Patents

Literature

58results about How to "No white spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive used for monocrystalline silicon wafer alkaline flocking and application method thereof

InactiveCN102312294AExtended failure cycleIncrease contact rateAfter-treatment detailsTO-18Temperature control

The invention relates to an additive used for monocrystalline silicon wafer alkaline flocking and an application method thereof, belonging to the technical field of solar batteries. The additive is prepared by the following components: ethanolamine, polyphosphate, sodium dodecylbenzene sulfonate, sodium hydroxide and water. A flocking agent is prepared through the following steps: (1) dissolving sodium hydroxide in deionized water so as to obtain alkaline flocking liquid; (2) adding the additive motioned above into the alkaline flocking liquid to obtain the flocking agent. During flocking, monocrystalline silicon wafers used for solar batteries are immersed in the flocking agent with temperature controlled to be 75 to 85 DEG C and flocking time controlled to be 15 to 18 minutes. The additive used for monocrystalline silicon wafer alkaline flocking in the invention enables flocking reaction time to be shortened and productivity to be enhanced; prepared texture surface pyramids have a uniform size and low reflectivity; the additive is applicable to solar battery silicon wafer alkaline flocking of different specifications and meets the purpose of industrial production.

Owner:浙江向日葵聚辉新能源科技有限公司

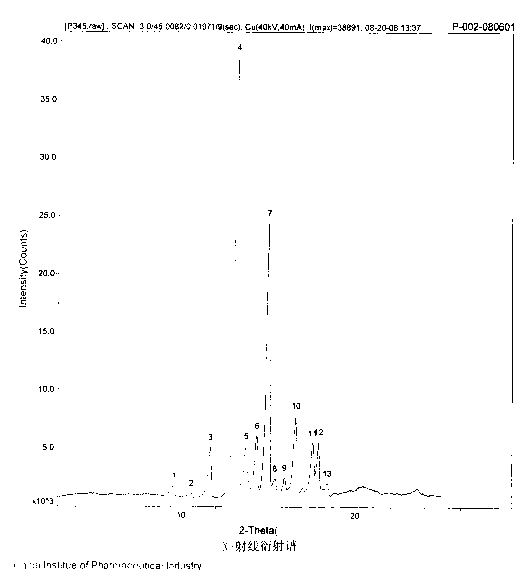

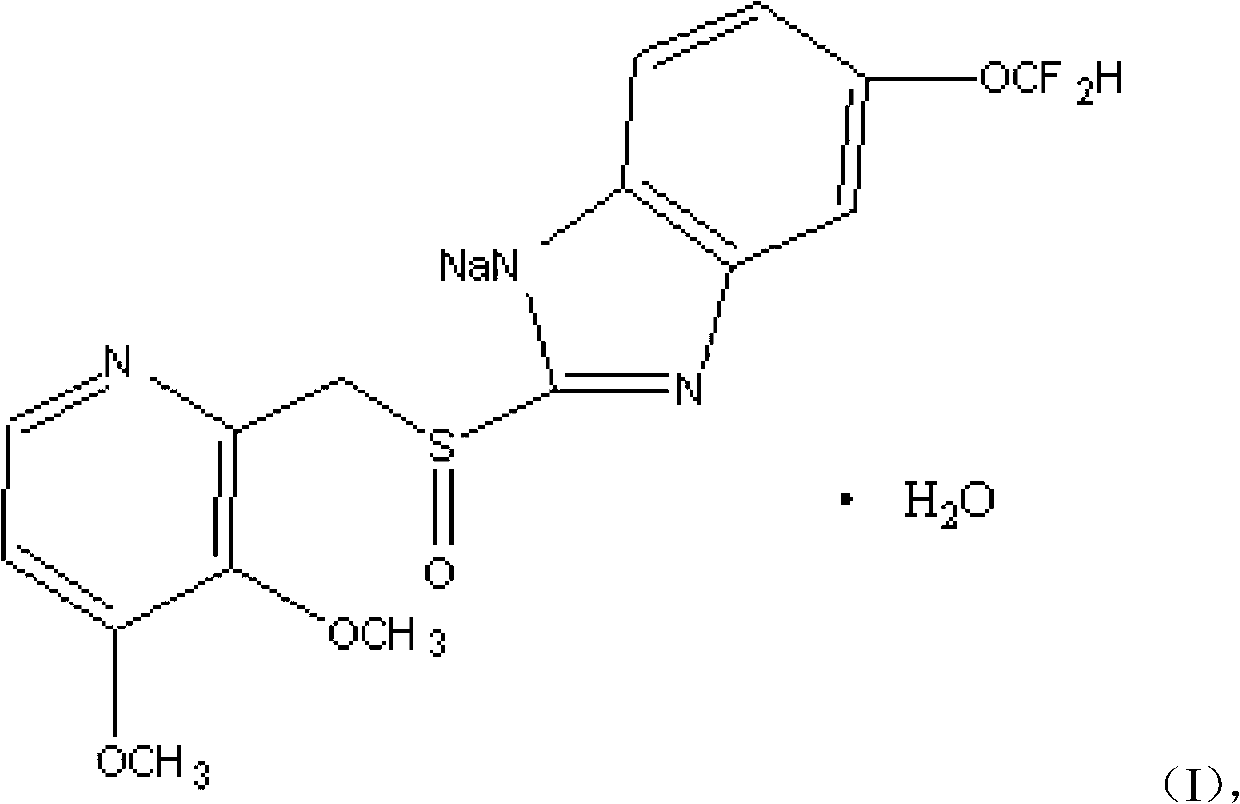

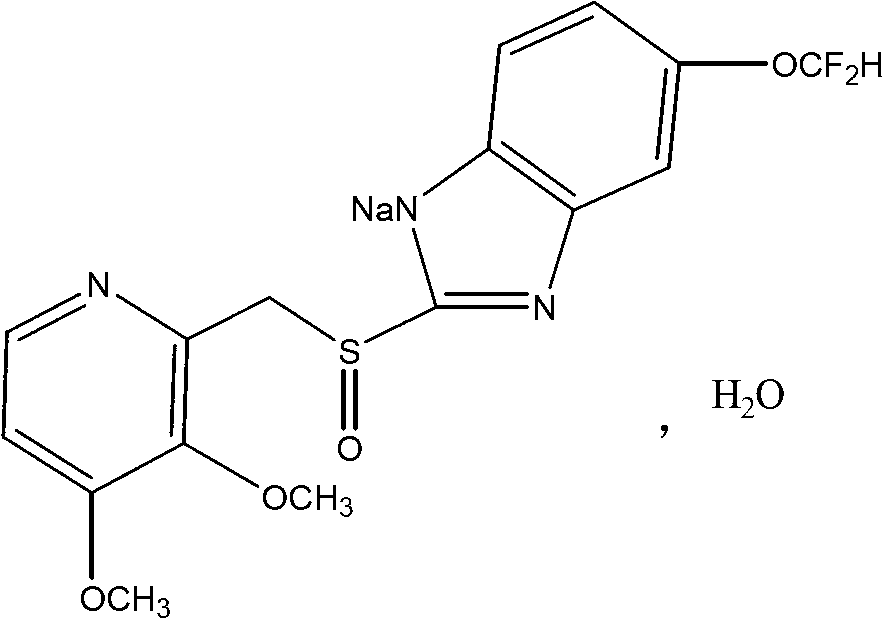

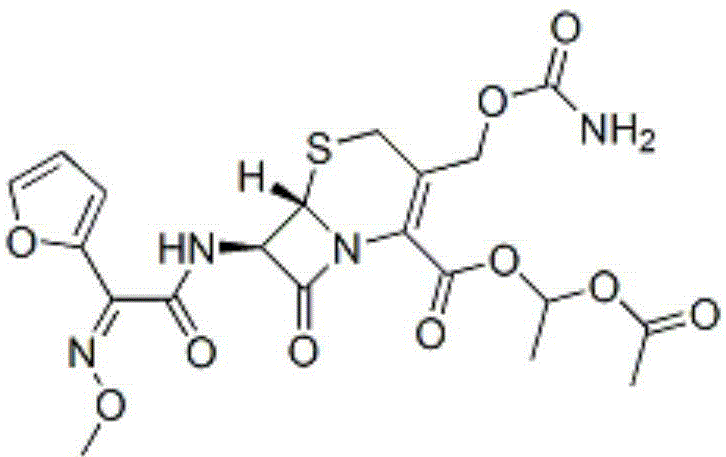

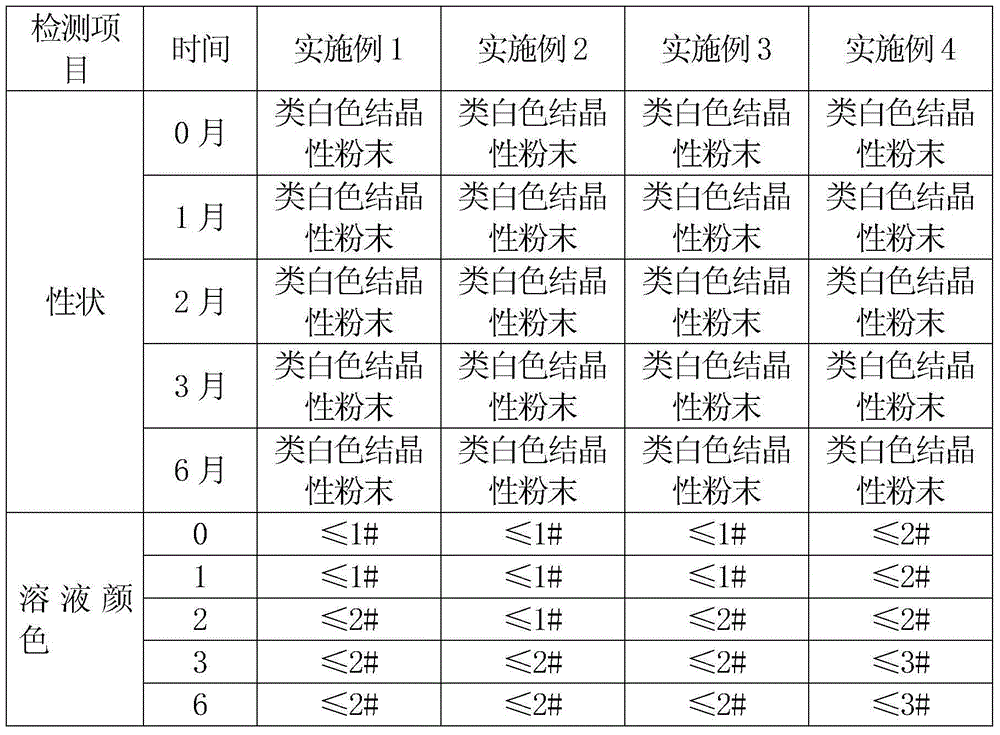

Pantoprazole compound, preparation methods and pharmaceutical preparations thereof

ActiveCN102796078AGood resolubilityHigh clarityOrganic active ingredientsPowder deliverySolubilityDrug compound

The invention belongs to the technical field of pharmaceutical compounds, and relates to a pantoprazole sodium compound entity, especially a pantoprazole sodium crystal form, preparation methods and pharmaceutical preparations thereof. The pantoprazole sodium compound is crystal, and measured by X-diffraction powder diffraction, and the diffraction pattern has the following diffraction angles (2Theta) in turn: 9.5 degrees, 10.4 degrees, 11.6 degrees, 13.1 degrees, 13.8 degrees, 14.2 degrees, 15.0 degrees, 15.3 degrees, 15.9 degrees, 16.5 degrees, 17.5 degrees, 18.0 degrees and 18.2 degrees. The pantoprazole sodium compound entity may be associated with a variety of lyophilization supporting agents and the prepared lyophilized powder for injection has good solubility, good clarity and low content of related substances, etc. simultaneously the use level of the used lyophilization supporting agent is relatively less, the cost of the products is reduced, and the stability and quality of the products are improved.

Owner:杭州澳亚生物技术股份有限公司

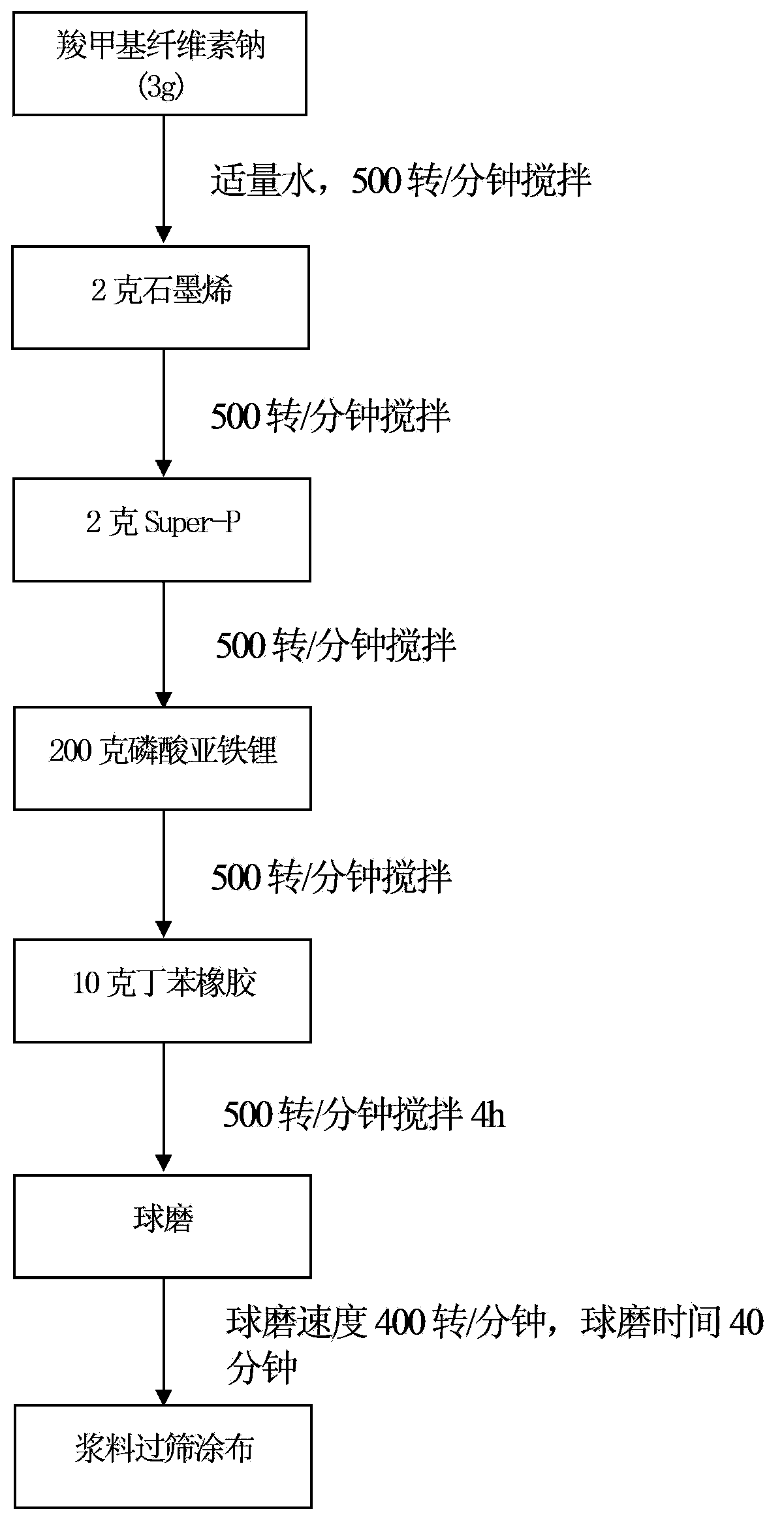

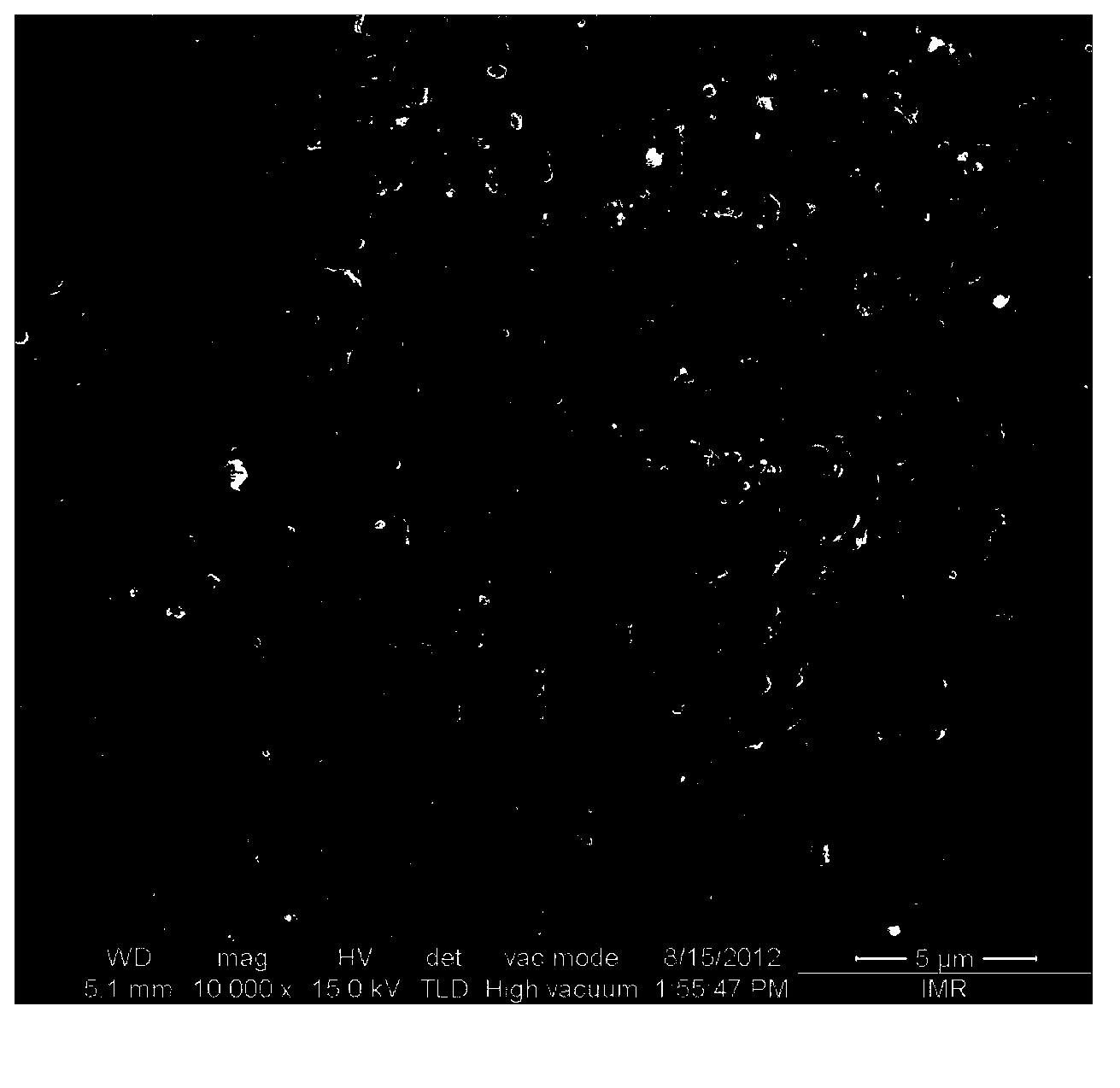

Method for using carbon nano conductive agent in lithium ion battery aqueous slurry

InactiveCN103840164AEffective dispersionEasy to smoothImpregnation manufacturingSlurrySurface-active agents

The invention discloses a method for using a carbon nano conductive agent in lithium ion battery aqueous slurry, and belongs to the technical fields of conductive agents and lithium ion batteries. According to the method disclosed by the invention, the carbon nano conductive agent is directly added into the lithium ion battery anode / cathode aqueous slurry (free from a surface active agent) and then is subjected to ball milling at a high speed after being stirred; the hydrophobic carbon nano conductive agent is effectively dispersed by utilizing shearing force generated during ball-milling at the high speed, so that various constituent materials in the lithium ion battery anode / cathode aqueous slurry can be uniformly dispersed, and therefore, the hydrophobic carbon nano conductive agent can also be applied in the lithium ion battery aqueous slurry in the absence of the surface active agent. The method disclosed by the invention is simple in process and low in cost; the current process is not changed; after being coated, the slurry prepared by utilizing the method disclosed by the invention is assembled to form a lithium ion battery, and therefore, the rate capability can be effectively increased.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Surface treatment method of amorphous alloy

InactiveCN103993314AConsistent colorConsistent textureAnodisationSuperimposed coating processAluminum metalAluminium oxides

The invention relates to the technical field of amorphous alloy and in particular relates to a surface treatment method of amorphous alloy. The method comprises the following steps: 1, performing cold spraying, namely spraying an aluminum layer or an aluminum alloy layer to the surface of the amorphous alloy by adopting a cold spraying process to obtain a semi-finished product; 2, performing anodizing treatment, namely performing anodizing treatment on the aluminum layer or the aluminum alloy layer in the semi-finished product obtained in the step 1 to enable an aluminum oxide film to be formed on the surface the aluminum layer or the aluminum alloy layer to obtain a finished product. According to the method, the treated amorphous alloy product can be perfectly matched with an aluminum alloy product in appearance, and the appearance requirements of industrial design are met; moreover, compared with a PVD (physical vapor deposition) technology, the method has the characteristics that the appearance requirements can be well met on the basis of the advantage of low cost, and the application range of the amorphous alloy is greatly expanded.

Owner:WINTOP DONGGUAN INDAL TECH

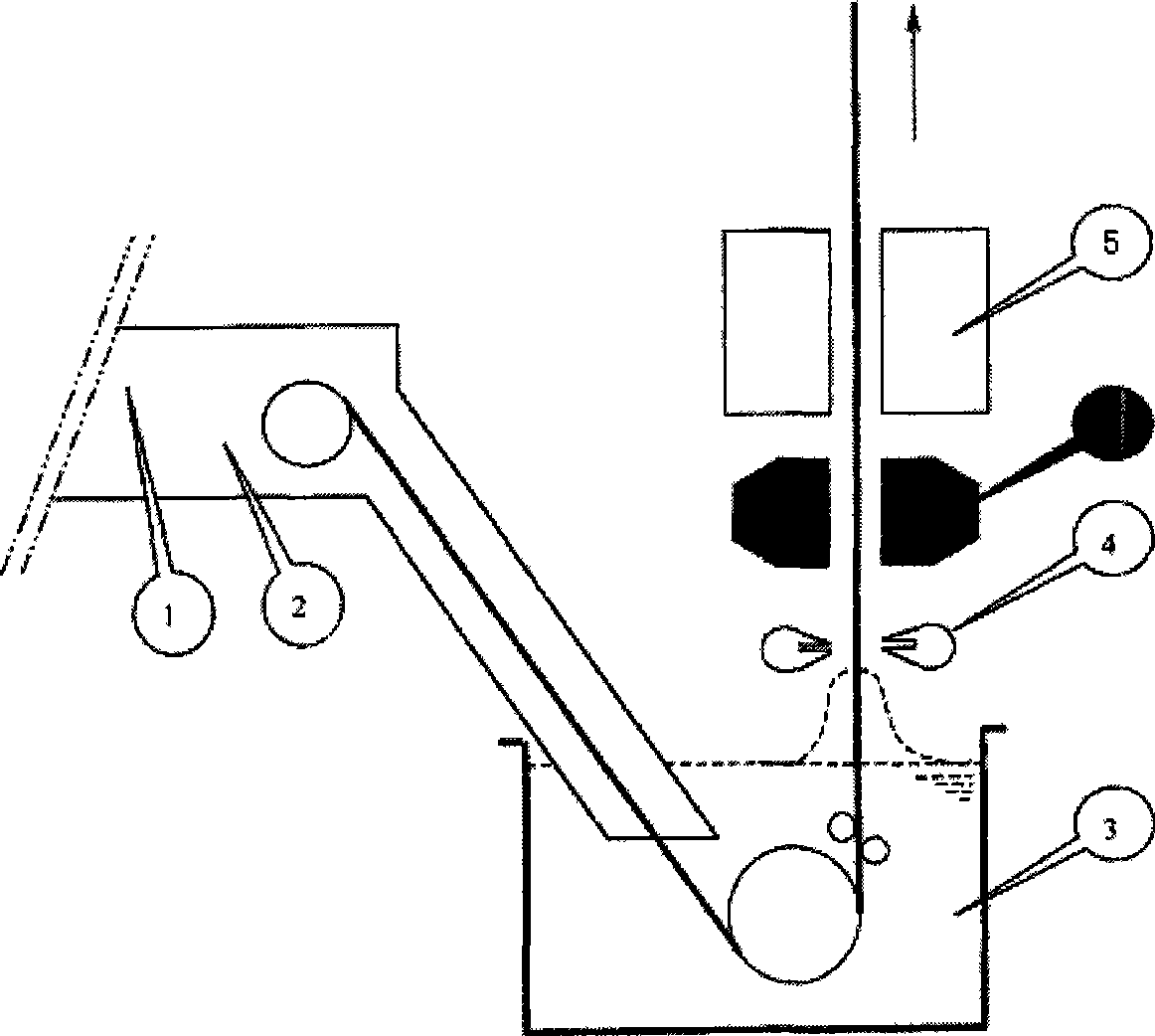

Steel plate minimum spangle galvanizing spray art

InactiveCN101545085ALow viscosityImprove atomization effectHot-dipping/immersion processesSheet steelAir knife

The invention discloses a steel plate minimum spangle galvanizing spray art, comprising that: the steel plate is heated by a heating stove and reduced to enter a zinc kettle for galvanizing and an air knife scrapes the excessive zinc liquor; the steel plate is sprayed and cooled by a minimum spangle machine on the surface to form a minimum spangle; the surface of the minimum spangle steel plate obtained in the step 2 is finished, wherein the diameter of the nozzle of the minimum spangle is 1.5-3 mm, water pressure is 1.5-4 bars, compressed-air pressure is 1.4-6 bars, the distance between the nozzle of the minimum spangle machine and the air knife is regulated to 400-600 mm, preferred 500 mm and the cooling water in the minimum spangle machine intake pipe is preheated to 30-50 DEG C. By checking-out, the plated surface spangle of the minimum spangle galvanizing steel plate removes the grain boundary and is suitable for subsequent coating. The subsequent coating plated surface is smooth and the oil paint quantity can be saved by 8% when the film thickness is 15 mum.

Owner:福建凯景新型科技材料有限公司

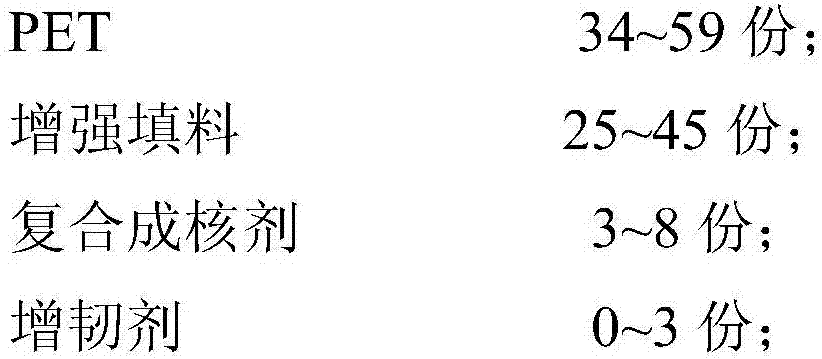

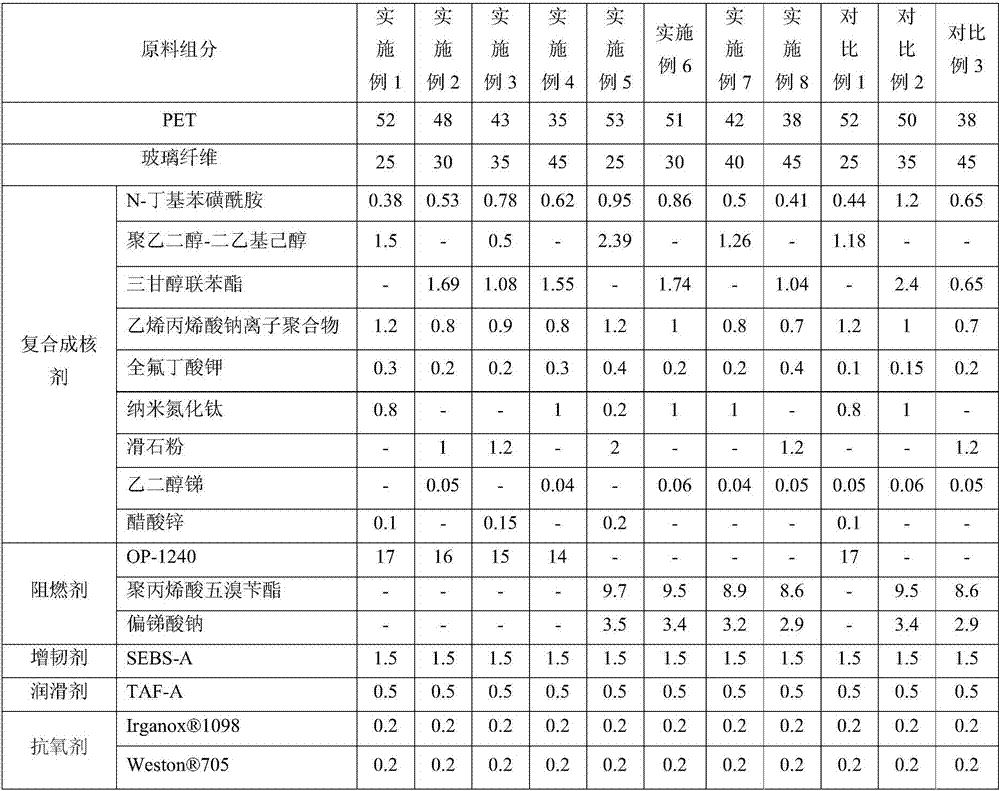

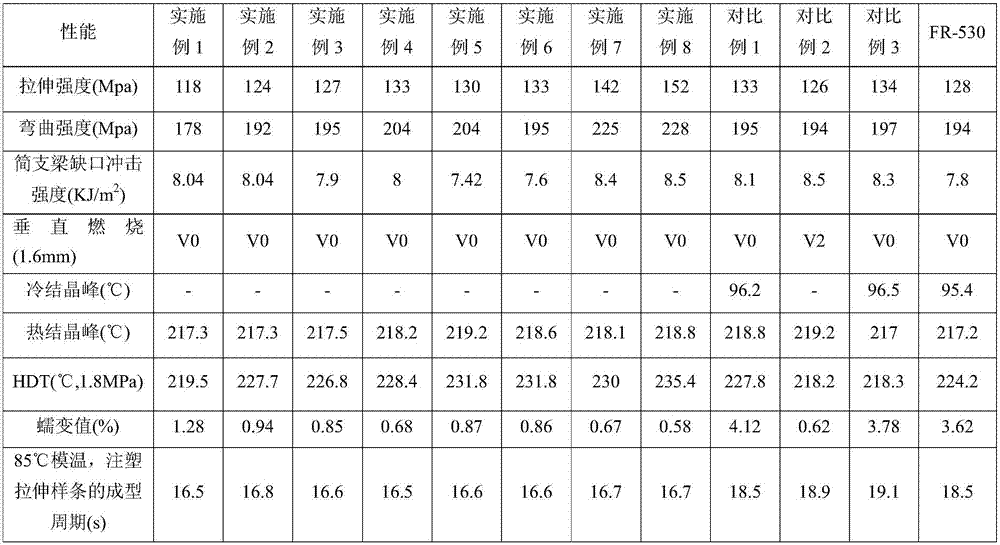

PET composite material

The invention discloses a PET composite material, which comprises the following components in parts by weight: 34 to 55 parts of PET, 25 to 45 parts of enhanced filling material, 3 to 8 parts of composite nucleating agent, and 0 to 3 parts of flexibilizer; wherein the composite nucleating agent comprises a chemical nucleating agent and a plasticizer, the weight ratio of the plasticizer to PET resin is 3.5-7:100, the plasticizer is prepared by compounding a benzsulfamide plasticizer with other plasticizers, other plasticizers can be one or more of polyethylene glycol-diethyl hexyl alcohol, neopentyl glycol diphenyl ester, tribenzyl propylidene ether diethyl hexyl alcohol, and triethylene glycol diphenyl ester, the structural formula of the benzsulfamide plasticizer is represented in the description, and in the structural formula, R represents a branched alkyl group or a straight chain alkyl group. The composite material is injection-moulded at a mould temperature of 85 DEG C, the crystallization is complete, the moulding period is short, and the PET composite material can be used to produce large moulded goods or precision thin-wall moulded goods.

Owner:本松新材料技术(芜湖)有限公司

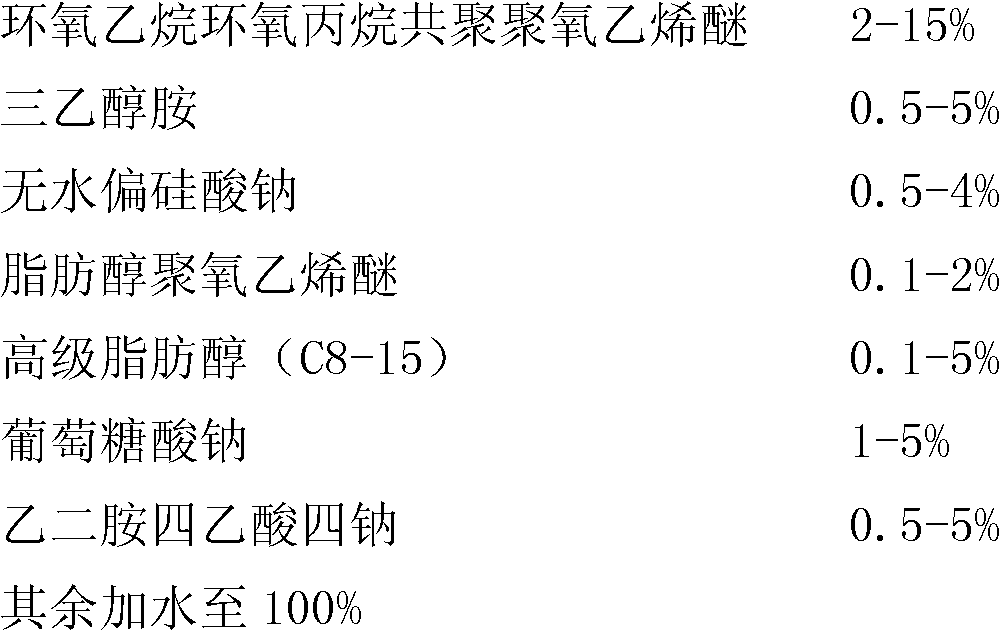

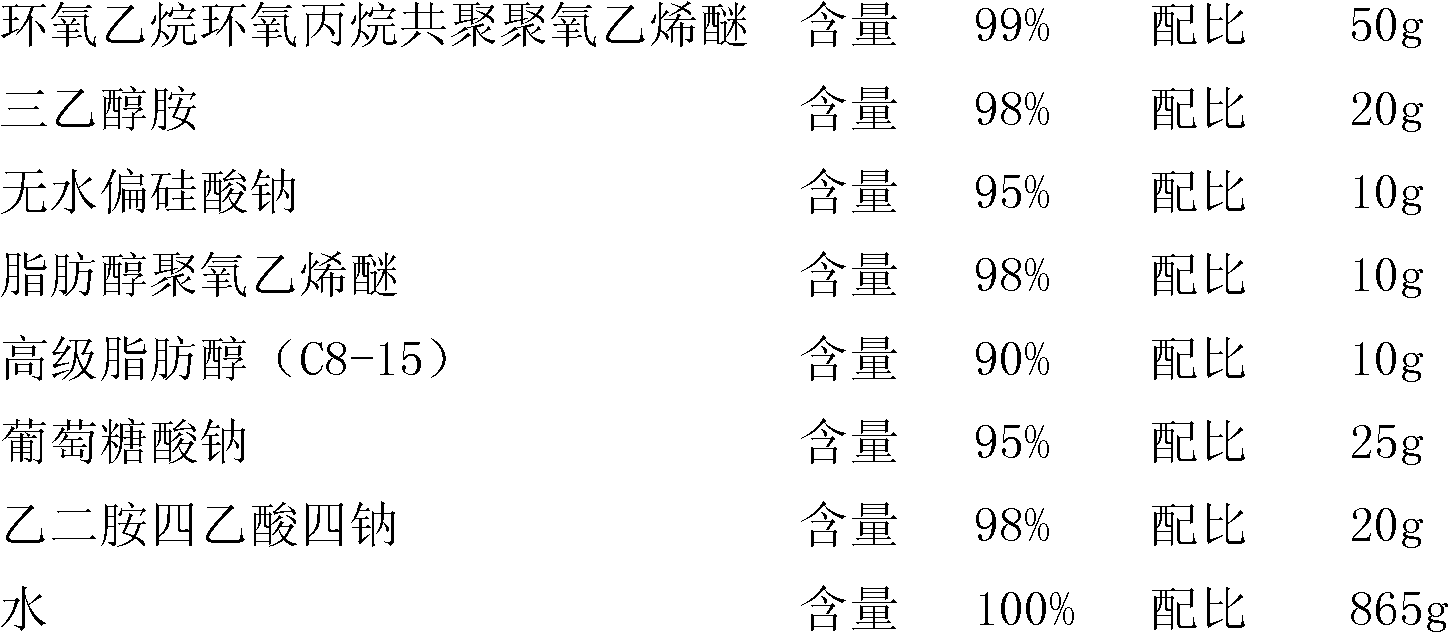

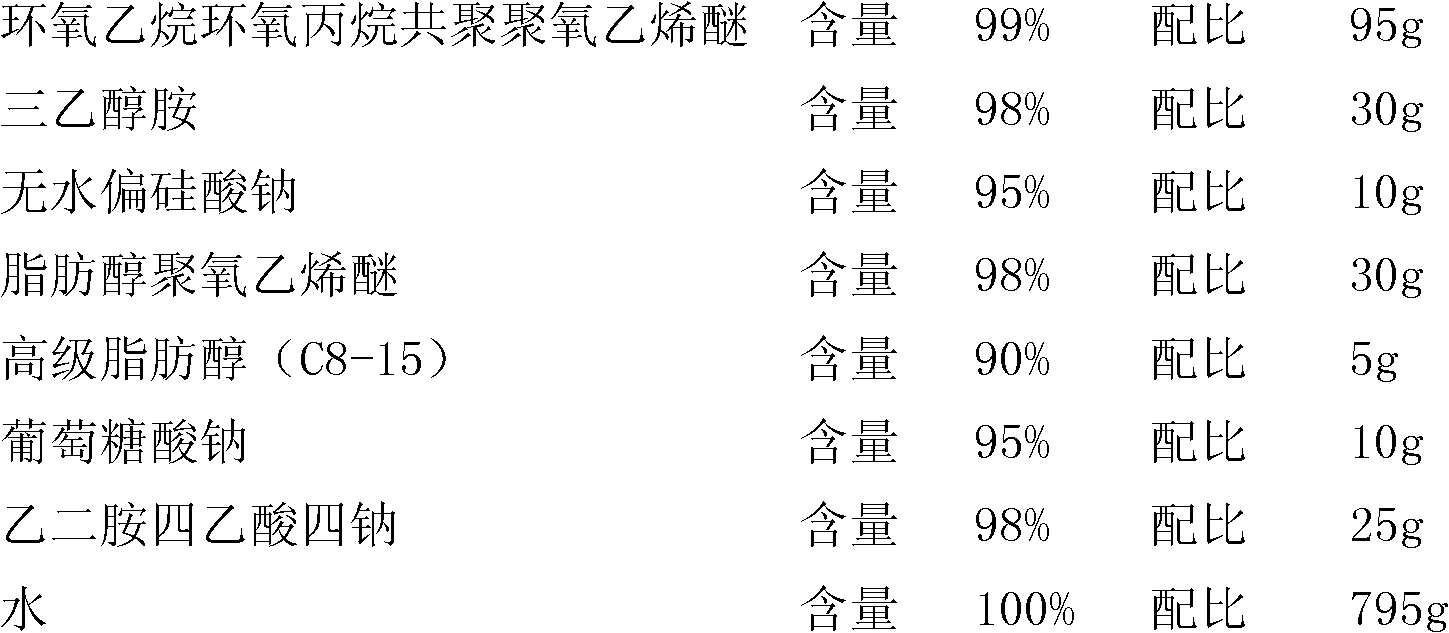

Water-based industrial detergent capable of self-defoaminng at normal temperature and preparation method thereof

InactiveCN102161939AReduce intensityThe principle of achieving self-defoamingInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater basedSodium metasilicate

The invention relates to a water-based industrial detergent capable of self-defoaming at normal temperature and a preparation method thereof. The detergent comprises the following components in percentage by weight: 2-15% of ethylene oxide epoxypropane copolymerized polyoxyethylene, 0.5-5% of triethanolamine, 0.5-4% of sodium metasilicate anhydride, 0.1-2% of fatty alcohol-polyxyethylene ether, 0.1-5% of advanced fatty alcohol (C8-15), 1-5% of sodium gluconate, 0.5-5% of ethylene diamine tetraacetic acid and the balance of water. The preparation method mainly comprises the following steps: dissolving the sodium metasilicate anhydride, the sodium gluconate and the ethylene diamine tetraacetic acid in the water; and then adding the ethylene oxide epoxypropane copolymerized polyoxyethylene, the triethanolamine, the fatty alcohol-polyxyethylene ether, the advanced fatty alcohol (C8-15) and the like in sequence, and mixing to finally obtain the industrial detergent. In the invention, based on the combined action of lipophilic group epoxypropane in the ethylene oxide epoxypropane copolymerized polyoxyethylene and lipophilic group in the system as well as industrial oil stain, the intensity of foam generated in the process of cleaning is reduced so as to realize the self-defoaming effect; through the synergistic effect of various components, optimal cleaning and antirust effects are achieved; simultaneously, through the synergistic effect of various surfactants, the defect that inorganic salts always form white spots on the surface of a workpiece is obviously improved.

Owner:华阳新兴科技(天津)集团有限公司

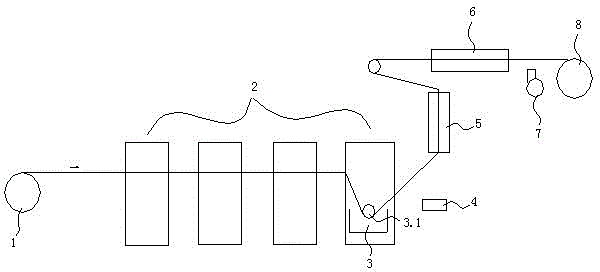

Device and method for coating OPP film with heat-seal glue in fixed point mode

ActiveCN104859290ASimple processOvercome costsLiquid surface applicatorsRotary pressesFilm structureEngineering

The invention relates to a device for coating an OPP film with heat-seal glue in a fixed point mode. The device comprises a printing film unreeling part, a printer unit, a heat-seal glue coating part, a first drying walkway, a second drying walkway, an air cooling device and a printing film reeling part which are sequentially arranged. The heat-seal glue coating part is provided with an electric engraving gravure roller, and the electric engraving gravure roller is matched with the heat-seal arrangement of a printing film so that the heat-seal arrangement area of the printing film can be coated with the heat-seal glue in the fixed point mode. The length of the first drying walkway ranges from 3 m to 4 m. The length of the second drying walkway ranges from 8 m to 10 m. The correspondingly produced heat-seal OPP printing film is of a single-layer film structure, is used for manufacturing a packaging bag, and has the advantages that transparency is higher, the heat-seal strength is low, and tearing is convenient. The whole coating technology process is simple, operation is convenient, and the production efficiency of the heat-seal OPP film is higher.

Owner:江阴市隆辉包装材料有限公司

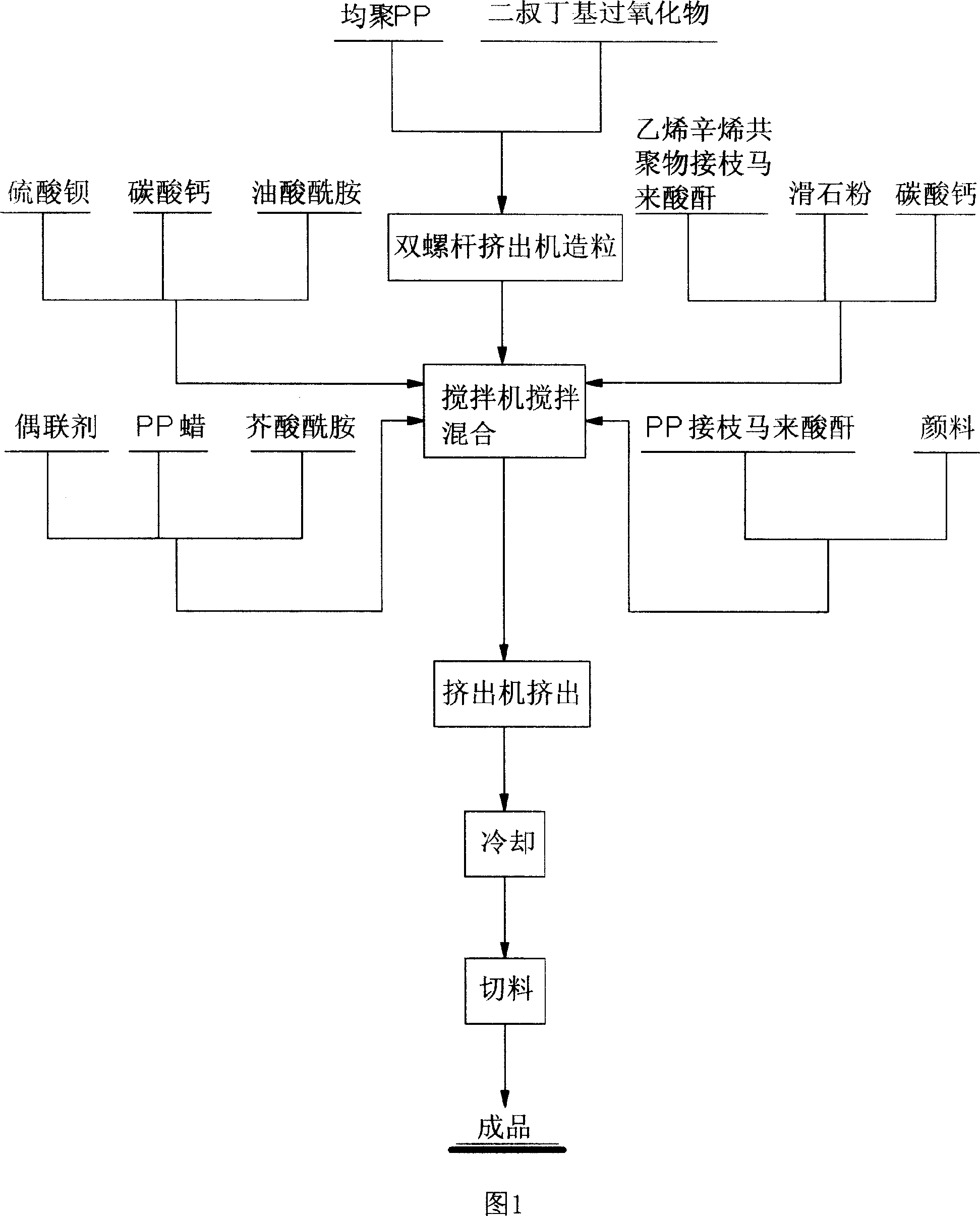

High density poly propylene (PP) composite material

The present invention discloses one kind of high density polypropylene composite material for making counters in entertainment industry. The high density polypropylene composite material consists of ethylene homopolymer 8-40 wt%, barium sulfate 40-80 wt%, talcum powder 0-20 wt%, calcium carbonate 0-20 wt%, PP-g-MAH 4-6 wt%, POE-g-MAH 0-3 wt%, molecular weight regulator 0.5-2 wt%, oleamide 0.5-1.5 wt%, erucyl amide 0.5-2 wt%, PP wax 0.5-2 wt%, coupling agent 1-1.5 wt%, and pigment 0-5 wt%. The high density polypropylene composite material has great specific weight, high strength, high toughness, excellent wear resistance, good handing and other advantages.

Owner:东莞金富亮塑胶颜料有限公司

Quicksand salted egg yolk wrapping sauce and production method and application thereof

The invention discloses a quicksand salted egg yolk wrapping sauce and a production method thereof. The quicksand salted egg yolk wrapping sauce is mainly prepared from salted egg yolk, vegetable oil,butter, white granulated sugar, salt, corn starch and potassium sorbate. The salted egg yolk wrapping sauce is in a fine-grained quicksand shape, attractive in appearance and golden yellow in color and luster, has specific salted egg yolk baking flavor and milk flavor, is sandy and smooth in taste, balanced in nutrition, wide in application and convenient in eating, can be eaten after a cover isopened, can be wrapped on the surface of food for deep frying, can also be applied on breads and used for being mixed with food and cooking.

Owner:HUBEI SHENDAN HEALTHY FOOD

Environment-friendly biological texture etch solution and application method thereof

ActiveCN102181934AThe source of raw materials is stableEasy to sourceAfter-treatment detailsFinal product manufactureCitrate sodiumSodium carbonate

The invention discloses an environment-friendly biological texture etch solution and an application method thereof, particularly relates to application of the texture etch solution to a solar single wafer during processing and manufacturing of a solar silicon wafer, and belongs to the technical field of preparation of a monocrystalline silicon solar cell. The application method is characterized by comprising the following steps of: adding a non-ionic surfactant, sodium citrate, anhydrous sodium carbonate and deionized water into a cleaned texture etch groove, stirring, and mixing uniformly toprepare the environment-friendly biological texture etch solution; heating the environment-friendly biological texture etch solution to between 75 and 85 DEG C; placing cut monocrystalline silicon wafers in the environment-friendly biological texture etch solution for etching reaction after the temperature is completely stable, wherein the reaction time is between 10 and 30 minutes; and taking the silicon wafers out after texture etching, placing the silicon wafers in an ultrasound tank which is filled with the deionized water, and rinsing for 5 to 15 minutes by ultrasound. The texture surface with fine, uniform and high-coverage rate pyramids can be obtained after the solar single wafer is subjected to texture etching through the texture etch solution, and the mass difference of the wafer before etching and after etching is between 0.1 and 1.0g.

Owner:SUZHOU CRYSTAL CLEAR CHEMICAL CO LTD

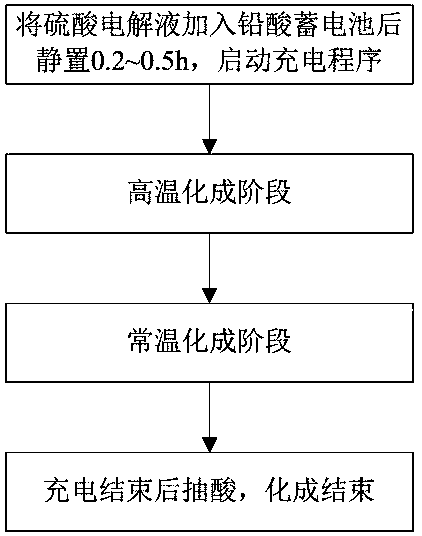

High-temperature inner formation method of power type lead-acid storage battery

ActiveCN107658430AImprove conversion efficiencyNo white spotsLead-acid accumulator electrodesSulfateRoom temperature

The invention discloses a high-temperature inner formation method of a power type lead-acid storage battery. The method includes steps of S1, adding sulfate electrolyte in the type lead-acid storage battery and then staying for 0.2-0.5 hour; starting a charging procedure; S2, high-temperature formation stage; S3, room-temperature formation stage; S4, after charging, pumping acid and finishing theformation. The method can guarantee the uniform formation of a positive plate of the lead-acid storage battery; the active matters of the type lead-acid storage battery are fully converted; the charging power amount before discharging a battery set is few and the formation charging time is short.

Owner:CHAOWEI POWER CO LTD

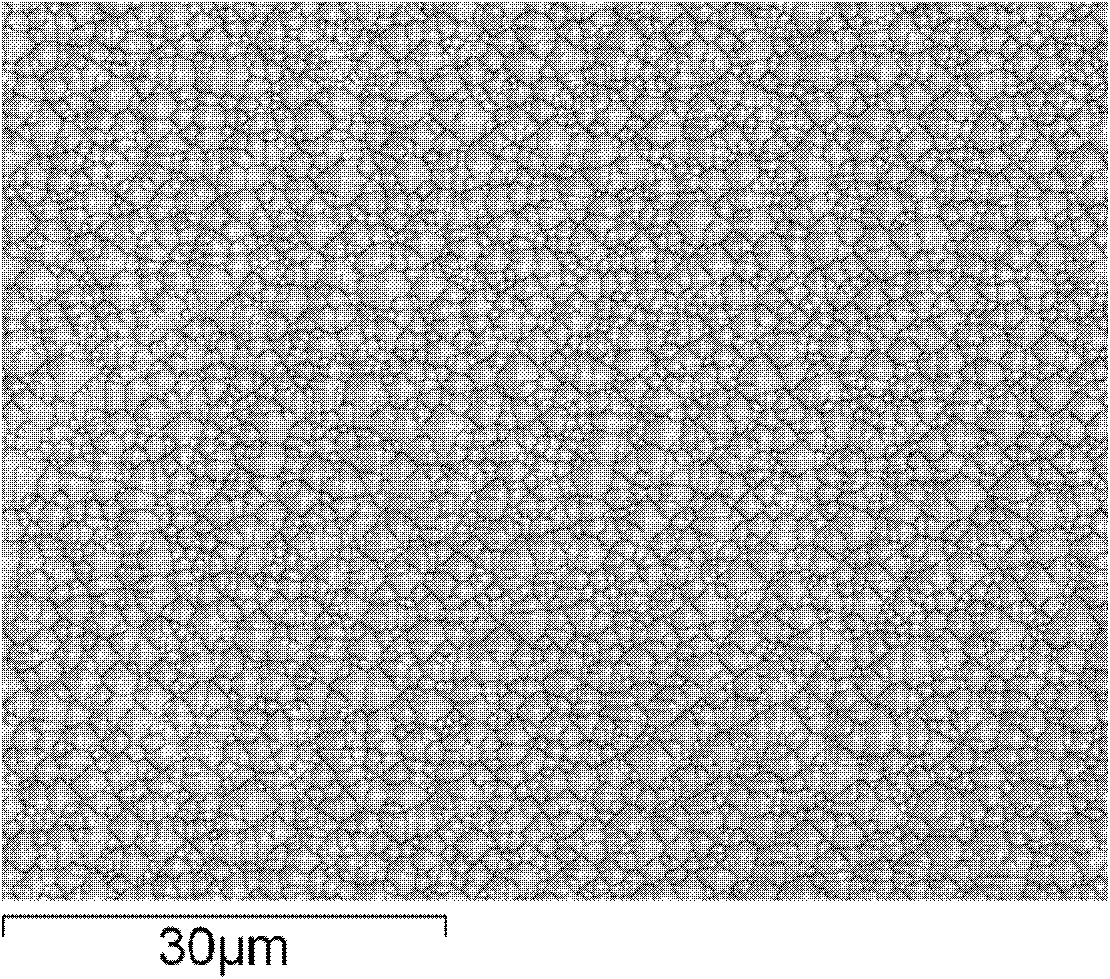

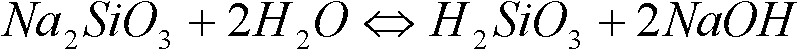

Monocrystalline silicon etching solution and application method thereof

ActiveCN102191565AEfficient formationUniform growthAfter-treatment detailsFinal product manufactureSURFACTANT BLENDAlkaline etching

The invention discloses a monocrystalline silicon etching solution which comprises an inorganic alkaline etching solution. The invention is characterized in that the inorganic alkaline etching solution contains surfactant and alcohol, wherein the surfactant accounts for 0.02-0.6% by mass of the alkaline etching solution, and the alcohol accounts for 0.1-8% by mass of the alkaline etching solution. By using the invention, the pyramids on the small etched surface of the monocrystalline silicon wafer are uniform, the dimensions of the pyramids are less than 2 mu m, and the small etched surface does not have white spots or obvious traces.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

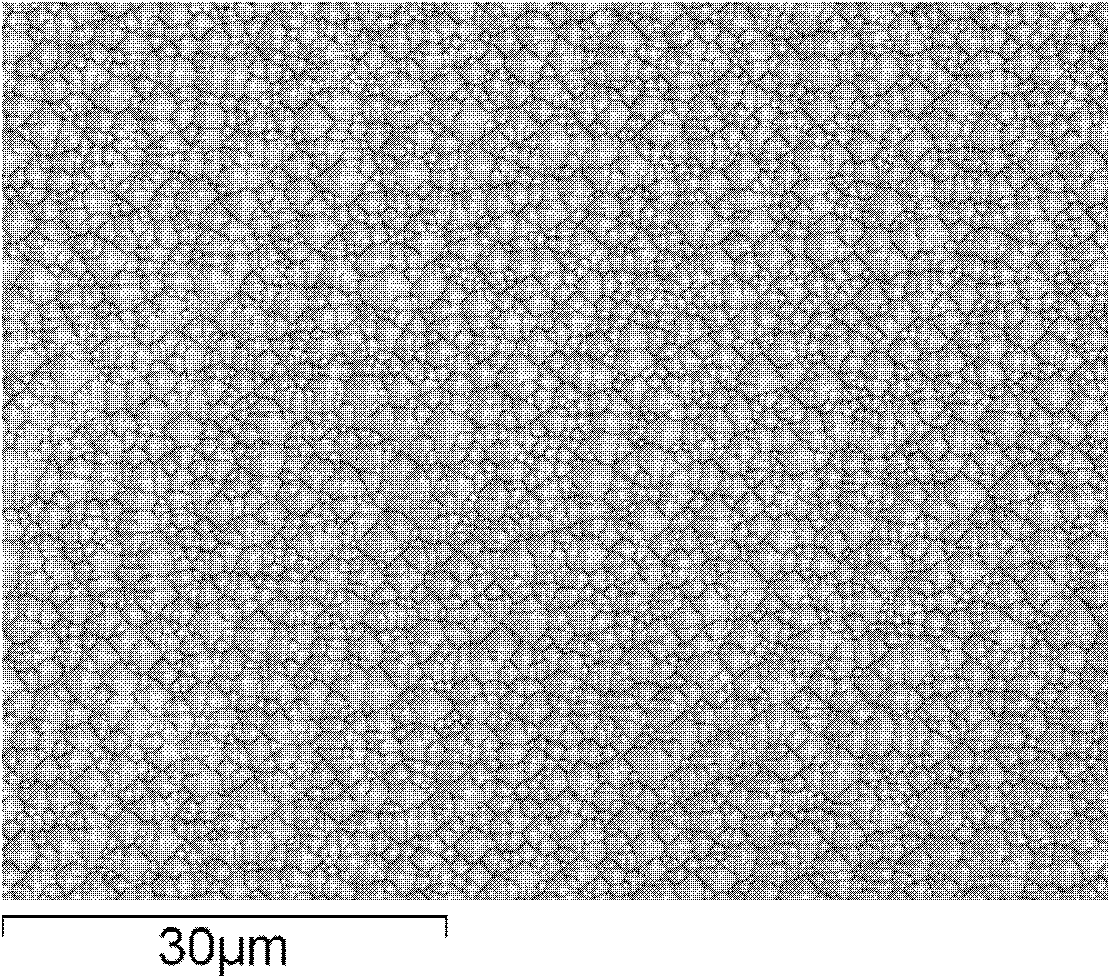

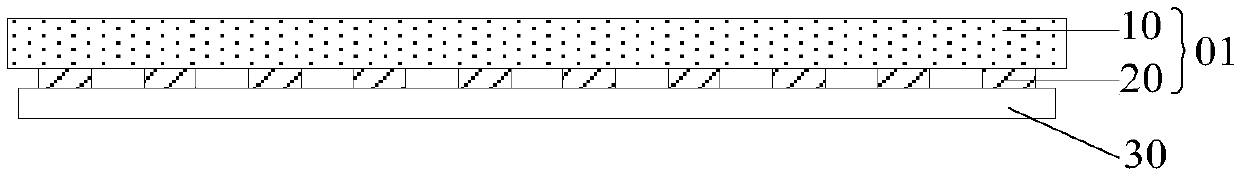

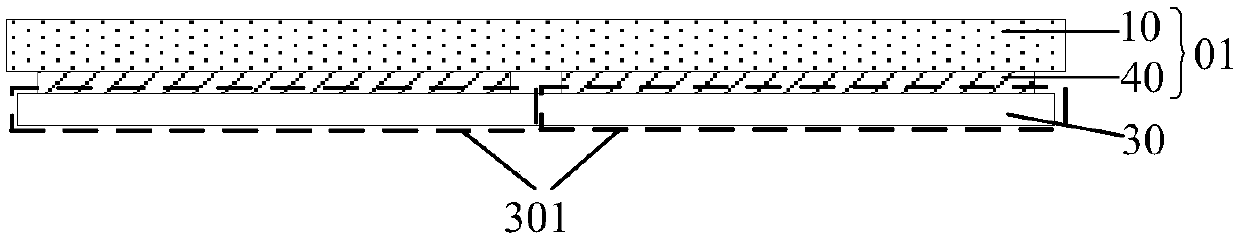

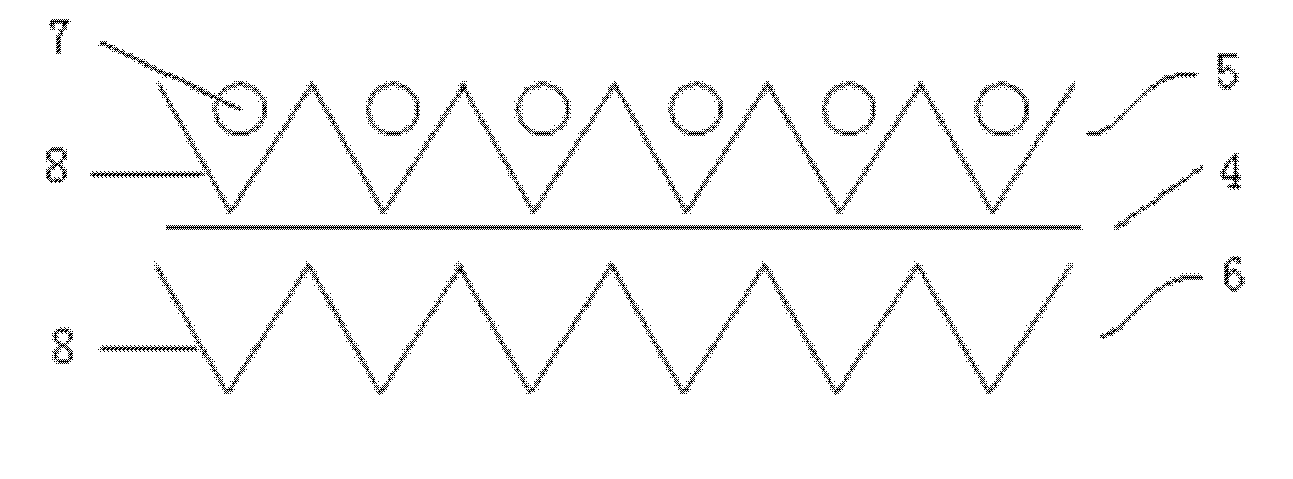

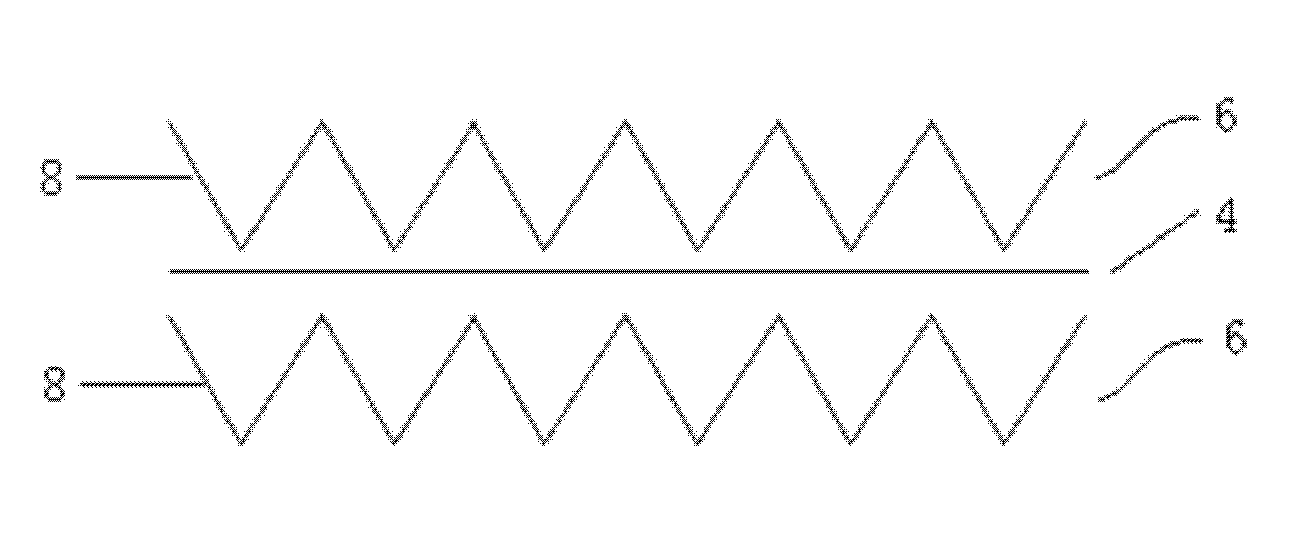

Evaporation touch plate and evaporation device

PendingCN107904566AUniform temperature distributionUniform resistanceVacuum evaporation coatingSputtering coatingEvaporationComputer science

The embodiment of the invention provides an evaporation touch plate and an evaporation device, and belongs to the technical field of evaporation. The evaporation touch plate and the evaporation devicesolve the problem that white point abnormal phenomenon occurs when a to-be-evaporated base plate is lightened. The evaporation touch plate is used for bearing the to-be-evaporated substrate, and theto-be-evaporated substrate comprises a plurality of sub-evaporation substrates. The evaporation touch plate comprises a base plate and a plurality of embosses, wherein the embosses are separately arranged on the base plate; each emboss corresponds to one sub-evaporation substrate; the orthographic projection of each emboss on the to-be-evaporated substrate overlaps a display region of the sub-evaporation base plate corresponding to the emboss, and the overlapping area is larger than 1 / 3 of the area of the corresponding display region and is smaller than the area of the corresponding sub-evaporation substrate; and the surface, used for making contact with the to-be-evaporated substrate, of each emboss is a plane or a cambered surface which protrudes towards the side away from the base plate. The evaporation touch plate and the evaporation device are used in the evaporation working procedures.

Owner:BOE TECH GRP CO LTD +1

Flexible printed circuit board washing agent, flexible printed circuit board washing method, flexible printed circuit board, and electronic equipment

ActiveCN107629887AEfficient removalGood decontamination and cleaning effectSurface-active detergent compositionsDetergent compounding agentsFlexible circuitsEngineering

The invention discloses a flexible printed circuit board washing agent, a flexible printed circuit board washing method, a flexible printed circuit board, and electronic equipment, and belongs to thetechnical field of circuit board washing. The flexible printed circuit board washing agent comprises, by mass, 30 to 45% of N-methyl pyrrolidone, 20 to 35% of butyrolactone, 1.5 to 3% of a carboxylicacid complexing agent, 0.5 to 2% of a penetrating agent, and the balance water. According to the flexible printed circuit board washing method, the flexible printed circuit board washing agent is usedfor washing the flexible printed circuit board. The flexible printed circuit board washing method is capable of solving problems in the prior art that complete removing of residual rosin is impossible to realize using conventional flexible printed circuit board washing agent, white spots are left on the flexible printed circuit board after washing, the conventional flexible printed circuit boardwashing agent is not safe, and is not friendly to the environment, and water washing is inconvenient to realize after applications of the conventional flexible printed circuit board washing agent. Theflexible printed circuit board washing agent is capable of removing rosin matters left on the flexible printed circuit board, and removing metal oxides and grease on the flexible printed circuit board, is excellent in stain removing effect, corrosion of flexible printed circuit board is not caused, after washing, the surface of the flexible printed circuit board is clean and bright, and no whitespot is generated.

Owner:LENS TECH CHANGSHA

Electric conduction board and manufacture method thereof

InactiveCN103129057AReduce expansion and contractionDimensionally stableNon-fibrous pulp additionLamination ancillary operationsElectrical resistance and conductanceEngineering

The invention discloses an electric conduction board and a manufacture method of the electric conduction board. Body paper after being steeped into melamino-formaldehyde resin undergoes primary drying, and impregnated paper is manufactured. The melamino-formaldehyde resin containing nanoscale conductive carbon black is coated on the surface of the impregnated paper, and secondary drying is performed so as to obtain electric conduction paper. The electric conduction paper and the impregnated paper are respectively pressed on different side surfaces of a flat board main body in a sticking mode, and the electric conduction board is manufactured. The surface of the manufactured electric conduction board is free of the defect of hickie, and blackness is even. Resistance value of the surface is in a range of 1 to 5 megohm. The electric conduction board and the manufacture method of the electric conduction board can be used in a microcomputer console cabinet, a switching room and areas prone to generate friction and release static naturally such as a running machine room.

Owner:天津市佩森木业有限公司

Preparation method of bamboo shoots with pickled peppers

The invention belongs to the technical field of food processing, and particularly relates to a preparation method of bamboo shoots with pickled peppers. The preparation method includes the following steps: A, weighing, by mass, 100-120 parts of the bamboo shoots, 25-30 parts of the pickled peppers, 10-12 parts of salt, 6-9 parts of Chinese prickly ash, 4-7 parts of baijiu, 5-7 parts of white sugar, 3-5 parts of white vinegar, 1-3 parts of garlic powder, 2-4 parts of ginger slices, 1-2 parts of anise, 0.8-1.3 parts of fennel, 0.21-0.25 part of lactic acid, 0.23-0.27 part of potassium sorbate and 1.7-2.5 parts of L-ascorbic acid; b, slicing the bamboo shoots after washing, boiling the bamboo shoots in boiling water with the lactic acid for 5-8 minutes, and soaking the bamboo shoots in water for 6-8 hours; C, adding the water, the salt, the Chinese prickly ash, the baijiu, the white vinegar, the garlic powder and the ginger slices into a pot, heating until boiling, adding the pickled peppers, the white sugar, the anise and the fennel, continuing to boil for 15-20 minutes, adding the potassium sorbate and the L-ascorbic acid, and cooling the mixture; D, putting the soaked bamboo shoots in the mixture obtained from the step C, and putting the bamboo shoots with the mixture in a closed container for 48-72 hours; E, sterilizing and cooling a product obtained from the step D. The bamboo shoots with the pickled peppers are faint yellow or brown yellow, are free from white and brown stains, mildewing, mildew spots, white films and foreign matters visible by normal sight, taste crisp and tender, have special taste of the pickled peppers, and do not have astringent taste and peculiar smell.

Owner:巫山县纯源农产品开发有限公司

High-elasticity rubber and preparation process thereof

Owner:ANHUI LIXIN RUBBER TECH CO LTD

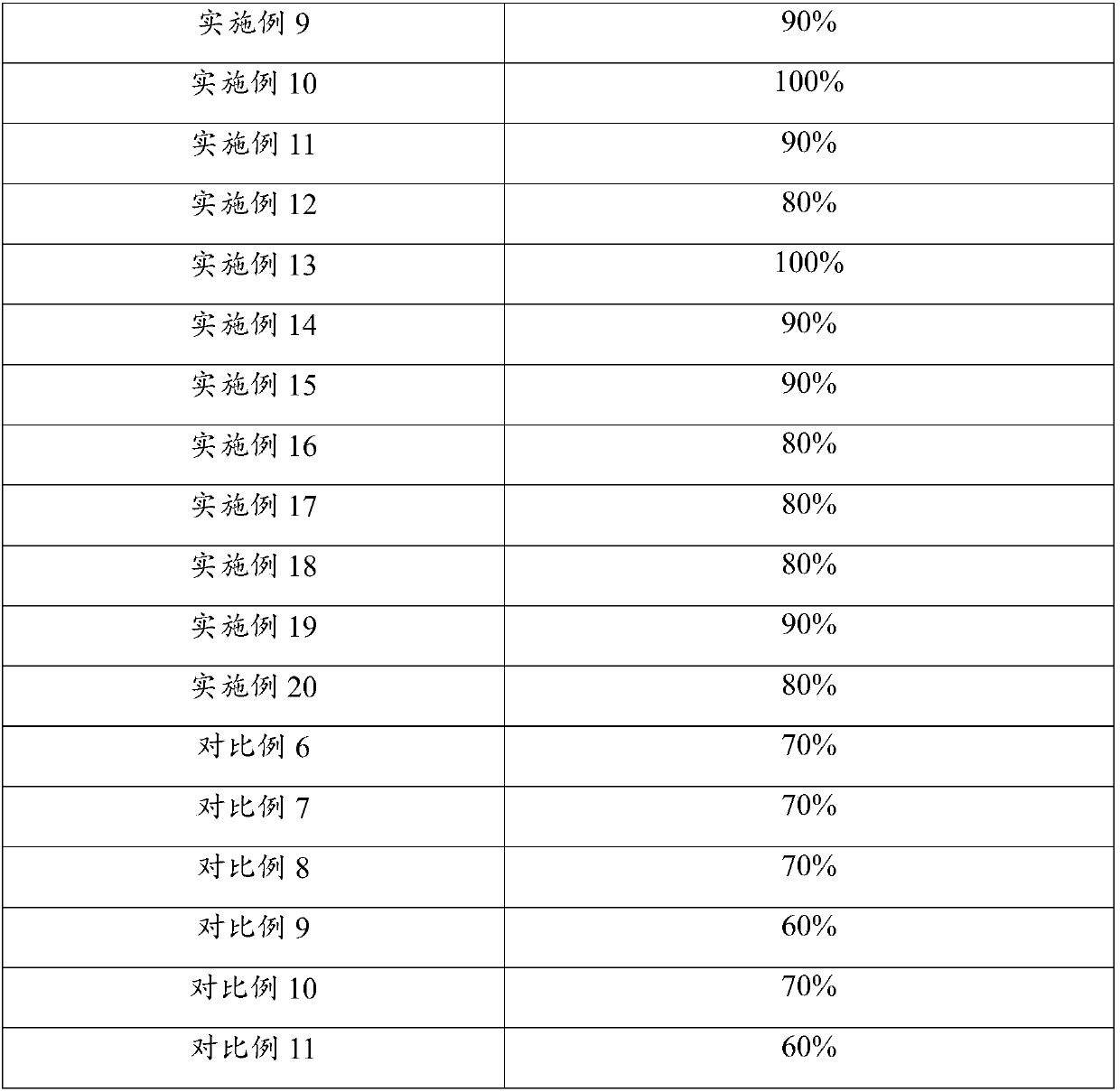

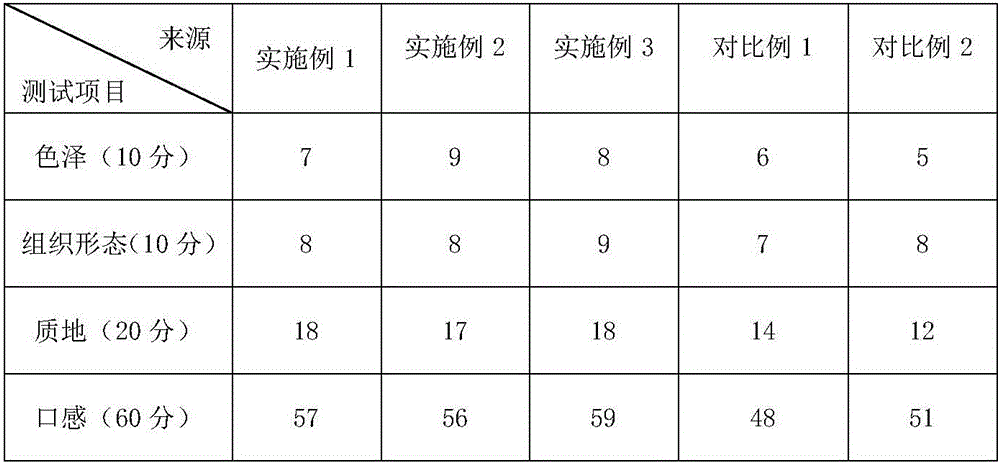

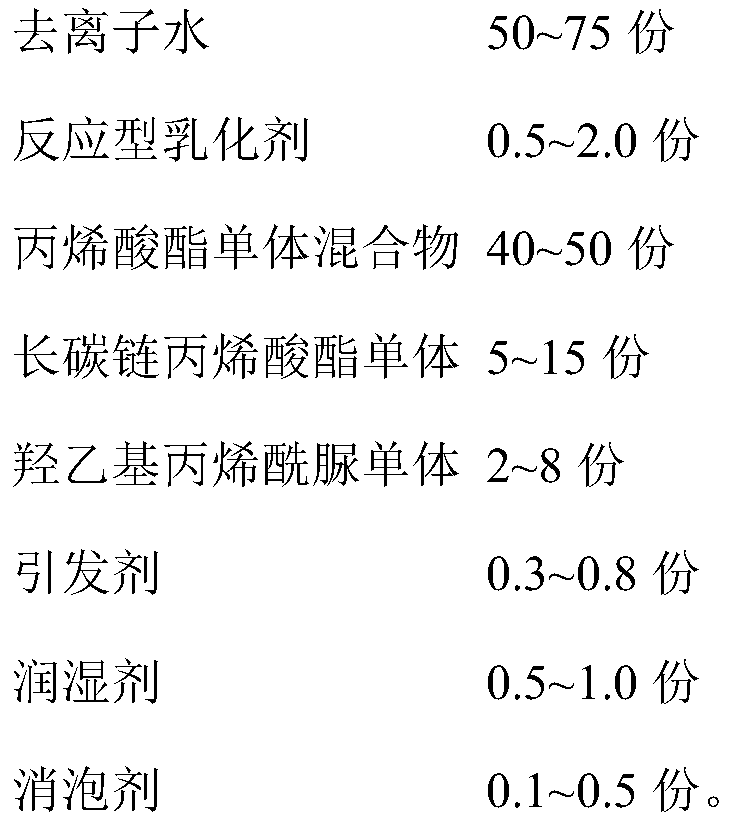

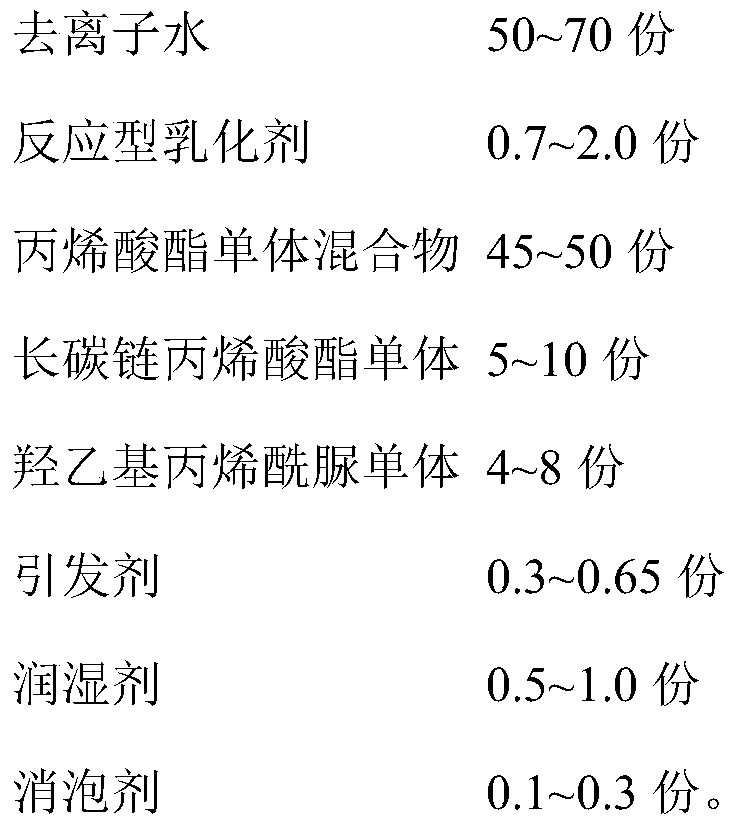

Water-based adhesive for deep embossed paper-plastic compounding, and preparation method thereof

ActiveCN109897576ALower glass transition temperatureStrong initial tackEster polymer adhesivesWater basedMolded pulp

The invention relates to the technical field of water-based adhesives, and concretely relates to a water-based adhesive for deep embossed paper-plastic compounding, and a preparation method thereof. The preparation method of the water-based adhesive comprises the following steps: preparing a monomer drop-by-drop addition solution from, by weight, 20-33 parts of deionized water, 0.4-1.5 parts of areactive emulsifier, 40-50 parts of an acrylate monomer mixture, 5-15 parts of a long carbon chain acrylate monomer, 2-8 parts of hydroxyethyl acryloyl urea and 0.2-0.6 part of an initiator; preparinga kettle bottom solution from 30-42 parts of deionized water, 0.1-0.5 part of the reactive emulsifier and 0.1-0.2 part of the initiator; and dropwise adding a part of the monomer drop-by-drop addition solution to the kettle bottom solution to prepare a seed emulsion, then dropwise adding the remaining monomer drop-by-drop addition solution, and carrying out a reaction under specific process conditions to prepare the water-based adhesive. The water-based adhesive can be stored at a high temperature of 50 DEG C and a high relative humidity of 85% for 120 h without generating white spots, foaming or degumming after being applied to paper-plastic compounding and deep embossing.

Owner:DONGGUAN STAR COSM POLYMER

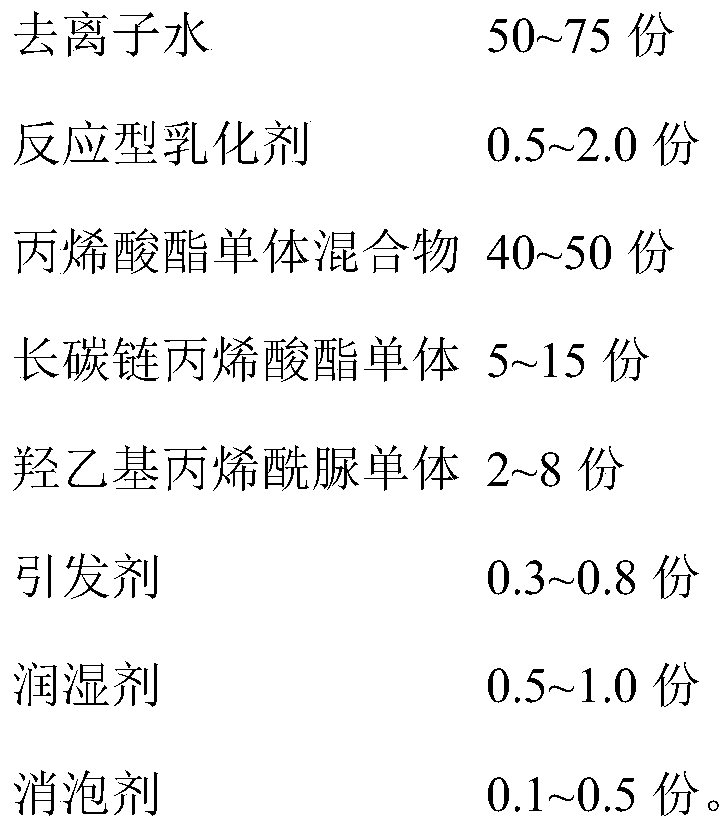

Children cefuroxime sodium compound entity and preparation thereof

InactiveCN104910187AIncrease internal pressureImprove solubilityAntibacterial agentsPowder deliveryFiltrationStructural formula

The present invention provides a children cefuroxime sodium compound entity, which has the following structural formula. The preparation method comprises: (1) dissolving a cefuroxime sodium crude product in water, adding active carbon, carrying out stirring decolorization, and filtering; (2) adding an extractant to the filtrate, transferring and filling into a pressure resistance container, removing air bubbles, carrying out temperature control freezing, and taking out; (3) carrying out liquid-solid separation, adding acetone in a dropwise manner after the solid melts, stirring at a slow speed, growing the grain, filtering, washing, and carrying out vacuum drying; and (4) adding acetone, water and the obtained cefuroxime acid to a crystallizer, stirring until achieving a dissolved state, adding a sodium liquid in a dropwise manner, continuously stirring, growing the grain, carrying out suction filtration washing, and carrying out vacuum drying to obtain the cefuroxime sodium finished product. The powder used for injection and prepared from the children cefuroxime sodium compound of the present invention has advantages of good clarity (no white point phenomenon), good stability, low impurity and the like.

Owner:ZHEJIANG CHANGDIAN PHARMA

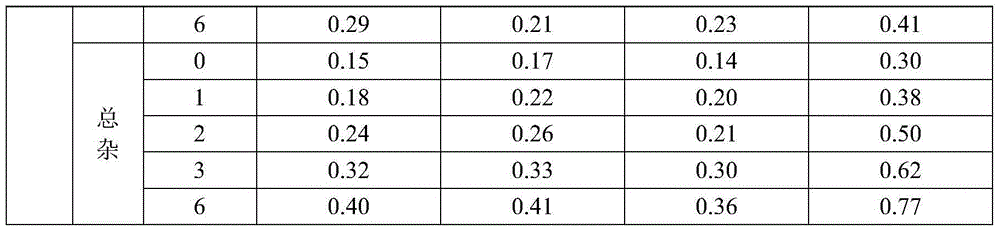

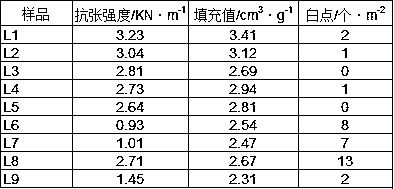

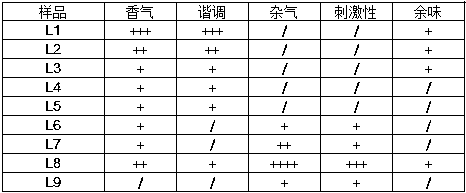

Method for preparing novel sheet special for tobacco by replacing wood pulp fibers with cotton fibers

InactiveCN110946312ALarge cohesionHigh tensile strengthTobacco preparationTobacco treatmentAdhesiveCotton fibre

The invention discloses a method for preparing a novel sheet special for tobacco by replacing wood pulp fibers with cotton fibers. The method comprises the following steps: S1, crushing tobacco leavesinto tobacco powder, and sieving; S2, mixing the tobacco powder with an adhesive to obtain a first mixture; S3, mixing cotton fibers, a dispersing agent and an atomizing agent, heating, uniformly mixing, defibering and dispersing to obtain a second mixture; S4, mixing the first mixture and the second mixture, forming by a roller press, drying and shredding, the heat-not-burn tobacco sheet is obtained, the fiber consumption is small, the filling value of the prepared tobacco sheet is high, the tensile strength is improved, the tobacco sheet is not prone to breakage, exogenous wood gas is reduced, and the sensory quality of a heat-not-burn special sheet product is improved.

Owner:HUBEI CHINA TOBACCO IND +1

Heat-resisting steel ferrule channel grinding technology

ActiveCN105965351AImprove channel surface qualityNo "white spots"Grinding machinesCorrosionWhite Spots

The invention relates to a grinding technology, in particular to a heat-resisting steel ferrule channel grinding technology to solve the problems that a heat-resisting steel ferrule is directly subjected to acid pickling after the rough channel grinding procedure and the fine channel grinding procedure, carbide falls off, small pits are formed in the surface of a ferrule channel, and white spots can be formed after corrosion of acid pickling. The heat-resisting steel ferrule channel grinding technology comprises the following steps that firstly, rough channel grinding is conducted; secondly, fine channel grinding is conducted; thirdly, primary rough channel grinding is conducted; fourthly, acid pickling is conducted; fifthly, hydrogen is removed; sixthly, fine polishing is conducted; seventhly, flaw detection is conducted; eighthly, secondary rough channel grinding is conducted; and ninthly, fine channel grinding is conducted. The grinding technology is used for grinding the ferrule.

Owner:AVIC HARBIN BEARING

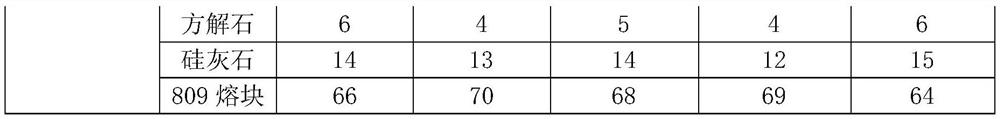

Easy-to-clean sanitary ceramic glaze, sanitary ceramic and preparation method

The invention discloses an easy-to-clean sanitary ceramic glaze, sanitary ceramic and a preparation method. The glaze comprises a first component glaze and a second component glaze, wherein the secondcomponent glaze is applied to the upper surface of the first component glaze; and the second component glaze is vitreous glaze, and glaze slip of the first component glaze is used for enabling a ceramic unfired green body to form a smooth and flat surface. The surface of the fired sanitary ceramic has excellent anti-fouling performance.

Owner:JIANGXI DONGPENG BATHROOM CO LTD +2

Method for improving glue shortage in open areas of multilayer boards

InactiveCN110213911ANo copper wrinkle phenomenonNo white spotsMultilayer circuit manufactureEngineeringSilica gel

The invention discloses a method for improving glue shortage in open areas of multilayer boards. The method comprises the steps of inner layer line exposing, targeting, browning, riveting, typesettingand pressing. A coating material is used for typesetting; multilayer base materials are overlapped in the open areas and pressed once; silica gel and a PE film are adopted for coating; the PE film ismade of the coating material; due to the use of the coating material, slight fluidity exists, so that the copper wrinkle phenomenon on the surface after pressing is avoided, and the white spot phenomenon in the open areas of the base materials after etching is avoided; and moreover, the overlapping design is not changed, the pressing production capacity is not reduced, the production efficiency is not influenced, a special material is used for production, and the production process is not added.

Owner:SHENZHEN CHANGDONGXIN PCB CO LTD

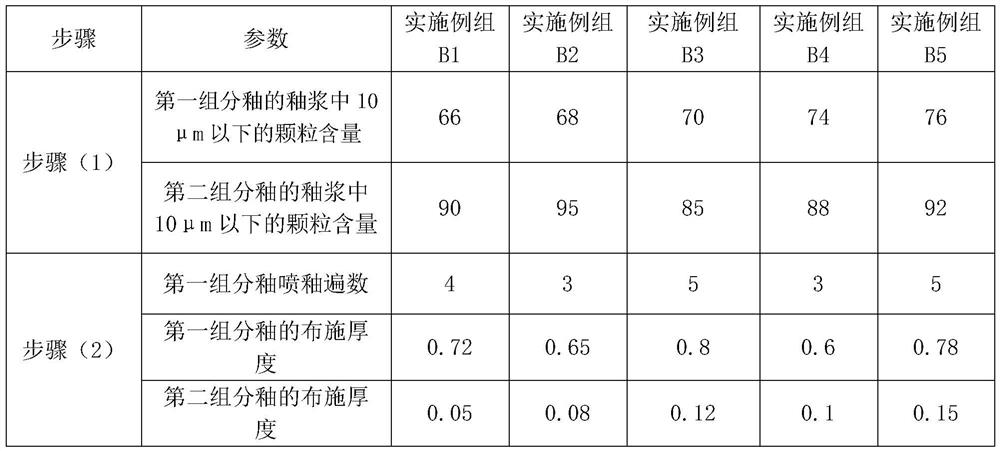

Children ampicillin sodium compound entity and pharmaceutical preparation thereof

InactiveCN104945418ALess impuritiesHigh purityAntibacterial agentsOrganic chemistrySolubilitySide effect

The present invention discloses a children ampicillin sodium compound entity, wherein the preparation method comprises: (1) adding ampicillin to a mixed solution of dichloromethane and triethylamine, cooling, adding a small amount of a sodium 2-ethylhexanoate solution, increasing the solution temperature, adding the remaining sodium 2-ethylhexanoate solution, carrying out suction filtration, washing, and carrying out vacuum drying to obtain an ampicillin sodium crude product; (2) dissolving the ampicillin sodium crude product in purified water, adding active carbon, carrying out stirring decolorizing, and filtering; (3) adding an extractant to the filtrate under the stirring, transferring and filling into a pressure resistance container, removing air bubbles, carrying out sealing oscillation, carrying out temperature control freezing, and taking out; and (4) carrying out liquid-solid separation, discarding the extractant, adding acetone in a dropwise manner at a temperature of 5 DEG C after the solid melts, stirring at a slow speed, growing the grain, filtering, washing, and carrying out vacuum drying to obtain the ampicillin sodium finished product. The children ampicillin sodium compound entity of the present invention has advantages of good solubility, good clarity, low related substance content, good stability, low toxic-side effect, and the like.

Owner:ZHEJIANG CHANGDIAN PHARMA

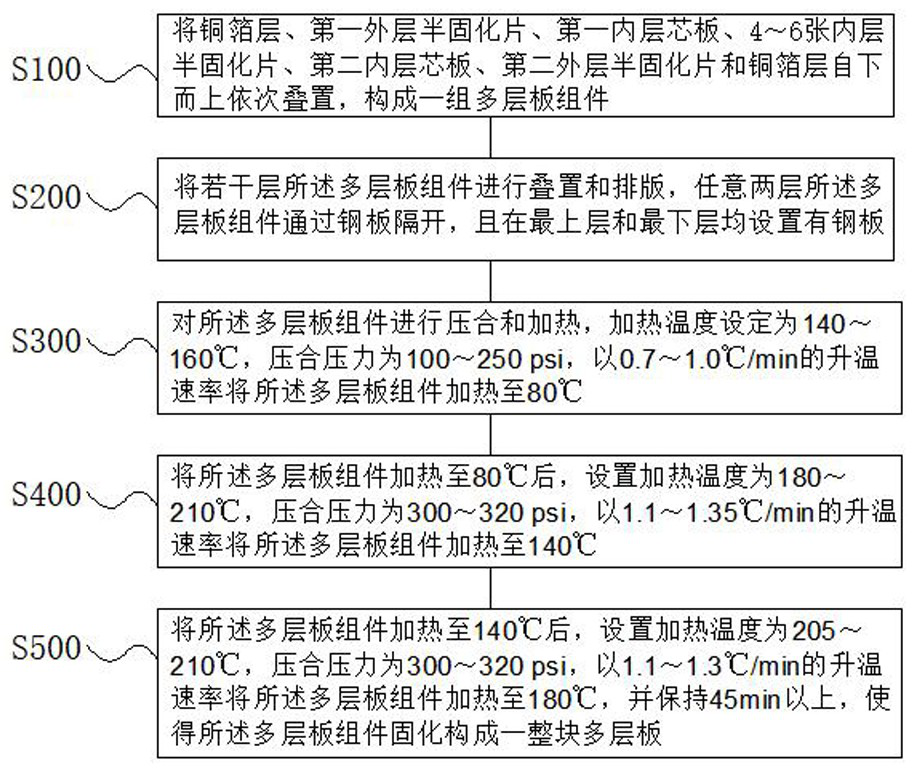

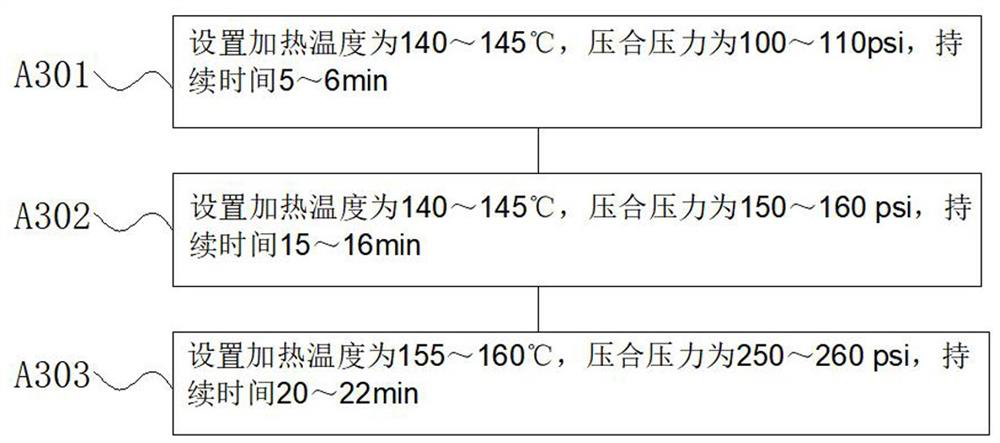

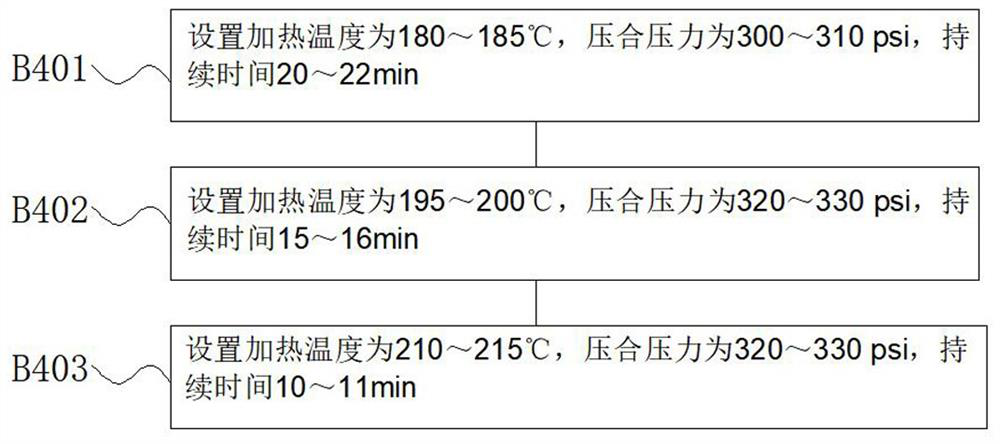

Combined plate pressing process of inner-layer thin core plate and multi-layer prepregs

ActiveCN113630990AEffective control of glue flowControl flow rateMultilayer circuit manufactureEngineeringCopper foil

The invention relates to the technical field of printed circuit plate pressing plates, in particular to a combined plate pressing process of an inner-layer thin core plate and multi-layer prepregs. By means of the plate pressing process, the appropriate glue flowing amount of the prepregs during plate pressing can be effectively controlled, it can be guaranteed that gaps between inner-layer lines are completely filled, air is exhausted, the problems of layer deviation, expansion and shrinkage, and difficult control over plate thickness uniformity and the like caused by pulling due to too large glue flowing when the inner-layer thin core plate is pressed into the multi-layer prepregs can be solved. Meanwhile, the problem of plate thickness caused by too small flowing glue is avoided, and the thickness uniformity of the plate is ensured by controlling the proper flowing glue amount, so that each inner-layer core plate and the copper foil can be completely bonded and further cured to form a whole multi-layer plate, the phenomena of no layering and plate explosion, no texture exposure, no white points, no glue shortage, no bubbles and the like on the plate surface through etching inspection are ensured, accurate control is achieved, and finally it is guaranteed that the multi-layer plate has good electrical performance and mechanical performance.

Owner:HUIZHOU XINGSHUNHE ELECTRONICS CO LTD

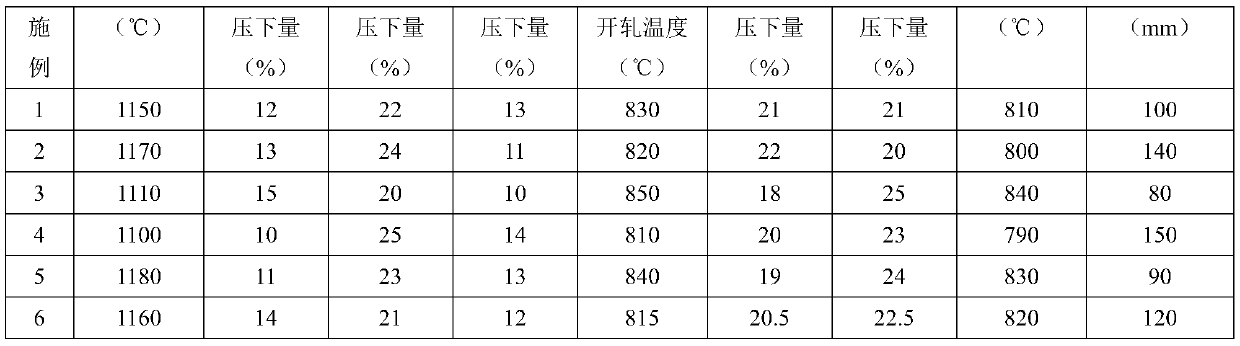

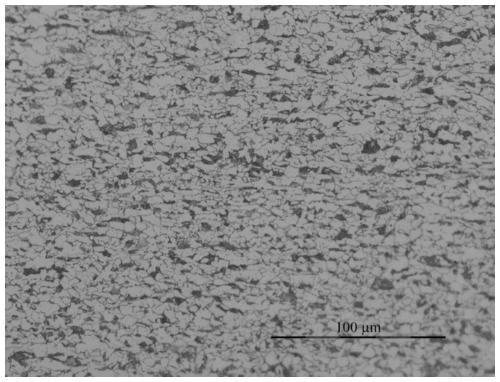

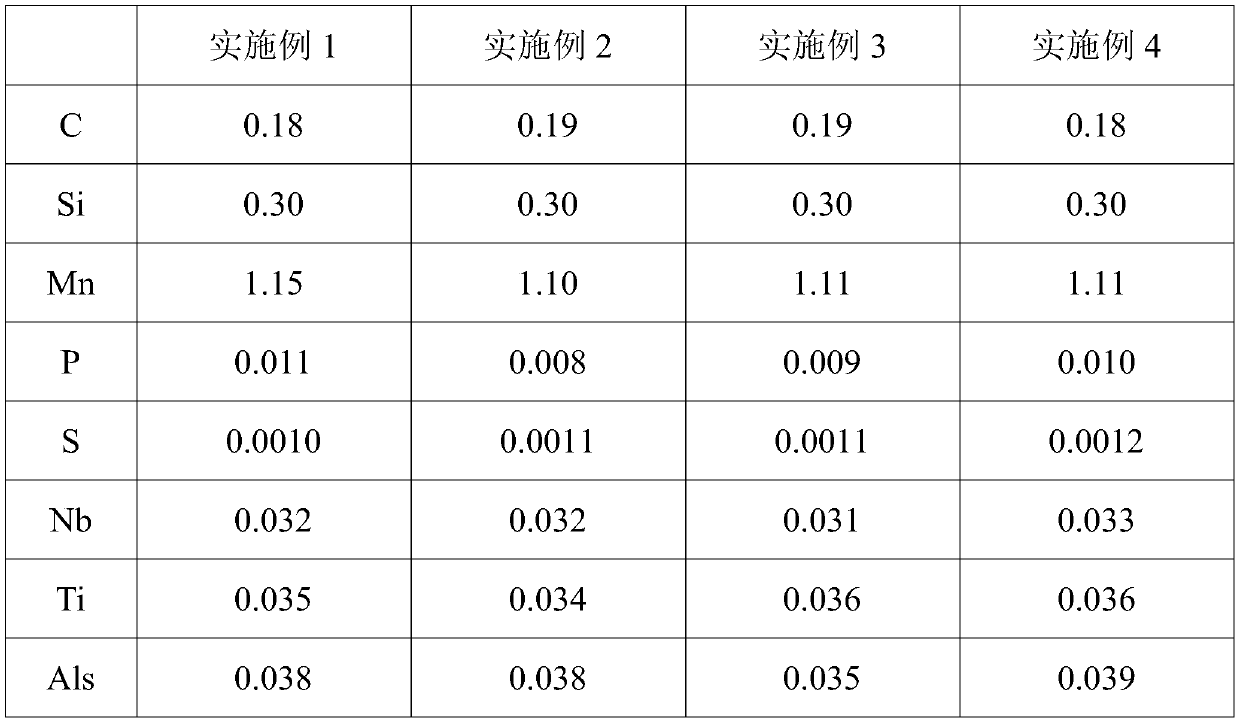

Microalloyed mold steel with high purity and preparation method thereof

ActiveCN110669982AFine cast structureNo white spotsFurnace typesHeat treatment furnacesMetallurgyProduction cycle

Owner:ANGANG STEEL CO LTD

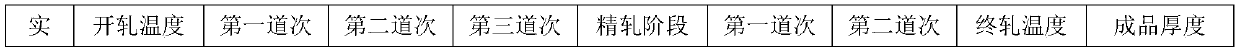

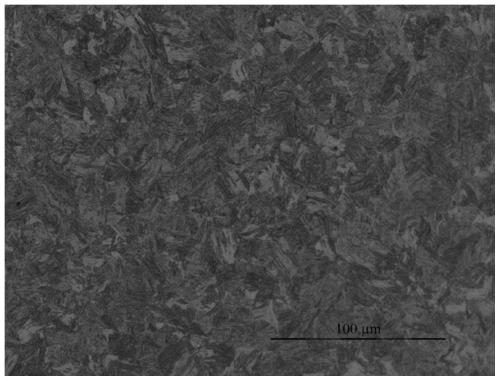

A niobium-titanium-chromium-boron alloy wear-resistant steel and preparation method thereof

Owner:MAGANG (GROUP) HOLDING CO LTD +1

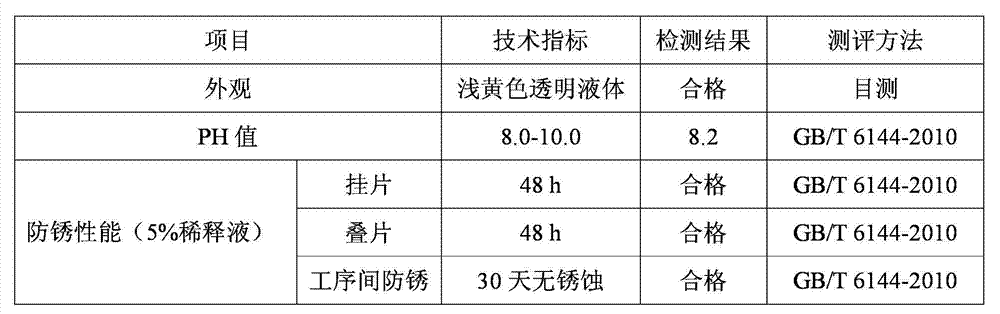

Environment-friendly water-based antirust agent and preparation method thereof

ActiveCN103255400BImprove rust resistanceLong anti-rust periodMetallic material coating processesWater basedFatty acid

The invention discloses an environment-friendly water-based antirust agent and a preparation method thereof. The antirust agent comprises the following raw materials in parts by mass: 5-10 parts of glycerin, 20-28 parts of diglycolamine, 4-8 parts of tartaric acid, 2.5-5 parts of itaconic acid, 0.5-1 part of sodium molybdate, 0.5-2 parts of sodium tungstate, 3-6 parts of coco fatty acid diethanol amide 6501, 0.5-1 part of anhydrous sodium carbonate and 39-64 parts of water. The preparation method comprises the steps of raw material mixing, reacting, heating and stirring. The environment-friendly water-based antirust agent disclosed by the invention is good in rust resistance, long in rust-proof life, wide in applicability, free of nitrite or phosphorus, safe to a human body and in line with the requirement of environmental protection.

Owner:洛斯石油(浙江)有限公司

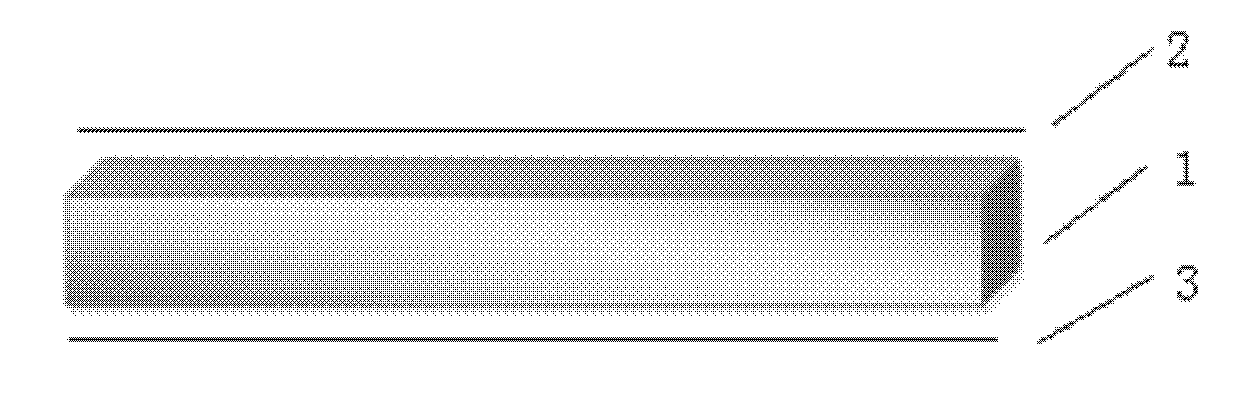

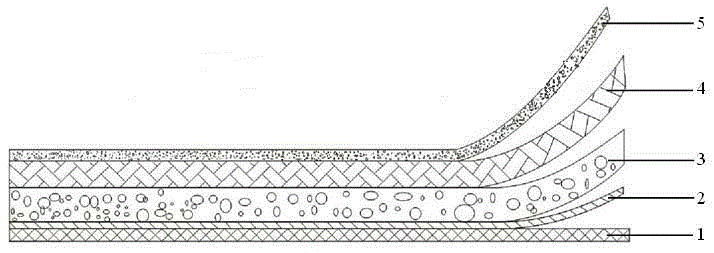

Fragrant artificial leather and preparation method thereof

ActiveCN103114459BImprove heat resistanceImprove durabilityLamination ancillary operationsSynthetic resin layered productsWater basedSolubility

The invention discloses fragrant artificial leather and a preparation method thereof and relates to the technical field of leather. The fragrant artificial leather comprises a surface layer, wherein a finishing layer is arranged on the surface layer and comprises the components of a controlled-release fragrance finishing agent, a compatilizer and a crosslinking agent, wherein the controlled-release fragrance finishing agent is composed of the components of beta-cyclodextrin and essence, and the compatilizer refers to a water-solubility linear parent high polymer material; the preparation method of the artificial leather comprises the steps of: coating a PVC (Polyvinyl Chloride) or water-based PU surface layer on release paper, and drying the surface layer; coating a PVC (Polyvinyl Chloride) or water-based PU foaming layer on the surface layer, foaming and drying the foaming layer; coating a water-based PU adhesive on the foaming layer, pasting base cloth on the foaming layer with the water-based PU adhesive, drying to obtain an artificial layer; and rolling a layer or multiple layers of water-based PU finishing agent comprising the components of the controlled-release fragrance finishing agent, the compatilizer, the crosslinking agent and a water-based PU finishing agent (water-based polyurethane) on the surface layer of the artificial leather by a three-edition printing machine, and drying to obtain the fragrant artificial leather. The heat resistance and the durability of fragrance volatilization of fragrant artificial leather prepared by the invention are improved, and the fragrance of the fragrant artificial leather is kept above 50% after the fragrant leather is baked for 168h at 100 DEG C.

Owner:广西鑫深科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com