Rubber composition and pneumatic tire

A rubber composition and rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of poor dispersion of silica, tire wear resistance, and decrease in breaking strength, and achieve wet skid resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

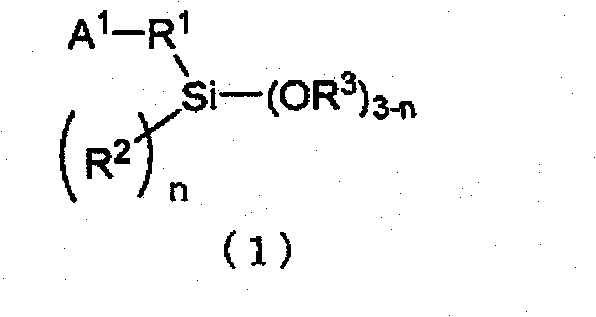

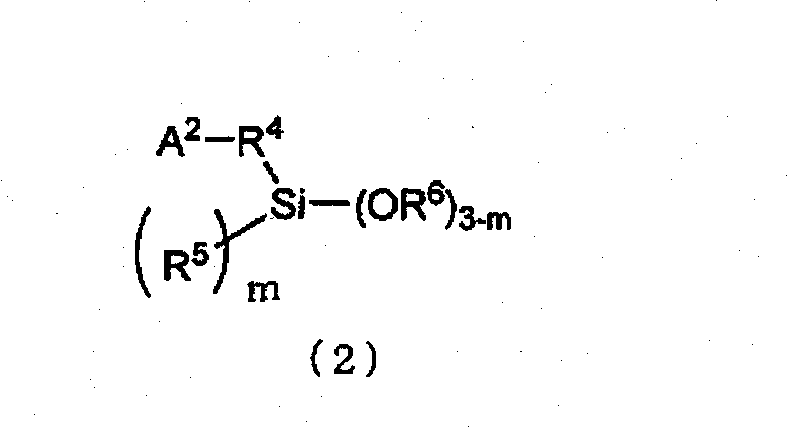

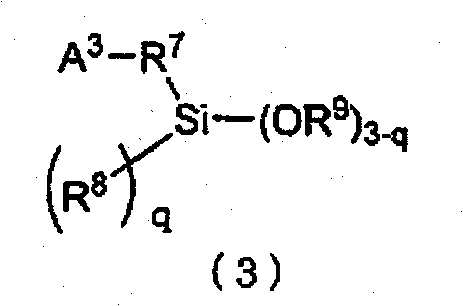

Method used

Image

Examples

Embodiment

[0202]Hereinafter, the present invention will be specifically described based on examples, but the present invention is not limited by these examples. In addition, "part" and "%" in an Example and a comparative example are a mass standard unless otherwise indicated. In addition, the measurement methods of various physical property values and the evaluation methods of various characteristics are as follows.

[0203] [Vinyl Bond Content (%) and Bonded Styrene Content (%)]: Use 1 H-NMR (270MHz) measurement and calculation.

[0204] [cis-1,4-bond content (%) and 1,2-vinyl bond content (%)]: Calculated by the infrared method (Morero method).

[0205] [Glass transition temperature (° C.)]: measured based on ASTM D3418.

[0206] [Molecular weight distribution (Mw / Mn)]: Using GPC with the trade name "HLC-8120" (manufactured by TOSOH Corporation) and using a differential refractometer as a detector, the weight average molecular weight (Mw) and The number average molecular weight ...

Synthetic example 1

[0215] 2500 g of cyclohexane, 25 g of tetrahydrofuran, 100 g of styrene, and 390 g of 1,3-butadiene were charged into a nitrogen-substituted autoclave reactor with an internal volume of 5 L. After adjusting the temperature of the contents of the reactor to 20° C., 375 mg of n-butyllithium was added to initiate polymerization. Polymerization under adiabatic conditions, the highest temperature reached 85 ℃. When the polymerization conversion rate reached 99%, 10 g of butadiene was added, and after further polymerization for 5 minutes, 1043 mg of methyltriethoxysilane was added as a modifier and reacted for 15 minutes. After the polymerization reaction was completed, 2,6-di-tert-butyl-p-cresol was added. Next, solvent removal was carried out by steam extraction, and drying was carried out with a heated roll adjusted to 110° C. to obtain a modified styrene-butadiene copolymer (SBR-A). The vinyl bond content of the obtained SBR-A is 55%, the bonded styrene content is 20%, the gla...

Synthetic example 2~5、7~10

[0217] Except using the formula shown in Table 1, modified styrene-butadiene copolymers (SBR-B, SBR-C, SBR-D, SBR-E, SBR -G, SBR-H, SBR-I, SBR-J). The vinyl bond content, bonded styrene content, glass transition temperature, Mooney viscosity (ML 1+4 , 100° C.) and weight average molecular weight (Mw) are shown in Table 1 and Table 2.

[0218] [Table 1]

[0219]

[0220] [Table 2]

[0221]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com