Gel Insole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

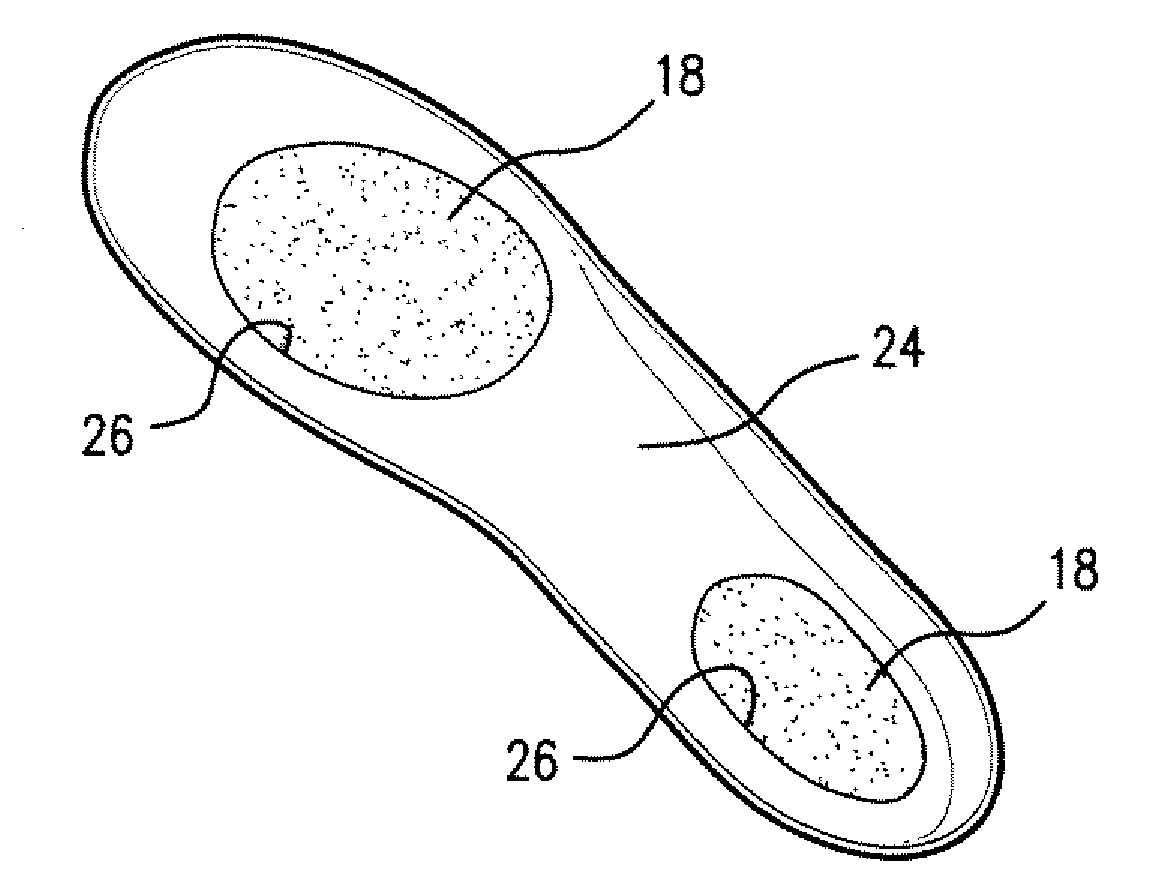

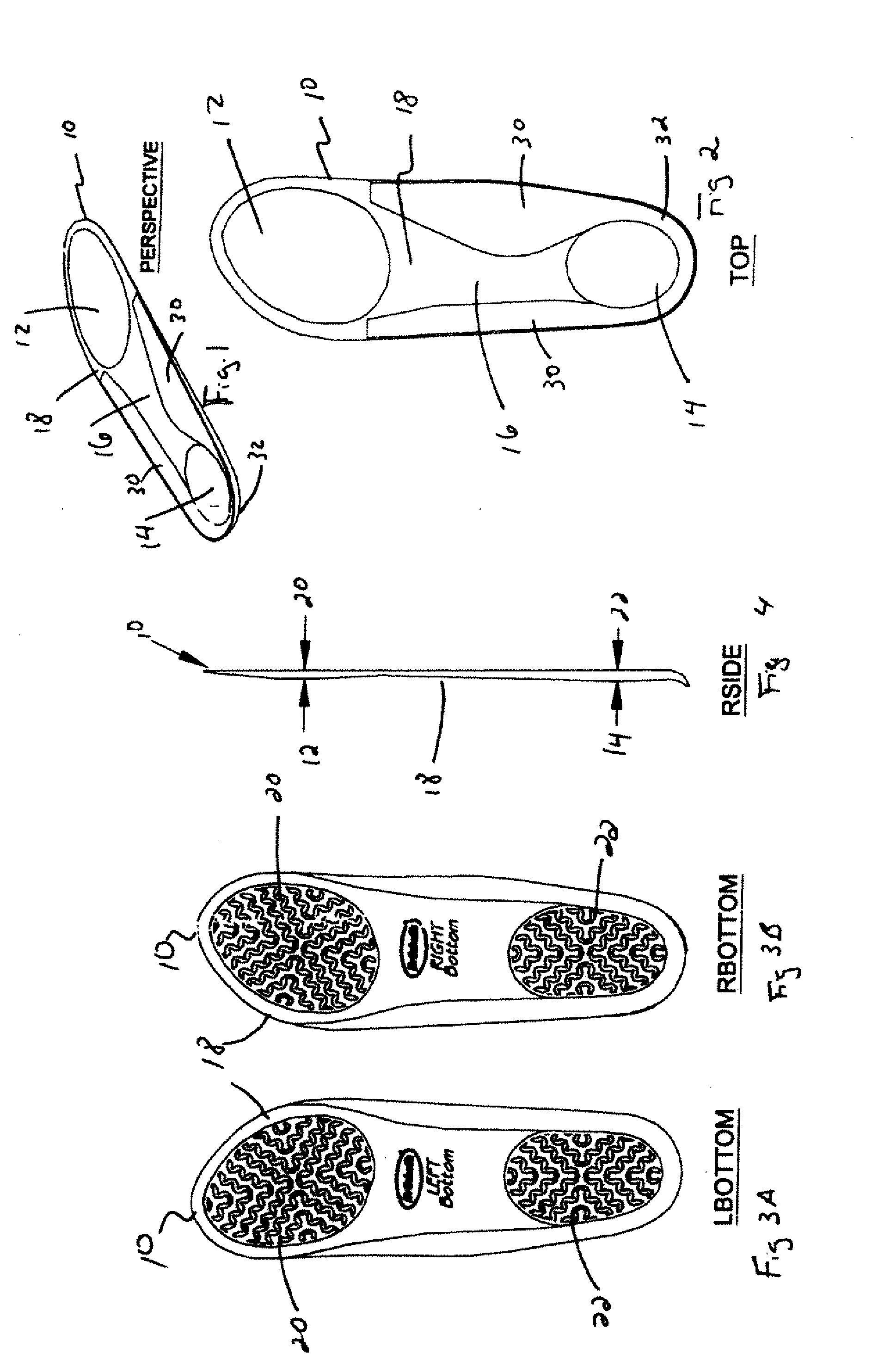

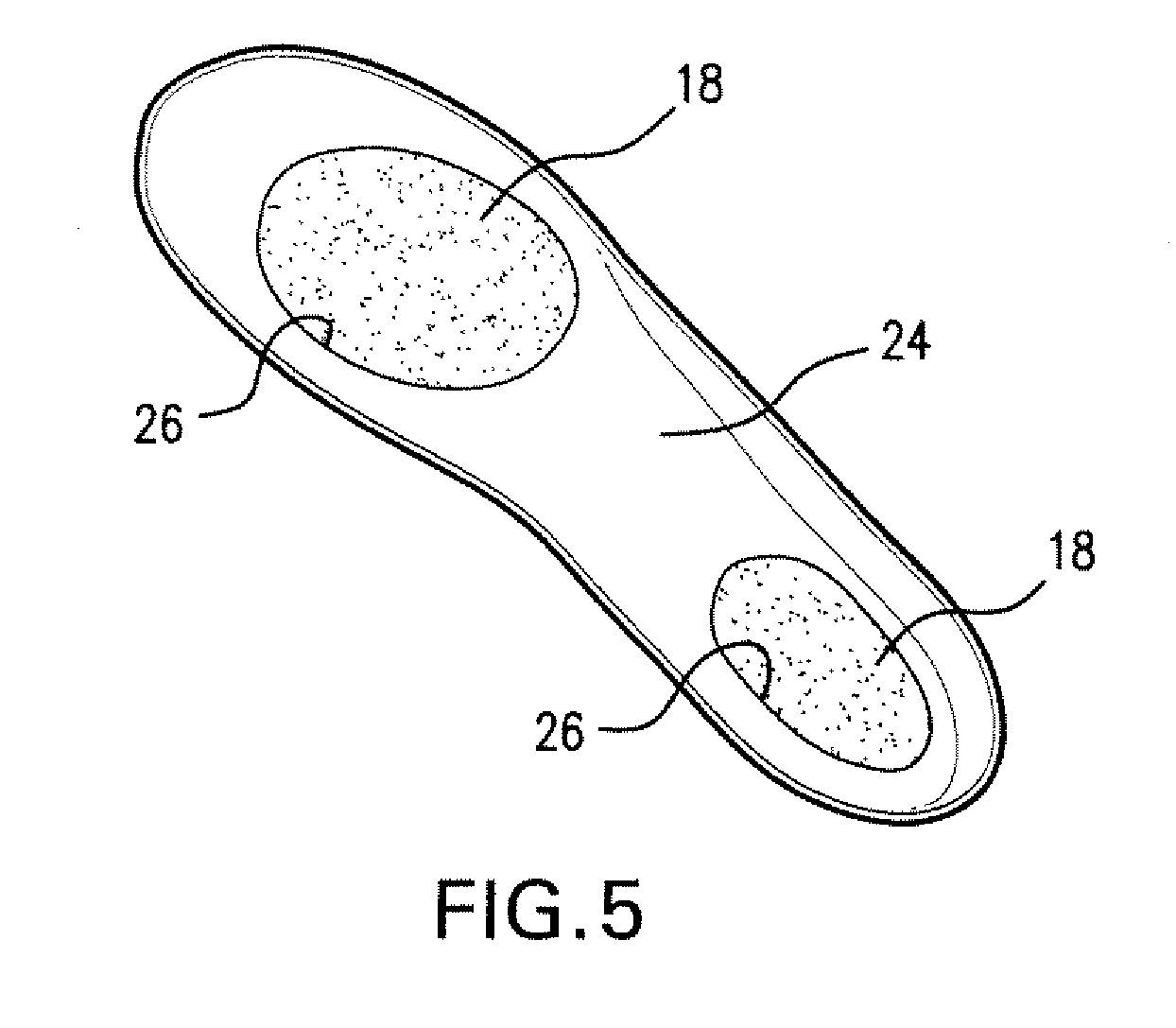

[0028]Referring to the drawings in detail, and initially to FIGS. 1-4 thereof, a left insole 10 according to a first embodiment of the present invention is adapted to be placed in an article of footwear, as is well known. A right insole (depicted in FIG. 3B) is identical to left insole 10 and is a mirror image thereof.

[0029]As depicted in FIGS. 1 and 2, insole 10 is designed to fit the shape of a human left foot and therefore includes a curved toe or forefoot portion 12, a heel portion 14, and a mid-foot portion 16 which connects forefoot portion 12 and heel portion 14 together. Cushioning layer 18, preferably generally planar throughout most of the insole, curves upward at the peripheral edges of the midfoot portion 30 and heal portion 32 of the insole in order to create a cradle for the side, heel and arch of the foot.

[0030]In one embodiment shown in FIGS. 3A and 3B, insole 10 comprises a pillow 20 extending from the lower surface of cushioning layer 18 at forefoot portion 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com