Preparation method for atomic scale precious metal nanoparticle stable colloidal suspension

A technology of nanoparticles and precious metals, which is applied in the field of preparation of stable colloidal suspensions of precious metal particles, can solve problems affecting performance, easy agglomeration, etc., and achieve the effect of regular shape and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

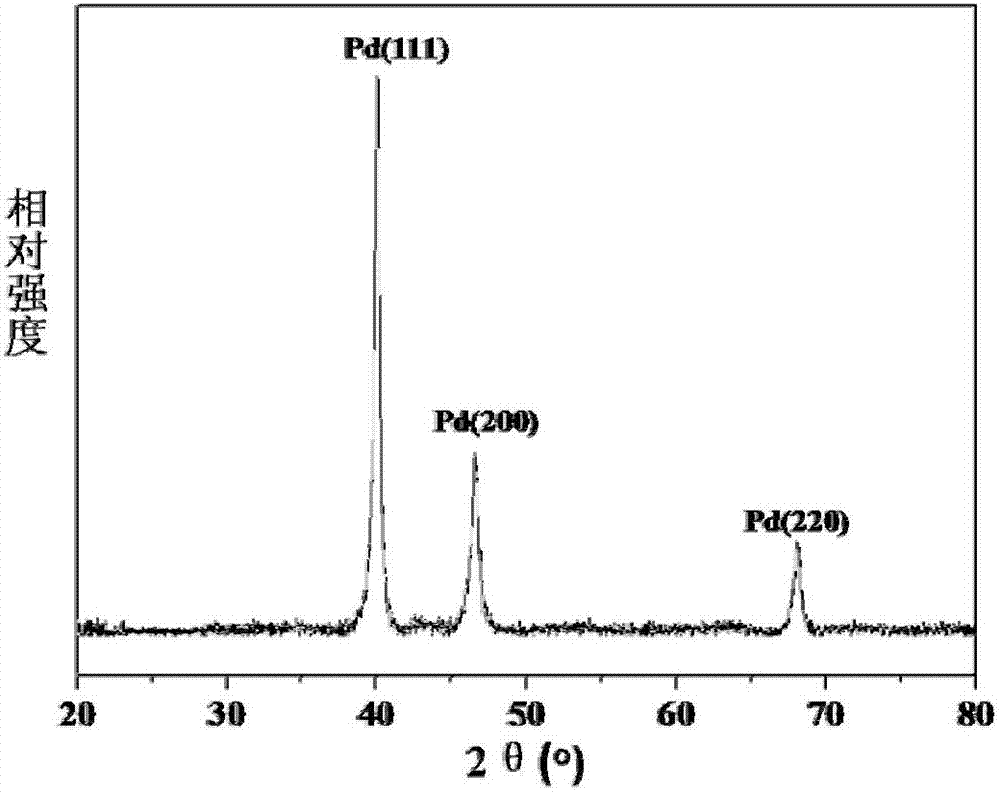

[0017] Weigh 0.0500g of chloropalladic acid and place it in 100mL of polyethylene glycol / ethylene glycol with a volume ratio of 1:1 for ultrasonic dispersion to obtain a yellow chloropalladic acid solution, and add sodium hydroxide solution dropwise under magnetic stirring, Adjust the pH to 9, transfer to a 500mL beaker after stirring for 30min, and heat in a microwave oven at 140°C for 3min. After the reaction was completed, it was naturally cooled to room temperature, and the obtained product was suction-filtered with a No. 6 sand core funnel, washed alternately with absolute ethanol and deionized water for 10 times, and then dispersed in absolute ethanol to obtain a stable colloidal suspension of palladium nanoparticles. The product is analyzed by atomic force microscope, the particle size is 1-3 nanometers, the average particle size is 2 nanometers, and it will not agglomerate after long-term storage. Such as figure 1 , the diffraction peaks in the XRD diagram are the cha...

example 2

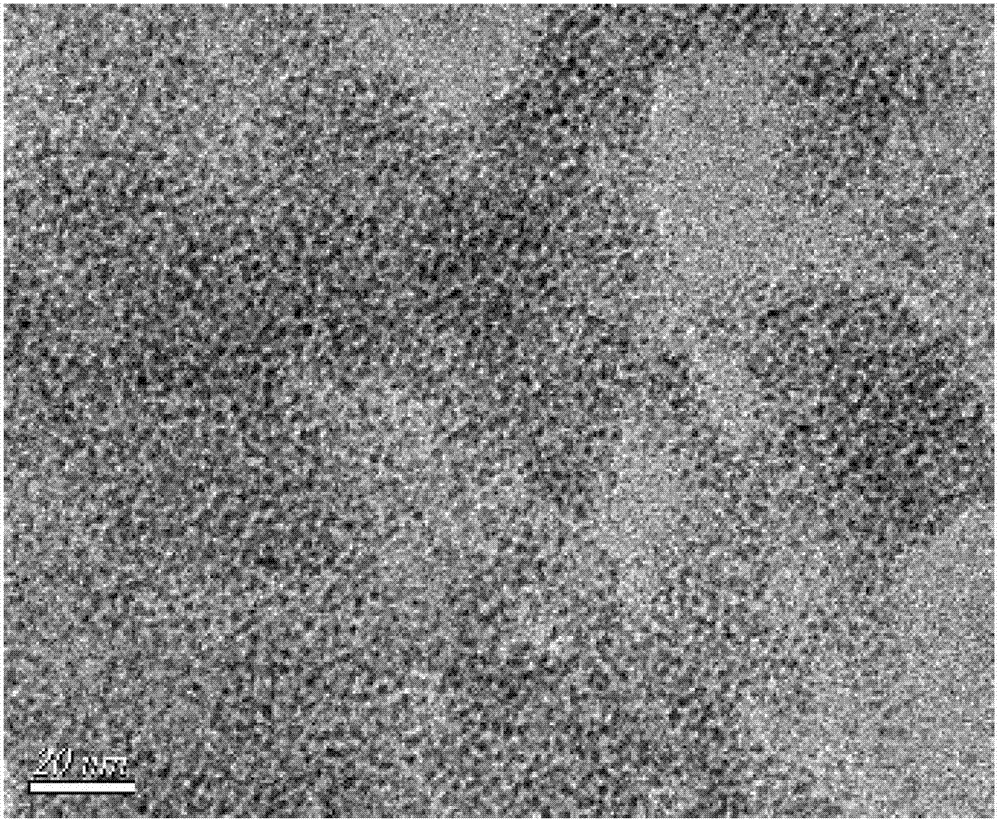

[0019] Weigh 0.0800g of chloroplatinic acid and place it in 100mL of polyethylene glycol / ethylene glycol with a volume ratio of 1:1 for ultrasonic dispersion to obtain a yellow chloroplatinic acid solution, and add sodium hydroxide solution dropwise under magnetic stirring, Adjust the pH to 9.5, transfer to a 500mL beaker after stirring for 30min, and heat in a microwave oven at 140°C for 3min. After the reaction was completed, it was naturally cooled to room temperature, and the obtained product was suction-filtered with a No. 6 sand core funnel, washed alternately with absolute ethanol and deionized water for 10 times, and then dispersed in absolute ethanol to obtain a stable colloidal suspension of palladium nanoparticles. The product is analyzed by atomic force microscope, the particle size is 0.5-2 nanometers, the average particle size is 1 nanometer, and it will not agglomerate for a long time. Such as figure 2 , which is a transmission electron micrograph of a stable ...

example 3

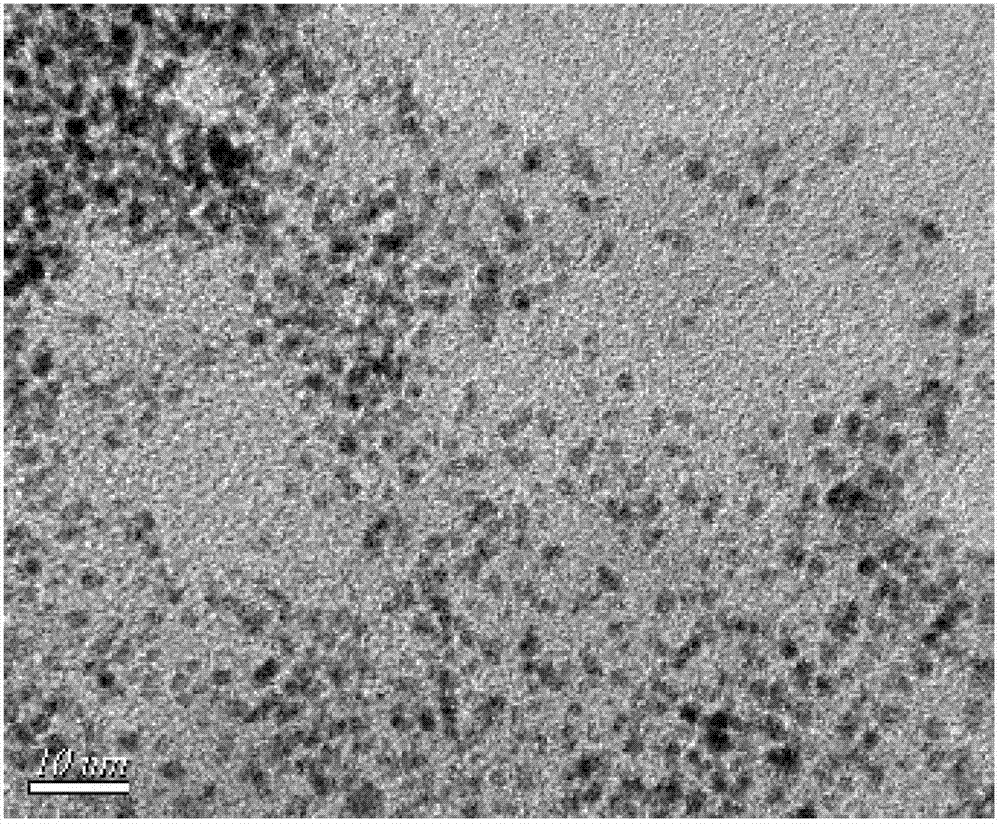

[0021] Weigh 0.0500g of chloroplatinic acid and place it in 100mL of polyethylene glycol / ethylene glycol with a volume ratio of 1:1 for ultrasonic dispersion to obtain a yellow chloroplatinic acid solution, and add sodium hydroxide solution dropwise under magnetic stirring, Adjust the pH to 9.5, transfer to a 500mL beaker after stirring for 30min, and heat in a microwave oven at 140°C for 3min. After the reaction was completed, it was naturally cooled to room temperature, and the obtained product was suction-filtered with a No. 6 sand core funnel, washed alternately with absolute ethanol and deionized water for 10 times, and then dispersed in absolute ethanol to obtain a stable colloidal suspension of platinum nanoparticles. The product is analyzed by atomic force microscope, the particle size is 1-3 nanometers, and the average particle size is 1.5 nanometers. Such as image 3 , the pH of the system is 9.5, and the polyethylene glycol / ethylene glycol volume ratio is the trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com