Patents

Literature

498results about How to "Wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

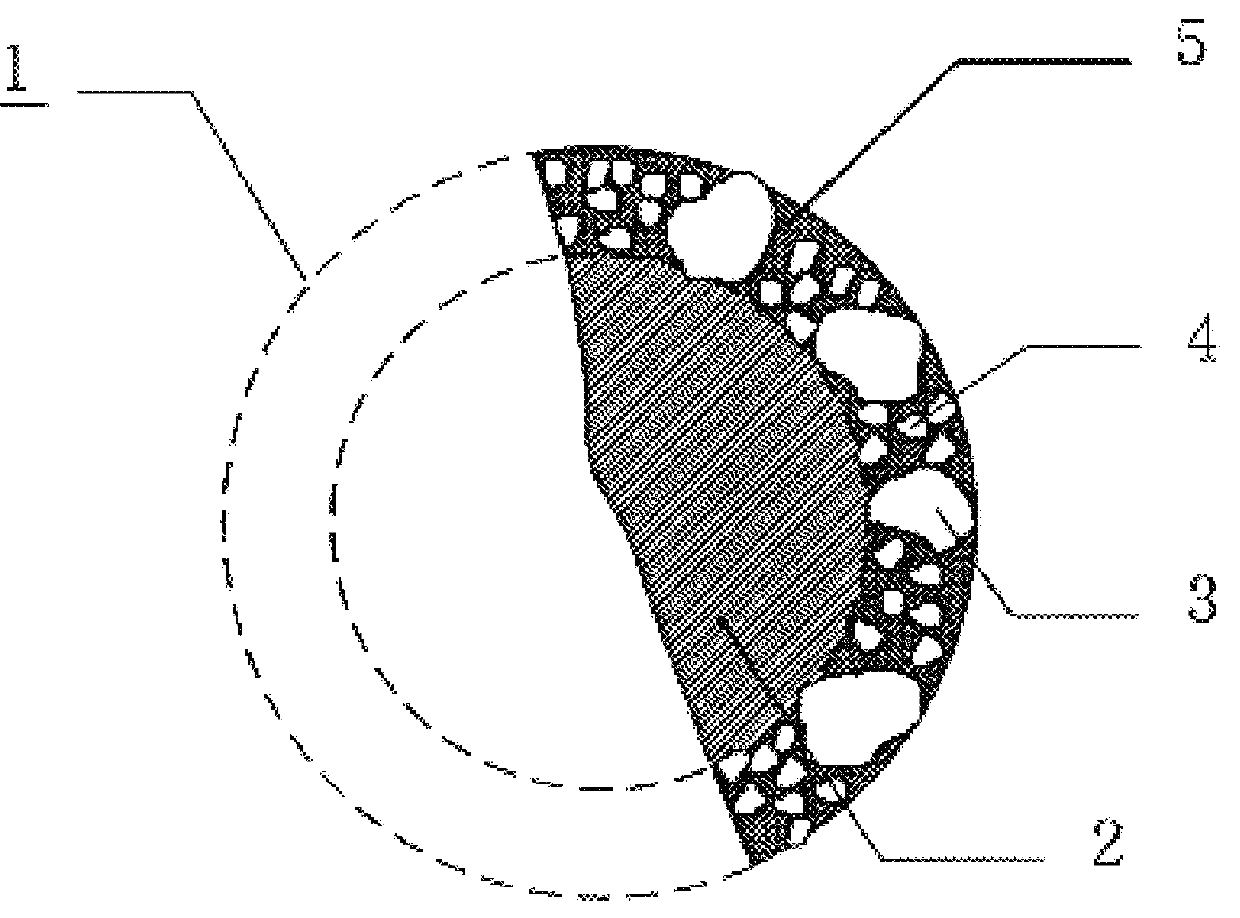

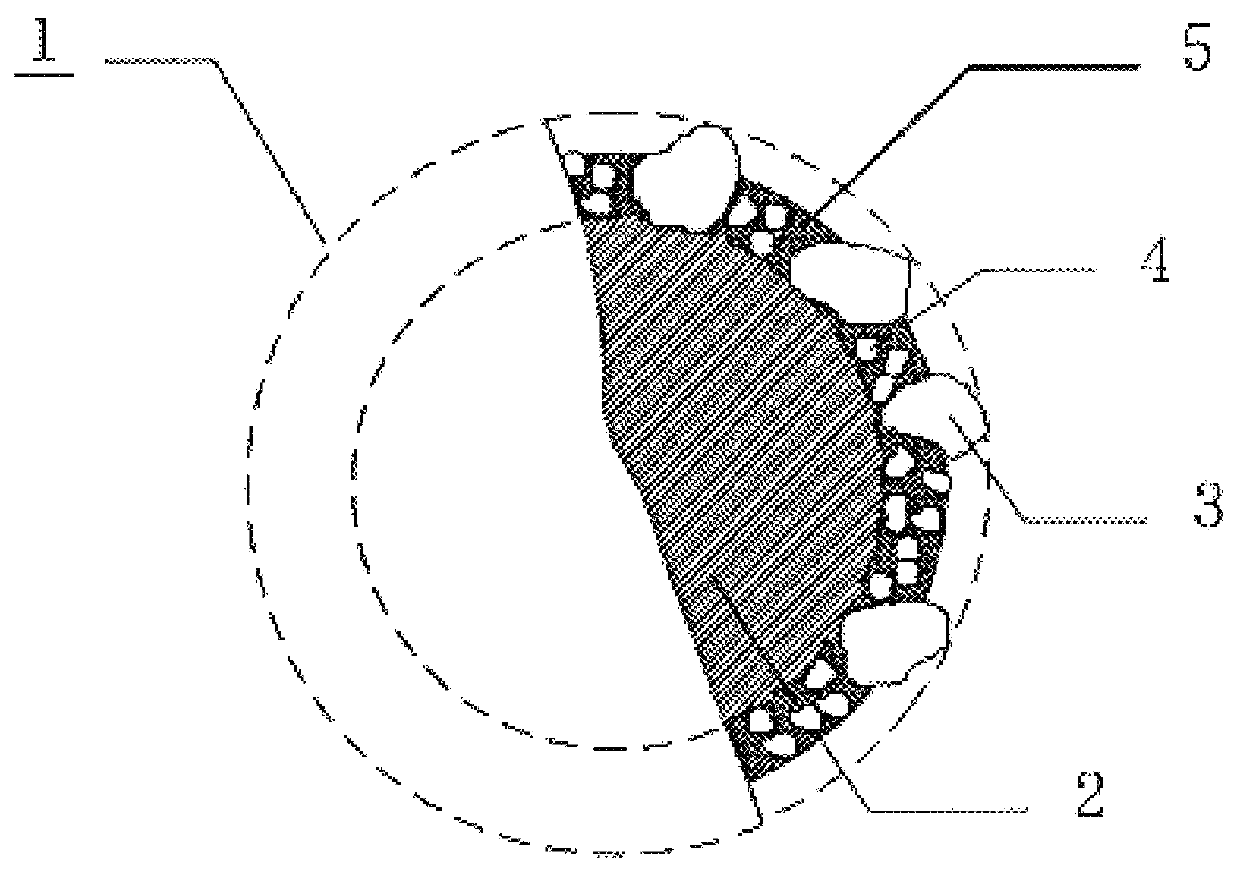

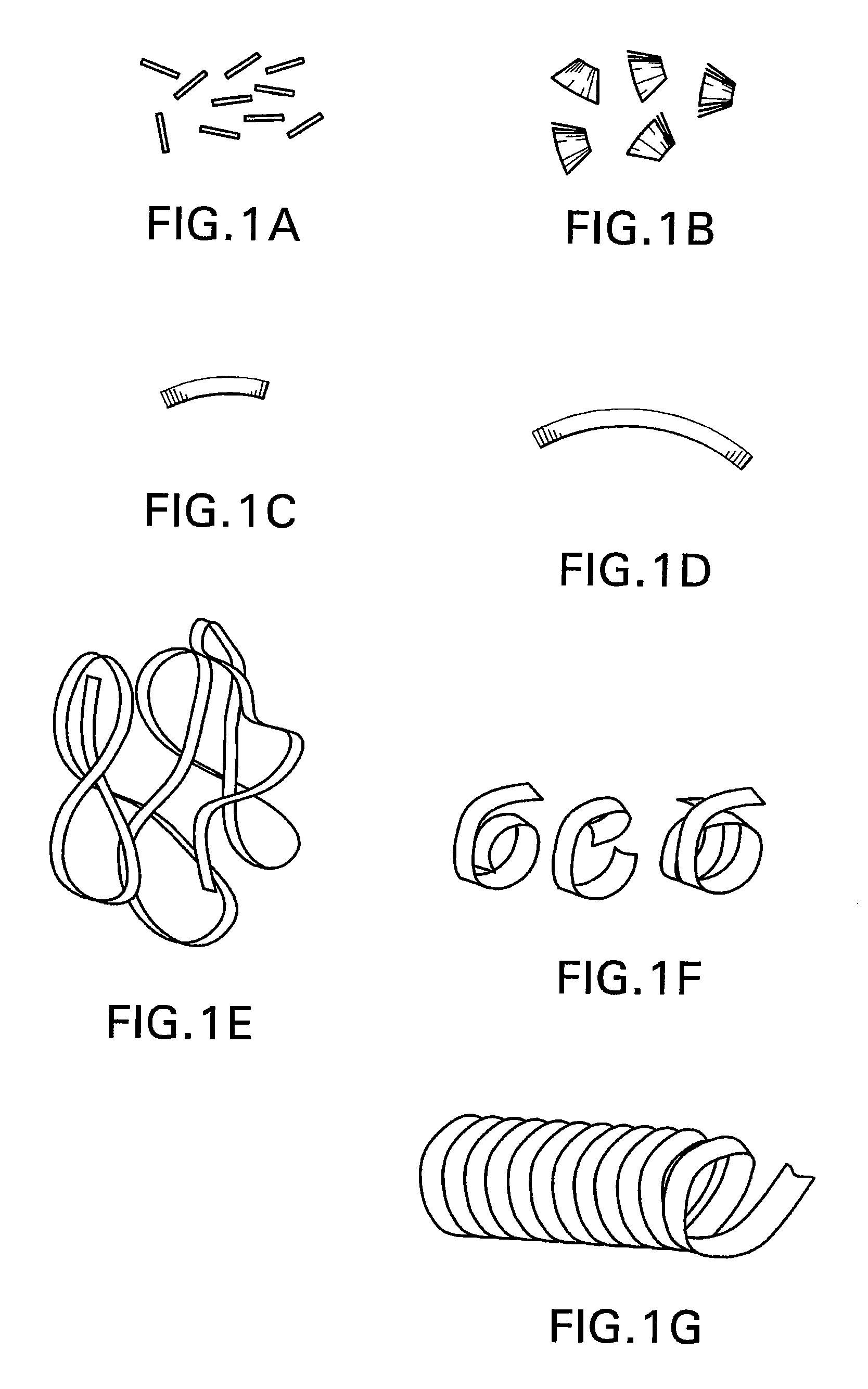

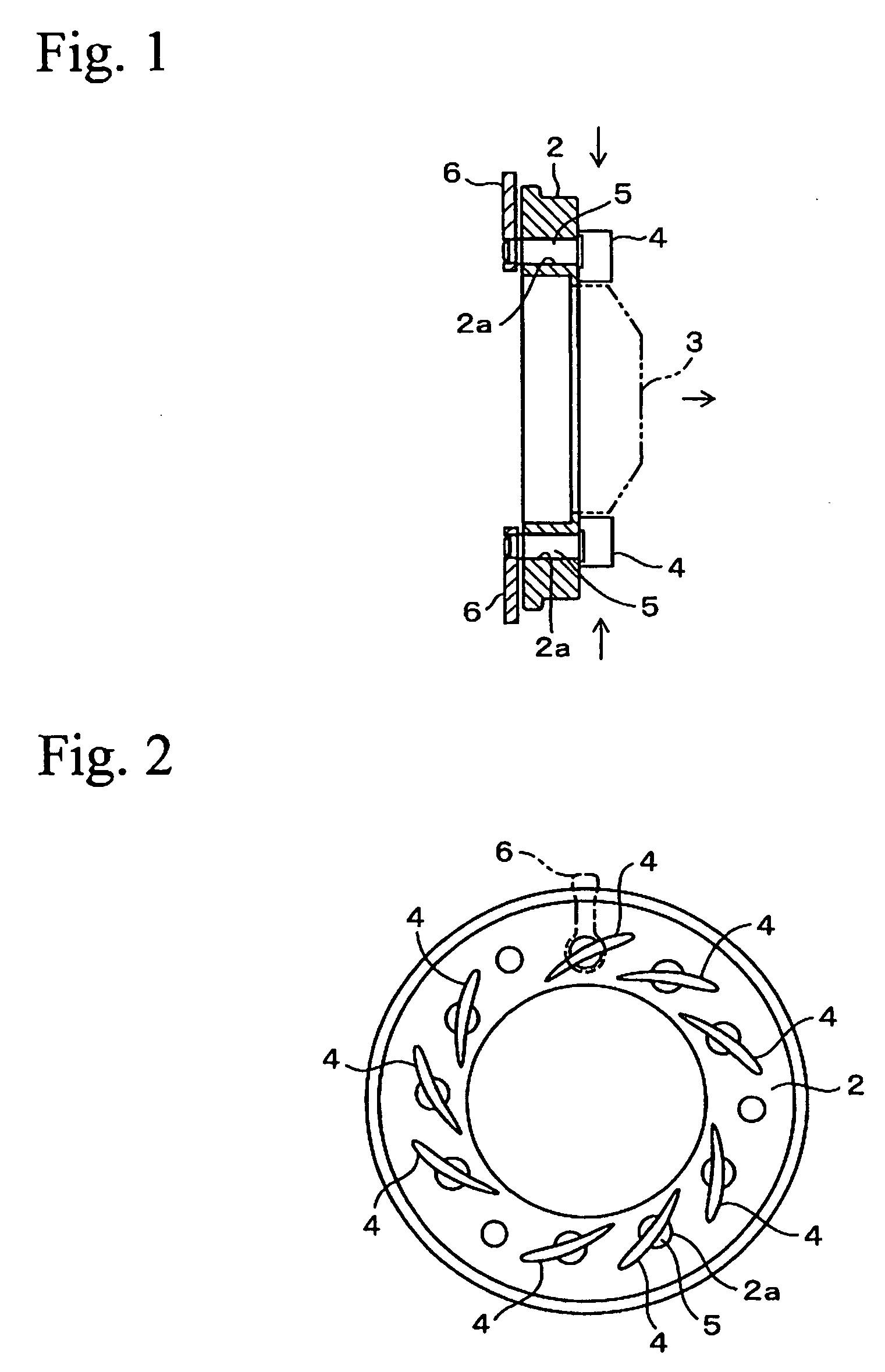

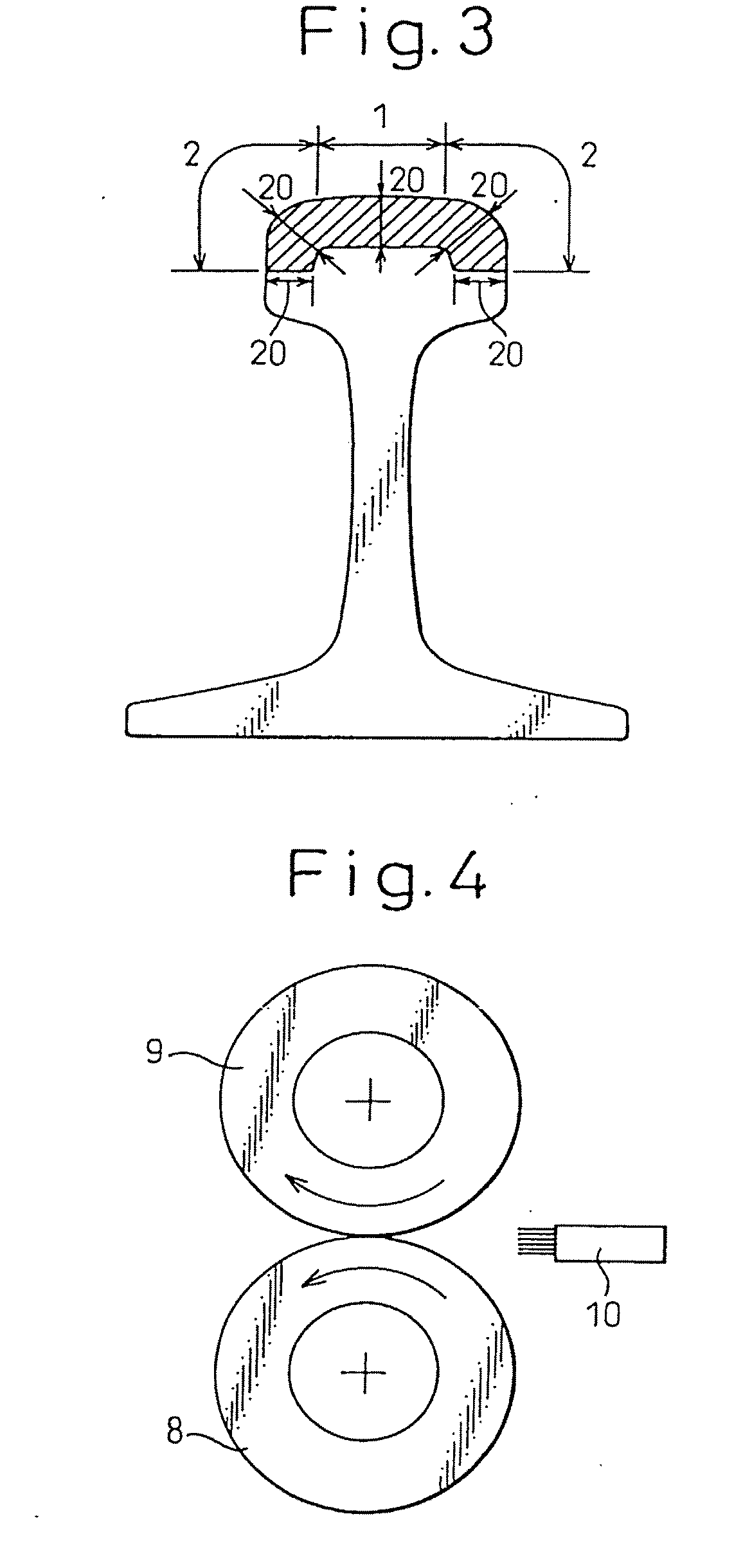

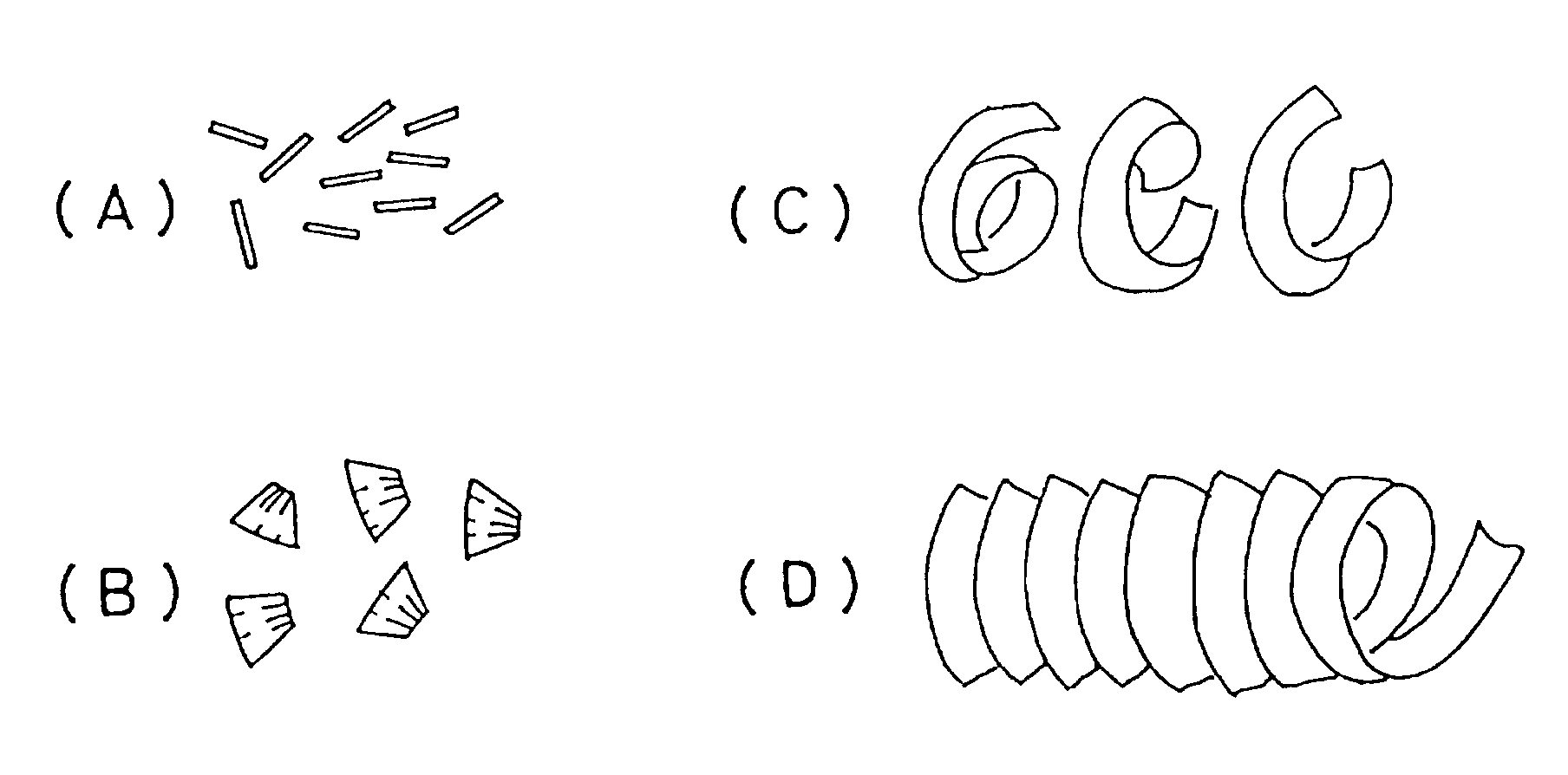

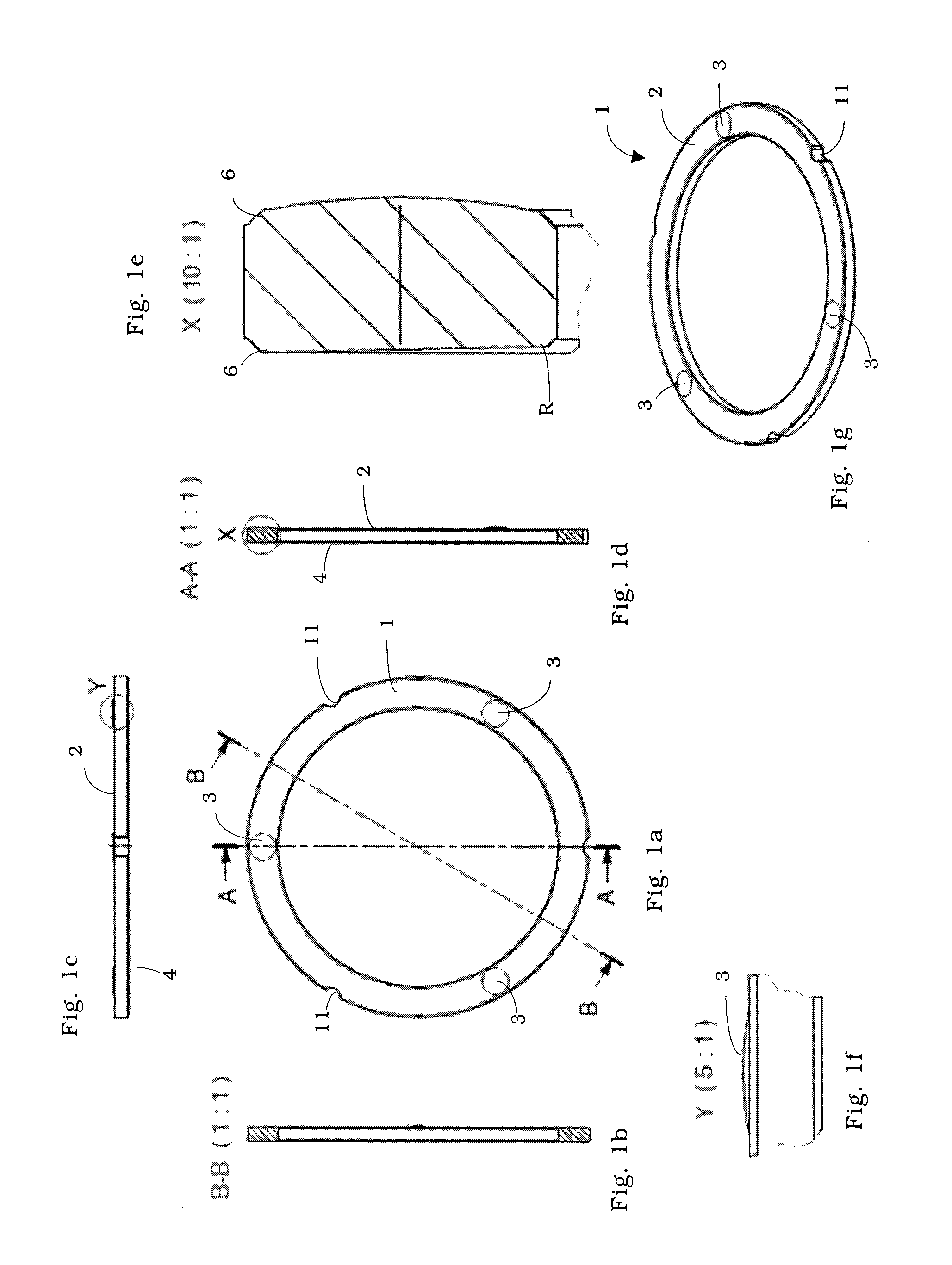

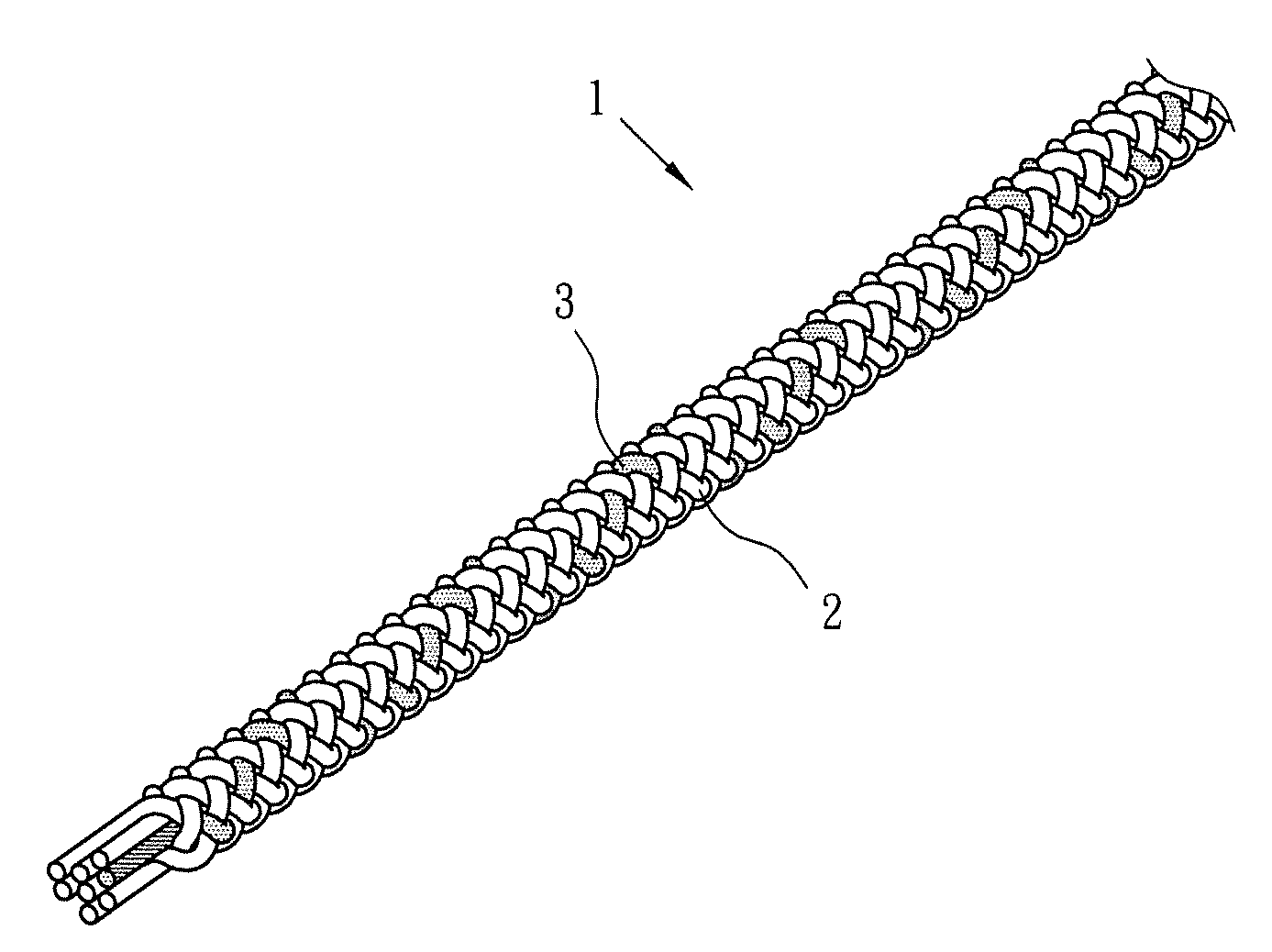

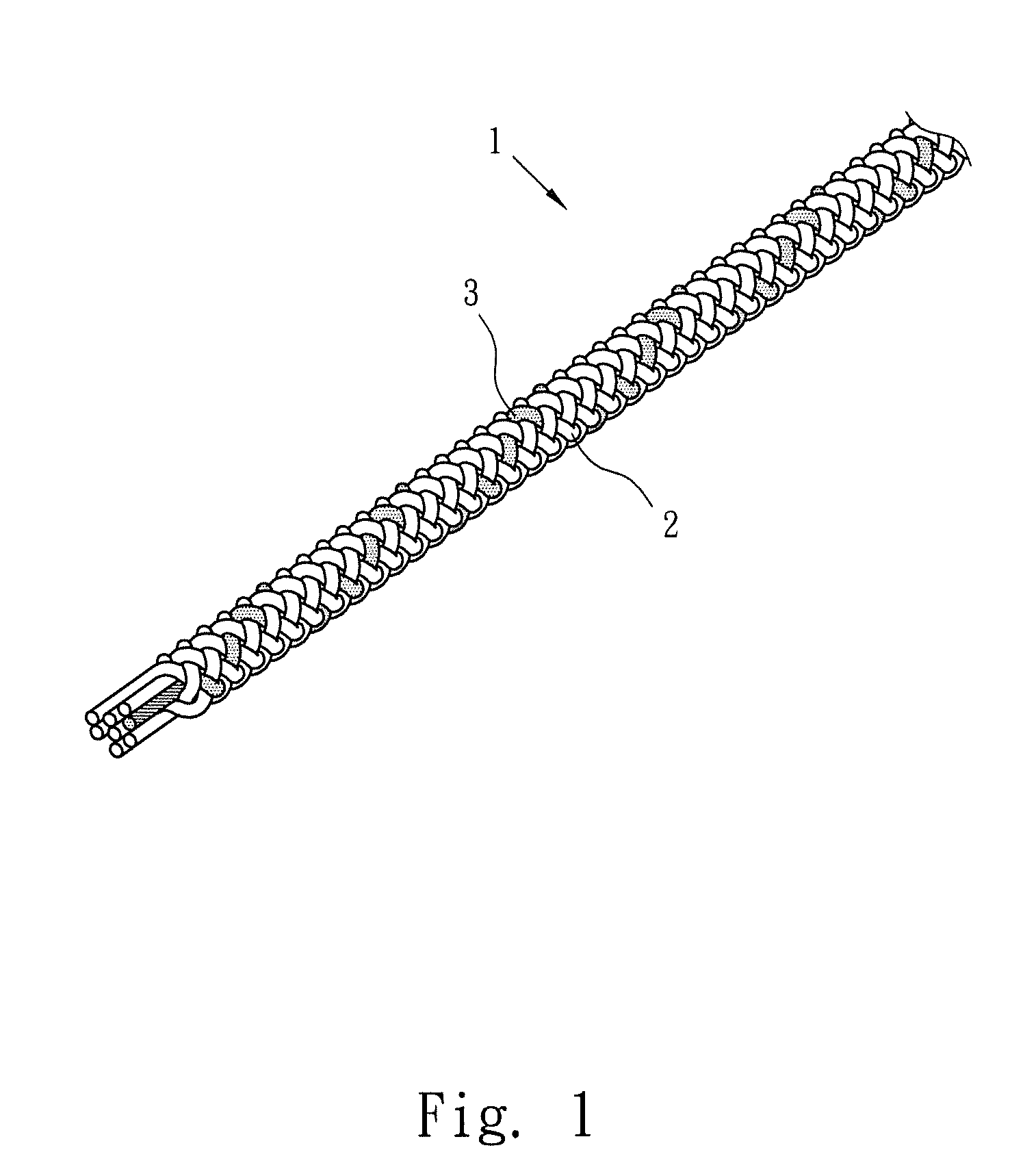

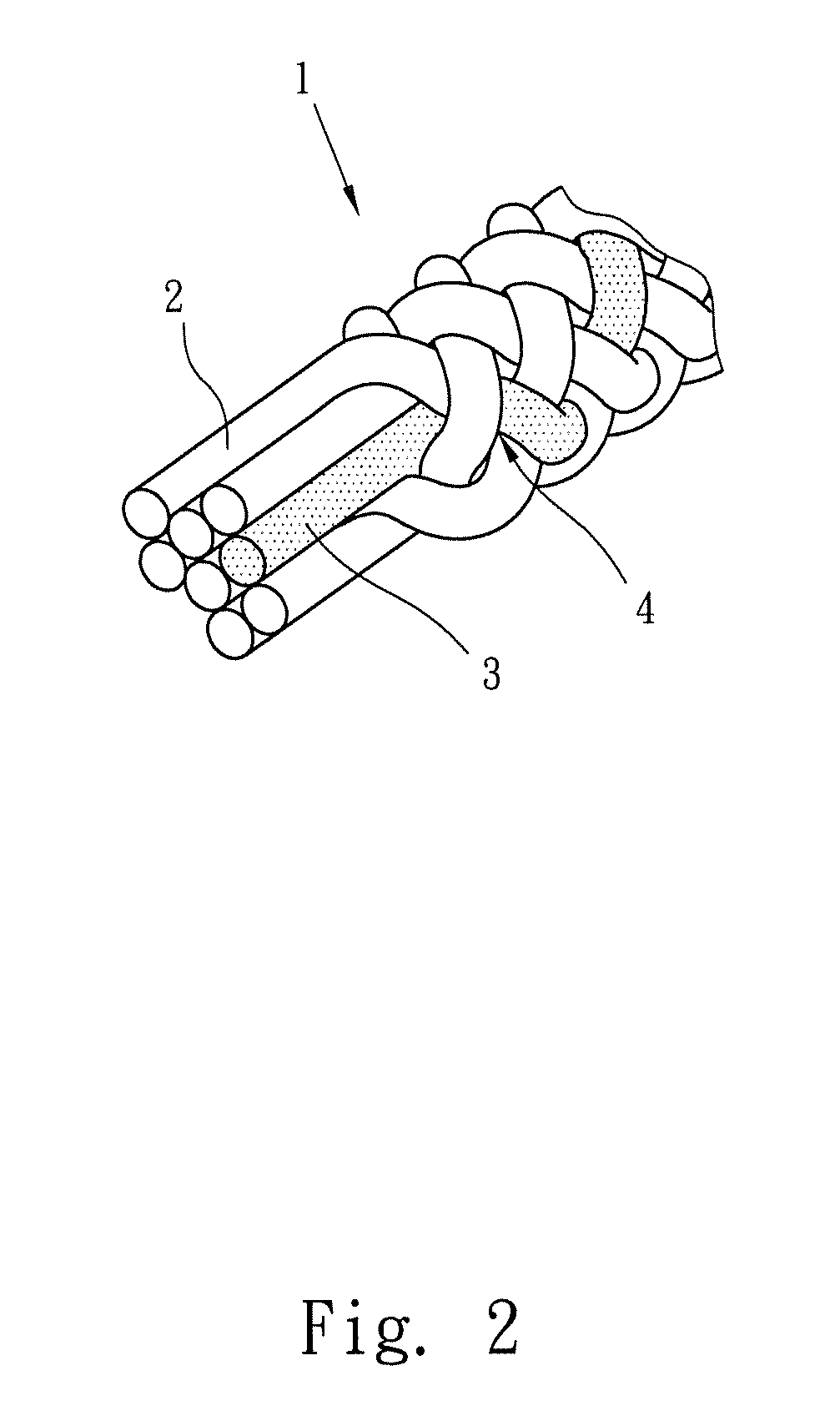

Wire-saw and its manufacturing method

InactiveUS6070570AReadily worked and finishedImprove homogeneityMetal sawing toolsGrinding devicesEngineeringElectronic materials

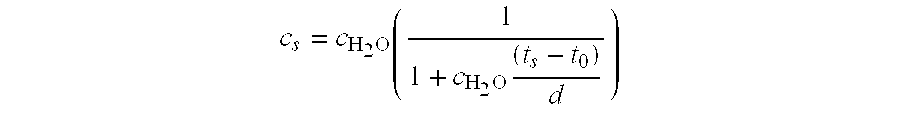

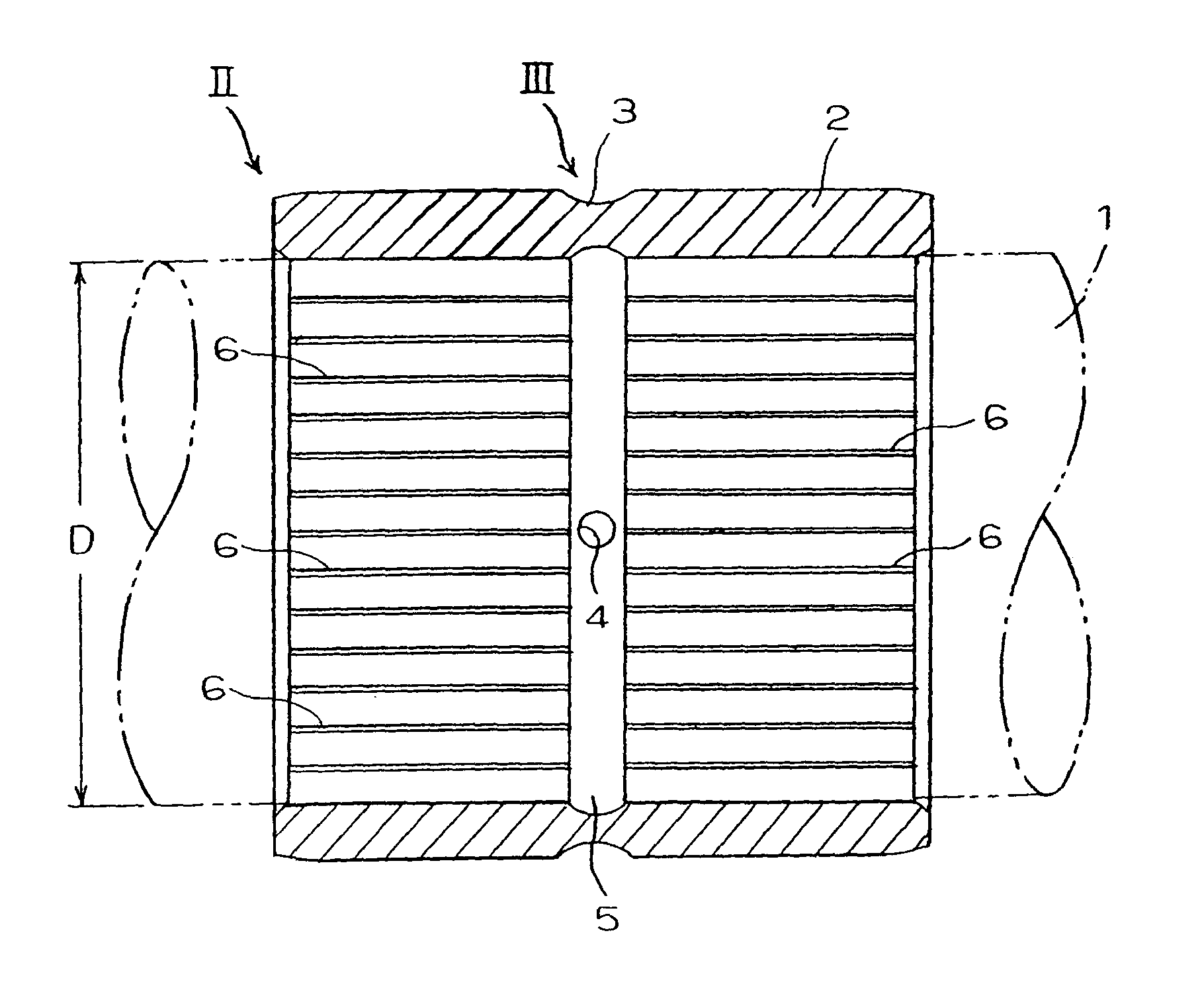

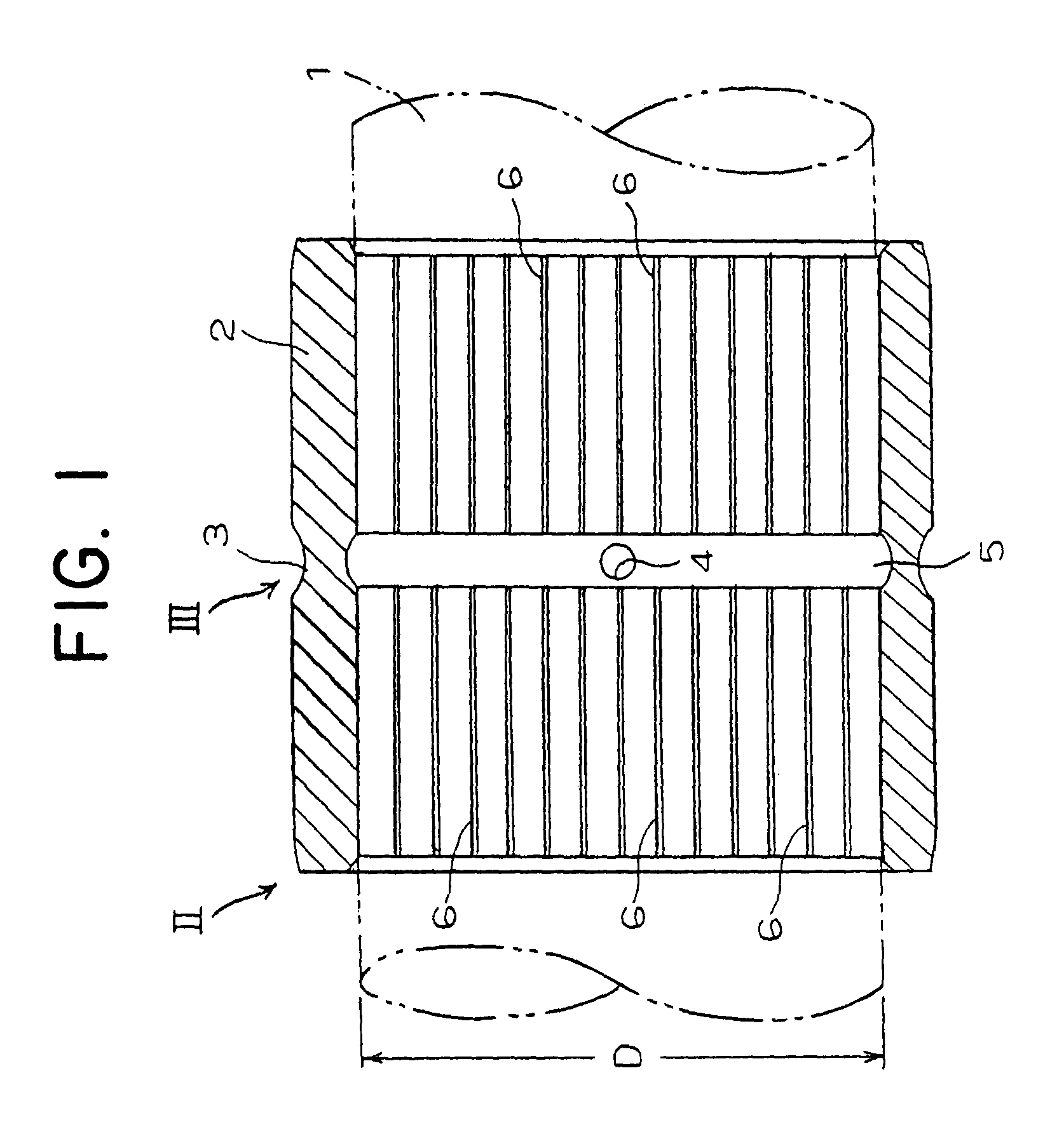

PCT No. PCT / JP98 / 00532 Sec. 371 Date Mar. 9, 1999 Sec. 102(e) Date Mar. 9, 1999 PCT Filed Feb. 9, 1998 PCT Pub. No. WO98 / 35784 PCT Pub. Date Aug. 20, 1998The present invention provides a wire saw for use in cutting works of electronics materials or optical materials and a method for manufacturing the same, said wire saw having the following characteristic features. Namely, onto a high-strength core wire 2, abrasive grains 3 having a grain size not smaller than two-thirds the thickness of a layer of resin bond 4 on said core wire 2 but not exceeding a half the diameter of said core wire are fixed with said resin bond, said resin bond containing a filler having a grain size smaller than two-thirds the thickness of said resin bond layer. The thus structured and arranged wire saw has an improved efficiency and precision in cutting. The wire saw can be manufactured readily by using an enamelling oven.

Owner:ALLIED MATERIAL +1

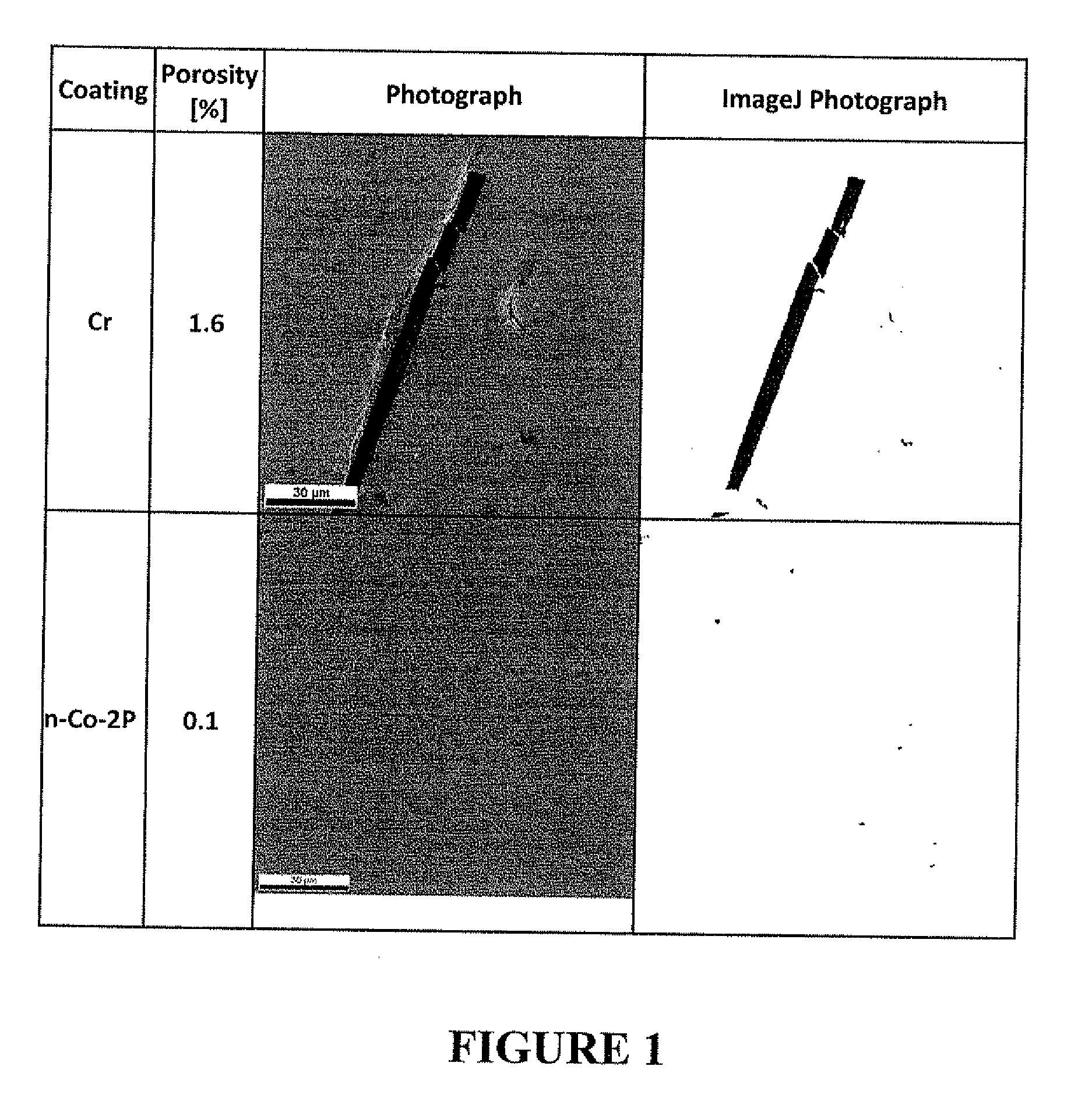

Electrodeposited metallic-materials comprising cobalt

ActiveUS20100304182A1Reduce resistanceEliminate security concernsEnvelopes/bags making machineryRecord information storageParticulatesPorosity

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness chromium coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial properties.

Owner:INTEGRAN TECH

Free-cutting copper alloy containing very low lead

The free-cutting copper alloy according to the present invention contains a greatly reduced amount of lead in comparison with conventional free-cutting copper alloys, but provides industrially satisfactory machinability. The free-cutting alloys comprise 71.5 to 78.5 percent, by weight, of copper, 2.0 to 4.5 percent, by weight, of silicon, 0.005 percent up to but less than 0.02, by weight, of lead, and the remaining percent, by weight, of zinc.

Owner:SANBO SHINDO KOGYO CO LTD

Electrophotographic photoconductor, electrophotographic apparatus and process cartridge

InactiveUS6899983B2Improve wear resistanceReduce adhesionElectrographic process apparatusCorona dischargeForeign matterElectrical conductor

The present invention aims to provide a photoconductor having improved wear resistance, and which has reduced foreign matter attached on the photoconductor surface.The electrophotographic photoconductor of the present invention is formed by sequentially disposing a photoconductive layer comprising at least one layer and a protective layer on an electroconductive support, and the protective layer comprises an acrylic resin and / or a methacrylic resin and a resin composition comprising an acryl-modified polyorganosiloxane compound which is dispersed in or compatible with the acrylic resin and / or the methacrylic resin.

Owner:RICOH KK

Methods of improving the wear resistance of prosthetic medical devices

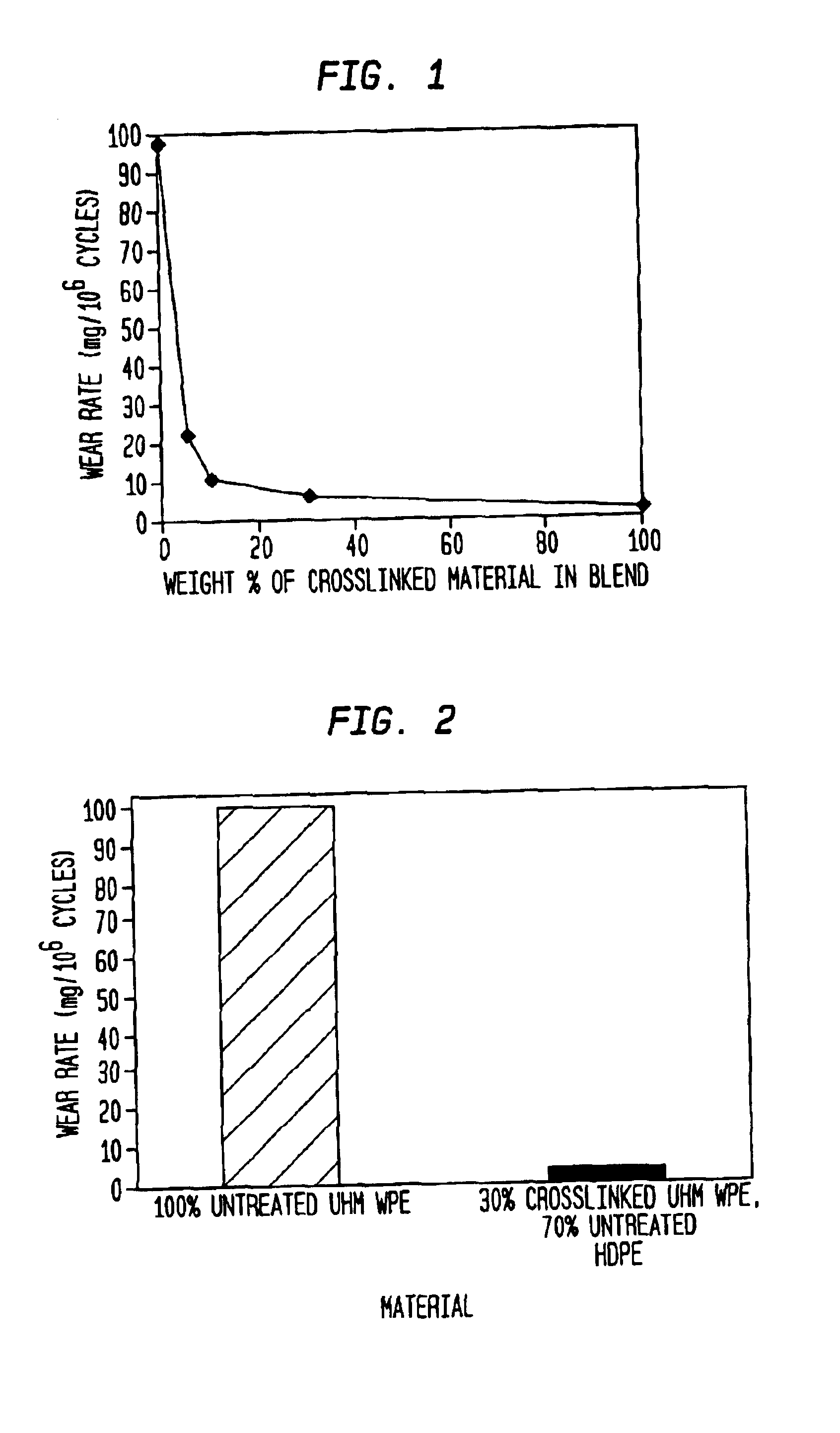

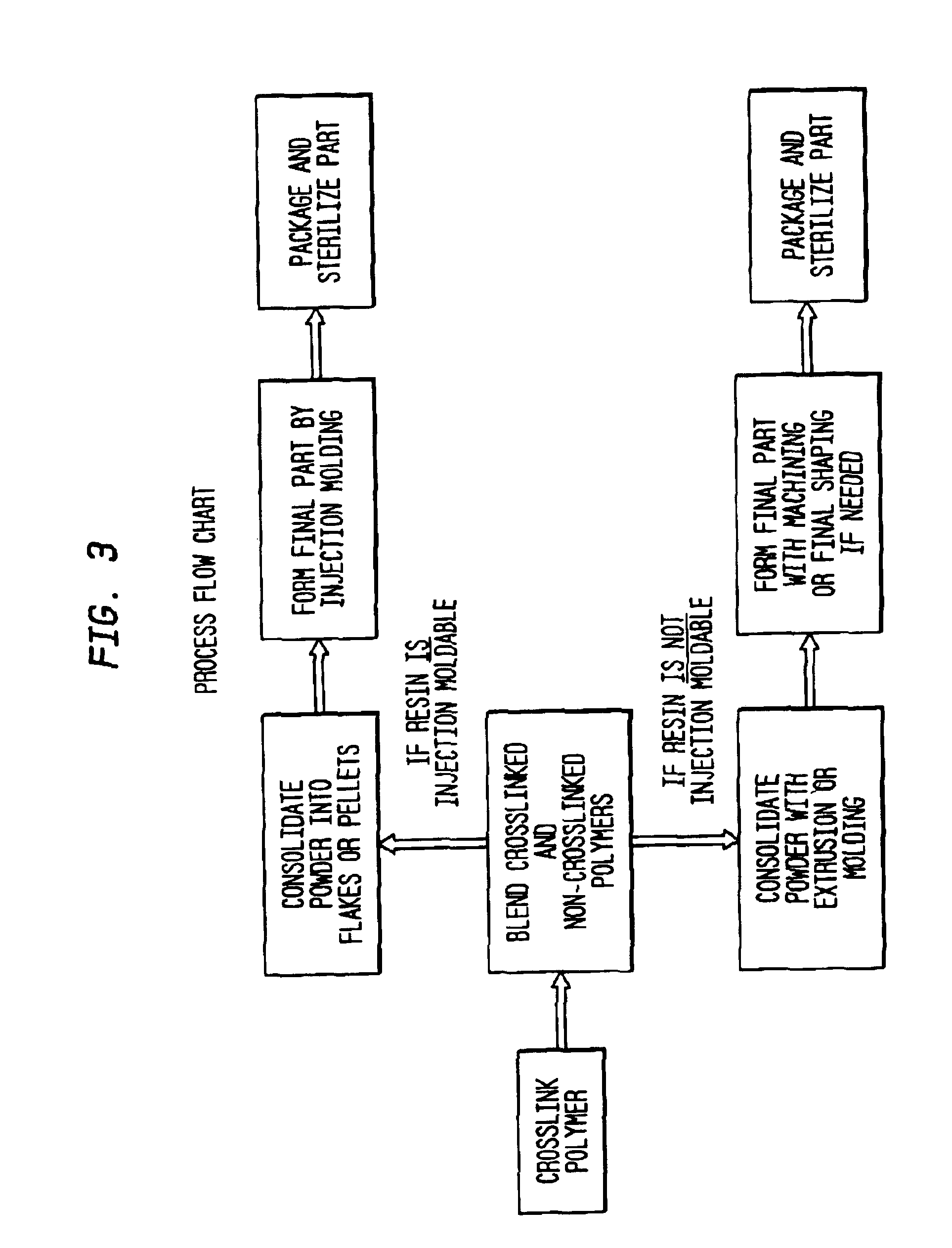

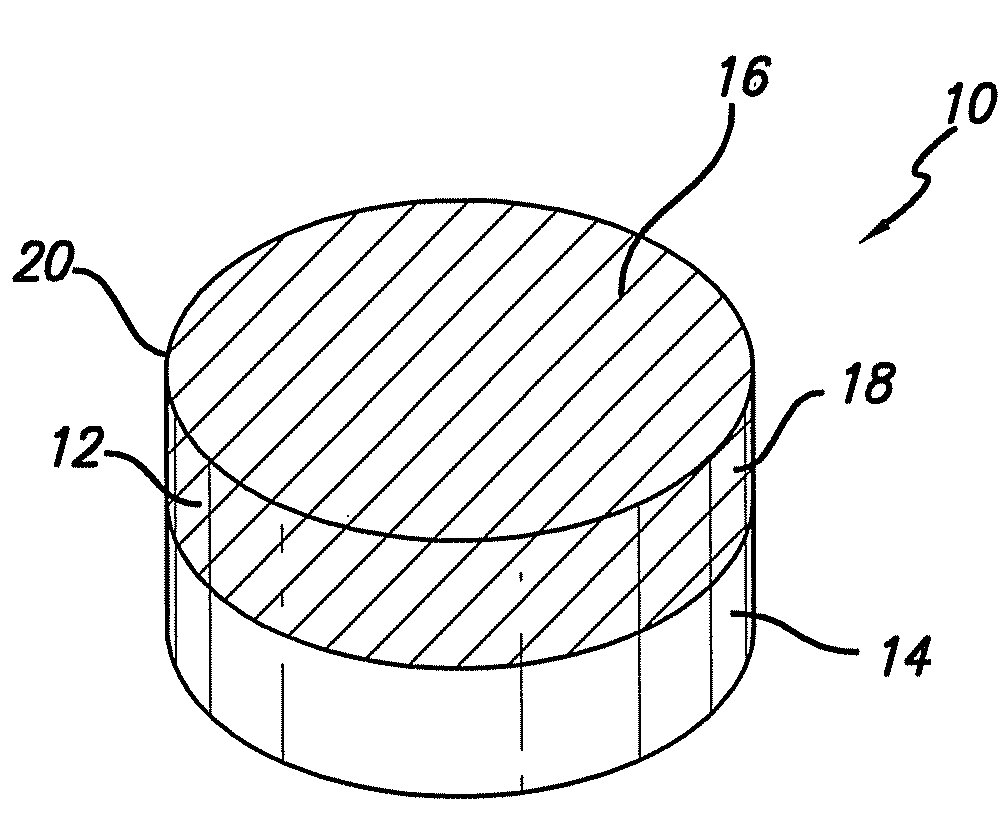

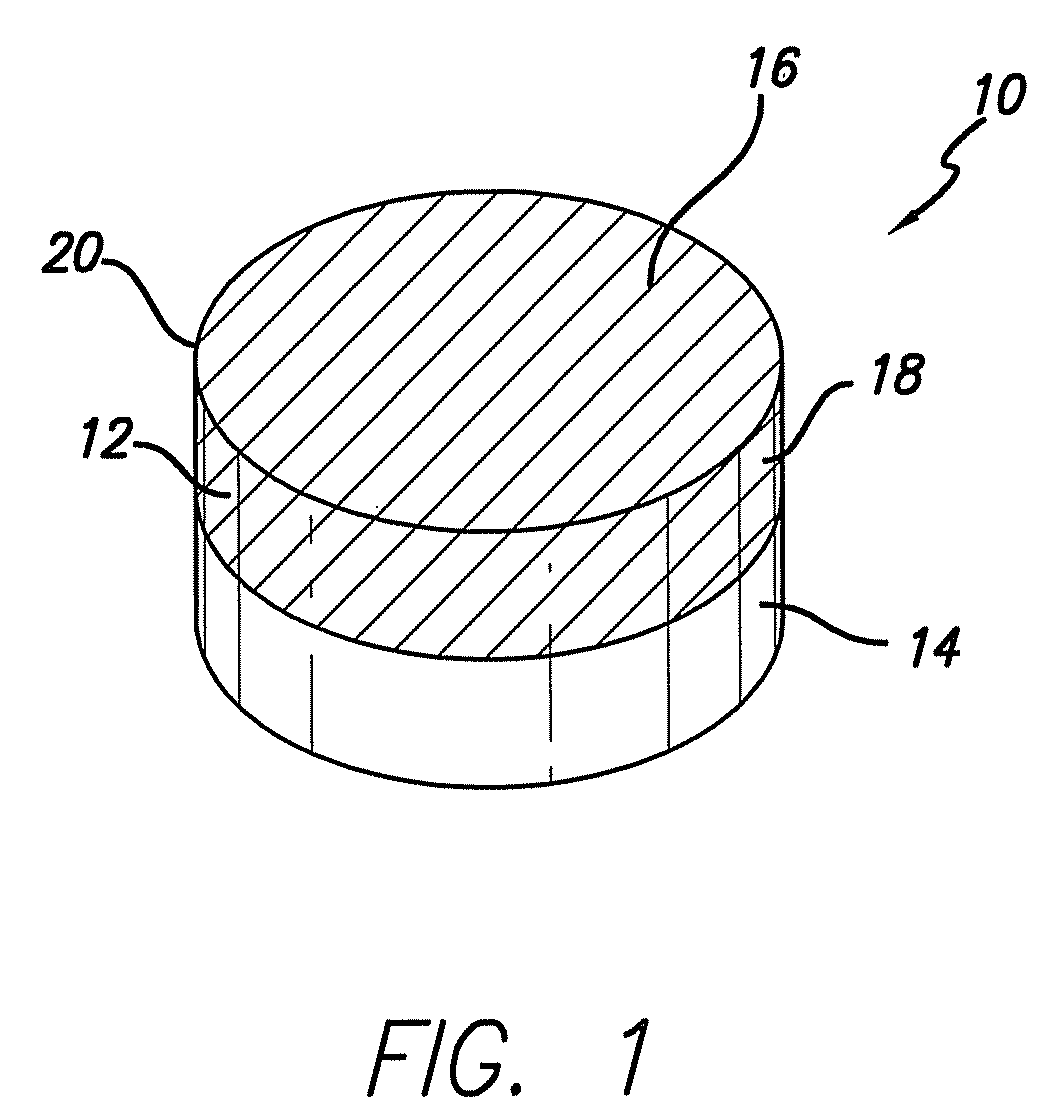

InactiveUS6905511B2Avoids and reduces levelWear resistanceImpression capsAnkle jointsCross-linkPolyolefin

A prosthetic medical device exhibiting improved wear resistance is fabricated by irradiating at least one polyolefinic material in the presence of an inert atmosphere to yield a cross-linked irradiated polyolefinic material; blending at least one non-irradiated polyolefinic material with the at least one irradiated polyolefinic material, and forming the prosthetic medical device from the blended material. Selectively cross-linked polymeric compositions may be created by blending a specific amount of cross-linked resins with a specific amount of uncross-linked resins then cured into a polymeric matrix whereby the desired degree or percentage of overall cross-linking is obtained. The polymeric material may then be formed directly into a finished article by injection molding the polymeric material.

Owner:HOWMEDICA OSTEONICS CORP

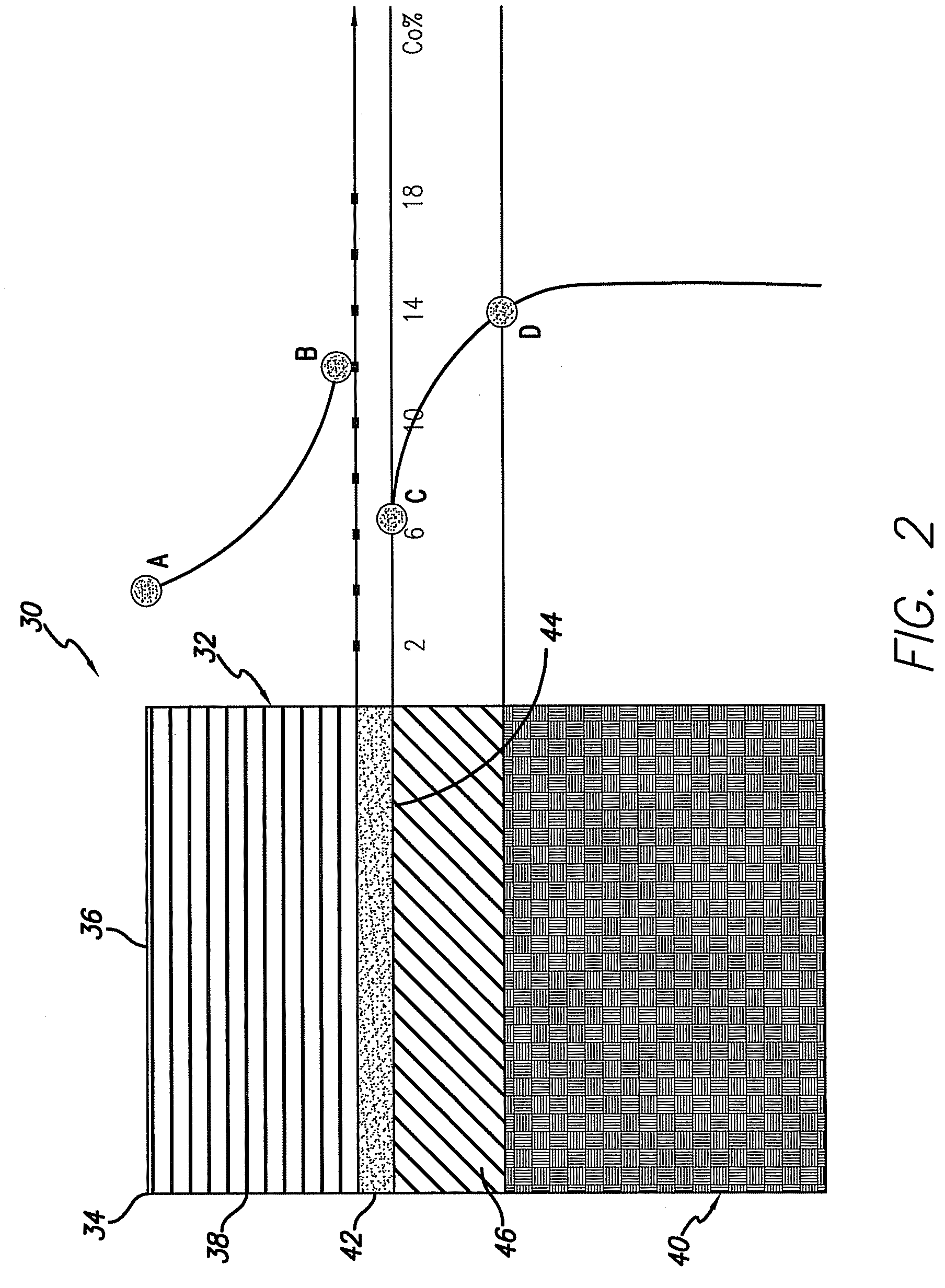

Polycrystalline diamond construction with controlled gradient metal content

ActiveUS20090152017A1Hardness resistanceResistance to stabilityDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Polycrystalline diamond constructions comprises a diamond body attached to a metallic substrate, and having an engineered metal content. The body comprises bonded together diamond crystals with a metal material disposed interstitially between the crystals. A body working surface has metal content of 2 to 8 percent that increases moving away therefrom. A transition region between the body and substrate includes metal rich and metal depleted regions having controlled metal content that provides improved thermal expansion matching / reduced residual stress. A point in the body adjacent the metal rich zone has a metal content that is at least about 3 percent by weight greater than that at a body / substrate interface. The metal depleted zone metal content increases gradually moving from the body, and has a thickness greater than 1.25 mm. Metal depleted zone metal content changes less about 4 percent per millimeter moving along the substrate.

Owner:SMITH INT INC

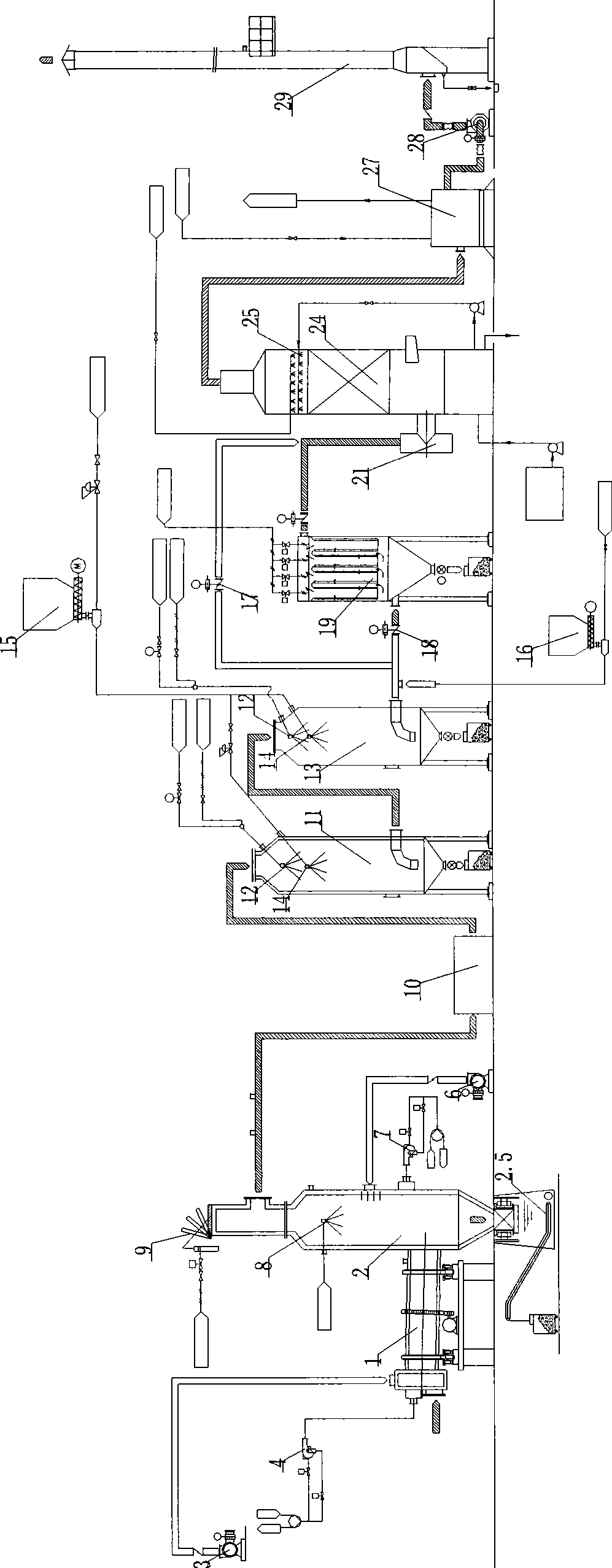

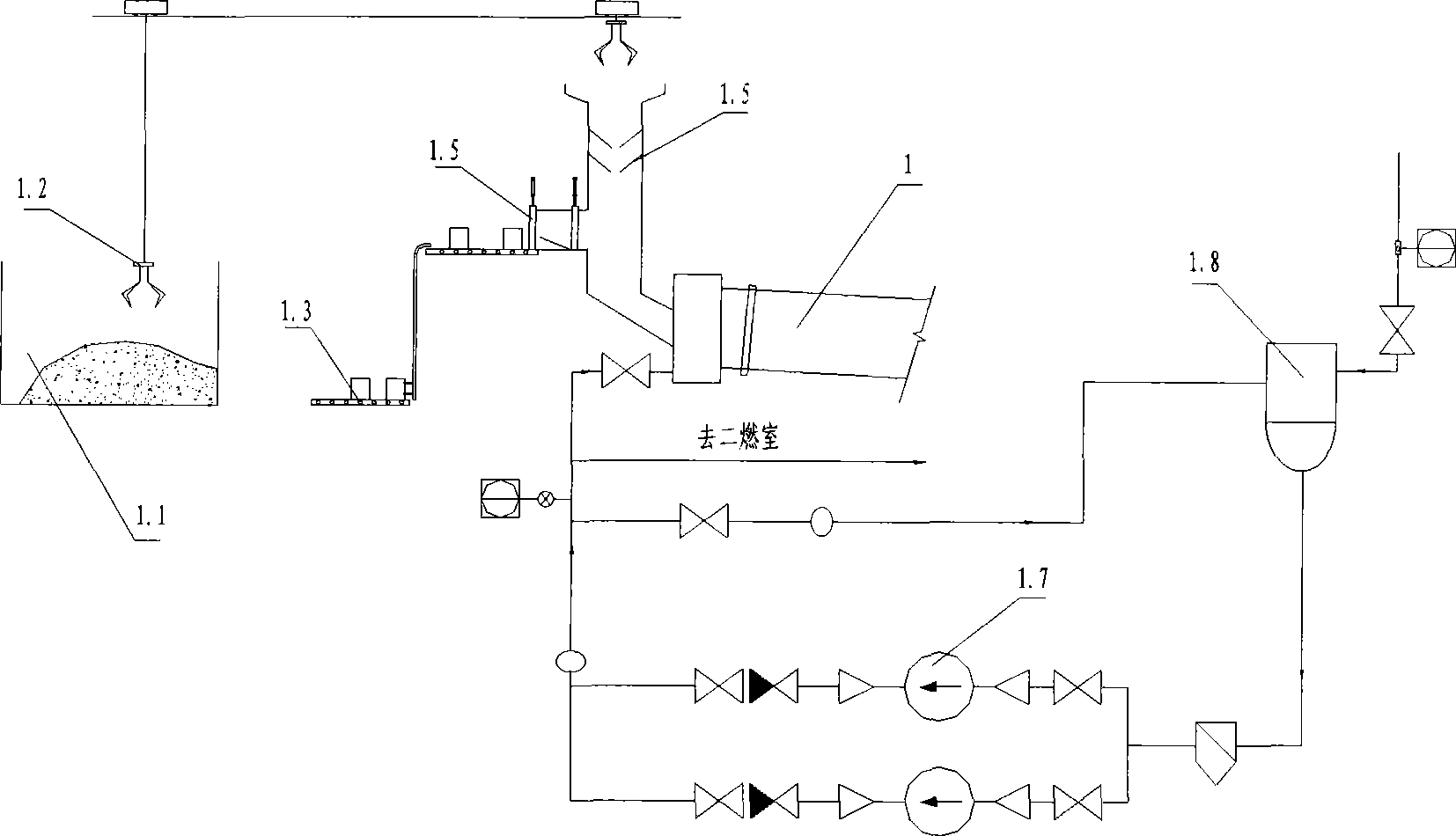

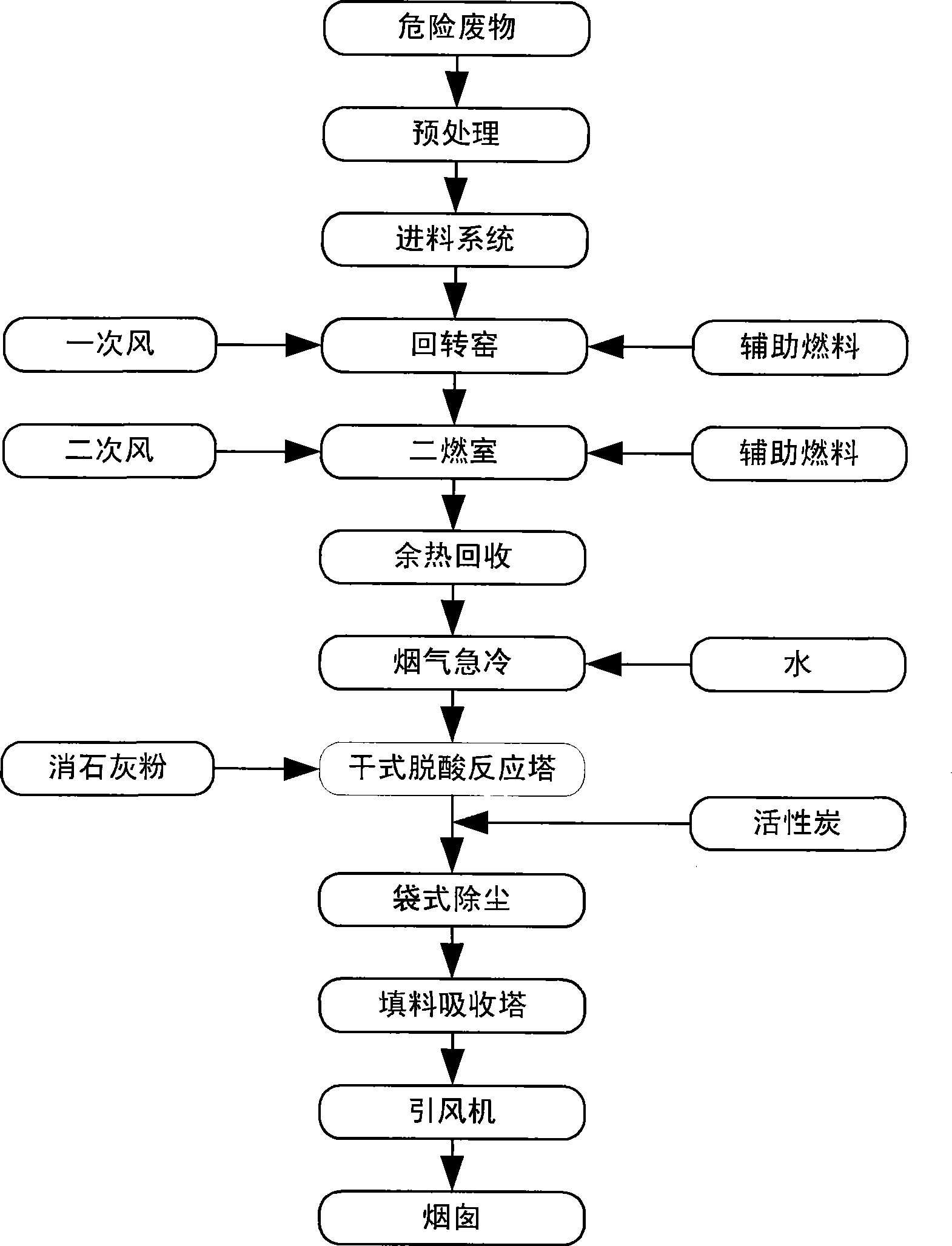

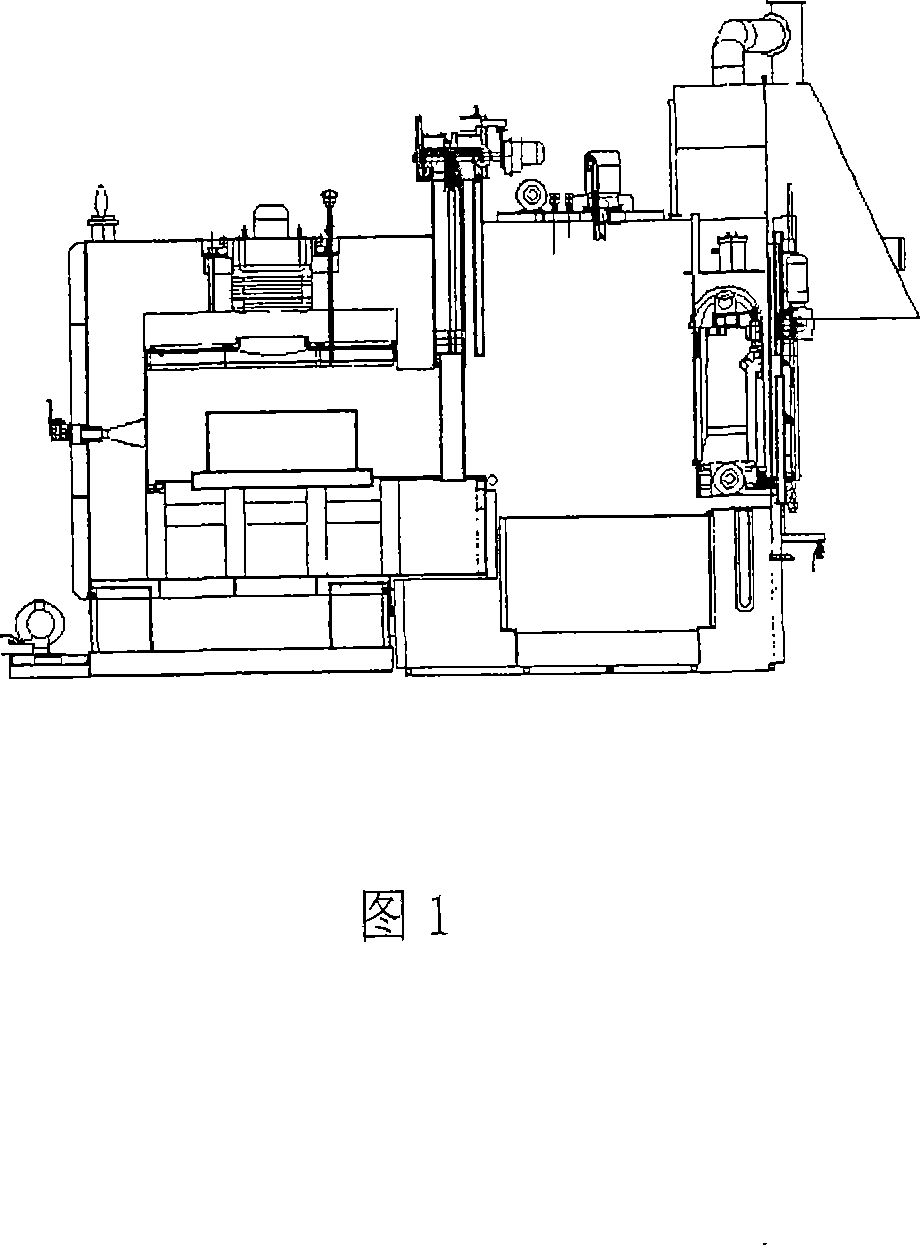

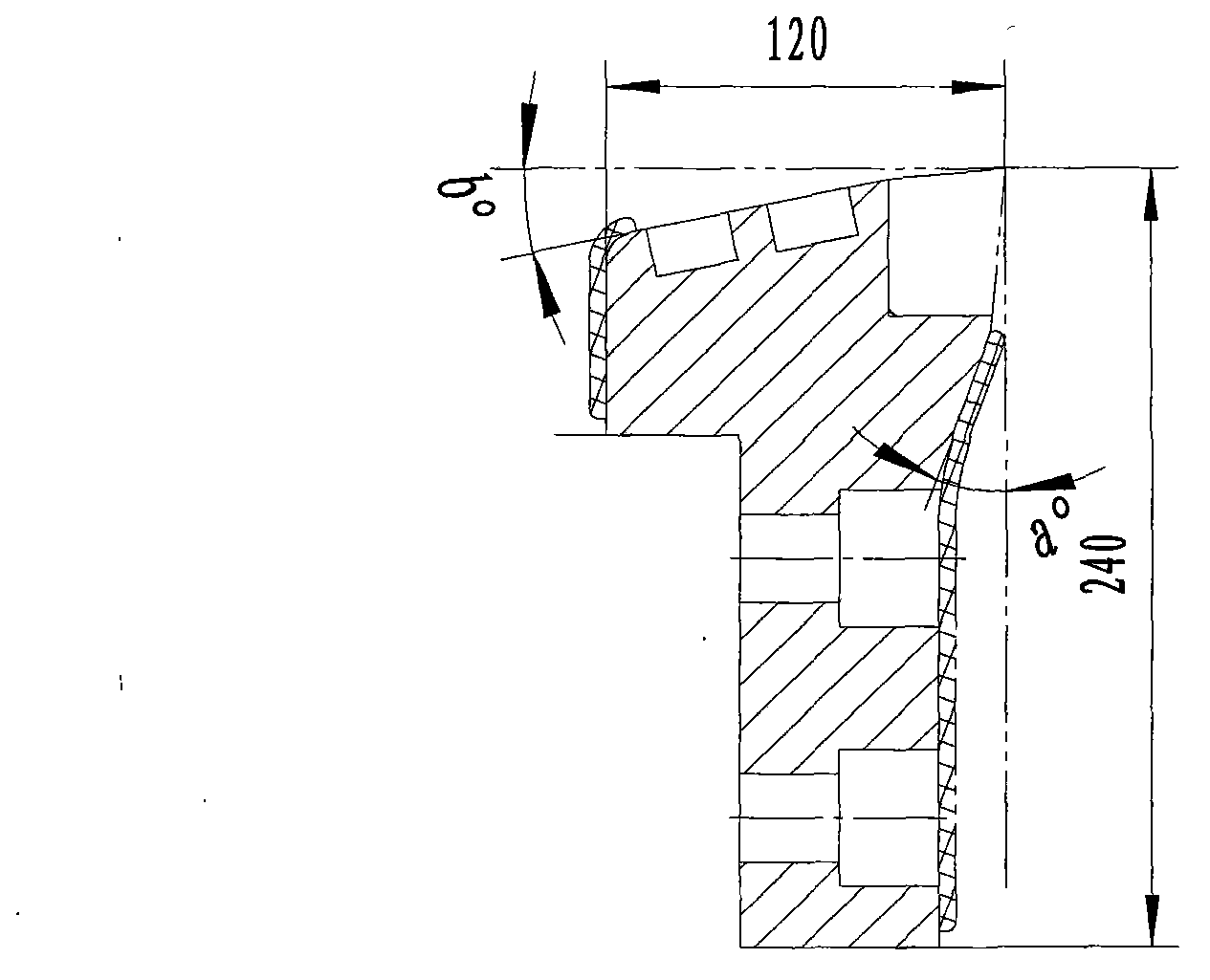

Industrial dangerous waste incineration processing system for realizing multiple physical states

A system for implementing multiple-physical state industry dangerous waste incineration and disposal relates to the garbage disposal technology of the environment protection technical field. Two seal doors are arranged at a bulk waste material feed port or a barreled waste material feed port on a rotary kiln feed hopper. The rotary kiln and a second combustion chamber frame all adopt carbon steel materials, refractory materials a working layer of the rotary kiln select chromium fused alumina abrasion-proof plastic materials, refractory materials of the second combustion chamber select abrasion-proof pouring materials. The rotary kiln is provided with a primary fan and a combustion-supporting combustor 1 which are connected with the rotary kiln, the second combustion chamber is provided with a second fan and a combustion-supporting combustor 2 which are connected with the second combustion chamber, a stuffing absorbing tower and a flue gas heater are connected in turn between the bag-type dust remover and a draught fan. Compared to the prior art, the invention can effectively destroy large quantities of toxic and noxious high molecule organic matters, can effectively avoid phenomenon of the collapse fall of the rotary kiln incineration furnace wall and the burning ring of the steel body, and can avoid high-temperature corrosion and low-temperature corrosion, the invention has advantages of good operation economical performance, fluent slag system and low pollution discharge index.

Owner:TONGFANG ENVIRONMENT

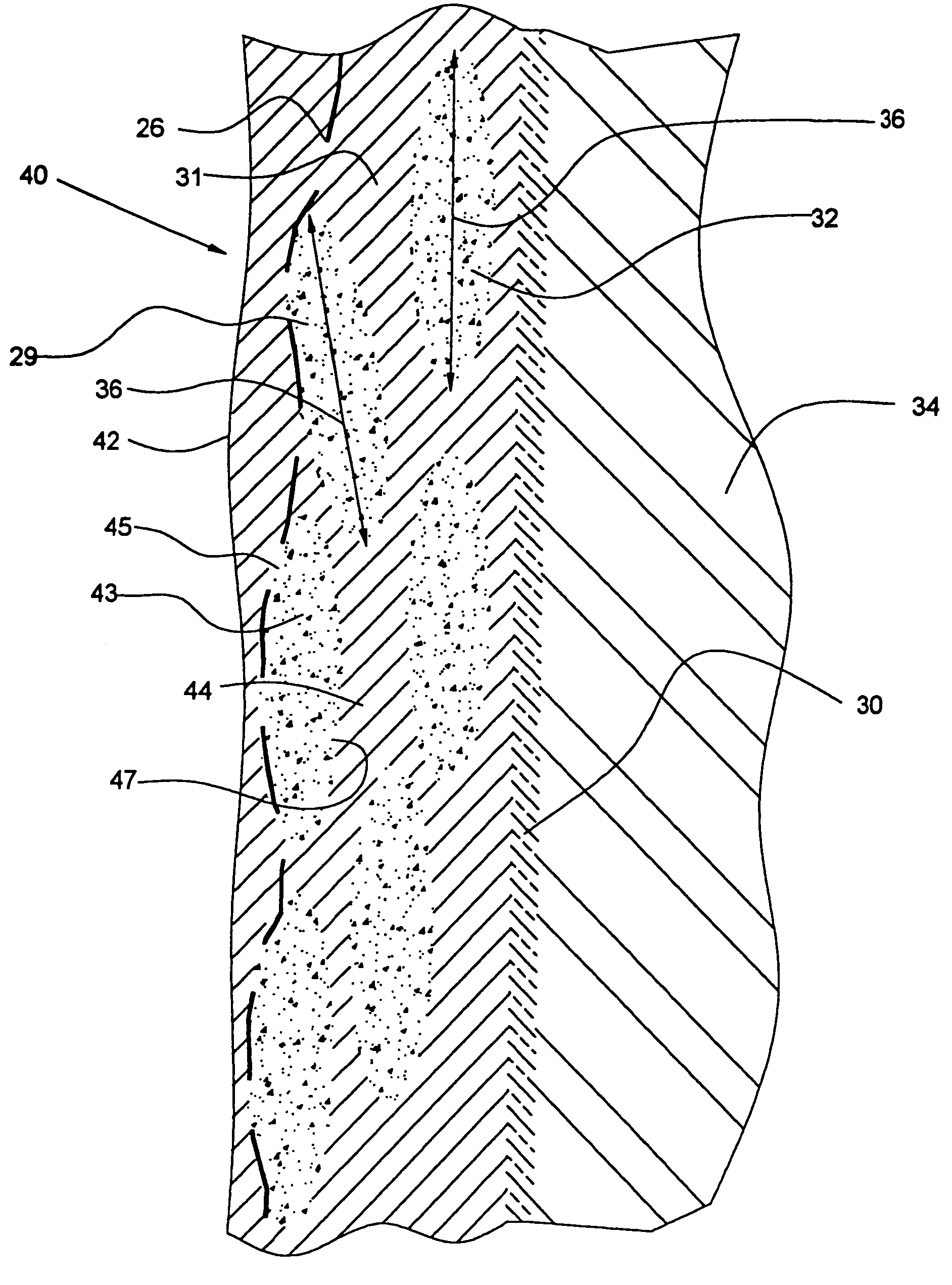

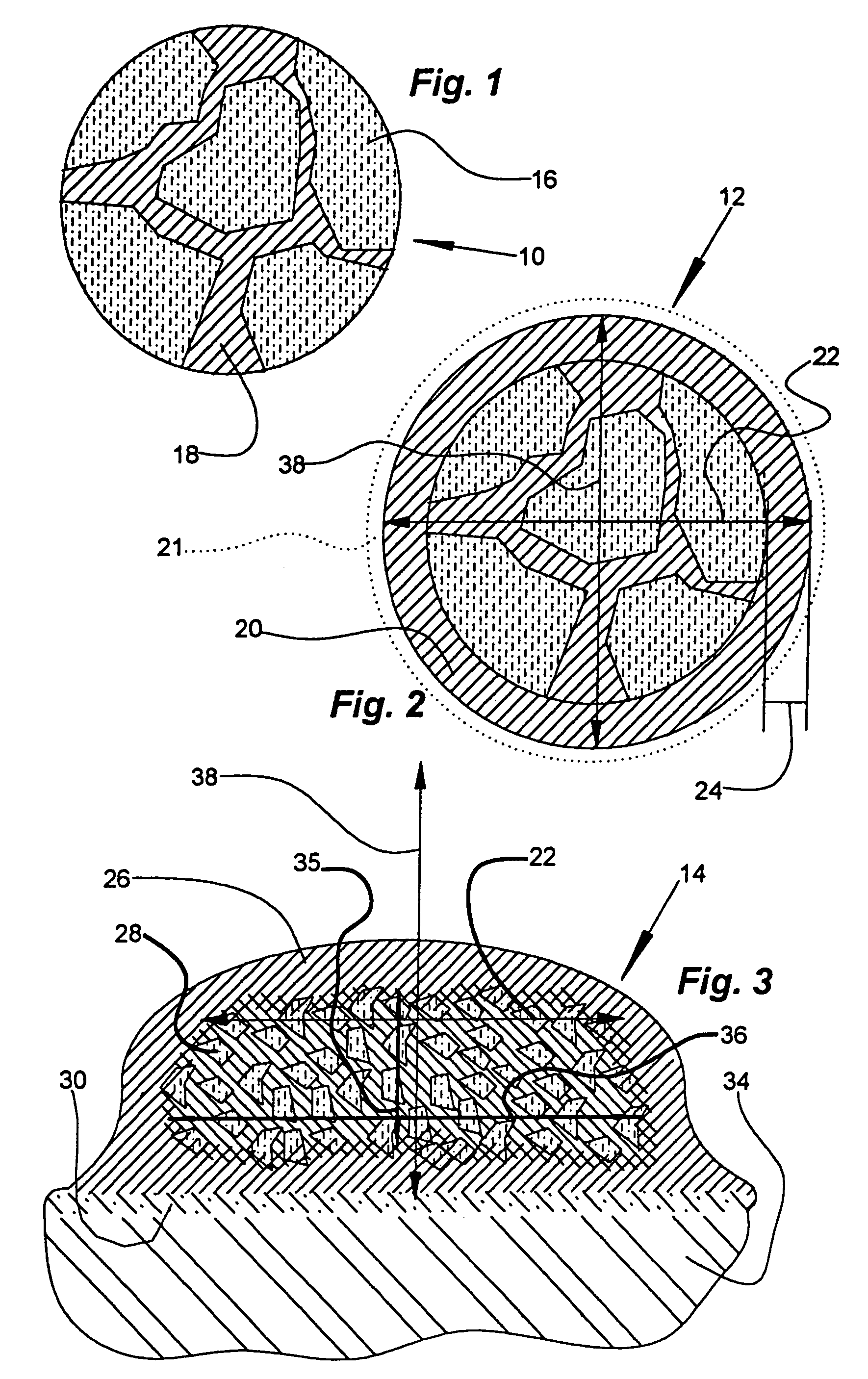

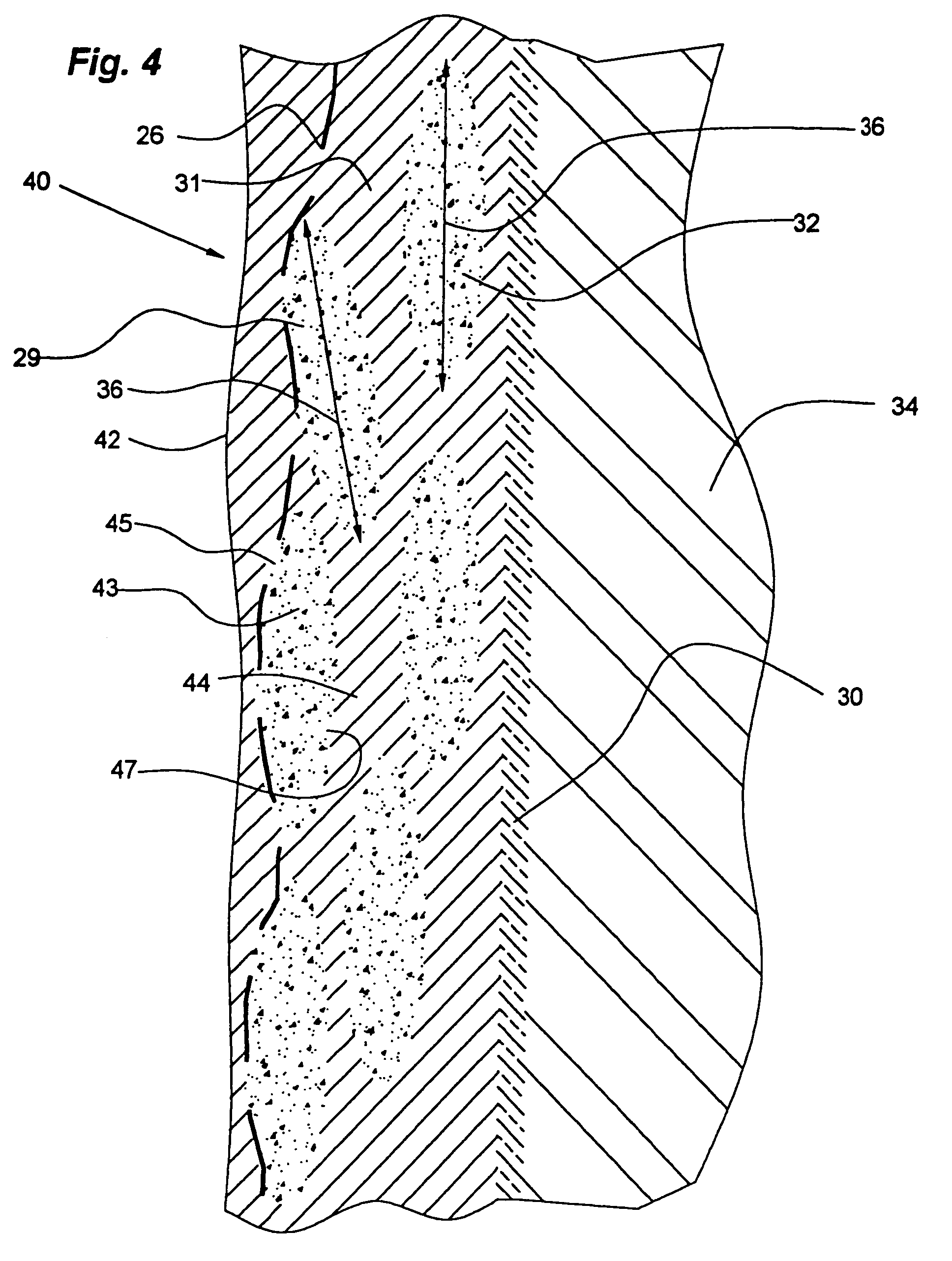

Heterogeneous composite bodies with isolated lenticular shaped cermet regions

ActiveUS7635515B1Increasing the thicknessIncrease spacingMolten spray coatingCeramic layered productsThermal sprayingSolid substrate

A heterogeneous body having ceramic rich cermet regions in a more ductile metal matrix. The heterogeneous bodies are formed by thermal spray operations on metal substrates. The thermal spray operations apply heat to a cermet powder and project it onto a solid substrate. The cermet powder is composed of complex composite particles in which a complex ceramic-metallic core particle is coated with a matrix precursor. The cermet regions are generally comprised of complex ceramic-metallic composites that correspond approximately to the core particles. The cermet regions are approximately lenticular shaped with an average width that is at least approximately twice the average thickness. The cermet regions are imbedded within the matrix phase and generally isolated from one another. They have obverse and reverse surfaces. The matrix phase is formed from the matrix precursor coating on the core particles. The amount of heat applied during the formation of the heterogeneous body is controlled so that the core particles soften but do not become so fluid that they disperse throughout the matrix phase. The force of the impact on the surface of the substrate tends to flatten them. The flattened cermet regions tend to be approximately aligned with one another in the body.

Owner:POWDERMET

Rubber composition and pneumatic tire

ActiveCN102348748AWear resistancePlay a destructive strengthSpecial tyresRolling resistance optimizationBreaking strengthRolling resistance

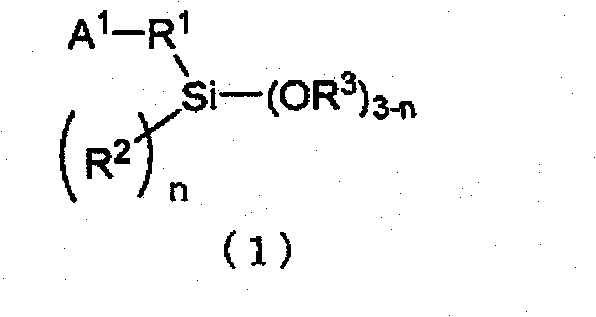

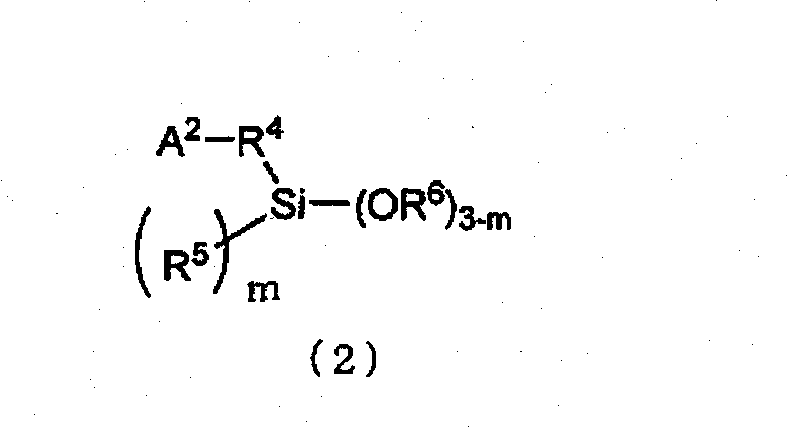

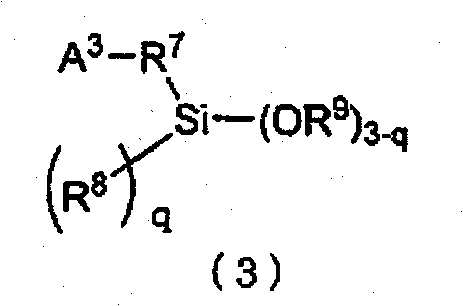

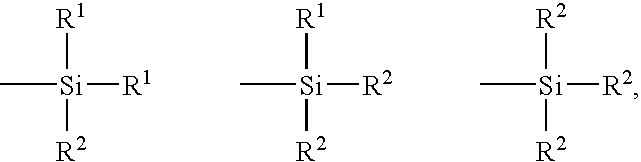

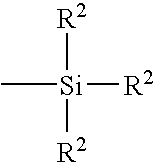

A rubber composition from which a vulcanized rubber suitable for producing, for example, a pneumatic tire having excellent wear resistance, breaking strength, rolling resistance, wet skid resistance, etc. can be prepared. The rubber composition comprises a rubber ingredient (A) comprising a diene rubber comprising at least 20 mass% modified styrene-butadiene copolymer (a1) and at least 5 mass% modified conjugated diene polymer (a2) and a filler (B), wherein the modified conjugated diene polymer (a2) is a polymer obtained by modifying, with an alkoxysilane compound, active ends of a conjugateddiene polymer having a cis-1,4 bond content of 80% or higher, and the filler (B) comprises 2-100 parts by mass of carbon black (b1) and / or 30-100 parts by mass of silica (b2) per 100 parts by mass of the rubber ingredient (A).

Owner:株式会社引能仕材料

Non-random styrene-butadiene rubber

InactiveUS7064171B1Exceptionally beneficial performance characteristicBalanced combinationSpecial tyresTyre tread bands/patternsPolymer scienceGlass transition

The present invention reveals a tire having a tread that is comprised of (1) 30 phr to 80 phr of a non-random styrene-butadiene rubber comprised of polymer chains that are derived from styrene and 1,3-butadiene, wherein from about 10 weight percent to about 50 weight percent of the repeat units in the styrene-butadiene rubber are derived from styrene, wherein from about 60 weight percent to about 90 weight percent of the repeat units in the styrene-butadiene rubber are derived from 1,3-butadiene, wherein from about 30 weight percent to about 50 weight percent of the styrene repeat units are in sequences containing 5 to 20 styrene repeat units, wherein the bound styrene content found in the first half of the polymer chains differs from the bound styrene content found in the second half of the polymer chains by at least 5 weight percent, wherein the styrene-butadiene rubber has a 1,2-vinyl content which is within the range of about 8 percent to about 20 percent, wherein the styrene-butadiene rubber has a number average molecular weight which is within the range of 200,000 to 475,000, and wherein the styrene-butadiene rubber has a glass transition temperature which is within the range of −82° C. to −50° C. and (2) 20 phr to 70 phr of polybutadiene. The tire tread formulation can optionally contain silica and lignin.

Owner:THE GOODYEAR TIRE & RUBBER CO

Production method for sintered machine components

InactiveUS20090269235A1Improve corrosion resistanceImprove heat resistanceMachines/enginesEngine componentsAlloyGraphite

A production method for sintered machine components, includes preparing an Fe alloy powder A, an Fe alloy powder B, an Fe—P powder, and a graphite powder. The Fe alloy powder A consists of, by mass %, 25 to 45% of Cr, 1.0 to 3.0% of Mo, 1.0 to 3.0% of Si, 0.5 to 1.5% of C, and the balance of Fe and inevitable impurities. The Fe alloy powder B consists of, by mass 15 to 35% of Cr, 15 to 30% of Ni, and the balance of Fe and inevitable impurities, and the Fe—P powder consists of 10 to 30 mass % of P and the balance of Fe and inevitable impurities. The production method further includes mixing 40 to 60 mass % of the Fe alloy powder B, 1.0 to 5.0 mass % of the Fe—P powder, and 0.5 to 3.5 mass % of the graphite powder with the Fe alloy powder A into a mixed powder. The production method further includes compacting the mixed powder into a green compact and sintering the green compact.

Owner:HITACHI POWDERED METALS COMPANY

Technique method of treatment for modifying surface of ferrous material

This invention relates to a method for surface modification of steel material or steel component by combined treatment of gaseous nitrocarburization and post oxidation. The method comprises: (1) performing vacuum washing of the steel material, and pre-oxidizing at 400 deg.C; (2) placing the steel material in a box-type nitrocarburization heat treatment furnace, introducing mixed gases of NH3, N2 and CO2, reacting at 550-570 deg.C, and cooling with oil; (3) polishing, placing in an oxidation furnace, performing post oxidation with high-temperature steam for 1 h, and polishing to obtain steel material with high wear resistance and high corrosion resistance.

Owner:上海上大热处理有限公司

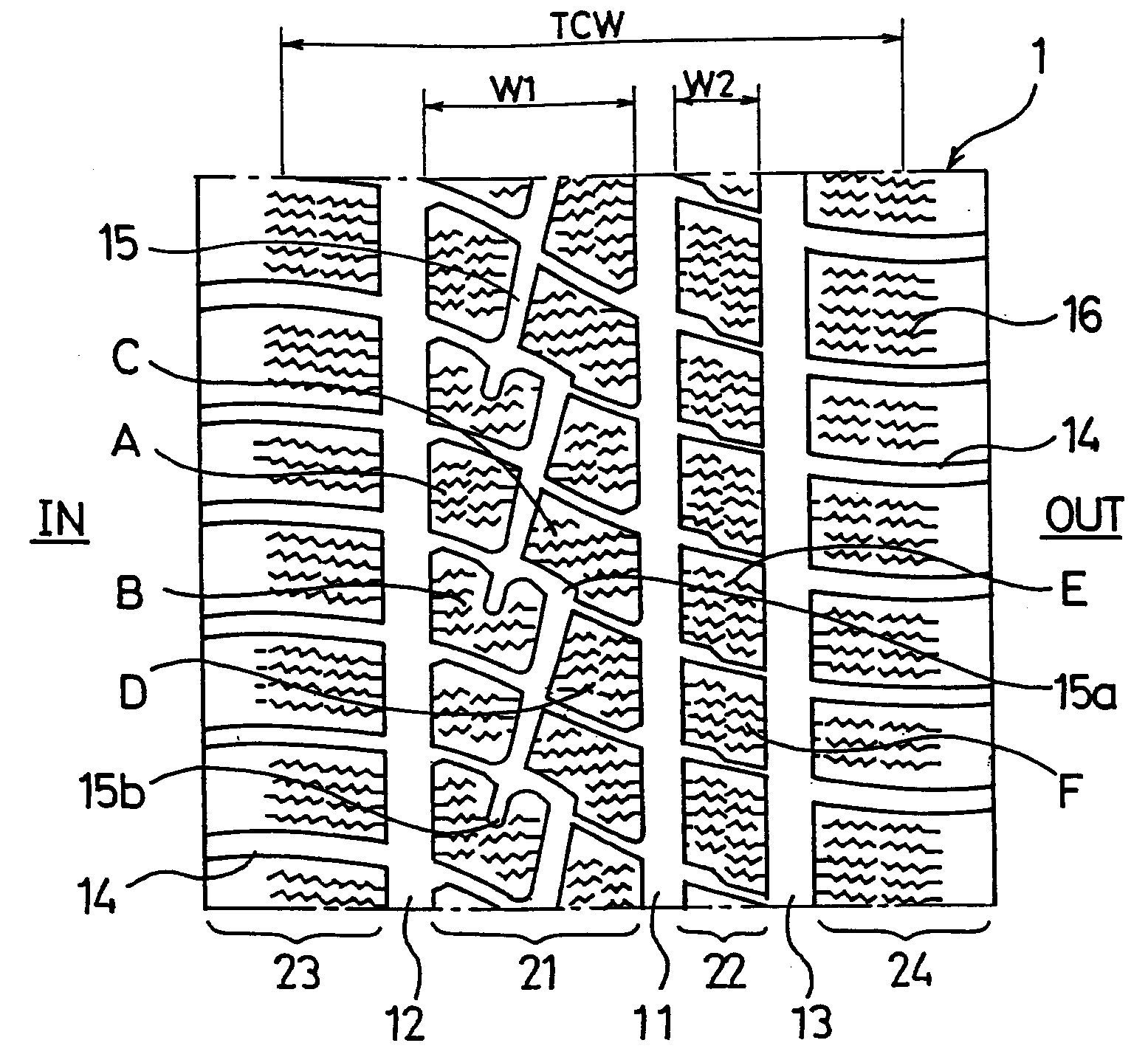

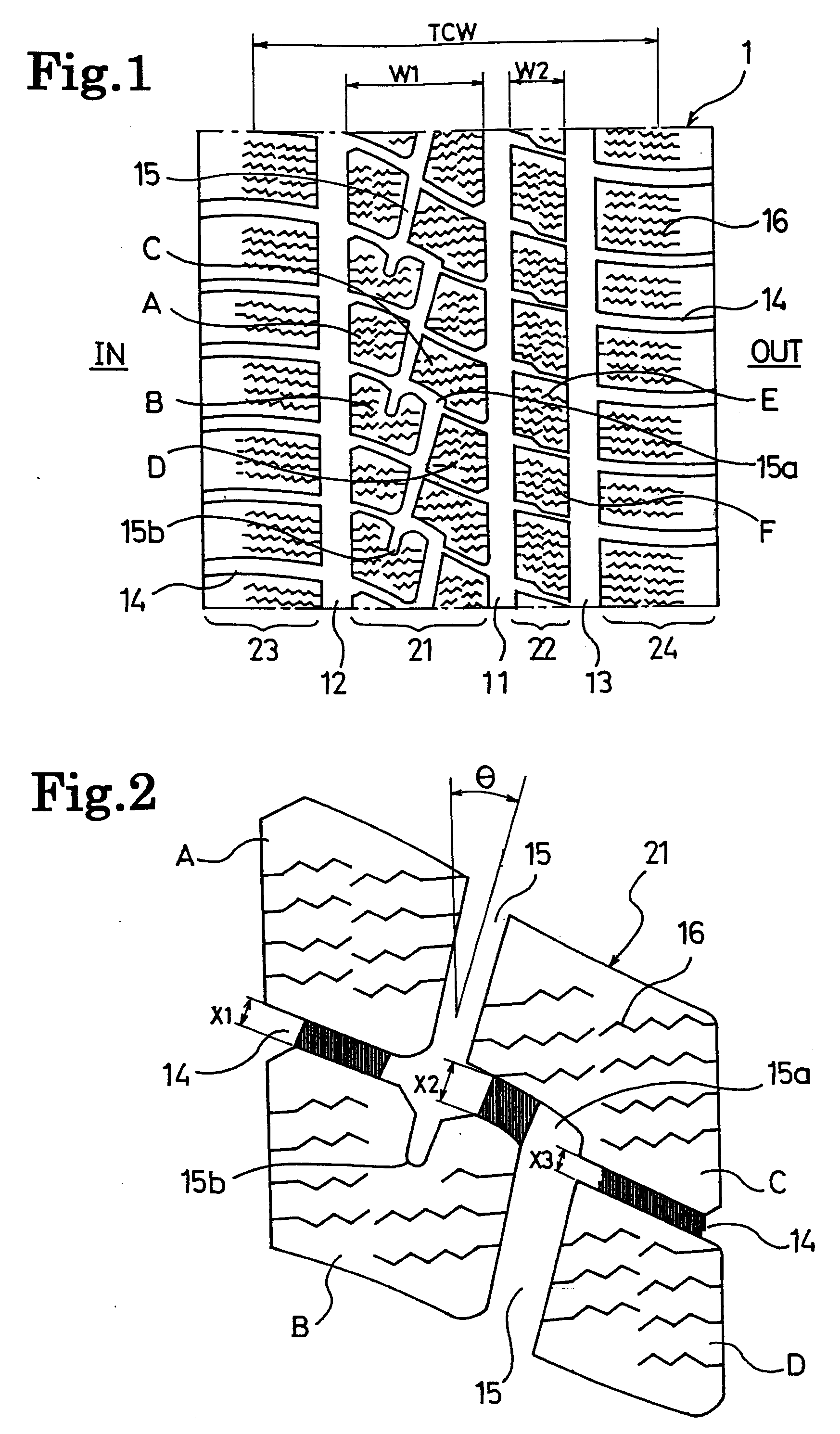

Pneumatic tire

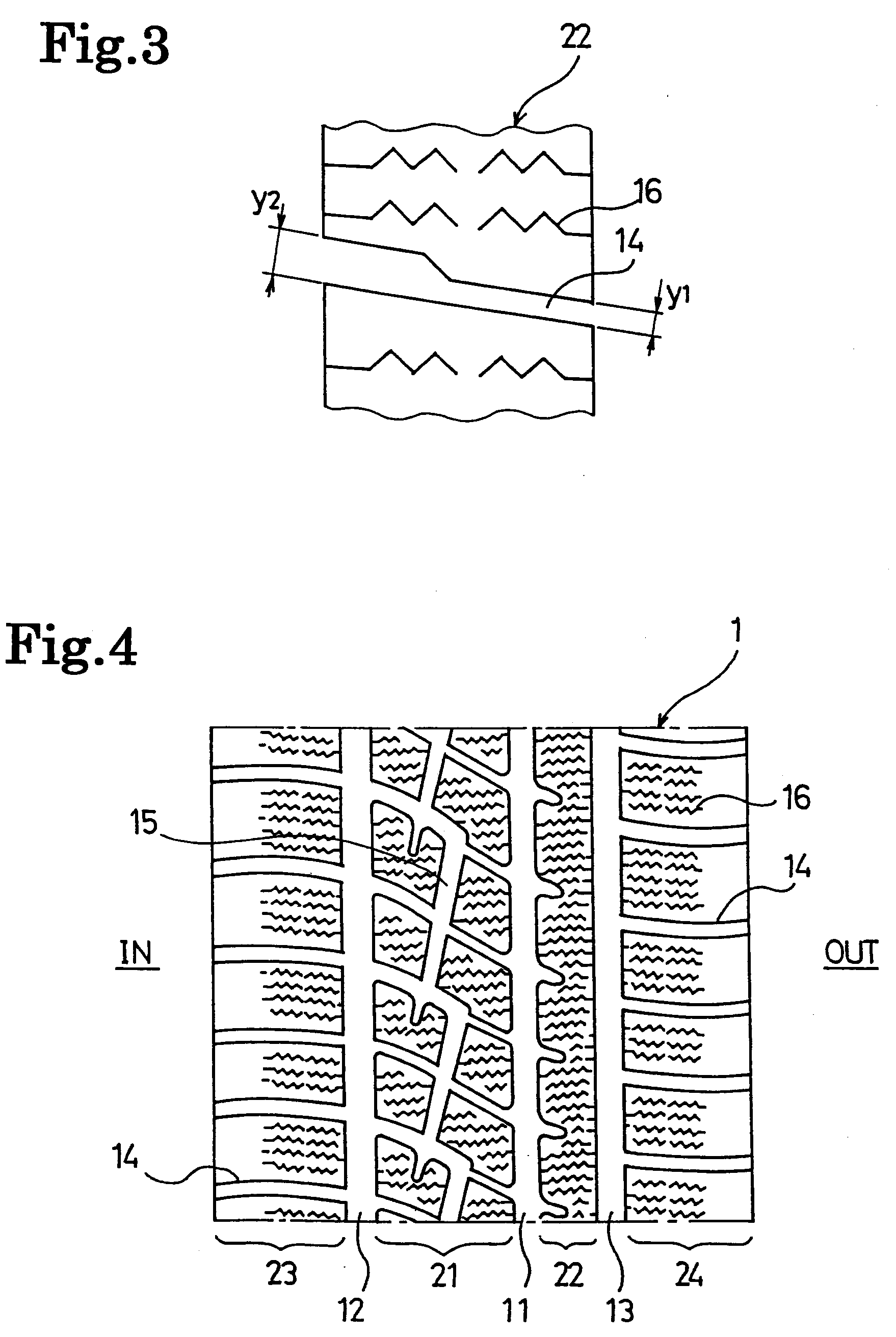

ActiveUS20090188595A1Effect be significantImprove stabilityTyre tread bands/patternsNon-skid devicesAutomotive engineeringShoulder region

Provided is a pneumatic tire having improved driving stability and wear resistance on dry road surfaces as well as an improved running performance on snow. The present invention provides a pneumatic tire designed to be mounted on a vehicle so that a designated side of the tire should face to the outside of the vehicle. The pneumatic tire includes a tread portion provided with: a first main groove extending in a tire circumferential direction; a second main groove extending in the tire circumferential direction in a shoulder region closer to the center of the vehicle than the first main groove; a third main groove extending in the tire circumferential direction in a shoulder region farther from the center of the vehicle than the first main groove; and a plurality of lug grooves each extending from one shoulder side to the other shoulder side. Moreover, in the pneumatic tire, a width of a first land section defined between the first and second main grooves is set greater than a width of a second land section defined between the first and third main grooves, a plurality of inclined grooves are provided in the first land section, each inclined groove communicating with at least three of the lug grooves while being inclined to the tire circumferential direction, and one end of each inclined groove is opened to one of the lug grooves while the other end thereof is terminated within a block.

Owner:YOKOHAMA RUBBER CO LTD

Vehicle composite friction material containing potassium titanate whisker and preparation method thereof

The present invention discloses vehicle composite friction material with potassium titanate crystal whisker and the preparation method. In terms of weight percentage, the composite friction material includes the following components: 10 to 50 percent of cashew oil modified phenol formaldehyde resin, 3 to 8 percent of NBR, 10 to 20 percent of crystal potassium titanate, 3 to 8 percent of squamose potassium titanate, 3 to 8 percent of vermiculite, 1 to 3 percent of aramid fiber, 3 to 8 percent of meerschaum fiber, etc. In preparation, the composite friction material is made into prepare material according to the proportion, the prepare material is evenly mixed and poured into a die for pressing and molding, and then the pressed finished product is taken out; the pressed finished product is put into a constant-temperature box and processed for 8 to 24 hours under the temperature of 145 to 165 DEG C, thus finally obtaining the vehicle composite friction material with potassium titanate crystal whisker. The prepared material has stable chemical performance and no toxin and harm; the potassium titanate powder produced by the friction of crystal whisker in braking process will rapidly settle down on the ground, thus preventing the body hurt and air pollution.

Owner:SOUTH CHINA UNIV OF TECH

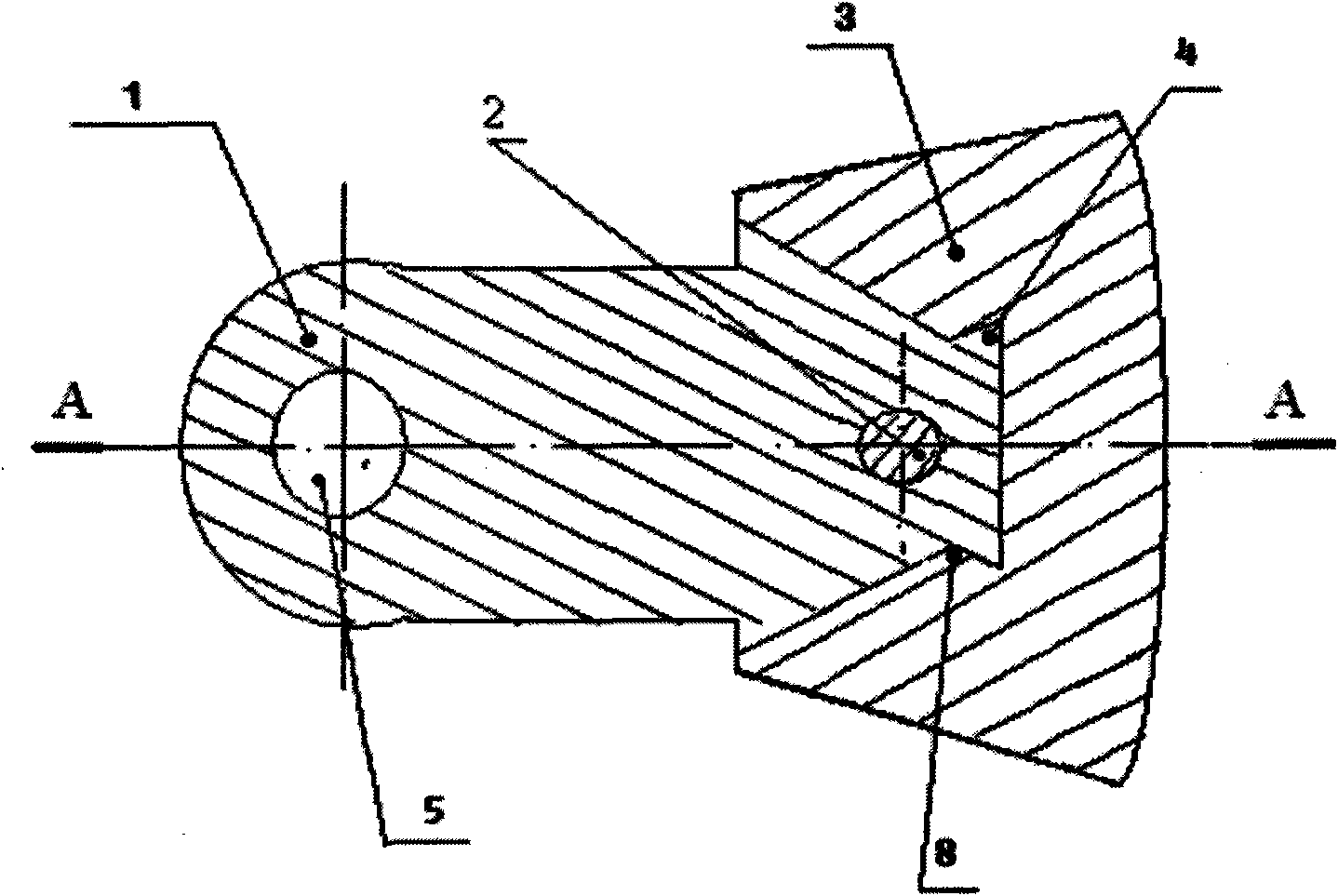

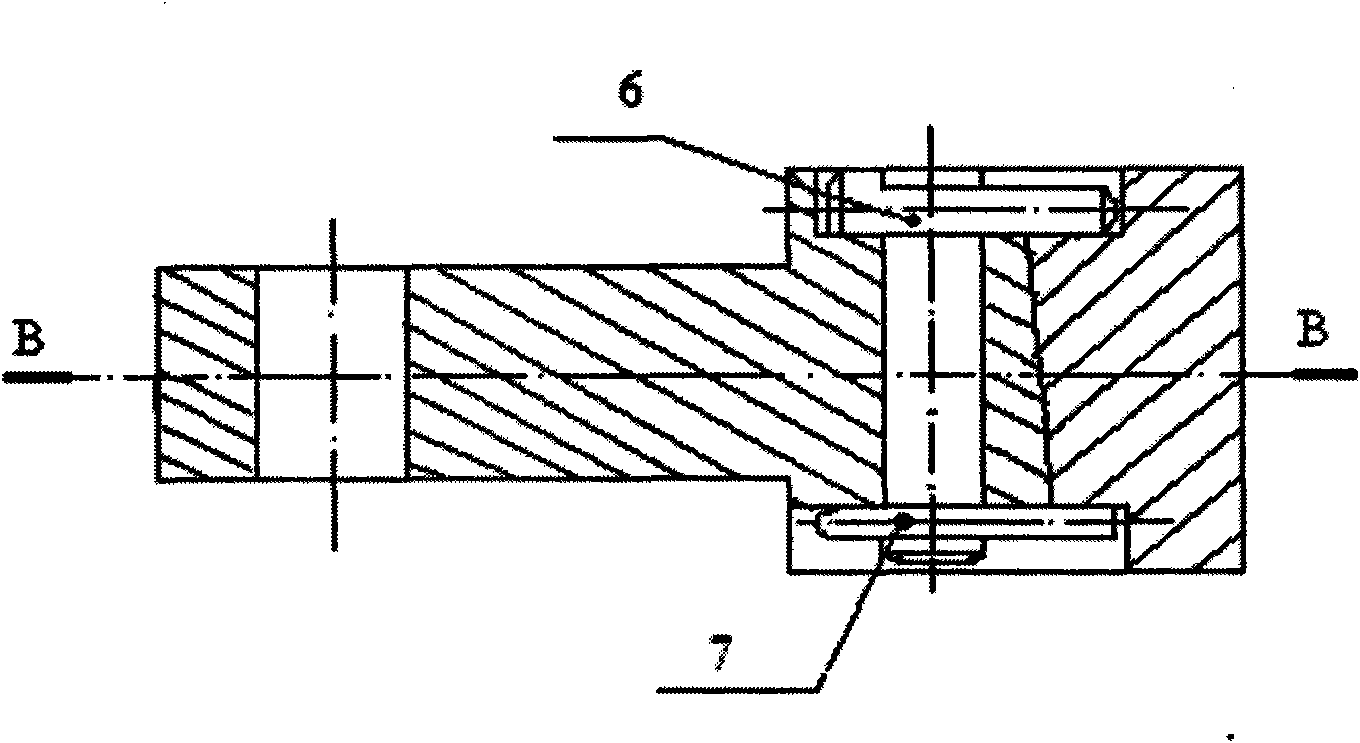

Combined type mechanically crushing machine hammer and manufacturing method thereof

The invention discloses a combined type mechanically crushing machine hammer and a manufacturing method thereof. The hammer comprises a head part (3) and a handle part (1) which are mechanically combined for forming the hammer, the head part (3) is formed by high-chromium cast iron lost foam casting, the handle part (1) is formed through high-manganese steel lost foam casting, an installing hole (5) connected with a circular disc of a crushing machine is arranged above the handle part (1), a rabbet (4) is arranged under the handle part (1), the head part (3) is provided with a mortice (8) matched with the rabbet (4) of the handle part, and the handle part (1) and the head part (3) are connected through the mutually matched rabbet (4) and the mortice (8) for forming the integral hammer. The hammer of the invention has the advantages of simple manufacture, wear resistance, good toughness, fast replacement of the head part, repeated use of the handle part, production efficiency improvement and metal material saving. The invention is particularly suitable for manufacturing reversible hammer type crushing machine hammers.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

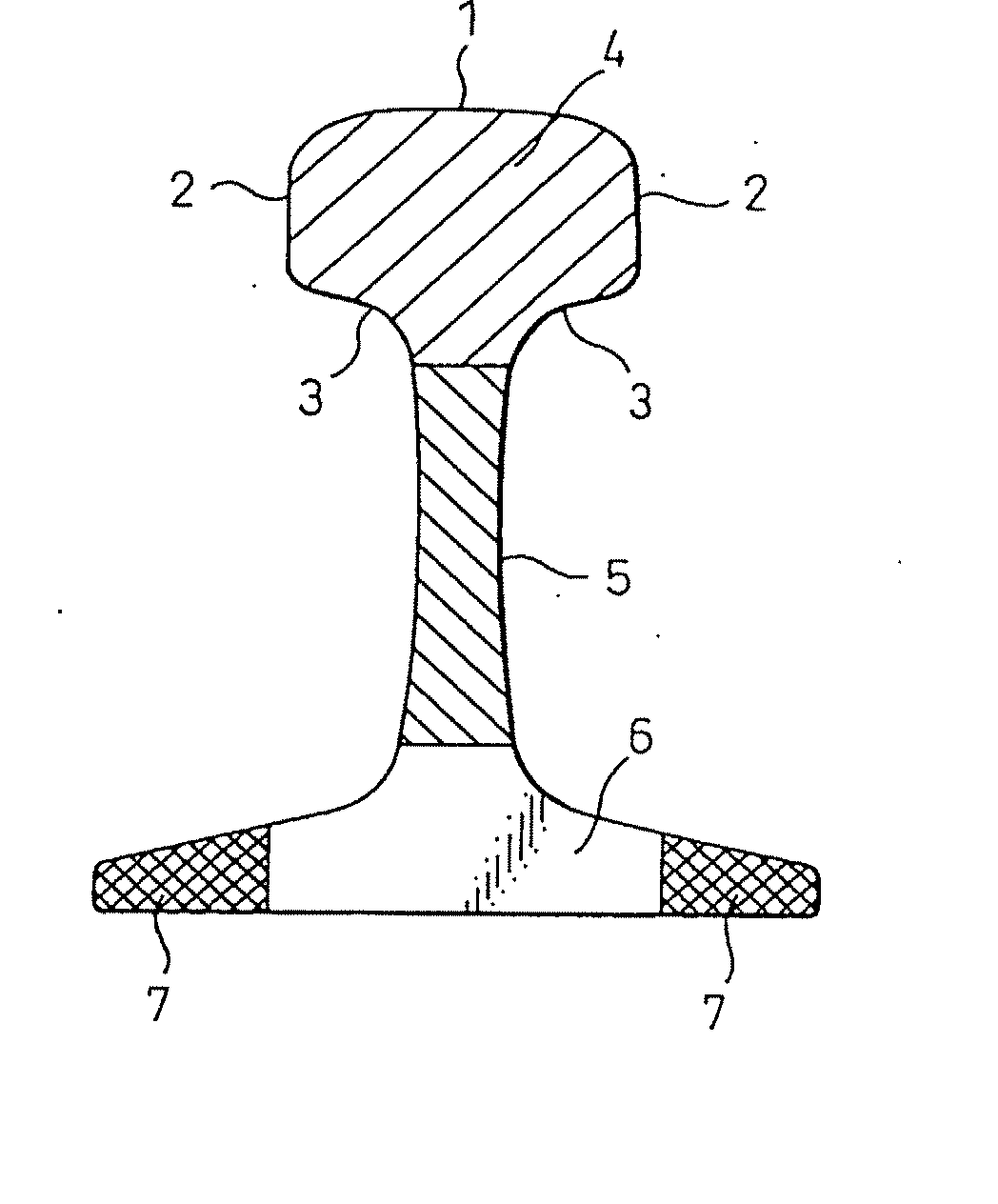

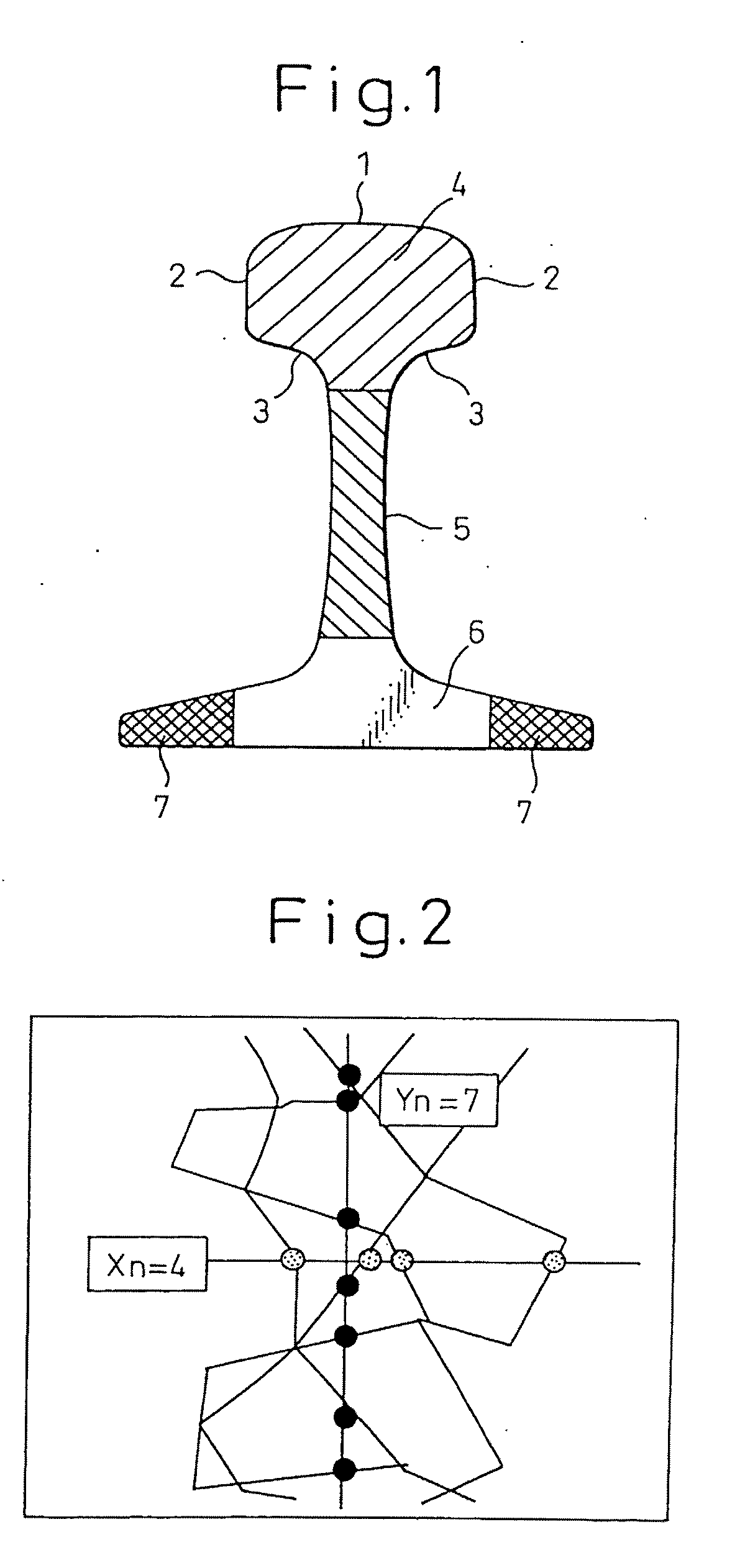

Pearlitic steel rail excellent in wear resistance and ductility and method for producing same

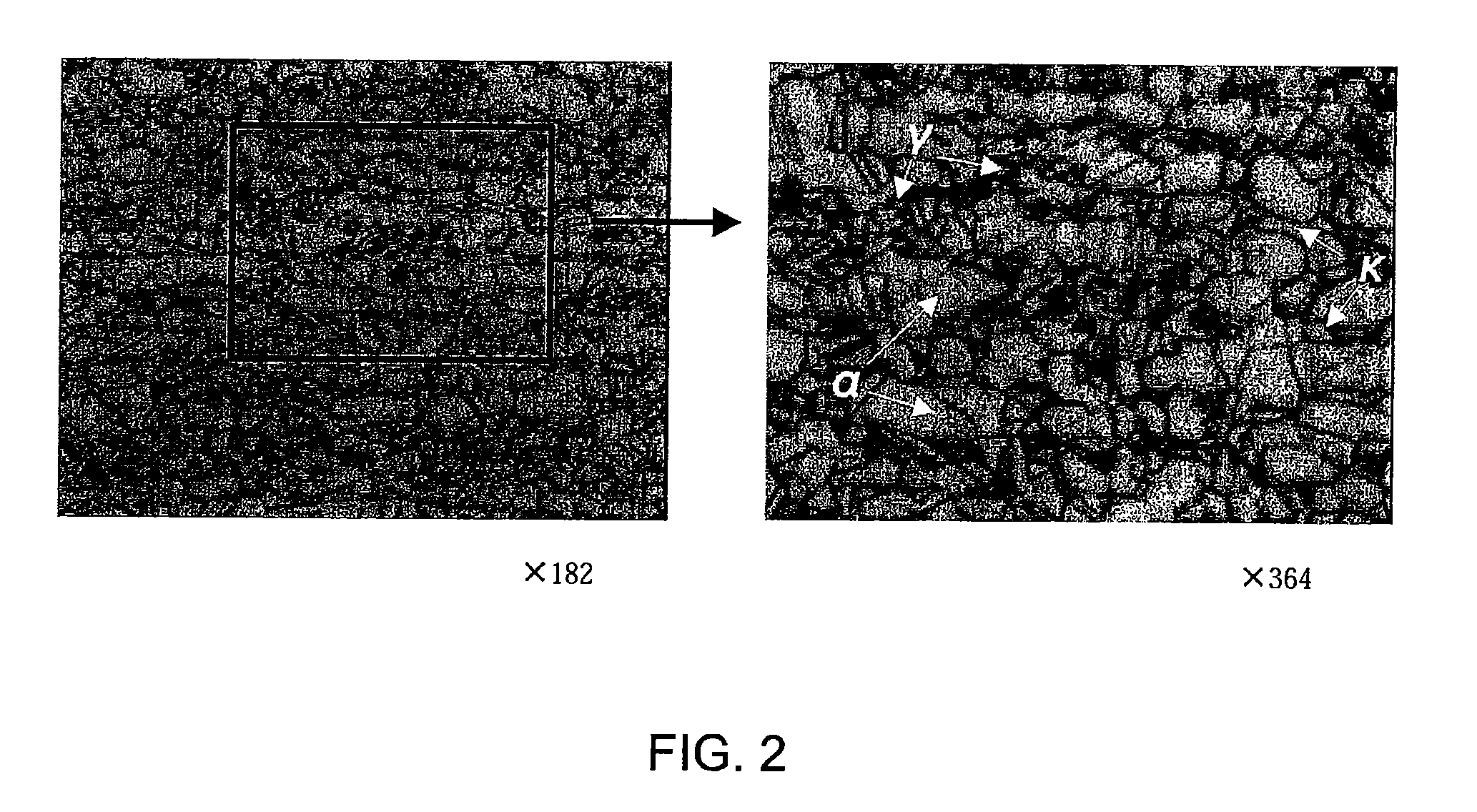

InactiveUS20080011393A1High carbon contentInhibition formationFurnace typesHeat treatment furnacesGranularityPearlite

The present invention is: a pearlitic steel rail excellent in wear resistance and ductility, characterized in that, in a steel rail having pearlite structure containing, in mass, 0.65 to 1.40% C, the number of the pearlite blocks having grain sizes in the range from 1 to 15 μm is 200 or more per 0.2 mm2 of an observation field at least in a part of the region down to a depth of 10 mm from the surface of the corners and top of the head portion; and a method for producing a pearlitic steel rail excellent in wear resistance and ductility, characterized by, in the hot rolling of said steel rail, applying finish rolling so that the temperature of the rail surface may be in the range from 850° C. to 1,000° C. and the sectional area reduction ratio at the final pass may be 6% or more, and then applying accelerated cooling to the head portion of said rail at a cooling rate in the range from 1 to 30° C. / sec. from the austenite temperature range to at least 550° C.

Owner:NIPPON STEEL CORP

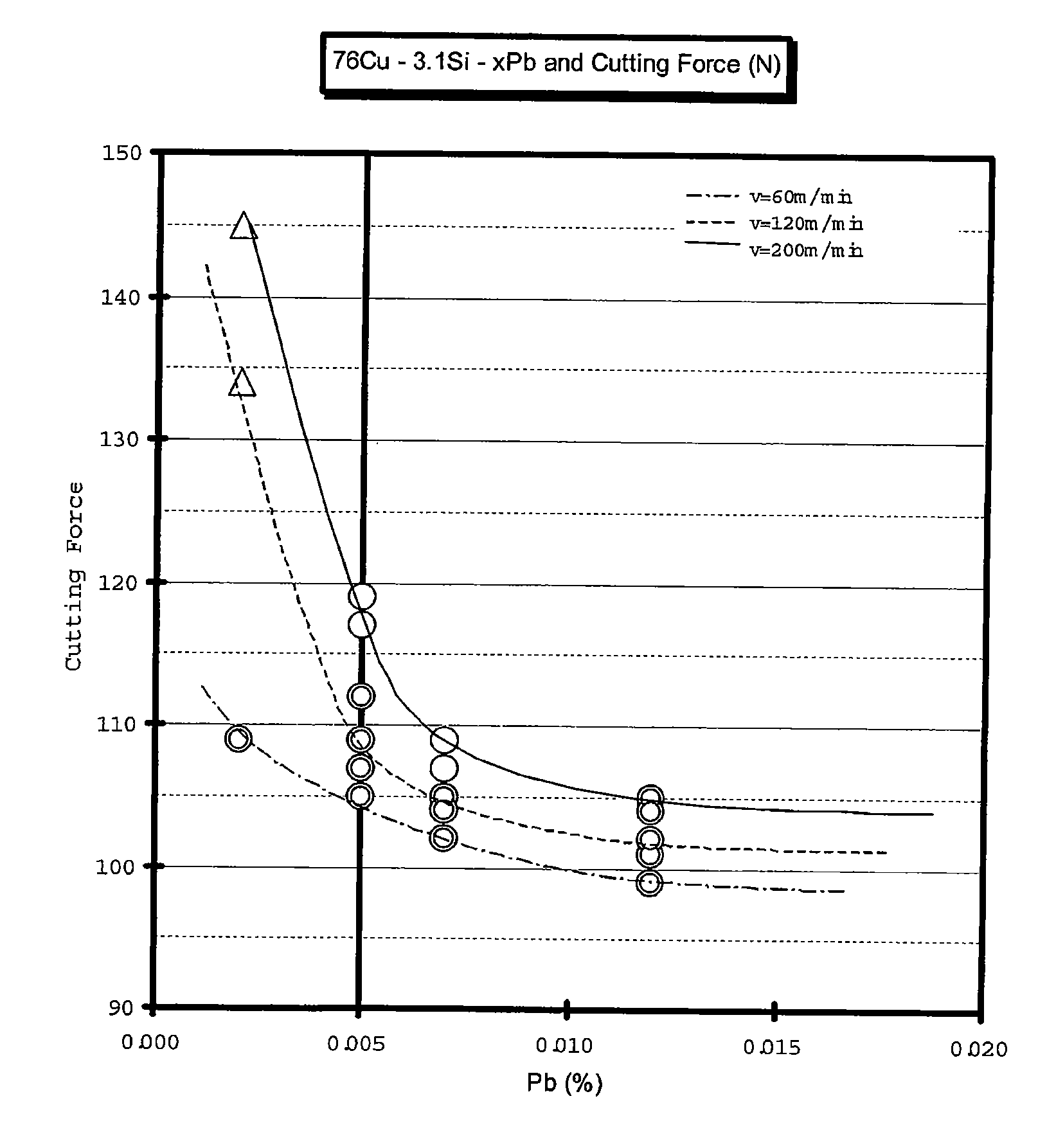

Copper/zinc alloys having low levels of lead and good machinability

The free-cutting copper alloy according to the present invention contains a greatly reduced amount of lead in comparison with conventional free-cutting copper alloys, but provides industrially satisfactory machinability. The free-cutting alloys comprise 69 to 79 percent, by weight, of copper, 2.0 to 4.0 percent, by weight, of silicon, 0.02 to 0.4, by weight, of lead, and the remaining percent, by weight, of zinc.

Owner:MITSUBISHI SHINDOH CO LTD

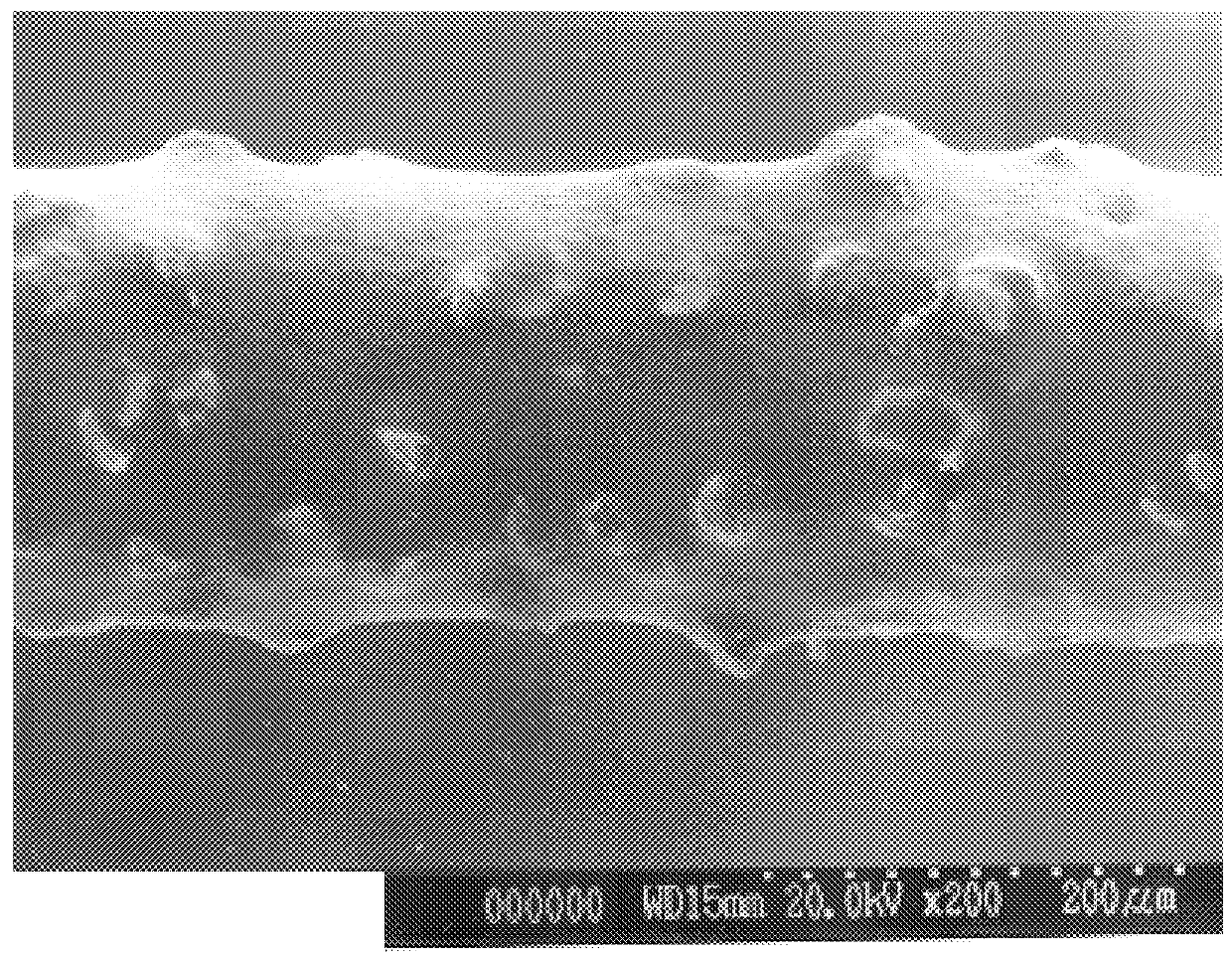

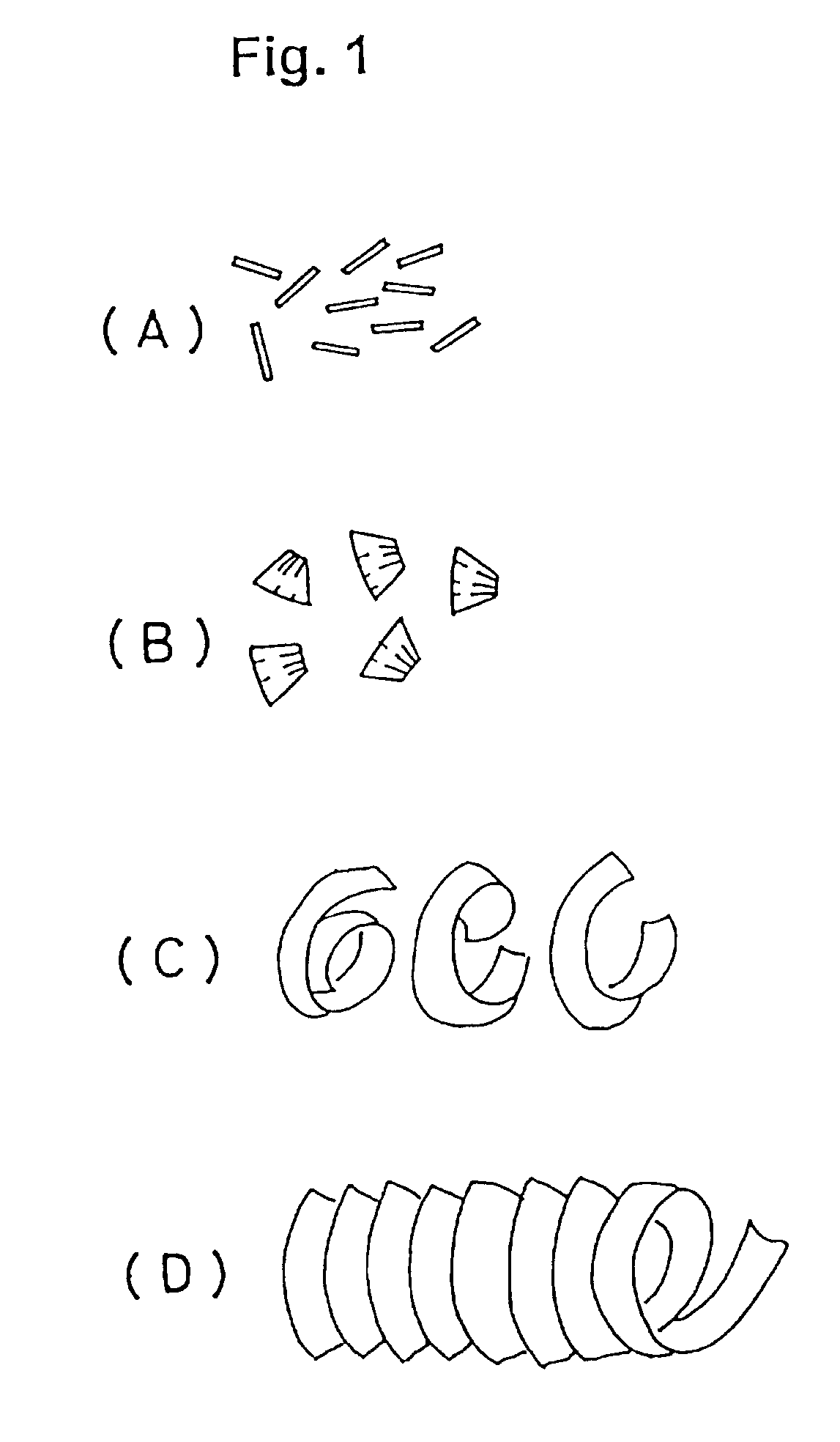

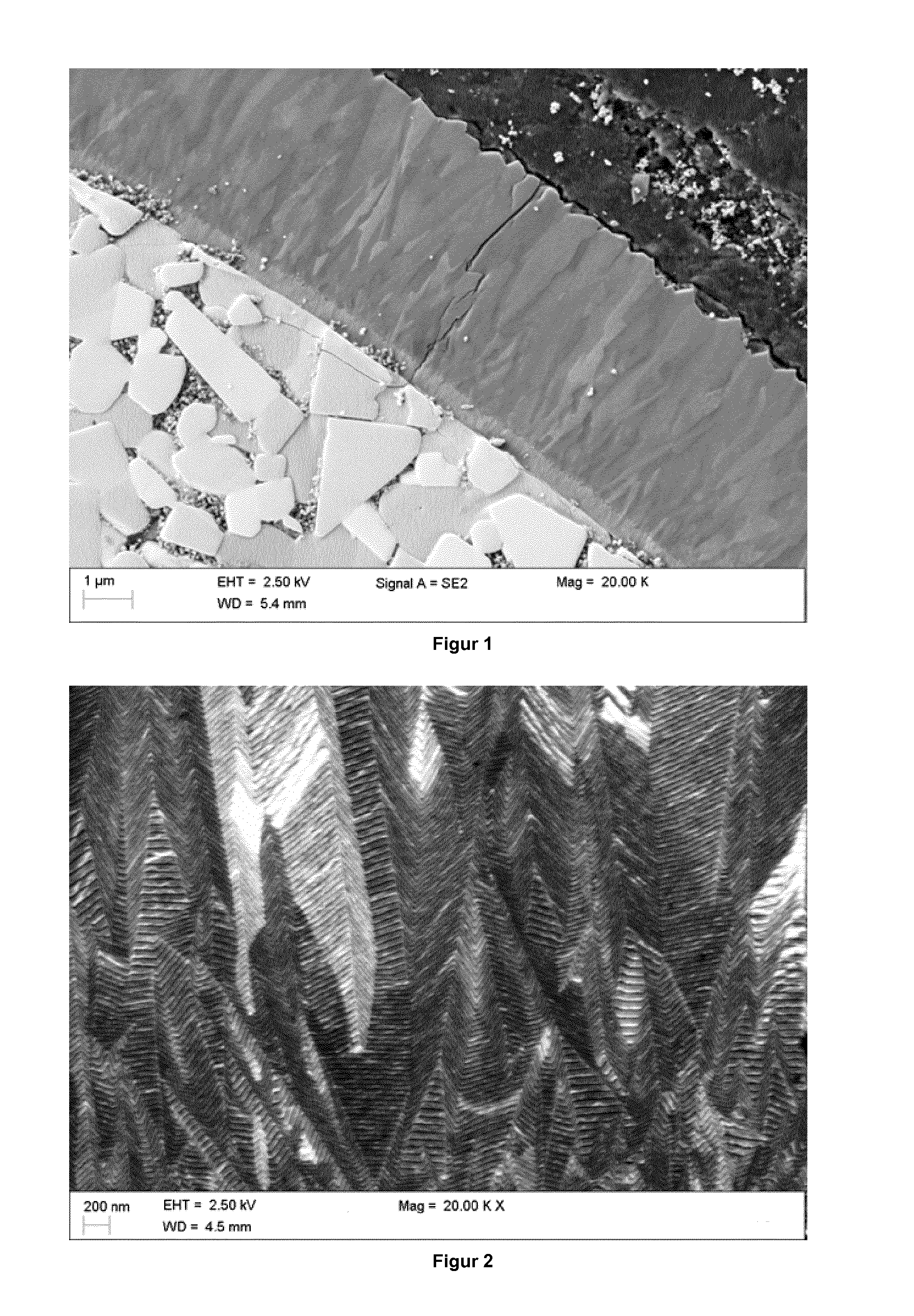

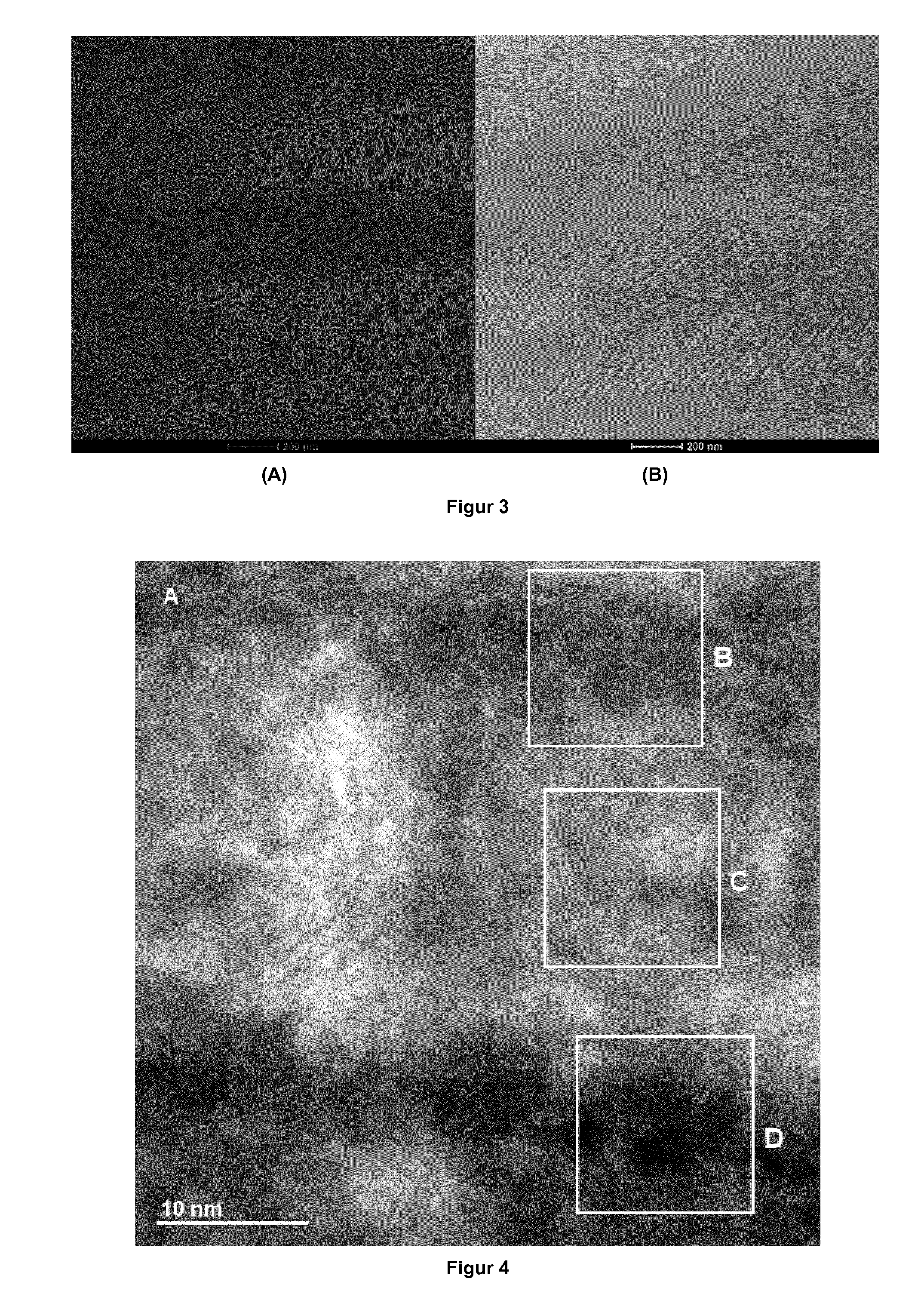

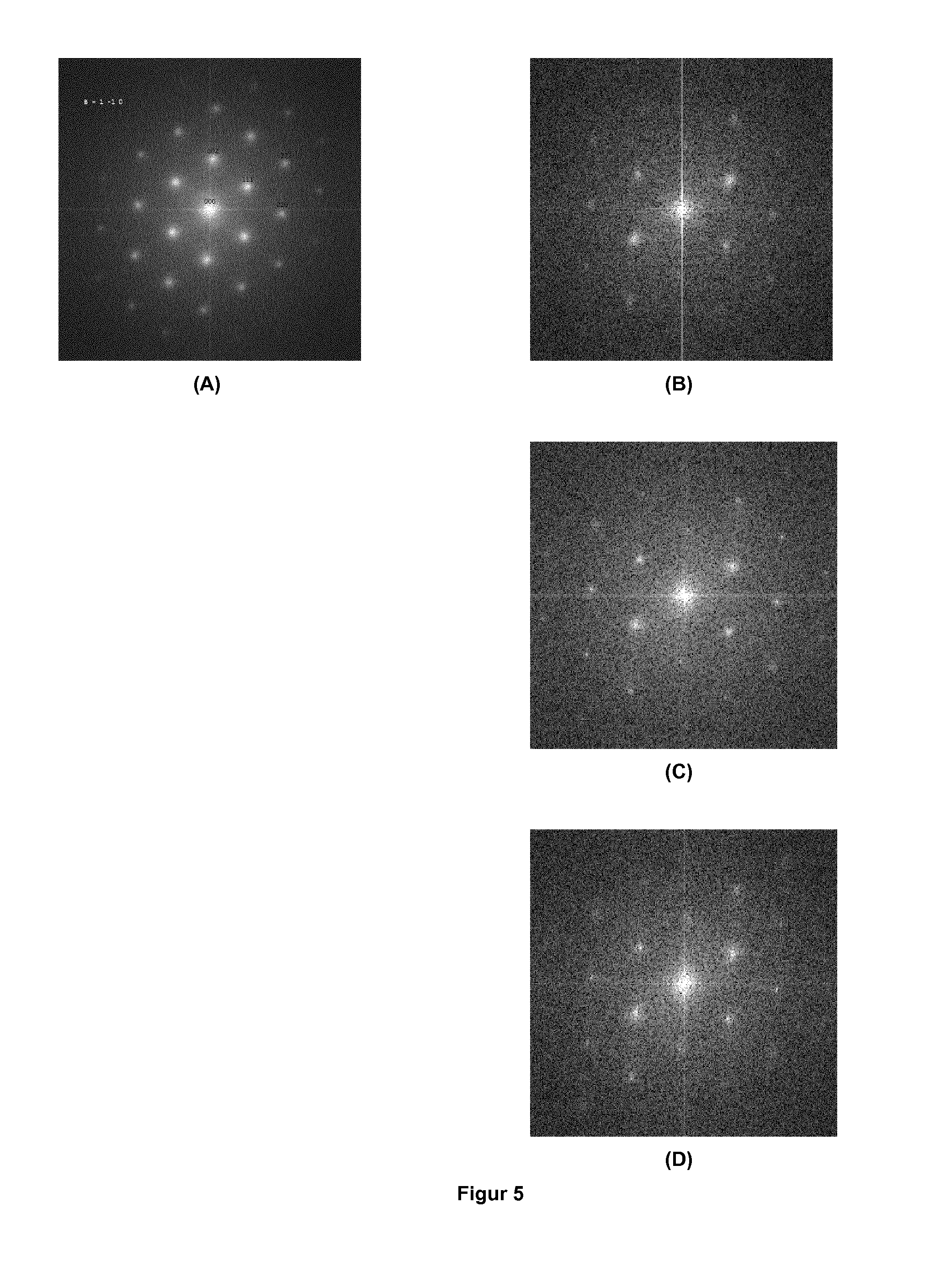

TiAlCN Layers With Lamellar Structure

ActiveUS20160333473A1Outstanding propertyImprove wear resistanceWorkpiecesTurning toolsPeriodic alternatingHard metal

A tool has a main part of hard metal, cermet, ceramic, steel, high-speed steel, and a single or multilayer wear protection coating applied onto the main part by CVD and which has a thickness from 3 μm to 25 μm. The wear protection coating has at least one Ti1-xAlxCyNz layer with stoichiometric coefficients 0.70≦x<1.0≦y<0.25 and 0.75≦z<1.15 and a thickness from 1.5 μm to 17 μm. The T1-xAlxCyNz layer has a lamellar structure with lamellae with thickness of no more than 150 nm, preferably no more than 100 nm, particularly preferably no more than 50 nm. Lamellae are made of periodically alternating regions of the Ti1-xAlxCyNz layer with alternatingly different stoichiometric proportions of Ti and Al, having the same crystal structure (crystallographic phase), and the Ti1-xAlxCyNz layer has at least 90% vol. % of face centered cubic (fcc) crystal structure.

Owner:WALTER AG

Silicone rubber compositions comprising bismuth oxide and articles made therefrom

InactiveUS20090243436A1Maintain good propertiesIncrease resistancePiezoelectric/electrostriction/magnetostriction machinesRecord information storagePhotopigmentParticulate metal

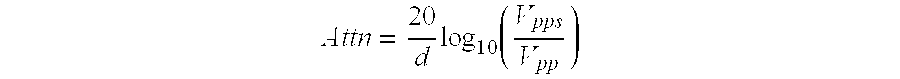

The present invention provides novel filled silicone compositions comprising a nano-particulate metal oxide filler selected from nano-particulate monoclinic alpha-phase bismuth oxide, nano-particulate erbium oxide, and mixtures thereof. The new composite compositions exhibit a combination of outstanding performance characteristics in both the cured and uncured states. Thus, the uncured formulations are typically free flowing liquids which are self-leveling, which de-gas readily under vacuum, are readily colorable through the addition of pigments, and which cure at temperatures of about 60° C. The cured compositions possess outstanding acoustic characteristics which make them ideally suited for use in applications such as acoustic lenses for medical imaging and therapy. For example, the acoustic impedance of compositions provided by the present invention is closely matched to the acoustic impedance of human tissue. This may result in an enhancement of ultrasound transmission efficiency between the lens of an ultrasound probe comprising such a composition and the patient.

Owner:GENERAL ELECTRIC CO

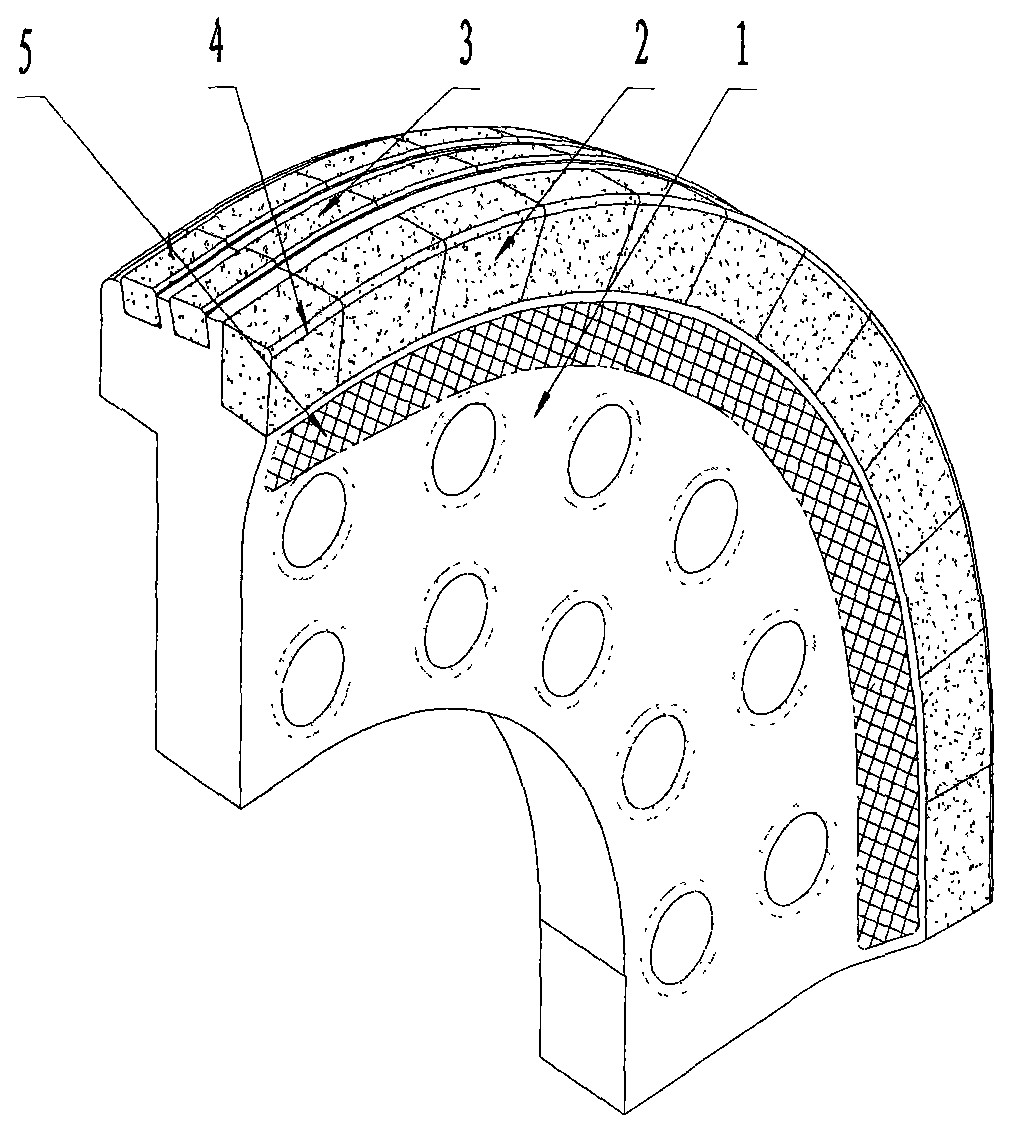

Manufacturing method of shield machine scraper

ActiveCN103008993ASolve the lack of hardnessWear resistanceSoldering apparatusNumerical controlWear resistant

The invention relates to a manufacturing method of a shield machine scraper. The manufacturing method comprises the following steps of: selecting the required feeding amount of a manufactured steel ingot according to the drawing size of a scraper body, carrying out die forging on the steel ingot by using a forging die to manufacture a scraper body blank, putting the scraper body blank in a thermal treatment furnace to carry out annealing treatment, and then carrying out mechanical rough machining on the scraper body blank, then putting the scraper body blank subjected to rough machining into the thermal treatment furnace again to carry out intermediate thermal treatment, so that the hardness of the scraper body blank is HRC 42-45; and then respectively overlying and coating a wear resistant layer on two sides of the scraper body, carrying out mechanical precise machining on one side of the scraper body on a numerically-controlled machine tool to form an alloy blade step and then machining at least one U-shaped groove in the periphery of the scraper body, brazing an auxiliary blade in the U-shaped groove, and sequentially brazing an end main blade and a main blade on the step at the outer side of the scraper body.

Owner:LUOYANG JIUJIU TECH

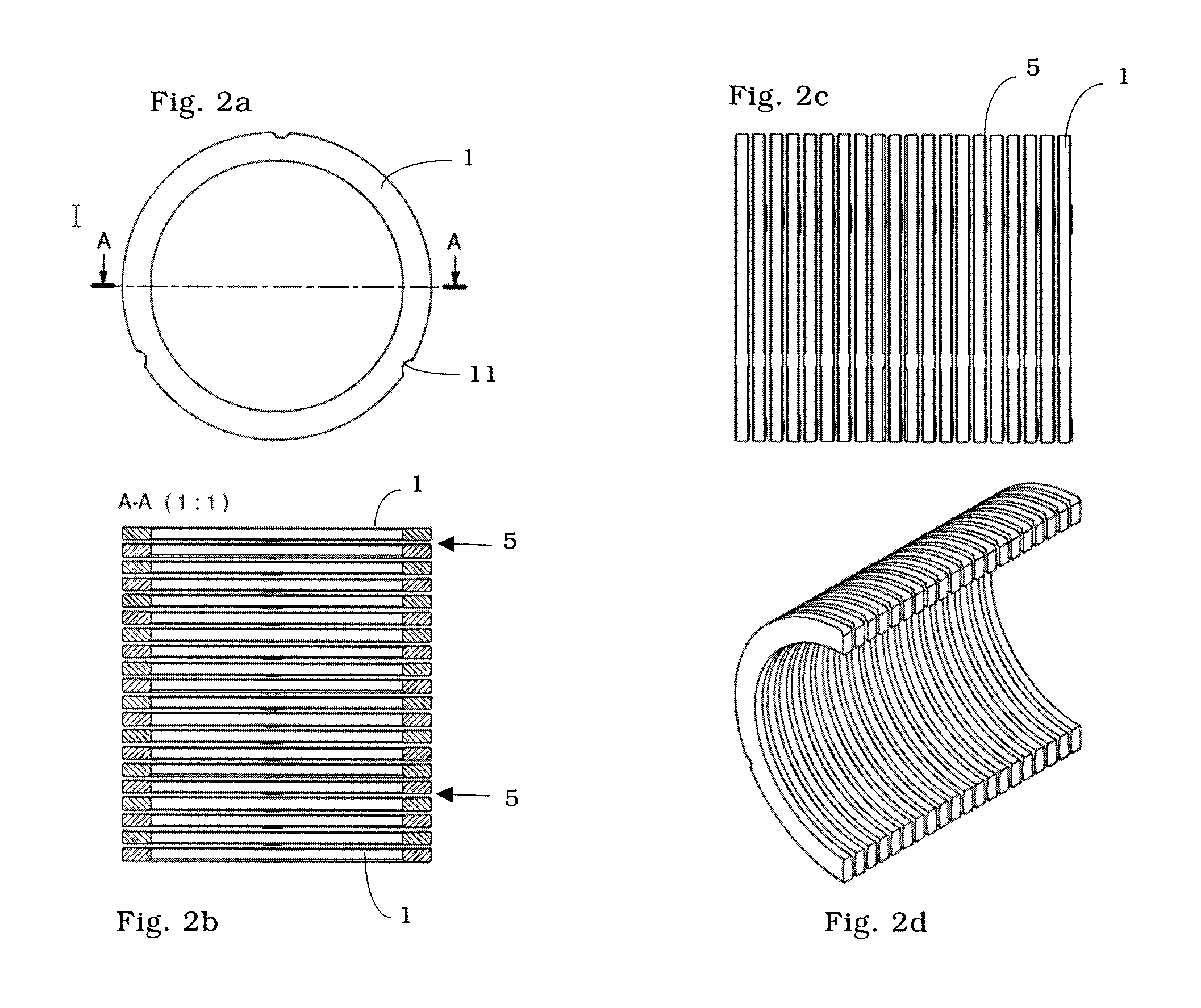

Separating device for removing sand and rock particles

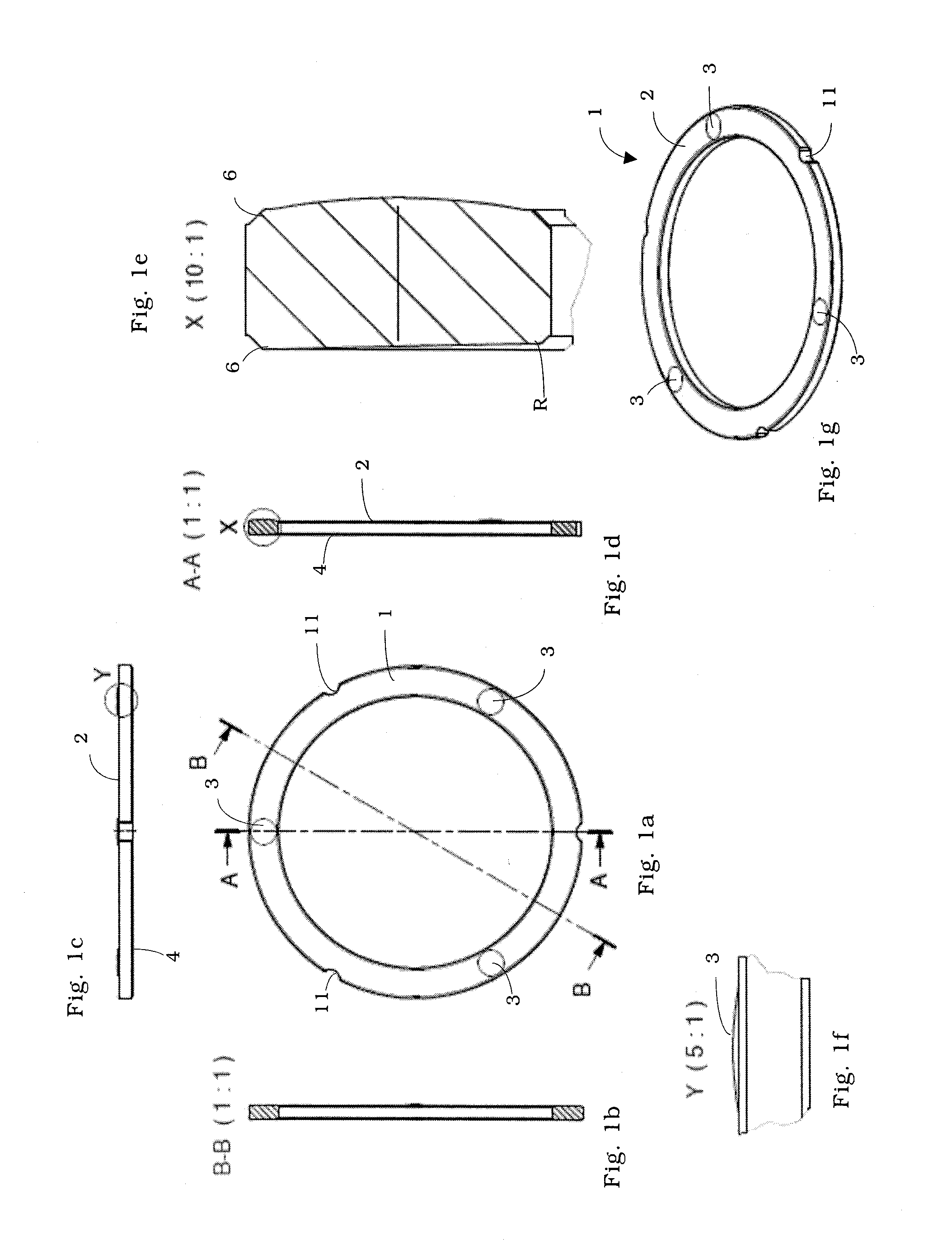

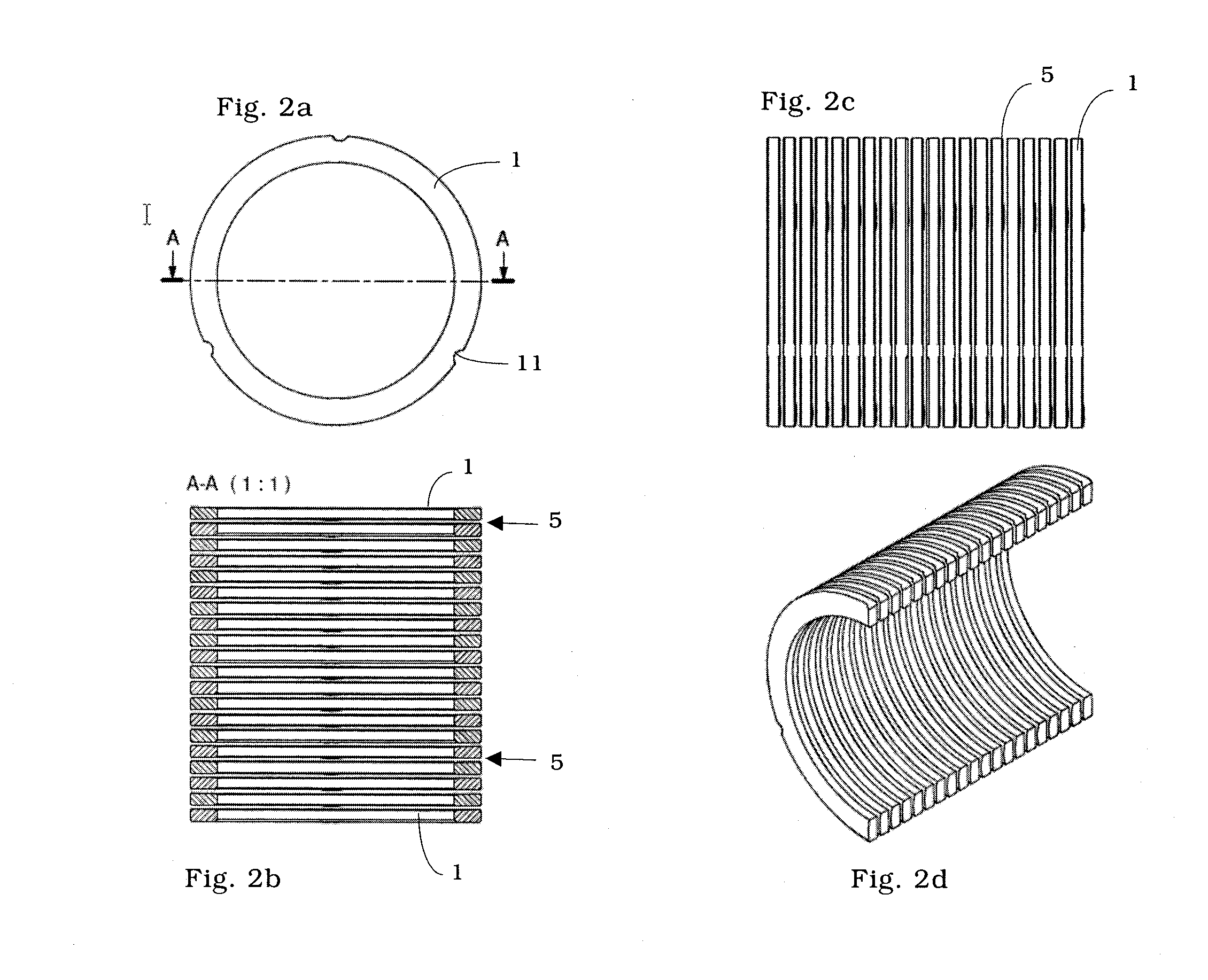

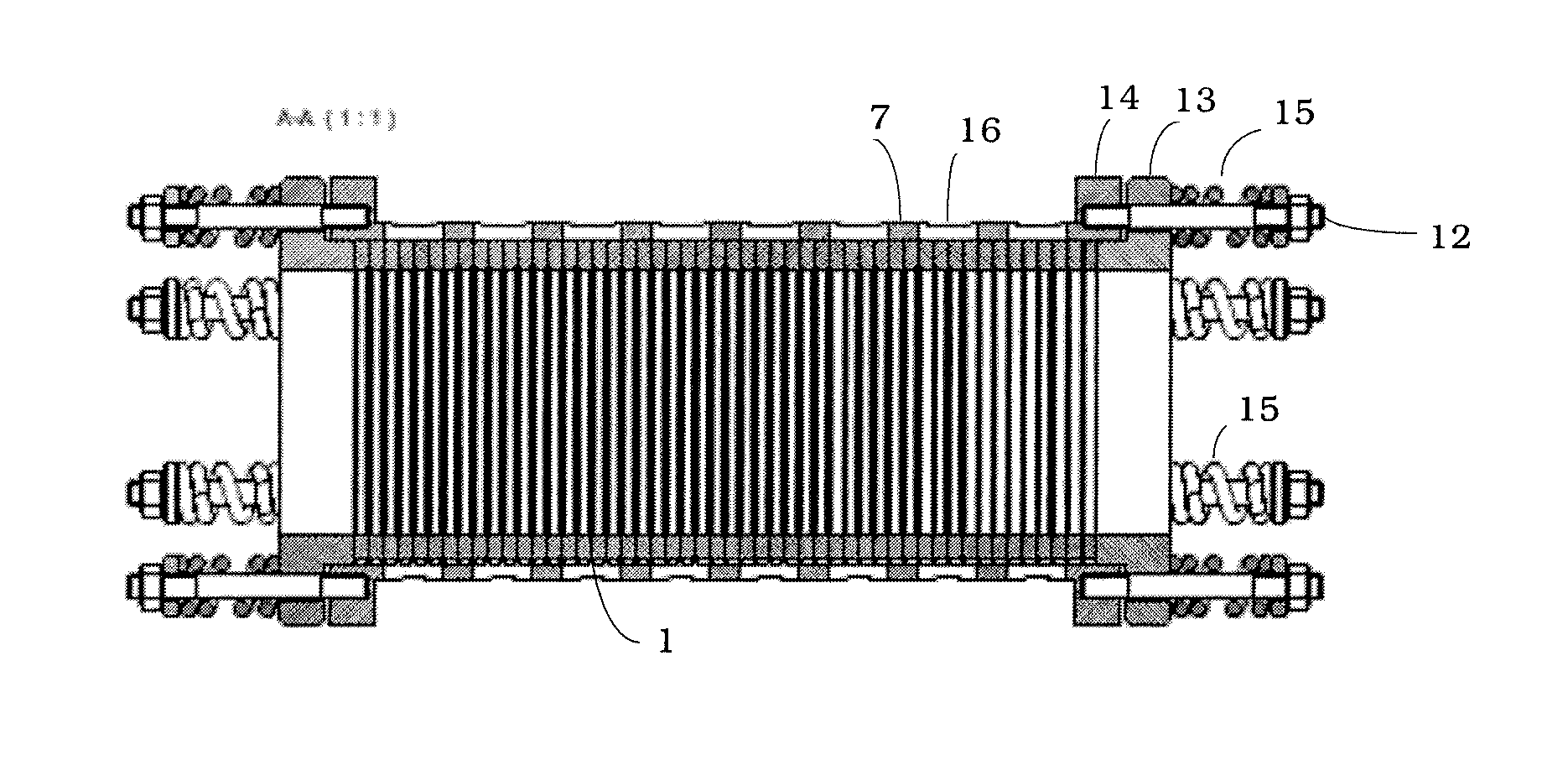

ActiveUS20110220347A1Resistance of separatingWear resistanceFluid removalDrinking water installationCircular discMining engineering

According to a first embodiment, the invention relates to a separating device for removing sand and rock particles in the extraction of liquids or gases from wells drilled in rock, comprising a plurality of annular discs of a brittle-hard material stacked one on top of the other and axially braced by means of a supporting structure, the discs having on their upper side at least three spacers uniformly distributed over the circular circumference of the discs, the discs being stacked one on top of the other in such a way that the spacers respectively lie one over the other, and that a separating gap with a height of 0.05-1 mm, preferably 0.2-0.5 mm, is present in each case between the individual discs.According to a second embodiment, the invention relates to a separating device for removing sand and rock particles in the extraction of liquids or gases from wells drilled in rock, comprising a plurality of bush-shaped elements of a brittle-hard material stacked one on top of the other and axially braced by means of a supporting structure, slits with a slit width of 0.05-1 mm, preferably 0.2-0.5 mm, being formed in the bush-shaped elements.

Owner:3M INNOVATIVE PROPERTIES CO

Separating device for removing sand and rock particles

ActiveUS8893781B2Resistance of separatingWear resistanceFluid removalDrinking water installationWell drillingEngineering

Owner:3M INNOVATIVE PROPERTIES CO

Preparation method of cut resistant yarn

The invention provides a preparation method of anti-cutting yarn. Two high-strength polyester filaments or ordinary polyester filaments are plyed and twisted, and then twisted and coated with ordinary glass fiber filaments or basalt fibers to form a core yarn. , On the basis of the above core fiber, the outer layer is covered with high-strength nylon or high-strength polyester filament or high-strength nylon and spandex as the outsourcing fiber to make a cut-resistant yarn. The core yarn provides the skeleton of the cut-resistant yarn, the spandex provides comfortable elasticity, and the outer covering yarn provides toughness resistant to direct cutting, which can be used in textiles including fabrics, gloves, sheaths, aprons and other fields. The present invention adopts conventional fiber varieties as the core yarn, rationally configures the twist of the yarn and the distribution and proportion of fibers, so that the yarn or textiles can reach different anti-cutting levels and the highest anti-cutting level, greatly reducing the production cost, and the cutting resistance is stable. And the yarn feels comfortable.

Owner:SHANGHAI SHUQUE TRADING CO LTD

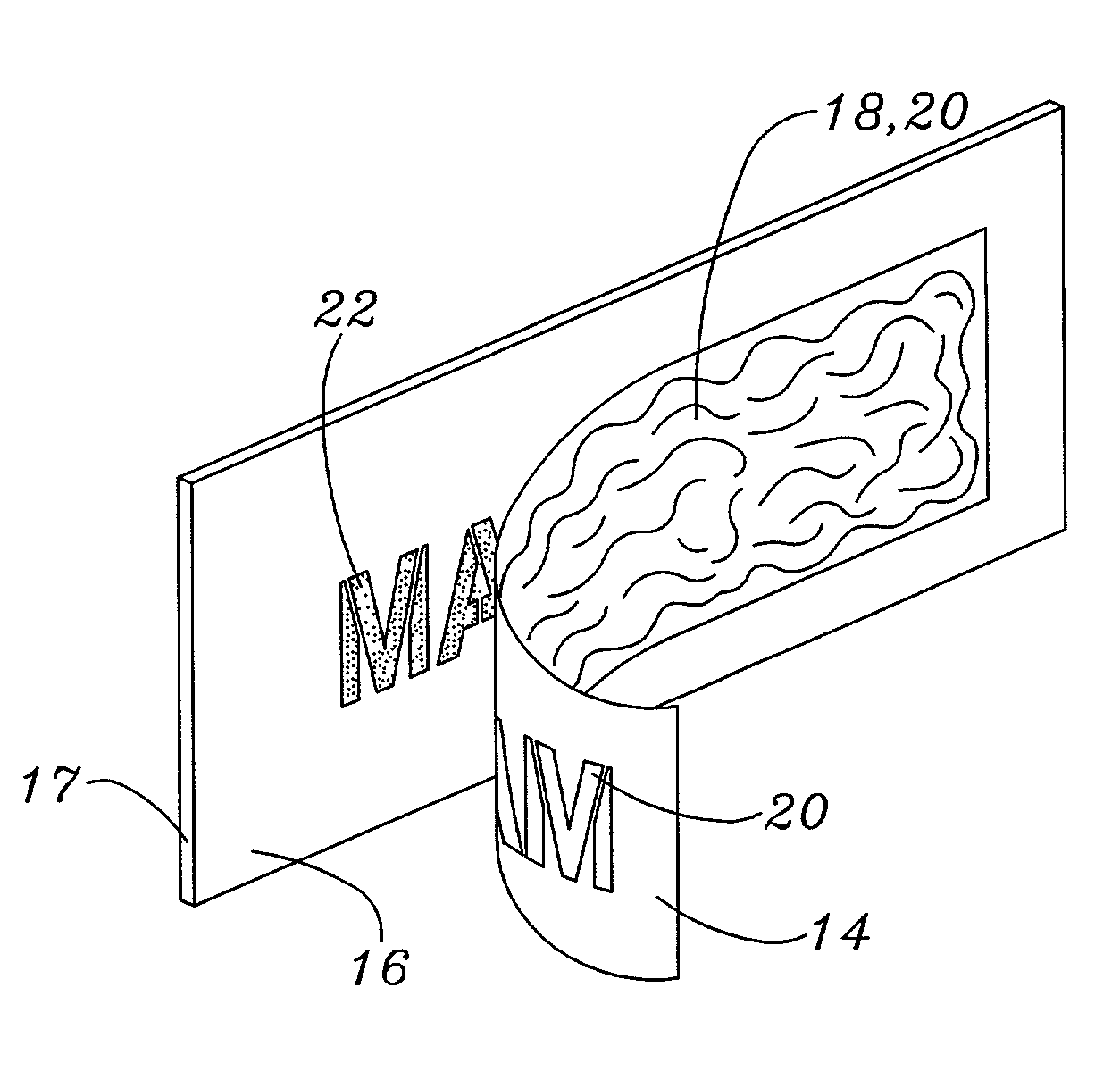

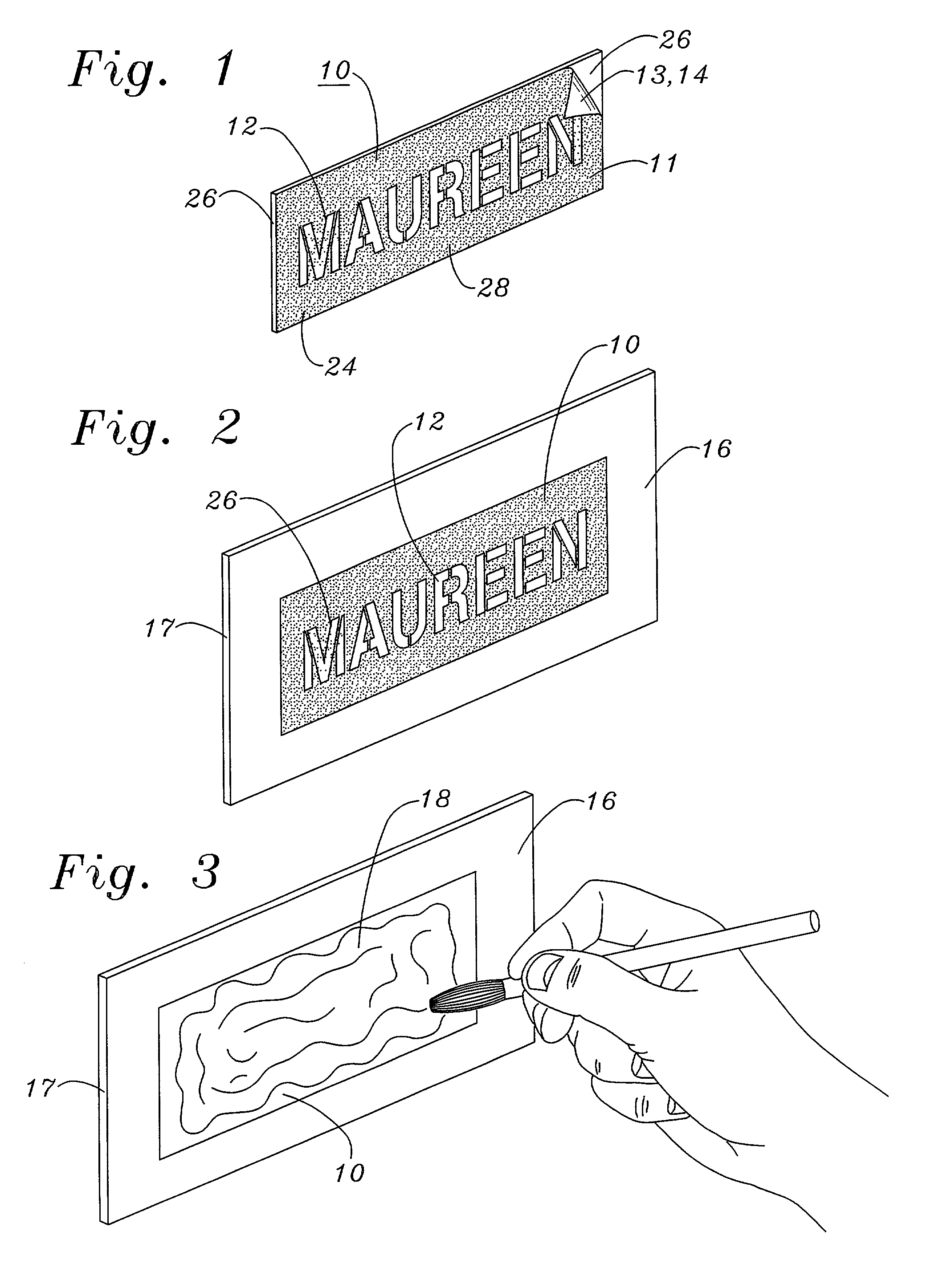

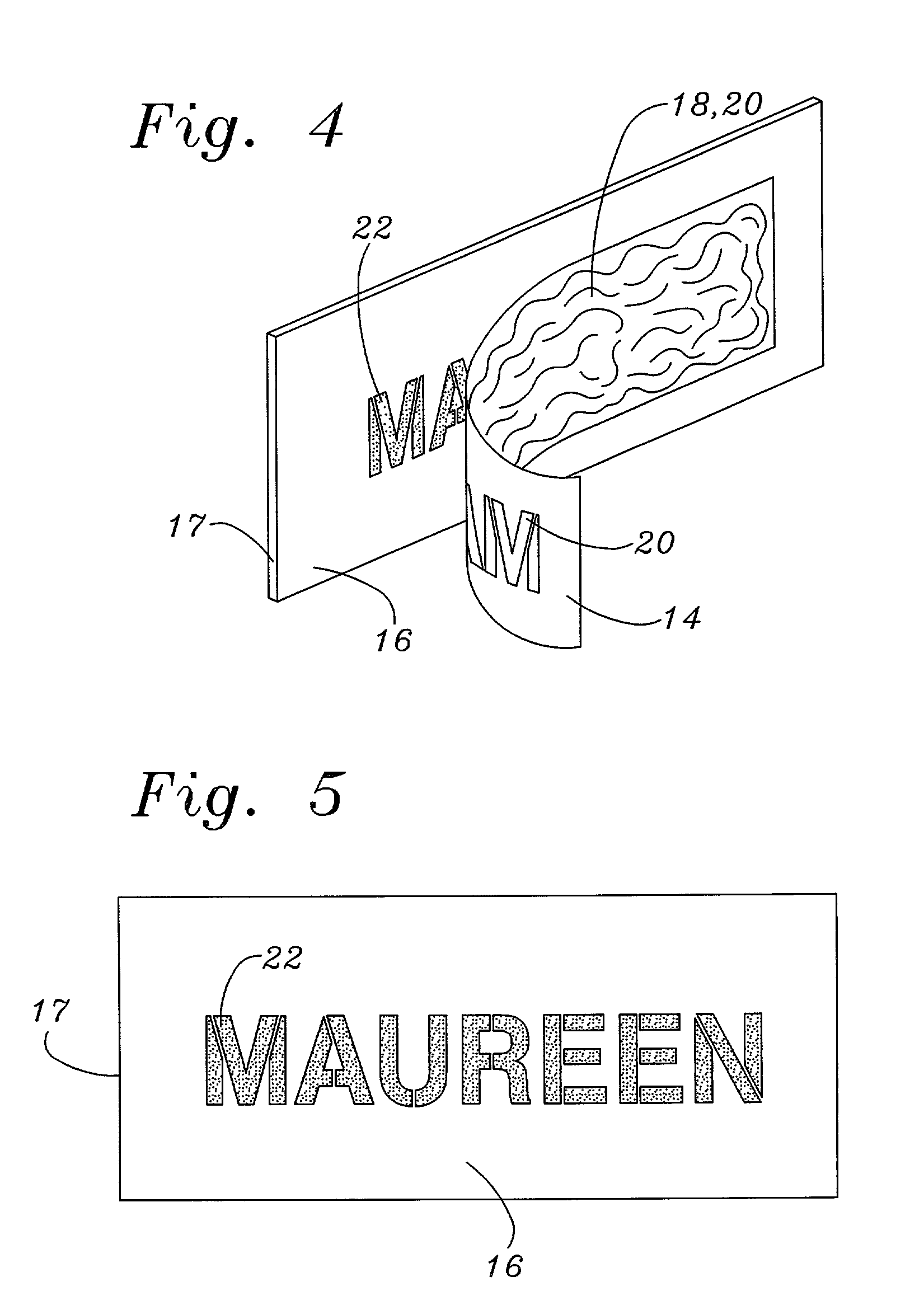

Peelable stenciling ink and method of using

A peelable stenciling ink for imprinting indicia such as letters, numbers and symbols on a surface of an article such as a sport ball made of leather or a synthetic polymer, e.g., a thermoplastic material, consists of a solvent, a dye dispersed in the solvent, and a film-forming polymer soluble in the dye-solvent solution to form a thick paste and hardenable into a solid, flexible film upon evaporation of the solvent from a thin layer of ink applied to an article surface. A method of using the ink comprises the steps of temporarily adhering a stencil sheet in fluid-tight contact to an article surface by a pressure-sensitive adhesive layer, smearing a layer of the ink on the obverse surface area of the stencil sheet through indicia-shaped openings through the sheet onto the article surface, allowing sufficient time for dye in the ink to penetrate the article surface, and for the solvent to evaporate and cause the film-forming substance to harden into a solid film peelable from the article surface, and peeling the stencil sheet and solid film together from the article surface, thereby leaving indicia markings imprinted on and dye-penetrated beneath the article surface, thus making the markings resistant to obliteration by scuffing or abrasion.

Owner:WYNNE JOHN H

Composite fishing line

InactiveUS20120285074A1Reduce the overall diameterImproved and convenient fishing line structureAgriculture tools and machinesLinesTetrafluoroethyleneWear resistance

The present invention discloses a composite fishing line manufactured by entangling eight bundles of fibers selected from two different types of fibers, one being a high molecular-weight polyethylene fiber and the other being a high molecular-weight expanded polytetrafluoroethylene (ePTFE) fiber, such that the composite fishing line has the properties of both high molecular-weight polytetrafluoroethylene (PTFE) fibers and polyamide fibers to improve the strength, wear-resistance, cross-sectional roundness, and water resistance of the high-performance fishing line and achieve the effect of reducing the diameter of the fishing line.

Owner:YAO I FABRIC

A floatable plant growth system and a floatation tray for use with the system

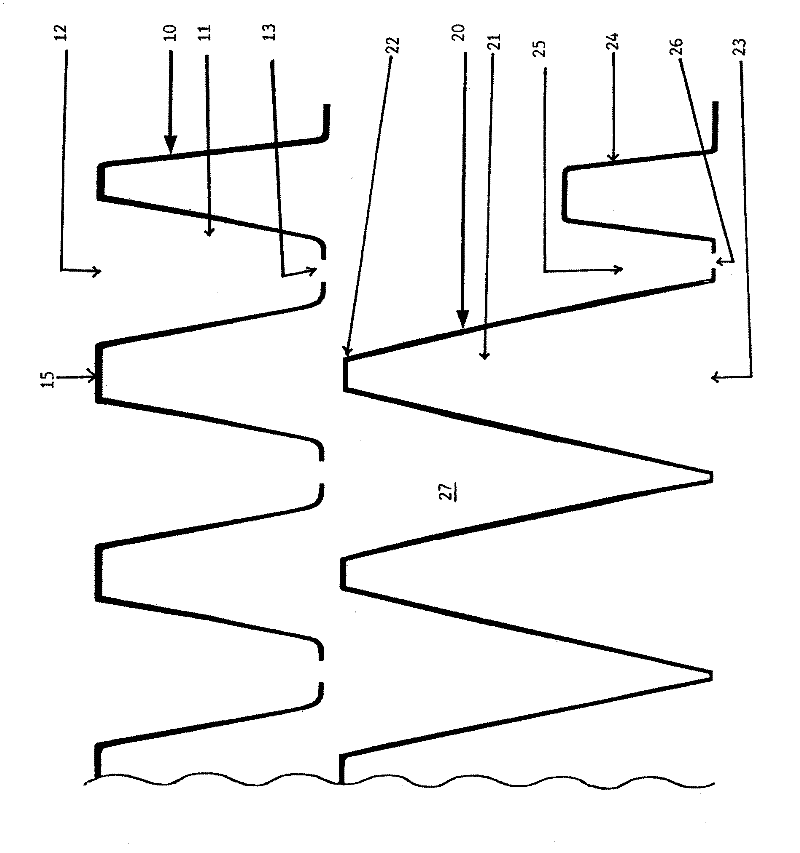

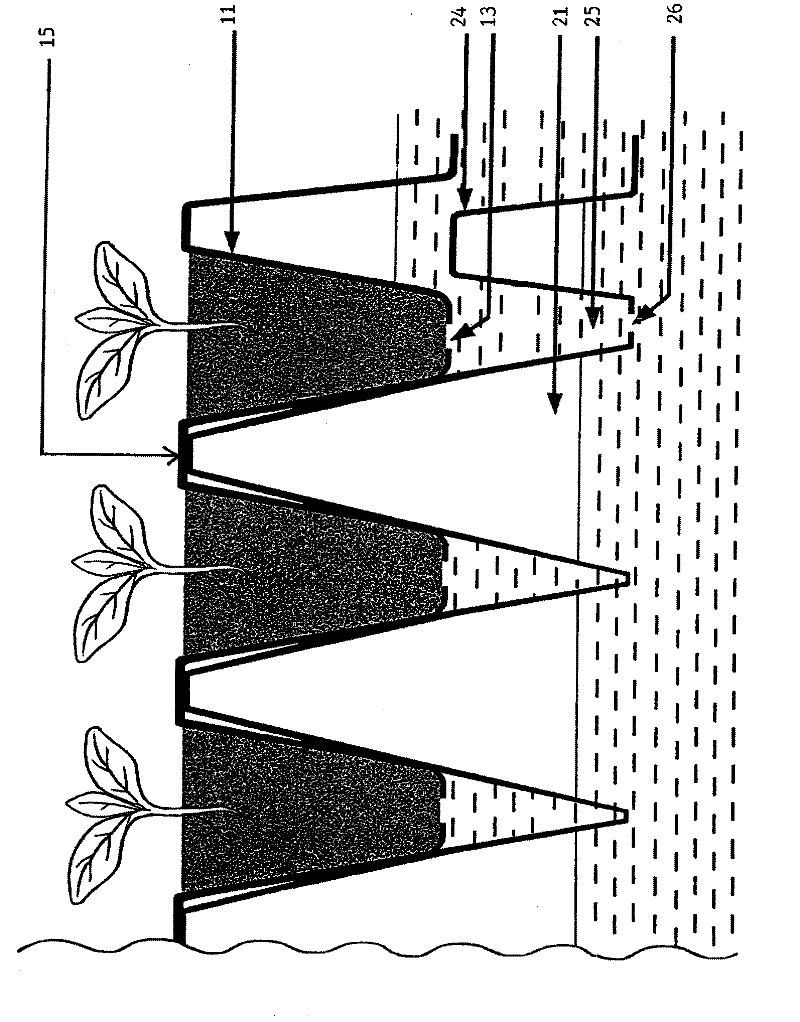

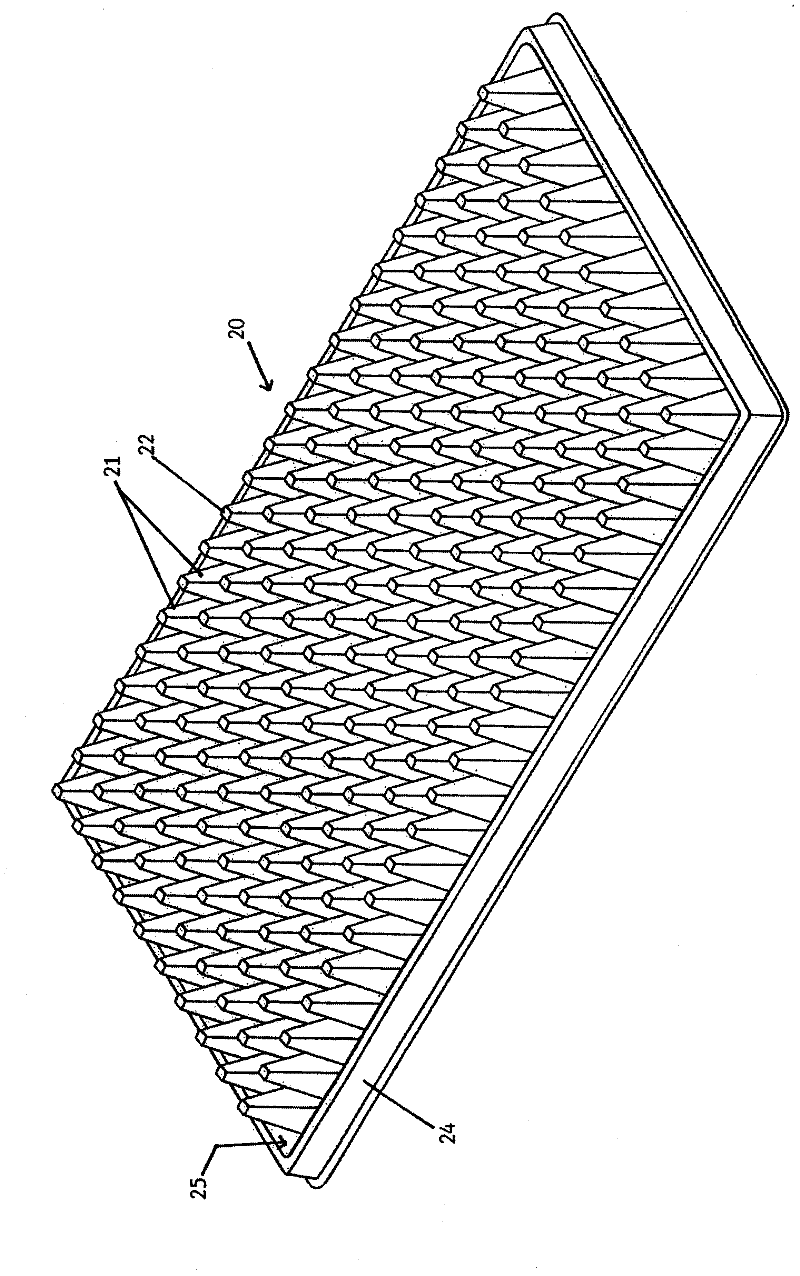

InactiveCN102378572AEasy to separateIncrease flexibilityArtificial islandsClimate change adaptationGrowth plantPlant cell

A floatable plant growth system is provided. The system comprises an upper tray (10) and a lower tray (20). The upper tray has a plurality of downwardly tapering cells (11 ) for receiving plant growth material, with each of the plant cells having an opening (13) at its bottom. The lower tray has a plurality of upwardly tapering cells (21) that trap air, enabling the system to float in use. The upper tray is removably mateable with the lower tray such that the plant cells of the upper tray are located in the space (27) between the air cells of the lower tray. The lower tray is provided with a plurality of openings (26). When the upper and lower trays are mated together and placed in a body of liquid, liquid enters the mated tray configuration (10, 20) through the openings (26) of the lower tray, fills the space (27) that is below the plant cells (11) between the air cells (21) of the lower tray, and in use may be taken up through the bottom opening (13) of each upper tray plant cell.

Owner:邱继宗

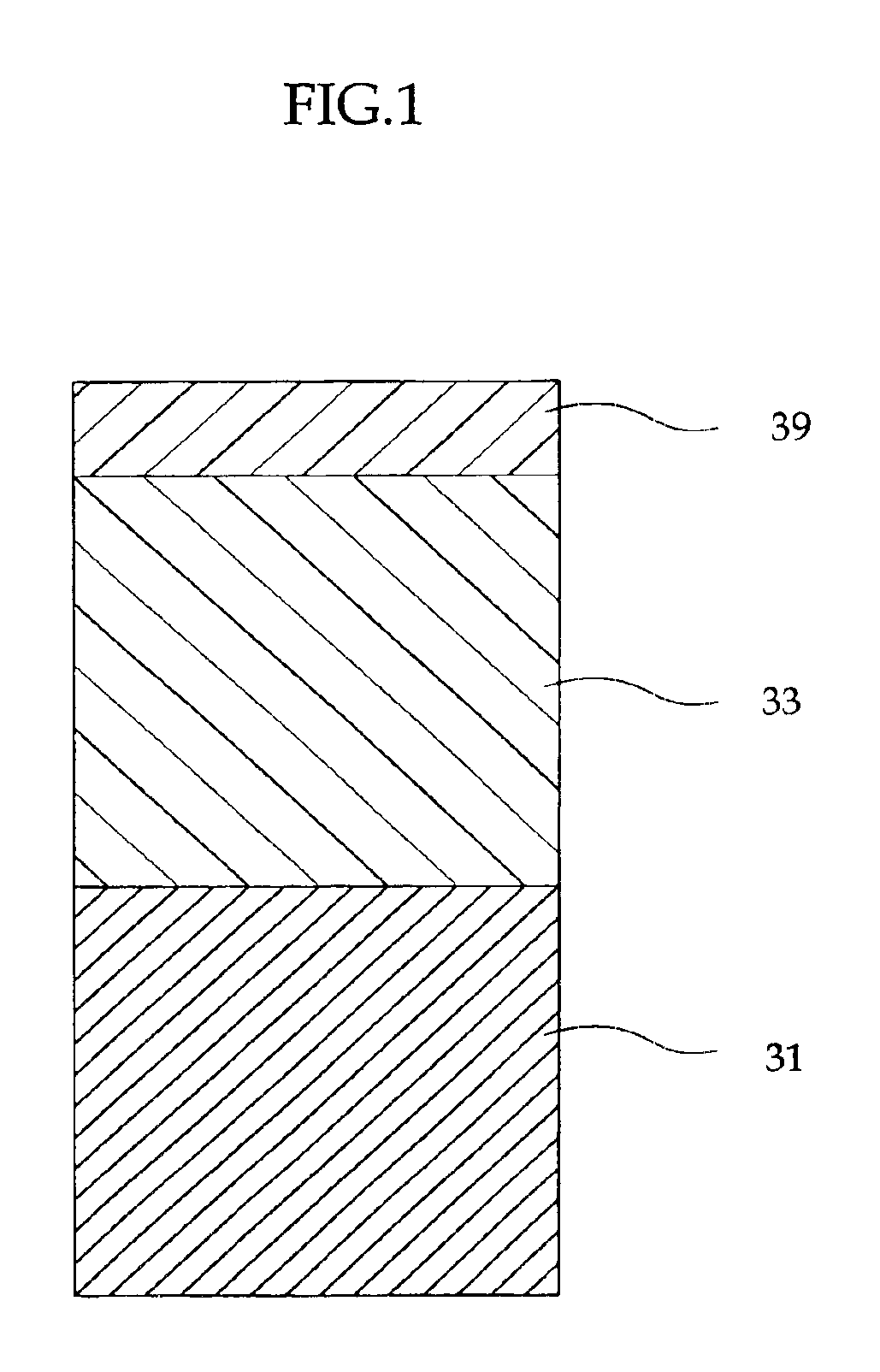

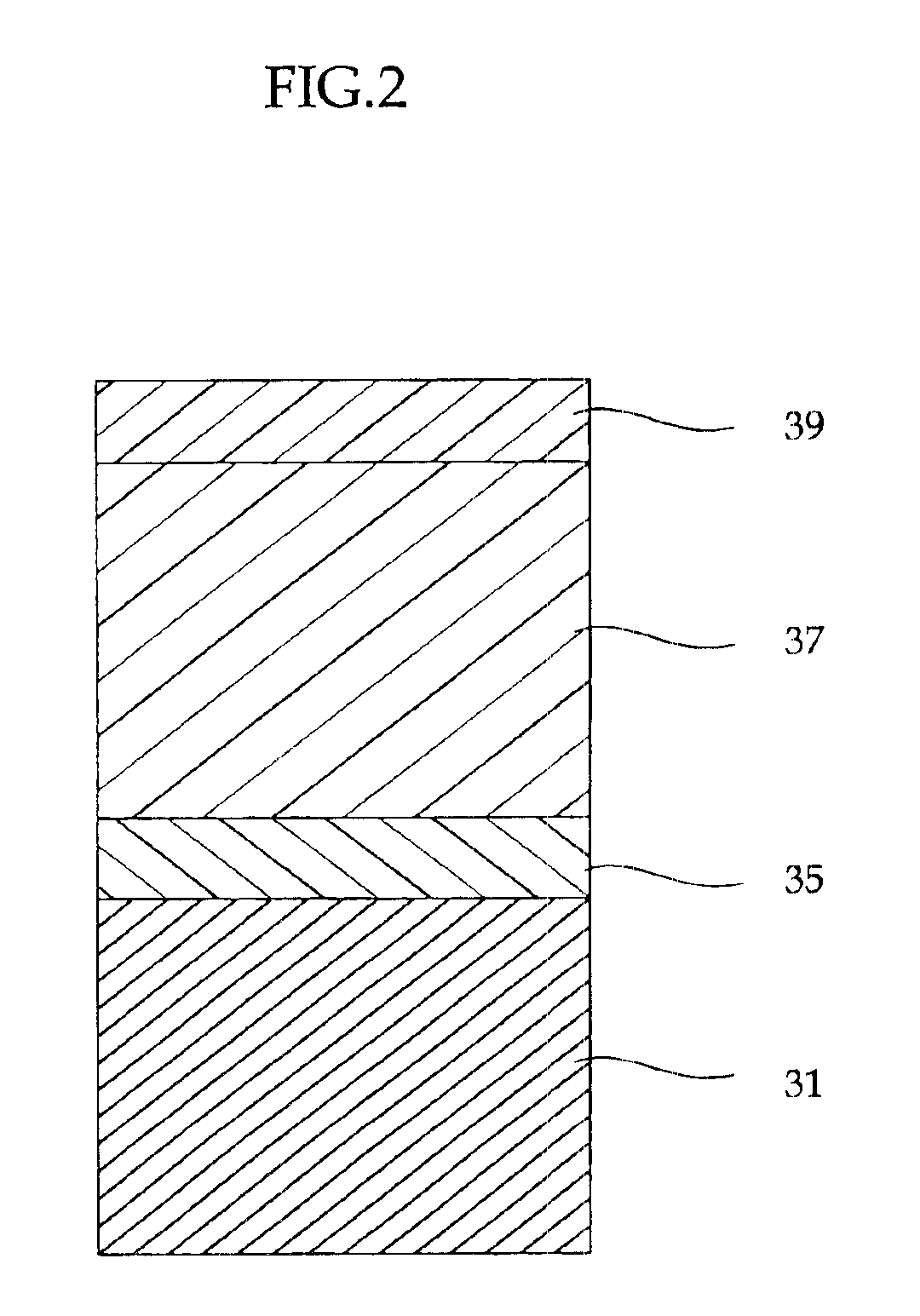

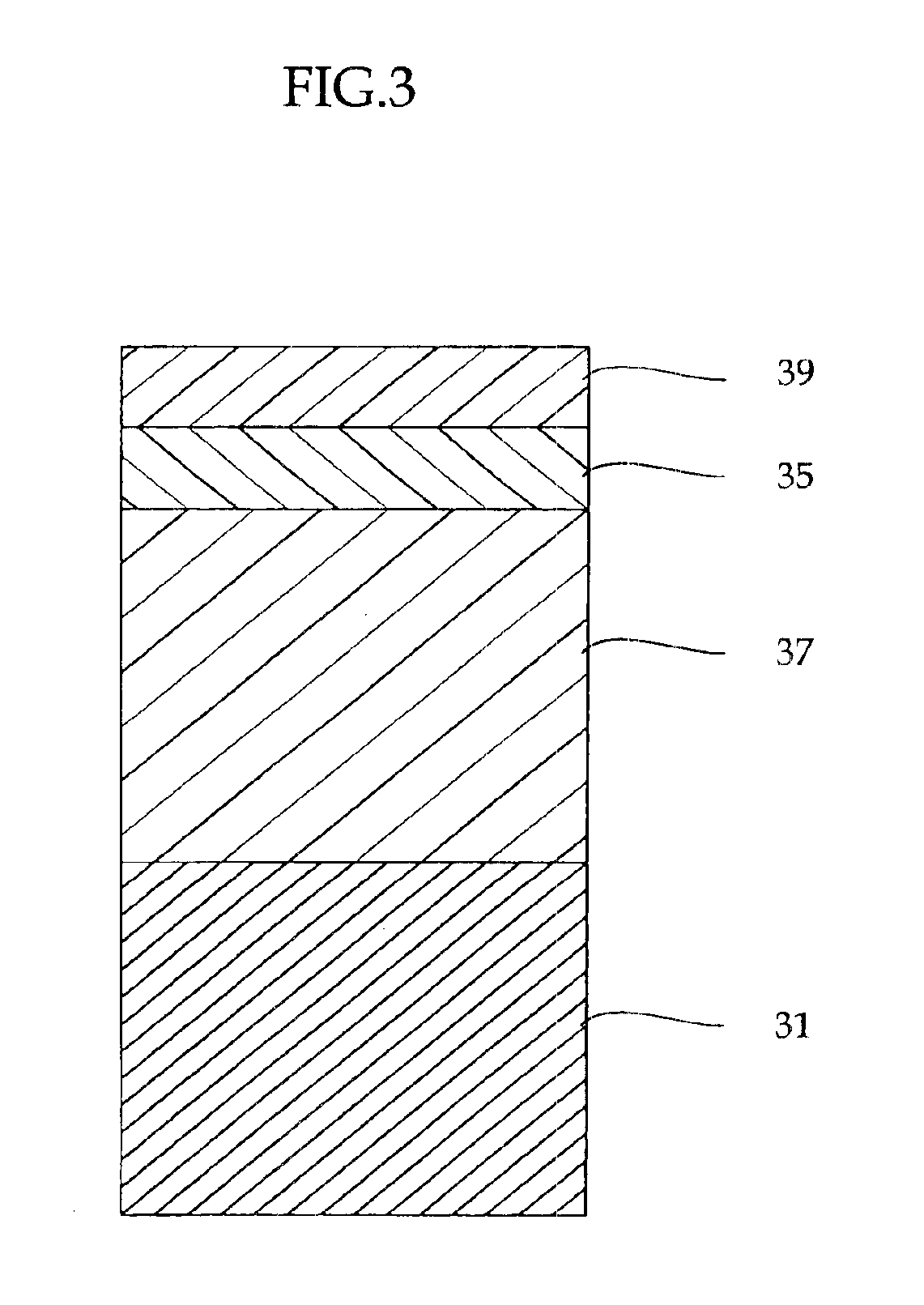

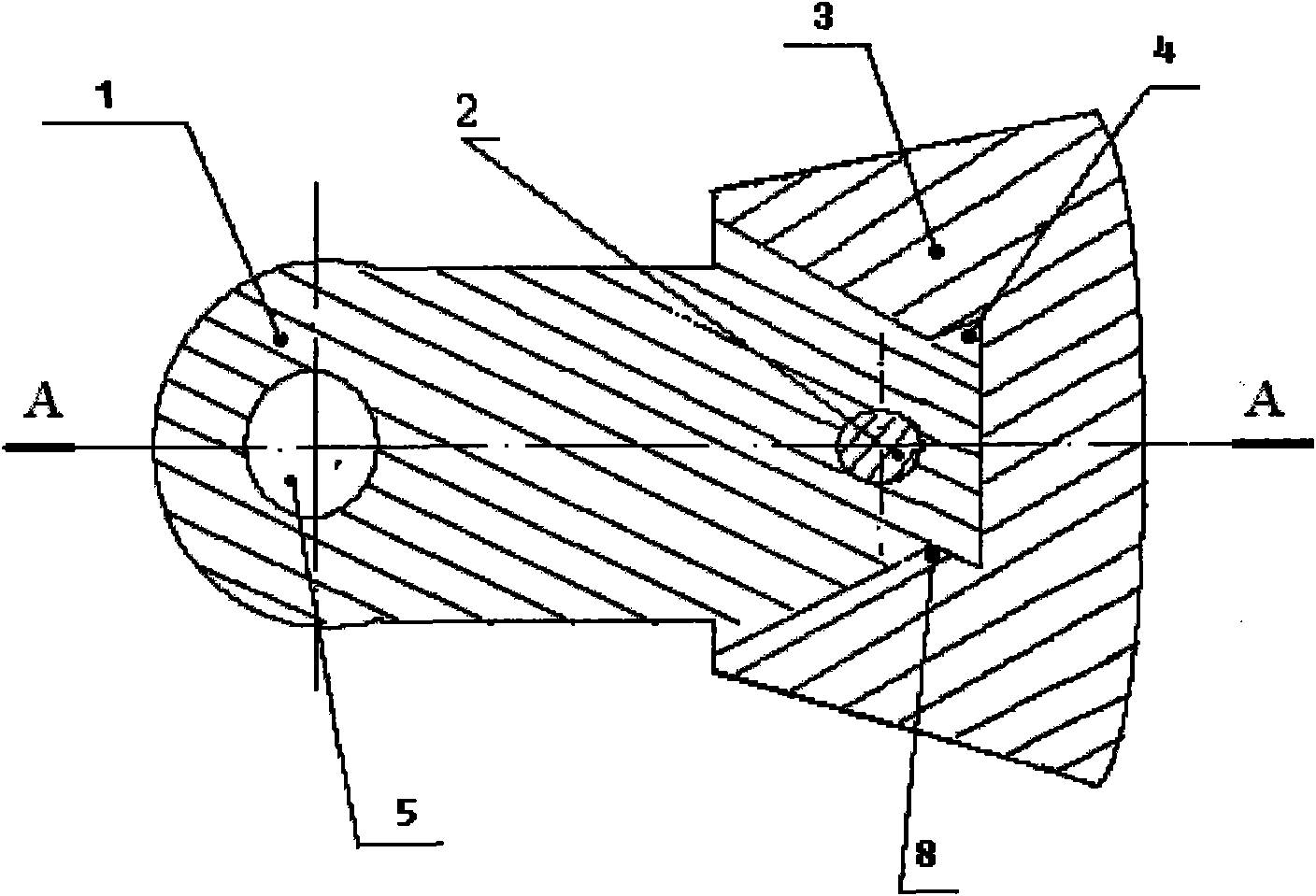

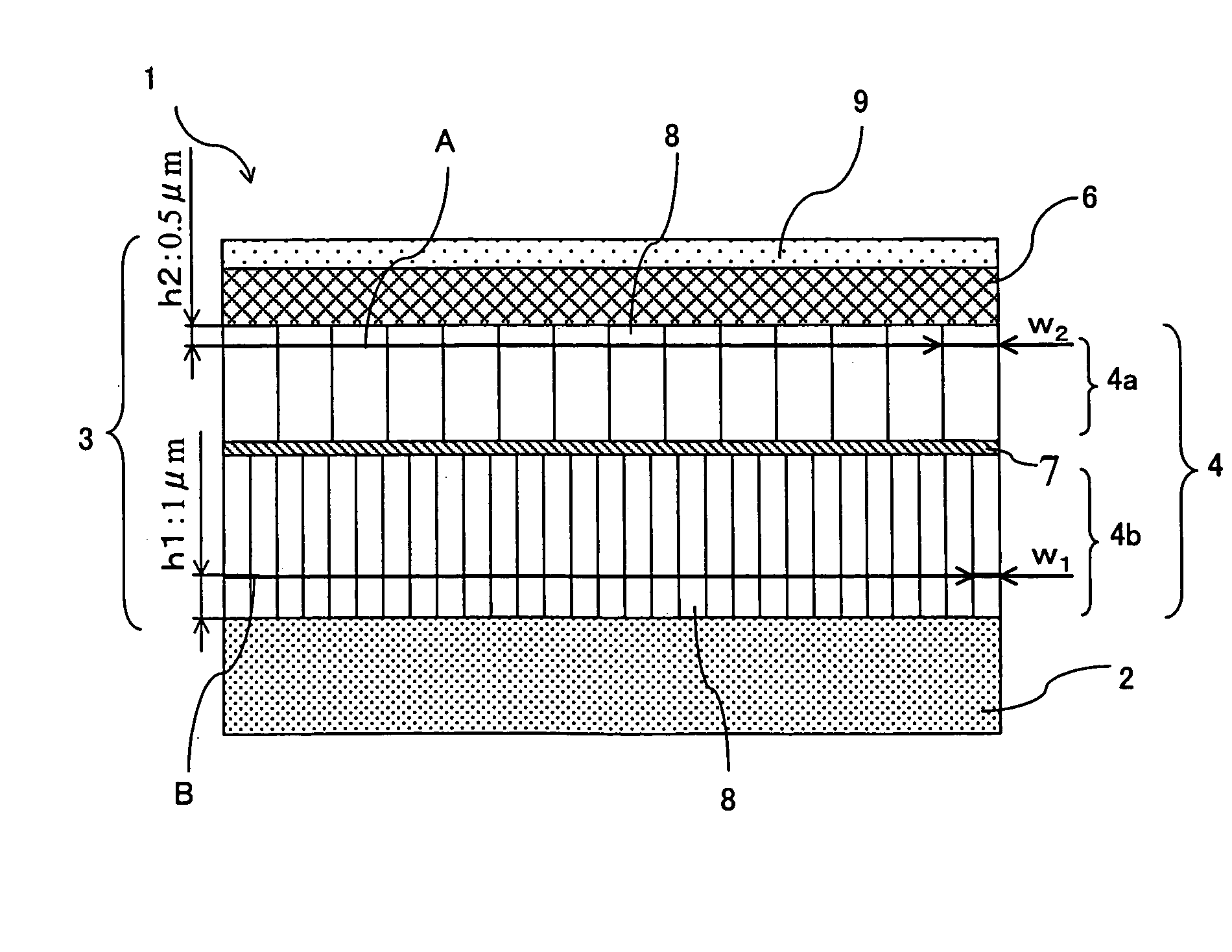

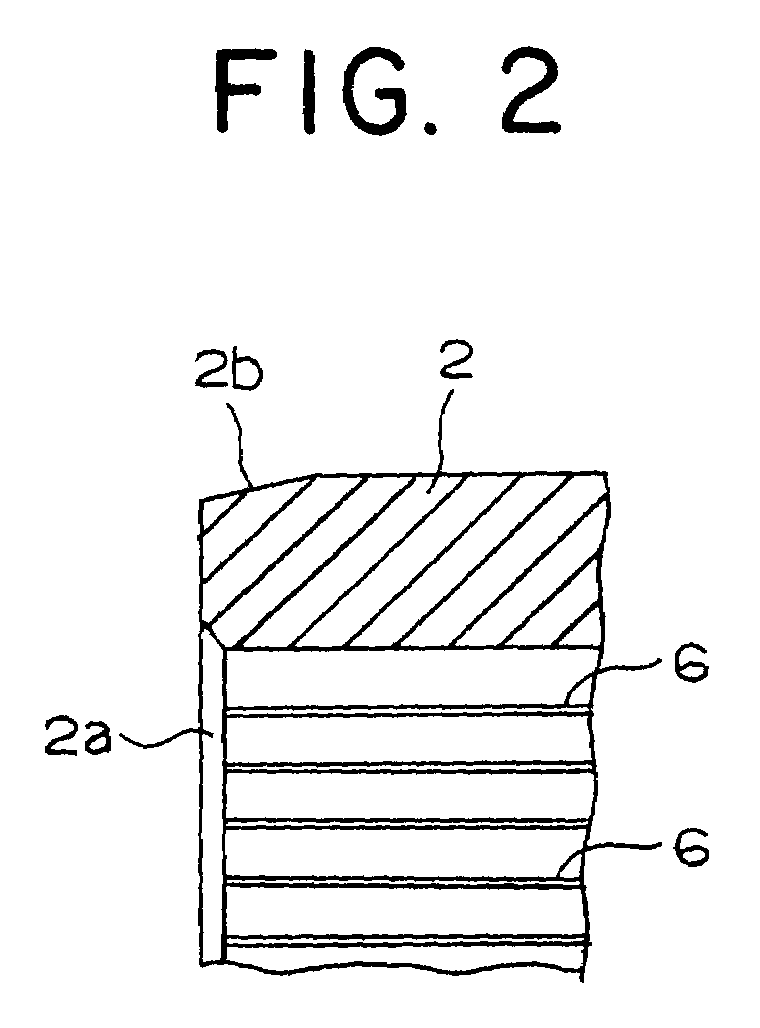

Surface-coated member

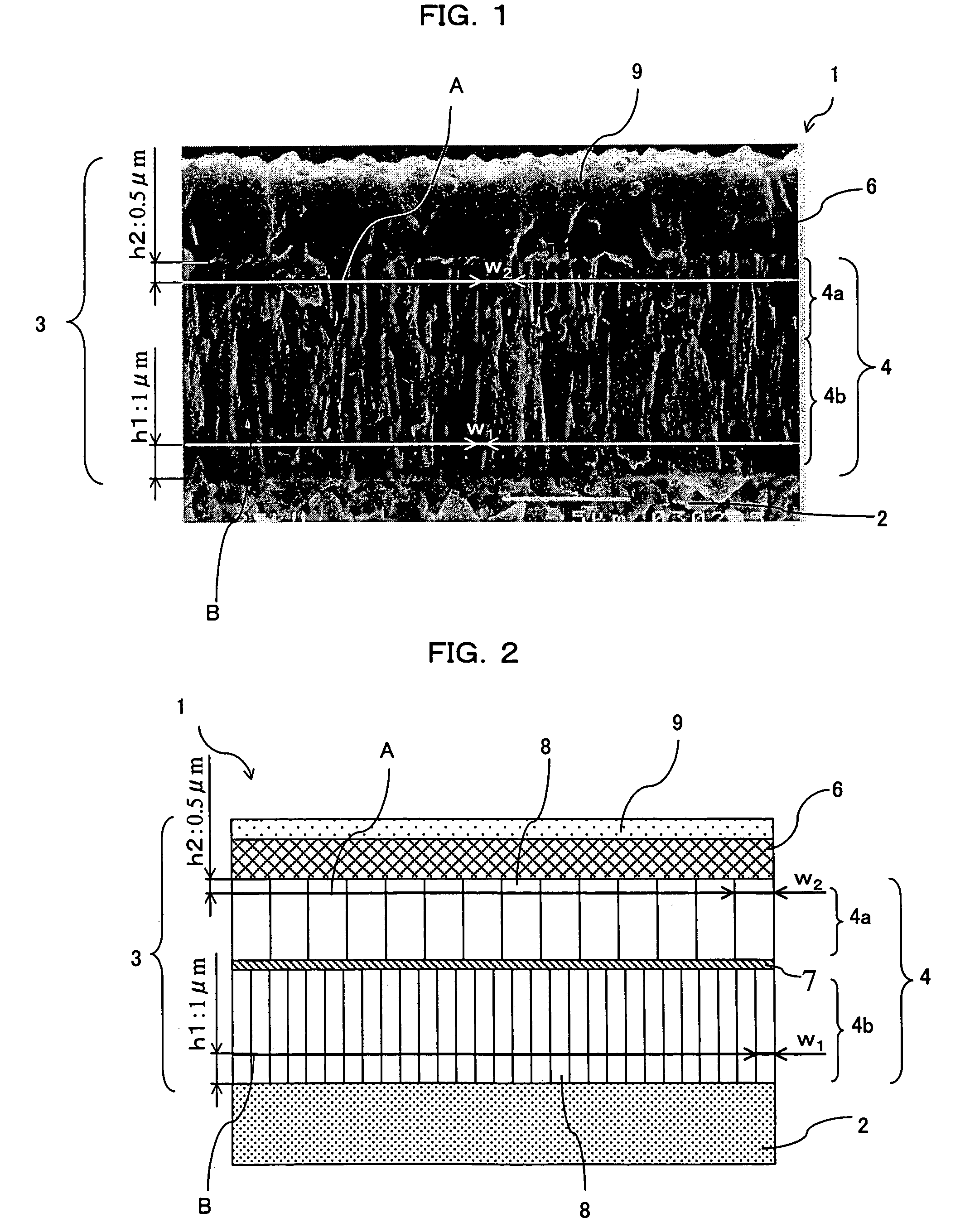

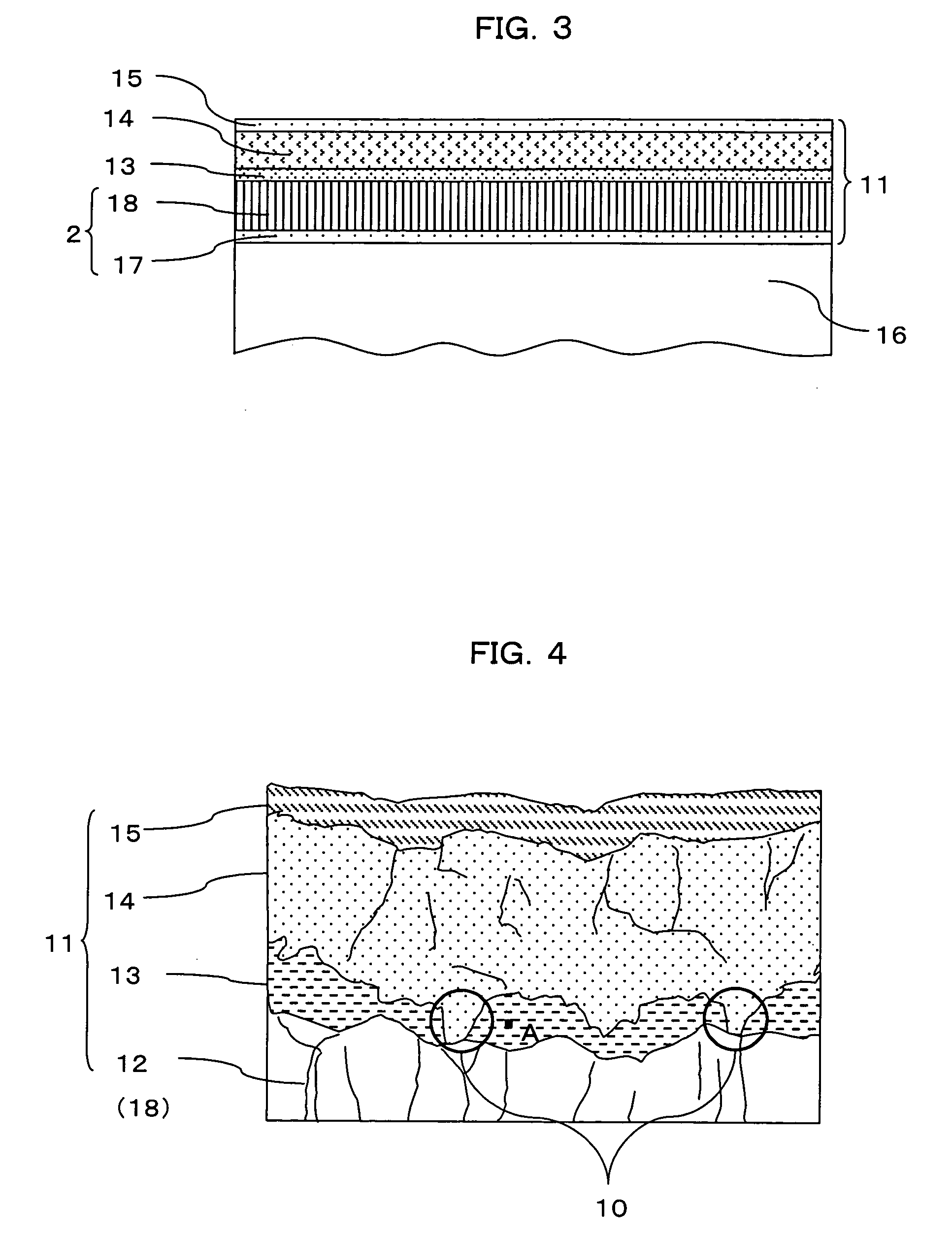

ActiveUS7172807B2Improve fracture resistanceImprove wear resistancePigmenting treatmentOther chemical processesAdhesion forceHigh wear resistance

The surface-coated member 1 is constituted by coating the surface of the base body 2, made of such a material as cemented carbide or cermet, with the hard coating layer 3 that comprises at least one TiCN layer 4 and the Al2O3 layer 6 formed on the surface of the TiCN layer 4, wherein the TiCN layer 4 is constituted from stringer-like TiCN crystal grown in a direction perpendicular to the base body 2 and mean crystal width w1 of the TiCN layer 4 on the Al2O3 layer 6 side is made larger than mean crystal width w2 on the base body 2 side. This surface-coated member, as a cutting tool, shows excellent breakage resistance and high wear resistance with a long service life, where strong adhesion force of the hard coating layer can be maintained without experiencing peel-off between the TiCN layer and the Al2O3 layer even in cutting operations under harsh cutting conditions, such as intermittent cutting operation where the cutting edge is subject to strong impact.

Owner:KYOCERA CORP

Bearing device

InactiveUS6991377B2Inexpensively formedSimple structureShaftsBearing componentsEngineeringArea ratio

A bush is provided at its sliding surface with oil-supply groove portions. An area ratio of the oil-supply groove portions to the sliding surface of the journal shaft is set to 30 to 90%. A length L1 between the oil-supply groove portions in a circumferential direction and an inner diameter D of the bearing satisfy L1<πD / 36. Even in a bearing device in which the journal shaft and the bush mutually rotate in a predetermined angle range or in which the journal shaft and the bush relatively and continuously rotate, the present invention can effectively be used while maintaining the existing sizes of the journal shaft and the bush, and it is possible to prevent partial break of oil film or shortage of oil film.

Owner:KOMATSU LTD

Extrusion molding method for high-strength TS-1 (Titanium Silicalite-1) catalyst

InactiveCN103041850AHigh mechanical strengthExtended service lifeMolecular sieve catalystsFiberMaterials science

The invention provides an extrusion molding method for a high-strength TS-1 (Titanium Silicalite-1) catalyst. The method is characterized by comprising the following steps of: proportionally kneading TS-1 raw powder, silica sol, an extrusion aid, activated carbon fibers and boric acid so as to form a wet plastomer; and then drying and roasting, thereby obtaining the extrusion-molded TS-1 catalyst. During molding, the activated carbon fibers are introduced, and diffusion channels which run through whole particles are then formed after roasting, so that the efficiency for heat and mass transfer is increased, the secondary side reaction and catalyst deactivation caused by product retention are avoided, and the agglomeration of catalyst particles caused by adverse heat dissipation is prevented. Meanwhile, during molding, the boric acid is introduced, and the mechanical strength of the molded catalyst is then improved after roasting, so that the impact generated during the processes of transporting, loading and using and the abrasion caused by fluid flow can be effectively resisted, thereby being beneficial to the prolongation of the service life of the catalyst.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH +1

Flux-cored welding wire for overlaying welding and application thereof

InactiveCN101537548AScientific and reasonable hardnessReasonable hardnessWelding/cutting media/materialsSoldering mediaHardnessWear resistance

Aiming at the disadvantages and market demands of the prior art, the invention discloses a flux-cored welding wire for overlaying welding, which consists of a low-carbon steel strip and a flux core; the weight percentage composition of the flux core comprises: 1 to 3 percent of Mo, 2 to 6 percent of B, 1 to 4 percent of Si, 1 to 4 percent of Mn, 0.5 to 4 percent of C, 3 to 7 percent of Nb, 10 to 40 percent of Cr, 1 to 4 percent of Re and the balance of Fe. The filling amount of the flux core is 30 percent of the total weight of the flux-cored welding wire. The flux-cored welding wire for overlaying welding can be used for the overlaying welding of a wearproof belt of a drill rod of an oil field. Compared with the prior art, the flux-cored welding wire has excellent welding manufacturability, small splashing, good compatibility and good repeated overlaying weldability; and as the wearing resistance and antifriction performance of the wearproof belt of the welded drill rod are improved, the hardness of the wearproof belt reaches HRC 59-61.

Owner:高智海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com