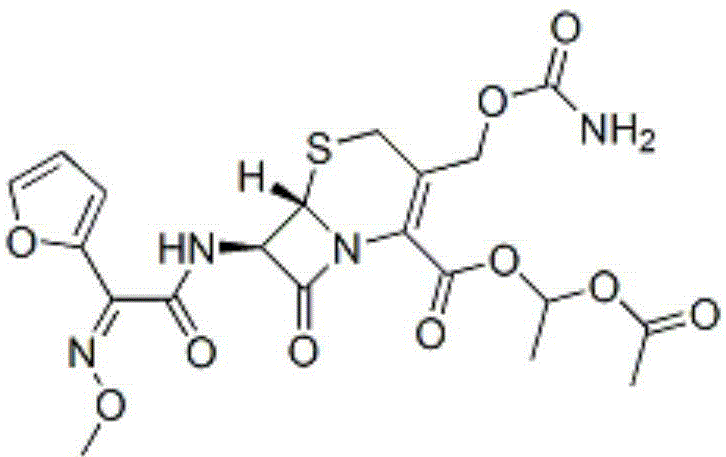

Children cefuroxime sodium compound entity and preparation thereof

The technology of cefuroxime sodium and compound is applied in the field of cefuroxime sodium compound entity and its preparation for children, and can solve the problems of poor stability of cefuroxime sodium, occurrence of degradation products, easy discoloration of appearance, etc., and achieves good clarity, Improve solubility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

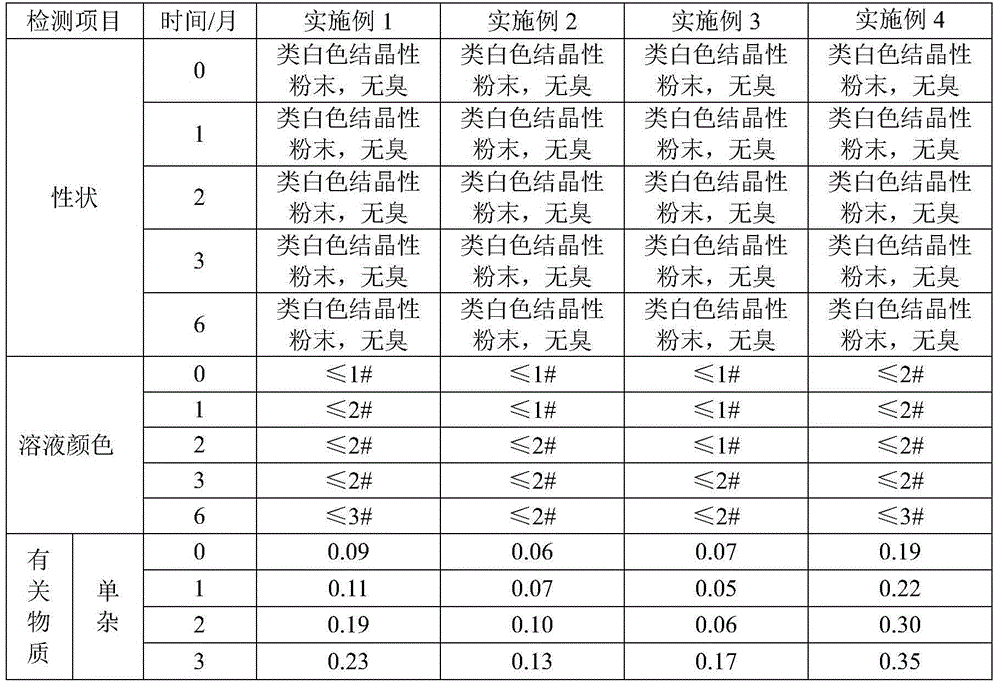

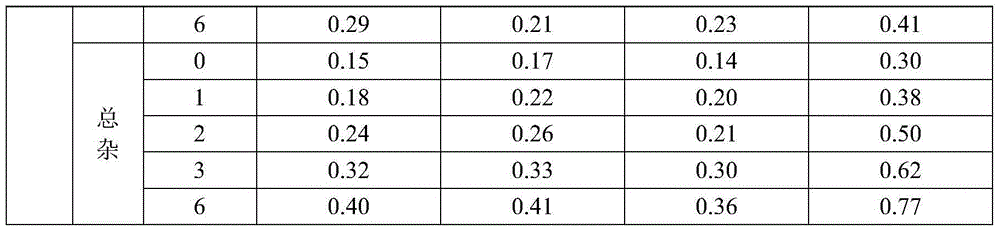

Embodiment 1

[0025] (1) Weigh 100 g of cefuroxime crude product, add 1000 ml of water, heat up to 30 ° C until completely dissolved, add 10 g of activated carbon, stir for decolorization, and filter;

[0026] (2) Add 10ml of ethyl acetate to the above filtrate under stirring, transfer it to a 1000ml pressure-resistant container, make sure it is full and the air bubbles are removed, seal the container, oscillate, freeze at -18°C for 8 hours, and then take it out;

[0027] (3) Remove the organic phase, transfer to the crystallization tank after the ice melts, add 5000ml of acetone dropwise for about 1 hour at 5°C, stir at a slow speed for 30 minutes, continue to grow crystals for 1 hour, filter with suction, wash with acetone, dry in vacuum, and aseptic Subpackage to obtain the cefuroxime finished product.

[0028] (4) Add 400ml of acetone, 60ml of water and 80g of cefuroxime acid into the crystallizer, stir at a temperature of 25°C until dissolved, add 100ml of 0.2g / ml anhydrous sodium acet...

Embodiment 2

[0030] (1) Weigh 100 g of cefuroxime crude product, add 1000 ml of water, heat up to 30 ° C until completely dissolved, add 10 g of activated carbon, stir for decolorization, and filter;

[0031] (2) Add 10ml of chloroform to the above filtrate under stirring, transfer it to a 1000ml pressure-resistant container, ensure that it is full and remove air bubbles, seal the container, oscillate, freeze at -18°C for 3 hours, and then take it out;

[0032] (3) Remove the organic phase, transfer to the crystallization tank after the ice melts, add 5000ml of acetone dropwise for about 1 hour at 5°C, stir at a slow speed for 30 minutes, continue to grow crystals for 1 hour, filter with suction, wash with acetone, dry in vacuum, and aseptic Subpackage to obtain the cefuroxime finished product.

[0033] (4) Add 400ml of acetone, 60ml of water and 80g of cefuroxime acid into the crystallizer, stir at a temperature of 25°C until dissolved, add 100ml of 0.2g / ml anhydrous sodium acetate ethano...

Embodiment 3

[0035] (1) Weigh 100 g of cefuroxime crude product, add 1000 ml of water, heat up to 30 ° C until completely dissolved, add 10 g of activated carbon, stir for decolorization, and filter;

[0036] (2) Add 5ml of ethyl acetate and 5ml of chloroform mixed solvent to the above filtrate under stirring, transfer it to a 1000ml pressure-resistant container, make sure it is full and the air bubbles are removed, seal the container, oscillate, freeze at -18°C for 3 hours, and then take it out;

[0037] (3) Remove the organic phase, transfer to the crystallization tank after the ice melts, add 5000ml of acetone dropwise for about 1 hour at 5°C, stir at a slow speed for 30 minutes, continue to grow crystals for 1 hour, filter with suction, wash with acetone, dry in vacuum, and aseptic Subpackage to obtain the cefuroxime finished product.

[0038] (4) Add 400ml of acetone, 60ml of water and 80g of cefuroxime acid into the crystallizer, stir at a temperature of 25°C until dissolved, add 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com