Tobacco baking room achieving full utilization of heat energy

A technology of tobacco leaves and heat energy, which is applied in the field of tobacco leaf curing facilities, can solve problems such as environmental pollution and insufficient use of heat energy, and achieve the effects of low energy consumption, shortening the curing cycle, and improving quality and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

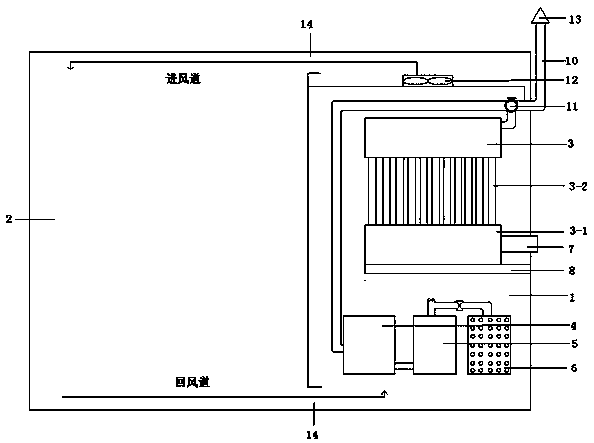

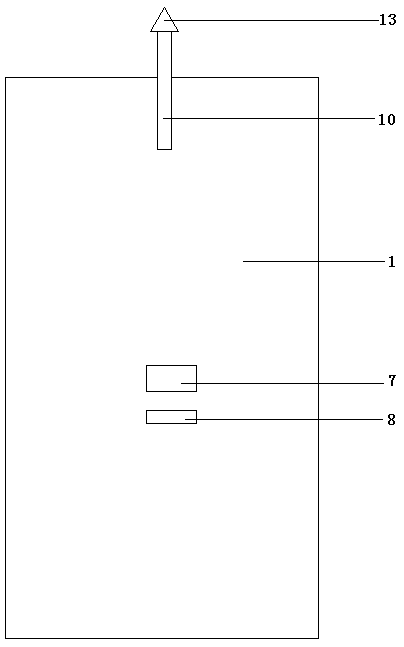

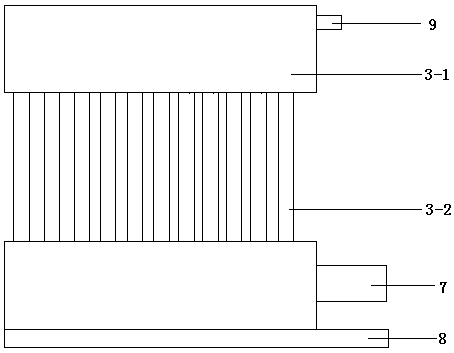

[0023] Embodiment 1: as Figure 1-6 As shown, the heat energy full utilization tobacco leaf curing room includes a heat supply chamber 1 and a flue-cured tobacco chamber 2, and the heat supply chamber 1 communicates with the flue-cured tobacco chamber 2 through the circulation air outlet 14 above and below, and it is characterized in that: the heat supply chamber 1 is provided with Heat exchanger 3, dust removal box 4, purification device 5, dust removal box 4 and purification device 5 are arranged at the bottom of heat supply chamber 1, and the outer end of heat supply chamber 1 is provided with a pyrotechnic inlet 7 for communicating with the combustion furnace pyrotechnic channel, and the heat exchanger The entrance of 3 is connected to the tail end of the heat collecting tube 3-1, the front end of the heat collecting tube 3-1 is connected to the pyrotechnic inlet 7, the lower end of the heat collecting tube 3-1 is provided with an ash collecting tank 8, and the flue gas out...

Embodiment 2

[0026] Embodiment 2: as Figure 1-6 As shown, the heat energy full utilization tobacco leaf curing room includes a heat supply chamber 1 and a flue-cured tobacco chamber 2, and the heat supply chamber 1 communicates with the flue-cured tobacco chamber 2 through the circulation air outlet 14 above and below, and it is characterized in that: the heat supply chamber 1 is provided with Heat exchanger 3, dust removal box 4, purification device 5, dust removal box 4 and purification device 5 are arranged at the bottom of heat supply chamber 1, and the outer end of heat supply chamber 1 is provided with a pyrotechnic inlet 7 for communicating with the combustion furnace pyrotechnic channel, and the heat exchanger The entrance of 3 is connected to the tail end of the heat collecting tube 3-1, the front end of the heat collecting tube 3-1 is connected to the pyrotechnic inlet 7, the lower end of the heat collecting tube 3-1 is provided with an ash collecting tank 8, and the flue gas out...

Embodiment 3

[0029] Embodiment 3: as Figure 1-6 As shown, the heat energy full utilization tobacco leaf curing room includes a heat supply chamber 1 and a flue-cured tobacco chamber 2, and the heat supply chamber 1 communicates with the flue-cured tobacco chamber 2 through the circulation air outlet 14 above and below, and it is characterized in that: the heat supply chamber 1 is provided with Heat exchanger 3, dust removal box 4, purification device 5, dust removal box 4 and purification device 5 are arranged at the bottom of heat supply chamber 1, and the outer end of heat supply chamber 1 is provided with a pyrotechnic inlet 7 for communicating with the combustion furnace pyrotechnic channel, and the heat exchanger The entrance of 3 is connected to the tail end of the heat collecting tube 3-1, the front end of the heat collecting tube 3-1 is connected to the pyrotechnic inlet 7, the lower end of the heat collecting tube 3-1 is provided with an ash collecting tank 8, and the flue gas out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com