Method for preparing white carbon black or high-purity silicon dioxide

A silicon dioxide and white carbon black technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of long production cycle, infeasibility, and low yield, and achieve low production cost, low cost, and high reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

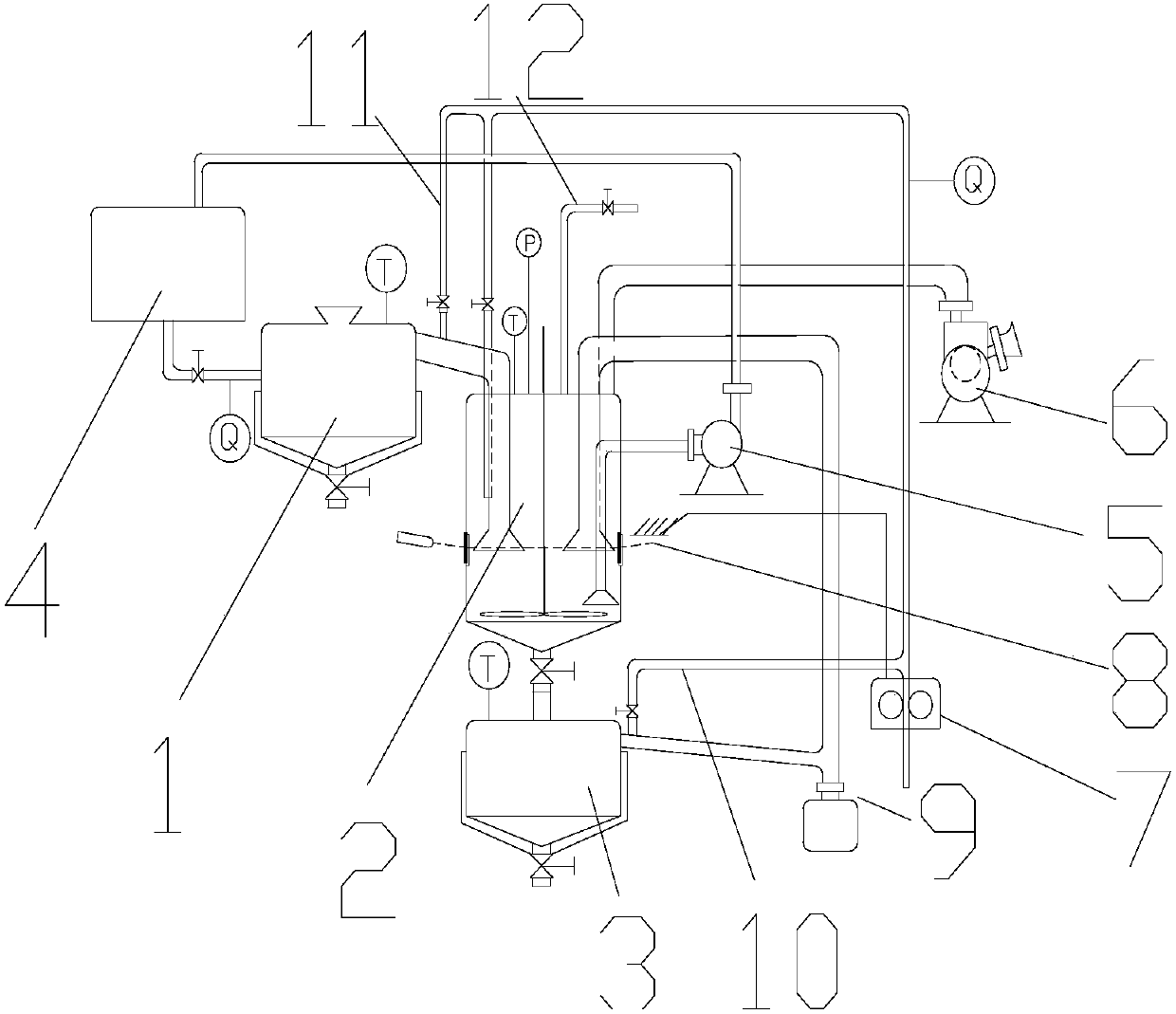

[0047] Example 1 Constructing a cyclic preparation device

[0048] build as figure 2 The circulation preparation device shown is mainly composed of a high temperature kettle 1, a stirring kettle 2, a drying kettle 3, a liquid storage tank 4, a centrifugal pump 5, a vacuum pump 6, a peristaltic pump 7, a collection tank 9, a first branch pipe 10, a second Branch pipe 11 and air pressure balance pipe 12 are formed. The liquid storage tank 4, the high temperature kettle 1, the stirring kettle 2, and the drying kettle 3 are connected together sequentially through pipelines, the centrifugal pump 5 is connected with the liquid storage tank 4, and the stirring kettle 2 respectively through pipelines, and the collection tank 9 is connected with the stirring kettle 2 and the drying kettle 3 are respectively connected through pipelines, the stirring tank 2 is connected with the vacuum pump 6 and the peristaltic pump 7 respectively through pipelines, and the peristaltic pump 7 is also ...

Embodiment 2

[0055] Embodiment 2 adopts circulation process to prepare white carbon black or high-purity silicon dioxide

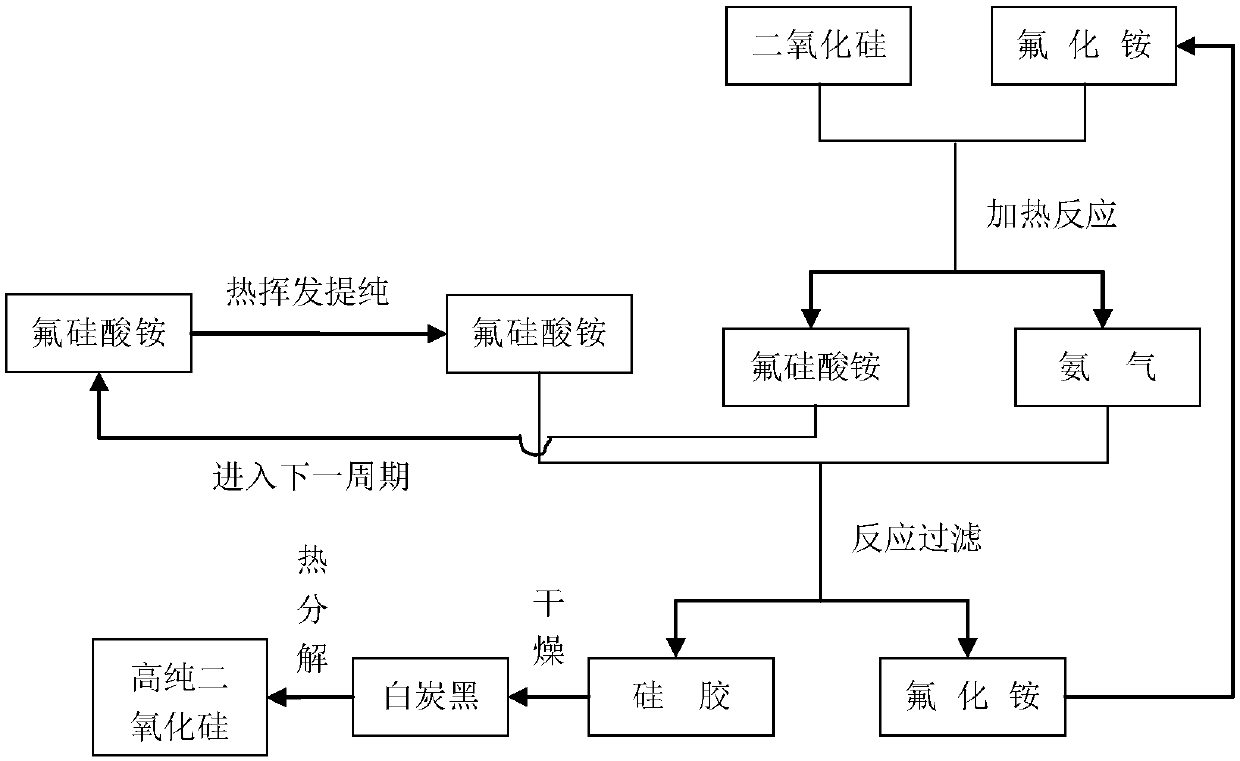

[0056] Utilize the circulation preparation device that embodiment 1 builds to prepare white carbon black or high-purity silicon dioxide, carry out according to the following steps (its technological process is as follows figure 1 shown):

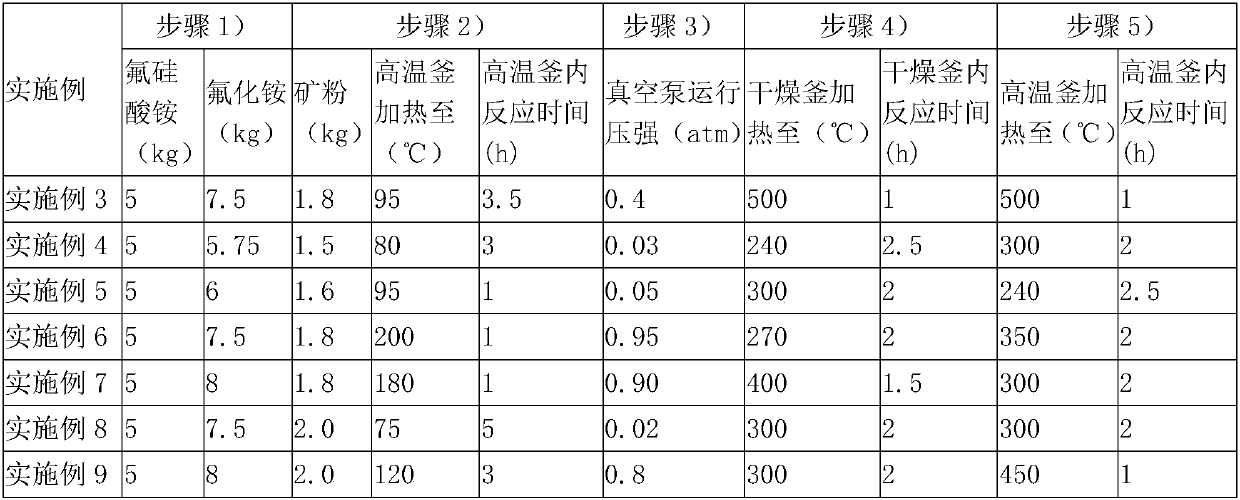

[0057] 1) Add 5.0 kg of solid ammonium fluorosilicate to the stirring tank 2, start the peristaltic pump 7 to pump distilled water into the stirring tank 2 to prepare an ammonium fluorosilicate solution, add 8.75 kg of ammonium fluoride to the liquid storage tank 4 and add water dissolve, spare;

[0058] 2) Pump the ammonium fluoride solution in the liquid storage tank 4 into the high-temperature kettle 1, add 1.8 kg of mineral powder containing silicon dioxide into the high-temperature kettle 1, and heat the high-temperature kettle 1 to 150° C. for 2.5 hours. Silicon oxide is reacted with ammonium fluoride solution to obtain solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com