Electric conduction board and manufacture method thereof

A conductive plate and conductive paper technology, which is applied in chemical instruments and methods, wood layered products, lamination, etc., can solve the problems of static area load bearing, easy peeling and warping, complicated process, etc., so that it does not need to be replaced frequently, Good decorative effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Dipping treatment

[0033] The dipping glue that adopts during dipping treatment is melamine formaldehyde resin (solid content is 53%), and its viscosity is 14 seconds 45 (coating four cups), and pH value is 7.0, and temperature is 25 ℃;

[0034] ST1500B horizontal secondary impregnation production line is used to transfer 80g black paper to the back coating roller through the feed roller for back coating, and then impregnated with dipping glue. The impregnated paper is obtained; one of the oven sections is a three-section oven, and the black paper after impregnation passes through the first section to the third section oven in turn. The temperature and wind speed of the first section oven are 145°C and 20HZ respectively, and the second section The temperature and wind speed of the oven are 150°C and 23HZ respectively, and the temperature and wind speed of the third oven are 145°C and 20HZ respectively;

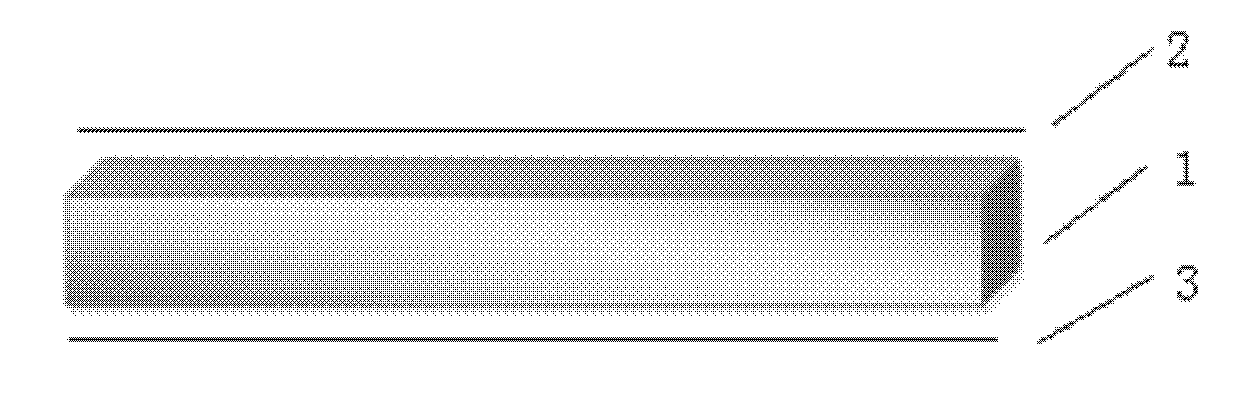

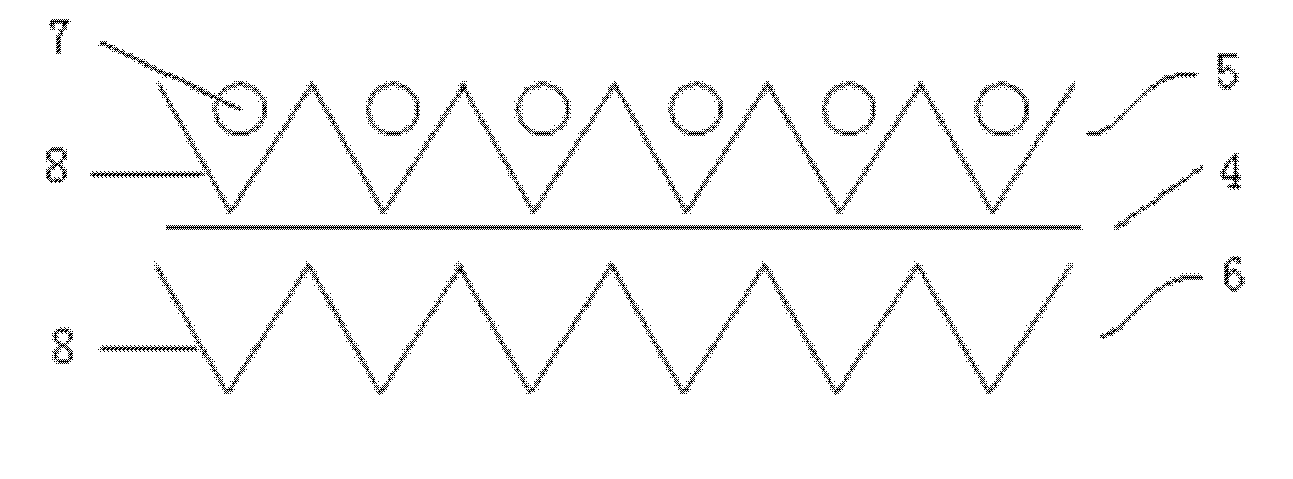

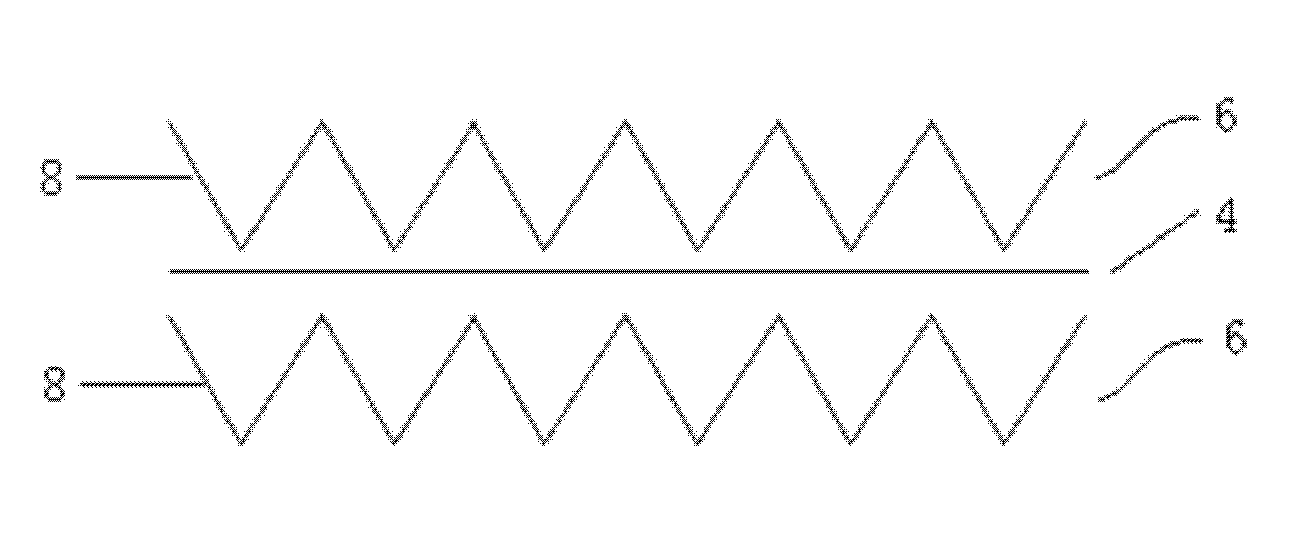

[0035] Such as image 3 As shown, the impregnated paper incl...

Embodiment 2

[0044] Except for the dipping treatment step, the viscosity of the dipping glue is 14 seconds (apply four cups), the pH value is 8.0, the temperature is 20°C, the temperature and wind speed of the first section, the second section and the third section oven are respectively 140°C and 15HZ, 145°C and 20HZ, 140°C and 15HZ;

[0045] In the overcoating process step, the viscosity of the melamine formaldehyde resin in the conductive glue is 14 seconds 50 (coated with four cups), the pH value is 8.0, the mass percentage of nanoscale conductive carbon black is 5%, and the temperature of the conductive glue is 20°C , the curing time is 18 minutes, the temperature and wind speed of the first to fifth ovens are 140°C and 20HZ, 145°C and 25HZ, 145°C and 25HZ, 150°C and 25HZ, 145°C and 25HZ, the prepared conductive The gluing amount of the paper is 180%, the volatile matter is 5.0%, and the pre-curing degree is 25%;

[0046] In the pressing process step, the EO grade density board is use...

Embodiment 3

[0048] In addition to the dipping treatment step, the viscosity of the dipping glue is 15 seconds (apply four cups), the pH value is 7.5, and the temperature is 30°C. The temperature and wind speed of the first section, the second section and the third section oven are respectively 150°C and 25HZ, 155°C and 25HZ, 150°C and 25HZ;

[0049] In the overcoating process step, the viscosity of the melamine formaldehyde resin in the conductive glue is 16 seconds (coated with four cups), the pH value is 8.0, the mass percentage of nanoscale conductive carbon black is 10%, and the temperature of the conductive glue is 28°C. The curing time is 12 minutes, the temperature and wind speed of the first to fifth ovens are respectively 150°C and 30HZ, 150°C and 30HZ, 155°C and 35HZ, 160°C and 35HZ, 155°C and 30HZ, the prepared conductive paper The gluing amount is 220%, the volatile matter is 10.0%, and the pre-curing degree is 35%;

[0050] In the pressing process step, the EO grade density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com