Wet flue gas desulphurizing method utilizing carbide slag slurry and device thereof

A wet flue gas desulfurization and calcium carbide slag slurry technology is applied in the field of flue gas purification, which can solve the problems of flexible configuration of desulfurization slurry concentration and lack of complete consideration of the process, so as to ensure long-term stable operation, meet the desulfurization standard requirements, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

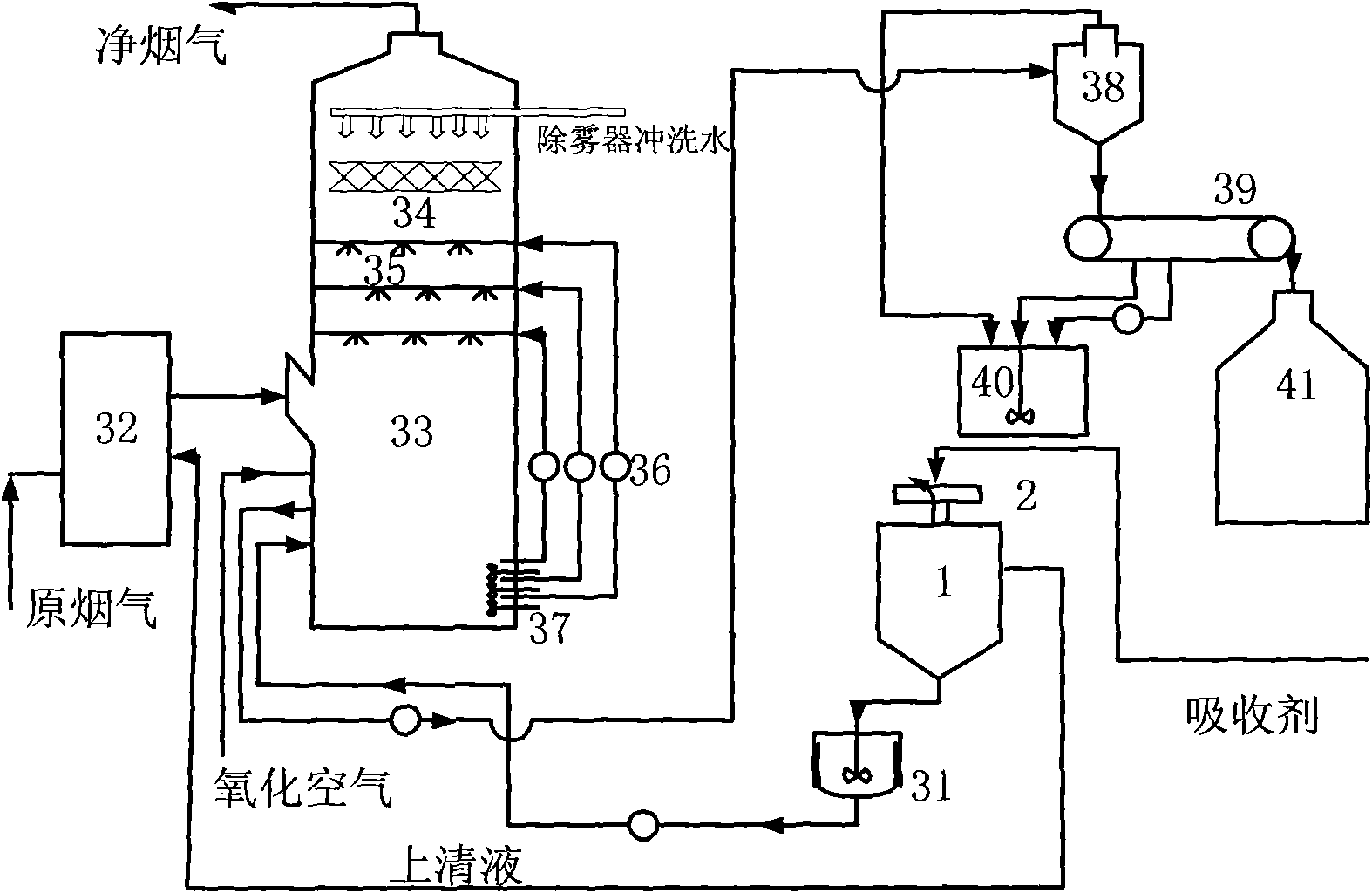

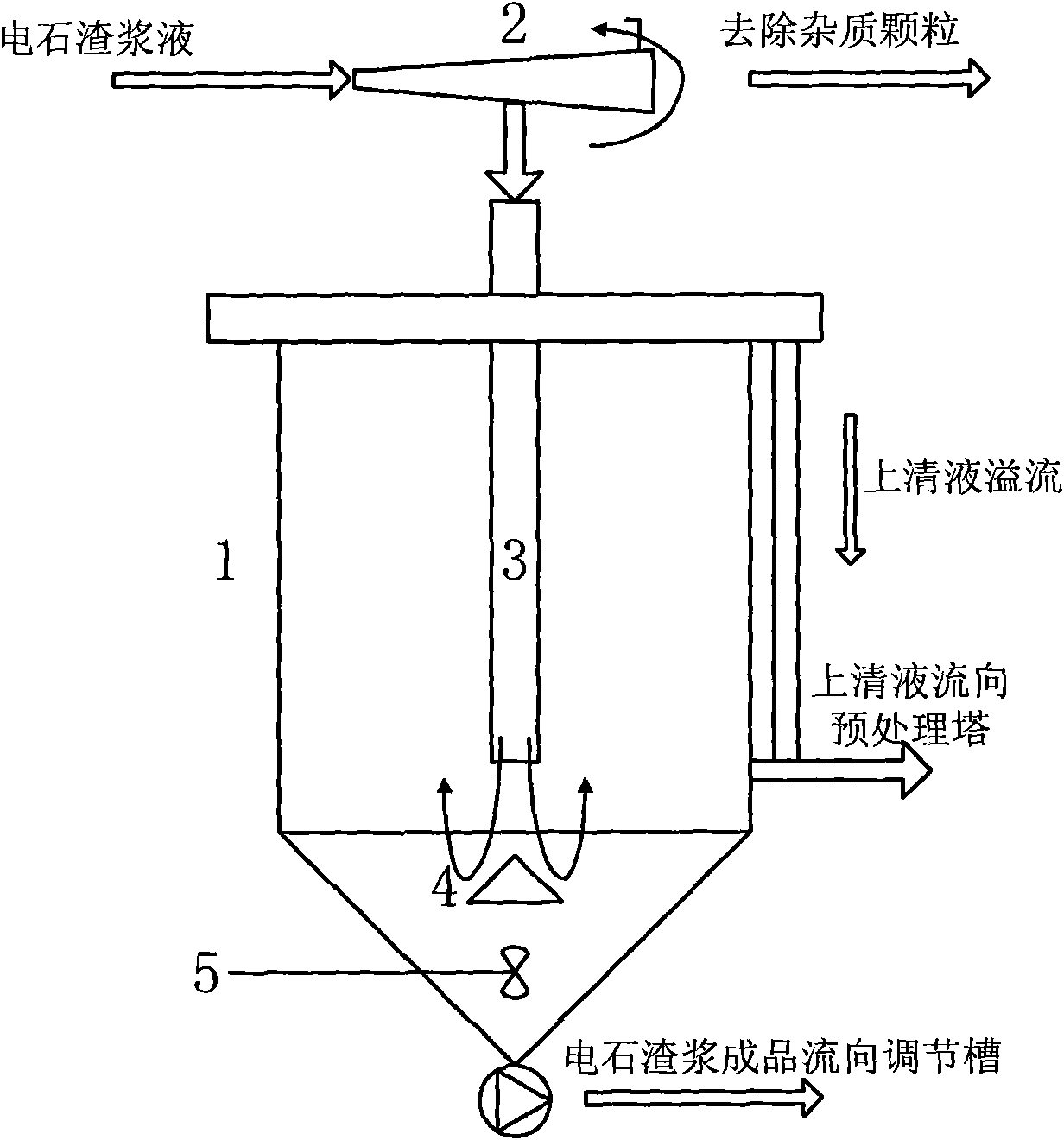

[0052] The function of the desulfurizer system is the preparation of the desulfurizer, which is mainly composed of a thickening device 1, a calcium carbide slurry regulating tank 31, an agitator, a pump and other equipment. The desulfurization agent is made of calcium carbide slurry in the chemical plant area, which is filtered to remove slag, concentrated, and then enters the regulating tank. At the same time, it is stirred to prevent precipitation, and the resulting slurry is transported to the absorption tower by a slurry pump.

[0053] (2) Desulfurization tower system

[0054] The flue gas from the dust collector first enters the pretreatment tower 32, and then enters the absorption tower 33. In the tower, the flue gas exchanges heat, mass transfers, and reacts with the desulfurization slurry atomized by spraying. The mist eliminator 34 removes most of the entrained liquid, which is discharged from the top of the absorption tower.

[0055] The absorption tower 33 is cylin...

Embodiment 1

[0063] A 3×90t / h boiler flue gas desulfurization device in a chemical plant adopts the technology of the present invention, and the flue gas volume at the inlet of the desulfurization device is 365610Nm 3 / h, inlet sulfur dioxide concentration 11000mg / m 3 , the concentration of sulfur dioxide at the outlet of the desulfurization unit is 380mg / m3 3 , when the Ca / S molar ratio of the system is 1.05-1.1, the desulfurization efficiency is >96%. Desulfurization gypsum moisture content ≤ 10%, CaSO in desulfurization gypsum 4 Content ≥ 87%. The diameter of the absorption tower is 5.8m, the height is 29m, the pressure drop of the absorption tower is 1200Pa, and the slurry circulation residence time is 6 minutes.

Embodiment 2

[0065] A 130+75t / h boiler flue gas desulfurization device in a chemical plant adopts the technology of the present invention, and the flue gas volume at the inlet of the desulfurization device is 313000Nm 3 / h, inlet sulfur dioxide concentration 12000mg / m 3 , the concentration of sulfur dioxide at the outlet of the desulfurization unit is 400mg / m 3 , when the Ca / S molar ratio of the system is 1.05-1.1, the desulfurization efficiency is >96%. Desulfurization gypsum moisture content ≤ 12%, CaSO in desulfurization gypsum 4 Content ≥ 86%. The diameter of the absorption tower is 5m, the height is 25m, the pressure drop of the absorption tower is 1000Pa, and the slurry circulation residence time is 5.5 minutes.

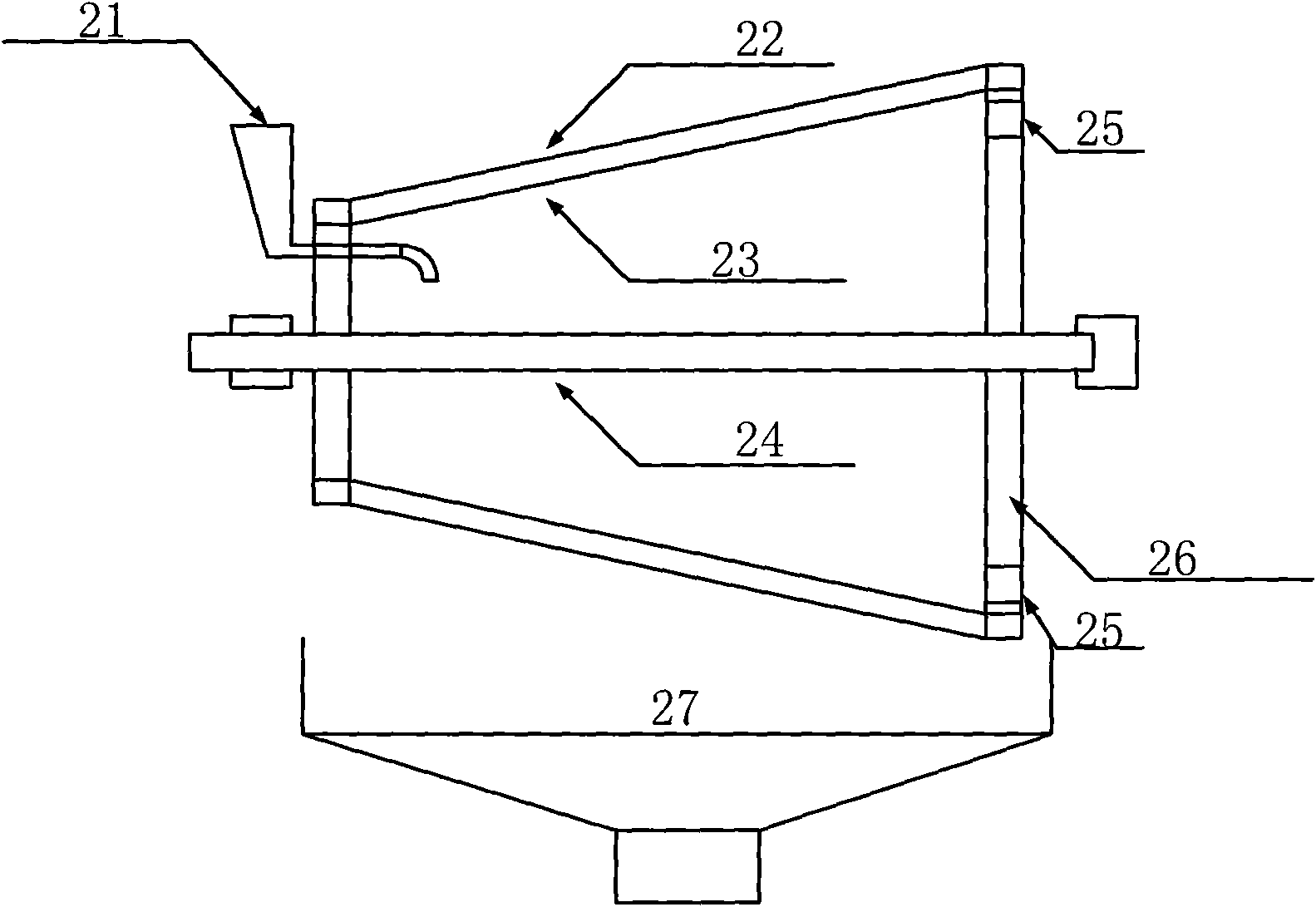

[0066] Such as image 3 As shown, the low-speed rotary filter 2 of the present invention includes: a slurry inlet 21 on the front end face, an outer screen 22, an inner screen 23, a rotating shaft 24, an outlet 25 and a water retaining plate 26, in this example , the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com