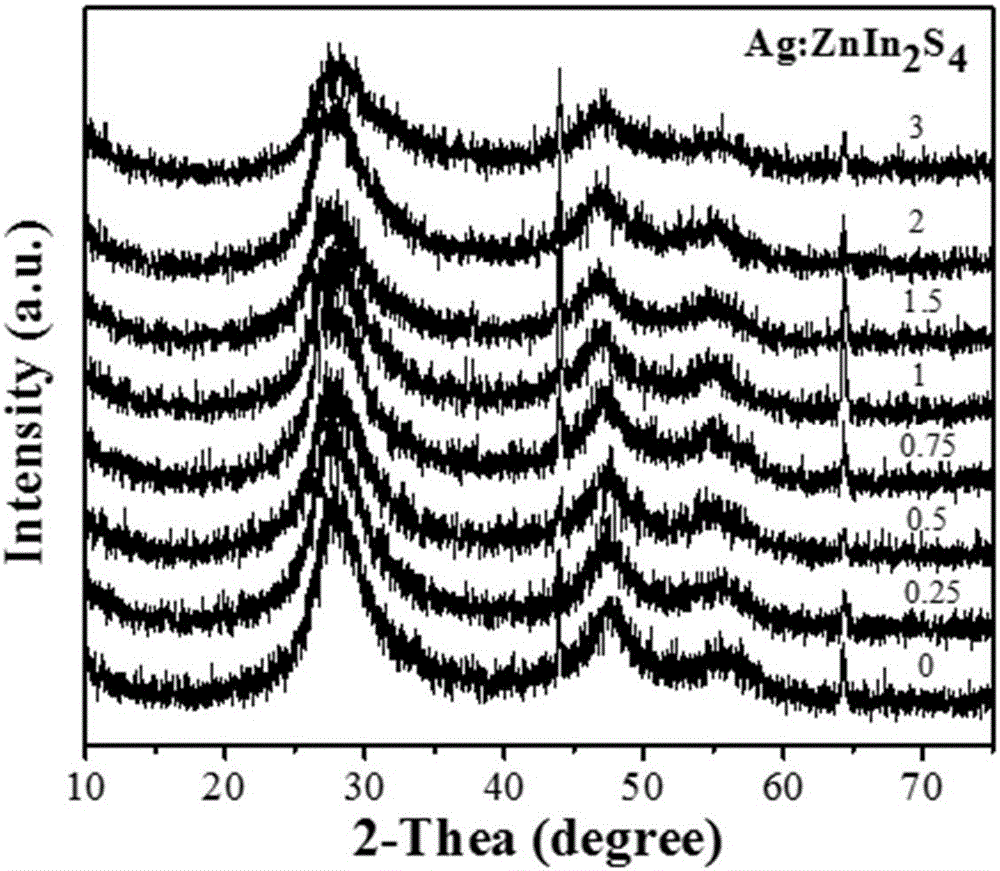

[0023] Such as figure 1 As shown, it can be seen from the figure that with the increase of the amount of doped Ag, it is still mainly ZnIn 2 S 4 A slight angular shift in the peaks of the quantum dots indicates increased crystallinity.

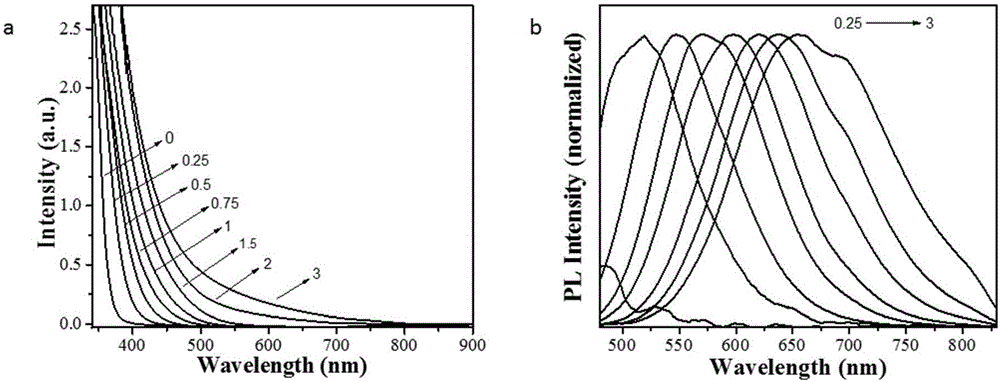

[0024] Such as figure 2 As shown, it can be seen from the figure that with the increase of the amount of doped Ag, the absorption spectrum red shifts, and the absorption range gradually shifts to the long-wavelength direction, which improves the utilization of visible light; the fluorescence emission peak moves to the near-infrared region, which can be used on biomarkers.

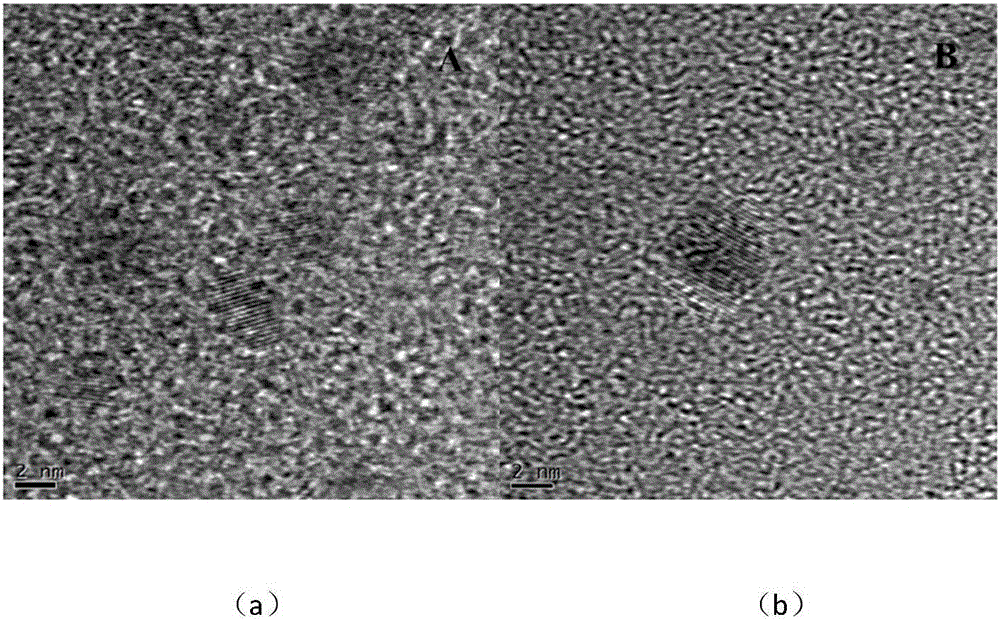

[0025] Such as image 3 As shown, it can be seen from the figure that different proportions of Ag:ZnIn 2 S 4 The luminescent quantum dots are only a few nanometers, and the nanometer size gradually increases with the increase of Ag doping.

[0026] Such as F...

Embodiment 3

[0027] Example 3 Ag:ZnIn 2 S 4 Visible light catalytic activity experiments of luminescent quantum dot photocatalysts

[0028] (1) The preparation concentration is 0.25MNa 2 SO 3 / 0.35MNa 2 The S mixed solution was used as a sacrificial reagent and stirred ultrasonically.

[0029] (2) Weigh a series of different ratios of Ag:ZnIn 2 S 4 Put 100mg of luminescent quantum dot photocatalysts in the photocatalytic reactor respectively, add 100mL of the target sacrificial reagent prepared in step (1), stir magnetically for 20 minutes, and wait for the photocatalyst to disperse evenly, with or without platinum, in a vacuum environment, Turn on the light source and conduct photocatalytic hydrogen production experiment.

[0030](3) Take a sample every 1 hour and detect it with a gas chromatograph.

[0031] (4) by Figure 4 It can be seen that the prepared photocatalyst has excellent visible light catalytic activity, especially the Ag:ZnIn2S4 luminescent quantum dot when the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com