PET composite material

A technology of composite materials and composite nucleating agents, applied in the field of polymer material preparation, can solve the problems of inability to guarantee the crystallinity of low mold temperature injection molding products, the effect of cold crystallization temperature is not obvious, and adapt to water cooling system technology, etc., to achieve Good comprehensive mechanical properties, shortened production process, good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

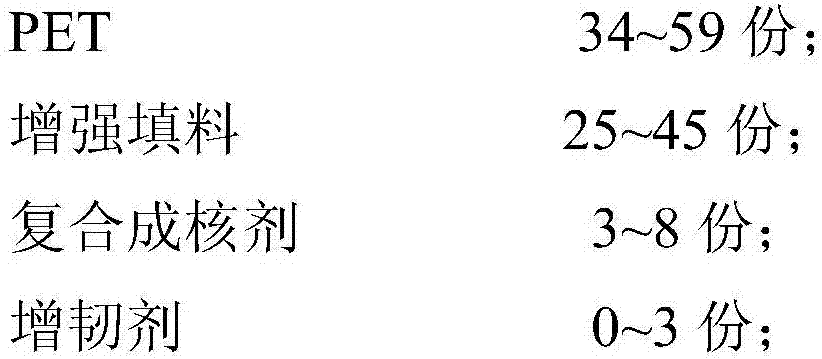

Method used

Image

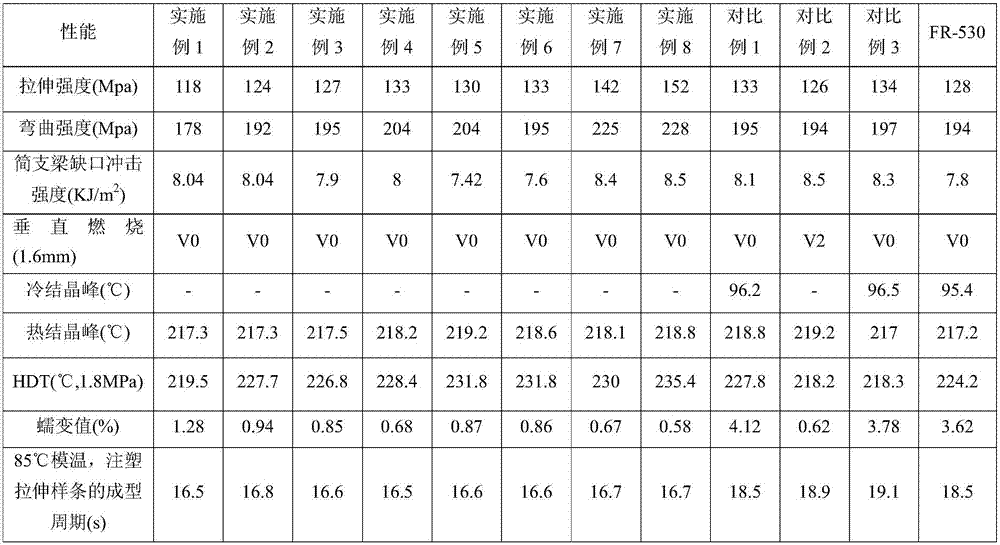

Examples

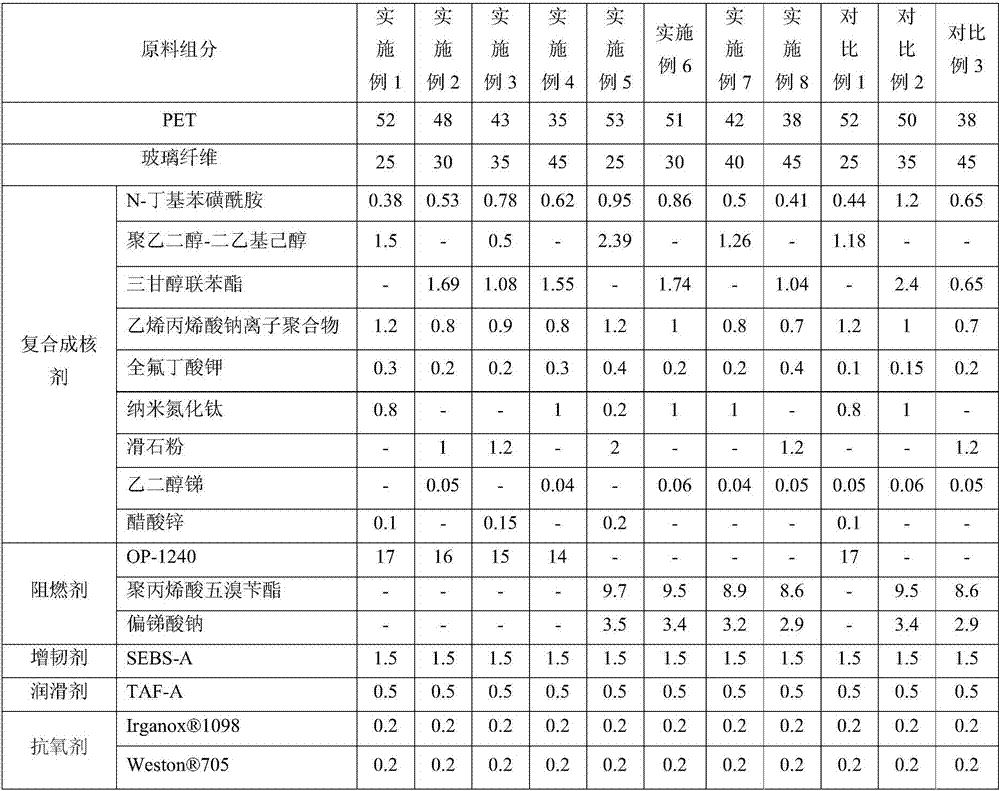

Embodiment 1~8

[0057] Weigh the corresponding formula components according to the formula table in Table 1, dry the weighed PET resin to a moisture content of ≤0.07%, mix it with other components except reinforcing fillers and plasticizers, Feed port feeding, glass fiber is fed from the side feeding port, plasticizer is pumped in from the middle of the extruder with a metering pump, plasticized, melted, then extruded, drawn, cooled, dried, cut pellets to obtain modified PET composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com