Patents

Literature

37results about How to "Reasonable hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flux-cored welding wire for overlaying welding and application thereof

InactiveCN101537548AScientific and reasonable hardnessReasonable hardnessWelding/cutting media/materialsSoldering mediaHardnessWear resistance

Aiming at the disadvantages and market demands of the prior art, the invention discloses a flux-cored welding wire for overlaying welding, which consists of a low-carbon steel strip and a flux core; the weight percentage composition of the flux core comprises: 1 to 3 percent of Mo, 2 to 6 percent of B, 1 to 4 percent of Si, 1 to 4 percent of Mn, 0.5 to 4 percent of C, 3 to 7 percent of Nb, 10 to 40 percent of Cr, 1 to 4 percent of Re and the balance of Fe. The filling amount of the flux core is 30 percent of the total weight of the flux-cored welding wire. The flux-cored welding wire for overlaying welding can be used for the overlaying welding of a wearproof belt of a drill rod of an oil field. Compared with the prior art, the flux-cored welding wire has excellent welding manufacturability, small splashing, good compatibility and good repeated overlaying weldability; and as the wearing resistance and antifriction performance of the wearproof belt of the welded drill rod are improved, the hardness of the wearproof belt reaches HRC 59-61.

Owner:高智海

Waterborne two component polyurethane coating compositions comprising alicyclic rigid polyols

ActiveUS9365739B2Easy to moveReasonable hardnessPolyurea/polyurethane coatingsPolymer scienceOligomer

Owner:ROHM & HAAS CO

Submerged arc welding flux and wire for welding ultra-low temperature high manganese steel and preparation methods

ActiveCN109530881ABeautiful weld shapeGood mechanical propertiesArc welding apparatusWelding/cutting media/materialsSlagSubmerged arc welding

The invention discloses a submerged arc welding flux for welding ultra-low temperature high manganese steel. The flux is prepared by the following components, by weight: 3-6 parts of SiO2, 30-50 partsof MgO, 30-40 parts of Al2O3, 10-20 parts of CaF2, 3-10 parts of TiO2, more than 0 and not more than 3.0 parts of Fe2O3, more than 0 and not more than 0.020 part of S and more than 0 and not more than 0.015 part of P. Compared with the prior art, the flux has the advantages of good welding processability, excellent slag removal, beautiful shape and better mechanical performance. The welding wireand flux of the invention can replace a nickel-based base material and welding material when welding ultra-low temperature high manganese having a manganese content of 13% or more and can meet the ultra-low temperature requirements of -196 DEG C.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Submerged-arc welding flux for 800MPa-grade high-strength steel for large-size hydropower facility and production method of submerged-arc welding flux

InactiveCN107745203AReduce P contentReasonable tensile strengthWelding/cutting media/materialsSoldering mediaCooking & bakingCrack resistance

The invention discloses submerged-arc welding flux for 800MPa-grade high-strength steel for a large-size hydropower facility and a production method of the submerged-arc welding flux. The submerged-arc welding flux comprises, by mass percentage, 9-23% of CaF2, 9-14% of Al2O3, 8-18% of SiO2, 18-34% of MgO, 15-22% of CaO, 1-5% of MnO, 0.5-3% of Fe2O3, less than or equal to 2.5% of Na2O, less than orequal to 2.5% of K2O and less than or equal to 2% of TiO2. The production method comprises the steps that after the elements are uniformly mixed according to the proportions, a binding agent accounting for 15% to 20% of the total amount of the materials is added for granulation; and then, 200-250 DEG C low-temperature baking, 670-780 DEG C high-temperature sintering and sieving are conducted, sothat a submerged-arc welding flux product is obtained. According to the submerged-arc welding flux and the production method thereof, a reasonable welding process is adopted to be matched with the chemical elements of the 800MPa high-strength steel, and therefore, chemical elements and textures of metal at each welding seam can reach the optimal state; the deposited metal S and the deposited metalP are low in content, and the flux has reasonable mechanical property indexes such as the tensile strength, the impact value, the bending property, the crack resistance and the hardness; and in addition, air holes, slag inclusion and cracks inside each welding seam as well as appearance edge excessiveness, undercuts and the like meet the standard requirements.

Owner:SICHUAN XIYE NEW MATERIAL

Waterborne two component polyurethane coating compositions comprising alicyclic rigid polyols

ActiveUS20140170327A1Improve curingEasy to movePretreated surfacesPolyurea/polyurethane coatingsEmulsionOligomer

The present invention provides two-component polyurethane compositions that are substantially free of VOCs and comprising, as one component, polyisocyanate compositions and, as a second component, a polyol which is chosen from a cycloaliphatic diol or polyol having a molecular weight of from 100 to 500 and containing one or more 4 to 7 member aliphatic ring and an oligomeric diol or polyol comprising the condensation reaction product of from 30 wt. % to 78 wt. %, based on the total weight of reactants used to make the oligomer, and an acrylic or vinyl emulsion polymer.

Owner:ROHM & HAAS CO

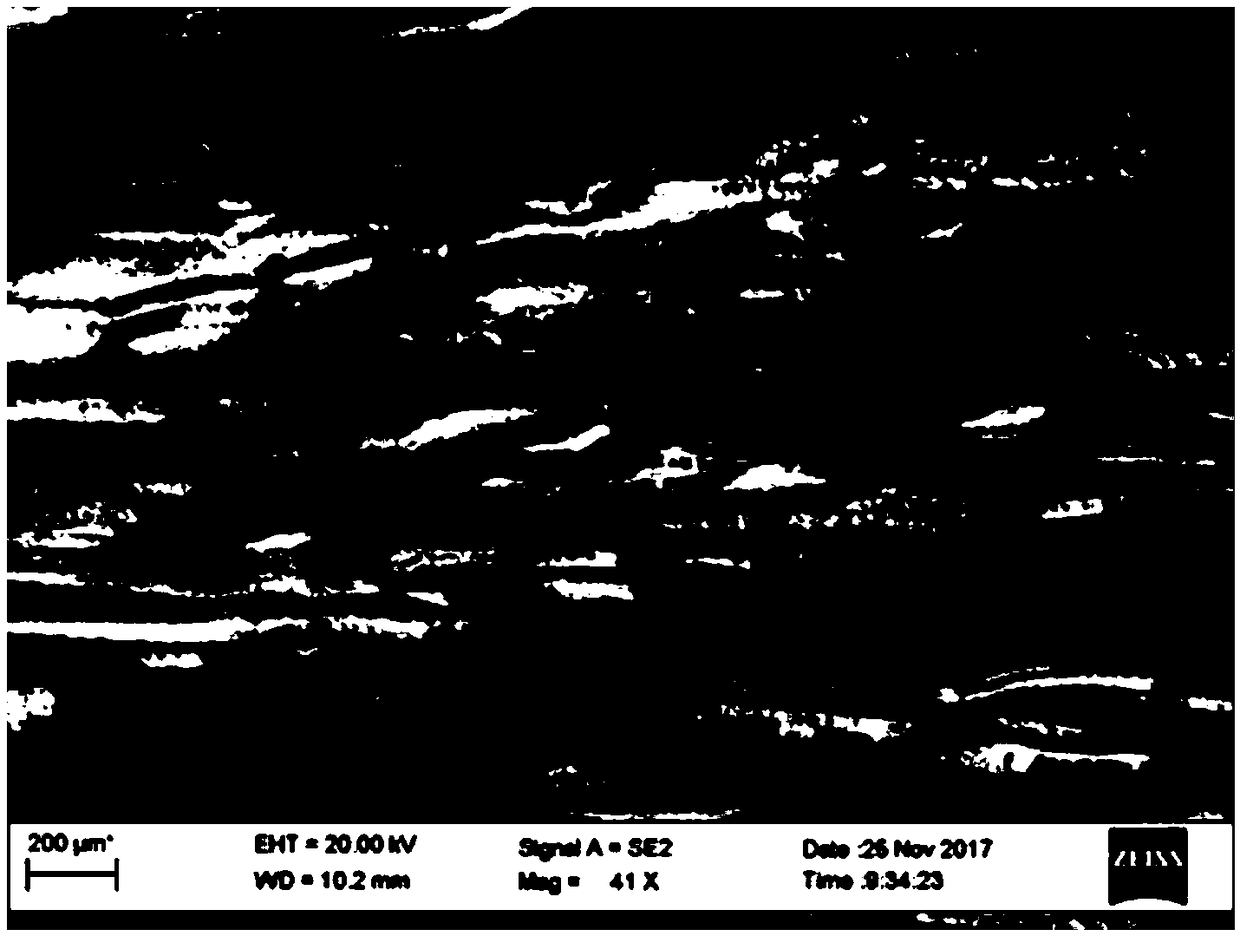

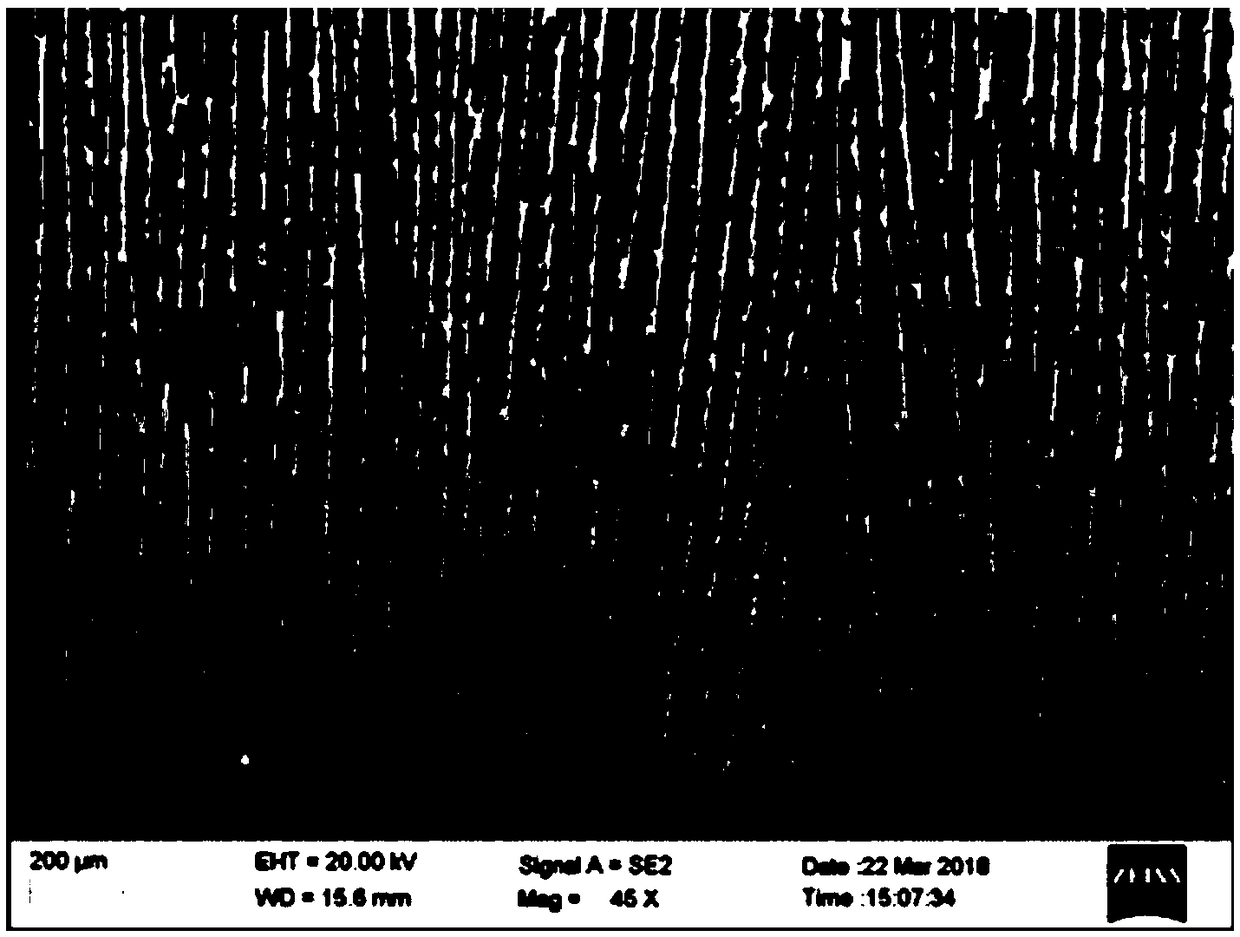

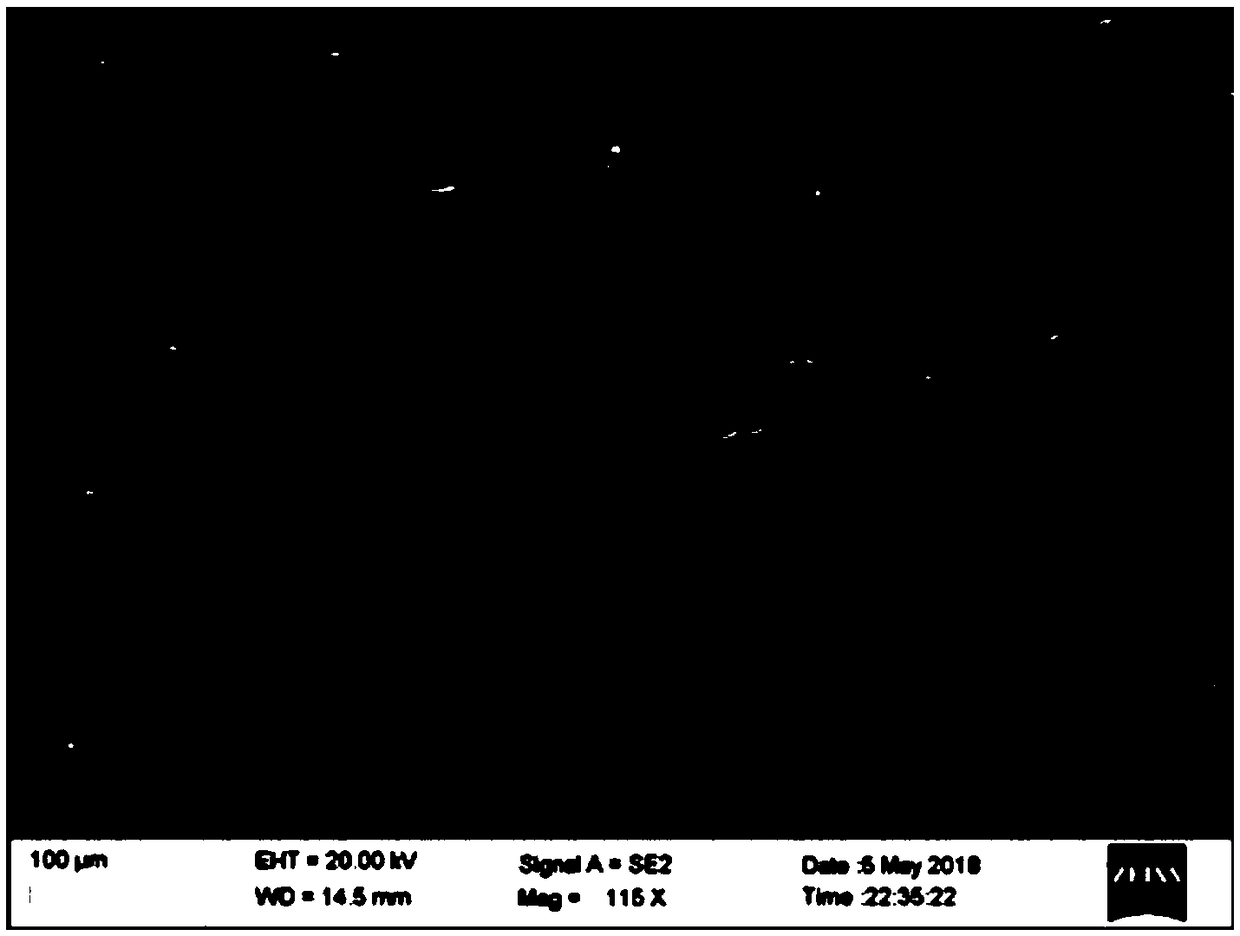

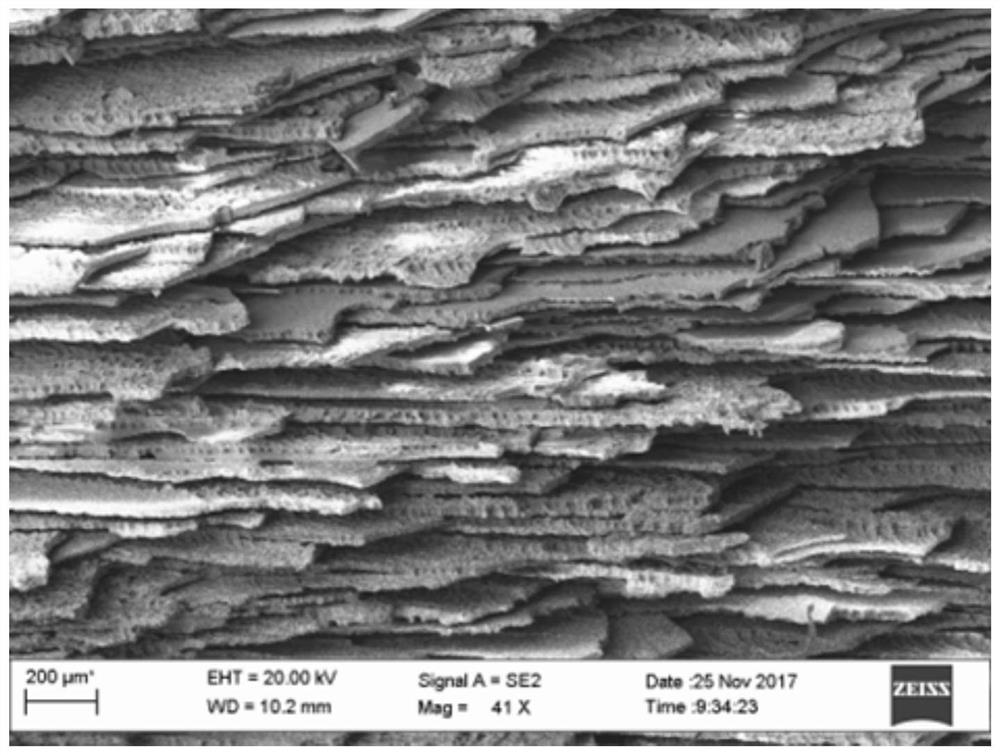

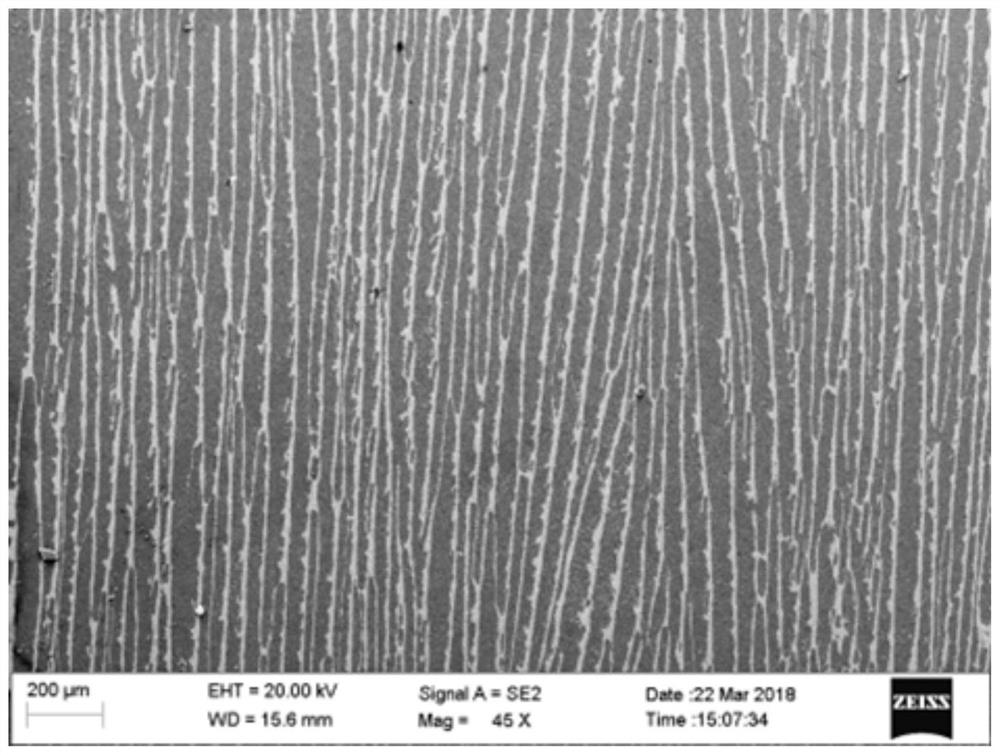

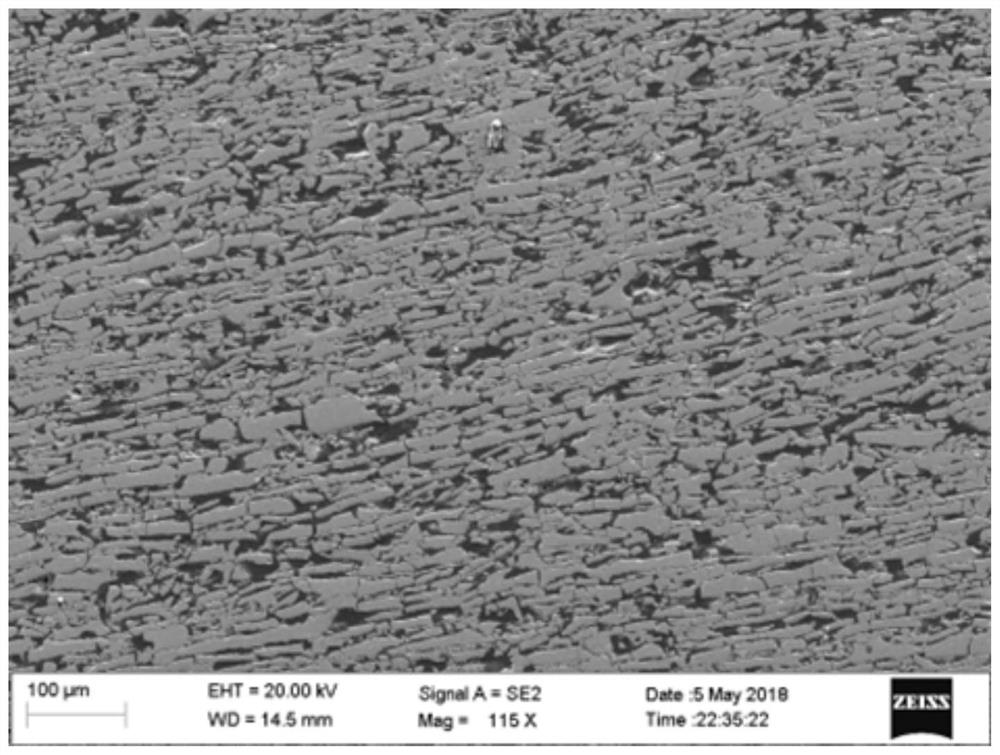

Zirconium oxide/resin bionic composite material for denture and preparation method thereof

ActiveCN108743405AGood biocompatibilityAccelerated corrosionImpression capsDentistry preparationsBrickFreeze-drying

The invention relates to the field of composite materials for denture, in particular to a zirconium oxide / resin bionic composite material for the denture and a preparation method thereof. The zirconium oxide / resin bionic composite material is prepared from the following components of 20vol% to 97vol% of zirconium oxide and biocompatible resin, and is of a bionic lamellar structure, a brick-wall structure or a crossed laminating structure in a microscopic way. The zirconium oxide / resin bionic composite material has the advantages that the oriented porous blank with the lamellar structure is obtained by slurry preparation, freezing-casting and vacuum freeze-drying, and is compressed along the lamellar structure direction to form the crossed laminating structure; the zirconium oxide skeletonwith the lamellar structure or crossing laminating structure can be prepared by removing organic matters and sintering, and the zirconium oxide skeleton of the brick-wall structure can be obtained through the vertical compression of the lamellar structure skeleton and the secondary sintering; the surface is subjected to surface modifying and liquid resin monomer permeating, and the resin is polymerized, so as to obtain the zirconium oxide / resin bionic composite material for the denture with the bionic structure; the prepared zirconium oxide / resin bionic composite material is mainly used as thedenture, so as to reduce the abrasion to the normal teeth of a human body by the denture.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Submerged arc welding flux for welding SA-508Gr.3Cl.1 steel of third-generation nuclear power equipment and preparation method thereof

ActiveCN104551446ASimple welding processBeautiful shapeArc welding apparatusWelding/cutting media/materialsSlagNuclear power

The invention discloses a submerged arc welding flux for welding SA-508Gr.3Cl.1 steel of third-generation nuclear power equipment and a preparation method thereof. The submerged arc welding flux comprises the following components in parts by weight: 8-15 parts of SiO2 (silicon dioxide), 20-30 parts of MgO (magnesium oxide), 20-30 parts of CaF2 (calcium fluoride), 20-30 parts of Al2O3 (aluminum oxide), 6-10 parts of CaO (calcium oxide), 2-4 parts of MnO2 (manganese dioxide), 0.3-1 parts of BaO (barium oxide), 1-2 parts of rare earth oxides, 0.014-0.016 part of S (sulfur), 0.013-0.015 part of P (phosphor), and 22-24 parts of water glass. Compared with the prior art, the submerged arc welding flux has the advantages that the welding technological property is excellent, the slag removal property is excellent, the forming appearance is attractive, and the mechanical property is more excellent.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

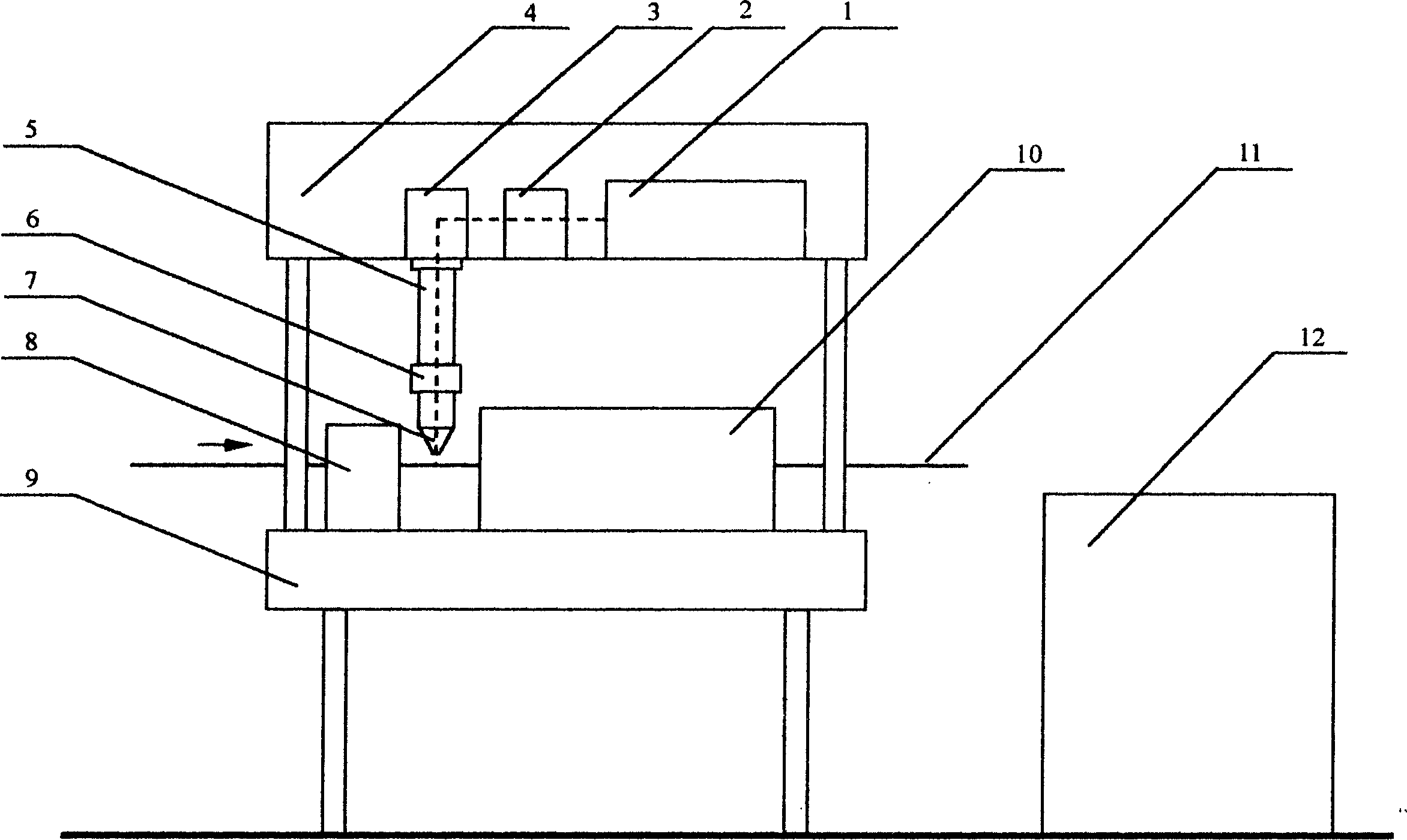

Carrier for electrophotographic developer, image forming method, and process cartridge

ActiveCN101206421AAppropriately express the effect of conductive treatmentEnough tonesElectrographic process apparatusDevelopersTin dioxideIndium

A carrier for electrophotographic developer that comprises a particle of core material and a coating layer that coats the particle of core material, wherein a toner and a carrier are supplied into a developing device where a toner and a carrier being contained, and the surplus developer within the developing device is discharged, a coating layer on at least one of the supplied carrier and the carrier contained in the developing device comprises a white conductive fine particle that includes tin dioxide and indium oxide on a base material.

Owner:RICOH KK

Soldering flux for submerged arc horizontal position welding of steel containment, preparation method and welding method

InactiveCN103737192ASimple welding processBeautiful shapeArc welding apparatusWelding/cutting media/materialsNuclear powerSlag

The invention relates to a soldering flux and discloses a soldering flux for submerged arc horizontal position welding of a steel containment. The soldering flux for submerged arc horizontal position welding of the steel containment comprises the following components of, by mass, 6-18% of SiO2, 22-40% of MgO, 12-28% of Al2O3, 15-30% of sigma CaO, 0.5-4% of MnO, 0.5-2% of Na2O, 0.2-2% of K2O, 0<TiO2<=3%, 0<Fe2O3<=3.0%, 0<S<=0.030%, and 0<P<=0.030%. Compared with soldering fluxes in prior art, the submerged arc soldering flux for submerged arc horizontal position welding of the steel containment is special for welding the steel containment for nuclear power and has the advantages of good welding manufacturability, slag removal effects and mechanical properties and attractive shaping.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

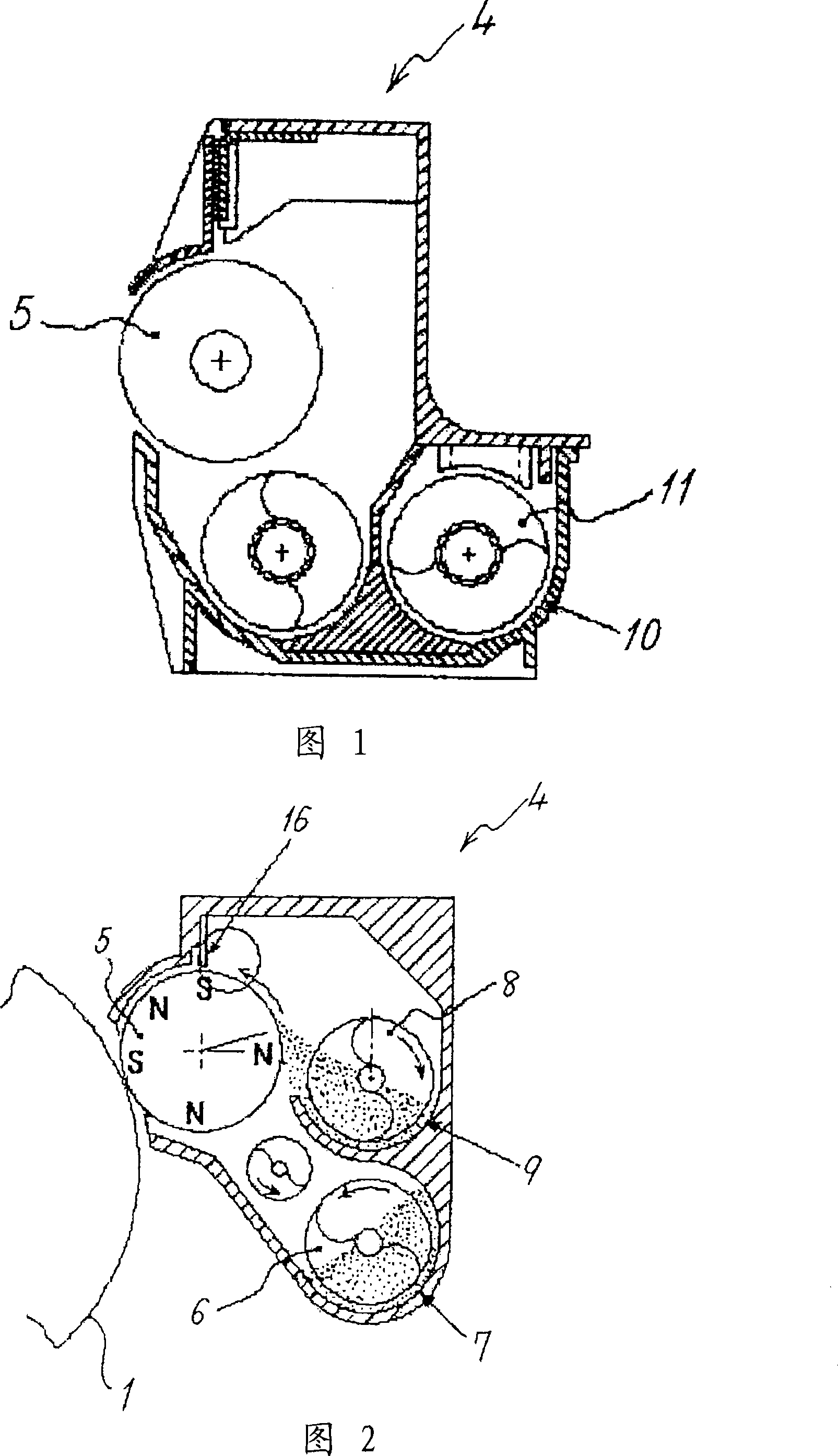

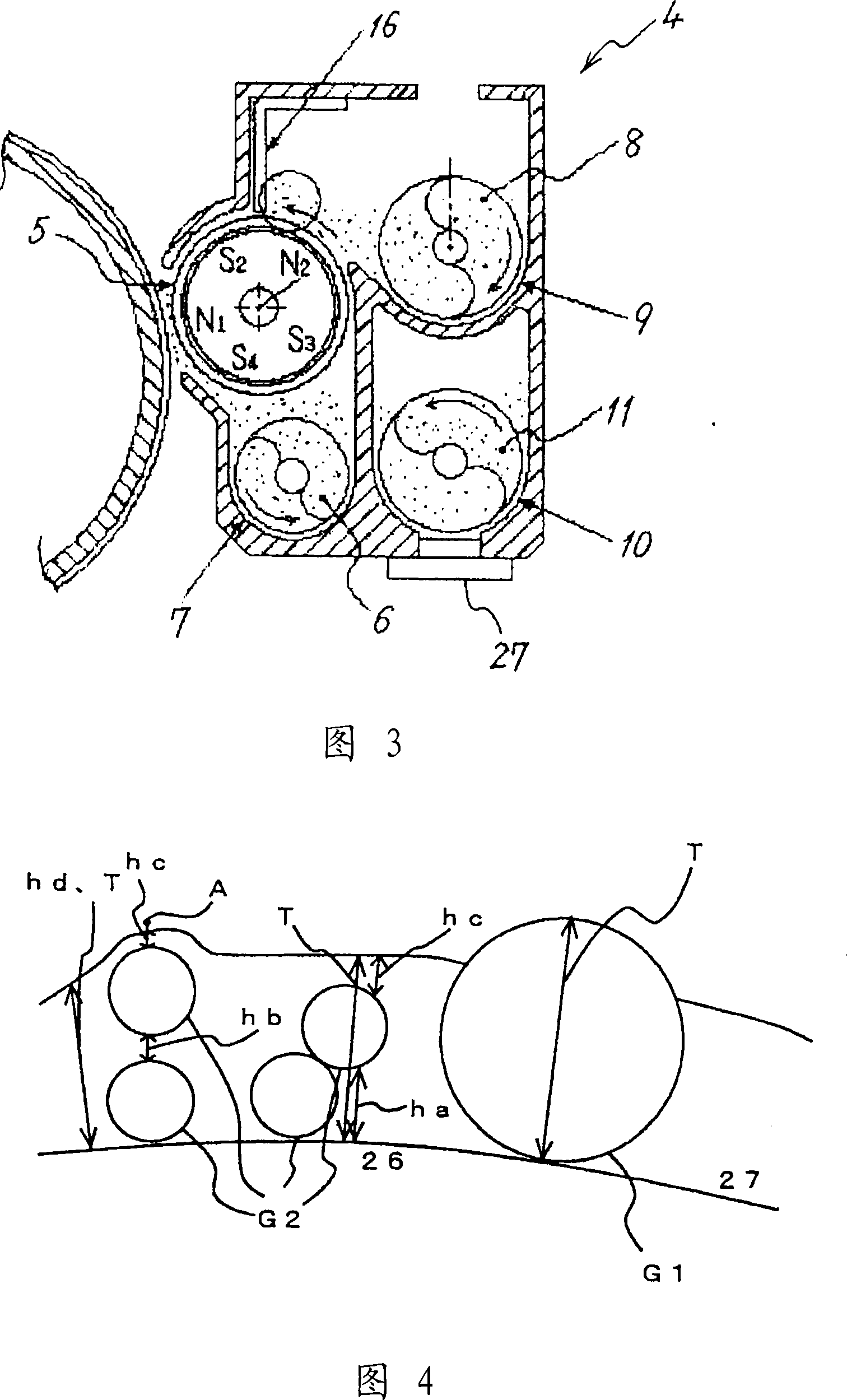

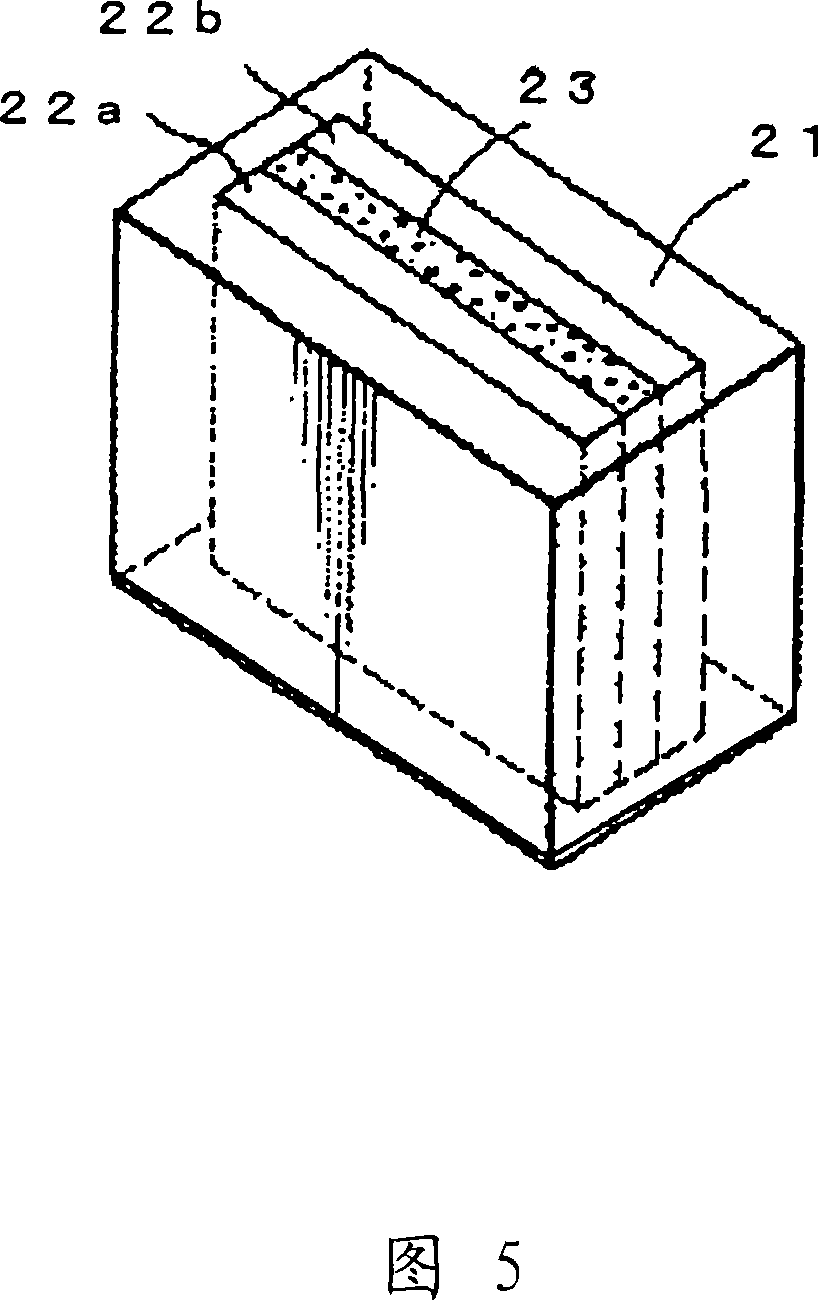

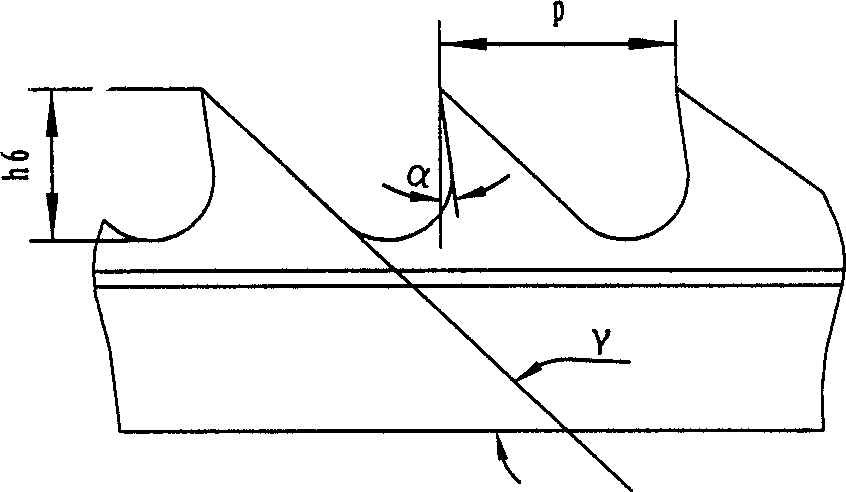

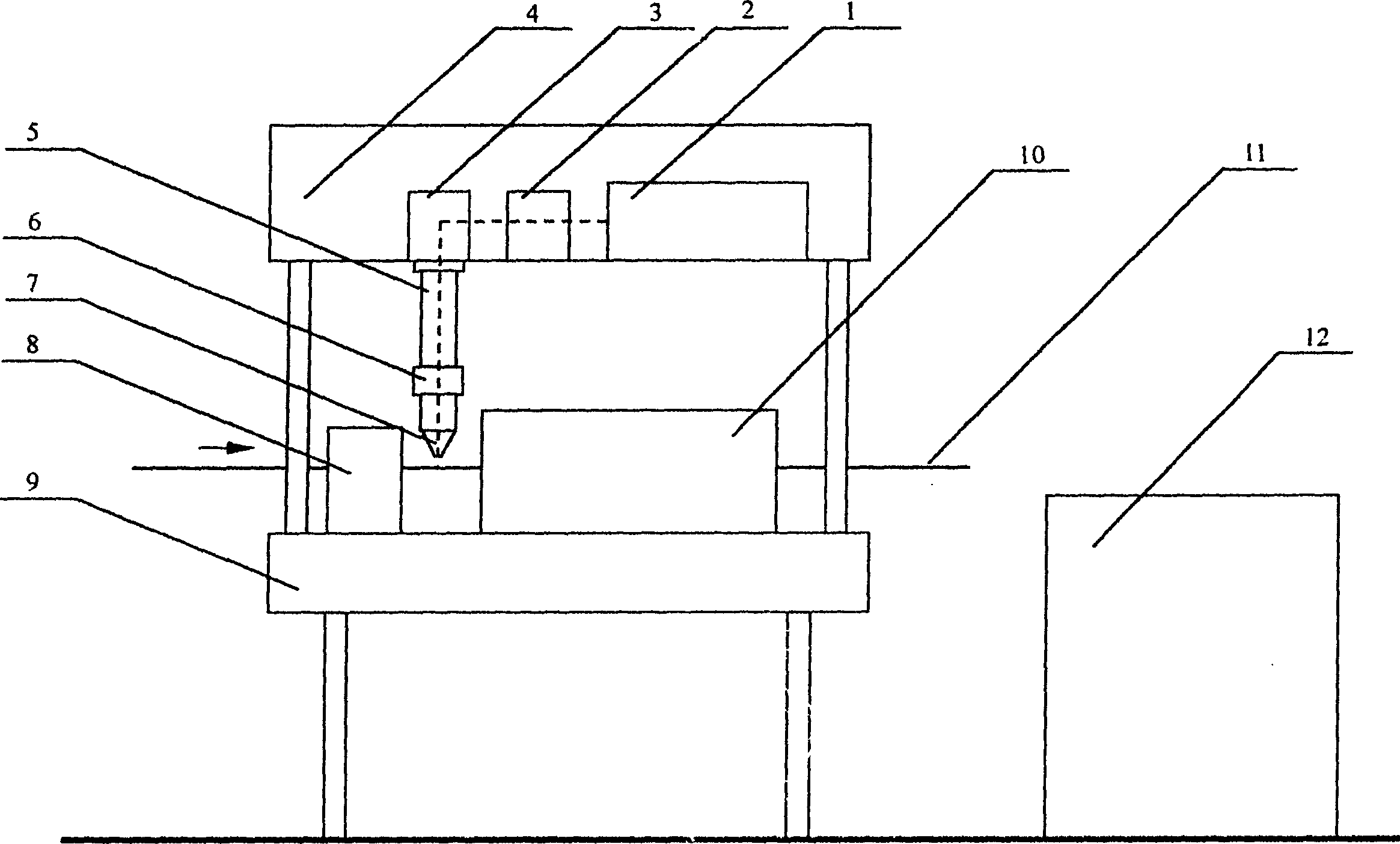

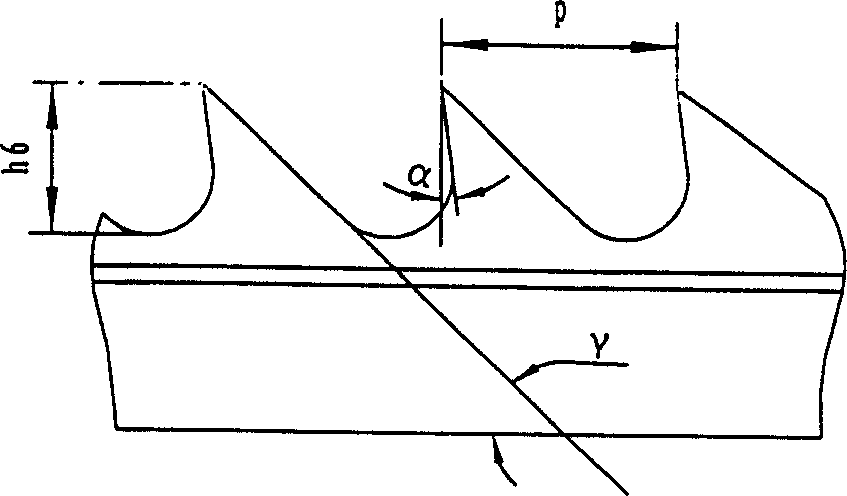

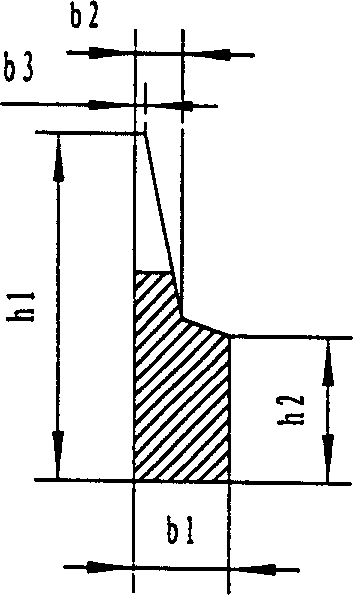

System and method for metal card clothing quenching treatment adopting YAG laser

InactiveCN1594606AUniform hardness distributionReasonable hardnessCarding machinesFurnace typesLight spotLight guide

The invention relates to a system and a method for rigid wire clothing quenching using YAG laser. The system includes: mounting beam enlarging lens, wholly reflective lens according to the YAG laser light path, reflective light entering into light guiding cartridge through light hole of work platform, other port of light guiding cartridge is connected with adjusting ring, adjusting ring is connected with focusing head, upper work platform is fixed on the low work platform, low work platform is fixed to ground, positioning device and cooling box is fixed to the low work platform, focusing head is in between, rigid wire clothing is fixing to movable mechanism of positioning device, the other end of rigid wire clothing pass through cooling box, controlling cabinet is mounted to ground, laser power resource and other bang-bang circuit is mounted in the controlling cabinet. Switching the laser power, YAG laser beam exported from laser is enlarged through beam enlarging lens, reflected by wholly reflective lens, focused by focusing lens in teeth of rigid wire clothing, form a high energy density light spot. That light spot energy is absorbed by teeth means thus the rigid wire clothing is quenched.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Flux-cored wire for build up welding and preparation method of flux-cored wire

InactiveCN105364337AReasonable hardnessWear resistance is sufficientWelding/cutting media/materialsSoldering mediaFriction reductionRoll forming

The invention discloses a flux-cored wire for build up welding and a preparation method of the flux-cored wire. The flux-cored wire for build up welding comprises a low-carbon steel belt and a flux core. The filling content of the flux core accounts for 30% of the total weight of the flux-cored wire. Powder of the flux core comprises, by weight percent, 1%-3% of Zr, 2%-6% of B, 1%-4% of Si, 1%-4% of Mn, 0.5%-4% of C, 3%-7% of Nb, 10%-40% of Cr, 1%-4% of Re and the balance Fe. The flux-cored wire for build up welding is prepared through pelleting, powder preparing, powder mixing, low-carbon steel belt clearing, roll forming and wire drawing forming. The flux-cored wire is good in welding manufacturability, small in splashing and good in compatibility and repeated build up welding performance. The wear resistance and friction reduction performance of a drill rod wear-resisting belt obtained through build up welding of the flux-cored wire are improved, the hardness of the wear-resisting belt is HRC59-61, and the flux-cored wire can be used for build up welding of the drill rod wear-resisting belt in an oil field.

Owner:上海博腾焊接材料有限公司

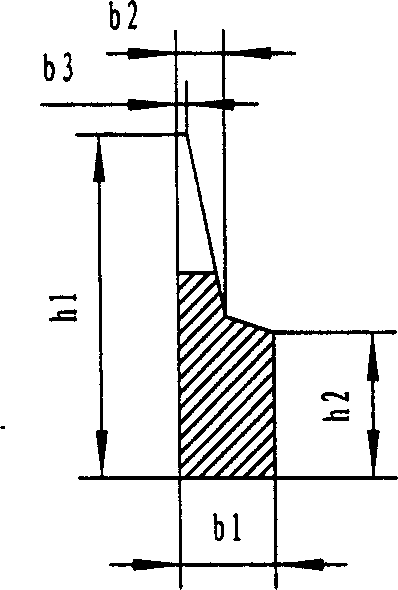

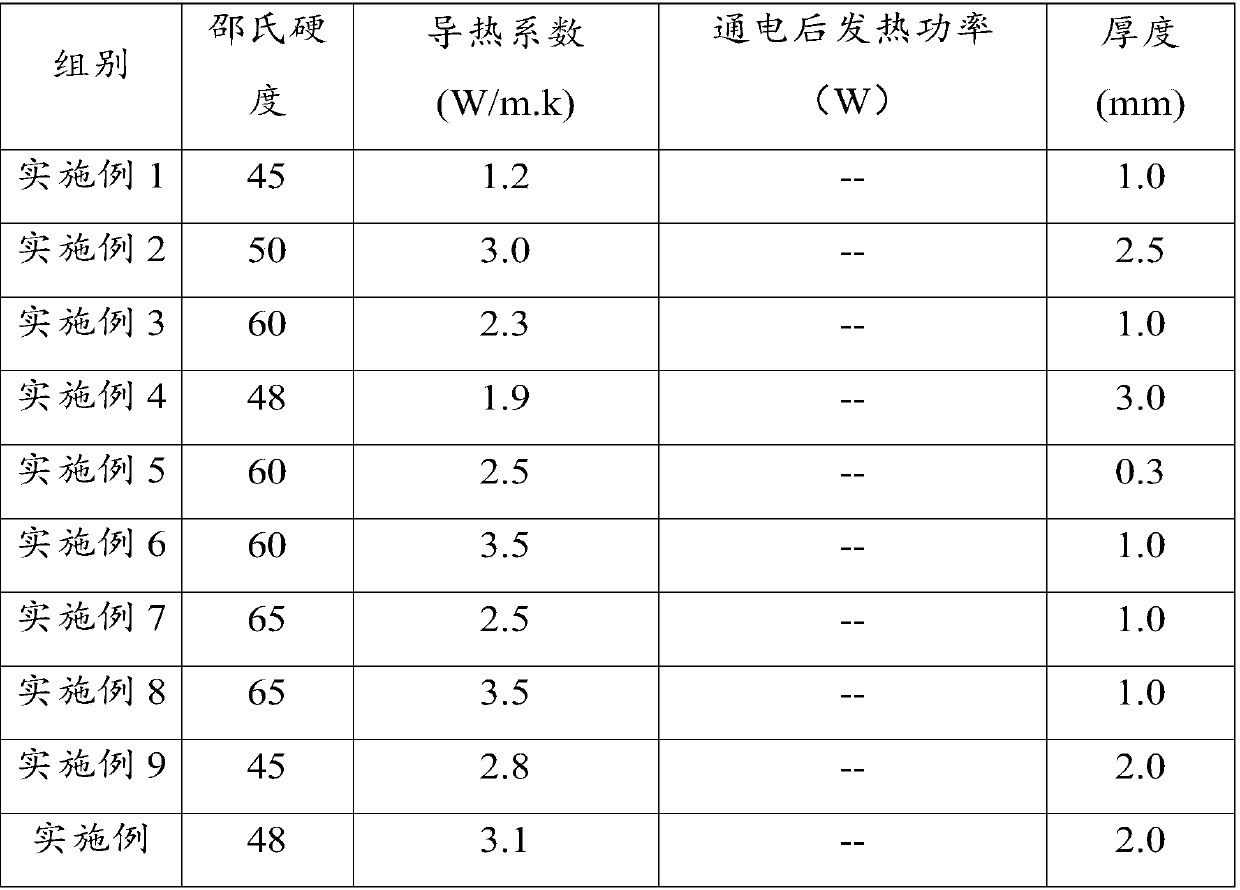

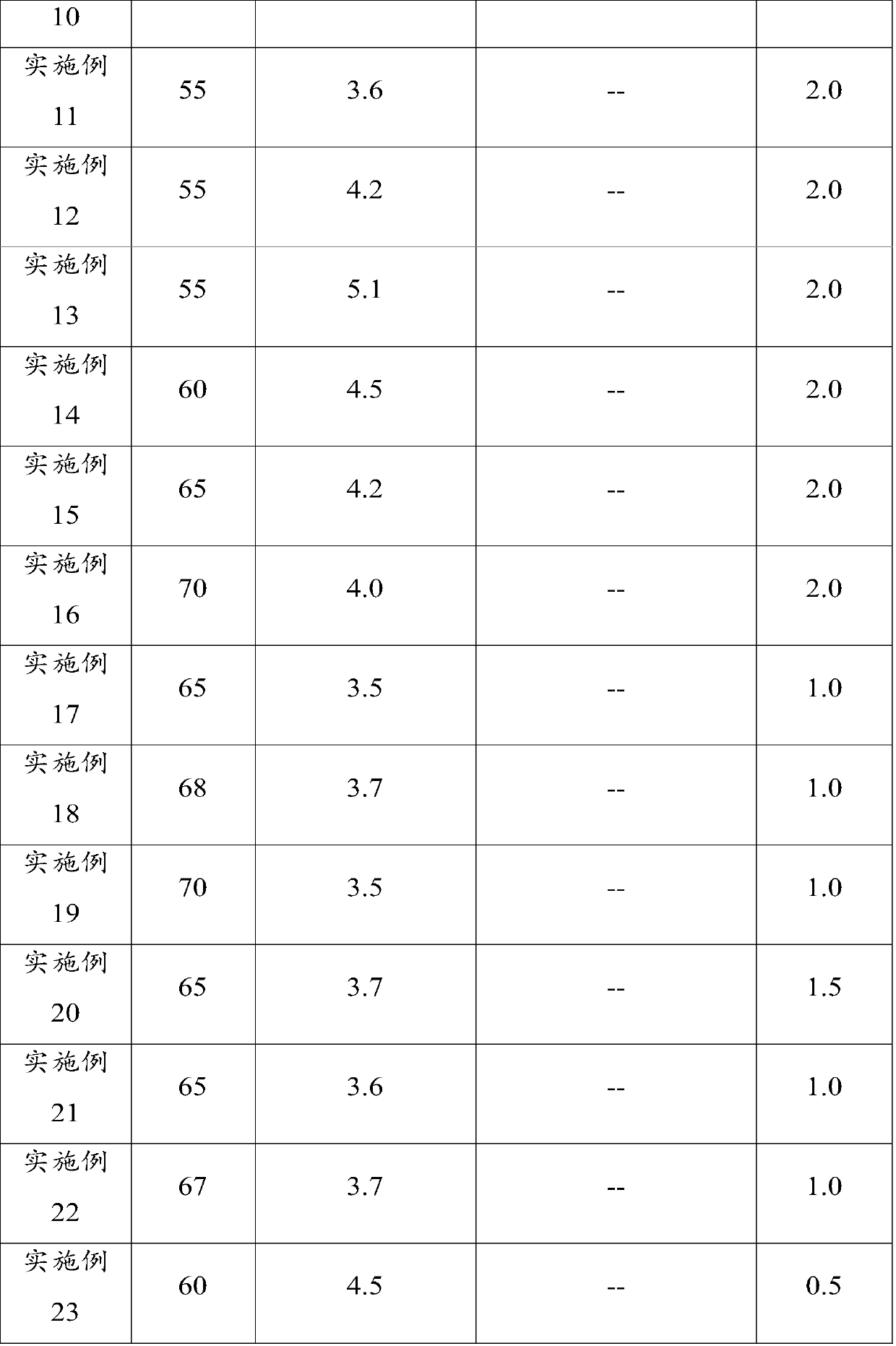

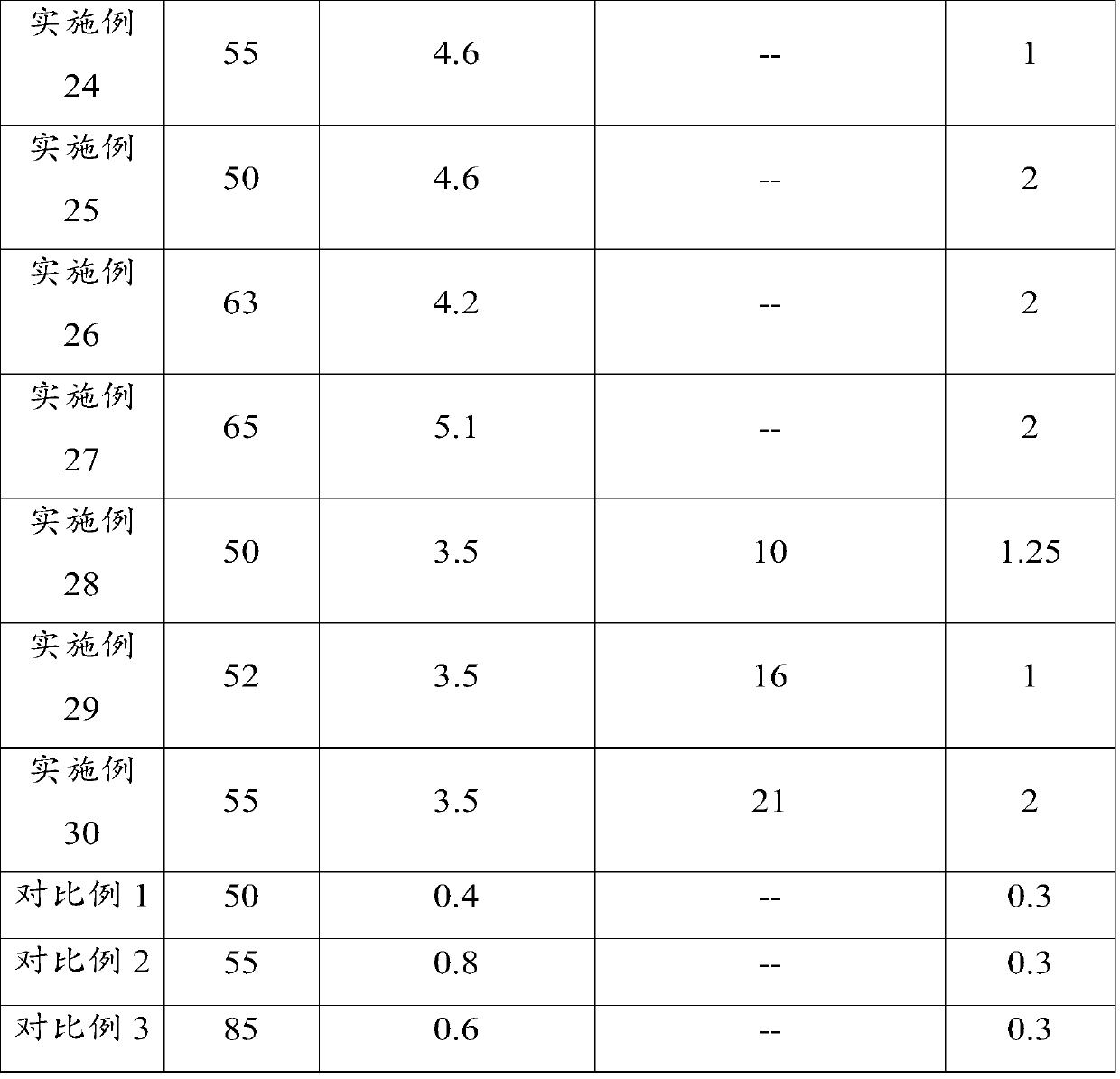

Thermally conductive silicone sheet as well as preparation method and application thereof, and thermally conductive heating silicone sheet as well as preparation method and application thereof

ActiveCN110172249AImprove thermal conductivityImprove high temperature resistanceHeat-exchange elementsModifications by conduction heat transferPolymer scienceHardness

The invention relates to the field of silicone sheets, and specifically provides a thermally conductive silicone sheet as well as a preparation method and application thereof, and a thermally conductive heating silicone sheet as well as a preparation method and application thereof. The thermally conductive silicone sheet is prepared from the following raw materials in parts by mass: 10-100 parts of silicone rubber, 300-1900 parts of a thermal conductive agent, 0.5-100 parts of a flame retardant agent, 0.3-6 parts of a reinforcing agent and 3-50 parts of a crosslinking agent, wherein the weightaverage molecular weight of the silicone rubber is 70-900,000. The thermally conductive silicone sheet has relatively high coefficient of thermal conductivity, reasonable hardness and relatively goodhigh temperature resistance, wherein the coefficient of thermal conductivity can reach 1-5 w / (m.k), and the hardness Shore OO is 40-80, so that the scope of application is wider.

Owner:杭州兆科电子材料有限公司

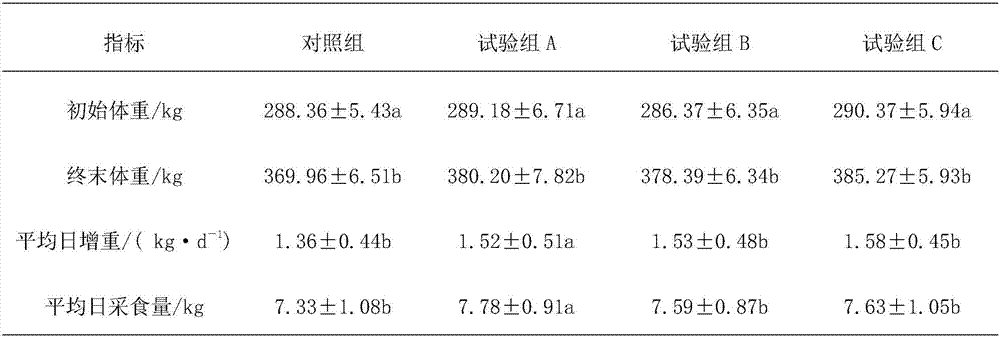

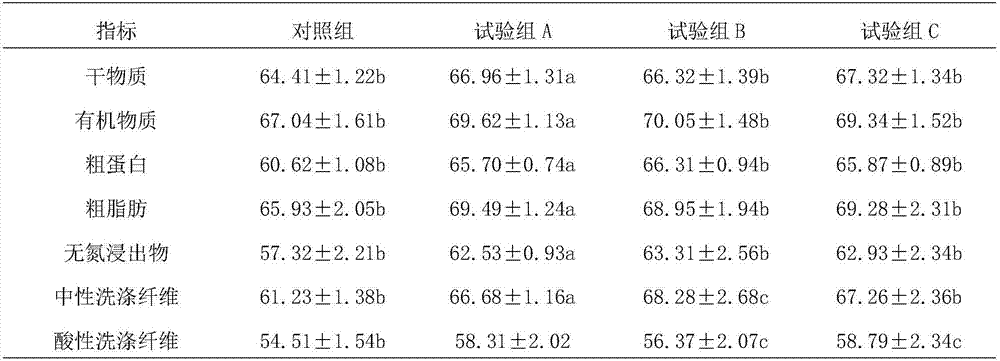

Parasite expelling and stomach strengthening compound premixed feed licking brick used for fattening cattle

InactiveCN107156469ASlow decompositionImprove absorption rateAnimal feeding stuffAccessory food factorsRumenCopper sulfate

The present invention relates to a licking brick for ruminants and specifically discloses a parasite expelling and stomach strengthening compound premixed feed licking brick used for fattening cattle. The compound premixed feed licking brick consists of edible made salt, haws, cellulase, ivermectin, albendazole, cement, bentonite, ammonium chloride, baking soda, calcium formate, a flavoring agent, calcium hydrogen phosphate, ferrous sulfate, copper sulfate, zinc sulfate, magnesium sulfate, manganese sulfate, sodium selenite, cobalt chloride, calcium iodate, rumensin, compound multi-vitamins and yeast powder. A density of the licking bricks is 1.8-2.2 g / cm<3>. The compound premixed feed licking brick has the following advantages: 1) the provided compound premixed feed licking brick is particularly suitable for licking of the fattening cattle, strengthens stomach, at the same time regulates body endocrine and gastrointestinal functions, promotes toxin removing and diuresis causing, effectively prevents food stagnation in rumen, gastroenteritis diseases, parasitic diseases, etc., and plays double effects of epidemic prevention and health care; and 2) the licking brick aims at nutrition needs and licking characteristics of the fattening cattle, is scientific in design and formula, rich in nutrition, appropriate in food intake, and reasonable in hardness, and can effectively improve production performances of the fattening cattle.

Owner:GUANGHAN LONGDA FEED

Technology for producing hard alloy woodworking blade by means of fine-particle return scraps

InactiveCN105642881ADoes not affect natureImprove wear resistanceTransportation and packagingMetal-working apparatusHeat resistanceHardness

The invention discloses a technology for producing a hard alloy woodworking blade by means of fine-particle return scraps. The technology comprises the following steps that S1, the fine-particle return scraps produced in the bar production process are recycled and dewaxed; S2, the return scrap treated in the step S1 are added into a rotary mill with hard alloy serving as a grinding body; and S3, spray particles are formed through a precision press and sintered in a pressure sintering furnace. The dewaxing technology is adjusted, so that it is guaranteed that dewaxing is carried out completely, and the property of the fine-particle return scraps is not influenced; the proper ball milling carbon addition technology is determined; by means of testing of the forming performance of various forming agents, a pressing test is carried out, the proper forming agents are screened out, and it is ensured that the pressing performance of a hard alloy woodworking cutter produced through the fine-particle return scraps is stable, and the forming agents are reasonable in ratio; and the wear resistance and heat resisting strength of the hard alloy woodworking blade manufactured through the technology are remarkably improved, hardness is reasonable, and the manufacturing cost is greatly reduced.

Owner:江西耀升钨业股份有限公司

High-hardness and low-carbon medium-cadmium wear-resisting steel ball and preparation method thereof

The invention discloses a high-hardness and low-carbon medium-cadmium wear-resisting steel ball. The high-hardness and low-carbon medium-cadmium wear-resisting steel ball comprises the following components in percentage by weight: 1.9-2.8% of C, 1.4-2.9% of Si, 0.6-0.8% of Mn, 3.6-5.4% of Cr, 0.6-1.2% of Cu, 0.1-0.3% of Mo, 0.1-0.3% of Re, less than 0.04% of S, less than 0.04% of P, and the balance Fe and inevitable impurities. The invention also discloses a preparation method of the high-hardness and low-carbon medium-cadmium wear-resisting steel ball. The low-cadmium wear-resisting steel ball is high in hardness and high in impact toughness.

Owner:WUHU BEISI SCI & TECH PARK

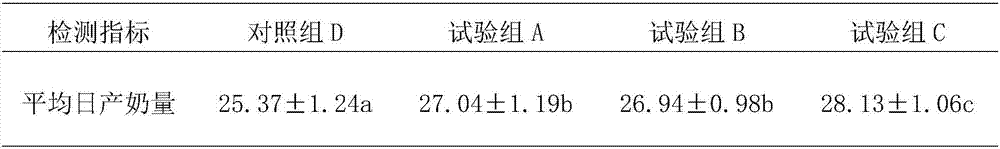

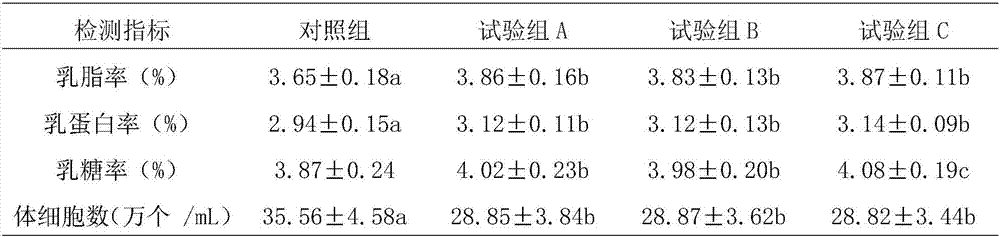

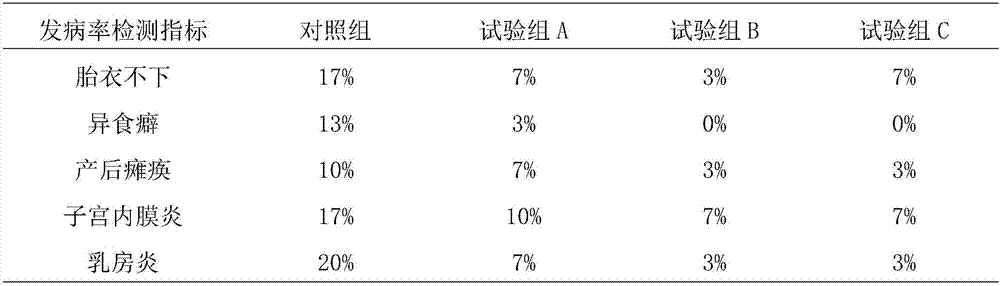

Special compound premixed feed lick brick for dairy cows in perinatal period

InactiveCN107333984AEnhance immune functionRaise the ratioFood processingAnimal feeding stuffBrickCalcium formate

The present invention relates to a lick brick for ruminants and particularly discloses a special compound premixed feed lick brick for dairy cows in a perinatal period. The special compound premixed feed lick brick for the dairy cows in the perinatal period comprises edible salt, cement, bentonite, calcium propionate, bacitracin zinc, baking soda, calcium formate, calcium carbonate, calcium hydrogen phosphate, a flavoring agent, glycine iron, copper glycinate, zinc glycinate, magnesium oxide, manganese glycinate, yeast selenium, cobalt chloride, calcium iodate, rumensin and compound multiple vitamins. A density of the lick brick is 1.7-1.9 g / cm<3>. According to nutritional requirements and licking characteristics of the dairy cows in the perinatal period, the compound premixed feed lick brick suitable for the dairy cows in the perinatal period is scientific in designs and formulas, rich in nutrition, adequate in feed intake and appropriate in hardness, and can effectively improve a production performance of the dairy cows in the perinatal period. Experiments show that a long-term licking of the lick brick can effectively reduce an incidence of trace element deficiency in the dairy cows in the perinatal period and can significantly improve milk production amount and quality.

Owner:GUANGHAN LONGDA FEED

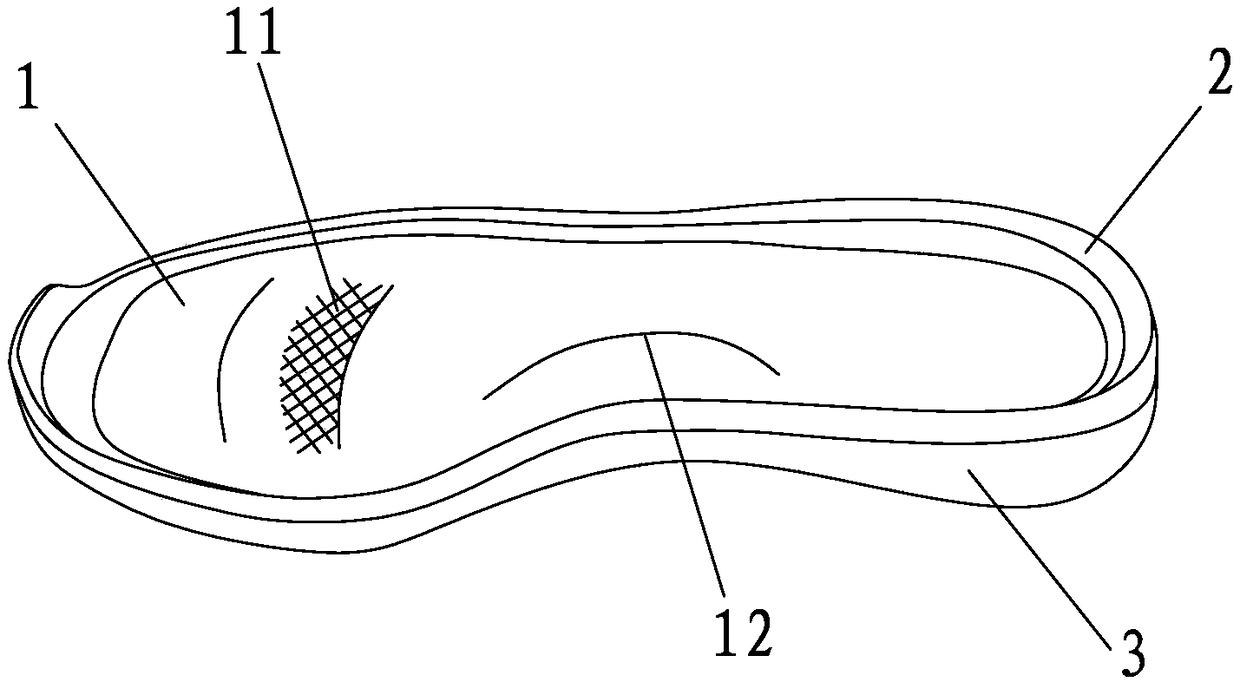

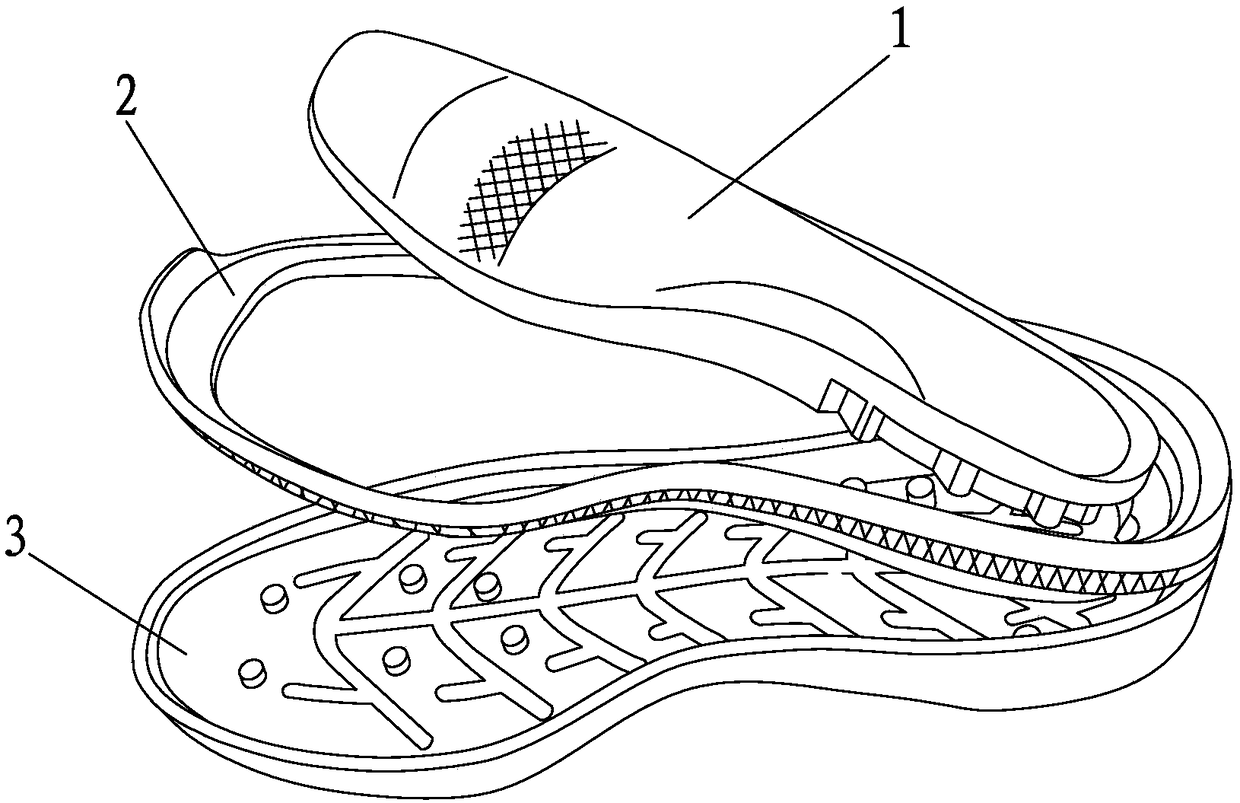

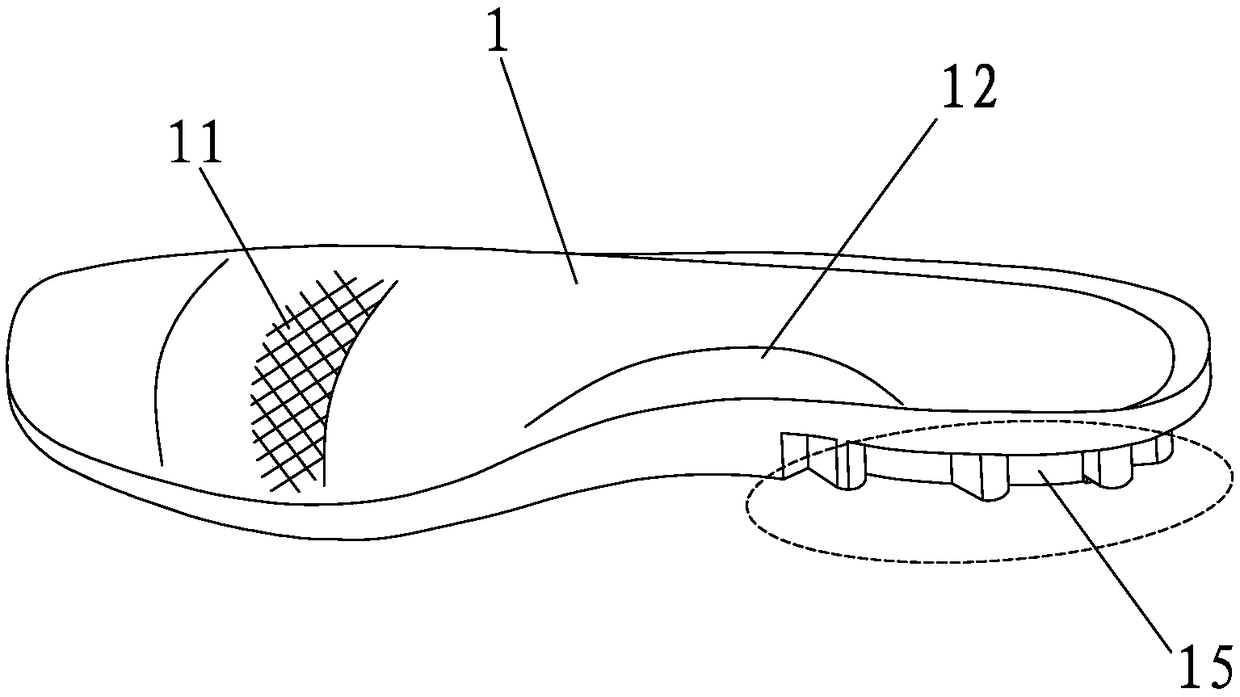

Multi-rigidity sole die and sole

The invention discloses a multi-rigidity sole and a sole die. The sole die comprises a sole body die and a core die, the upper surface of the core die is provided with a first toe joint protrusion which is arranged horizontally and a first inner vertical protrusion which is arranged vertically, and the sole is formed through lamination, clamping and foaming of the core die and the sole body die. Compared with the prior art, the multi-rigidity sole and the sole die have the advantages that the toe joint protrusion and the first inner vertical protrusion of the upper surface of the core die aredesigned according to human engineering, a foamed sole core accords with the structure characteristics of the feet of the human body, the wrapping performance of shoes can be improved, and the feet are better protected. In addition, the rigidity of the core is lower than that of a shoe body, and the wearing comfort and stability of supporting the feet are guaranteed.

Owner:黑天鹅智能科技(福建)有限公司

System and method for metal card clothing quenching treatment adopting YAG laser

InactiveCN1245525CUniform hardness distributionReasonable hardnessCarding machinesFurnace typesLight spotLight guide

The invention relates to a system and a method for rigid wire clothing quenching using YAG laser. The system includes: mounting beam enlarging lens, wholly reflective lens according to the YAG laser light path, reflective light entering into light guiding cartridge through light hole of work platform, other port of light guiding cartridge is connected with adjusting ring, adjusting ring is connected with focusing head, upper work platform is fixed on the low work platform, low work platform is fixed to ground, positioning device and cooling box is fixed to the low work platform, focusing head is in between, rigid wire clothing is fixing to movable mechanism of positioning device, the other end of rigid wire clothing pass through cooling box, controlling cabinet is mounted to ground, laser power resource and other bang-bang circuit is mounted in the controlling cabinet. Switching the laser power, YAG laser beam exported from laser is enlarged through beam enlarging lens, reflected by wholly reflective lens, focused by focusing lens in teeth of rigid wire clothing, form a high energy density light spot. That light spot energy is absorbed by teeth means thus the rigid wire clothing is quenched.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

Aluminum alloy for decoration and production process thereof

The invention discloses an aluminum alloy for decoration and a production process thereof and relates to the field of building materials. The aluminum alloy contains, by mass, 1.5-4.5% of Fe, 0.6-1.0% of Cu, 1.0-3.0% of Co, 0.2-0.5% of Sb, 0.5-1.0% of Sc, 0.5-0.9% of Zn, 0.3-0.7% of Rb, 0.4-0.8% of Si, 0.5-0.8% of Mo, 0.2-0.4% of Pb, 0.15-0.3% of Mn and the balance of aluminum and unavoidable impurities. By adopting the technical scheme, production efficiency is high, corrosion resistance of the aluminum alloy is guaranteed, glossiness of the surface of an aluminum alloy section is improved, the surface of the aluminum alloy section is free of cracks, peeling and air bubbles, and the aluminum alloy section is ensured to have reasonable tensility, strength and hardness.

Owner:肥西县碧涛建材有限公司

Preparation method of adhesive for wafer cutting

InactiveCN104497942AHigh hardnessReasonable hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveWafer dicing

The invention relates to a preparation method of an adhesive for wafer cutting. The preparation method comprises the following steps of: (1) preparing a component A; (2) preparing a component B; (3) weighing the component A and the component B in parts by weight, sufficiently and uniformly mixing, then uniformly carrying out knife coating on the surfaces of a crystal bar and a glass plate, tightly pressing and fixing on the glass plate, standing for 1 hour, then moving the crystal bar, sufficiently solidifying for 4 hours, and then cutting on a machine to obtain a finished product. The adhesive has the characteristics of easiness for debonding, high hardness, good toughness and the like, is suitable for the cutting of a wafer and can be used for reducing the wafer drop and edge brightening and enhancing the superior product rate.

Owner:杨大华

A welding third-generation nuclear power equipment sa-508gr. 3cl. 1 Submerged arc flux for steel and its preparation method

ActiveCN104551446BSimple welding processBeautiful shapeArc welding apparatusWelding/cutting media/materialsNuclear powerSlag

The invention discloses a submerged arc welding flux for welding SA-508Gr.3Cl.1 steel of third-generation nuclear power equipment and a preparation method thereof. The submerged arc welding flux comprises the following components in parts by weight: 8-15 parts of SiO2 (silicon dioxide), 20-30 parts of MgO (magnesium oxide), 20-30 parts of CaF2 (calcium fluoride), 20-30 parts of Al2O3 (aluminum oxide), 6-10 parts of CaO (calcium oxide), 2-4 parts of MnO2 (manganese dioxide), 0.3-1 parts of BaO (barium oxide), 1-2 parts of rare earth oxides, 0.014-0.016 part of S (sulfur), 0.013-0.015 part of P (phosphor), and 22-24 parts of water glass. Compared with the prior art, the submerged arc welding flux has the advantages that the welding technological property is excellent, the slag removal property is excellent, the forming appearance is attractive, and the mechanical property is more excellent.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

Adhesive for cutting wafer

InactiveCN104497894AReasonable hardnessGood toughnessNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveChemistryPlasticizer

The invention relates to an adhesive for cutting wafer. The adhesive comprises a component A and a component B at a weight part ratio of (25-40) to (17-31), wherein the component A comprises the following components in parts by weight: 80-100 parts of epoxy resin, 40-50 parts of polyvinyl alcohol, 15-30 parts of sodium hydrogen sulfite, 10-25 parts of precipitated barium sulphate, 1-5 parts of crylic acid, 2-10 parts of ethanol and 1.5-7.5 parts of 2-ethylhexyl epoxystearate; and the component B comprises the following components in parts by weight: 40-50 parts of nitrile rubber, 10-12.5 parts of butyl acrylate, 1-5 parts of a plasticizer and 0.1-2 parts of a coupling reagent. The adhesive has the characteristics of being easy to degum, relatively high in hardness and good in tenacity, and is applicable to cutting thin wafers; and meanwhile, a chip shell and a bright side are reduced, so that the good-grade rate is improved.

Owner:陆锋

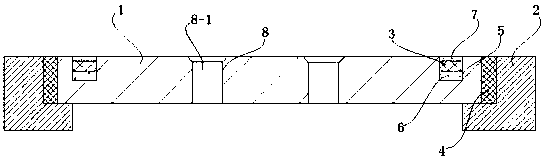

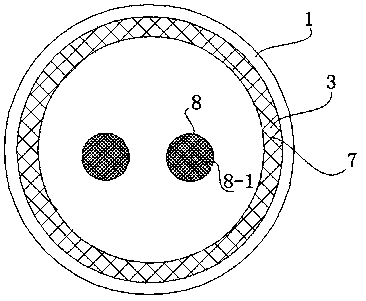

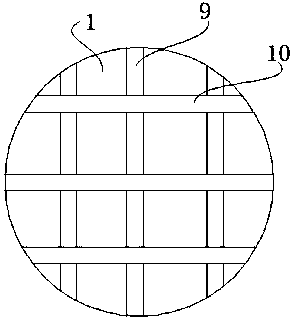

Inspection well lid used for rainwater and sewage integrated pipeline

InactiveCN110397147AExtended service lifeAvoid damageSewerage structuresSewageMechanical engineering

The invention discloses an inspection well lid used for a rainwater and sewage integrated pipeline. The inspection well lid used for the rainwater and sewage integrated pipeline comprises an inspection well lid body (1), a bearing ring body (2), a light-reflecting loop (3) and a sealing ring (4). The sealing ring is arranged on the inner side wall of the bearing ring body. The inspection well lidbody is embedded in the sealing ring and is matched with the bearing ring body. An annular groove (5) is formed in the upper end face of the inspection well lid body along the edge of the inspection well lid body. An adhesive layer (6) is arranged in the annular groove. The light-reflecting loop is arranged in the annular groove through the adhesive layer. A protective steel wire mesh (7) is embedded above the annular groove, and the upper surface of the protective steel wire mesh is flush with the upper end face of the inspection well lid body. Floor drain mounting holes (8) are formed in theinspection well lid body, and floor drains (8-1) matched with the floor drain mounting holes are mounted in the floor drain mounting holes. Longitudinal reinforcing ribs (9) and horizontal reinforcing ribs (10) are arranged on the lower end face of the inspection well lid body. The inspection well lid used for the rainwater and sewage integrated pipeline is reasonable in structural design.

Owner:徐天宏

Zirconia/resin biomimetic composite material for dentures and preparation method thereof

ActiveCN108743405BGood biocompatibilityAccelerated corrosionImpression capsDentistry preparationsFreeze-dryingLiquid resin

The invention relates to the field of composite materials for denture, in particular to a zirconium oxide / resin bionic composite material for the denture and a preparation method thereof. The zirconium oxide / resin bionic composite material is prepared from the following components of 20vol% to 97vol% of zirconium oxide and biocompatible resin, and is of a bionic lamellar structure, a brick-wall structure or a crossed laminating structure in a microscopic way. The zirconium oxide / resin bionic composite material has the advantages that the oriented porous blank with the lamellar structure is obtained by slurry preparation, freezing-casting and vacuum freeze-drying, and is compressed along the lamellar structure direction to form the crossed laminating structure; the zirconium oxide skeletonwith the lamellar structure or crossing laminating structure can be prepared by removing organic matters and sintering, and the zirconium oxide skeleton of the brick-wall structure can be obtained through the vertical compression of the lamellar structure skeleton and the secondary sintering; the surface is subjected to surface modifying and liquid resin monomer permeating, and the resin is polymerized, so as to obtain the zirconium oxide / resin bionic composite material for the denture with the bionic structure; the prepared zirconium oxide / resin bionic composite material is mainly used as thedenture, so as to reduce the abrasion to the normal teeth of a human body by the denture.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

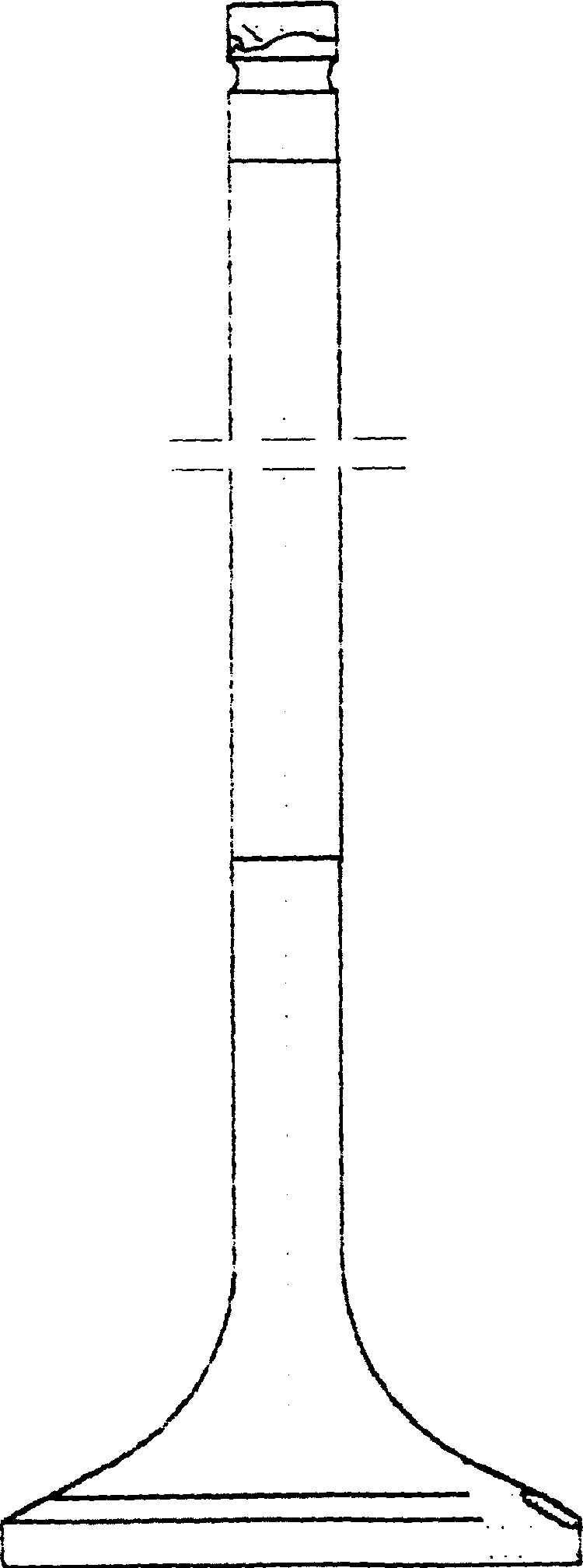

Method of manufacture reinforcing air intake valve for diesel engine of diesel locomotive

InactiveCN1281852CImprove performanceSimple processInternal combustion piston enginesLift valveDiesel locomotiveInlet valve

The reinforcing air intake valve for diesel engine of diesel locomotive is manufactured with reinforced martensite steel comprising C 0.38-0.50 wt%, Si 2.50-3.75 wt%, Mn less than or equal to 0.80 wt%, Ni less than or equal to 0.50, Cr 8.5-11.0 wt%, S less than or equal to 0.002 wt%, P less than or equal to 0.003 wt%, Mo 0.2-0.3 wt% other than Fe. The gate material has good performance and machinability, stable quality and high performance / cost ratio. The gate after heat treatment has high strength, excellent comprehensive performance, high roughness and good fitting with plastic.

Owner:BEIJING TEYE IND & TRADE

Aluminum alloy for decoration and production process thereof

The invention discloses aluminum alloy for decoration and a production process thereof, and relates to the field of building materials. The aluminum alloy for decoration comprises, by mass, 1.5-4.5% of Fe, 0.6-1.0% of Cu, 1.0-3.0% of Co, 0.2-0.5% of Sb, 0.5-1.0% of Sc, 0.5-0.9% of Zn, 0.3-0.7% of Rb, 0.4-0.8% of Si, 0.5-0.8% of Mo, 0.2-0.4% of Pb, 0.15-0.3% of Mn, and the balance aluminum and inevitable impurities. By the adoption of the technical scheme provided by the invention, the production efficiency is high, the corrosion resistance of the aluminum alloy is guaranteed, meanwhile, the surface glossiness of aluminum alloy sections is improved, the surfaces of the aluminum alloy sections are free of cracks, peeling and bubbles, and the aluminum alloy sections have reasonable extensibility, strength and hardness.

Owner:合肥慧林建材有限公司

Adhesive for wafer cutting

InactiveCN104497894BHigh hardnessReasonable hardnessNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyAdhesive cement

The invention relates to an adhesive for cutting wafer. The adhesive comprises a component A and a component B at a weight part ratio of (25-40) to (17-31), wherein the component A comprises the following components in parts by weight: 80-100 parts of epoxy resin, 40-50 parts of polyvinyl alcohol, 15-30 parts of sodium hydrogen sulfite, 10-25 parts of precipitated barium sulphate, 1-5 parts of crylic acid, 2-10 parts of ethanol and 1.5-7.5 parts of 2-ethylhexyl epoxystearate; and the component B comprises the following components in parts by weight: 40-50 parts of nitrile rubber, 10-12.5 parts of butyl acrylate, 1-5 parts of a plasticizer and 0.1-2 parts of a coupling reagent. The adhesive has the characteristics of being easy to degum, relatively high in hardness and good in tenacity, and is applicable to cutting thin wafers; and meanwhile, a chip shell and a bright side are reduced, so that the good-grade rate is improved.

Owner:陆锋

Polishing liquid for stainless steel processing

The invention discloses a polishing solution for stainless steel processing, and relates to a polishing solution. The polishing solution for stainless steel processing is specifically prepared from deionized water, diamond, boron carbide, silicon carbide, zirconium oxide, lanthanum oxide, scandium oxide, hydrotalcite, diethanol amine, pentaerythritol, 1,2-diethoxyethane, urotropin, polyoxyethylene poly-oxypropylene pentaerythrilol ether, sodium dodecyl benzene sulfonate, cetyl sodium sulfate and glycerol. The finally prepared polishing solution can complete polishing of stainless steel rapidly and efficiently, the processing quality is high and stable, the defective rate is decreased, and the polishing solution has good application and promotion value.

Owner:ANHUI BAOHENG ADVANCED MATERIAL TECH CO LTD

Submerged arc welding flux, welding wire and preparation method for welding ultra-low temperature high manganese steel

ActiveCN109530881BSimple welding processGuaranteed low temperature impact toughnessArc welding apparatusWelding/cutting media/materialsManganeseWelding process

The present invention disclosed a buried arc welded welding for welding ultra -low -temperature high -manganese steel, which is made from the following components: SIO 2 3‑6 weight, MGO 30 50 weight, Al 2 O 3 30 40 weight, CAF 2 10‑20 weight, TIO 2 3‑10 weight portion, 0 <fE 2 O 3 ≤3.0 weight portion, 0

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Submerged-arc flux for low-temperature impact of Cr-Mo heat-resistant steel and narrow-gap submerged-arc welding and preparation method thereof

ActiveCN103056558BSimple welding processBeautiful weld shapeWelding/cutting media/materialsSoldering mediaSubmerged arc welding

The invention discloses a submerged-arc flux for low-temperature impact of Cr-Mo heat-resistant steel and narrow-gap submerged-arc welding, and relates to the welding field. The flux comprises the following ingredients by mass percent, SiO28-20%; MgO20-40%; A12O315-30%; sigmaCaO15-28%; MnO0.5-5%; Na2O0.5-2%; K2O0.5-2%; TiO20.5-3%; Fe2O3< / =3.0%; S< / =0.030%; P< / =0.030%. The flux is special for the narrow-gap welding and the submerged-arc welding on the low-temperature impact of the Cr-Mo heat-resistant steel.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com