Patents

Literature

52results about How to "Reduce P content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength weathering resistant steel and its preparation method

The invention provides high-strength weathering resistant steel and its preparation method. The high-strength weathering resistant steel is characterized by comprising the following chemical components: by weight, C being less than or equals to 0.06% and greater than or equals to 0.05%, Cu being less than or equals to 0.35% and greater than or equals to 0.25%, Si being less than or equals to 0.45% and greater than or equals to 0.36%, Mn being less than or equals to 1.00% and greater than or equals to 0.80%, Al being less than or equals to 0.065% and greater than or equals to 0.055%, Ni being less than or equals to 0.19% and greater than or equals to 0.10%, Cr being less than or equals to 0.50% and greater than or equals to 0.41%, Mo being less than or equals to 0.15% and greater than or equals to 0.05%, Ti being less than or equals to 0.02% and greater than or equals to 0.01%, V being less than or equals to 0.030% and greater than or equals to 0.016%, Nb being less than or equals to 0.010% and greater than or equals to 0.005%, B being less than or equals to 0.008% and greater than or equals to 0.005%, S being less than or equals to 0.010%, P being less than or equals to 0.025%, N being less than or equals to 0.005%, and the balance being Fe. According to the invention, a plurality of microalloy elements such as Al, Mo, V, Nb, B and the like are added into components of traditional weathering resistant steel so as to carry out combination alloying. Thus, contents of Cu and P in weathering resistant steel are reduced, copper brittleness and phosphorus brittleness hazards caused by Cu and P in weathering resistant steel are eliminated, and strength and weatherability of the steel are raised.

Owner:JIANGYIN ZHENGBANG TUBE MAKING

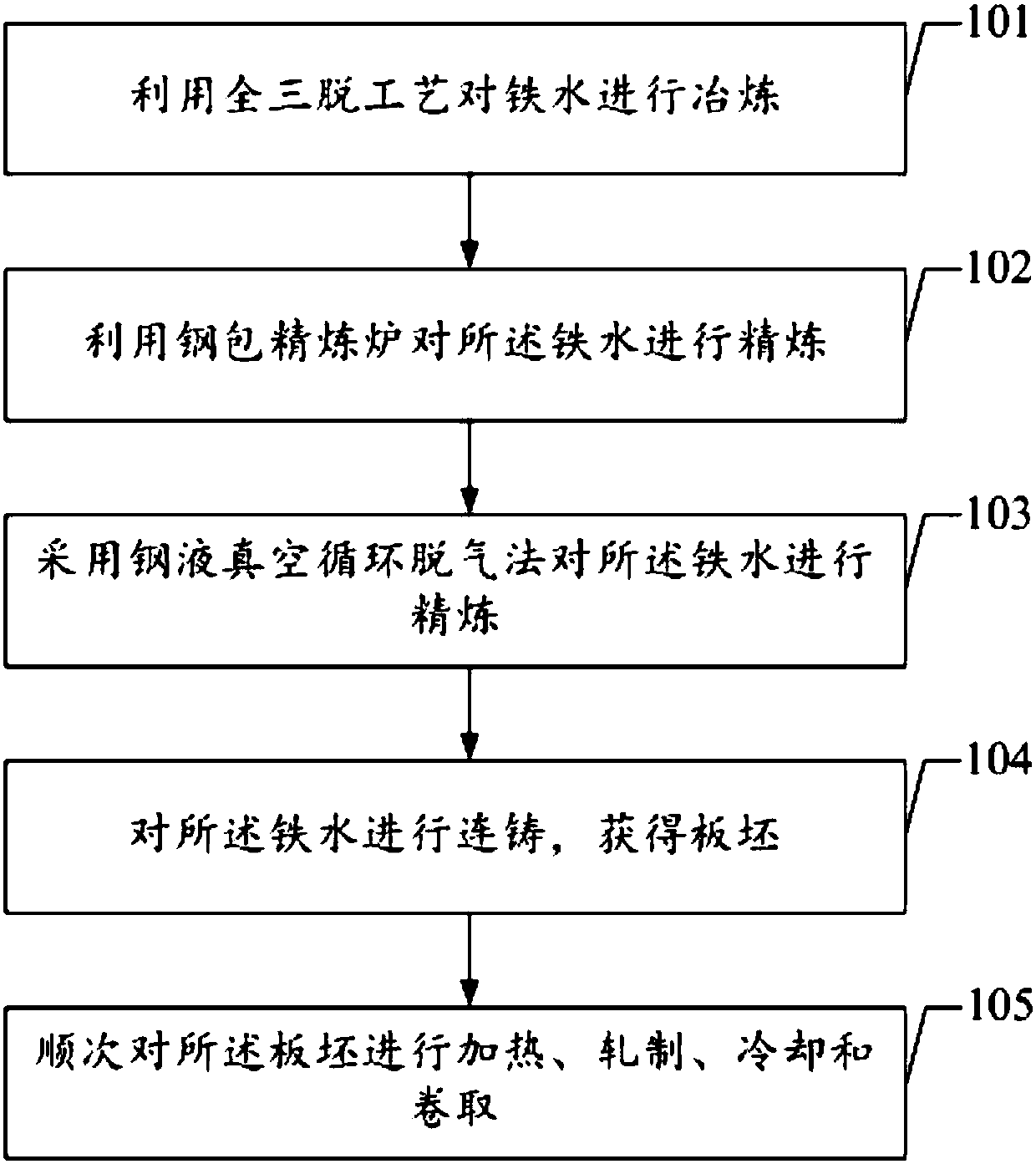

700 MPa-stage-or-over ultra-high-strength weather-resisting steel plate and hot continuous rolling production method thereof

The invention relates to the technical field of steel and iron metallurgy, in particular to a 700 MPa-stage-or-over ultra-high-strength weather-resisting steel plate and a hot continuous rolling production method thereof. The 700 MPa-stage-or-over ultra-high-strength weather-resisting steel plate comprises the chemical components of, by mass, 0.06-0.08% of carbon, 0.15-0.25% of silicon, 1.25-1.35%of manganese, 0.018% or the less of phosphorus, 0.005% or the less of sulfur, 0.02-0.05% of total aluminum, 0.05-0.07% of niobium, 0.09-0.13% of titanium, 0.37-0.45% of chrome, 0.20-0.28% of copper,0.10-0.15% of nickel, 0.0050% or the less of nitrogen and the balance iron. According to the 700 MPa-stage-or-over ultra-high-strength weather-resisting steel plate and the hot continuous rolling production method, the content of Cu and P in weather-resisting steel is reduced, thus through control over the content of harmful elements of S and N, harm of copper brittleness and phosphorus brittleness caused by Cu and P is eliminated, and the ultra-high strength and good weather-resisting property of the steel are ensured; and meanwhile, through a mode of combination of LF refining and RH refining, the element content is accurately adjusted in the alloying process, through the hot continuous rolling production method, the process is simple, the production efficiency is high, and the manufacturing cost is low.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

Submerged-arc welding flux for 800MPa-grade high-strength steel for large-size hydropower facility and production method of submerged-arc welding flux

InactiveCN107745203AReduce P contentReasonable tensile strengthWelding/cutting media/materialsSoldering mediaCooking & bakingCrack resistance

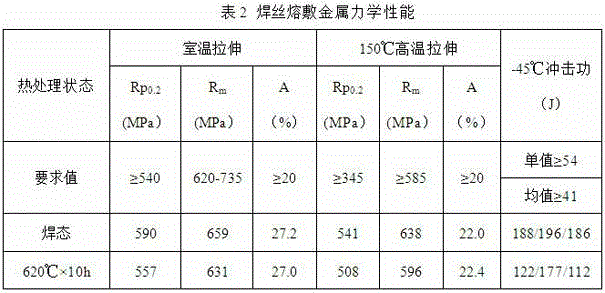

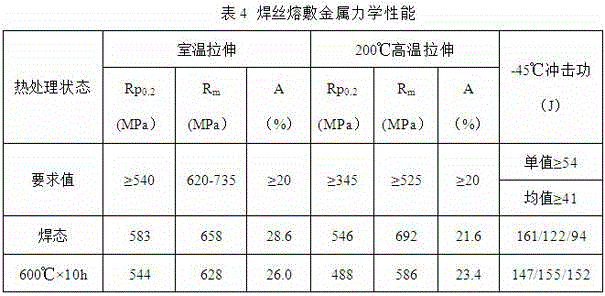

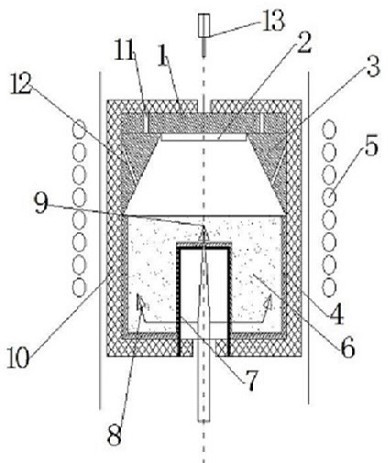

The invention discloses submerged-arc welding flux for 800MPa-grade high-strength steel for a large-size hydropower facility and a production method of the submerged-arc welding flux. The submerged-arc welding flux comprises, by mass percentage, 9-23% of CaF2, 9-14% of Al2O3, 8-18% of SiO2, 18-34% of MgO, 15-22% of CaO, 1-5% of MnO, 0.5-3% of Fe2O3, less than or equal to 2.5% of Na2O, less than orequal to 2.5% of K2O and less than or equal to 2% of TiO2. The production method comprises the steps that after the elements are uniformly mixed according to the proportions, a binding agent accounting for 15% to 20% of the total amount of the materials is added for granulation; and then, 200-250 DEG C low-temperature baking, 670-780 DEG C high-temperature sintering and sieving are conducted, sothat a submerged-arc welding flux product is obtained. According to the submerged-arc welding flux and the production method thereof, a reasonable welding process is adopted to be matched with the chemical elements of the 800MPa high-strength steel, and therefore, chemical elements and textures of metal at each welding seam can reach the optimal state; the deposited metal S and the deposited metalP are low in content, and the flux has reasonable mechanical property indexes such as the tensile strength, the impact value, the bending property, the crack resistance and the hardness; and in addition, air holes, slag inclusion and cracks inside each welding seam as well as appearance edge excessiveness, undercuts and the like meet the standard requirements.

Owner:SICHUAN XIYE NEW MATERIAL

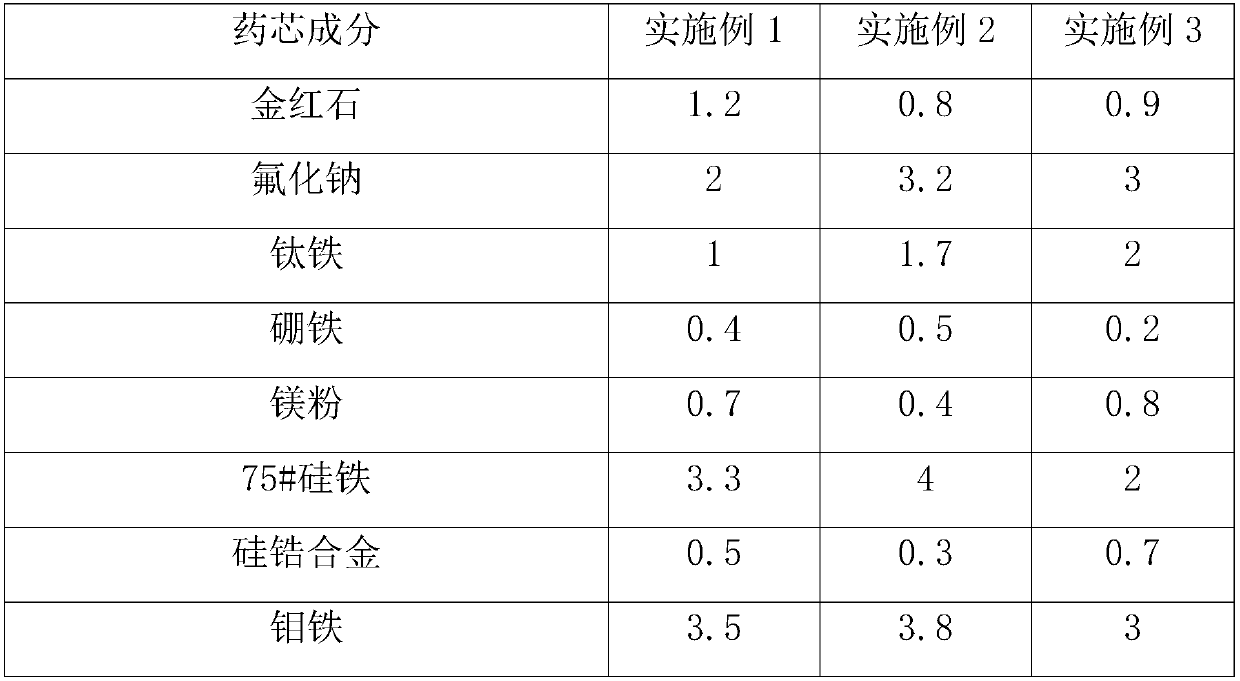

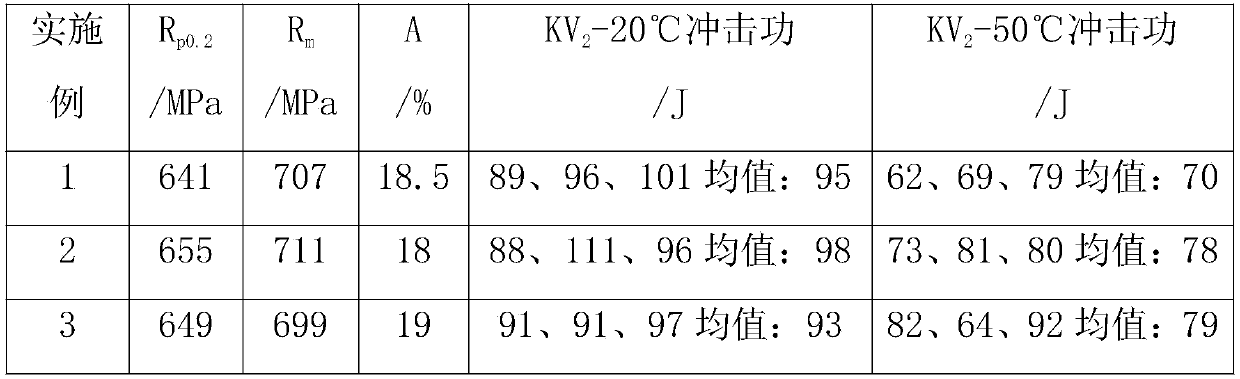

Metal powder core type flux-cored wire for additive manufacturing and welding method thereof

ActiveCN108672977AReduce oxygen contentImprove crack resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceArc stability

The invention provides a metal powder core type flux-cored wire for additive manufacturing. The metal powder core type flux-cored wire for additive manufacturing comprises carbon steel outer skin anda flux core arranged in the carbon steel outer skin. The flux core comprises the following components in percentage by mass based on total mass: 0.8-1.2% of rutile, 2-3.2% of sodium fluoride, 1-2% offerrotitanium, 0.2-0.5% of ferroboron, 0.4-0.8% of magnesium powder, 2-4% of 75# atomized ferrosilicon, 0.3-0.7% of a silicon-zirconium alloy, 3-3.8% of ferromolybdenum, 25-30% of nickel powder, 0.4-1.1% of anhydrous feldspar, 0.2-0.6% of rare earth fluoride, 2.2-3.1% of electrolytic manganese and the balance iron powder. According to the flux-cored wire, the oxygen content of a weld joint is reduced by way of combined deoxygenation of Mn-Mg-Si-Ti-Zr, and meanwhile, by adding a proper amount of minerals, the weld joint forming and arc stability is improved; by adding the iron powder, the deposition efficiency of the flux-cored wire is improved; by adding the rare earth alloy, the S content in weld joint metal is reduced and the shape of the occluded foreign substances is changed, so that the low-temperature toughness is improved, and therefore, the flux-cored wire is stable in mechanical property of melted metal, good in crack resistance and excellent in low-temperature toughness at 50DEG C below zero.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

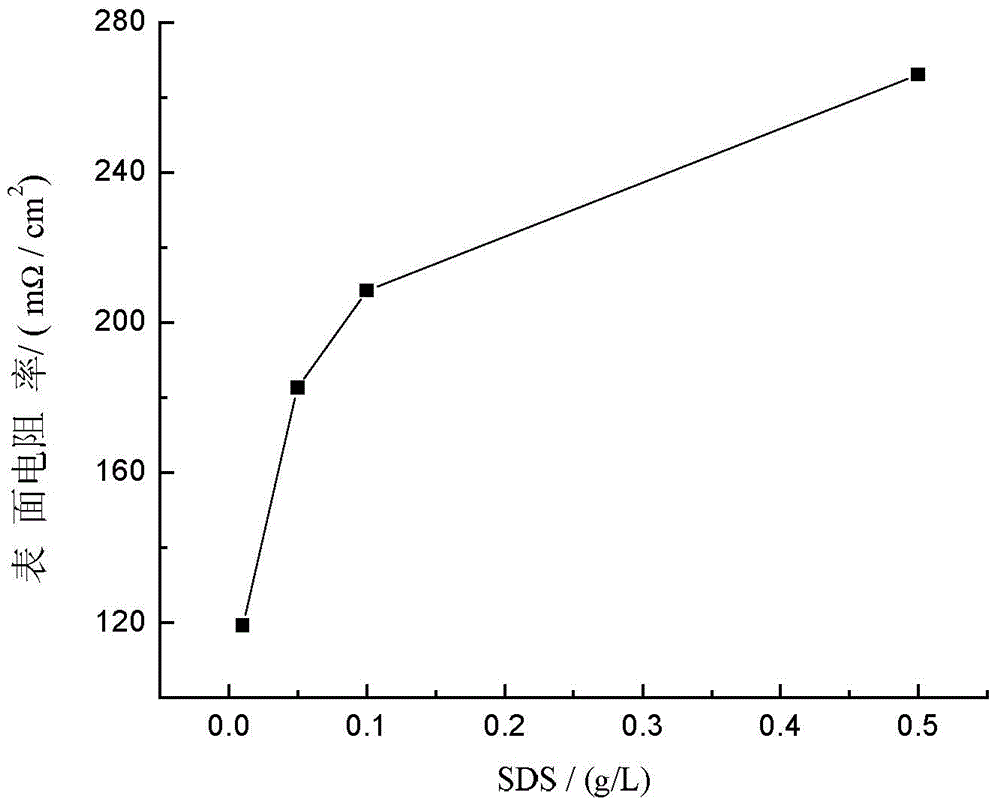

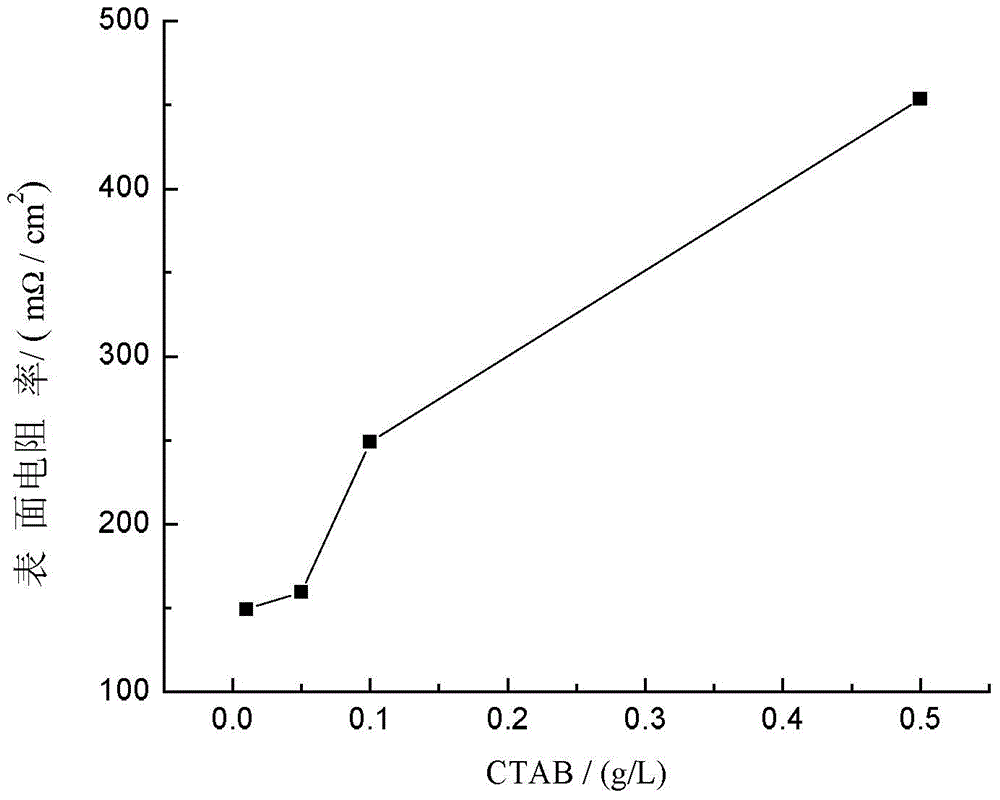

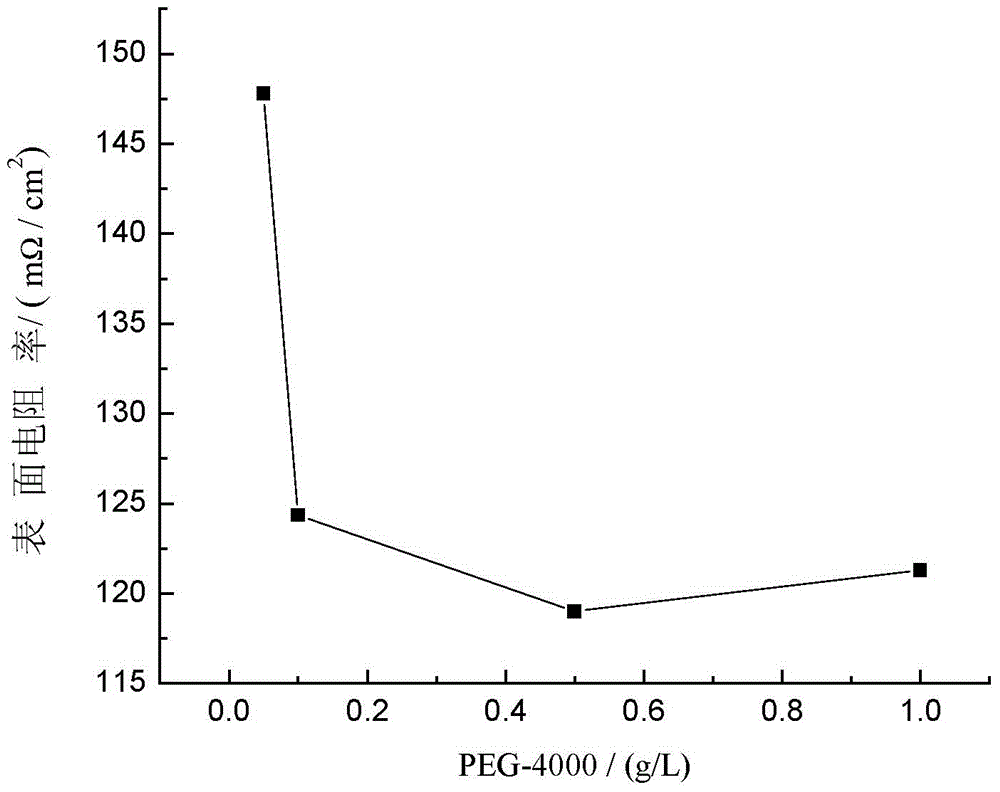

Preparation method of corrosion-resisting high-conductivity wood electromagnetic shielding material

ActiveCN104947092AImprove organizational structureImprove performanceLiquid/solution decomposition chemical coatingSodium acetateAviation

The invention provides a preparation method of a corrosion-resisting high-conductivity wood electromagnetic shielding material, relates to a surface chemical plating method for wood, and aims to solve the technical problem of poor decay resistance of wood on which copper, an Ni-P binary alloy and an Ni-Fe-P ternary alloy are plated in the prior art. The preparation method comprises the following steps: adding nickel sulfate, sodium hypophosphite, sodium citrate, lactic acid, sodium acetate and thiocarbamide into water; stirring to obtain a uniform mixture; adding the pH value of the mixture to be 8 to 10; adding a surfactant and nano alumina; stirring to obtain a uniform plating solution; soaking wood in a 3-aminopropyl triethoxy silane solution; drying the soaked wood; soaking the dried wood into a palladium chloride; soaking with a sodium hypophosphite solution; cleaning; soaking in the plating solution for chemical plating, so as to obtain the corrosion-resisting high-conductivity wood electromagnetic shielding material. The corrosion-resisting high-conductivity wood electromagnetic shielding material is as low as 127.86 [m]Omega / cm<2>, is higher than 45 dB in electromagnetic shielding efficiency, and can be applied to the fields of electronics, aviation and medicine.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

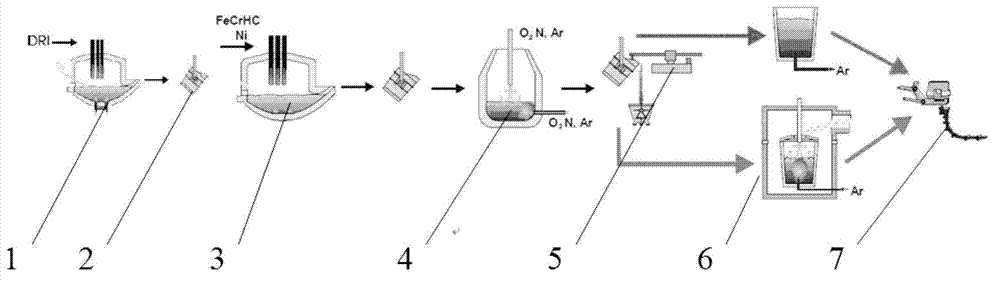

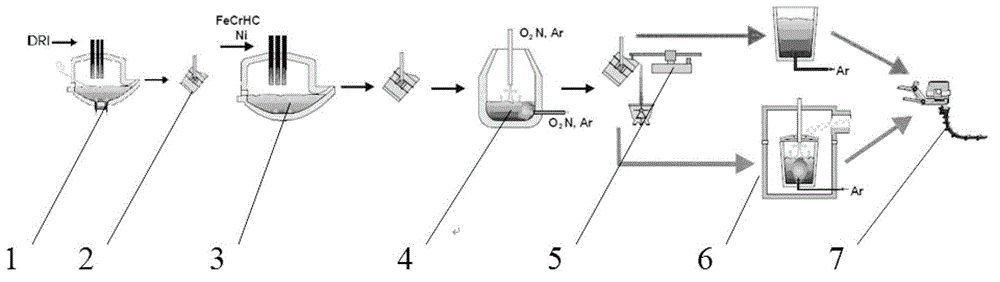

Stainless-steel smelting method

ActiveCN102787195AP content is easy to controlReduce P contentElectric furnaceElectric arc furnaceSmelting process

The invention relates to a stainless-steel smelting method, belonging to the technical field of steel smelting. The process comprises the following steps: melting by using an ultrahigh-power electric-arc furnace with an eccentric bottom to reduce iron directly, wherein the electric-arc furnace is provided with a large-flow furnace wall cluster coal oxidation gun; alloying by using the electric-arc furnace in the steel tapping spout structure; refining by using an AOD furnace; refining by using a VOD furnace; and casting continuously. Each step of the stainless-steel smelting process has a definite target, and the equipment has a definite division of work, namely, the first electric furnace is used for melting to reduce iron directly and dephosphorize so as to provide the qualified crude molten steel, and the second electric furnace is used for alloying so as to provide the qualified mother liquid for the AOD furnace and finish the refining by the AOD furnace; the time rhythms are combined reasonably, thus the burden of the subsequent AOD furnace is reduced; more than 85% of alloy is added in the electric furnaces, thus the components of the alloy are easy to control; when the waste stainless steel resources are sufficient, the waste stainless steel can be smelted in the second electric furnace, and the mother liquid can be provided for the AOD furnace; and second electric furnace can be used for producing special steel according to the change of the market.

Owner:BEIJING SHOUGANG INT ENG TECH

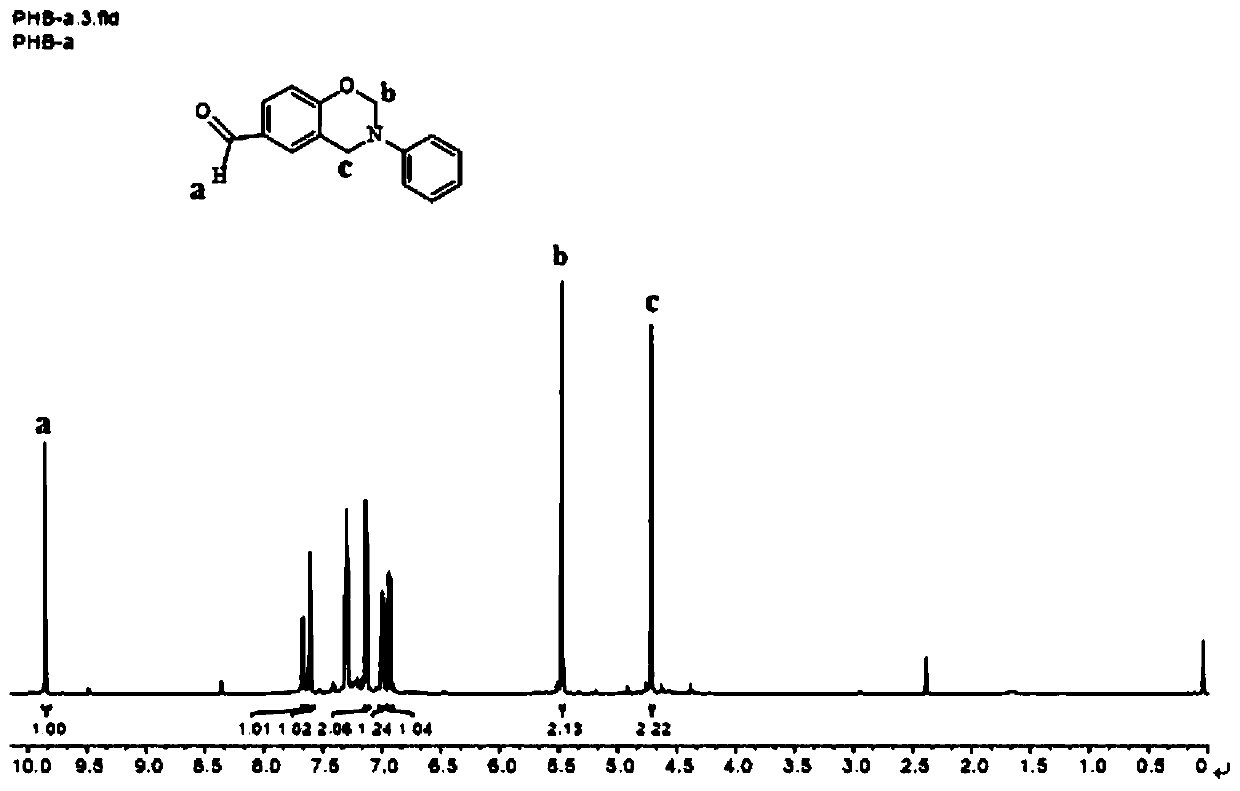

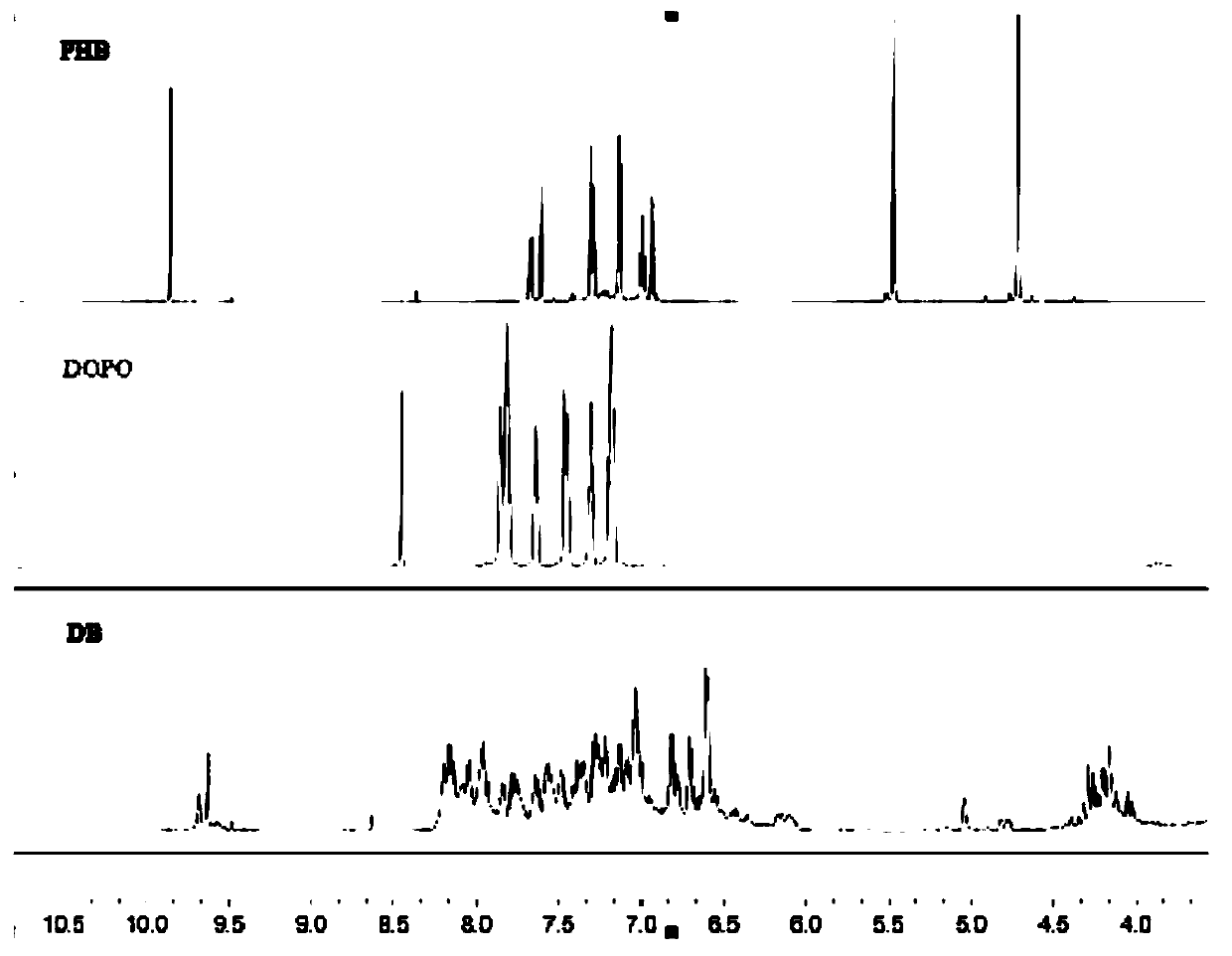

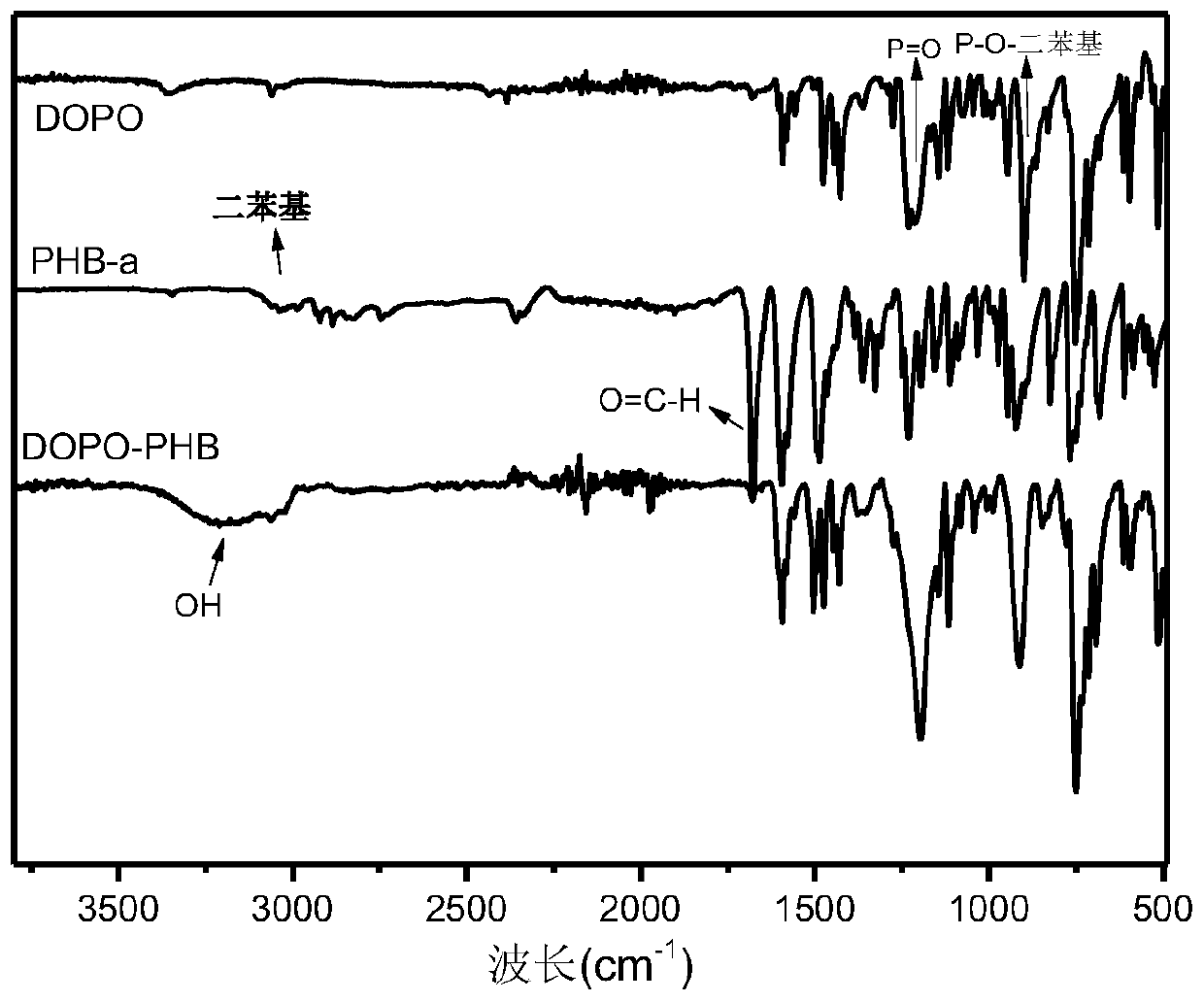

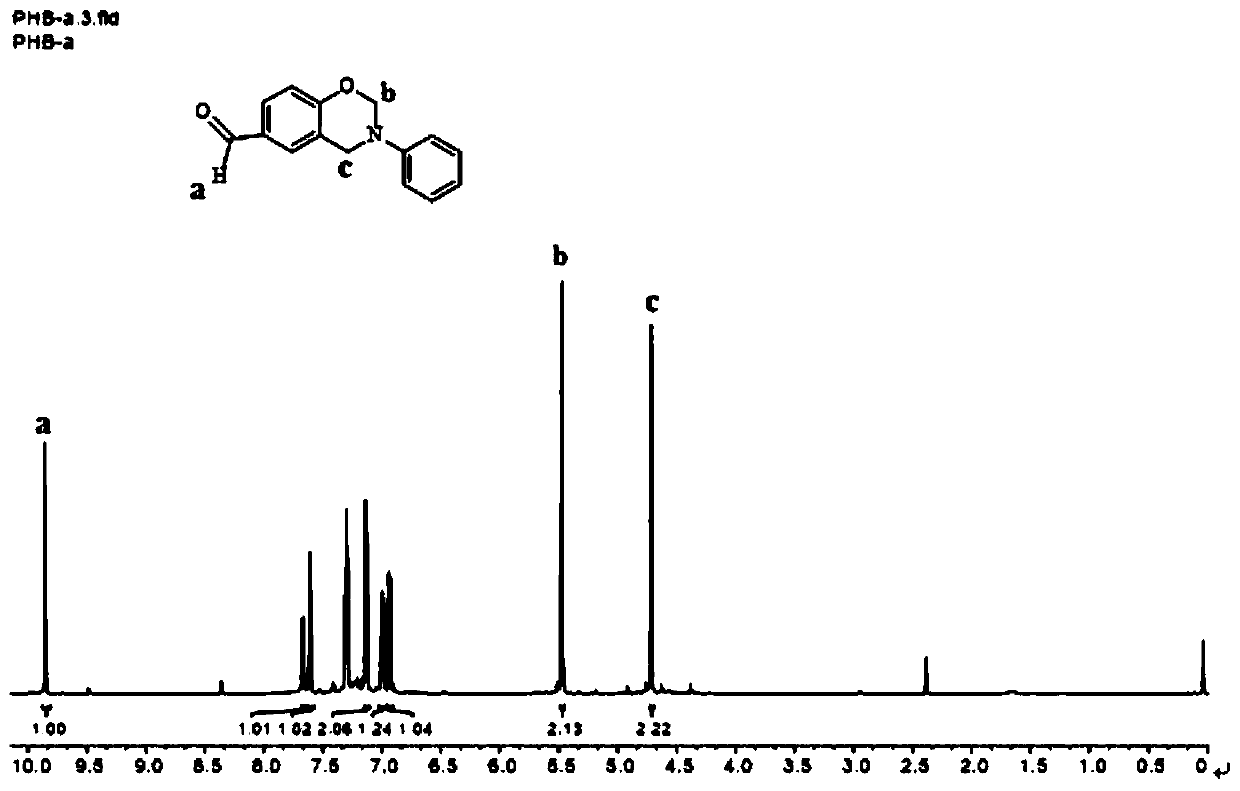

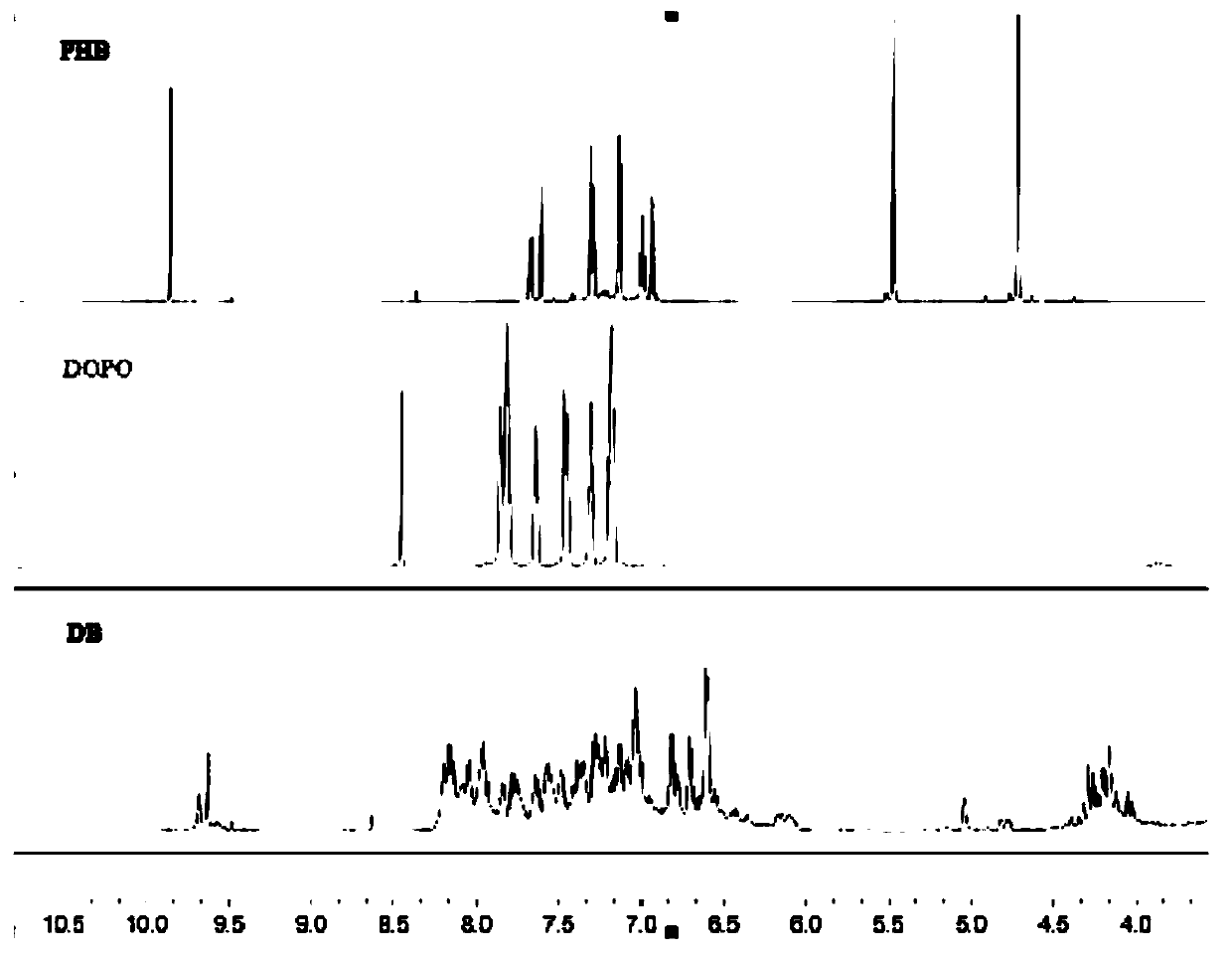

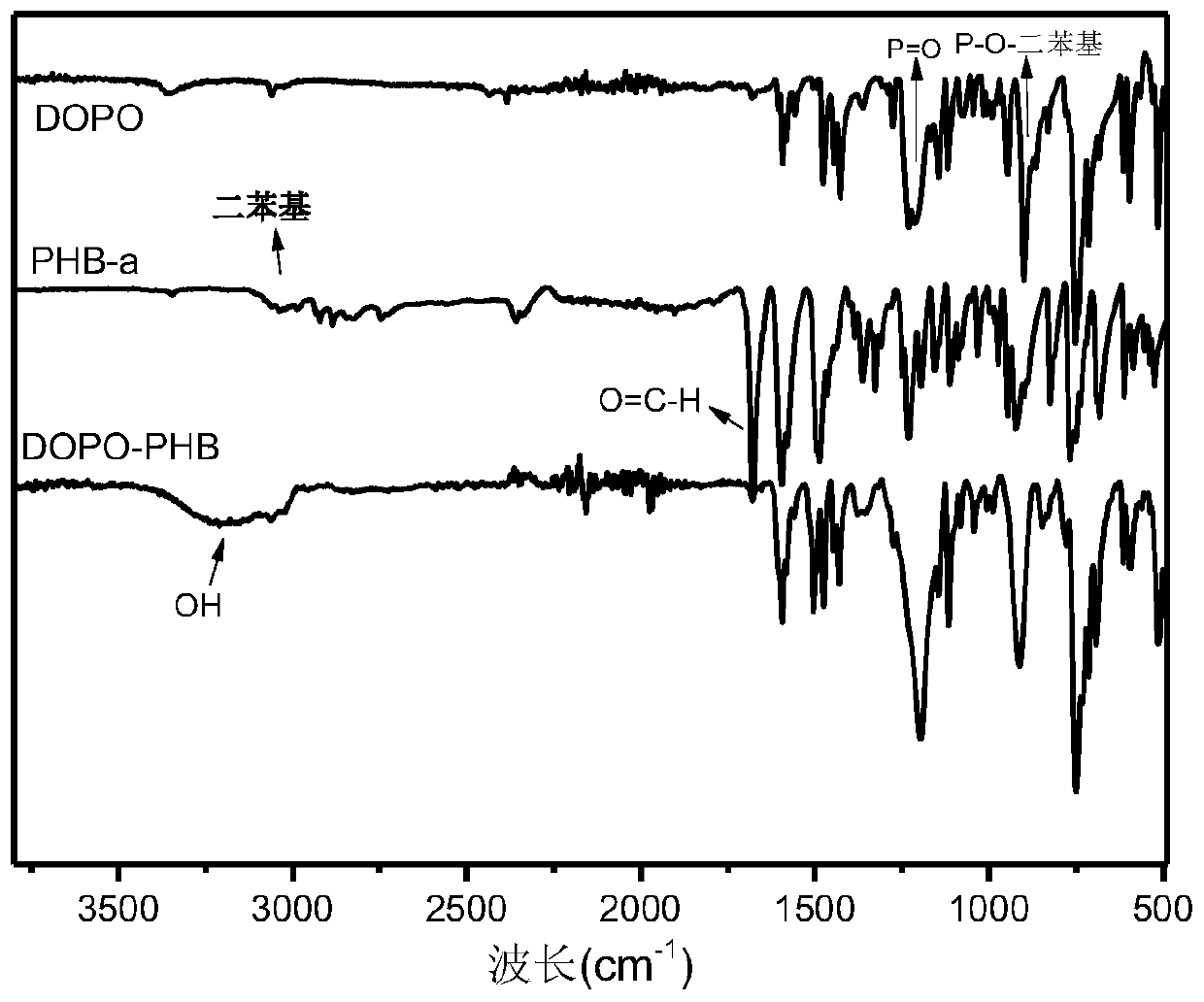

Reactive flame retardant containing double DOPO groups and nitrogen, and preparation method and application thereof

ActiveCN110157041AImprove flame retardant performanceImprove thermal stabilityFireproof paintsGroup 5/15 element organic compoundsEpoxySynthesis methods

The invention discloses a reactive flame retardant containing double DOPO groups and nitrogen, and a preparation method and an application thereof. The reactive flame retardant containing double DOPOgroups and nitrogen can be prepared in a high yield through a two-step reaction by the simple and efficient synthesis method. The reactive groups on the molecule of the reactive flame retardant are reacted with an epoxy resin to effectively improve the flame retardation property of the epoxy resin and improve the mechanical properties to a certain degree; the epoxy resin is modified with the reactive flame retardant to simultaneously improve the flame retardation effect and the mechanical strength of the epoxy resin, the synergistic flame-retardant effect of phosphorus and nitrogen greatly improves the flame retardation property of the modified epoxy resin at a very low dosage of the flame retardant, and results of limiting oxygen index and UL-94 vertical burning test show that the flame retardancy reaches V-0 level, and the limiting oxygen index (LOI) reaches 30.9. The preparation method of the reactive flame retardant containing double DOPO groups and nitrogen has the advantages of simplicity, and cheap and easily available raw materials, so the reactive flame retardant containing double DOPO groups and nitrogen is a reactive flame retardant hopeful to be industrialized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

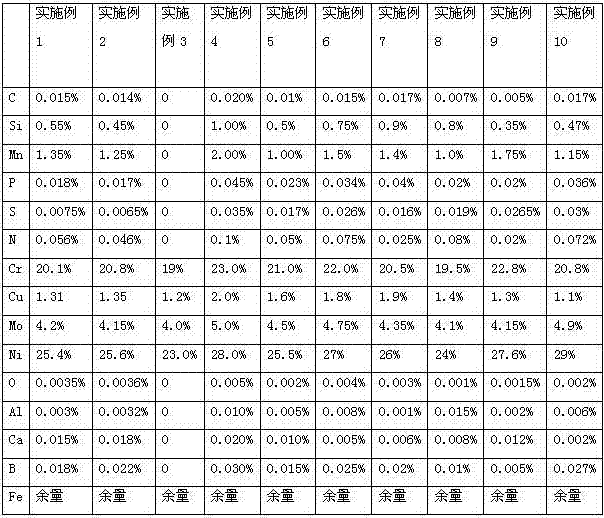

Superaustenitic stainless steel and preparing method thereof

ActiveCN107058905ASolve the smelting and continuous casting technologyImprove corrosion resistanceCopperAustenite

The invention provides superaustenitic stainless steel and a preparing method thereof. The superaustenitic stainless steel is prepared in the following percent by weight: smaller than or equal to 0.020% of C, smaller than or equal to 1.00% of Si, smaller than or equal to 2.00% of Mn, smaller than or equal to 0.045% of P, smaller than or equal to 0.035% of S, smaller than or equal to 0.1% of N, 19.0-23.0% of Cr, 1.2-2.0% of Cu, 4.0-5.0% of Mo, 23.0-28.0% of Ni, smaller than or equal to 0.0050% of O, smaller than or equal to 0.010% of Al, smaller than or equal to 0.020% of Ca, smaller than or equal to 0.030% of B and the balance of Fe. The method adopts a protection process of smelting superaustenitic stainless steel mother liquid by adopting a Consteel electric furnace and an intermediate frequency furnace, AOD, LF and continuous casting of a sheet billet, and can smelt the high-Ni, high-Cr, high-Mo, Cu-containing and low-C superaustenitic stainless steel, and both the surface quality and internal quality of the continuous casting billet are good.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

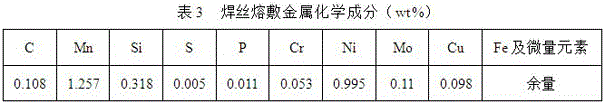

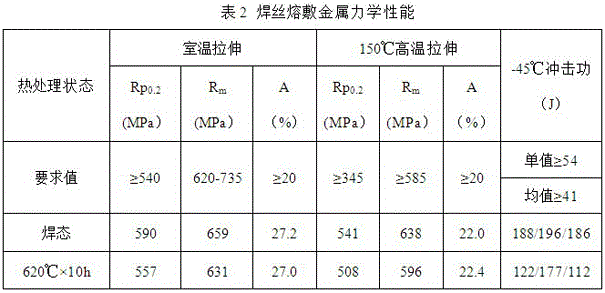

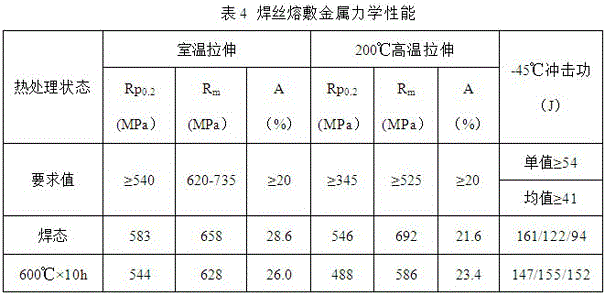

Gas protection welding wire for nuclear power steel containment vessel

ActiveCN104128715AImprove toughnessReduce manufacturing costWelding/cutting media/materialsSoldering mediaNuclear powerWeld seam

The invention provides a gas protection welding wire for a nuclear power steel containment vessel and belongs to the field of welding materials. The gas protection welding wire comprises, by mass, 0.07%-0.12% of C, 1.10%-1.60% of Mn, 0.25%-0.55% of Si, 0.80%-1.40% of Ni, at most 0.025% of S, at most 0.025% of P, at most 0.20% of Cr, 0.10%-0.30% of Mo, at most 0.50% of Cu, and the balance iron and inevitable impurities. The gas protection welding wire is low in cost, welding arcs are stable, welding spatter is slight, welding seams are formed neatly, obtained deposited metal and welded joints are high in comprehensive mechanical performance in the welded condition, low-temperature impact performance is high, and tenacity is extremely high. The gas protection welding wire can be widely applied to steel structure welding in nuclear power engineering.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +2

Plastic mould steel and production technology thereof

InactiveCN108085601AReduce P contentImprove internal porosityFurnace typesProcess efficiency improvementChemical compositionUltimate tensile strength

The invention belongs to plastic mould steel and a production technology thereof. The plastic mould steel comprises the chemical compositions of, by mass, 0.37-0.40% of C, 0.4-0.5% of Si, 1.4-1.5% ofMn, 1.8-2.0% of Cr, 0.4-0.5% of Mo, 1.0-1.1% of Ni, no more than 0.008% of P, no more than 0.003% of S, 0.018-0.030% of Als, and the balance Fe and remaining elements. The thickness of the plastic mould steel is 150 mm, the carbon equivalent in the chemical compositions of the plastic mould steel is 1.1-1.3, and the plastic mould steel has the advantages of being high in strength, high in hardnessand excellent in performance.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Growth process method of large-diameter high-purity semi-insulating silicon carbide

ActiveCN113151895AHigh resistivityReduce spreadPolycrystalline material growthFrom condensed vaporsCarbide siliconCrucible

The invention provides a growth process method of large-diameter high-purity semi-insulating silicon carbide, which comprises the following steps: (1) preparing growth materials, and completing the assembly of seed crystals, raw materials and a thermal field; and (2) starting process growth, and completing the processes of impurity removal, heating, growth, cooling and furnace shutdown. According to the method disclosed by the invention, the high-purity silicon carbide single crystal is easy to obtain through the technical means of hydrogen introduction, crucible internal structure design, optimized seed crystal selection, heating structure combination design, optimized process parameters and the like, and semi-insulating single crystal preparation with high technical indexes, high raw material utilization rate and low cost is realized.

Owner:BEIJING CENTURY GOLDRAY SEMICON CO LTD

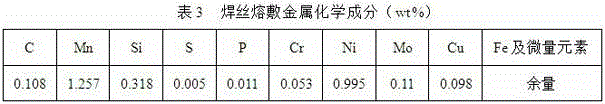

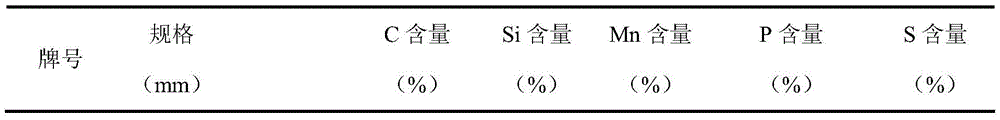

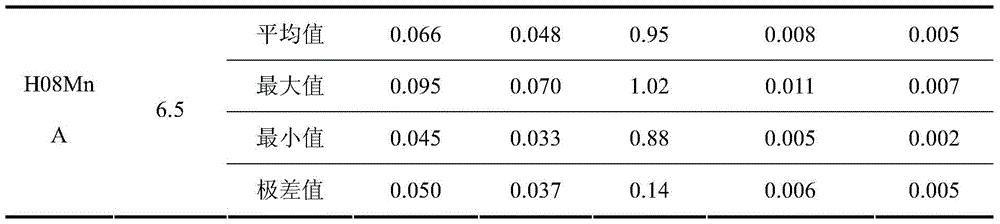

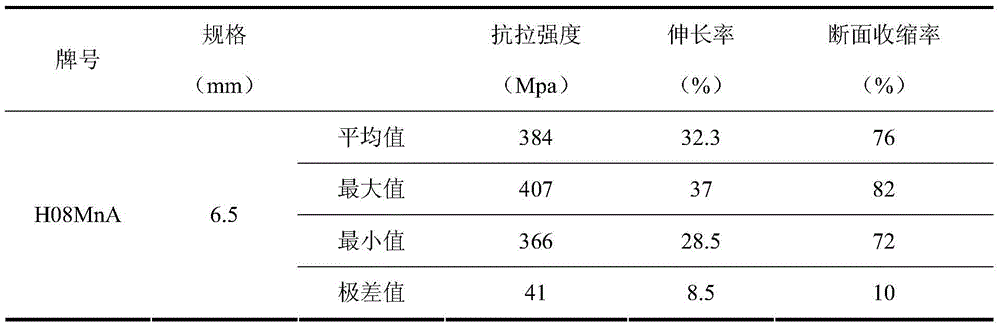

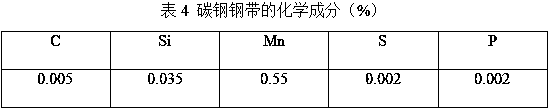

Preparation method for H08MnA no-twist controlled-cooling hot-rolled wire rod for submerged-arc welding wire

InactiveCN105562961ALow S contentIncreased sensitivityWelding/cutting media/materialsSoldering mediaWire rodMaterials science

The invention relates to a preparation method for a wire rod for a welding wire, in particular to a preparation method for an H08MnA no-twist controlled-cooling hot-rolled wire rod for a submerged-arc welding wire. According to the technical scheme adopted by the invention, the preparation method for the H08MnA no-twist controlled-cooling hot-rolled wire rod for the submerged-arc welding wire is characterized in that the wire rod consists of the following chemical components in proportion: 0.045-0.095% of C, 0.88-1.02% of Mn, 0.035-0.065% of Si, less than or equal to 0.009% of P, less than or equal to 0.009% of S and the balance of Fe; the wire rod is rolled through a no-twist high-speed wire rolling mill, and then is cooled by a delay type Stelmor process after being rolled. According to the preparation method for the H08MnA no-twist controlled-cooling hot-rolled wire rod for the submerged-arc welding wire provided by the invention, product metallurgical quality, chemical components and drawing properties are guaranteed to meet usage needs.

Owner:BENGANG STEEL PLATES

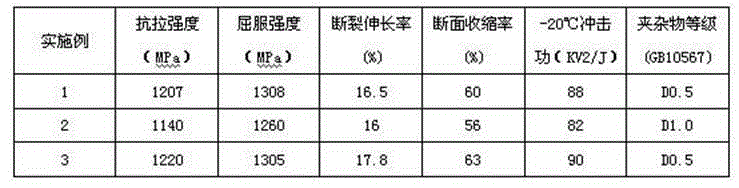

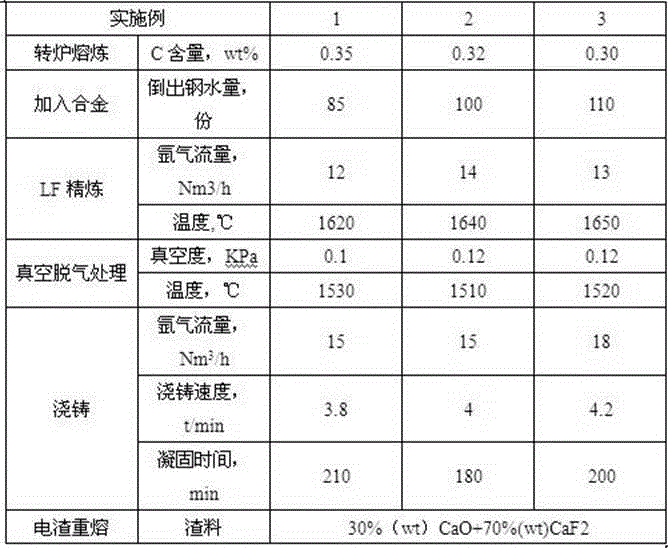

Manufacturing method of steel ingot for gas cylinder

ActiveCN103555881AGuaranteed purityReduce contentProcess efficiency improvementWorking pressureGas cylinder

The invention belongs to the technical field of manufacturing of steel ingots and discloses a manufacturing method of a steel ingot for a gas cylinder. The manufacturing method of the steel ingot for the gas cylinder comprises the following steps of: raw material purporting, converter smelting, alloy addition, LF (Low Frequency) steel ladle refining, vacuum degreasing treatment, casting as well as electroslag re-melting, wherein the raw material contains not less than 4wt% of C, not more than 0.015wt% of P and blast furnace molten iron with a temperature being not lower than 1200 DEG C; in a converter smelting stage, content of P is lowered by P-removing pretreatment; the LF steel ladle refining adopts an aluminum-free deoxidation process; after the electroslag re-melting and the secondary refining are carried out onto the steel ingot obtained by primary refining and casting so that S and impurities in the steel are lowered. According to the manufacturing method disclosed by the invention, the quantity of harmful elements and impurities in the steel ingot are controlled by twice refining, so that a purpose of controlling components and structure of the steel ingot is reached, the steel ingot for the gas cylinder with excellent strength and toughness is finally obtained, and therefore, working pressure and safety of the steel ingot for the gas cylinder are improved.

Owner:中船双瑞(洛阳)特种装备股份有限公司

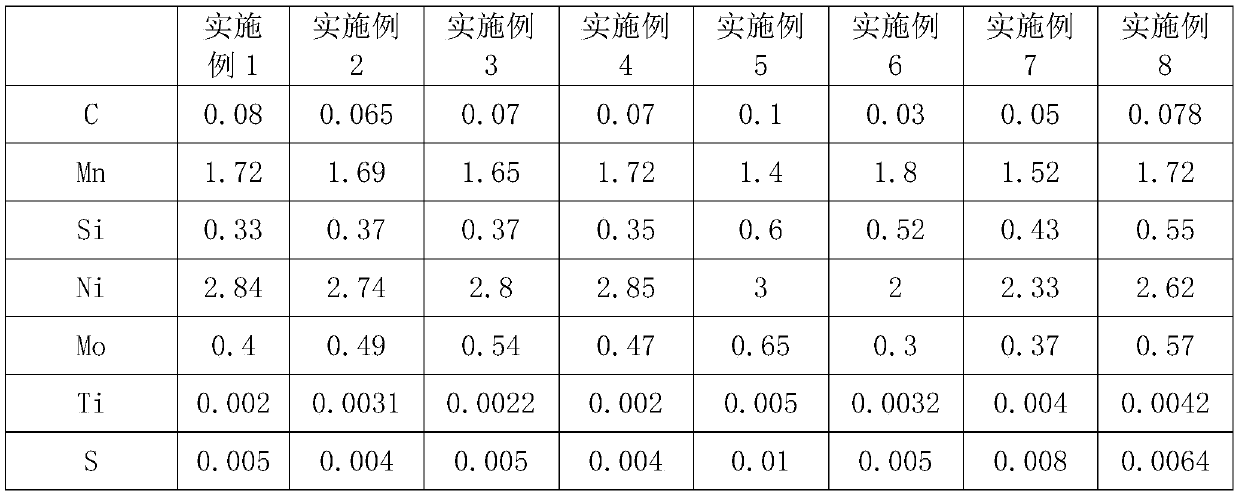

Gas shielded welding wire matched with weather-resistant bridge steel Q690qE and preparation method thereof

InactiveCN110549033ASimple welding processReduce splashWelding/cutting media/materialsSoldering mediaCopper platingGas protection

The invention discloses a gas shielded welding wire and a preparation method thereof. The welding wire comprises the following components of, in percentage by weight, 1.40% to 1.80% of Mn; 2.00% to 3.00% of Ni; 0.30% to 0.65% of Mo; greater than 0 and less than or equal to 0.10% of C; greater than 0 and less than or equal to 0.60% of Si; greater than 0 and less than or equal to 0.010% of S; greater than 0 and less than or equal to 0.010% of P; greater than 0 and less than or equal to 0.60% of Cr; greater than 0 and less than or equal to 0.35% of Cu; greater than 0 and less than or equal to 0.005% of Ti; greater than 0 and less than or equal to 0.005% of V; and the balance Fe and other impurities. The preparation method comprises the following steps of (a) preparing a disc strip according to the formula of the welding wire, and then drawing the disc strip roughly; (b) annealing the disc strip treated in the step (a) to remove an oxidation layer on the surface of the disc strip; (c) roughly drawing the disc strip treated in the step (b) again to a certain specification; and (d) finely drawing the disc strip treated in the step (c), plating copper on the surface of the disc strip, andwinding the disc strip. According to the gas shielded welding wire, through a reasonable welding process, the tensile strength of weld metal is greater than 810 MPa and the yield strength is larger than 755 MPa, which is close the mechanical property of a base material, and meets the mechanical property requirement of the bridge steel Q690qE.

Owner:SICHUAN XIYE NEW MATERIAL +1

Preparation method of super-pure industrial iron

The invention relates to a preparation method of super-pure industrial iron. The preparation method includes: melting sponge iron in an induction furnace under a non-vacuum state; adding slagging material for slagging after molten steel has no bubbles; adding carbon powder into the molten steel in batches, vacuumizing at the same time to deoxidize the molten steel, and allowing the vacuum degree to increase gradually; desulfurizing the molten steel, to be more specific, slagging again, controlling the alkalinity of slag to be at 3-5, and adding aluminum powder to the surface of the slag in one step according to a proportion that 5-20g of aluminum powder is added to each kilogram of slag material; tapping and pouring into blanks. The super-pure industrial iron prepared by the method has the advantages that the super-pure industrial iron is high in purity, extremely good in quality and capable of perfectly satisfyting the requirements of high-end users, the C and O contents and Si, Mn and Al contents of the super-pure industrial iron is evidently lowered as compared with those of conventional industrial pure iron, and better economic benefits can be brought to production enterprises.

Owner:武汉钢铁有限公司

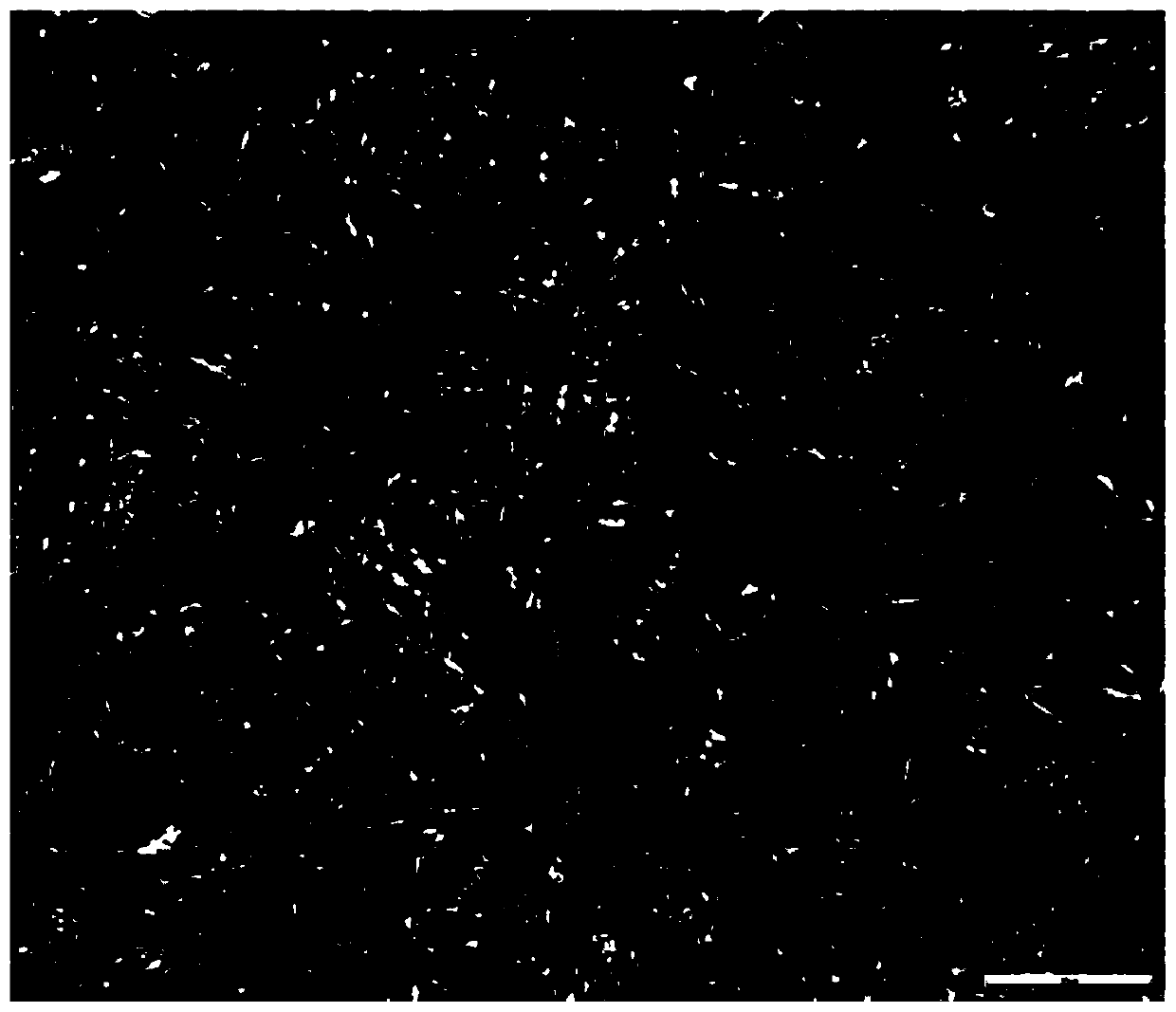

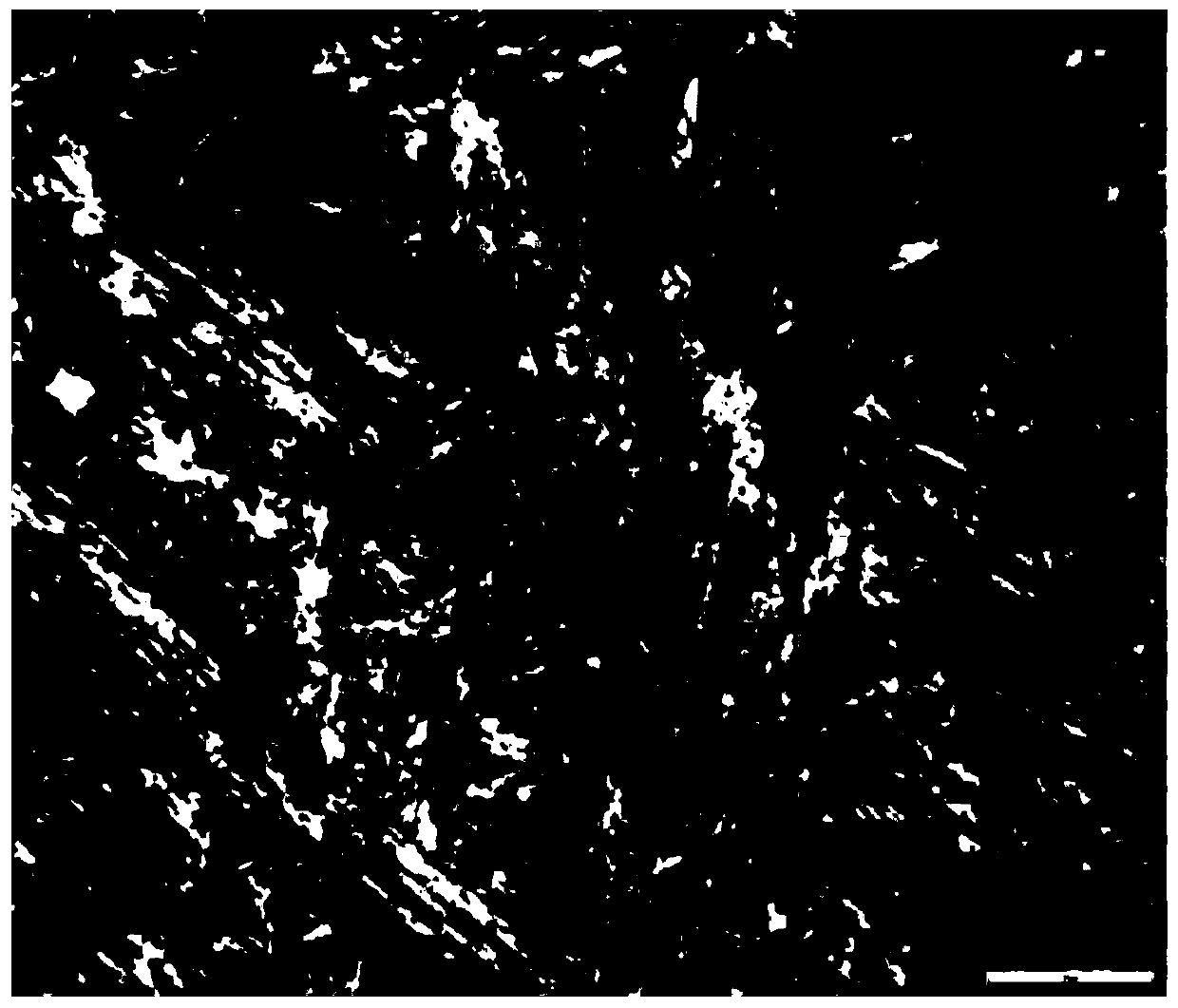

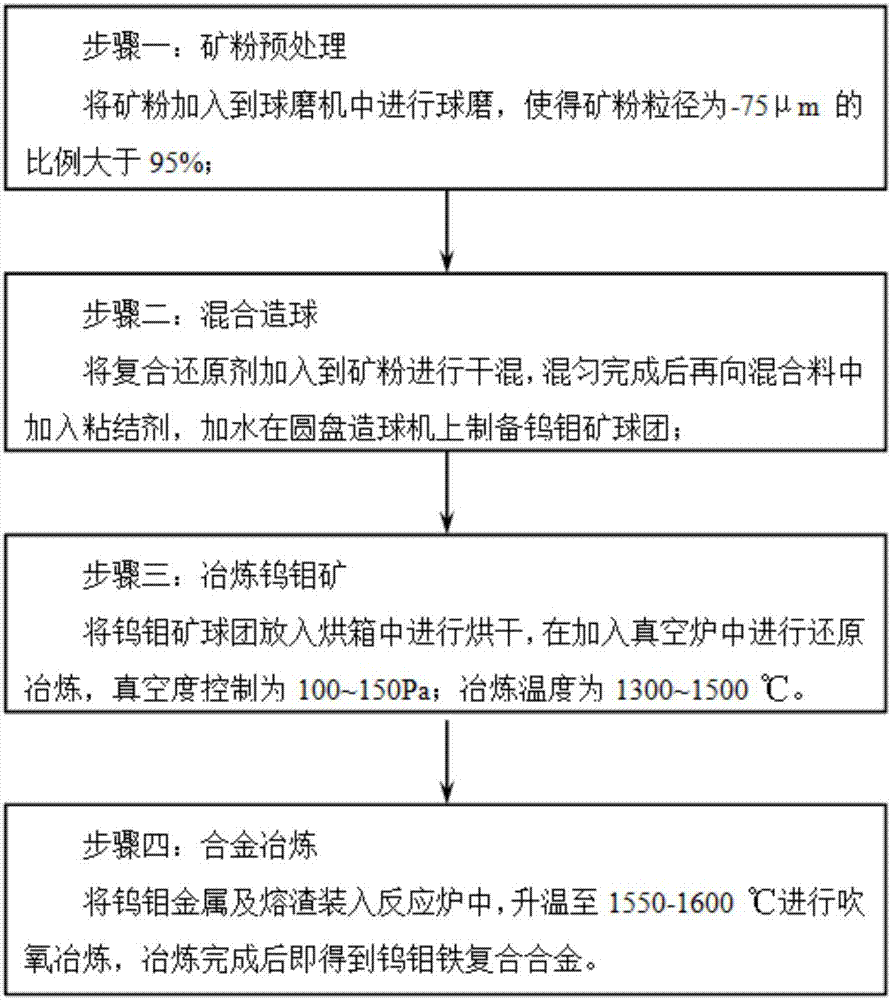

Method for smelting ferrotungston-molybdenum-iron alloy by adopting low-grade tungsten and molybdenum ore

ActiveCN107254590AStrong reductionImprove reduction efficiencyProcess efficiency improvementSlagResource utilization

The invention discloses a method for smelting a ferrotungston-molybdenum-iron alloy by adopting a low-grade tungsten and molybdenum ore, and belongs to the field resource utilization of low-grade tungsten and molybdenum ores. The method includes the steps that a compound reducing agent is added into the low-grade tungsten and molybdenum ore, the proportion of the compound reducing agent and the low-grade tungsten and molybdenum ore is phi, as the formula shows in an original text that, wherein the value of gamma is 5-6, and the alpha is the mass ratio of modified silicon carbide to modified quartz; and the value of kappa is as the formula showing in the original text; and the compound reducing agent and the low-grade tungsten and molybdenum ore are added into a vacuum furnace, tungsten and molybdenum metal and slag are obtained through reduction, the tungsten and molybdenum metal and the slag are contained in a reaction furnace, steel scrap is added into the reaction furnace, temperature rising smelting is conducted, and the ferrotungston-molybdenum-iron alloy is obtained after smelting is completed. According to the method for smelting the ferrotungston-molybdenum-iron alloy by adopting the low-grade tungsten and molybdenum ore, tungsten and molybdenum in the low-grade tungsten and molybdenum ore can be utilized sufficiently, the harmful elements like P in the alloy can be reduced, and the quality of the alloy is improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

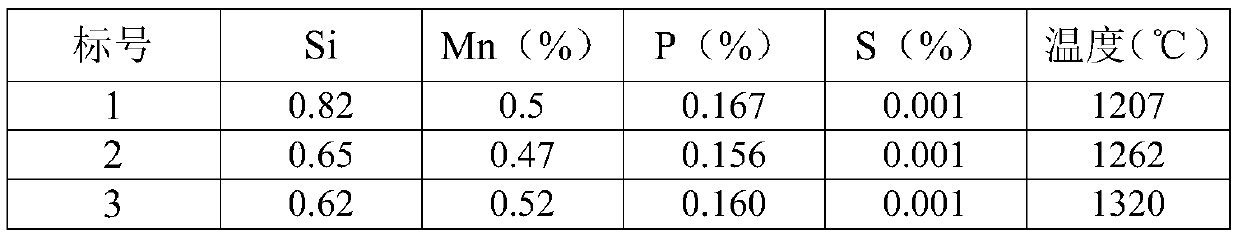

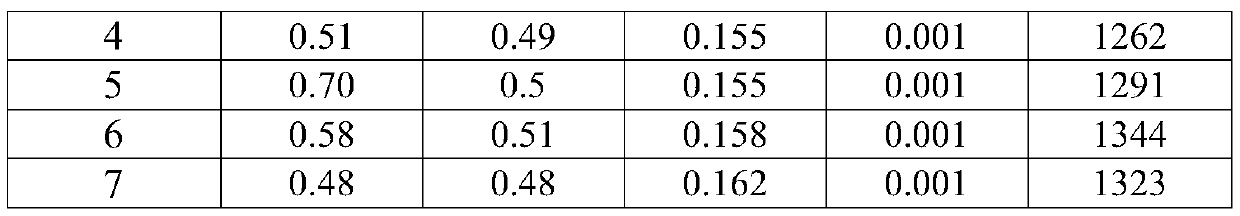

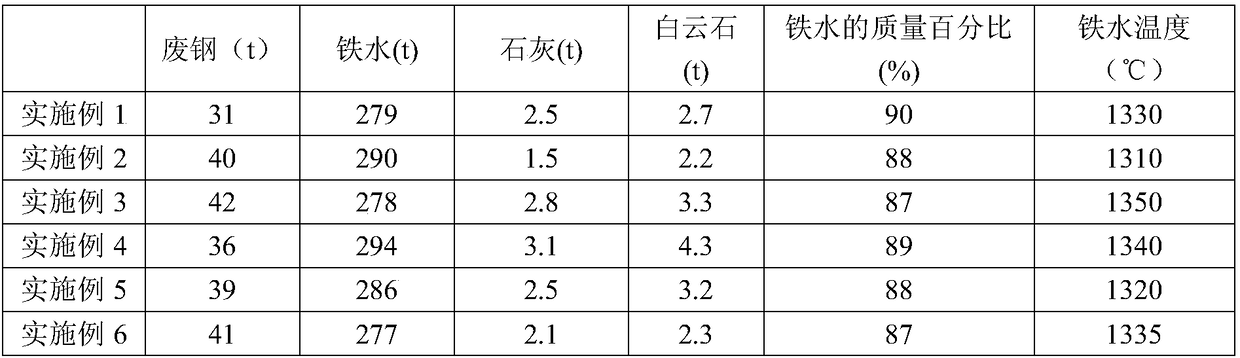

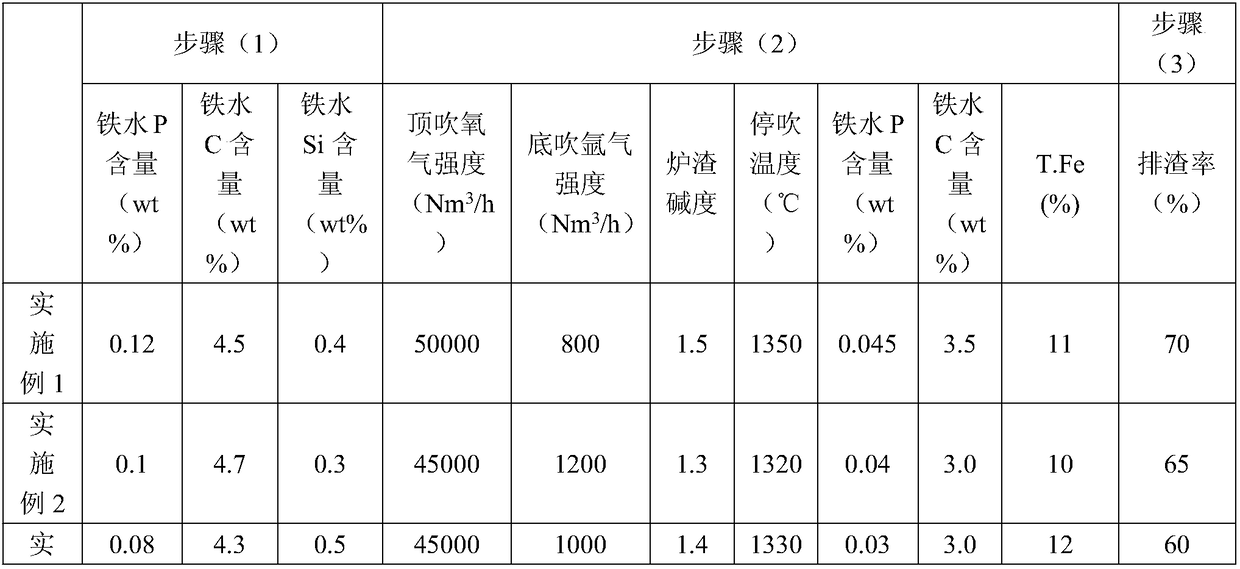

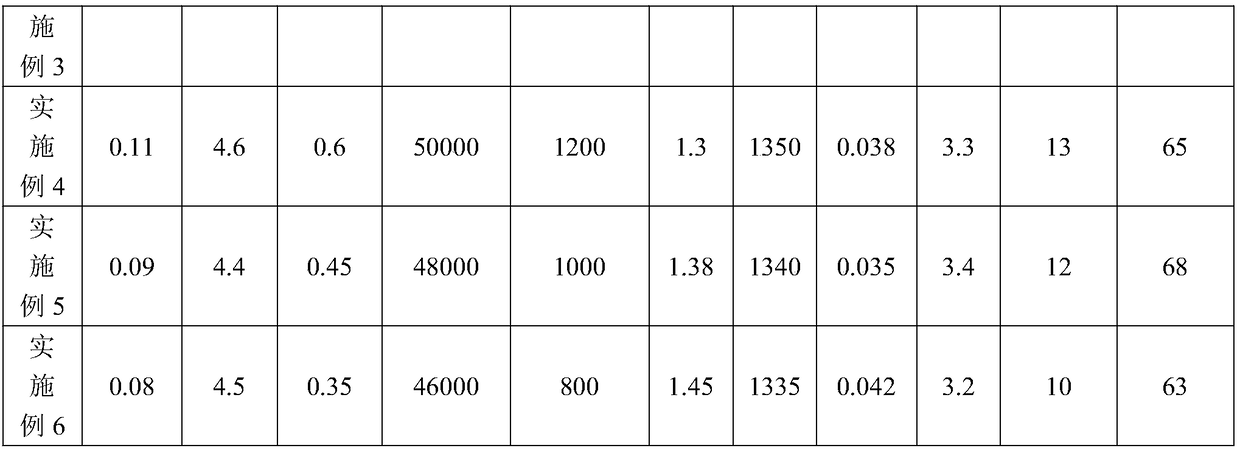

Technological method of using high-phosphorus molten iron to produce ultralow-phosphorus steel

ActiveCN109778054AGive full play to the dephosphorization reaction abilityStable productionManufacturing convertersProcess efficiency improvementAlkalinitySlag

The invention relates to the field of steel and iron smelting, in particular to a technological method of using high-phosphorus molten iron to produce ultralow-phosphorus steel. The technological method comprises the steps that pretreatment of the KR molten iron is conducted; converter smelting is conducted, specifically, the alkalinity of final slag is controlled to range from 3.0 to 4.5, and thefinishing point converting temperature is controlled to range from 1600 DEG C to 1620 DEG C; slag stopping and steel tapping operation is conducted, specifically, molten steel deoxidizing agents andfurnace slag deoxidizing agents are not added in the steel tapping process; LF refining operation is conducted, specifically, high-alkalinity furnace slag is generated in the refining process, argon is blown to the bottom of a steel ladle, stir operation is conducted, and the temperature of molten steel ranges from 1520 DEG C to 1560 DEG C; the slag is removed, and slag formation is conducted again; and deoxidization treatment is conducted. By the adoption of the technology, the molten steel which is formed by the molten iron can be used, the phosphorus content of the molten iron is larger than 0.160%, the content of the component P element which is processed can be stably lower than or equal to 0.005%, the minimum content of the P element can be 0.002%, the requirements of various steel grades for the component P element of the molten steel can be met, the purpose of producing the ultralow-phosphorus steel can also be achieved, and the technological control process is stable and reliable.

Owner:BAOTOU IRON & STEEL GRP

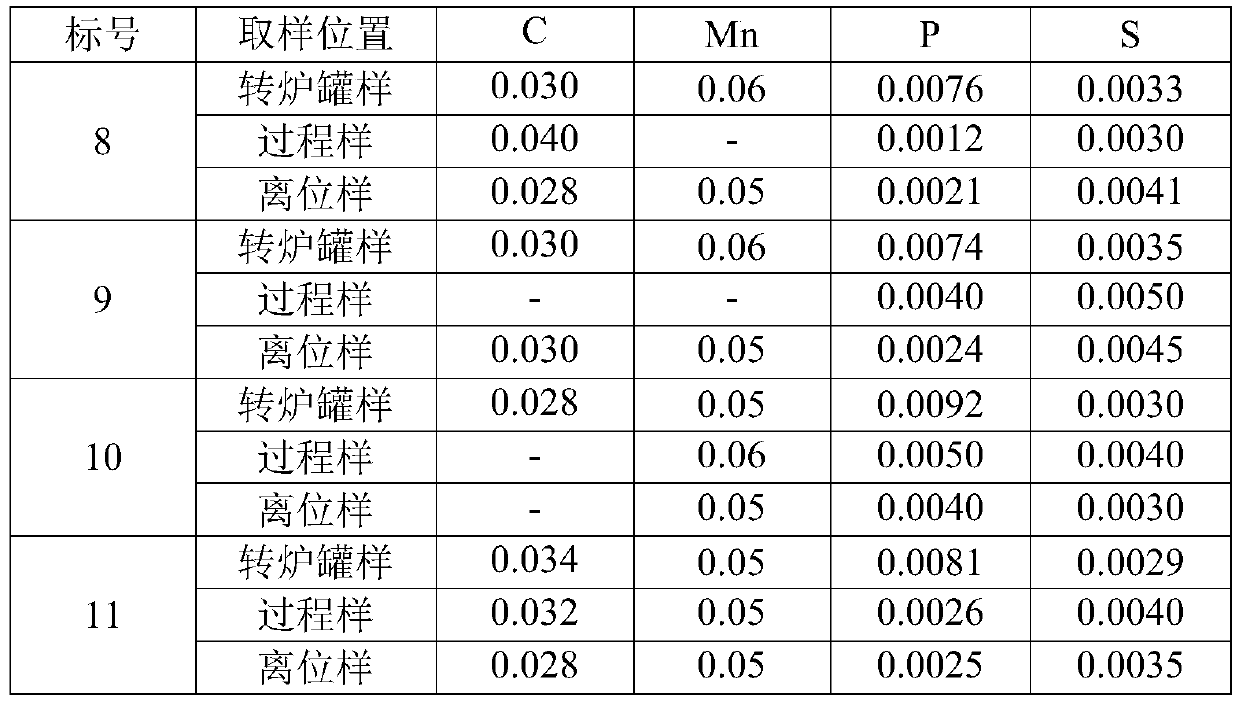

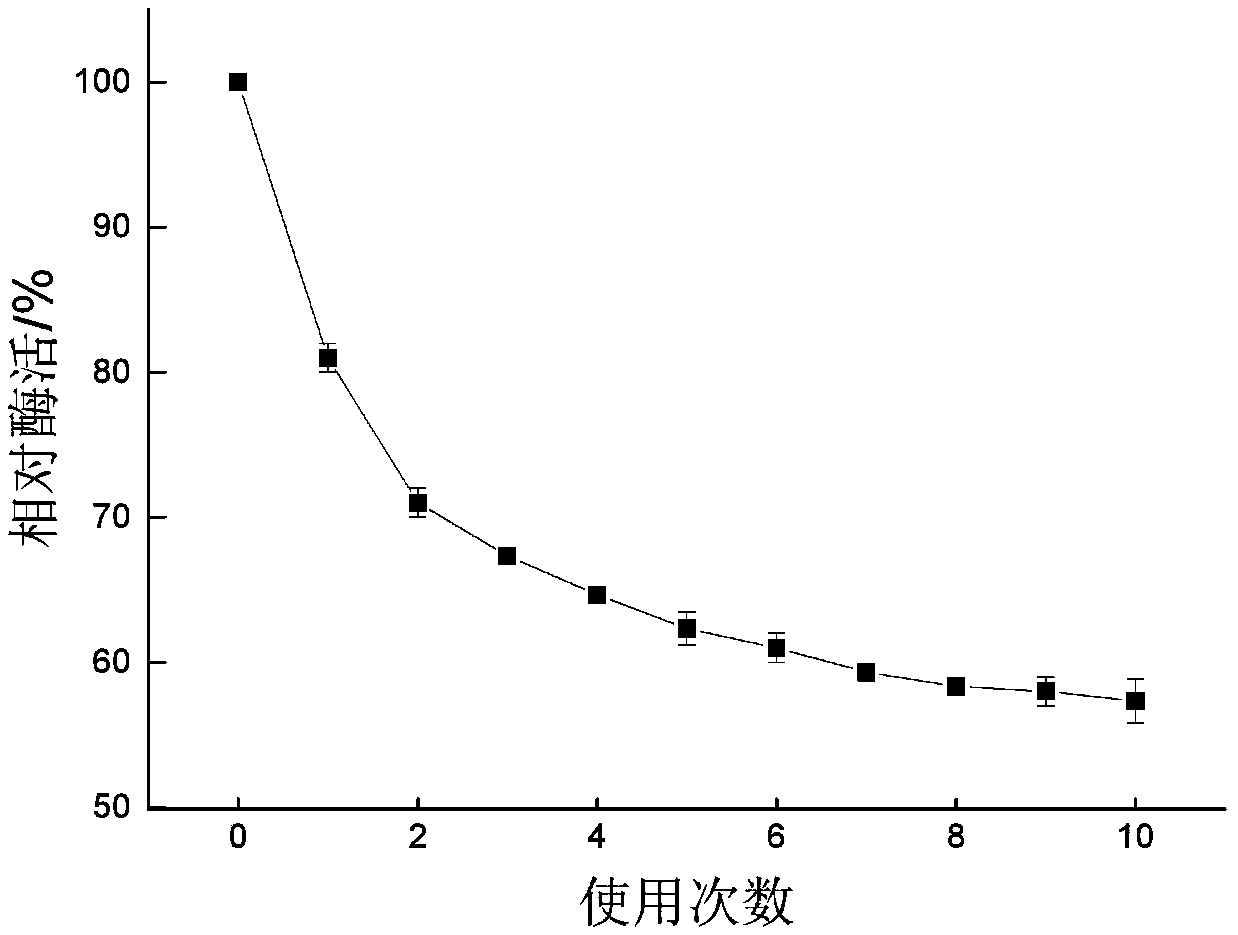

Vegetable oil degumming method

PendingCN109694776AImprove degumming efficiencyHigh yieldFatty-oils/fats refiningChemistryPhospholipases C

The invention provides a vegetable oil degumming method, and relates to the technical field of enzymatic degumming of oils and fats. The method comprises the following steps: 1, immobilizing phospholipase; and 2, degumming oil by the immobilized phospholipase. The immobilization of the phospholipase includes immobilization of phospholipase A1 and immobilization of phospholipase C; and degumming ofoil comprises pretreatment of vegetable oil, primary degumming of the vegetable oil by using the immobilized phospholipase C; and secondary degumming of the primarily degummed vegetable oil by usingthe immobilized phospholipase A1. The method adopts an immobilized phospholipase C and phospholipase A1 combined degumming technology, and the degumming effects of the two enzymes on the oil are fullyshown, so the yield of the neutral oil is increased; and the immobilized phospholipase can be repeatedly used, so the production cost is saved.

Owner:HEFEI UNIV OF TECH

A low-sulfur and low-phosphorus steel welding rod for resisting hydrogen induced crack hydrogen sulfide corrosion

ActiveCN110524135AExcellent production processArc stabilizationWelding/cutting media/materialsSoldering mediaCrazingManganese

The invention discloses a low-sulfur and low-phosphorus steel welding rod for resisting hydrogen induced crack hydrogen sulfide corrosion. The welding rod is composed of a low-sulfur-phosphorus core wire and coating flux powder wrapping the surface of the core wire. Composition and content of the coating flux powder are as follows: 40- 44 parts by mass of carbonate, 15-18 parts by mass of fluoride, 4-7.5 parts by mass of rutile, 6-8 parts by mass of silicon dioxide, 3-6 parts of electrolytic manganese, 8-11 parts by mass of silicon iron, 8-10 parts by mass of iron powder, 0.5-1.0 part by mass of sodium carbonate, 0.5-1.0 part by mass of sodium alginate and 0.10-0.15 part by mass of graphite. Compared with the prior art, the welding rod is stable in electric arc, small in splashing, goodin deslagging, attractive in molding and good in all-position operation performance.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Thin rare earth-containing hot rolled steel plate for enamel liner of water heater, and production method of steel plate

InactiveCN103243259ALow costSave resourcesRoll force/gap control deviceTemperature control deviceSheet steelTrace element

The invention relates to a thin rare earth-containing hot rolled steel plate for an enamel liner of a water heater, and a production method of the steel plate. The material of the steel plate comprises the following chemical components in percentage by weight: 0.02 to 0.05 percent of C, 0.015 to 0.50 percent of Si, 0.10 to 0.20 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.025 percent of S, more than or equal to 0.015 percent of Alt, less than or equal to 0.01 percent of Re and the balance of Fe and inevitable impurities. The tissue of the steel plate comprises ferrite and a small amount of pearlite. According to the steel plate, the yield strength is more than 230 Mpa, the tensile strength is more than 320 Mpa and the extension rate is more than 45 percent. The heating temperature is 1,080 to 1,150 DEG C, the initial rolling temperature is 1,050 to 1,100 DEG C, the finishing rolling temperature is 860 to 890 DEG C, the reeling temperature is 550 to 600 DEG C, the total press-down rate of rolling is more than or equal to 85 percent, and rolling is performed in a dispersing and cooling form. The thin rare earth-containing hot rolled steel plate disclosed by the invention has the advantages that the trace element Re is added on the basis of C-Mn steel, and a controlled rolling and controlled cooling technology is adopted, so the cost performance is high, the cost is low, and the performance completely accords with the requirements of the thin steel plate for the enamel liner.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

High-temperature-resisting abrasion-resisting material for circulating fluidized bed boiler

The invention discloses a high-temperature-resisting abrasion-resisting material for a circulating fluidized bed boiler. The high-temperature-resisting abrasion-resisting material comprises, by mass percent, 2.2% to 3.4% of Nb, 1.34% to 2.5% of Si, 16% to 25% of Cr, 1.0% to 2.5% of Mn, 0.5% to 1% of Mo, 1.2% to 2% of Cu, 0.1% to 0.3% of V, 0.02% to 0.2% of Ti, 0.5% to 1.5% of Al, 0.5% to 1.5% of W, 2% to 8% of Ni, 0.05% to 0.6% of C, 0.5% to 2% of Ce and the balance Fe. The prepared high-temperature-resisting abrasion-resisting material for the circulating fluidized bed boiler is excellent in high temperature corrosion resistance and high temperature wear resistance performance.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

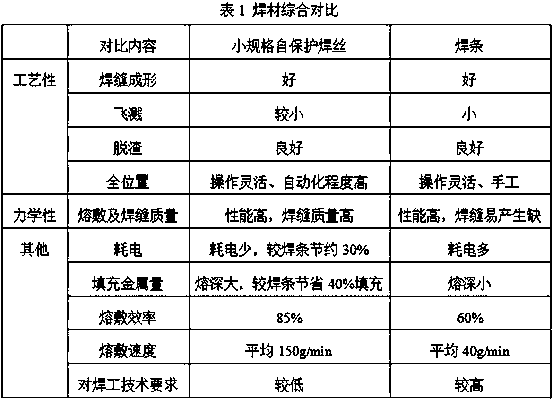

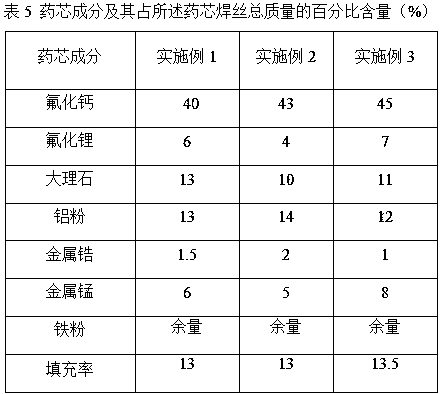

Small-sized self-shielded flux-cored wire suitable for flat position welding and horizontal position welding and application thereof

ActiveCN109530959ALess welding spatterAvoid it happening againWelding/cutting media/materialsSoldering mediaPorositySlag

The invention belongs to the technical field of welding materials, and particularly relates to a small-sized self-shielded flux-cored wire suitable for flat position welding and horizontal position welding. The small-sized self-shielded flux-cored wire comprises a carbon steel skin and a flux core filled in the carbon steel skin, wherein the flux core comprises the following the components according to the total mass percent of the flux core: 40-45% of calcium fluoride, 4-7% of lithium fluoride, 10-13% of marble, 12-14% of aluminum powder, 1-2% of zirconium metal, 5-8% of manganese metal and the balance being iron powder. The small-sized self-shielded flux-cored wire suitable for flat position welding and horizontal position welding is used for the welding of a light steel structure. The small-sized self-shielded flux-cored wire provided by the invention adopts a calcium fluoride-lithium fluoride-marble slag system, and the slag system is mainly composed of high calcium fluoride; a large amount of fluoride improves the anti-porosity ability of the flux-cored wire; meanwhile, the lithium fluoride with the relatively good arc-stabilizing effect is added, so that little welding spatter occurs at the flat position of welding; gas protection is not needed; and the small-sized self-shielded flux-cored wire meets E71T-GS related requirements in American Standard AWS 5.20.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Stainless-steel smelting method

ActiveCN102787195BP content is easy to controlReduce P contentElectric furnaceElectric arc furnaceSmelting process

The invention relates to a stainless-steel smelting method, belonging to the technical field of steel smelting. The process comprises the following steps: melting by using an ultrahigh-power electric-arc furnace with an eccentric bottom to reduce iron directly, wherein the electric-arc furnace is provided with a large-flow furnace wall cluster coal oxidation gun; alloying by using the electric-arc furnace in the steel tapping spout structure; refining by using an AOD furnace; refining by using a VOD furnace; and casting continuously. Each step of the stainless-steel smelting process has a definite target, and the equipment has a definite division of work, namely, the first electric furnace is used for melting to reduce iron directly and dephosphorize so as to provide the qualified crude molten steel, and the second electric furnace is used for alloying so as to provide the qualified mother liquid for the AOD furnace and finish the refining by the AOD furnace; the time rhythms are combined reasonably, thus the burden of the subsequent AOD furnace is reduced; more than 85% of alloy is added in the electric furnaces, thus the components of the alloy are easy to control; when the waste stainless steel resources are sufficient, the waste stainless steel can be smelted in the second electric furnace, and the mother liquid can be provided for the AOD furnace; and second electric furnace can be used for producing special steel according to the change of the market.

Owner:BEIJING SHOUGANG INT ENG TECH

Sponge iron for furnace charge and its manufacturing method

A spongy iron for burden is proportionally prepared from the iron ore concentrate powder with iron content more than 66%, or iron scales and spongy iron additive prepared proportionally from carbon powder, carbonate of alkali metal or alkali-earth metal and the halide of alkali metal or alkali-earth metal.

Owner:张和起

A gas shielded welding wire for nuclear power steel containment

ActiveCN104128715BImprove toughnessReduce manufacturing costWelding/cutting media/materialsSoldering mediaNuclear powerWeld seam

The invention provides a gas protection welding wire for a nuclear power steel containment vessel and belongs to the field of welding materials. The gas protection welding wire comprises, by mass, 0.07%-0.12% of C, 1.10%-1.60% of Mn, 0.25%-0.55% of Si, 0.80%-1.40% of Ni, at most 0.025% of S, at most 0.025% of P, at most 0.20% of Cr, 0.10%-0.30% of Mo, at most 0.50% of Cu, and the balance iron and inevitable impurities. The gas protection welding wire is low in cost, welding arcs are stable, welding spatter is slight, welding seams are formed neatly, obtained deposited metal and welded joints are high in comprehensive mechanical performance in the welded condition, low-temperature impact performance is high, and tenacity is extremely high. The gas protection welding wire can be widely applied to steel structure welding in nuclear power engineering.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +2

Converter smelting method for low-phosphorus low-oxygen steel

The invention discloses a converter smelting method for low-phosphorus low-oxygen steel. The converter smelting method comprises: (1) adding raw materials, and slagging; (2) carrying out blowing smelting, wherein oxygen is blown at the top of a converter, argon is blown at the bottom of the converter, and blowing smelting is stopped when the alkalinity of the slag is 1.2-1.5; (3) discharging the slag; (4) continuously carrying out slagging and blowing smelting, wherein oxygen is blown at the top of the converter, argon is blown at the bottom of the converter, and blowing smelting is stopped when the alkalinity of the slag is 3.5-4.5; and (5) simultaneously carrying out bottom blowing at unequal flow rates on the bottom of the converter after lifting the gun so as to finally obtain the molten steel with the P content of less than 0.01 wt% and the O content of less than 0.06 wt%, wherein the bottom blowing comprises high-flow rate bottom blowing and low-flow rate bottom blowing, the flowrate of the high-flow rate bottom blowing is 800-1200 Nm<3> / h, the flow rate of the low-flow rate bottom blowing is 400-800 Nm<3> / h, and the bottom blowing time is 2-5 min. According to the present invention, the converter smelting method is suitable for the bottom blowing with different flow rates to promote mass transfer, such that the phosphorus content and the oxygen content in the steel areeffectively reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of reactive flame retardant containing double dopo group and nitrogen and its preparation method and application

ActiveCN110157041BImprove flame retardant performanceImprove thermal stabilityFireproof paintsGroup 5/15 element organic compoundsEpoxyPolymer science

The invention discloses a reactive flame retardant containing double DOPO groups and nitrogen, and a preparation method and an application thereof. The reactive flame retardant containing double DOPOgroups and nitrogen can be prepared in a high yield through a two-step reaction by the simple and efficient synthesis method. The reactive groups on the molecule of the reactive flame retardant are reacted with an epoxy resin to effectively improve the flame retardation property of the epoxy resin and improve the mechanical properties to a certain degree; the epoxy resin is modified with the reactive flame retardant to simultaneously improve the flame retardation effect and the mechanical strength of the epoxy resin, the synergistic flame-retardant effect of phosphorus and nitrogen greatly improves the flame retardation property of the modified epoxy resin at a very low dosage of the flame retardant, and results of limiting oxygen index and UL-94 vertical burning test show that the flame retardancy reaches V-0 level, and the limiting oxygen index (LOI) reaches 30.9. The preparation method of the reactive flame retardant containing double DOPO groups and nitrogen has the advantages of simplicity, and cheap and easily available raw materials, so the reactive flame retardant containing double DOPO groups and nitrogen is a reactive flame retardant hopeful to be industrialized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-temperature and abrasion resisting high manganese material for circulating fluidized bed boiler

The invention discloses a high-temperature and abrasion resisting high manganese material for a circulating fluidized bed boiler. The material comprises the following components in percentage by mass: 2.2-3.4 of Nb, 1.34-2.5 of Si, 16-25 of Cr, 10-18 of Mn, 0.5-1 of Mo, 1.2-2 of Cu, 0.1-0.3 of V, 0.02-0.2 of Ti, 0.5-1.5 of Al, 0.5-1.5 of W, and the balance of Fe. The circulating fluidized bed boiler prepared by the material is excellent in high-temperature corrosion resistance and high-temperature abrasion resistance.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

Electric arc furnace steelmaking method for making foaming slag by adopting calcium carbonate instead of calcium oxide

InactiveCN107201423AReduce consumptionAvoid pollutionElectric furnaceSteelmakingElectric arc furnace

The invention relates to the field of smelting, in particular to an electric arc furnace steelmaking method using calcium carbonate instead of calcium oxide to form foam slag, comprising the following steps: 1) charging step; 2) melting step; 3) heating step; 4) oxidation step , when making steel in electric arc furnace, by adding calcium carbonate pyrolysis to produce CO2 and highly active CaO, CO2 is non-polluting, CO2 bubbles float up to form foam slag, and the foam slag can be completely buried in the arc, effectively avoiding the exposure of the arc to high-temperature corrosion of the furnace wall At the same time avoid the energy loss caused by the exposure of the arc and effectively reduce the noise generated by the electrode during the arc generation process. The foam slag layer can react with the C in the smoke to generate CO, thereby reducing the pollution of the operating environment by the C-containing smoke generated during the smelting process. High activity CaO and P2O5 in molten steel produce oxidation reaction to generate CaO. P2O5 is stably stored in steel slag and removed, so as to achieve the effect of P removal.

Owner:什邡市三裕锻件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com