Electric arc furnace steelmaking method for making foaming slag by adopting calcium carbonate instead of calcium oxide

A calcium carbonate and foamed slag technology, applied in the field of electric arc furnace steelmaking, can solve the problems of high temperature corrosion of furnace walls, shortening the service life of furnace walls, and large consumption of CaO, so as to promote the steelmaking process, avoid energy loss, consumption small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

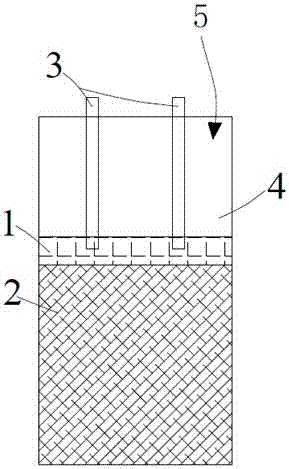

[0029] as attached figure 1 As shown, a method for foaming electric arc furnace slag in this embodiment includes foamed slag 1, molten steel 2, electrode rod 3, electric arc furnace 4, and calcium carbonate 5. During steelmaking in electric arc furnace 4, calcium carbonate can be 1%~ 100% instead of CaO, by adding calcium carbonate 5 pyrolysis to produce CO2 and highly active CaO, CO2 is non-polluting, CO2 bubbles float up and form foam slag 1 on the surface of molten steel 2, and foam slag 1 is completely ambushed, which can effectively avoid high-temperature corrosion caused by arc exposure Furnace wall, prolonging the service life of the furnace wall by more than two times, thereby saving 40%~60% of refractory materials, arc buried in foam slag 1 can reduce 20% energy loss and 40% noise, foam slag 1 can absorb refining The soot generated in the steel process can reduce 40% of the soot and react with the C in the soot to generate CO, which is burned to generate CO2, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com