High frequency injection-based oxygen sensor internal resistor detection circuit

A technology of oxygen sensor and high-frequency injection, which is applied in the direction of measuring electrical variables, measuring resistance/reactance/impedance, instruments, etc., can solve problems such as inability to measure in real time, and achieve real-time detection and optimize the effect of output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

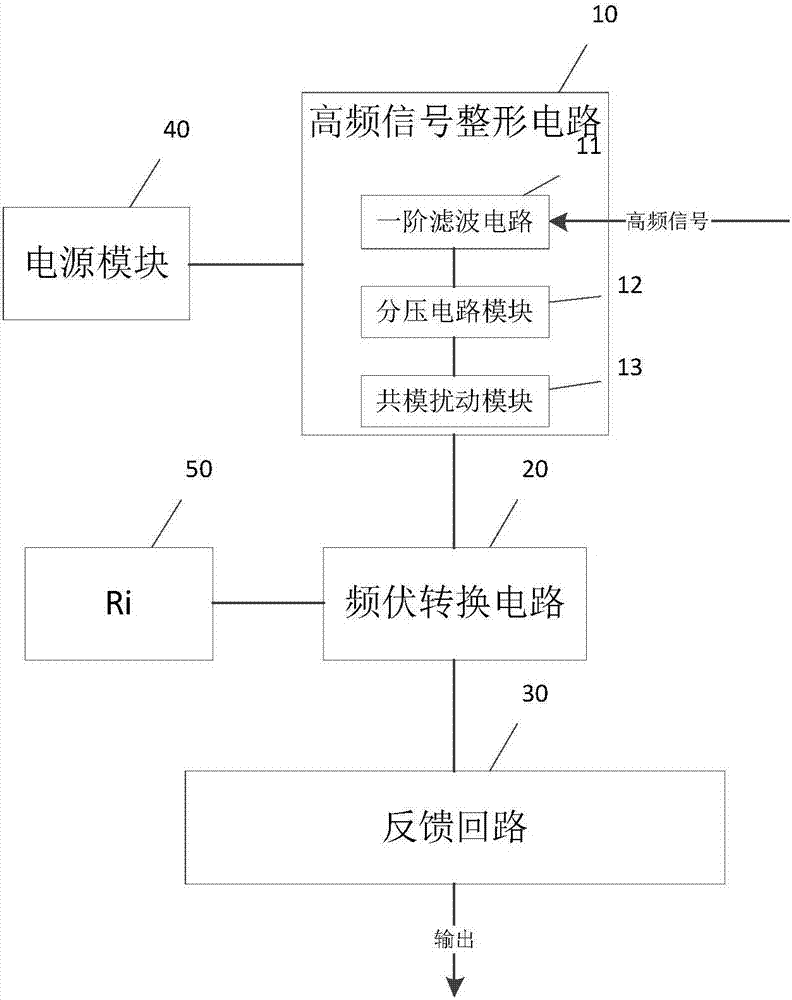

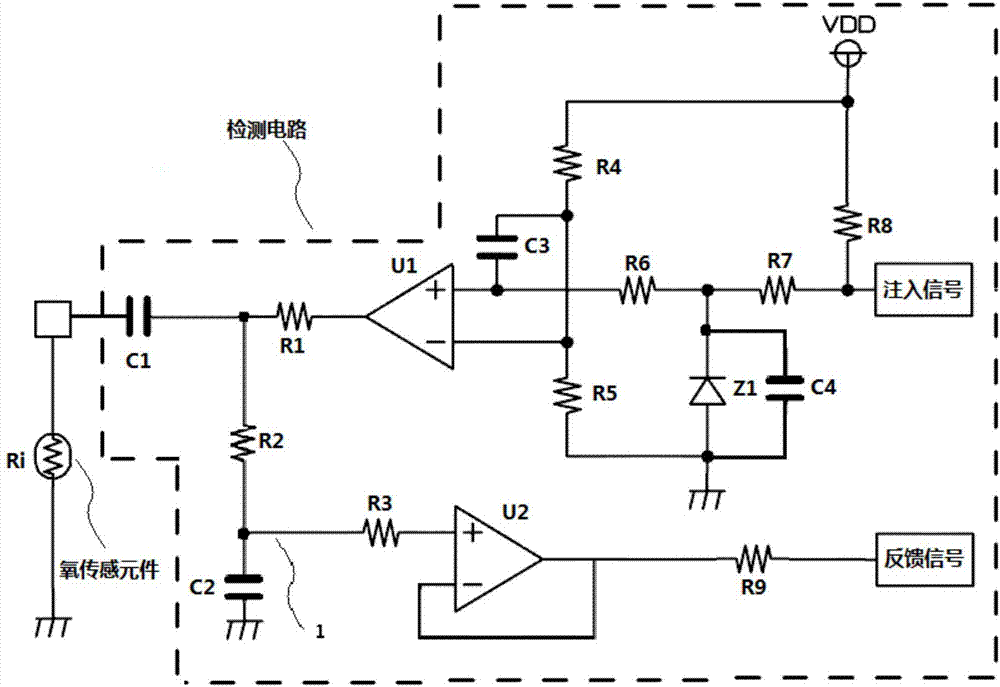

[0026] like Figure 1-2 As shown, a detection circuit for the internal resistance of an oxygen sensor based on high-frequency injection includes a high-frequency signal shaping circuit 10, a frequency-voltage conversion circuit 20, a feedback loop 30, an internal resistance Ri50 of the oxygen sensor, and a power supply for supplying power to the detection circuit Module VDD40, the high-frequency signal is input to the high-frequency signal shaping circuit 10, the output end of the high-frequency signal shaping circuit 10 is electrically connected to the input end of the frequency-voltage conversion circuit 20, and the frequency-voltage conversion circuit 20 is connected to the oxygen sensor The resistance Ri50 is electrically connected, and the output end of the frequency-to-voltage conversion circuit 20 is electrically connected to the input end of the feedback loop 30 .

[0027] In the above circuit:

[0028] High-frequency signal shaping circuit 10: used to receive high-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com