Stainless-steel smelting method

A smelting method and stainless steel technology, applied in the field of steelmaking, can solve problems such as affecting product quality, large investment, environmental pollution, etc., and achieve the effect of easy control of alloy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

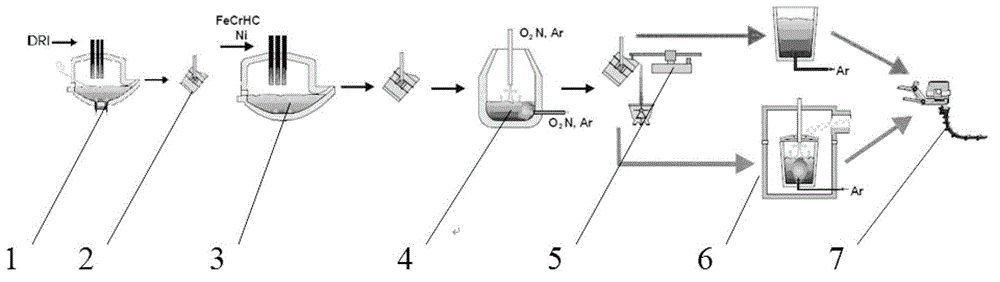

[0018] 1) Use the eccentric bottom electric arc furnace 1 to melt direct reduced iron to smelt crude molten steel with low phosphorus content. The main components of direct reduced iron are: C 1.4%; S 0.01%; P 0.04%; total iron content 92%; metallic iron content 84.64% %; FeO 9.47%; tapping temperature 1560°C, P content 0.025%, and then tapping into ladle 2.

[0019] 2) Mix the crude molten steel in the ladle 2 into the tapping groove structure electric arc furnace 3. Its task is to melt high-carbon ferrochromium, stainless steel return material and a small amount of scrap steel. These raw materials plus the molten steel provided by the eccentric furnace bottom electric arc furnace 1 are After smelting, the steel is tapped by mixing steel slag (for reducing chromium oxide in the slag), and the tapping temperature is 1660°C. After the slag is removed, the molten steel is blended into the AOD furnace 4 .

[0020] 3) The oxygen lance and the tuyeres on the side of the furnace bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com