[0010] In the invention, in order to overcome problems remaining from existing technologies, a further improvement is applied to the existing technologies. The invention intends to provide an air cushioning material that, in

spite of a compact structure, can cope with a variety of articles to be packed. Specifically, the invention intends to form an air cushioning material from a single

raw material and thereby to provide a universal air cushioning material that can

package goods made of products or components having various dimensions and shapes, accommodate in a container and stably transport even under very severe conditions.

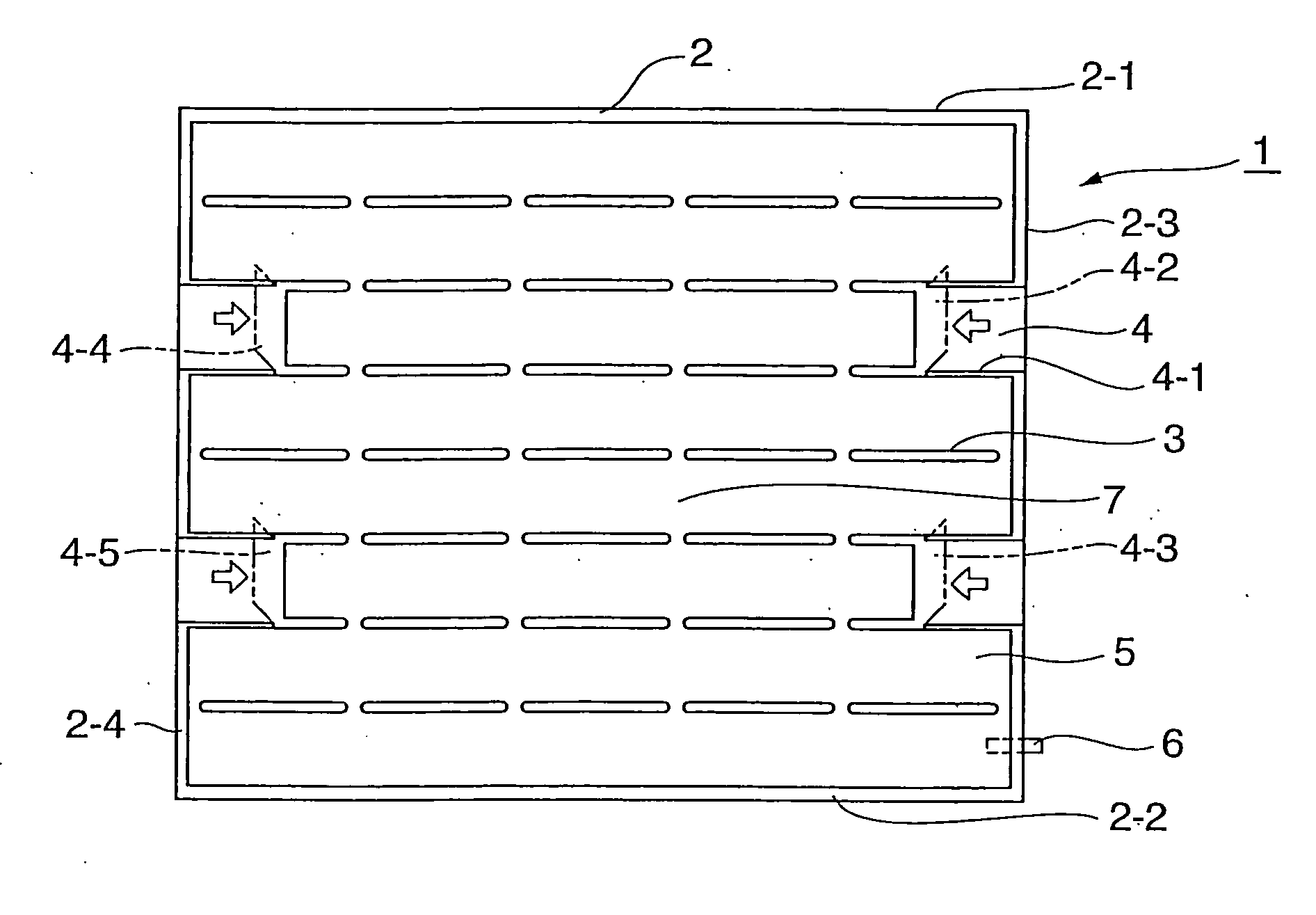

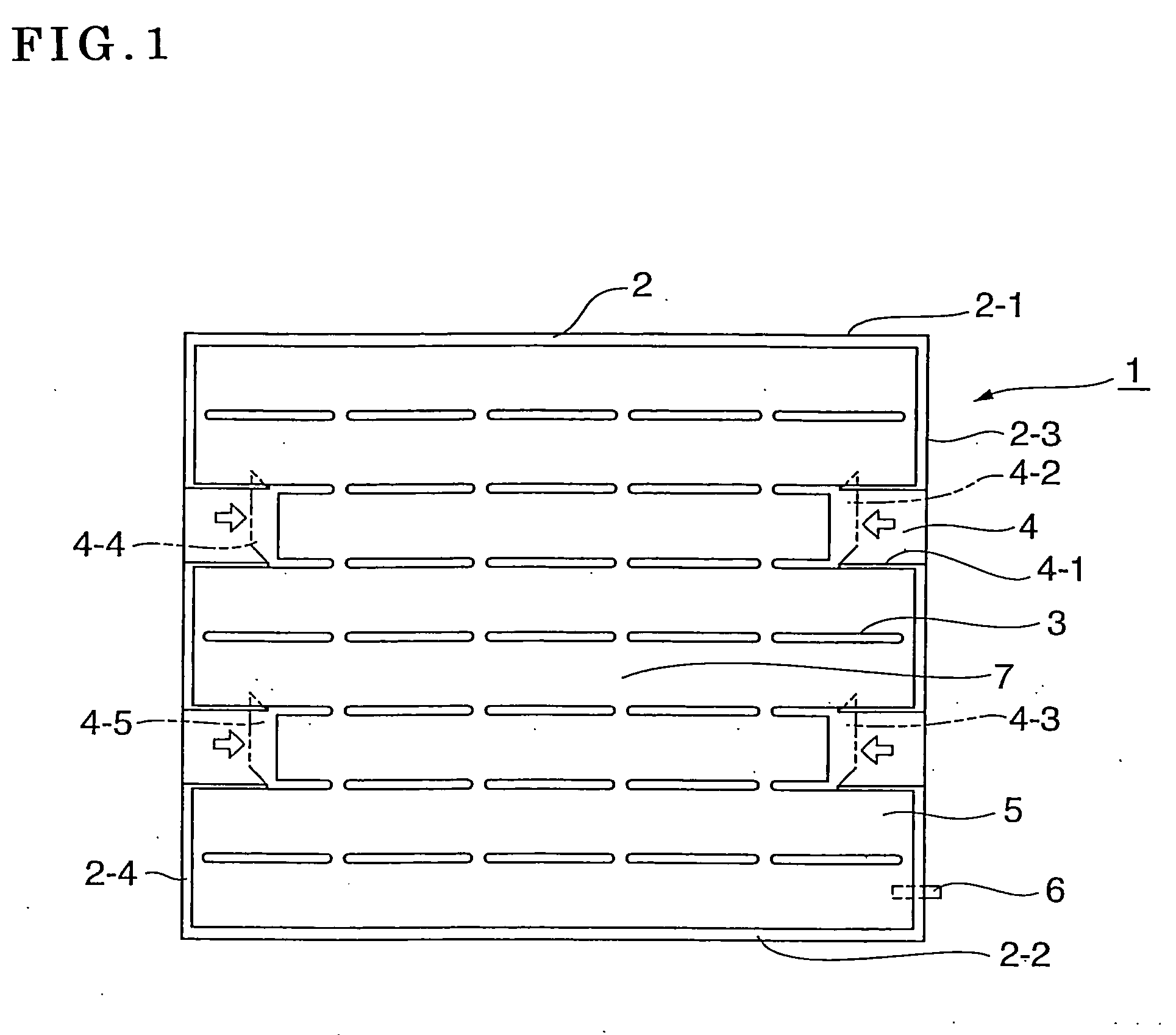

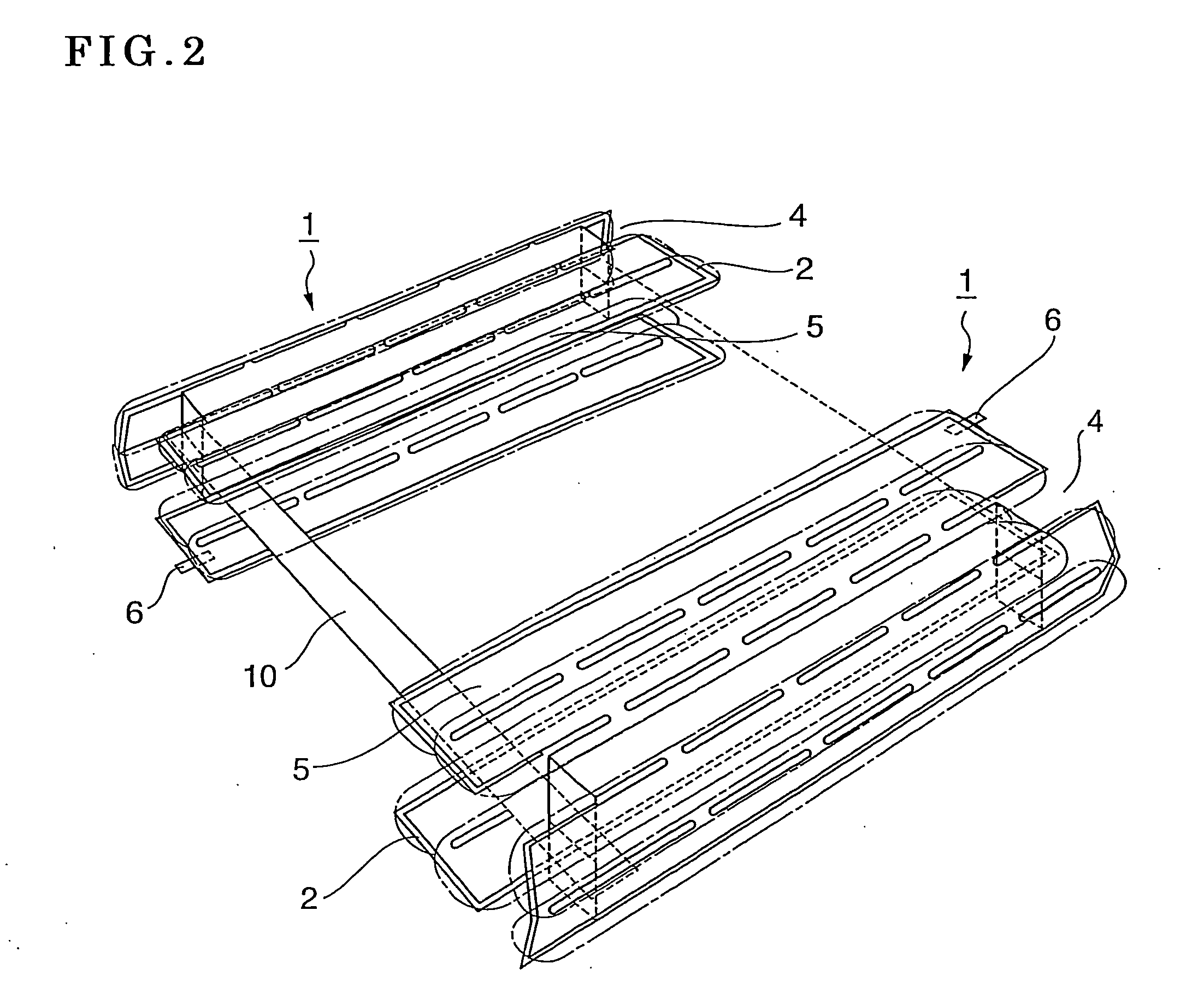

[0018] The universal air cushioning material according to the invention is provided with air chambers as mentioned above. Thereby, a contact area between goods to be packed or an inner wall of a transporting vessel (a container or the like) and the air chambers can be arbitrarily controlled. Accordingly, when air is injected from an air

injection port disposed to at least one of the air chambers to expand the air chambers and thereby an inside thereof is pressed against the goods and an outside thereof is pressed against an inner wall of the transporting vessel to work as a cushioning material, a broad mutual contact area can be obtained. Accordingly, the stress can be previously inhibited from concentrating and thereby a stable cushioning function can be secured. As a result, to an extent that can flexibly cope with fluctuations of a temperature or pressure,

internal pressure can be increased. Accordingly, a function as the cushioning material under severe conditions can be maintained over a long period.

[0019] Furthermore, in the cushioning material according to the invention, when, in accordance with a shape of an article to be packed, for instance, on an arbitrary position on a side surface thereof, at least a pair of notches is disposed horizontally symmetrically and remaining portions after the formation of notches are mutually thermally fused, a substantially horseshoe-shaped cushioning material can be formed. Thereby, with the cushioning material, corners of a rectangular article are not only simply sandwiched with two of the air cushioning materials like in the existing technology but also protected by strongly grasping. When, in addition to the above, edge portions vertically symmetrical are as well thermally fused to form a bottomed cylindrical cushioning material, for instance, bottles can be accommodated. When, without thermally fusing the remaining portions after

notching, only edge portions vertically symmetrical are thermally fused or stitched to form a cylindrical cushioning material, cylindrical, columnar or circular articles can be protected.

[0020] Thus, in the air cushioning material according to the invention, in

spite of being fundamentally simple in the structure, since a magnitude of a

synthetic resin film can be arbitrarily varied and periphery portions or notched portions can be arbitrarily changed, a portion or a position that is thermally fused (or stitched) can be arbitrarily varied in accordance with a shape or a dimension of an article to be packed. Accordingly, literally, a universal air cushioning material that can readily cope with a variety of articles to be packed can be provided. Furthermore, the air cushioning material is packed in a space with a packaging container so as to grasp respective essential portions from side surfaces or up and down and interposed so as to dispose a constant gap between the article and the packaging container. Accordingly, even when a temperature or pressure varies to lower the pressure in the air chambers and thereby a cushioning effect becomes scarce, the article can be protected from the impulse.

[0021] In the universal air cushioning material according to the invention, when two films made of the same material, specifically, PE / PE cloth / PE or PP / PP cloth / PP, are superposed and used, an arbitrary position thereof can be freely thermally fused; accordingly, a process such as mentioned above can be realized. Furthermore, being the same

raw material, maintenance such as repair can be readily applied and, after the use, it is expected to recycle to effectively use. Furthermore, different from the existing air cushioning material that wraps an article to be packed as a whole, the universal air cushioning material according to the invention, which protects only essential portions, being very compact in its body itself, can be reduced in the cost involving the storage and transportation in an unused state. Even when it is unavoidably incinerated to dispose, there is no

anxiety of generating a poisonous material, and, not only effective use of the resources but also the

environmental protection is sufficiently considered.

Login to View More

Login to View More  Login to View More

Login to View More