Equipment and method for preparing constant-pressure fuel gas

A technology of fuel gas and normal pressure, which is applied in the direction of manufacturing combustible gas, granular/powdered fuel gasification, gasification process, etc. It can solve the problems of decreased overall benefit of the device, decreased reliability of the device, and high cost of fuel gas, and achieves a solution Reliability issues, avoidance of pollution, effects of low carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0041] In the present invention, pulverized coal is preferably used as raw material, oxygen and steam are used as gasification agents, and high-temperature combustion is carried out in a combustion radiation heat exchange device integrated with a radiation heat exchanger, which can adapt to various coal types from bituminous coal, anthracite to lignite, It can realize the localization of raw coal, so that enterprises can freely choose coal types according to the coal market conditions and the supply of coal resources, and minimize the cost of raw materials. In addition, the present invention can also burn industrial combustibles such as petroleum coke or coke powder as raw materials.

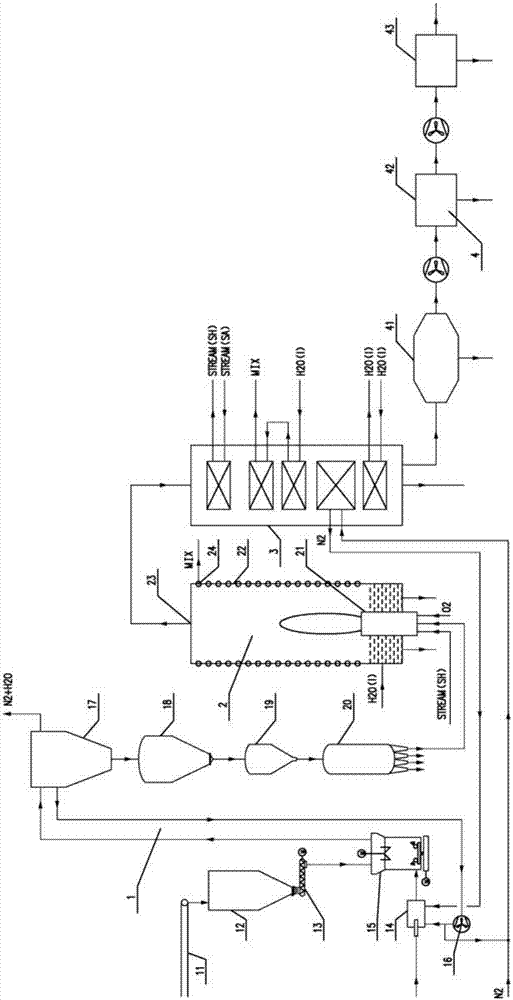

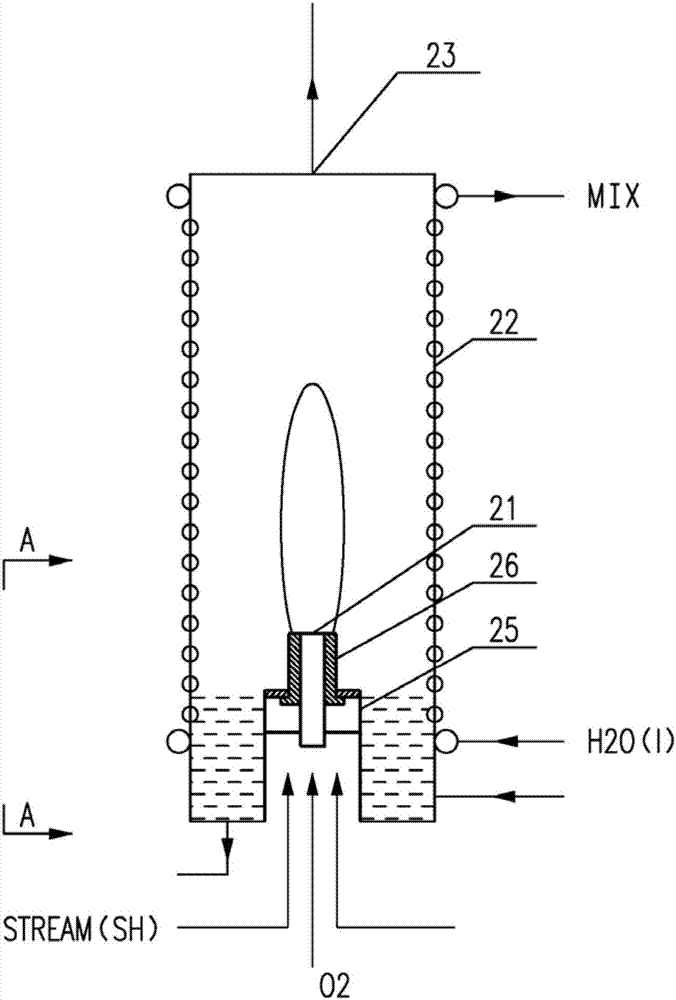

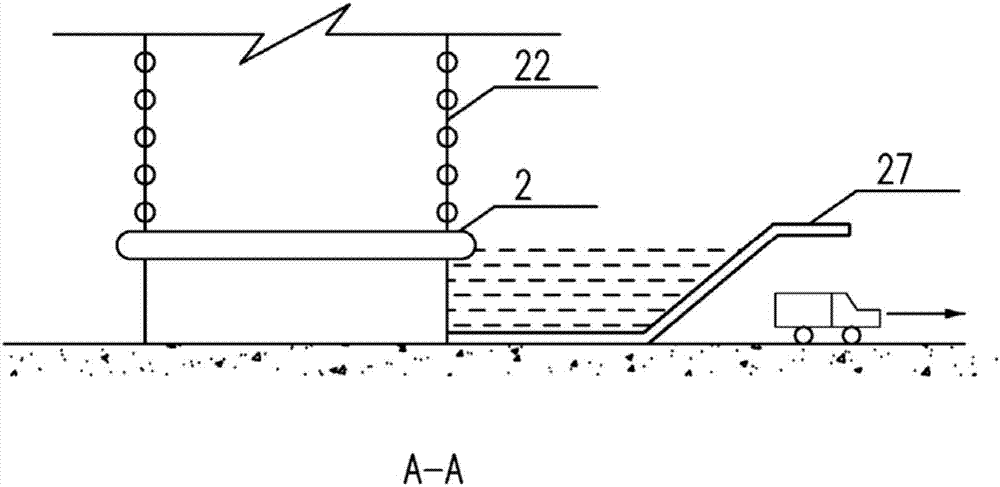

[0042] Such as figure 1 As shown, the equipment for preparing atmospheric pressure fuel gas includes: feeding device 1 , combustion radiation heat exchange devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com