Nitrate-water separating device

A separation device and nitrate technology, which is applied in water/sewage treatment, metallurgical wastewater treatment, water/sludge/sewage treatment, etc. It can solve the problem of unusable cleaning liquid, non-compliance with energy saving and emission reduction policies, and the salt concentration of cleaning liquid Low-level problems, to avoid the influence of temperature and corrosion, save energy, save water and nitrate resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

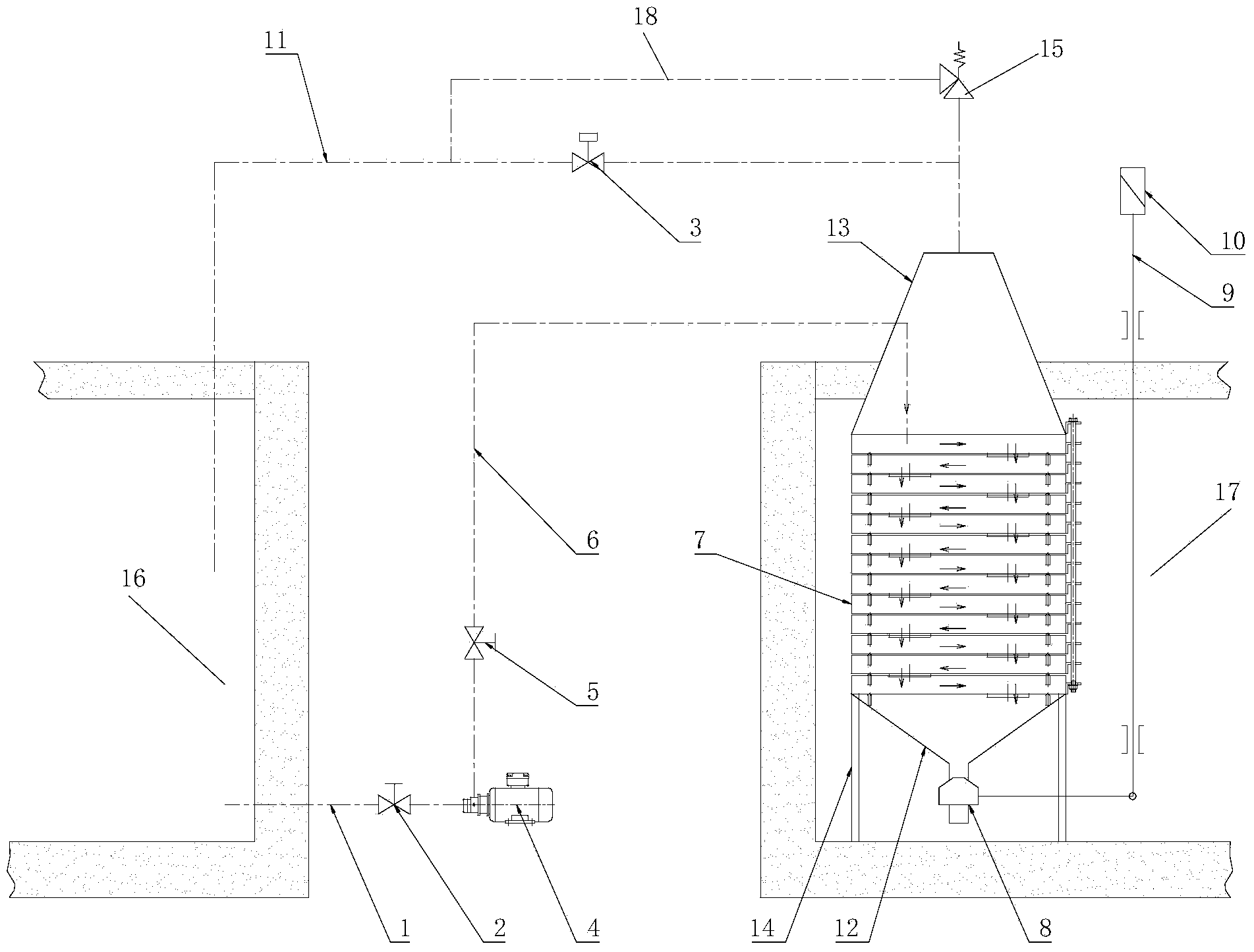

[0016] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention includes a hot cleaning machine water tank 16 and a nitrate quenching tank 17. The hot cleaning machine water tank 16 is connected with a hot cleaning tank containing liquid outlet pipe 1, and the hot cleaning tank containing salt liquid outlet pipe 1 is connected with a The salt cleaning liquid inlet pipe 6 is connected, and a pipeline pump 4 is connected between the salt liquid outlet pipe 1 of the hot cleaning tank and the salt cleaning liquid inlet pipe 6; the salt cleaning liquid inlet pipe 6 is connected to the In the heat exchanger fin group tube 7, the heat exchanger fin group tube 7 is fixed in the nitrate quenching tank 17 through the heat exchanger base bracket 14; the top of the heat exchanger fin group tube 7 is provided with water Vapor collection cover 13, this water vapor collection cover 13 is connected with hot clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com