Patents

Literature

494results about How to "Uniform material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

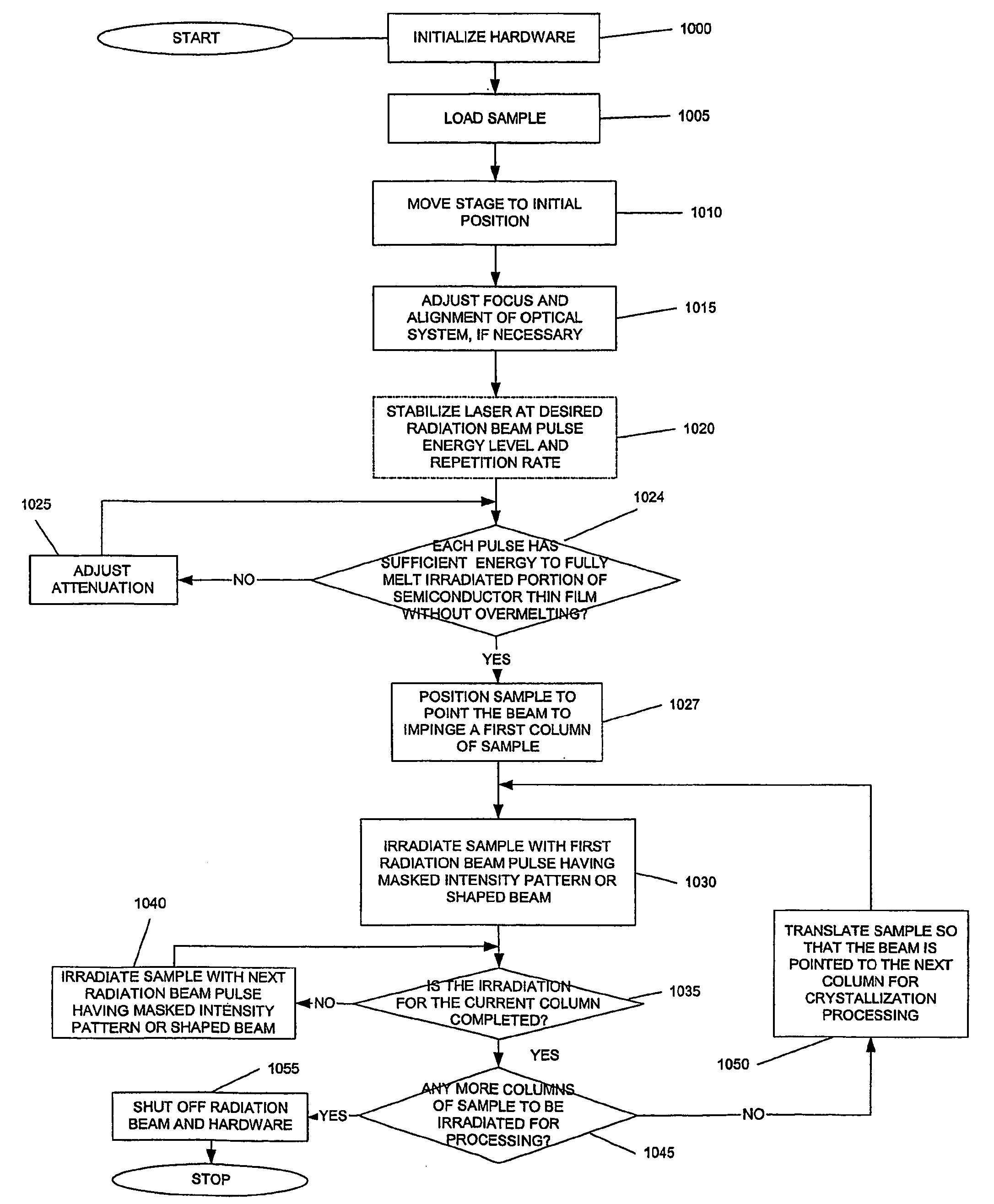

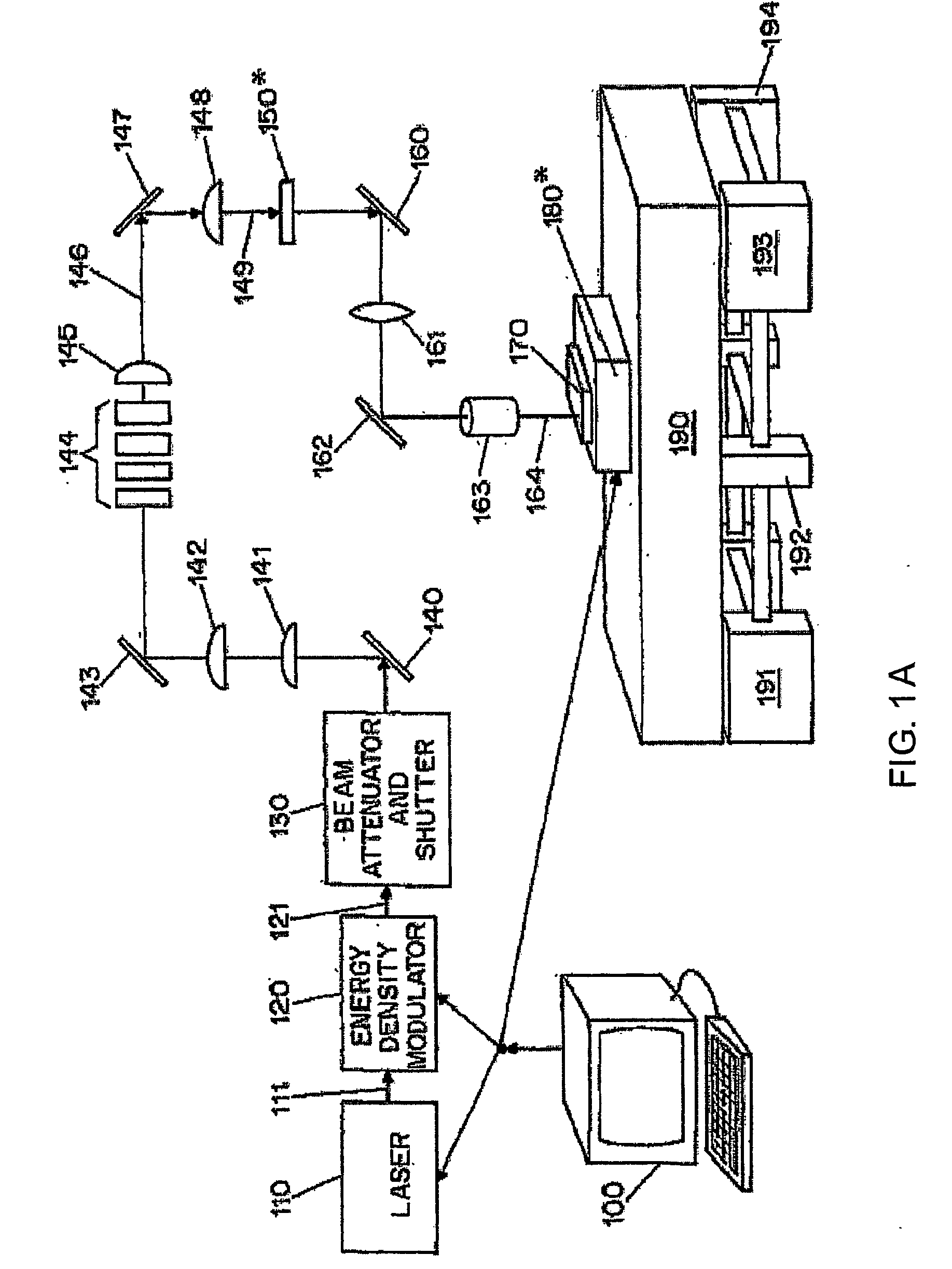

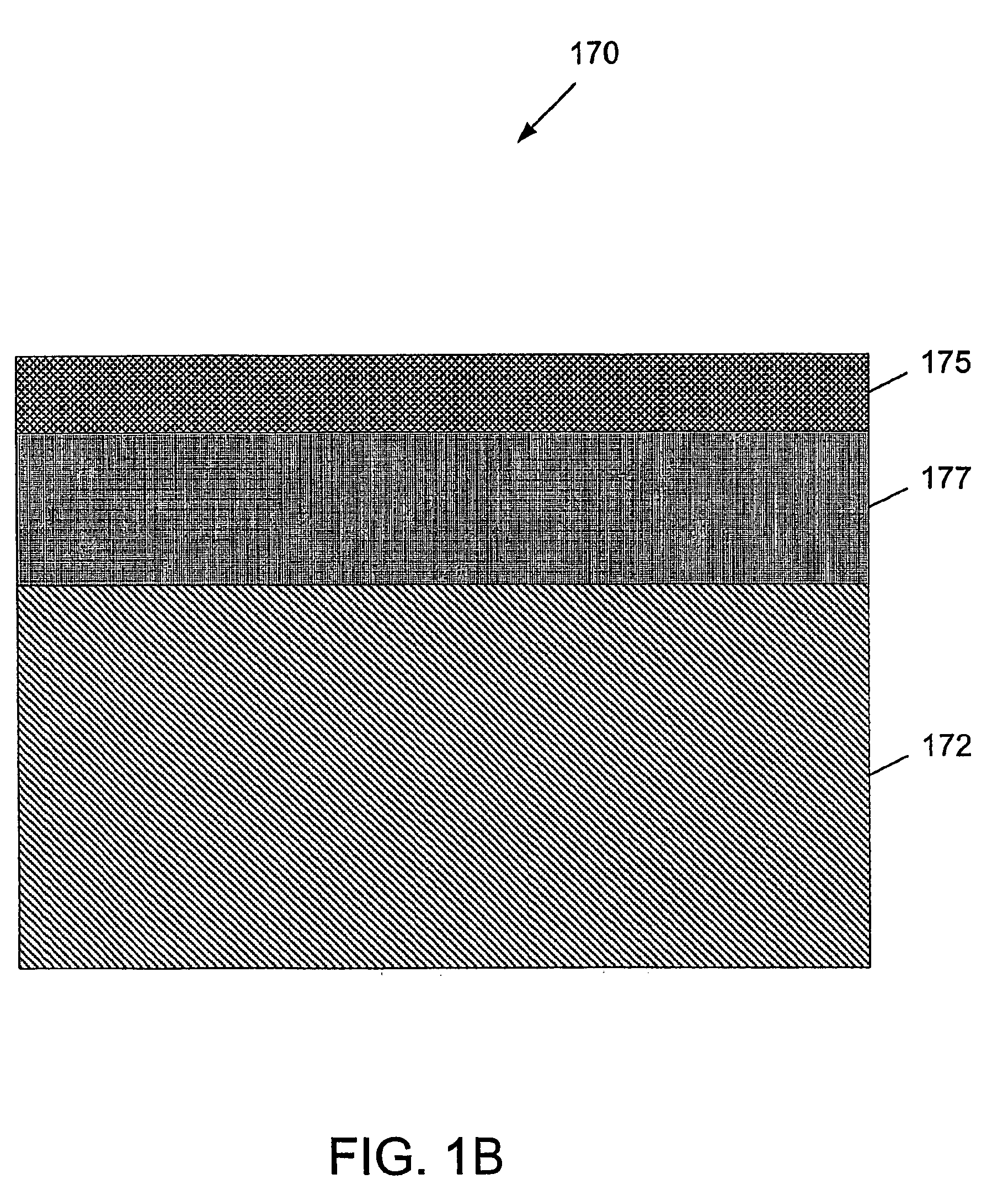

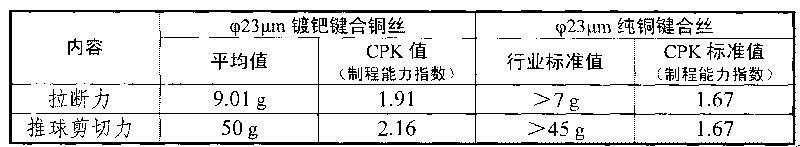

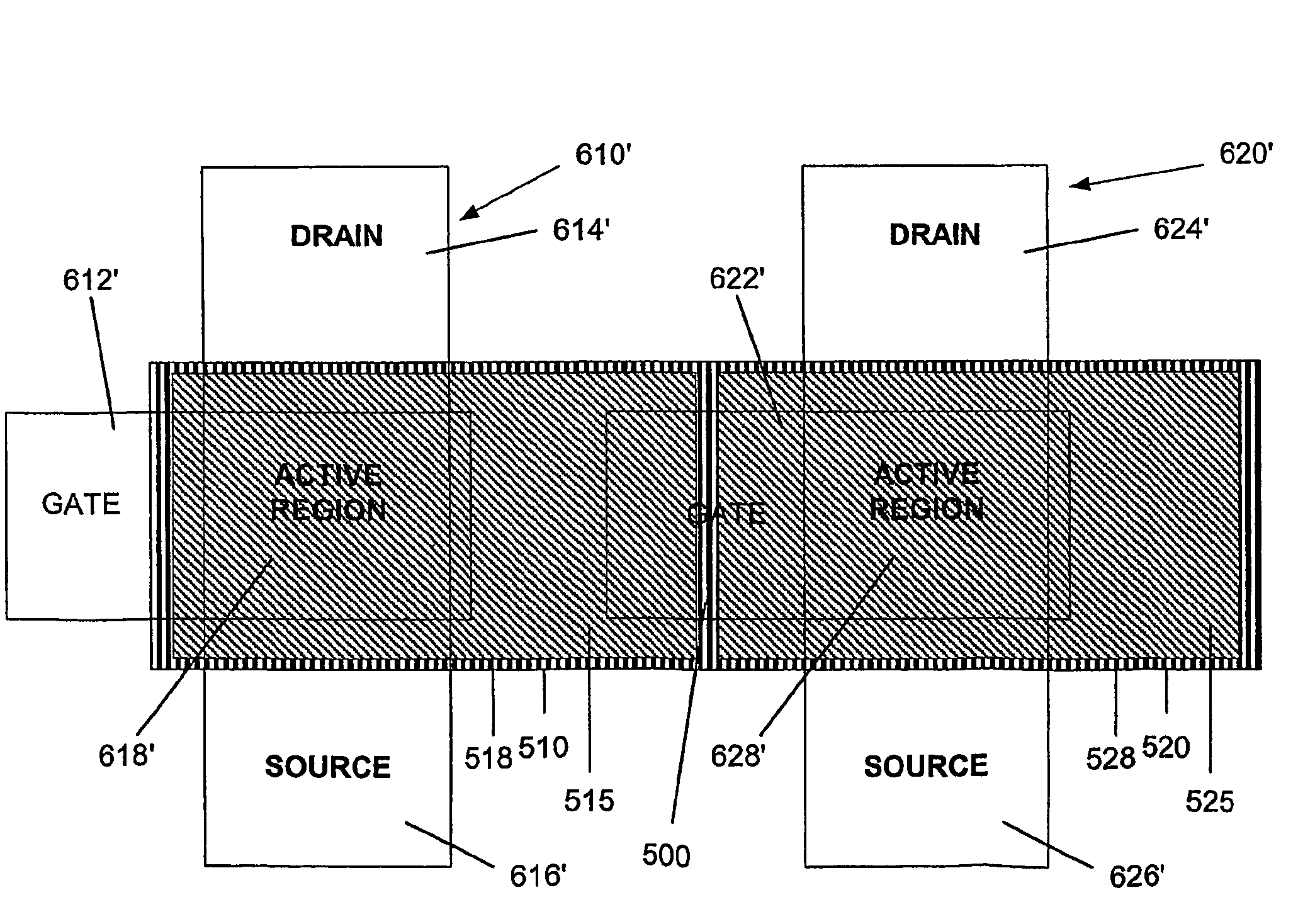

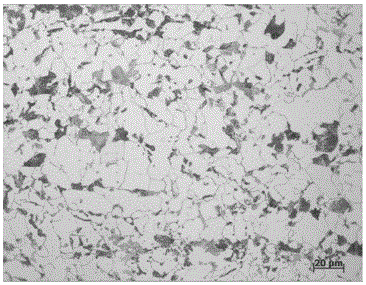

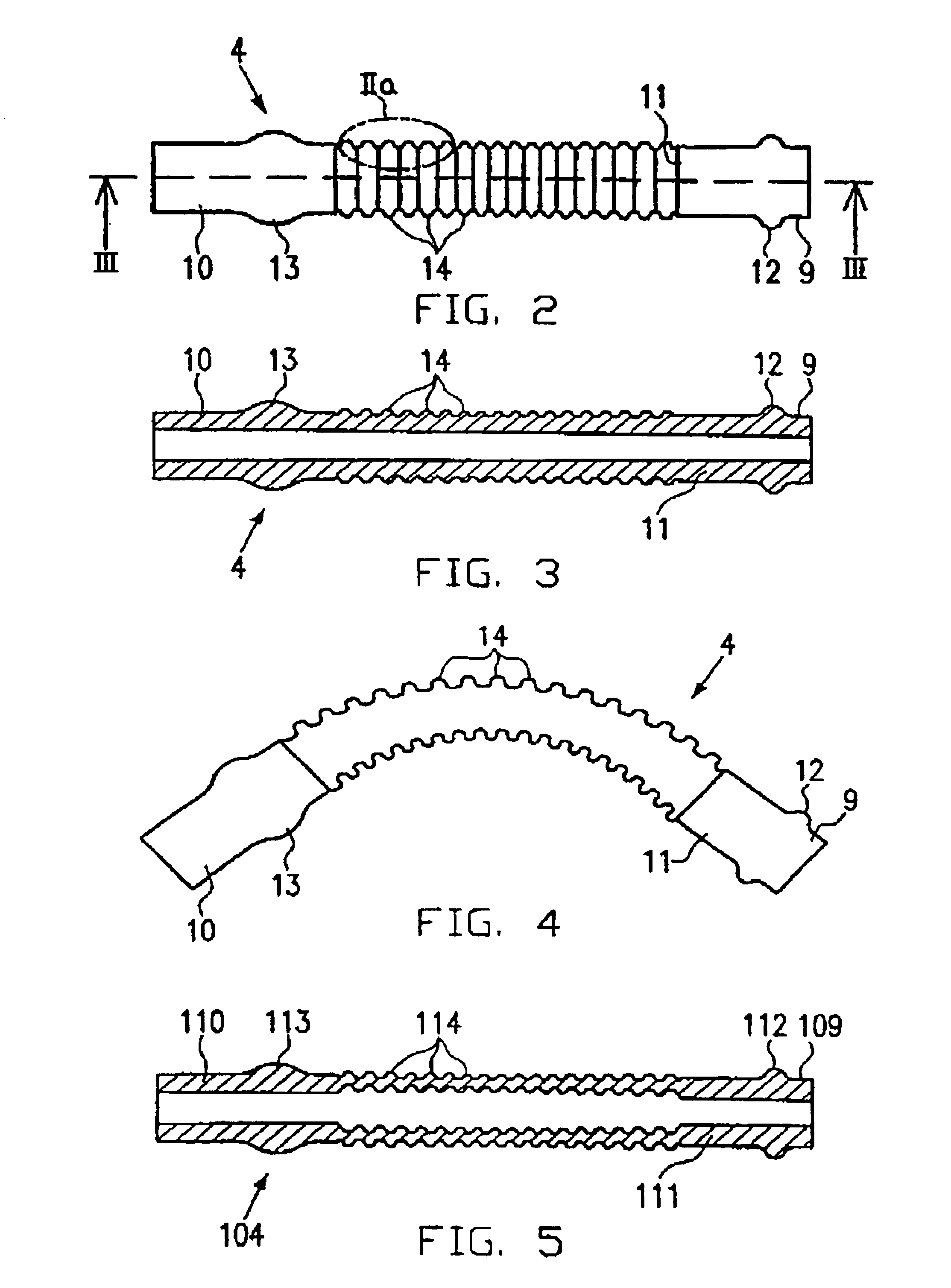

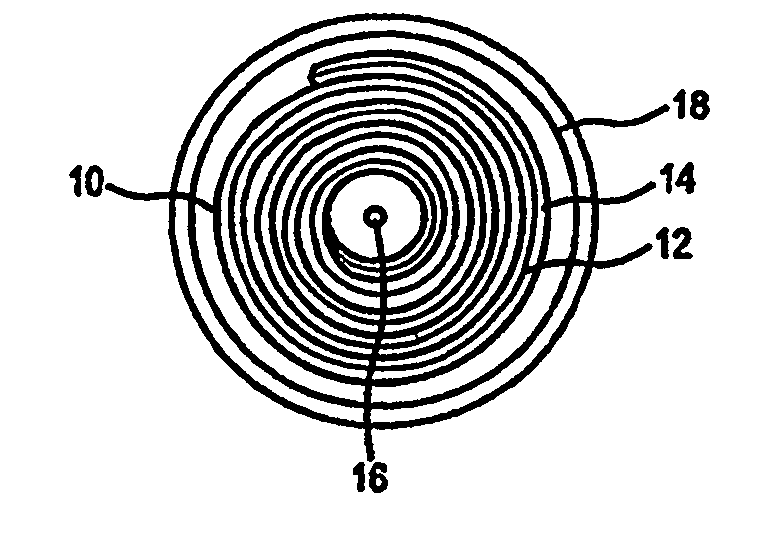

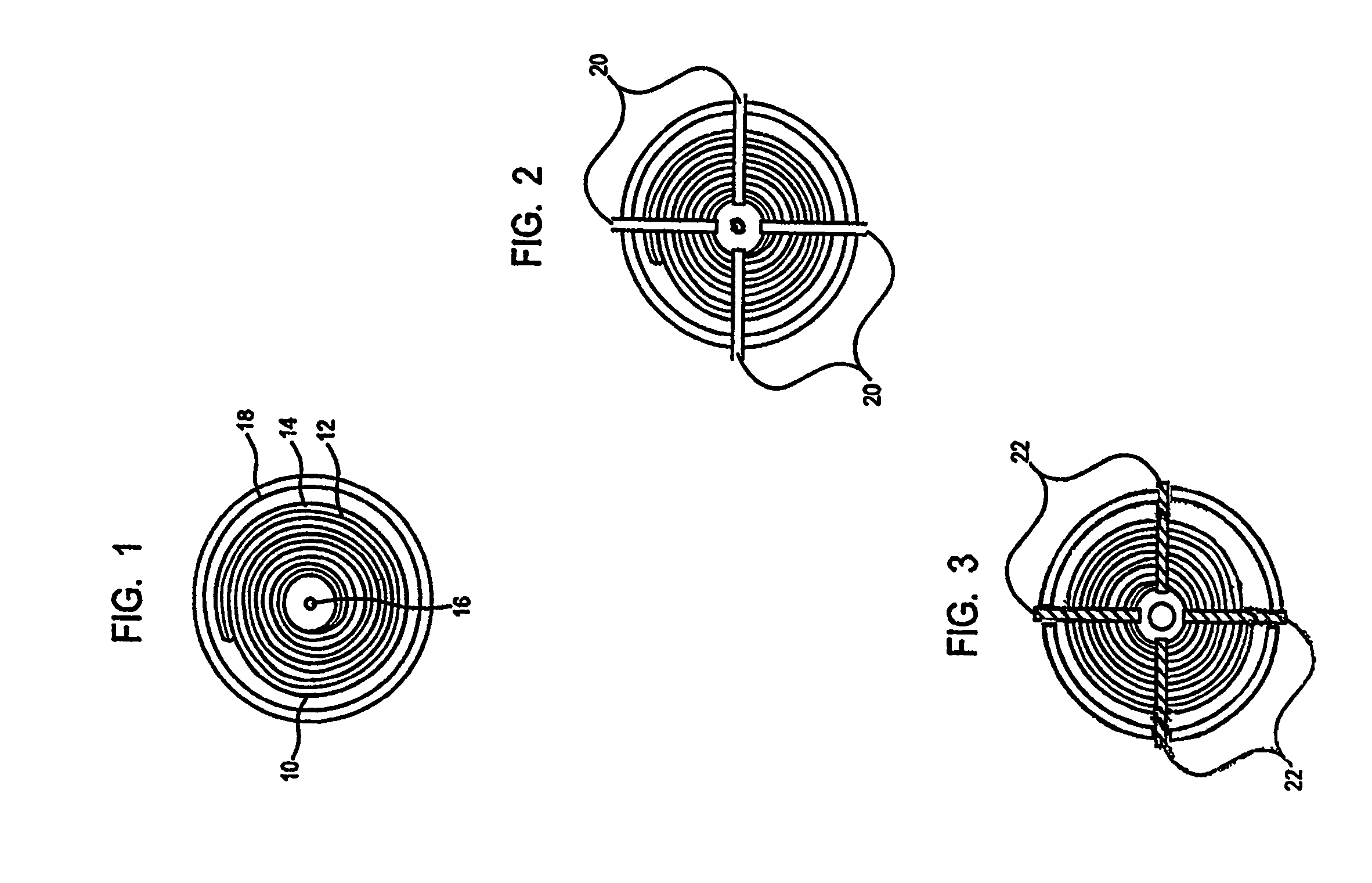

Process and system for laser crystallization processing of film regions on a substrate to provide substantial uniformity, and a structure of such film regions

InactiveUS20050202654A1Increase speedUniform materialAfter-treatment apparatusTransistorLaser crystallizationGrain structure

A process and system for processing a thin film sample (e.g., a semiconductor thin film), as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit at least one beam pulse. With this beam pulse, at least one portion of the film sample is irradiated with sufficient intensity to fully melt such section of the sample throughout its thickness, and the beam pulse having a predetermined shape. This portion of the film sample is allowed to resolidify, and the re-solidified at least one portion is composed of a first area and a second area. Upon the re-solidification thereof, the first area includes large grains, and the second area has a region formed through nucleation. The first area surrounds the second area and has a grain structure which is different from a grain structure of the second area. The second area is configured to facilitate thereon an active region of an electronic device.

Owner:IM JAMES S

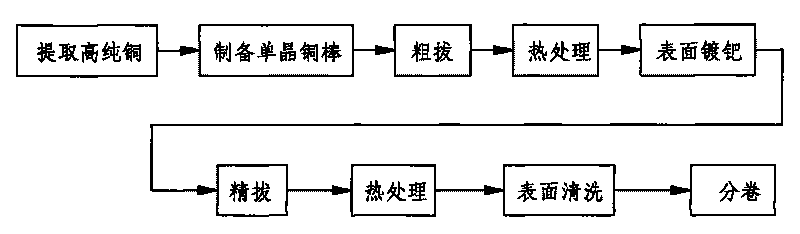

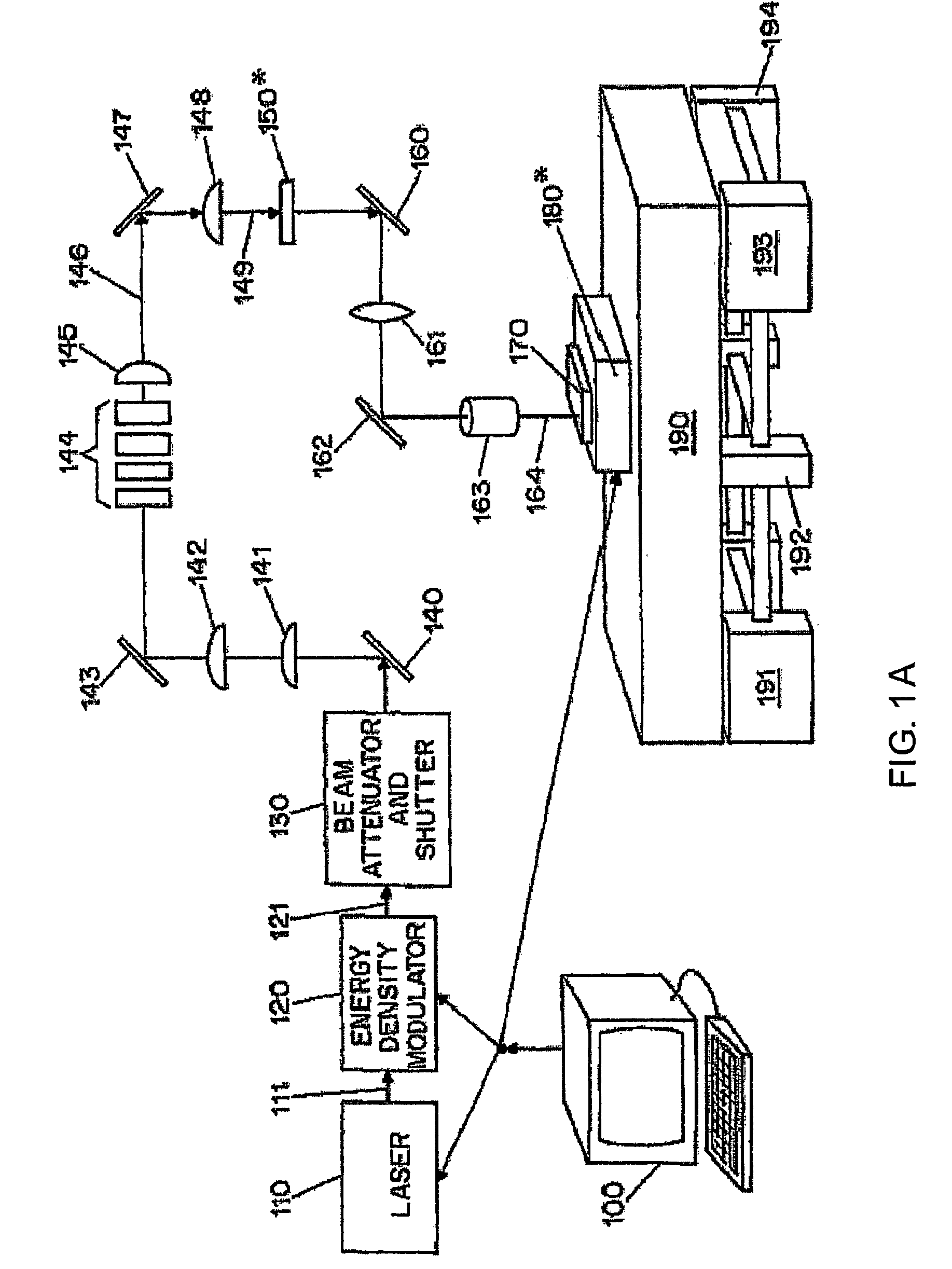

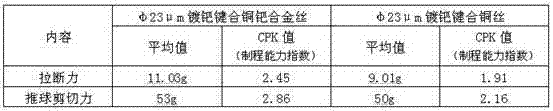

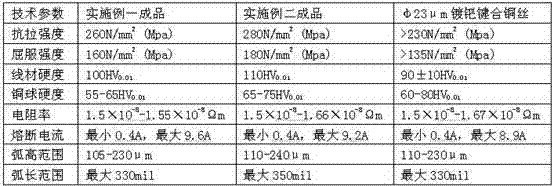

Palladium-plated bonded copper wire and production method thereof

InactiveCN101707194ADense materialUniform materialSemiconductor/solid-state device detailsSolid-state devicesHigh densityCopper wire

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Process and system for laser crystallization processing of film regions on a substrate to provide substantial uniformity, and a structure of such film regions

InactiveUS7259081B2Increase speedUniform materialTransistorAfter-treatment apparatusLaser crystallizationGrain structure

A process and system for processing a thin film sample (e.g., a semiconductor thin film), as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit at least one beam pulse. With this beam pulse, at least one portion of the film sample is irradiated with sufficient intensity to fully melt such section of the sample throughout its thickness, and the beam pulse having a predetermined shape. This portion of the film sample is allowed to resolidify, and the re-solidified at least one portion is composed of a first area and a second area. Upon the re-solidification thereof, the first area includes large grains, and the second area has a region formed through nucleation. The first area surrounds the second area and has a grain structure which is different from a grain structure of the second area. The second area is configured to facilitate thereon an active region of an electronic device.

Owner:IM JAMES S

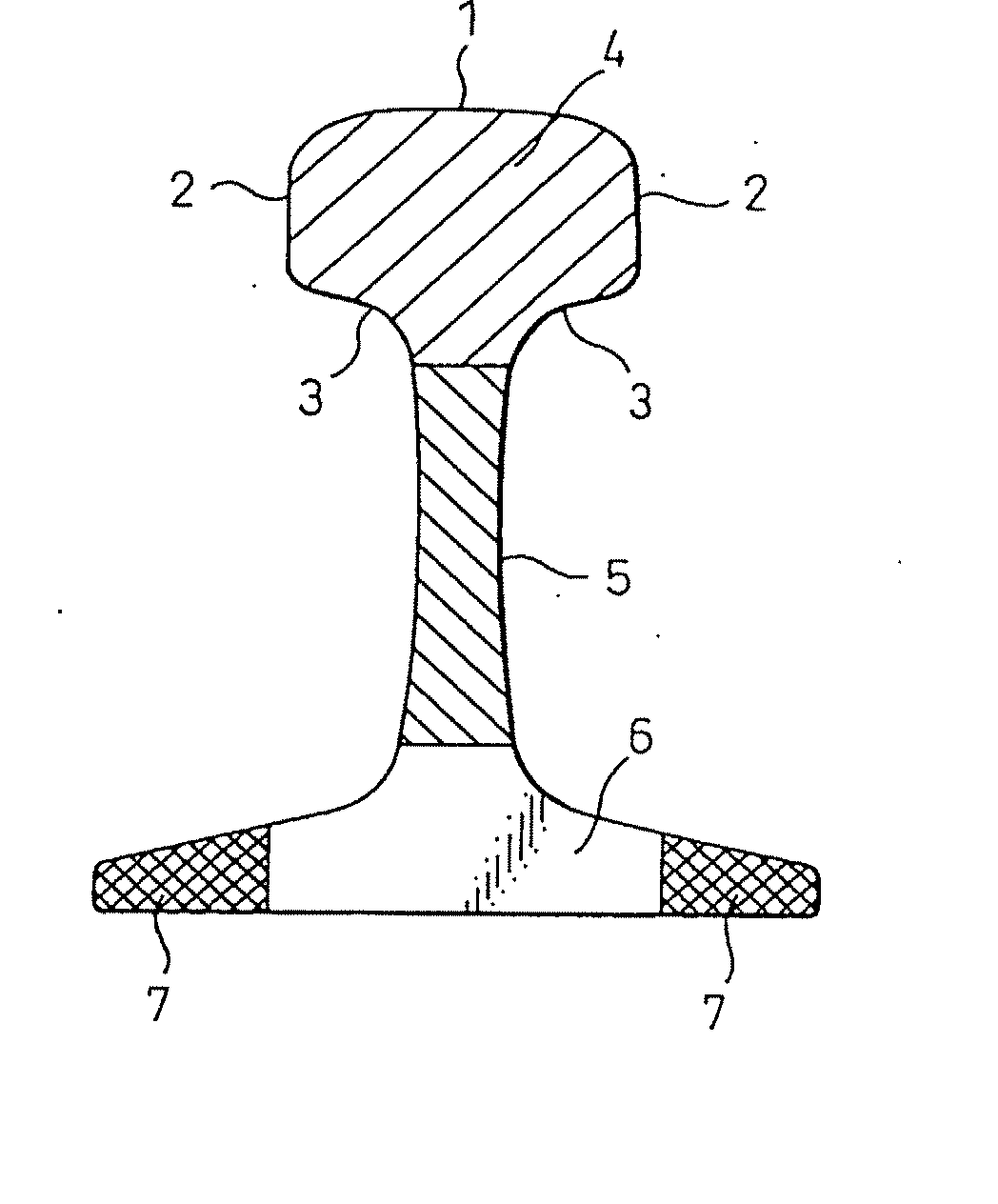

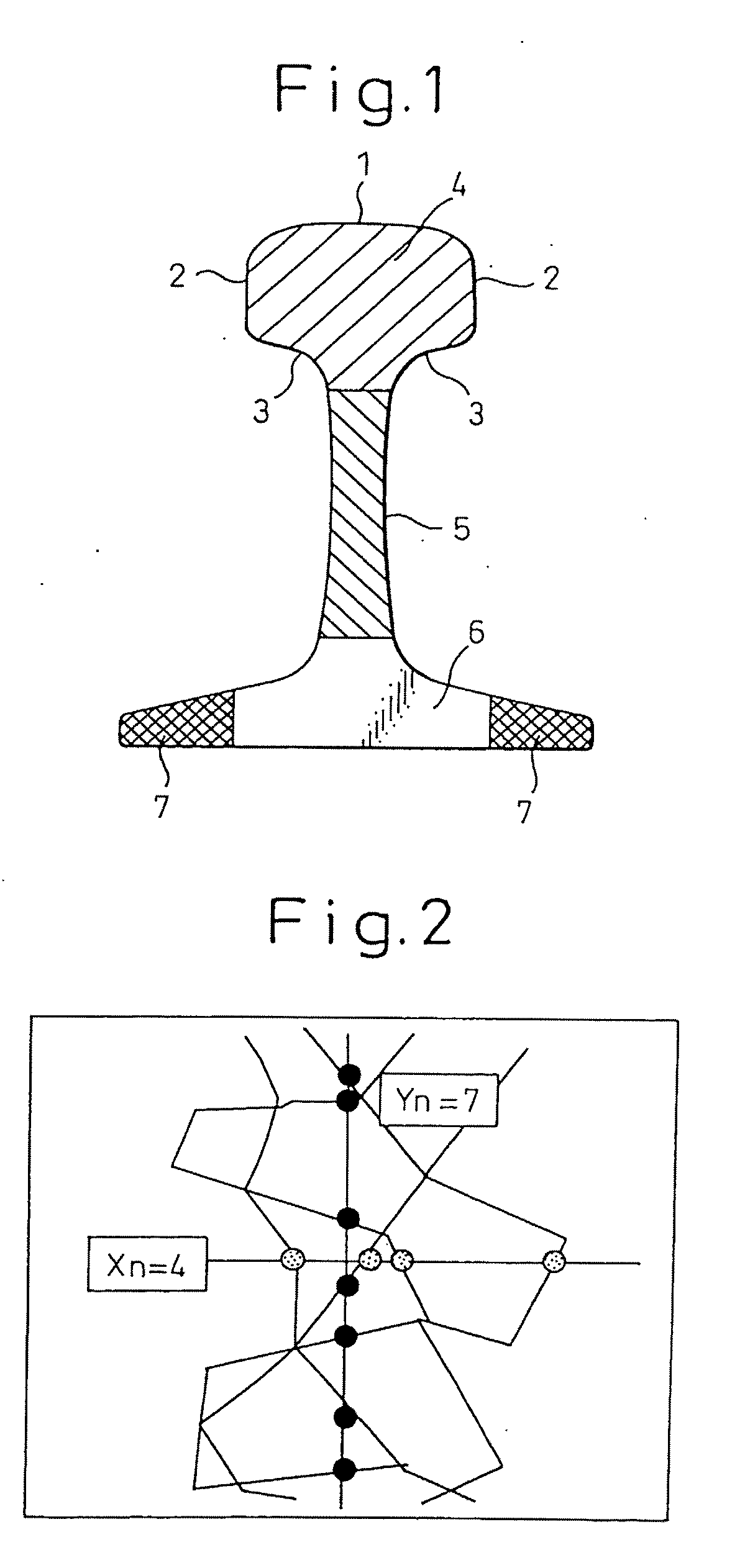

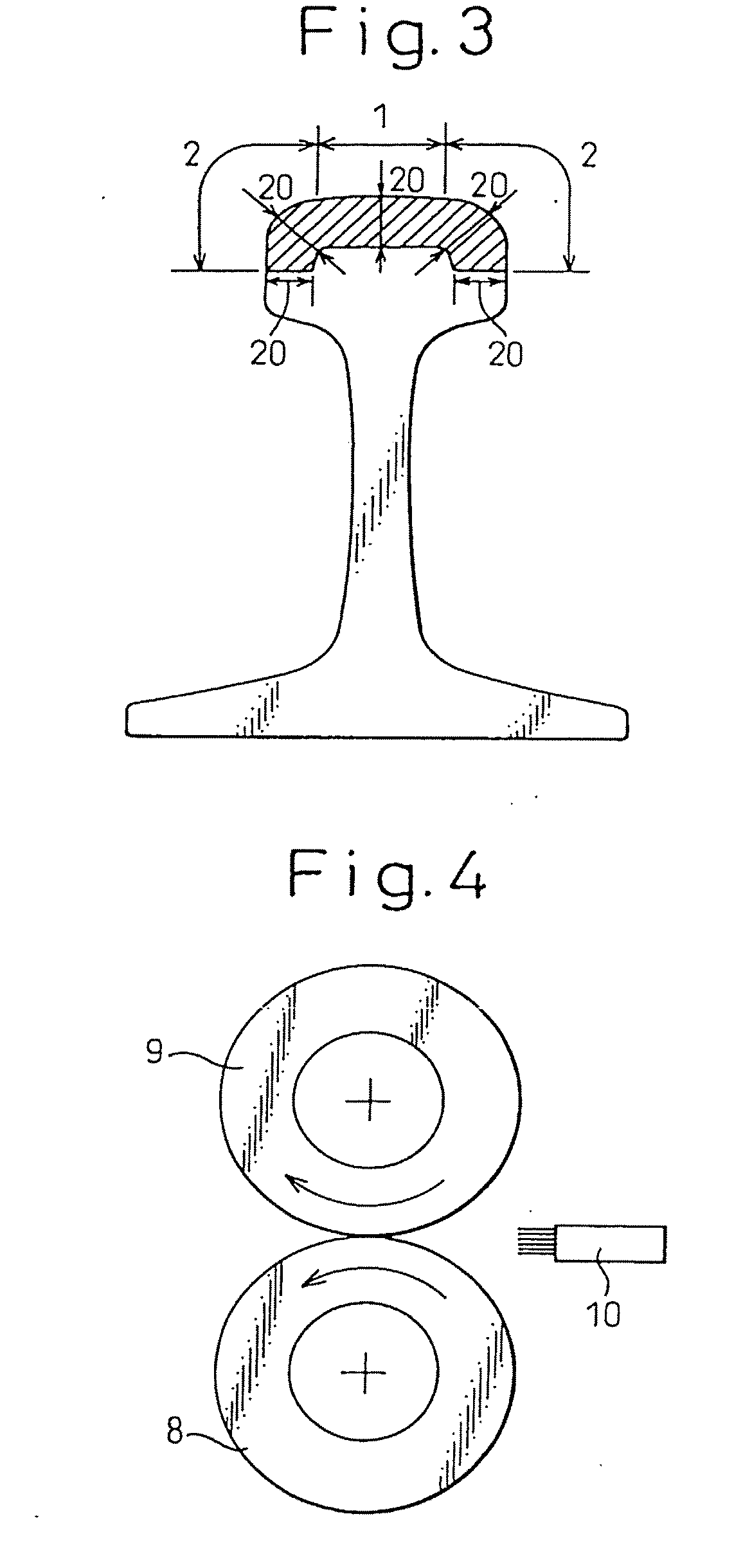

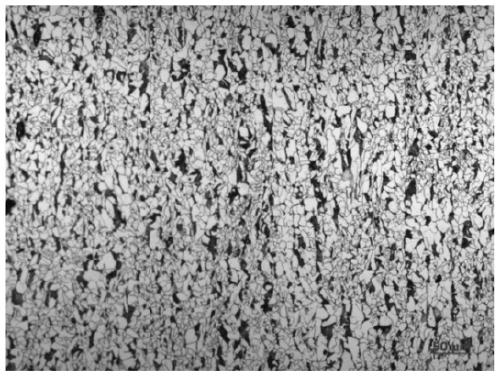

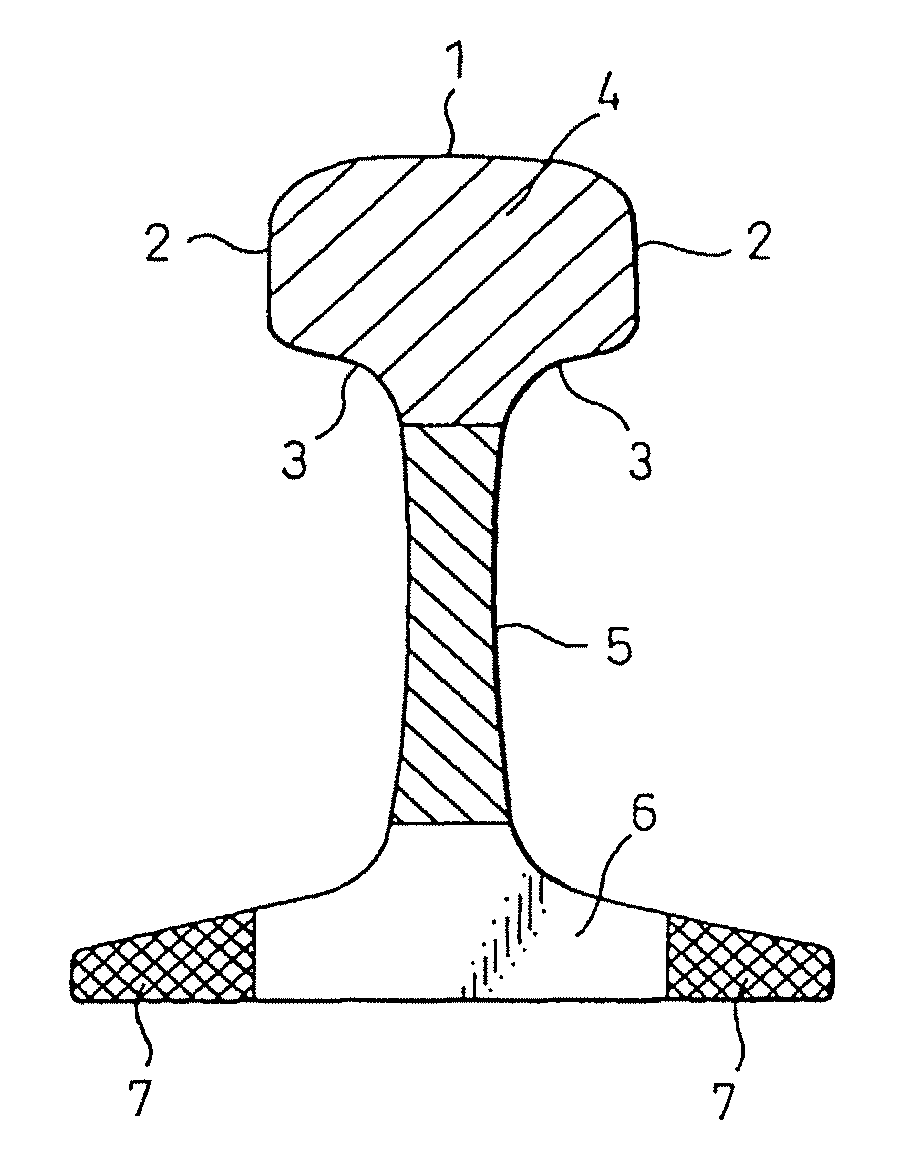

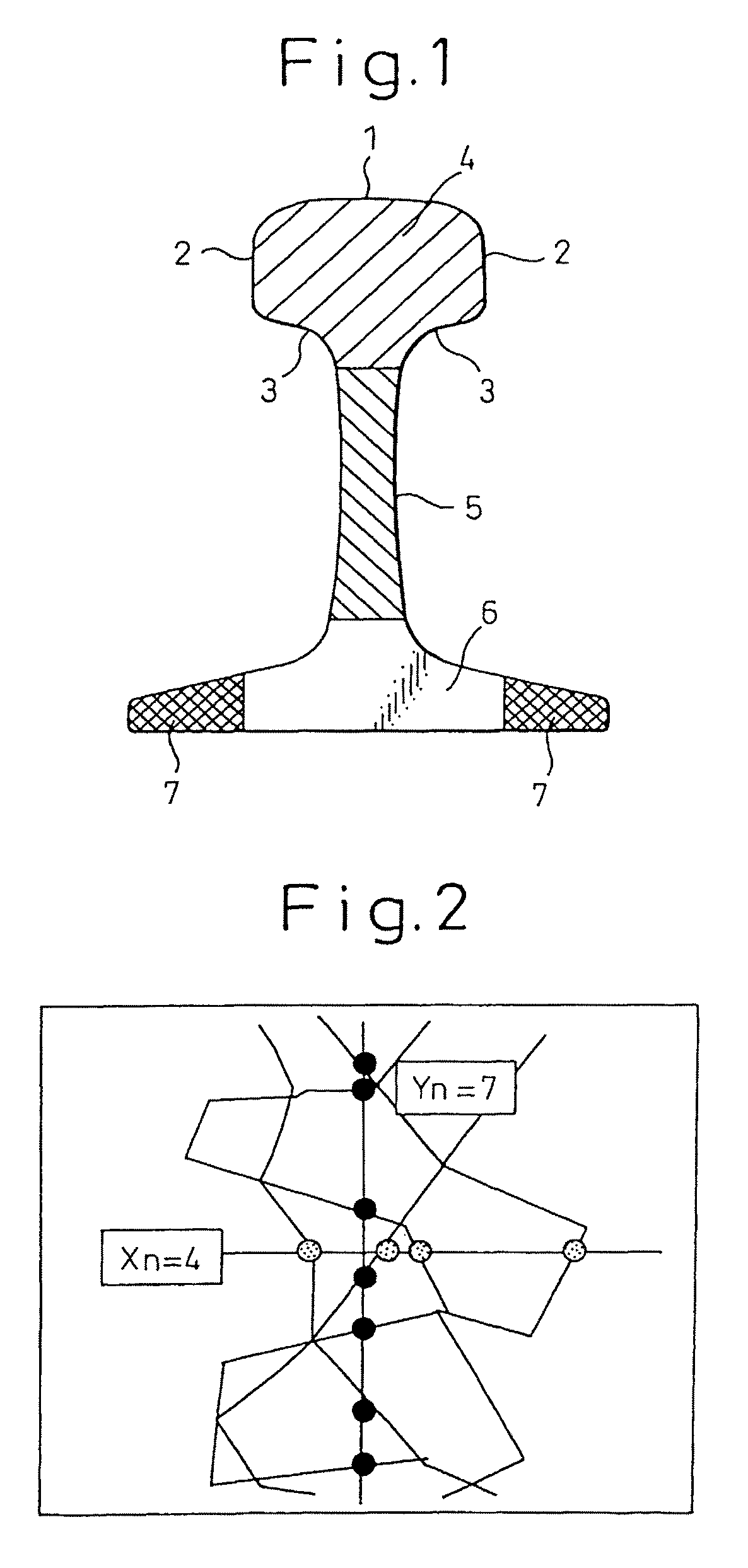

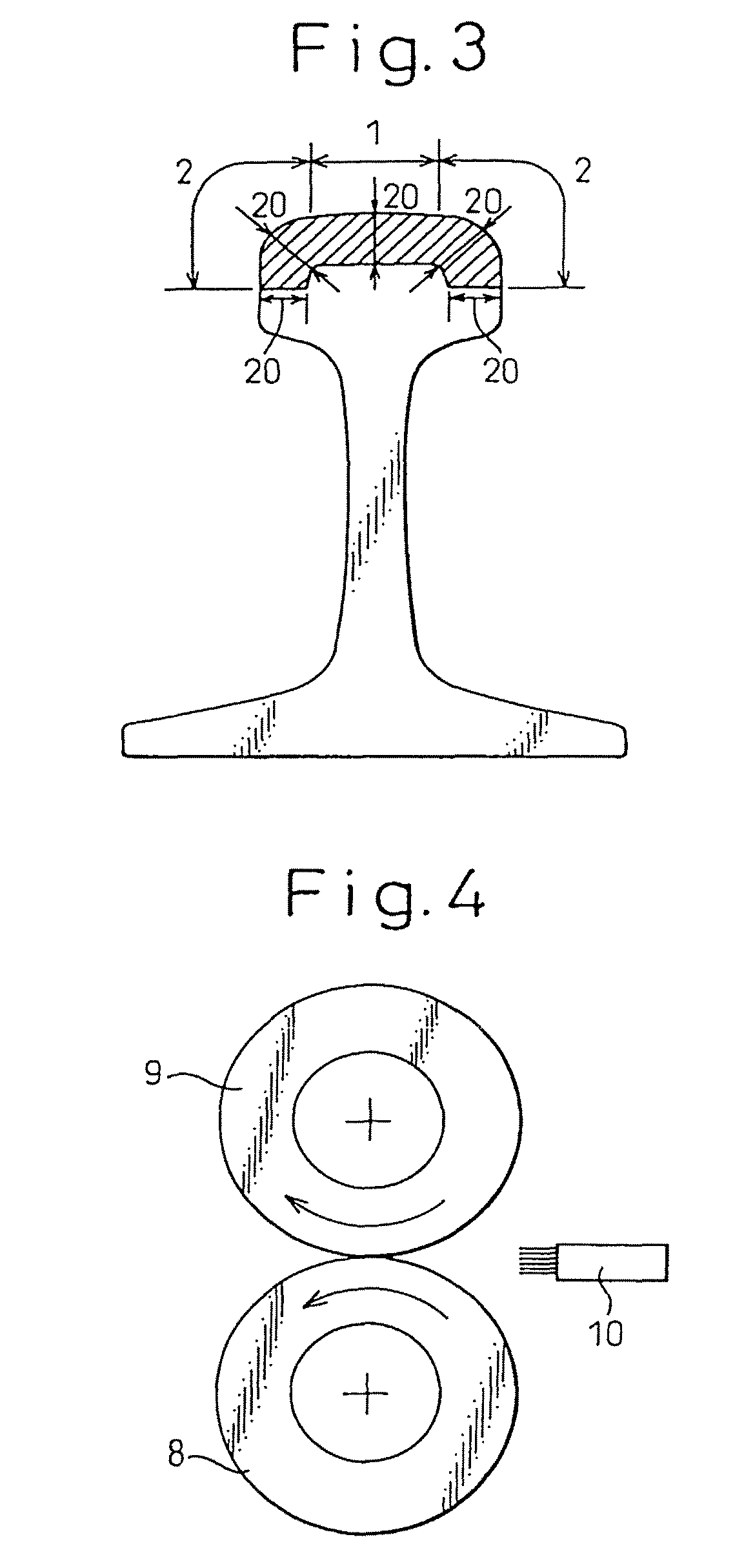

Pearlitic steel rail excellent in wear resistance and ductility and method for producing same

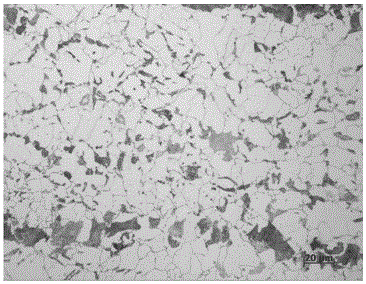

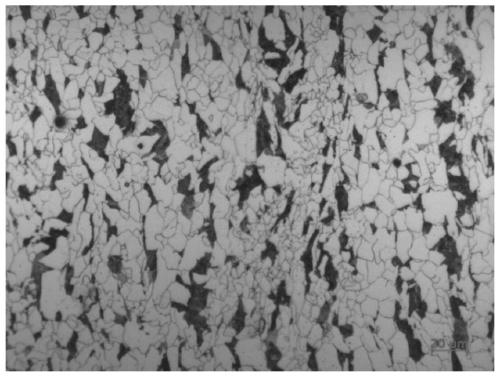

InactiveUS20080011393A1High carbon contentInhibition formationFurnace typesHeat treatment furnacesGranularityPearlite

The present invention is: a pearlitic steel rail excellent in wear resistance and ductility, characterized in that, in a steel rail having pearlite structure containing, in mass, 0.65 to 1.40% C, the number of the pearlite blocks having grain sizes in the range from 1 to 15 μm is 200 or more per 0.2 mm2 of an observation field at least in a part of the region down to a depth of 10 mm from the surface of the corners and top of the head portion; and a method for producing a pearlitic steel rail excellent in wear resistance and ductility, characterized by, in the hot rolling of said steel rail, applying finish rolling so that the temperature of the rail surface may be in the range from 850° C. to 1,000° C. and the sectional area reduction ratio at the final pass may be 6% or more, and then applying accelerated cooling to the head portion of said rail at a cooling rate in the range from 1 to 30° C. / sec. from the austenite temperature range to at least 550° C.

Owner:NIPPON STEEL CORP

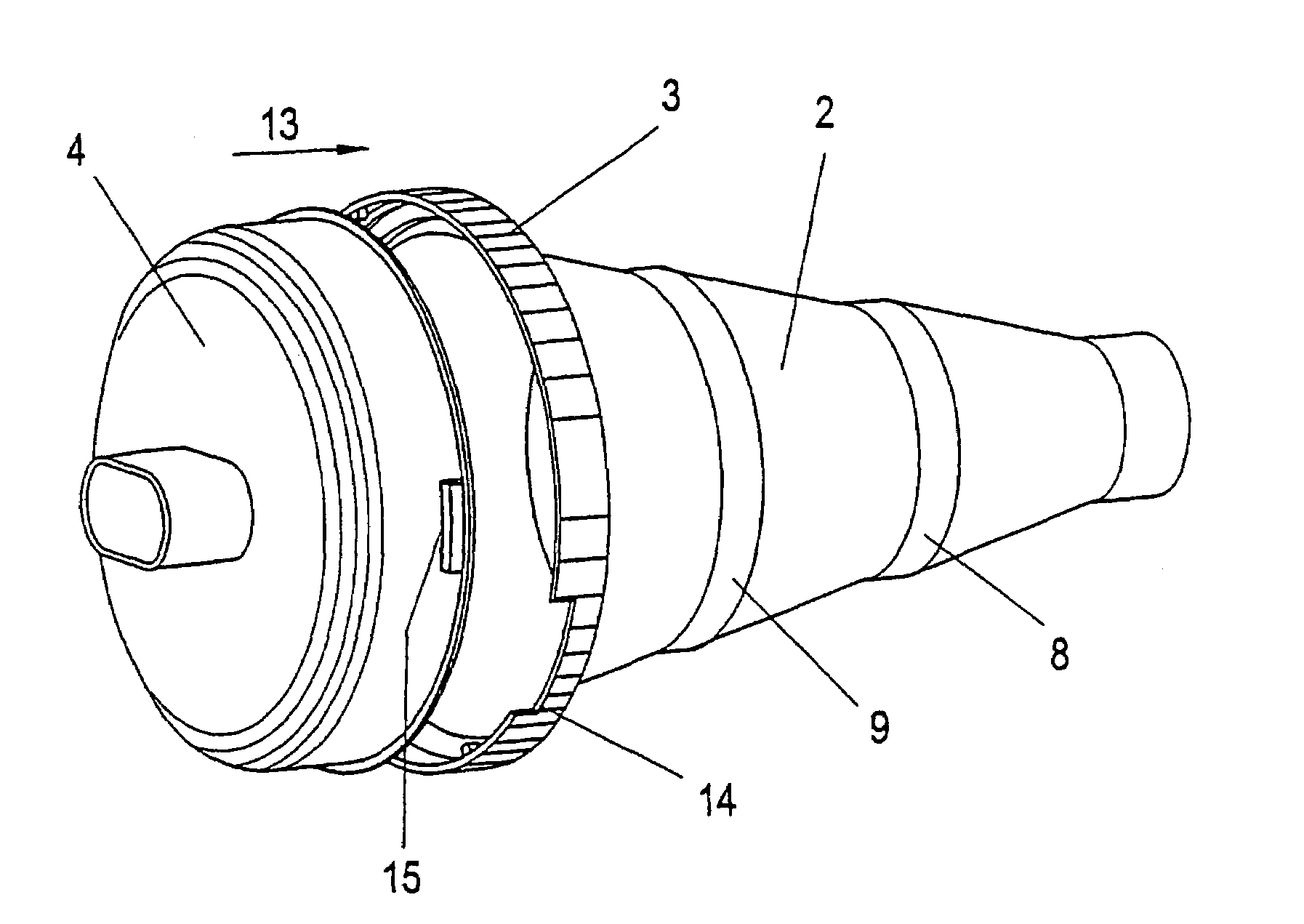

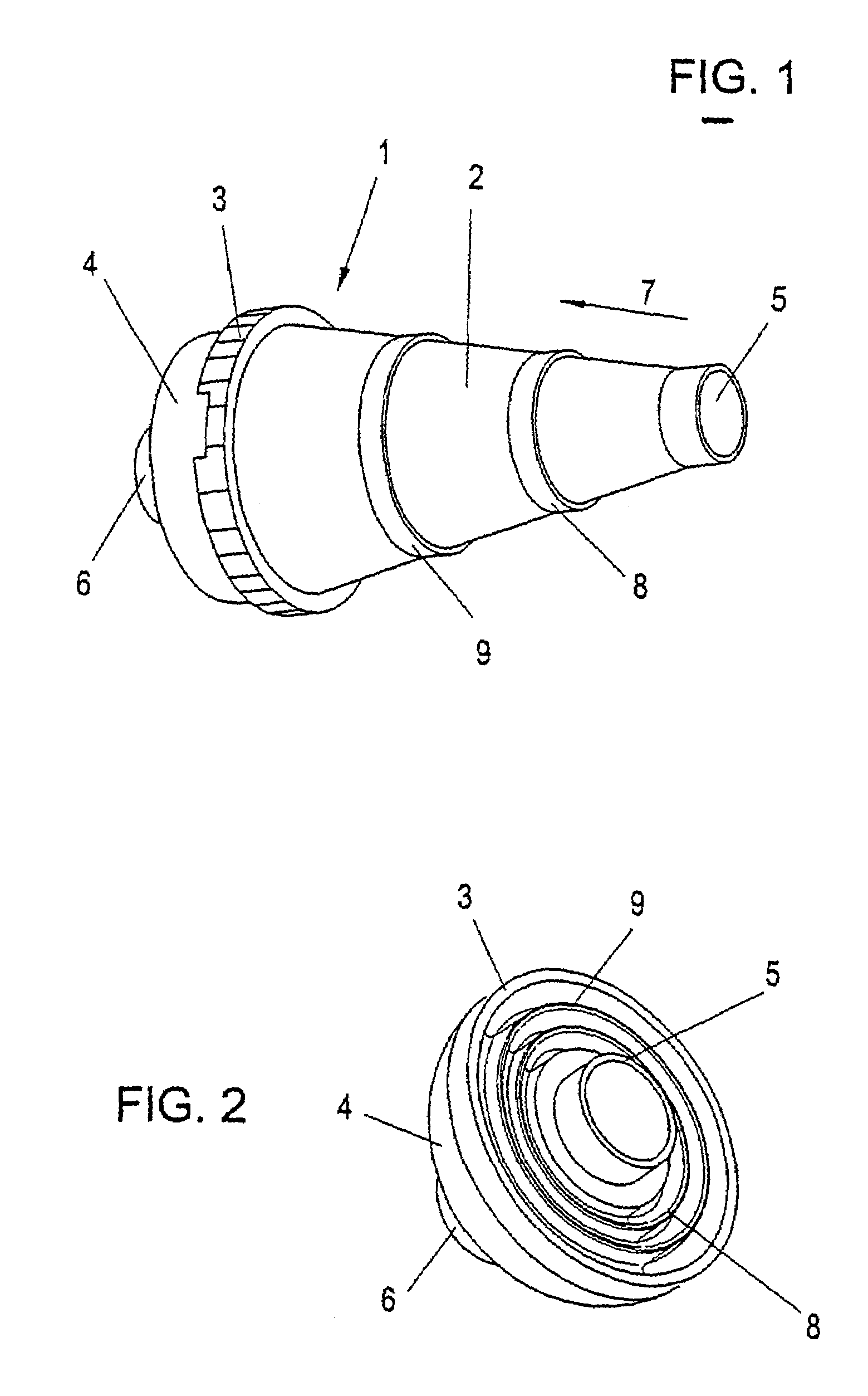

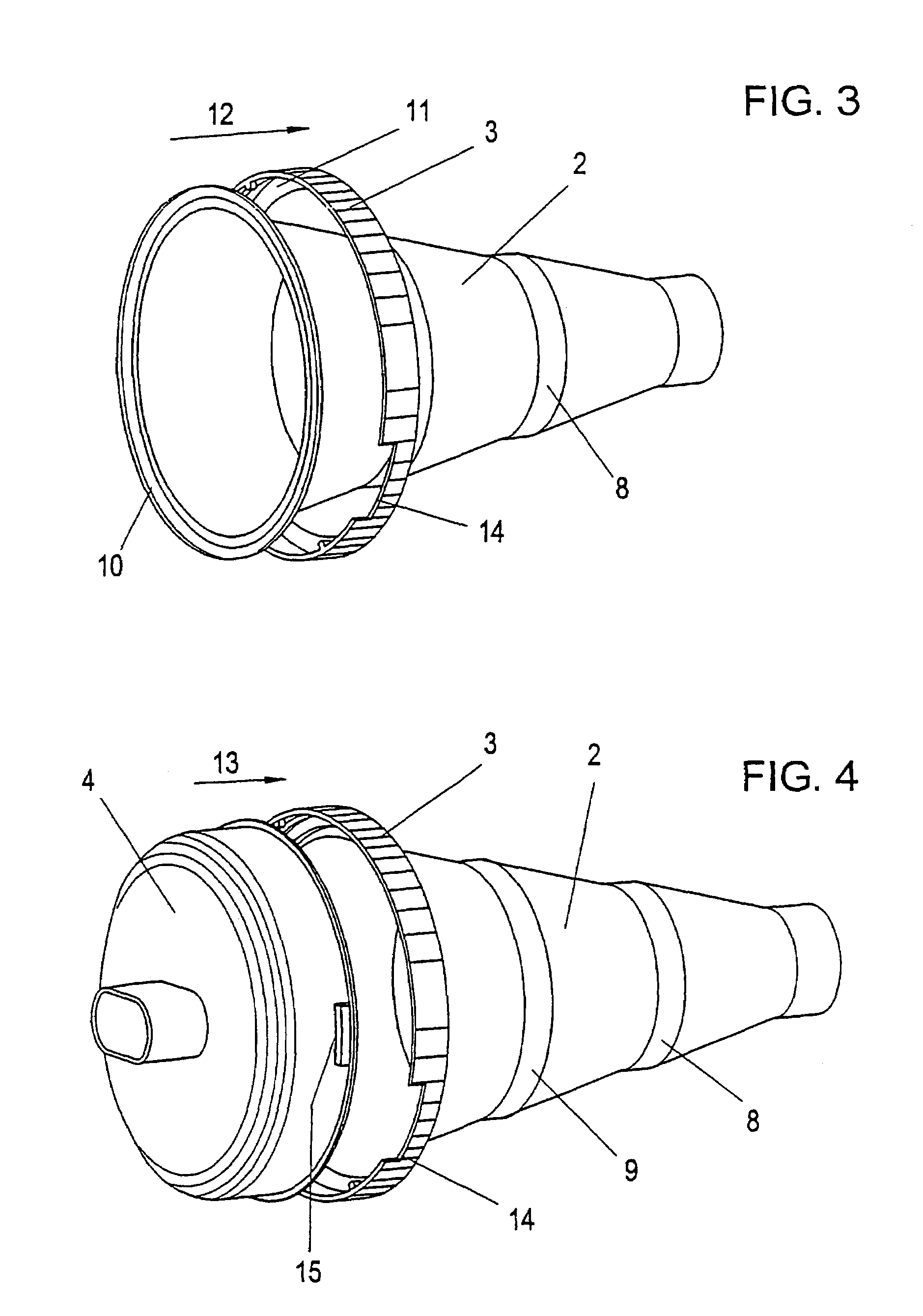

Inhalation aid

InactiveUS7556037B2Increase in sizeUniform materialRespiratorsLiquid surface applicatorsMedicineInhalation

Owner:INT PROD & SERVICES GRP

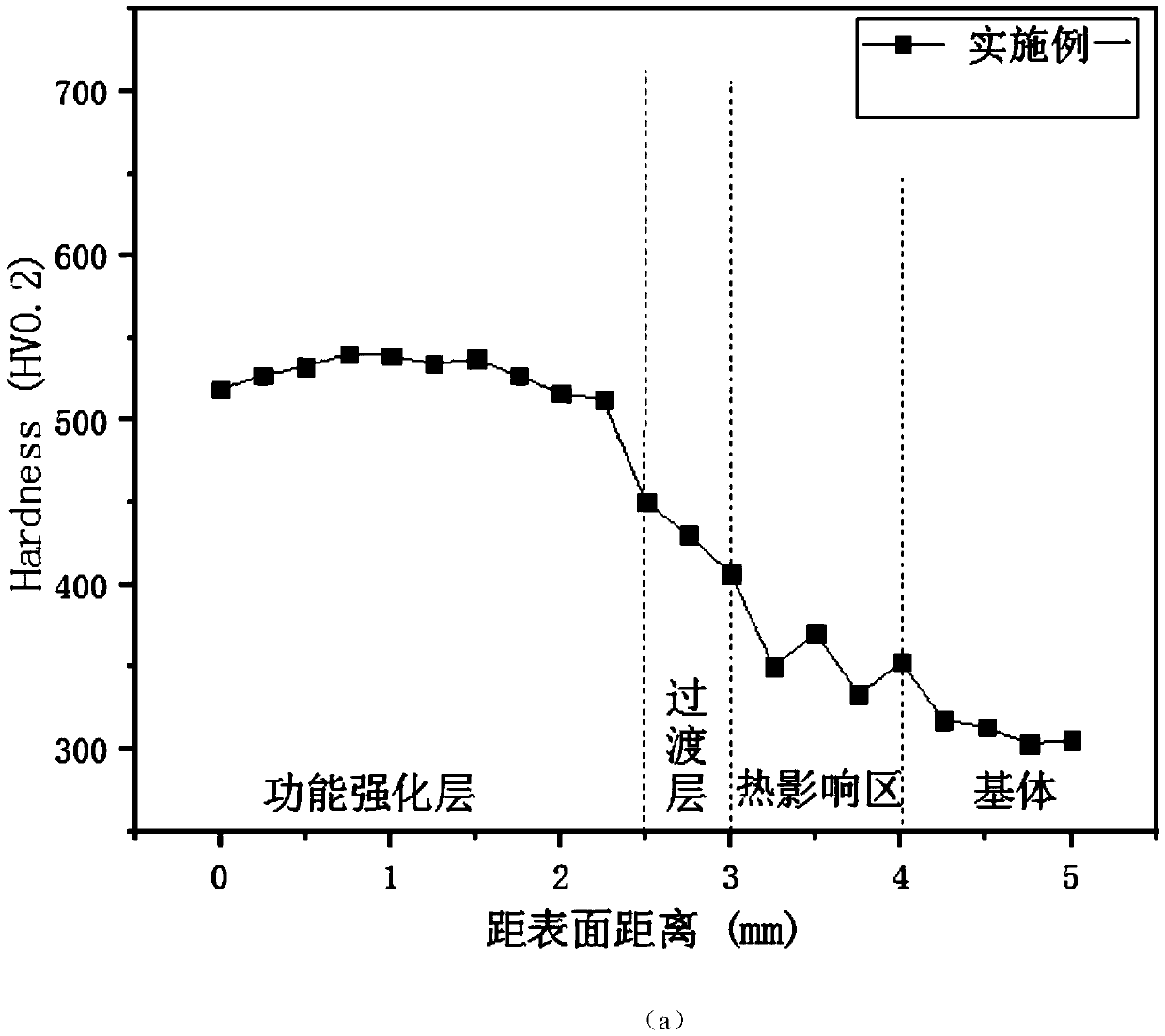

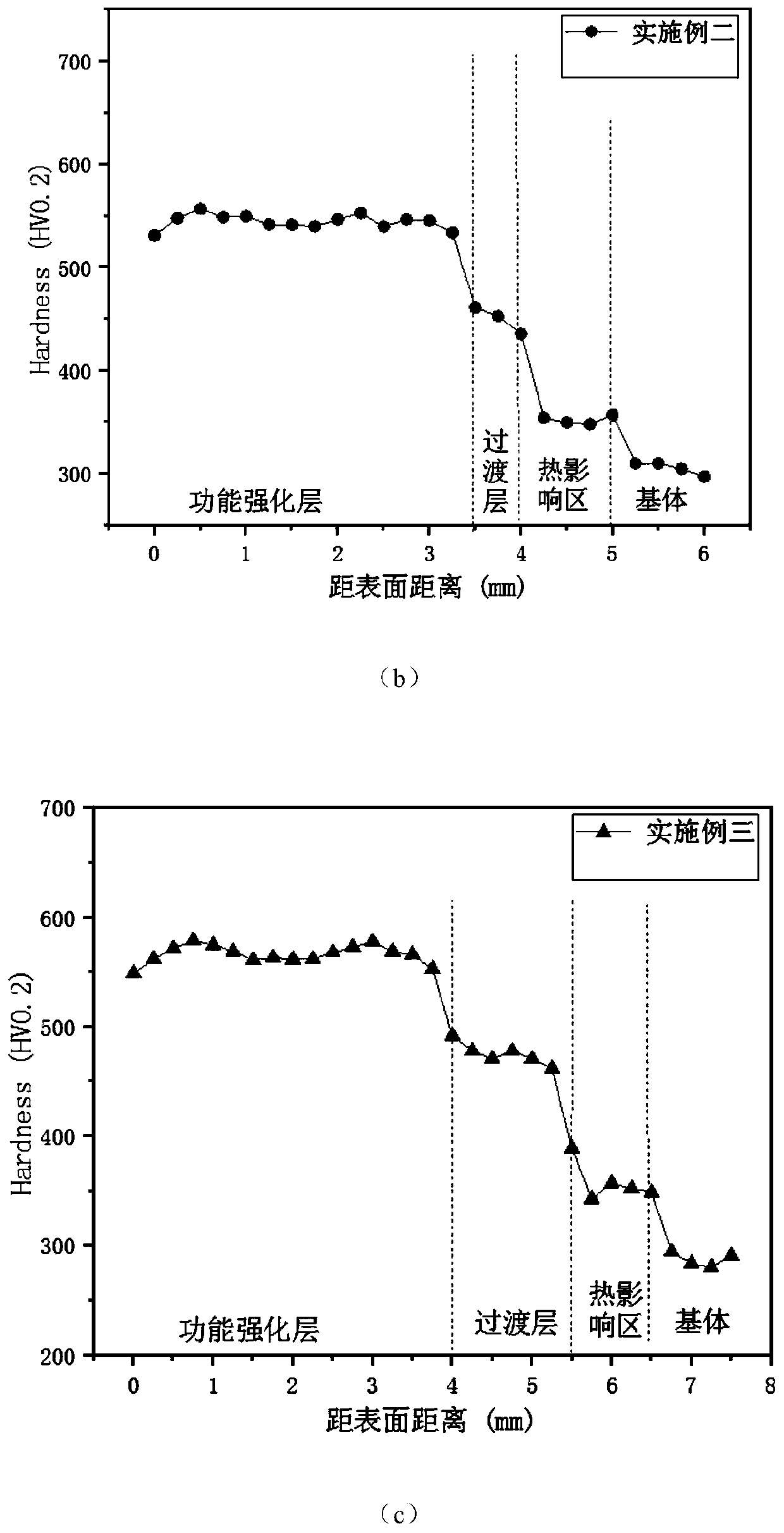

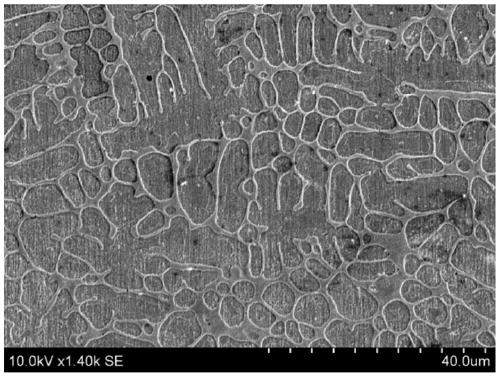

Gradient material steel rail frog prepared by laser cladding

ActiveCN110129674AImprove wear resistanceImprove carrying capacityMetallic material coating processesHeat-affected zoneGradient material

The invention provides a gradient composite material steel rail turnout coating prepared by laser cladding. The composite material is characterized in that a transition layer adopts a Fe-based alloy material, wherein the Fe-based alloy material comprises the following components of, in percentage by weight, 13wt%-17wt% of Cr, 3wt%-6wt% of Ni, 1wt%-1.5wt% of Si, 0.5wt%-1wt% of Mn, 0.3wt%-1.2wt% ofNb, 1wt%-1.5wt% of B, 0.05wt%-0.7wt% of C, 0.5wt%-1.2wt% of V, and the balance Fe; a strengthening layer is arranged above the transition layer, and the strengthening layer adopts a Fe-based metal nano-phase composite material. The preparation method comprises the following steps of preparing the Fe-based metal powder and the Fe-based metal nano-phase composite material coating; preheating a steelrail by using laser scanning heating so as to reduce the temperature gradient; preparing the gradient composite material coating on the surface of the steel rail by utilizing a laser cladding technology, and performing laser scanning heat treatment; and reducing the cooling rate after laser cladding, so that the martensite of the heat affected zone is prevented from being generated, and the cracking property of the coating is reduced. The prepared steel rail frog has the advantages that the hardness curve is smooth, the overall toughness and bearing performance are good, the strength and hardness is higher than a common heavy-load railway frog, the service life is longer, and manufacturing integration is relatively strong.

Owner:BEIJING UNIV OF TECH +2

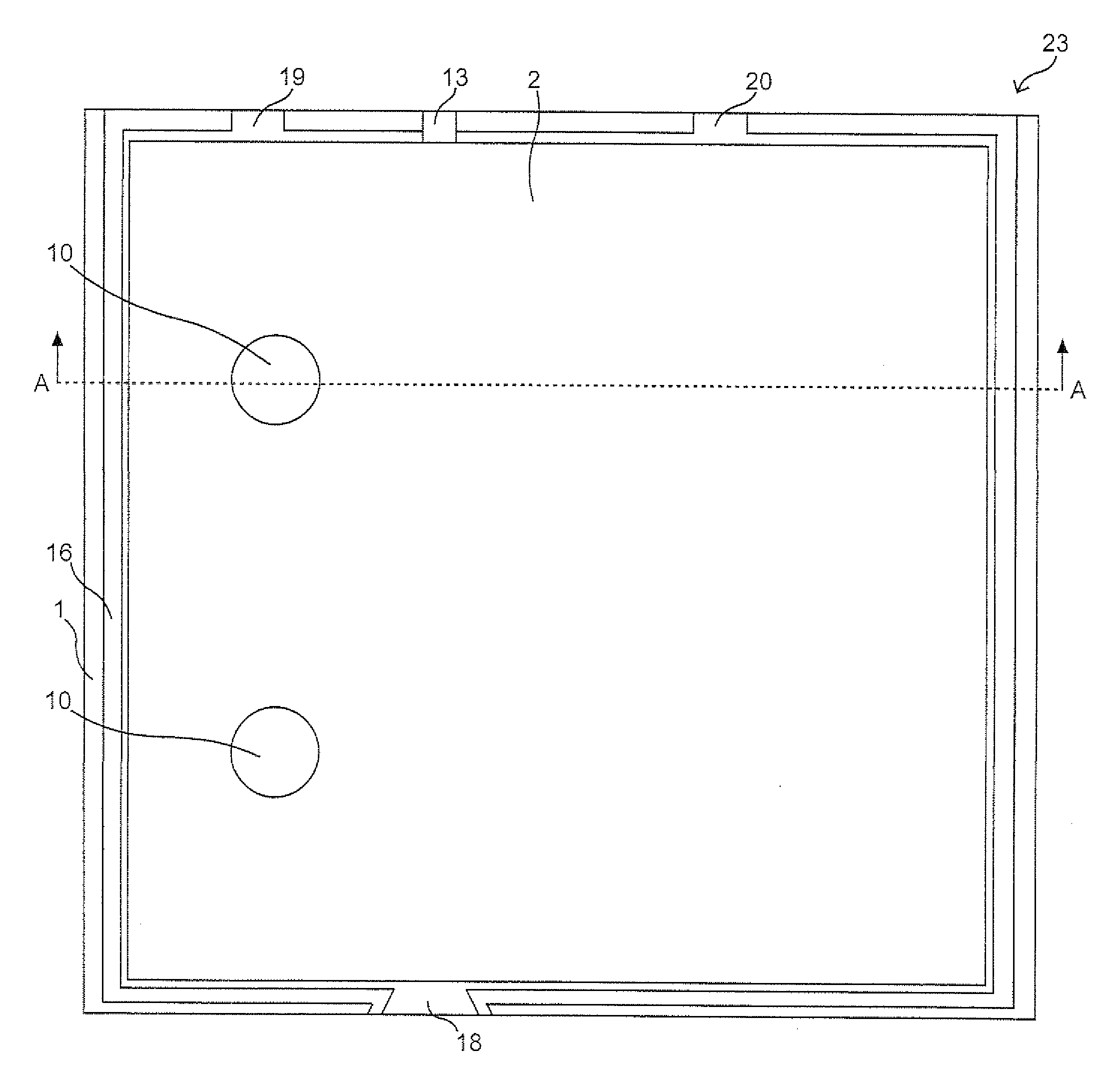

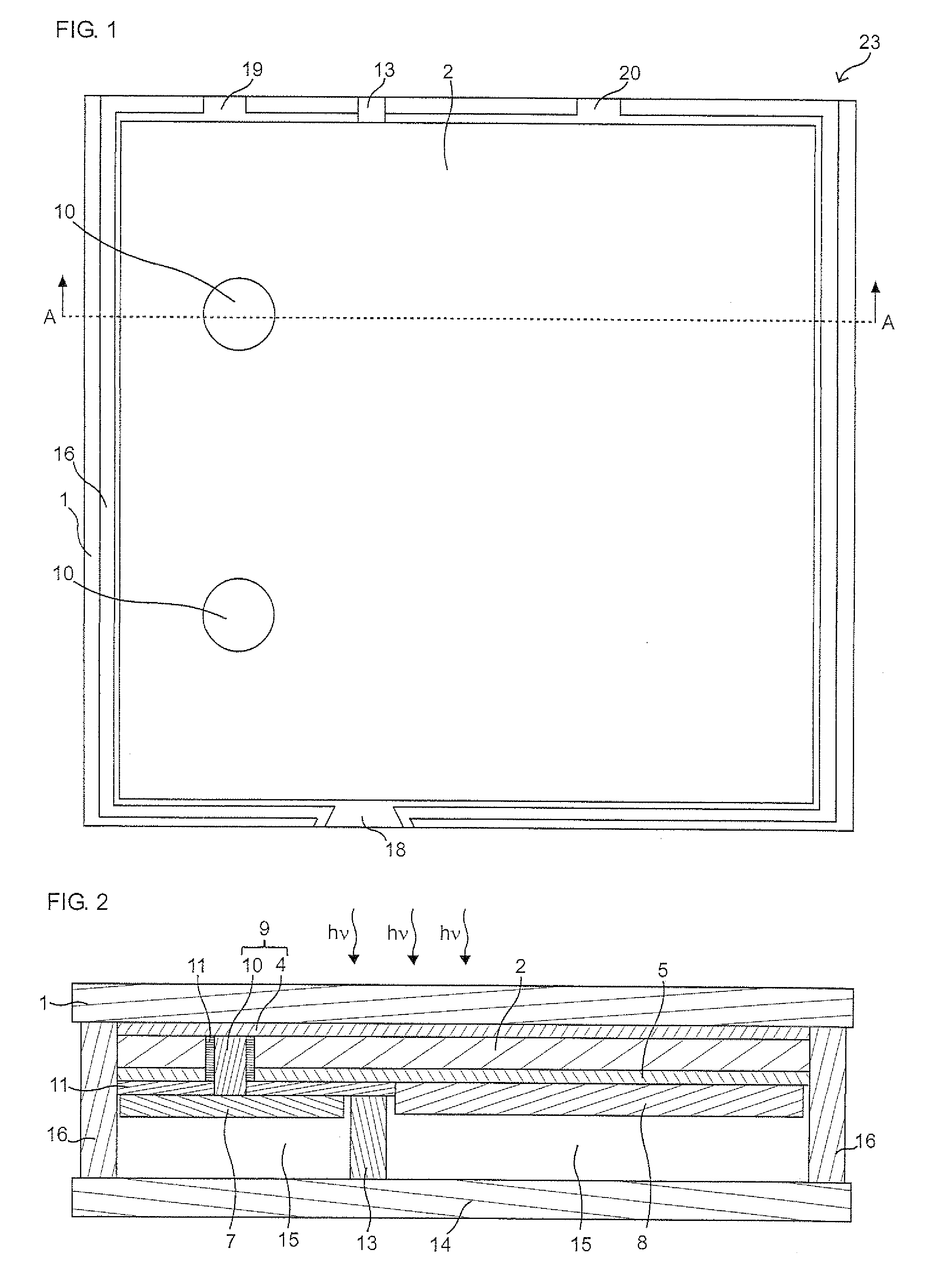

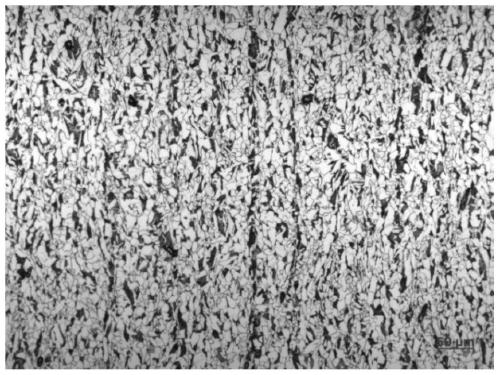

Hydrogen production device and method for producing hydrogen

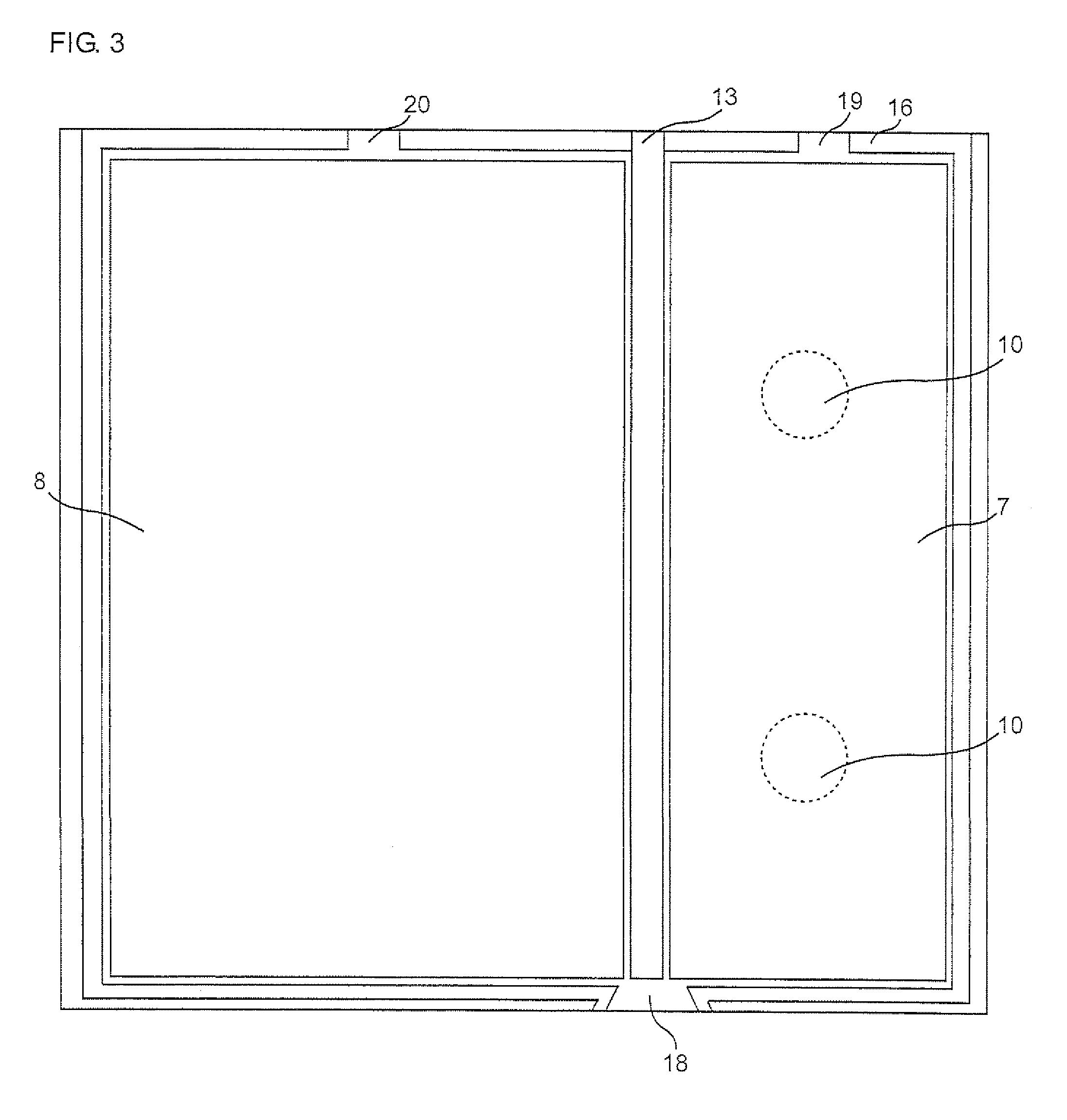

ActiveUS20110214996A1High light use efficiencyCut costCellsOxygen/ozone/oxide/hydroxideProcess engineeringElectricity

There is provided a hydrogen production device high in light use efficiency and capable of producing hydrogen with high efficiency.The hydrogen production device according to the present invention includes a photoelectric conversion part having a light acceptance surface and a back surface, a first gas generation part provided on the back surface, and a second gas generation part provided on the back surface, in which one of the first gas generation part and the second gas generation part is a hydrogen generation part to generate H2 from an electrolytic solution, another one thereof is an oxygen generation part to generate O2 from the electrolytic solution, the first gas generation part is electrically connected to the back surface, and the second gas generation part is electrically connected to the light acceptance surface via a first conductive part.

Owner:SHARP KK

Building thermal insulation dry powder mortar

A building thermal insulation dry powder mortar belongs to a building thermal insulation material. The weight ratio of a dry powder to water is 1: 1.5. The dry powder is prepared by mixing 450 parts by mass of ordinary portland cement, 70 parts by mass of a calcined gypsum powder, 37.5 parts by mass of a redispersible emulsion powder, 15 parts by mass of fine xylem fibers, 13 parts by mass of polypropylene staple fibers, 10 parts by mass of slaked lime, 10 parts by mass of sierozem, 10 parts by mass of heavy calcium carbonate, 3 parts by mass of hydroxypropyl methyl cellulose, 364 parts by mass of a calcined expanded perlite and 17.5 parts by mass of a premixed auxiliary agent. The thermal insulation building dry powder mortar has the advantages of strong thermal insulation, strong bond with walls, high compressive strength, strong drawing force, excellent weather resistance, and environmental protection, and also has the advantages of fire resistance, cracking resistance, leakage resistance, moisture resistance, sliding resistance, earthquake resistance and the like.

Owner:王荣

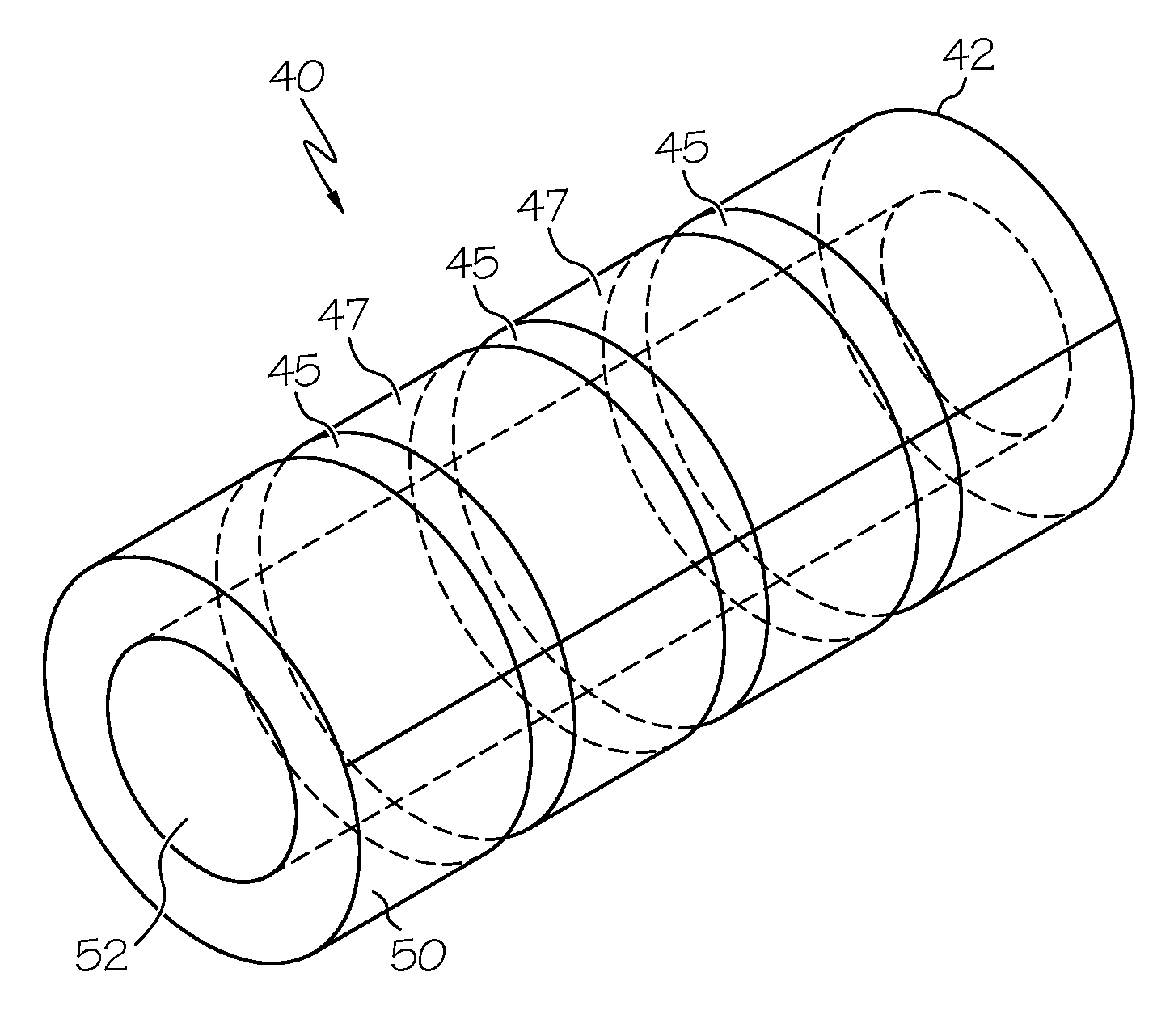

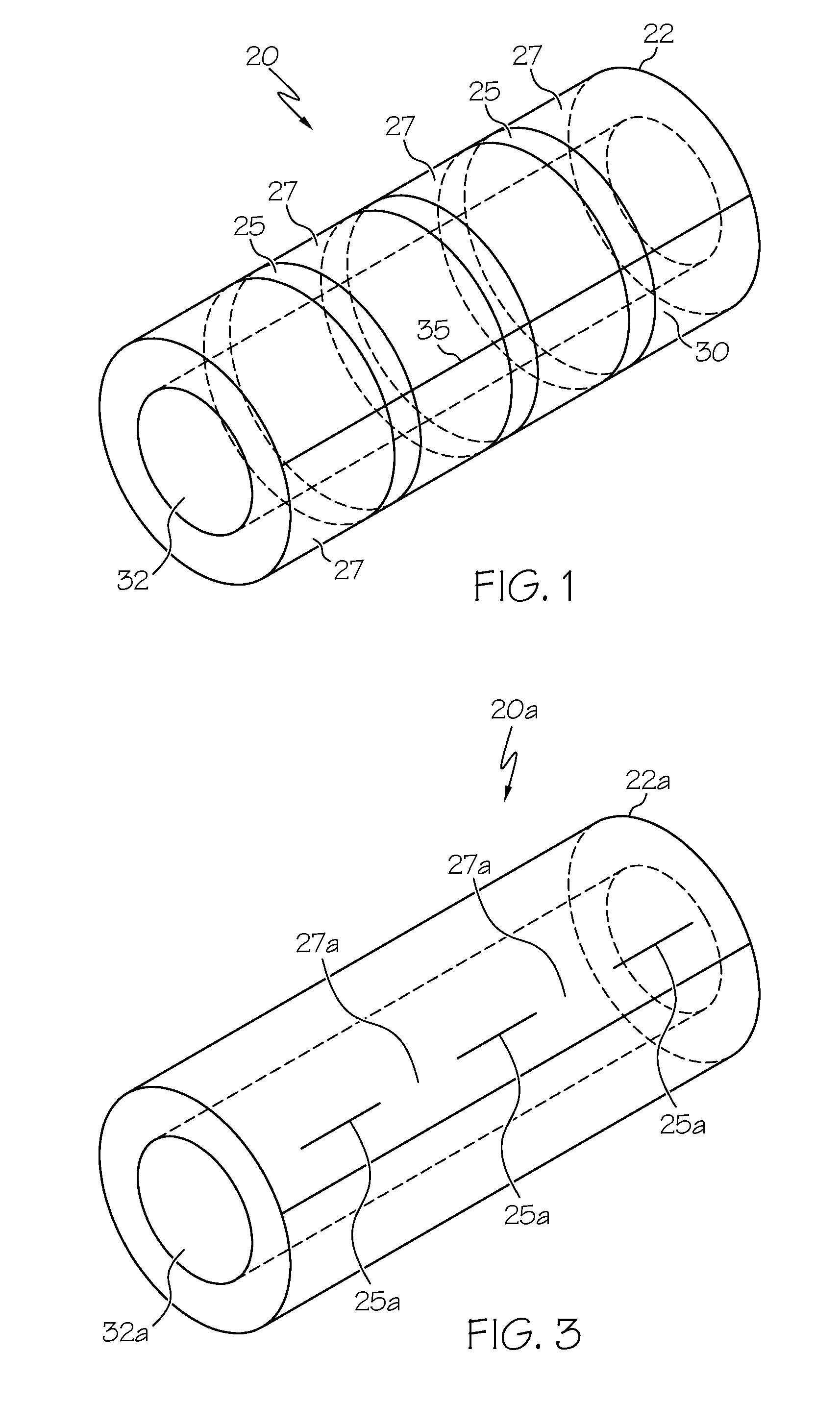

Sintered ring supported vascular graft

InactiveUS7806922B2Uniform materialRule out the possibilityDomestic articlesBlood vesselsVascular graftBlood vessel

The vascular graft includes a PTFE tube having non-expanded portions formed from sintering a PTFE green tube extrudate. The non-expanded portions are distributed longitudinally along the PTFE tube. The PTFE tube also has expanded portions formed subsequent to the sintering of the PTFE green tube extrudate. The expanded and non-expanded portions are integral with one another, and alternate with one another along the length of the PTFE tube. The expanded and non-expanded portions each have a respective stiffness, where the stiffness of the non-expanded portion is greater than that of the expanded portion.

Owner:LIFESHIELD SCI

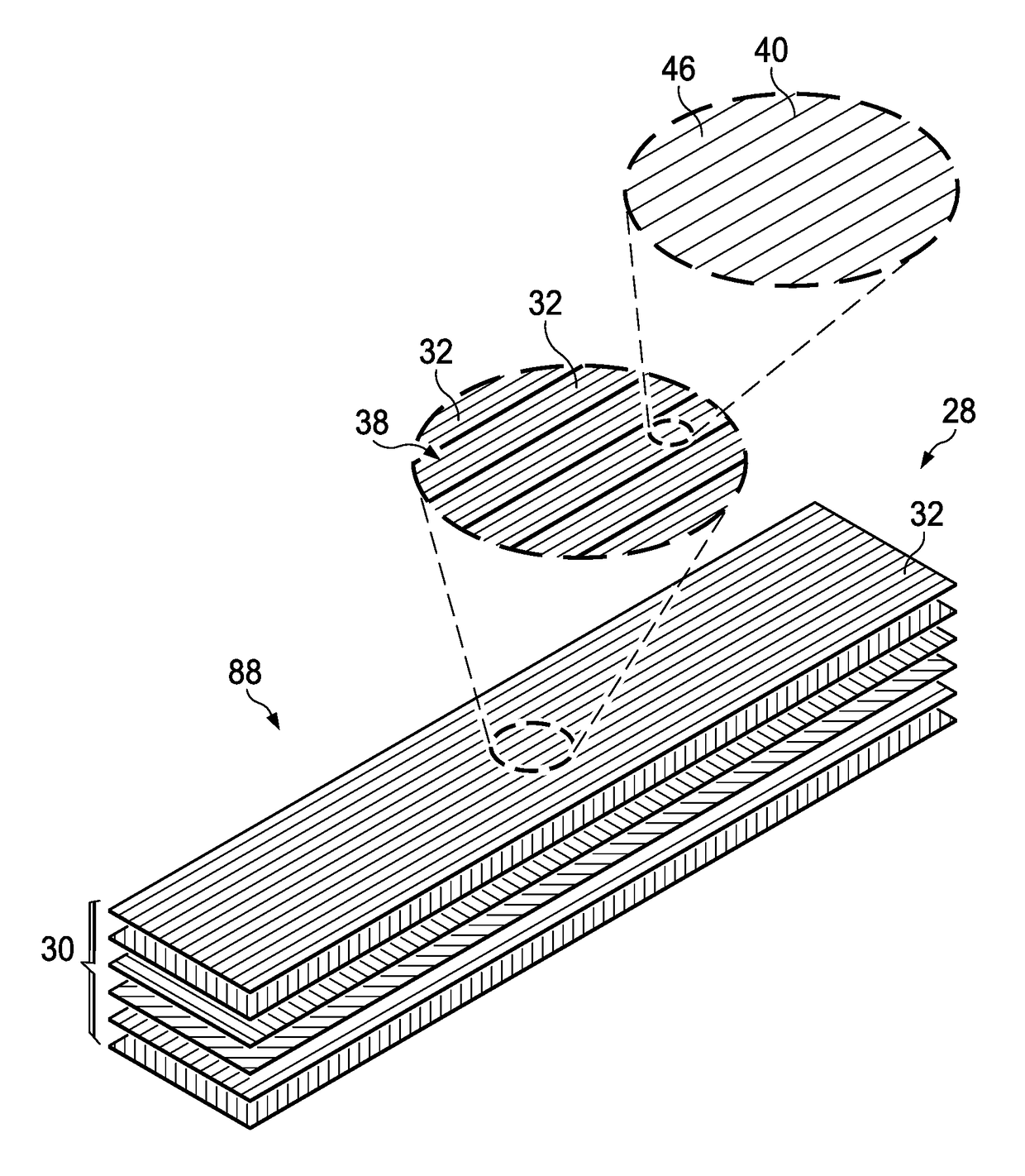

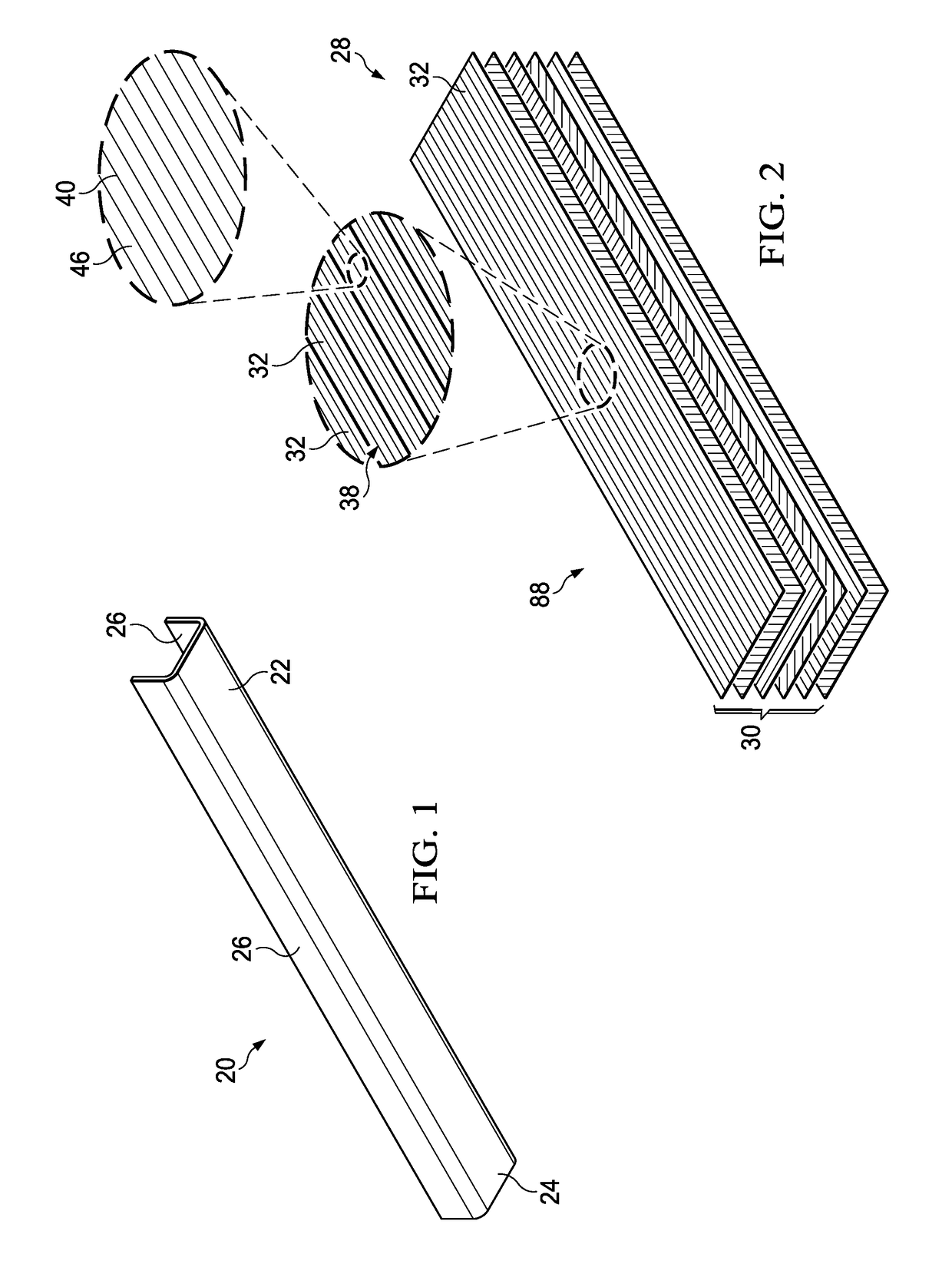

Method of Making Thermoplastic Composite Structures and Prepreg Tape Used Therein

ActiveUS20180229452A1Reduce the possibilityUniform materialSynthetic resin layered productsLaminationThermoplastic compositesMelt temperature

A thermoplastic composite structure is produced by consolidating and forming a composite preform to a desired shape. The preform comprises plies of a high melt temperature thermoplastic prepreg that are tacked together by a low melt temperature thermoplastic adhering the plies together in fixed registration.

Owner:THE BOEING CO

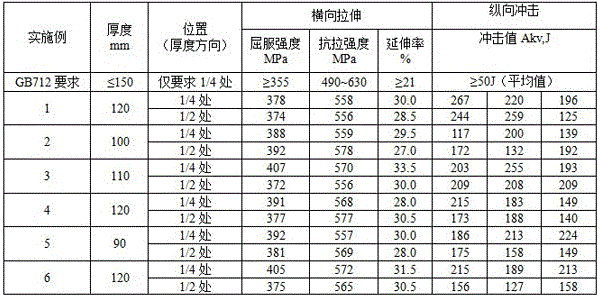

Super-thick EH36 steel for offshore wind power pipe pile and preparation method thereof

The invention relates to super-thick EH36 steel for an offshore wind power pipe pile. The super-thick EH36 steel for the offshore wind power pipe pile comprises the following chemical components in percentage by mass: .015 to 0.18 percent of C, 0.15 to 0.30 percent of Si, 1.40 to 1.60 percent of Mn, less than or equal to 0.0070 percent of P, less than or equal to 0.0030 percent of S, 0.050 to 0.070 percent of Nb, 0.015 to 0.030 percent of V, 0.08 to 0.020 percent of Ti, 0.030 to 0.050 percent of Al, 0.15 to 0.40 percent of Ni, 0.10 to 0.20 percent of Cr, and the balance of Fe. A production process flow comprises the following steps: performing converter operation, performing LF refining, performing vacuum degasifying, performing Ca treatment, performing continuous casting, dehydrogenizing, rolling, performing air cooling, performing high-temperature hot straightening, and normalizing. According to the production process flow, the super-thick EH36 steel of 90 to 120 mm for the offshore wind power pipe pile, which is high in unit weight, high in strength, high in impact toughness, small in thickness tolerance and high in straightness and does not have a surface defect is obtained.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

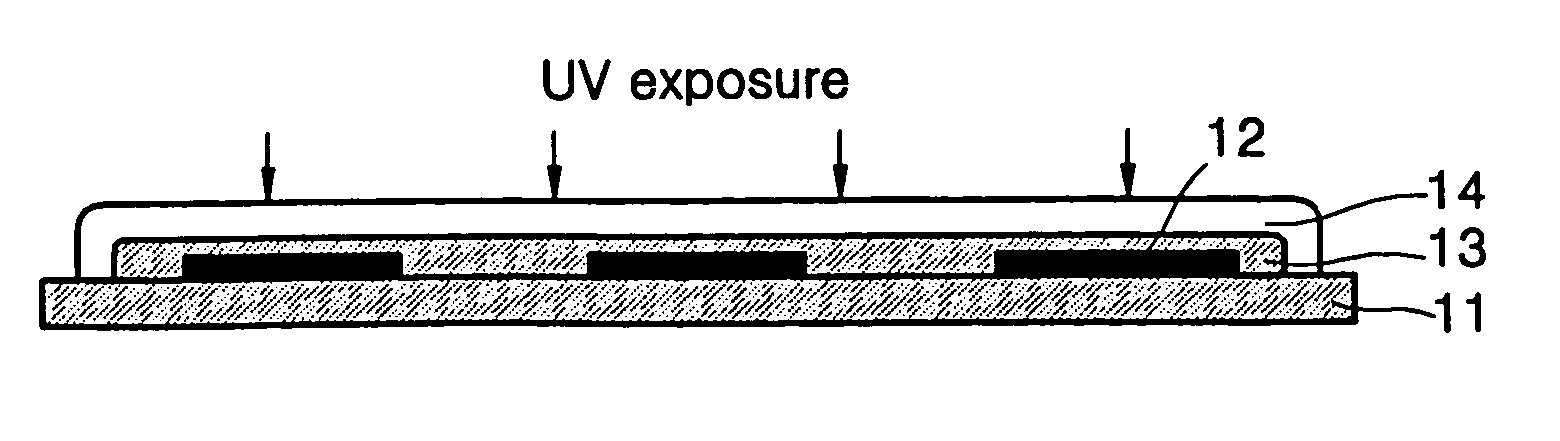

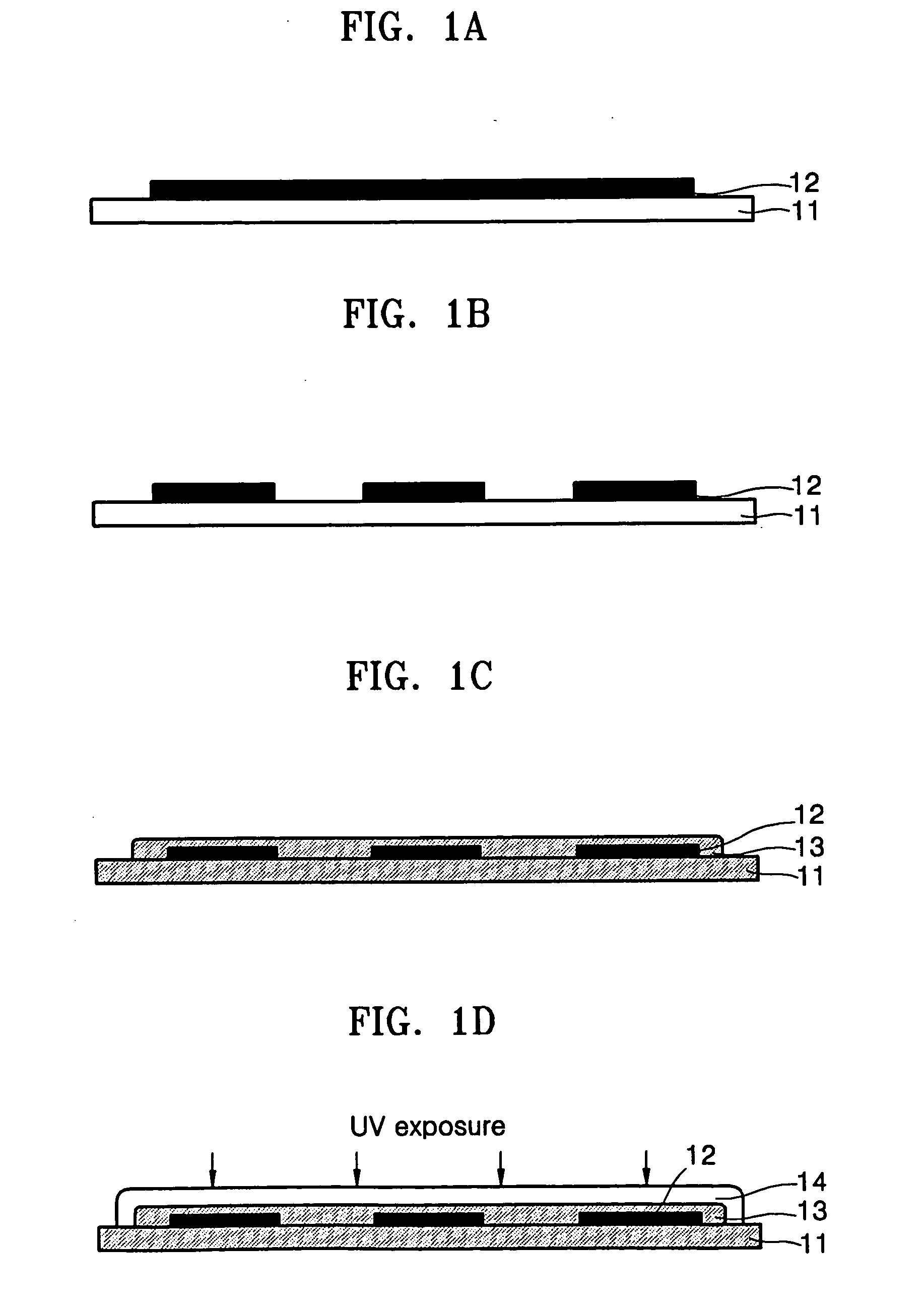

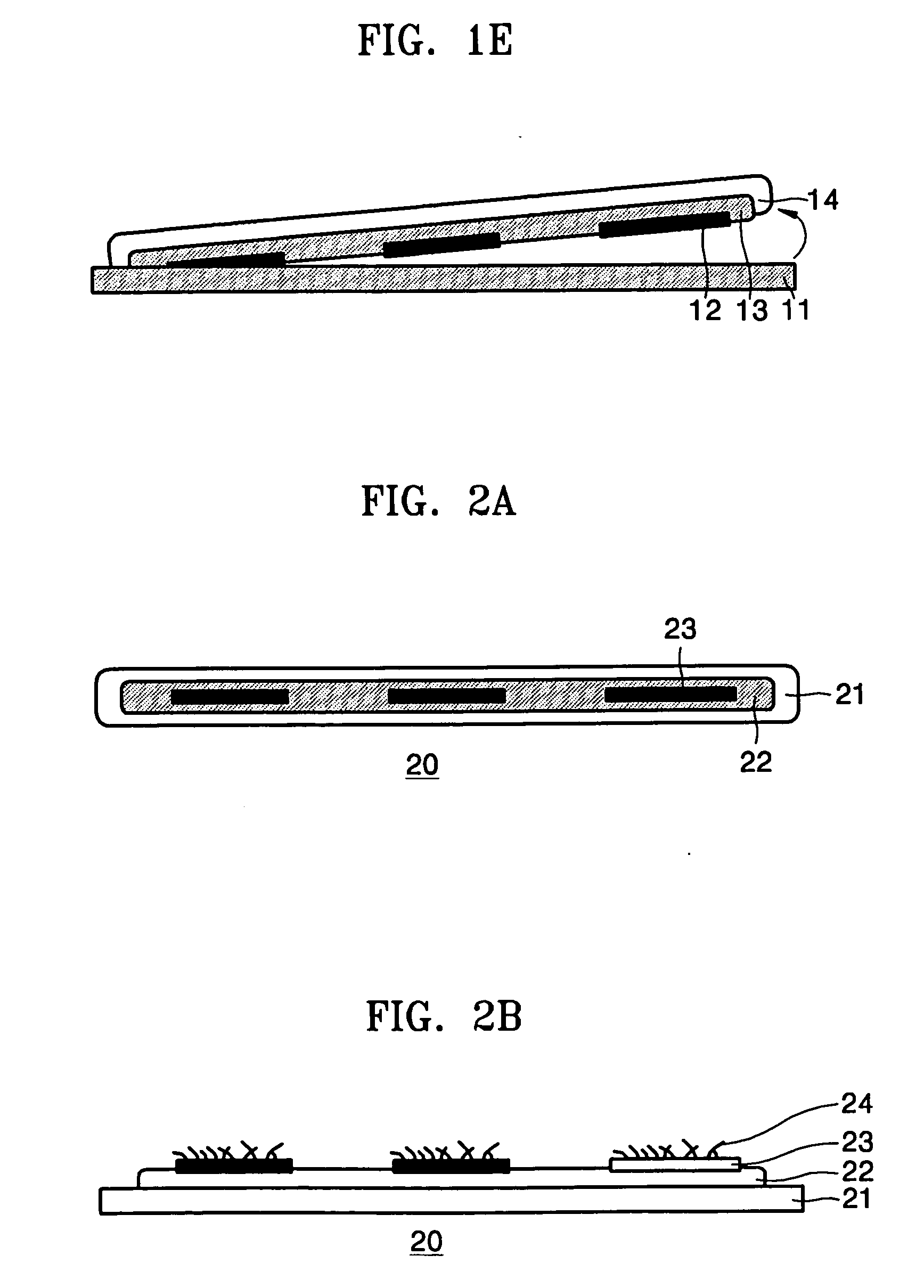

Flexible emitter using high molecular compound and method for fabricating the same

InactiveUS20050263388A1Eliminate needSimple methodMaterial nanotechnologyVacuum evaporation coatingPolymer gelPolymer chemistry

A method of fabricating a flexible emitter using a high molecular compound, including forming an electro-luminescent carbon material on a glass substrate in a predetermined pattern in order to form an emitter pattern thereon, forming an electrode layer of a predetermined height on the emitter pattern and the glass substrate, applying a polymer gel material on the electrode layer, curing the polymer gel material, and separating the flexible emitter from the glass substrate.

Owner:SAMSUNG SDI CO LTD

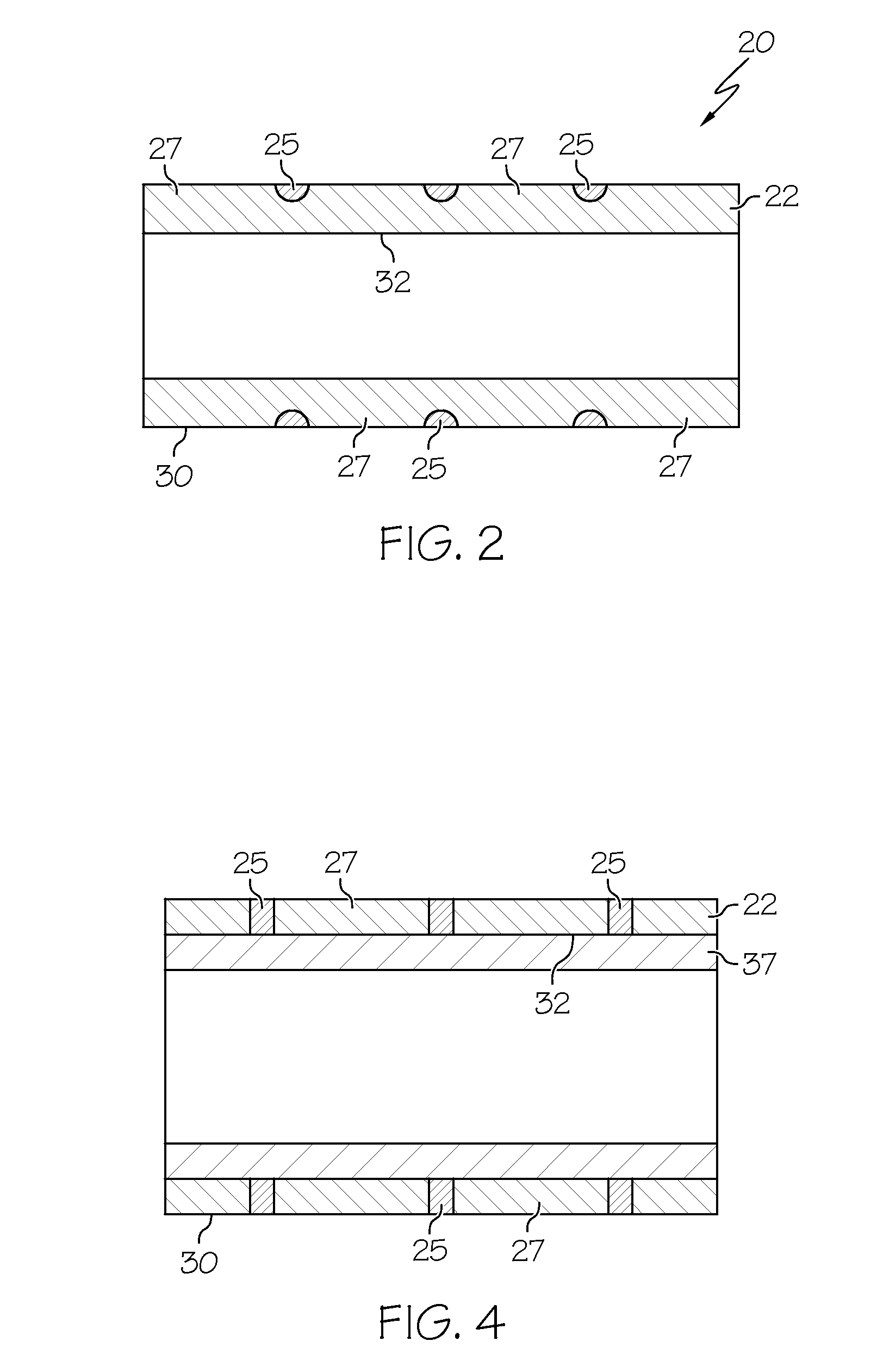

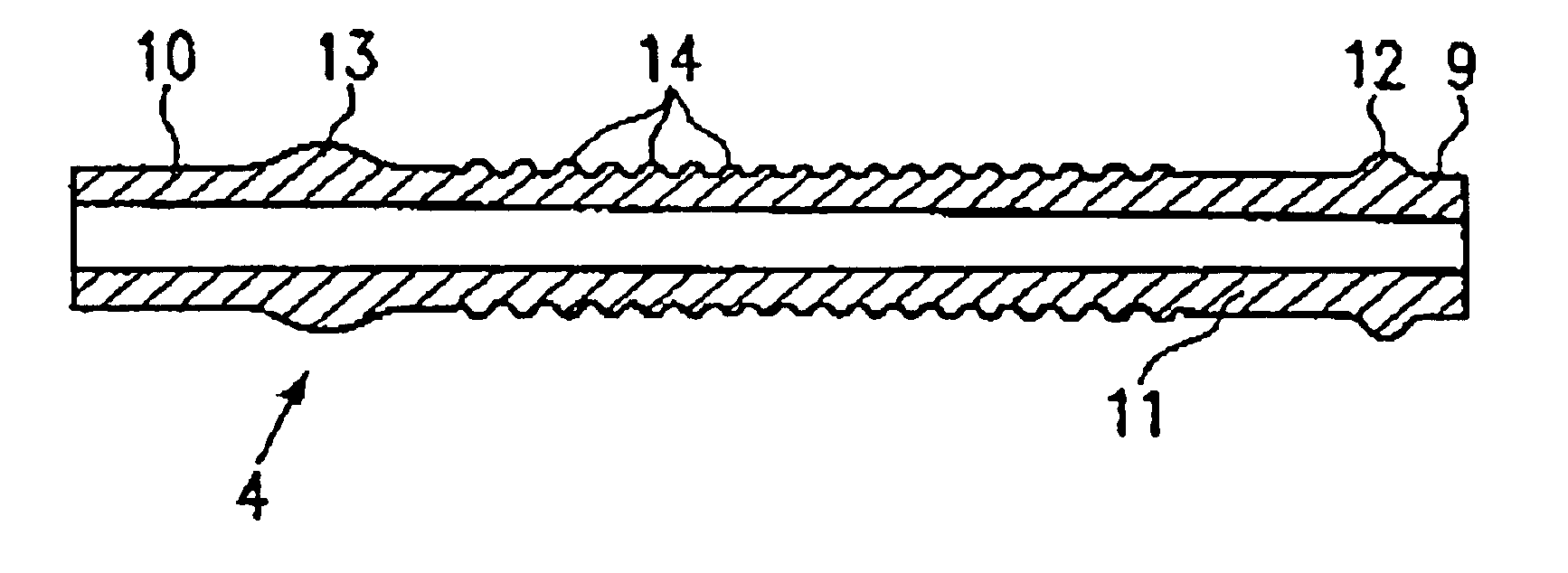

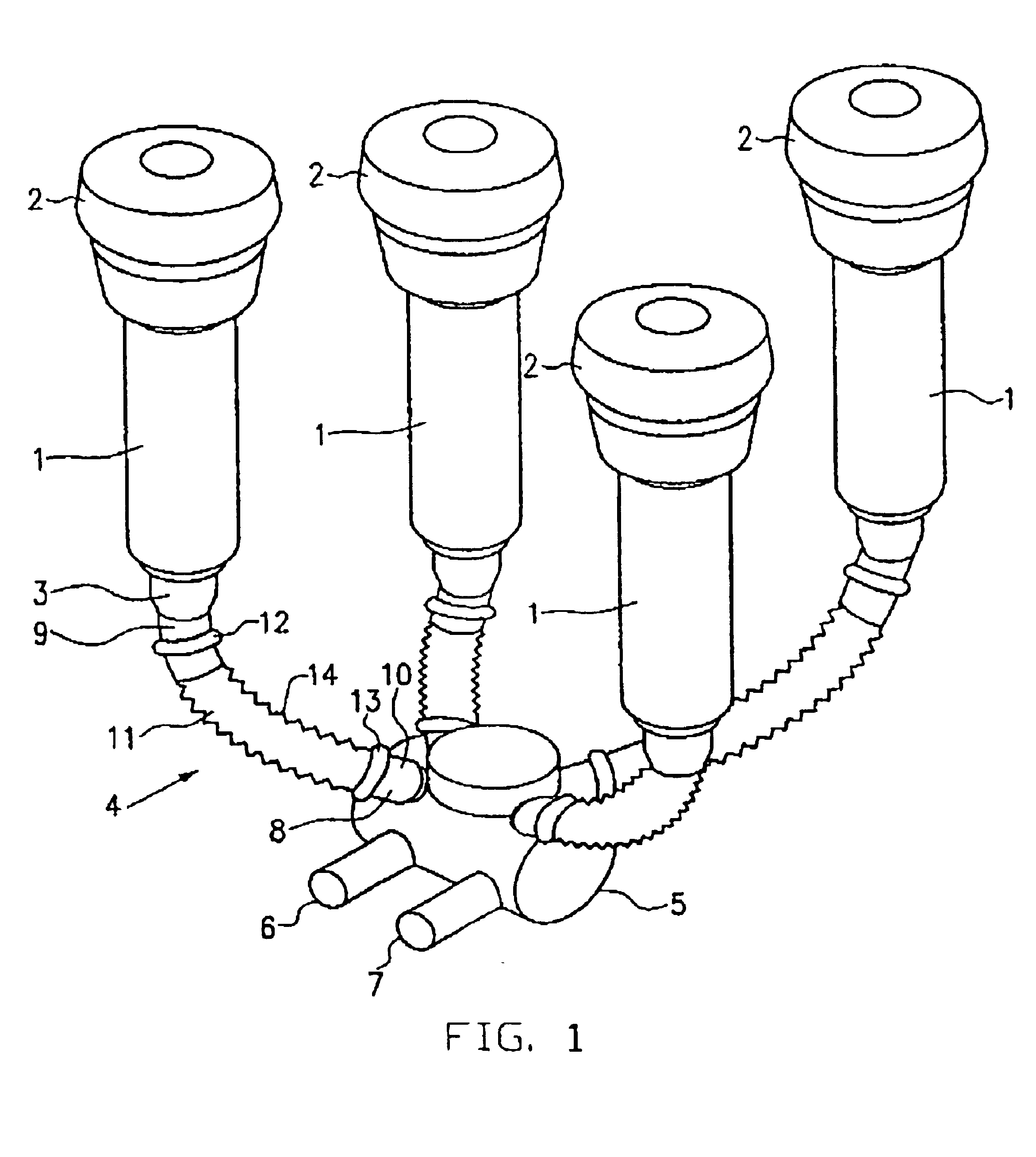

Flexible milk hose for an automatic milking plant

InactiveUS6895890B1Guaranteed mechanical stabilityUniform materialFlexible pipesMilking devicesMechanical stabilityAutomatic milking

An automatic milking plant is provided with a short milk hose, which, due to spaced-apart elevations in its center piece, has sufficient mechanical stability vis-a-vis pressure differences as well as a high flexibility. The use of the short milk hose according to the present invention leads to a reduction of the mechanical strain on the udder and thus also reduces irritations of the animal to be milked.

Owner:MAIER JR JAKOB

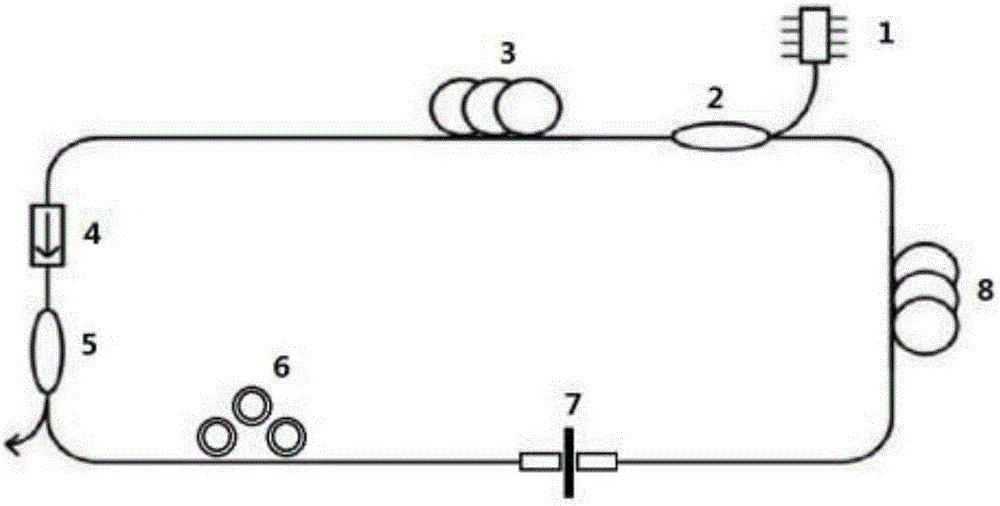

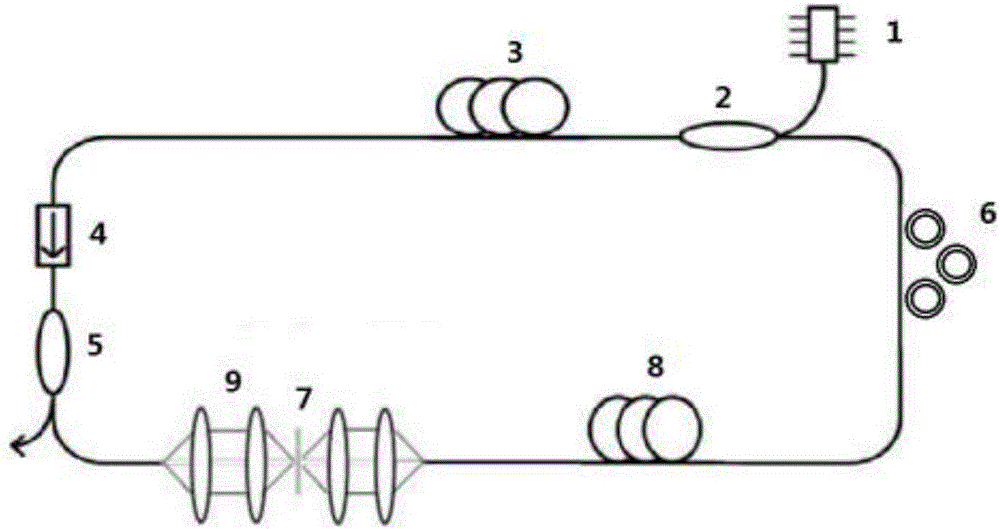

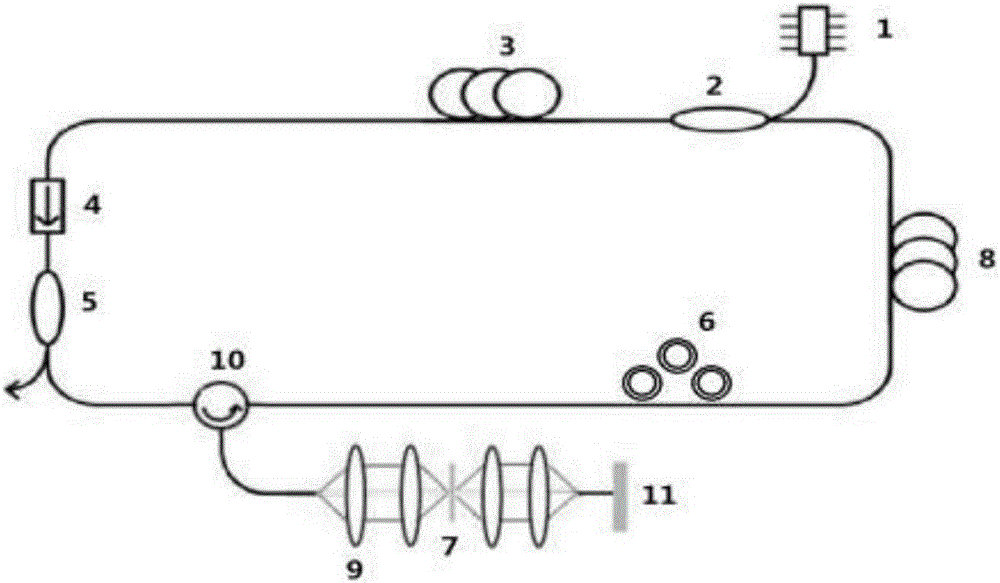

Cadmium arsenide film-based passively mode-locked fiber laser

PendingCN106785842AImprove stabilityUniform materialActive medium shape and constructionPhysicsWave band

The invention discloses a cadmium arsenide film-based passively mode-locked fiber laser. By adopting an annular cavity structure, a second end of a wavelength division multiplexer, a gain fiber (3), an isolator (4), an optical fiber coupler (5), a polarization controller (6), a cadmium arsenide saturable absorber (7), a single-mode fiber and a third end of the wavelength division multiplexer are sequentially connected to form a ring and the other end of the isolator is connected with an input end of the optical fiber coupler; a first output end of the optical fiber coupler is taken as pulse laser output, and a second output end is connected with the first end of the polarization controller in a loop; the other end of the polarization controller is connected with one end of the cadmium arsenide saturable absorber and the second end of the cadmium arsenide saturable absorber is connected with the first end of the single-mode fiber; and a pumping source injects pump light into the rare-earth-doped gain fiber in a coupling manner through the first end of the wavelength division multiplexer, namely a pump input end. By using the ultrafast saturable absorption characteristics of cadmium arsenide on near-infrared and mid-infrared bands, mode-locked pulse output of high pulse energy is achieved.

Owner:南京诺派激光技术有限公司

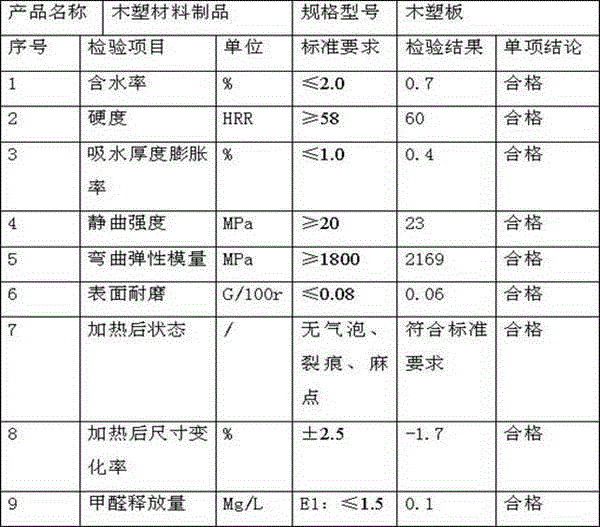

Wallboard and preparation method thereof

The invention relates to the field of wallboard manufacturing, in particular to a wallboard and a preparation method thereof. The wallboard is made of 90-110Kg of polyvinyl chloride, 60-70Kg of dry crop straw powder, 60-70Kg of lightweight calcium carbonate, 5-6Kg of composite stabilizer, 1.5-2Kg of lubricating agent, 5-16Kg of foaming modifier, 1.4-1.6Kg of AC (activated carbon) foaming agent, 0.5-1Kg of tribasic products and 0.9-1.1Kg of plasticizer. The preparation method of a wood-plastic board includes: preparing raw materials, well mixing the raw materials, cooling the mixed raw materials, adding the raw materials treated at the last step into extruding equipment for extrusion forming after mould-head thermal forming and stock-mould flowing water cooling forming, and cutting the board subjected to extrusion forming for placement. The wallboard has better dimension stability and is high in surface strength and uniform in material quality.

Owner:濮阳市东宝科技发展有限公司

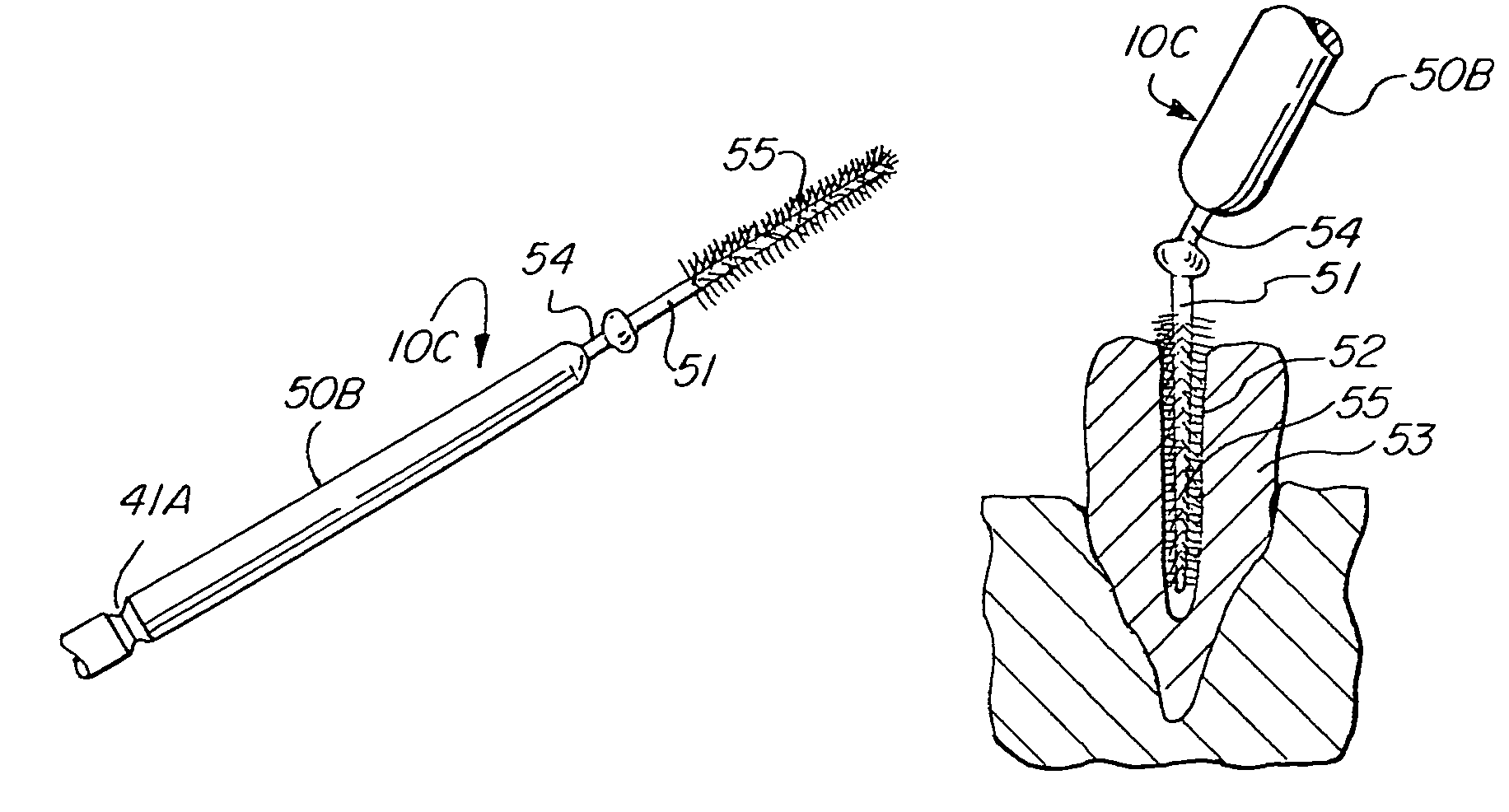

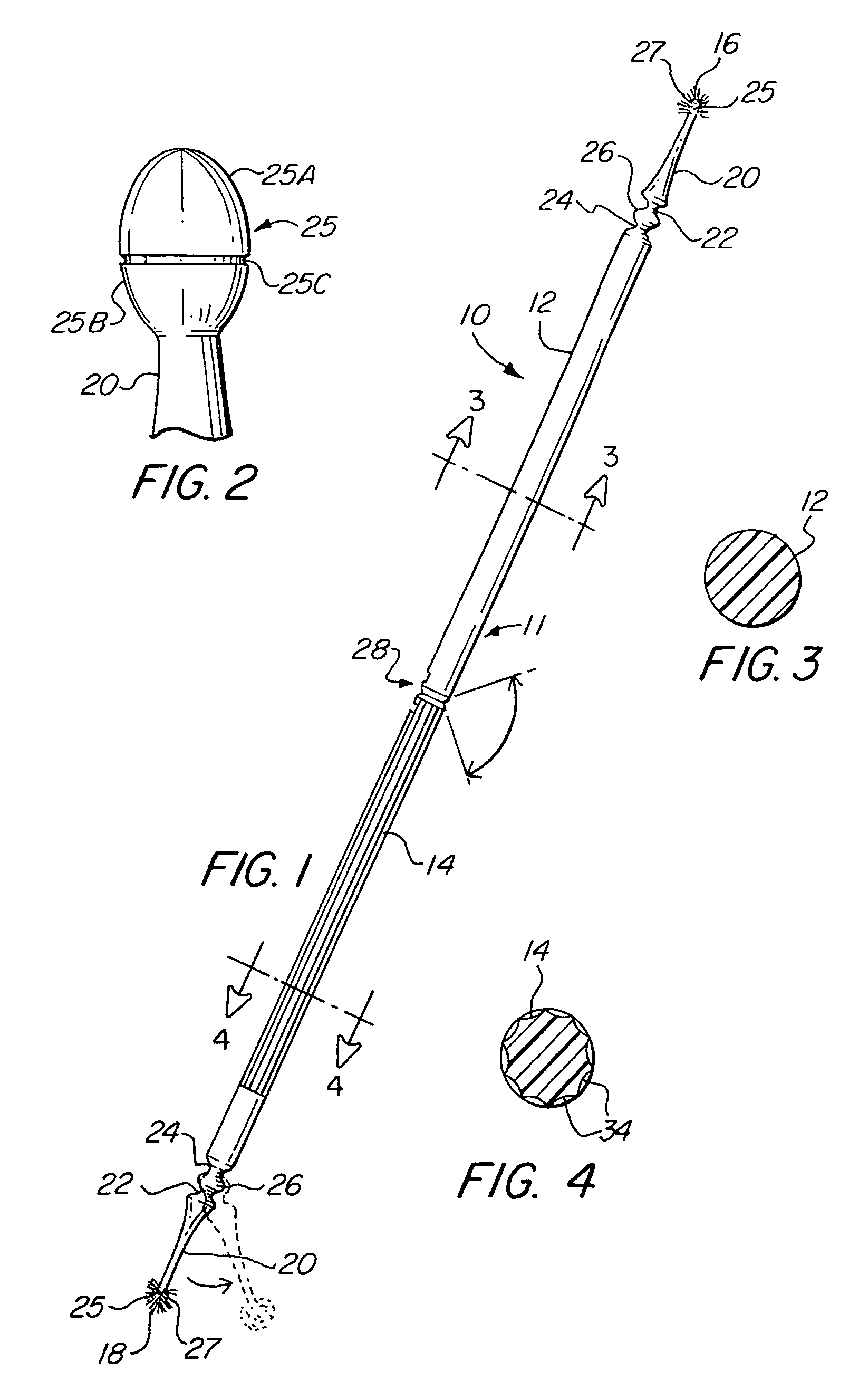

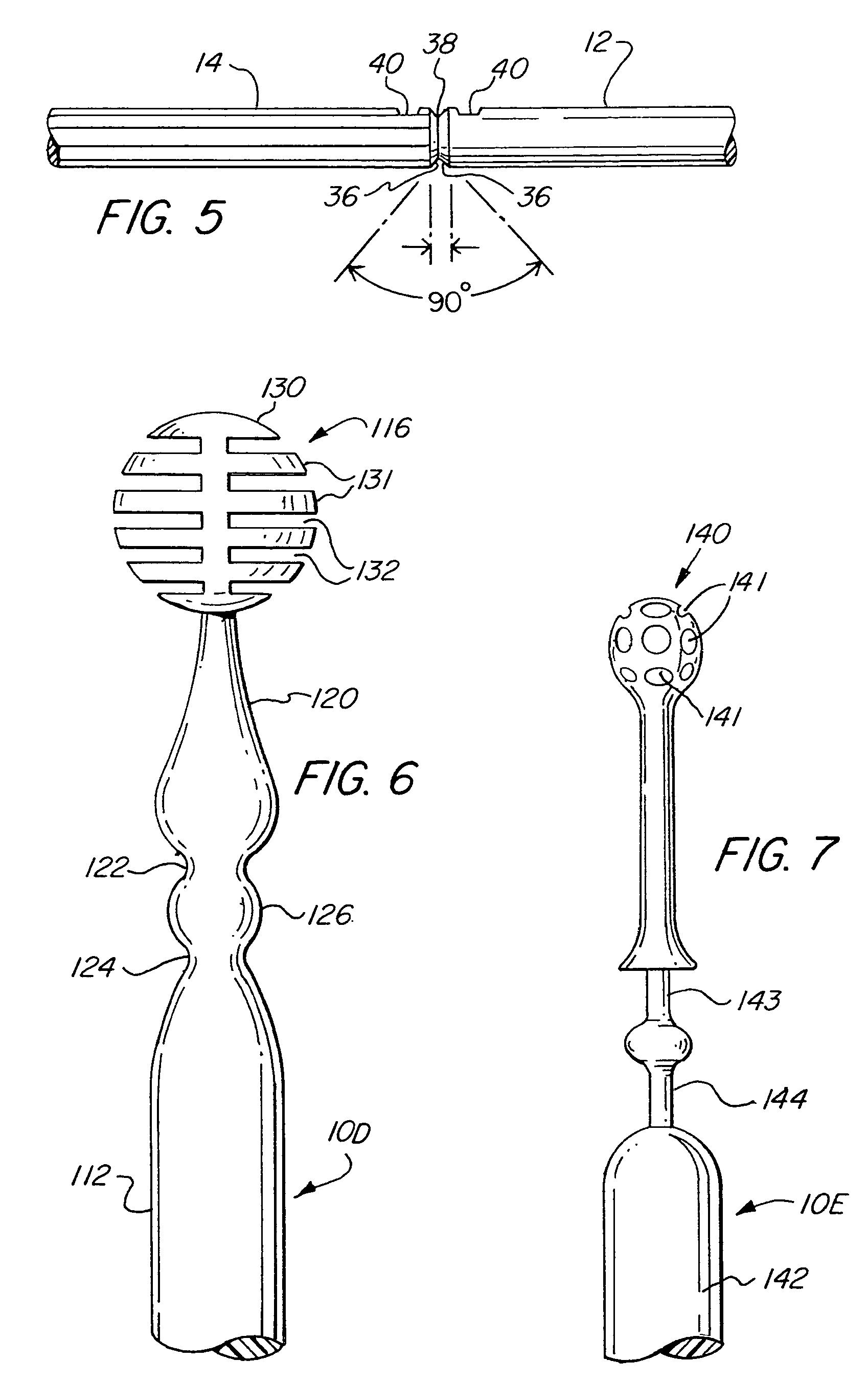

Disposable dental applicator

InactiveUS7882588B2Promotes even distributionIncrease surface areaLiquid surface applicatorsBrush bodiesBiomedical engineeringDental applicator

An applicator principally for use in the dental profession, for the placement of different materials as may be required. The applicator includes an elongated handle having an applicating end portion formed at the opposed ends thereof which may be either of like or unlike construction, i.e. formed as a brush and / or a flocked applicating end portion. The flock may extend from the distal end a predetermined longitudinal distance over an extended portion. Intermediate the opposed applicating end portion, the elongated handle is provided with a circumscribing groove to define a frangible area by which the user, at his or her option, can cleanly sever the applicator handle to form two separate and distinct applicators. The applicator is also provided with a hinging arrangement adjacent the opposed applicating end portions whereby the applicating end portions may be angularly bent relative to the elongated handle at the option of the user.

Owner:CENTRIX

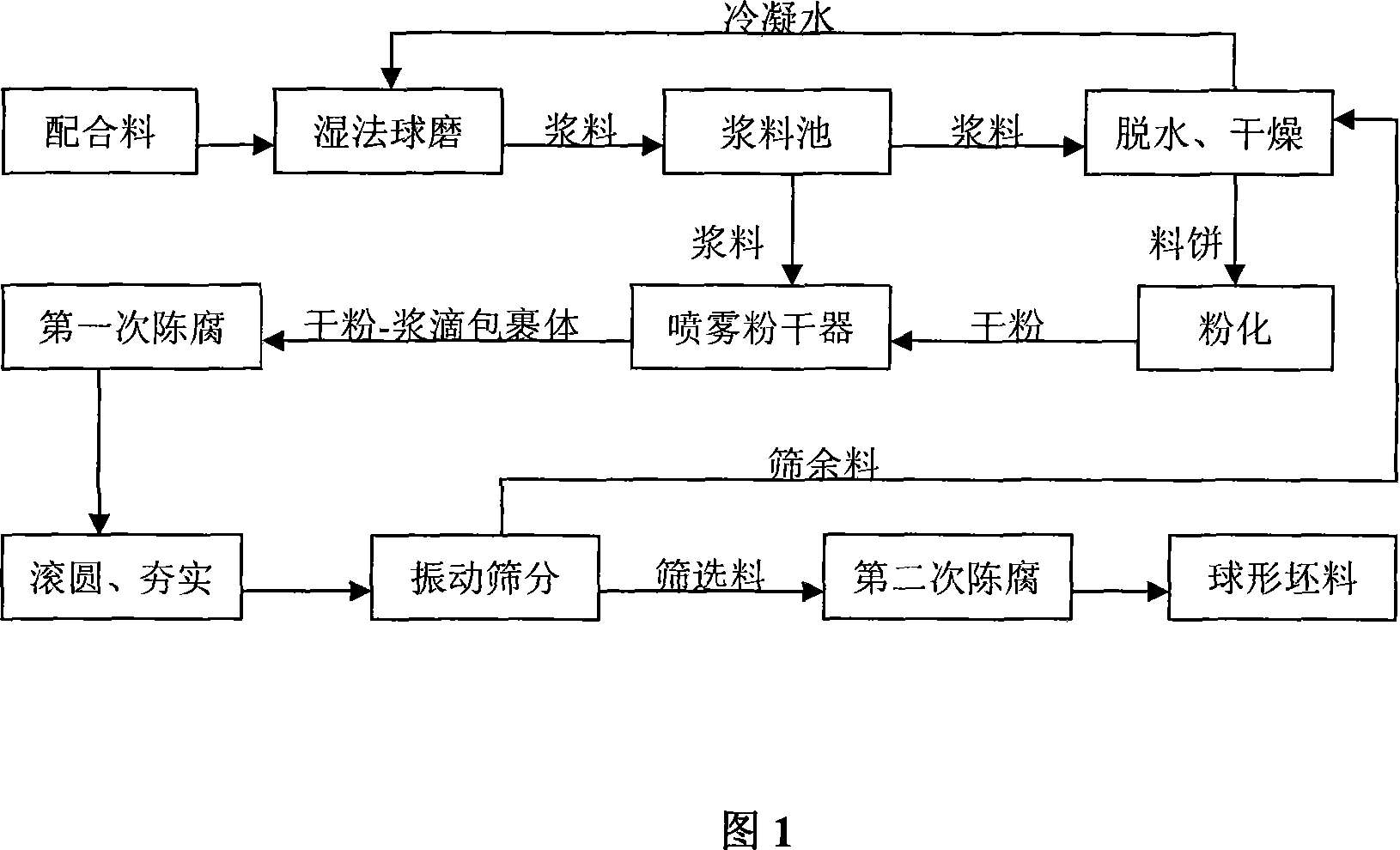

Technology for preparing blank for constructive ceramic with semi-drying method

ActiveCN101121282AReduce energy consumptionHigh energy consumptionClay processing apparatusLight pollutionRegular Production

The present invention relates to a technology for manufacturing the blank of architectural ceramics. The technology is a semi-dry one for manufacturing the blank of architectural ceramics; the technology is characterized in that the technology comprises the following steps: materials batching that materials are quantified according to regular production materials proportion of architectural ceramics and the materials is put into a ball grinder; wet ball grinding; the iron material is sifted out; the dry powder is manufactured: a part of the pulp manufactured through the process (3) is made into dry powder; spraying powder dry grain manufacturing: one share of the pulp made through the process (3) is sprayed into a spraying powder drier to form pulp fogdrop, i.e. wet core; 4 to 7.5 shares of dry powder are sprayed into the spraying powder drier made through the process (4) to form a dispersed distribution state; the wet core contacts and fully absorbs the dispersed dry powder to from grains of dry powder-pulp drop inclusion which is wet inside and dry outside; rolling and solidifying of the grains to form ball blank; vibrating and sifting out; water content is modulated and fossilized to form the blank used for architectural ceramics. The present invention boasts of low energy consumption, light pollution, material evenness and no iron pollution.

Owner:浙江中地大科技有限公司

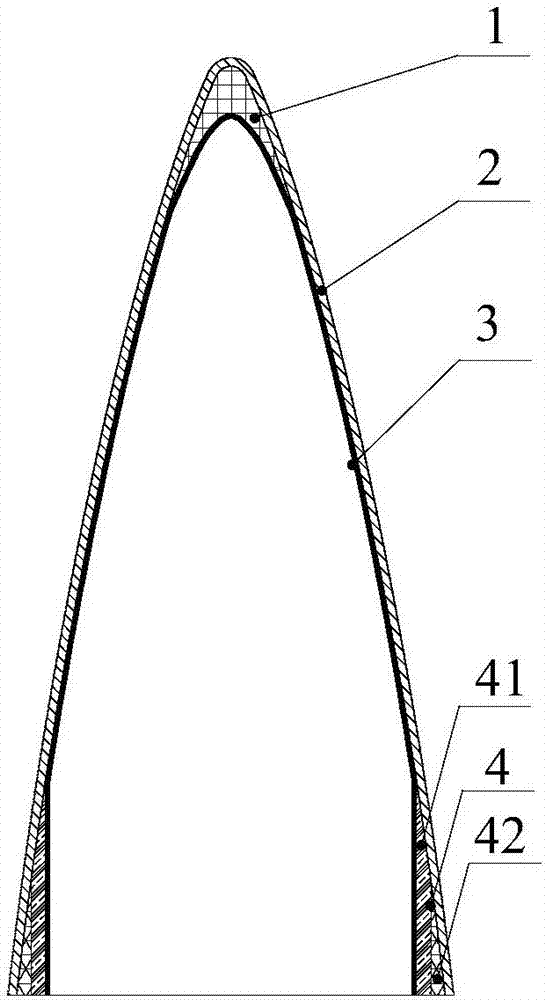

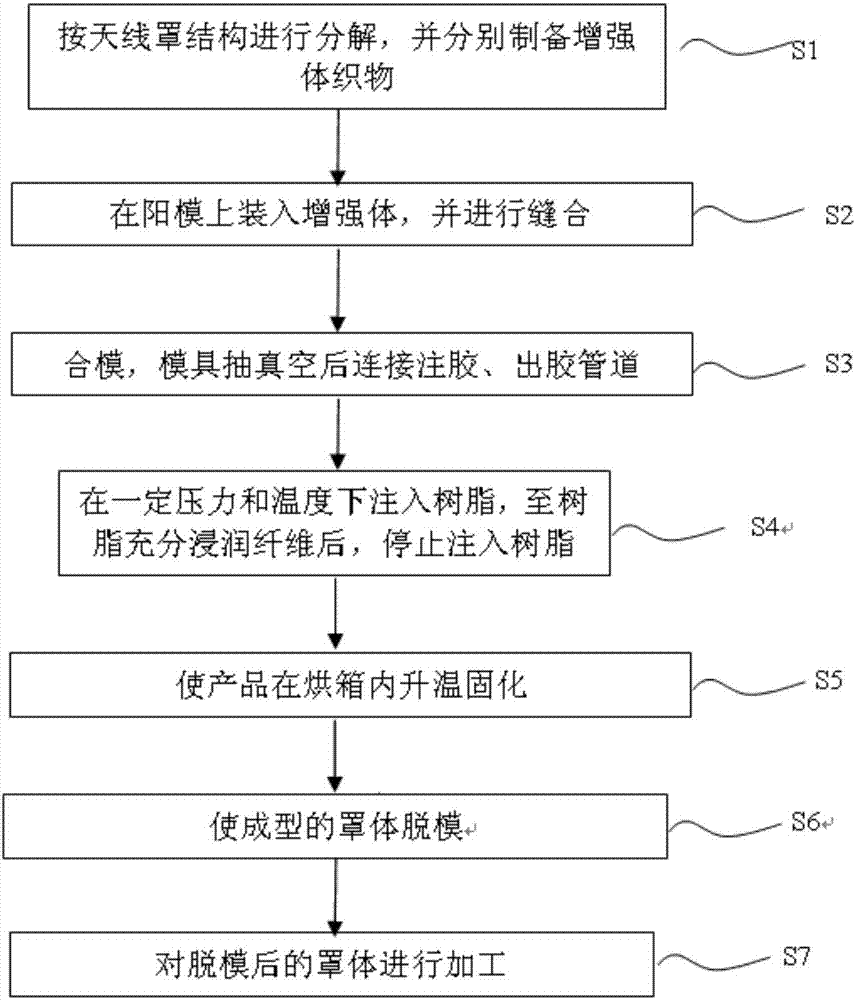

Forming method for thin-wall changeable thickness composite antenna cover

ActiveCN107244082AEasy to implementLow manufacturing costRadiating element housingsDomestic articlesThin walledYarn

The invention discloses a forming method for a thin-wall changeable thickness composite antenna cover. The method comprises the steps that firstly, enhanced body fabrics including an outer equal-thickness enhanced body, an inner equal-thickness enhanced body, a top changeable thickness enhanced body and a root changeable thickness enhanced body are prepared; secondly, the enhanced body fabrics are arranged in a forming die male die, and integral sewing is conducted through fiber yarn the same as the enhanced body fabrics in material; thirdly, die assembly is conducted, and after the die is subjected to vacuum pumping, heating is conducted to the resin injection temperature; fourthly, resin is heated to the injection temperature, and the resin is injected into a die cavity; fifthly, curing forming is conducted on the antenna cover in an oven; sixthly, the die is dismounted, and the antenna cover is taken out; and seventhly, the demoulded antenna cover is machined. The method achieves the purpose about precise forming of the thin-wall changeable thickness antenna cover, achieving is convenient, and the manufacturing cost is low. The overall sewing method is adopted, reliable fixing of the thickened area fabrics is achieved, and inter-laminar shear strength of the antenna cover is increased.

Owner:SHANGHAI RADIO EQUIP RES INST

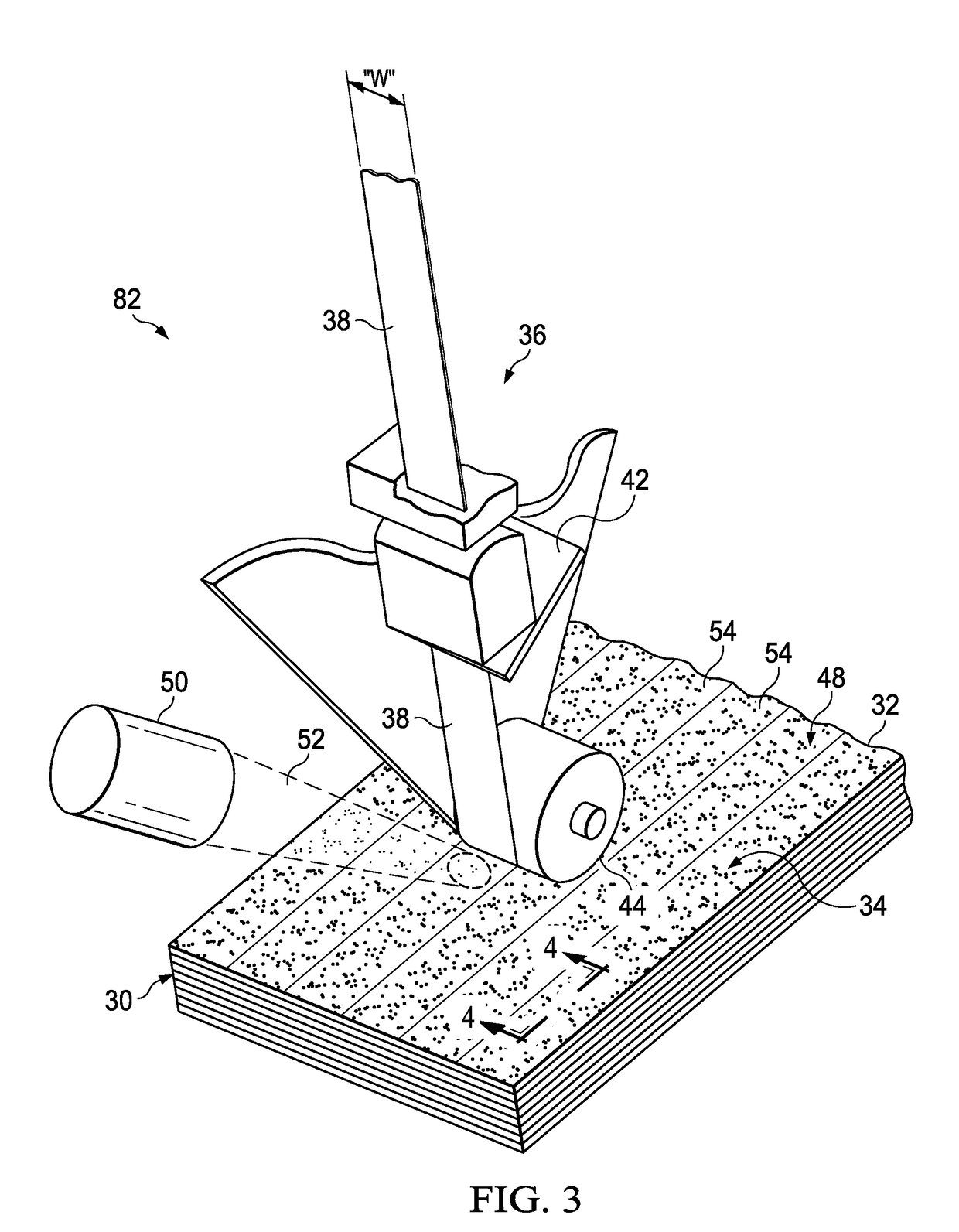

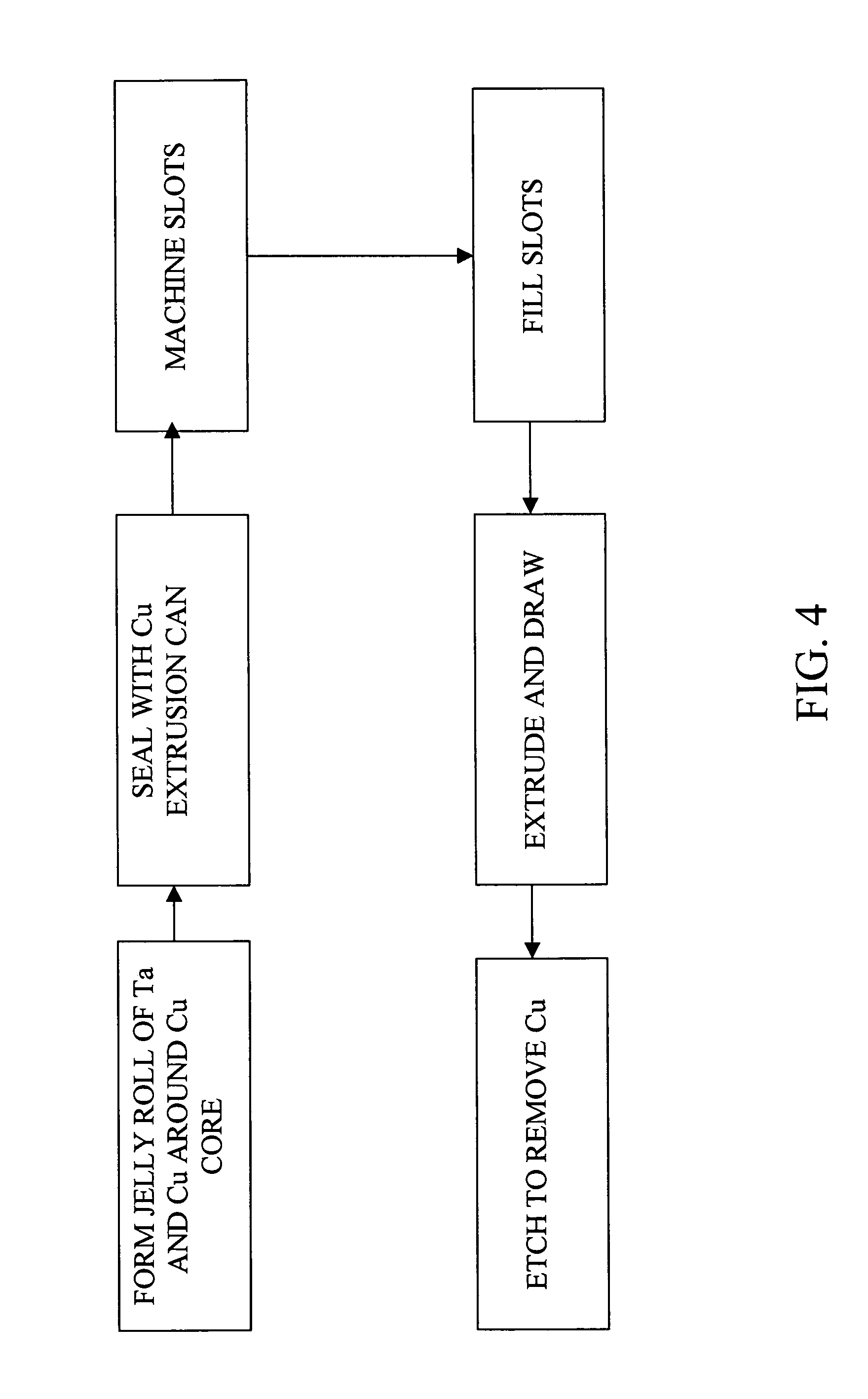

Methods for fabrication of improved electrolytic capacitor anode

ActiveUS8858738B2Easy to assembleIncrease valueElectrolytic capacitorsLayered productsElectrolysisMetal

Owner:COMPOSITE MATERIALS TECH

Chromic-nickel-free high-strength high ductility structural steel and manufacturing method thereof

InactiveCN101082101AControl and optimize contentControl UniformityTemperature control deviceHeat treatment process controlNickel freeHeating temperature

The high strength and high toughness structural steel without Cr and Ni consists of C 0.24-0.30 wt%, Si 1.10-1.40 wt%, Mn 1.30-1.70 wt%, Mo 0.40-0.60 wt%, V 0.20-0.35 wt%, Al 0.015-0.050 wt%, Cu not more than 0.30 wt%, S not more than 0.012 wt%, P not more than 0.020 wt%, and Fe and inevitable impurities for the rest. Its production process includes the following steps: 1. smelting and casting ingot; 2. rolling in the heating temperature 1100-1180 deg.c, finishing temperature of 850-900 deg.c and cooling rate of 40-80 deg / hr; and 3. annealing at the temperature of 720+ / -10 deg.c for 8-10 hr, cooling to below 450 deg.c in the rate no higher than 30 deg / hr and discharging. The high strength and high toughness structural steel with cheap Si and Mn as main elements has yield strength not lower than 1170 MPa, tensile strength not lower than 1274 MPa, specific elongation not lower than 9 %, reduction of area not lower than 45 %, and impact toughness not lower than 62J.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

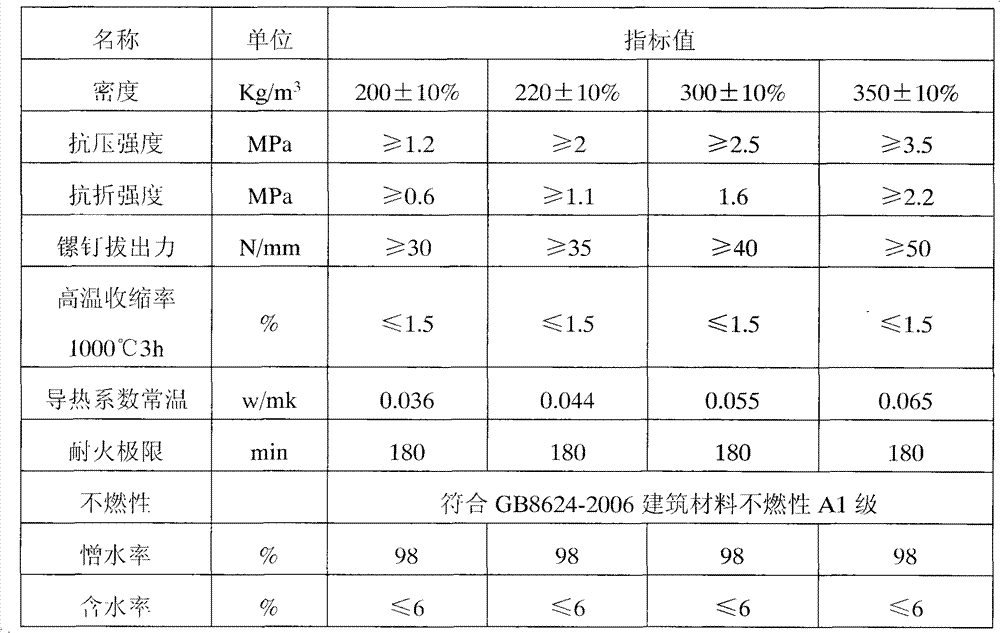

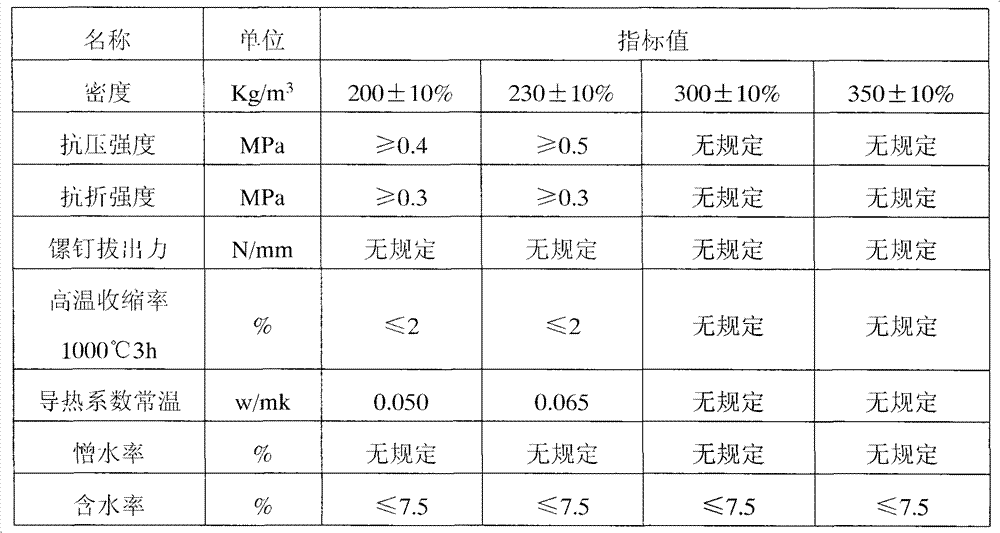

Making method of high-strength light-weight integral-hydrophobic xonotlite fireproof insulation board

ActiveCN102825650AOvercome the effects of poor activityHigh activityCeramic shaping apparatusCalcium in biologyFiber

The invention discloses a making method of a high-strength light-weight integral-hydrophobic xonotlite fireproof insulation board, comprising the following steps of: (1) mixing silicon raw materials and calcium raw materials according to a Ca / Si mole ratio of 0.9-1.1, then, injecting the mixed raw materials into a dynamic reaction kettle, synthesizing by using superheated steam of 250-400 DEG C at the steam pressure of 2.0-2.7MPa for 3-8hours to obtain xonotlite slurry, and adding reinforced fibers; (2) removing redundant water in the xonotlite slurry obtained in the step (1) and adding 0.1-8% of inorganic glue (according to the weight ratio of the slurry to the inorganic glue); (3) adding 0.1-8% of reaction type organic silicon waterproof agent in the xonotlite slurry obtained in the step (2) to enable the reaction type organic silicon waterproof agent and the slurry to form interface combination; and (4) carrying out compression molding on the xonotlite slurry prepared in the step (3), and drying to obtain the material-uniform high-strength light-weight complete-hydrophobic xonotlite board. The fireproof insulation board produced by the invention has the characteristics of high strength, uniform material, no bubble hole, light weight and complete hydrophobicity.

Owner:山东昊海凤栖新材料科技有限公司

O-shaped rubber sealing ring and production technology thereof

The invention discloses an O-shaped rubber sealing ring and a production technology thereof. The O-shaped rubber sealing ring is prepared by mixing the following raw materials: 95-100 parts of butadiene nitrile rubber, 10-15 parts of zinc oxide, 3-5 parts of stearic acid, 1-3 parts of an antioxidant 4010, 3-5 parts of paraffin, 5-7 parts of a carbon black N660, 8-10 parts of a coumatone resin, 1-2 parts of an antioxidant RD, 7-9 parts of a fluorescent whitening agent CBS, 2-4 parts of dibutyl phthalate, 2-3 parts of sulphur and 1-1.2 parts of a promoter TMTD. The production technology is reasonable, various raw materials are mixed uniformly and a uniformly-mixed product is obtained. The O-shaped rubber sealing ring has advantages of aging resistance, liquid resistance, good tensile strength and elongation, no phenomena of wearing and oil leakage, steady product quality, long service life and the like.

Owner:JIAOZUO WANRUI IND & TRADE CO LTD

Preparation method of 80-100mm extra-thick EH36 steel for offshore wind power

ActiveCN111455255AGuaranteed StrengthGrain refinementFurnace typesHeat treatment furnacesMetallurgyOffshore wind power

The invention relates to a preparation method of 80-100mm extra-thick EH36 steel for offshore wind power. The preparation method comprises the following steps of: converter processing-LF refining-RH vacuum degassing-Ca treatment-continuous casting-casting blank hydrogen diffusion-heating-normalizing rolling-air cooling-steel plate stacking and slow cooling- unstacking, wherein the normalizing rolling adopts two stages of rough rolling and finish rolling; the initial rolling temperature of the rough rolling is 1050-1100 DEG C, the single-pass reduction rate of three passes after the rough rolling is greater than or equal to 15%, and the cumulative reduction rate in the rough rolling stage is greater than or equal to 50%; and the initial rolling temperature of the finish rolling is 860-890 DEG C, the austenite non-recrystallization interval is expanded by adding sufficient Nb, the initial rolling temperature of the finish rolling is above the austenite ferrite equilibrium transformationpoint Ac3, the total rolling pass is 8-12, air cooling is carried out after rolling, Nb is separated out in the steel plate in the air cooling process, and the triangular grain boundary, the grain boundary and the grain interior of ferrite grains are pinned to limit the rapid growth of the ferrite. Therefore, the normalized and rolled EH36 steel plate for offshore wind power is obtained.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Thermal-conductivity nano-composite material and preparation method thereof

The invention relates to a thermal-conductivity nano-composite material and a preparation method thereof. The thermal-conductivity nano-composite material comprises the following components by weight percentage: 10-80% of polyolefin, 2-15% of nano-material, 5-50% of thermal conductivity additive, 3-10% of environmental stress resistant cracking additive, 4-19% of impact resistant modifier additive, 0.1-0.5% of antioxidant, a coupling agent of 0.4-3% of the total amount of the nano-material and the thermal conductivity additive, and a wetting agent of 1-6% of the total amount of the nano-material and the thermal conductivity additive. The preparation method comprises the following steps that: firstly, the nano-material, the polyolefin, the impact resistant modifier additive, the coupling agent, and the wetting agent are melted and co-blended according to a certain ratio to be made into masterbatches; secondly, the polyolefin, the masterbatches, the thermal conductivity additive, the environmental stress resistant cracking additive, the impact resistant modifier additive, the antioxidant, the coupling agent and the wetting agent are melted and co-blended according to a certain ratio to be extruded and dried; and thirdly, the materials are melted and co-blended to be extruded and dried to obtain a product. The materials provided by the invention have excellent thermal conductivity and good mechanical properties, and are widely used in heat exchange equipment in various industries.

Owner:HANGZHOU RUNPAQ ENVIRONMENT EQUIP

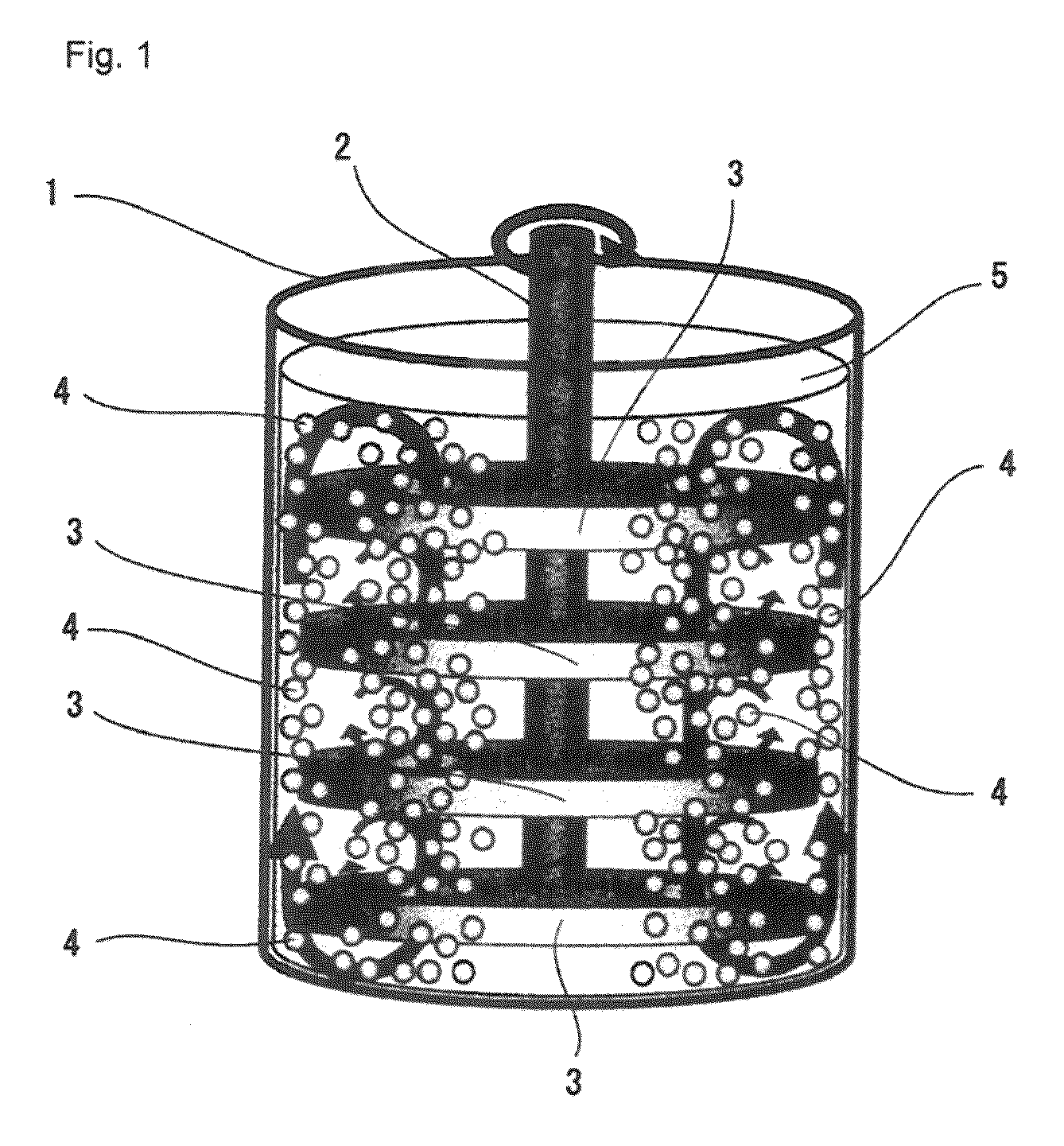

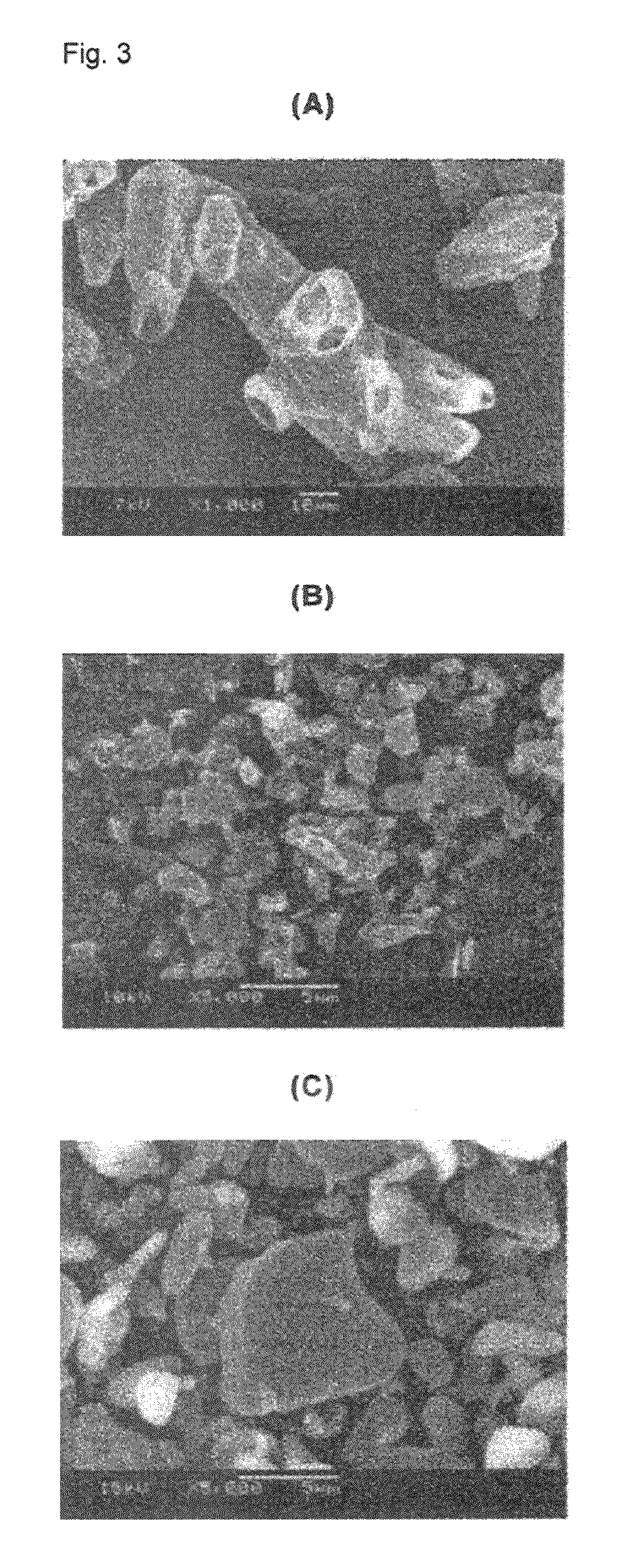

Method for producing fine powder and the fine powder produced by the same

ActiveUS9044758B2Inhibit aggregationEasily water-solvable materialsBiocideCarbon compoundsMetallurgyDry ice

Disclosed is a manufacturing method for a fine powder exhibiting improved solubility, little impurity contamination, and a high recovery rate. Material to be ground and a grinding medium are suspended and stirred in a liquefied inert gas dispersion medium such as dried ice, and the material to be ground is made into a sub-micron or nano-sized fine powder. A uniform fine powder can be obtained when the material to be ground is a mixture having two or more components. Impurity contamination can be reduced by using granular dry ice as the grinding medium.

Owner:MORIROKU CHEM

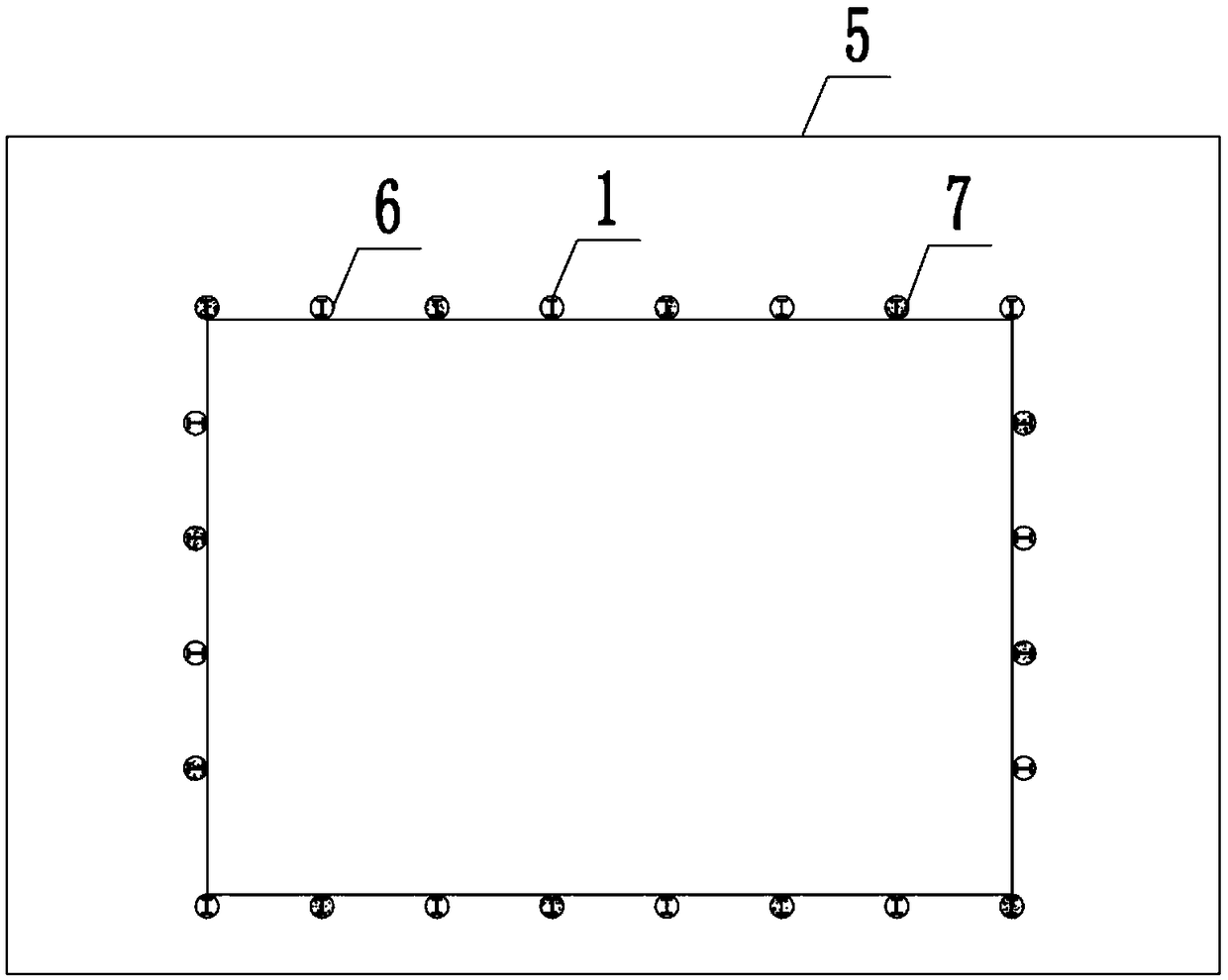

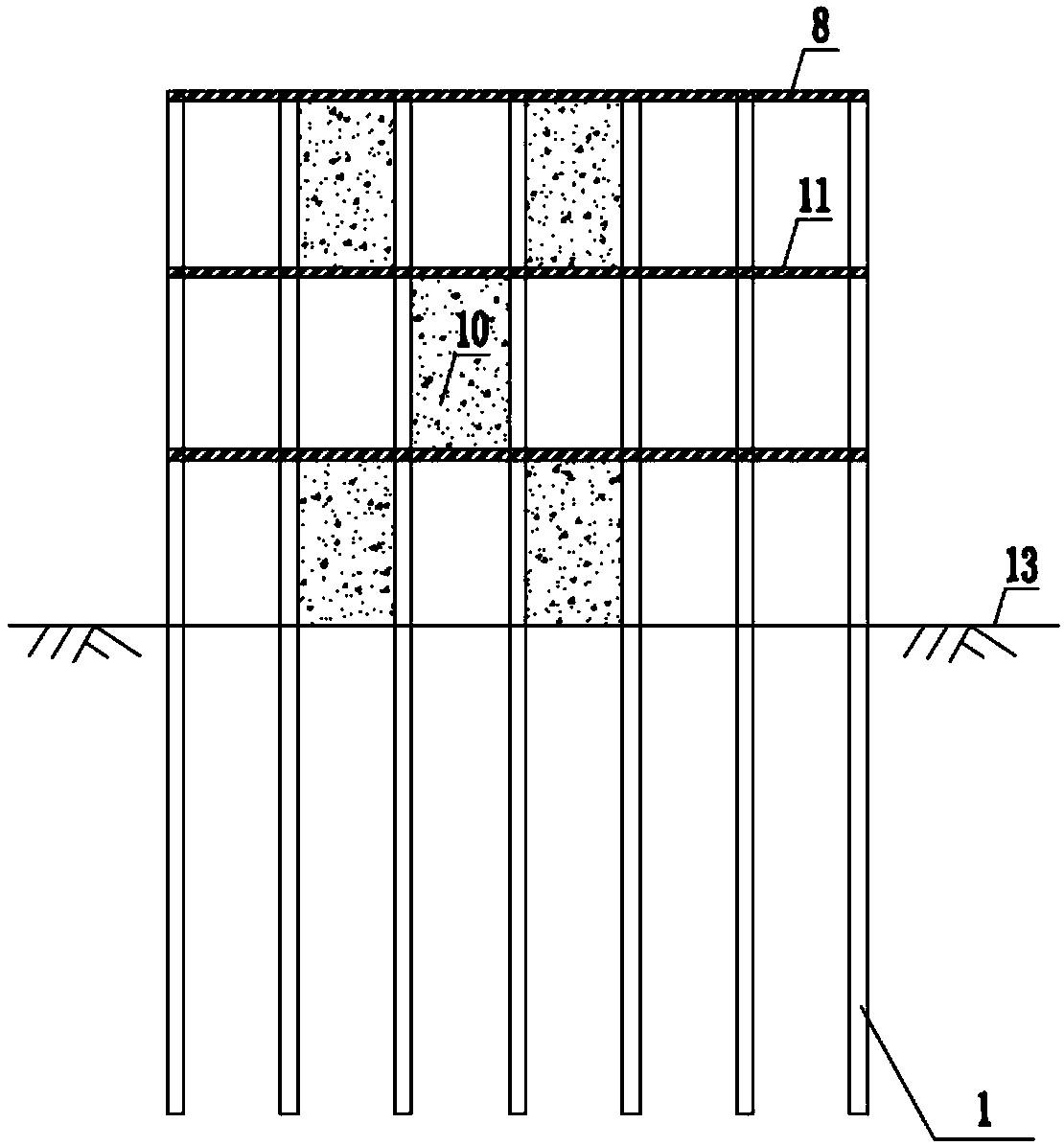

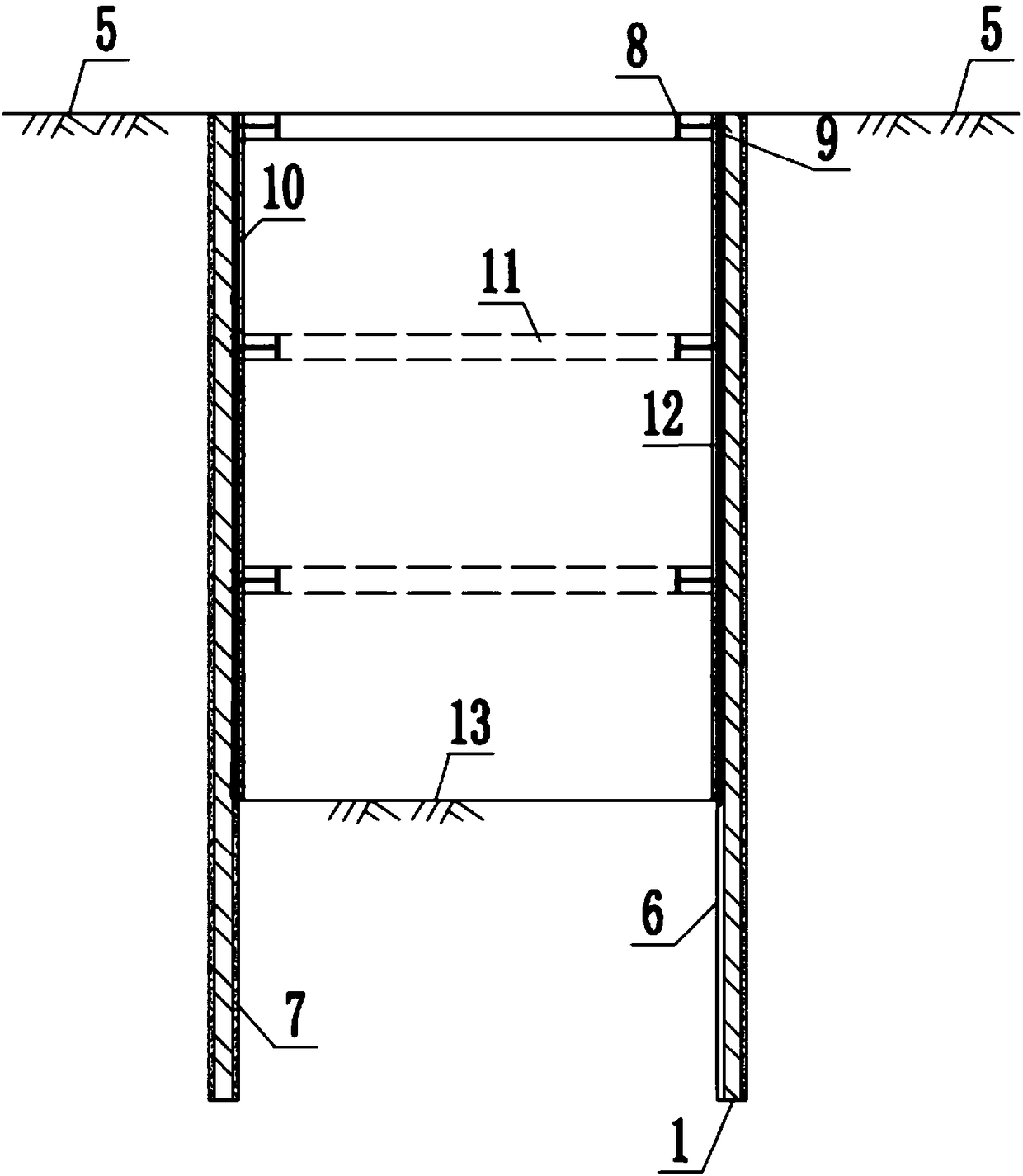

Design construction method of flexible compound fabricated recoverable rectangular working well supporting structure

InactiveCN109056746AMeet the positioning and installation accuracy requirementsAdvanced technologyExcavationsStructure systemHigh polymer

The invention relates to a standardized design construction method of a flexible compound fabricated recoverable rectangular working well supporting structure. The method comprises the following stepsthat (1) construction of minisize supporting piles is carried out; (2) construction of pile top crown beams; (3) a rectangular working well is excavated, panels and waist beams are installed, and high polymers are poured to side walls for sealing; (4) excavation is carried out layer by layer sequentially in the vertical direction, and the step (3) is carried out repeatedly till the design depth is met, that is, construction of the rectangular working well supporting structure is completed accordingly; and (5) after the supporting structure fulfills the usage function, the supporting structurerecovery work can be carried out as the backfilling work is started. Through standardized design construction of the established supporting structure system, one supporting structure can meet the construction requirement of most rectangular working wells in a region, the advantages of safety, reliability, quick and convenient construction, advanced technologies, high recoverability, superior economic indicators and the like are achieved, and the application and development prospects are considerable.

Owner:南方工程检测修复技术研究院

Pearlitic steel rail excellent in wear resistance and ductility and method for producing same

InactiveUS7972451B2Improve wear resistanceHigh carbon contentFurnace typesHeat treatment furnacesGranularityPearlite

The present invention is: a pearlitic steel rail excellent in wear resistance and ductility, characterized in that, in a steel rail having pearlite structure containing, in mass, 0.65 to 1.40% C, the number of the pearlite blocks having grain sizes in the range from 1 to 15 μm is 200 or more per 0.2 mm2 of an observation field at least in a part of the region down to a depth of 10 mm from the surface of the corners and top of the head portion; and a method for producing a pearlitic steel rail excellent in wear resistance and ductility, characterized by, in the hot rolling of said steel rail, applying finish rolling so that the temperature of the rail surface may be in the range from 850° C. to 1,000° C. and the sectional area reduction ratio at the final pass may be 6% or more, and then applying accelerated cooling to the head portion of said rail at a cooling rate in the range from 1 to 30° C. / sec. from the austenite temperature range to at least 550° C.

Owner:NIPPON STEEL CORP

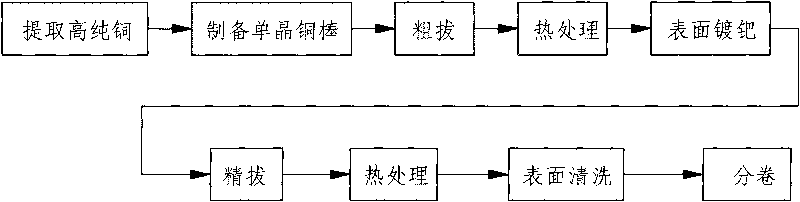

Copper palladium alloy monocrystal bonding wire and manufacturing method thereof

ActiveCN102226991ADense materialFlat surfacePolycrystalline material growthSemiconductor/solid-state device detailsIntegrated circuitSingle crystal

A copper palladium alloy monocrystal bonding wire and a manufacturing method thereof are disclosed. Base material of the copper palladium monocrystal bonding wire comprises, by weight, 1.35%-10.18% of palladium, 0.0001%-0.0003% of Calcium, 0.0002%-0.0008% of Rhenium and the balance copper. The manufacturing method comprises the following steps: extracting high purity copper and high purity palladium; preparing monocrystalline copper palladium alloy rod; plating palladium on surface; coarse drawing and fine drawing; carrying out a heat treatment; cleaning the surface; shunting winding. The invention abandons the traditional technique: drawing firstly and then electroplating. In the method of the invention, the monocrystalline copper palladium alloy wire with a wire diameter of less than 3mm is produced, then palladium layer is electroplated, and finally, the palladium copper alloy bonding wire finished product is produced by drawing. By using the invention, oxidation resistance of bonding copper wire can be effectively raised; the oxidation resistance of the bonding copper wire can be equal to the oxidation resistance of bonding gold wire; shelf-life of the bonding copper wire product after being sealed off can be substantially prolonged. Mechanical strength of alloy finished products which are added elements, such as palladium, calcium, rare earth and the like, can be higher than materials produced by other ways, which is beneficial to further reduce the wire diameter of the bonding wire and shorten welding spacing, and is suitable for integrated circuit package with high-density and multi-pin.

Owner:江西蓝微电子科技有限公司

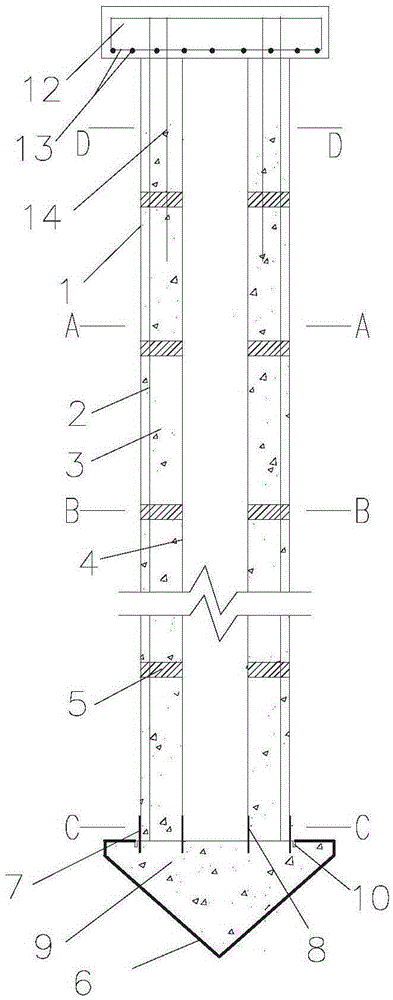

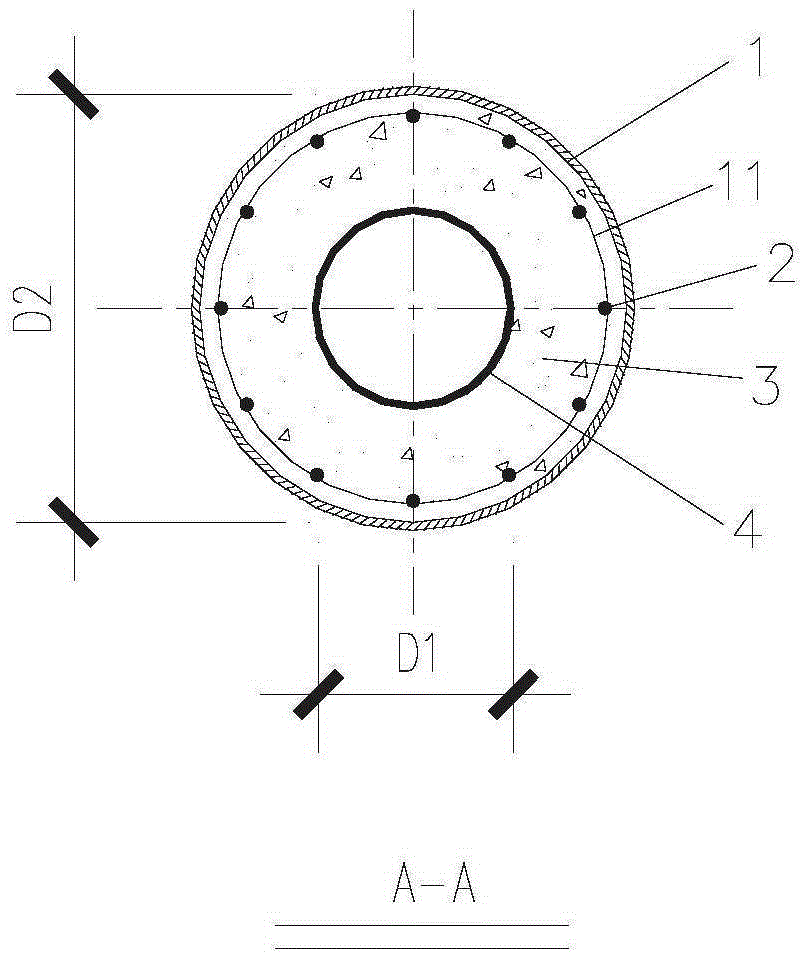

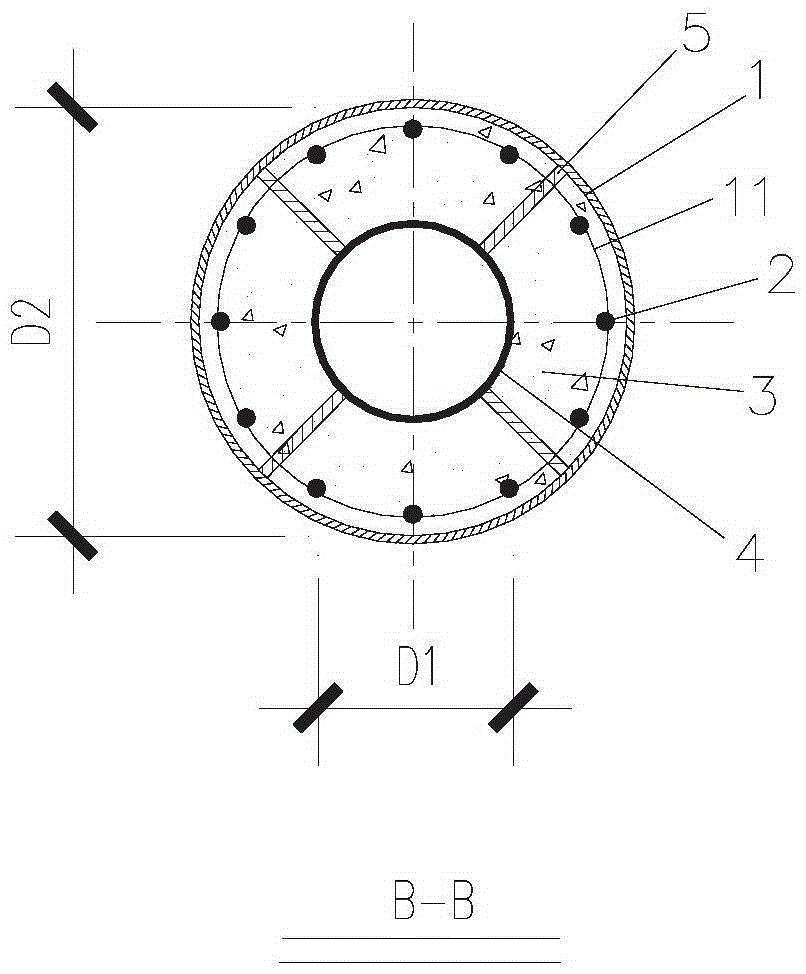

FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile

InactiveCN105386443AStop erosionInhibit deteriorationBulkheads/pilesThick wallFoundation engineering

The invention discloses an FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile which is mainly formed by an FRP pipe, a round reinforcement cage framework, a thick-wall steel pipe and recycled concrete. The round reinforcement cage framework and the thick-wall steel pipe are arranged in the FRP pipe, and the round reinforcement cage framework, the thick-wall steel pipe and the FRP pipe are arranged concentrically. The recycled concrete is poured in annular space between the FRP pipe and the thick-wall steel pipe. The bearing capacity and deformation resisting capacity of the single pile can be greatly improved through the built-in thick-wall steel pipe. The wrapping FRP pipe can effectively prevent a pile body from being corroded, and the durability of the pile body is improved. Meanwhile, the FRP pipe and spiral stirrups are combined to restrain the inner recycled concrete, and the bearing force of the compounding pile is further improved. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated. In a word, the compounding hollow recycled concrete pile has the advantages of being good in pile forming quality, high in bearing force, good in deformation resisting capacity and durability, small in influence on the environment, high in construction speed and the like.

Owner:GUANGXI UNIV

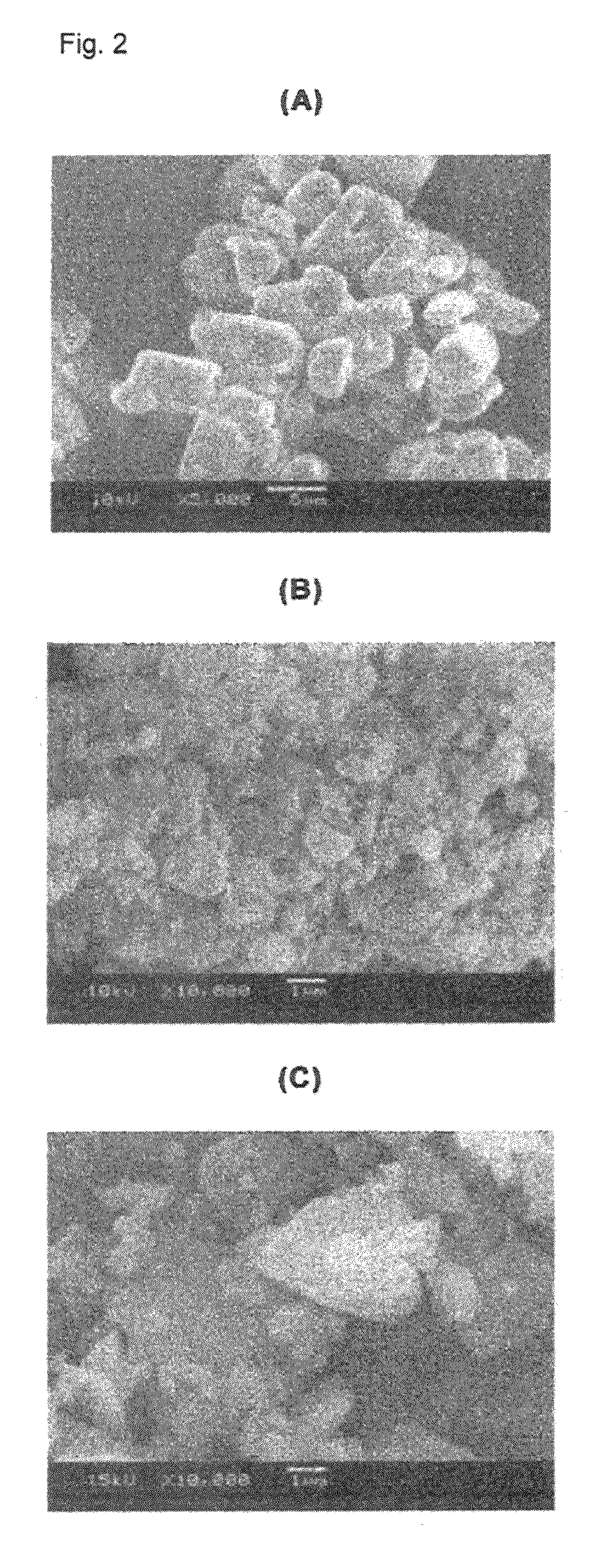

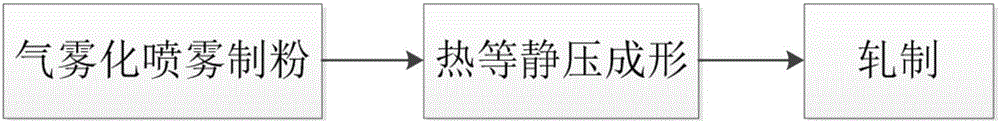

High-boron stainless steel neutron-absorbing material and preparation method thereof

ActiveCN106378459AUniform materialImprove mechanical propertiesShieldingHot isostatic pressingProtective shielding

The invention provides a high-boron stainless steel neutron-absorbing material and a preparation method thereof, and belongs to the field of neutron-absorbing materials. The high-boron stainless steel neutron-absorbing material comprises the following components in percentage by mass: 0.2-3% of B, 12-26% of Cr, 1.5-23% of Ni, 0.02-0.6% of C, 1-11% of Mn, 0-7% of Mo, no less than 3% of Si, no less than 0.2% of P, no less than 0.030% of S and the balance of iron. The preparation method comprises the following steps: atomization spraying for powder preparation; hot-isostatic-pressing sintering, and rolling. The prepared high-boron stainless steel has the advantages that the stainless steel density is high, the relative density is higher than 99.8%, the stainless steel structure is uniform; the room-temperature tensile strength is higher than 500 MPa, the yield strength is higher than 200 MPa and the ductility is higher than 5%. Meanwhile, the prepared high-boron stainless steel is applicable to a nuclear radiation protective shielding material, a spent fuel storage material, a reactor control material and the like, and has good economic benefit and social benefit.

Owner:安泰核原新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com