Gradient material steel rail frog prepared by laser cladding

A laser cladding, gradient material technology, applied in the field of high load-carrying performance rail frog, high wear resistance, gradient material rail frog field, can solve the problems of high martensite hardness, low toughness, etc., to achieve excellent mechanical properties, hardness The effect of smooth curve and wear resistance of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

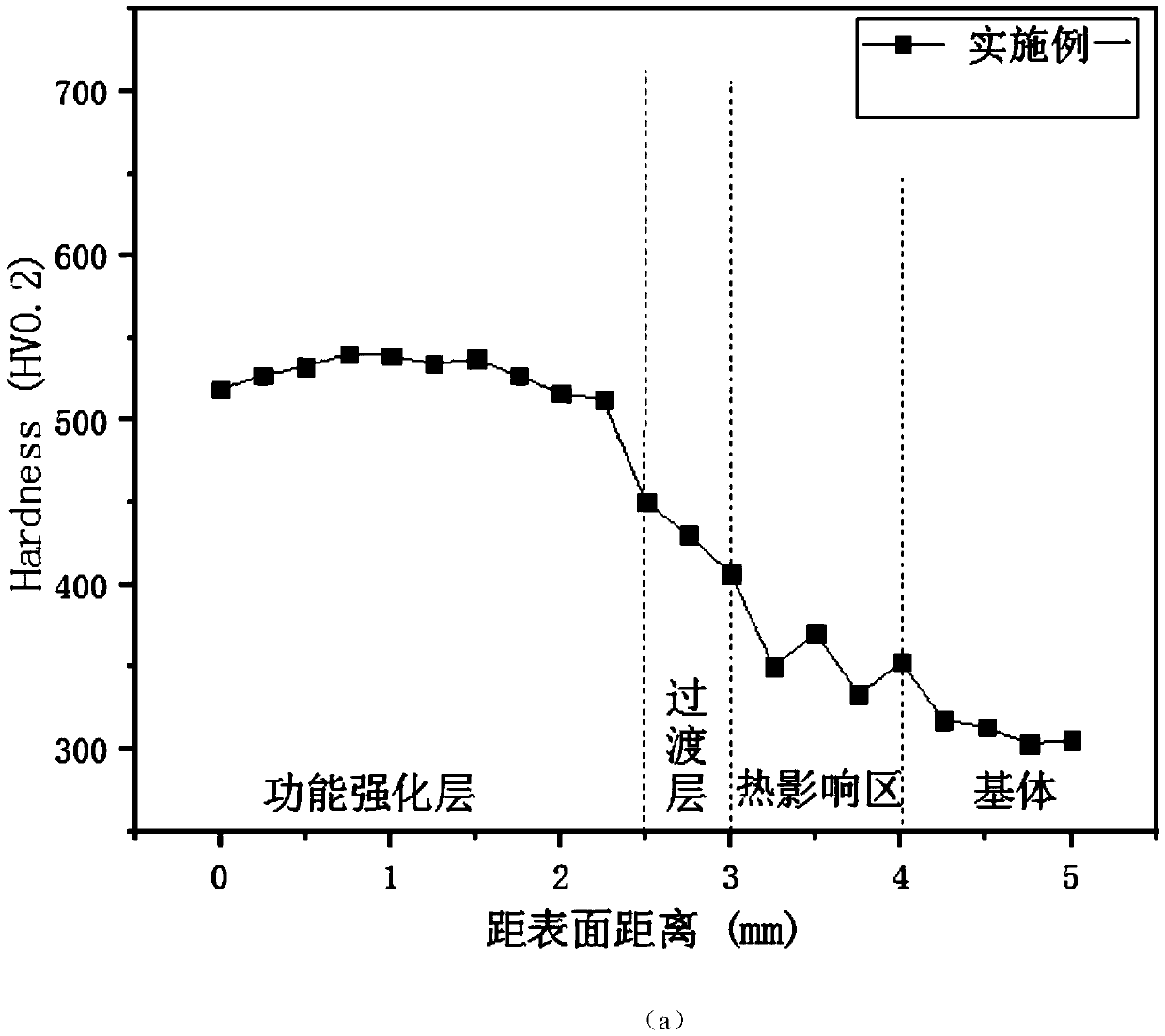

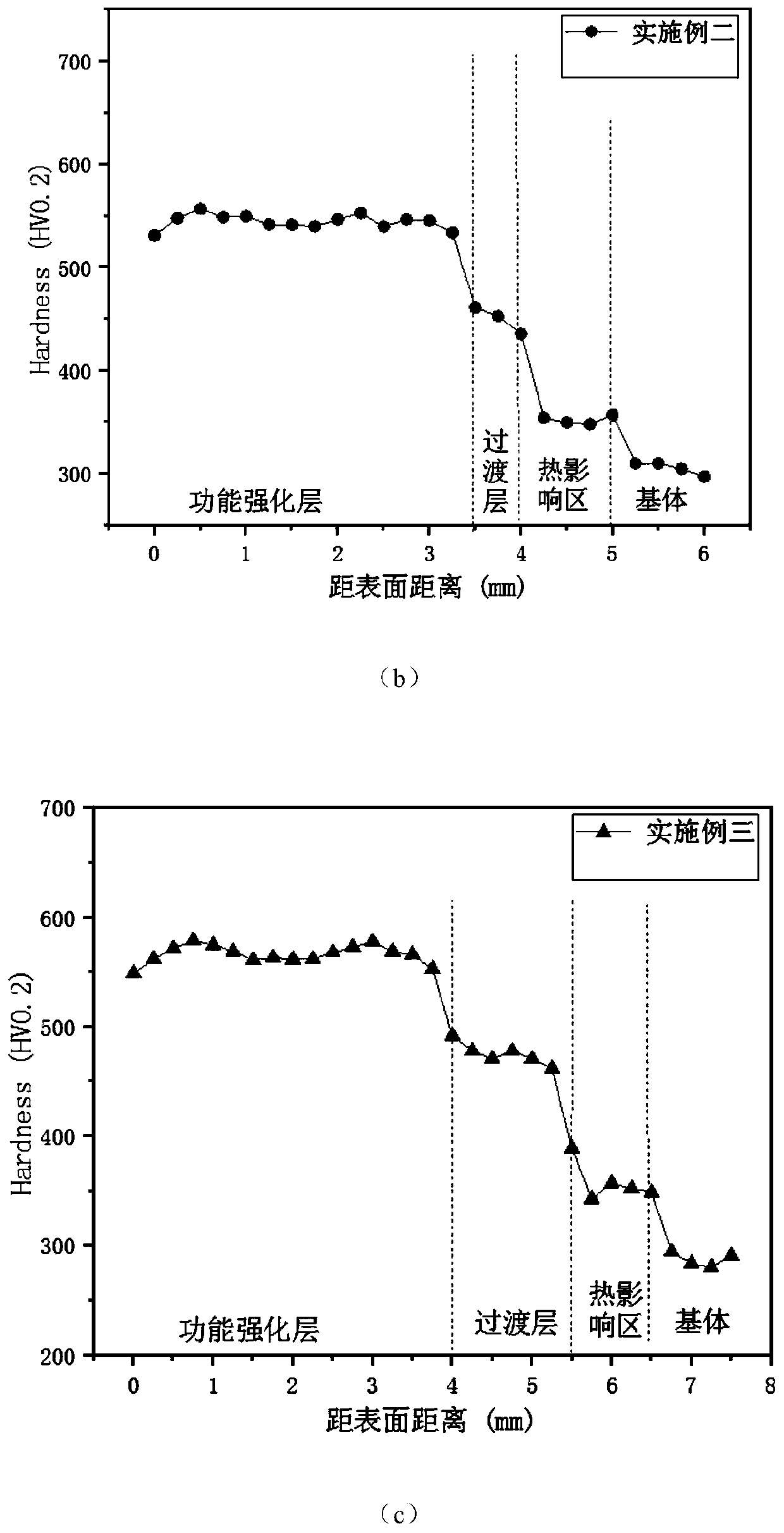

Embodiment 1

[0023] Embodiment one comprises the following steps:

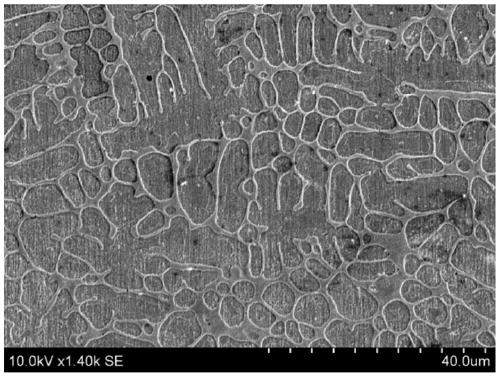

[0024] U75V rail frog is selected as the substrate, and the components of the transition layer ferroalloy powder in the laser cladding layer are respectively Fe: 71wt%, Cr: 17wt%, Ni: 6wt%, Si: 1.5wt%, Mn: 1wt%, B: 1wt%, Nb: 1.2wt%, V: 1.2wt%, C: 0.1wt%; the reinforcement layer Fe-based composite coating is Cr: 15wt%, Ni: 5wt%, Mo: 2wt% in mass percentage , Mn: 1wt%, C: 0.05wt%, V: 1wt%, WC: 0.5wt%, TiC: 0.5wt%, NbC: : 0.3wt%, La 2 O3:0.5wt%, Al 2 o 3: 0.5wt%, Fe73.65wt%. Weigh and configure the raw materials according to the mass percentage of the above components, melt the transition layer alloy powder and use gas atomization to obtain Fe-based alloy powder respectively, so as to realize the homogenization of the powder; then compound the Fe-based metal nanophase of the strengthening layer The non-nano-phase powder of the material is smelted and powdered by gas atomization, and then the prepared powder is mechanical...

Embodiment 2

[0033] The same part as in Example 1 will not be described again, and the U75V rail frog is selected as the substrate. The difference in the coating is that the components of the layer are proportioned by mass percentage, and the components of the transition layer ferroalloy powder are respectively Fe: 74.4wt by mass percentage. %, Cr: 15wt%, Ni: 5wt%, Si: 1wt%, Mn: 1wt%, B: 1.5wt%, C: 0.5wt%, Nb: 0.8wt%, V: 0.8wt%; function strengthening layer Fe According to the mass percentage of the matrix composite coating, Cr: 18wt%, Ni: 6wt%, Mo: 3wt%, Mn: 2wt%, C: 0.3wt%, V: 1wt%, WC: 1wt%, TiC: 0.7wt% %, NbC: : 0.6wt%, La 2 o 3: 0.8wt%, Al 2 o 3: 0.6wt%, Fe: 66wt%.

[0034] Using Trumpf 4000 watt fiber output semiconductor laser (wavelength 1070nm), adjust the distance between the laser processing head and the workpiece, and preheat the rail parts under laser scanning (power 3KW, scanning speed 20mm / min), the preheating temperature is 400 ℃ , circular spot size 5mm. The transit...

Embodiment 3

[0038] Embodiment 1 The same part will not be described again, the difference is that the U71Mn rail frog is selected as the substrate, the components of the coating are proportioned by mass percentage, and the components of the transition layer ferroalloy powder are respectively Fe: 79.5wt% by mass percentage , Cr: 13wt%, Ni: 3wt%, Si: 1.5wt%, Mn: 0.5wt%, B: 1wt%, C: 0.7wt%, Nb: 0.3wt%, V: 0.5wt%; strengthening layer Fe-based The composite material coatings are respectively Cr: 20wt%, Ni: 7wt%, Mo: 4wt%, Mn: 3wt%, C: 1wt%, V: 1.5wt%, WC: 2wt%, TiC: 0.8wt% in mass percentage , NbC: : 0.9wt%, La 2 o 3: 1wt%, Al 2 o 3: 0.8wt%, Fe: 58wt%.

[0039] Using a semiconductor laser with 8000 watts of optical fiber output (wavelength 920-1040nm), adjust the distance between the laser processing head and the workpiece, and preheat the rail parts under laser scanning (power 5KW, scanning speed 50mm / min), and the preheating temperature is 500 ℃, circular spot size 8mm. The circular s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com