Patents

Literature

315 results about "Idle speed control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

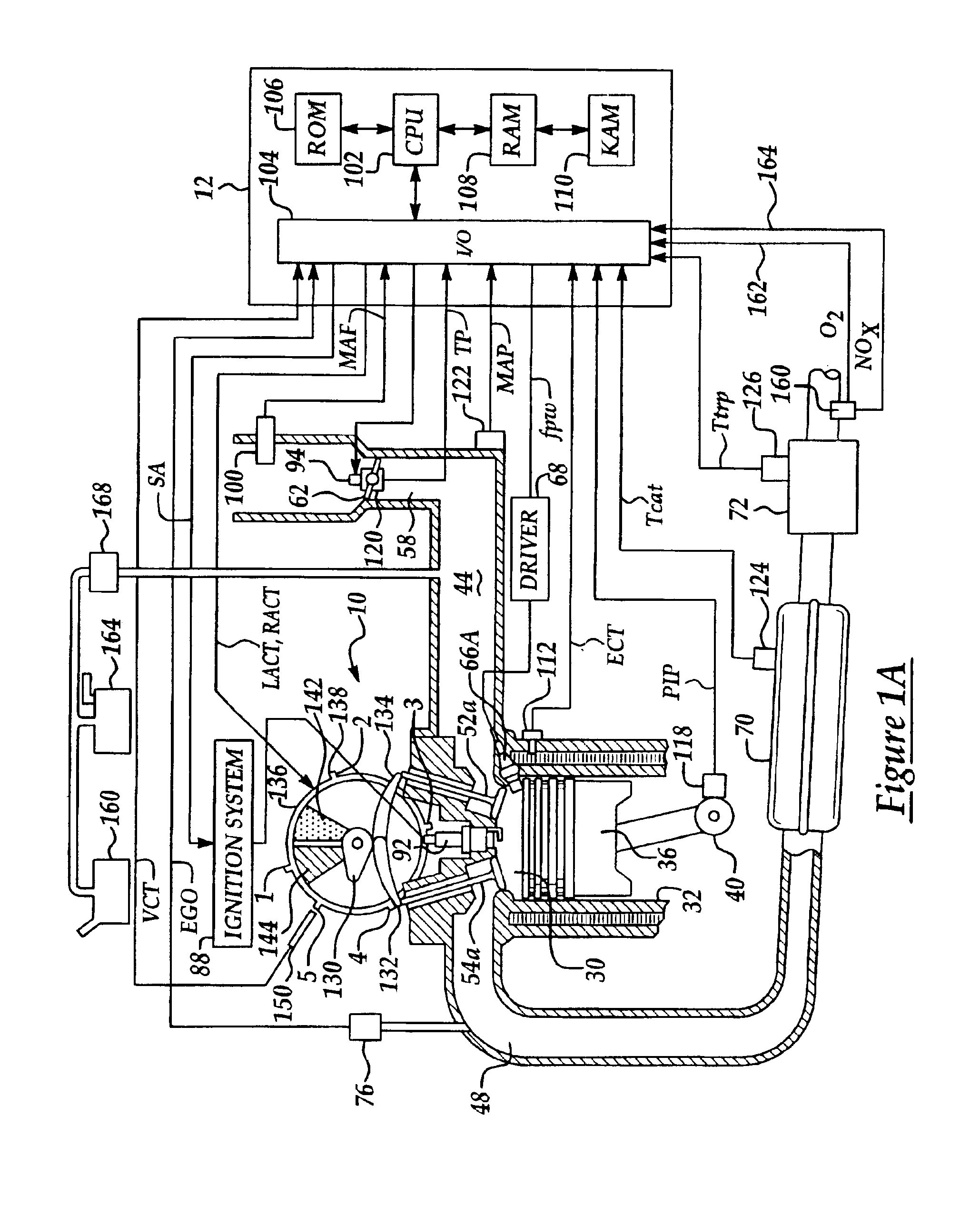

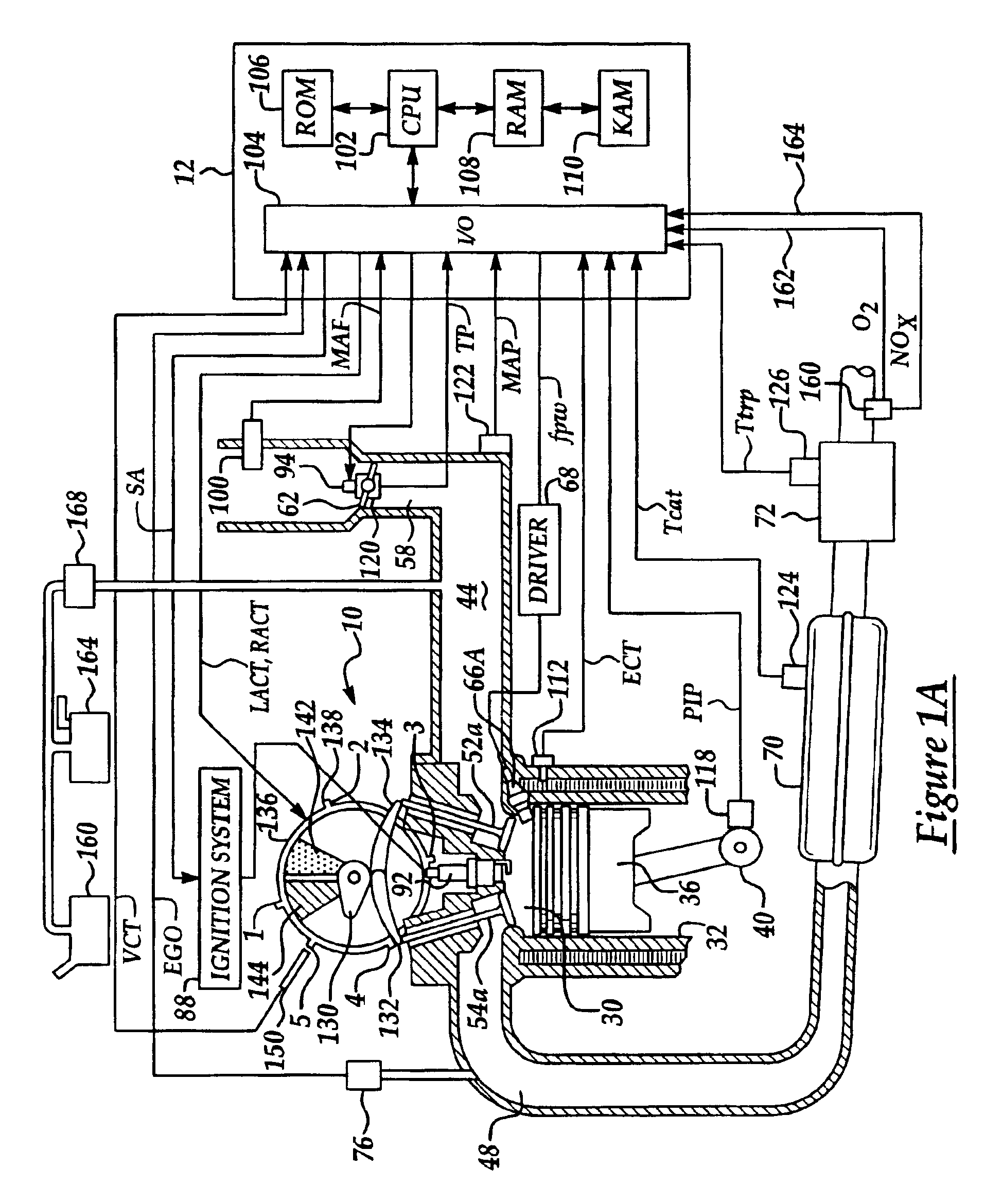

Method for rapid catalyst heating

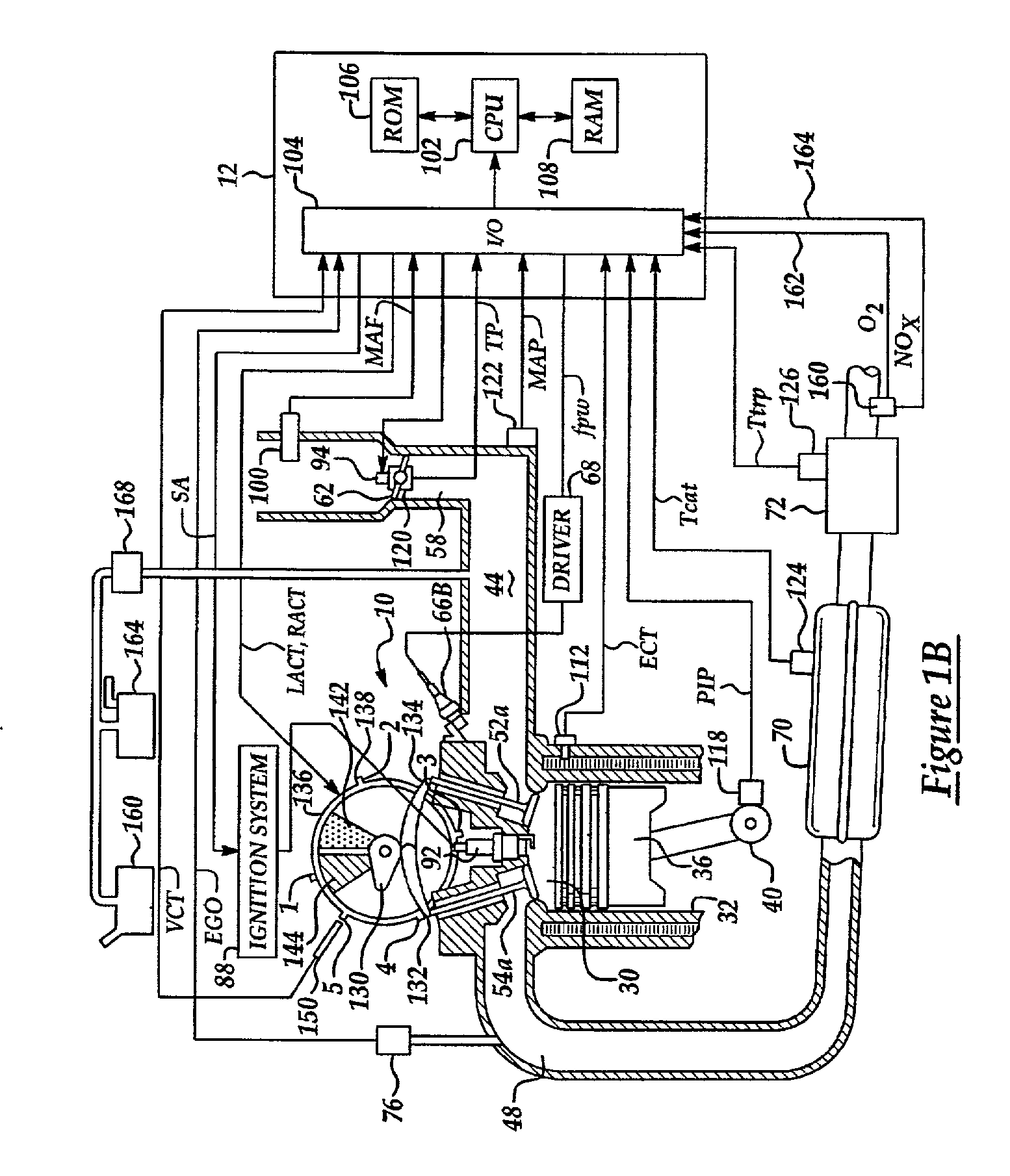

InactiveUS6568177B1High load conditionMore ignition timingElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

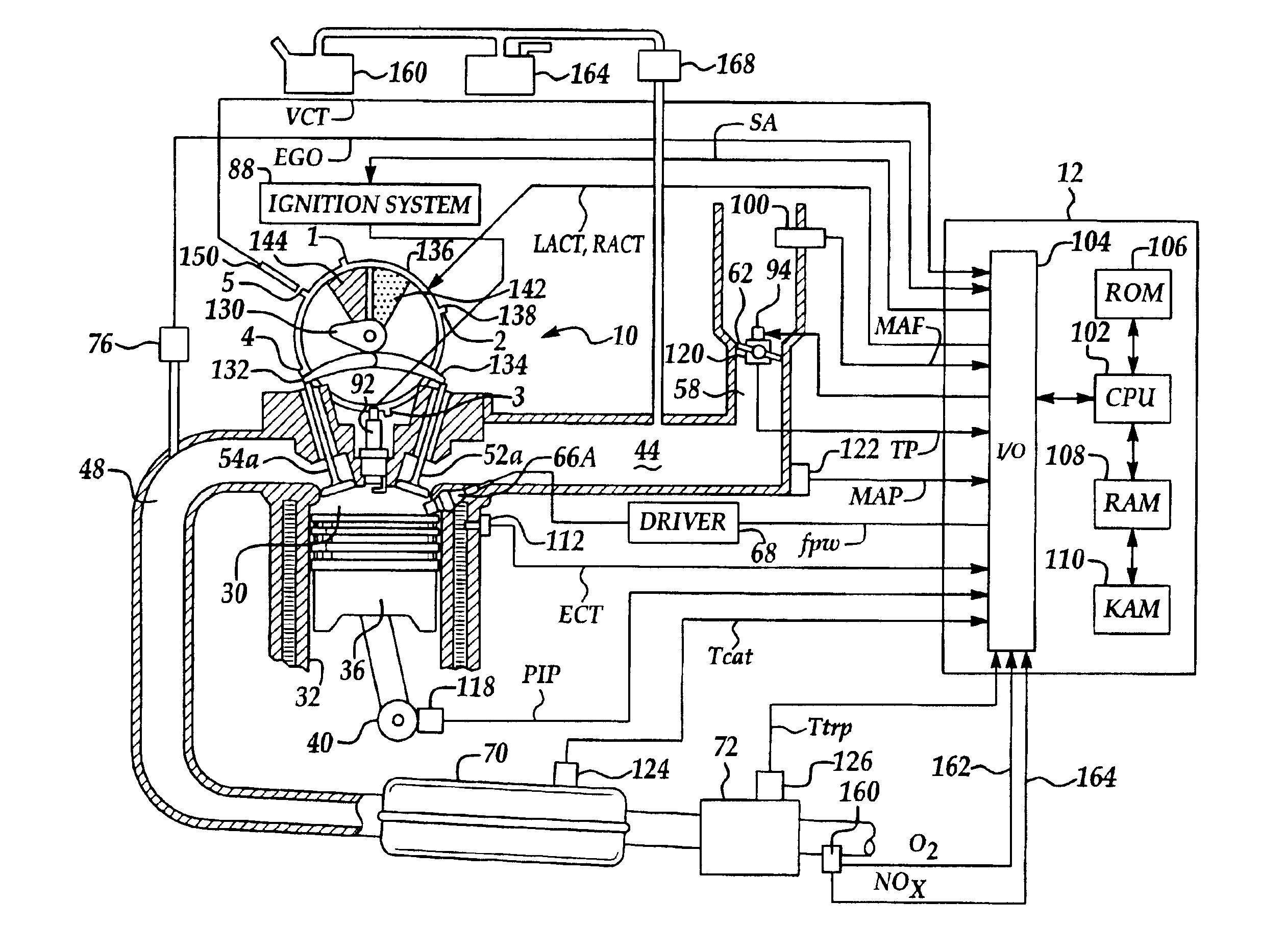

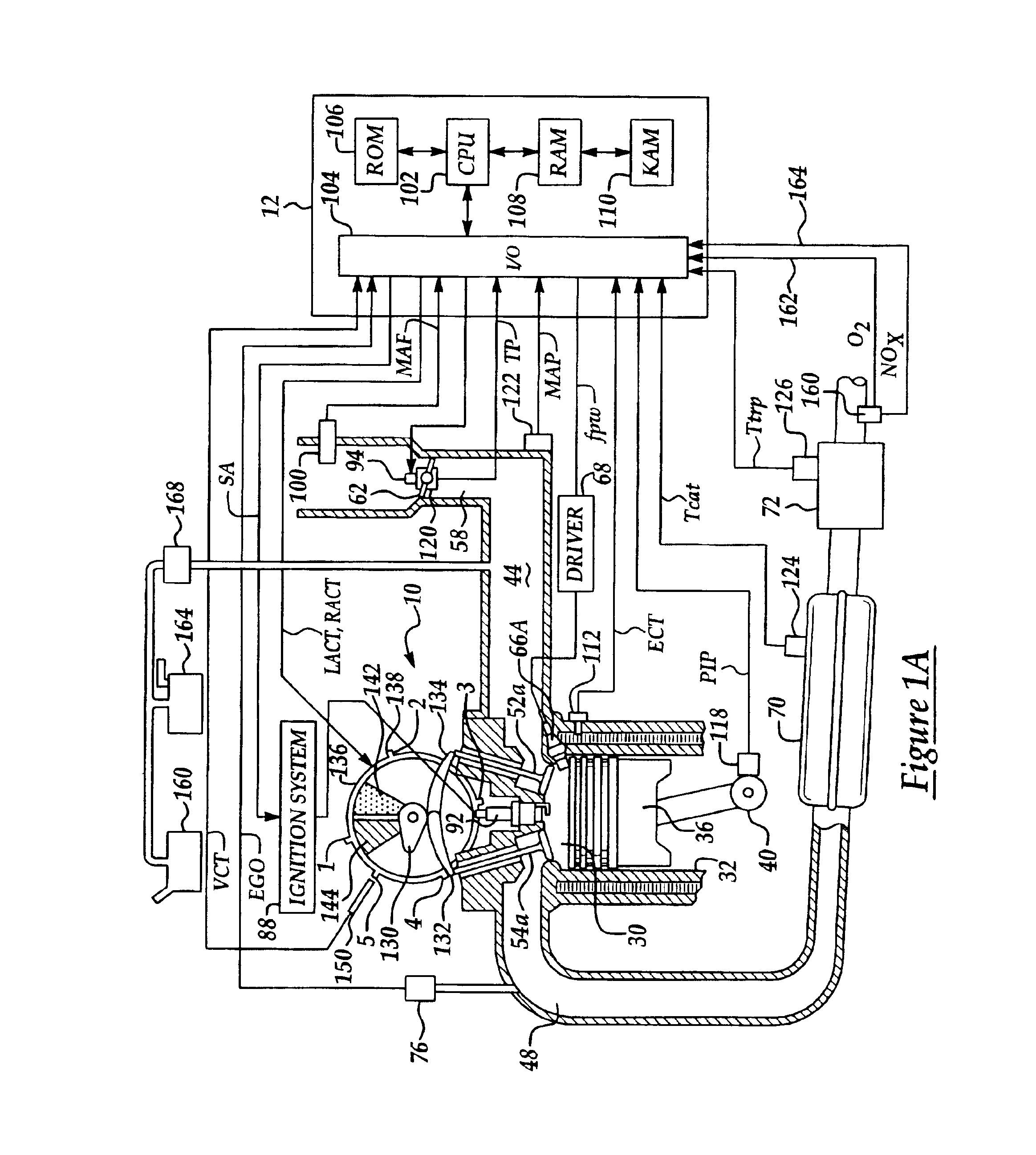

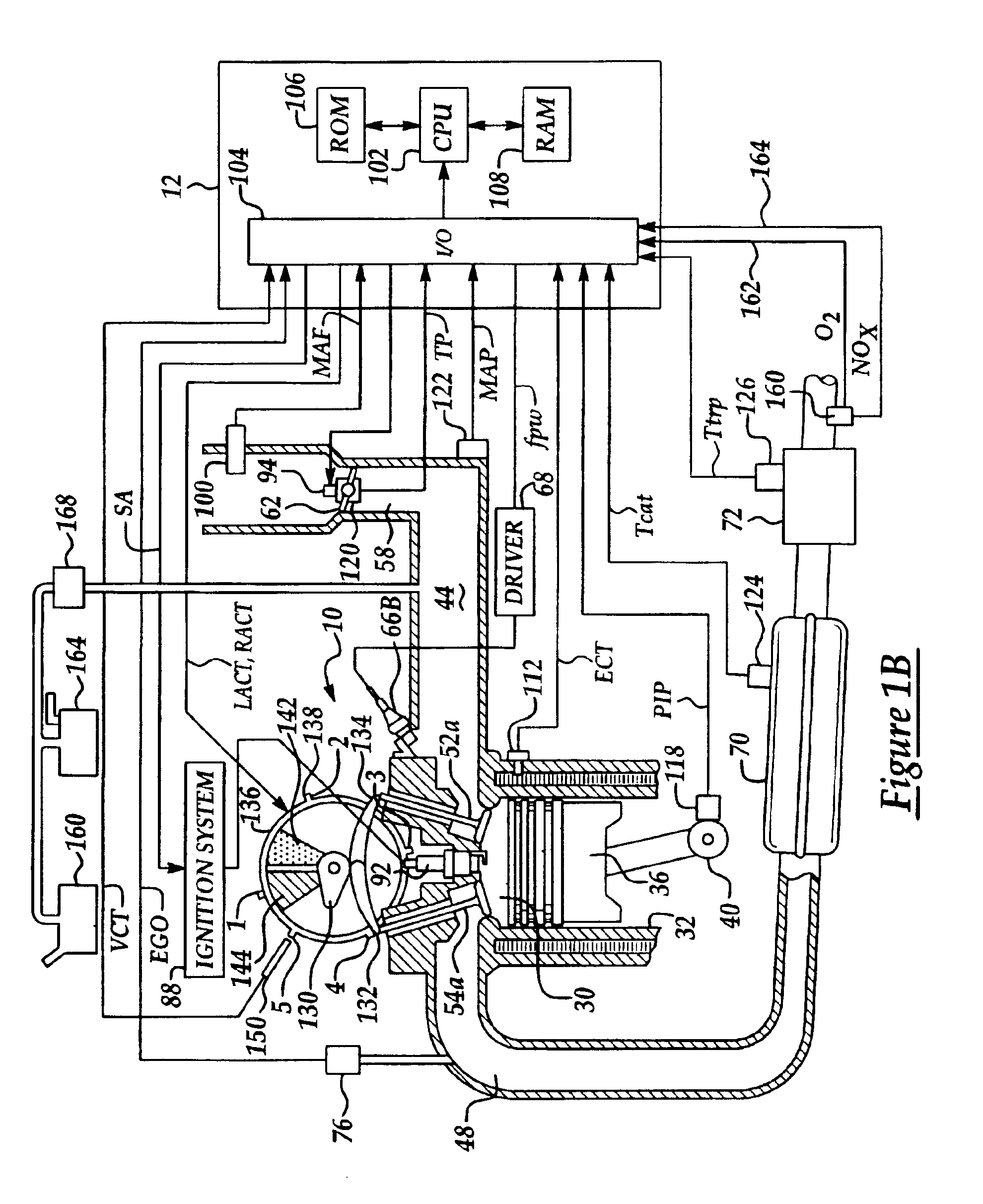

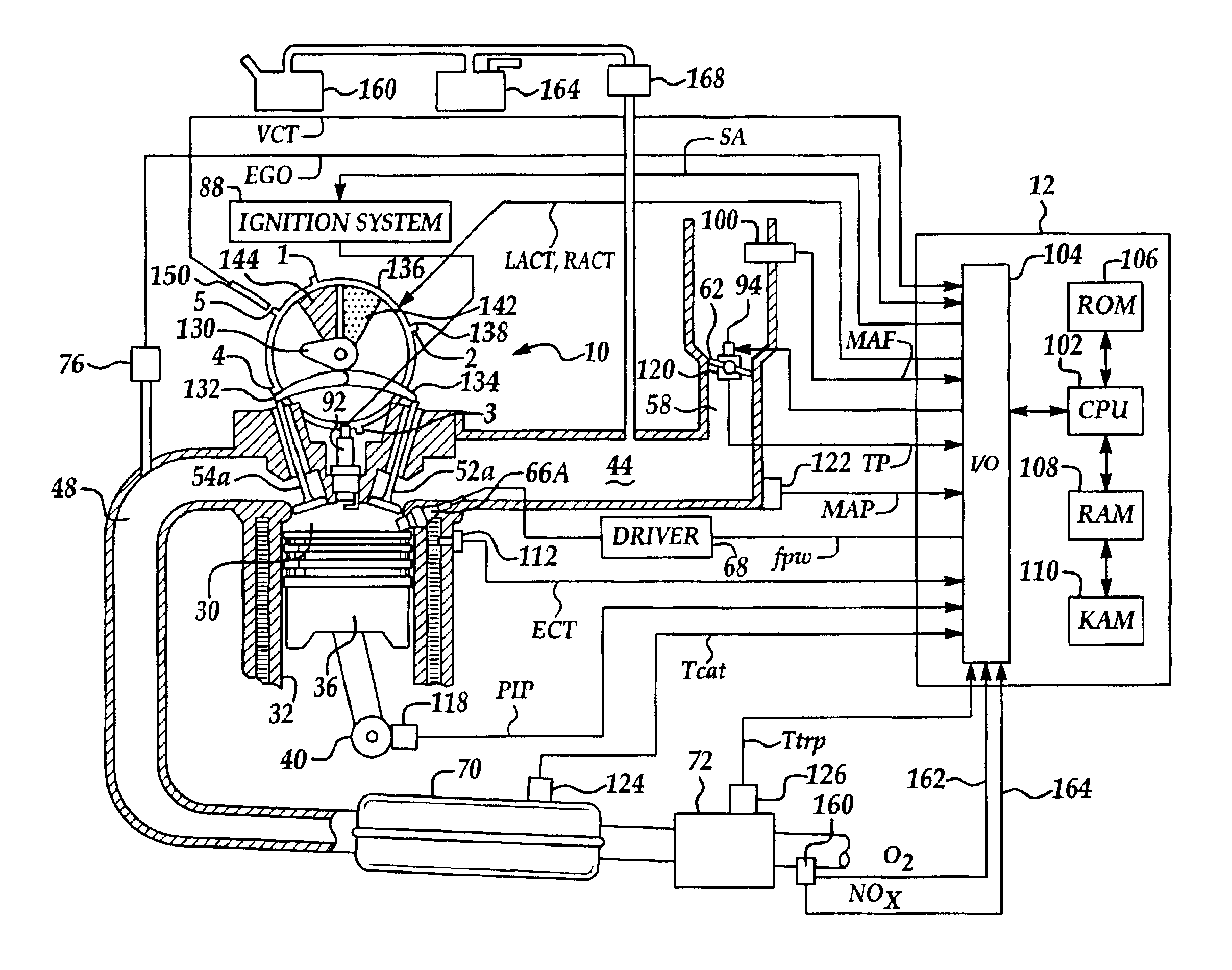

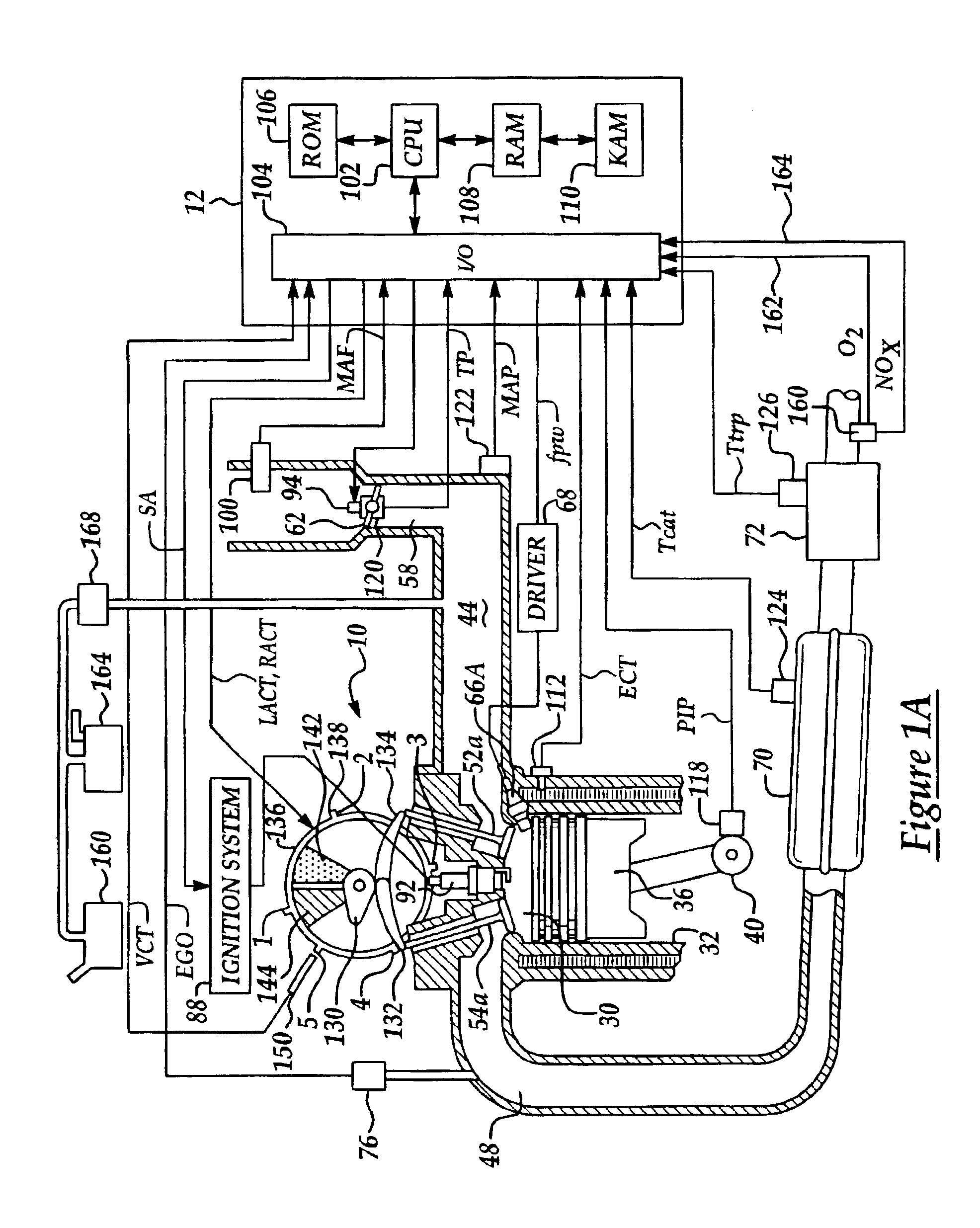

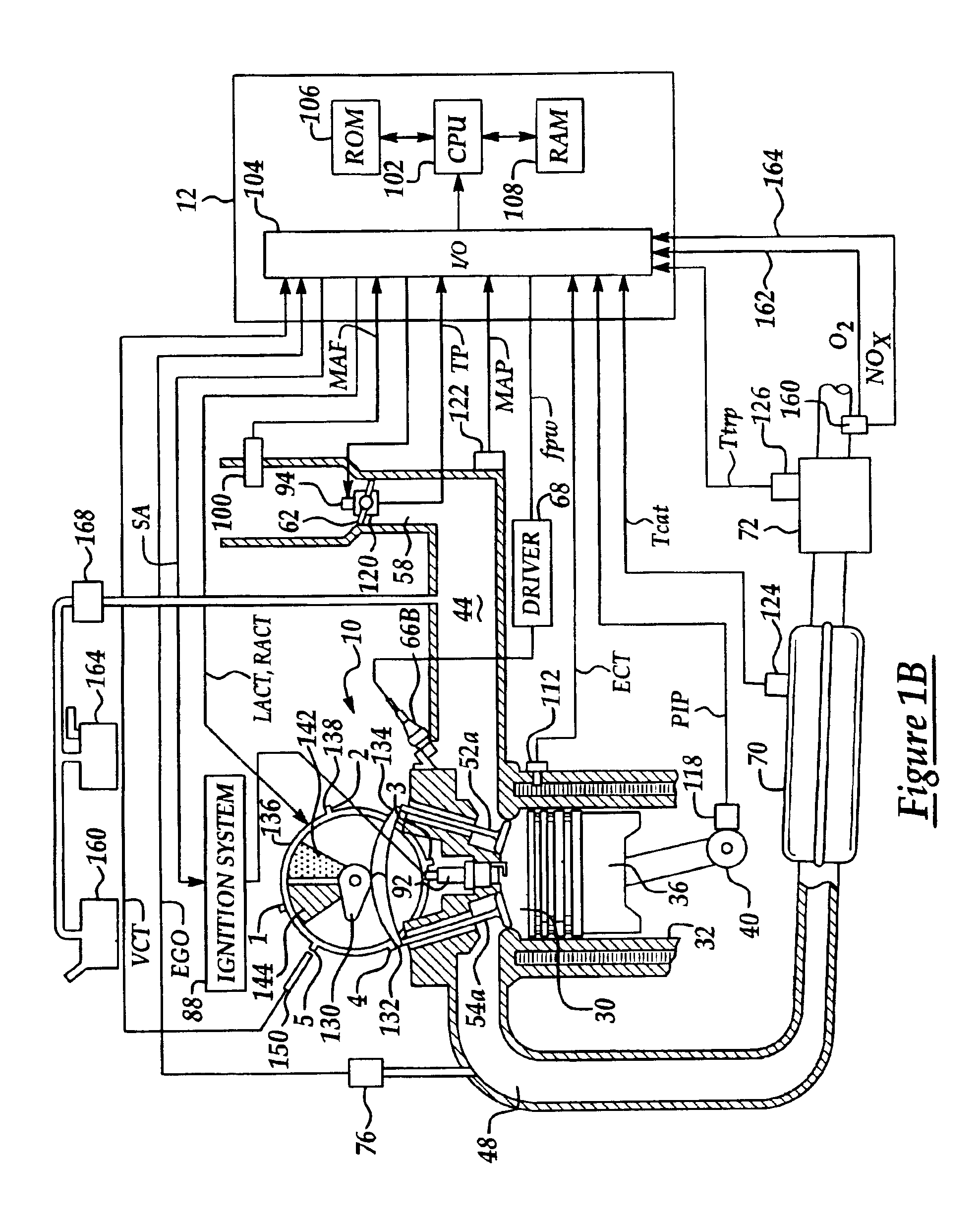

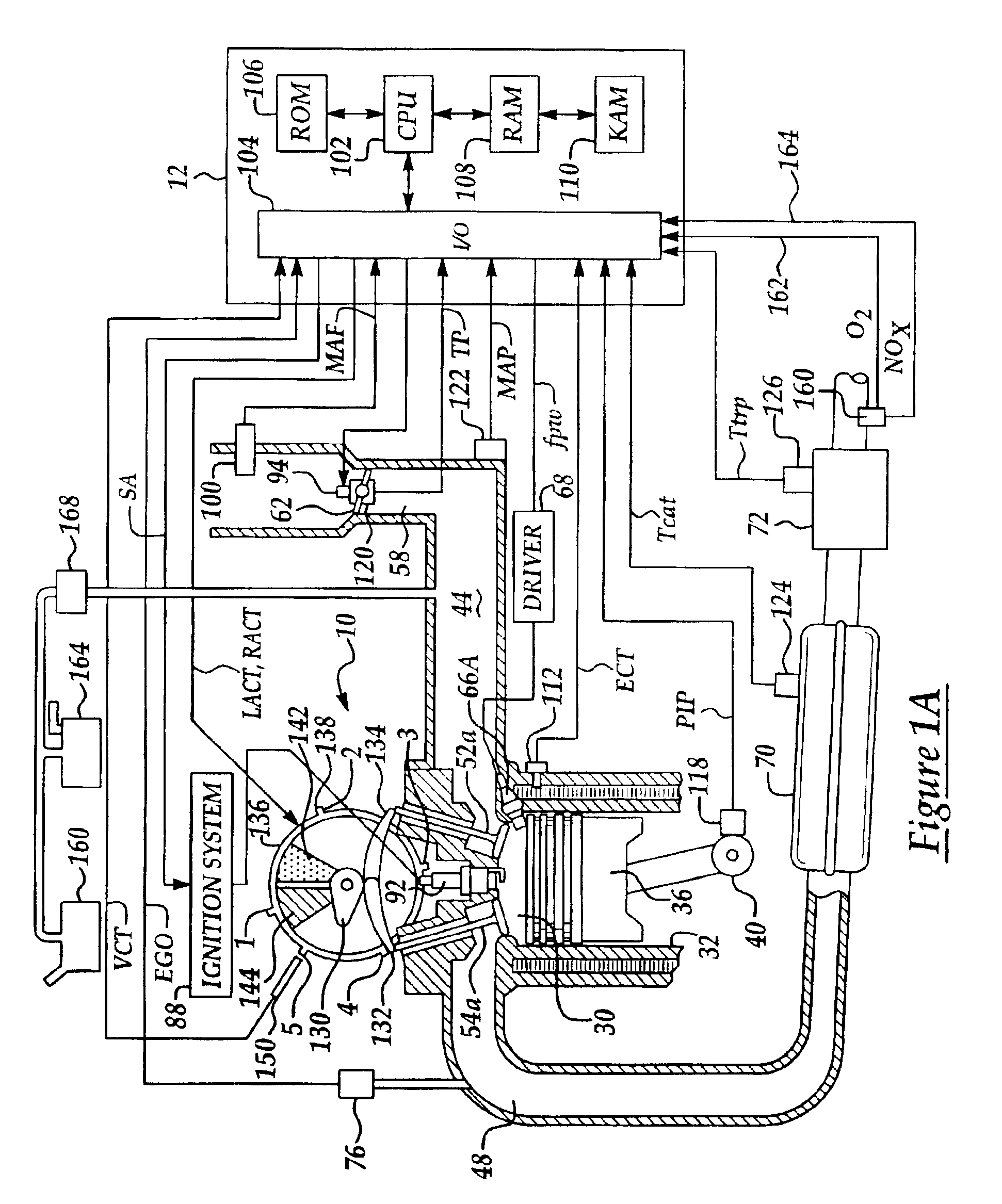

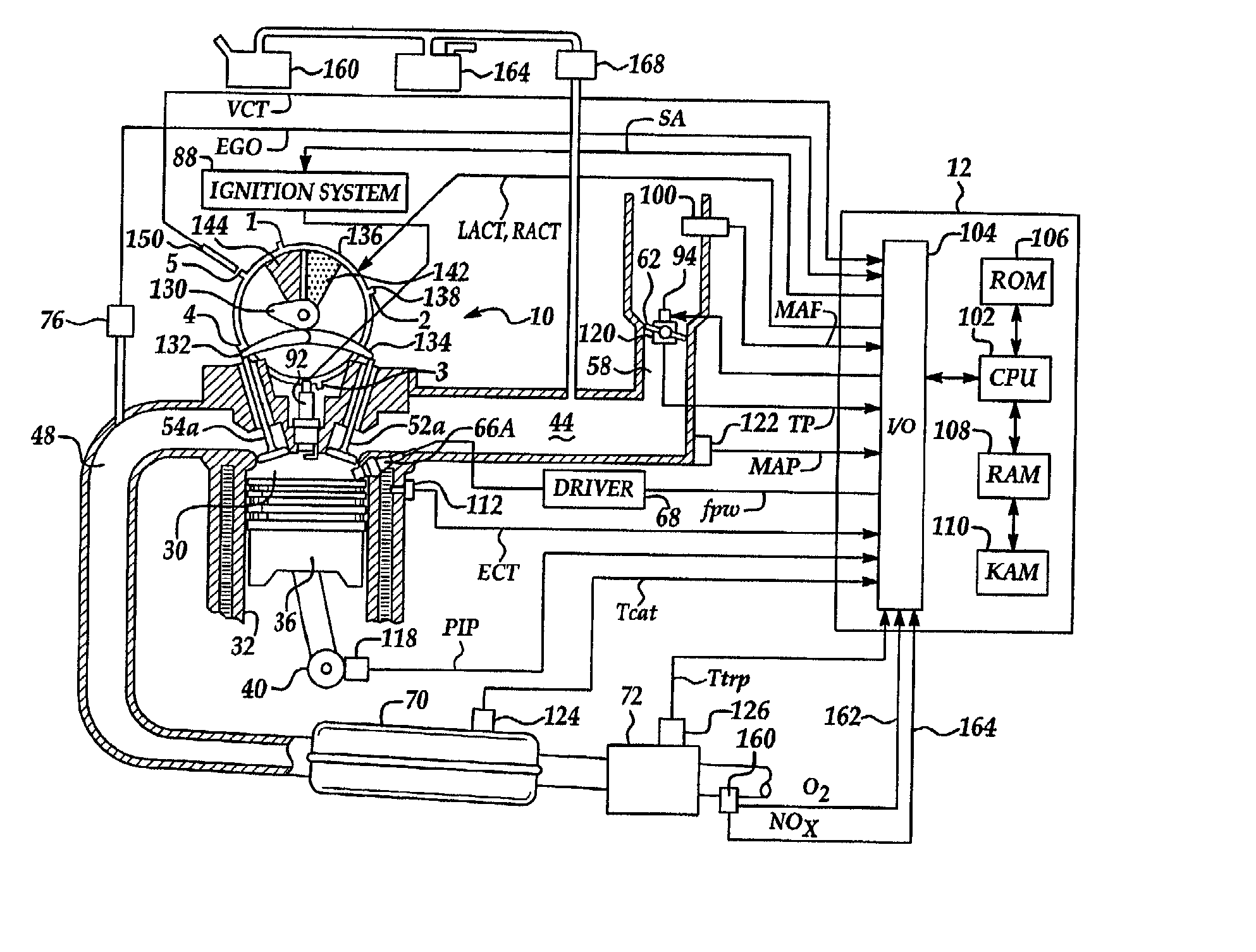

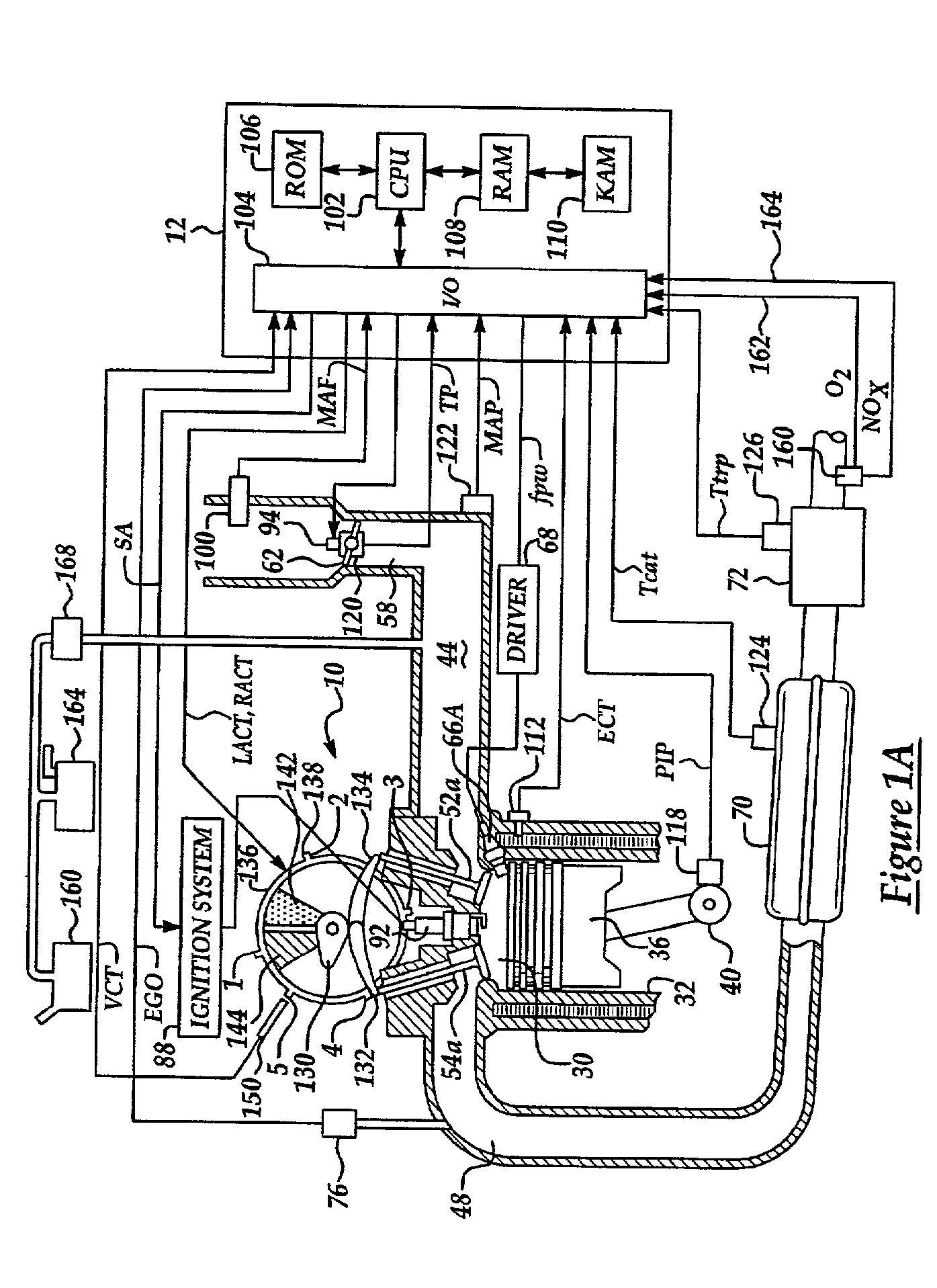

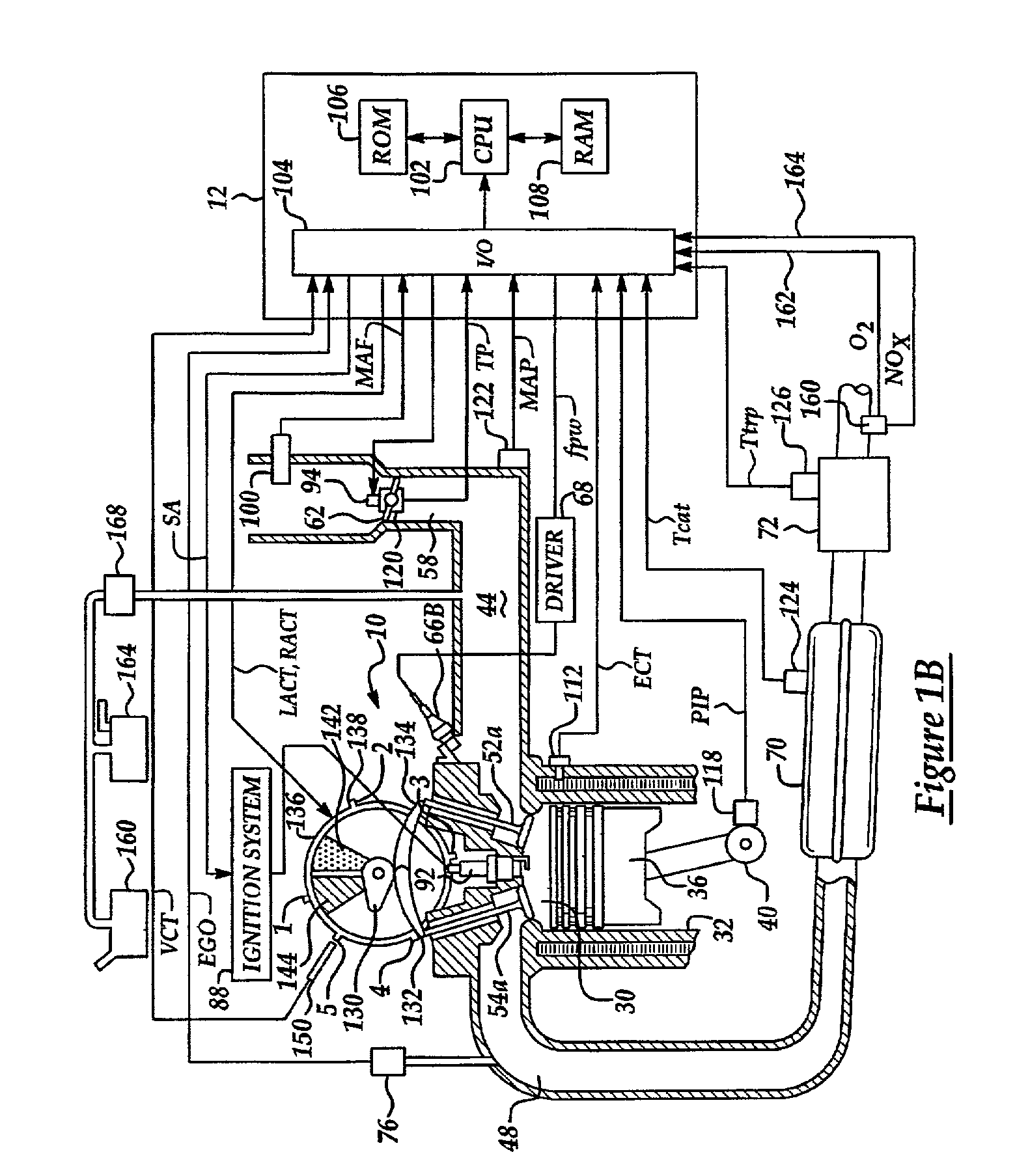

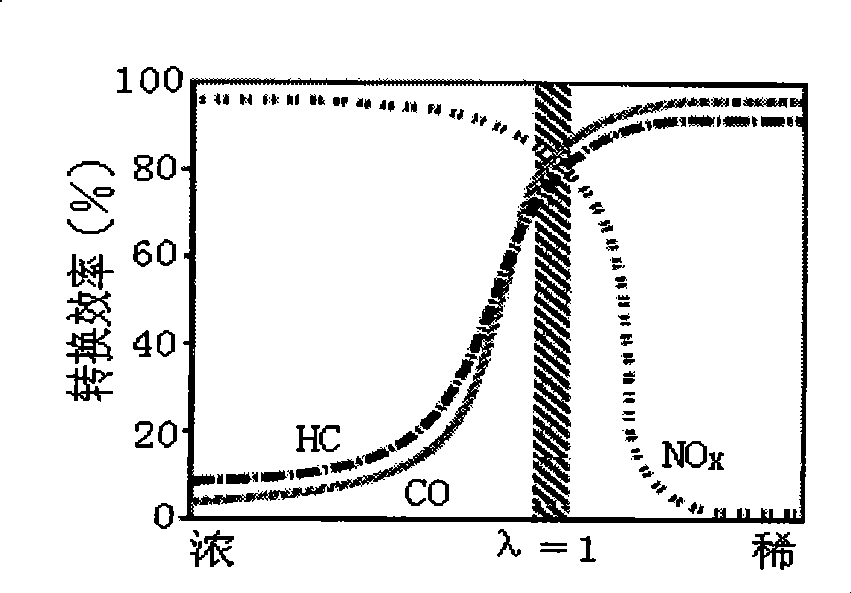

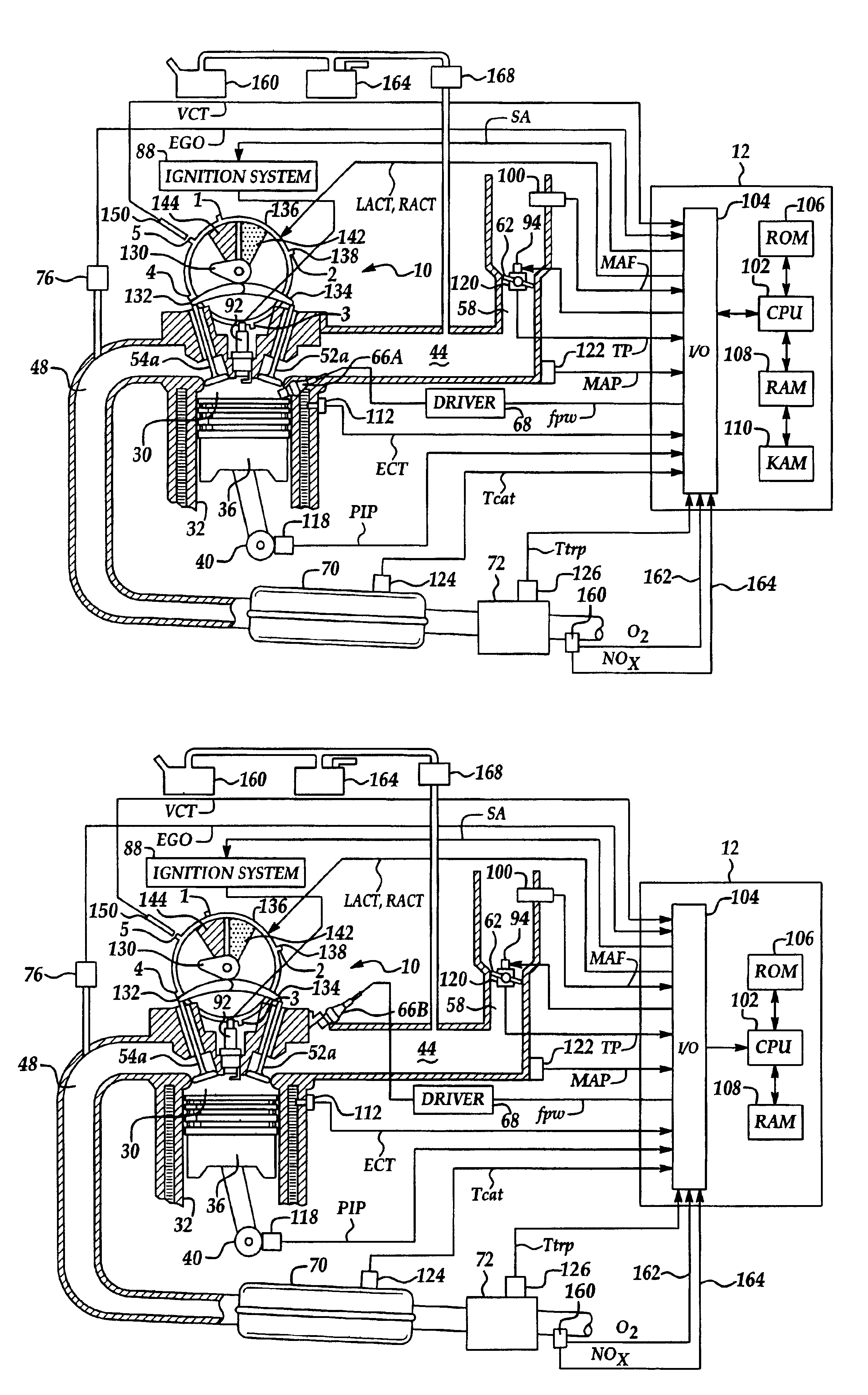

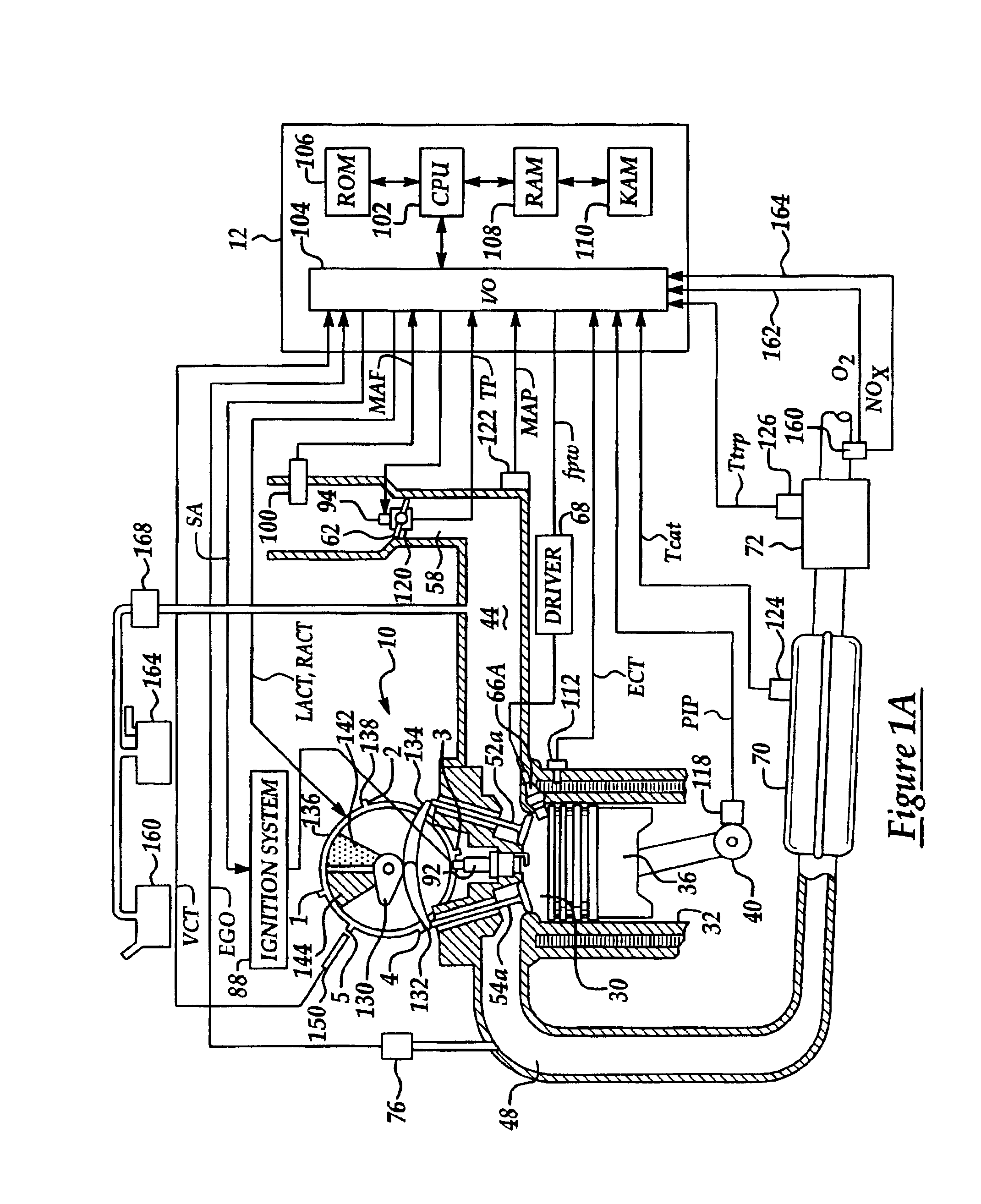

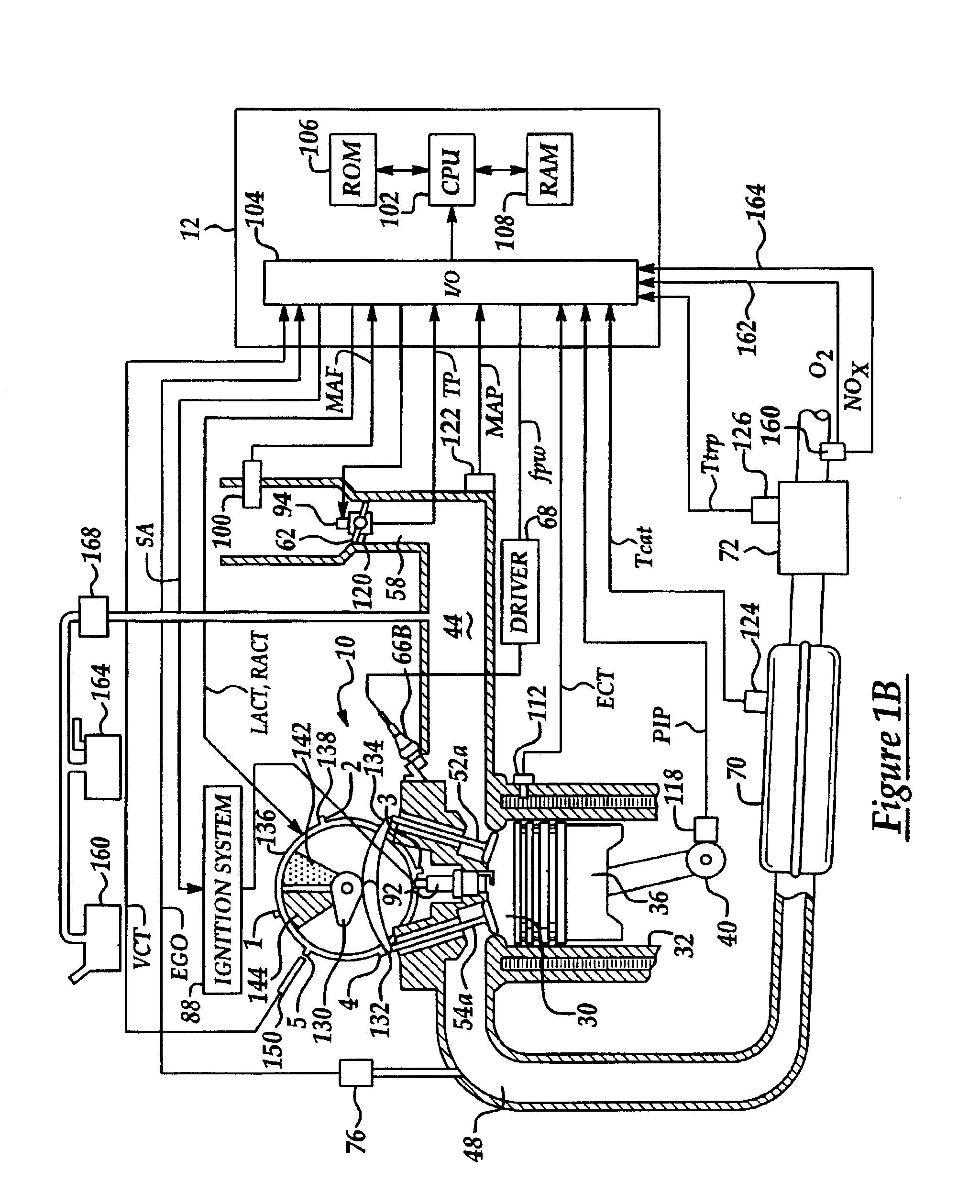

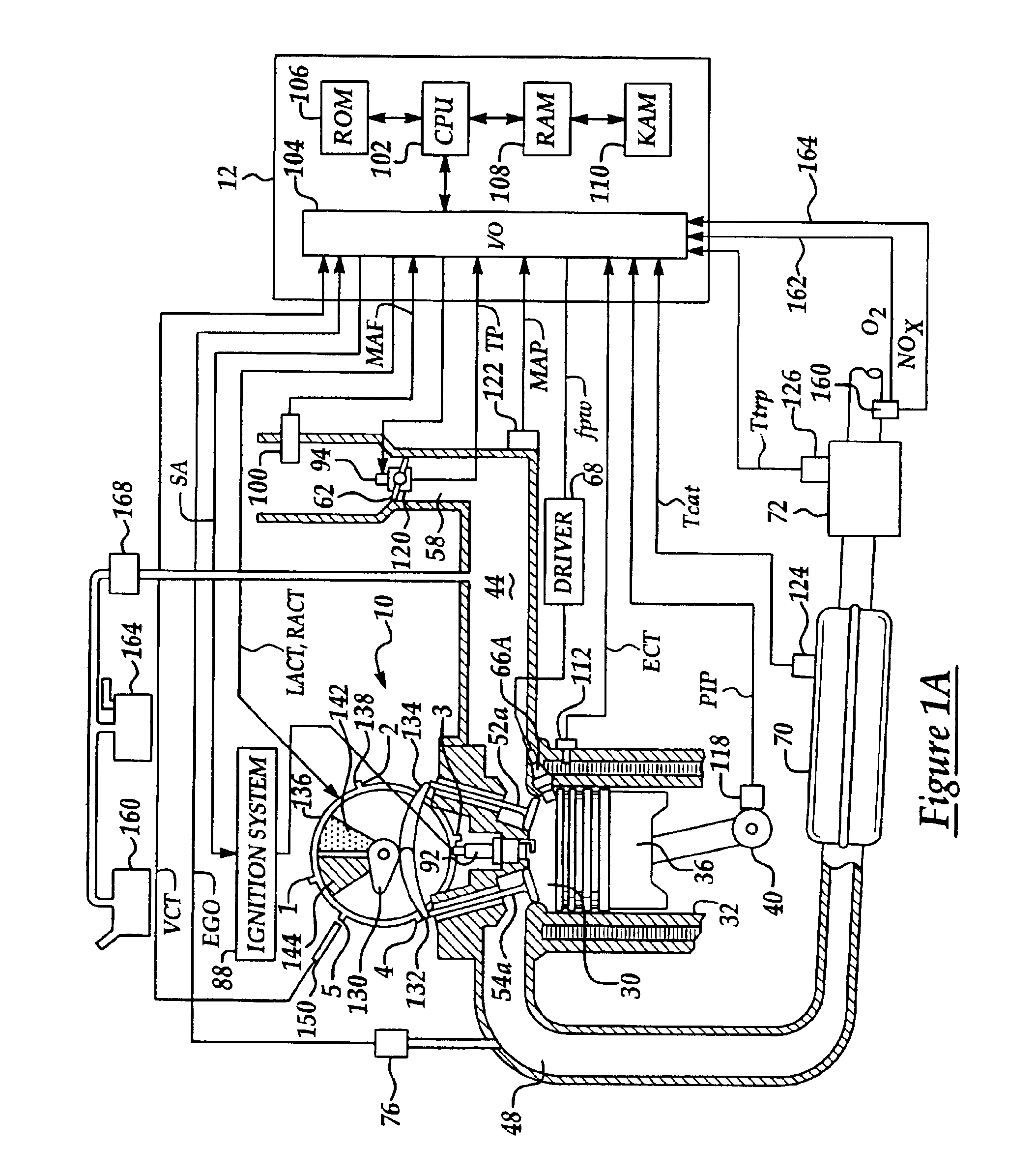

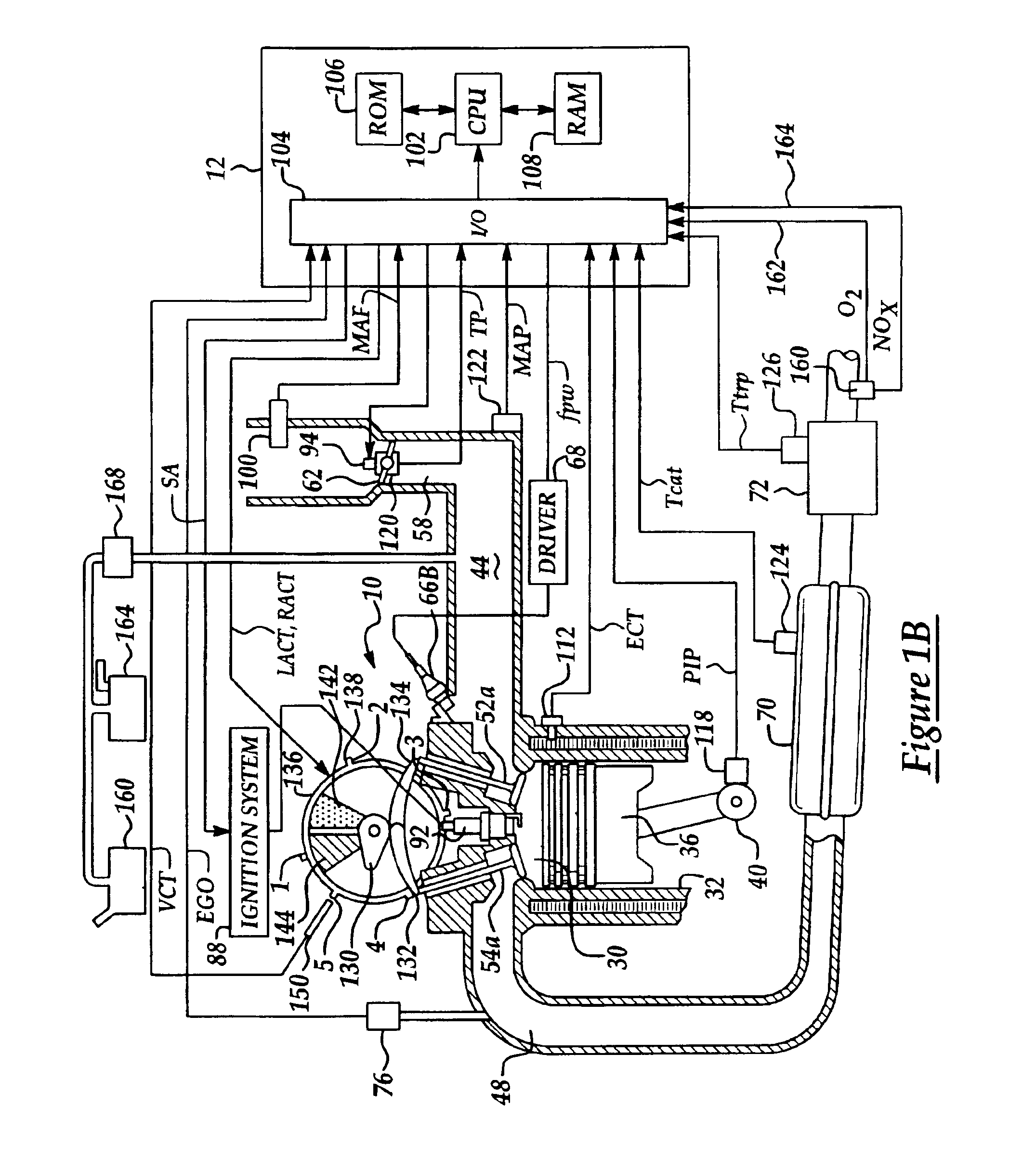

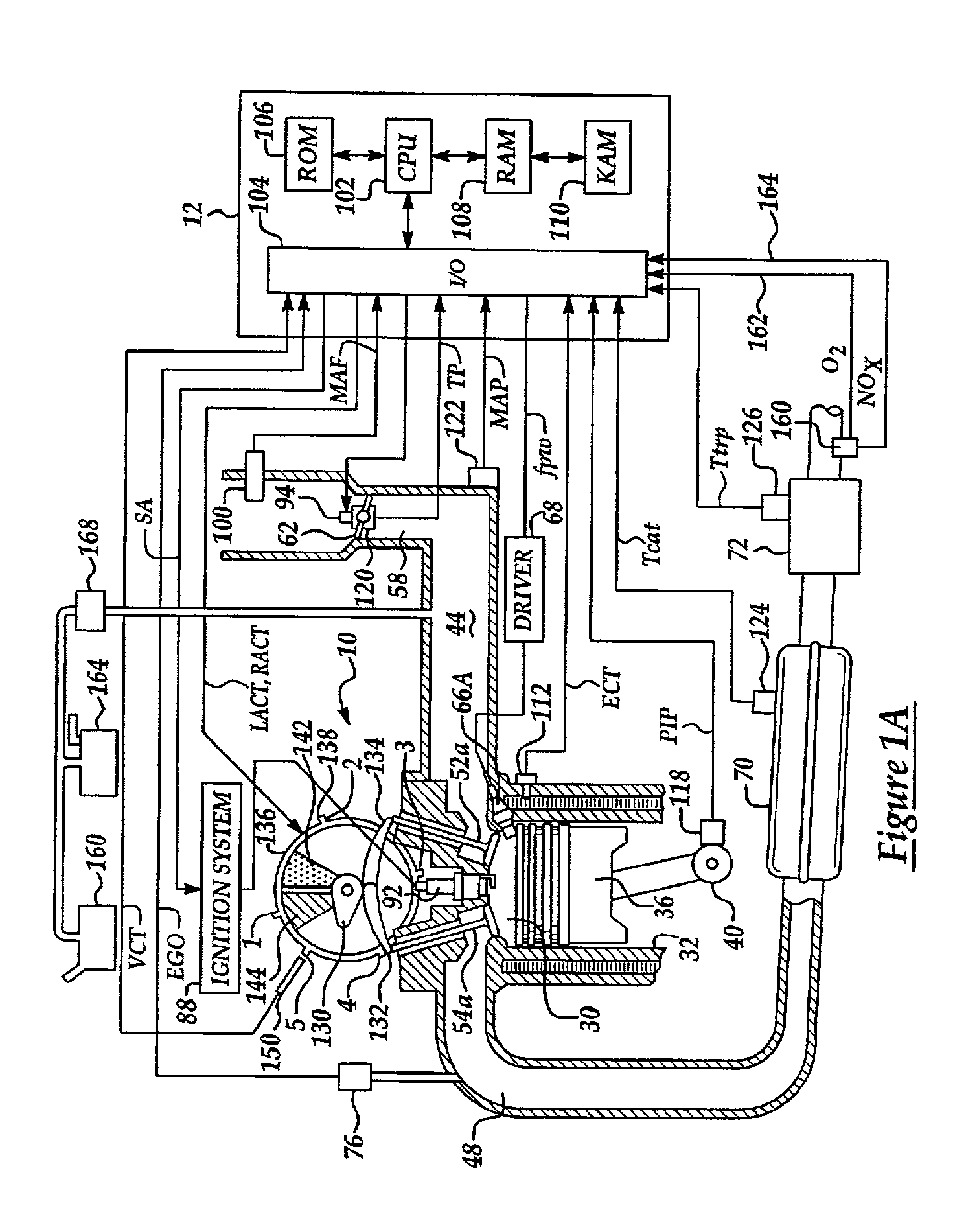

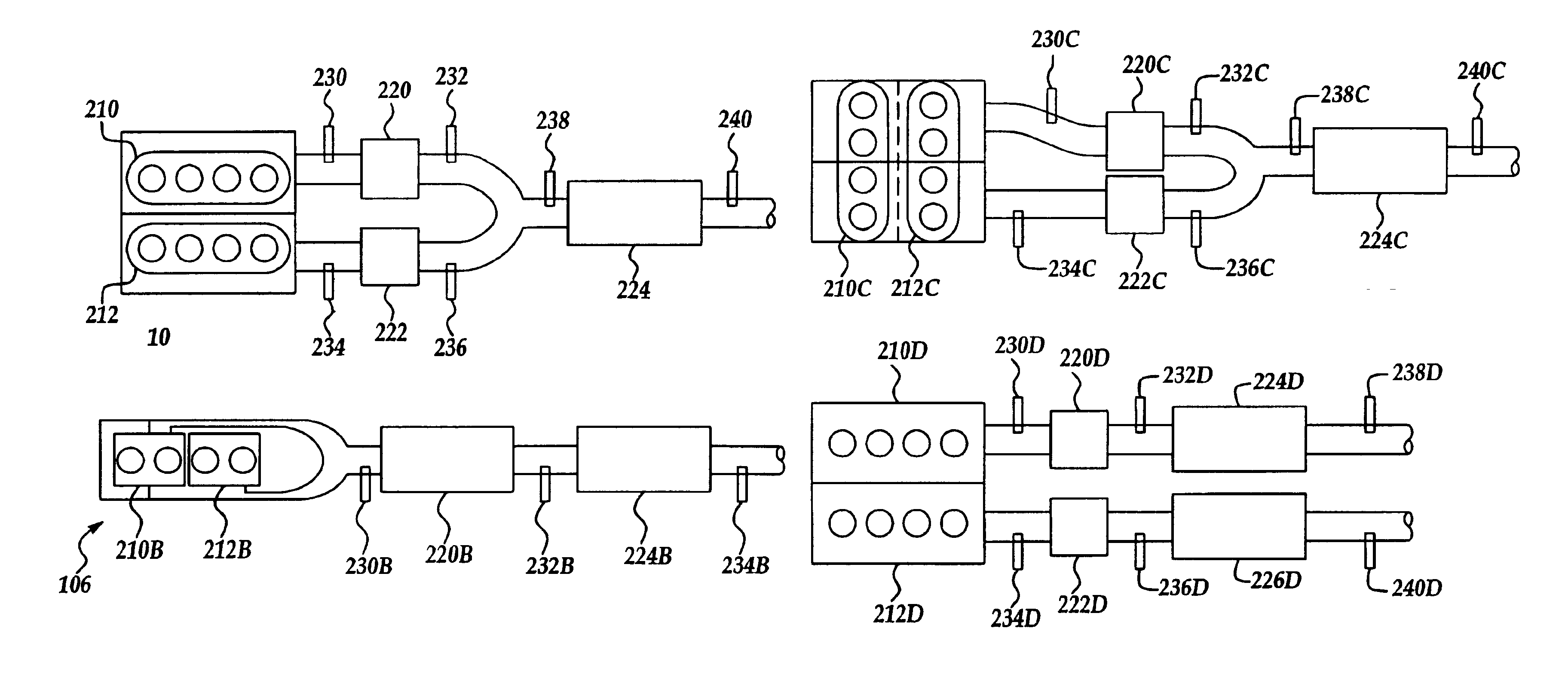

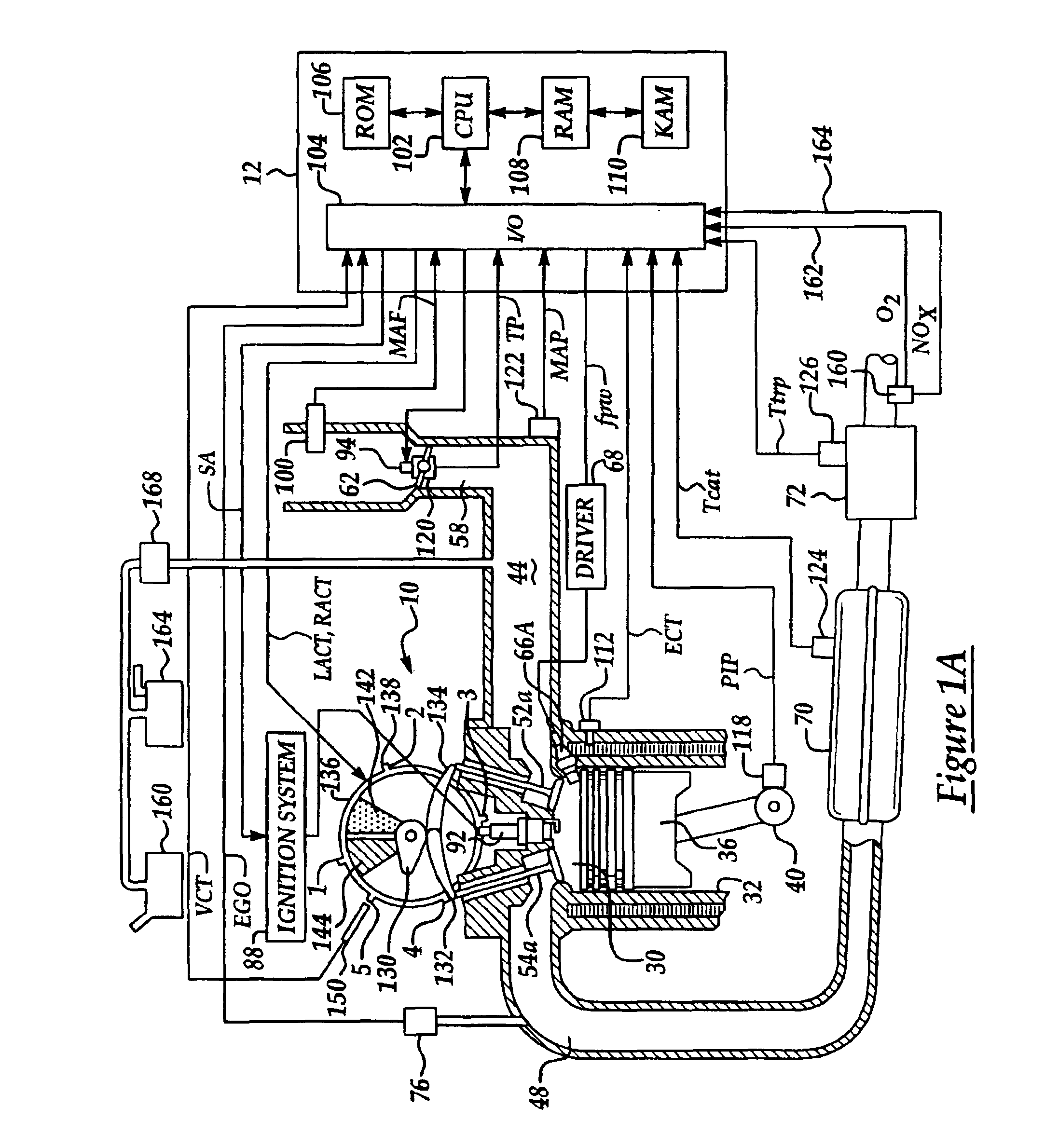

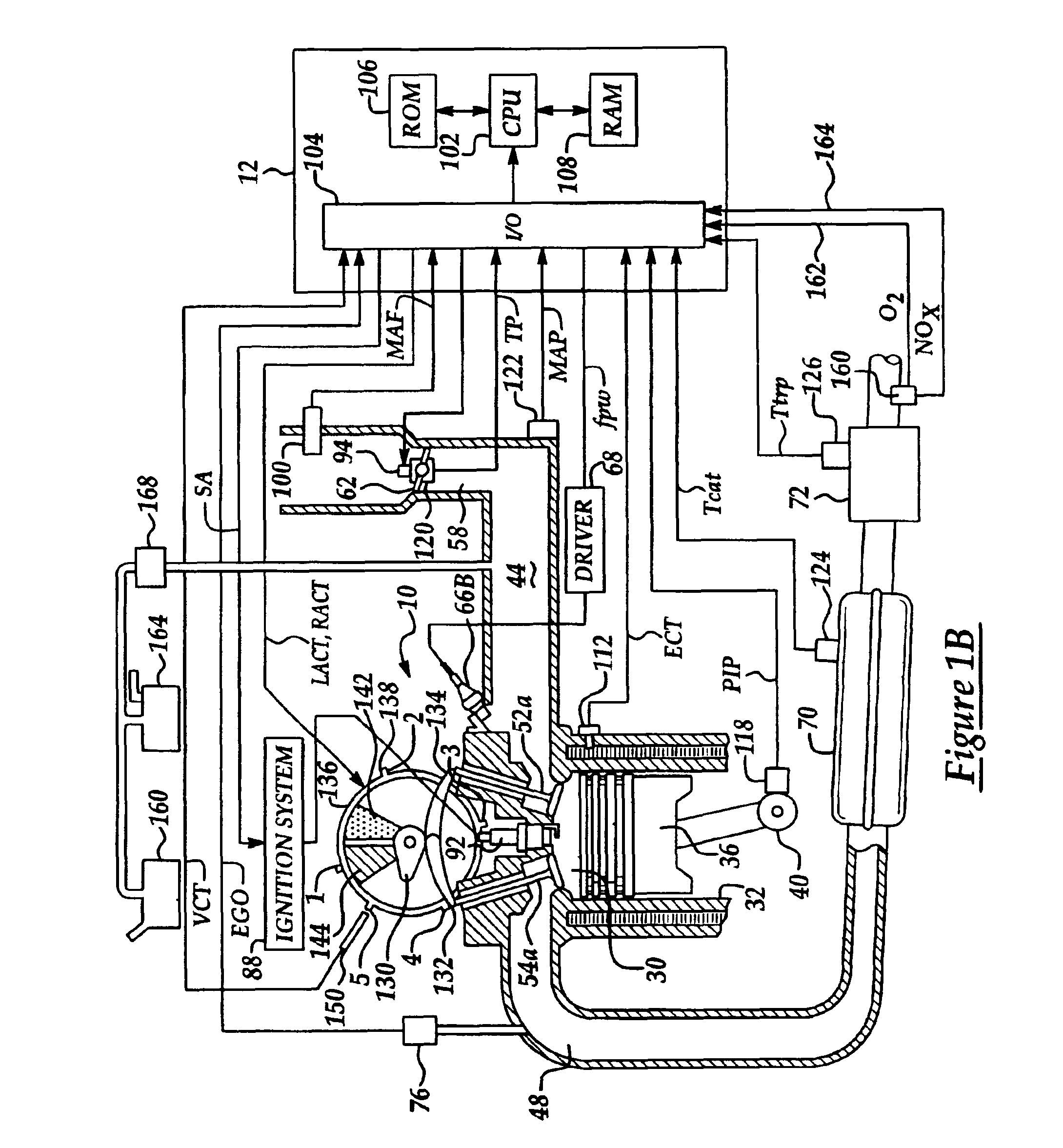

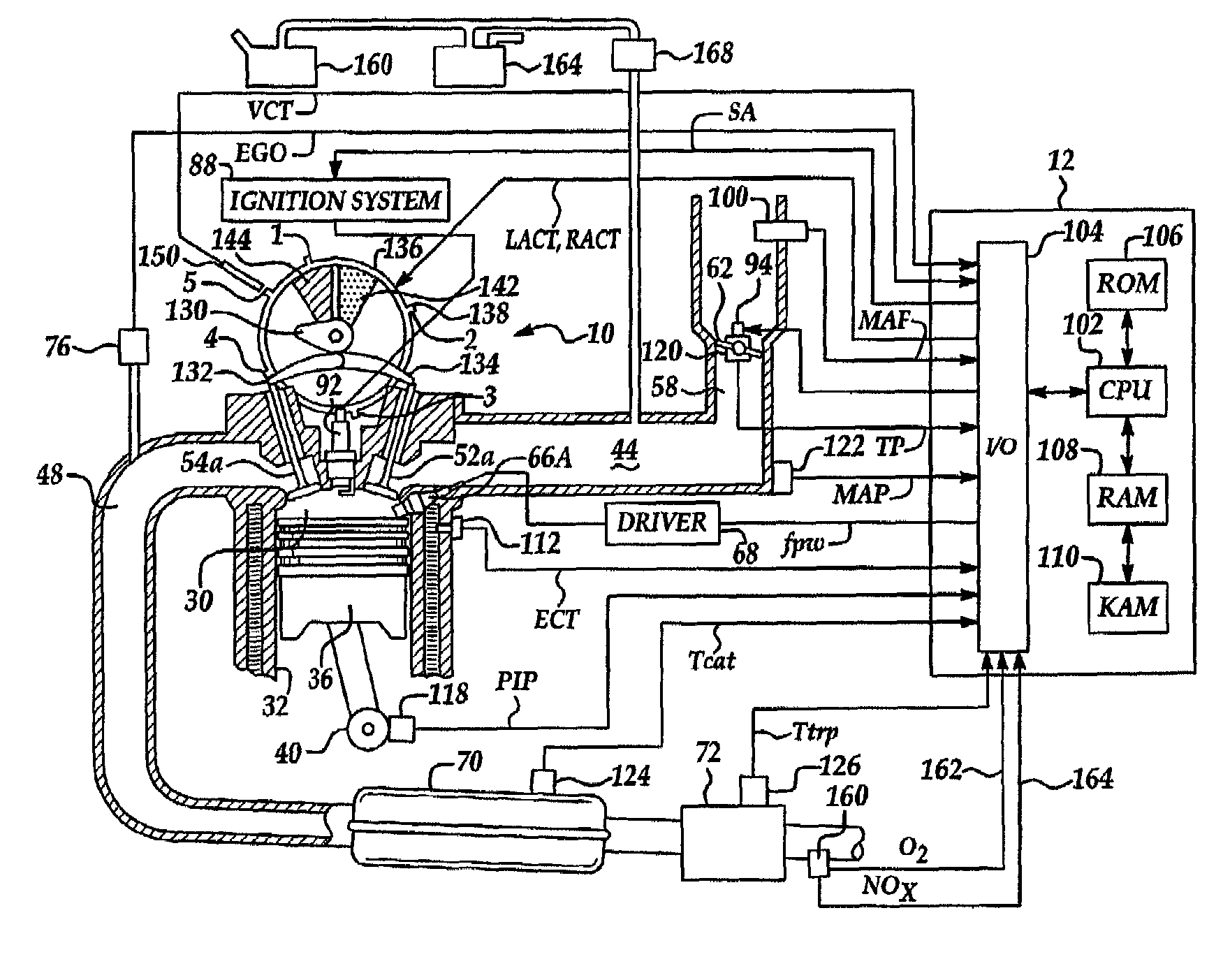

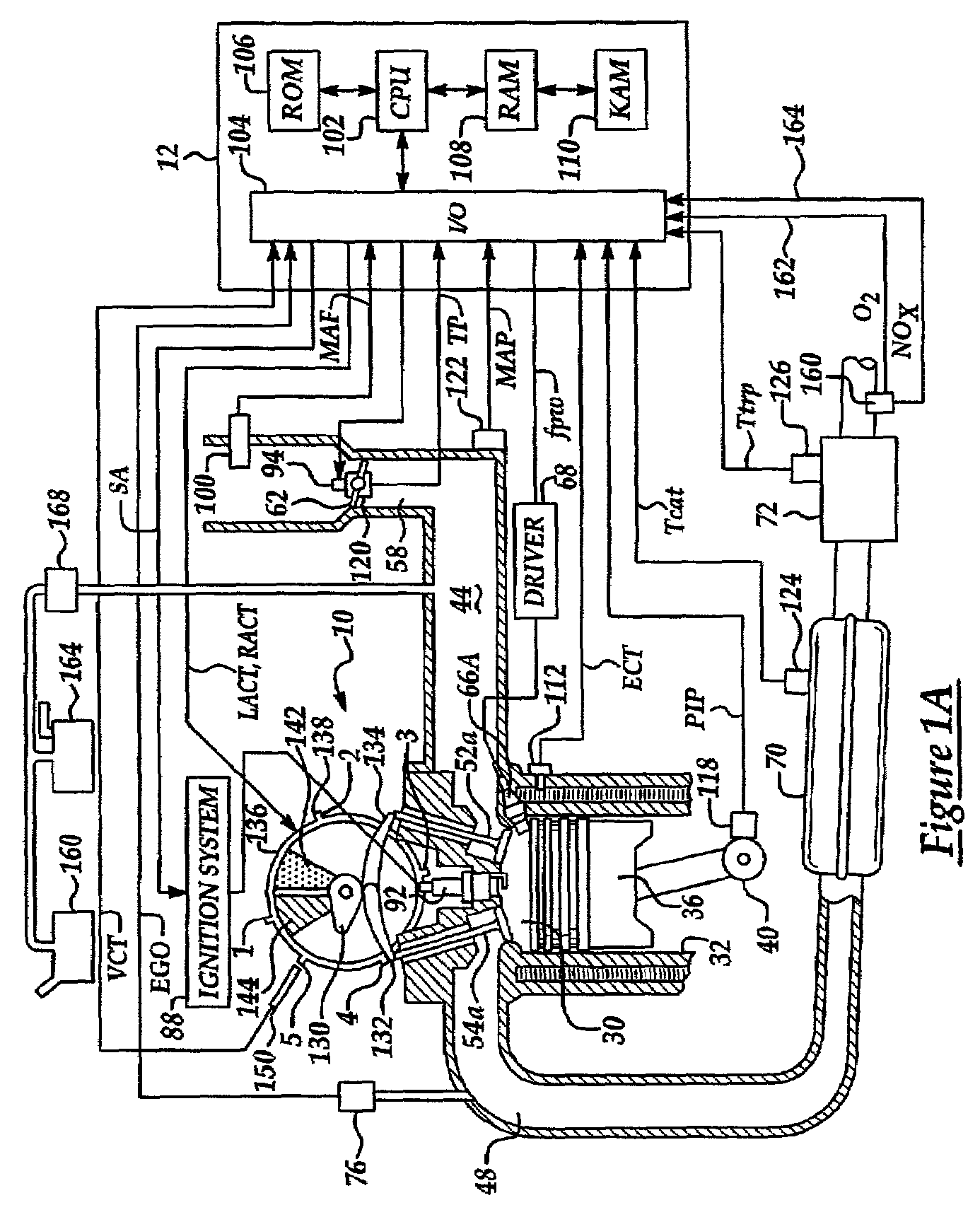

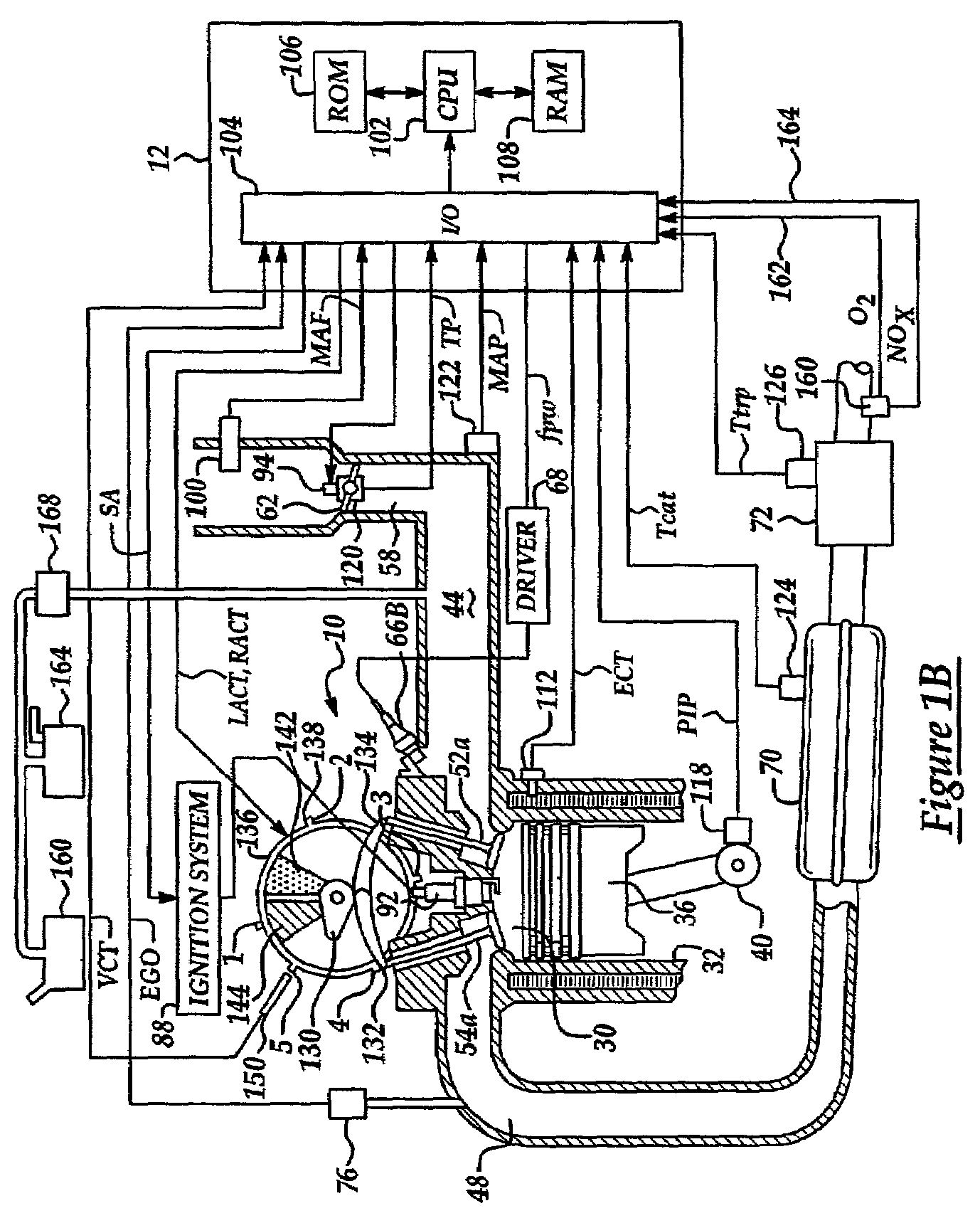

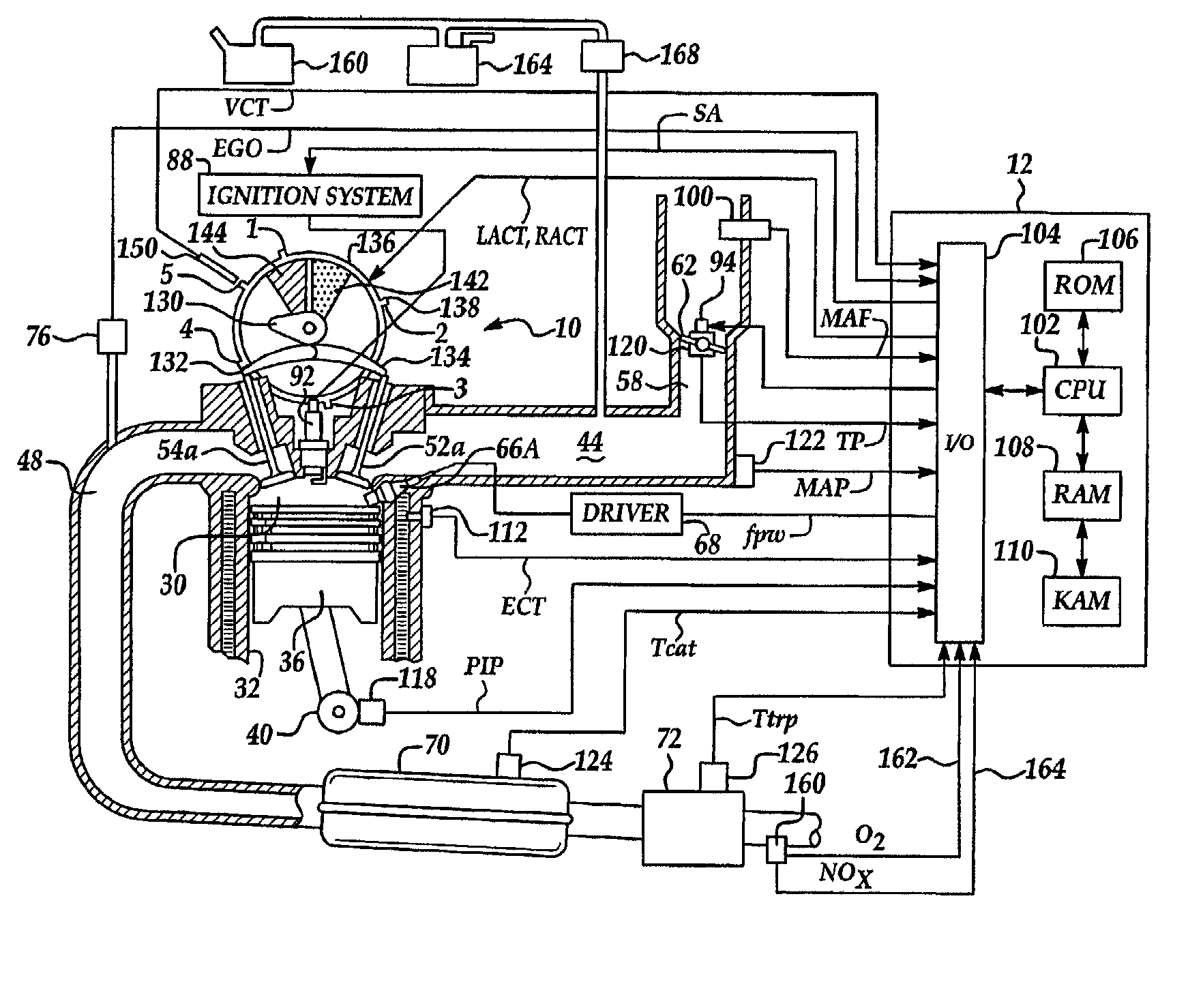

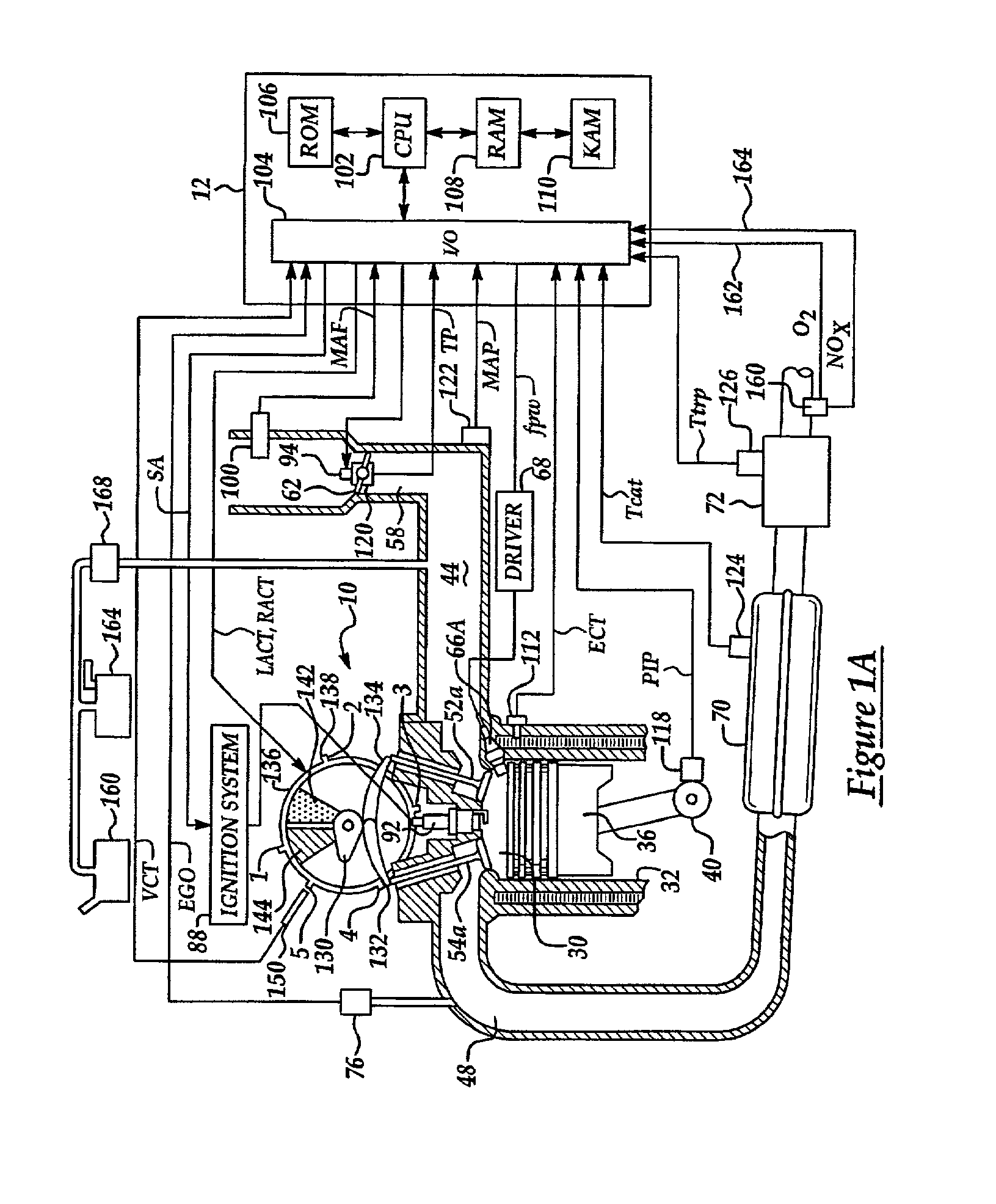

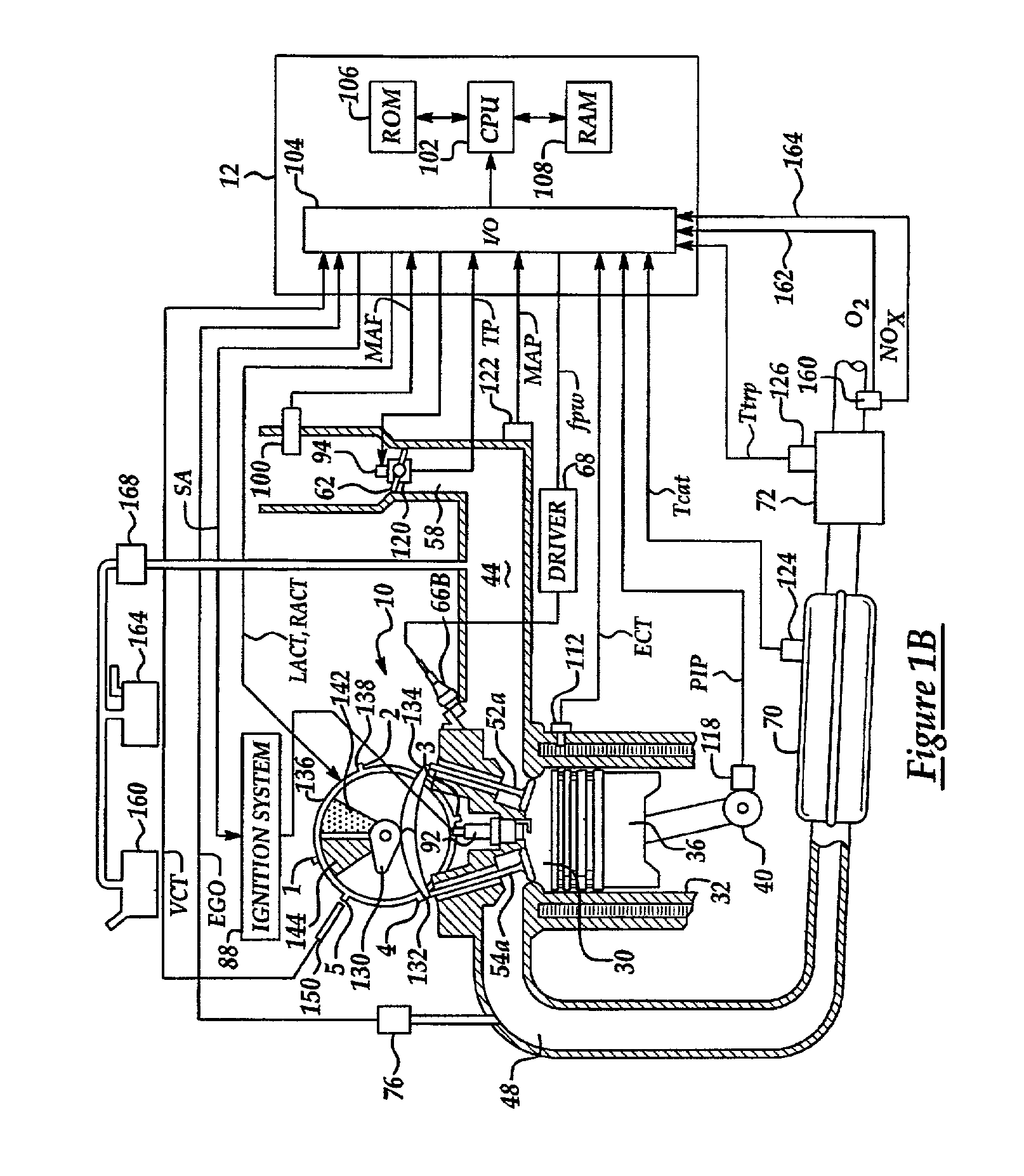

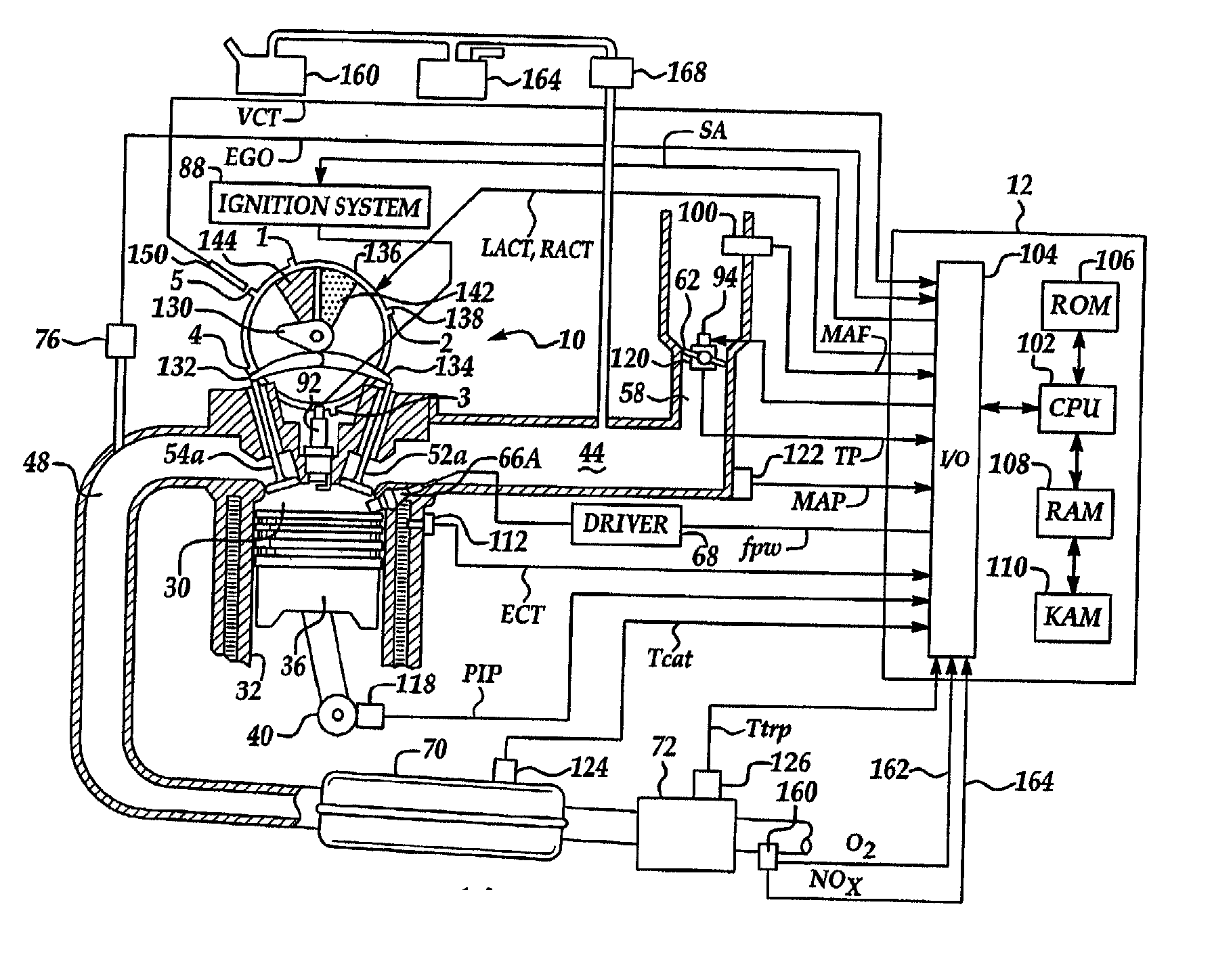

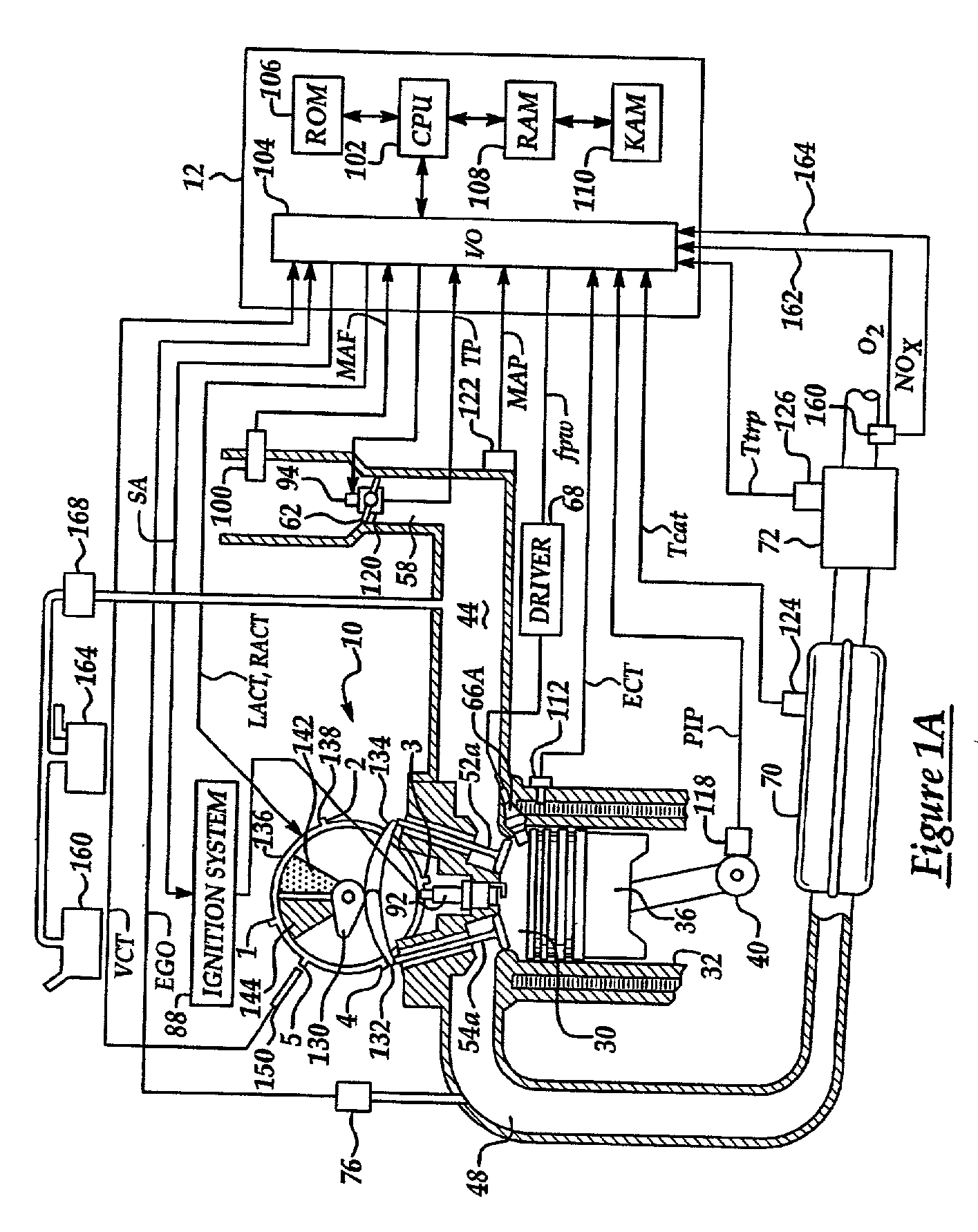

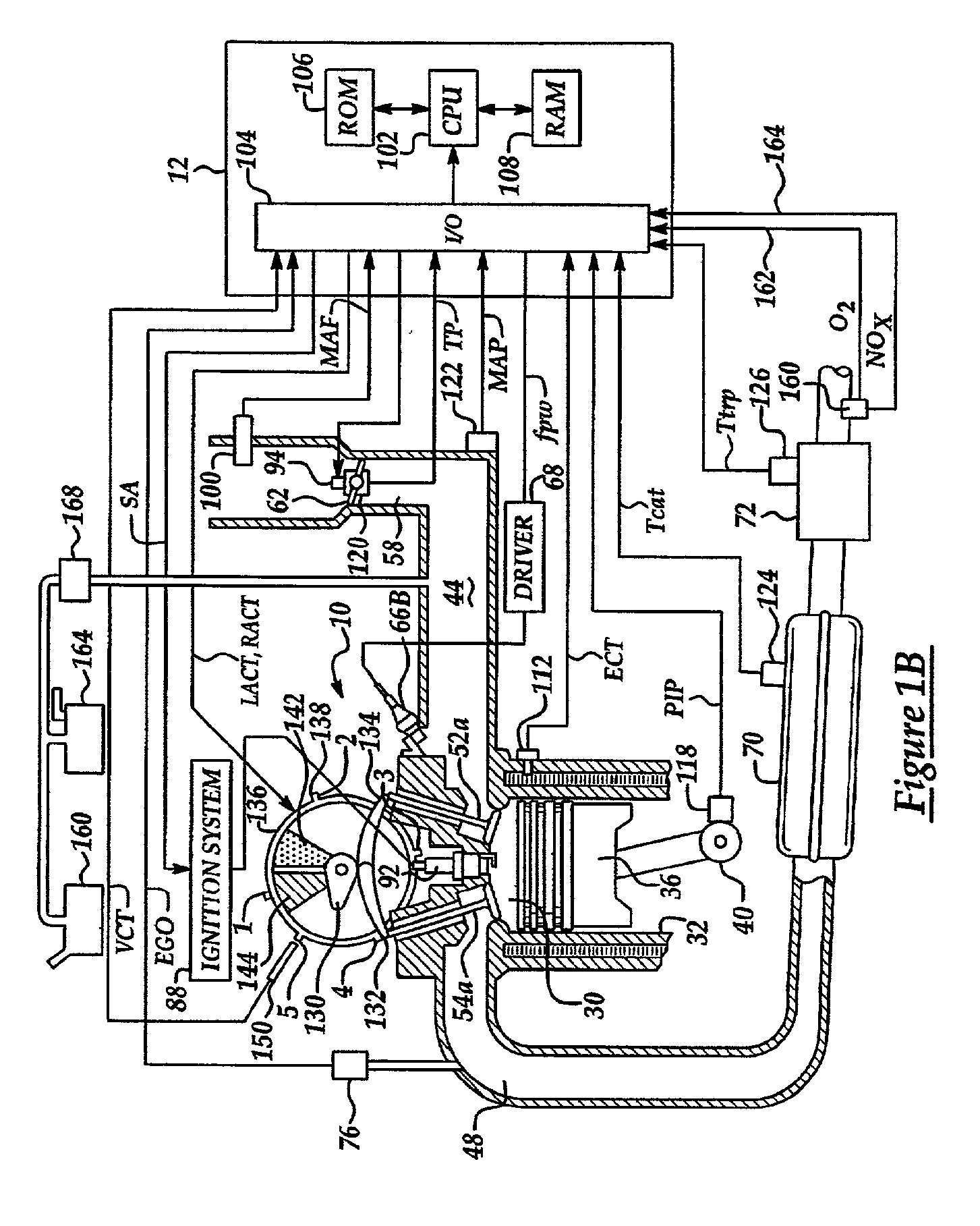

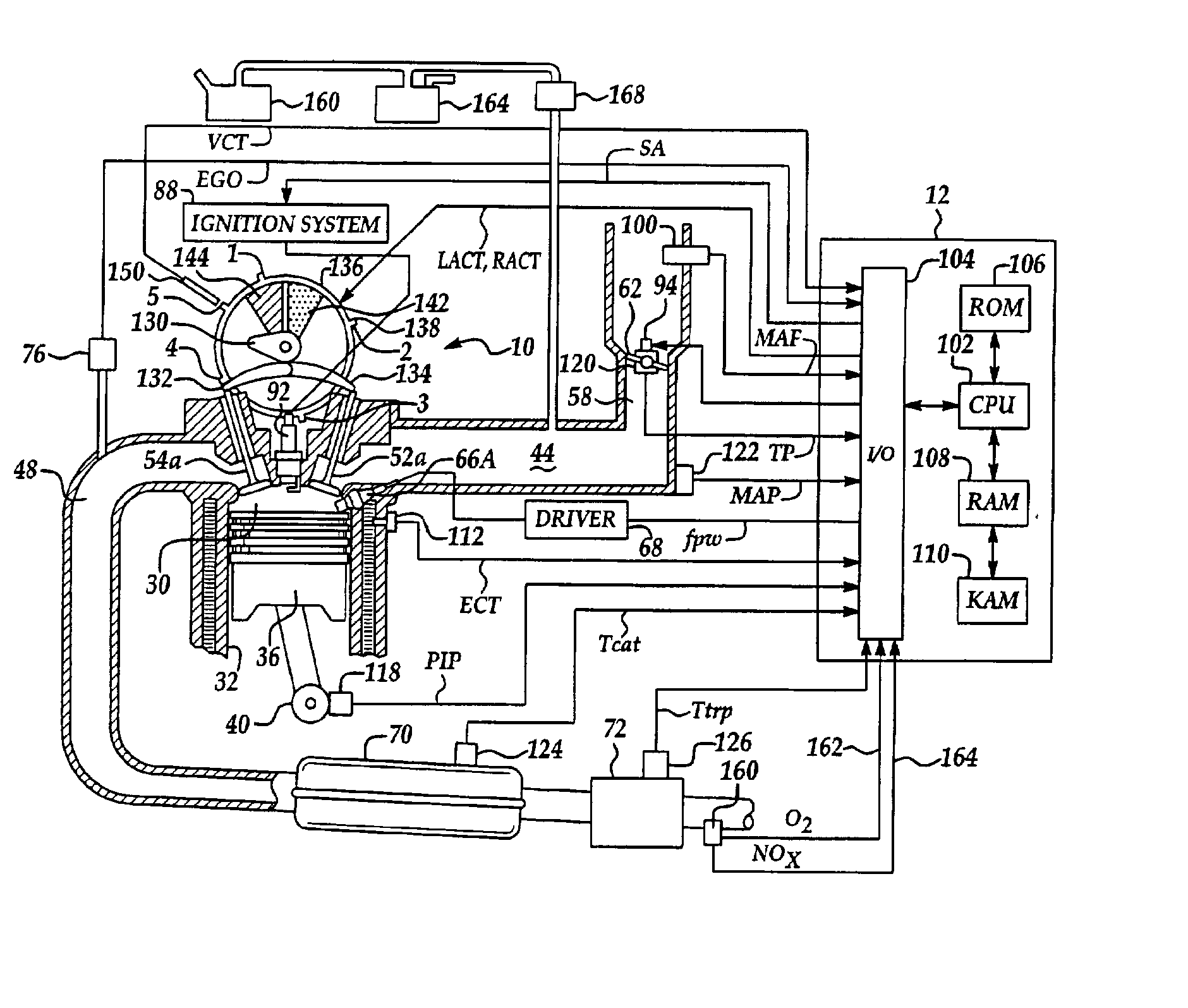

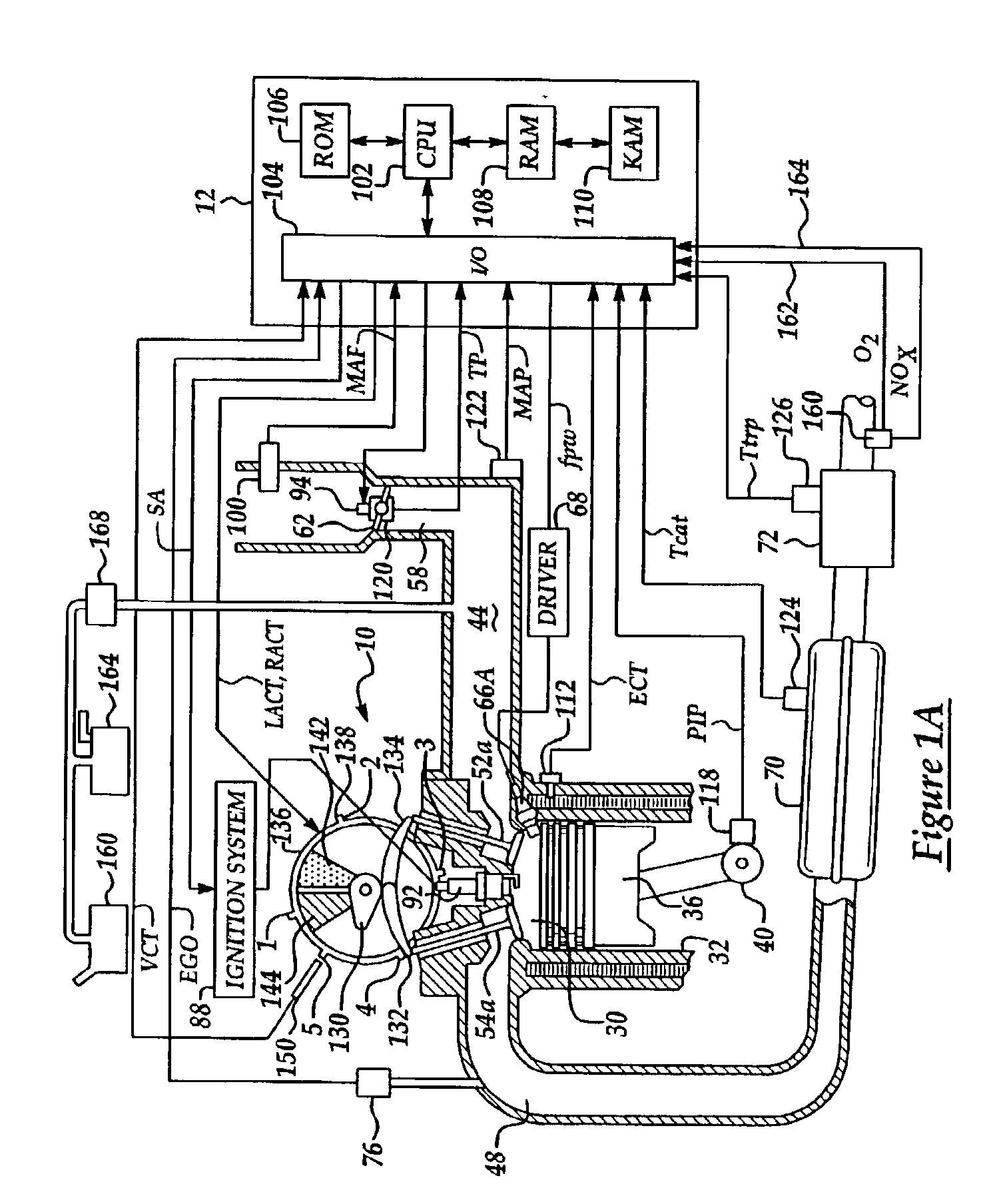

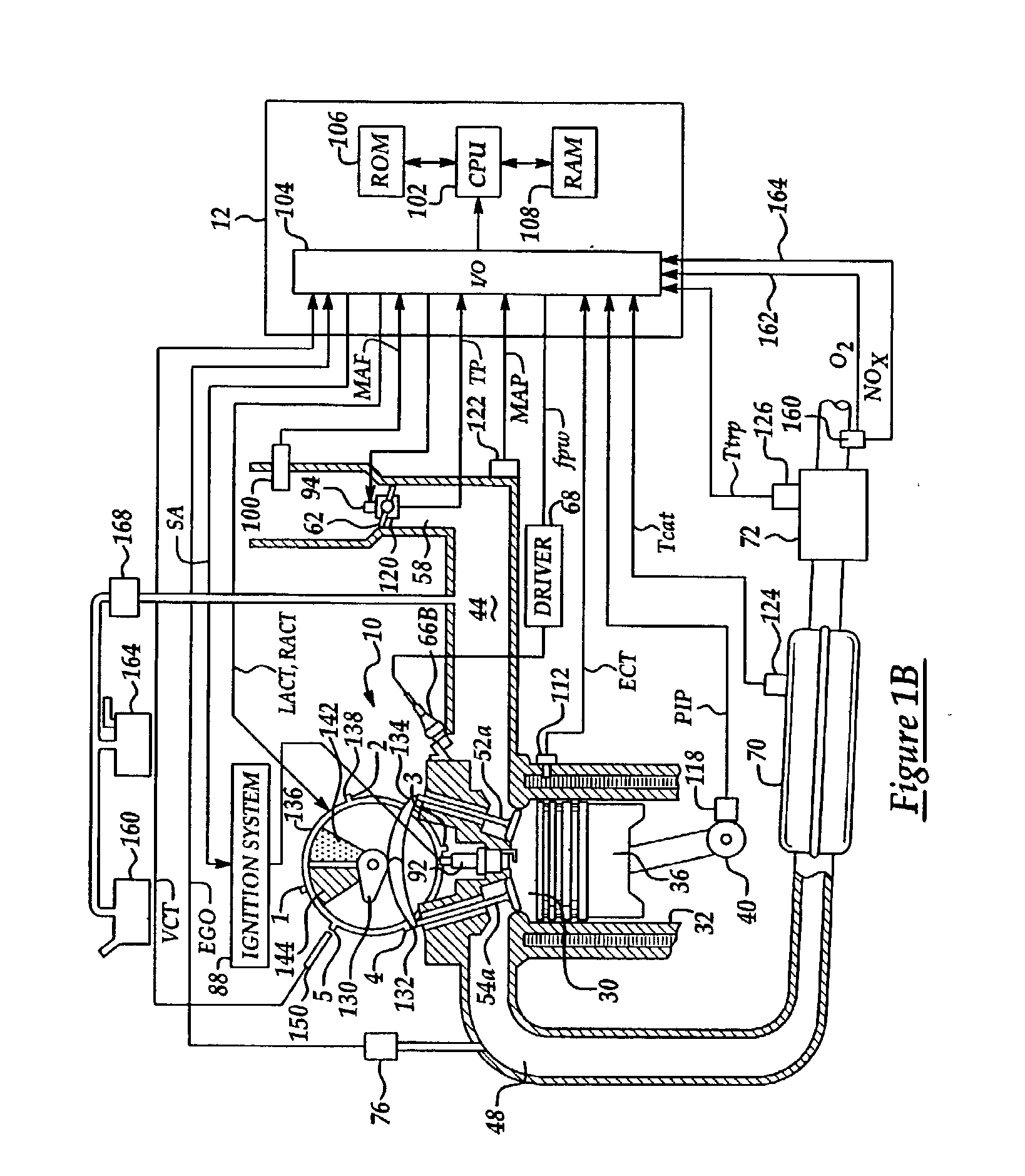

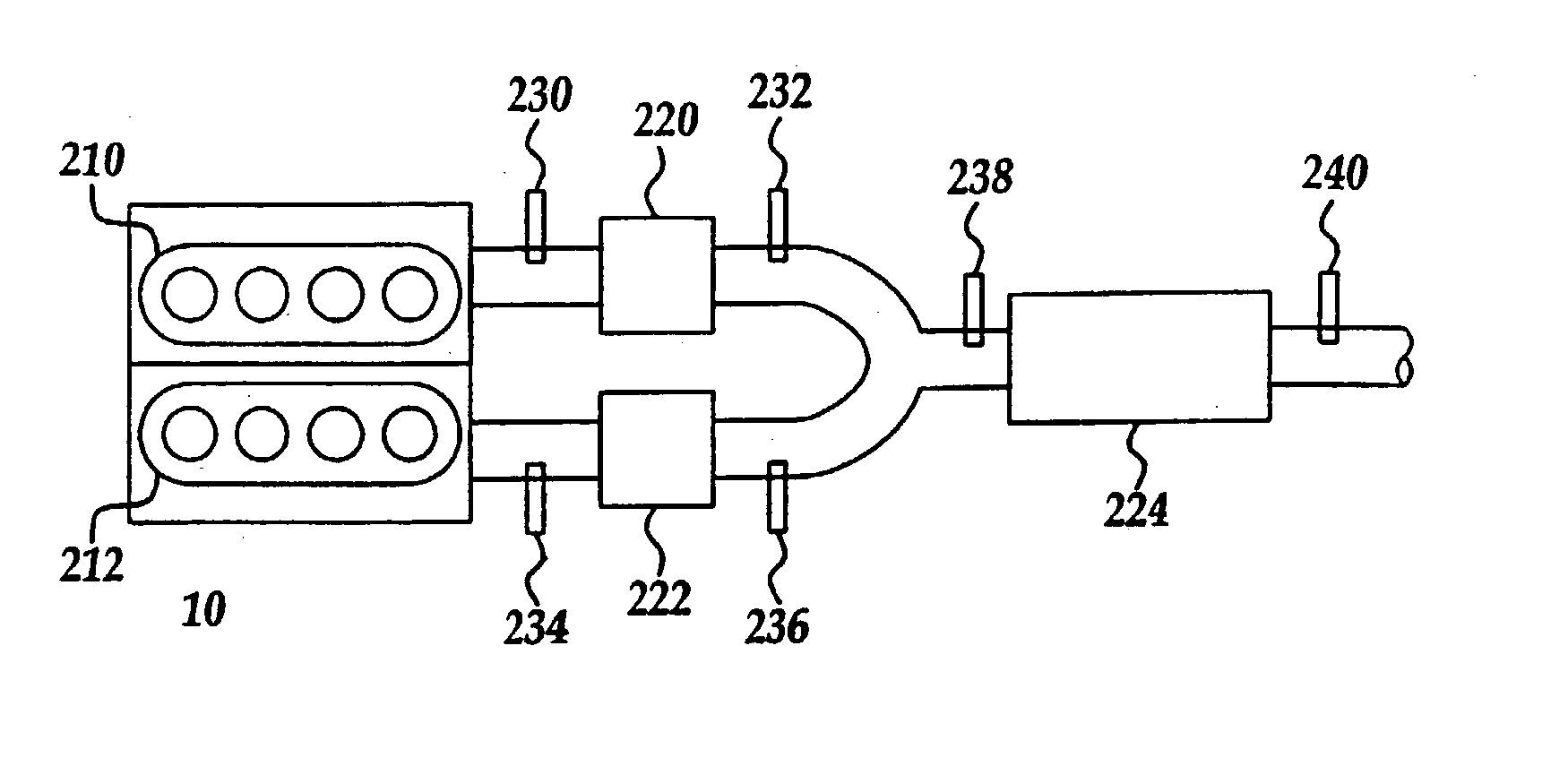

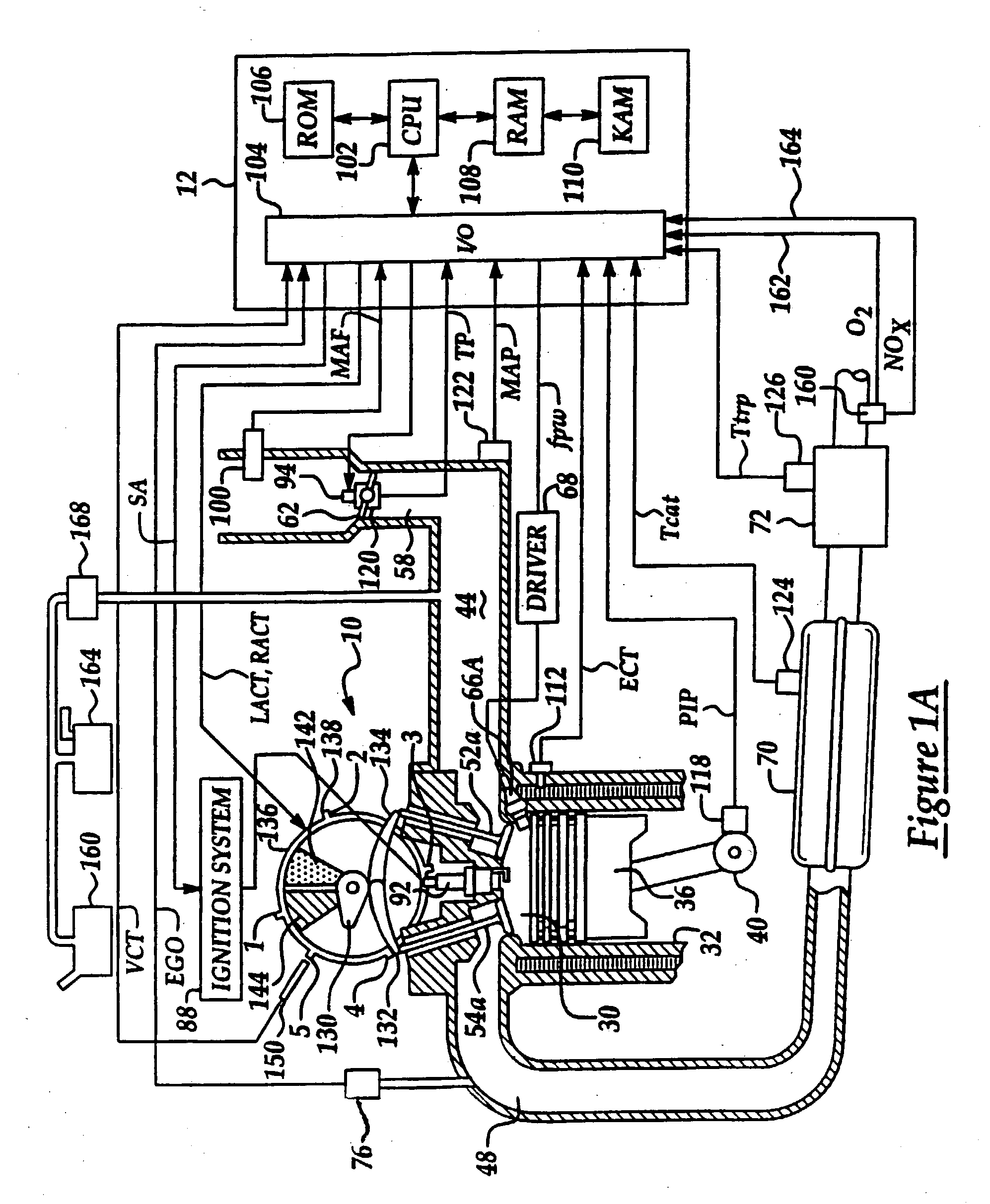

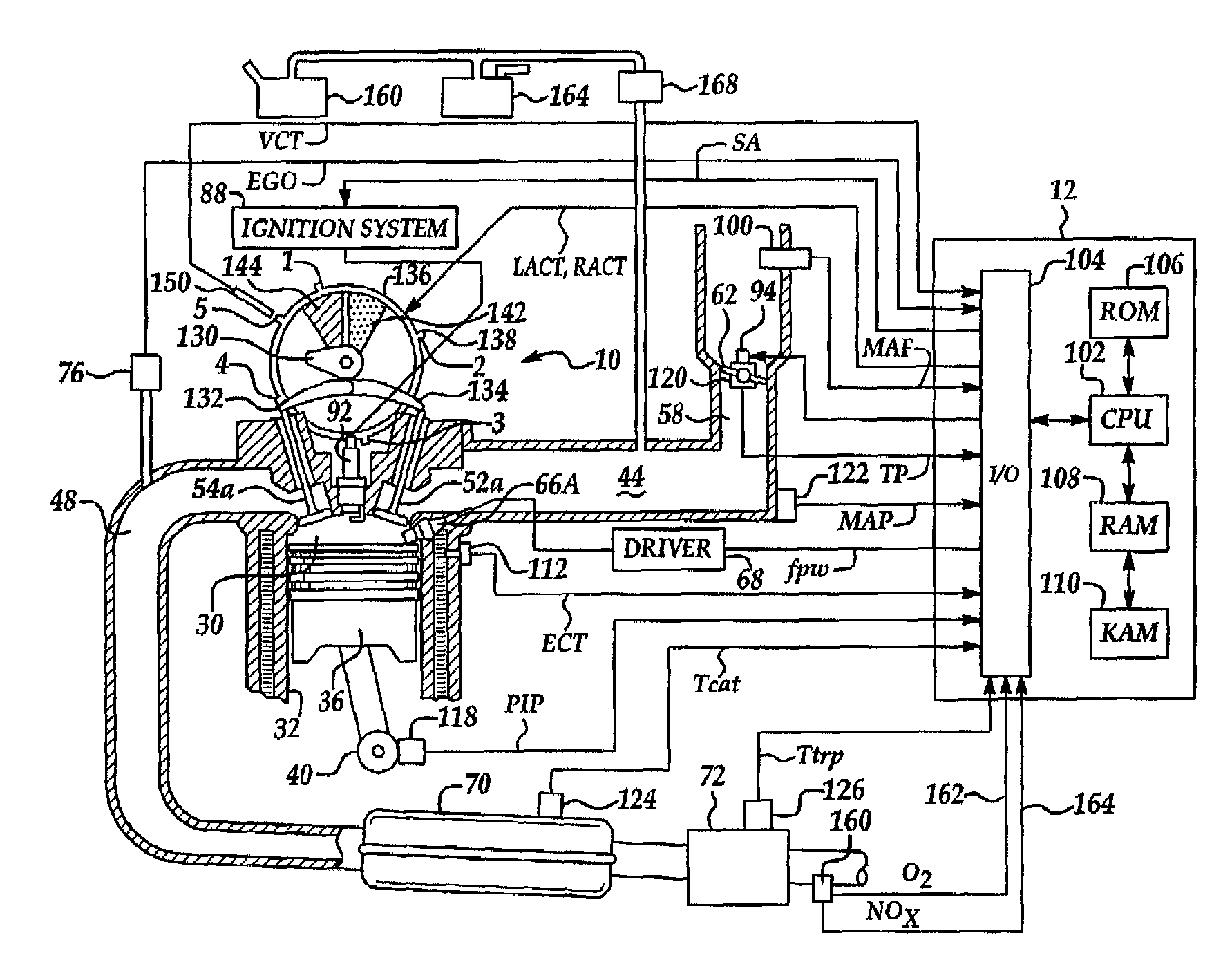

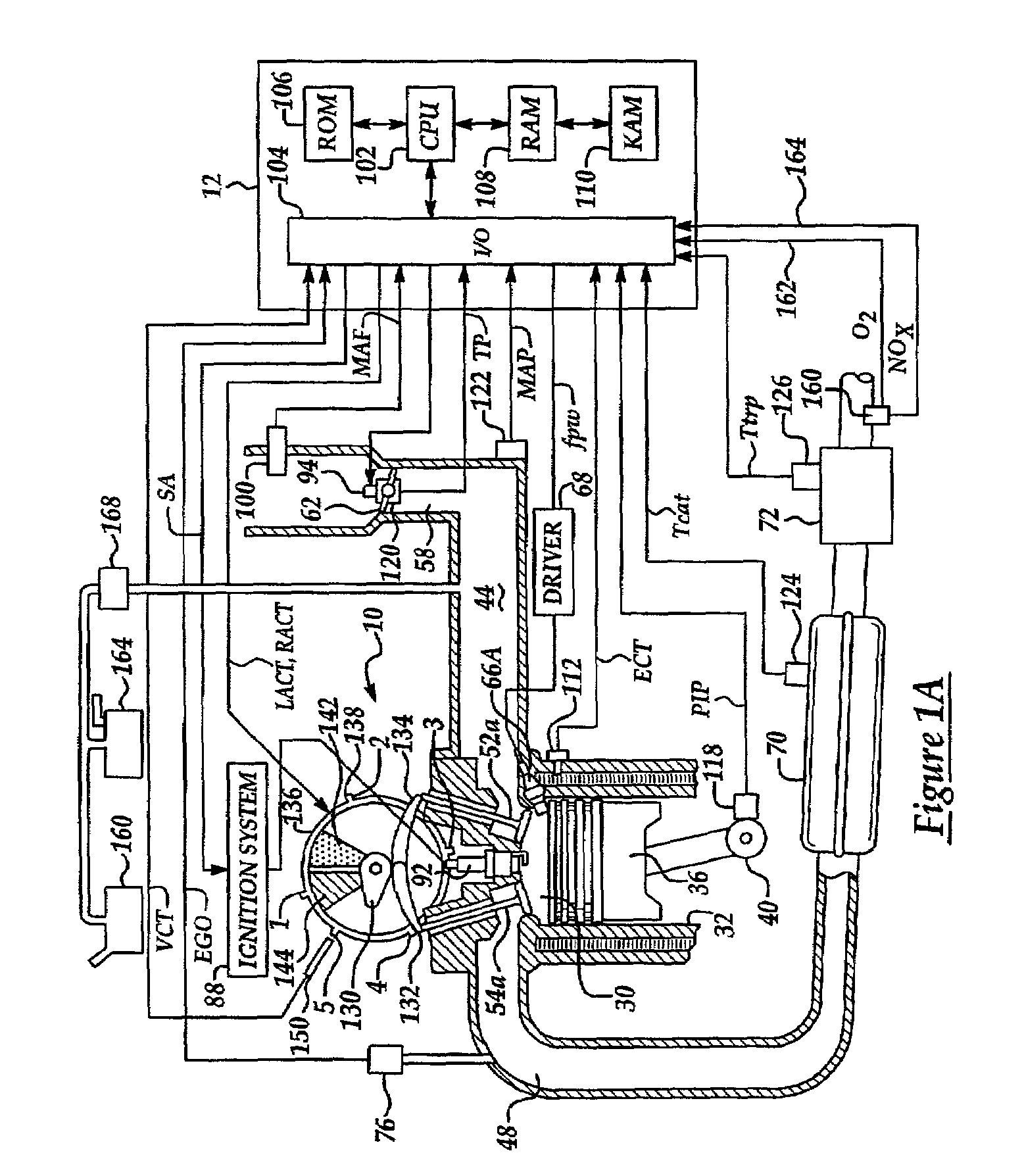

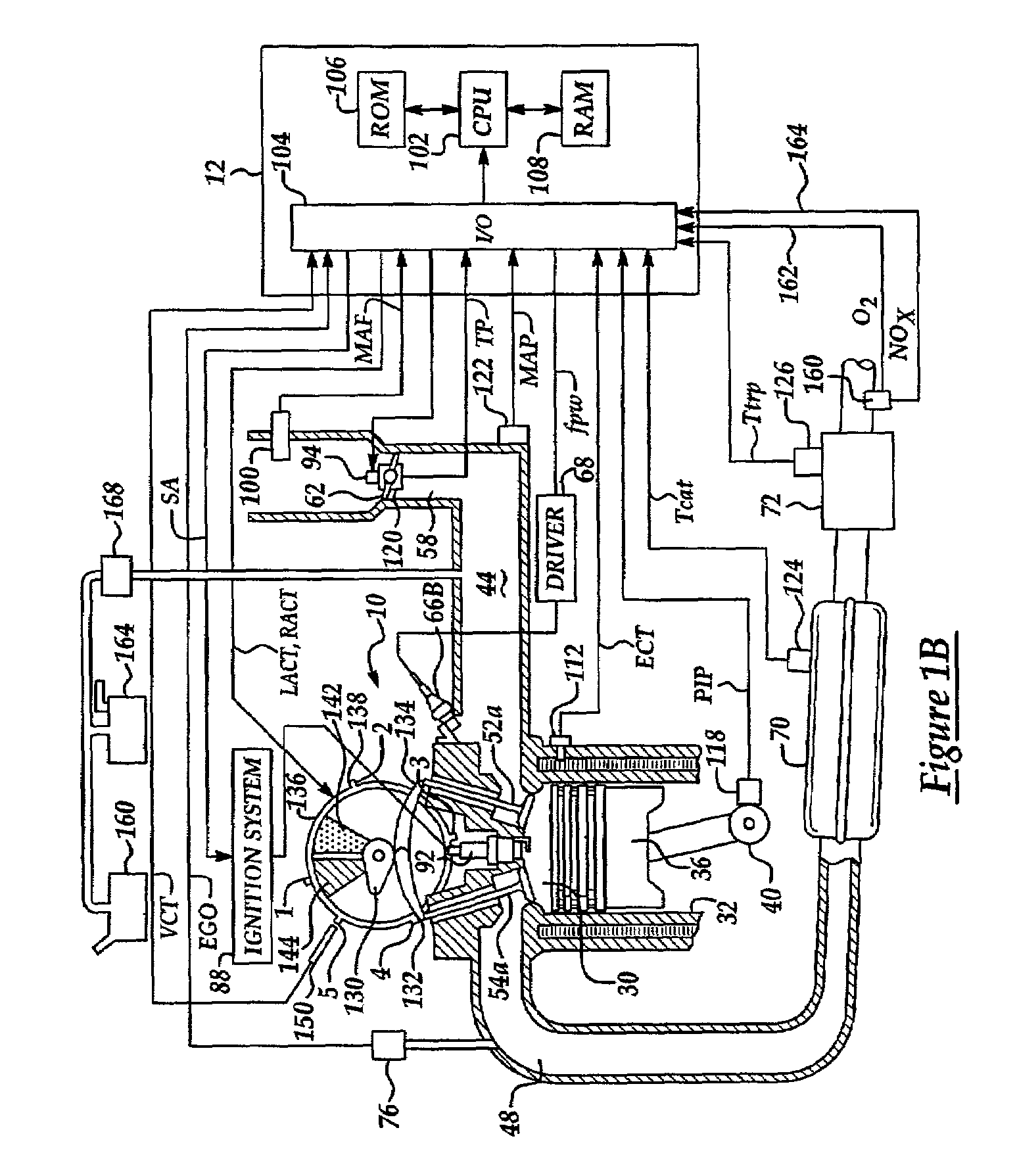

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

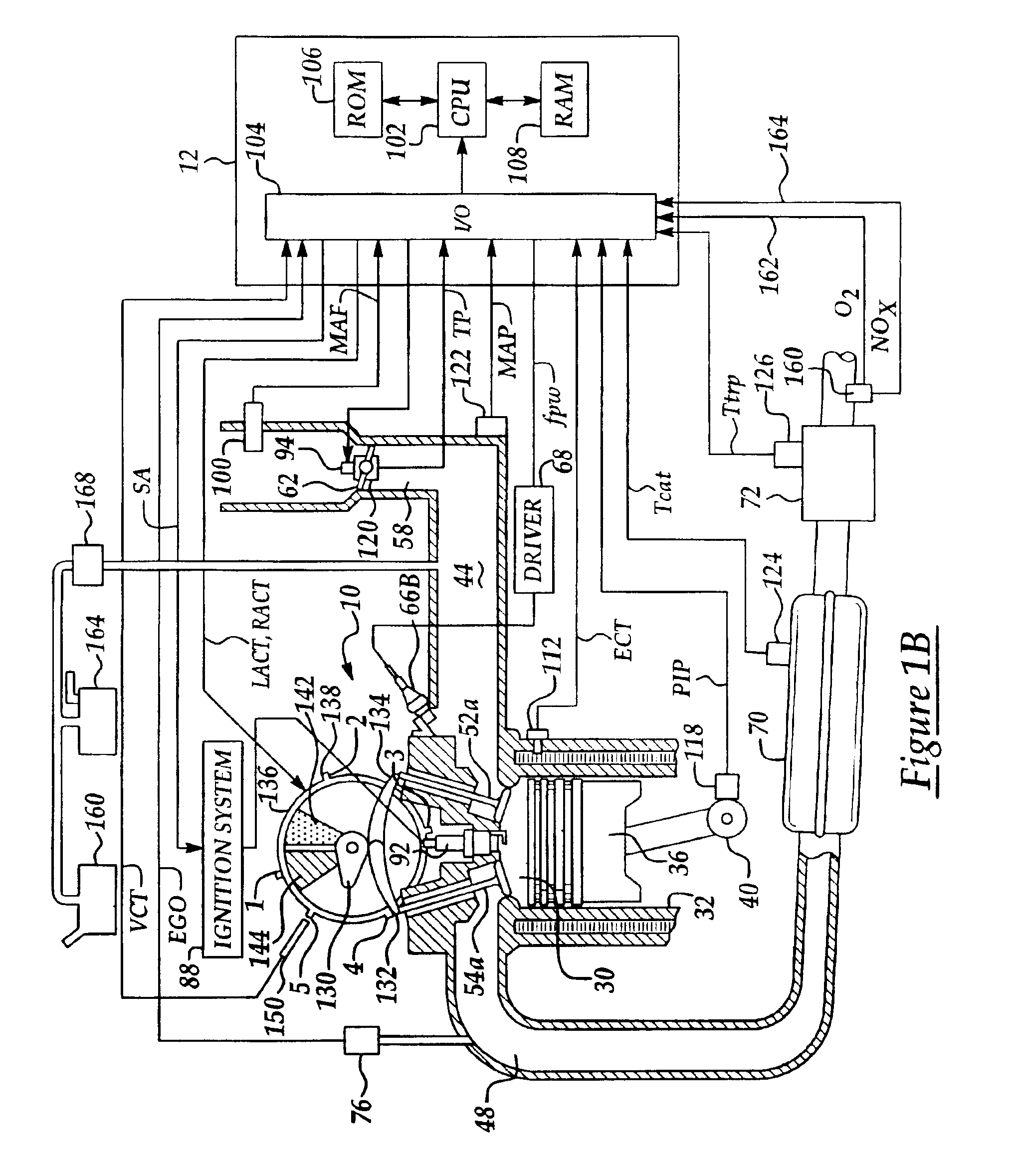

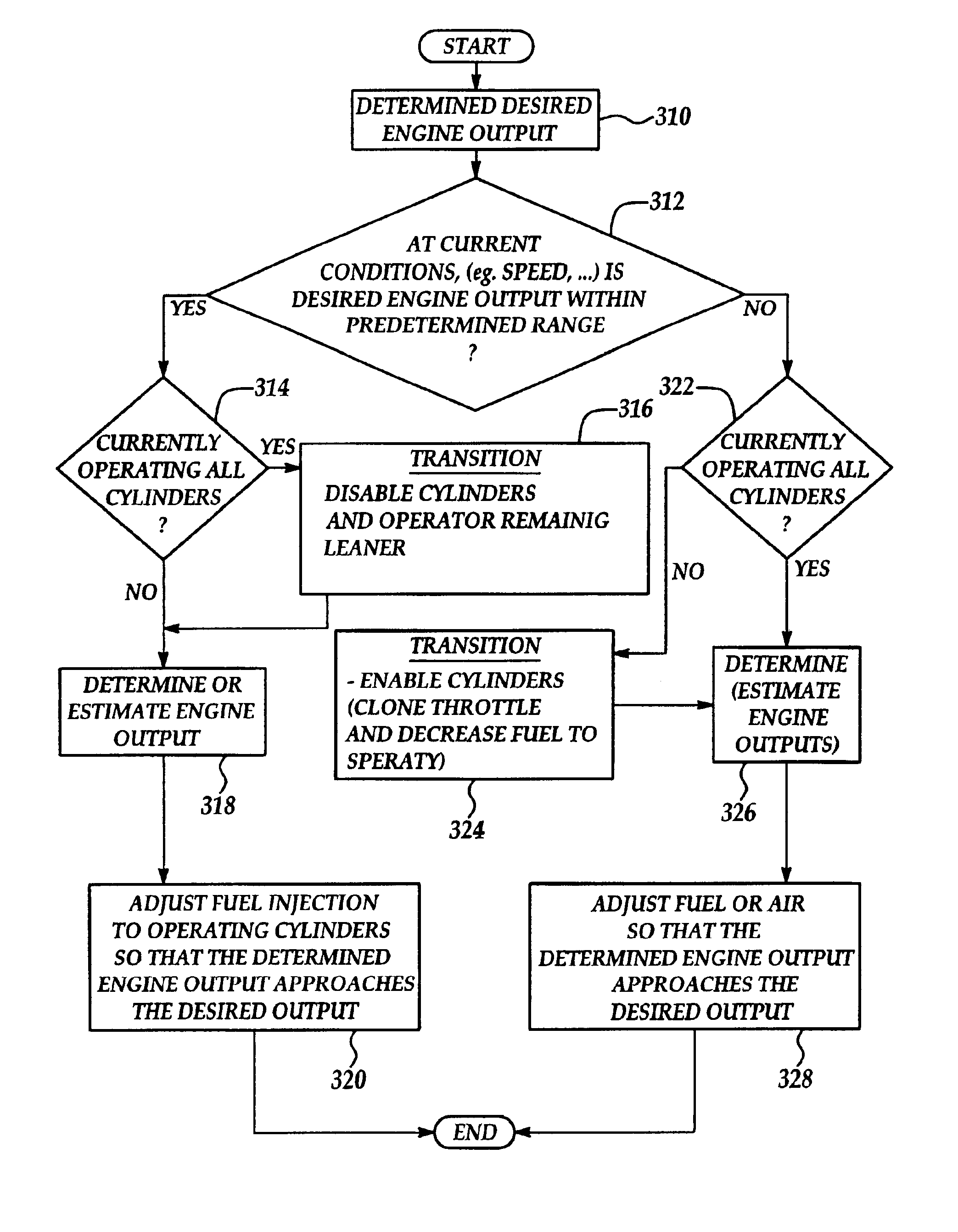

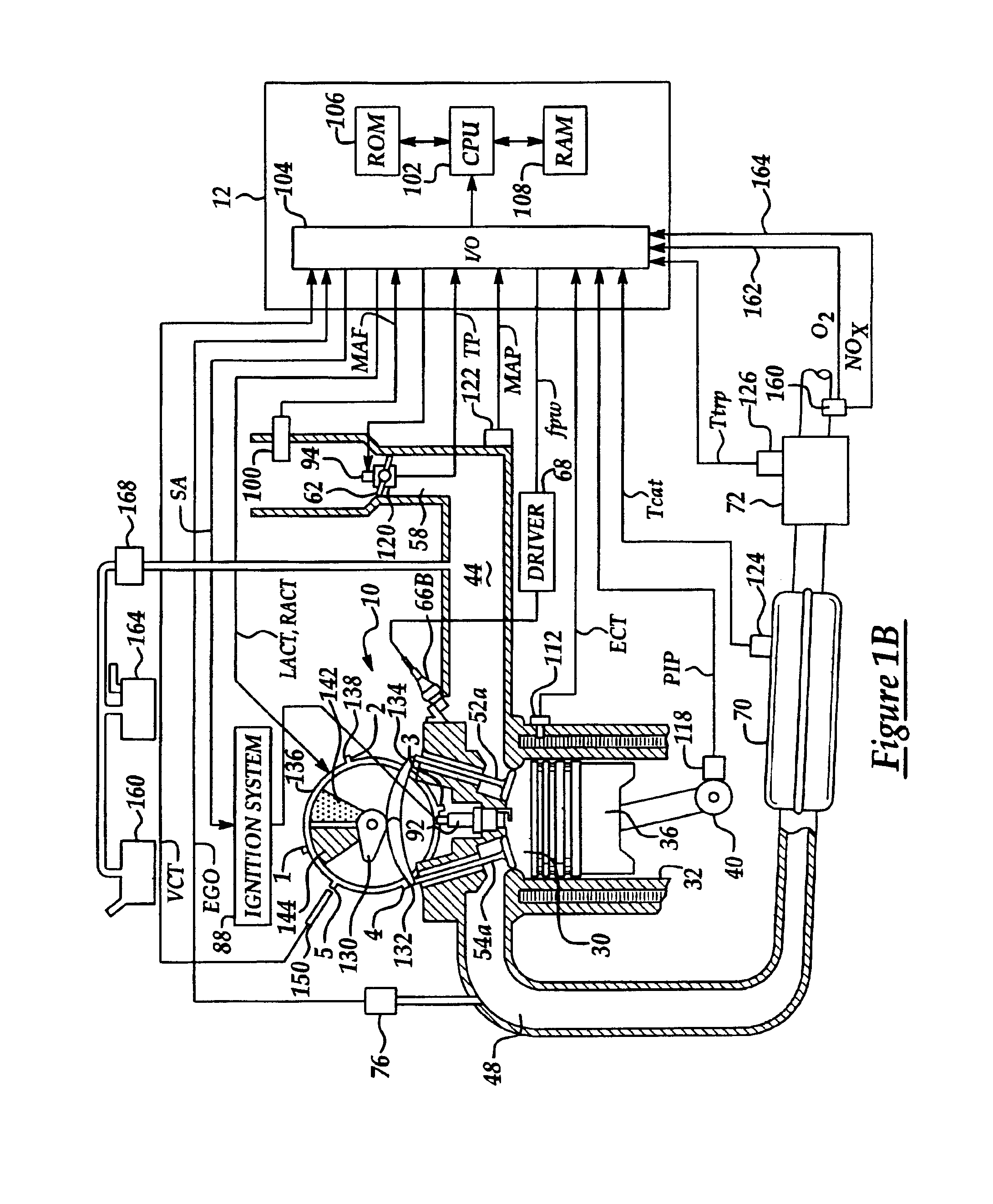

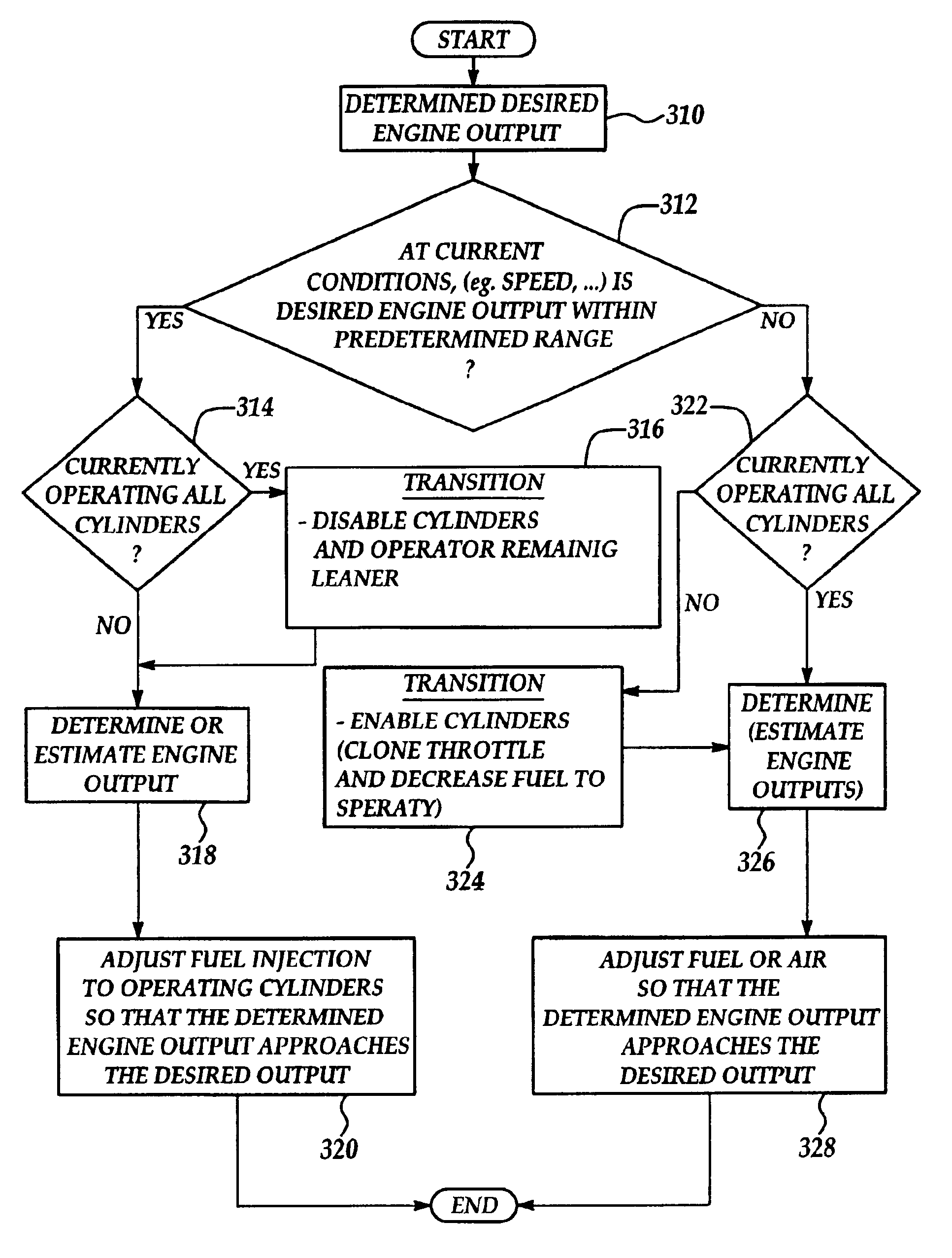

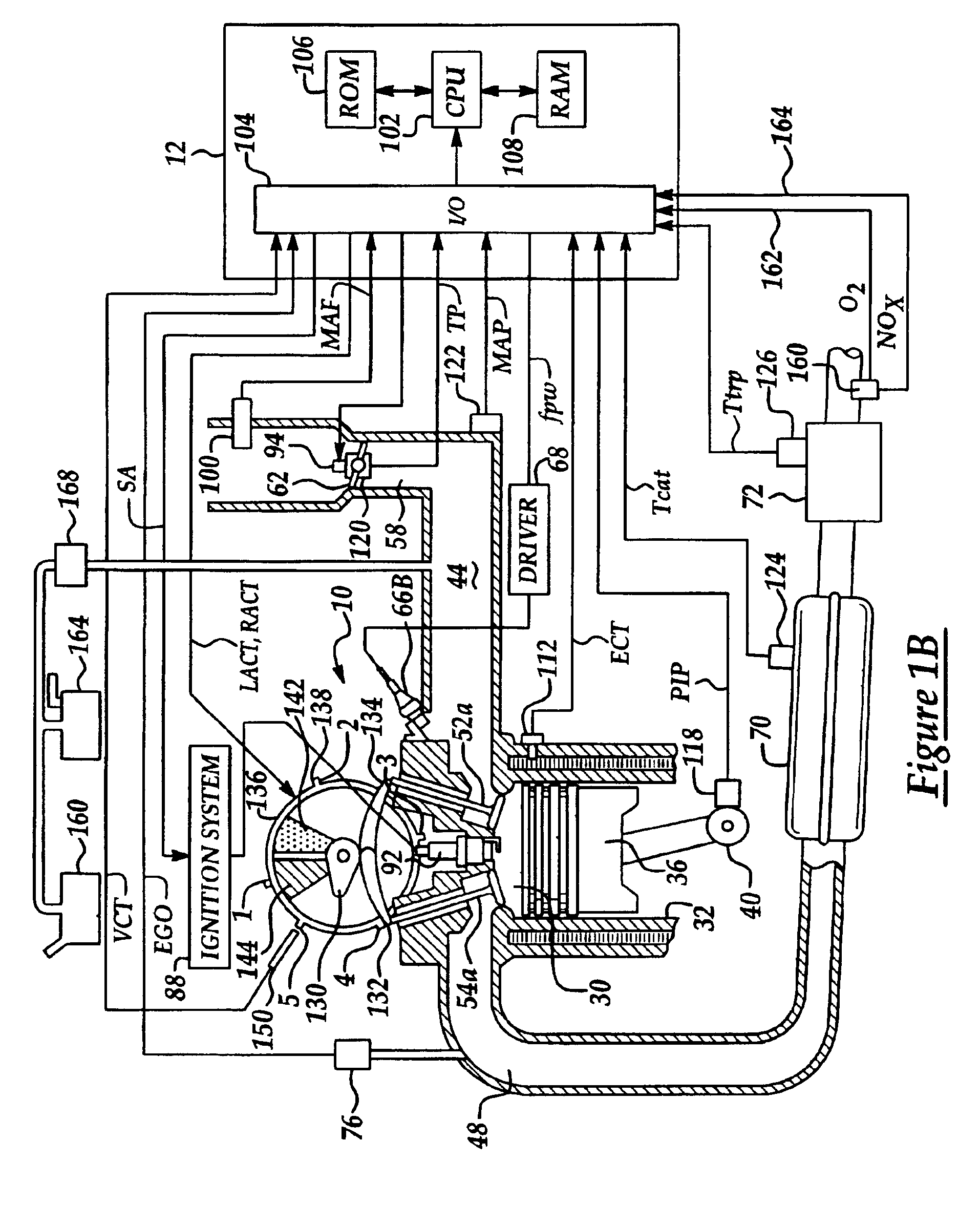

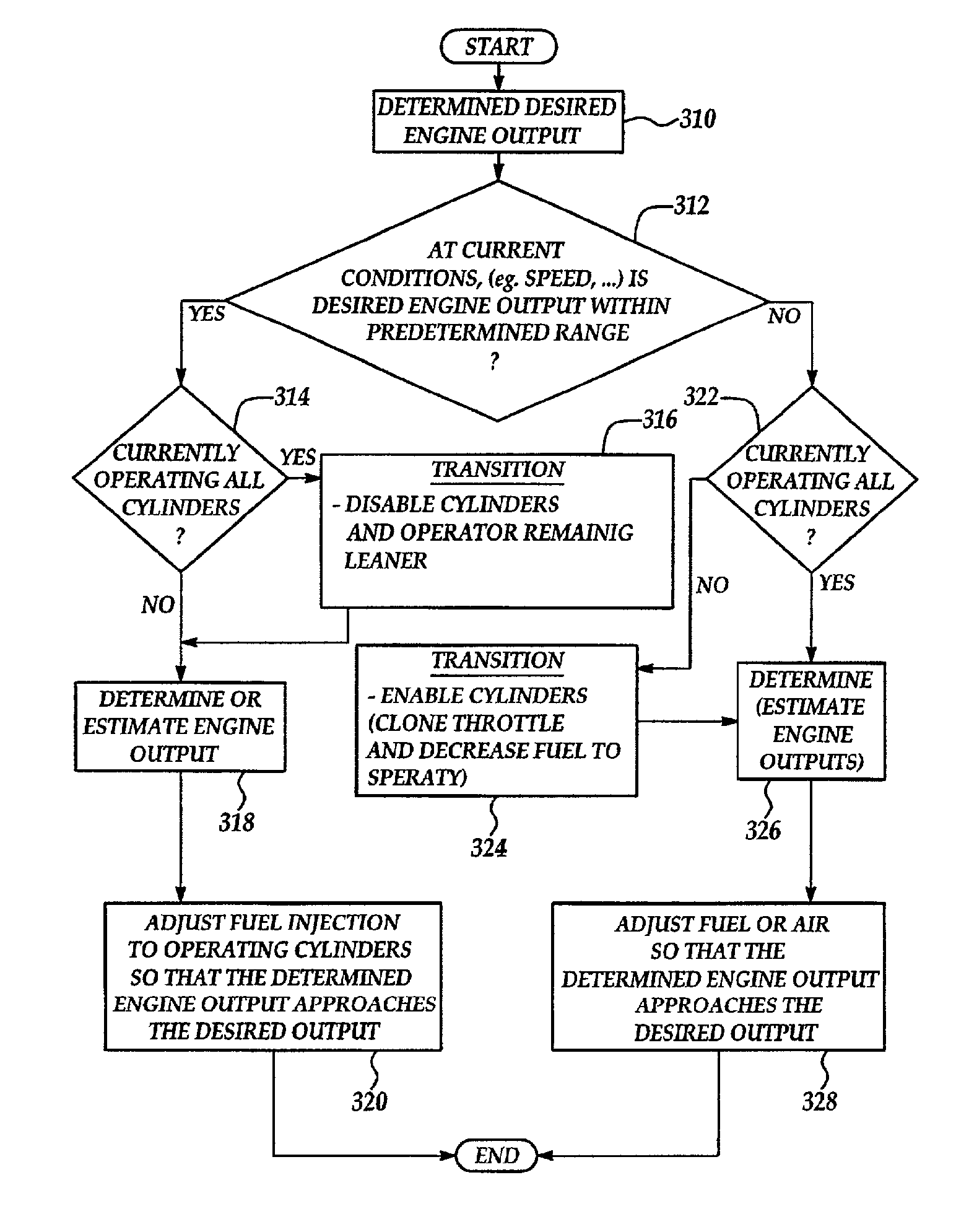

Method to control transitions between modes of operation of an engine

InactiveUS6735938B2Improve carrying capacityFuel to the remaining cylinders is rapidly increasedElectrical controlVehicle fittingsTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

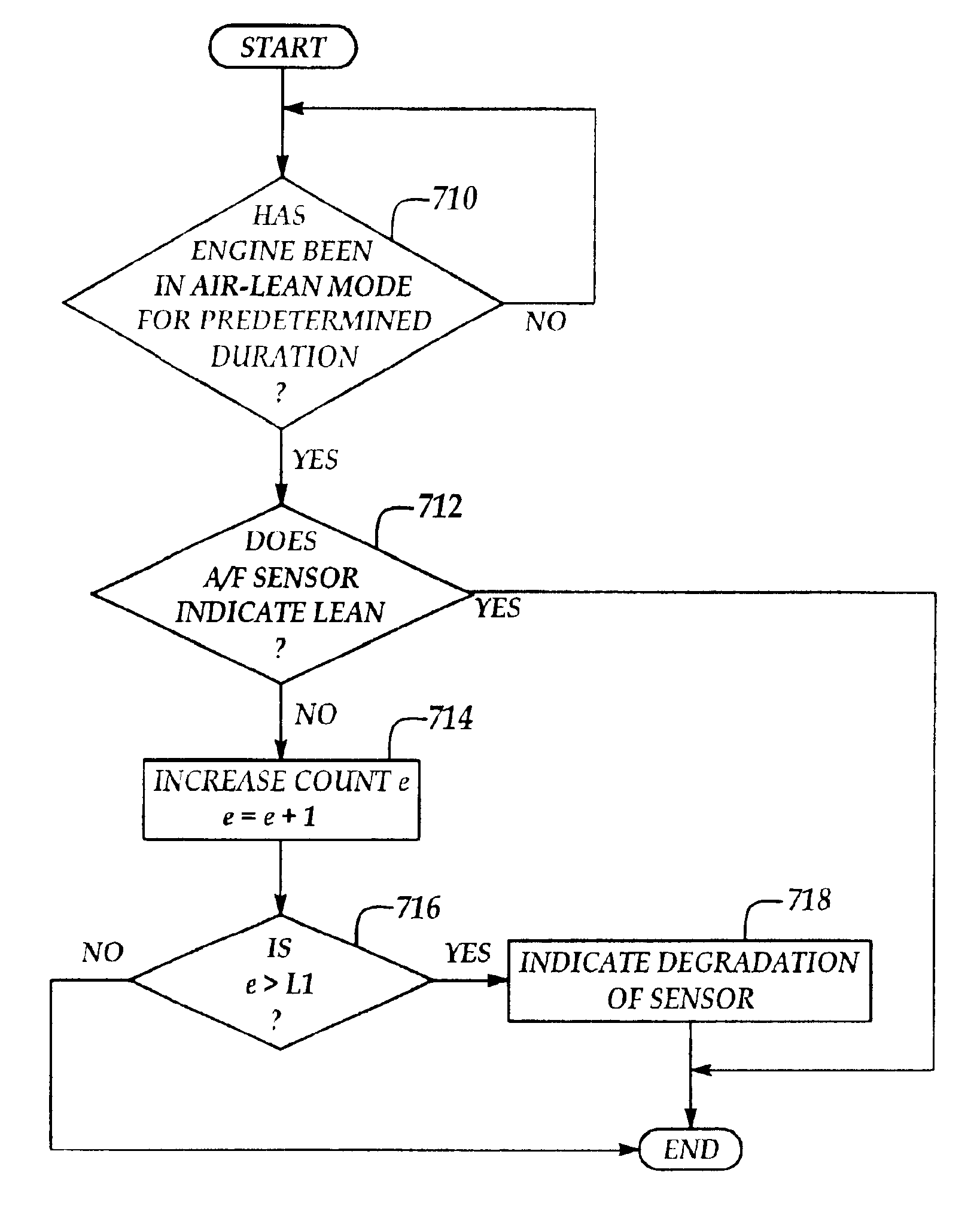

Method for air-fuel ratio sensor diagnosis

InactiveUS6736121B2Avoid false indicationsLow heat generationElectrical controlExhaust apparatusTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, such as after an engine cold start, the method operates an engine with a first group of cylinders having a first ignition timing, and a second group of cylinders having a second ignition timing more retarded than the first group. In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also can change to combusting all cylinders at substantially the same ignition timing under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Idle speed control for lean burn engine with variable-displacement-like characteristic

InactiveUS6769398B2Easy to operateDegradation of combustionElectrical controlIdling devicesAdaptive learningIdle speed control

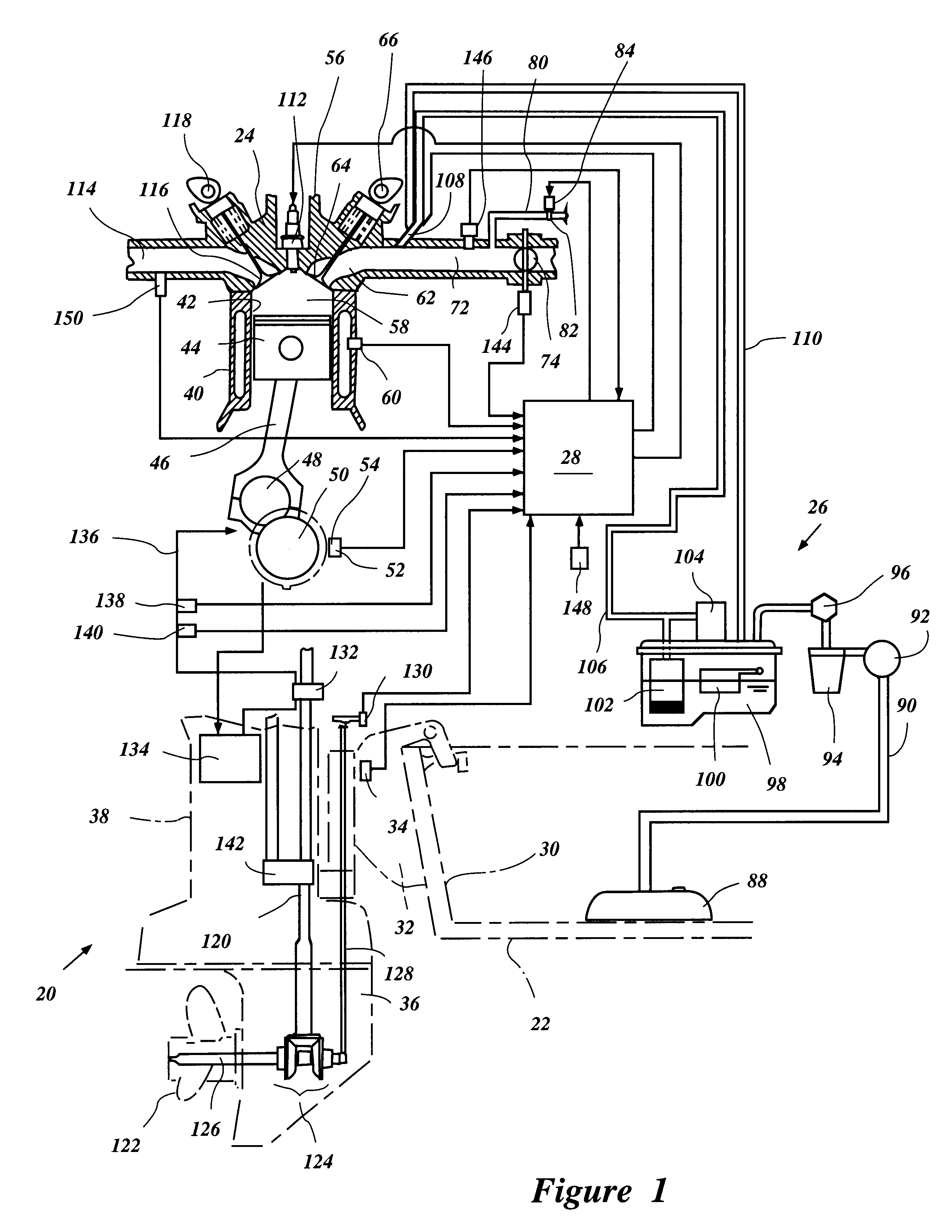

A method is disclosed for controlling operation of a engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air-fuel mixture and a second group of cylinders pumping air only (i.e. without fuel injection.) In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: auto speed control, sensor diagnostics, air-fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, and default operation. In addition, the engine control method also disables the split air / lean operating mode under preselected operating conditions.

Owner:FORD GLOBAL TECH LLC

Method for split ignition timing for idle speed control of an engine

InactiveUS20030221664A1High load conditionMore ignition timingAnalogue computers for vehiclesElectrical controlTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, such as after an engine cold start, the method operates an engine with a first group of cylinders having a first ignition timing, and a second group of cylinders having a second ignition timing more retarded than the first group. In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also can change to combusting all cylinders at substantially the same ignition timing under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method to improve fuel economy in lean burn engines with variable-displacement-like characteristics

InactiveUS6758185B2Easy to operateOverall engine torque fallsElectrical controlNon-fuel substance addition to fuelTemperature controlAdaptive learning

Owner:FORD GLOBAL TECH LLC

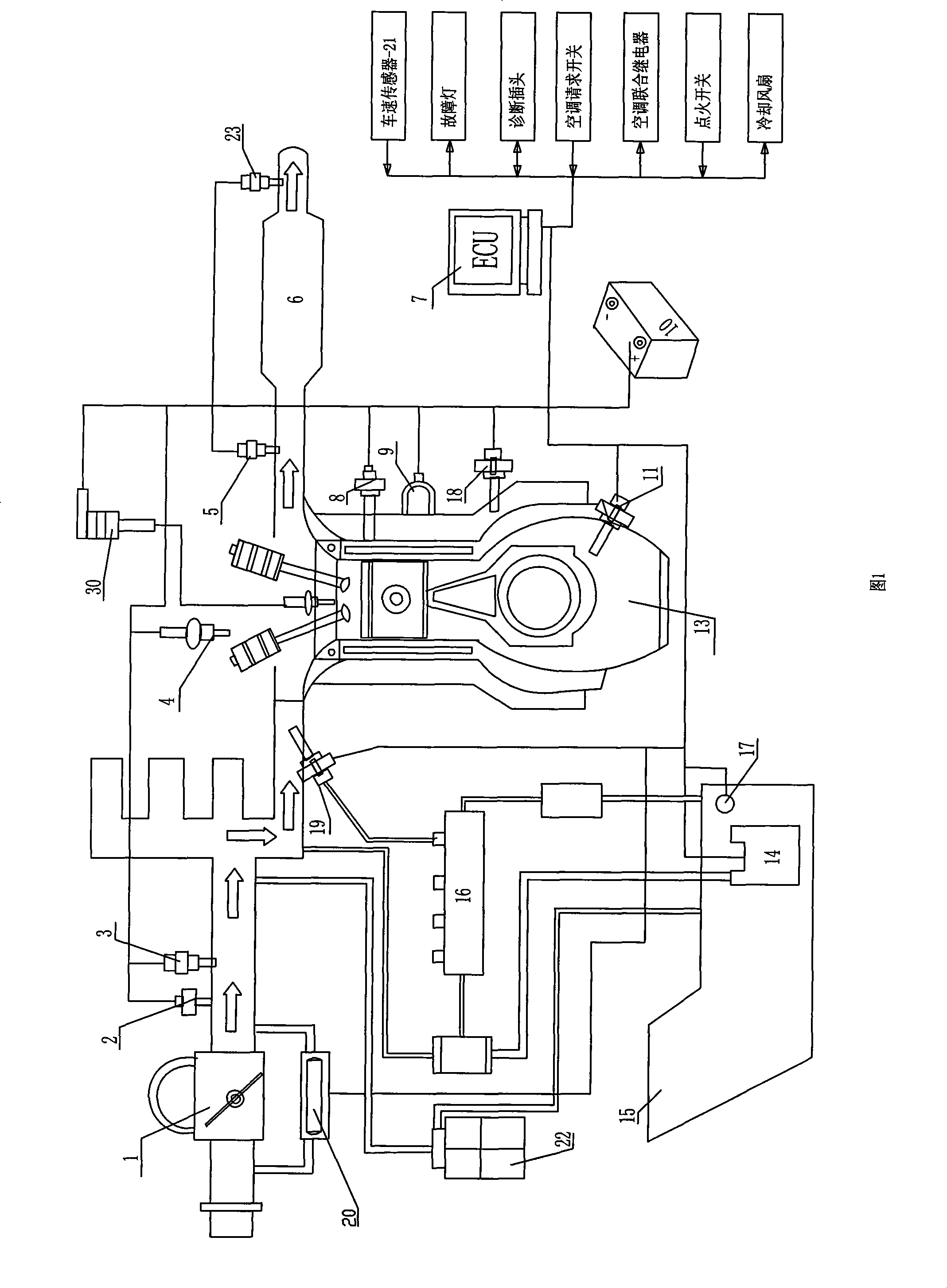

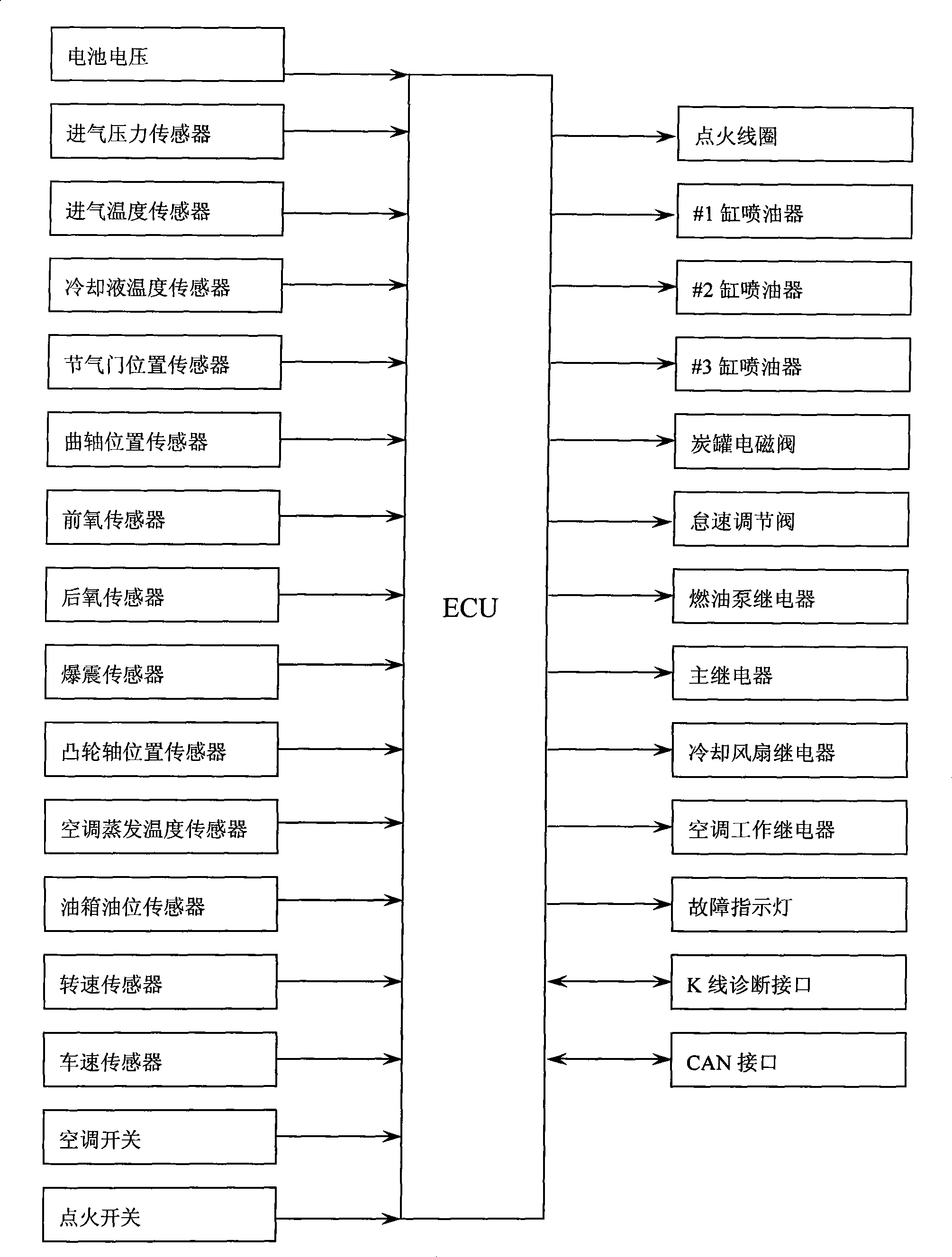

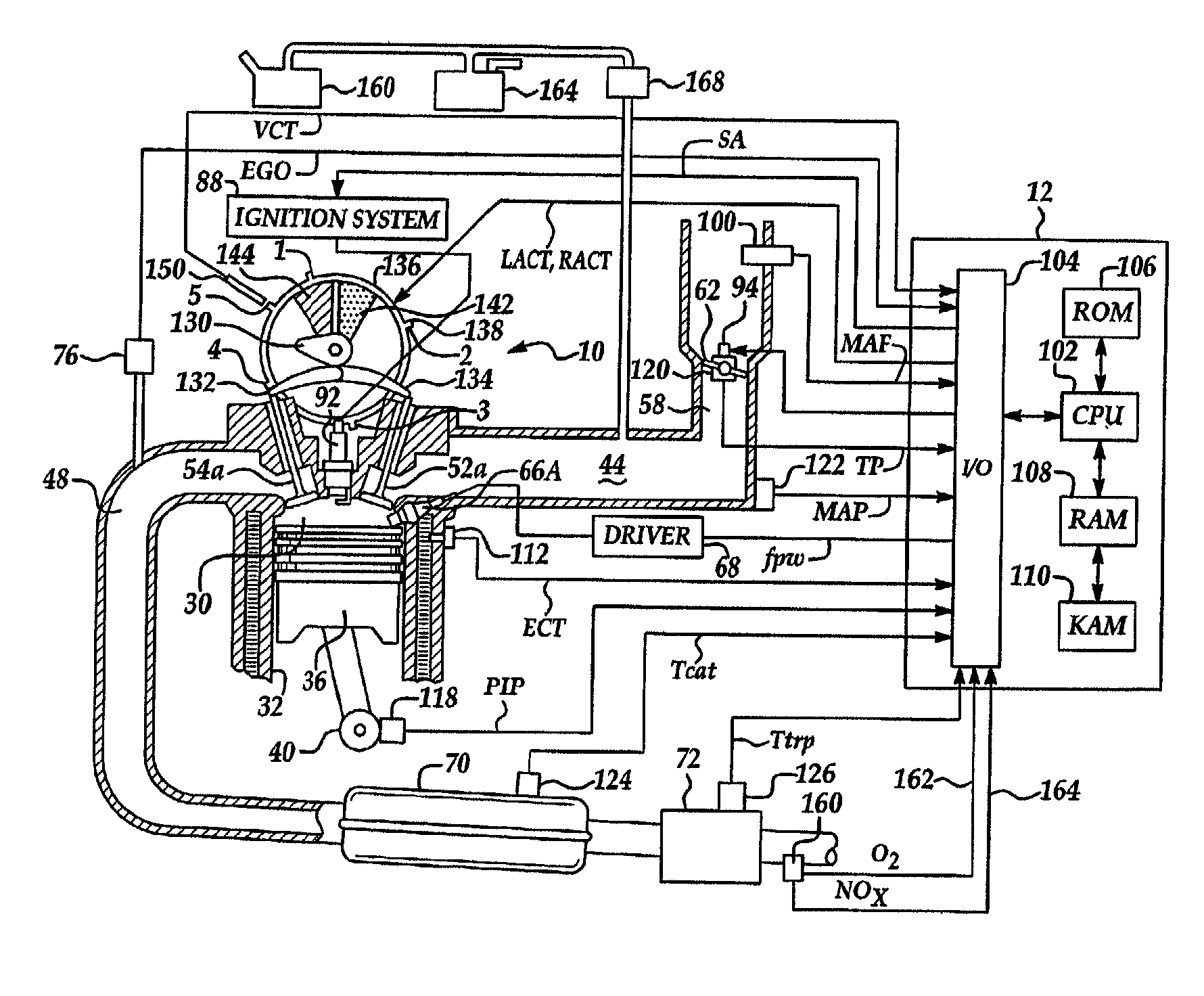

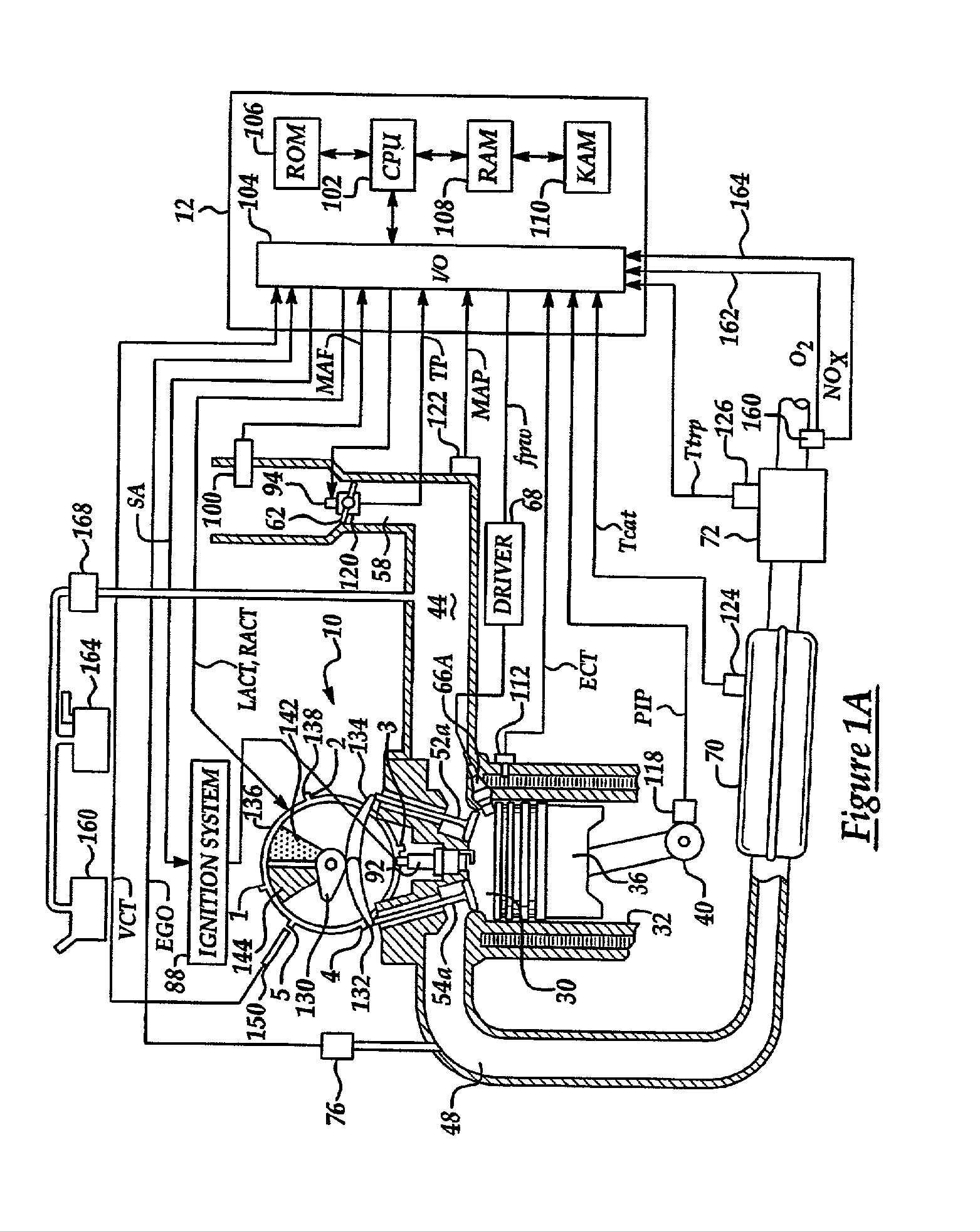

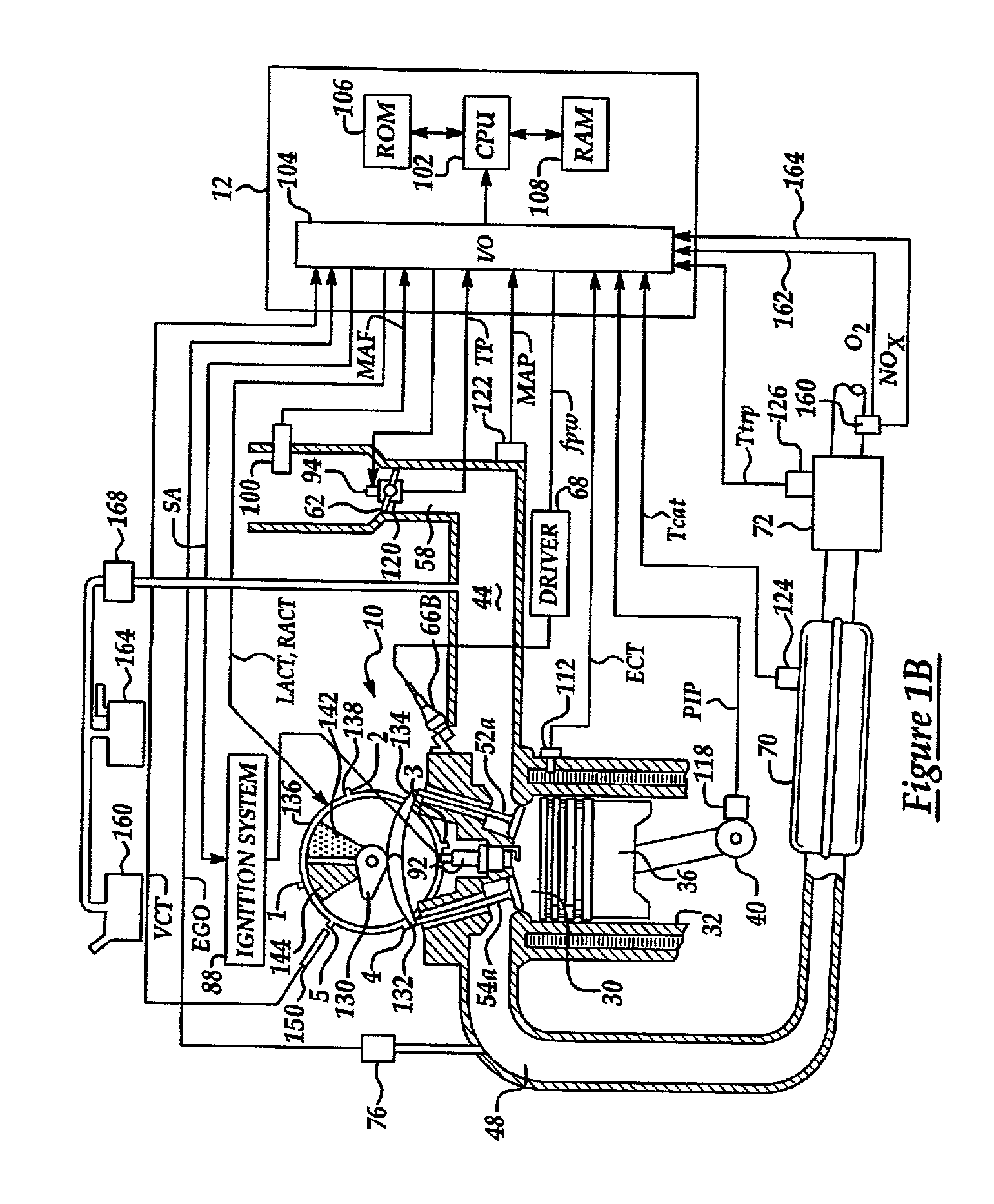

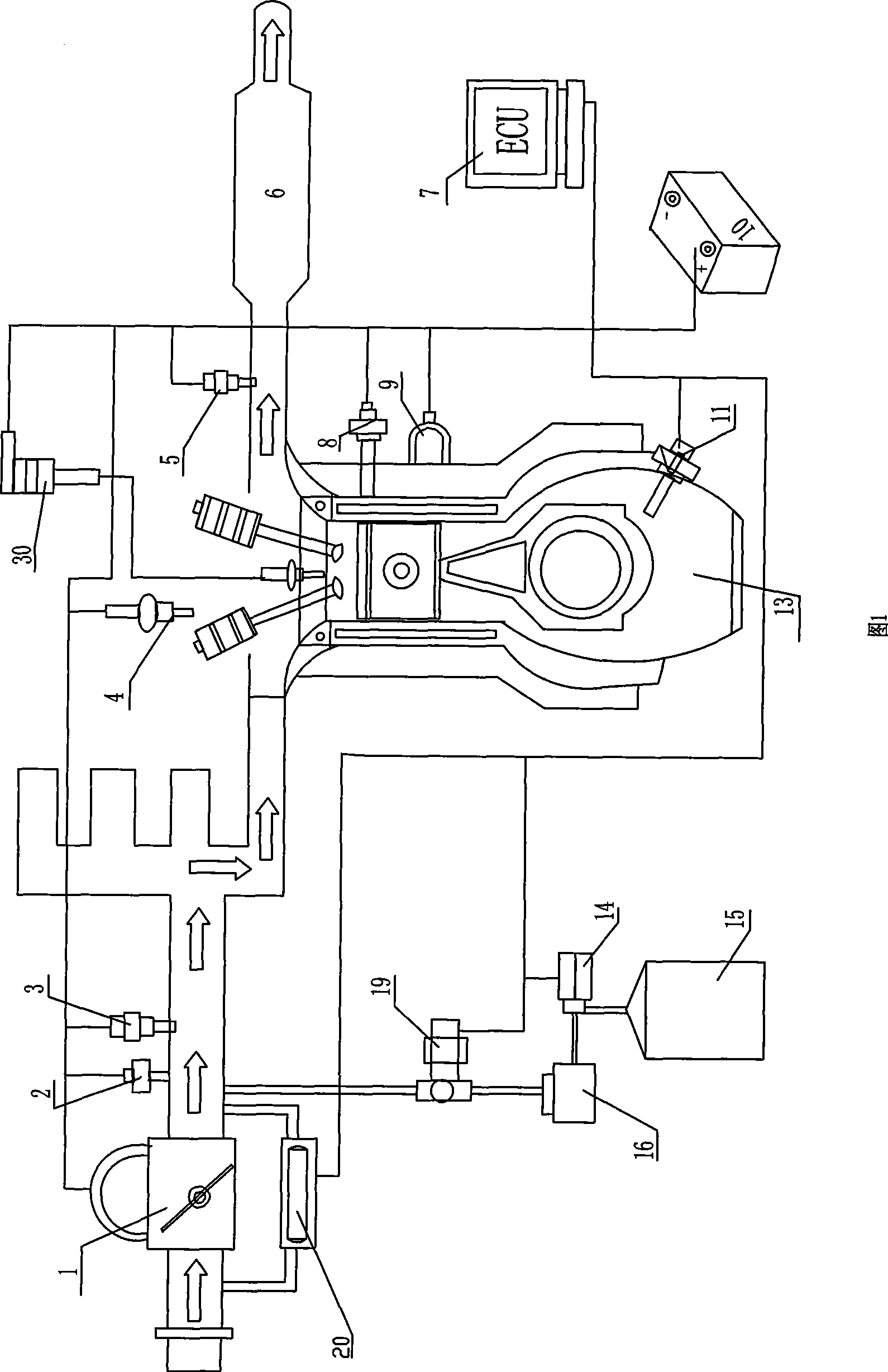

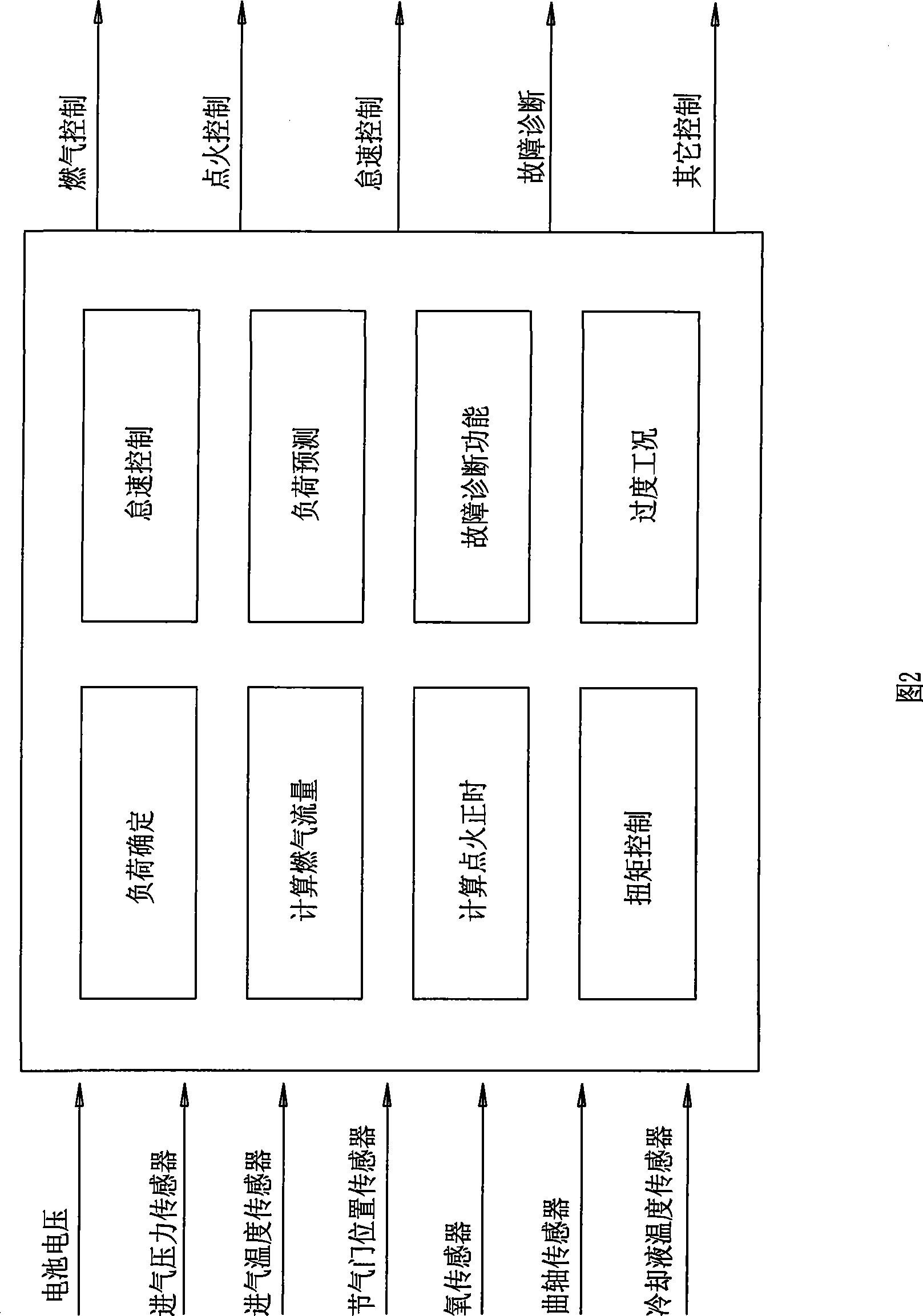

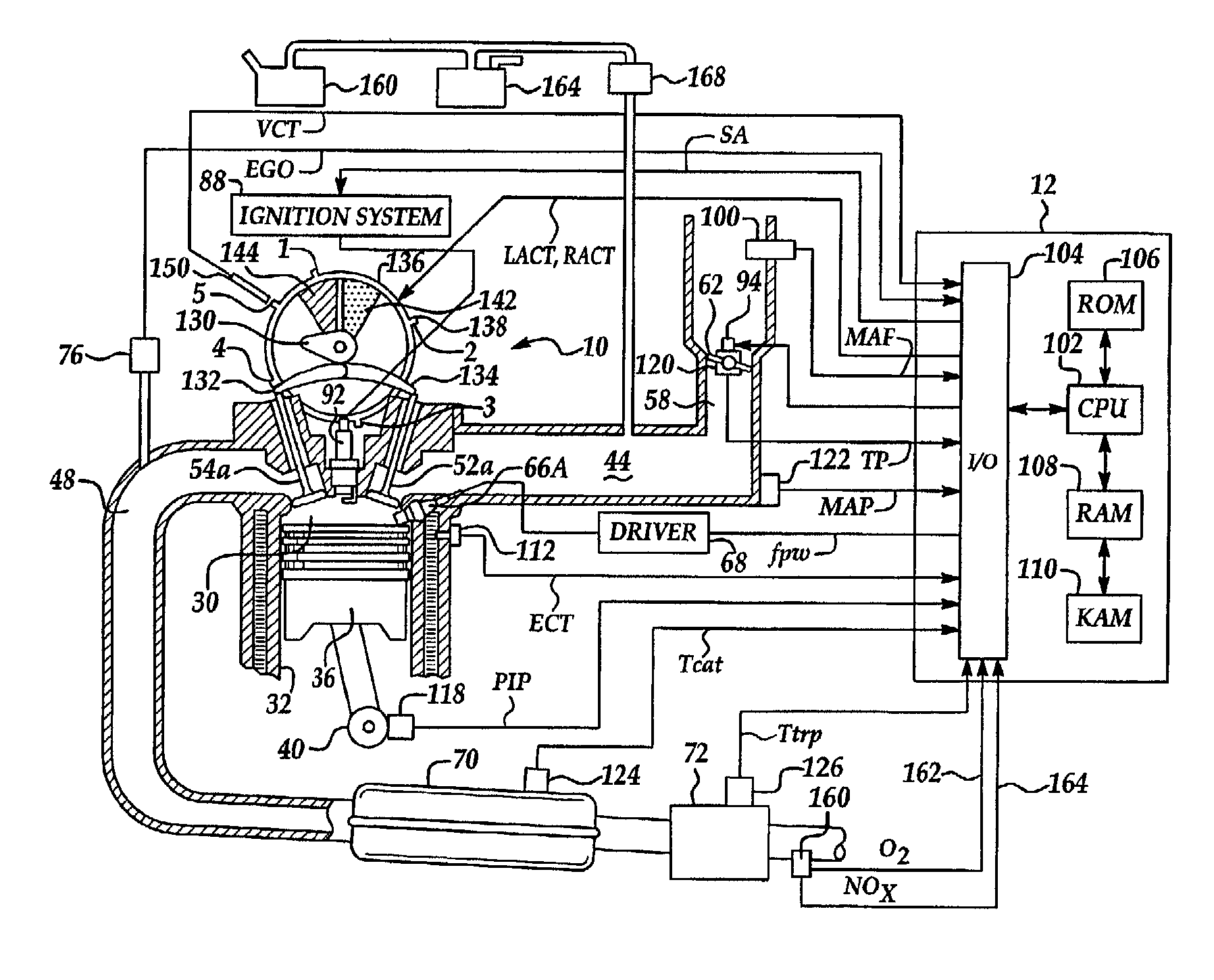

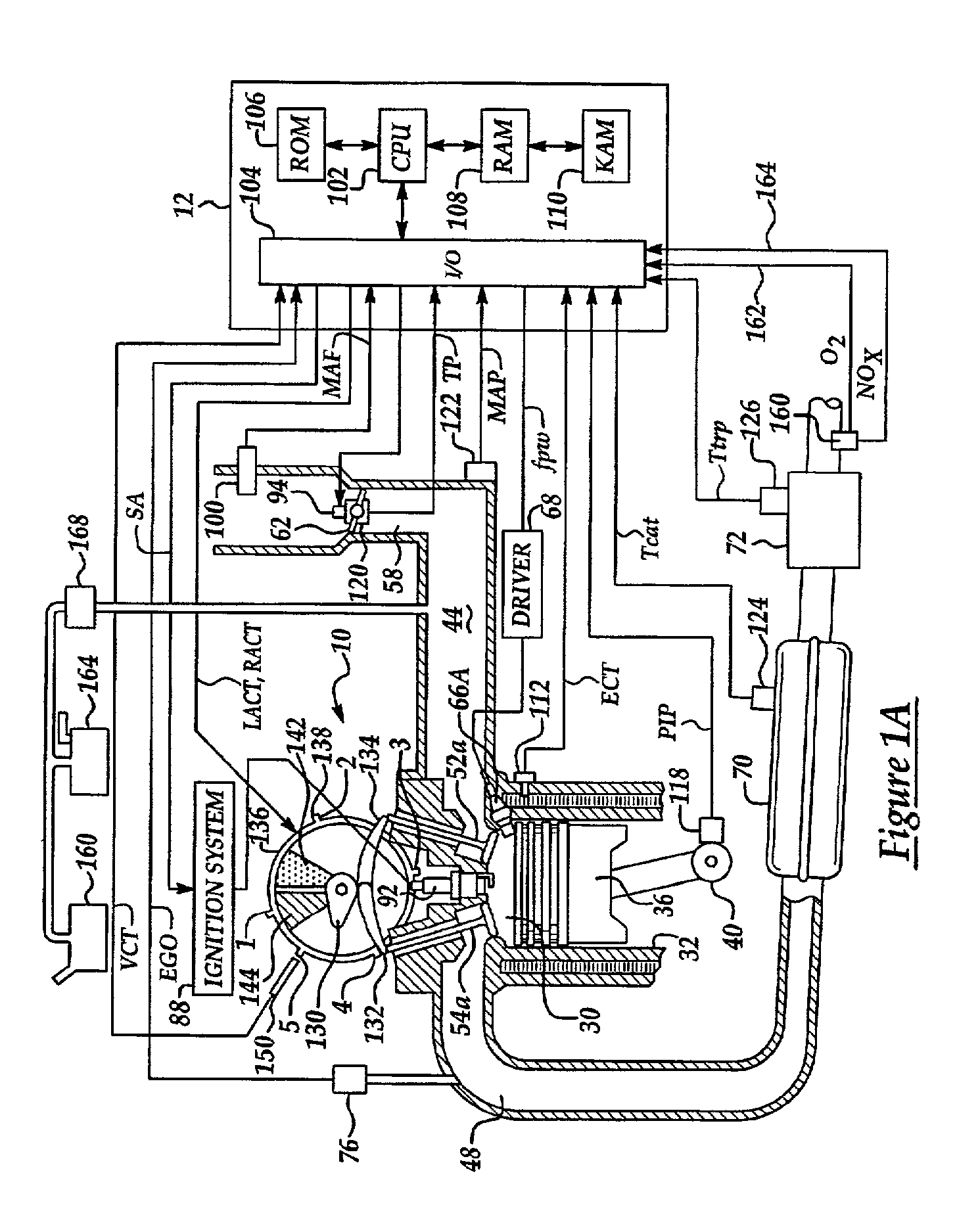

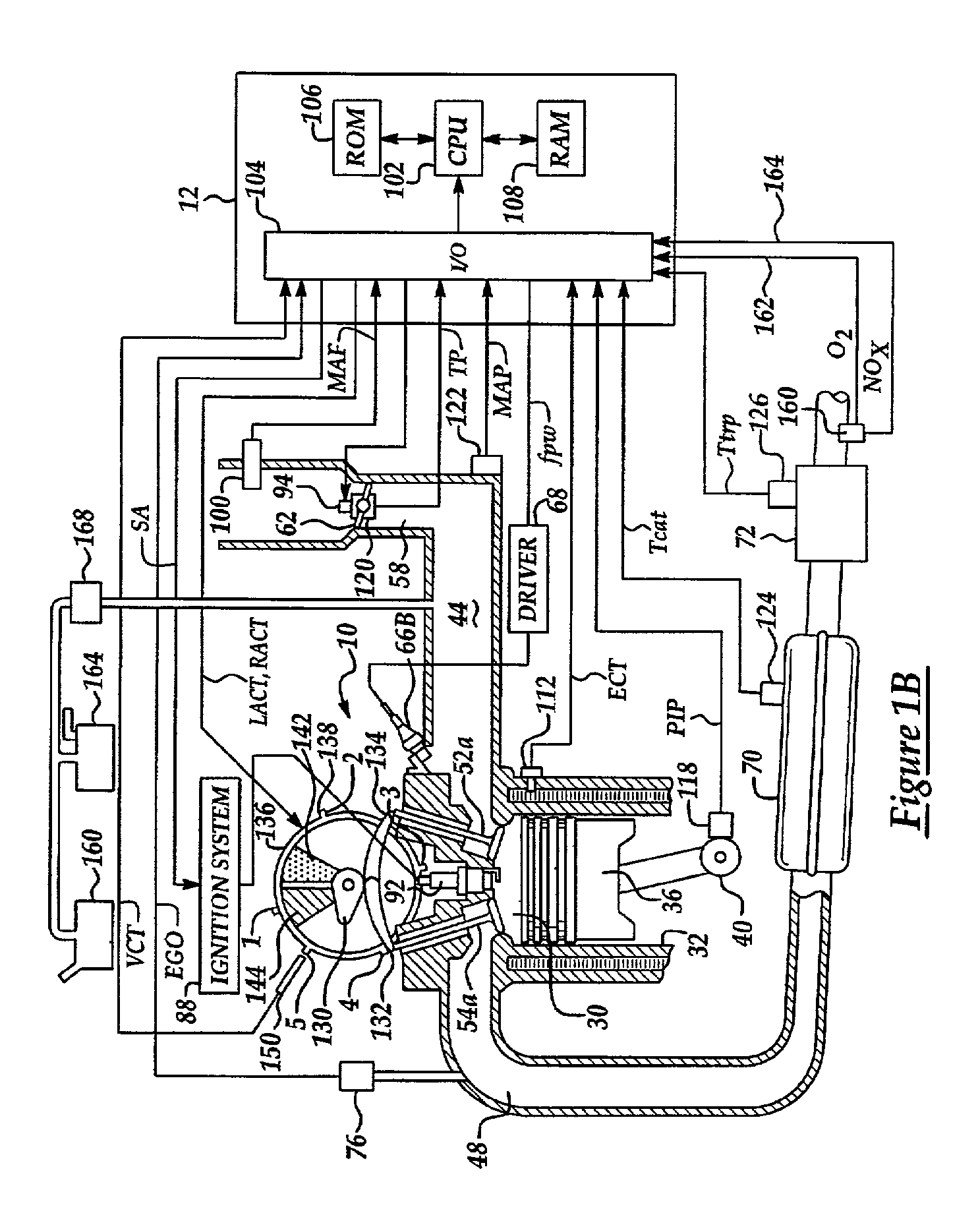

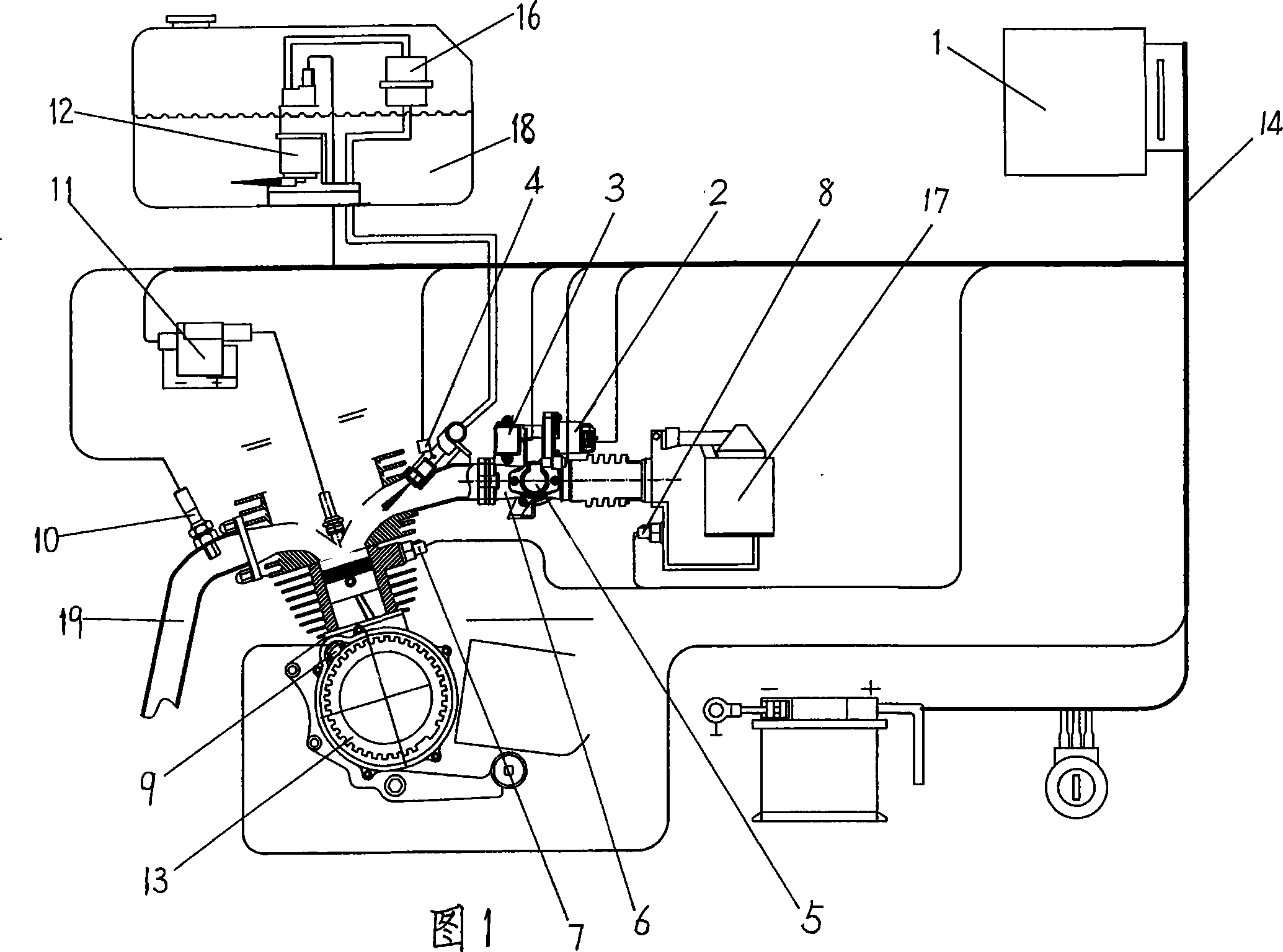

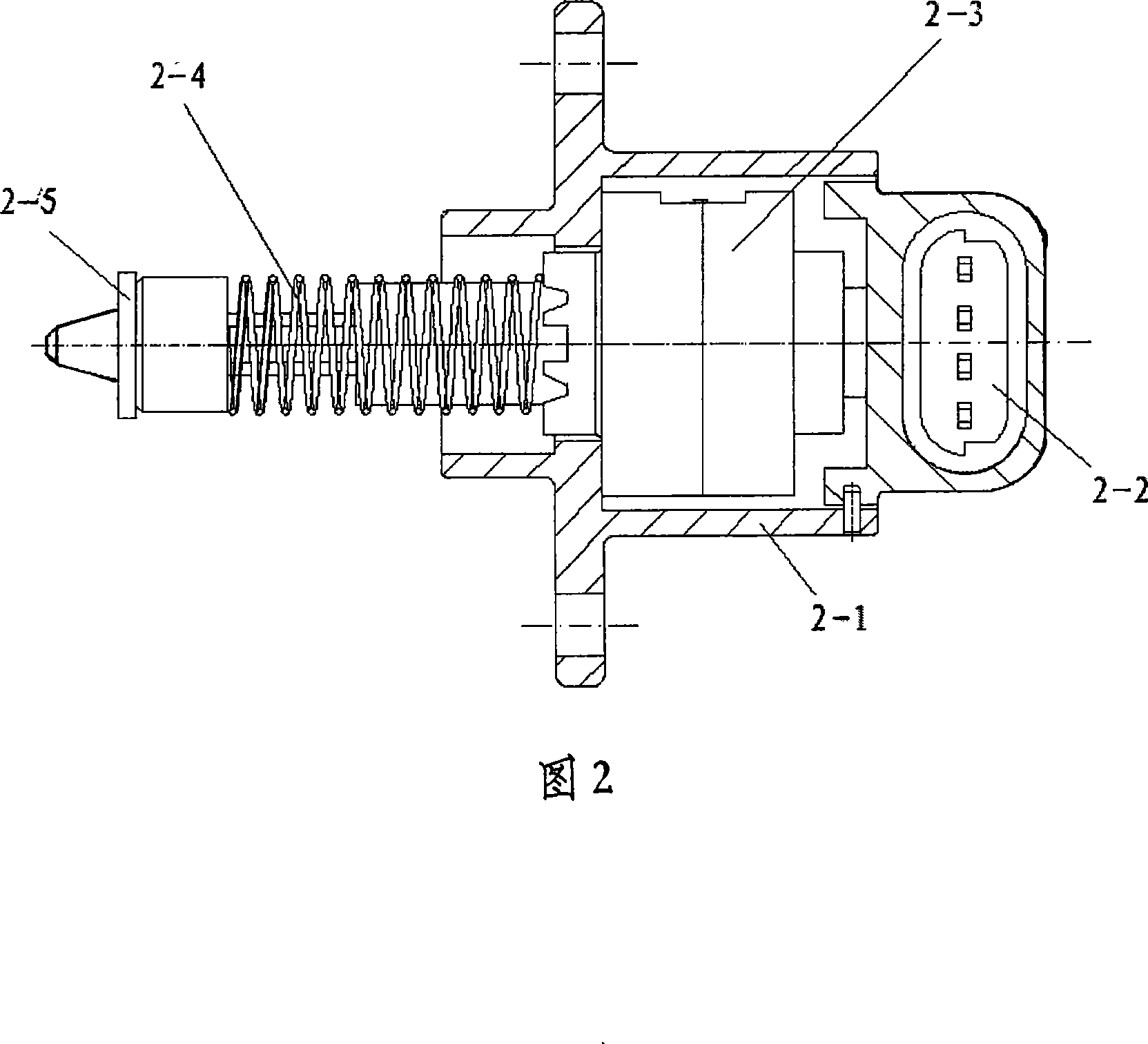

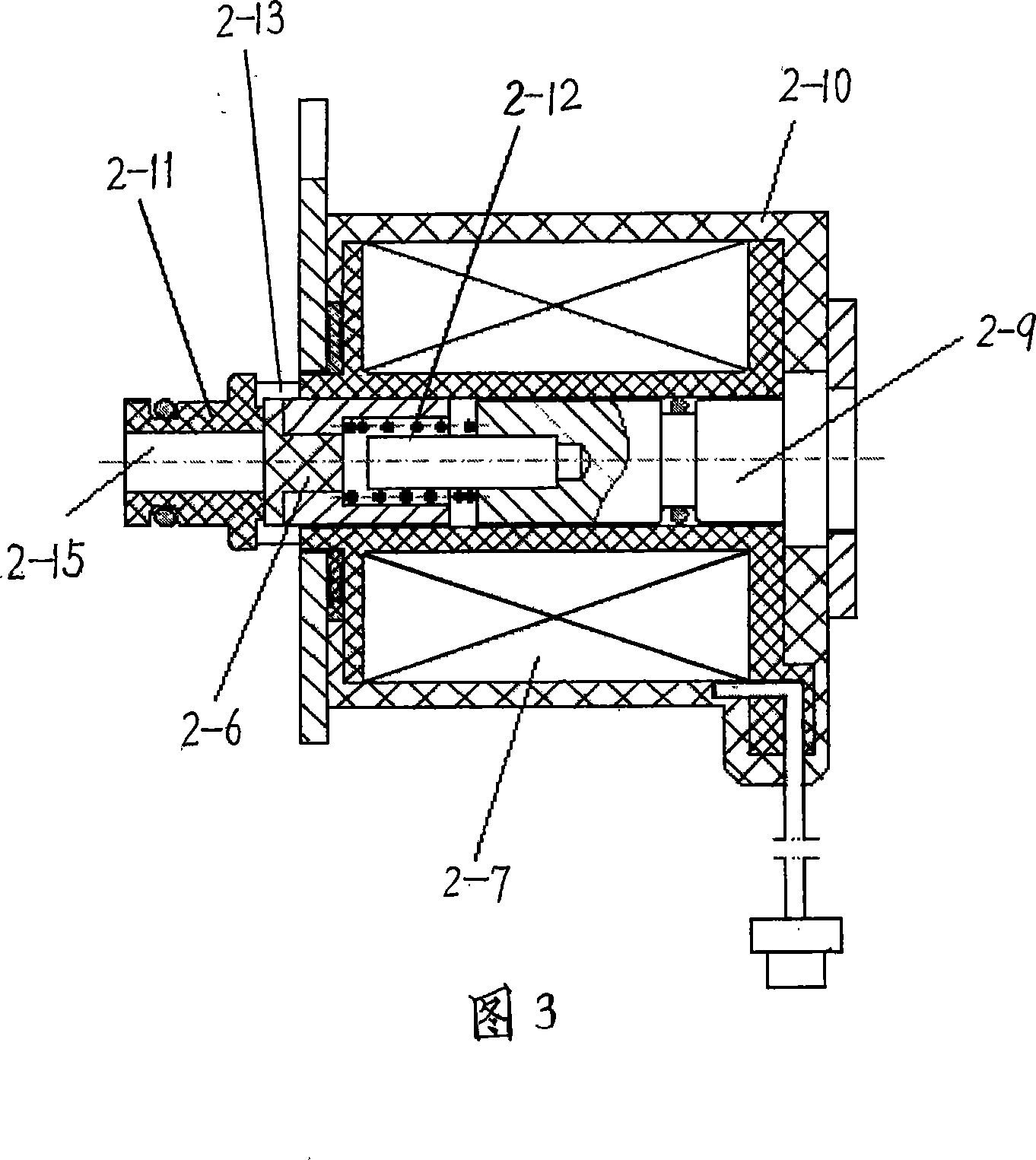

Electric-controlled petrol engine work system

InactiveCN101363380ARich control functionsGood control function integration performanceElectrical controlMachines/enginesIdle speed controlIgnition coil

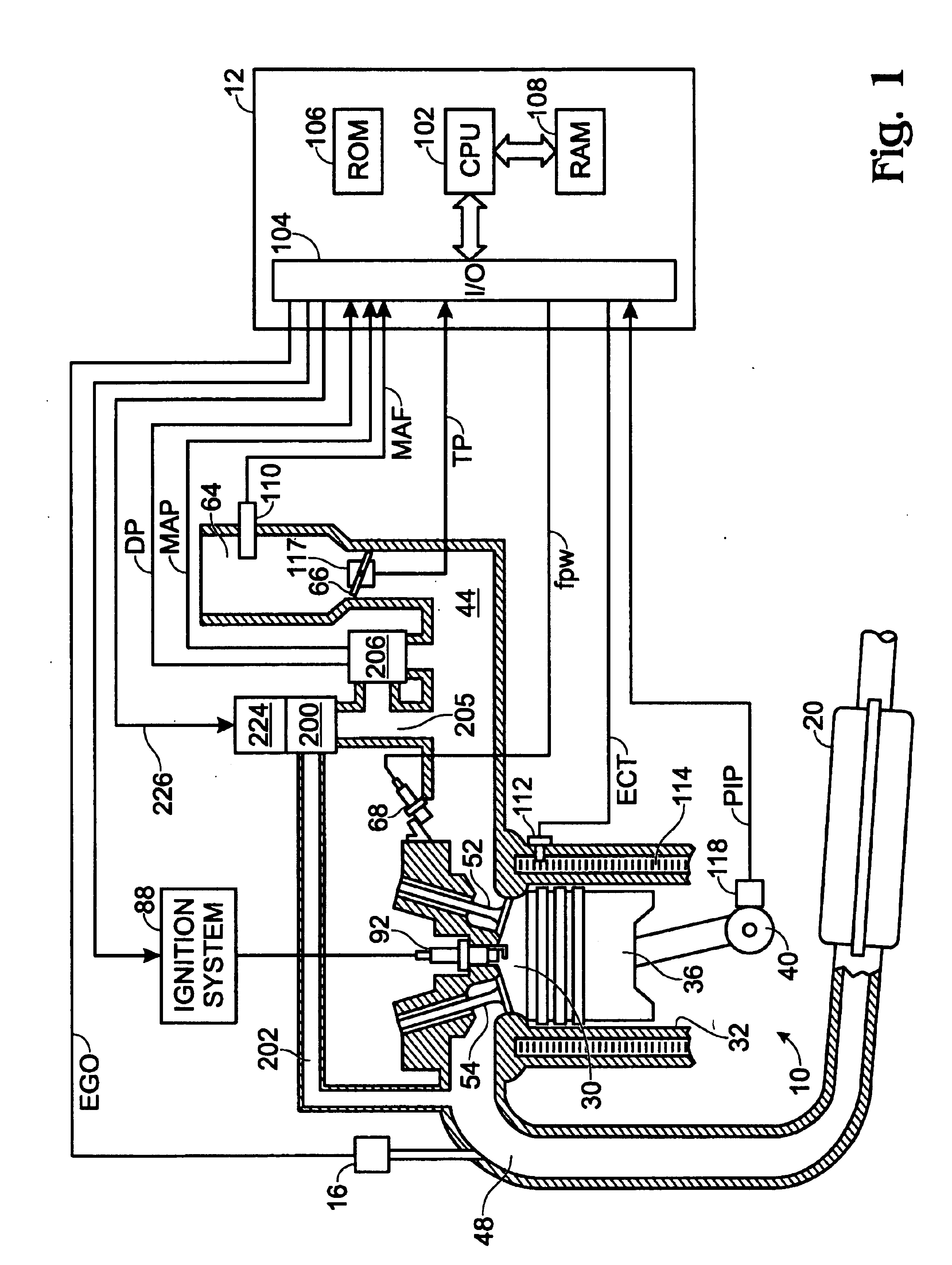

The invention provides a work system of an electronically controlled gasoline engine, comprising an air intake system, a fuel oil supply system, an ignition system as well as an electronic control system; the electronic control system consists of a sensor section, an electronic control unit ECU and an actuator section, wherein, the sensor section includes a throttle position sensor, an intake pressure and temperature sensor and an intake temperature sensor which are arranged on an intake pipe of an intake system, a camshaft position sensor, a coolant temperature sensor and a crankshaft position sensor which are arranged on the engine, a front oxygen sensor arranged in front of a three-way catalyst converter on an exhaust pipe of the engine, and the components of the sensor section are all connected with the ECU, and the actuator section consists of an electric fuel pump, an oil sprayer, an idle speed regulating valve and an ignition coil; the components of the actuator section are all connected with the ECU, and the ECU includes a fuel injection control program, an ignition control program and an idle speed control program; the system adopts reasonable control strategy and has comprehensive control function, good integrated performance of control function and fine system portability.

Owner:张和君 +1

Overall scheduling of a lean burn engine system

InactiveUS6691669B2Improve carrying capacityFuel to the remaining cylinders is rapidly increasedElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

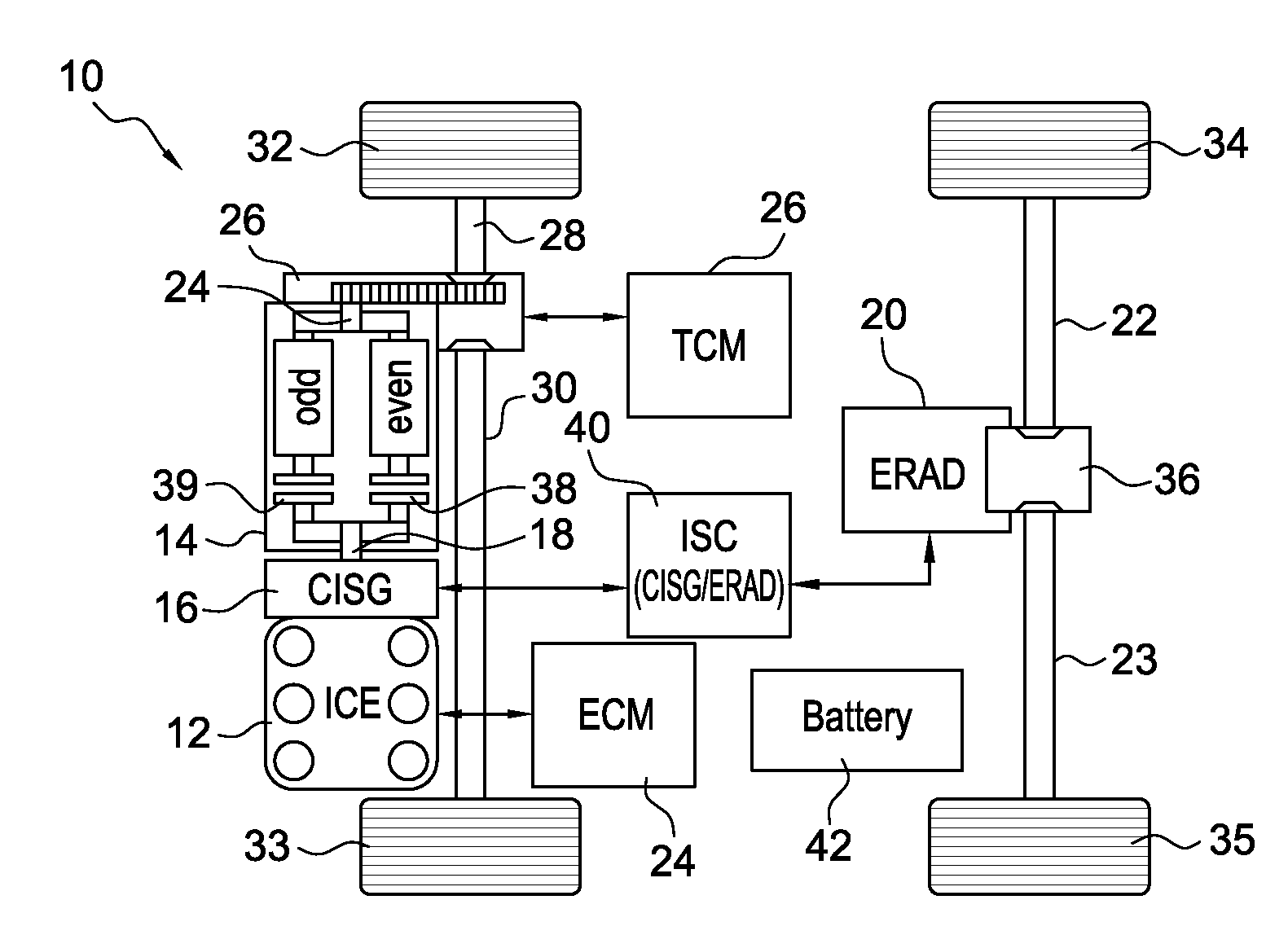

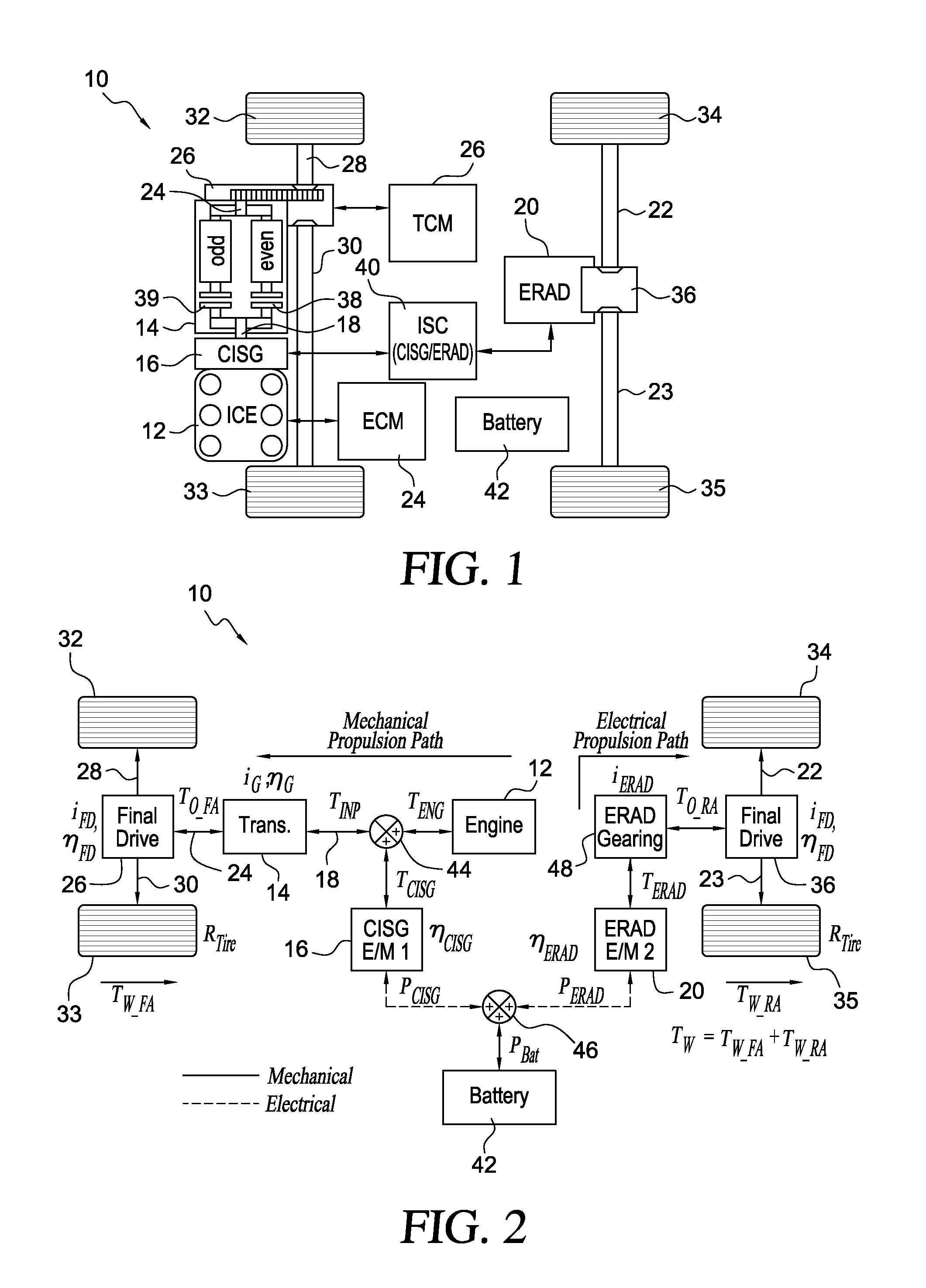

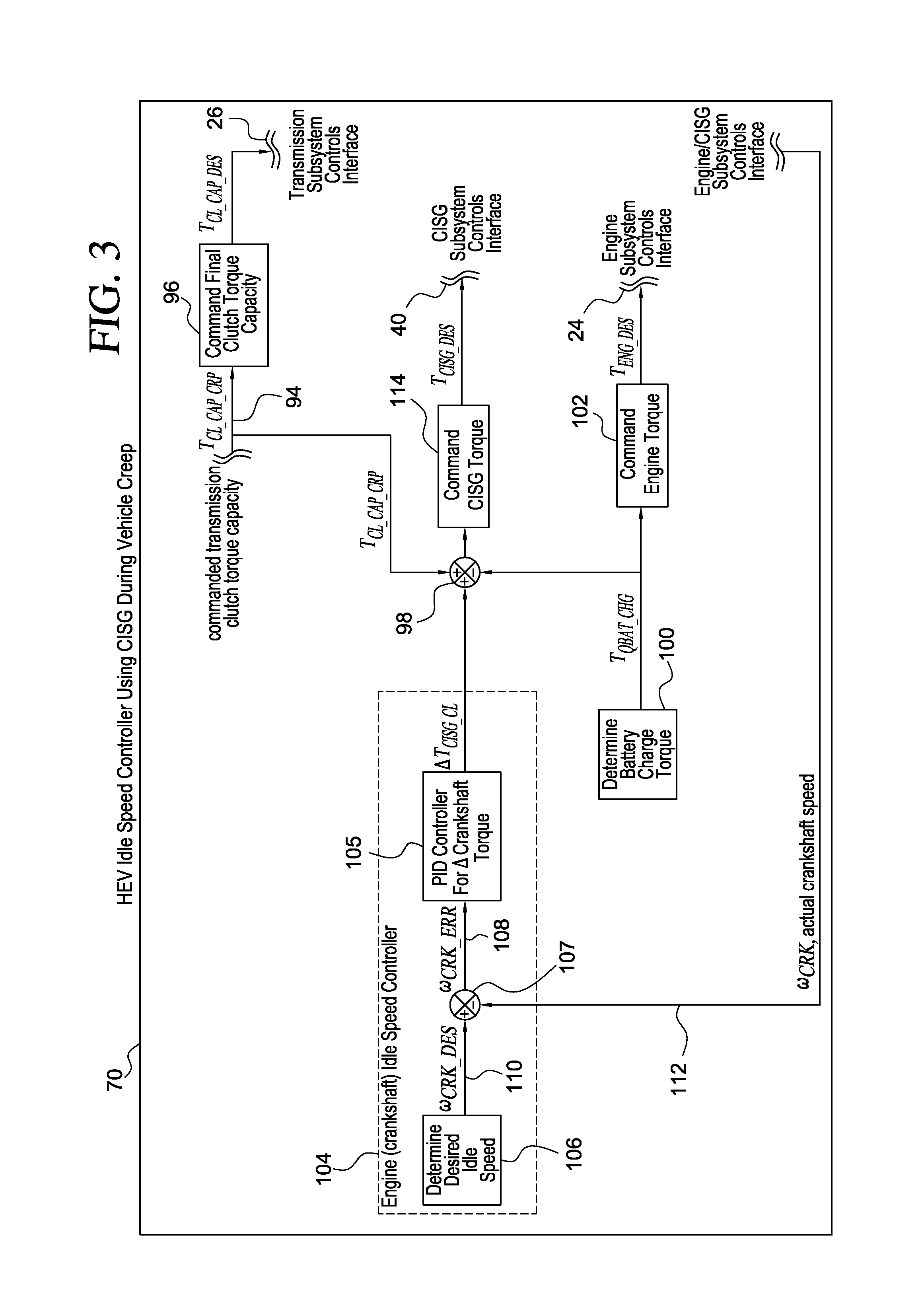

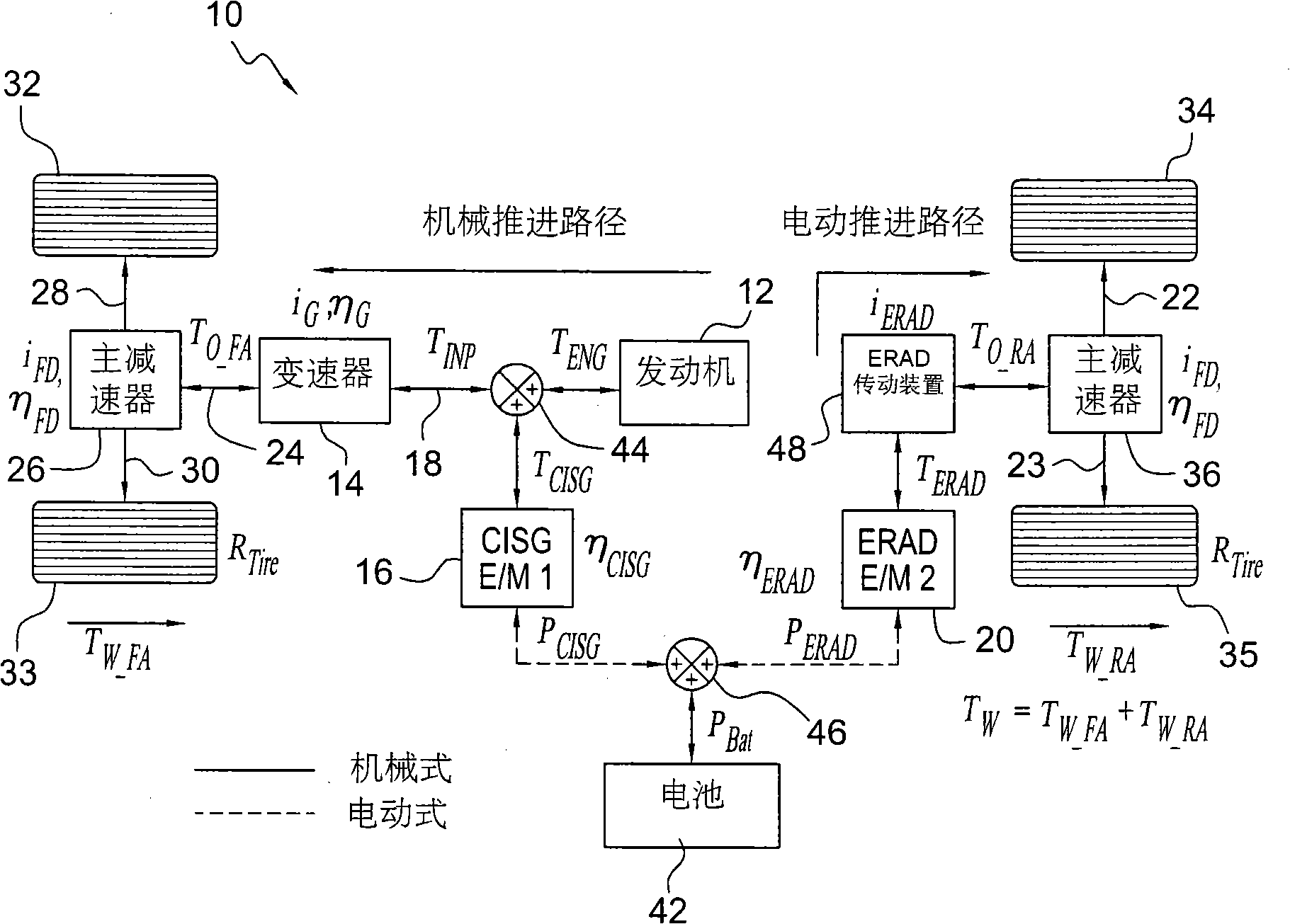

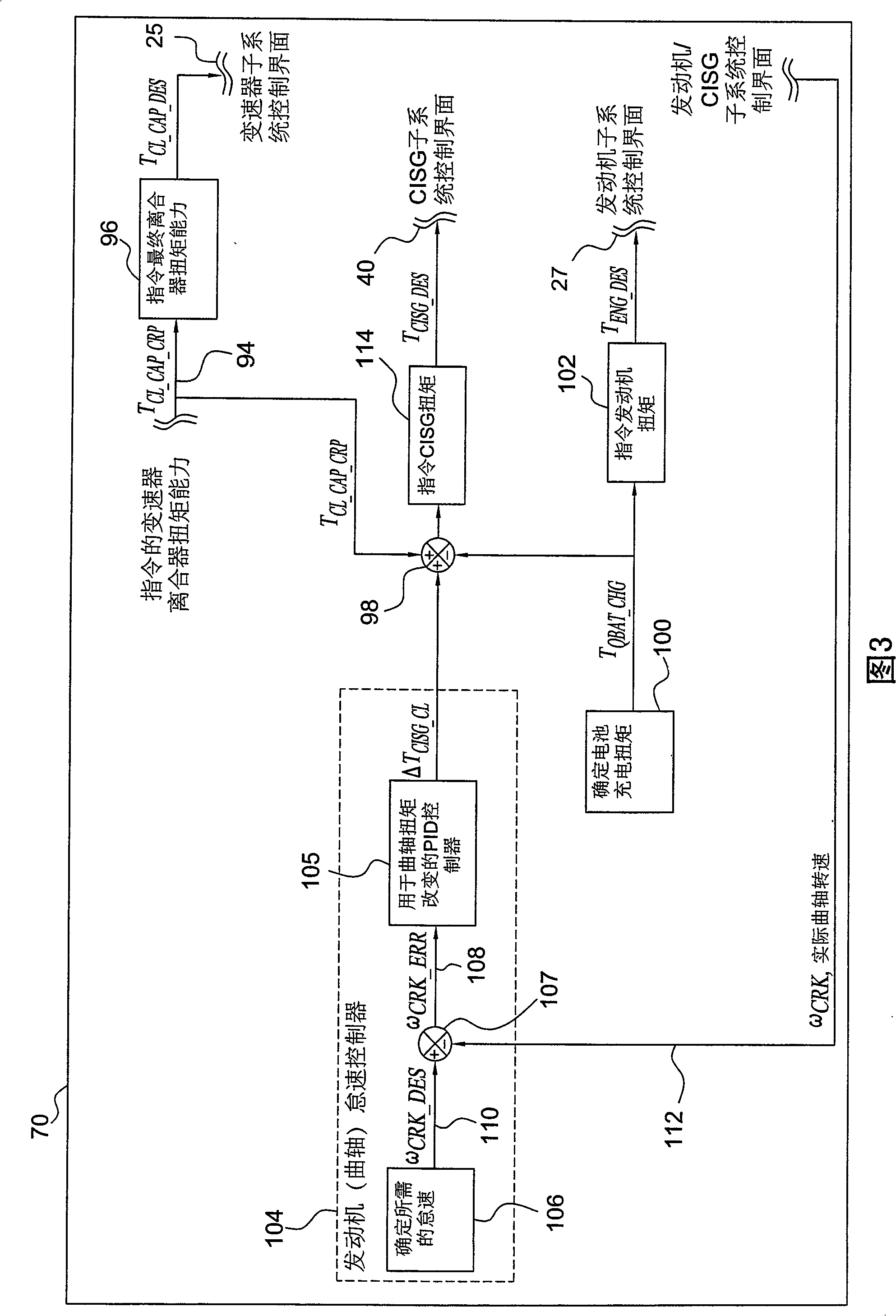

Idle Speed Control of a Hybrid Electric Vehicle

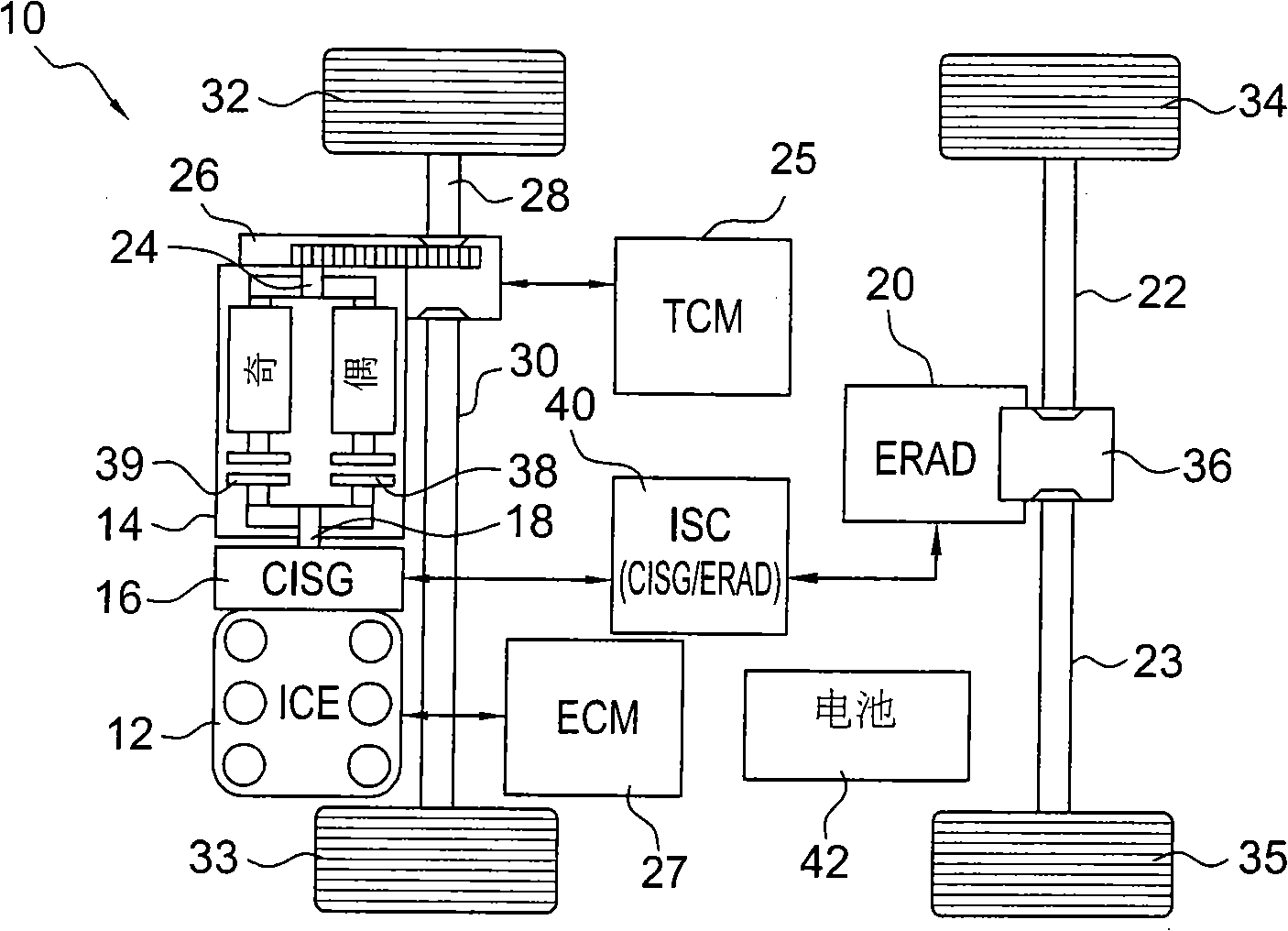

ActiveUS20090143188A1Electrical controlDigital data processing detailsIdle speed controlHybrid electrical vehicle

In a powertrain that includes wheels for driving a vehicle, a crankshaft, a machine driveably connected to the crankshaft and able to operate alternately as an electric motor and electric generator, a transmission including an input clutch driveably connected to the crankshaft and an output driveably connected to the wheels, a method for controlling idle speed including producing a desired magnitude of input clutch torque capacity, producing a desired wheel torque, using an error represented by a difference between a desired crankshaft idle speed and a current crankshaft speed to determine a desired change in torque produced by the machine, using the magnitude of input clutch torque capacity and the desired change in torque produced by the machine to determine a desired magnitude machine torque, and using the machine to produce said desired magnitude of machine torque.

Owner:FORD GLOBAL TECH LLC

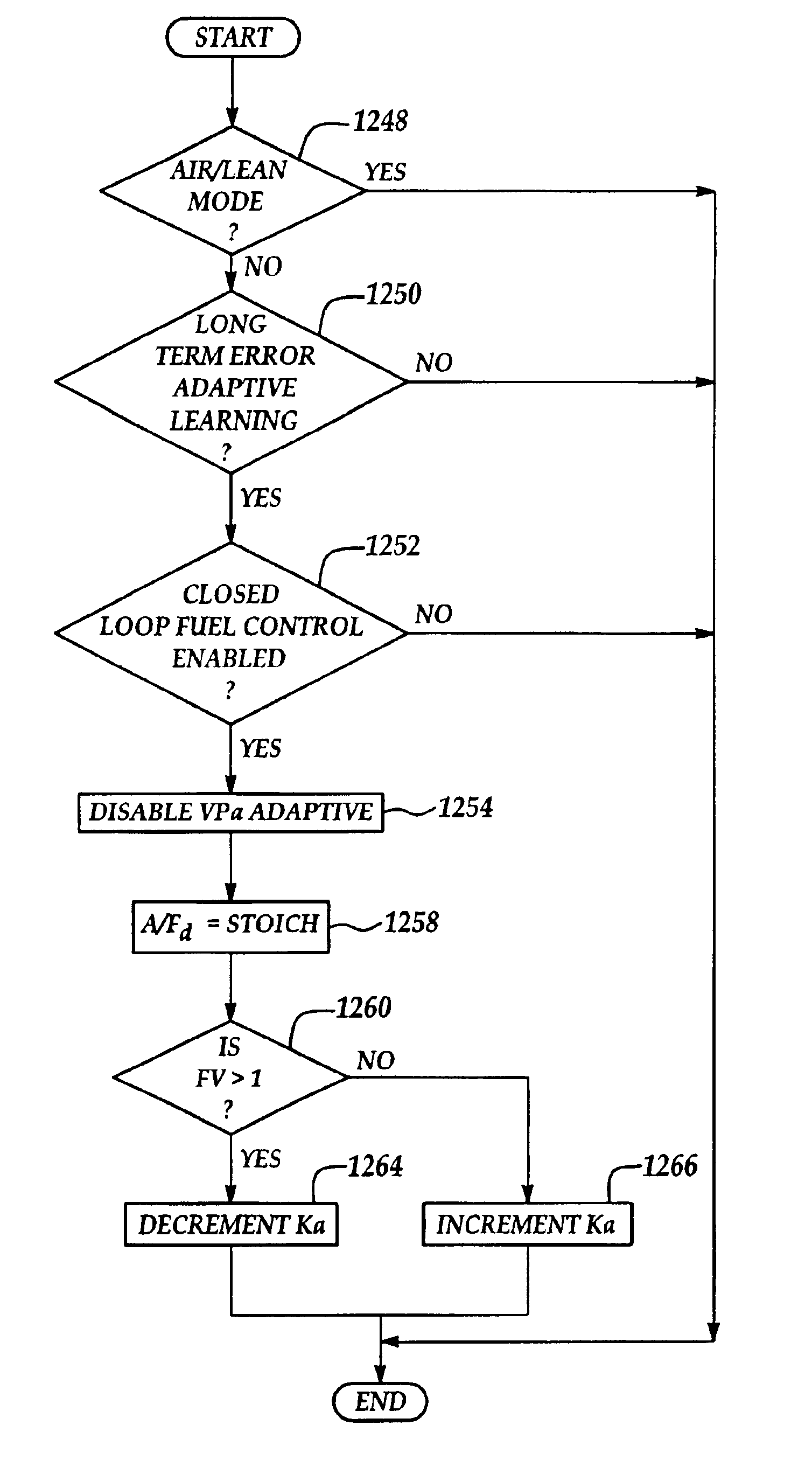

Method and system of adaptive learning for engine exhaust gas sensors

InactiveUS6736120B2Accurate operationLow heat generationElectrical controlExhaust apparatusTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method to improve fuel economy in lean burn engines with variable-displacement-like characteristics

InactiveUS20030221655A1Accurate air-fuel ratioIncrease in temperature of catalystElectrical controlNon-fuel substance addition to fuelTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

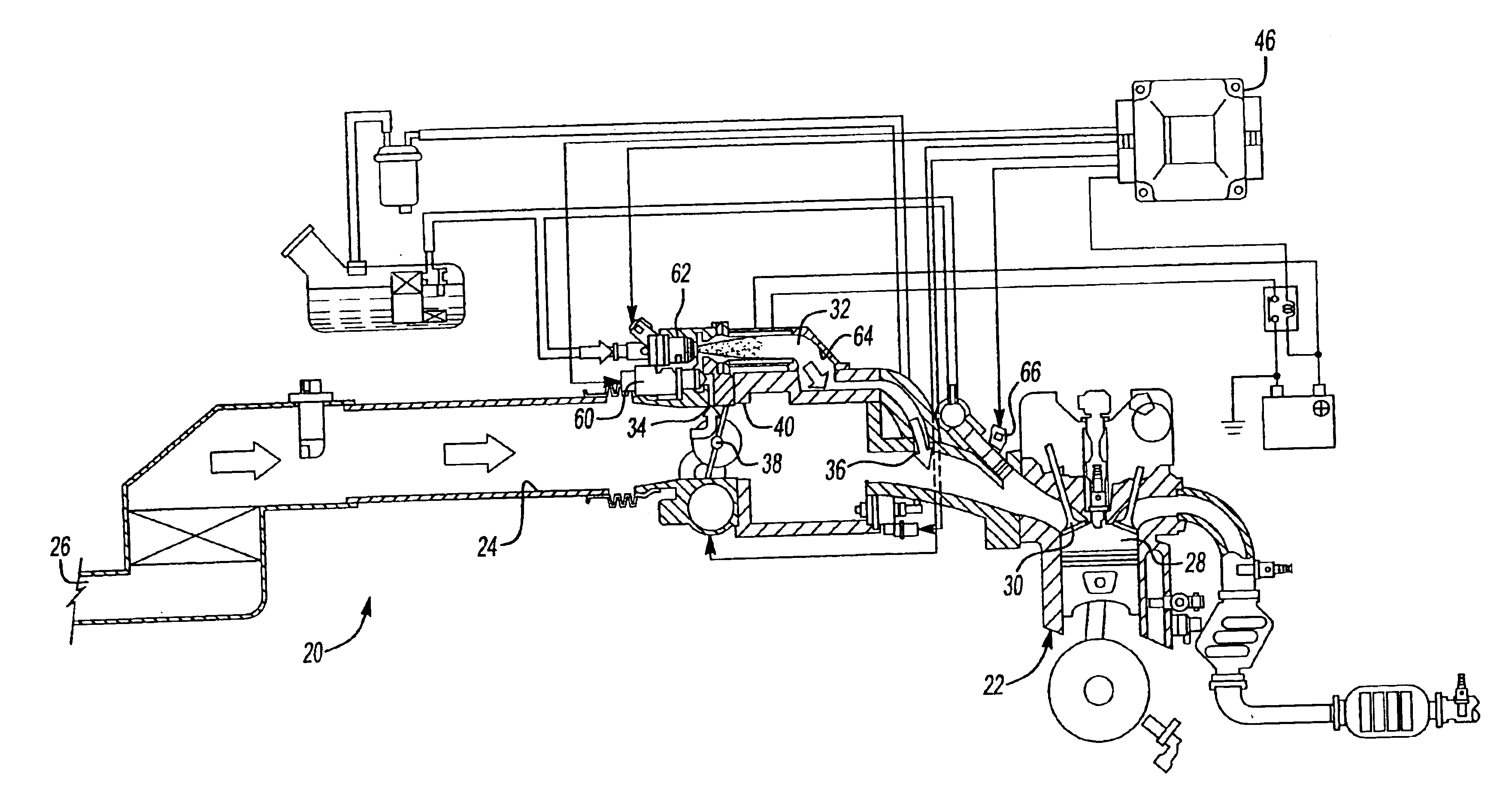

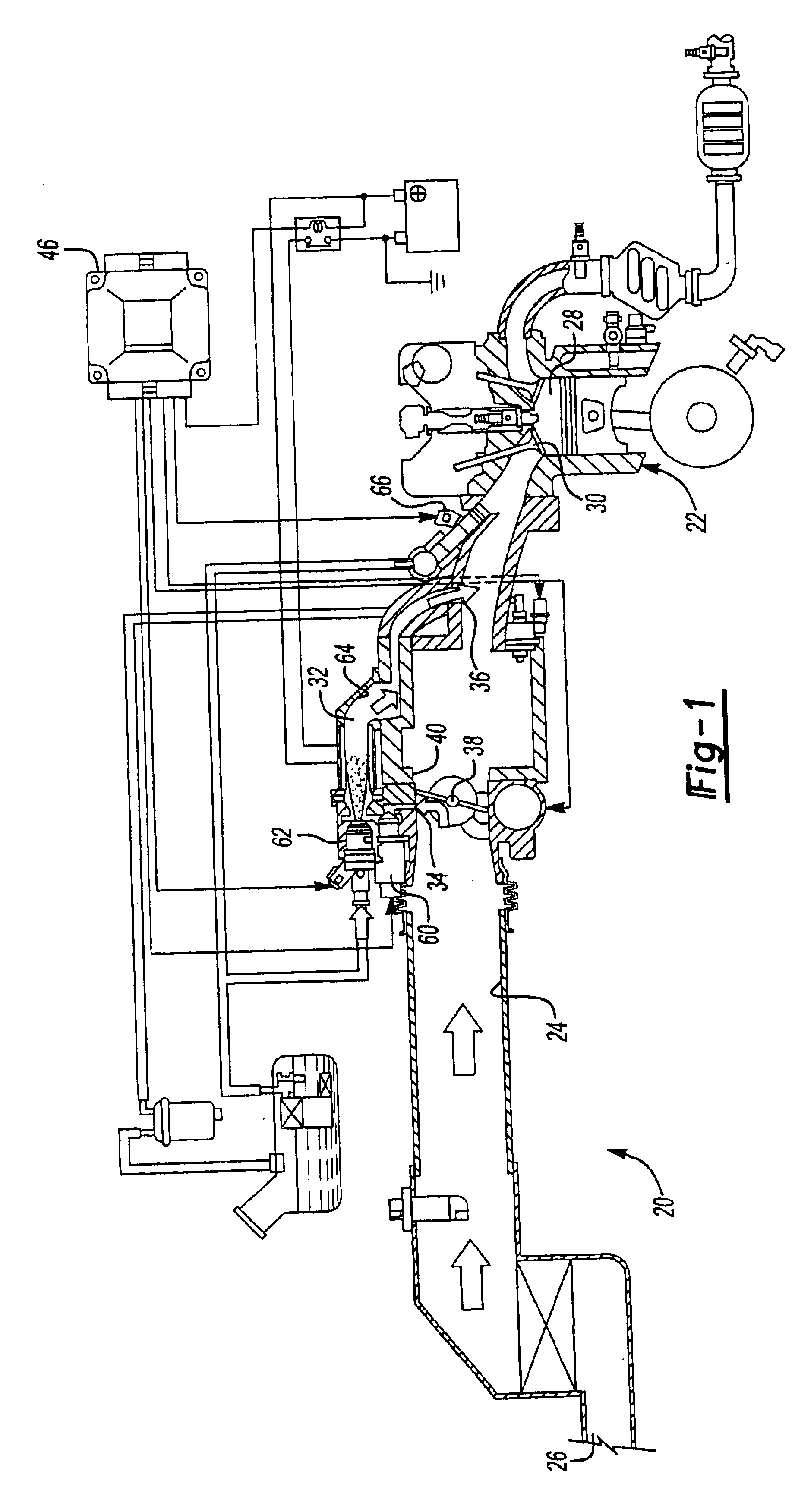

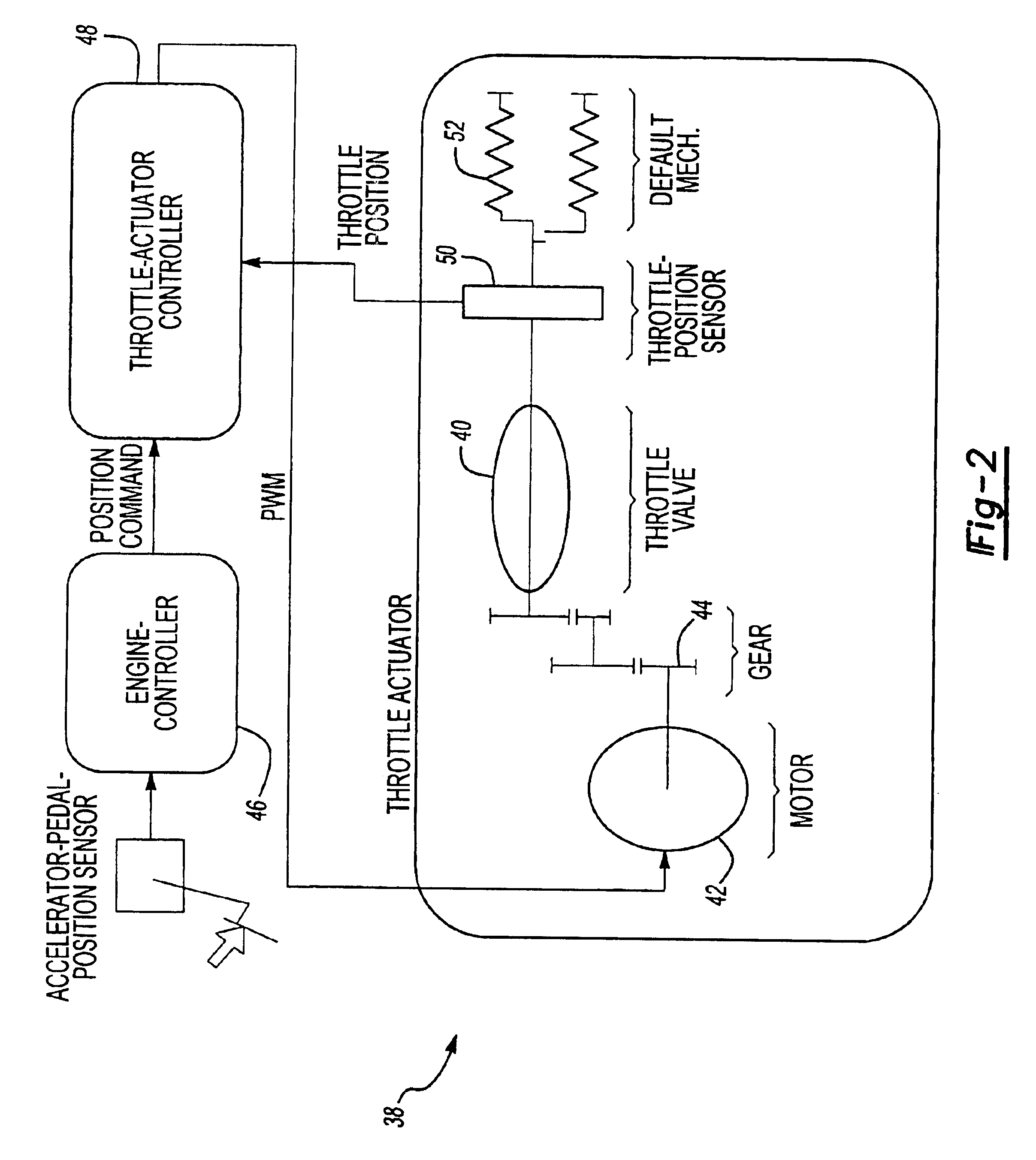

Fuel delivery system for an internal combustion engine

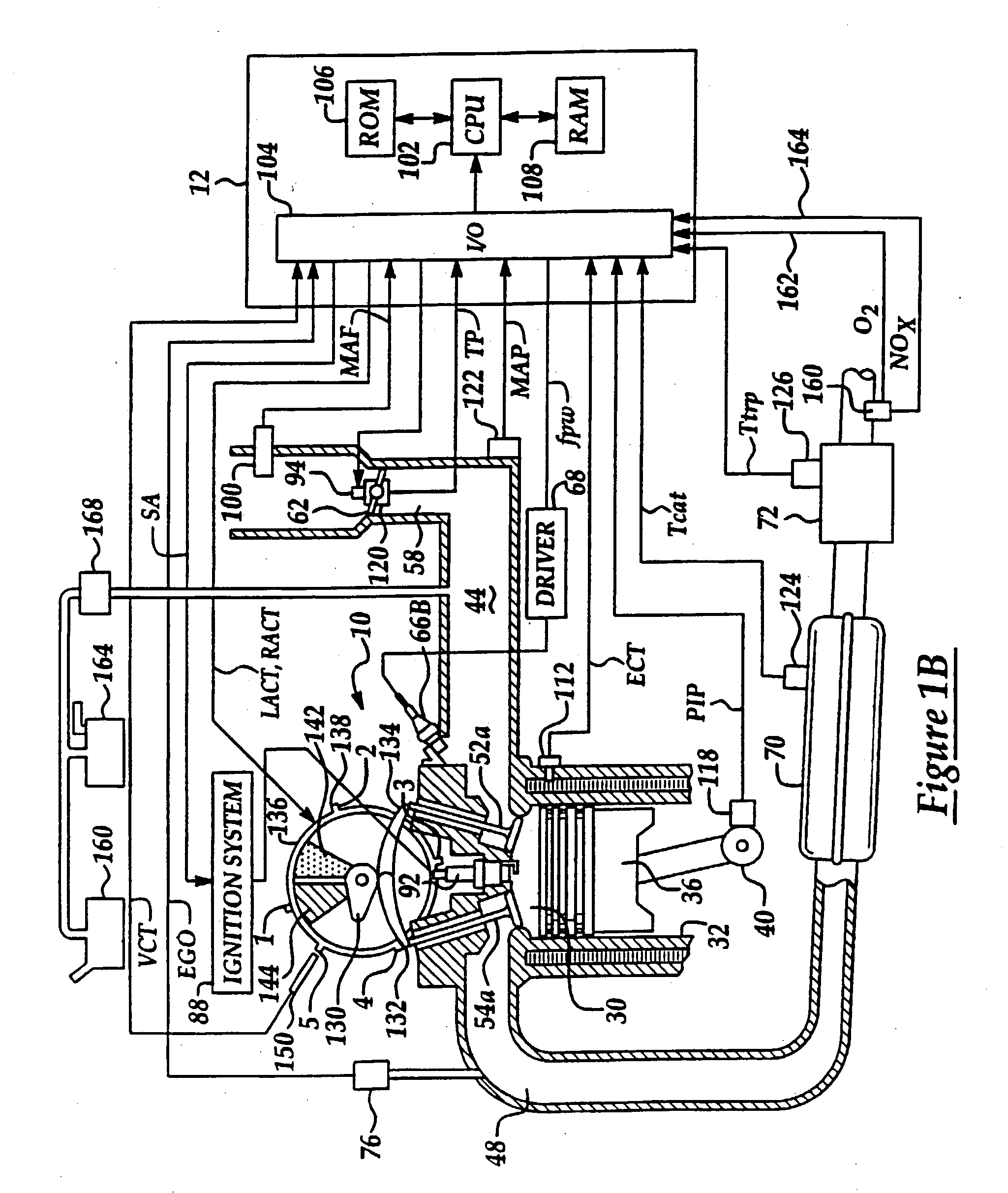

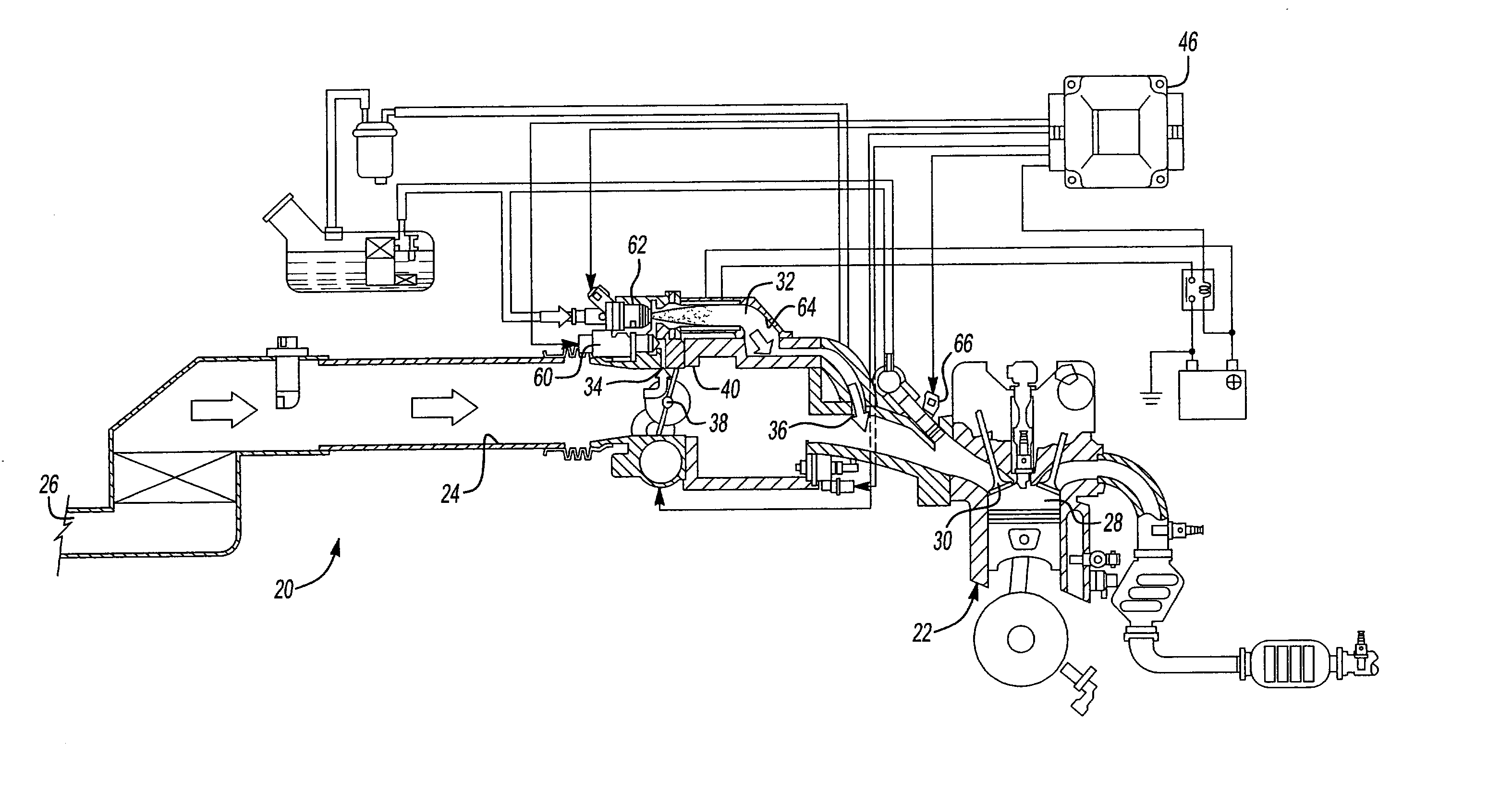

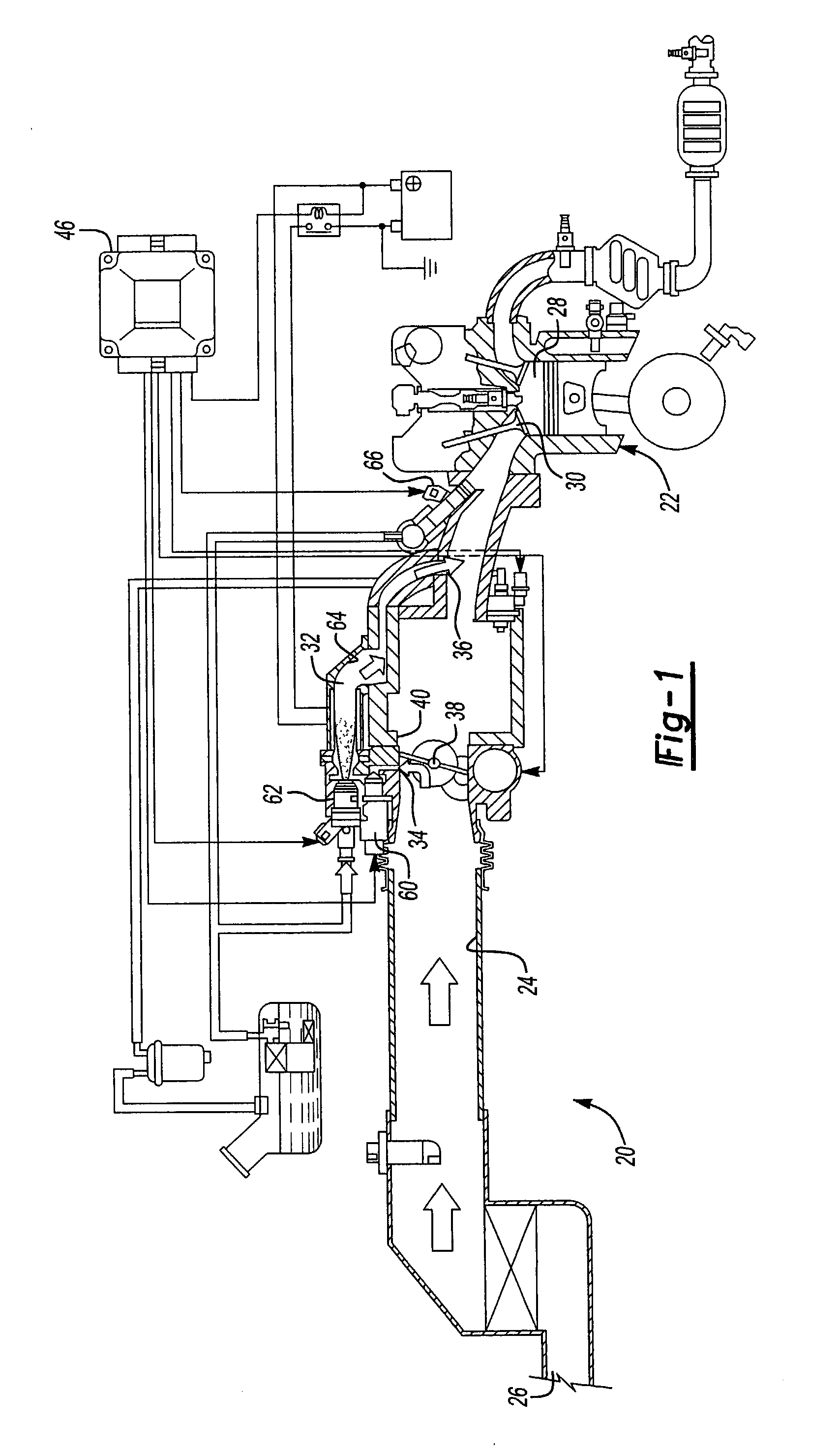

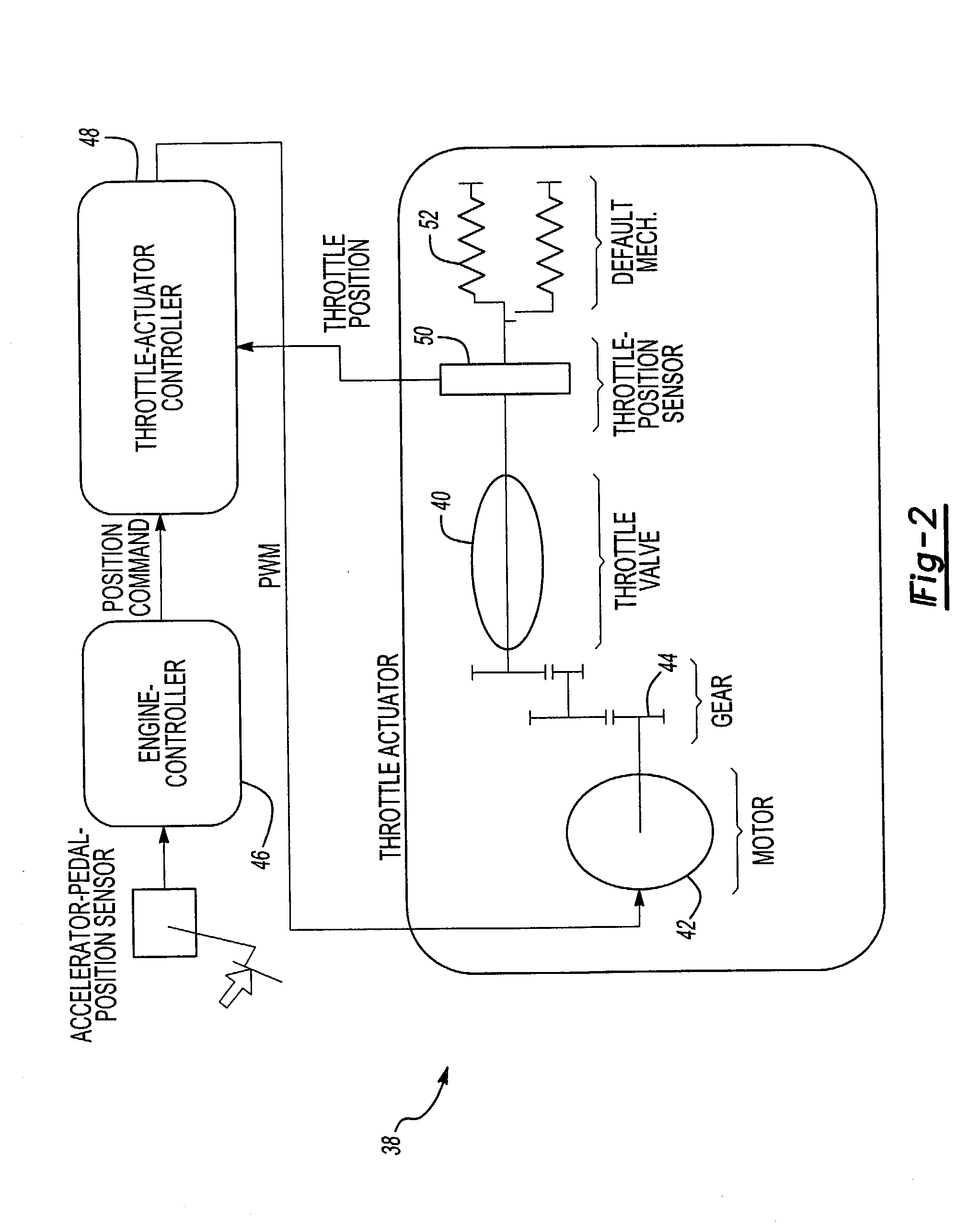

InactiveUS6874467B2Improved vaporizationElectrical controlNon-fuel substance addition to fuelEngine efficiencyIdle speed control

A fuel delivery system having an electronically controlled throttle valve operatively disposed in an intake manifold. An idle speed control valve is operatively disposed within a bypass gas flow passageway. A control system controls the actuation of both the throttle valve and idle speed control valve to control the delivery of a combustible charge to the internal combustion engine to maximize engine efficiency and minimize noxious emissions.

Owner:HITACHI LTD

Method to control fuel vapor purging

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method for controlling the temperature of an emission control device

InactiveUS7111450B2Increase temperatureElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method to control transitions between modes of operation of an engine

InactiveUS20030224907A1Small torqueIncrease loadElectrical controlVehicle fittingsTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Overall scheduling of a lean burn engine system

InactiveUS20030221659A1Efficient engine operationElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Overall scheduling of a lean burn engine system

InactiveUS20030221660A1Improve carrying capacityFuel to the remaining cylinders is rapidly increasedElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Method for rapid catalyst heating

InactiveUS20030221418A1Heating fastSolve excessive vibrationElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

Owner:FORD GLOBAL TECH LLC

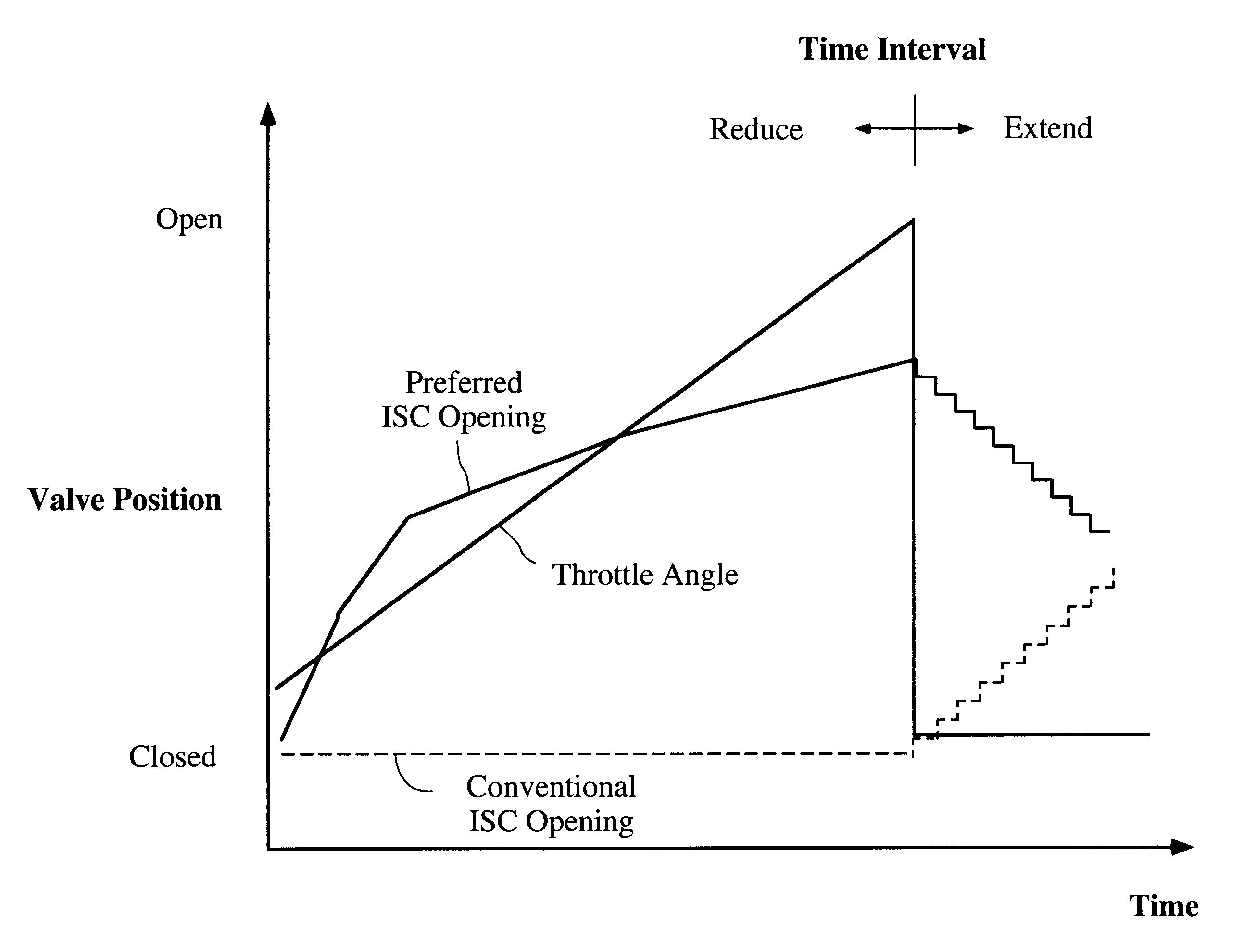

Fuel delivery system for an internal combustion engine

InactiveUS20040025837A1Improved vaporizationElectrical controlNon-fuel substance addition to fuelEngine efficiencyIdle speed control

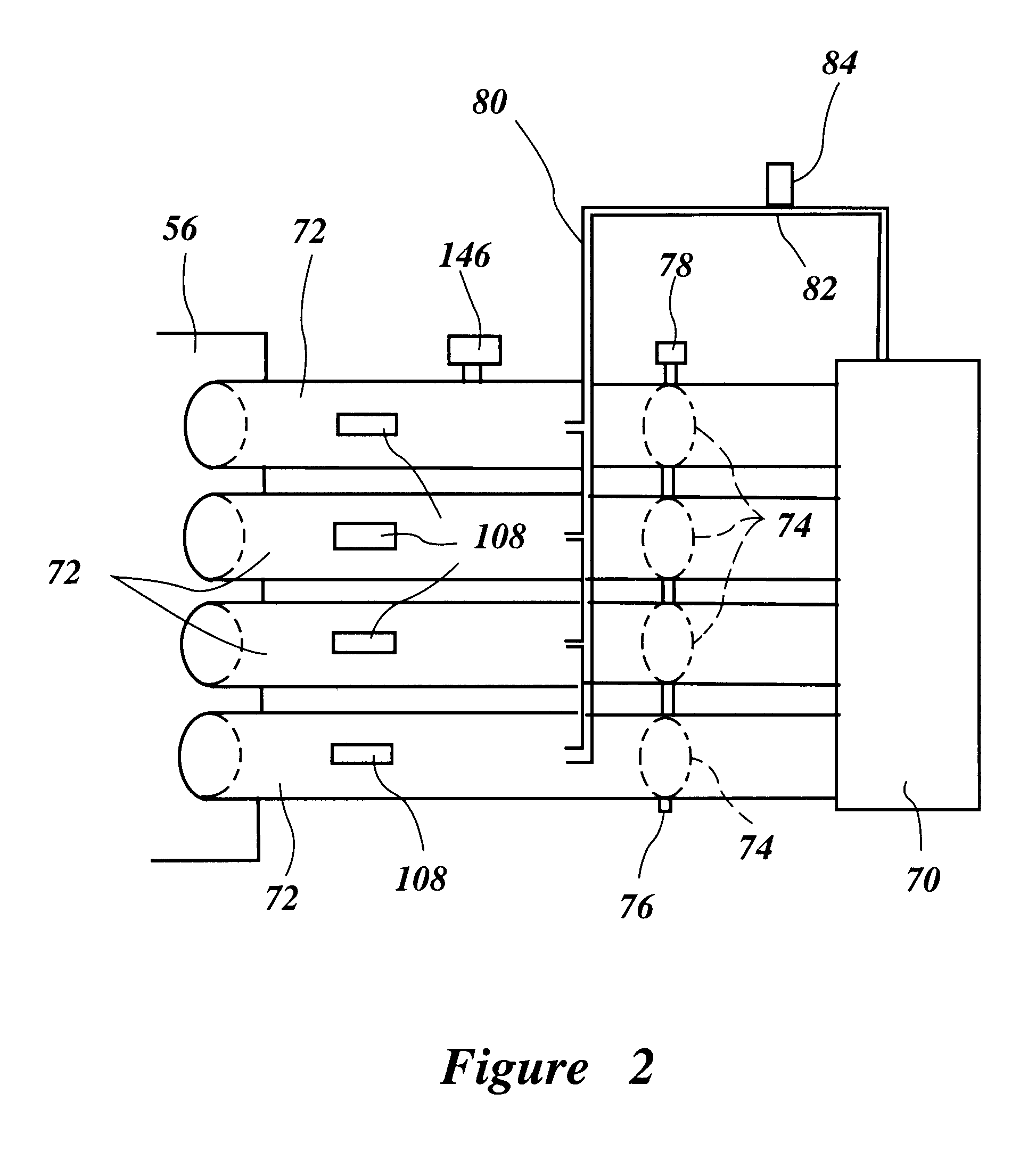

A fuel delivery system for an internal combustion engine of the type having an intake manifold selectively fluidly connected to a combustion chamber and a bypass gas flow passageway having an inlet open to the intake manifold and an outlet open to the intake manifold downstream for the inlet is disclosed. The system includes an electronically controlled throttle valve operatively disposed in the intake manifold and movable between an open and a closed position to control air flow through the intake manifold. An idle speed control valve is operatively disposed within the bypass gas flow passageway, and the idle speed control valve is also movable between an open and a closed position to control air flow through the bypass gas flow passageway. A control system controls the actuation of both the throttle valve and idle speed control valve to control the delivery of a combustible charge to the internal combustion engine to maximize engine efficiency and minimize noxious emissions. Optionally, a cold start fuel injector is disposed within the bypass gas flow passageway to provide the fuel charge to the engine during a cold start condition. In an alternate form of the invention, two electronically controlled throttle valves are disposed within the intake manifold to control both the air flow through the intake manifold as well as the air flow through the bypass gas flow passageway.

Owner:HITACHI LTD

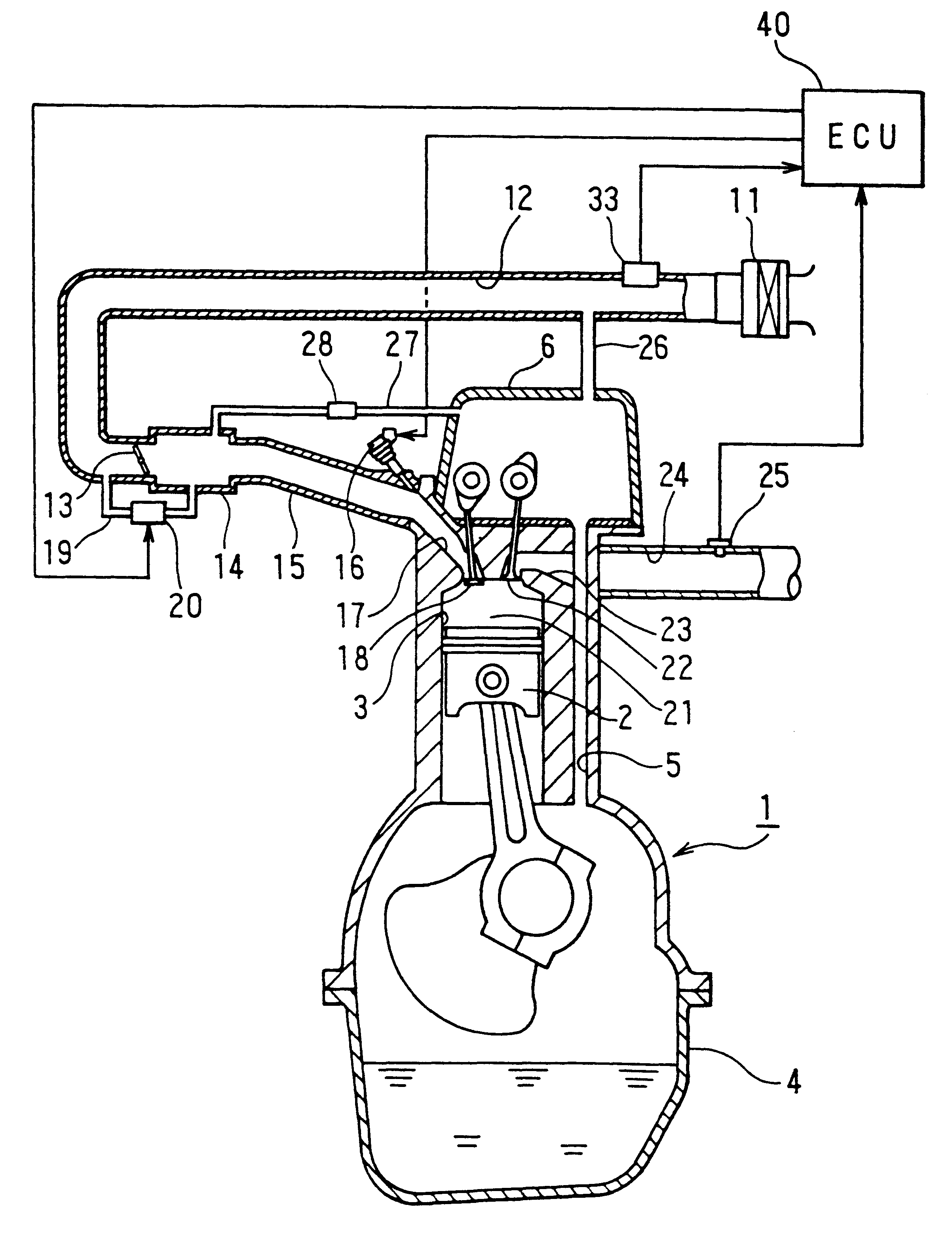

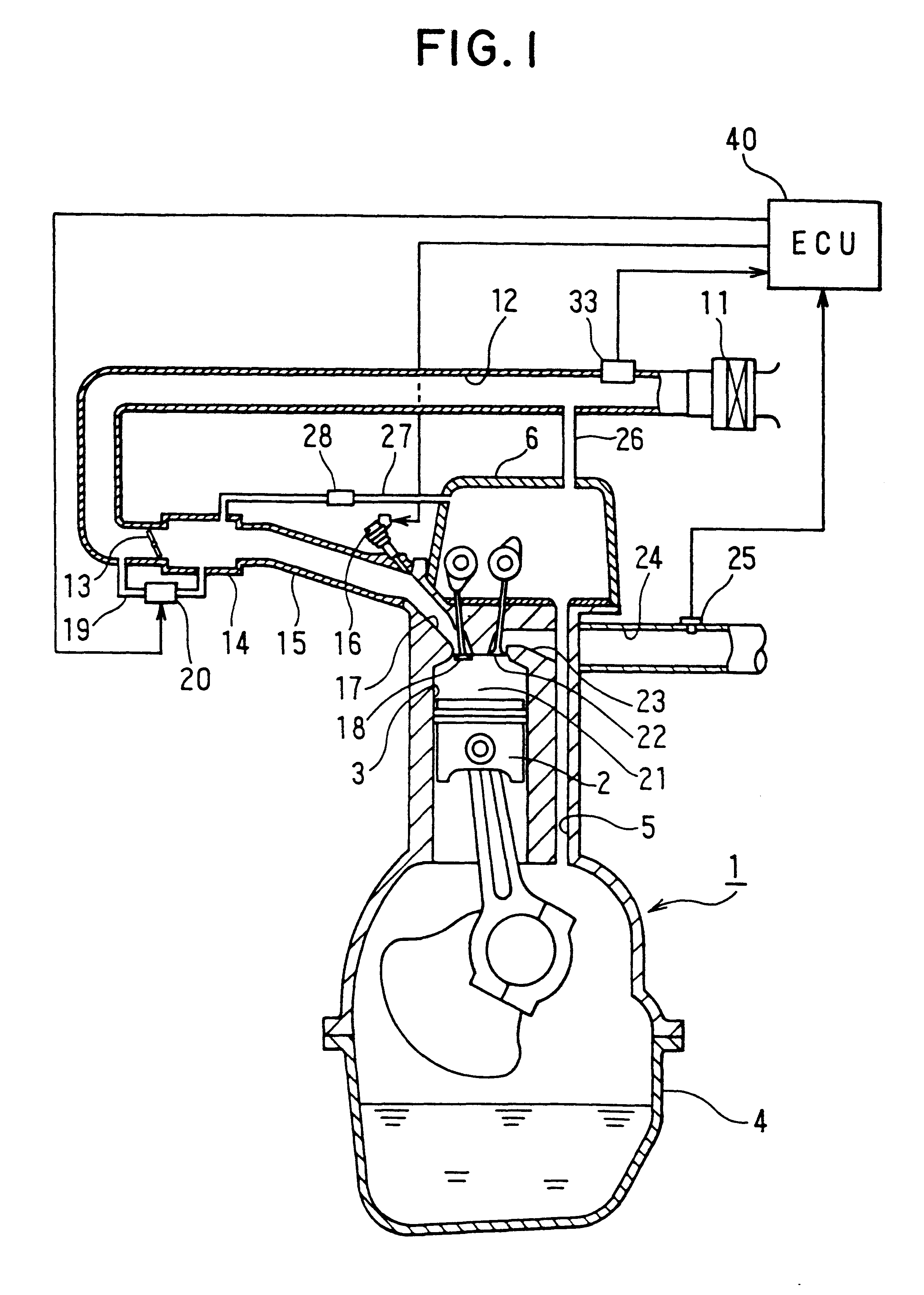

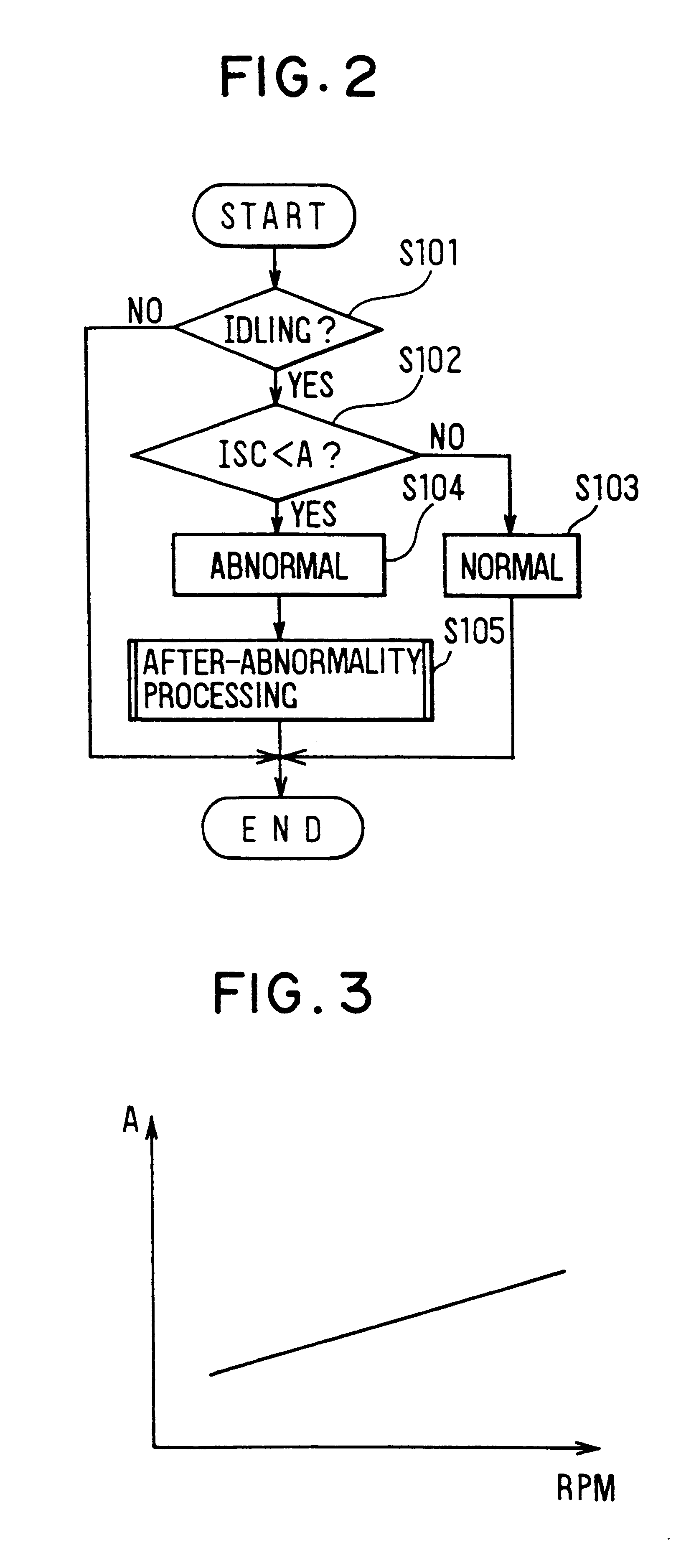

Blow-by gas passage abnormality detecting system for internal combustion engines

InactiveUS6247464B1Minimize releaseAccurate detectionElectrical controlNon-fuel substance addition to fuelCombustionIdle time

A blow-by gas passage abnormality detecting system for an internal combustion engine detects, only under the condition that the running state of the engine is idle, a leakage of a blow-by gas coming from a blow-by gas passage for returning the blow-by gas produced in the engine to an intake passage, on the basis of a parameter varying with a change in the air flow to be sucked into the engine. The abnormality such as leakage or clogging in the blow-by gas passage is detected if the ISC opening of an idle speed control valve measured as a load amount at an idle time of the engine is smaller than a predetermined value. Alternatively, the abnormality may be detected by detecting the blow-by gas pressure in the blow-by gas passage downstream of a PCV valve by a gas pressure sensor.

Owner:DENSO CORP

Method for controlling an engine to obtain rapid catalyst heating

InactiveUS7032572B2Analogue computers for vehiclesElectrical controlTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Idle speed control of a powertrain for a hybrid electric vehicle

ActiveCN101513869ASensitive idle speed controlElectrical controlElectric propulsion mountingIdle speed controlElectric machine

In a powertrain that includes wheels for driving a vehicle, a crankshaft, a machine driveably connected to the crankshaft and able to operate alternately as an electric motor and electric generator, a transmission including an input clutch driveably connected to the crankshaft and an output driveably connected to the wheels, a method for controlling idle speed including producing a desired magnitude of input clutch torque capacity, producing a desired wheel torque, using an error represented by a difference between a desired crankshaft idle speed and a current crankshaft speed to determine a desired change in torque produced by the machine, using the magnitude of input clutch torque capacity and the desired change in torque produced by the machine to determine a desired magnitude machine torque, and using the machine to produce said desired magnitude of machine torque.

Owner:FORD GLOBAL TECH LLC

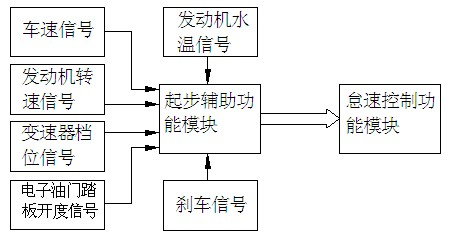

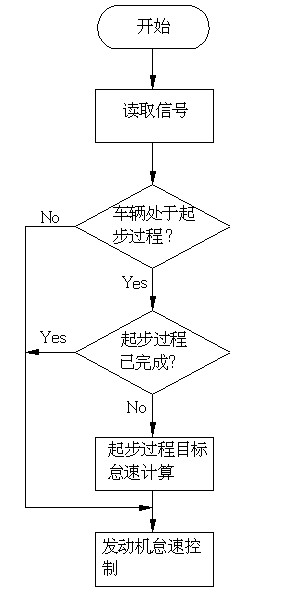

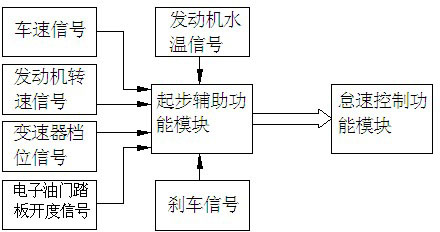

Logic control method for improving starting performance of vehicle

InactiveCN102536479AImprove starting performanceGuaranteed NVH performanceProgramme-controlMachines/enginesIdle speed controlWater temperature

The invention relates to a logic control method for improving the starting performance of a vehicle, which comprises the following steps of: judging whether the vehicle is in a starting process at present or not by a starting-assisting function module according to a vehicle-speed signal, an engine rotating-speed signal, a speed-changer gear signal, an electronic accelerator-pedal opening signal and a braking signal; if so, calculating and outputting a starting-target idling-speed increment to an idle-speed control function module according to a current engine water-temperature signal, and controlling an engine by the idle-speed control function module to increase the starting-target idling-speed increment part to be used as a target idle speed in the starting process by the engine on the basis of an original target idle speed; and after the starting process of the vehicle is judged to be finished by the starting-assisting function module according to the vehicle-speed signal, the speed-changer gear signal, the electronic accelerator-pedal opening signal or the braking signal, quitting a starting-assisting function to enable the engine to be restored at the original target idle speed to normally operate. Through the control method, the engine can have a lower idling speed in an idle-speed state, and the vehicle has a higher idling speed in the starting process.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Method for controlling the temperature of an emission control device

InactiveUS20030221419A1Small torqueIncrease loadElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

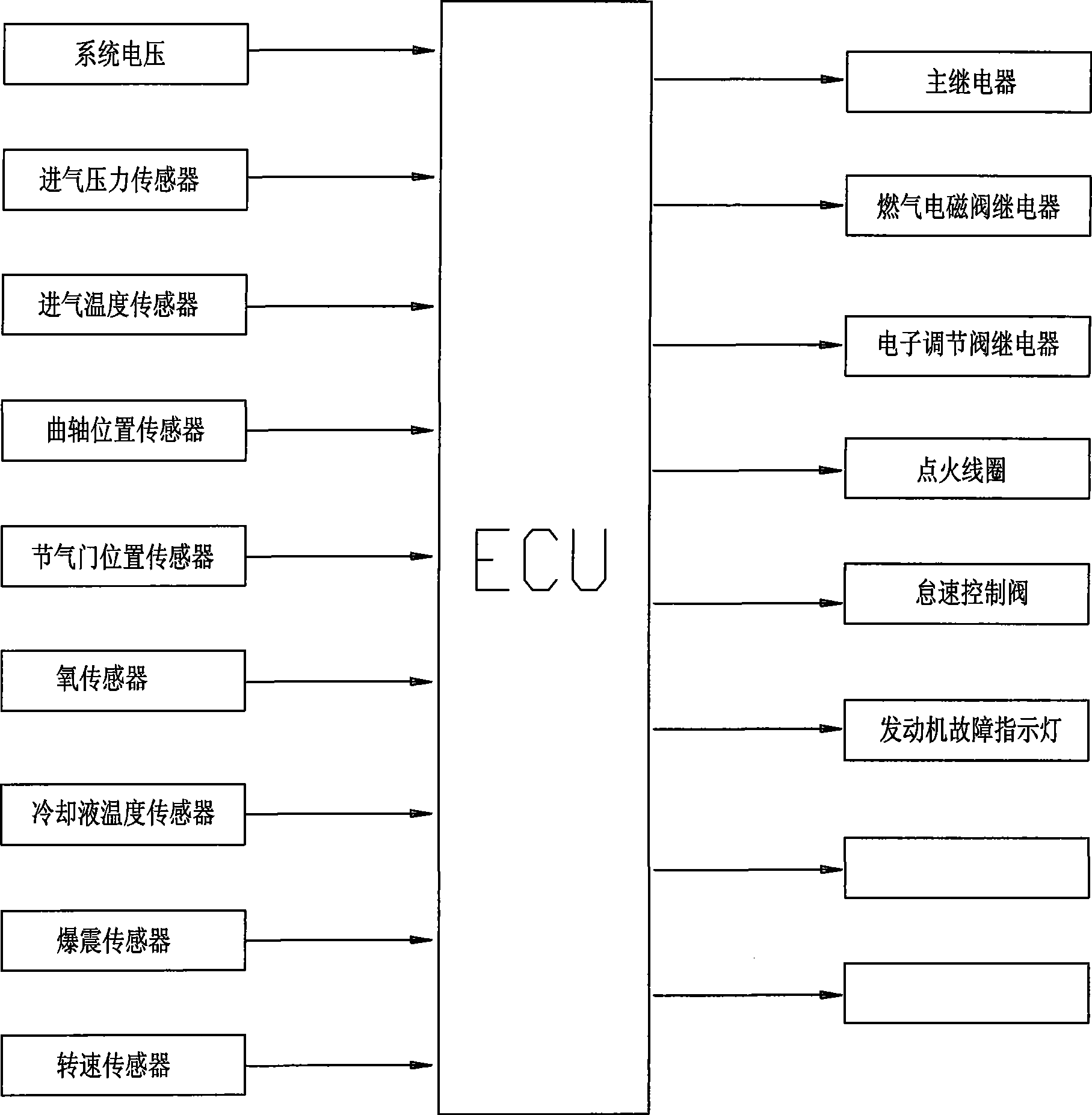

Electric-controlled natural gas engine operating system and control method thereof

InactiveCN101424224AImprove good performanceLow costElectrical controlInternal combustion piston enginesIdle speed controlElectric control

The invention provides a working system of an electrically controlled natural gas engine. A natural gas supply system comprises a natural gas storage tank, a switch electromagnetic valve and a pressure reducing valve which are connected in turn, and a natural gas introducing device introduces natural gas into a gas intake manifold; the natural gas introducing device is an electronic adjusting valve or an ejector and is controlled by an ECU; the ECU comprises a natural gas introducing control program, an ignition control program and an idle speed control program; in addition, a gas storage tank with function of stabilizing pressure is arranged between the pressure reducing valve and the ejector, so that the natural gas engine and an electronic control system thereof run more stably; the control of the natural gas introducing amount is achieved through the control of output pulse width; a self-absorption system has the advantages of stable performance and lower cost, and is comparatively suitable for refit of old gasoline engines and diesel engines; and a direct injection type system has the advantages of good performance, good acceleration performance and high efficiency, and can meet higher discharge normative requirement.

Owner:张和君 +1

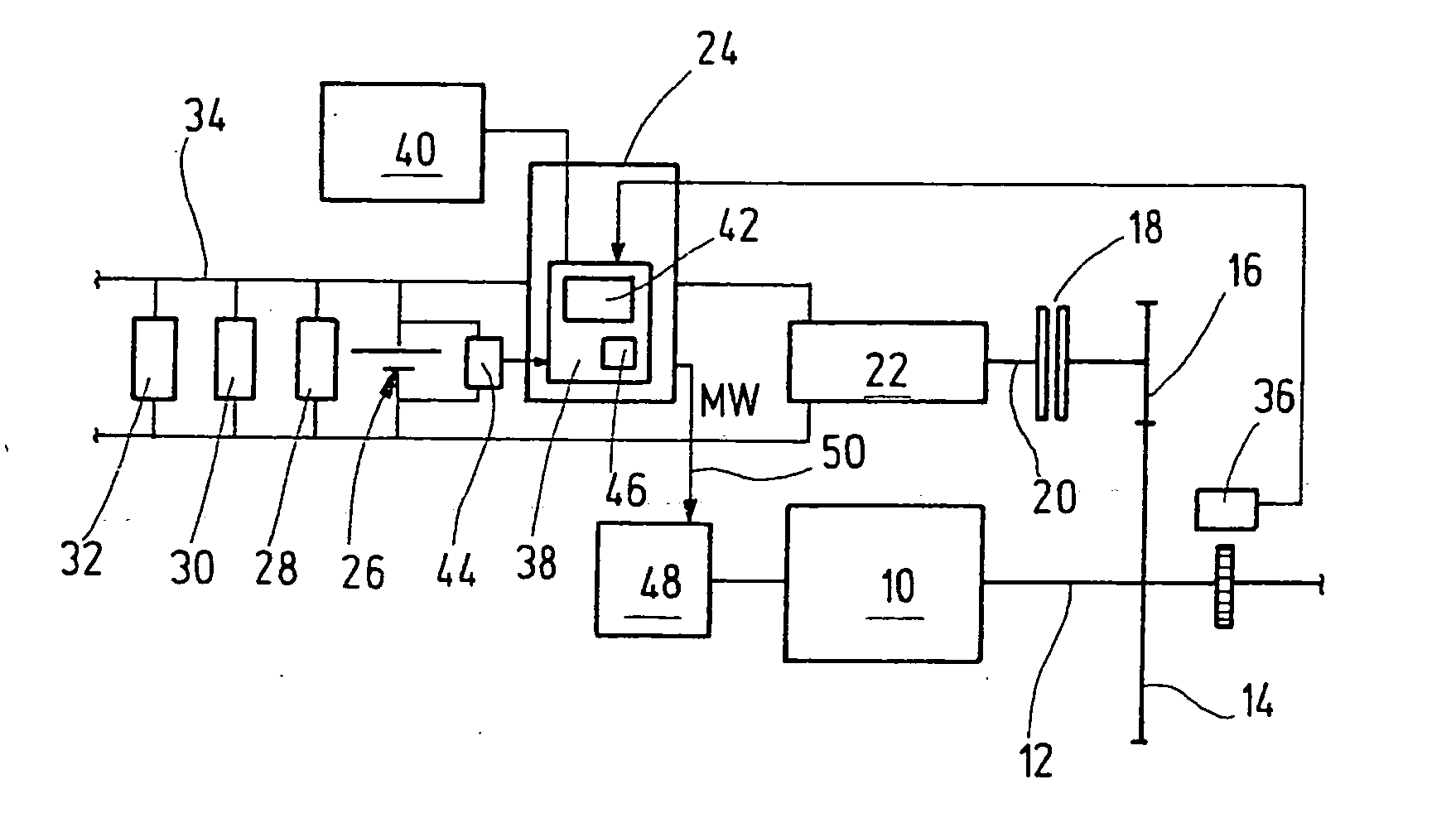

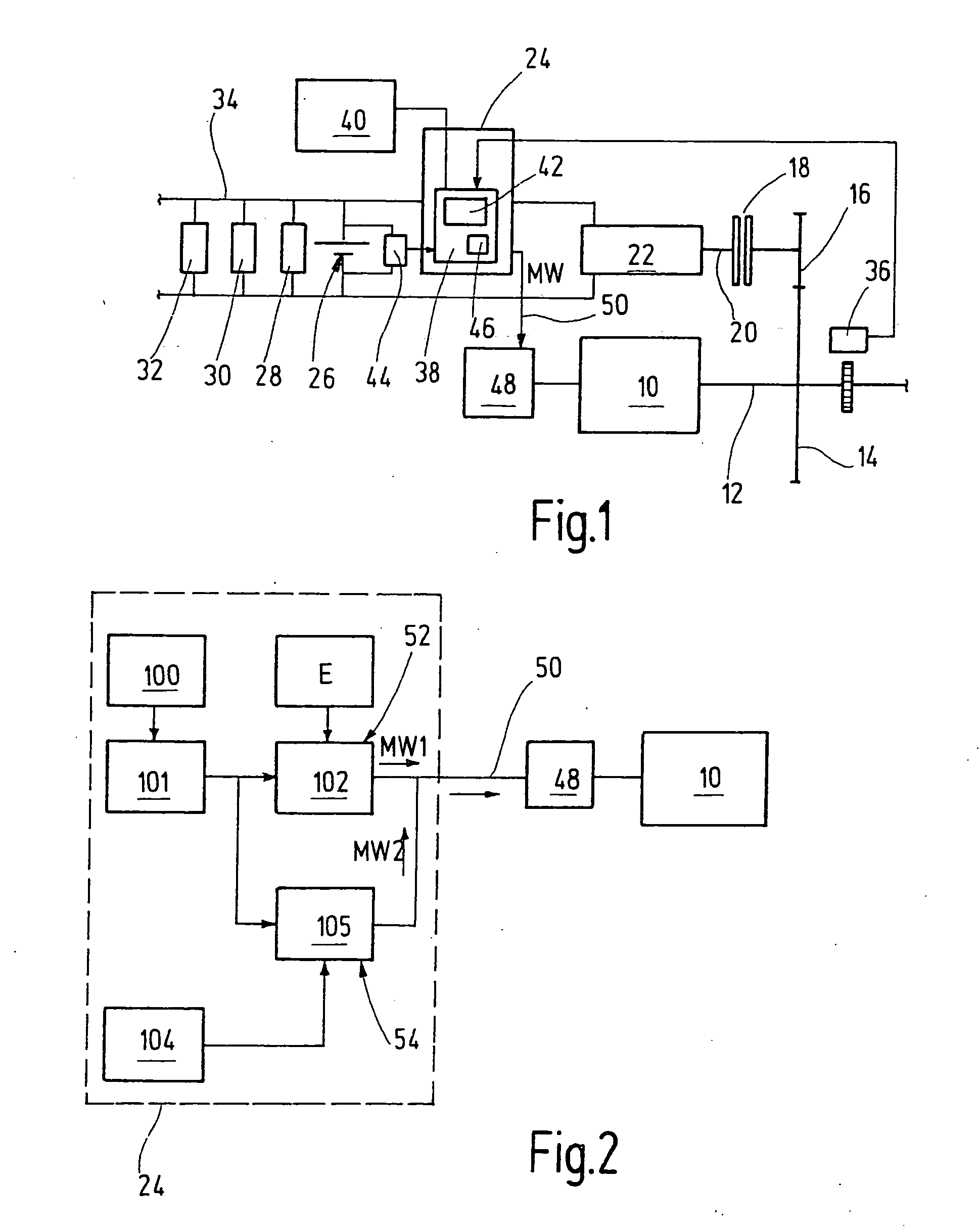

Motor vehicle comprising a hybrid drive and method for controlling the idle speed of a hybrid drive of a motor vehicle

ActiveUS20060102393A1Improve controlReduce extent of applicationBatteries circuit arrangementsElectrical controlIdle speed controlDrive shaft

A motor vehicle having a hybrid drive and a method for idle-speed control of a hybrid drive of a motor vehicle are provided. The hybrid drive includes an internal combustion engine having an engine management system, and at least one speed-controlled electric machine which is coupled to a drive shaft of the internal combustion engine during idling. During idling, the internal combustion engine is controlled by the engine management system in open or closed loop as a function of power demands of an electrical system of the motor vehicle.

Owner:ROBERT BOSCH GMBH

Method and system of adaptive learning for engine exhaust gas sensors

InactiveUS20030221679A1High load conditionMore ignition timingElectrical controlExhaust apparatusTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Motor engine electric control fuel oil spraying system

InactiveCN101144437AReasonable designSimple structureElectrical controlMachines/enginesIdle speed controlIgnition coil

The invention discloses a motorcycle engine electronic control fuel injection system, and comprises an electronic control unit, and a sensor and an executive mechanism connected with the electronic control unit; the sensor comprises a crankshaft position signal generator, a crankshaft position sensor and a throttle position sensor corresponding to the crankshaft position signal generator, an intake pressure sensor communicated with an air intake tube, an intake air temperature sensor communicated with the air intake tube, a cylinder body temperature sensor installed on the engine body, and an oxygen sensor arranged on an exhaust tube, wherein, the executive mechanism comprises an idle speed control valve, an electric fuel pump, a fuel pressure regulator, an oil ejector and an ignition coil. The invention has the advantages that the design is reasonable, the structure of the system is perfect, the operating performance is stable and reliable, and the engine combines the electronic control system with the exhaust gas aftertreatment technology, to lead the exhaust gas emission to meet the requirements of the motorcycle country more than three issues emission regulation as well as the more than Euro III exhaust emission regulation.

Owner:西安易道汽车电器有限责任公司 +2

Idle speed control valve control system

An outboard motor comprises an engine mounted within an engine compartment. The engine comprises an induction system having an induction passage extending between an air intake box to a combustion chamber. A throttle valve is positioned along the passage. A bypass passage communicates with the passage at a location between the throttle valve and the combustion chamber. An adjustable valve controls flow through the bypass passage. The adjustable valve is opened as the throttle valve is opened or as the engine speed is increased. The adjustable valve is closed when the throttle valve is rapidly closed or when the engine speed is rapidly decreased.

Owner:SANSHIN KOGYO CO LTD

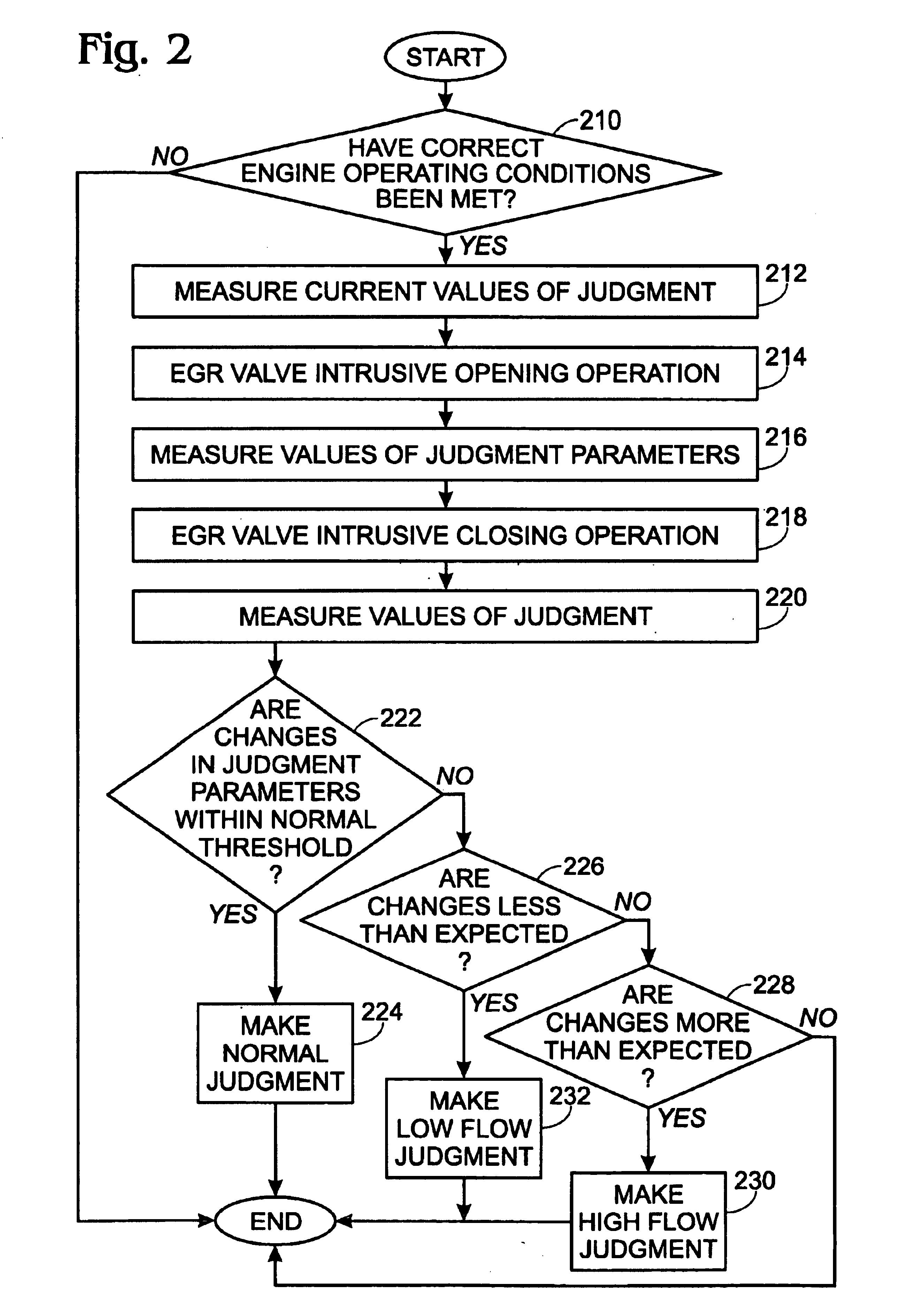

External exhaust gas recirculation on board diagnostic using EGR effect on a combination of engine operating parameters

ActiveUS6848418B1Accurate identificationAccurately determineElectrical controlNon-fuel substance addition to fuelIdle speed controlExhaust gas recirculation

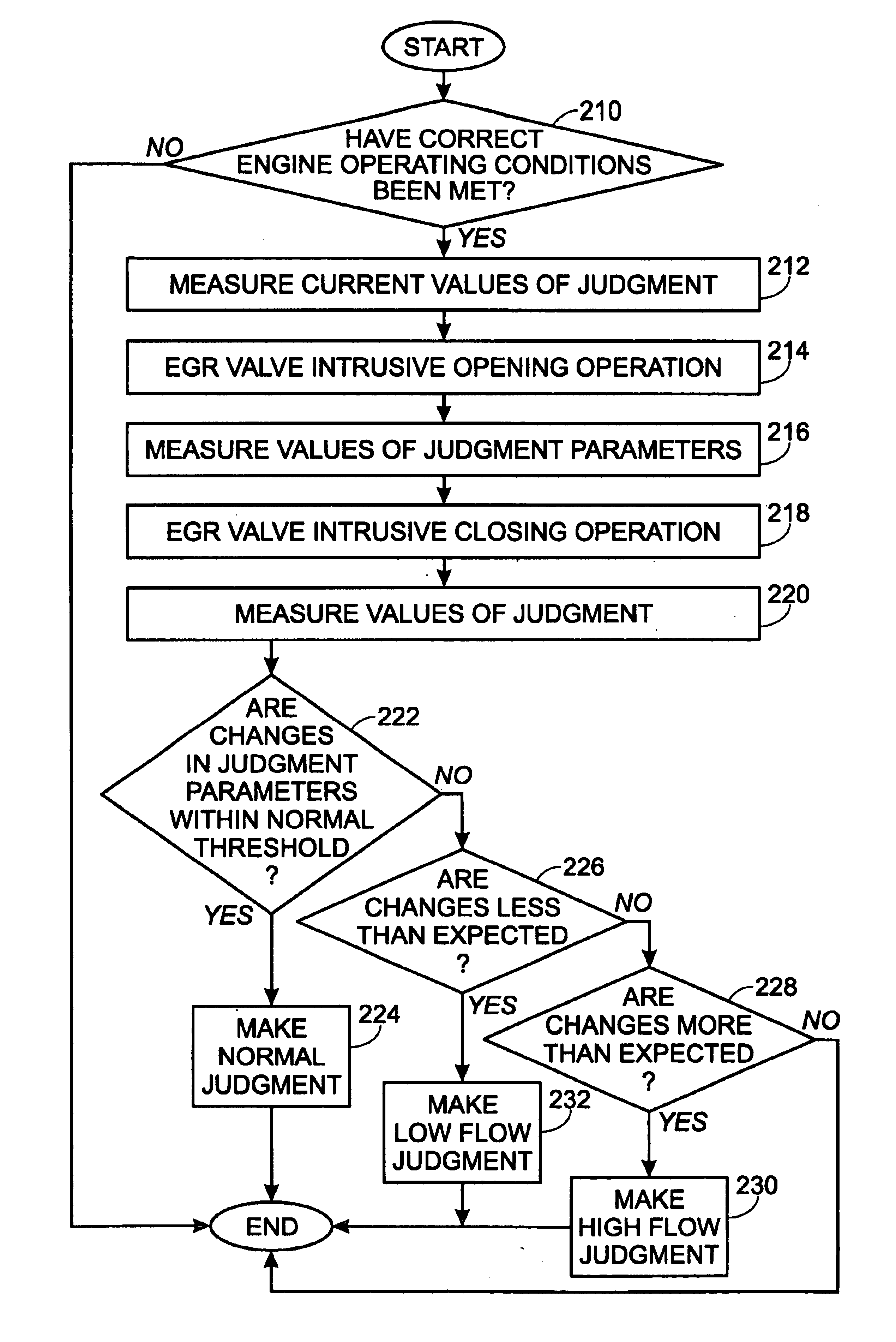

A system is described for determining degradation of an exhaust gas recirculation system of an internal combustion engine. This method utilizes a combination of parameters to accurately determine degradation of the exhaust gas recirculation system. For example, the system utilizes changes in intake manifold pressure, changes in idle speed control operation, changes in ignition timing, and fueling changes to accurately determine operation of the exhaust gas recirculation system.

Owner:JAGUAR LAND ROVER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com