Patents

Literature

70results about How to "Avoid discharge pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for manufacturing building board by utilizing mine tailing residue

The invention discloses a preparation method for manufacturing building board by utilizing mine tailing residue. The following raw materials are used by weight ratio: 30-75% of tailing residue and 25-70% of additive; brine with the weight percent concentration of 25-28% is utilized to stir the material into paste, the paste is placed into a mould to be rolled and moulded, and the tailing residue is one or more than one of gold slag, copper slag and ferrum slag. The invention utilizes tailing residue to produce building board, massive tailing residue is consumed, pollution harm of tailing discharge is solved, the produced building board has low cost and high strength, tailing residue can be made into various building boards by utilizing the technology, and various building section bars, stone pillar, brick and lattice prism used for historic building restoration as well as modern city sculpture, roman column pendant, external decorative wall, leisure chair, rail and sidewalk lattice brick can be cast.

Owner:王琦 +3

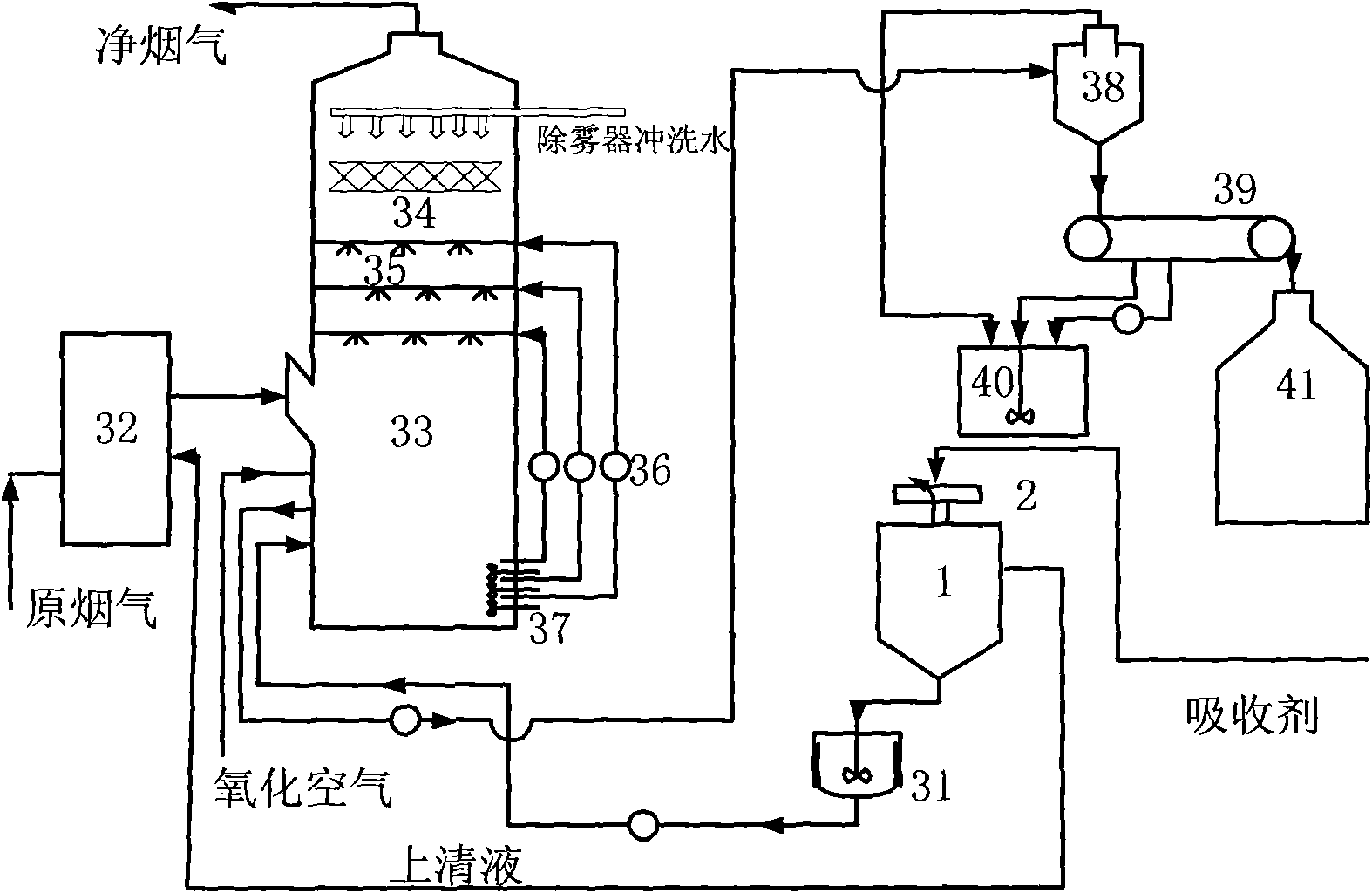

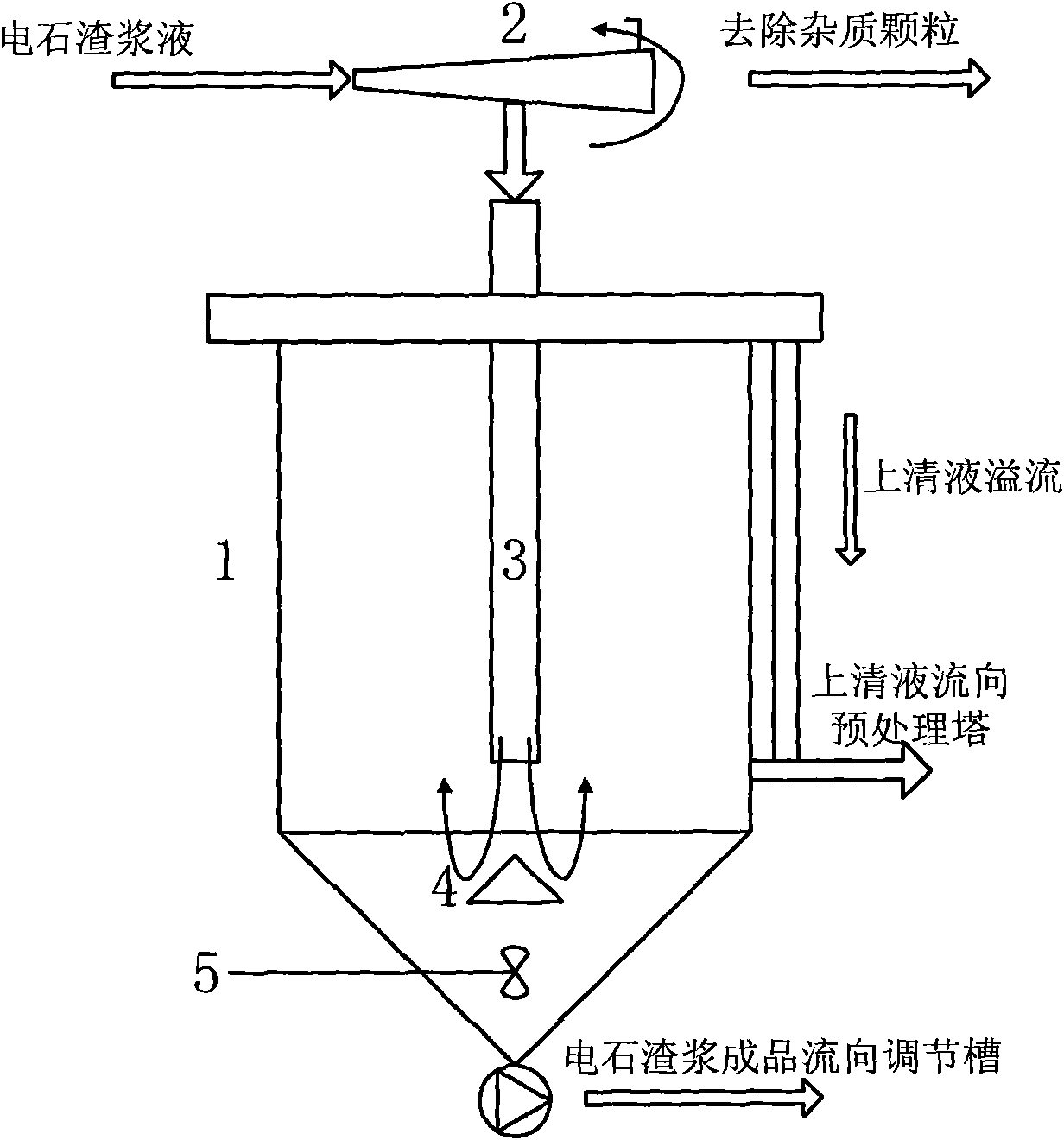

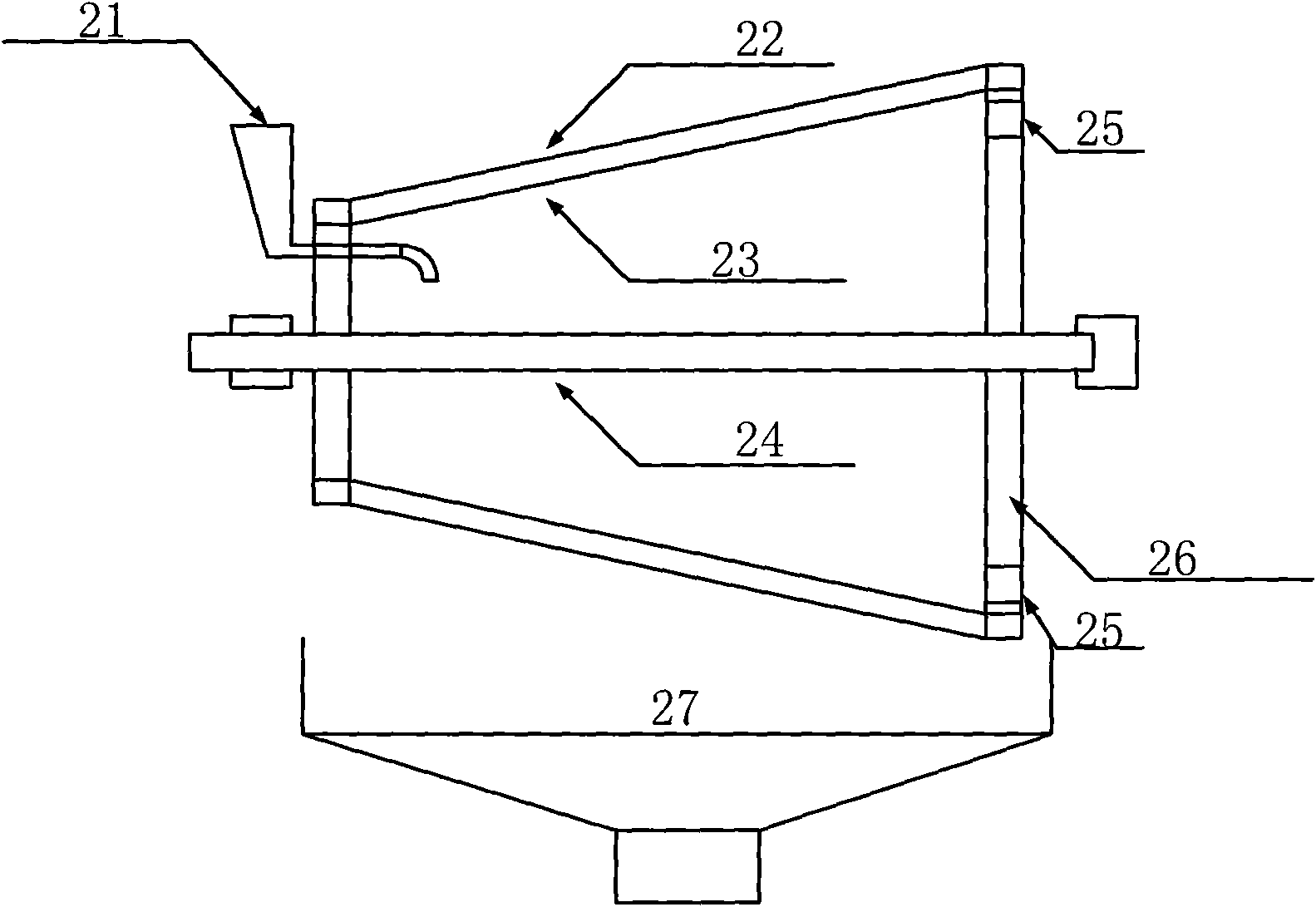

Wet flue gas desulphurizing method utilizing carbide slag slurry and device thereof

The invention discloses a wet flue gas desulphurizing method utilizing carbide slag slurry and a device thereof. The method comprises the following steps: 1) firstly, concentrating carbide slag slurry into carbide slag seriflux the concentration of which is 20-30%; 2) adjusting the concentration of sulphur content in flue gas, controlling the concentration of the carbide slag seriflux within the range of 28%-35% when the sulphur content in flue gas is larger than 8000mg / m3, controlling the concentration of the carbide slag seriflux is within the range of 22%-28% when the sulphur content in flue gas is between 4000mg / m3 and 8000mg / m3, controlling the concentration of the carbide slag seriflux within the range of 15%-22% when the sulphur content in flue gas is smaller than 4000mg / m3, regulating to proper concentration and then entering an absorption tower to carry out desulfuration reaction; 3) carrying out preliminary desulfuration reaction on flue gas which comes out from a deduster and firstly enters a pretreater; and 4) carrying out reaction on flue gas and sprayed and atomized carbide slag slurry in an absorption tower to realize rapid heat exchange, mass transfer and reaction, removing most of the entertainment liquid in the flue gas after reaction by a demister and discharging the flue gas from the top of the absorption tower. The invention can be applied to flue gas desulfurization of coal-fired boilers of a chemical plant, thereby achieving the purposes of treating waste by waste and utilizing comprehensively.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

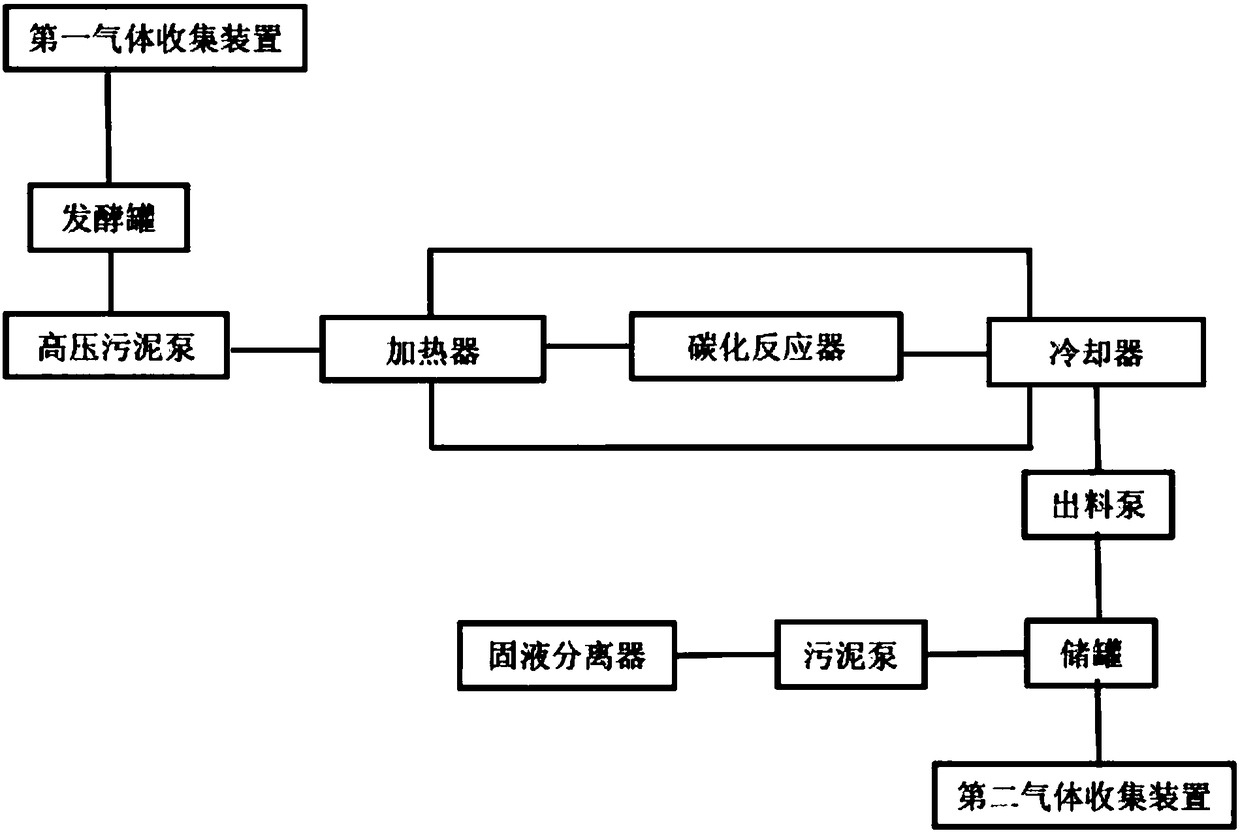

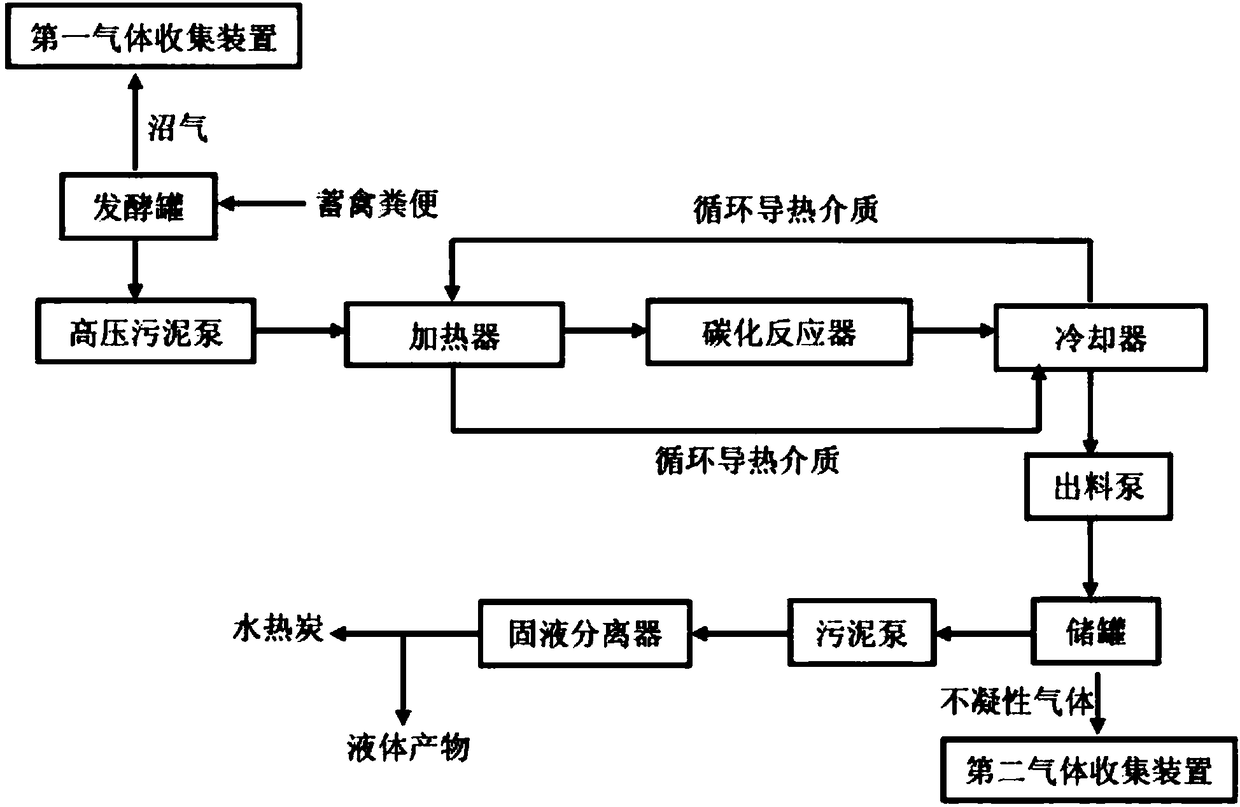

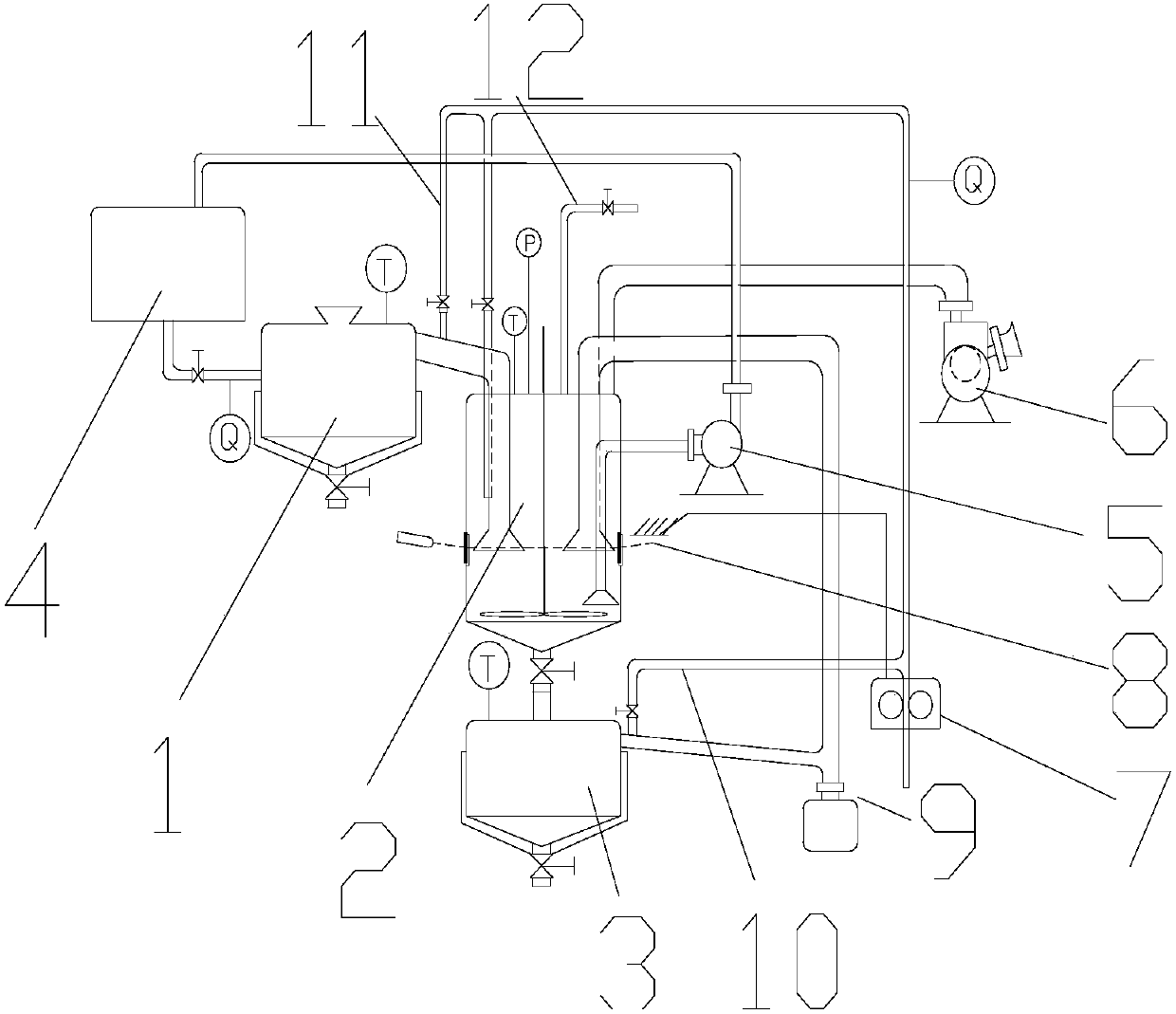

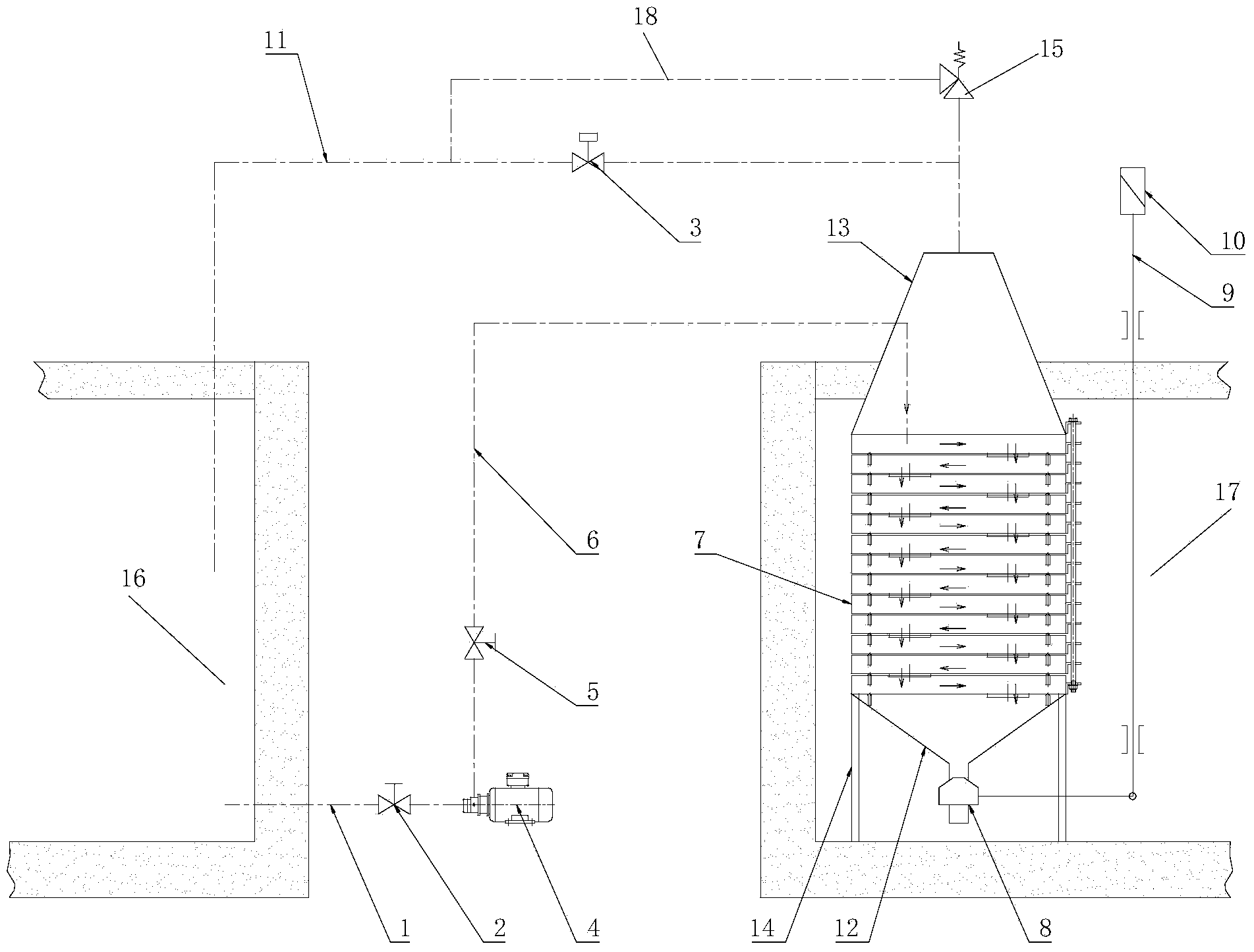

Continuous hydrothermal carbonization system and process for livestock and poultry excrement

InactiveCN108129001AReduce the difficulty of handling operationsEasy to handleSludge treatment by pyrolysisSpecial form destructive distillationSludgeResource utilization

The invention relates to the technical field of the resource utilization of livestock and poultry breeding waste, and discloses a continuous hydrothermal carbonization system for livestock and poultryexcrement. The continuous hydrothermal carbonization system comprises a fermentation tank, a high-pressure sludge pump, a heater, a carbonization reactor, a cooler, a storage tank, a sludge pump anda solid-liquid separator, wherein the fermentation tank, the high-pressure sludge pump, the heater, the carbonization reactor, the cooler, the storage tank, the sludge pump and the solid-liquid separator are communicated in sequence; the fermentation tank is also communicated with a first gas collection device through a pipeline; the storage tank is also communicated with a second gas collection device through a pipeline. The invention also discloses a continuous hydrothermal carbonization process for the livestock and poultry excrement. The continuous hydrothermal carbonization process comprises the following steps of fermenting the pretreated livestock and poultry excrement in the anaerobic fermentation tank, then continuously inputting into the heater, the carbonization reactor and cooler through power provided by the high-pressure sludge pump, and separating a temperature-lowered carbonization product through the solid-liquid separator to obtain hydrothermal carbon and carbonized liquid. The system is used for treating the livestock and poultry excrement by adopting a continuous hydrothermal carbonization method to prepare the hydrothermal carbon, meanwhile, is used for obtaining the by-product carbonized liquid, and have the advantages of being convenient to operate, easy to maintain, low in production cost, zero-release in pollutant and low in energy consumption, and thelike.

Owner:ZHEJIANG FORESTRY UNIVERSITY

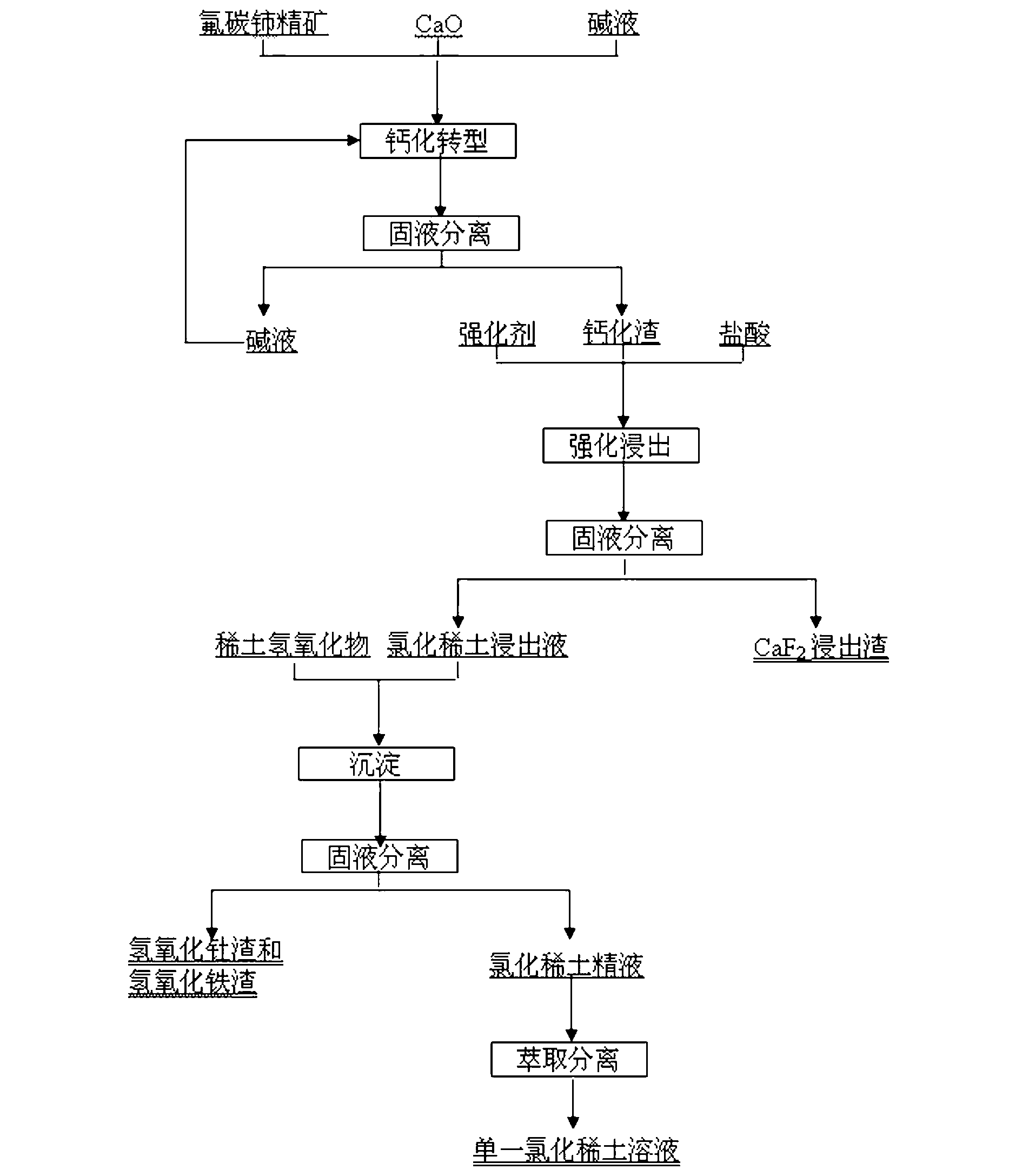

Method for decomposing bastnaesite through calcification transformation-leaching

The invention belongs to the technical field of rare earth metallurgy, and particularly relates to a method for decomposing bastnaesite through calcification transformation-leaching. The method comprises the following the steps of: carrying out activation pretreatment on rare earth ore concentrate, carrying out calcification transformation pretreatment on the activated ore, carrying out acid leaching on transformed slag, extracting rare earth chloride fine liquid to finally obtain a solution with thorium-iron slag and cerium chloride or lanthanum chloride or praseodymium chloride or neodymium trichloride, and efficiently separating valuable elements such as a rare earth element, a fluorine element and a thorium element. According to the method, energy consumption and fuel consumption are reduced, and when the low-temperature baking is carried out below 500 DEG C, only carbonates are decomposed, so that the reaction activity of the rare earth ore concentrate is supplied, and simultaneously the waste of fluorine resources and the emission pollution are avoided; and therefore, the method belongs to a green clean technology.

Owner:NORTHEASTERN UNIV

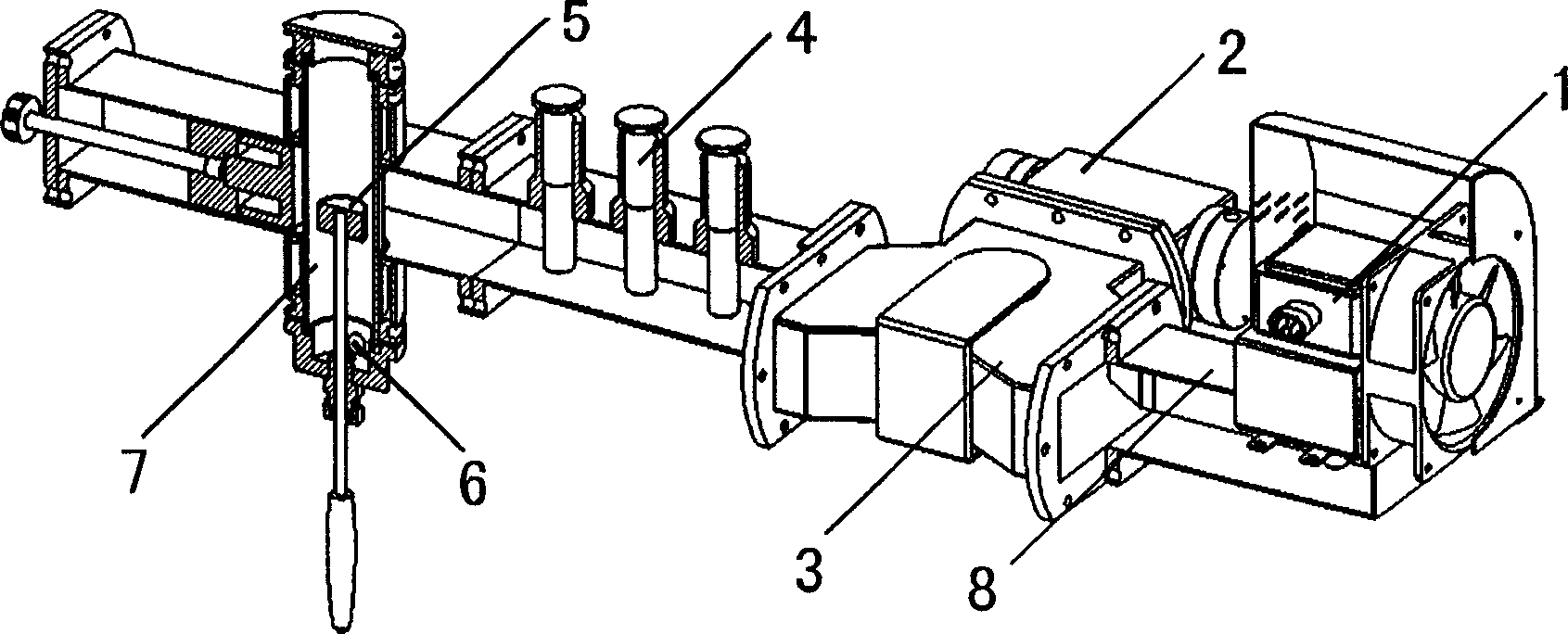

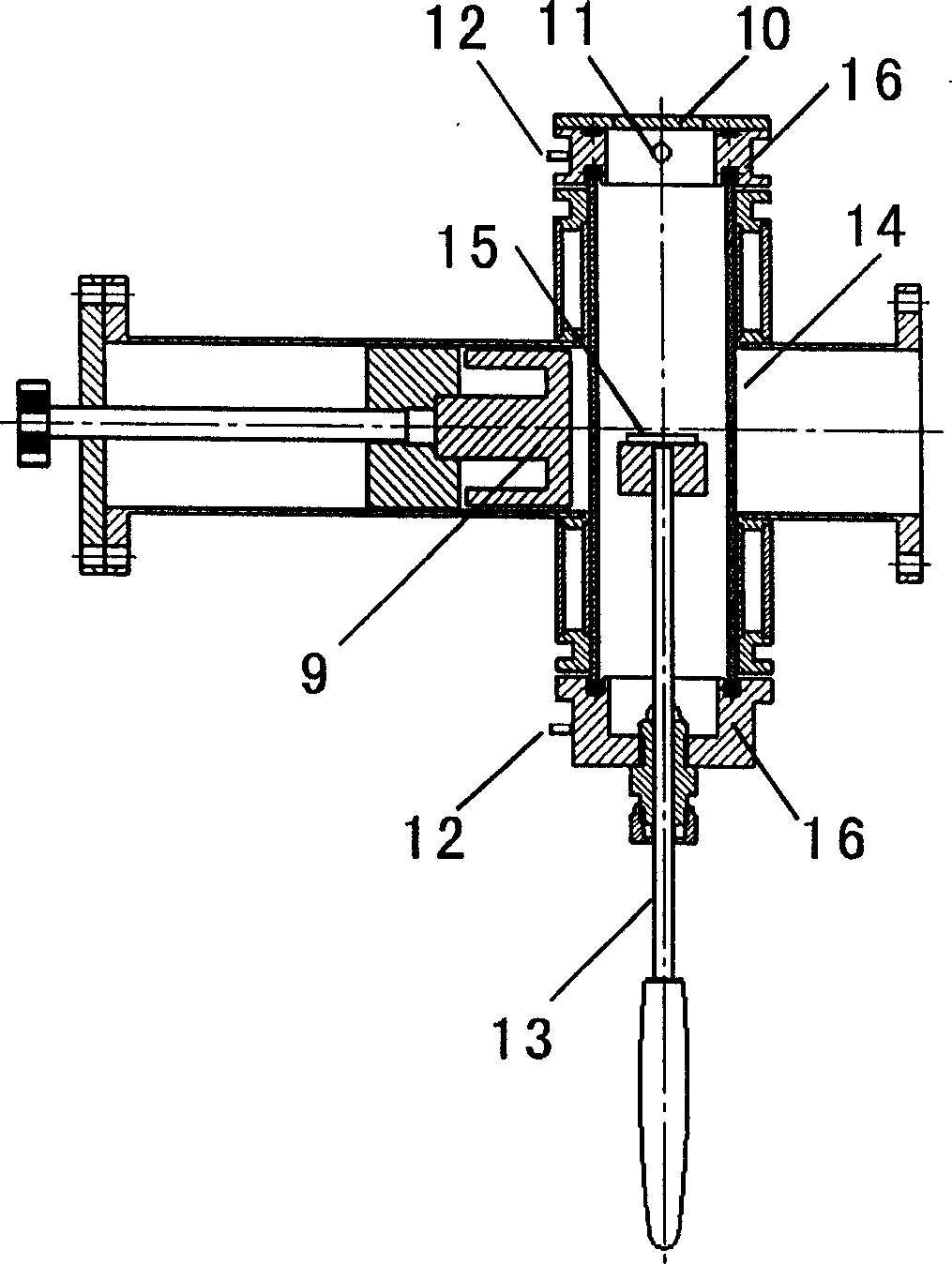

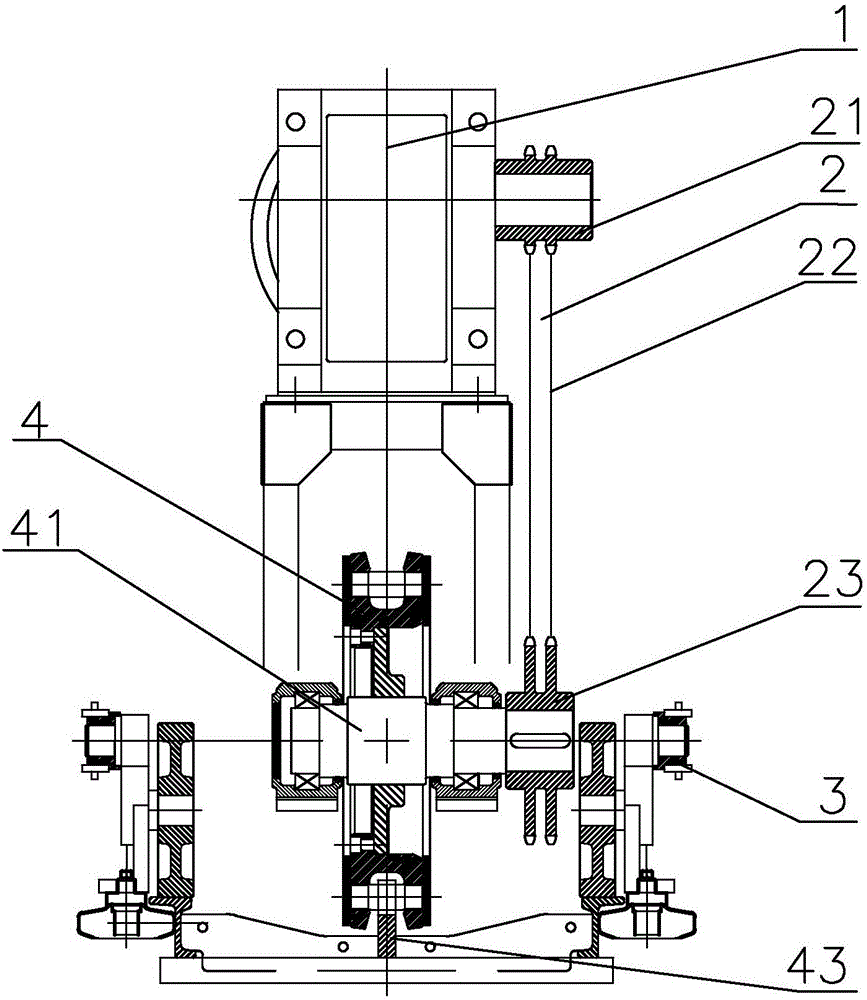

Microwave plasma device and method for preparing diamond film and etched carbon film

InactiveCN1858299AHigh cost performanceWide range of operating pressureElectric discharge tubesChemical vapor deposition coatingWaveguideVacuum pump

The present invention relates to microwave plasma device and method for preparing diamond film and etched carbon film. The microwave plasma device includes at least one magnetron as the microwave source, one rectangular waveguide, one impedance regulator, one microwave resonant cavity, one quartz tube reactor inside the microwave resonant cavity and one circuit-shorting piston on side of the resonant cavity. The preparation process of diamond film includes the following steps: setting the chip on the chip table, running the vacuum pump and raising the work voltage of the magnetron gradually to generate plasma; introducing carbon containing work gas, regulating the impedance regulator to reach the maximum microwave power, working for 20-40 min to nucleate; further introducing carbon containing work gas, working stably for 2-5 hr to form diamond film on the chip. Similarly, etched carbon film may be prepared.

Owner:HANGZHOU DAHUA INSTR MFG CO LTD

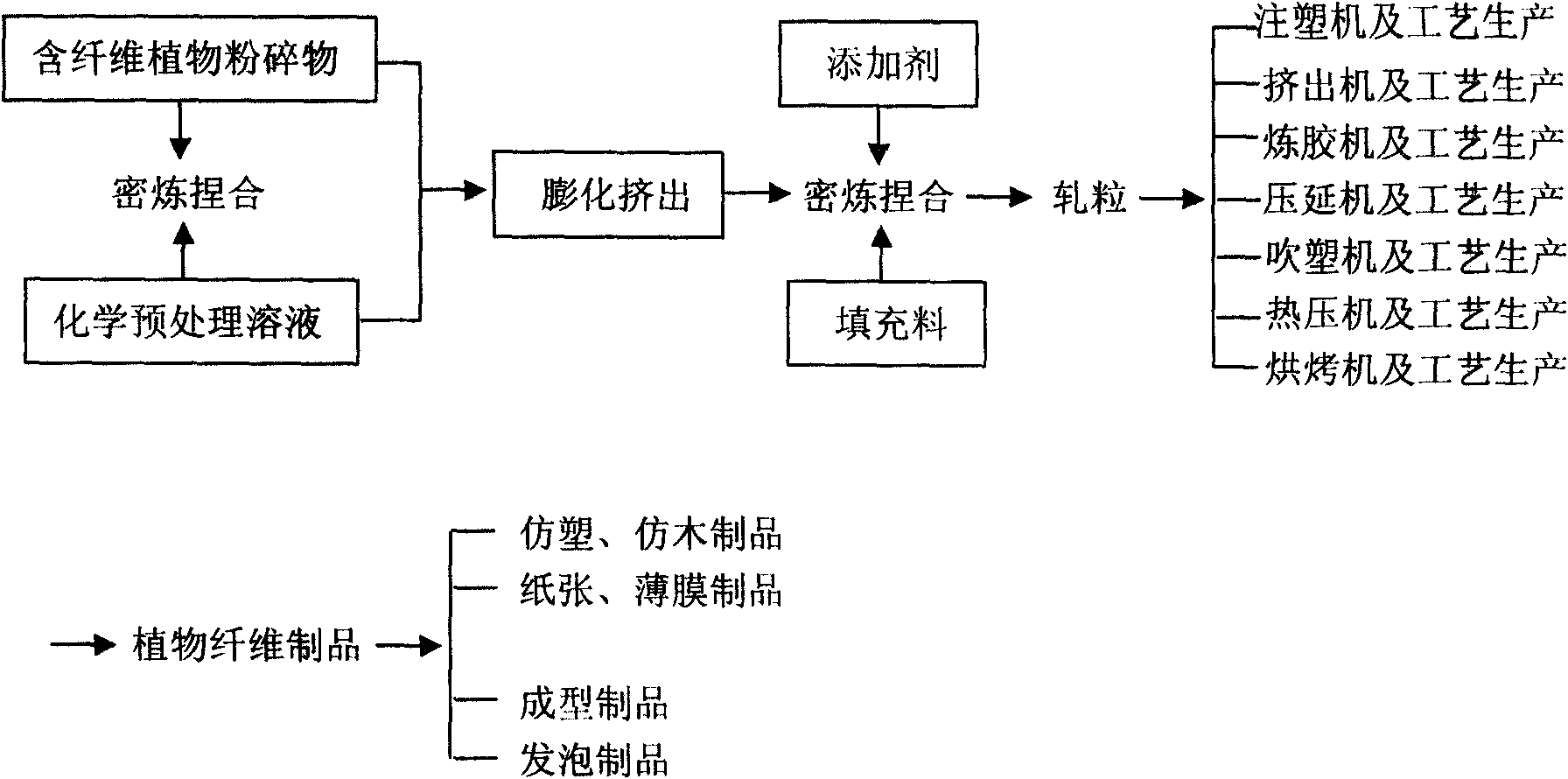

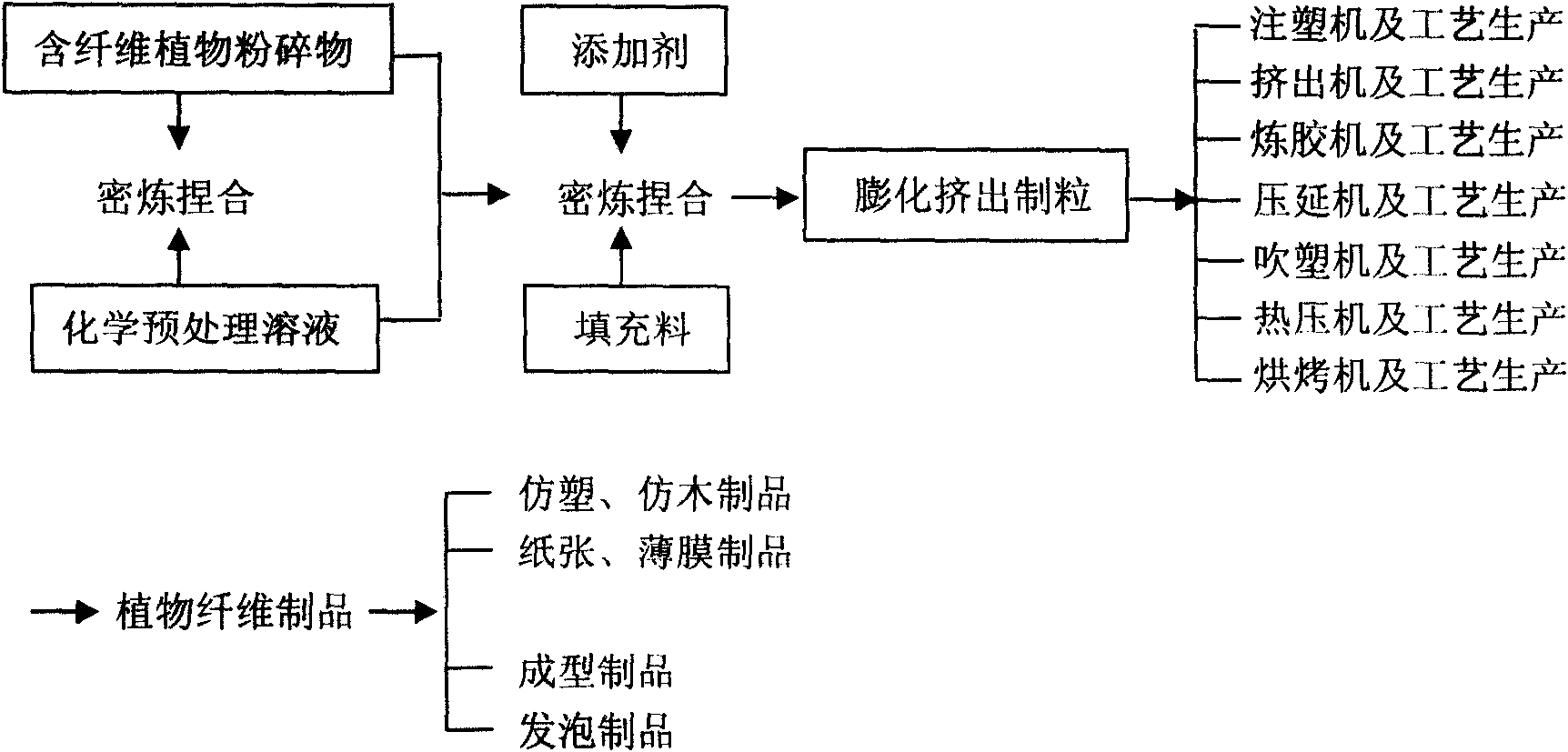

Manufacturing method of plant fibre products

The invention relates to a manufacturing method of plant fibre products, which comprises the steps: pulverized substances containing textile plants are poured into a banburying kneader and chemical pretreatment solution is added, so the fibre pretreatment chemical modification is realized simultaneously when mechanical physics modifying is realized; after entering into an expansion extruder for expansion modification, the pulverized substances are added with various additives and fillings, which are banburied and kneaded together, and the banburying kneading substance is rolled into particles by a particle rolling machine; or plant fibre subjected to banburying kneading chemical modification and various additives and fillings are directly and together banburied and kneaded and then are extruded and produced to form particles or extrusion sectional materials by the expansion extruder; the produced particles or sectional materials can be used for producing plant fibre products of various types and performances and plant fibre products of sheets, sectional materials, paper, membranes, and the like by utilizing the prior plastic injection machine, extruder, blow moulding machine, rubber refining machine, calander, hot press, and equipment and technology principles of microwave and infrared, steam drying, and the like so as to replace plastic, plastic foam, woodworks, paper and membranes.

Owner:朱秀刚

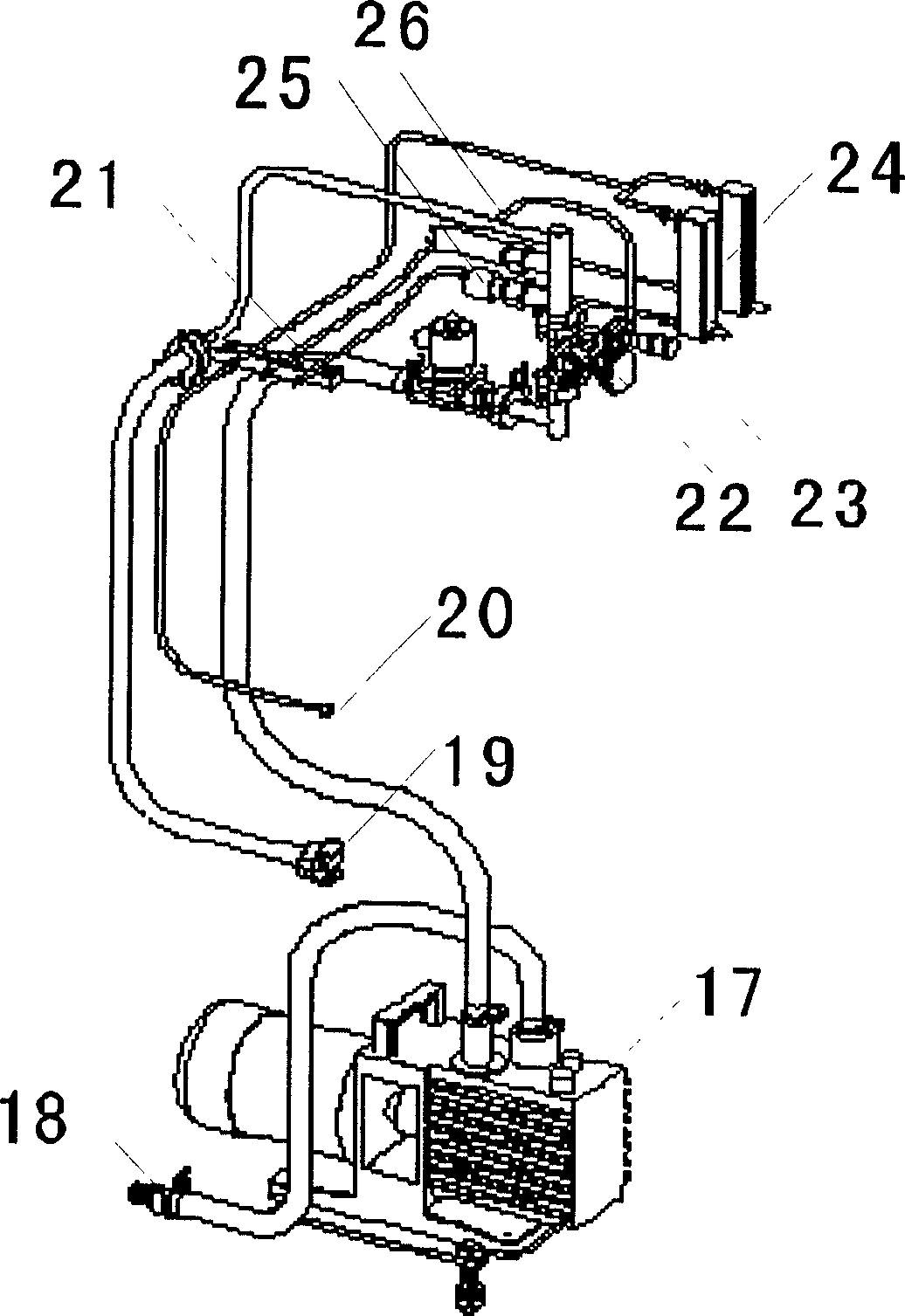

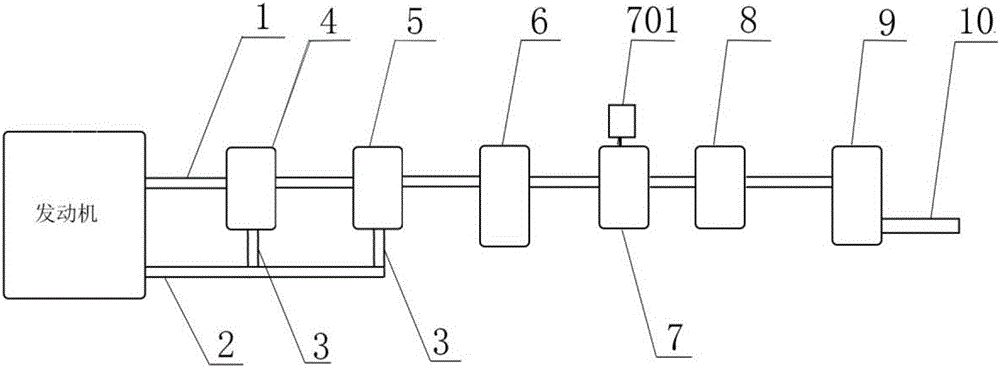

Multi-power hybrid driving system

InactiveCN106627605AGuaranteed unobstructedAvoid strandedBraking element arrangementsRack railwaysHydraulic motorDrive wheel

The invention provides a multi-power hybrid driving system and relates to the field of hybrid power driving. The multi-power hybrid driving system adopts modularized hybrid driving, environmental pollution is low, and multi-power interconversion is facilitated. The multi-power hybrid driving system comprises power sources, driving modules and driving wheels; the power sources are connected with the driving modules which are connected with the driving wheels, the power sources comprise a storage battery power supplying system, a cable conveying power supplying system and a fuel oil power system; and the driving modules comprise a permanent magnet motor drive, a speed reducer drive and a hydraulic motor drive, hybrid power driving modes are formed by means of the method that any two of the power sources are connected with any one or two of the driving modules, and the multiple mixing power driving modes are integrated to form the multi-power mixing driving system of a rack rail vehicle or a trapped rail vehicle.

Owner:秦皇岛鸿鼎轨道交通设备有限公司

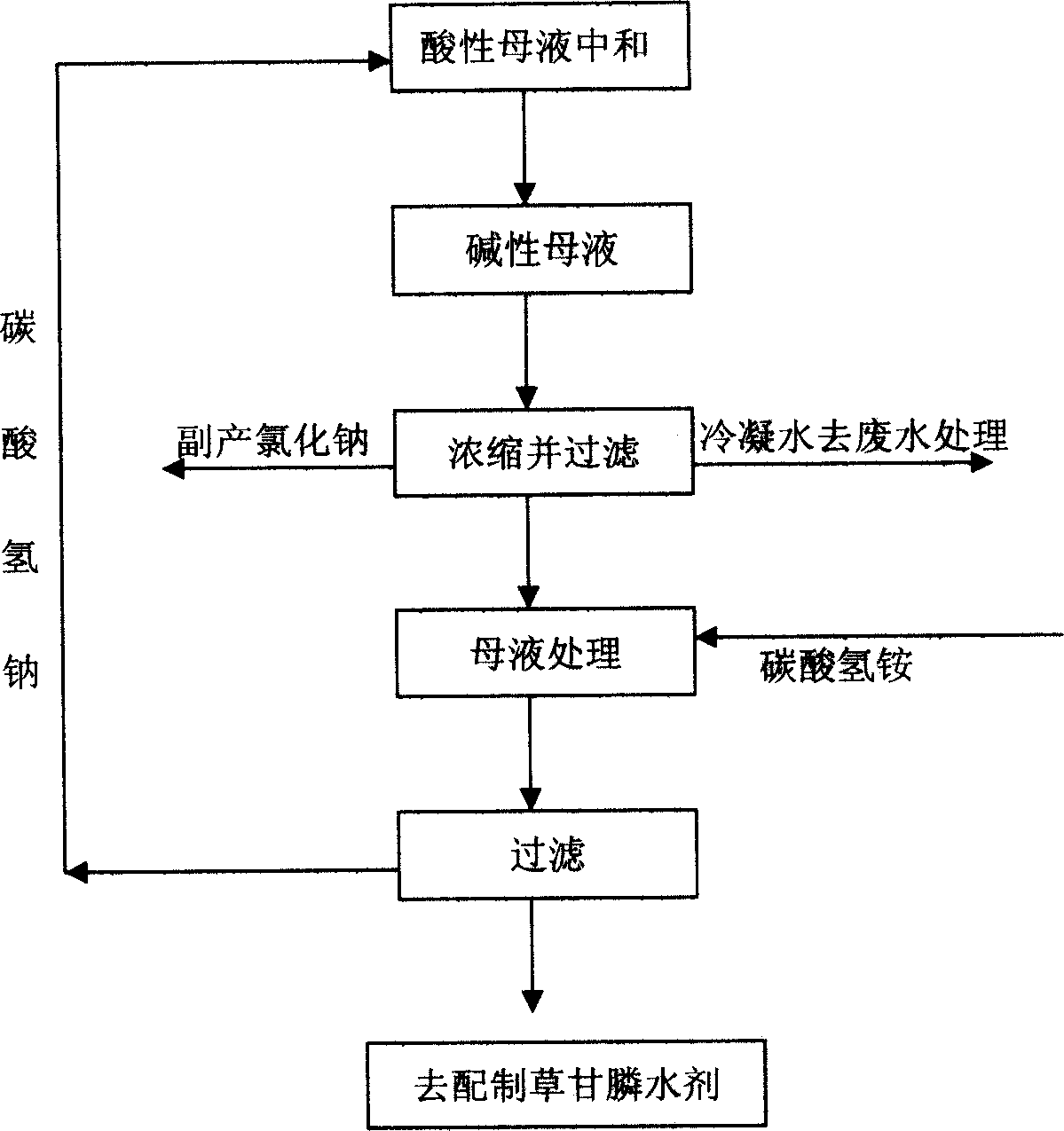

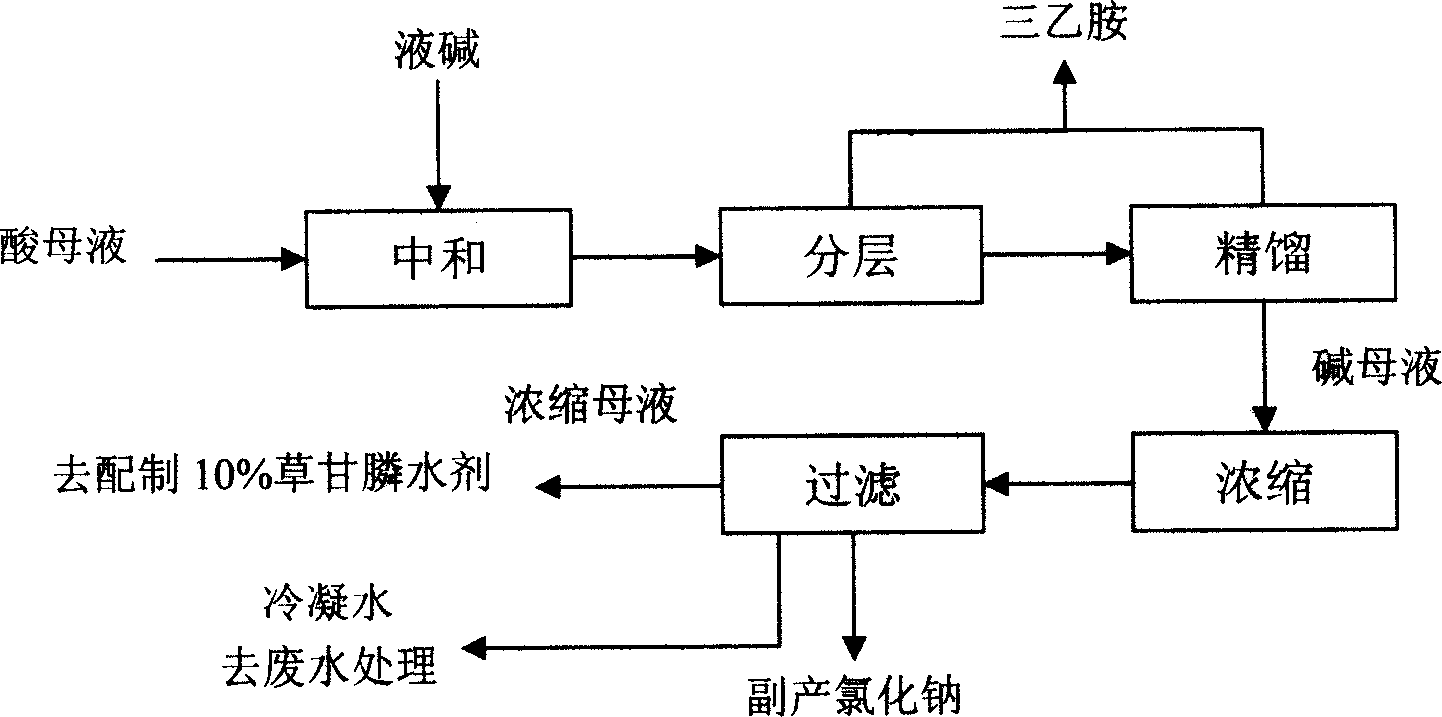

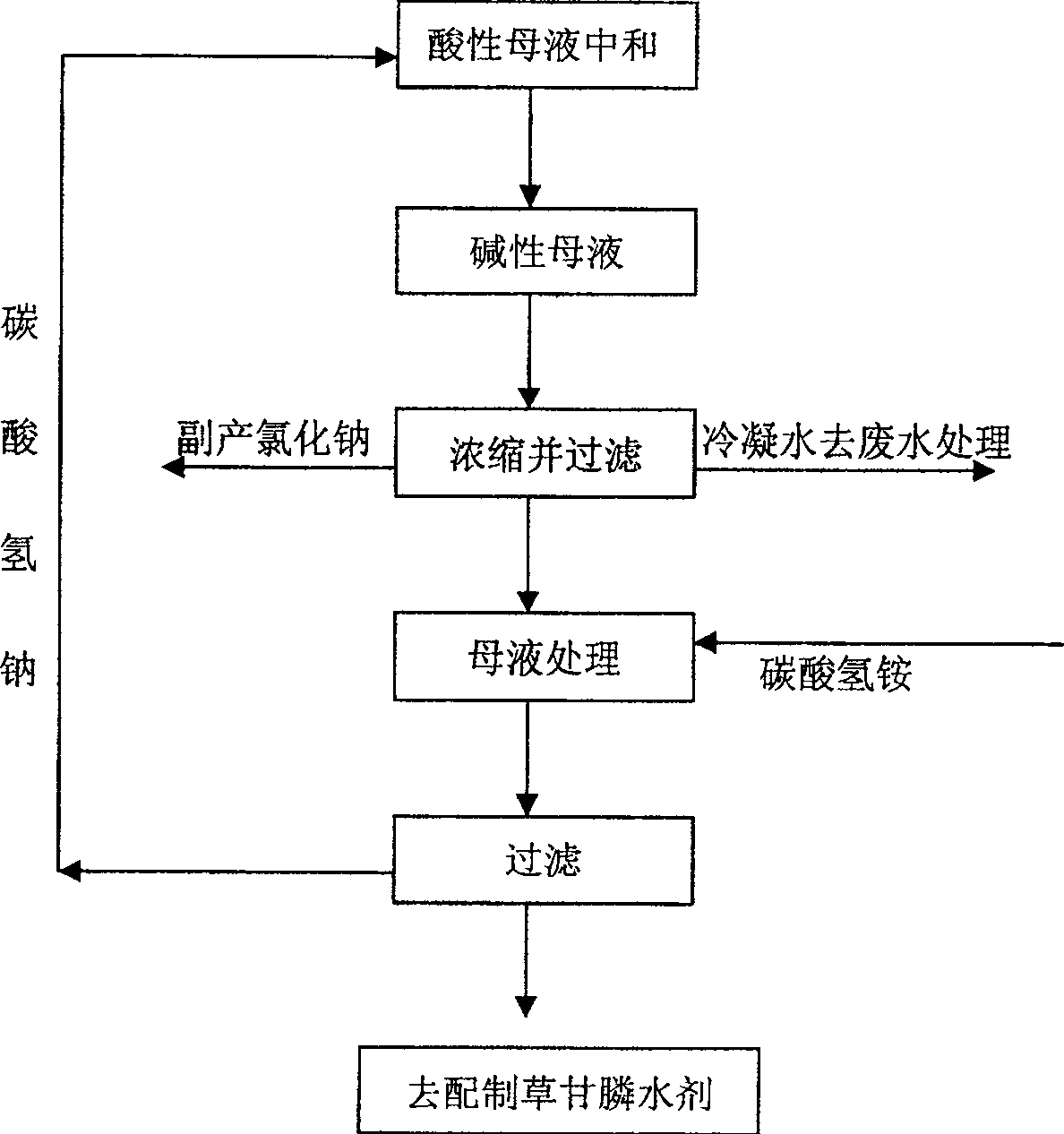

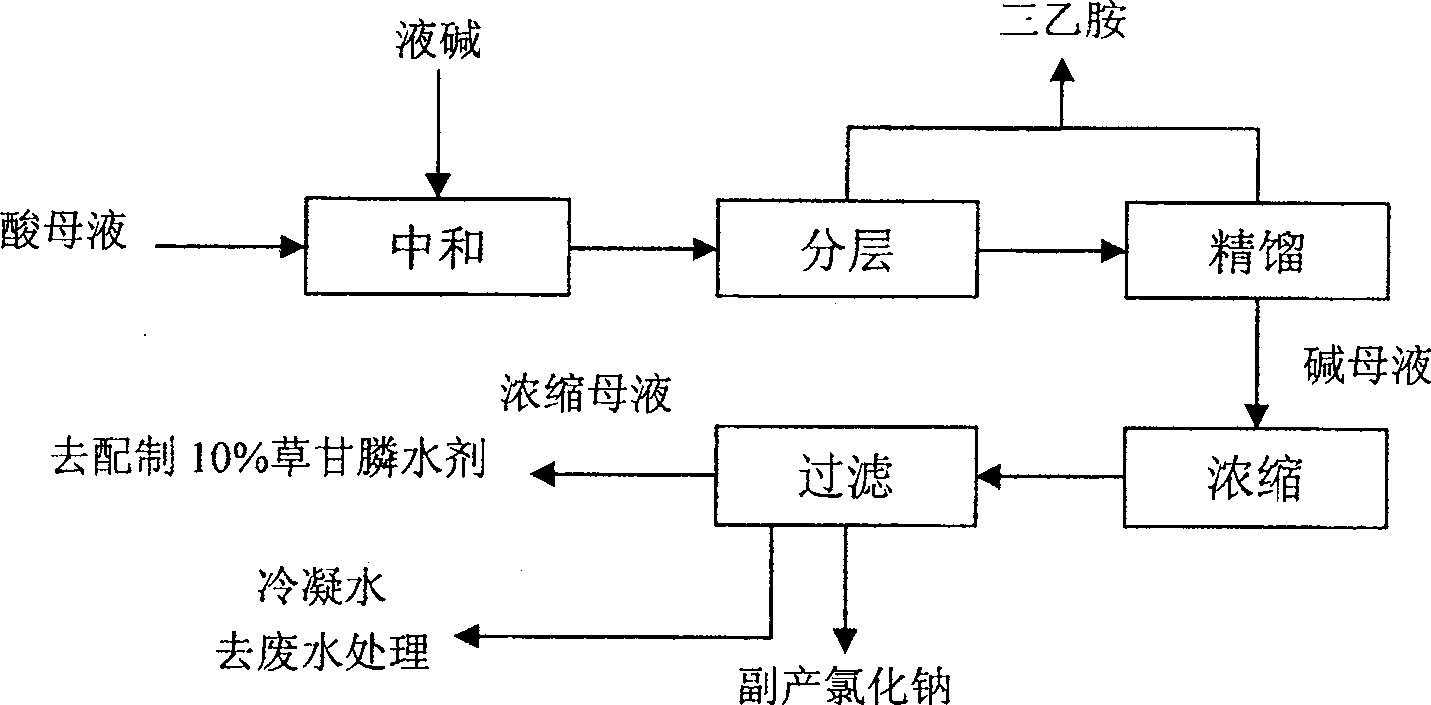

Glyphosate mother liquid treating method

ActiveCN1676527AImprove weed control effectEliminate pollutionGroup 5/15 element organic compoundsEnergy consumptionChloride sodium

This invention relates to a treatment method of mother liquid from alkyl esterification composing glyphosate. This method mainly reclaims TEA, condenses alkali mother liquid to get off large amount of byproduct soldium chloride, after which adds ammonium bicarbonate in the alkali mother liquid, fully reacts, filters to collocate glyphosate solution. This invention can not only get rid of the alkalization problem cause by too much sodium chloride in glyphosate, and also improves the medical effect of this solution collocated by this method, and lower the cost and save the energy consumption.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

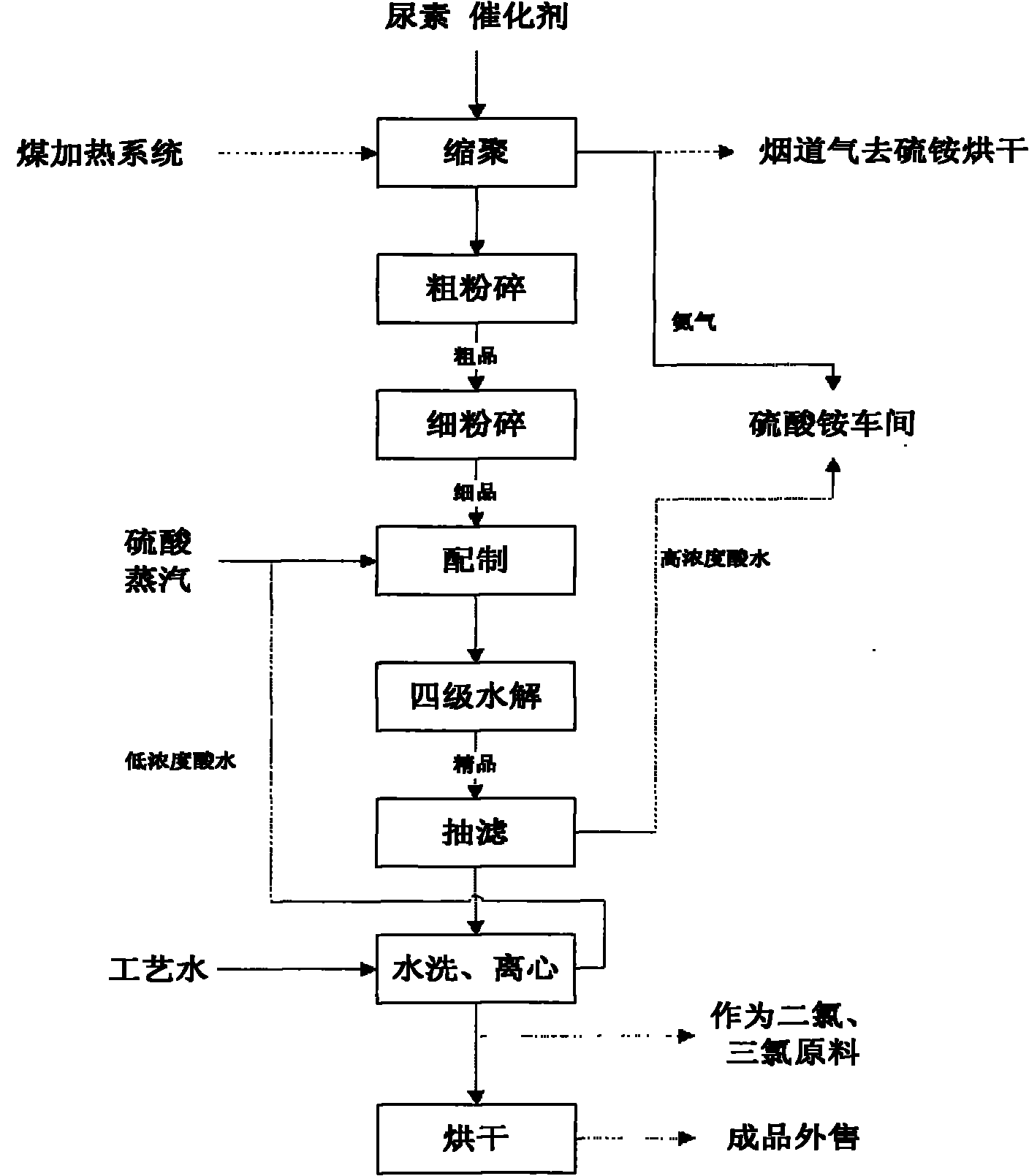

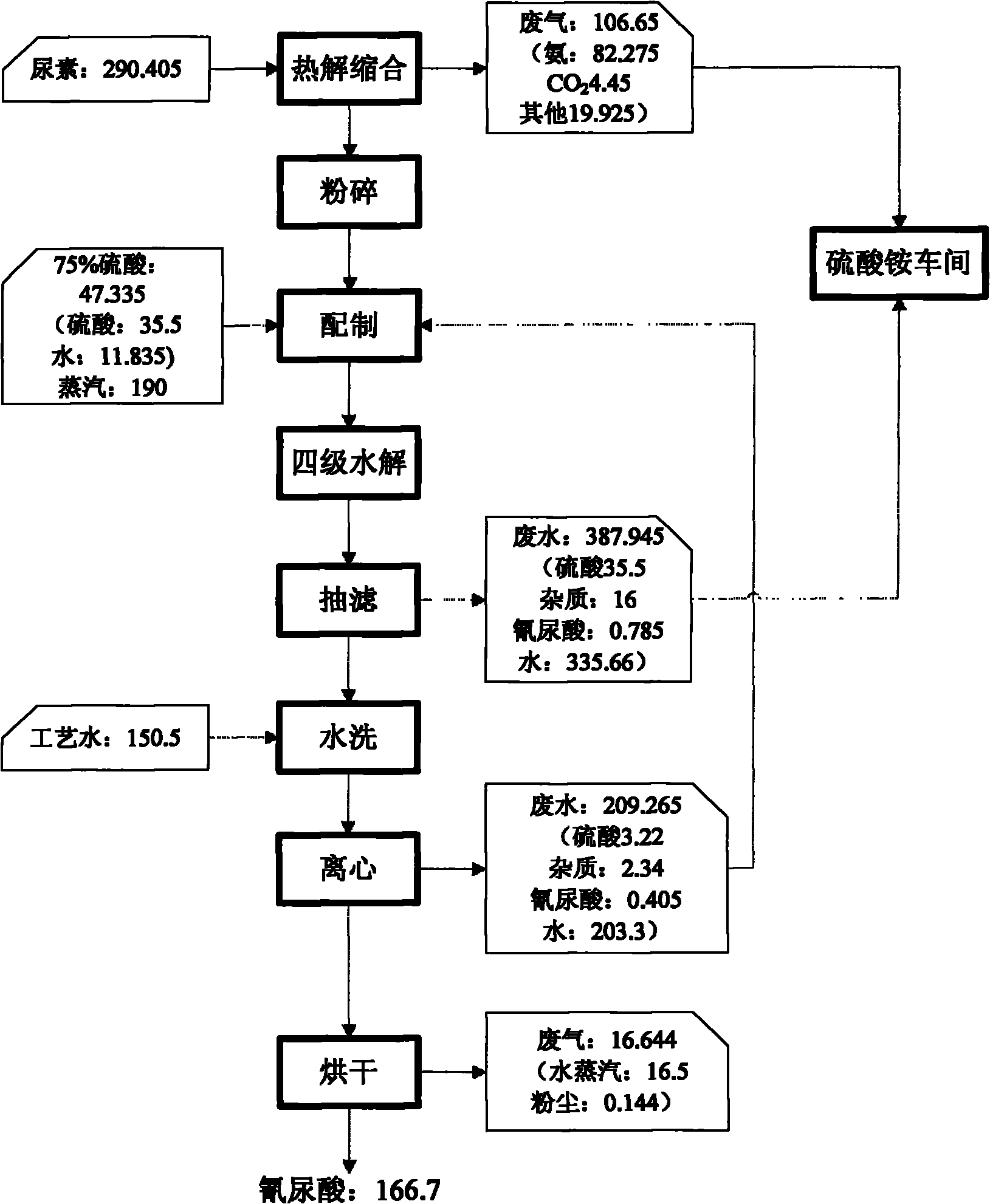

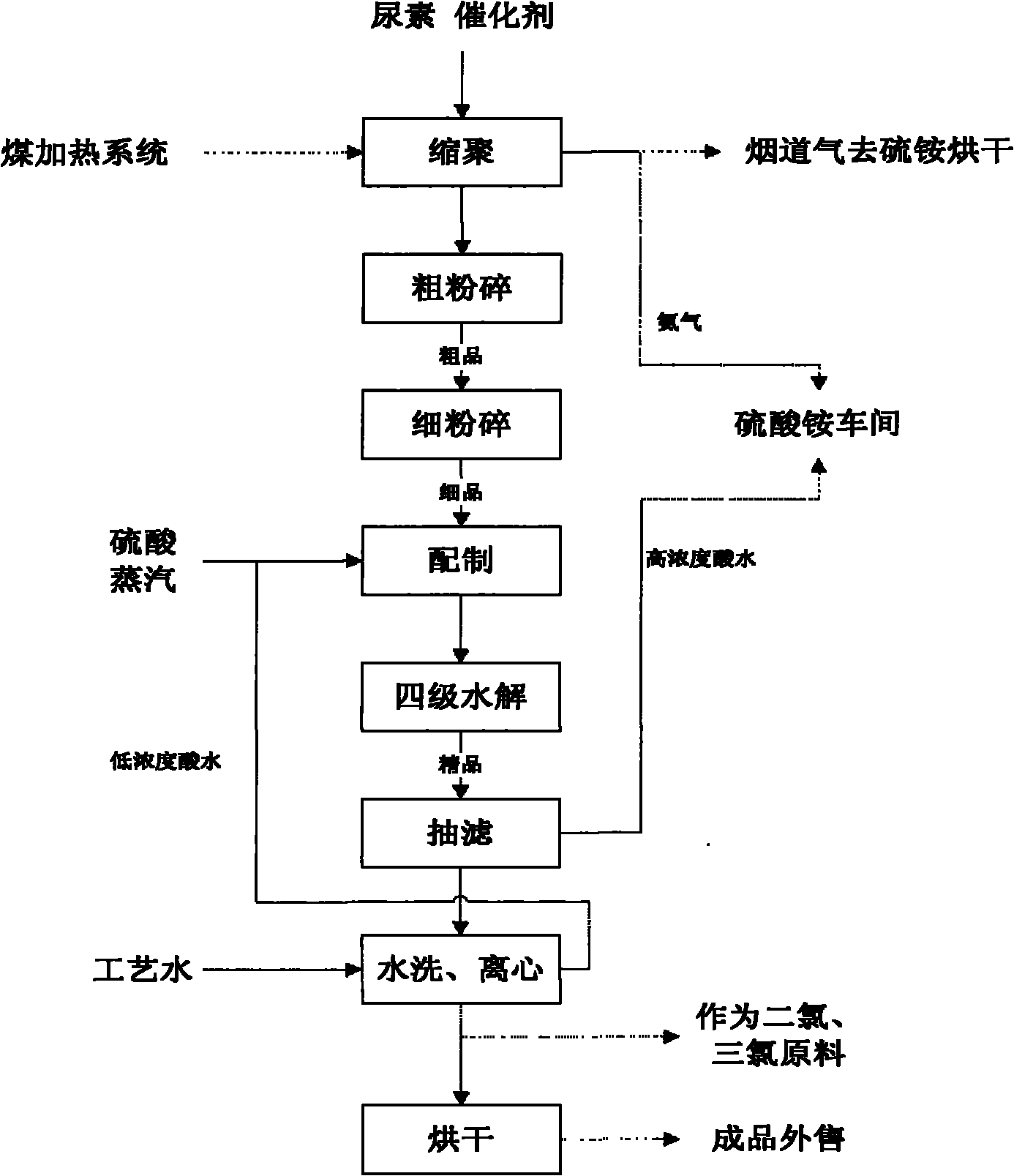

Production method of isocyanuric acid

The invention discloses a production method of isocyanuric acid, in particular relates to a method for producing isocyanuric acid by adopting fully-enclosed continuous four-stage vapour pressure differential reaction. The production method of the isocyanuric acid is characterized in that after isocyanuric acid fine material and sulfuric acid the weight percent of which is 25 percent are evenly mixed, the hydrolysis reaction is generated in sequence by a closed four-stage pressurizing reaction kettle under the action of vapour heating, and feed liquid enters a cooling reaction kettle for being cooled after the reaction is ended, therefore, the production method of the isocyanuric acid has the advantages of not only effectively utilizing energy sources and saving cost but also greatly reducing the smoke discharge amount, saving coal and electricity and greatly improving the production efficiency.

Owner:HEZE WOLAN CHEM

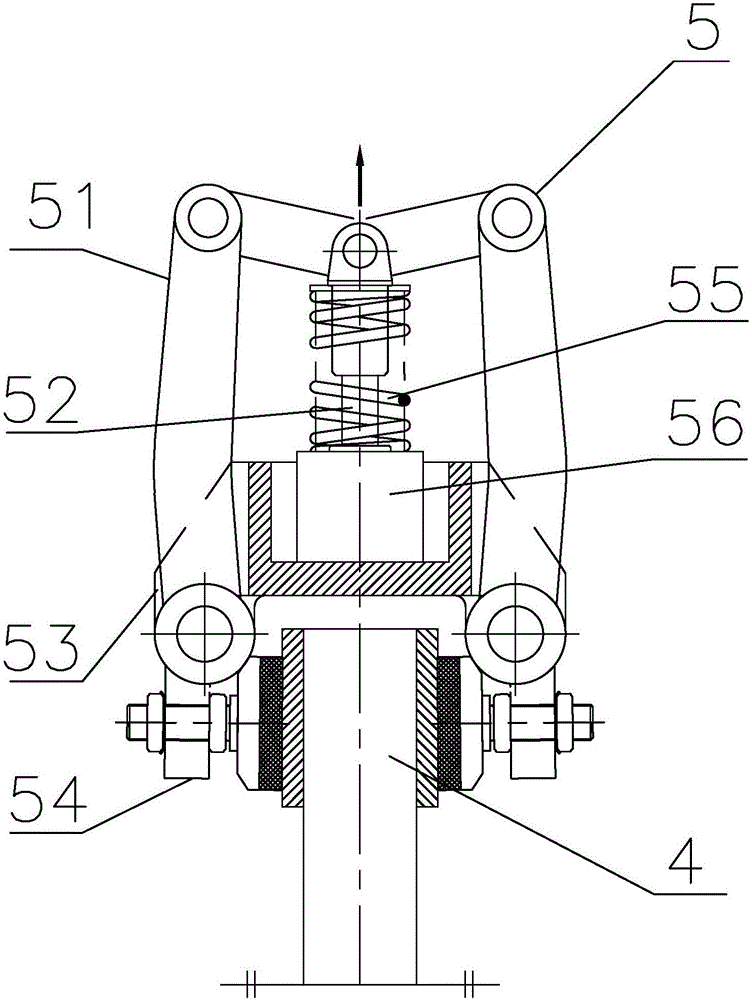

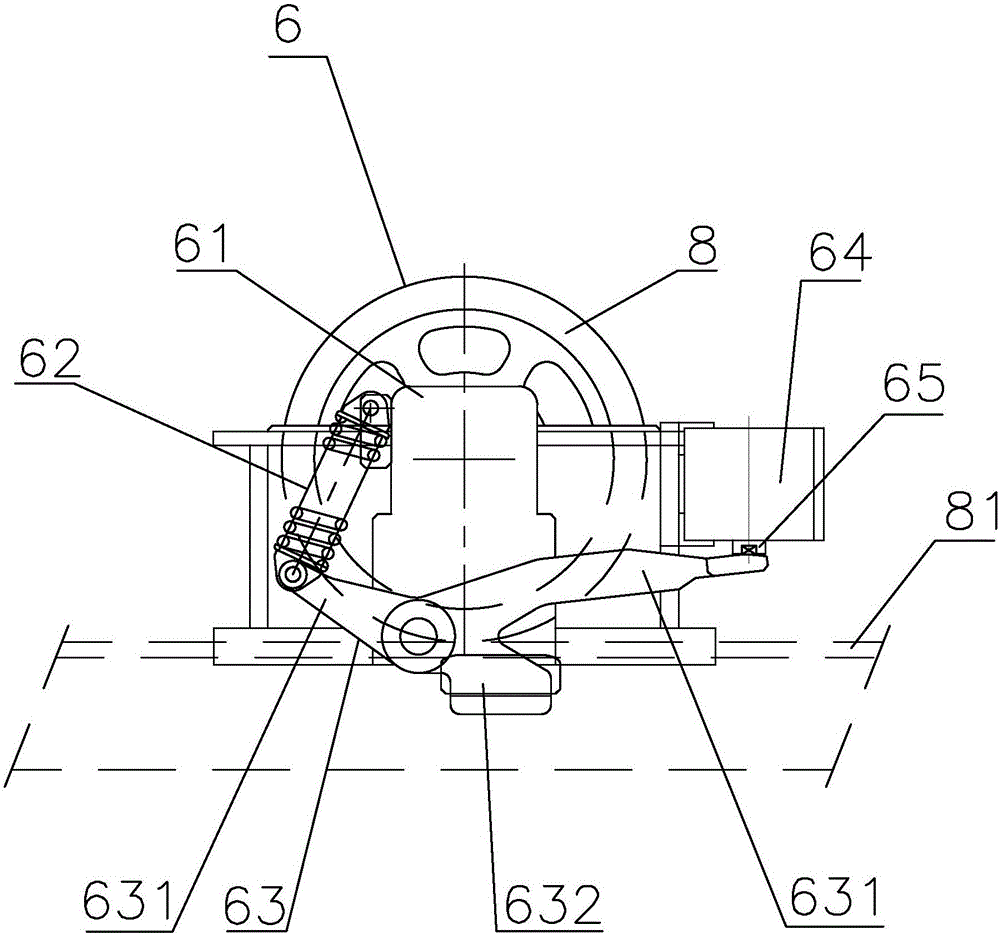

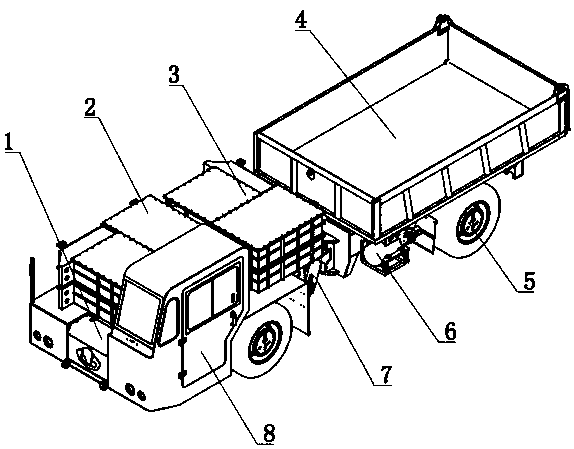

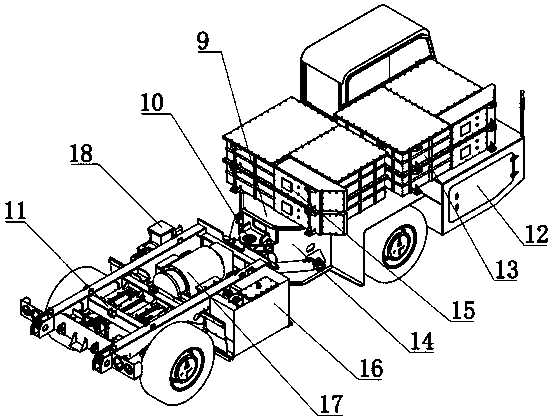

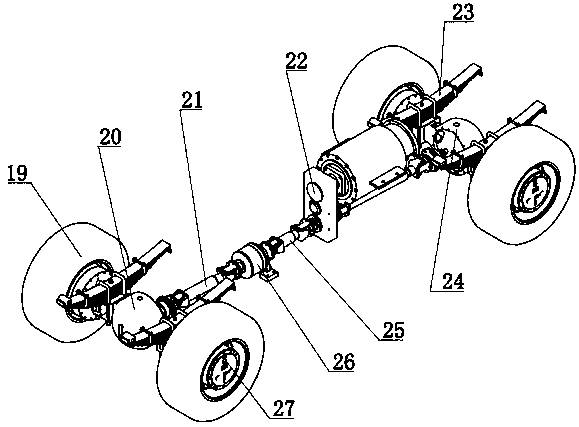

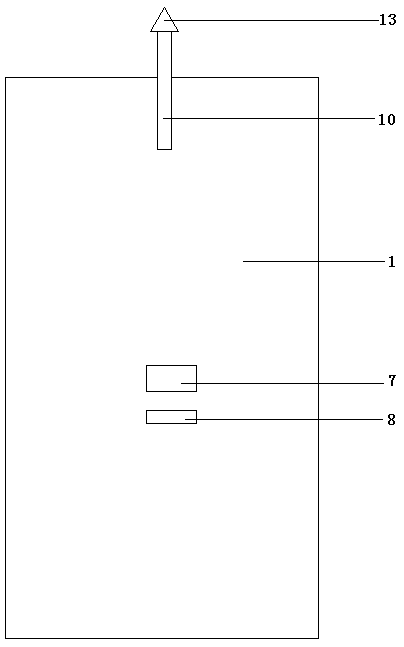

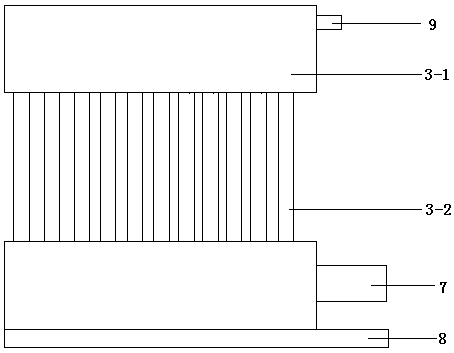

Mining super-capacitor hybrid storage battery power anti-explosion trackless transport vehicle

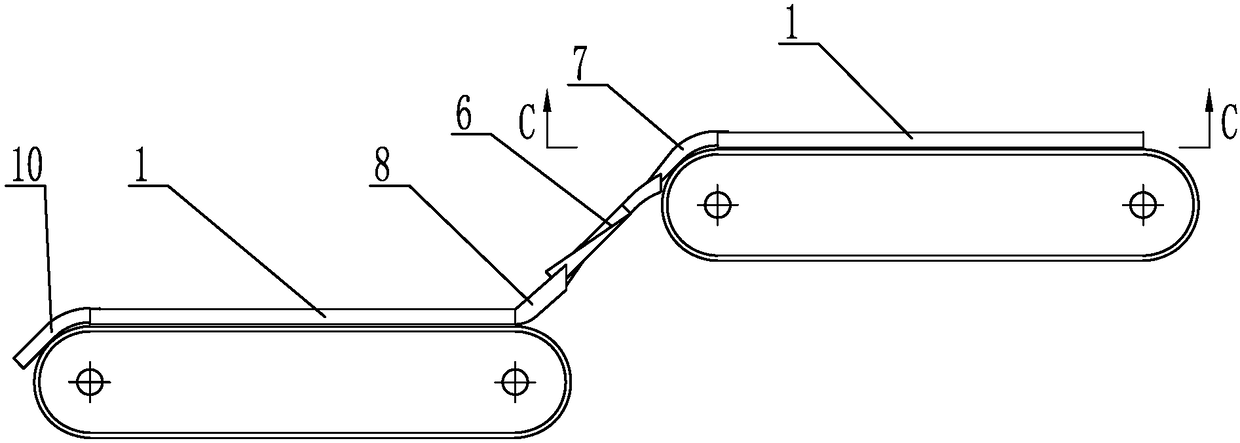

InactiveCN109720219AAvoid discharge pollutionReduce noisePropulsion by capacitorsPropulsion by batteries/cellsPower batteryCapacitance

The invention discloses a mining super-capacitor hybrid storage battery power anti-explosion trackless transport vehicle which comprises a hinge type vehicle body, an anti-explosion power battery device, an electrical control mechanism, a self-dumping container, a transmission mechanism, an anti-explosion variable frequency motor system, a hydraulic mechanism and an independent cab. The hinge typevehicle body comprises a front rack, a rear rack and a center hinging mechanism, wherein the front rack and the rear rack are arranged above the transmission mechanism, and the center hinging mechanism connects the front rack with the rear rack. The anti-explosion power battery device and the electrical control mechanism are arranged on the front rack front and back, and the independent cab and the anti-explosion power battery device are adjacently arranged on the front rack. The self-dumping container, the anti-explosion variable frequency motor system and the hydraulic mechanism are all arranged on the rack, and the self-dumping container is located in the upmost position. The transport vehicle can effectively improve the underground mine construction operation environment and improve the underground coal mine trackless auxiliary transport industry electrification level and mine production efficiency.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Liquid cleaning environmental-protection diesel fuel and preparation method thereof

ActiveCN103627448AAvoid discharge pollutionQuality improvementLiquid carbonaceous fuelsLiquid fuelEnvironmental engineering

The present invention relates to an efficient environmental-protection liquid fuel, particularly to a liquid cleaning environmental-protection diesel fuel and a preparation method thereof. The liquid cleaning environmental-protection diesel fuel is prepared from the following raw materials according to a certain weight ratio, wherein the optimal weight ratio of oleic acid to methanol to methylal to water to ammonia water to n-butanol to dimethyl carbonate is 40%:20%:10%:8%:8%:6.5%:7.5%. The preparation steps comprise: 1, selecting methanol, methylal and water, pouring into oleic acid to mix, and then adding ammonia water; 2, completely mixing the components in the step 1, and carrying out a static reaction for 5 min to spare; 3, selecting n-butanol and dimethyl carbonate, and carrying out a mixing reaction to spare; 4, adding the mixture obtained in the step 2 to the mixture obtained in the step 3, carrying out slight stirring for 10-20 min, taking 50% of the obtained solution to spare; and 5, mixing any one material selected from 0# international diesel fuel, -10# international diesel fuel and -20# international diesel fuel and the solution, and carrying out slight stirring for 10-20 min to obtain the liquid cleaning environmental-protection diesel fuel. The liquid cleaning environmental-protection diesel fuel has characteristics of strong power, low emission, wide application range and long shelf life.

Owner:杨戈坪

Epipastic mineral surface solidifying agent

InactiveCN101492597AReduce churnDo not change the original performanceOther chemical processesLoading/unloadingNon toxicitySodium Bentonite

The invention discloses a powdered mineral surface curing agent which comprises swelling starch, alum, anhydrous calcium chloride, bentonite of calcium, borax and other accessory ingredients. The powdered mineral surface curing agent has the advantage that a 'liquid tarpaulin' is used in a way of spraying in the process of transporting coal or powdered ore by utilizing swelling adhesive technology. As the coal layer or the powdered ore layer is effectively sprayed and covered, the loss, the environmental pollution and potential safety hazard which are caused in the transportation of coal or powdered ore can be reduced. Being different from the original method for oxidizing and pasting by using other formulation under the condition of liquidoid, the invention reduces a great deal of equipment and complicated working procedures. For the transportation of coal or powdered ore, the powdered mineral surface curing agent does not change the original properties of coal or powdered ore and has the advantages of lower cost, non-toxicity, no corrosion, no pollution, light weight, good fluidity, rapid dryness, fine toughness, high primary adhesive force, stable viscocity, high intensity, strong curing force, high stability, simple and convenient use, etc.

Owner:王耀权 +1

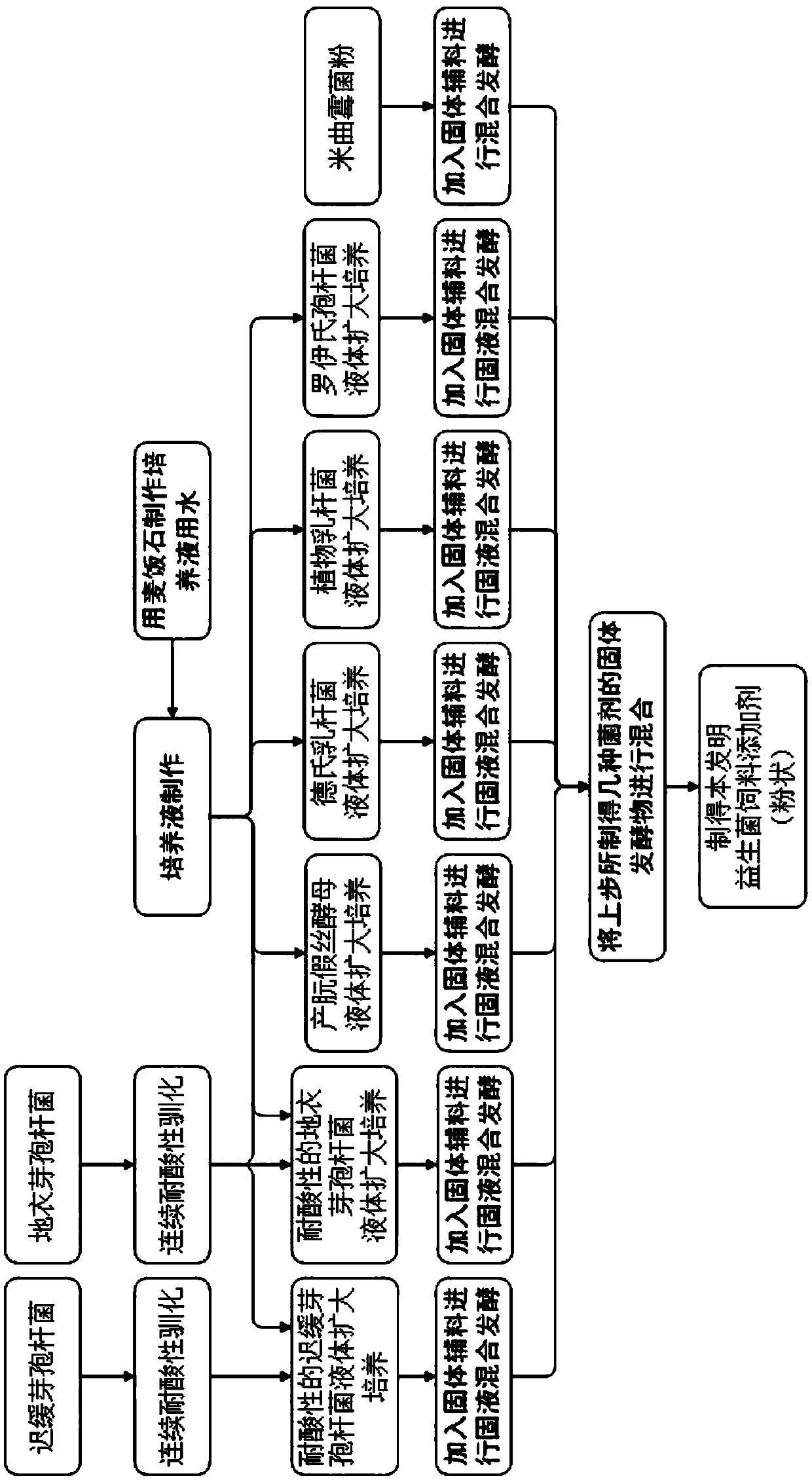

Probiotic feed additive for realizing zero discharge of manure waste and preparation method thereof

InactiveCN109527209AImprove acid resistanceArrive smoothly and play an effectFungiBacteriaBacillus licheniformisAspergillus oryzae

The invention discloses a probiotic feed additive for realizing zero discharge of manure waste. The feed additive for realizing zero discharge of manure waste is characterized by comprising Candida utilis, Bacillus lentus, Bacillus licheniformis, Lactobacillus delbrueckii, Lactobacillus plantarum, Lactobacillus reuteri, and Aspergillus oryzae. The bacterial strain matching used by the probiotic feed additive of the invention has the advantages of improving animal immunity and reducing the risk of disease caused by livestock, does not use antibiotics, and is healthy and environmentally friendly.

Owner:共 放鸣

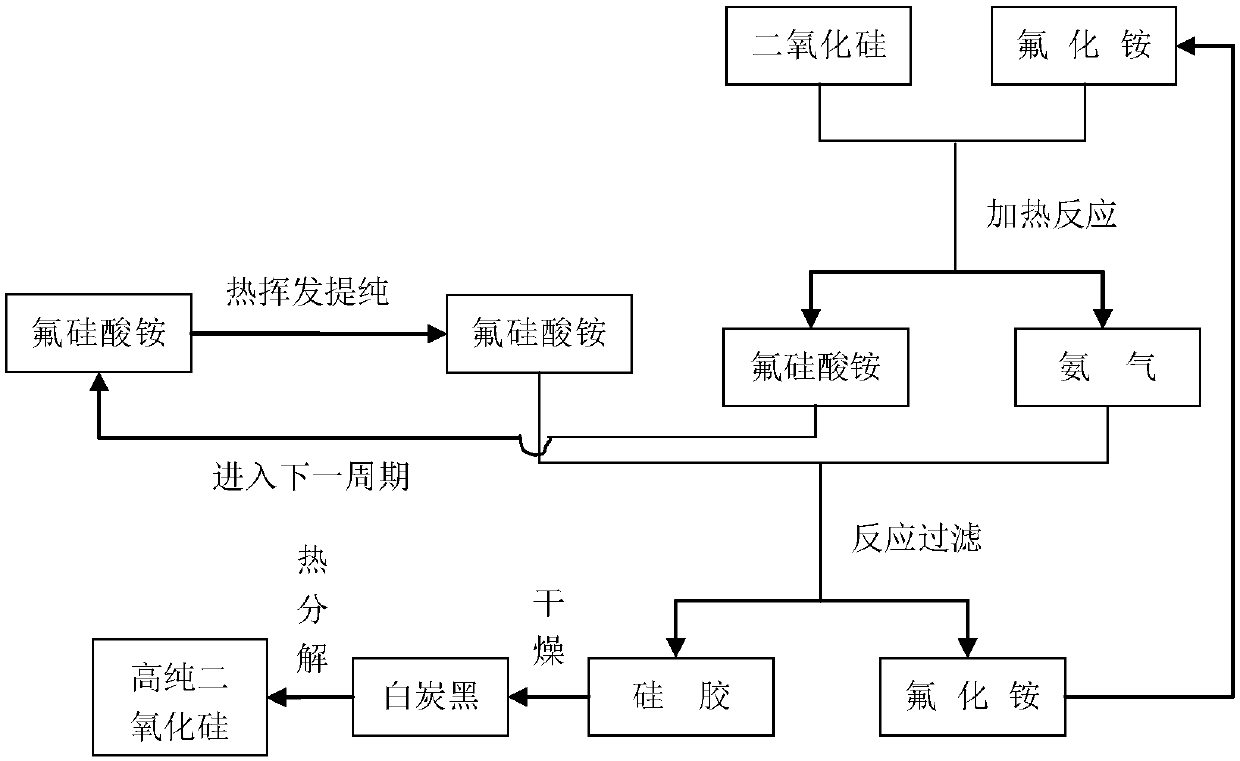

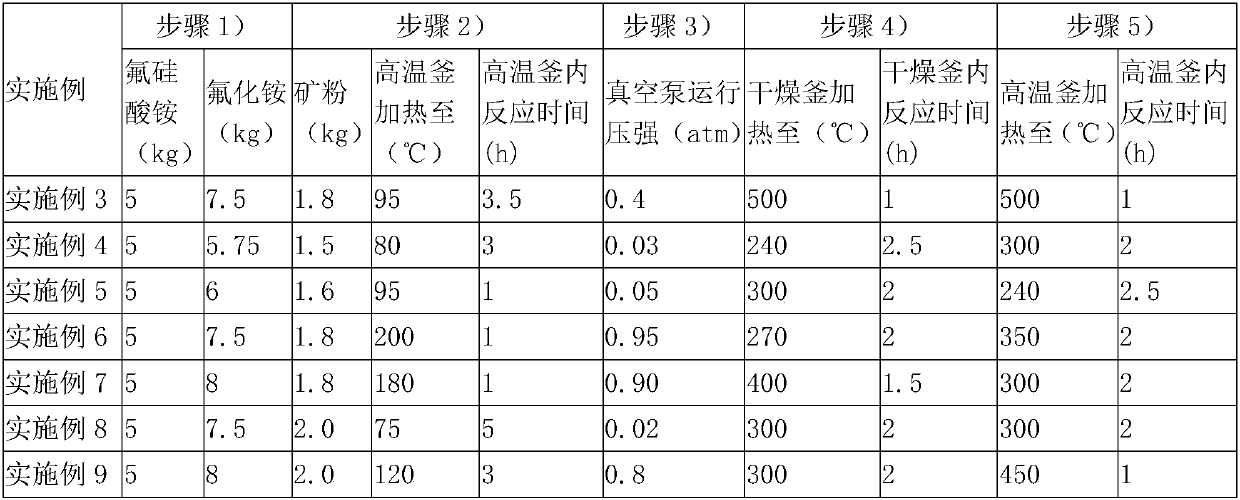

Method for preparing white carbon black or high-purity silicon dioxide

The invention discloses a method for preparing white carbon black or high-purity silicon dioxide. The method comprises the following steps: 1) preparing an ammonium fluosilicate solution and an ammonium fluoride solution for later use, 2) conducting a heating reaction on mineral powder containing silicon dioxide and the ammonium fluoride solution to form solid ammonium fluosilicate for later use and ammonia, 3) supplying the ammonia into the ammonium fluosilicate solution for reaction to form silica gel and ammonium fluoride containing filtrate for later use, 4) heating and drying the silica gel to form the white carbon black, thereby accomplishing a first production cycle, 5) allowing the mineral powder containing silicon dioxide and the ammonium fluoride containing filtrate obtained in the reaction in the last production cycle to react to form solid ammonium fluosilicate and ammonia, supplying the ammonia into the ammonium fluosilicate solution obtained in the reaction in the last production cycle to form silica gel and ammonium fluoride filtrate, and processing the silica gel to form the white carbon black, and 6) repeating step 5) and entering a circular production technology,wherein the mineral powder containing silicon dioxide is only required to be added in each new production cycle.

Owner:张旭

Glyphosate mother liquid treating method

ActiveCN100537580CImprove weed control effectEliminate pollutionGroup 5/15 element organic compoundsEnergy consumptionChloride sodium

This invention relates to a treatment method of mother liquid from alkyl esterification composing glyphosate. This method mainly reclaims TEA, condenses alkali mother liquid to get off large amount of byproduct soldium chloride, after which adds ammonium bicarbonate in the alkali mother liquid, fully reacts, filters to collocate glyphosate solution. This invention can not only get rid of the alkalization problem cause by too much sodium chloride in glyphosate, and also improves the medical effect of this solution collocated by this method, and lower the cost and save the energy consumption.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

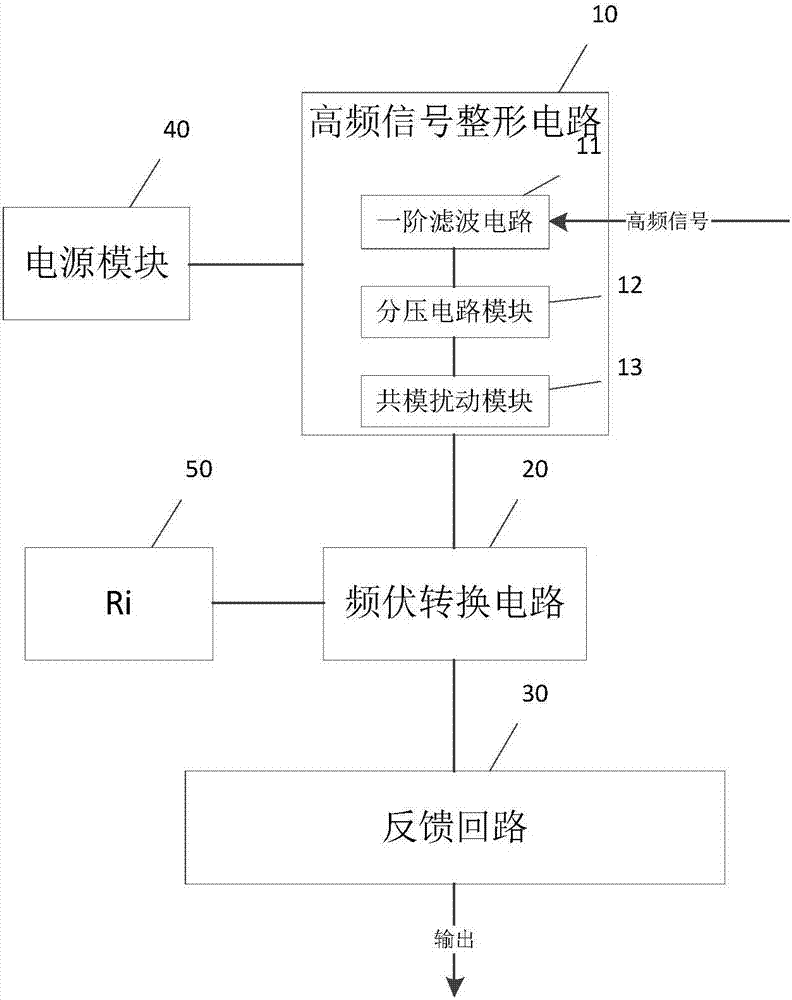

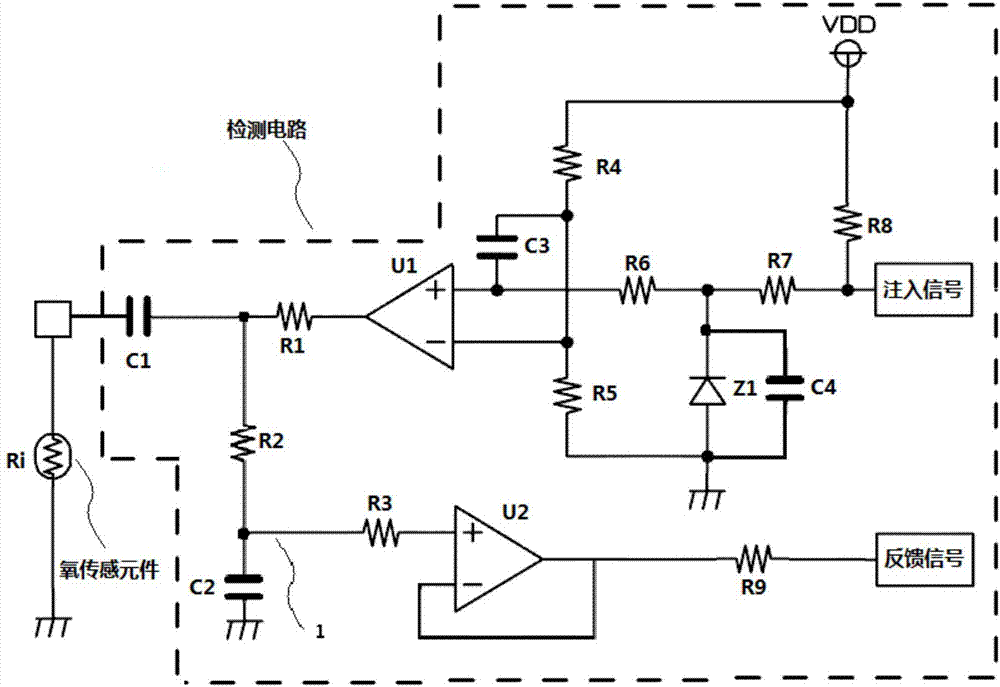

High frequency injection-based oxygen sensor internal resistor detection circuit

PendingCN106932644AImprove output voltageReal-time detectionResistance/reactance/impedenceAir–fuel ratioEngineering

The present invention provides a high frequency injection-based oxygen sensor internal resistor detection circuit. The high frequency injection-based oxygen sensor internal resistor detection circuit comprises a high-frequency signal shaping circuit, a frequency-to-voltage conversion circuit and a power supply module which is used for supplying power to the detection circuit; high-frequency signals are inputted into the high-frequency signal shaping circuit; the output end of the high-frequency signal shaping circuit is electrically connected with the input end of the frequency-to-voltage conversion circuit; the output end of the frequency-to-voltage conversion circuit outputs a voltage signal amplitude value corresponding to an oxygen sensor internal resistor Ri; and the frequency-to-voltage conversion circuit is electrically connected with the oxygen sensor internal resistor Ri. According to the high frequency injection-based oxygen sensor internal resistor detection circuit of the invention, the inner resistor of the oxygen sensor is detected real time, the internal resistor of the oxygen sensor can be judged accurately, and the output voltage of the oxygen sensor can be optimized, and an air-fuel ratio can be accurately calculated.

Owner:凯晟动力技术(嘉兴)有限公司

Technology for making paper without sewage drainage and apparatus and adhesives

InactiveCN1560358AAvoid discharge pollutionAvoid wastingPulp de-wateringWater dischargePolyvinyl alcohol

The invention relates to a paper making process, device and adhesive. Its process: pulping-milling pulp-storing pulp-batching-desanding and deslagging-flowing pulp-wet-making paper-dehydrating-drying, where the batching working procedure adds the adhesive in a batching tank, the flowing pulp working procedure makes the paper pulp in a flowing pulp box formed into wet-made paper, and its main character: the sewage water circulating and recycling working procedure is behind the dehydrating working procedure. The conveyer belt of the paper maker adopts nylon net, and does need washing in running course, avoiding the pollution caused by washing water; the adhesive is prepared of starches, polyvinyl alcohol and polystyrene,has good flocculating effect on paper pulp, and thoroughly separates paper pulp from water, thus able to directly circulate and reuse the sewage water, and avoiding the pollution caused by sewage water discharge.

Owner:厉龙松

Method for preparing isooctyl nitrate by recovering waste acid

PendingCN110683954AHigh purityEfficient use ofNitric acid ester preparationEnvironmental chemistrySulfuric acid

The invention provides a method for preparing isooctyl nitrate by recovering waste acid. The method comprises: A) adding 98% sulfuric acid into waste acid to obtain waste acid with a sulfuric acid concentration of 90-95%, wherein the mass concentration of the sulfuric acid in the waste acid is 80-85%, and the mass concentration of the nitric acid in the waste acid is 2-6%; B) adding nitric acid into the waste acid with the sulfuric acid concentration of 90-95% to obtain a mixed acid raw material, wherein a mass ratio of the nitric acid in the mixed acid raw material to the waste acid obtainedin the step A) is 1:(1.5-4); and C) pumping the mixed acid raw material and isooctyl alcohol into a micro-channel reactor, and carrying out a reaction to obtain isooctyl nitrate. According to the invention, the product isooctyl nitrate can be prepared by using the waste acid, and no other impurities are introduced, so that the product quality is good; the problem of nitrogen oxide emission pollution caused by post-treatment of nitric acid-containing waste acid is solved; and the nitric acid in the waste acid can be reused so as to reduce the unit consumption of nitric acid.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

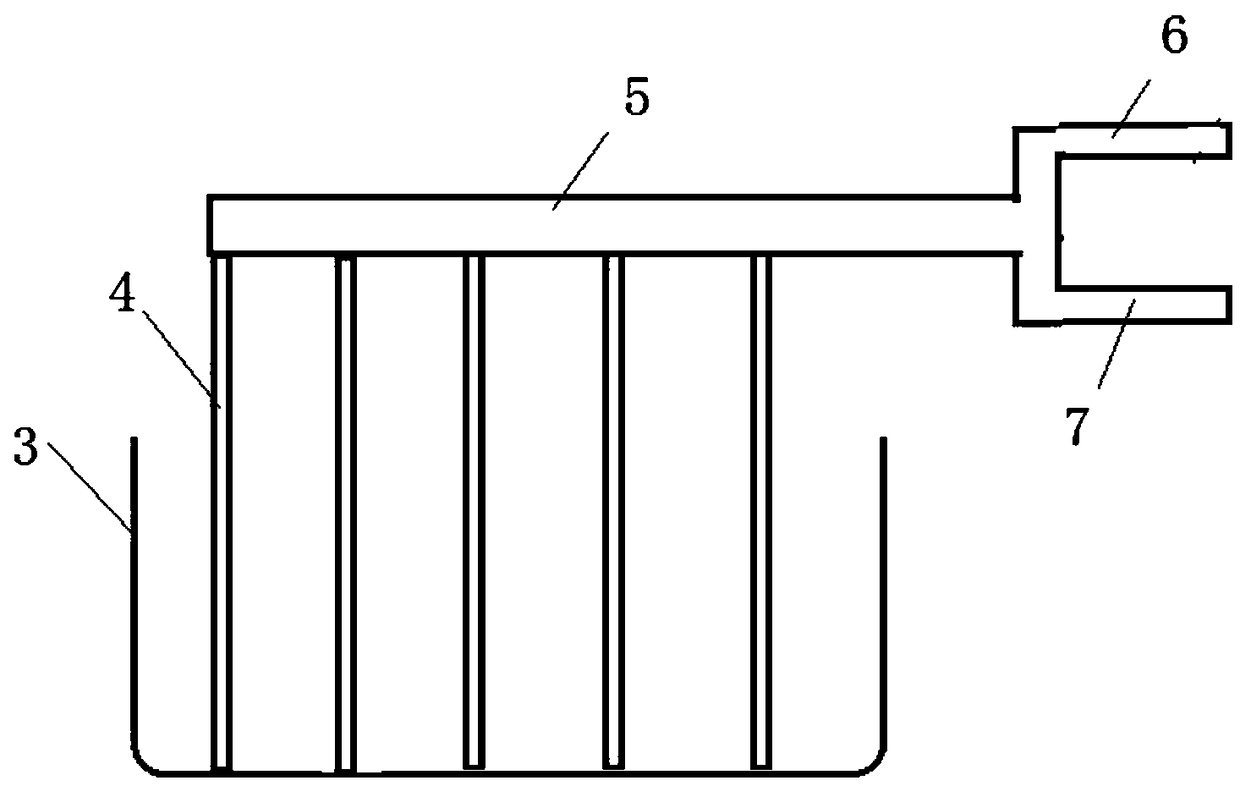

Nitrate-water separating device

ActiveCN103849725AAchieve recyclingSave heatNitrogen compoundsChemical industryWater vaporSaline solutions

The invention relates to a nitrate-water separating device. The nitrate-water separating device comprises a thermal cleaning machine water tank and a nitrate quenching tank, wherein a saliferous liquid outlet pipe of a thermal cleaning tank is connected to the thermal cleaning machine water tank, the saliferous liquid outlet pipe of the thermal cleaning tank is connected with a saliferous cleaning liquid, and a pipe pump is connected between the saliferous liquid outlet pipe of the thermal cleaning tank and a saliferous cleaning liquid inlet pipe; the saliferous cleaning liquid inlet pipe leads to a fin group tube of a heat exchanger and the fin group tube of the heat exchanger is fixed in the nitrate quenching tank through a heat exchanger base support; a water vapor collecting cover is arranged above the fin group tube of the heat exchanger and connected with the thermal cleaning machine water tank through a non-saliferous water vapor outlet pipe; a concentrated saline solution accumulating funnel is arranged under the fin group tube of the heat exchanger, and a concentrated saline solution valve of the heat exchanger is arranged at the outlet end of the concentrated saline solution accumulating funnel. The nitrate-water separating device is capable of either saving energy or reducing emission, and is also capable of recycling resources and energy sources.

Owner:杭州竞舟轴承有限公司

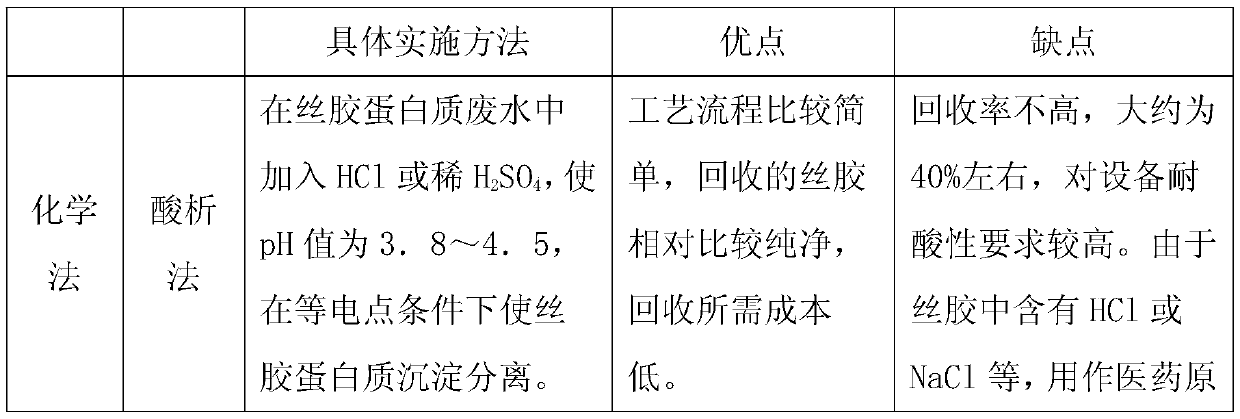

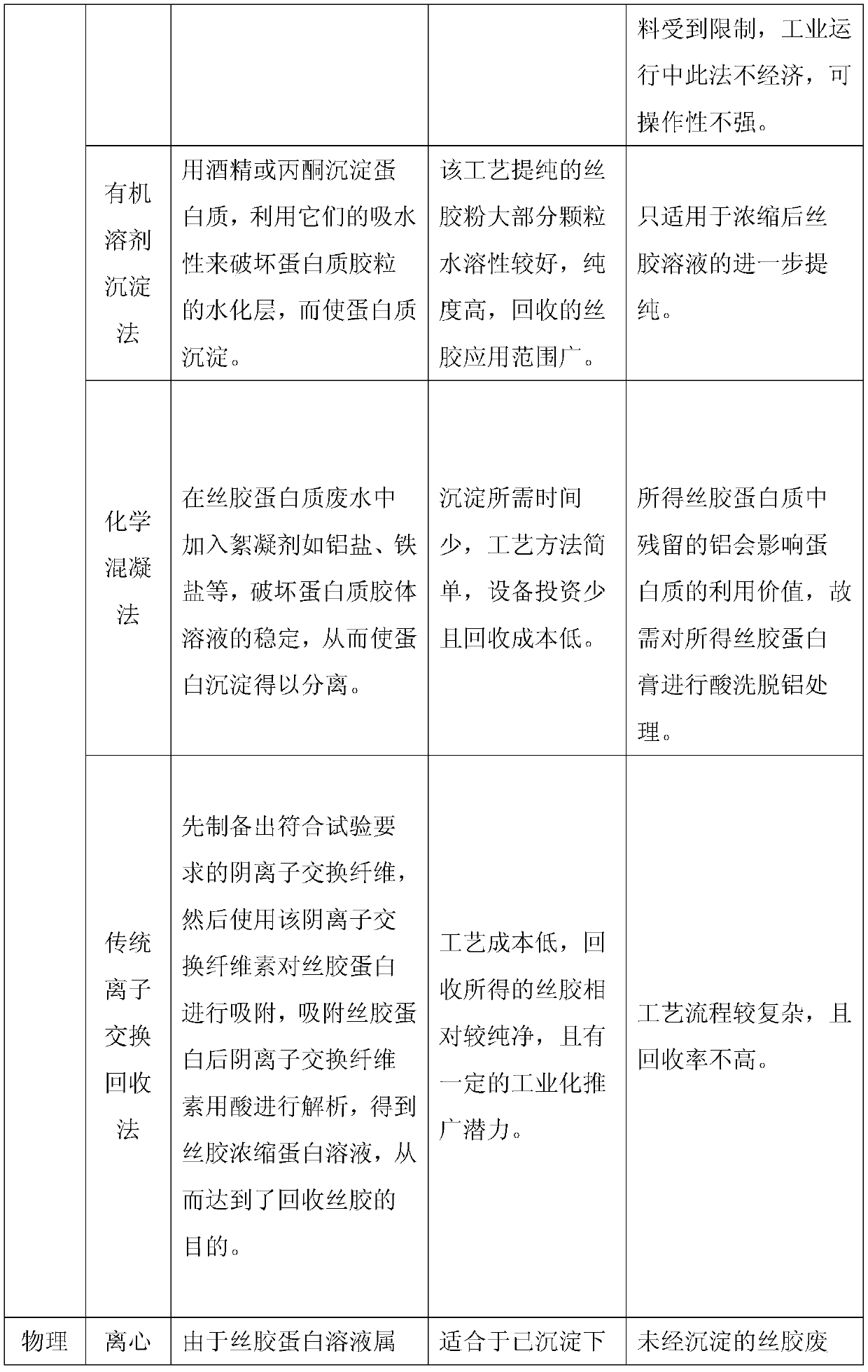

Process for recycling sericin in reeling silk industrial waste water by utilizing 201*7 ion exchange resin

InactiveCN110040818AEfficient recyclingImprove adsorption capacityConnective tissue peptidesWater/sewage treatment by ion-exchangeIndustrial waste waterFiltration

The invention discloses a method for recycling sericin in reeling silk industrial waste water. The reeling silk industrial waste water is subjected to processes, which comprise impurity removal via precipitation and filtration, resin adsorption, elution, collection and drying, to obtain sericin protein powder; the special points of the method are that in a resin adsorption process, adopted resin is 201*7 ion exchange resin, while the concrete processes of the impurity removal via precipitation and filtration, the resin adsorption, the elution, the collection and drying can refer to and adopt the prior art in the belonged field and relevant field. The recycle process of the recycle method adopts normal temperature operation, the equipment investment is low, the energy consumption is low, the operation is simple, and secondary pollution does not exist; by the 201*7 ion exchange resin which is selected via multiple times of experiments, has stronger adsorbability to sericin protein in reeling silk waste water and is extremely good in analytic effect simultaneously, the efficient recycle and enrichment of the sericin protein and the recycling efficient utilization of the resin are realized, and the comprehensive production cost is relatively low; and a resin switching production mode is combined.

Owner:ZHEJIANG UNIV OF TECH

Novel automobile energy-saving clean fuel and preparation method thereof

InactiveCN101555421AExcellent physical and chemical propertiesHigh cost performanceLiquid carbonaceous fuelsCoalPentene

The invention relates to a novel automobile energy-saving clean fuel and a preparation method thereof. The prior automobile clean fuel and highly-clean gasoline fail to perfectly solve the automobile use performance on the technical prescription. The novel automobile energy-saving clean fuel contains 5-90 parts of methanol, 10-80 parts of clean oil, 2-10 parts of hydrogenation pentene, 3-20 parts of methyl tertiary butyl ether, 5-20 parts of chemical lighter hydrocarbons, 2-6 parts of mixed ctane, and 6-20 parts of coal chemical light oil. The automobile- energy-saving clean fuel is used for substituting gasoline.

Owner:裴日焕

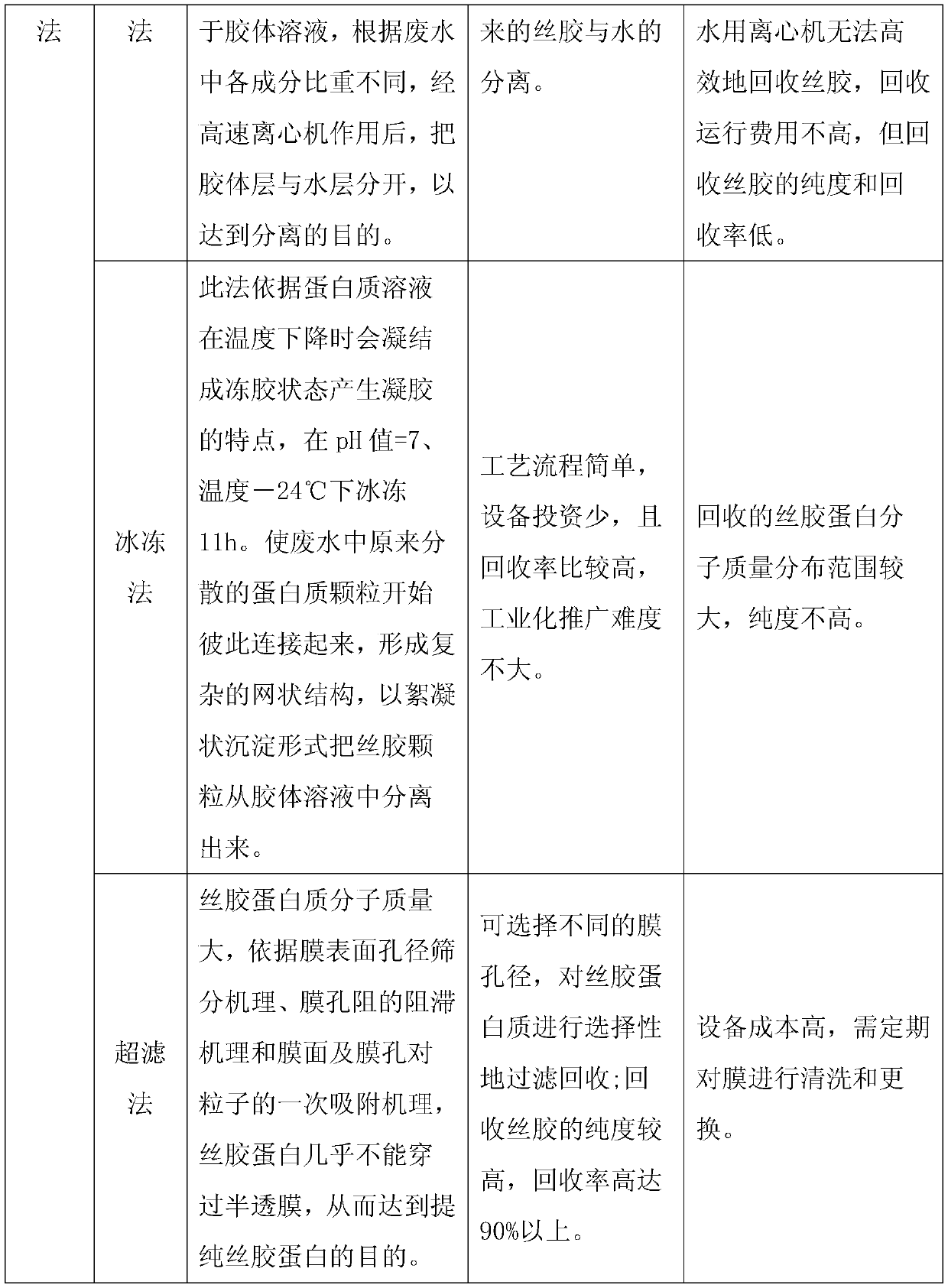

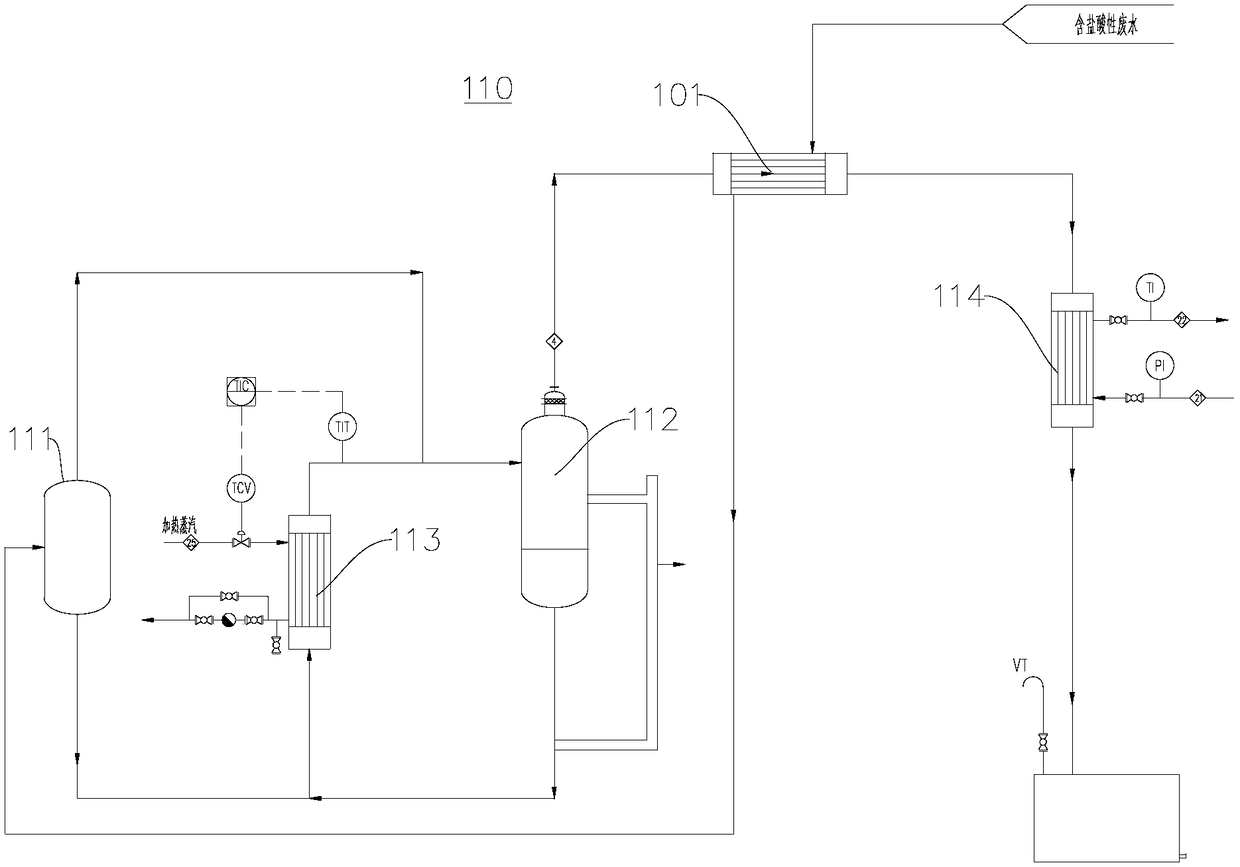

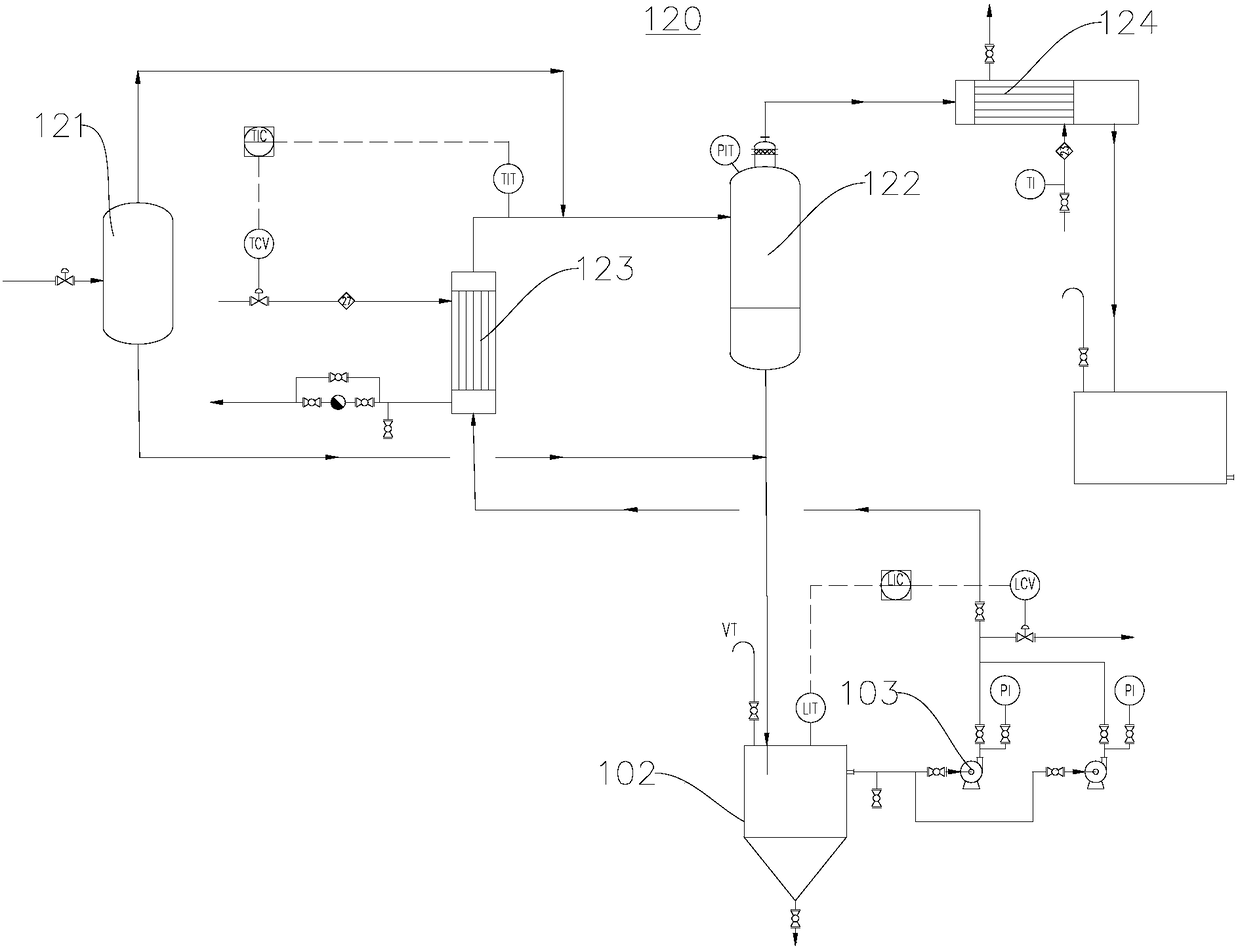

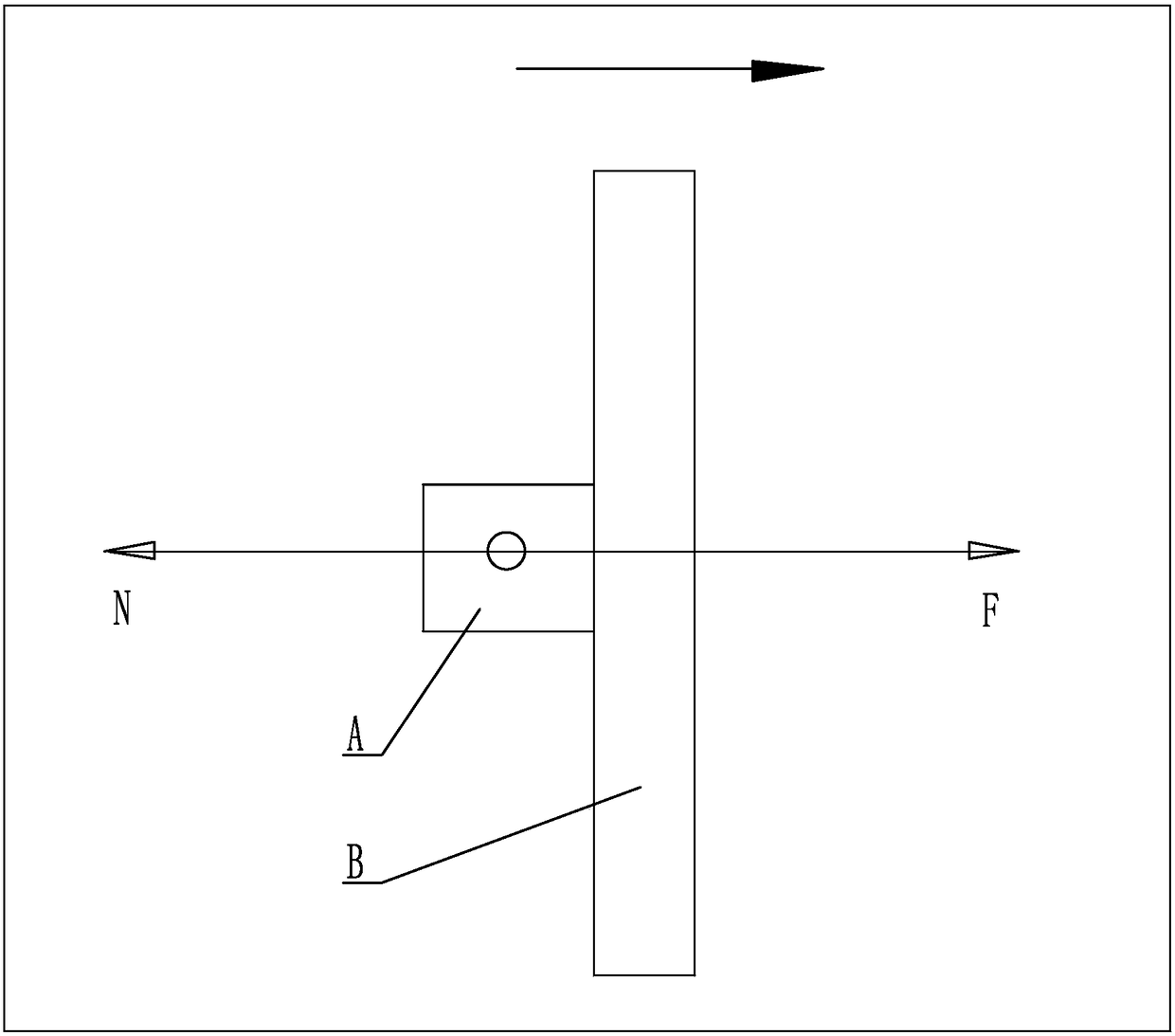

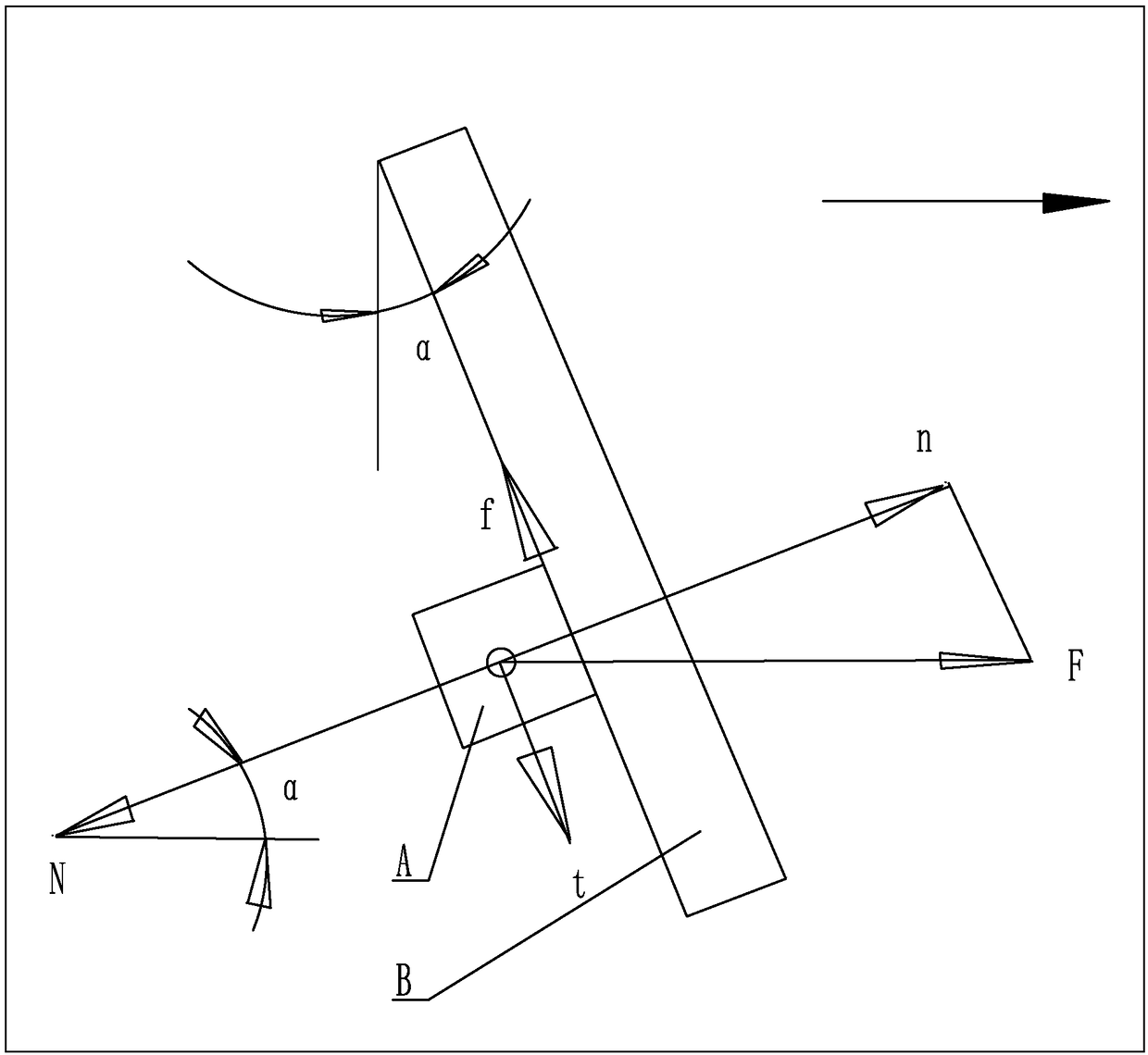

Process and system for treating hydrochloric acid-containing wastewater

InactiveCN108516603AAvoid discharge pollutionAchieve the purpose of separationWater/sewage treatment by heatingChemical industryVapor liquid

The invention relates to the field of chemical industry, in particular to a process and system for treating hydrochloric acid-containing wastewater. The system for treating the hydrochloric acid-containing wastewater comprises a first-stage evaporation concentration section and a second-stage evaporation concentration section which are sequentially connected. The hydrochloric acid-containing wastewater is flashed through a first-stage flash tank, the hydrochloric acid-containing wastewater is concentrated and separated in a first-stage vapor-liquid separation tank, after separation in the first-stage vapor-liquid separation tank, the hydrochloric acid-containing wastewater is introduced into a secondary flash tank to be concentrated again, the hydrochloric acid-containing wastewater is saturated, part of salt is precipitated, waste acid is concentrated, and the dissolved salt is evaporated and crystallized simultaneously to achieve the purpose of separation. Concentrated operating environment is good, acid gas emission pollution is completely avoided, there is no three waste emission, and the system has the advantages of environmental protection and emission reduction.

Owner:无锡英罗唯森科技有限公司

Deburring device for stamped chain baffle blade

ActiveCN108161668AIncrease profitAvoid wastingBelt grinding machinesGrinding/polishing safety devicesAgricultural engineeringSewage

The invention discloses a deburring device for a stamped chain baffle blade, and relates to the technical field of machining. The invention aims to solve the problems of a roller method used for current deburring of small stamped parts that time and labor are consumed; a large amount of water and abrasive are consumed; and water material and sewage emission pollutes the environment. The deburringdevice comprises a reversing guide rail mechanism, two guiding groove plates and two abrasive belt mechanisms; the two abrasive belt mechanisms are separately horizontally arranged at different heights; an upper end of each abrasive belt is fixedly connected with the corresponding guiding groove plate; an S-shaped material guiding groove is formed in a lower end surface of each guiding groove plate; an upper end of the reversing guide rail mechanism is connected with a material outlet end of the S-shaped material guiding groove in the upper end abrasive belt mechanism; a lower end of the reversing guide rail mechanism is connected with a material inlet end of the S-shaped material guiding groove in the lower end abrasive belt mechanism; each abrasive belt mechanism comprises an abrasive belt, a servo motor and two groups of belt wheels which are parallelly arranged; an output shaft of each servo motor is connected with one group of the corresponding belt wheels; and every two groups ofthe belt wheels are connected through the corresponding abrasive belt. The deburring device is used for deburring machining of small stamped parts.

Owner:HARBIN INST OF TECH

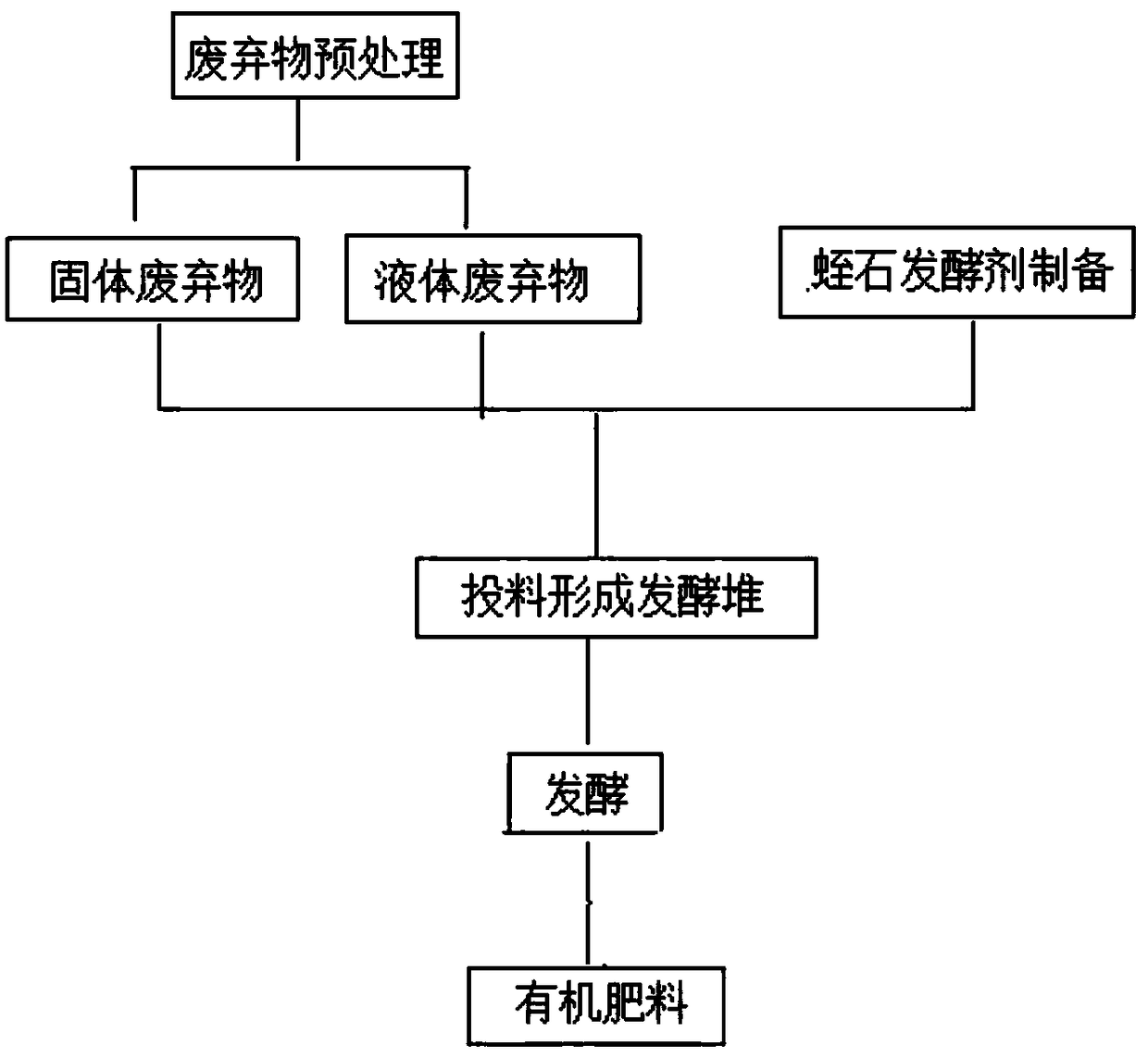

Method for processing organic fertilizer by utilizing agricultural wastes

InactiveCN108640801AAvoid pollutionAvoid discharge pollutionBio-organic fraction processingOrganic fertiliser preparationLiquid wasteWater source

The invention discloses a method for processing organic fertilizer by utilizing agricultural wastes. The method comprises the following steps: preprocessing the wastes, preparing a vermiculite fermenting agent, feeding to form fermentation heaps and carrying out fermentation. The processing of the wastes comprises the following steps: pulverizing solids in agricultural wastes and uniformly mixingthe solids to obtain solid wastes; using liquid in the agricultural wastes as liquid waste for storage and subsequent use; preparation of the vermiculite fermenting agent comprises the following steps: mixing ferment bacteria with expanded vermiculite to obtain the vermiculite fermenting agent; the fermentation heaps comprise multiple fermentation layers sequentially arranged in the height direction, wherein the fermentation layers comprises: paving a layer of solid waste; then uniformly spraying liquid waste on the solid waste until the humidity of the solid waste reaches a predetermined value, and uniformly putting the vermiculite fermenting agent on the solid waste. According to the method disclosed by the invention, the agricultural wastes are made into organic fertilizer, so that theproblems that atmosphere pollution caused by the agricultural wastes is effectively solved, underground water source pollution and carbon emission pollution are effectively solved, and the surface source pollution program is effectively solved.

Owner:谢职刚

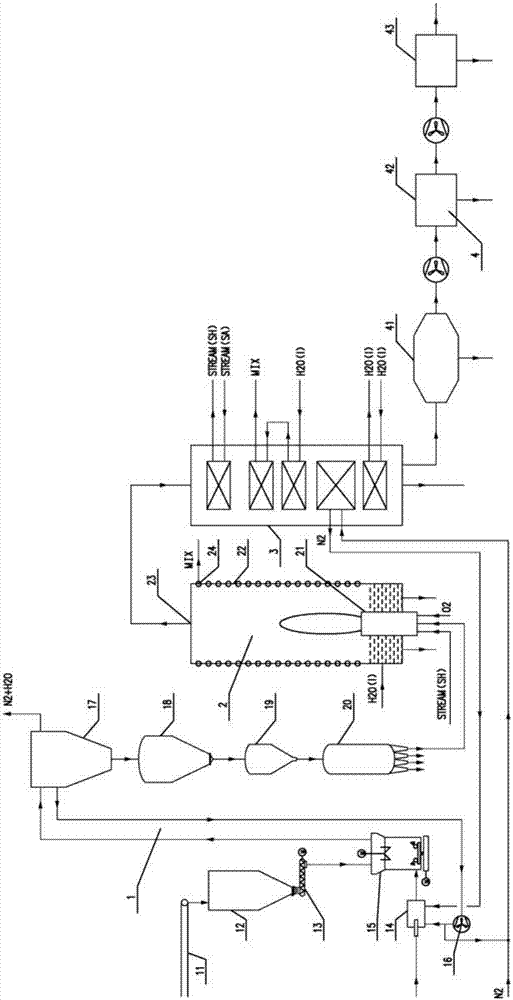

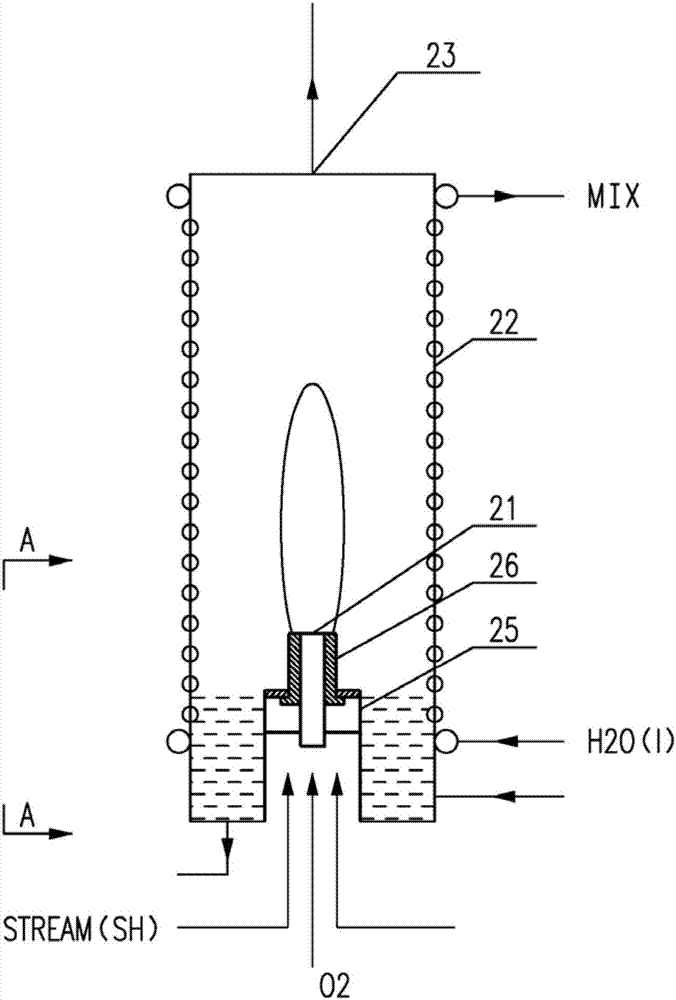

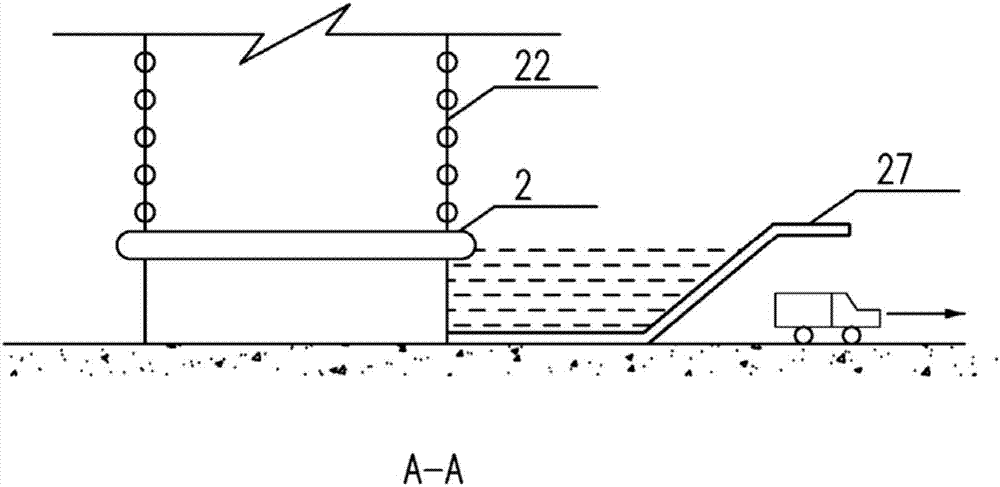

Equipment and method for preparing constant-pressure fuel gas

PendingCN106995726ALow costReduce energy consumptionChemical industryGasification processes detailsSuperheated steamEconomizer

The invention relates to equipment and a method for preparing constant-pressure fuel gas, and provides the equipment and the method for preparing the fuel gas in a clean, high-efficient and energy-saving manner. The equipment comprises a feeding device, a burning radiation heat transfer device and a convection heat transfer device, wherein the feeding device comprises a hot-blast stove and a coal mill; the burning radiation heat transfer device comprises a burner which is arranged at the bottom of the device, a water cooled wall which is arranged on the inner wall of the device, and a fuel gas outlet and a steam-water mixture outlet which are formed in the upper part of the device; the convection heat transfer device comprises an over-heater, a steam generator and a coal economizer. By the equipment and method disclosed by the invention, most of high-temperature fuel gas and heat energy of high-temperature molten slag inside the burning radiation heat transfer device are recycled; through convection heat transfer, high-quality overheat steam is produced, so that energy consumption is saved to the maximum, and the cost of the fuel gas is generally reduced.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

Method for producing smelting flux by using manganese-containing melt

InactiveCN105154695AReduce construction costsReduce labor intensityWelding/cutting media/materialsSoldering mediaManganesePollution

The invention discloses a method for producing a smelting flux by using a manganese-containing melt. The method comprises the following steps: making use of a high-temperature manganese-containing melt generated in a smelting process of a blast furnace or an electric furnace, namely collecting the manganese-containing melt by virtue of foundry ladles, and then pouring into a flux furnace; adding an appropriate amount of manganese, magnesium, silicon and fluorite raw material components; heating to about 1700 DEG C by virtue of the electric furnace to smelt for about 30 minutes; and performing water quenching to prepare the smelting flux. According to the method disclosed by the invention, the consumption of manganese minerals is low, the electricity consumption is low, the production cycle is short, the production efficiency is high, and meanwhile, the emission of harmful gases can be effectively reduced, so that the method is an environment-friendly type flux preparation method; the consumption of heat energy can be effectively reduced, the labor intensity is reduced, the working efficiency is improved, heat pollution, discharge pollution and space occupation of waste residues are avoided, 70% of the production cost is saved, the utilization ratio of the manganese minerals is improved by 8-30%, the emission of waste gases is reduced by 30-60%, the convenience for waste gas treatment is significantly improved, and the waste gas treatment cost is reduced by 60-80%.

Owner:HUNAN UNIV OF SCI & ENG

Compound Chinese-medicinal preparation for treating clavus

InactiveCN1895445AAvoid discharge pollutionRich sources of medicineAnthropod material medical ingredientsDermatological disorderCarthamusANGELICA ROOT

A Chinese medicine for treating corn is prepared from Chinese angelica root, safflower, wolfberry bark, Chinese gall and sesame oil.

Owner:栾继习

A kind of production method of ultraviolet absorber bp-3

ActiveCN111302920BAvoid discharge pollutionImprove efficiencyOrganic compound preparationCarbonyl compound preparation by hydrolysisBenzyl chlorideSolvent

The present invention relates to a production method of ultraviolet absorber BP-3, which specifically comprises the following steps: S1: Condensation reaction: put solvent and resorcinol into the reaction kettle, stir and heat up, then add trichlorobenzyl, keep warm and carry out condensation Reaction; S2: hydrolysis stratification and material transfer: add deionized water to the reaction product of S1, hydrolysis reaction, stand and stratify, the upper water layer is applied mechanically, and the lower layer material is transferred to another reaction kettle with solvent and water; S3: esterification Reaction: Add sodium carbonate and dimethyl sulfate to the reaction kettle containing the lower layer materials in S2, and keep warm for reaction; S4: Prepare finished product: centrifugally filter the product after the esterification reaction, and pack the filtered sodium sulfate by-product, The filtrate is evaporated to recover the solvent, and the solvent is used mechanically. The material after the solvent is evaporated is sequentially rectified, refined, centrifuged, and dried to obtain the finished product. The production process adopted in this application makes the production of BP-3 more concise, smooth, and safer, reduces the production cost by more than 40%, and brings considerable profits to the enterprise. At the same time, the production process is cleaner, more efficient, and more friendly to the environment.

Owner:HUBEI MEIKAI CHEM

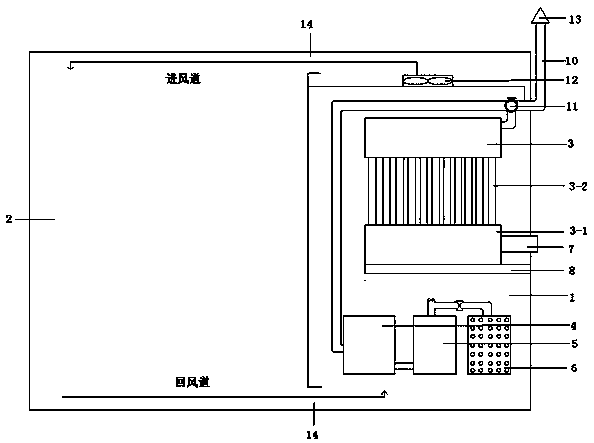

Tobacco baking room achieving full utilization of heat energy

The invention discloses a tobacco baking room achieving full utilization of heat energy, and belongs to the technical field of tobacco baking facilities. The tobacco baking room comprises a heat supply chamber and a tobacco baking chamber which communicates with the heat supply chamber, wherein a heat exchanger, a dust removal box and a purifying device are arranged in the heat supply chamber; thedust removal box and the purifying device are arranged at the bottom of the heat supply chamber; a smoke fire inlet, which communicates with a smoke fire channel of a combustion furnace, is formed inthe outer end of the heat supply chamber; an inlet of the heat exchange communicates with the tail end of a heat collection drum; the front end of the heat collection drum communicates with the smokefire inlet, and a smoke outlet of the heat exchanger communicates with the inlet of the dust removal box or a chimney via a three-way valve and a pipeline; the inlet of the purifying device communicates with the outlet of the dust removal box; the purifying device is composed of a medium-efficiency filter layer, a high-pressure electronic dust collector and an activated carbon honeycombed filterlayer which sequentially communicate with each other; and the outlet of the purifying device communicates with an inner cavity of the heat supply chamber and is provided with an airflow control valve.According to the tobacco baking room provided by the invention, dust in smoke is removed via the tail gas purifying device, and the smoke is recycled to bake tobacco after harmful gas is adsorbed; therefore, the tobacco baking room has the characteristics of achieving full utilization of heat energy, avoiding pollution, reducing energy consumption and the like.

Owner:云南乾程科技开发有限公司

Purification device for automobile tail gas

InactiveCN106401706AReduce pollution hazardsHarm reductionHuman health protectionNon-fuel substance addition to fuelParticulatesEngineering

The invention provides a purification device for automobile tail gas. The purification device comprises an engine exhaust pipe, an engine air inlet pipe, exhaust particle conveying pipes, a particle separator, a superfine particle filter, a three-way catalytic purifier, a temperature reductioner, a smoke eliminator, a gas purification box and a purified gas exhaust pipe, wherein the engine exhaust pipe is connected with the particle separator; the particle separator is connected with the superfine particle filter; the particle separator and the superfine particle filter are connected with the engine air inlet pipe through the exhaust particle conveying pipes; the superfine particle filter is connected with the three-way catalytic purifier; the three-way catalytic purifier is connected with the gas purification box; and the gas purification box is connected with the purified gas exhaust pipe. According to the purification device, the structure is reasonable, the cost is relatively low, and the purification effect is remarkable.

Owner:ANQING VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com