Patents

Literature

3772 results about "Air–fuel ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air–fuel ratio (AFR) is the mass ratio of air to a solid, liquid, or gaseous fuel present in a combustion process. The combustion may take place in a controlled manner such as in an internal combustion engine or industrial furnace, or may result in an explosion (e.g., a dust explosion, gas or vapour explosion or in a thermobaric weapon).

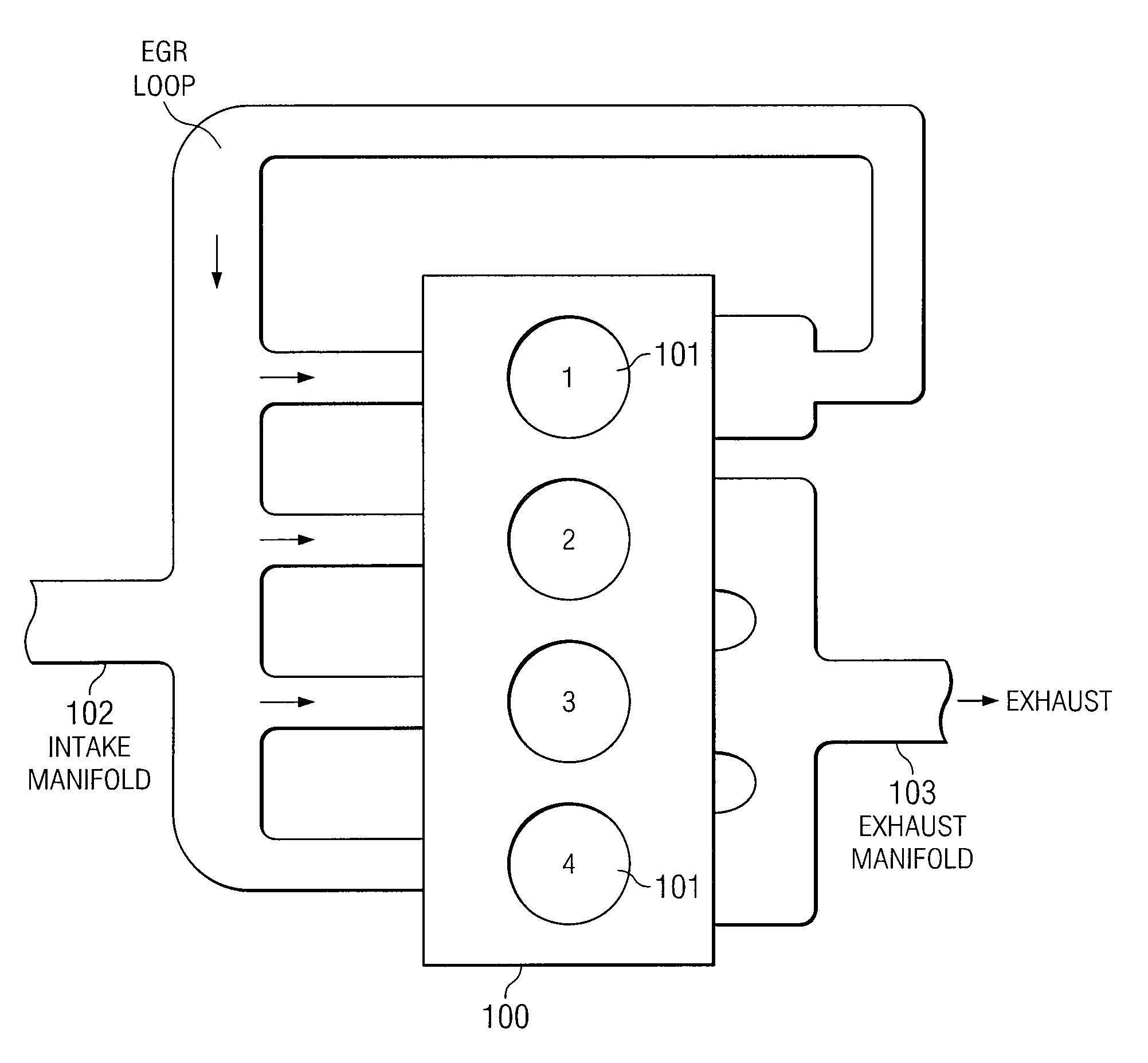

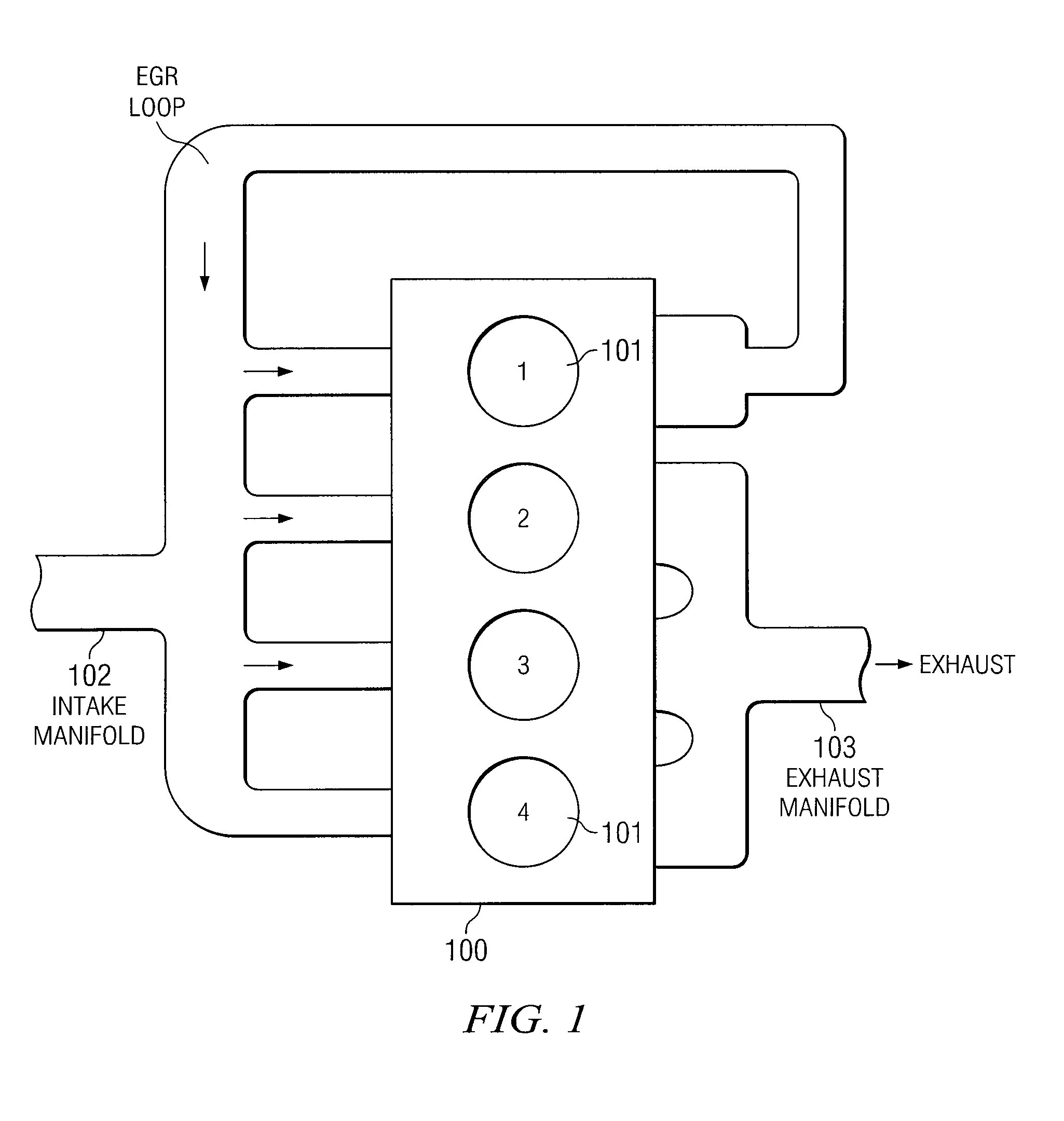

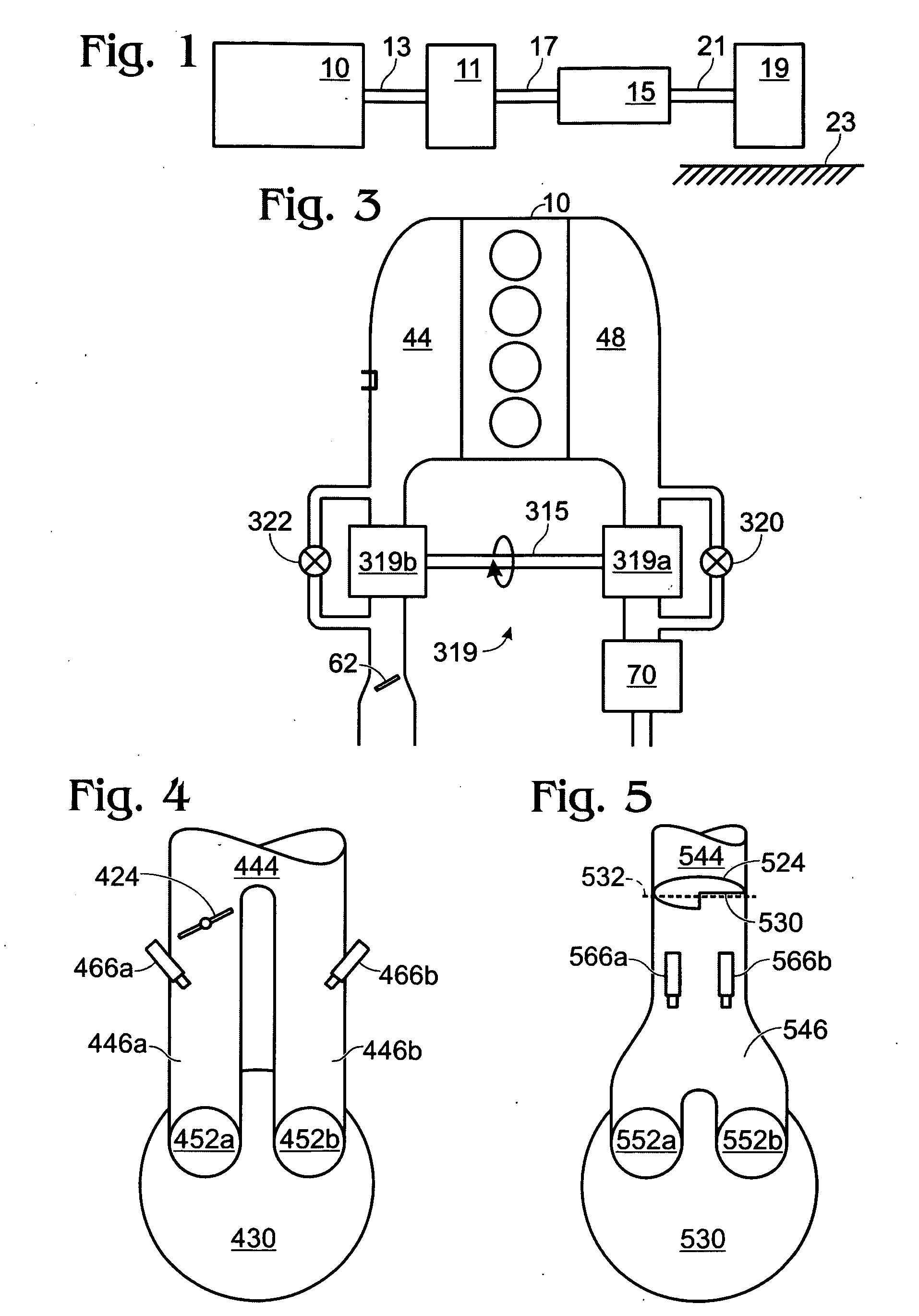

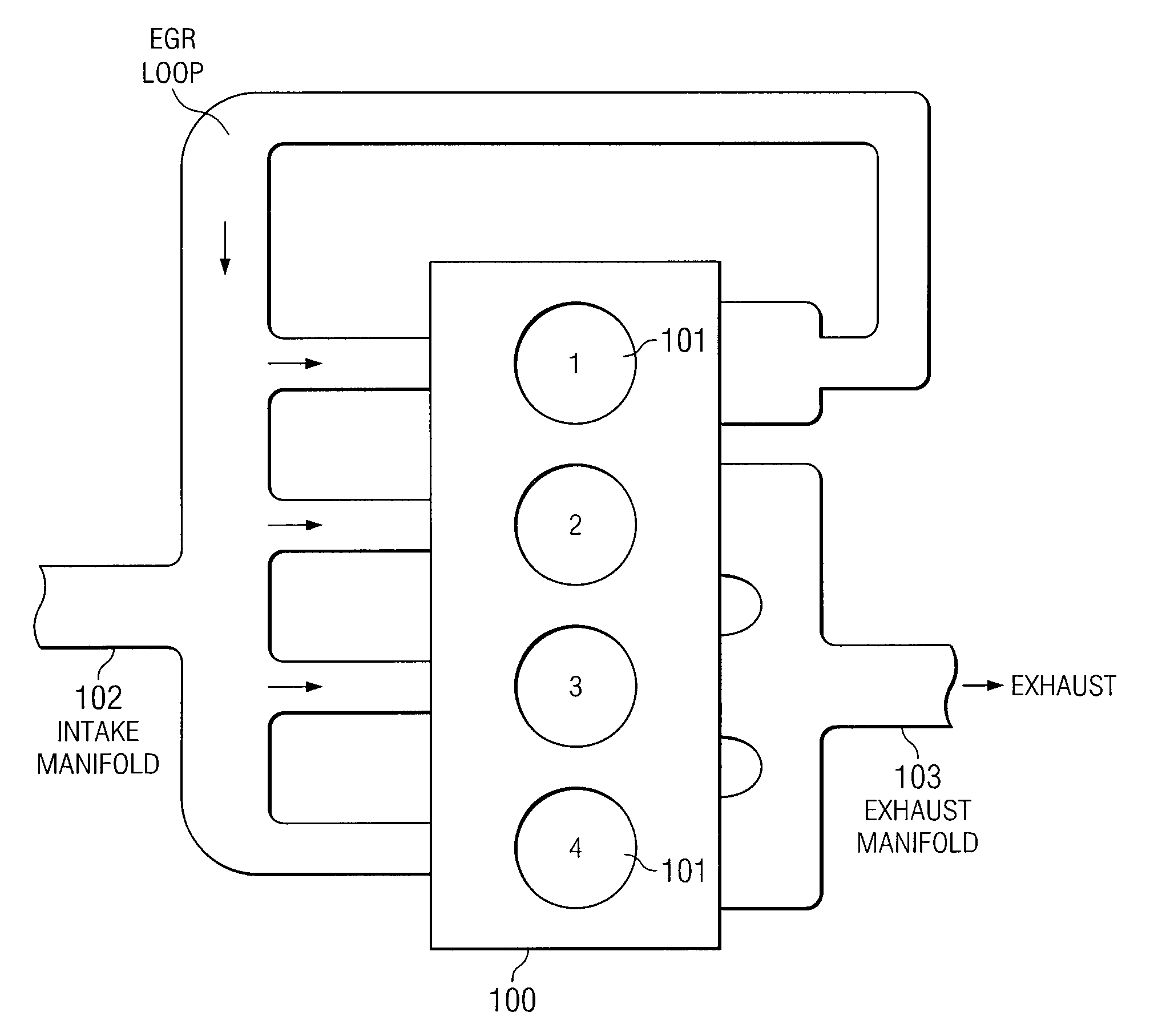

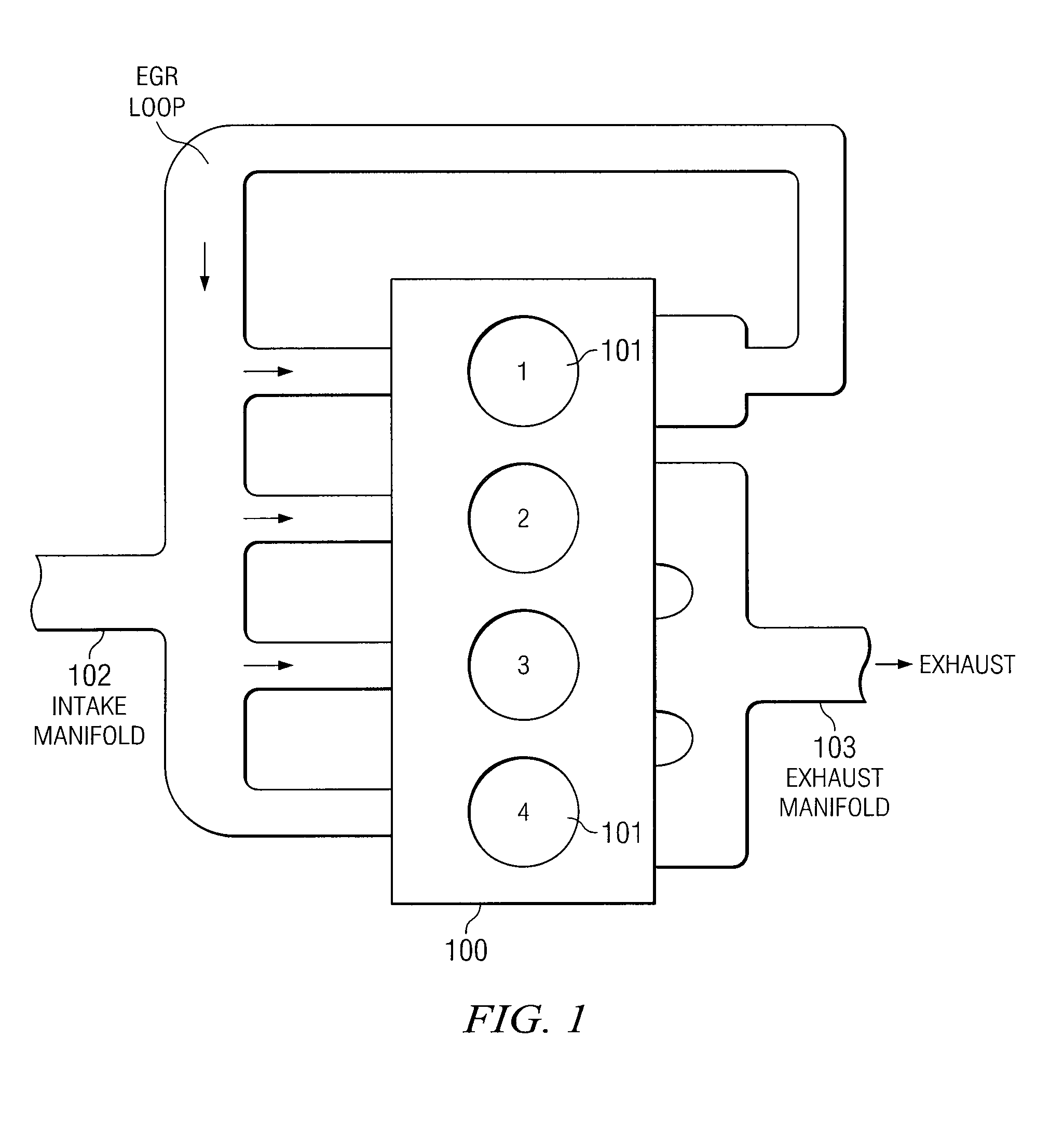

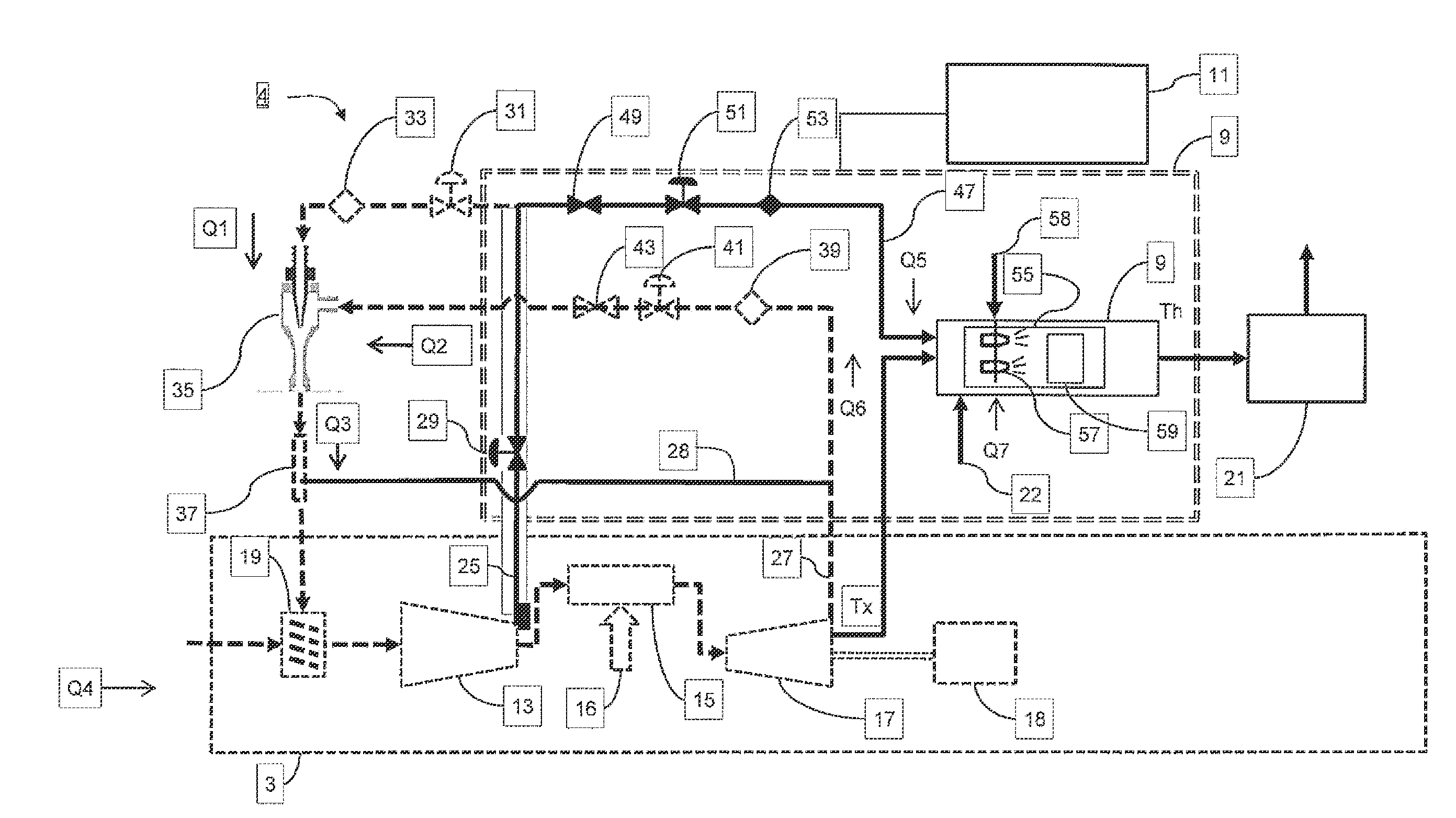

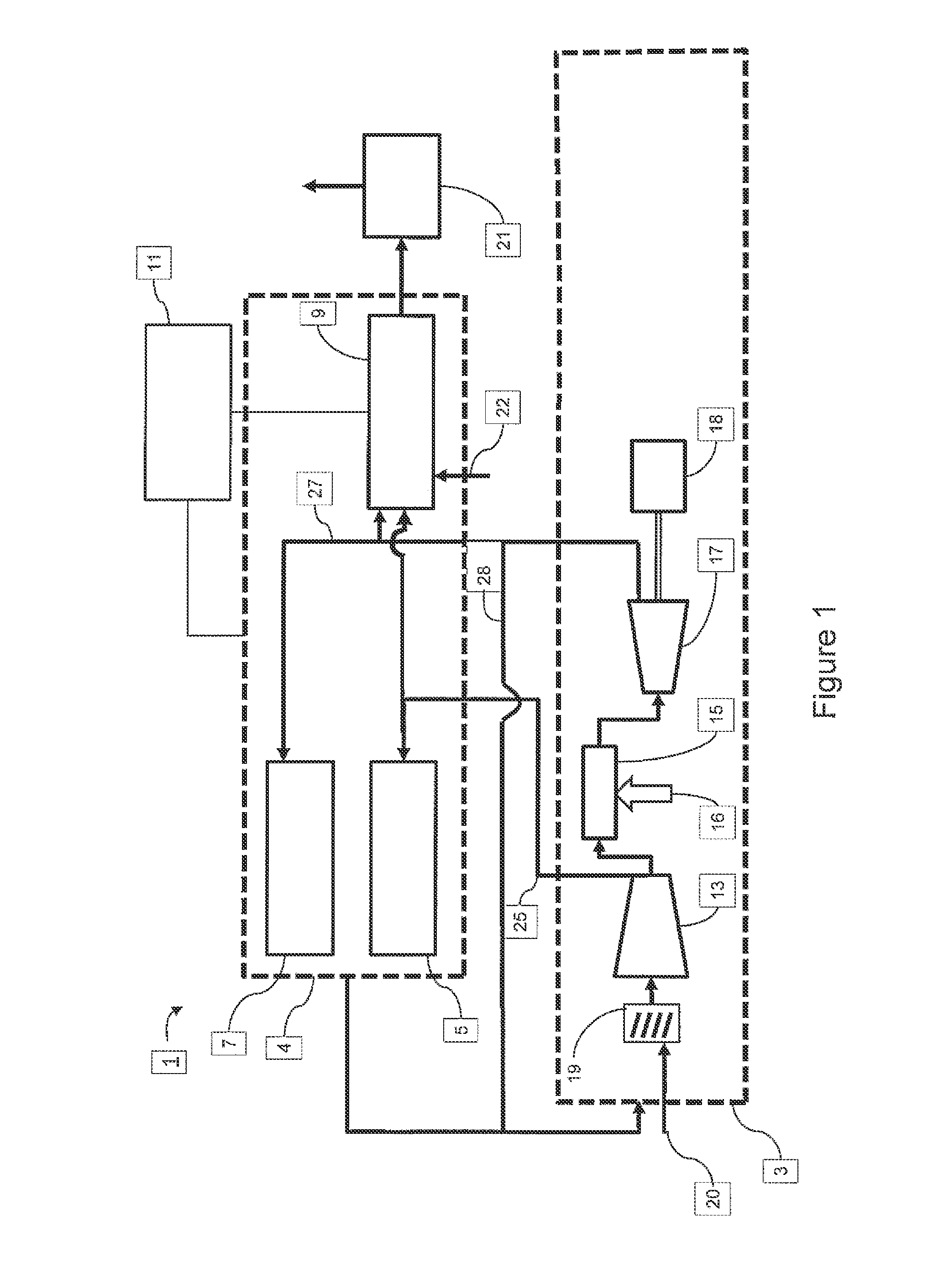

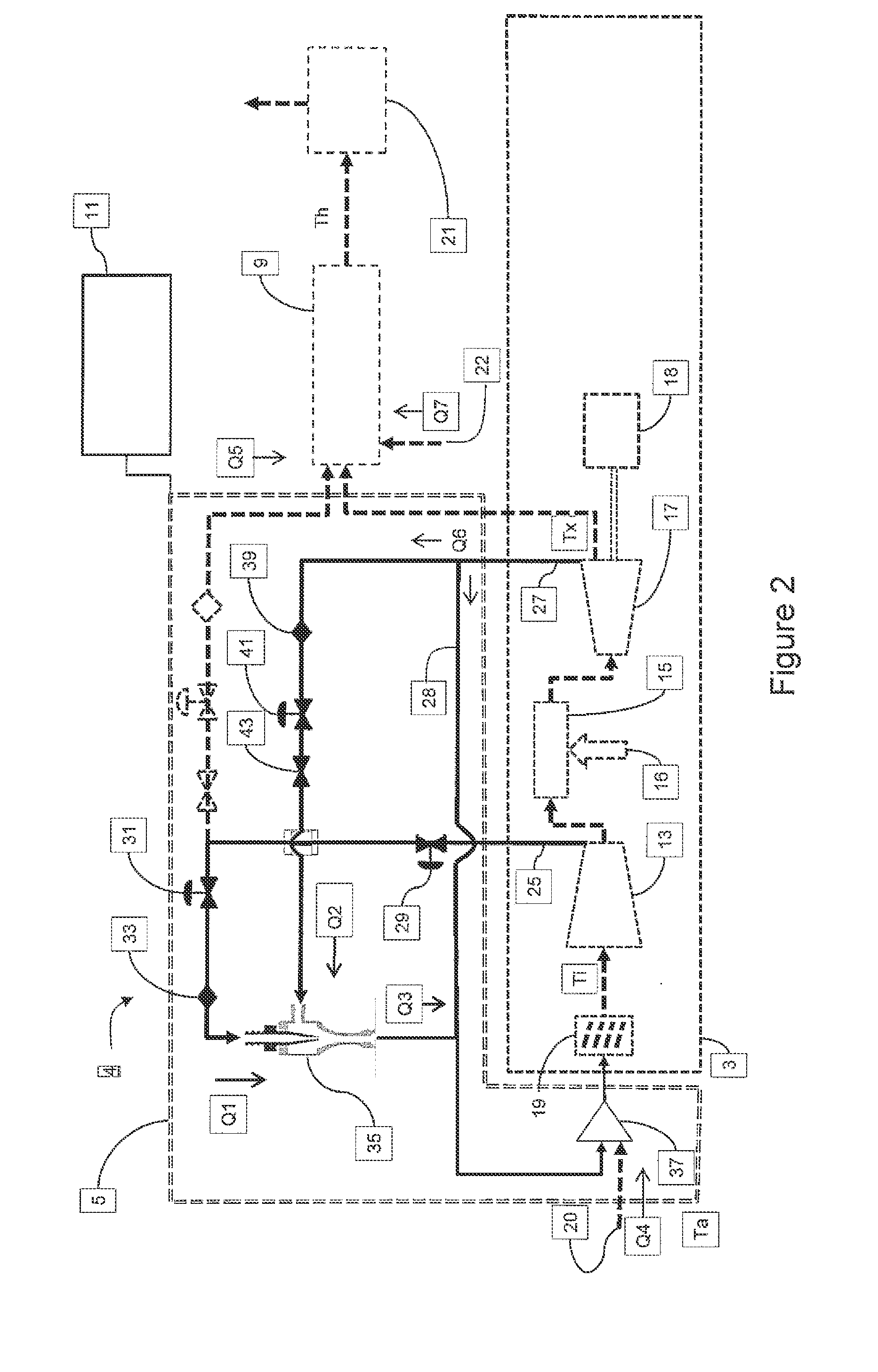

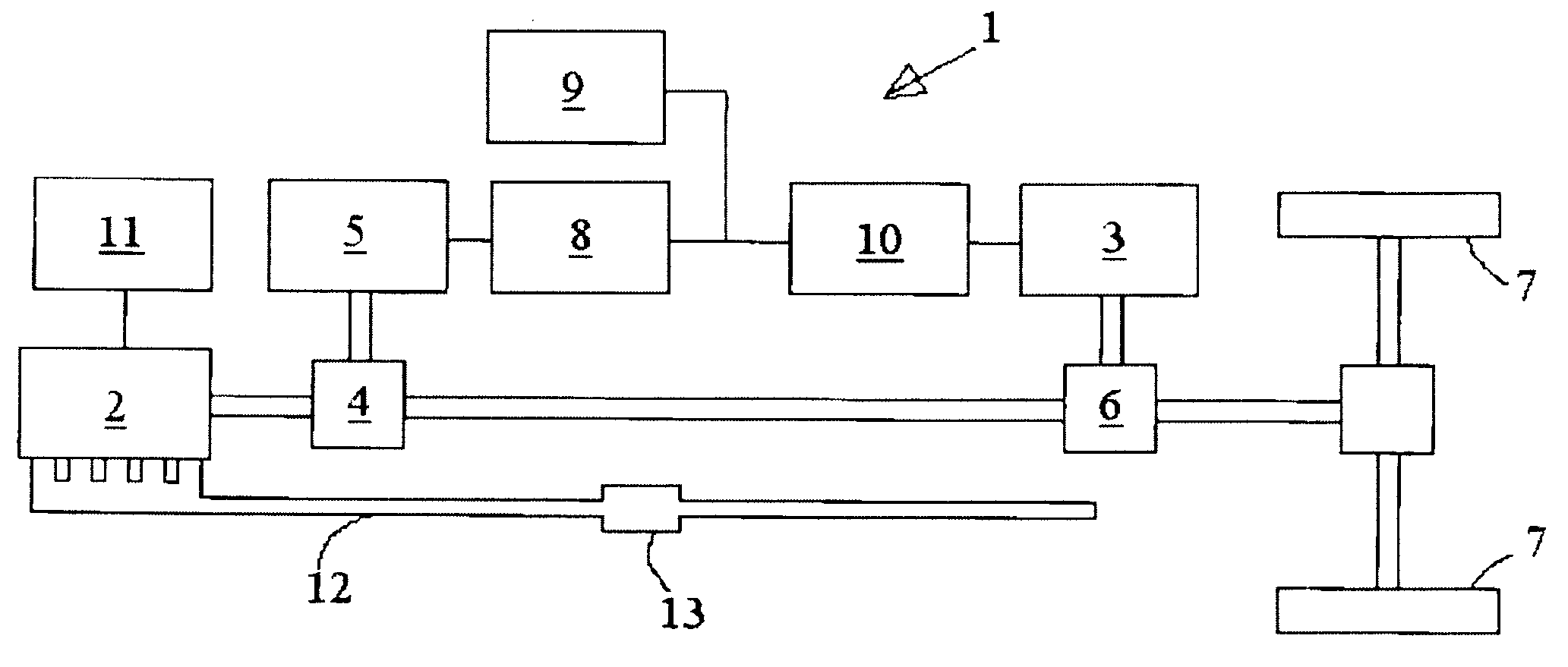

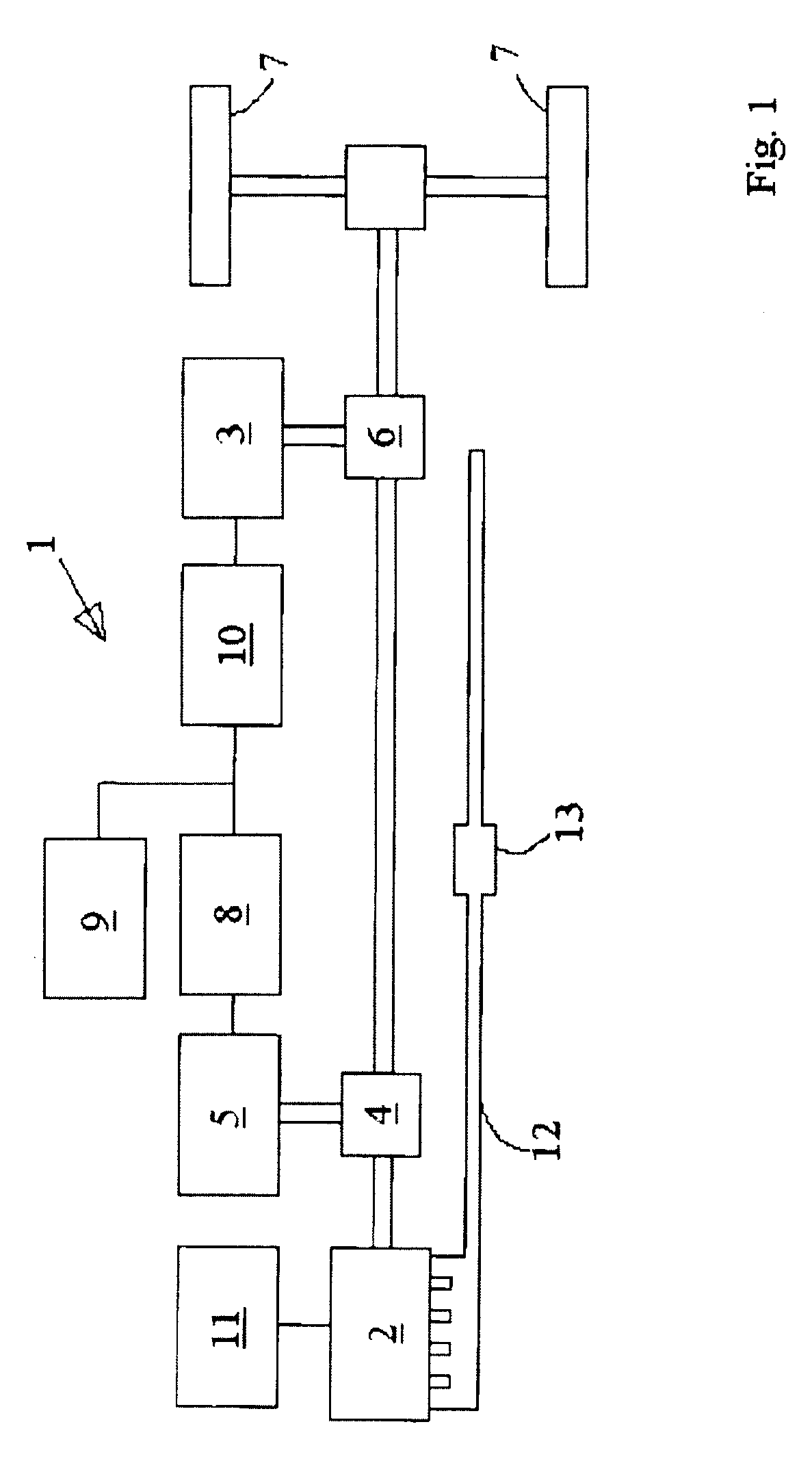

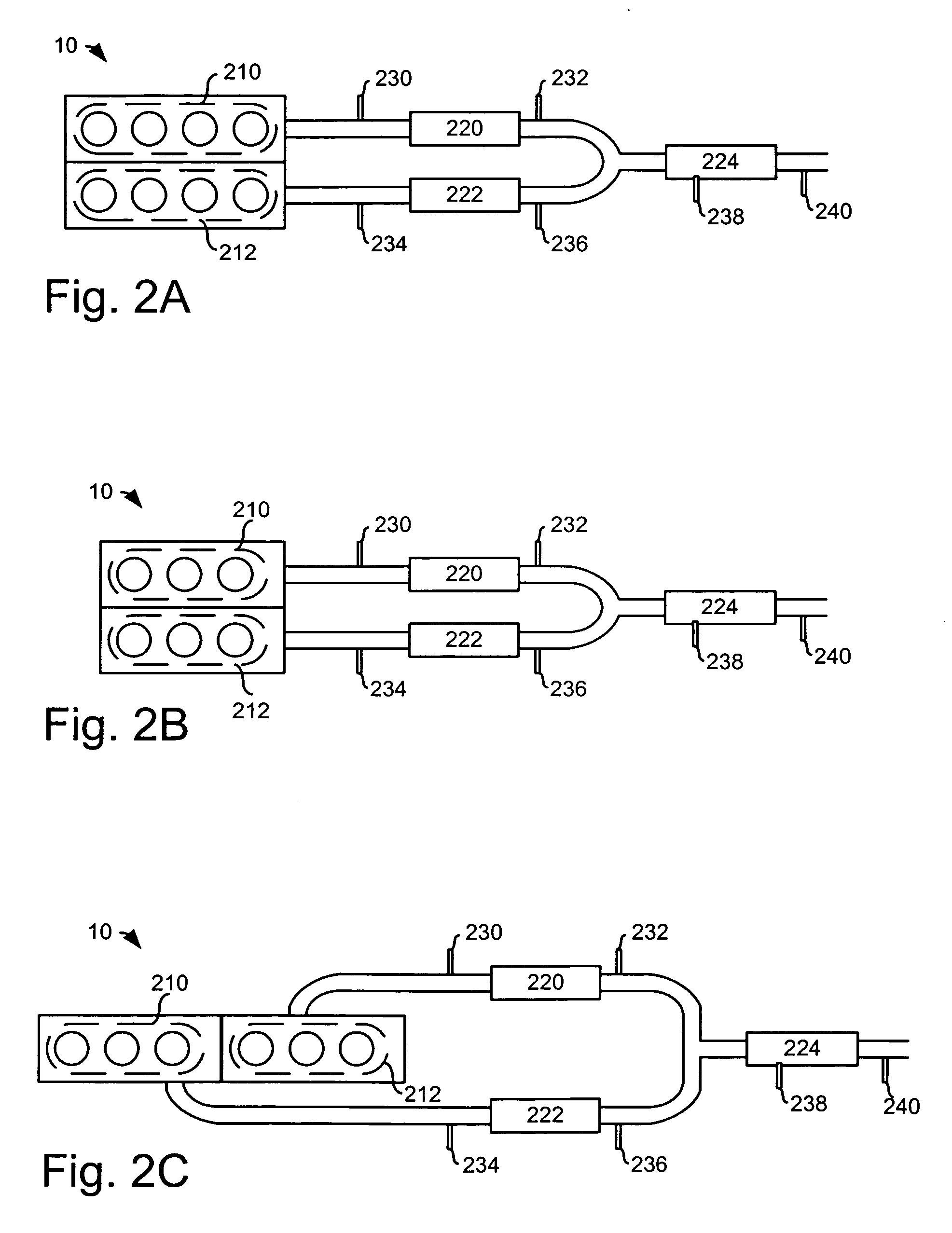

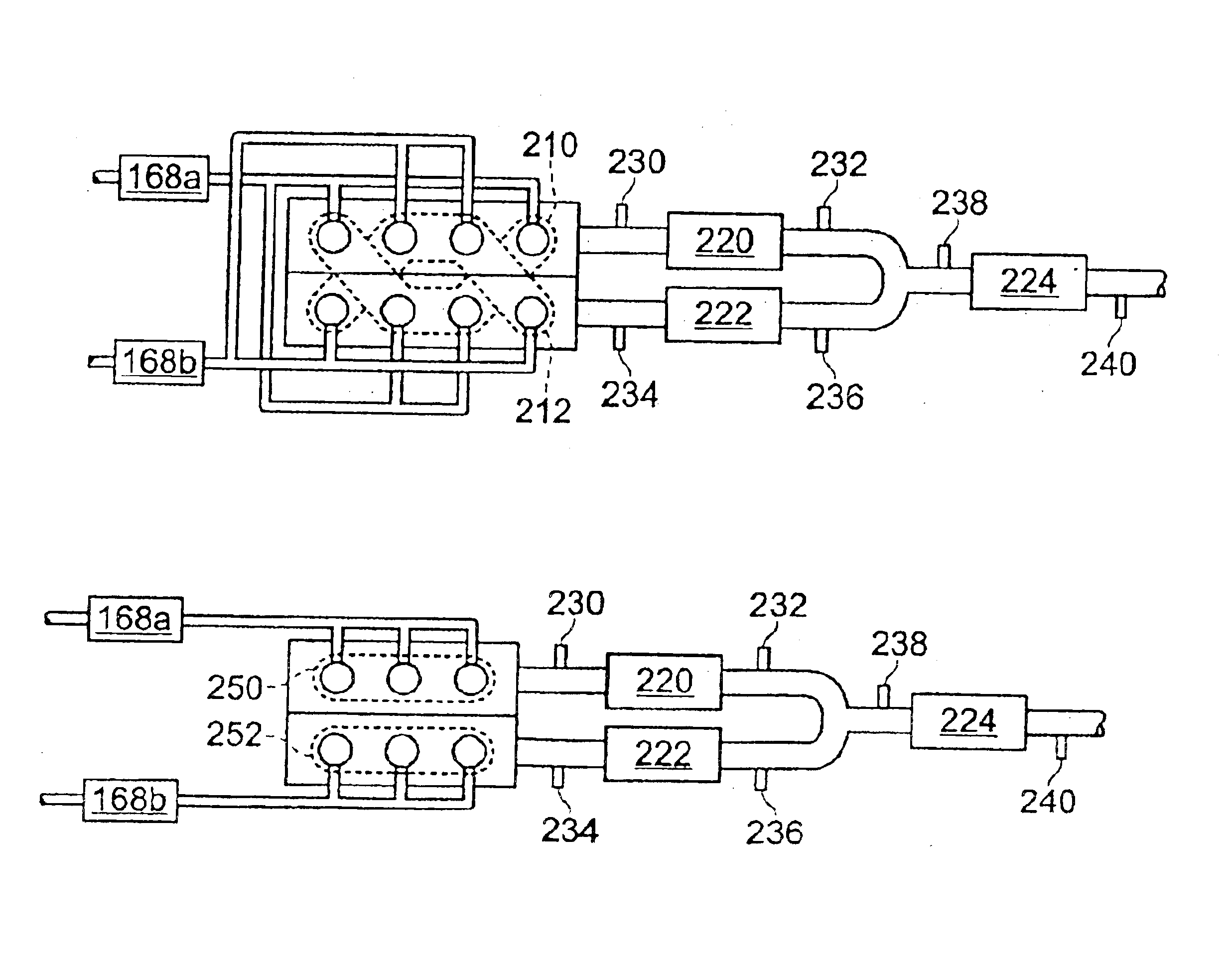

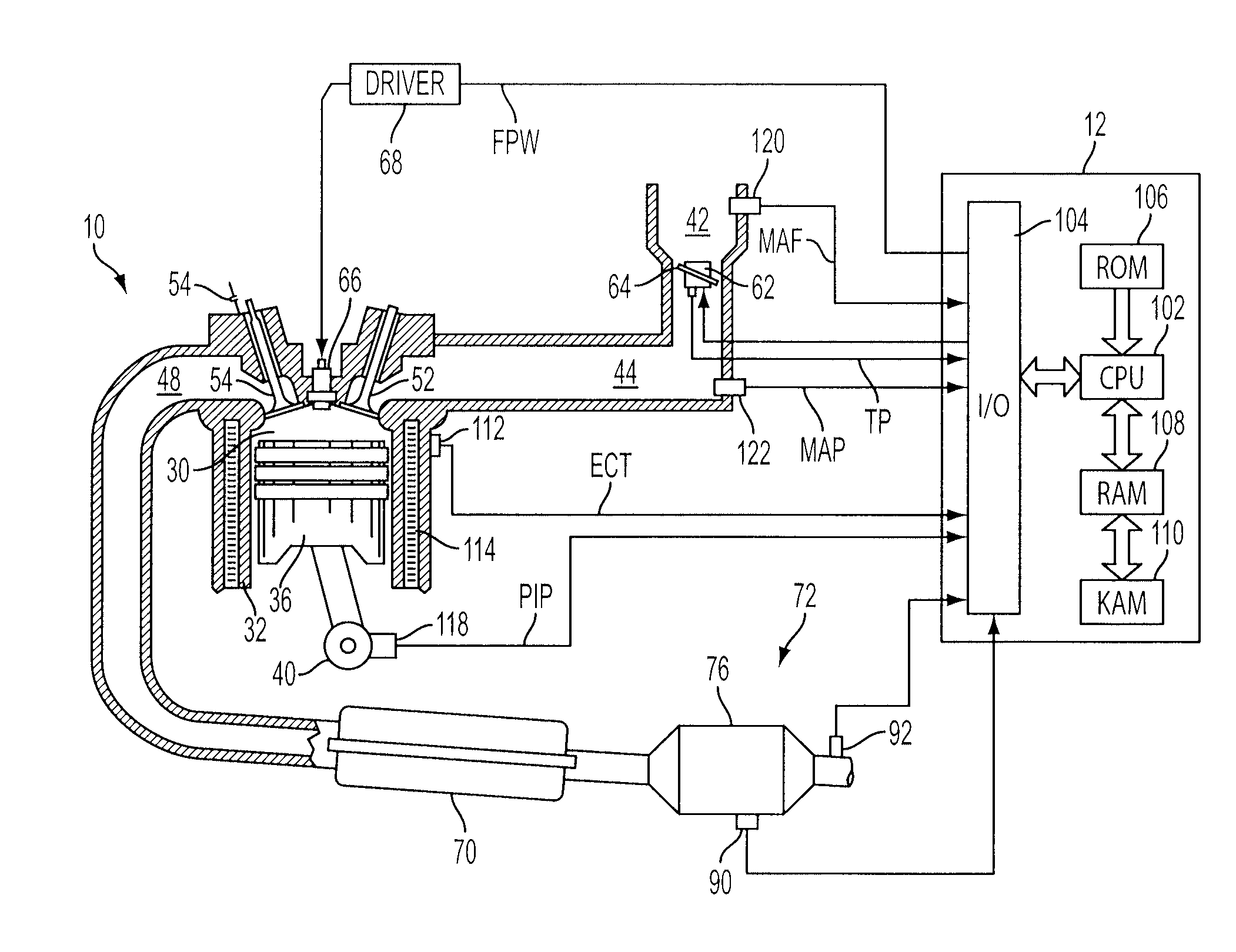

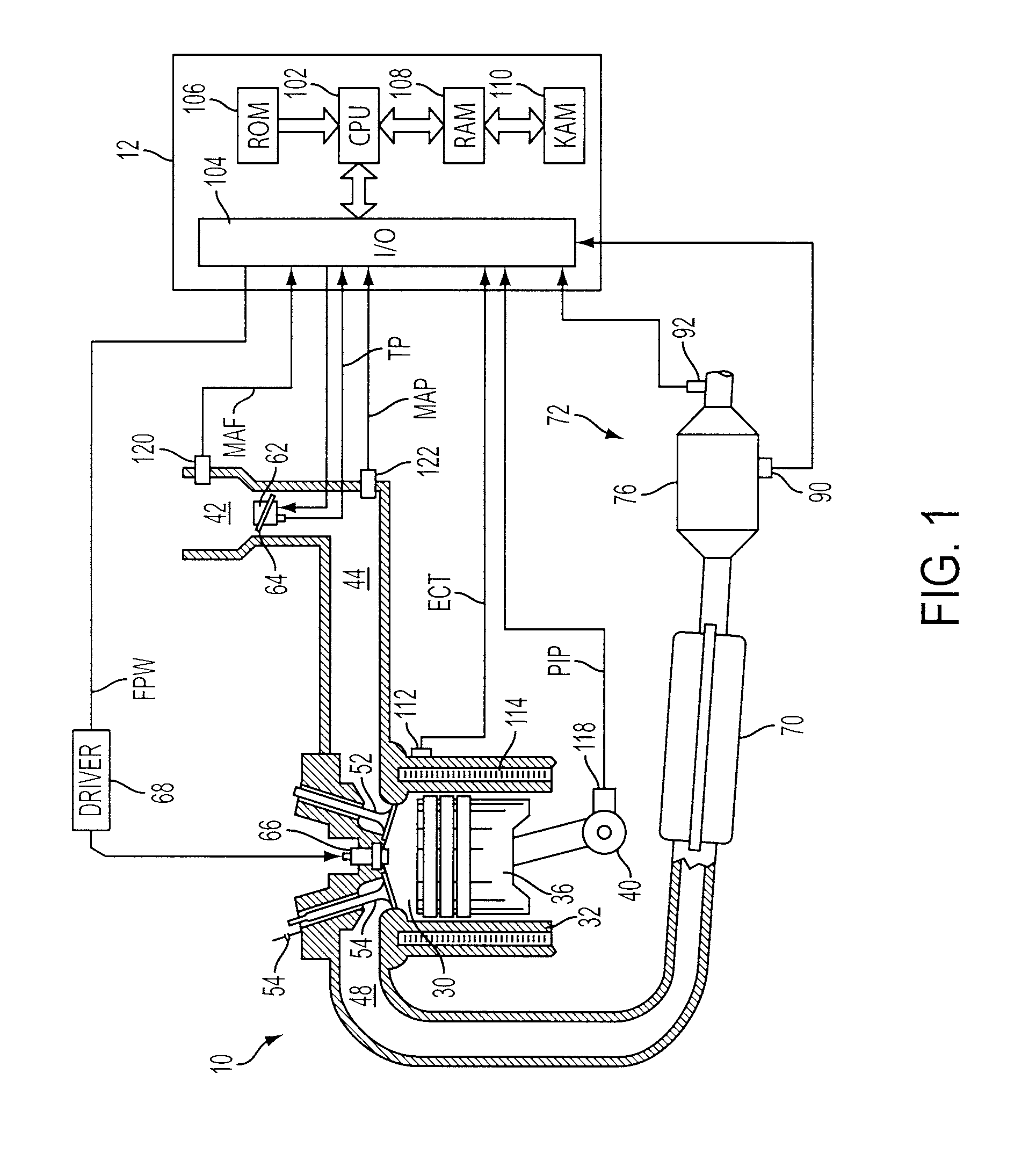

Egr system with dedicated egr cylinders

Improved exhaust gas recirculation system and methods that use one or more of the engine's cylinders as dedicated EGR cylinders. All of the exhaust from the dedicated EGR cylinders is recirculated back to the engine intake. Thus, the EGR rate is constant, but the EGR mass flow may be controlled by adjusting the air-fuel ratio of the dedicated EGR cylinders or by using various variable valve timing techniques.

Owner:SOUTHWEST RES INST

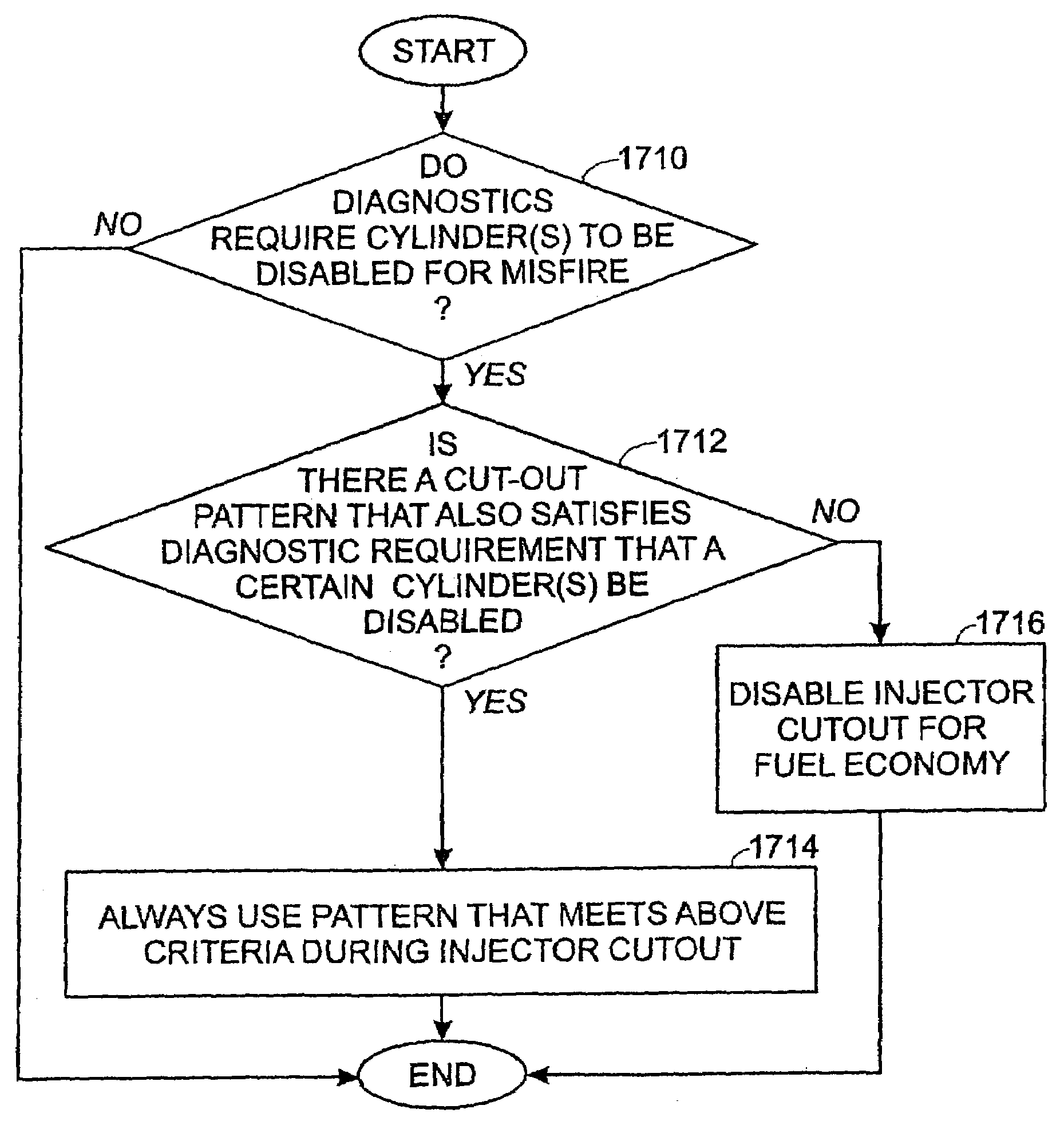

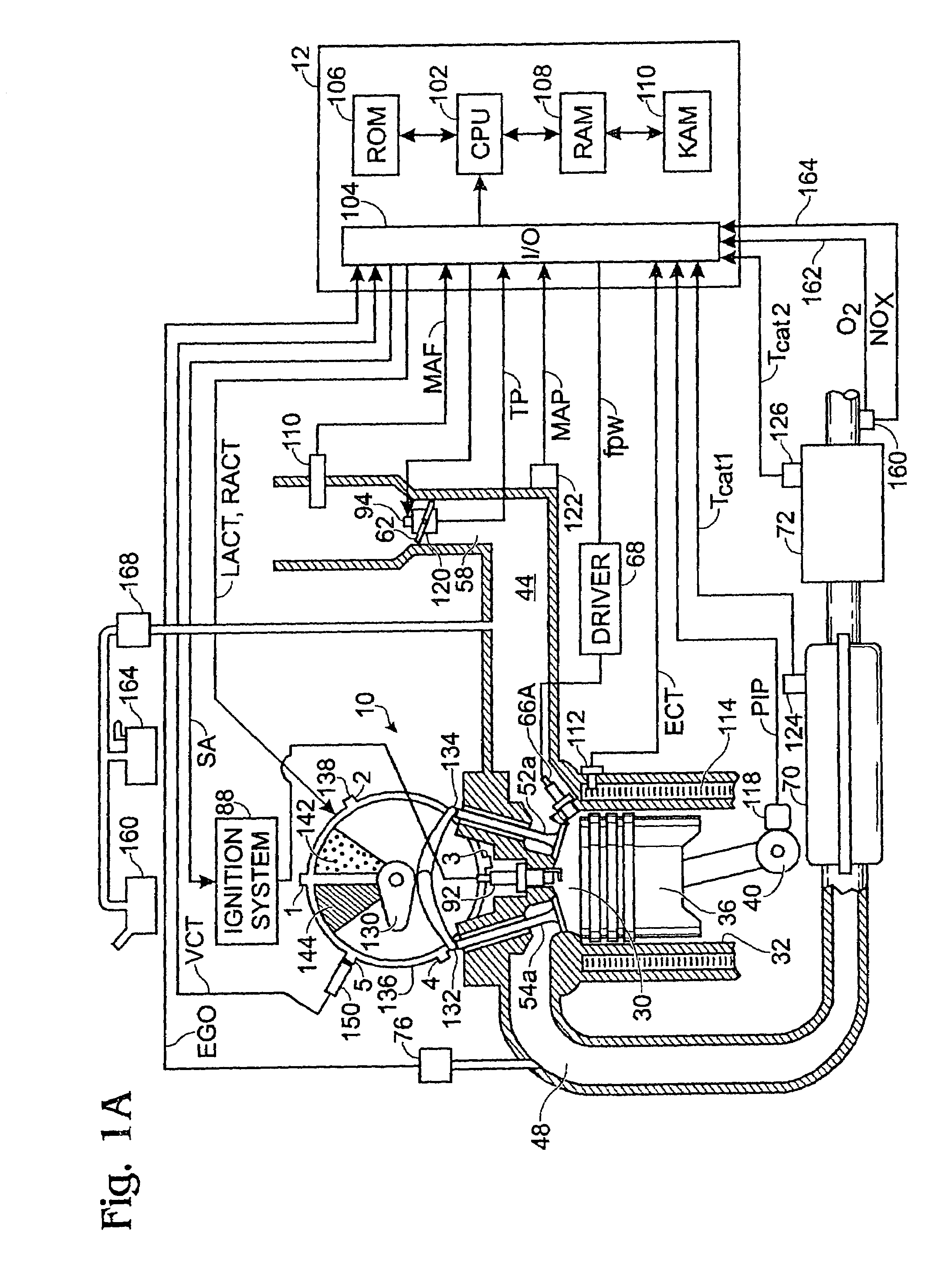

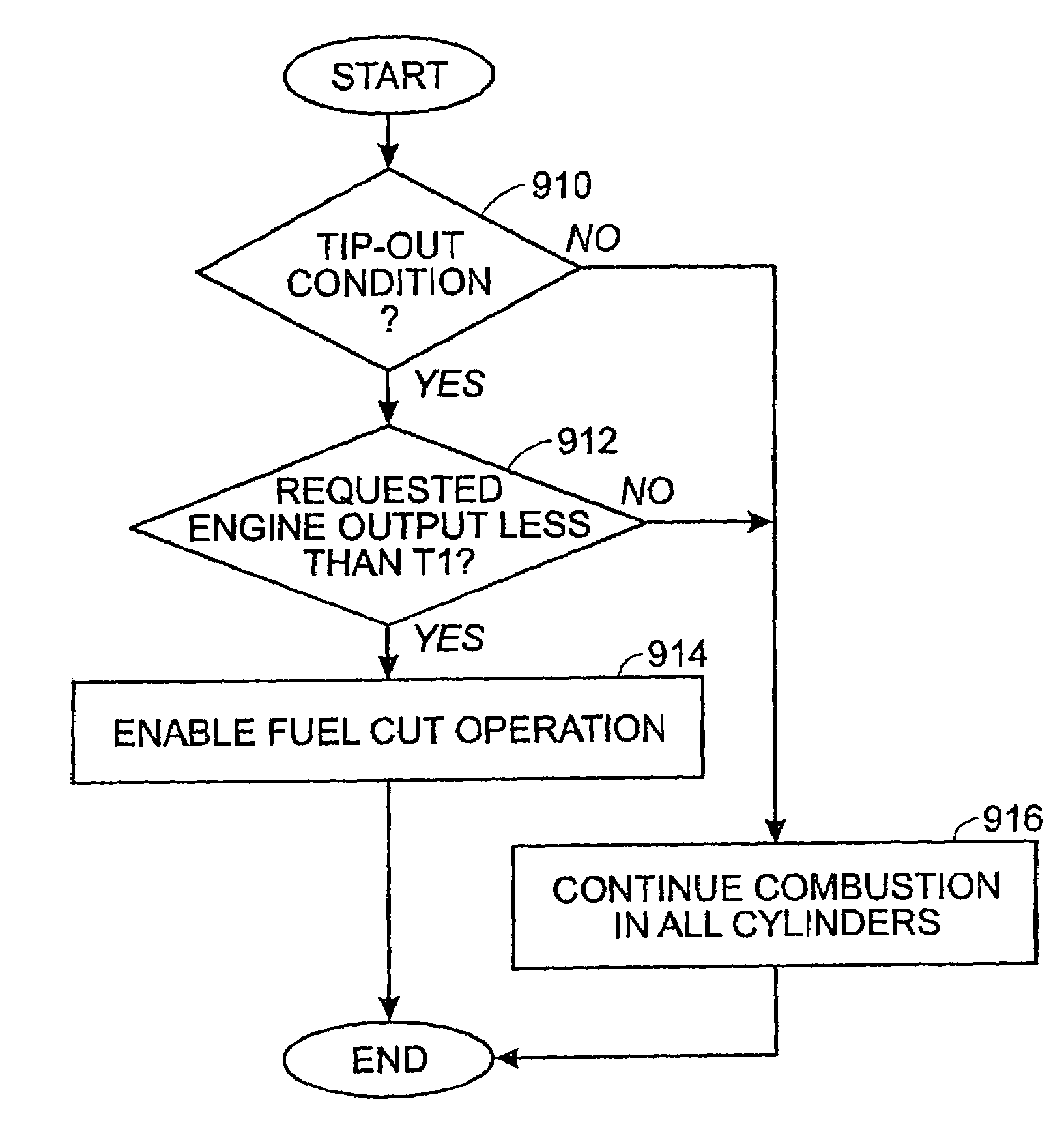

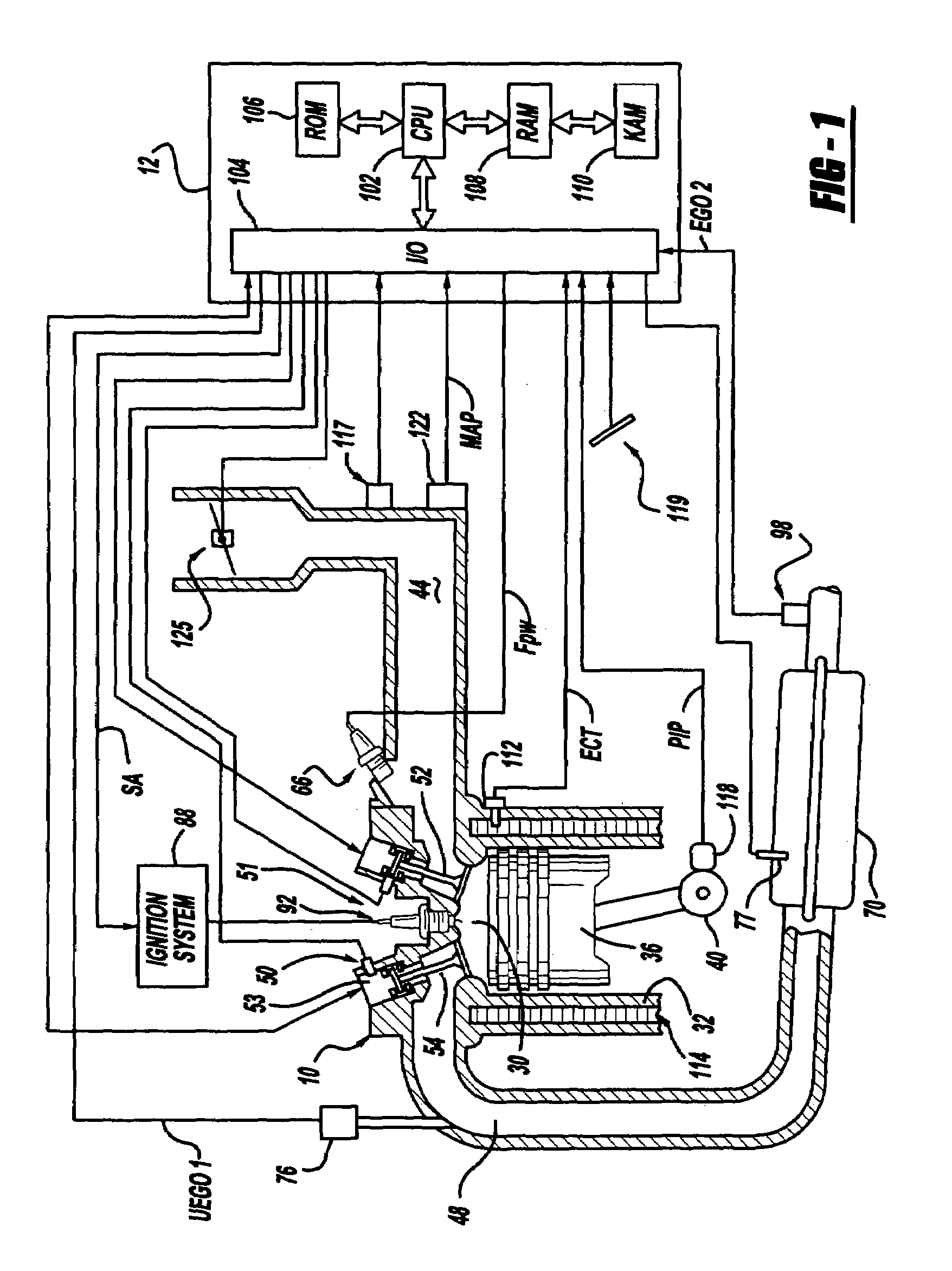

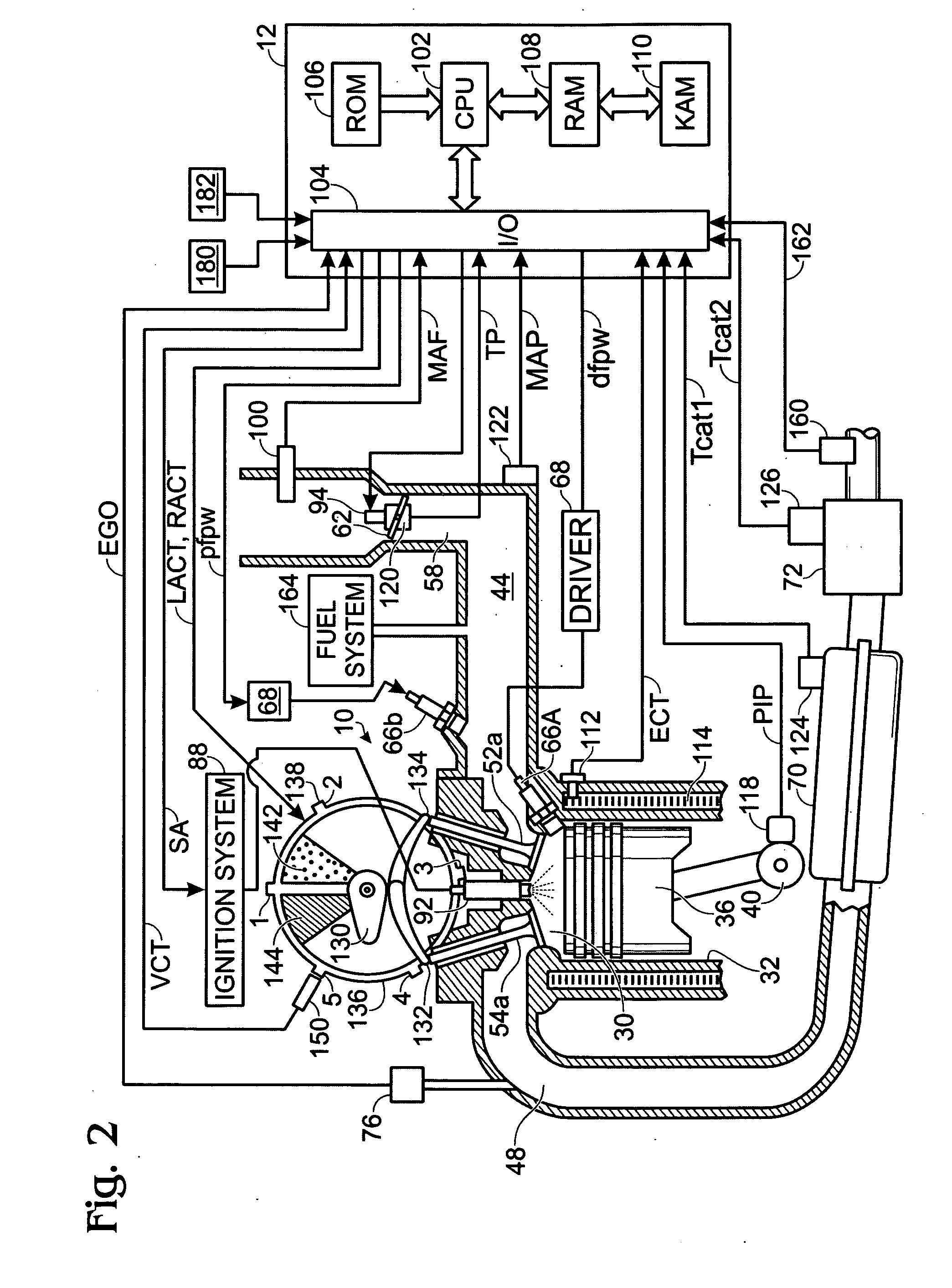

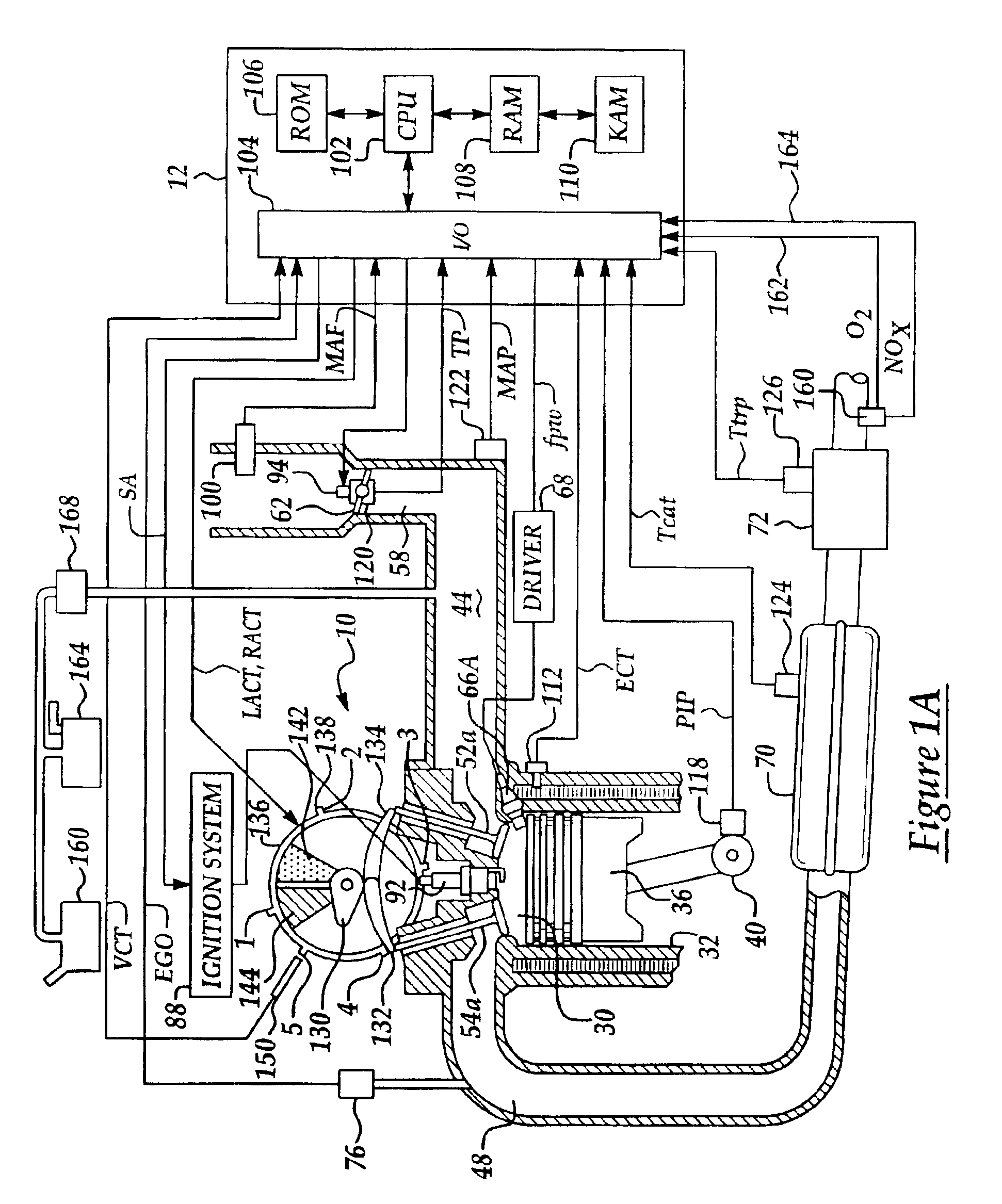

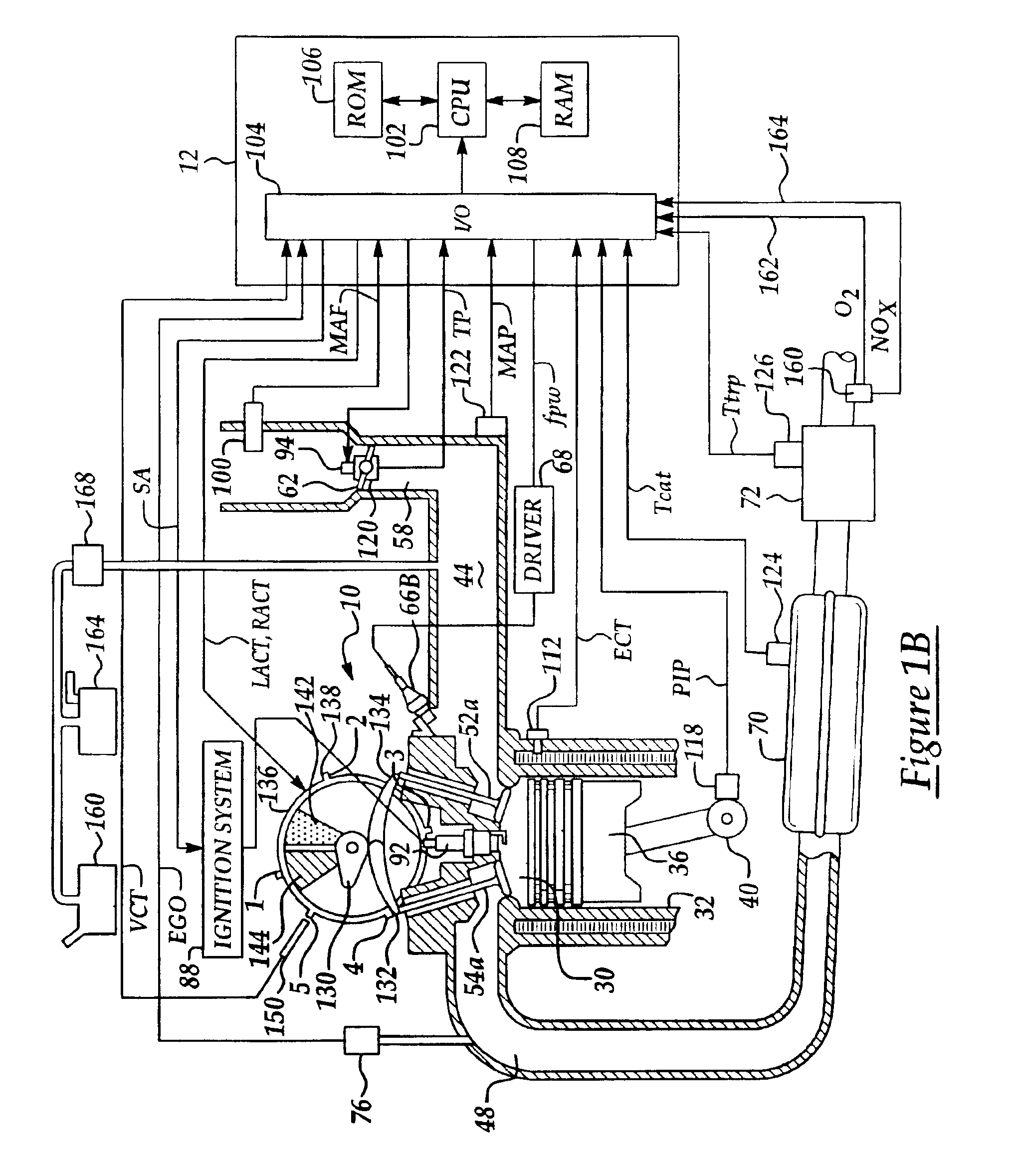

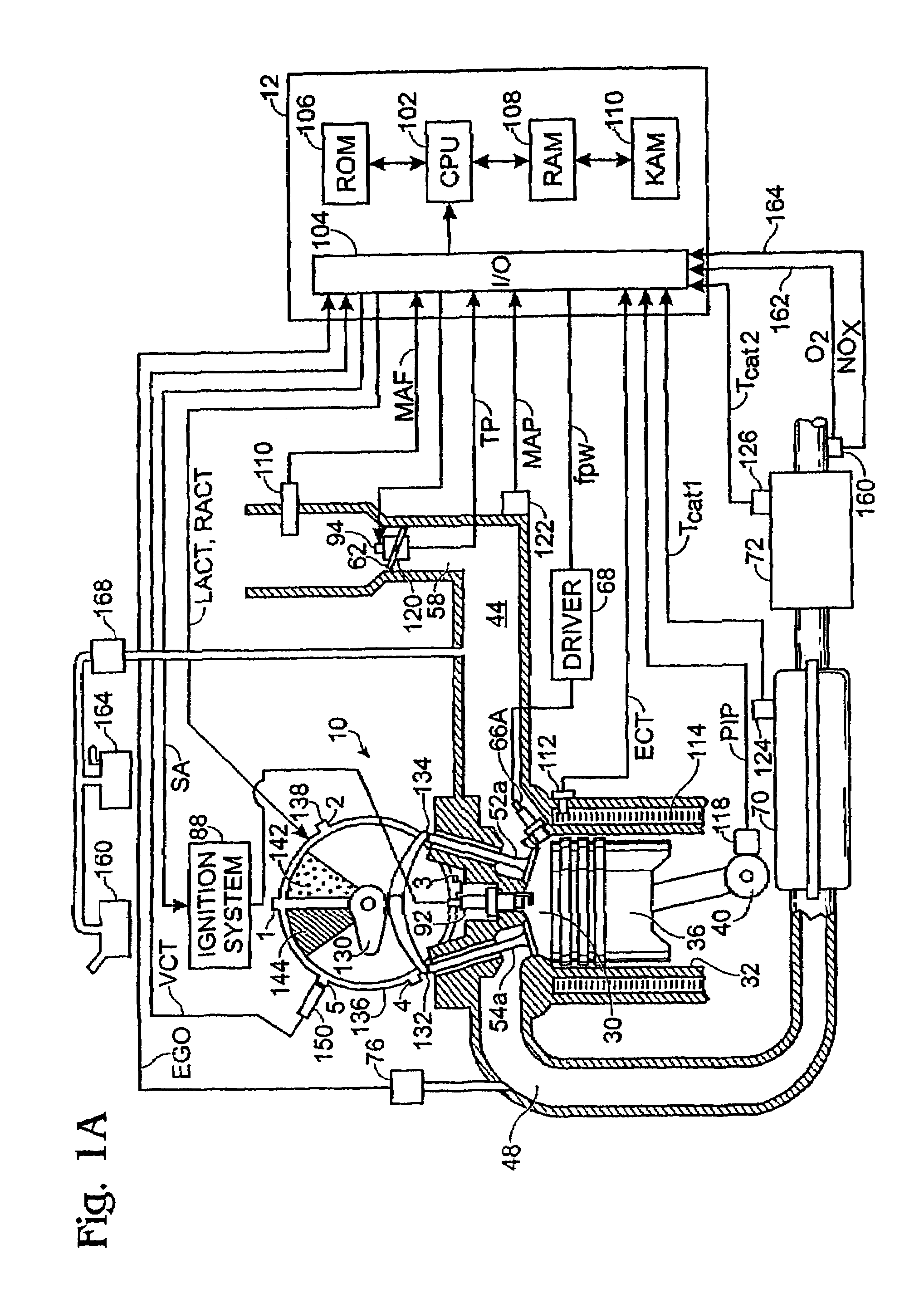

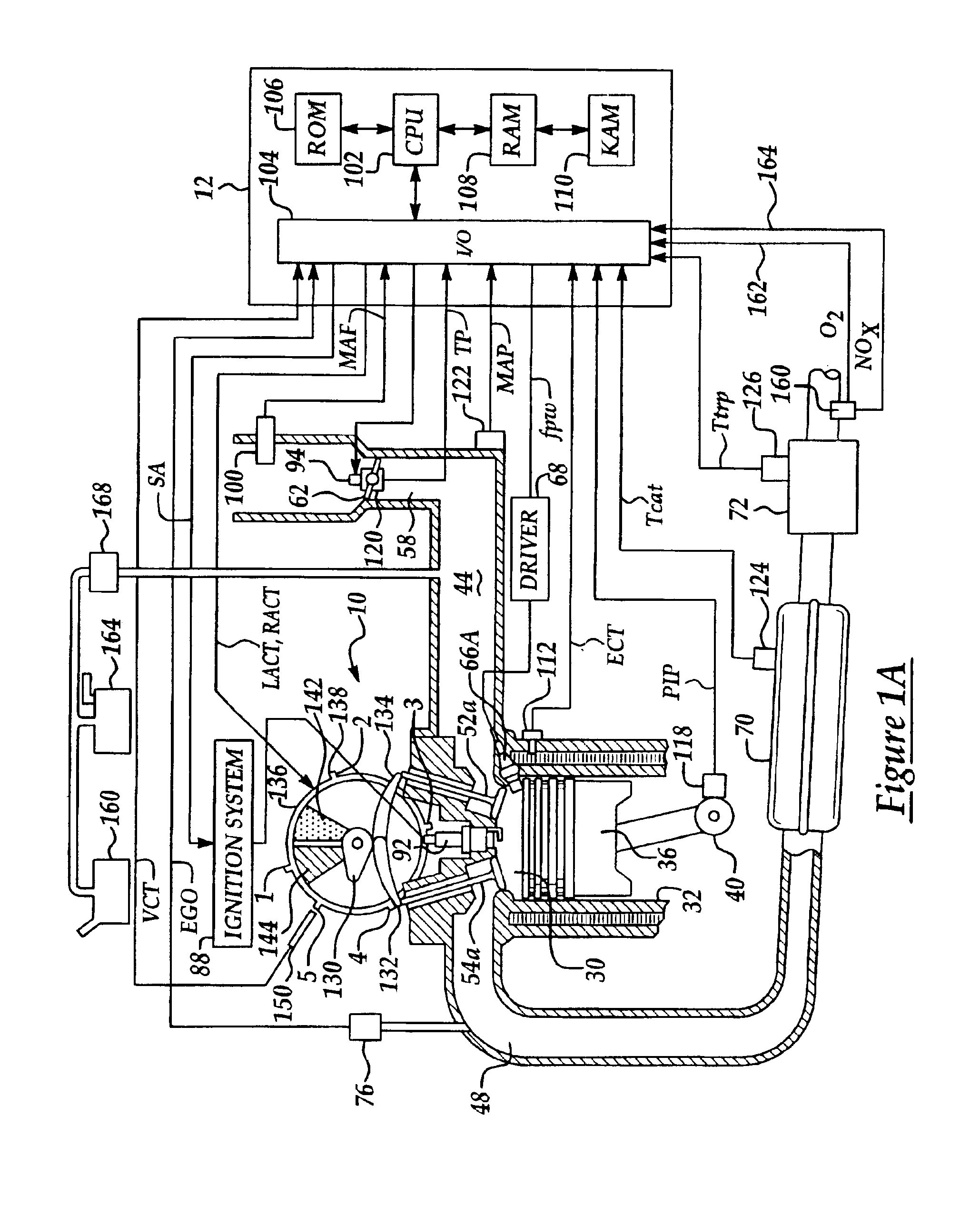

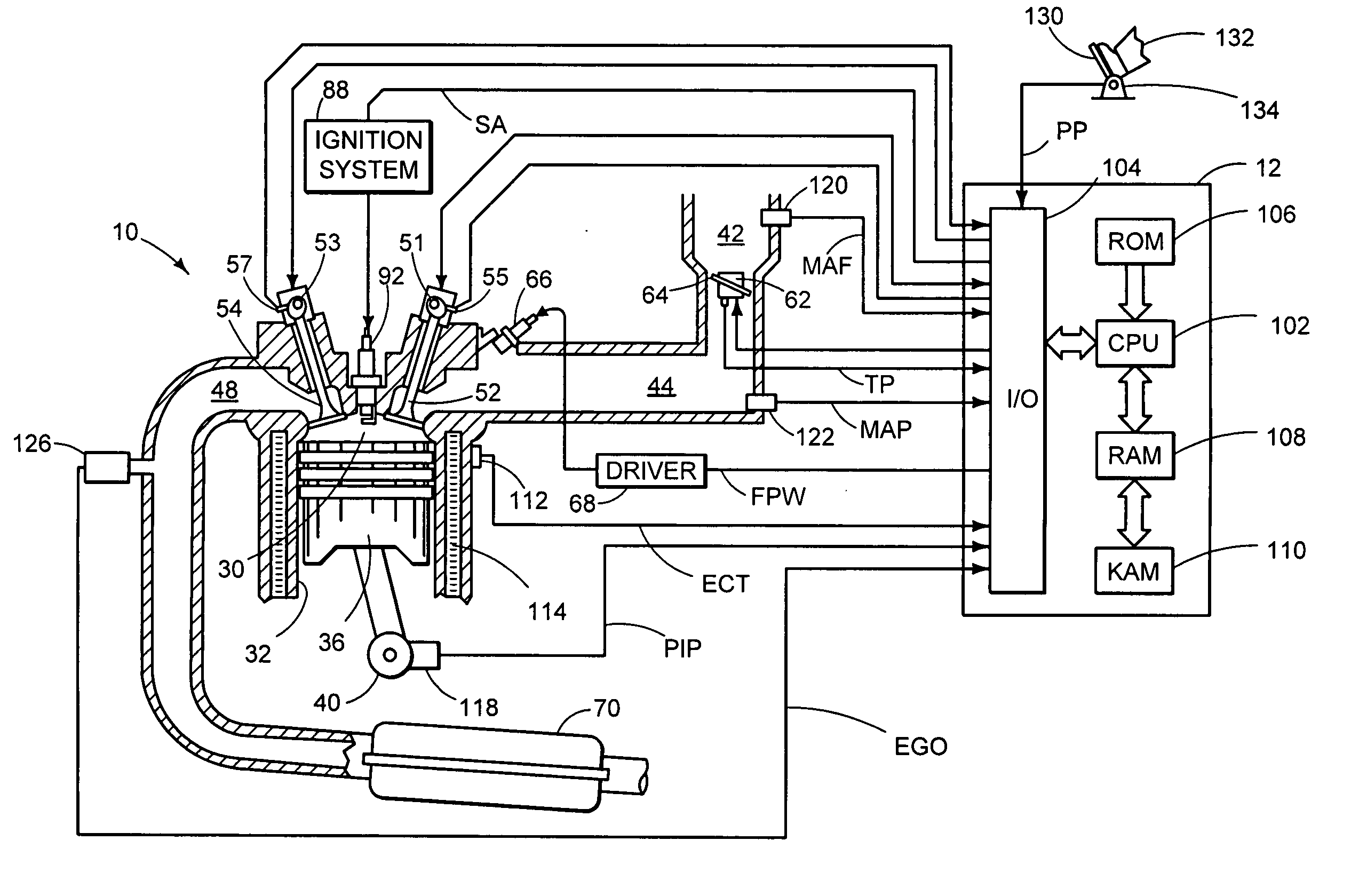

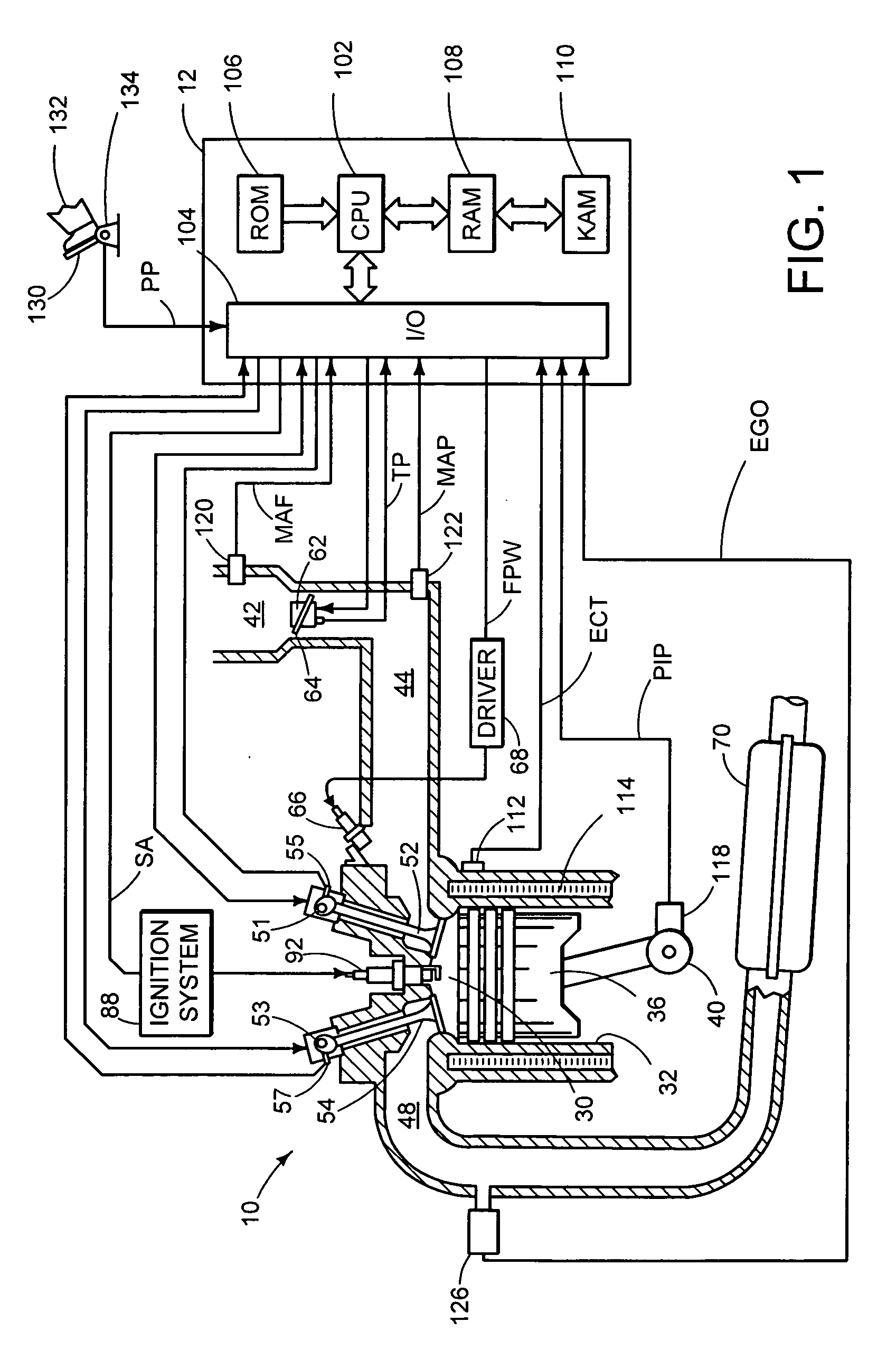

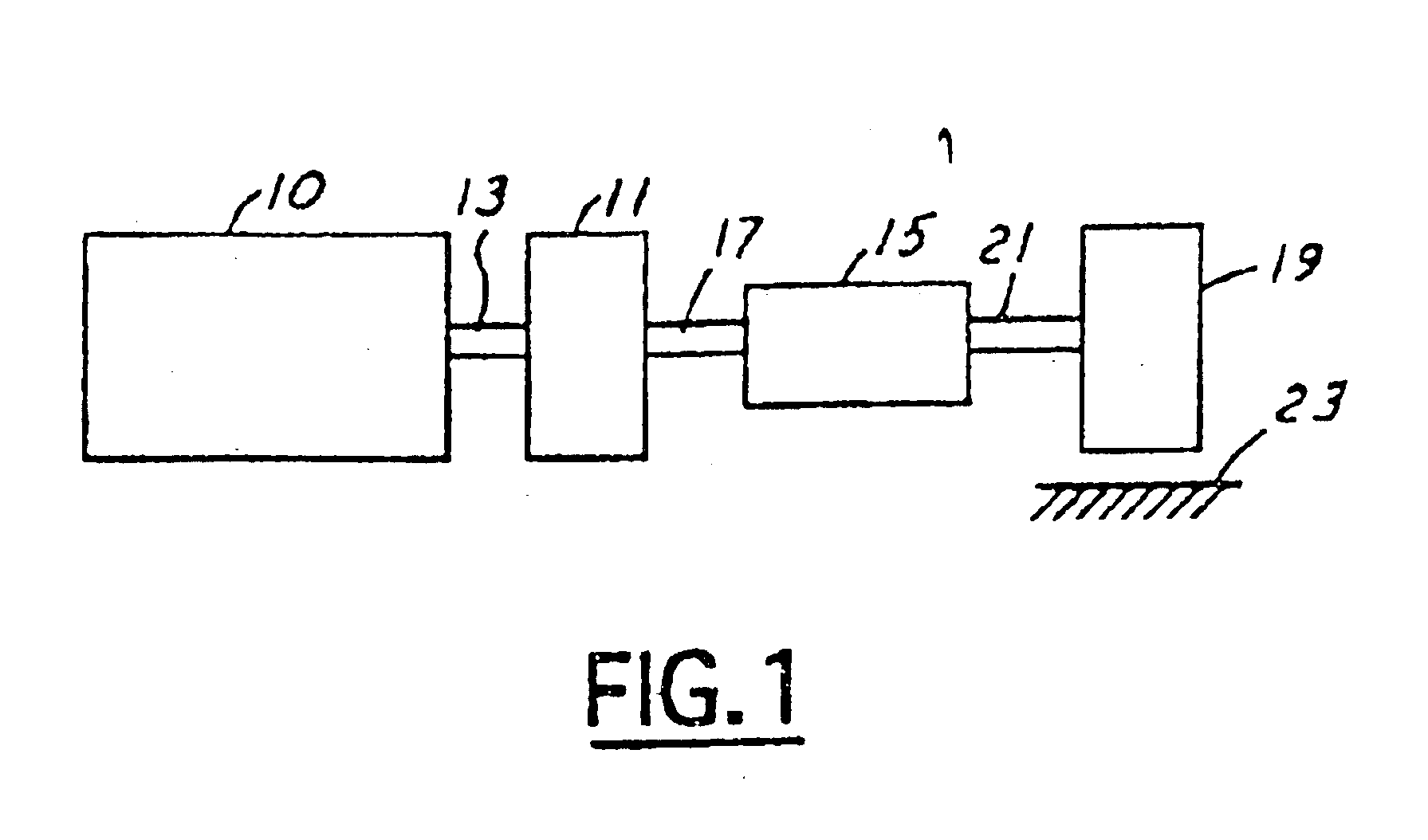

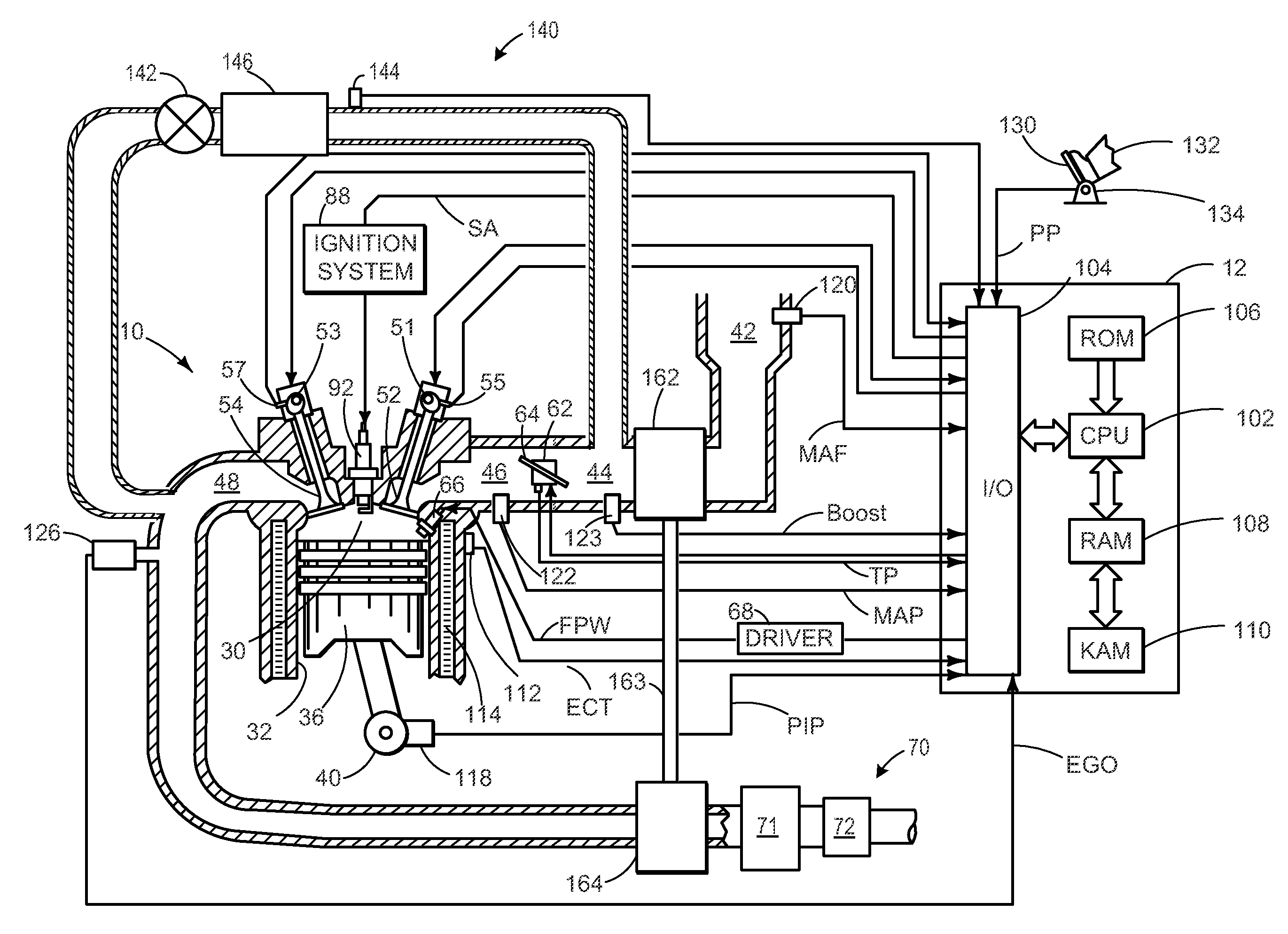

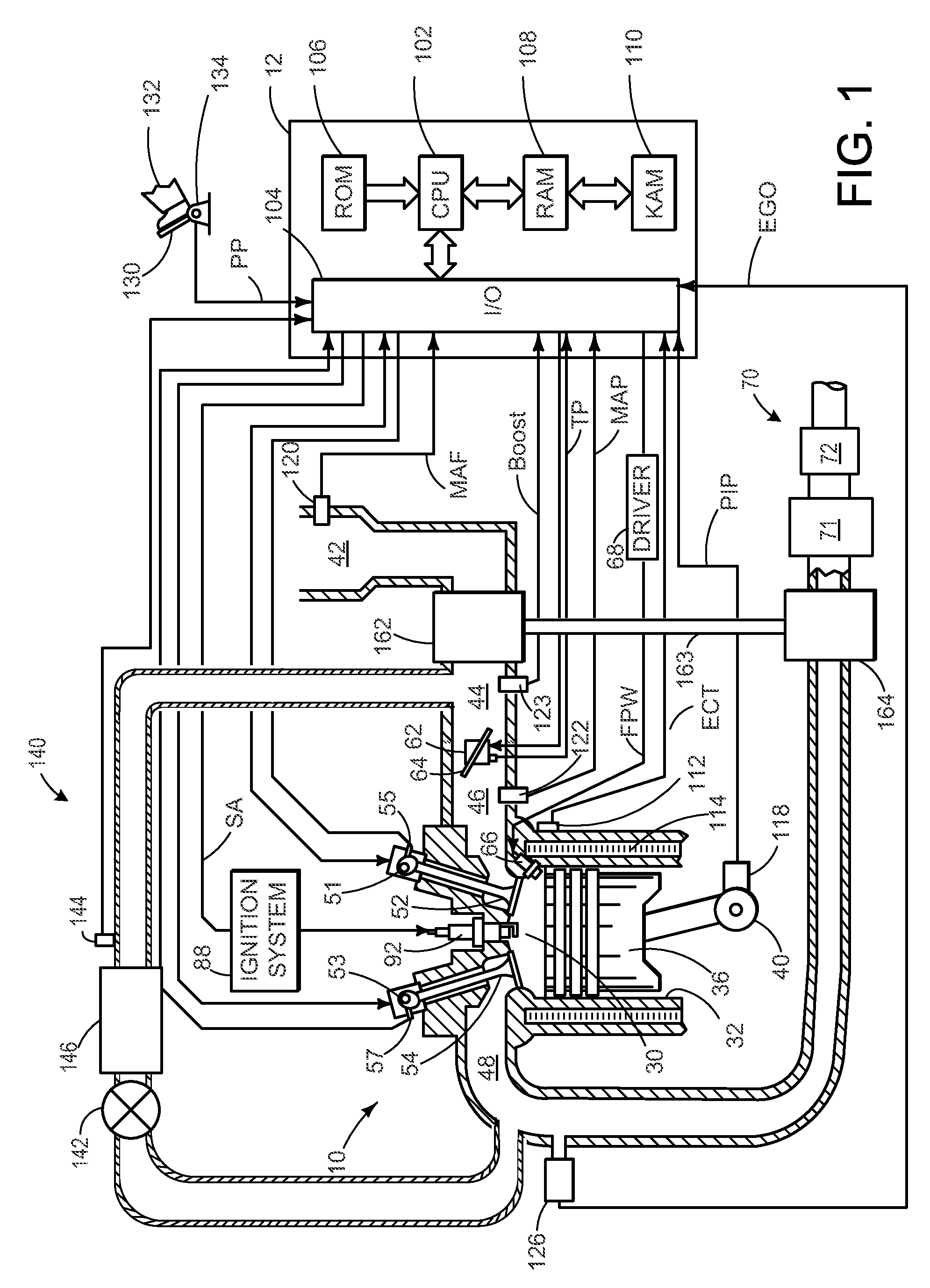

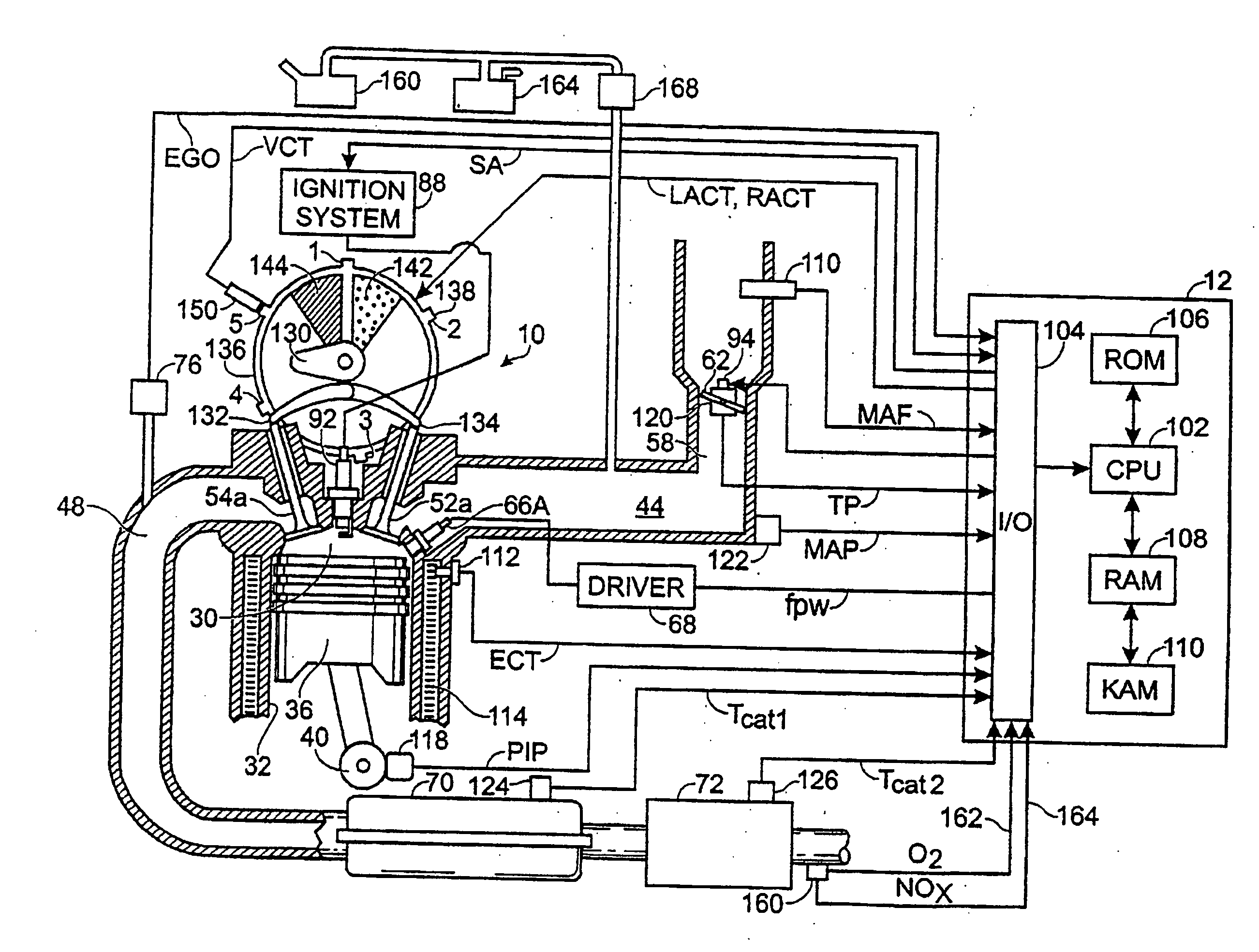

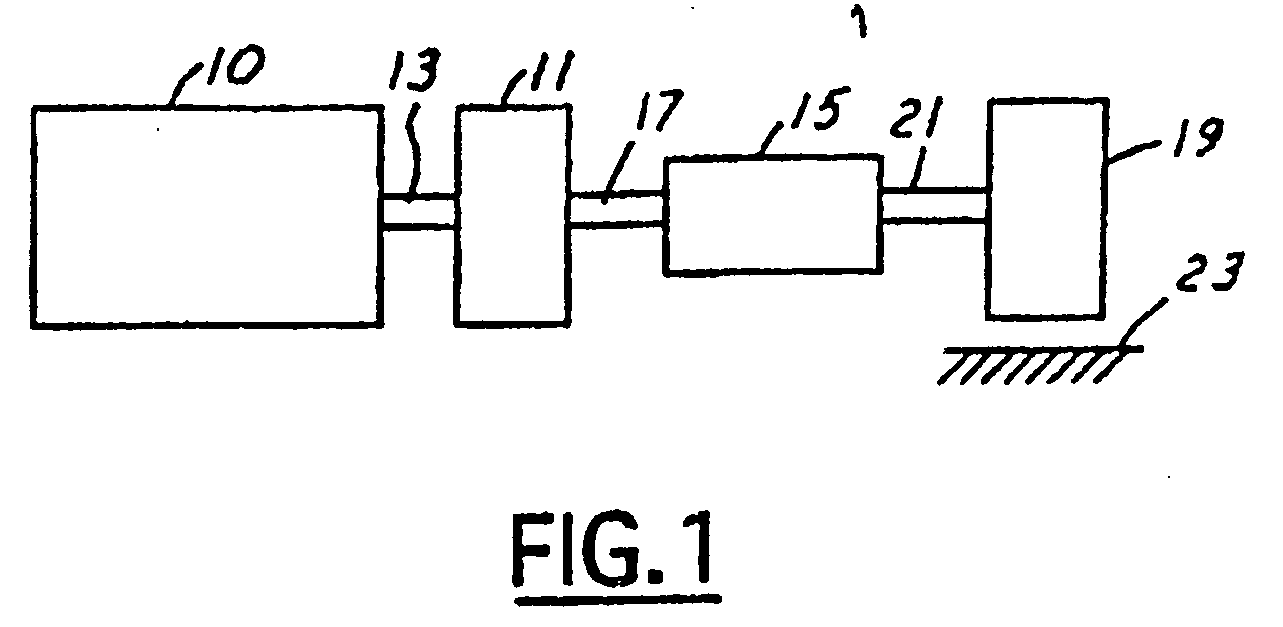

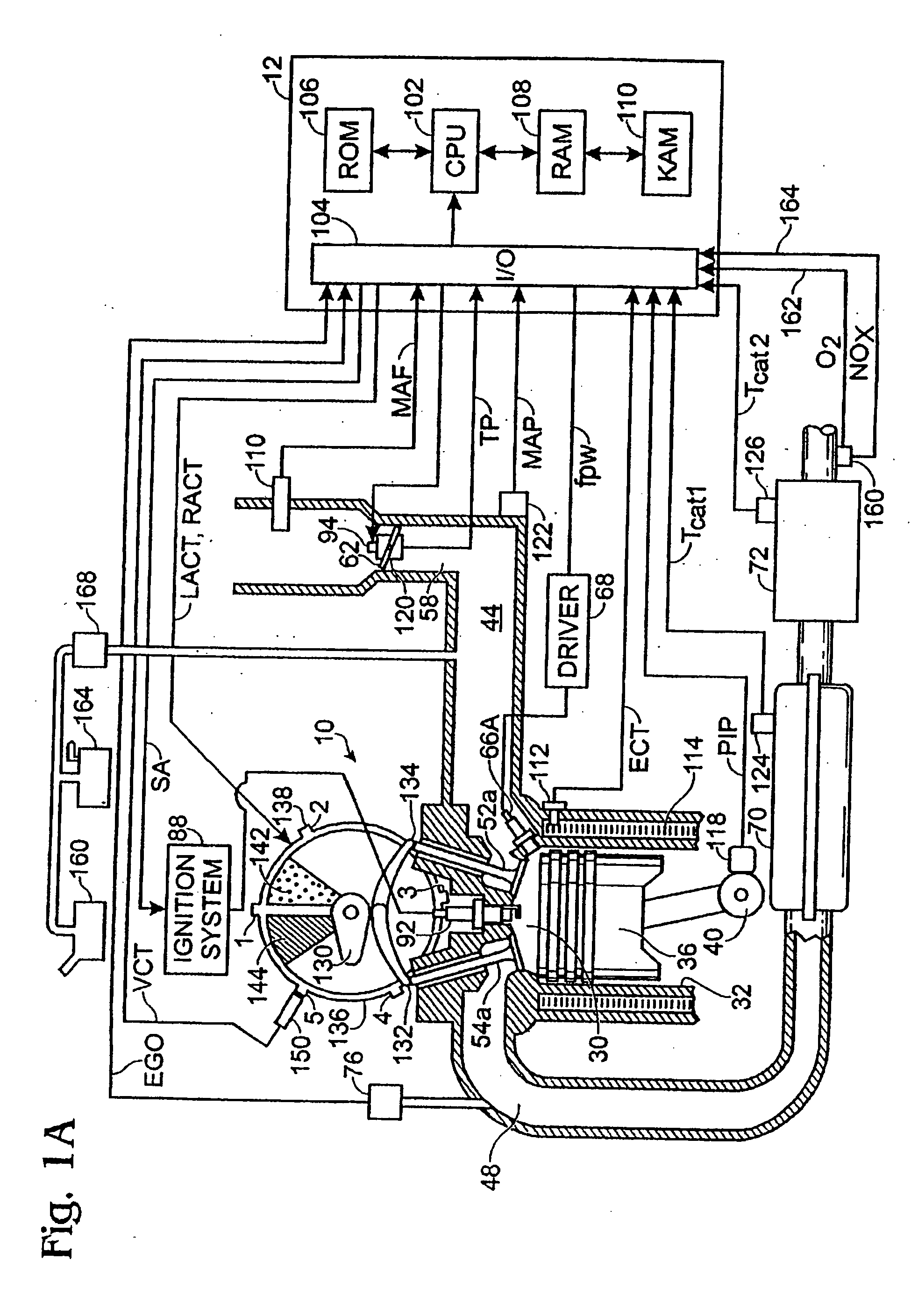

Engine system and method accounting for engine misfire

ActiveUS7086386B2Reducing engine pumping lossesMore efficientCombustion enginesOutput powerSystems designFuel vapor

Various systems and methods are disclosed for carrying out combustion in a fuel-cut operation in some or all of the engine cylinders of a vehicle. Further, various subsystems are considered, such as fuel vapor purging, air-fuel ratio control, engine torque control, catalyst design, and exhaust system design.

Owner:FORD GLOBAL TECH LLC

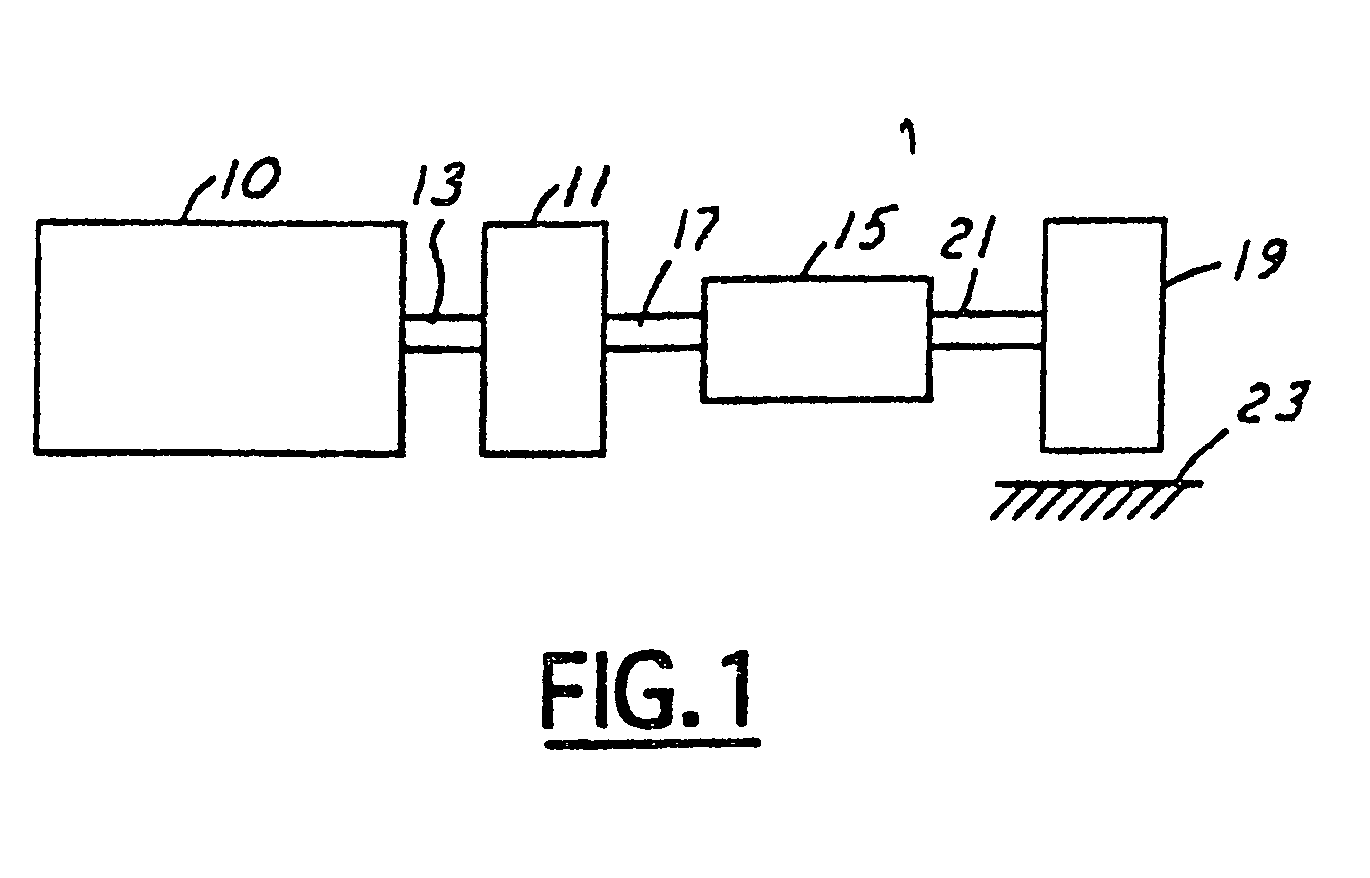

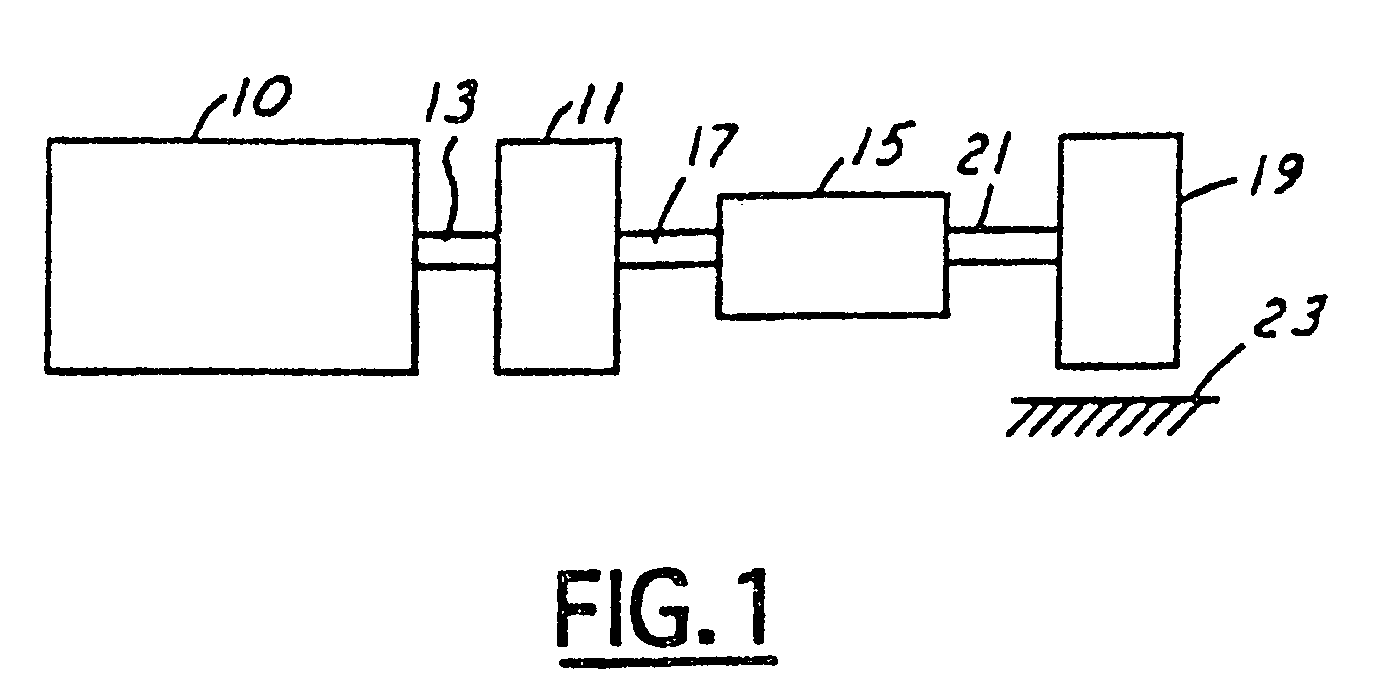

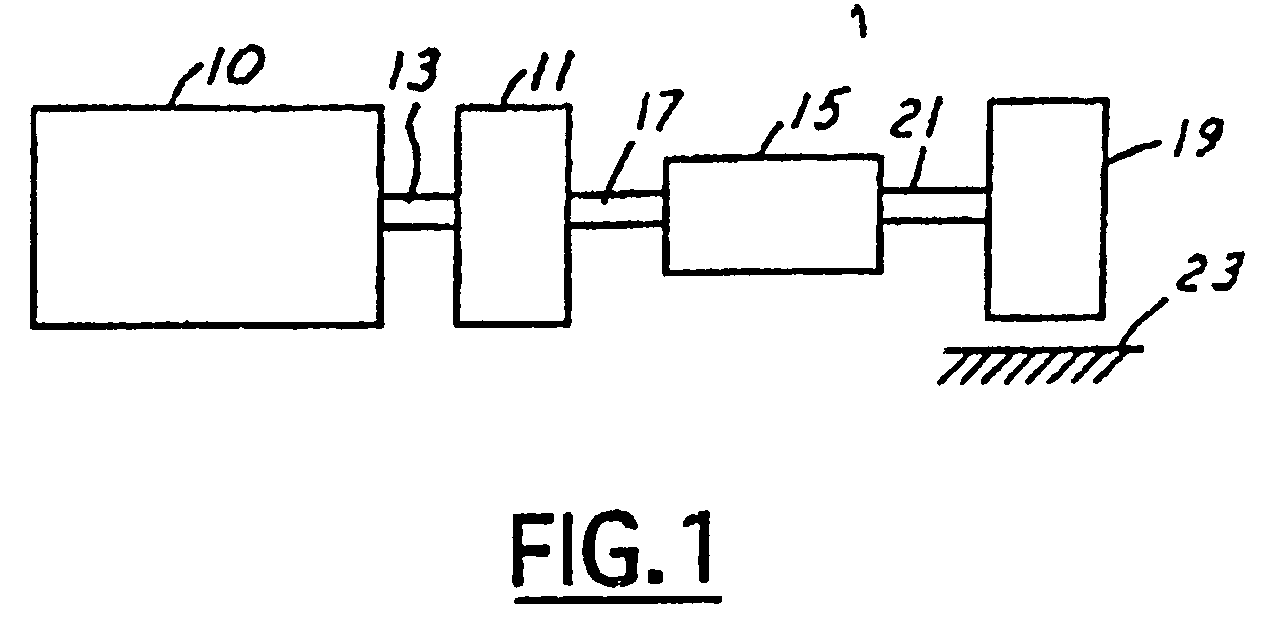

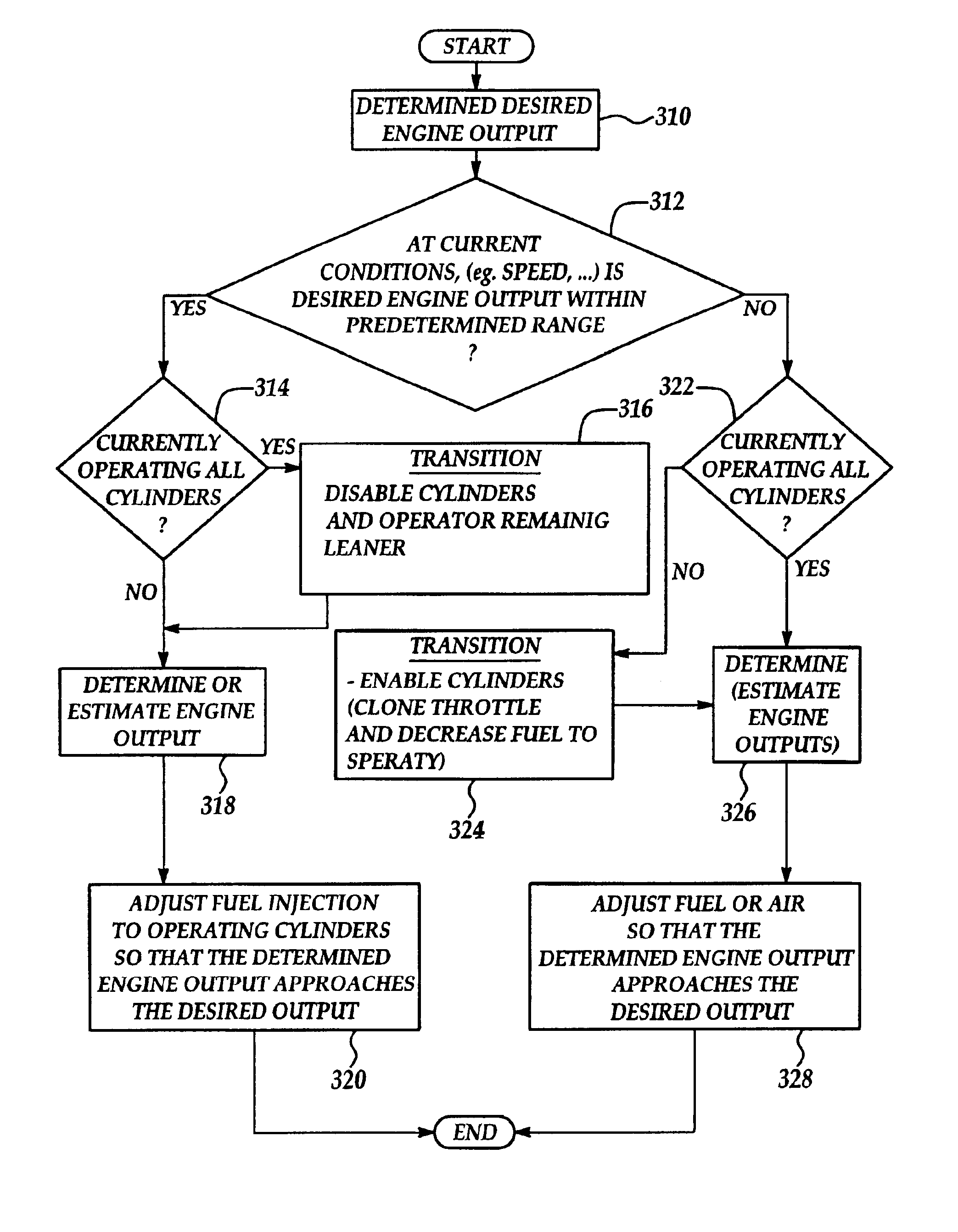

Engine system and method with cylinder deactivation

ActiveUS6978204B2Increase varietyEasy to controlElectrical controlInternal combustion piston enginesSystems designFuel vapor

Various systems and methods are disclosed for carrying out combustion in a fuel-cut operation in some or all of the engine cylinders of a vehicle. Further, various subsystems are considered, such as fuel vapor purging, air-fuel ratio control, engine torque control, catalyst design, and exhaust system design.

Owner:FORD GLOBAL TECH LLC

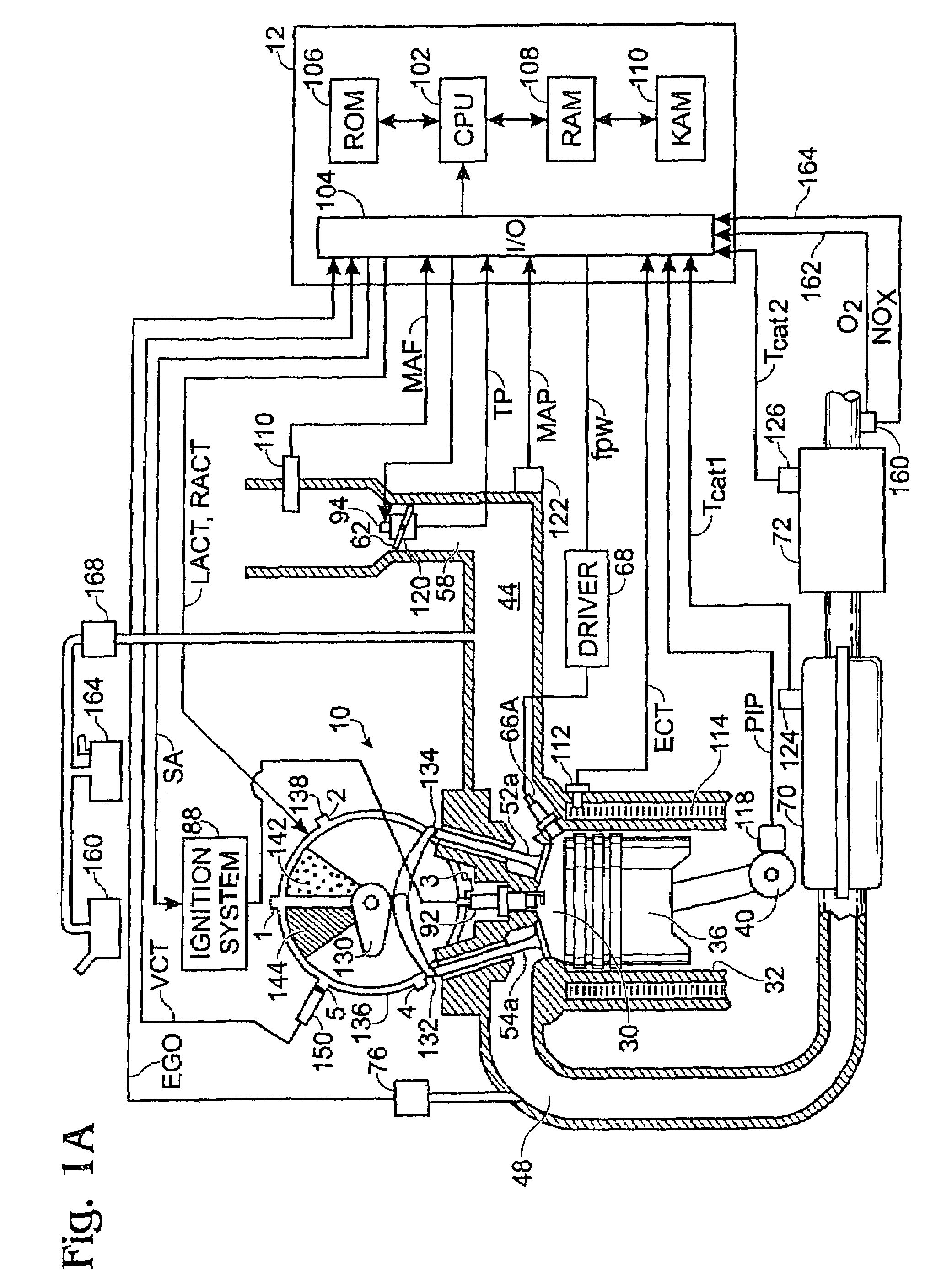

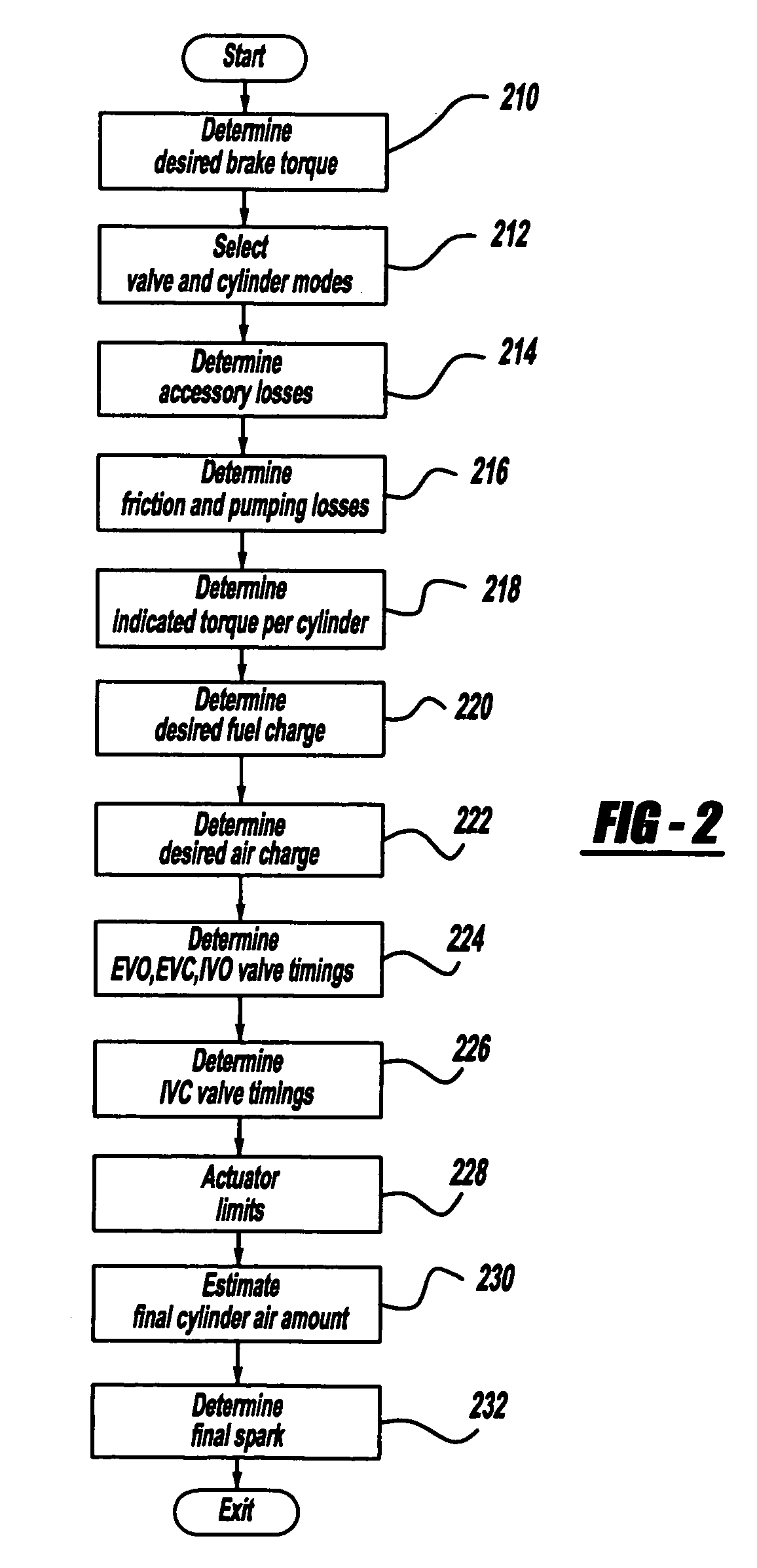

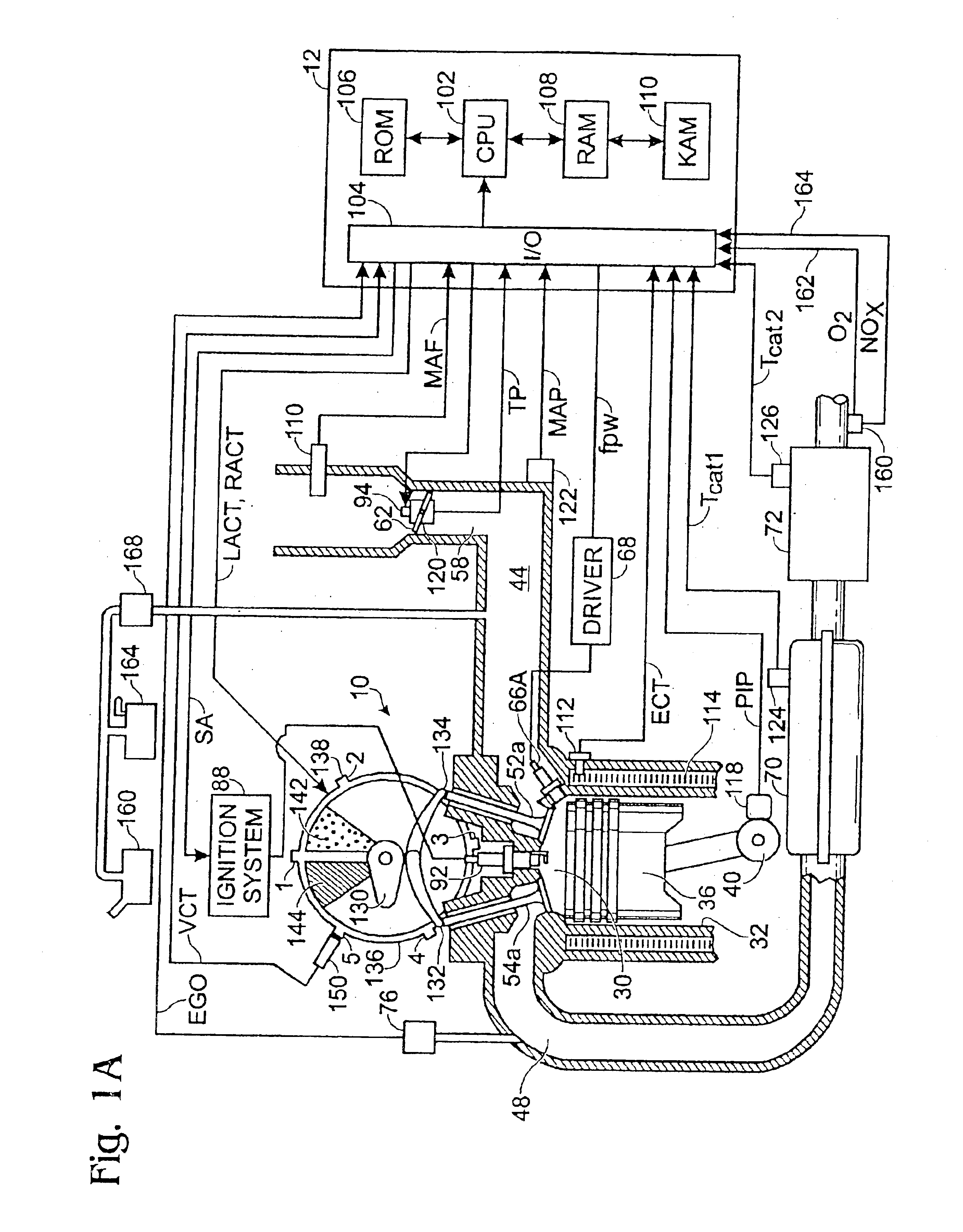

Engine air-fuel control for an engine with valves that may be deactivated

ActiveUS7032581B2Weaken influenceEasy to controlElectrical controlInternal combustion piston enginesEngine valveAir–fuel ratio

A system and method to control engine valve timing to improve air-fuel control in an engine with valves that may be deactivated. Valves that may be deactivated are controlled in a manner to improve detection of individual cylinder air-fuel ratios.

Owner:FORD GLOBAL TECH LLC

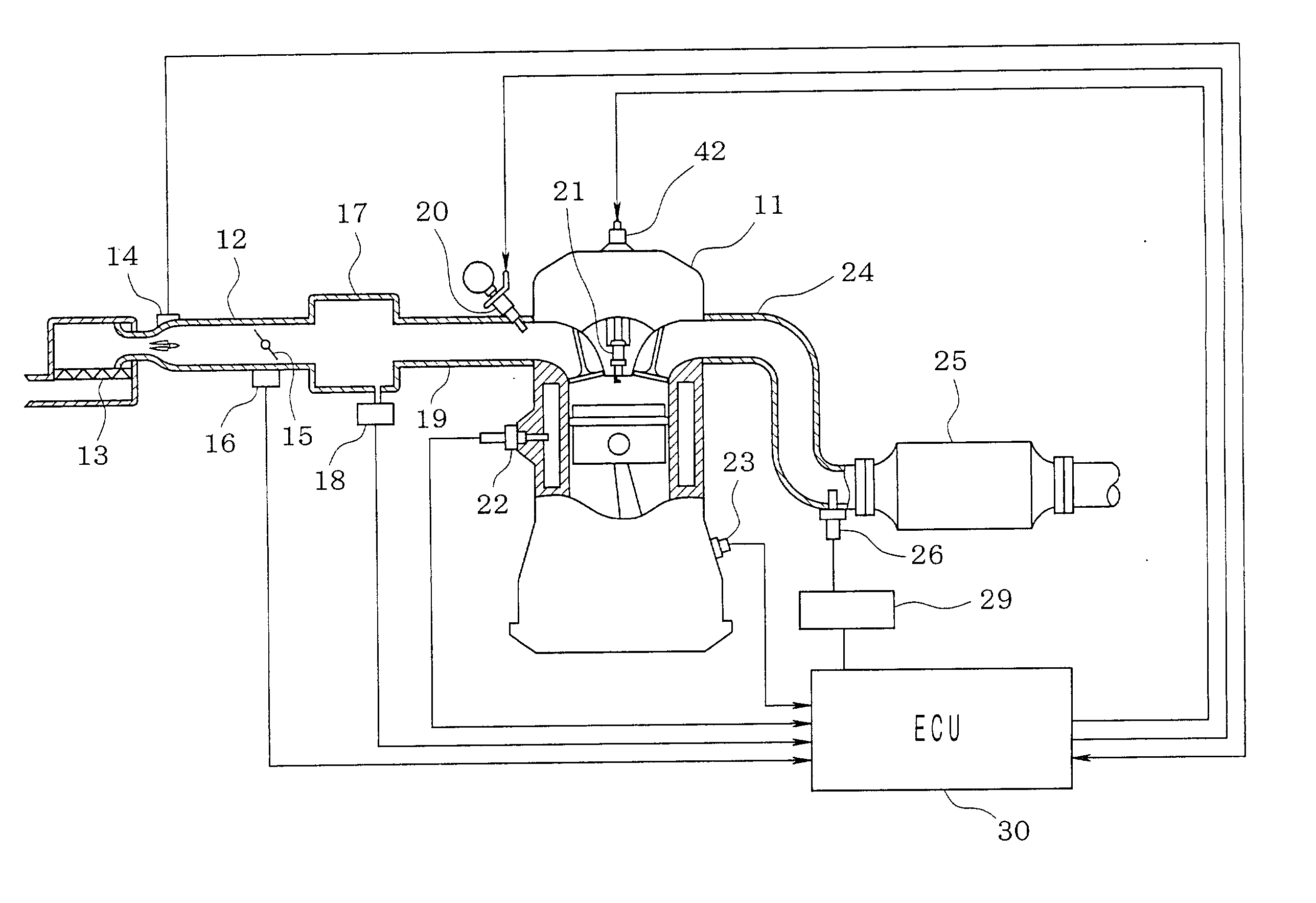

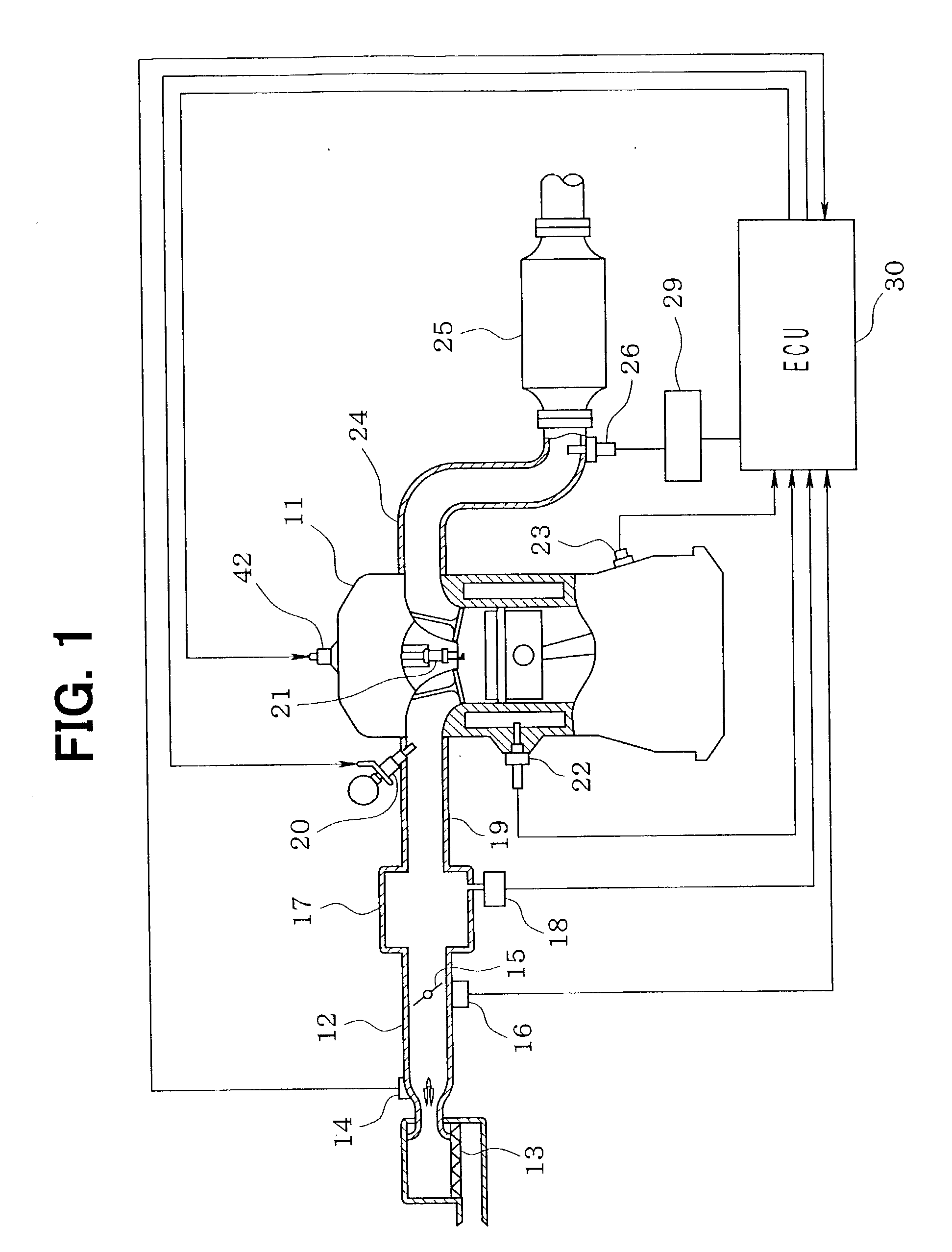

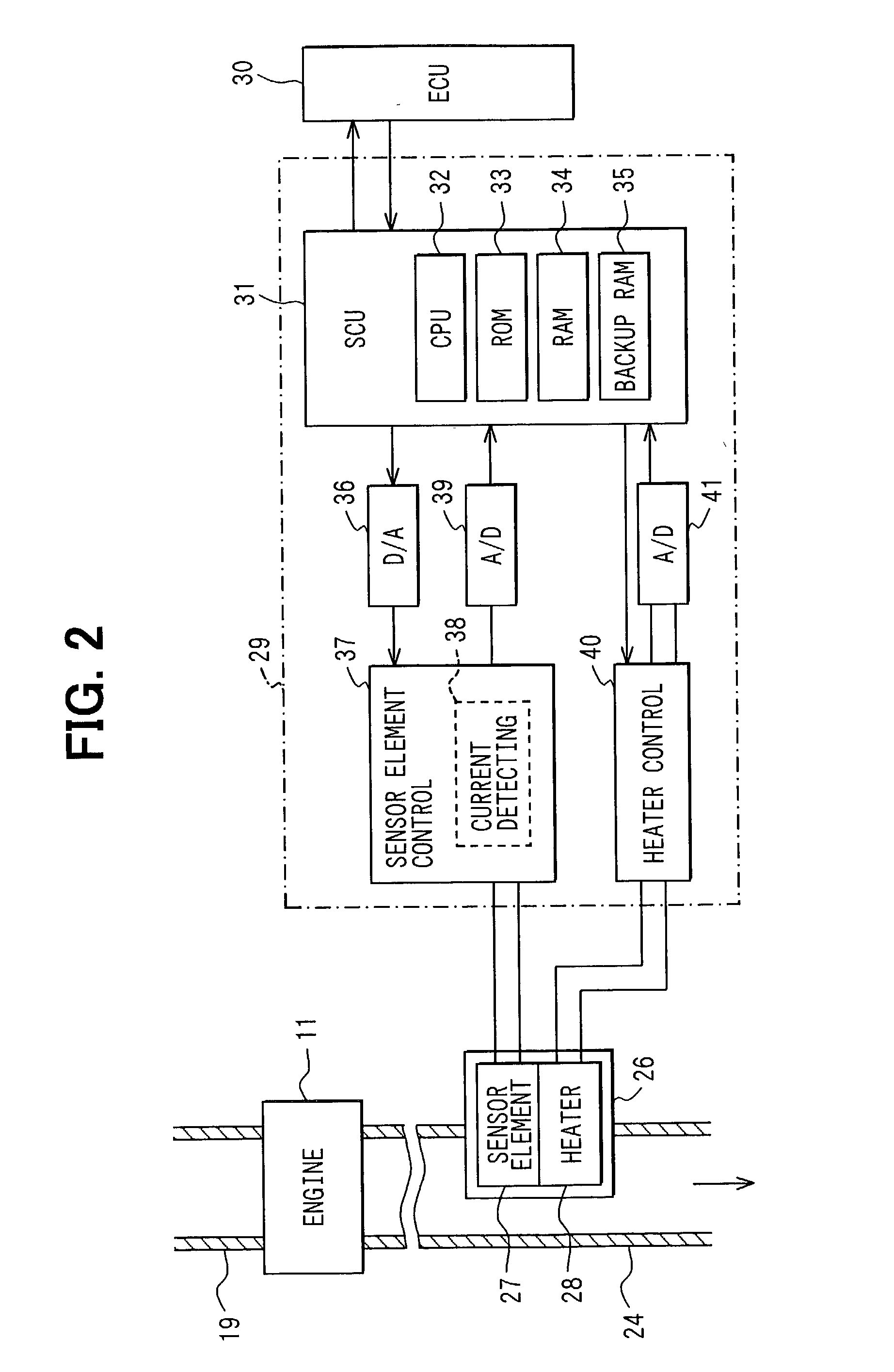

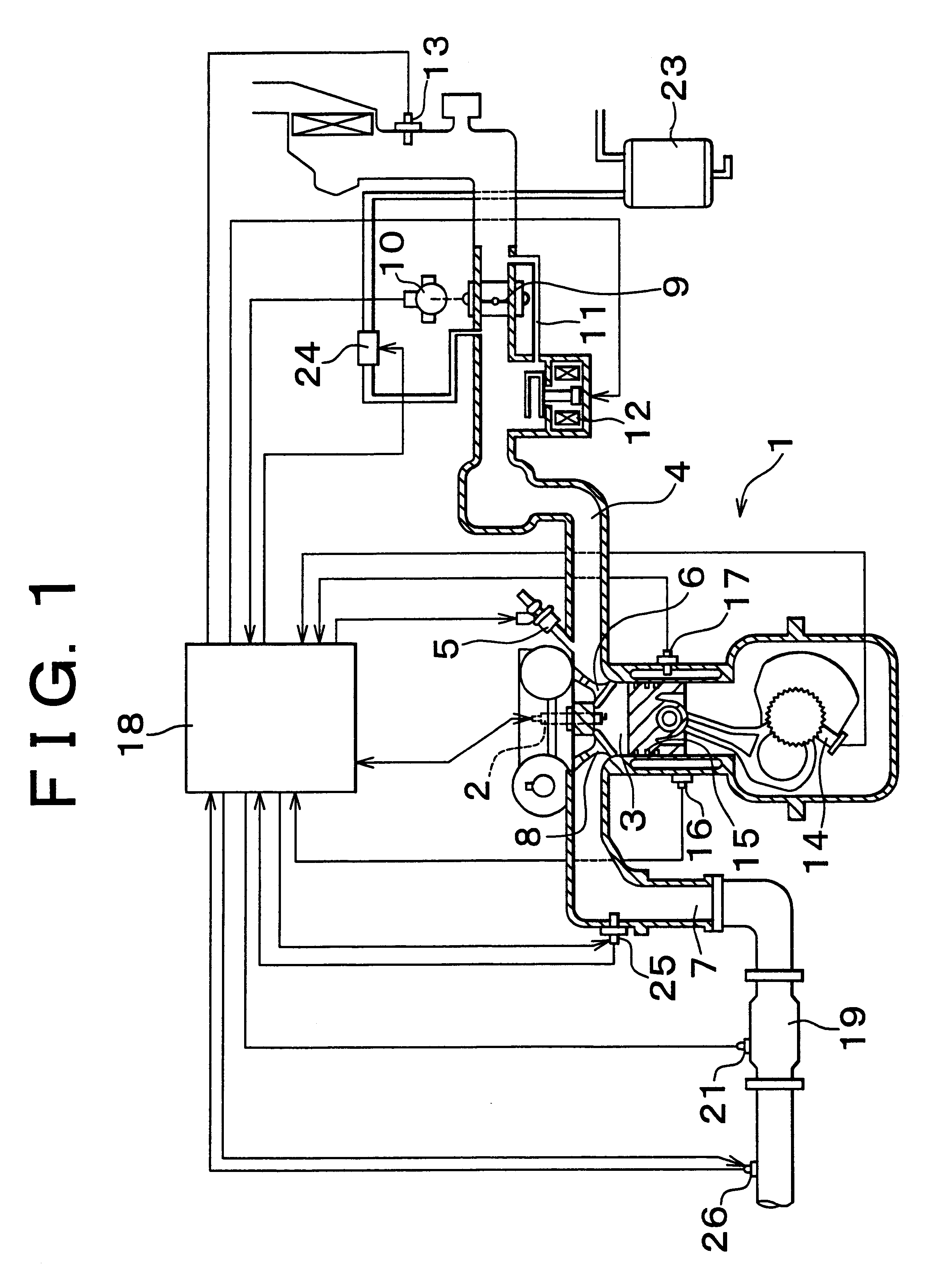

Emission control system with catalyst warm-up speeding control

InactiveUS20030070423A1High precisionElectrical controlInternal combustion piston enginesAir volumeControl system

An emission control system has a catalyst and a sensor responding to a component of exhaust gas. In order to speed warming up the catalyst, the emission control system increases the amount of heat dissipated by exhaust gas. A diagnosis of the emission control system is carried out by determining whether the amount of heat dissipated by exhaust gas is sufficient or insufficient. The amount of heat dissipated by exhaust gas is represented by the length of time to an activated state of the sensor. In the diagnosis, the amount of heat generated by a heater provided in the sensor is taken into consideration. The diagnosis can also be carried out before and after the warming up the catalyst. The heater can also be deactivated. Detection of an abnormality of a secondary air control system can be based on a component of exhaust gas. If the amount of heat dissipated by exhaust gas is found insufficient, additional control can be executed. The amount of heat dissipated by exhaust gas can also be represented by an intake air volume and an air-fuel ratio.

Owner:DENSO CORP

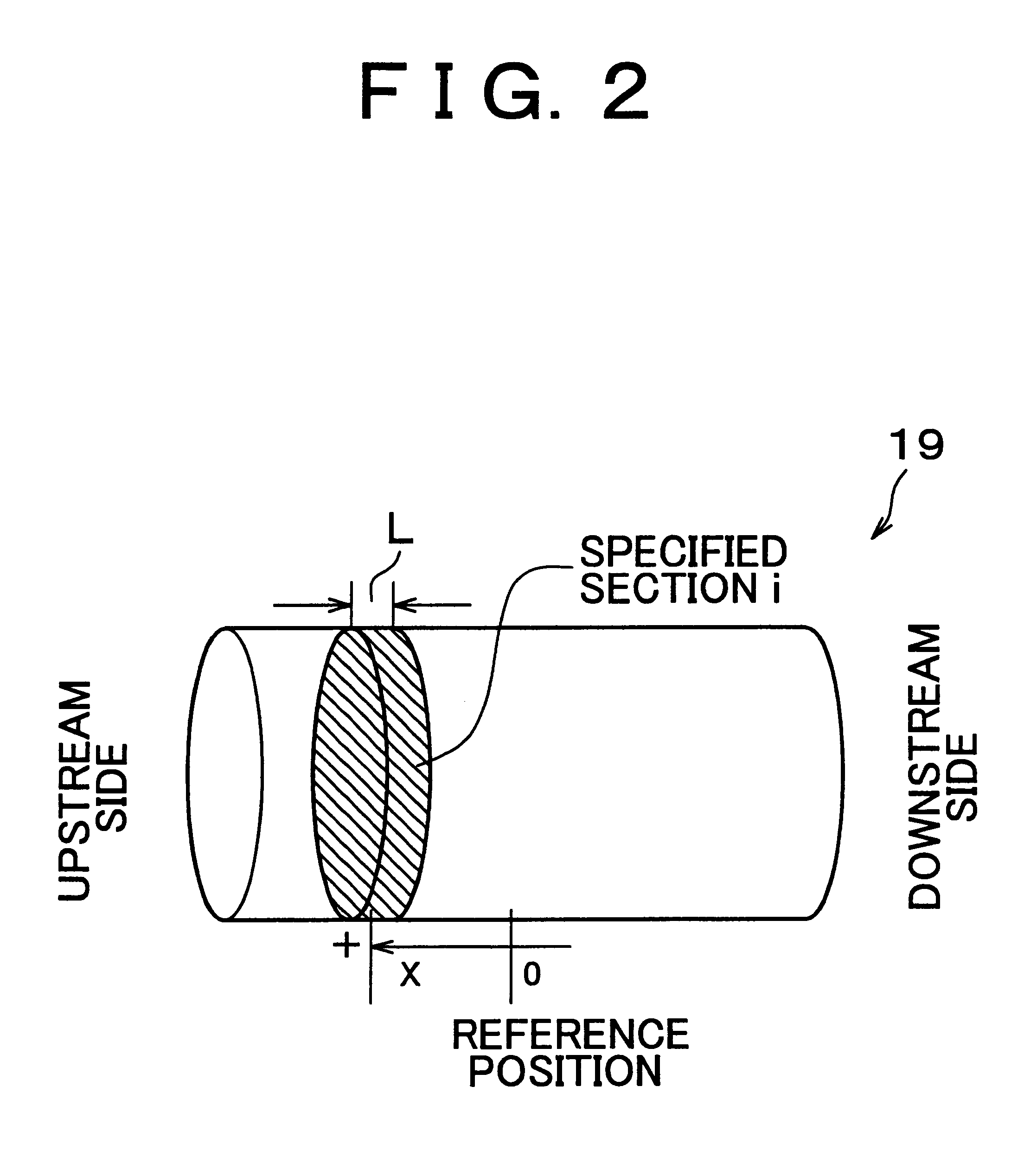

Air-fuel ratio control system for internal combustion engine and control method therof

An air-fuel ratio control system for an internal combustion engine estimates an oxygen storage amount of a catalyst based on a record of an oxygen storage amount, and controls an air-fuel ratio based on the estimated oxygen storage amount. The catalyst is divided into multiple sections in a flow direction of an exhaust gas, the oxygen storage amount in a specified section is estimated according to a behavior of an exhaust gas on upstream and downstream sides of the respective specified sections, and the air-fuel ratio is controlled based on the estimated oxygen storage amount in the specified section.

Owner:TOYOTA JIDOSHA KK

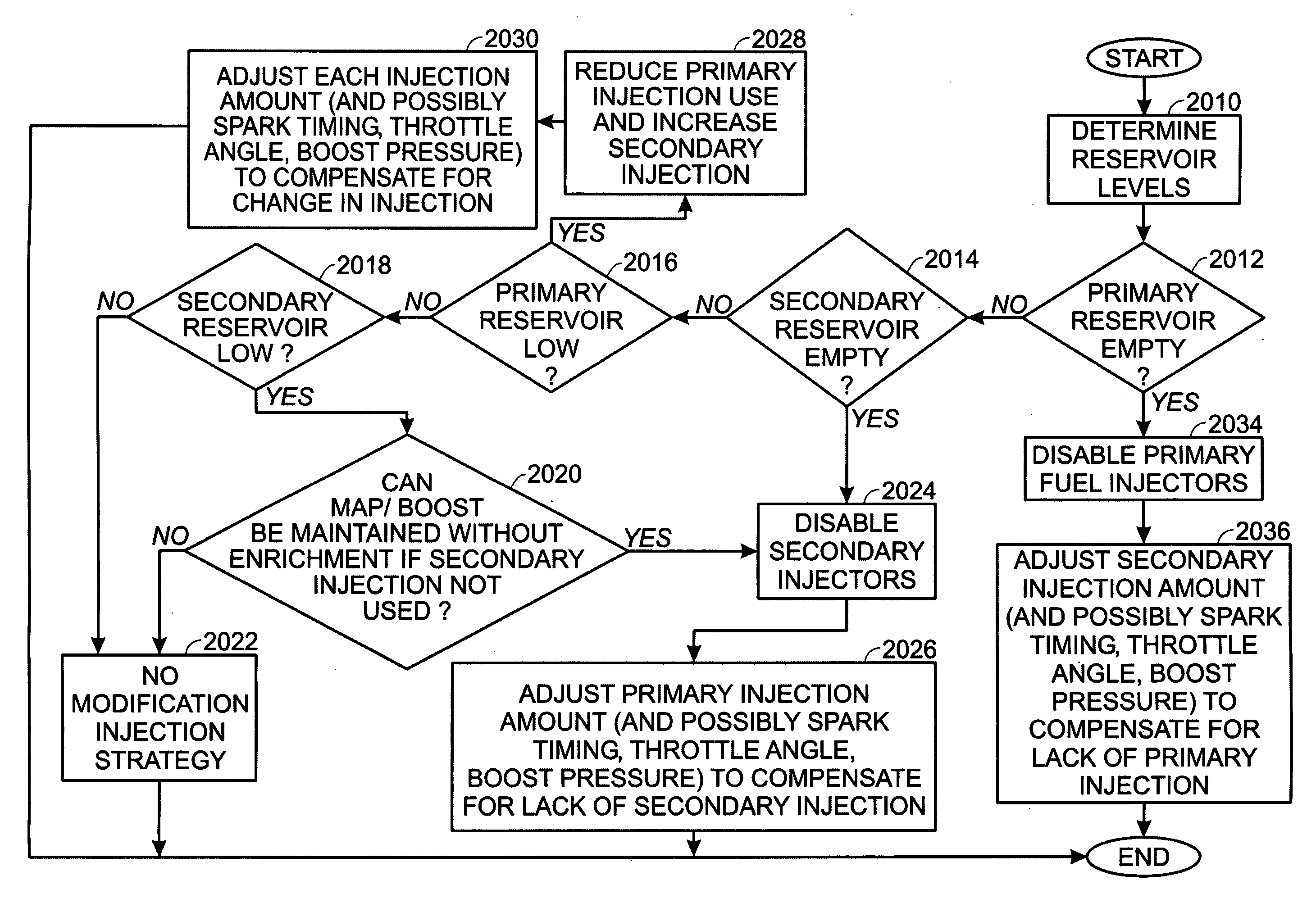

System and method for engine air-fuel ratio control

InactiveUS20070119415A1Improve engine performanceLow costElectrical controlNon-fuel substance addition to fuelOxygen sensorOperant conditioning

A method for operating an engine having a first injector for injecting a first fuel into a cylinder of the engine and a second injector for injection a second fuel into said cylinder of the engine, the engine further having at least an exhaust gas oxygen sensor, the method comprising of varying an amount of said first fuel injection in response to said sensor under a first operating condition, and varying an amount of said second fuel injection in response to said sensor under a second operating condition.

Owner:FORD GLOBAL TECH LLC

EGR system with dedicated EGR cylinders

Improved exhaust gas recirculation system and methods that use one or more of the engine's cylinders as dedicated EGR cylinders. All of the exhaust from the dedicated EGR cylinders is recirculated back to the engine intake. Thus, the EGR rate is constant, but the EGR mass flow may be controlled by adjusting the air-fuel ratio of the dedicated EGR cylinders or by using various variable valve timing techniques.

Owner:SOUTHWEST RES INST

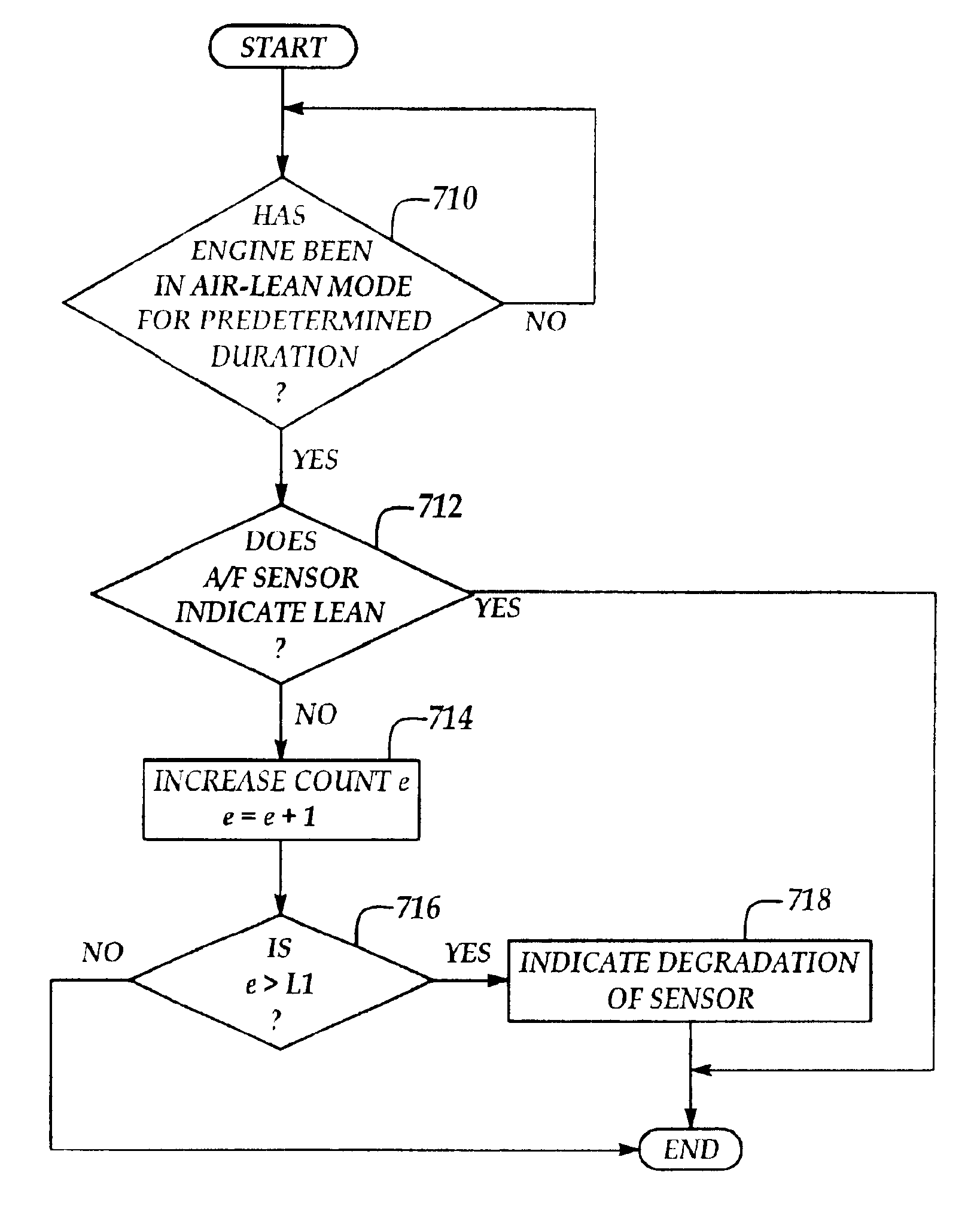

Method for air-fuel ratio sensor diagnosis

InactiveUS6736121B2Avoid false indicationsLow heat generationElectrical controlExhaust apparatusTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, such as after an engine cold start, the method operates an engine with a first group of cylinders having a first ignition timing, and a second group of cylinders having a second ignition timing more retarded than the first group. In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also can change to combusting all cylinders at substantially the same ignition timing under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

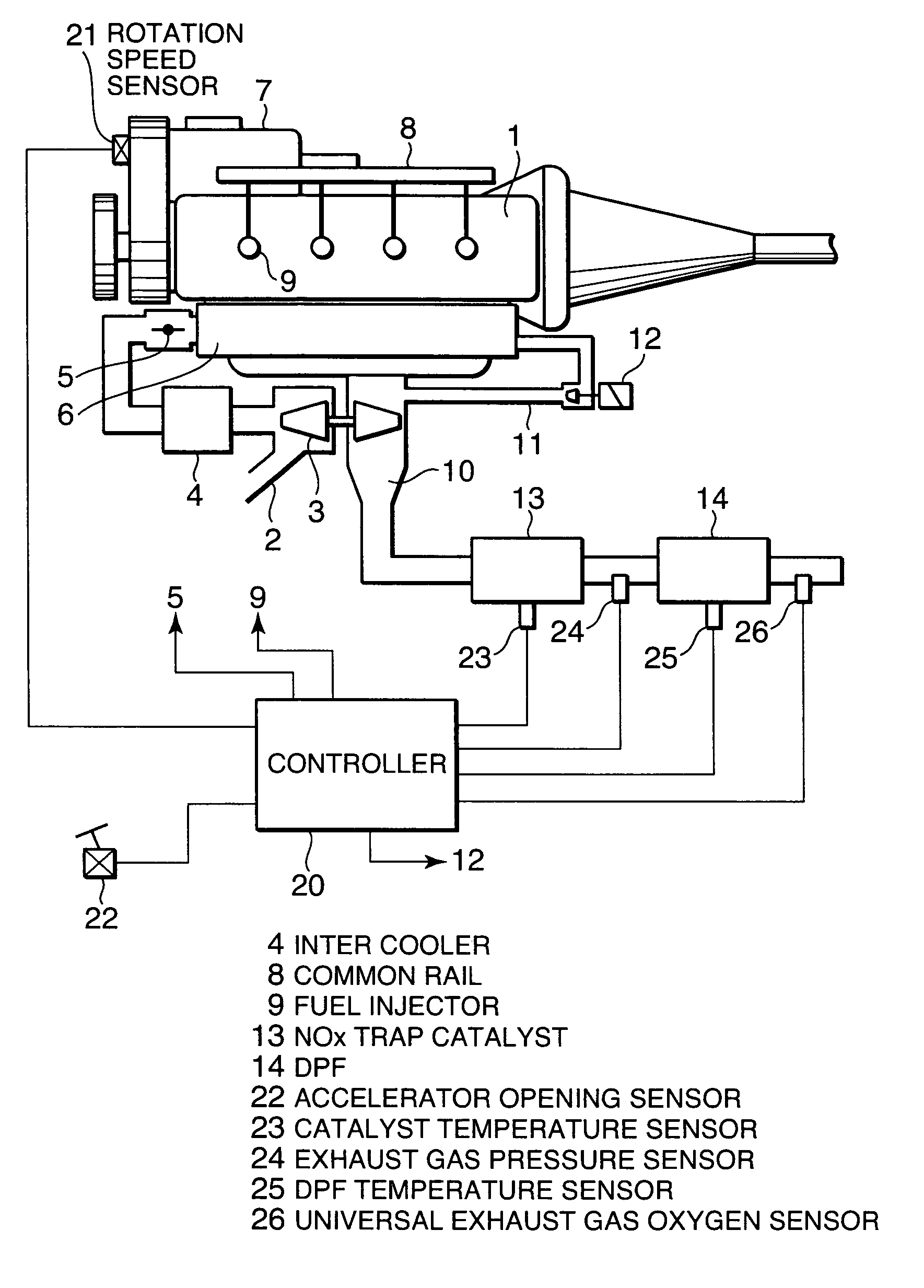

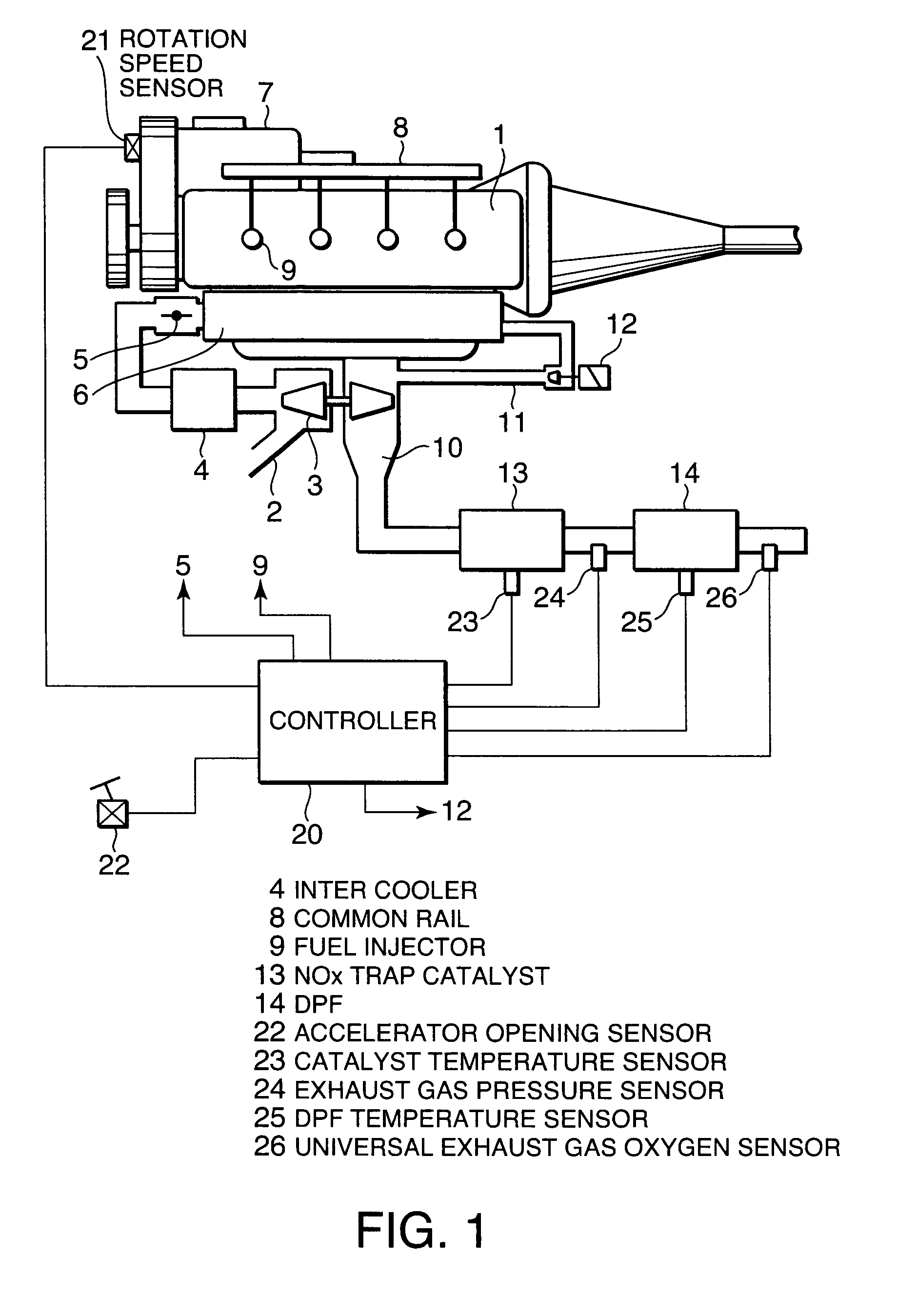

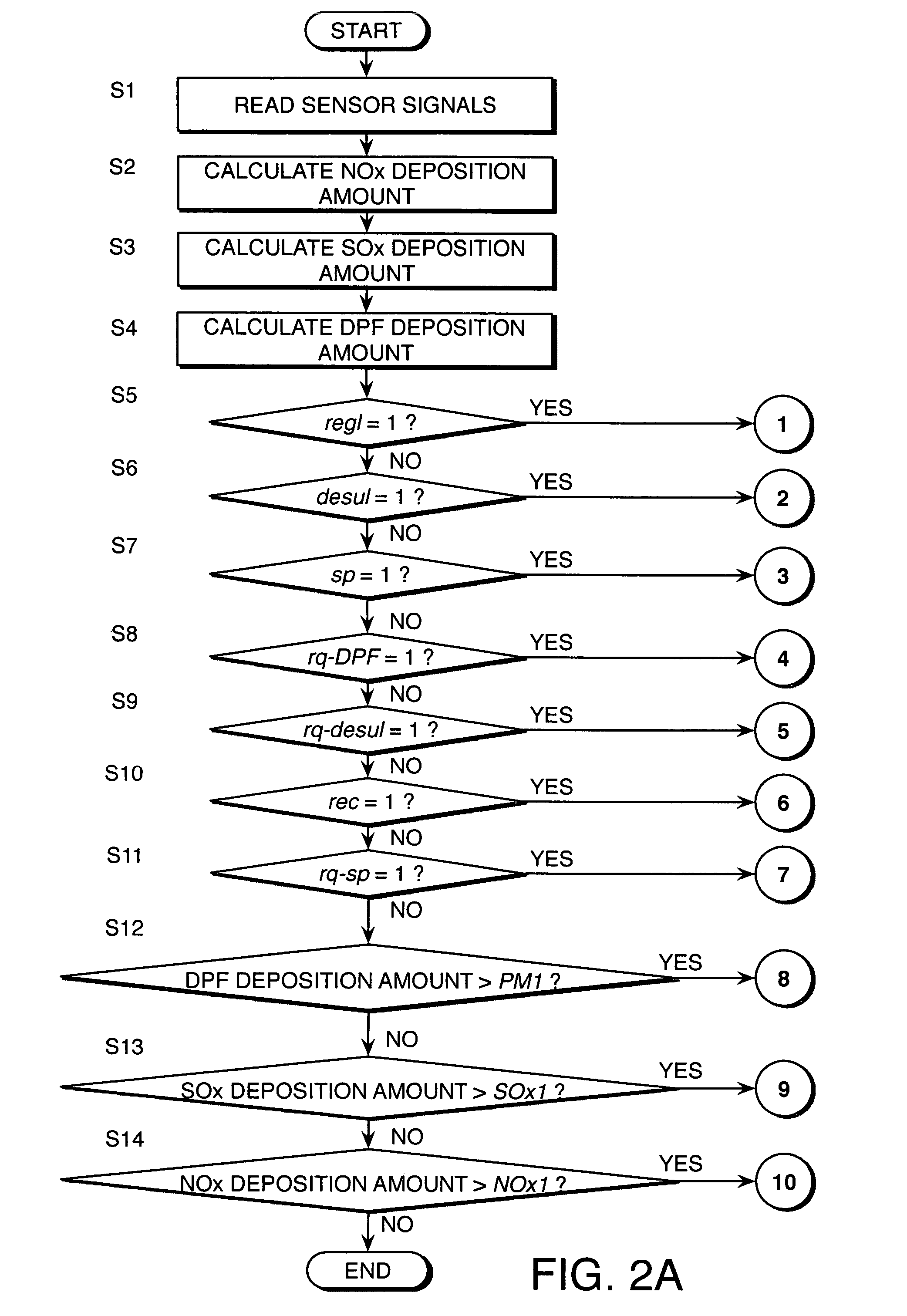

Exhaust gas purification control of diesel engine

InactiveUS7631493B2Reduce the amount of solutionCombination devicesElectrical controlNitrogen oxidesExhaust fumes

A diesel particulate filter (14) which traps particulate matter and a NOx trap catalyst (13) which traps nitrogen oxides are installed in series in an exhaust passage (10) of a diesel engine (1). A controller (21) calculates a particulate matter deposition amount in the diesel particulate filter (14) (S4). The controller (21), when the particulate matter deposition amount exceeds a first predetermined amount (PM2), prevents sharp increase of the particulate matter deposition amount by prohibiting rich spike where the oxygen concentration of the exhaust gas is controlled to a value corresponding to a rich air-fuel ratio in order to regenerate the NOx trap catalyst (13) (S301, S302, S306), and prevents the particulate matter deposition amount of the diesel particulate filter (14) from reaching a limit.

Owner:NISSAN MOTOR CO LTD

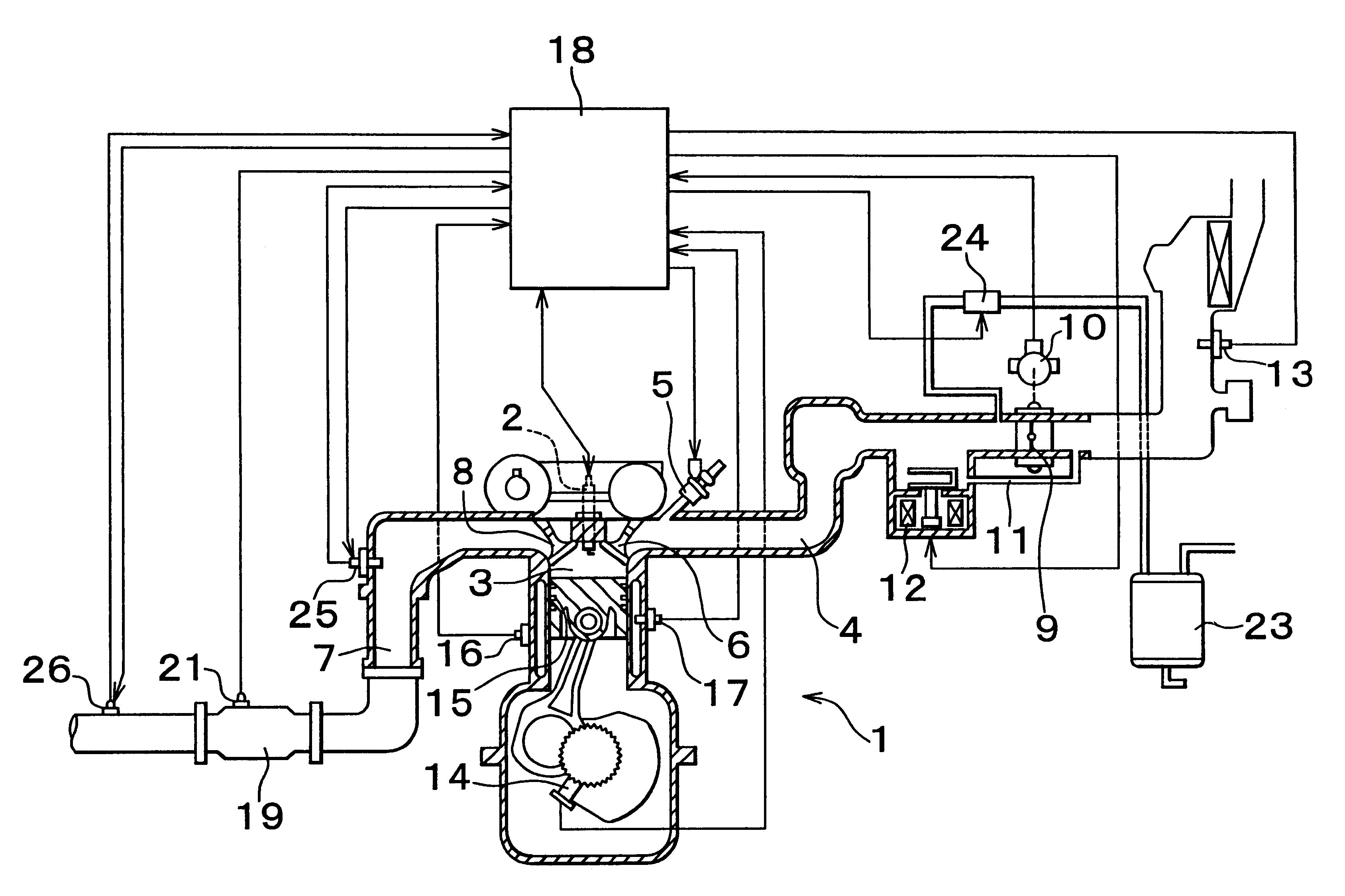

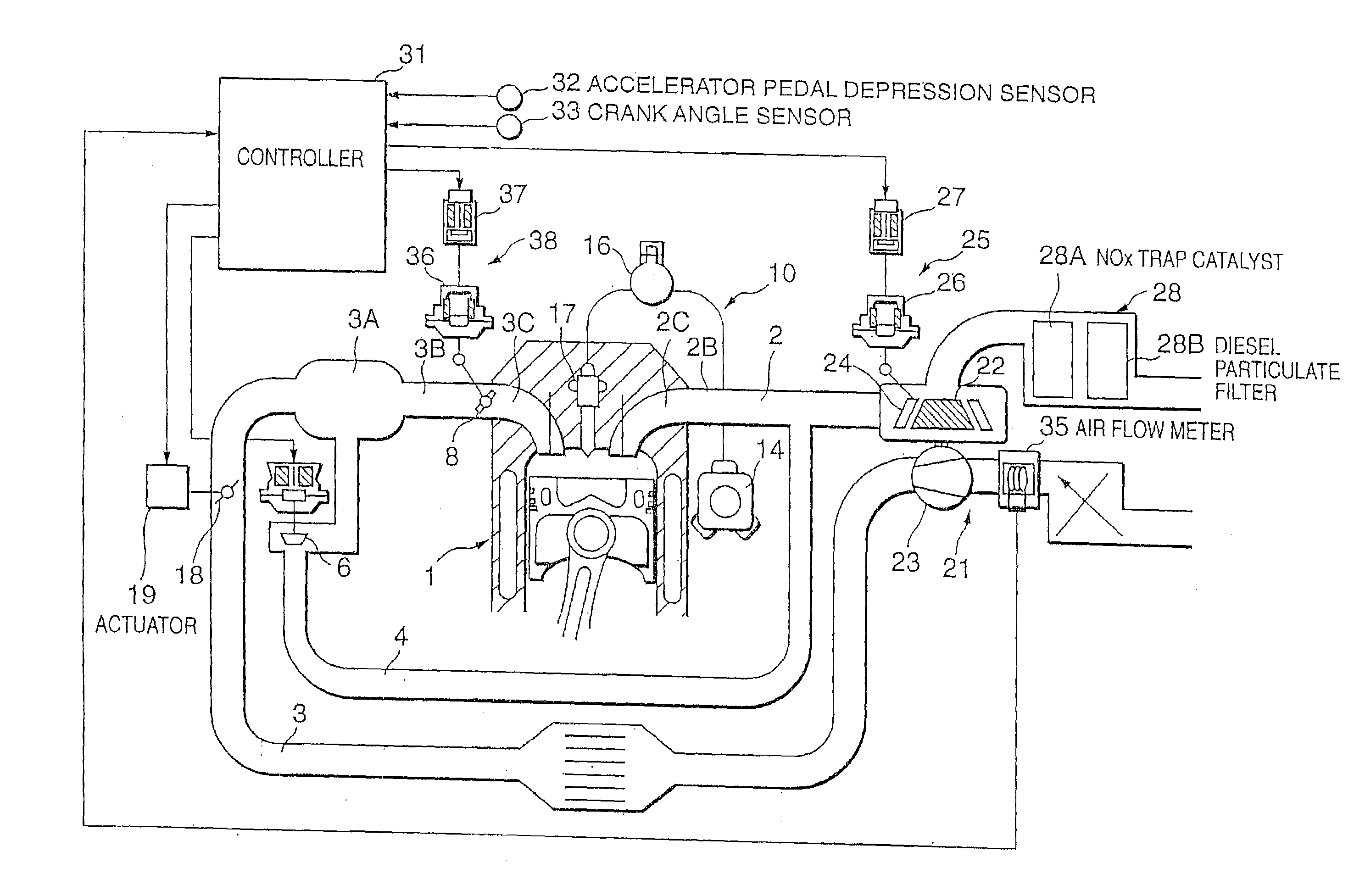

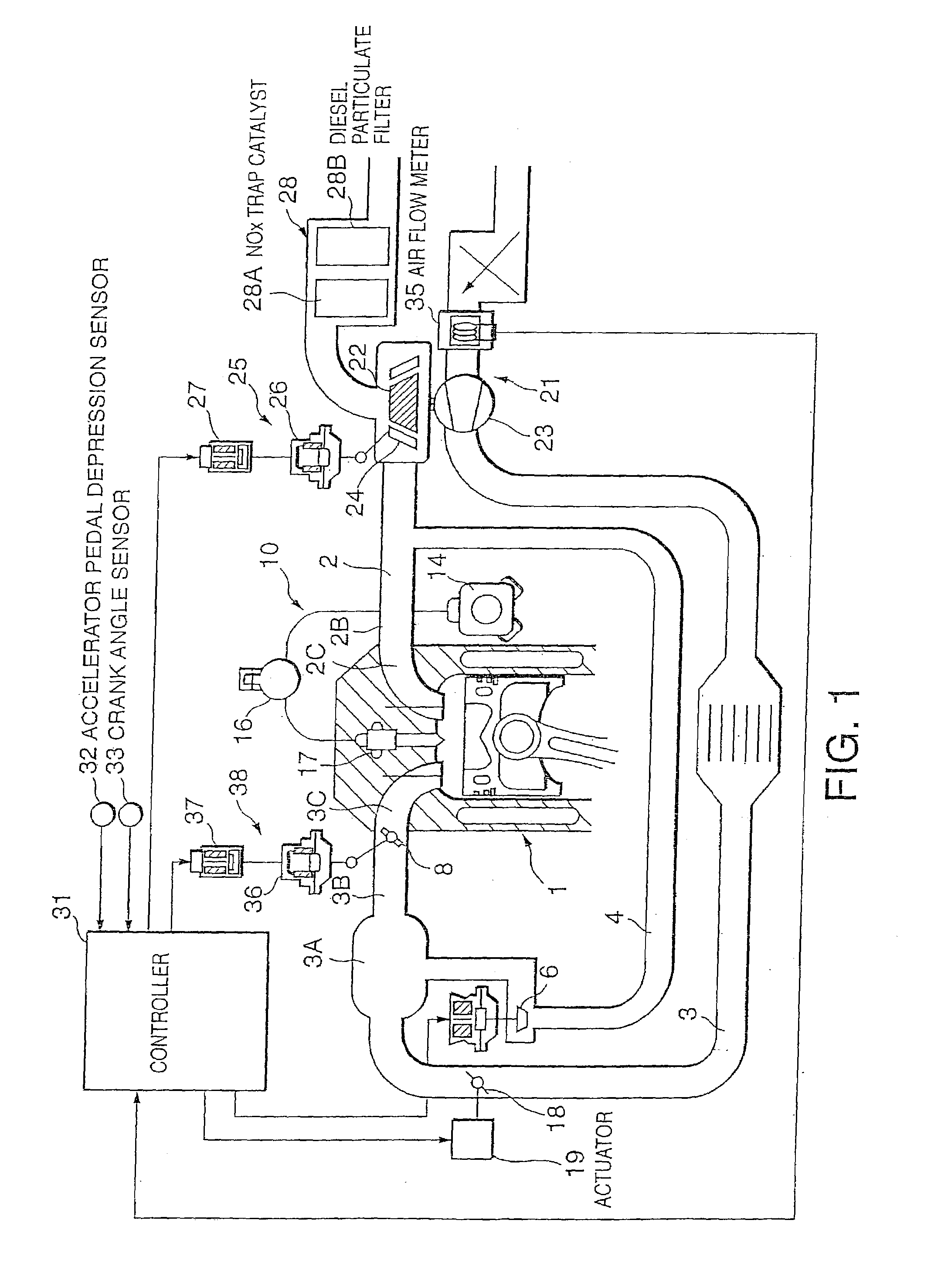

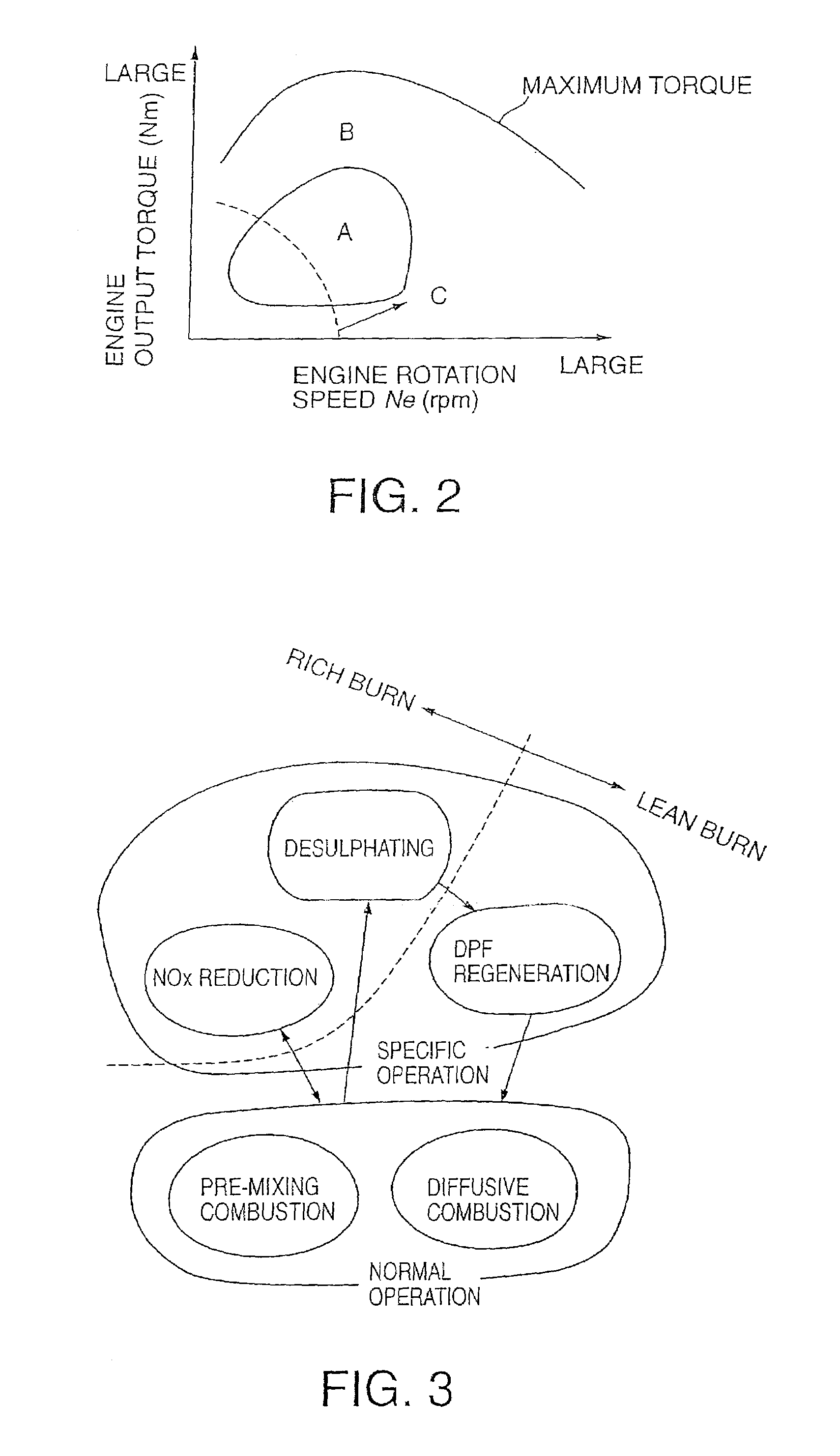

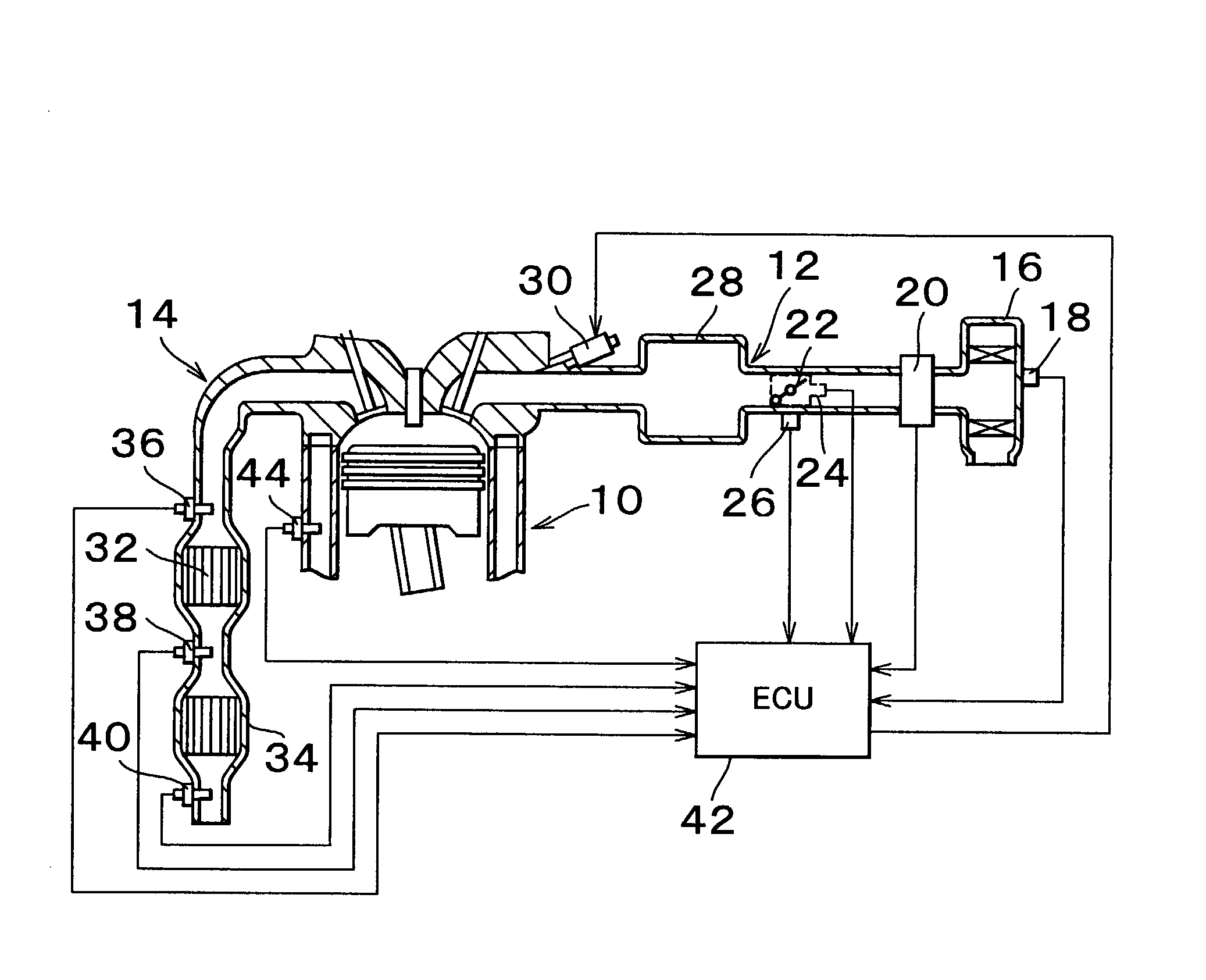

Excess air factor control of diesel engine

InactiveUS6993901B2Improve accuracyImprove responseElectrical controlNon-fuel substance addition to fuelEngineeringDiesel particulate filter

A diesel engine (1) provided with a NOx catalyst (28A) and a diesel particulate filter (28B) performs lean burn operation during normal running, rich burn operation during regeneration of the NOx catalyst (28A), operation under the stoichiometric air-fuel ratio during desulphating of the NOx catalyst (28A), and operation under a slightly lean air-fuel ratio to regenerate the filter after desulphating of the NOx catalyst (28A). When the lean burn operation is applied, a controller (31) first controls the fuel injection amount, and controls an air supply amount based on the fuel injection amount. When rich burn operation is applied, the controller (31) first controls the air supply amount and controls the fuel injection amount based on the air supply amount. Due to this control, the response of the excess air factor control is enhanced while preventing torque fluctuation accompanying the variation of the target excess air factor.

Owner:NISSAN MOTOR CO LTD

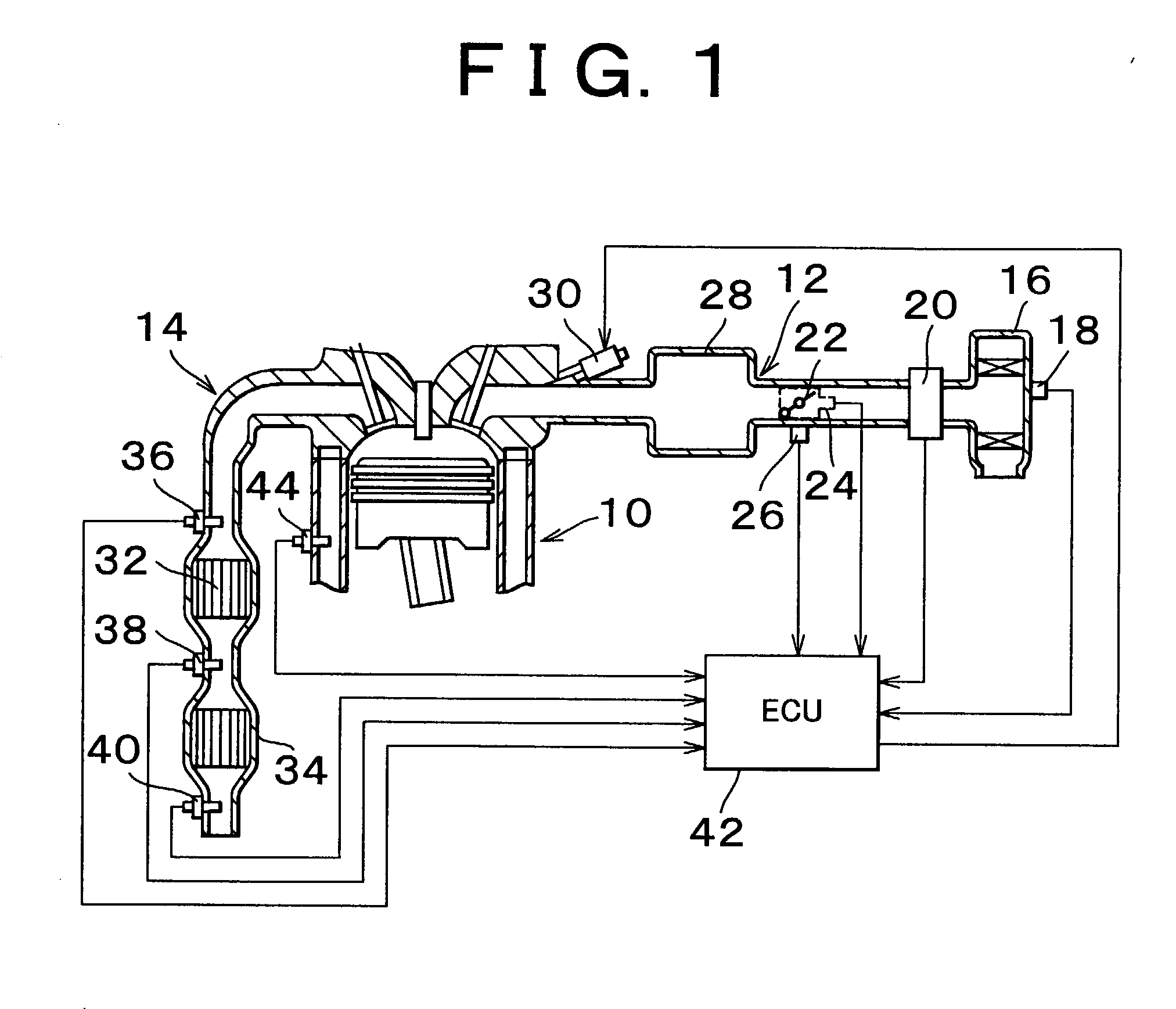

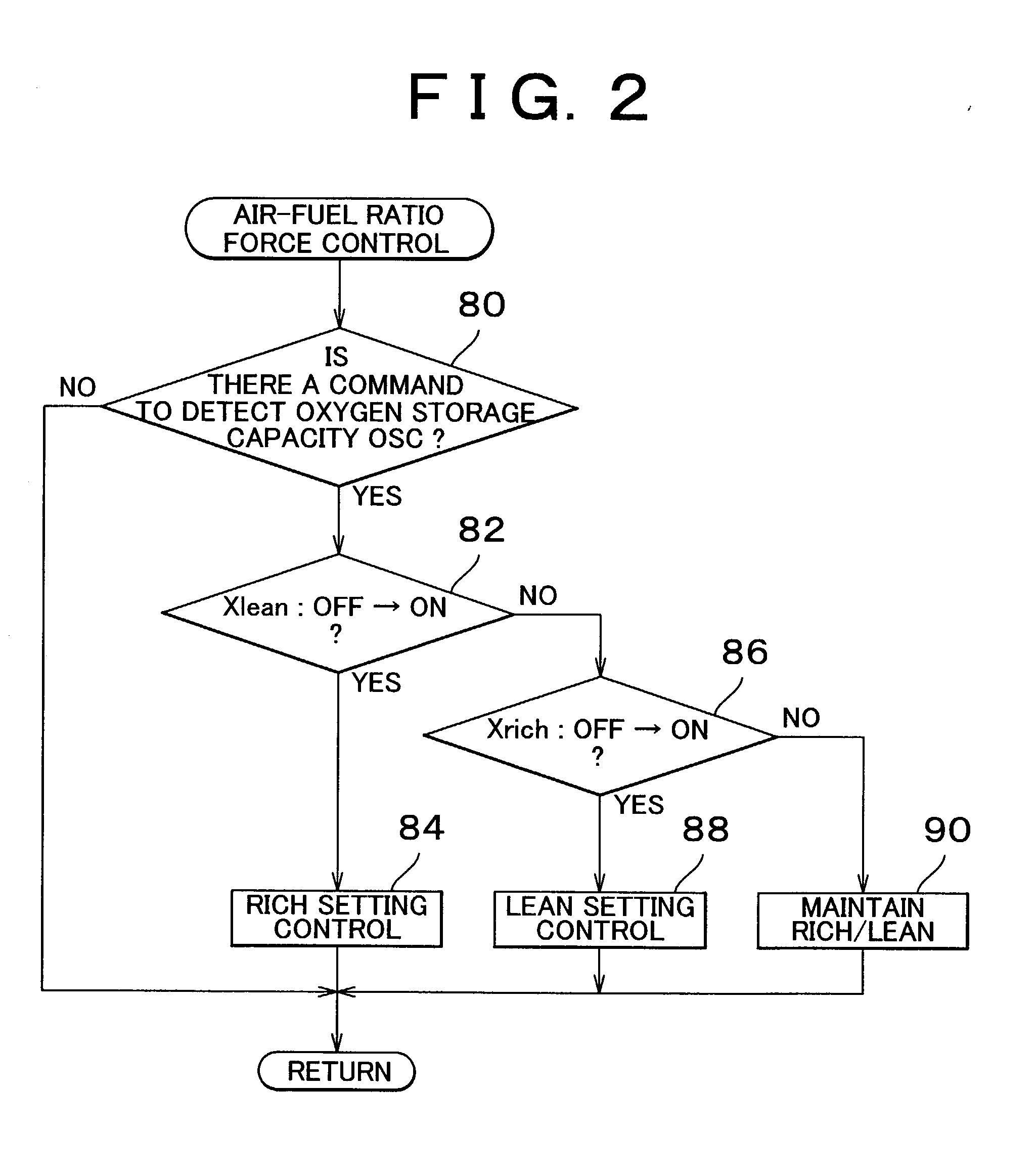

Catalyst deterioration detecting apparatus and method

InactiveUS20030017603A1Electrical controlInternal combustion piston enginesOxygen sensorEnvironmental engineering

An upstream side catalyst and a downstream side catalyst are disposed in an exhaust passage. A first oxygen sensor is disposed between these two catalysts and a second oxygen sensor is disposed downstream of the downstream side catalyst. The air-fuel ratio is forcibly oscillated and the oxygen storage capacity of the upstream side catalyst is detected. Deterioration of the upstream side catalyst is then detected based on whether this oxygen storage capacity is larger than a predetermined value. The forced oscillation of the air-fuel ratio is performed only when the oxygen storage state of the downstream side catalyst is appropriate.

Owner:TOYOTA JIDOSHA KK

Method and apparatus for optimizing the operation of a turbine system under flexible loads

ActiveUS20130125557A1Expand the adjustment rangeImprove efficiencyContinuous combustion chamberEngine fuctionsCombustorStream flow

A gas turbine system includes a compressor protection subsystem; a hibernation mode subsystem; and a control subsystem that controls the compressor subsystem and the hibernation subsystem. At partial loads on the turbine system, the compressor protection subsystem maintains an air flow through a compressor at an airflow coefficient for the partial load above a minimum flow rate coefficient where aeromechanical stresses occur in the compressor. The air fuel ratio in a combustor is maintained where exhaust gas emission components from the turbine are maintained below a predetermined component emission level while operating at partial loads.

Owner:GENERAL ELECTRIC CO

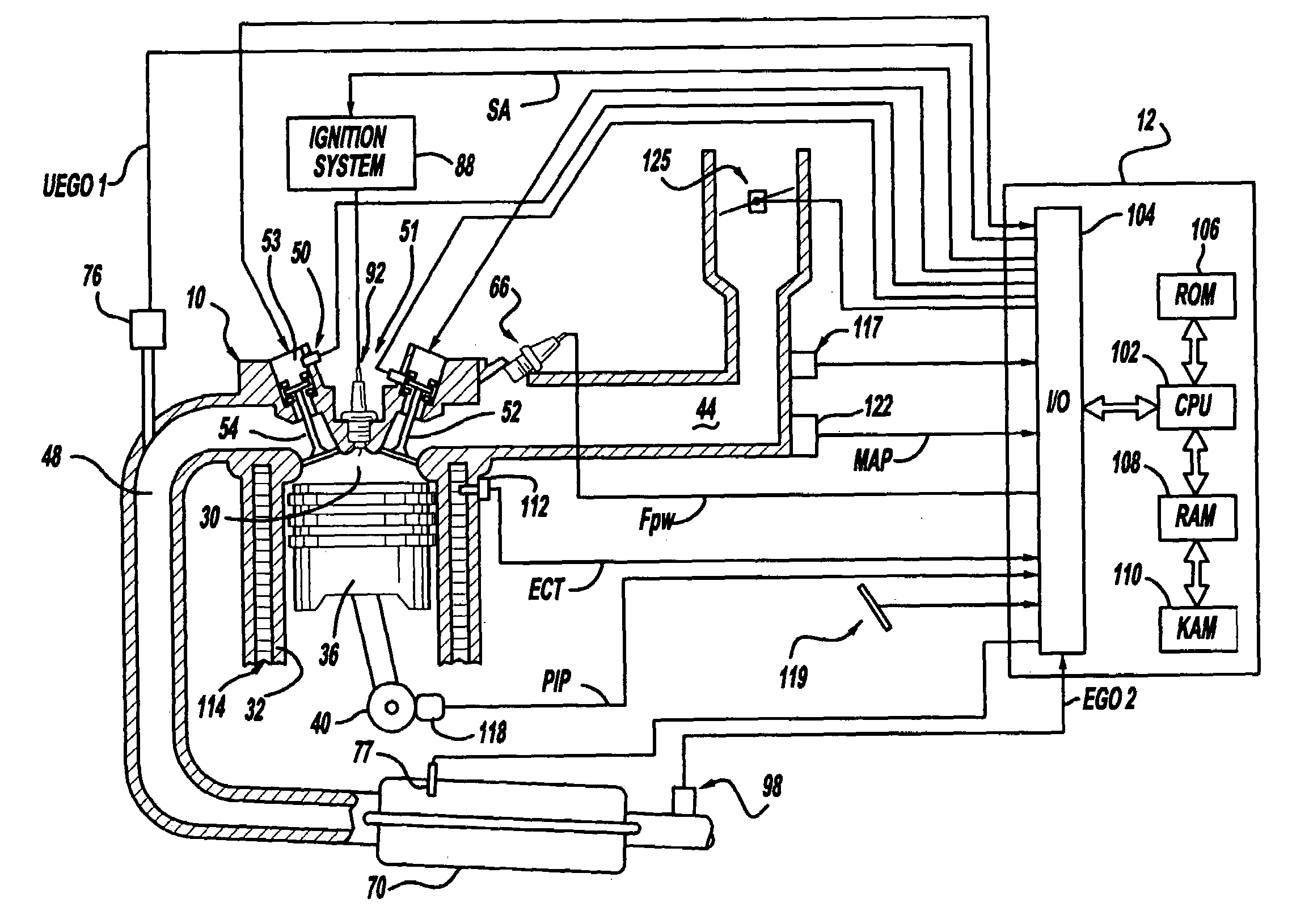

System for controlling valve timing of an engine with cylinder deactivation

InactiveUS7249583B2Sufficient NOx reduction and fuel economy benefitsEasy to operateValve arrangementsElectrical controlSystems designEngineering

Various systems and methods are disclosed for carrying out combustion in a fuel-cut operation in some or all of the engine cylinders of a vehicle. Further, various subsystems are considered, such as fuel vapor purging, air-fuel ratio control, engine torque control, catalyst design, and exhaust system design.

Owner:FORD GLOBAL TECH LLC

Idle speed control for lean burn engine with variable-displacement-like characteristic

InactiveUS6769398B2Easy to operateDegradation of combustionElectrical controlIdling devicesAdaptive learningIdle speed control

A method is disclosed for controlling operation of a engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air-fuel mixture and a second group of cylinders pumping air only (i.e. without fuel injection.) In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: auto speed control, sensor diagnostics, air-fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, and default operation. In addition, the engine control method also disables the split air / lean operating mode under preselected operating conditions.

Owner:FORD GLOBAL TECH LLC

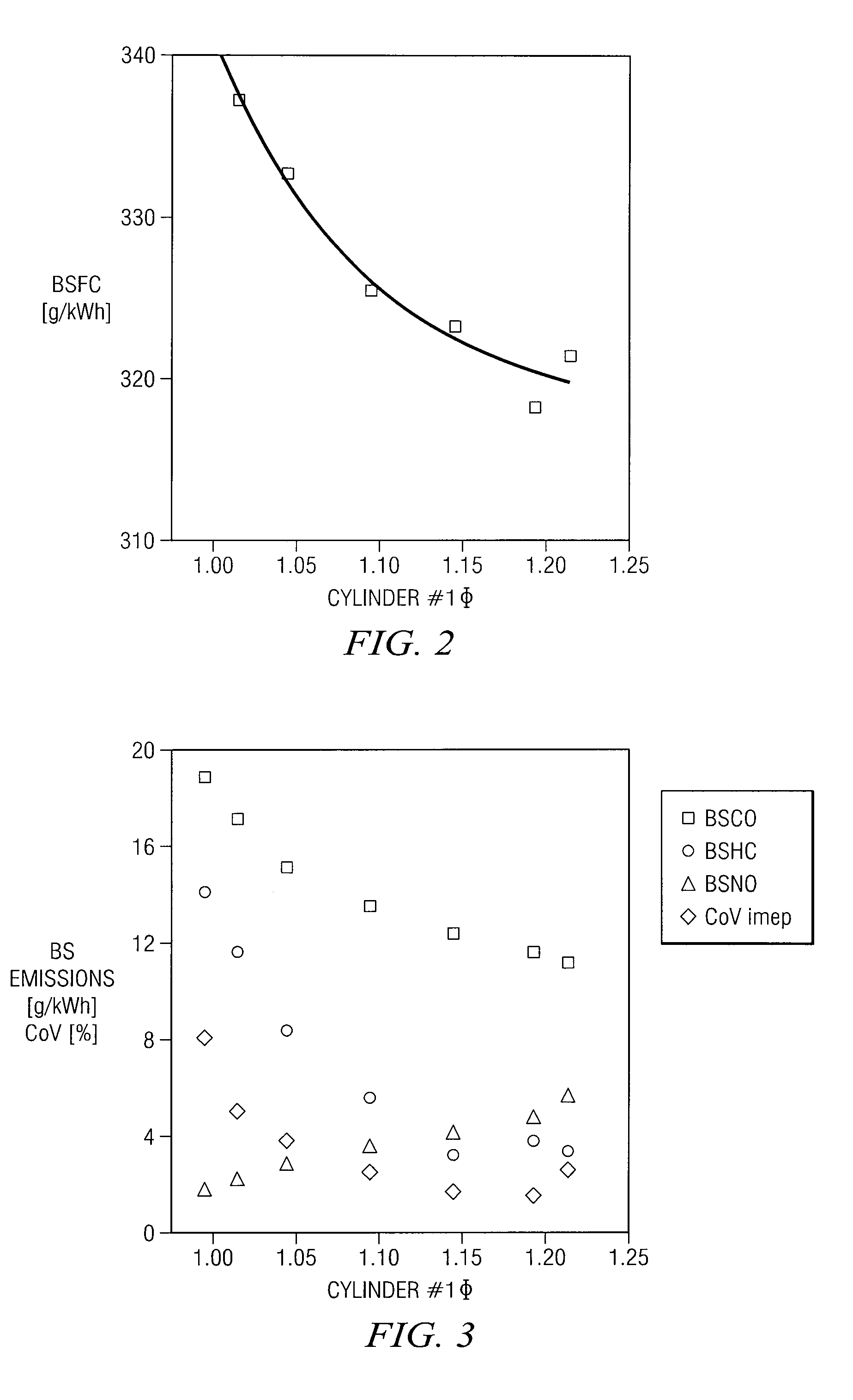

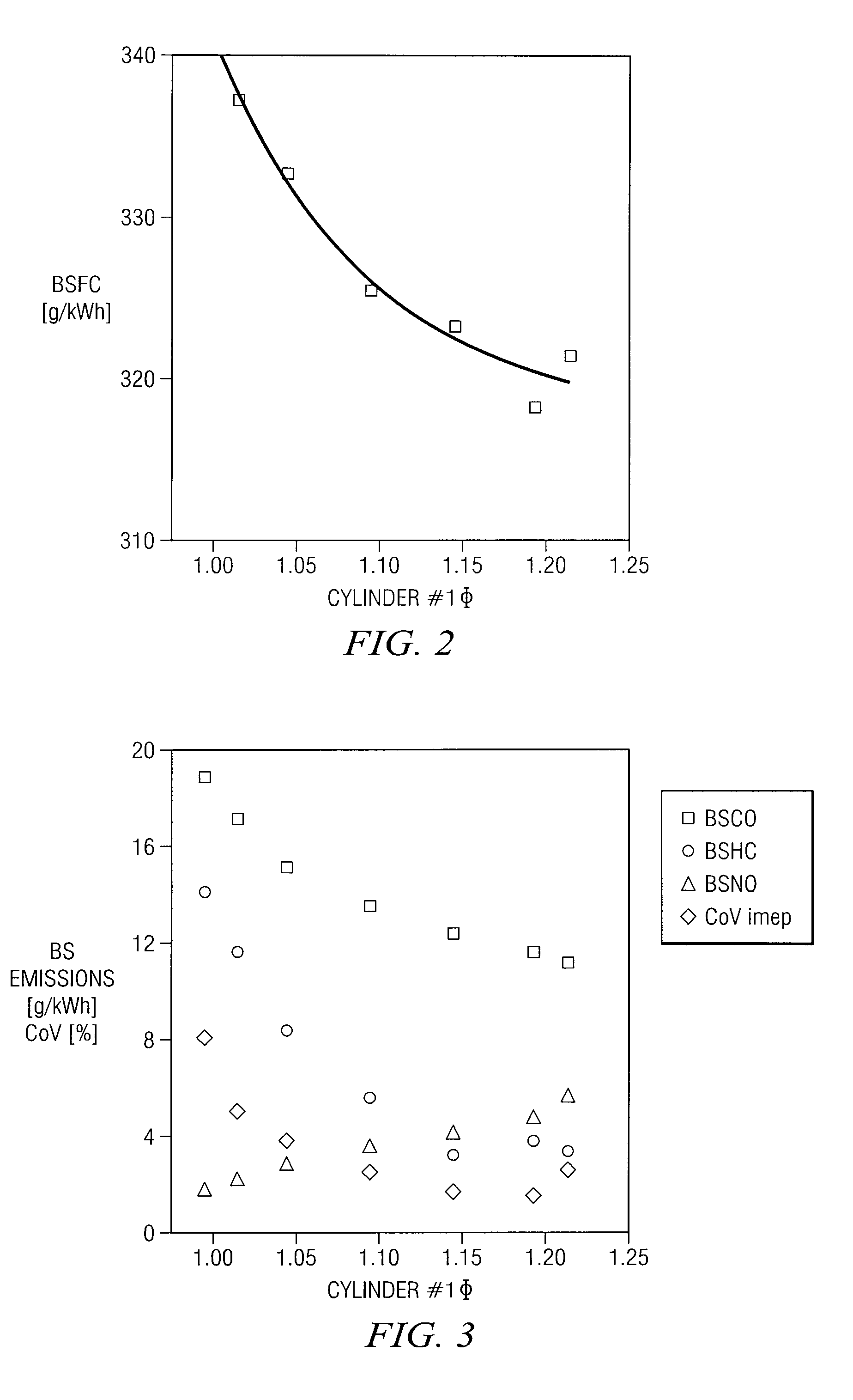

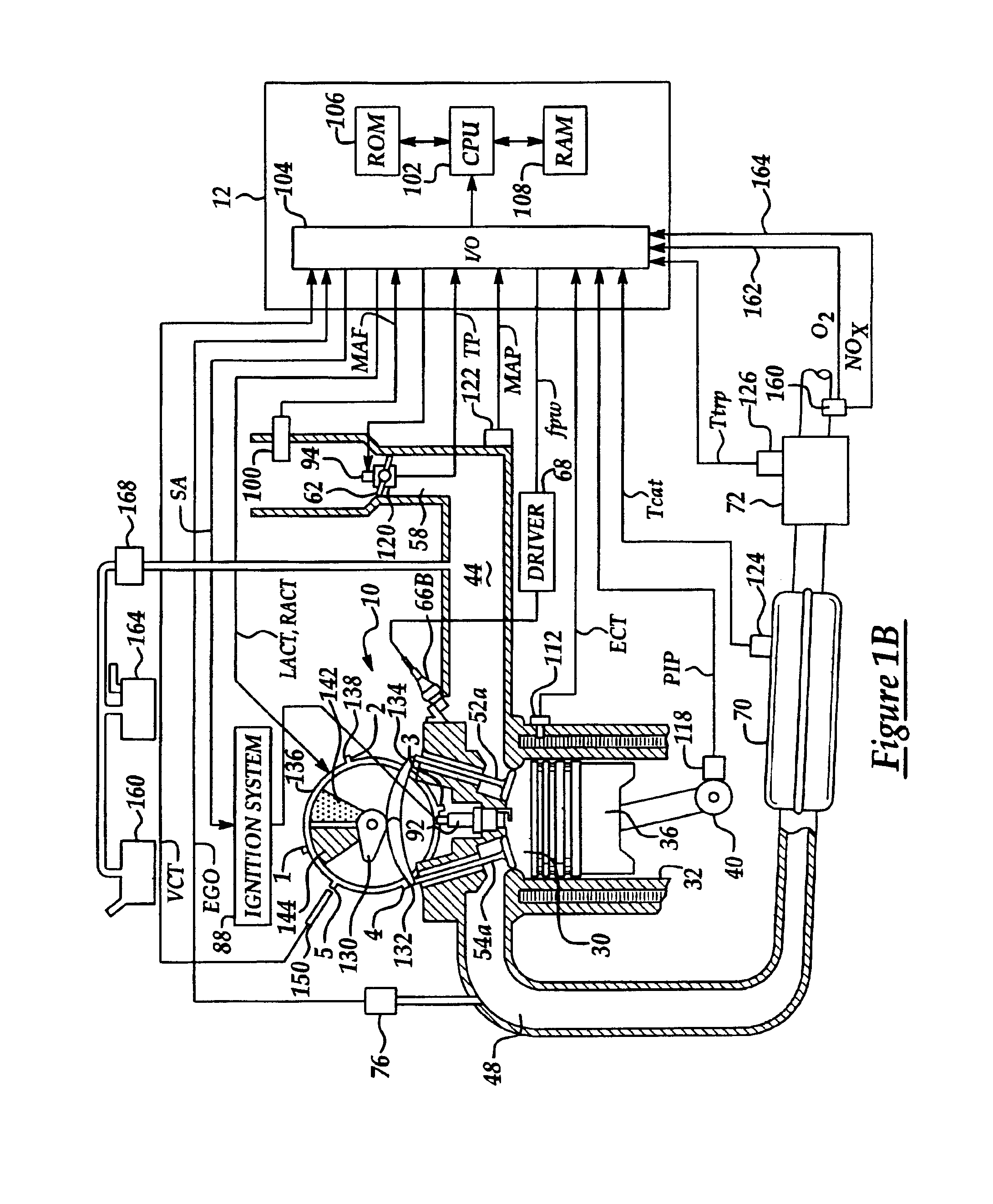

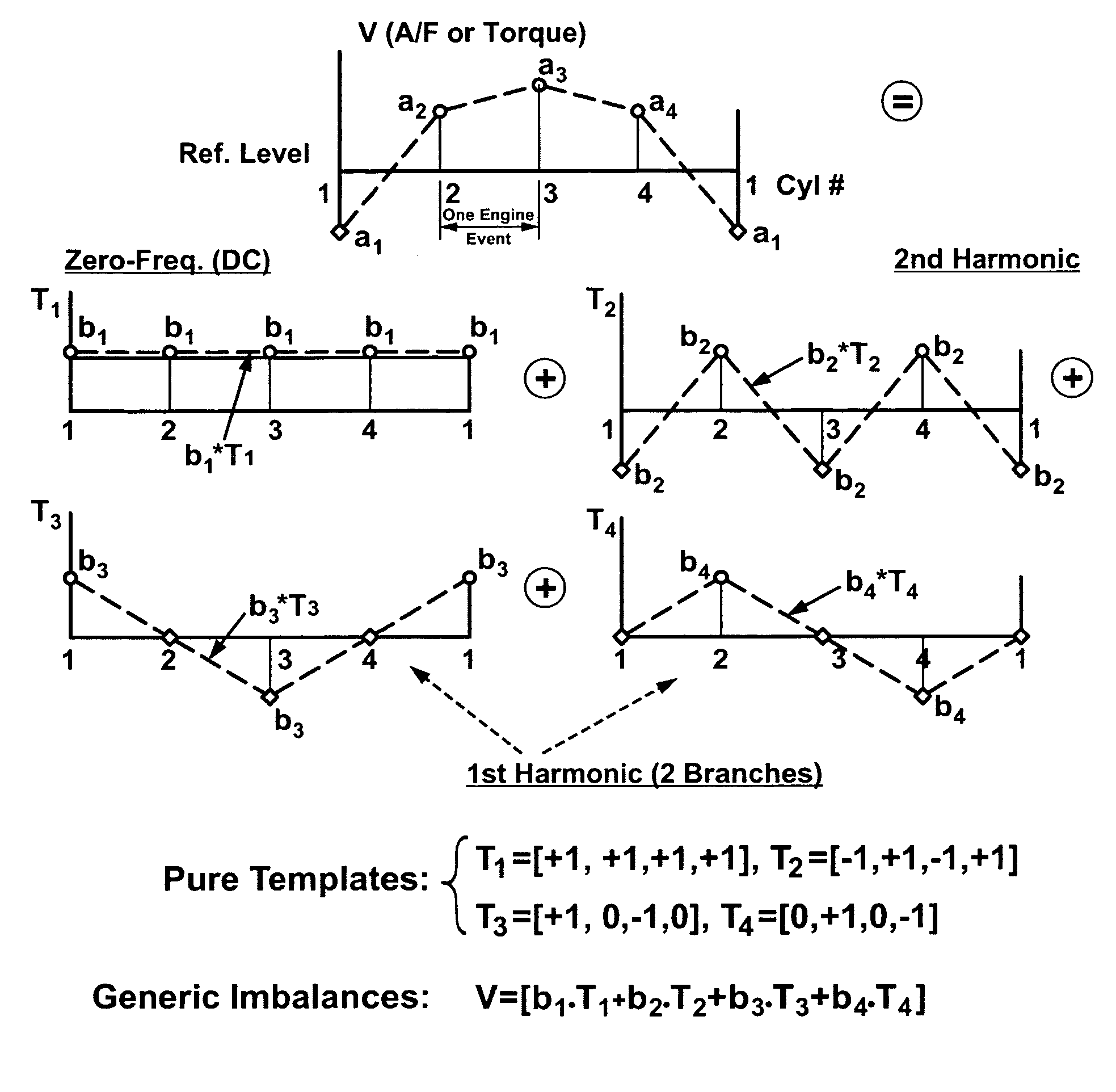

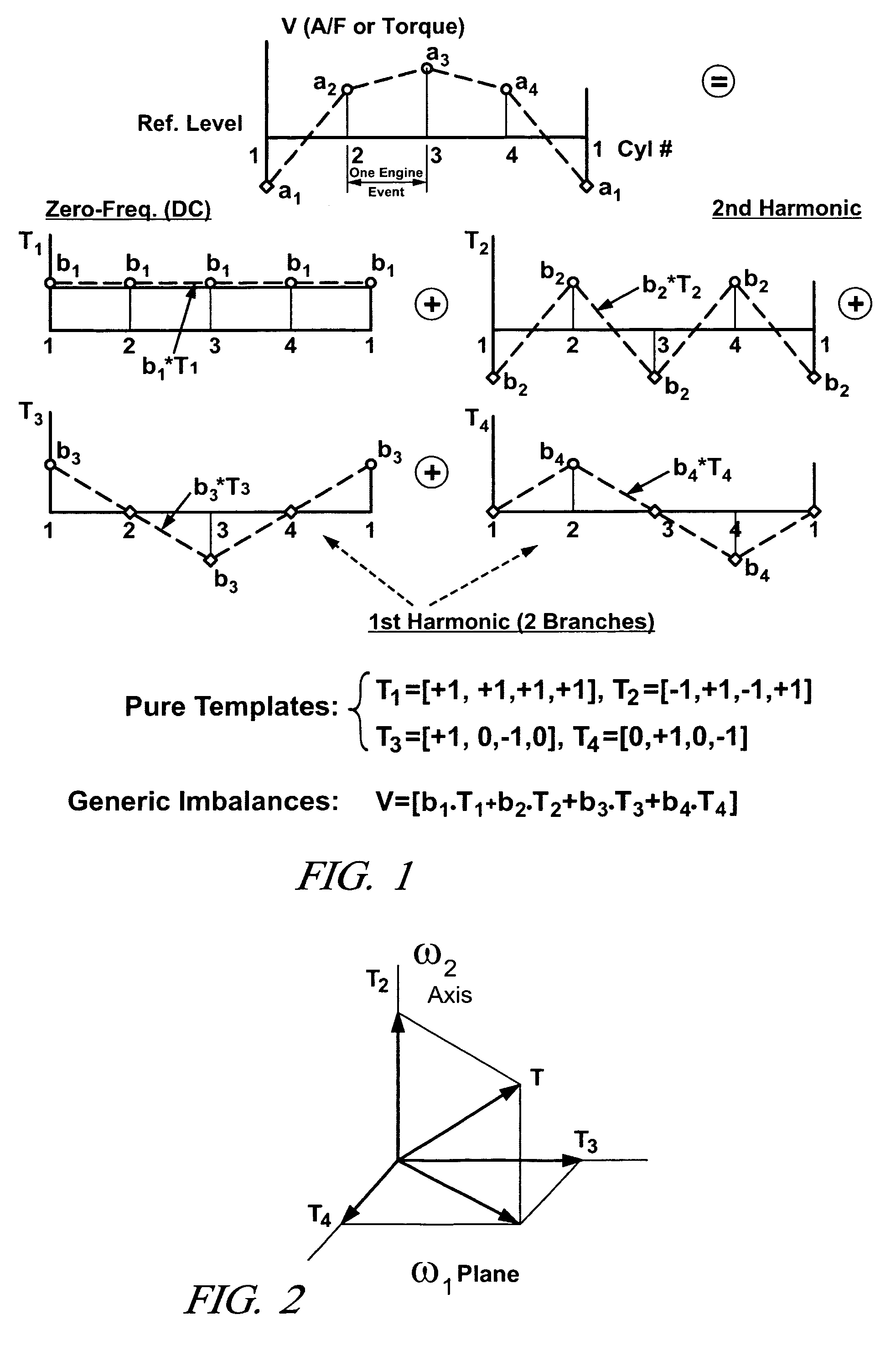

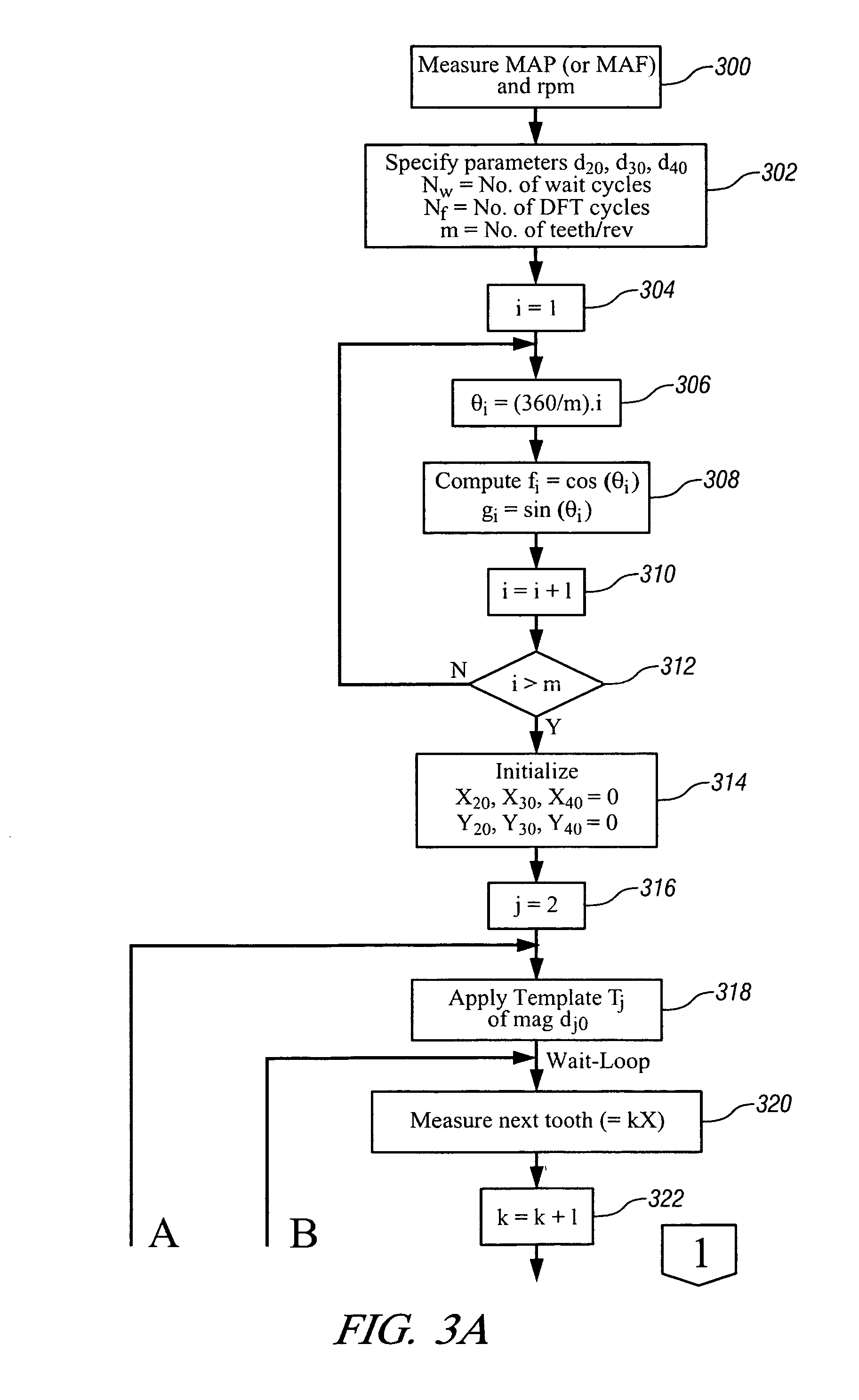

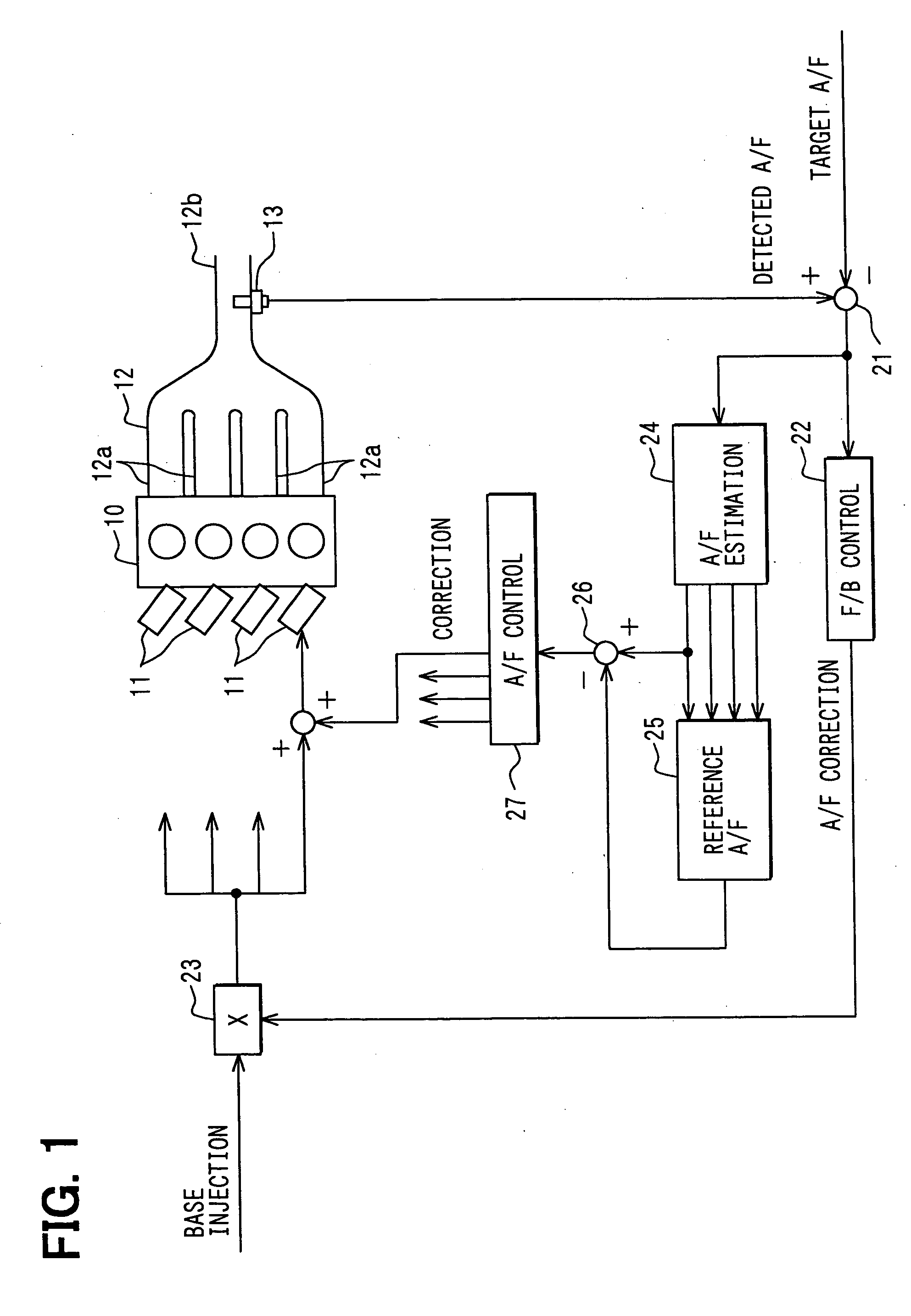

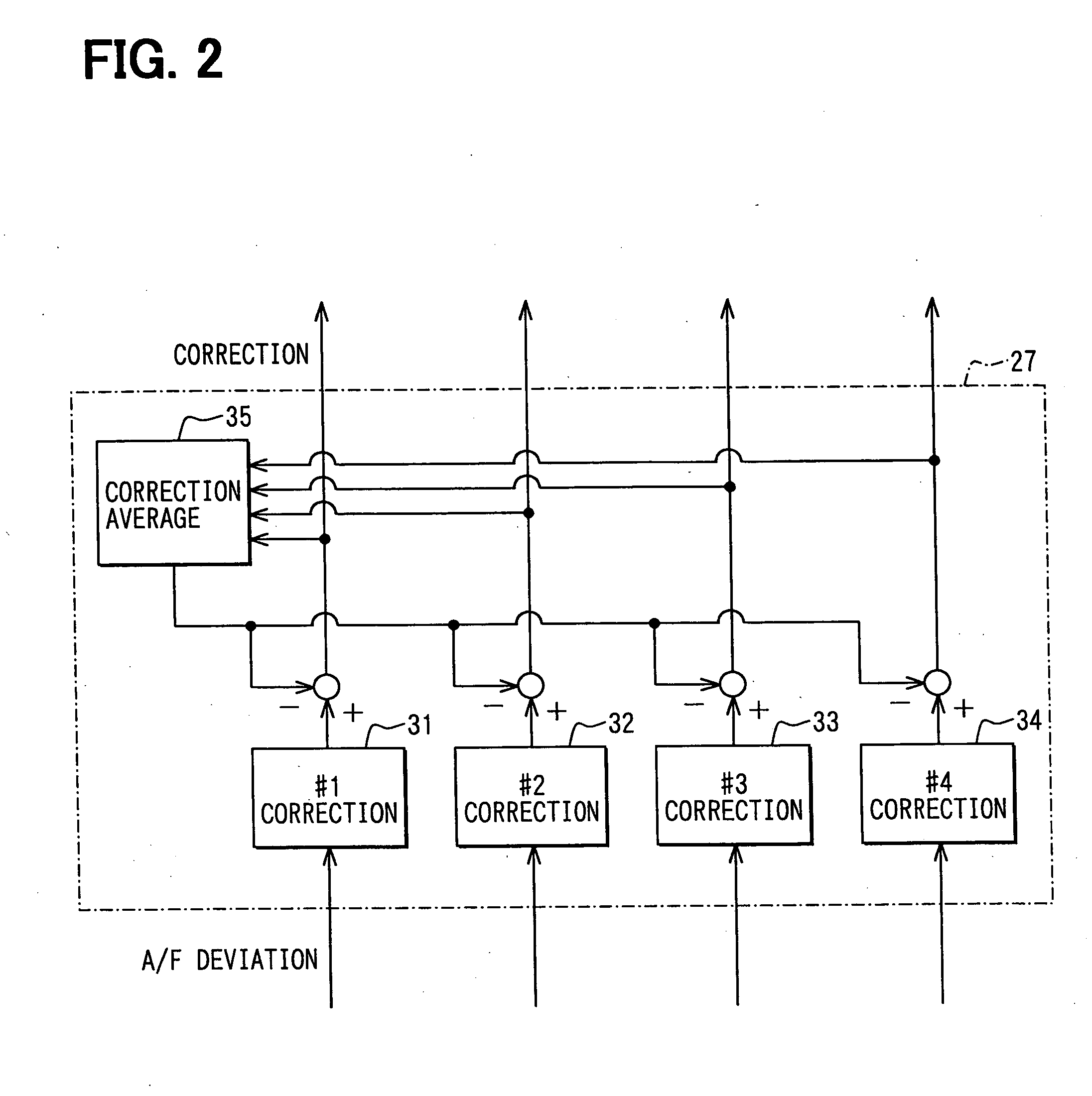

Individual cylinder controller for four-cylinder engine

A generic technique for the detection of air-fuel ratio (or torque) imbalances in a 4-cylinder engine equipped with either a production oxygen sensor or a wide-range A / F sensor (or a crankshaft torque sensor) is developed. The method is based on a novel frequency-domain characterization of pattern of imbalances and its geometric decomposition into four basic templates. Once the contribution of each basic template to the overall imbalances is computed, templates of opposite direction are imposed to restore air-fuel ratio (or torque) balance among cylinders. At any desired operating condition, elimination of imbalances is achieved within few engine cycles. The method is applicable to current and future engine technologies with variable valve actuation, fuel injectors and / or individual spark control.

Owner:GM GLOBAL TECH OPERATIONS LLC

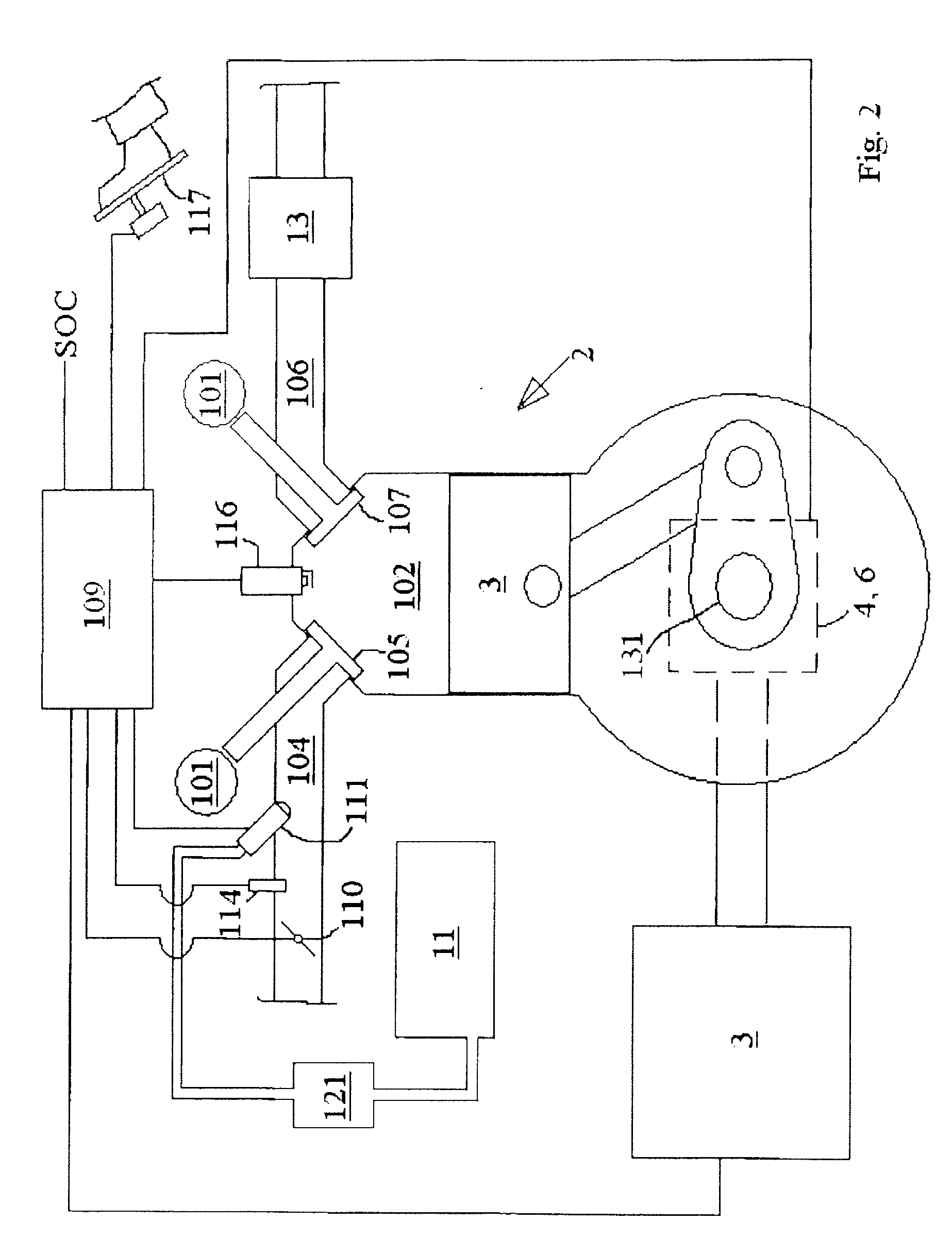

Control of an Exhaust Gas Aftertreatment Device in a Hybrid Vehicle

ActiveUS20090025371A1Emission reductionAccelerate emissionsElectrical controlInternal combustion piston enginesHybrid vehicleCrankshaft

The present invention involves a method for maintaining temperature in an exhaust gas treatment device for an internal combustion engine in a hybrid vehicle. The engine has a crankshaft and at least one cylinder. The hybrid vehicle has a fuel storage device and a fuel supply device. An exhaust gas treatment device is located downstream of the cylinder. The method comprises, in an engine off mode, pumping air to the exhaust gas aftertreatment device controlling the fuel supply device so that fuel is allowed to the exhaust gas aftertreatment device. Air flow to the exhaust gas aftertreatment device can be controlled by a throttle in an inlet duct to the engine and / or the fuel supply device to control the combustion and air-fuel ratio in the exhaust gas treatment device.

Owner:VOLVO CAR CORP

Robust maximum engine torque estimation

ActiveUS20070051351A1Improve economyImprove efficiencyElectrical controlCombustion enginesControl theoryLinearity

A system for a vehicle comprising of an engine including a first cylinder group and a second cylinder group; a linear exhaust gas sensor coupled exclusively to the first cylinder group; a switching exhaust gas sensor coupled exclusively to the second cylinder group; and a controller configured to operate the engine in at least a first mode and a second mode, where in the first mode the first and second cylinder groups combust air and fuel, where in the second mode at least one of the first and second cylinder groups combusts air and injected fuel and the other one of the first and second cylinder groups pumps air without injecting fuel, and where the controller is further configured to estimate torque of the engine in each of the first and second modes of operation based on the air-fuel ratio of the first cylinder group and the air-fuel ratio of the second cylinder group independent of the switching sensor and dependent on the linear sensor.

Owner:FORD GLOBAL TECH LLC

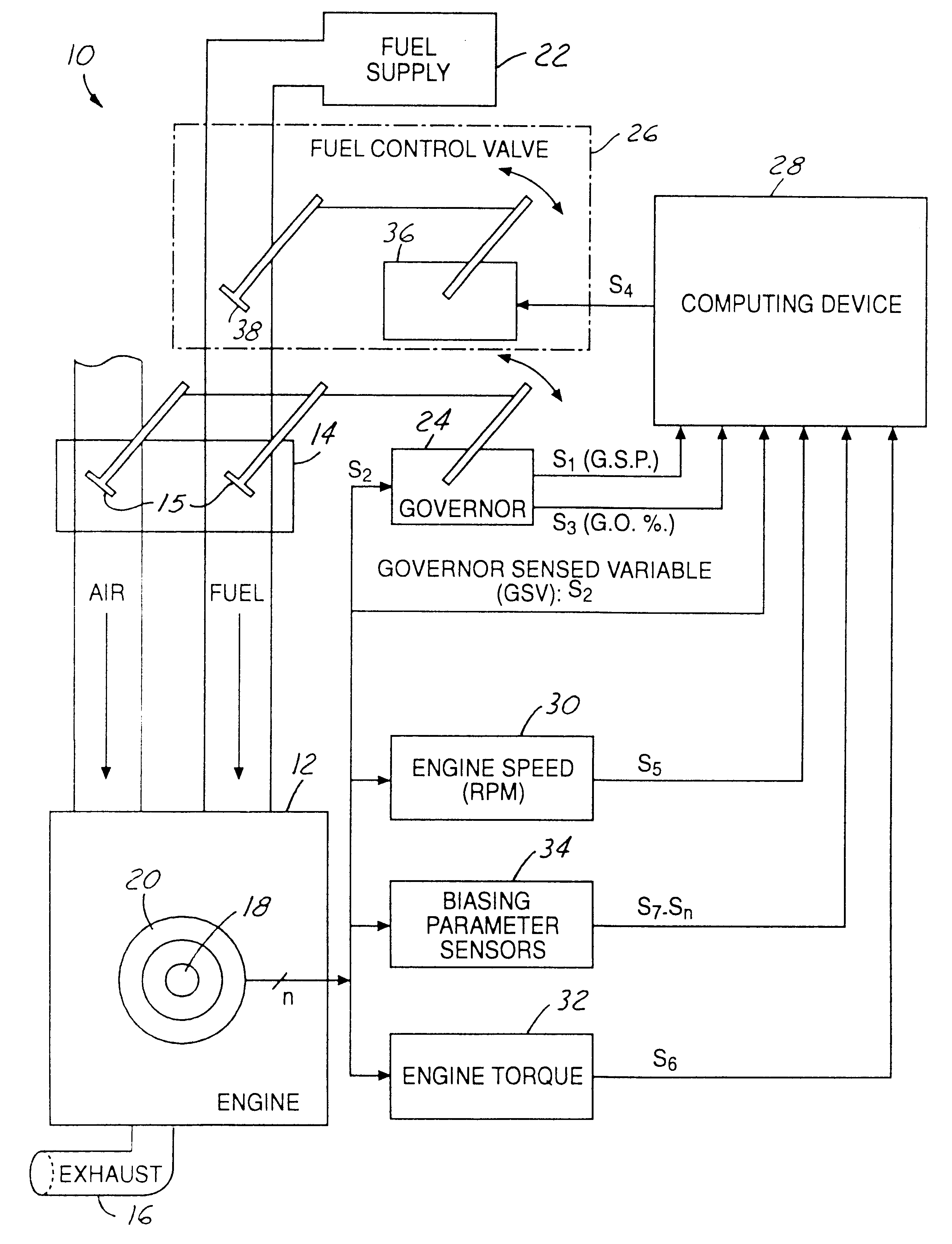

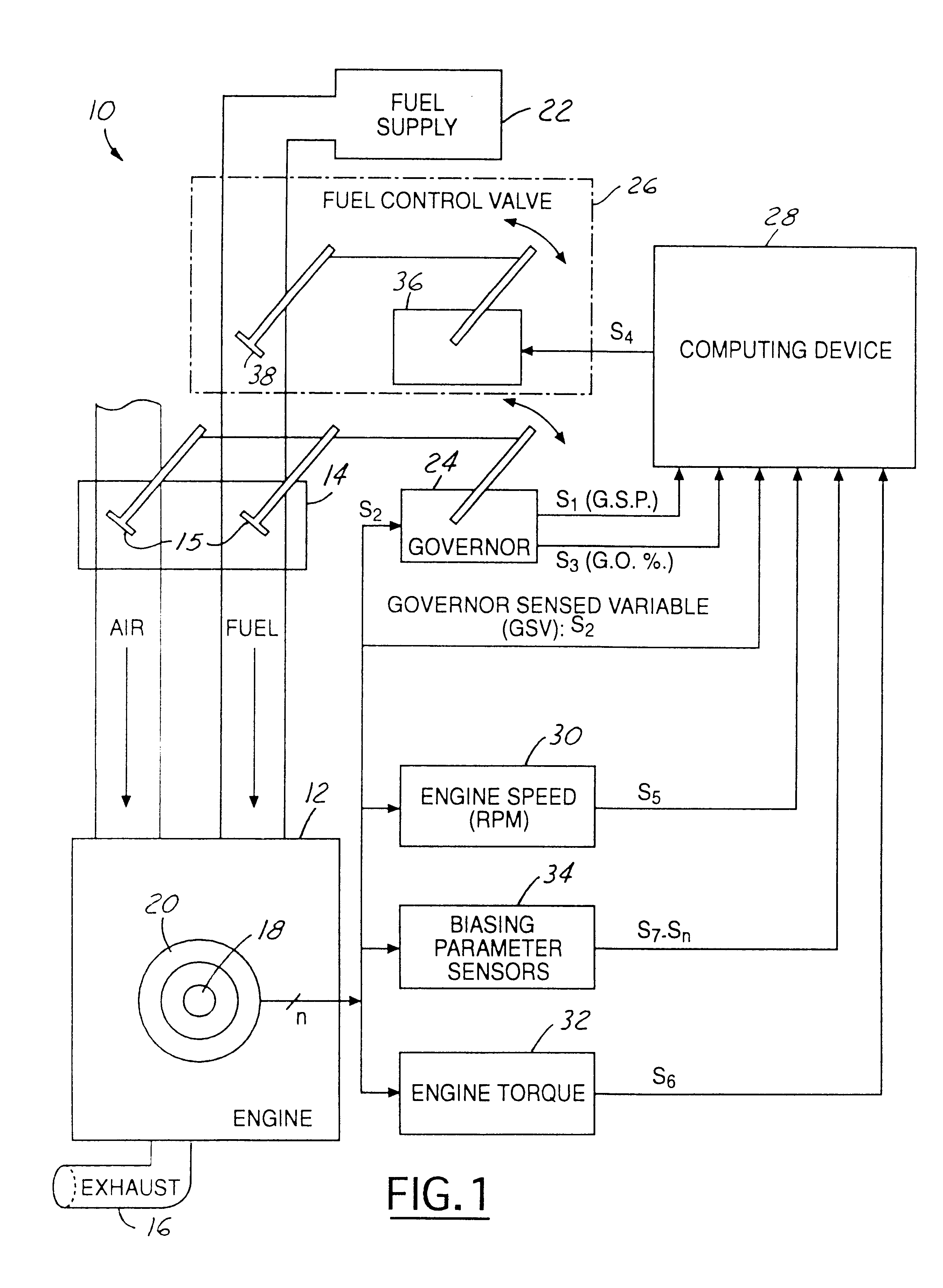

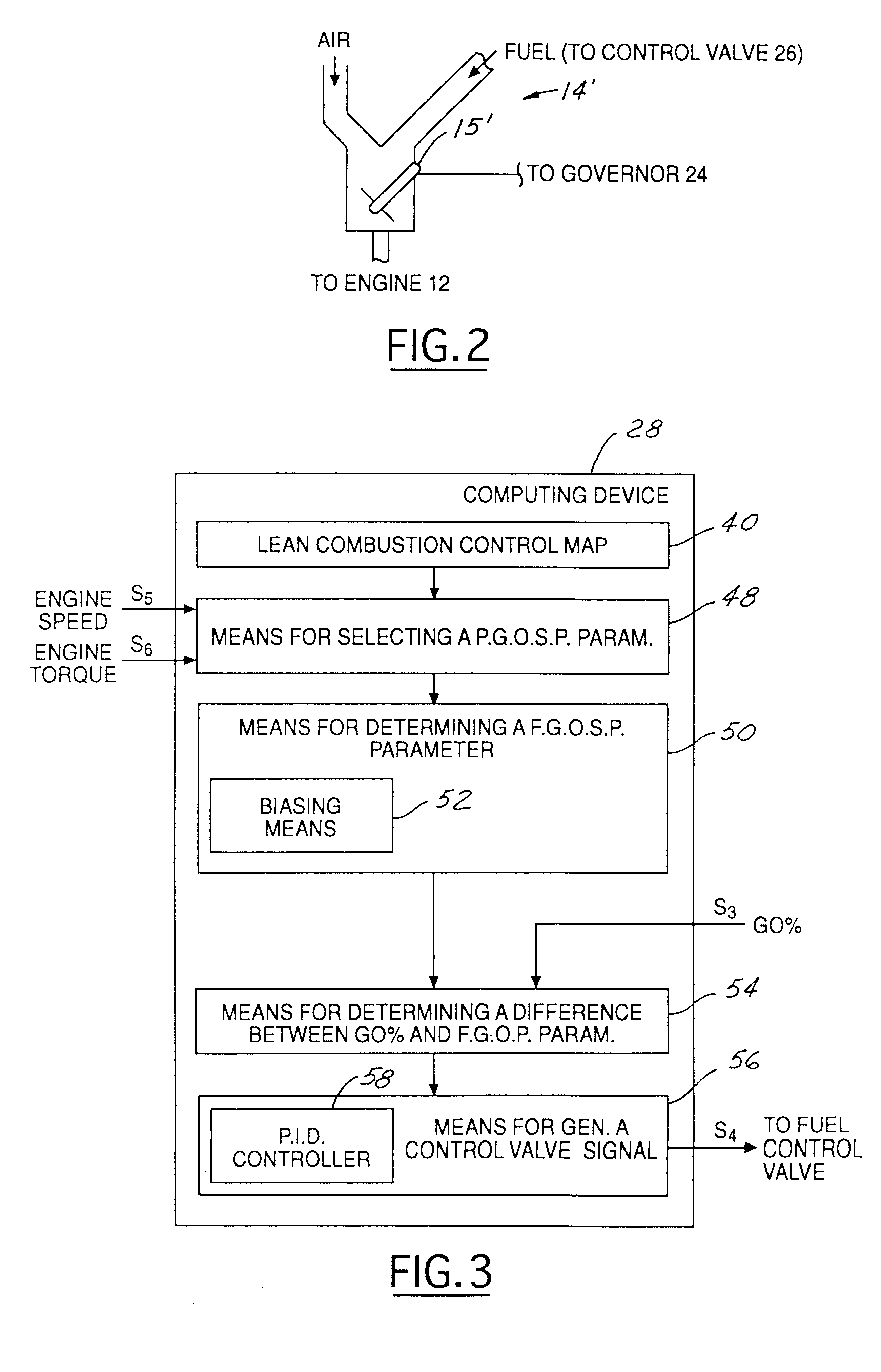

Method and system for controlling an air-to-fuel ratio in a non-stoichiometric power governed gaseous-fueled stationary internal combustion engine

InactiveUS6189523B1Reduces "pumping losses.Less importantAnalogue computers for vehiclesElectrical controlControl signalExhaust fumes

A gaseous-fueled reciprocating internal combustion engine includes a carburetor having a throttle valve that is controlled by a speed governor. A proportional fuel control valve is disposed intermediate a fuel supply and the carburetor, and is controlled by an air fuel computing device. The computing device generates a control signal to adjust the fuel control valve based on a governor sensed variable indicative of engine speed, sensed engine torque, a governor output signal from the governor indicative of an opening position of the throttle valve wherein 100% corresponds to a wide open throttle position, and 0% corresponds to a closed position, and a lean combustion control map containing predetermined set point values stored in memory. During operation, the control valve is responsive to the control signal generated by the computing device for adjustment of a fuel flow therethrough so as to obtain a ratio of air to fuel provided to the engine that is substantially at a lean misfire limit of the engine, thereby reducing fuel consumption, NOx emissions, and reducing exhaust gas temperatures. Alternatively, the control signal is generated using engine speed alone.

Owner:ANR PIPELINE

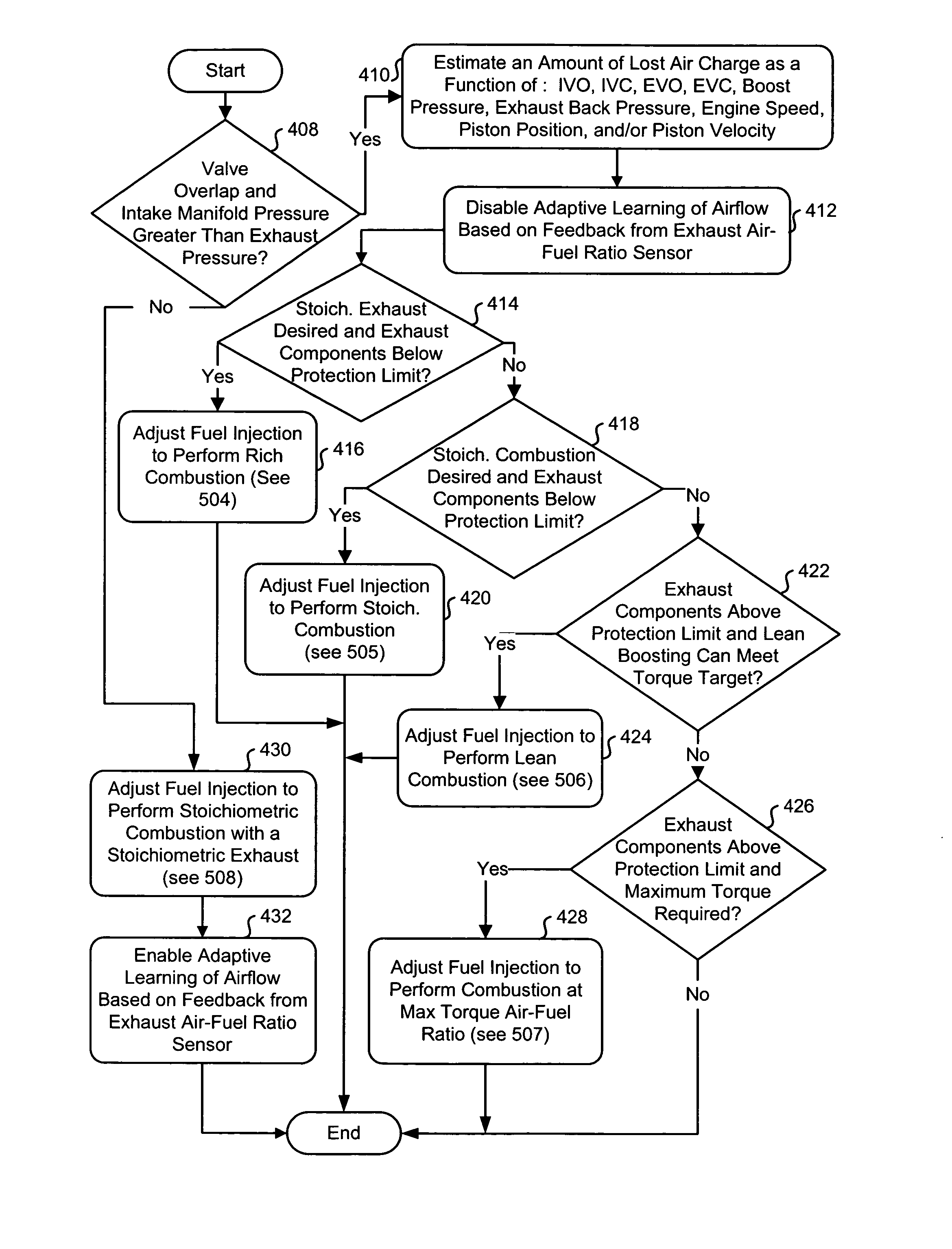

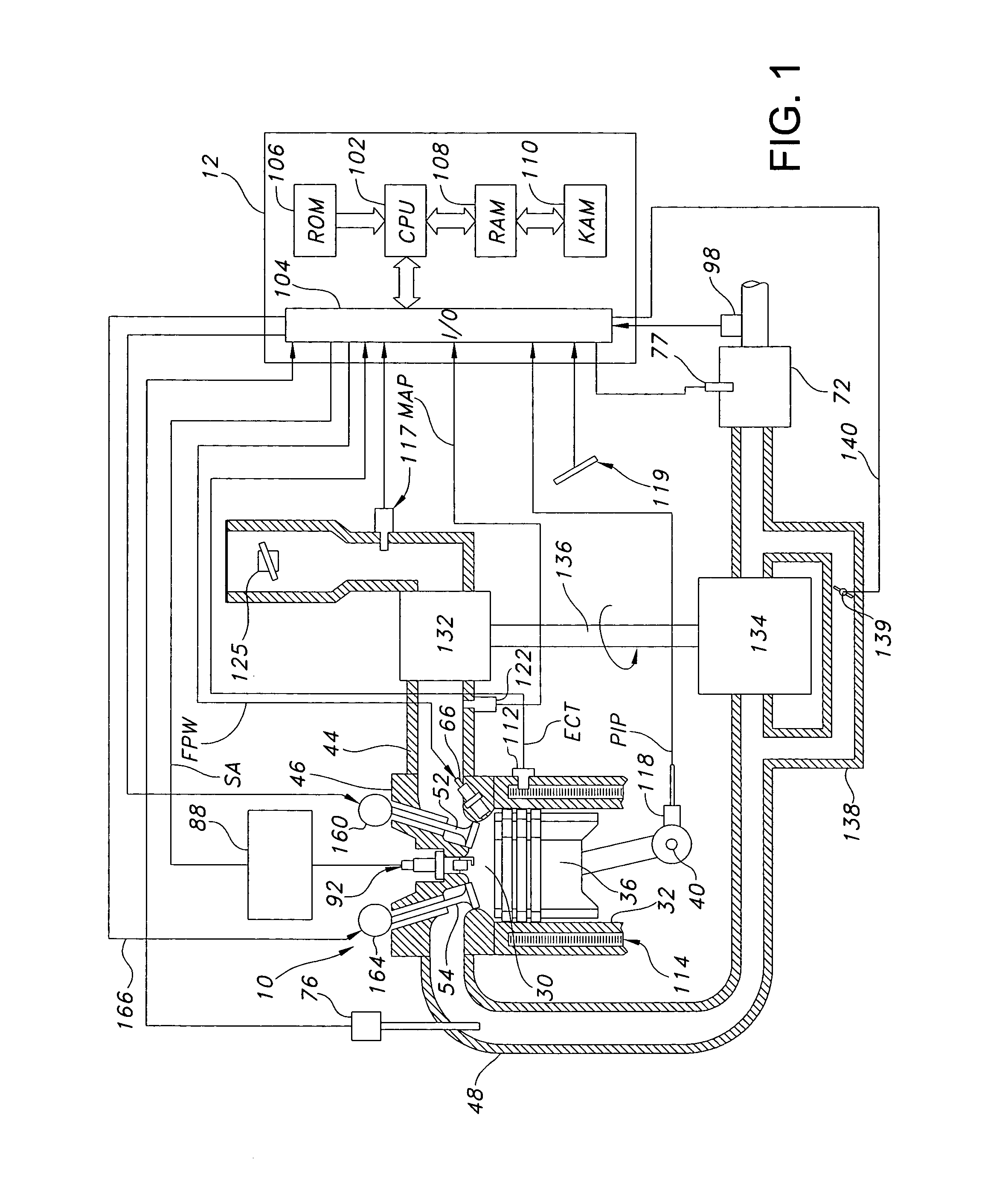

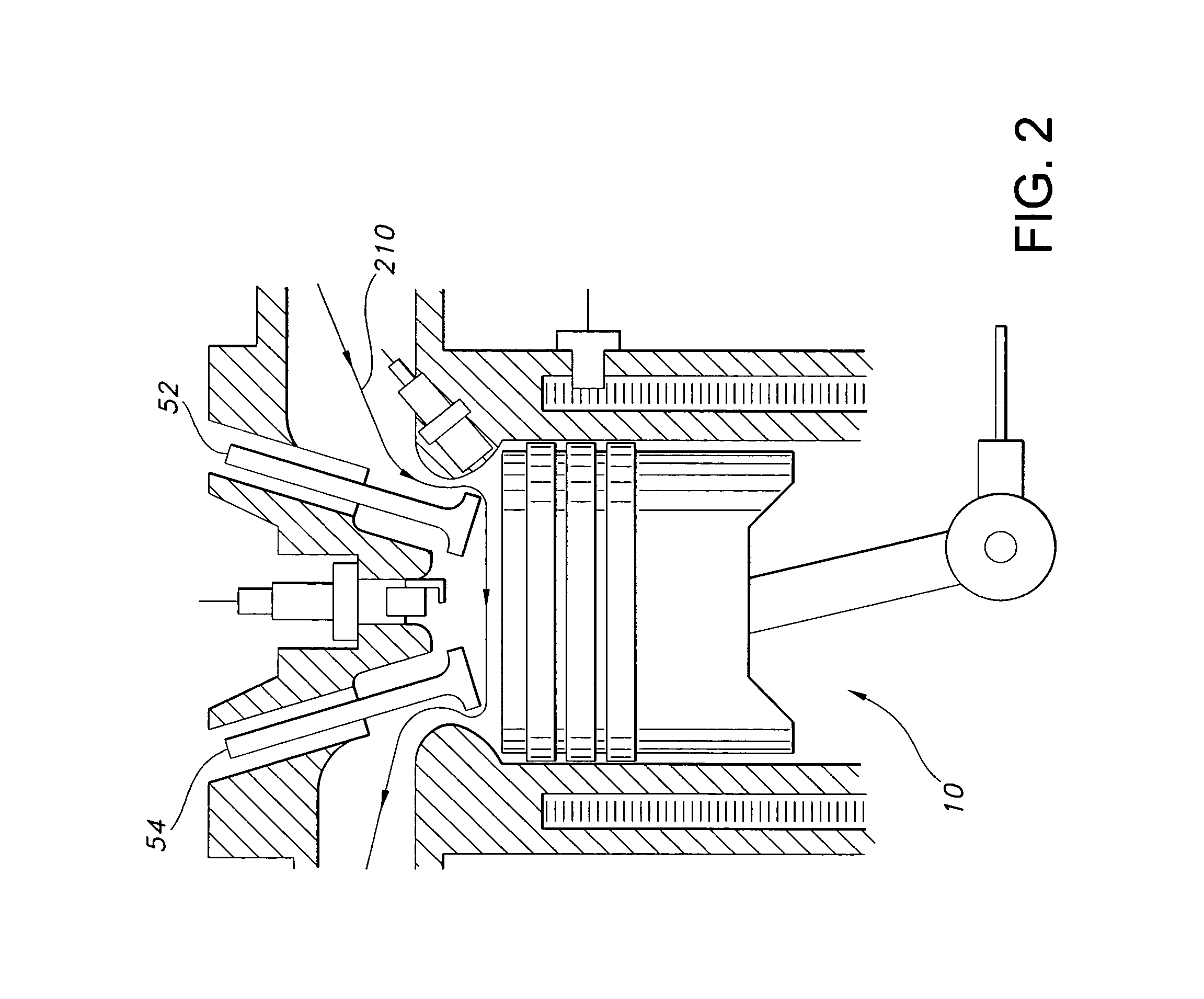

System and method for boosted direct injection engine

ActiveUS7275516B1Increase engine power densityReduced fuel efficiencyElectrical controlInternal combustion piston enginesExhaust valveInlet valve

A method for operating and engine having a cylinder with at least an intake and exhaust valve, comprising of performing a combustion cycle in the cylinder in which exhaust valve closing occurs after intake valve opening thereby creating valve overlap, boosting intake air above exhaust pressure, where said boosted intake air is inducted into said cylinder while said intake valve is open and at least a first portion of said inducted boosted intake air flows past the exhaust valve with both said intake and exhaust valves are open during said overlap, directly injecting fuel to said cylinder that is combusted in said cylinder, where a beginning of said fuel injection occurs after said exhaust valve closing and said directly injected fuel is mixed with at least a second portion of said inducted boosted intake air, and combusting said mixture at a rich air-fuel ratio.

Owner:FORD GLOBAL TECH LLC

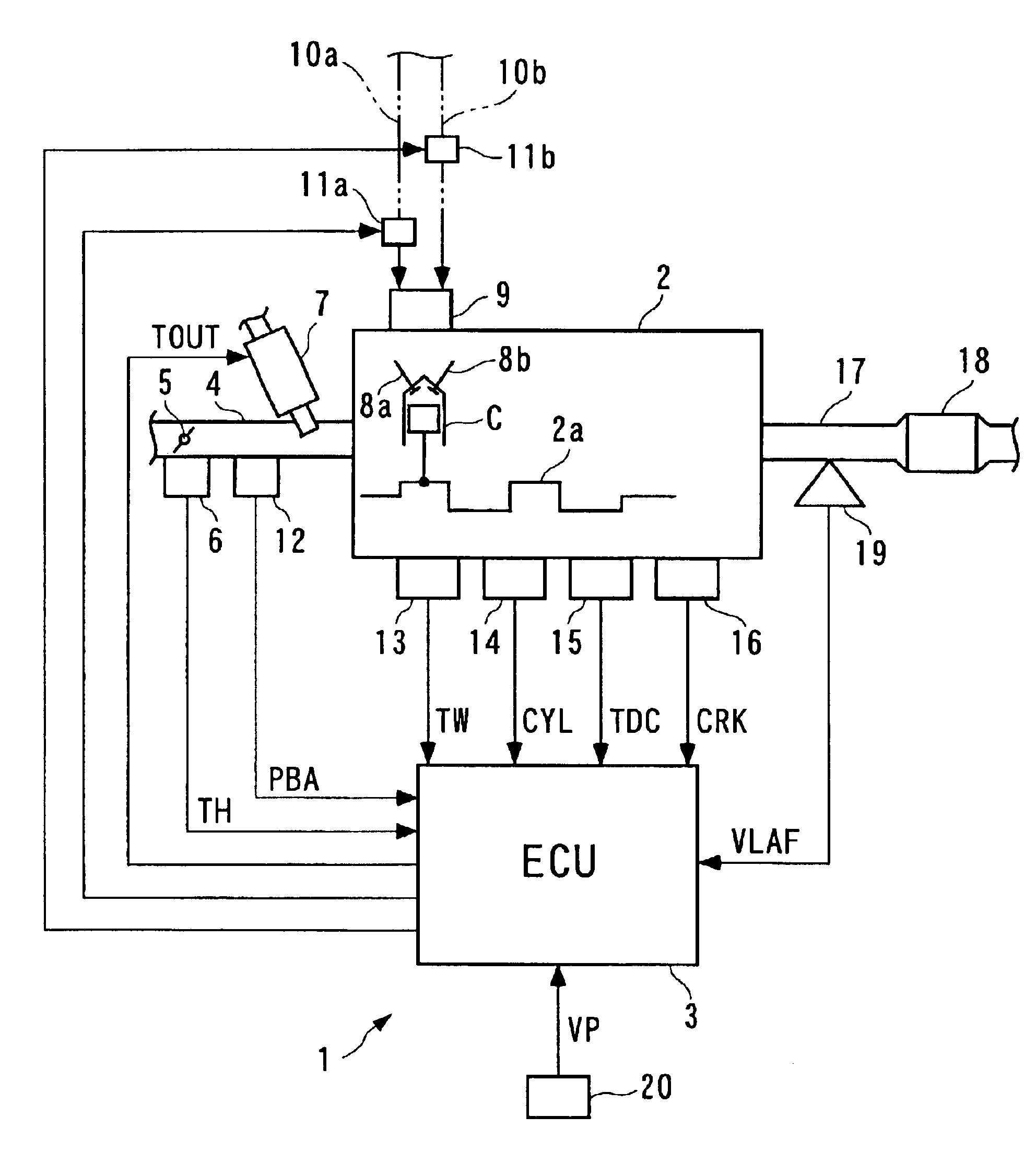

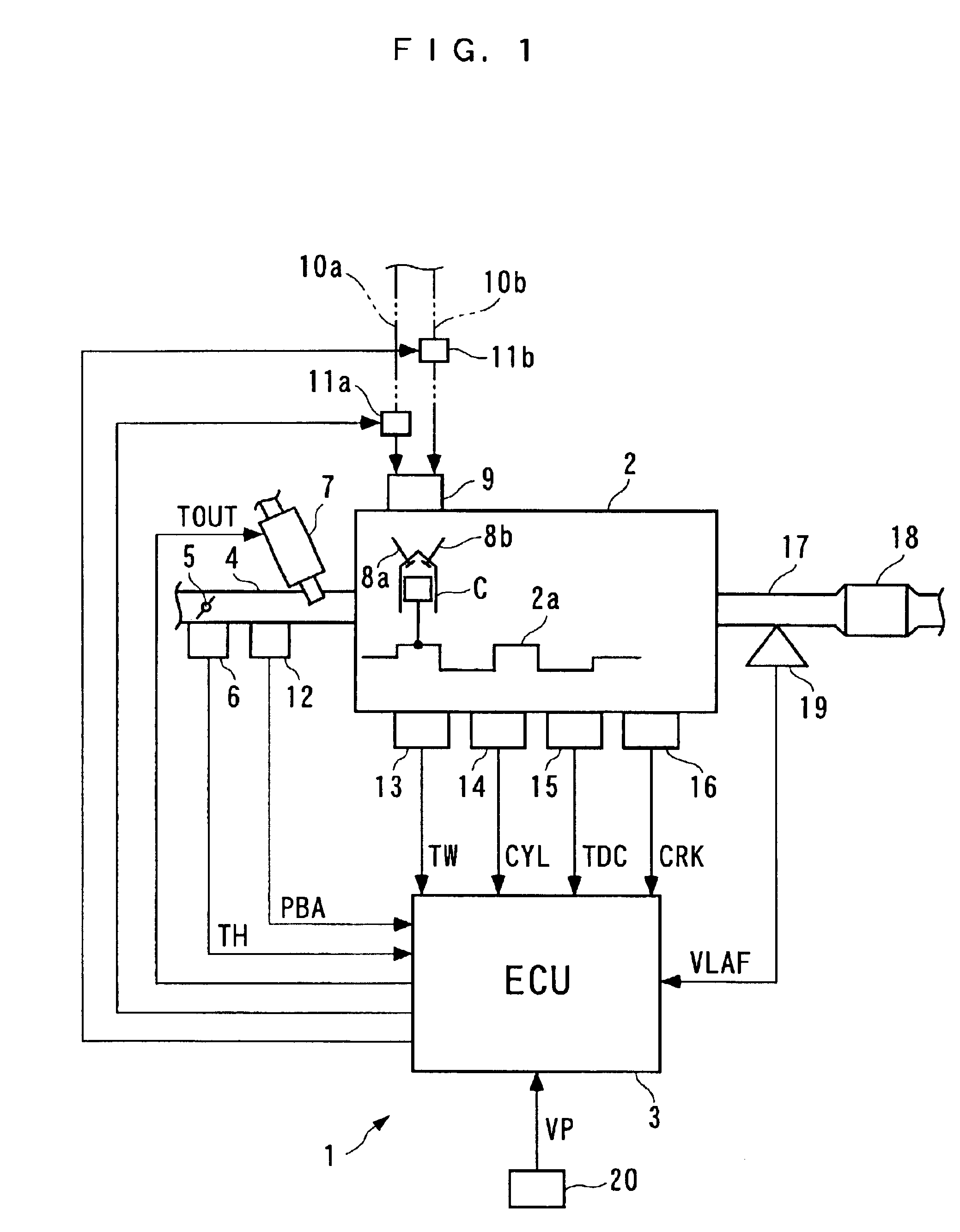

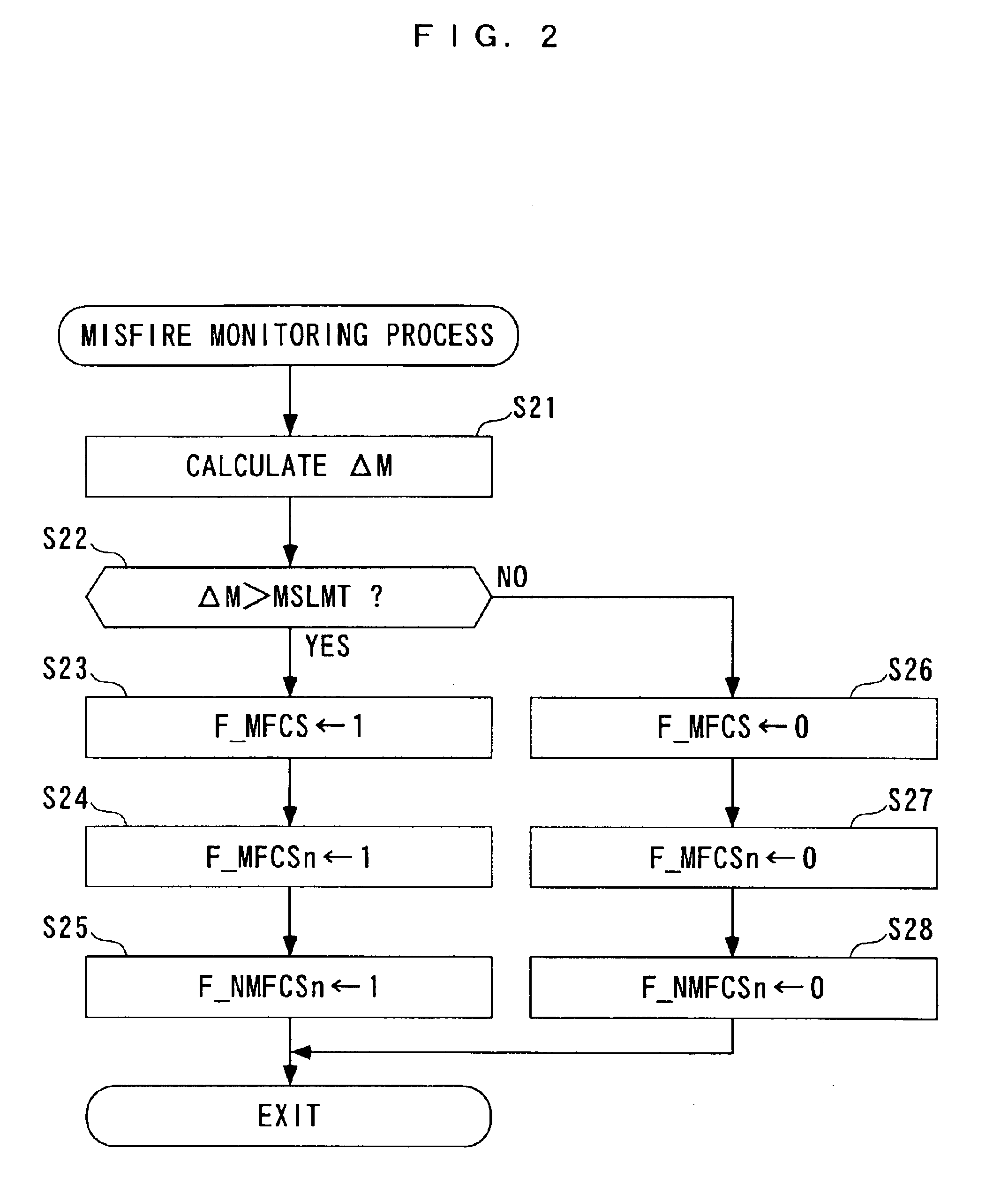

Failure determination system and method for internal combustion engine and engine control unit

InactiveUS6763707B2Internal-combustion engine testingValve arrangementsExternal combustion engineOxygen

A failure determination system and method for an internal combustion engine and an engine control unit are provided which are capable of properly determining a failure of a variable valve mechanism for inactivating a valve system associated with at least one of cylinders during a predetermined operation of the engine, by discriminating a misfire caused by the failure of the mechanism from a normal misfire. Fuel injection valves inject fuel for each cylinder and oxygen concentration of exhaust gases is detected. A misfire condition is detected on a cylinder-by-cylinder basis. Fuel injection to a misfiring cylinder is stopped. A failure of the mechanism is determined, when a parameter based on the oxygen concentration detection indicates a richer value of an actual air-fuel ratio of the exhaust gases than a predetermined reference value does, under a condition of the fuel injection being stopped.

Owner:HONDA MOTOR CO LTD

Engine system and dual fuel vapor purging system with cylinder deactivation

ActiveUS6820597B1Easy to operateNon-fuel substance addition to fuelEngine controllersSystems designFuel vapor

Various systems and methods are disclosed for carrying out combustion in a fuel-cut operation in some or all of the engine cylinders of a vehicle. Further, various subsystems are considered, such as fuel vapor purging, air-fuel ratio control, engine torque control, catalyst design, and exhaust system design.

Owner:FORD GLOBAL TECH LLC

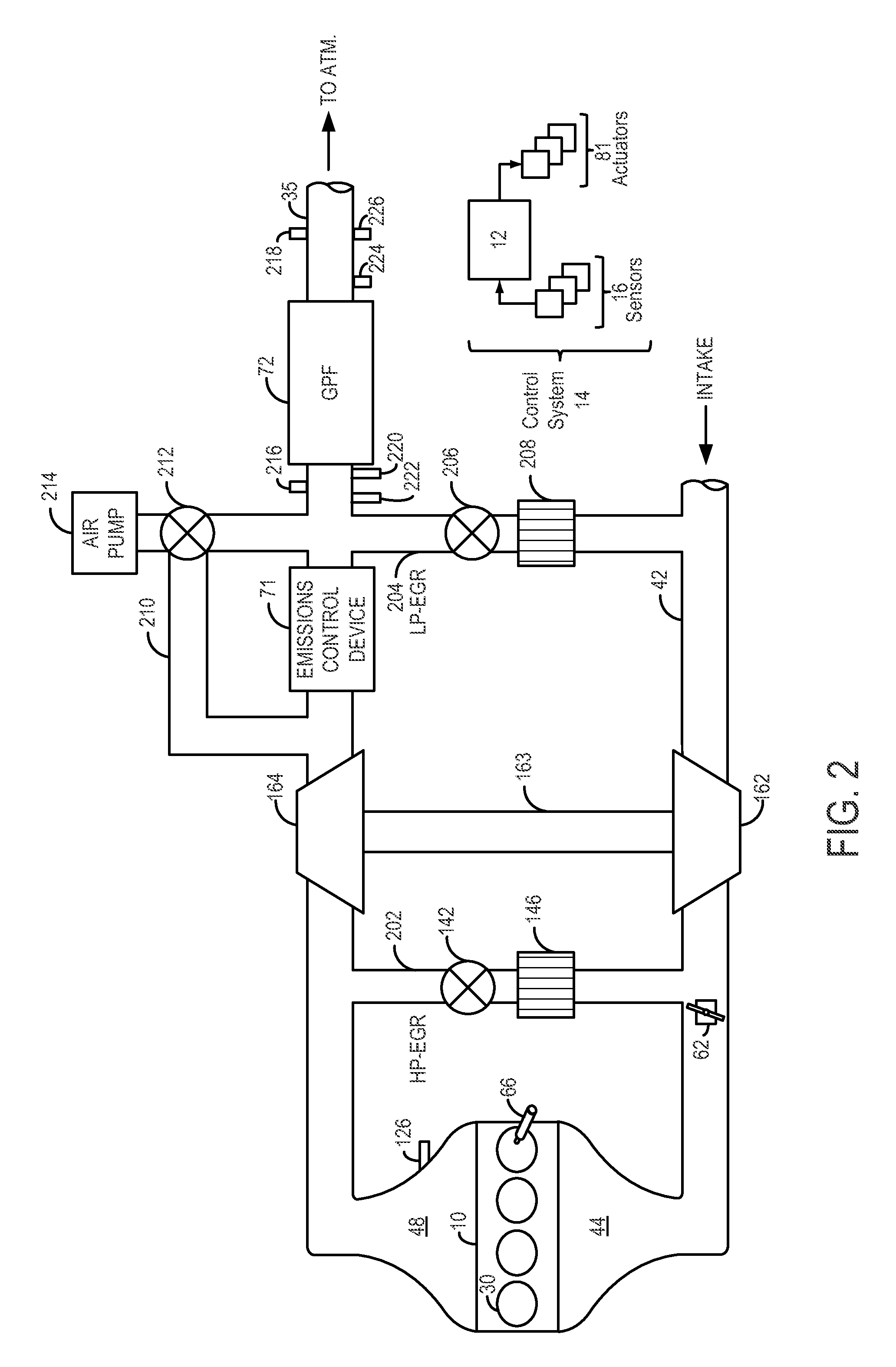

Gasoline particulate filter regeneration and diagnostics

ActiveUS20110072788A1Improve engine performanceReduce transient air-fuel disturbanceElectrical controlNon-fuel substance addition to fuelParticulatesGasoline

Owner:FORD GLOBAL TECH LLC

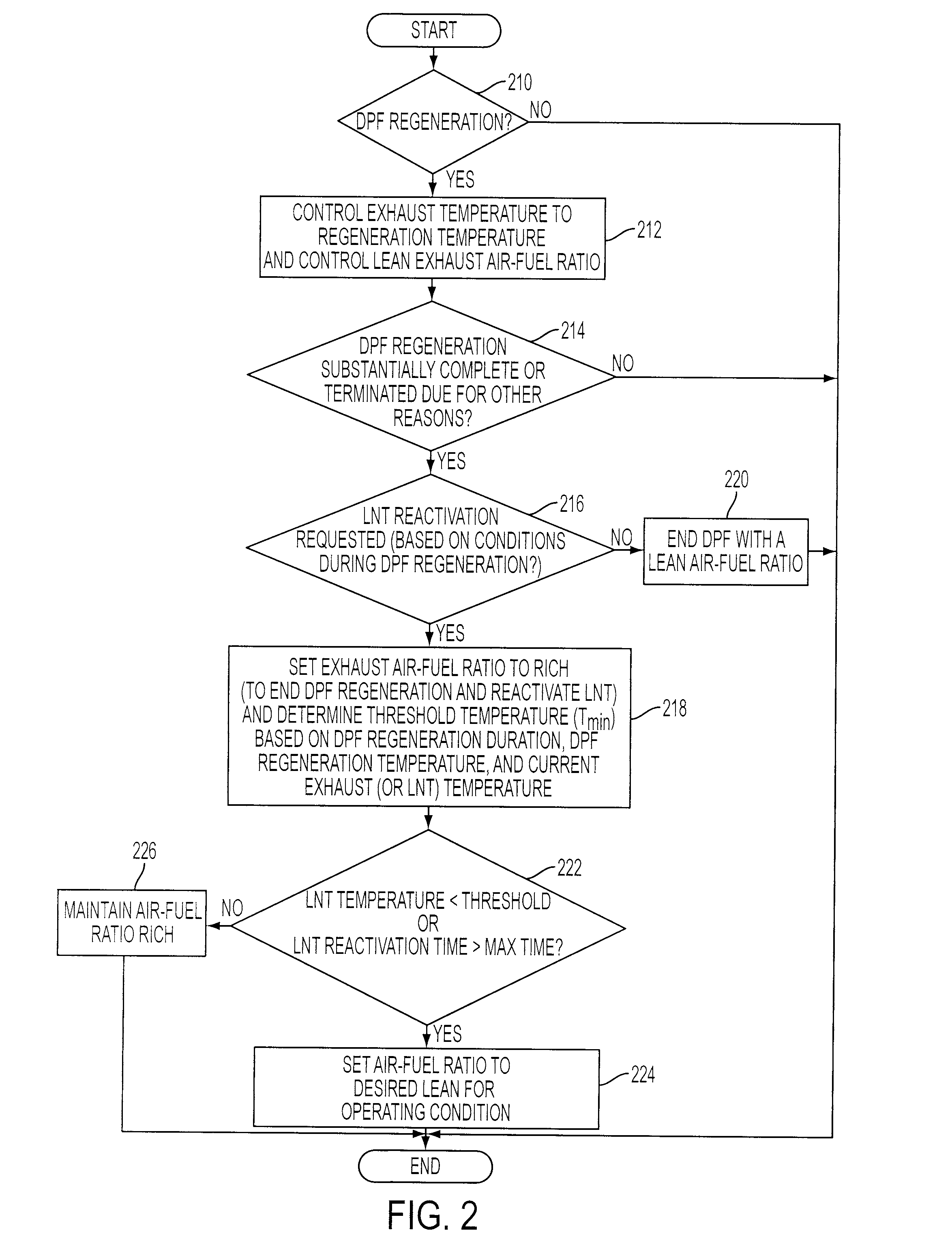

Particulate Filter Regeneration and NOx Catalyst Re-Activation

InactiveUS20080276602A1Improve performanceReduce sulfur poisoningElectrical controlInternal combustion piston enginesParticulatesControl system

A system and method may be provided for operating a system having an engine with an emission control system, the emission control system including a lean NOx trap and a particulate filter, where after lean exhaust gas air-fuel ratio regeneration of the particulate filter at an elevated regeneration temperature, a rich or intermittently rich exhaust air-fuel ratio is provided for a duration lasting until LNT temperature falls to a minimum threshold, where said rich or intermittently rich operation reactivates catalysts in the LNT and reverses deactivation caused by the elevated temperature lean operation associated with previous particulate filter regeneration.

Owner:FORD GLOBAL TECH LLC

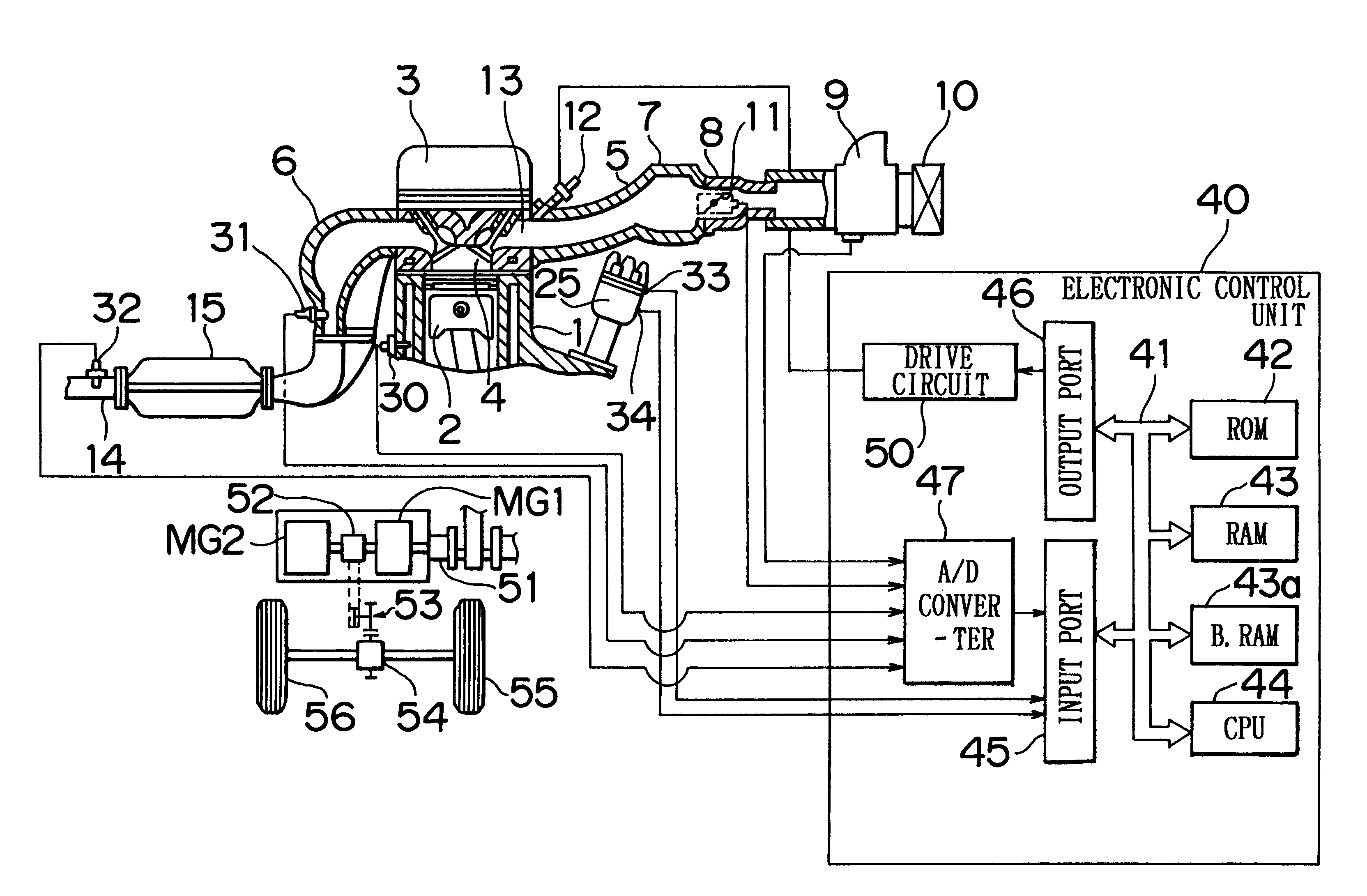

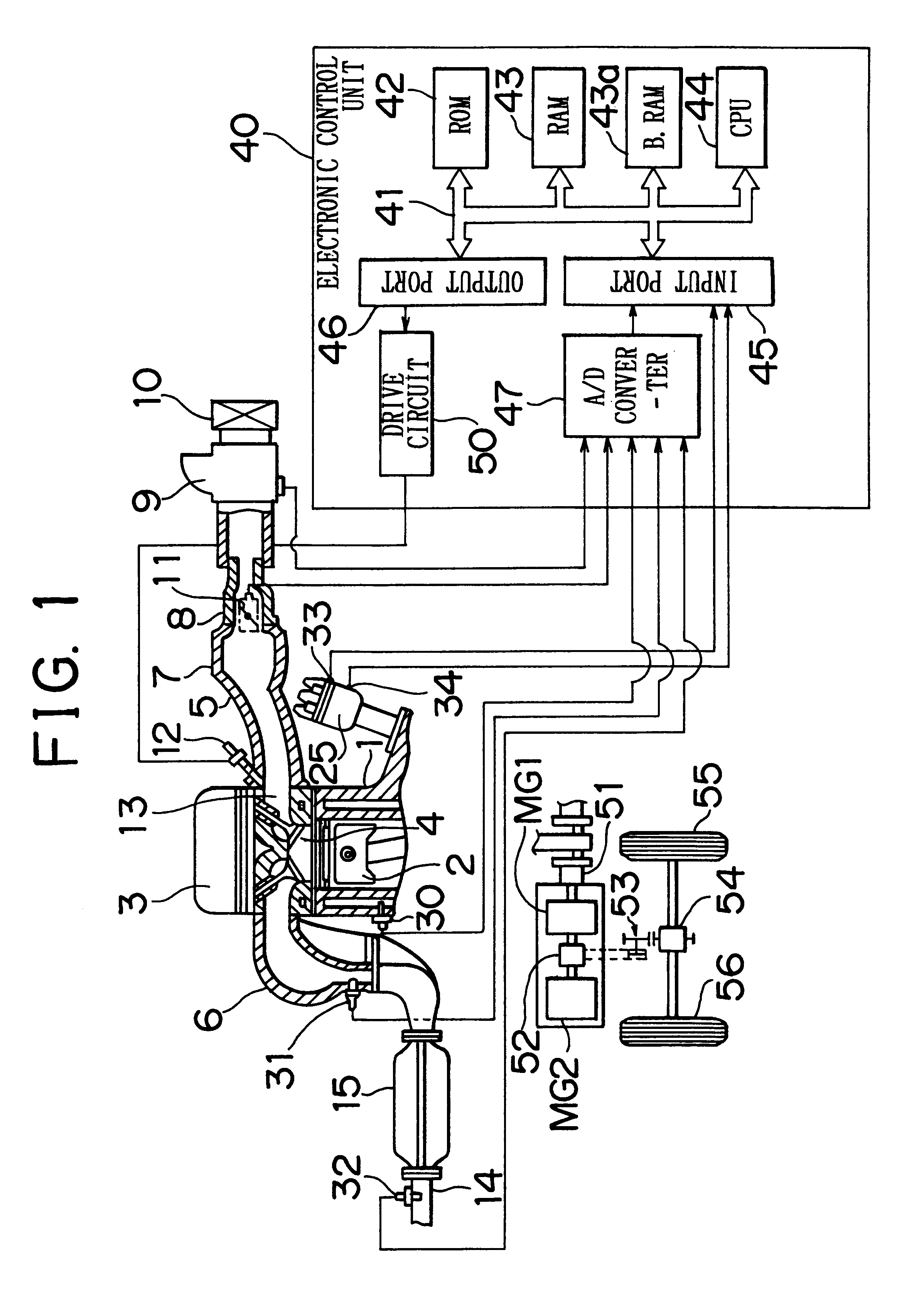

Catalyst deterioration detecting apparatus for internal combustion engine

InactiveUS6173569B1Improve accuracyDegree of deterioration can be determinedHybrid vehiclesElectrical controlExternal combustion engineOxygen

A catalyst deterioration detecting apparatus for a hybrid vehicle having an internal combustion engine and an electric motor as power sources includes an air-fuel ratio sensor downstream of a catalyst disposed in an exhaust passage of the engine. An amount of oxygen stored in the catalyst is estimated and, based on the estimated amount of oxygen and an output produced by the air-fuel ratio sensor after the engine is restarted after having been temporarily stopped, it is determined whether the catalyst has excessively deteriorated.

Owner:TOYOTA JIDOSHA KK

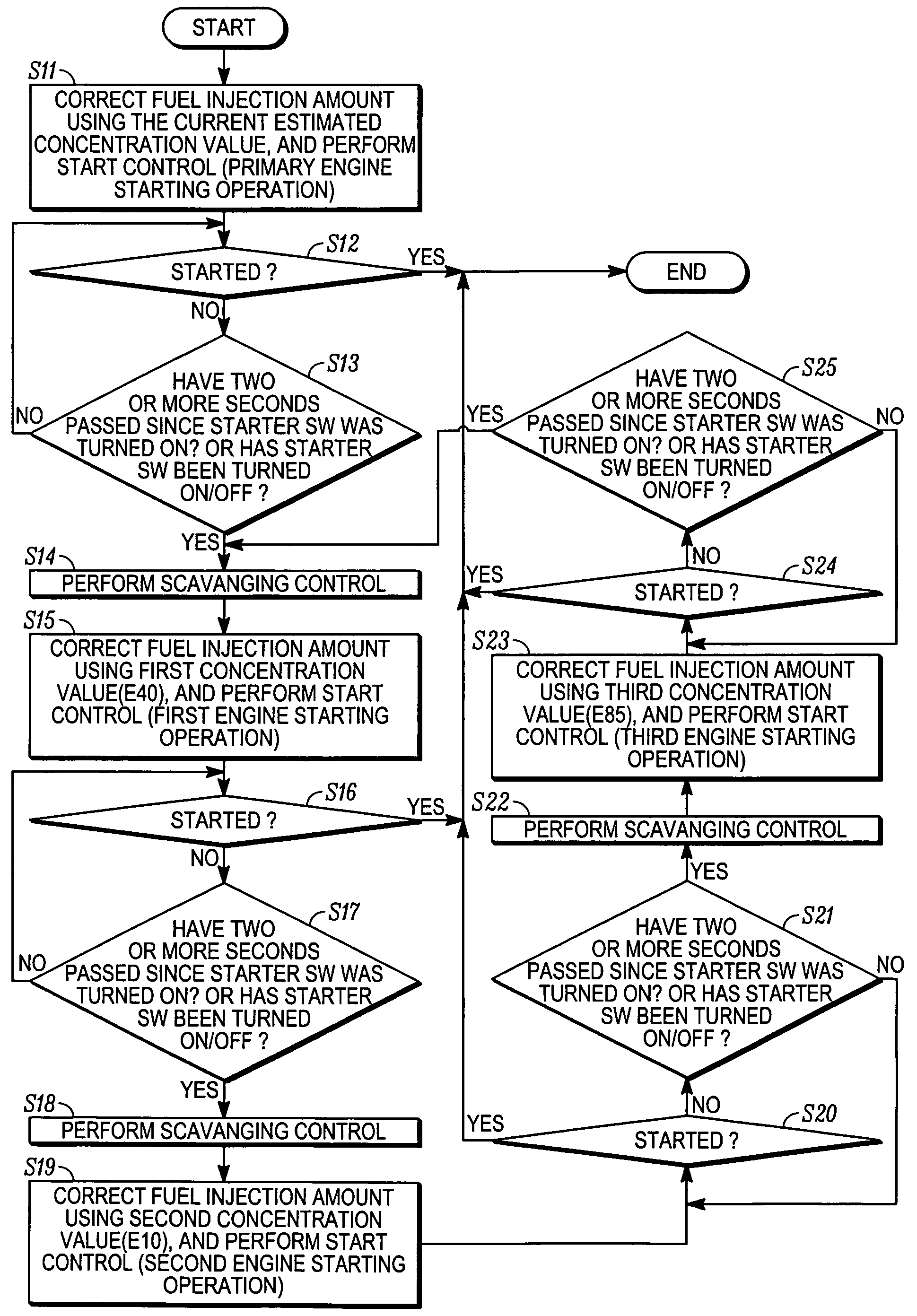

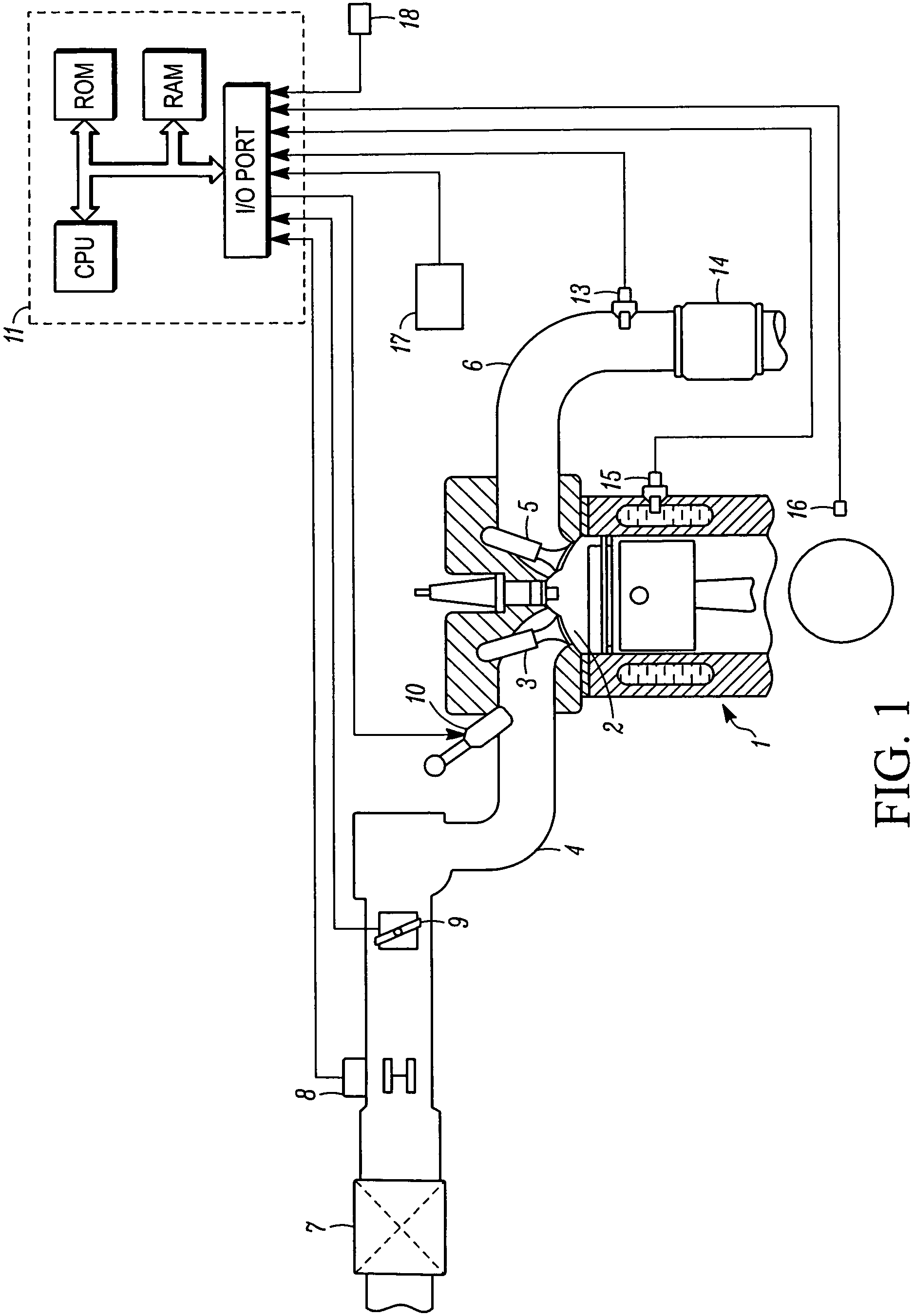

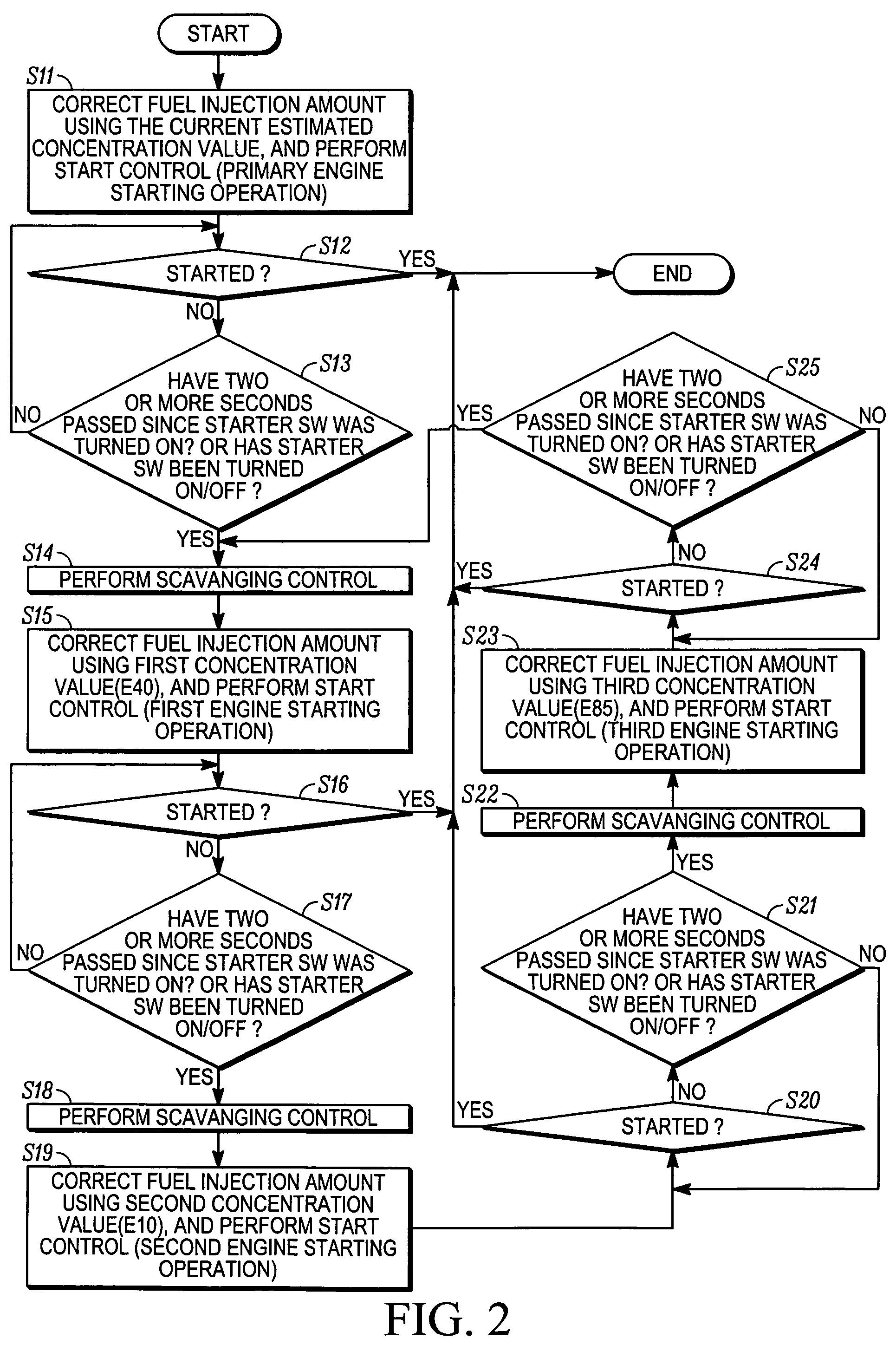

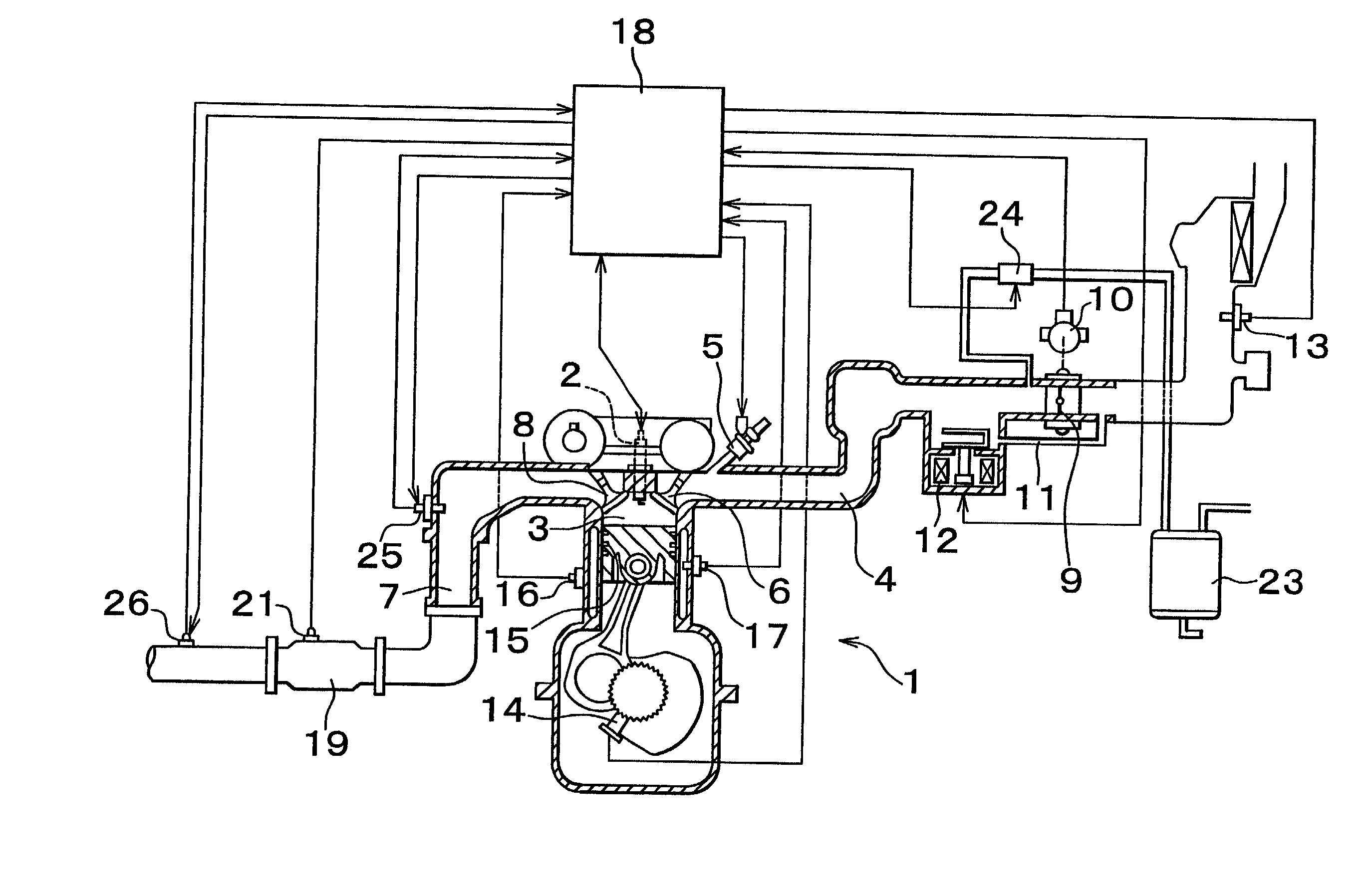

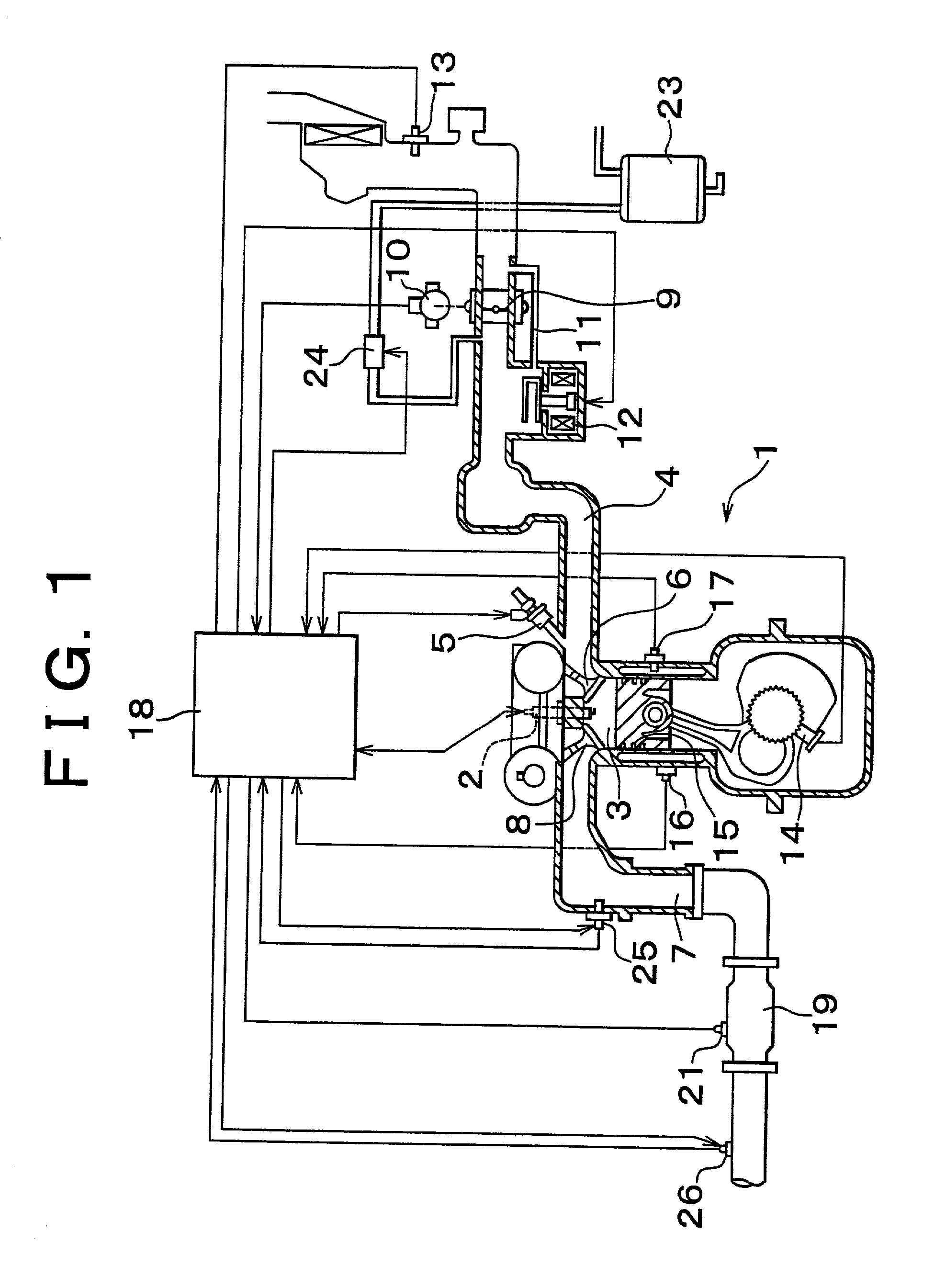

Apparatus and method for controlling an internal combustion engine

When an internal combustion engine controller determines that an internal combustion engine is experiencing difficulty in starting, the fuel injection amount is corrected according to a first estimated ethanol (alcohol) concentration value that is approximately in the middle concentration value between the alcohol concentration of the fuel with the highest alcohol concentration and the alcohol concentration of the fuel with the lowest alcohol concentration among the fuels that can possibly be purchased in the market. If it is determined that the engine is experiencing difficulty in starting using the corrected fuel injection amount, the fuel injection amount is corrected a second time using a second estimated alcohol concentration value different from the first estimated alcohol concentration value. As a result, the engine air-fuel ratio can be optimized when starting the engine, so that poor engine starting can be quickly overcome.

Owner:NISSAN MOTOR CO LTD

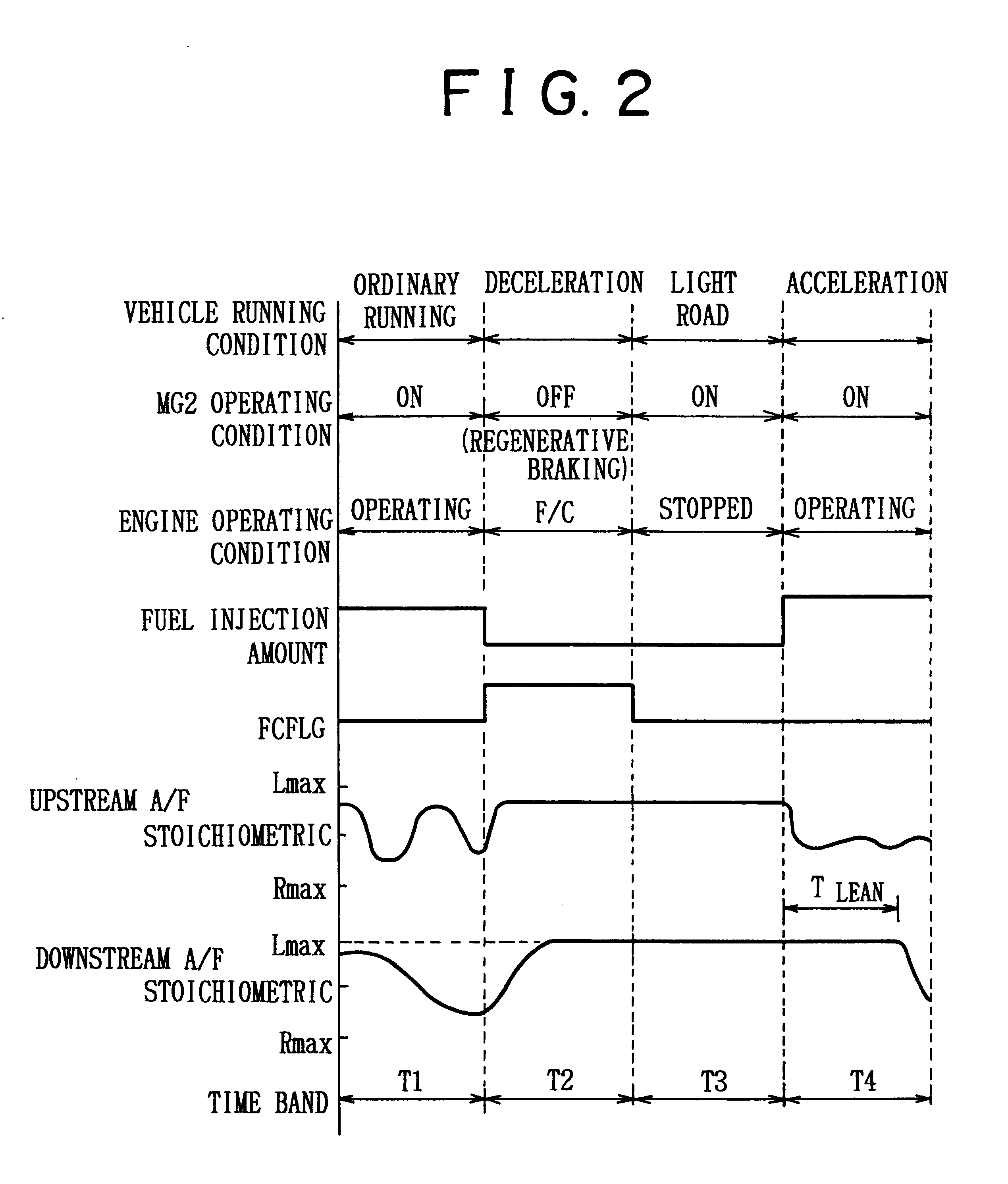

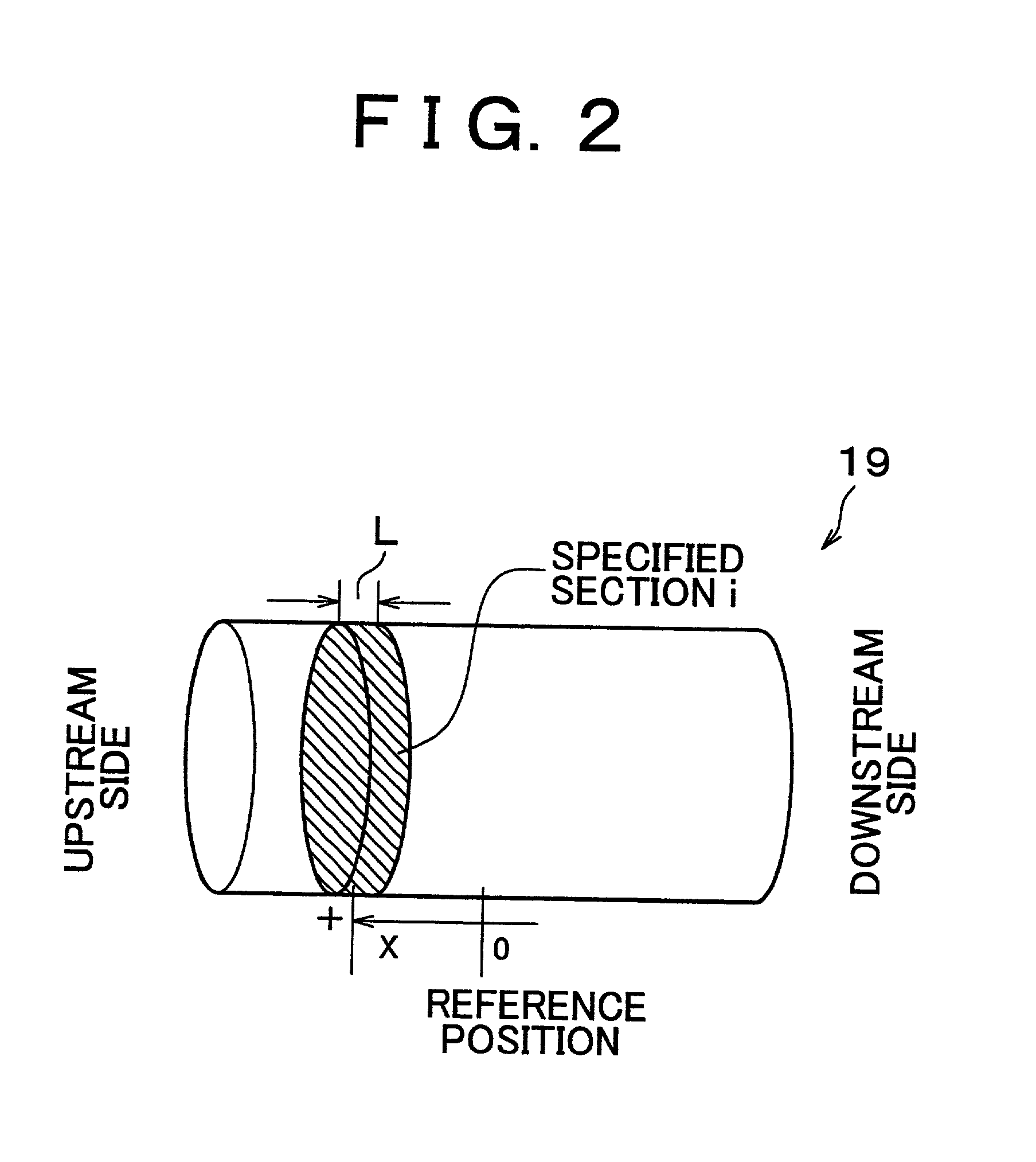

Air-Fuel ratio control system for internal combustion engine and control method thereof

An air-fuel ratio control system for an internal combustion engine estimates an oxygen storage amount of a catalyst based on a record of an oxygen storage amount, and controls an air-fuel ratio based on the estimated oxygen storage amount. The catalyst is divided into multiple sections in a flow direction of an exhaust gas, the oxygen storage amount in a specified section is estimated according to a behavior of an exhaust gas on upstream and downstream sides of the respective specified sections, and the air-fuel ratio is controlled based on the estimated oxygen storage amount in the specified section.

Owner:TOYOTA JIDOSHA KK

System for controlling valve timing of an engine with cylinder deactivation

ActiveUS20050268880A1Sufficient NOx reduction and fuel economy benefitsEasy to operateValve arrangementsElectrical controlSystems designControl valves

Various systems and methods are disclosed for carrying out combustion in a fuel-cut operation in some or all of the engine cylinders of a vehicle. Further, various subsystems are considered, such as fuel vapor purging, air-fuel ratio control, engine torque control, catalyst design, and exhaust system design.

Owner:FORD GLOBAL TECH LLC

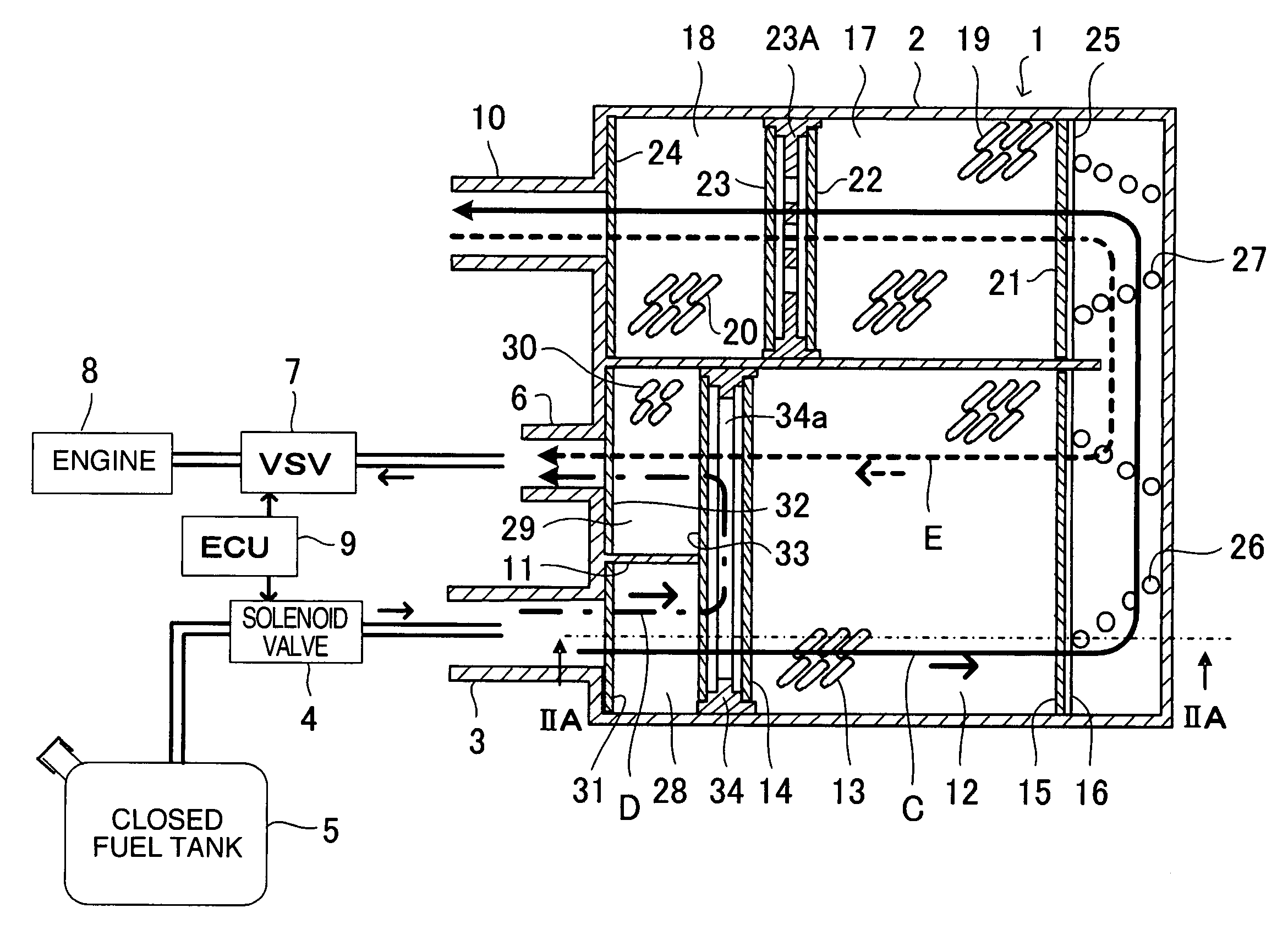

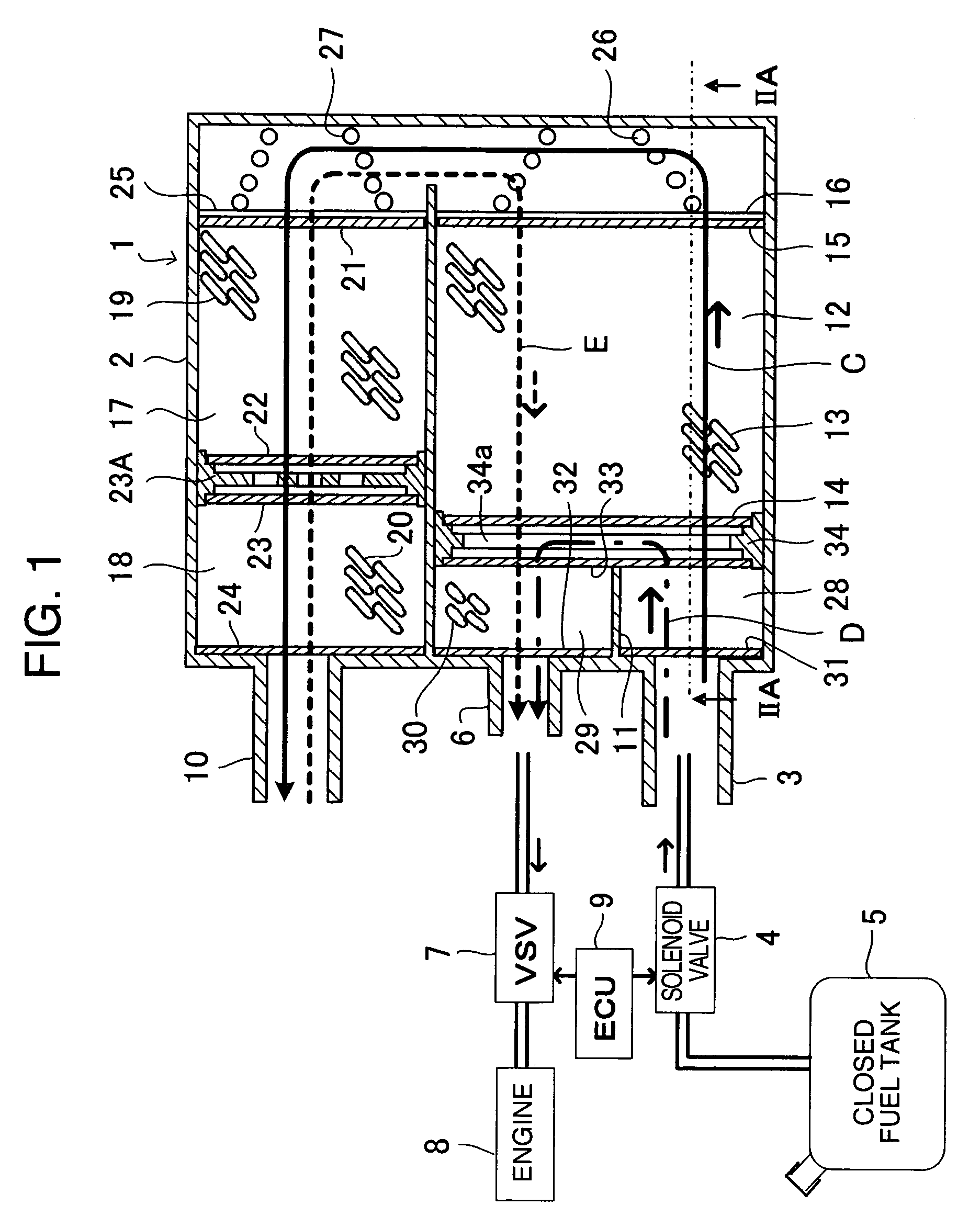

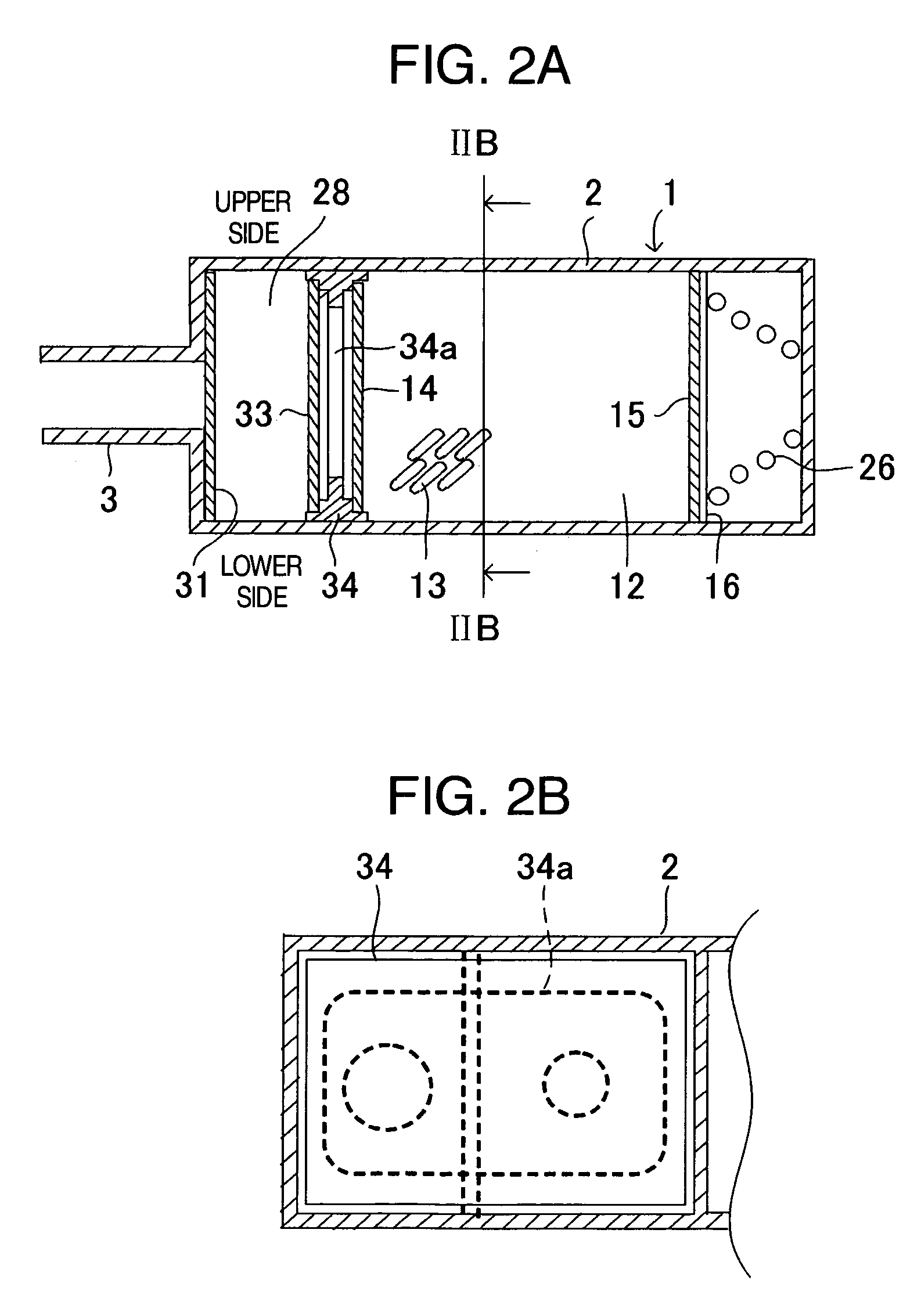

Canister

A canister comprises a tank port communicated with an upper air chamber in a closed fuel tank, a purge port communicated with an intake passage of an engine, an atmospheric port opened to the atmosphere, and a main adsorbent chamber containing activated carbon, and the canister is further provided with a partition plate between the tank port and the purge port for preventing both ports from being directly communicated with each other, so as to form a first chamber between the main adsorbent chamber and the tank port, and a second chamber between the main adsorbent chamber and the purge port, and a purge buffer plate is further provided in the main adsorbent chamber between the tank port and the purge port, for communicating between the first and second chambers with each other, the first chamber serves as an air chamber containing no activated carbon while the second chamber contains activated carbon. With this configuration, the canister has no external pipe line, the time change in fuel concentration of purged gas during treatment of evaporated fuel from the fuel tank is moderated in order to restrain an engine air-fuel ratio from being abruptly changed, and the operation ability of the engine can be satisfied.

Owner:AISAN IND CO LTD +1

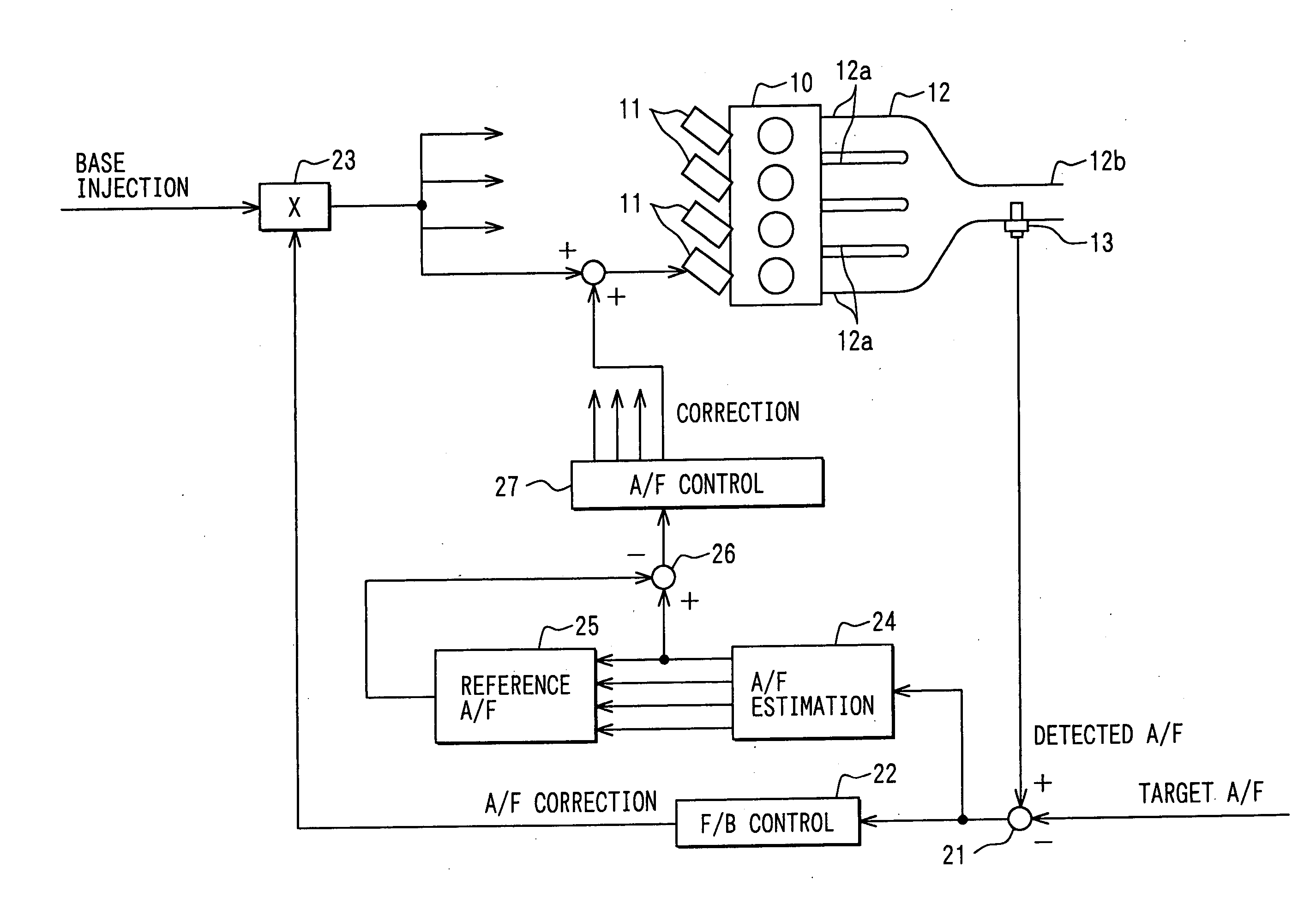

Cylinder-by-cylinder air-fuel ratio calculation apparatus for multi-cylinder internal combustion engine

ActiveUS20050022797A1Improve accuracyResolve complicationsElectrical controlNon-fuel substance addition to fuelControl theoryAir–fuel ratio

An air-fuel ratio deviation calculated by an air-fuel ratio deviation calculation part is inputted to a cylinder-by-cylinder air-fuel ratio estimation part. A cylinder-by-cylinder air-fuel ratio is estimated in the cylinder-by-cylinder air-fuel ratio estimation part. In the cylinder-by-cylinder air-fuel ratio estimation part, attention is paid to gas exchange in an exhaust collective part of an exhaust manifold, and a model is created. In this model, a detection value of an A / F sensor is obtained by multiplying histories of the cylinder-by-cylinder air-fuel ratio of an inflow gas in the exhaust collective part and histories of the detection value of the A / F sensor by specified weights respectively and by adding them. The cylinder-by-cylinder air-fuel ratio is estimated on the basis of the model.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com