Sulfydryl cellulose type straw adsorbent and preparation method thereof as well as recycling of noble metal silver

A technology of cellulose and adsorbent, which is applied in the field of green adsorbent preparation and precious metal extraction, can solve the problems of long process, high operating cost, complicated operation, etc., and achieve the effects of reduced processing cost, wide application range and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

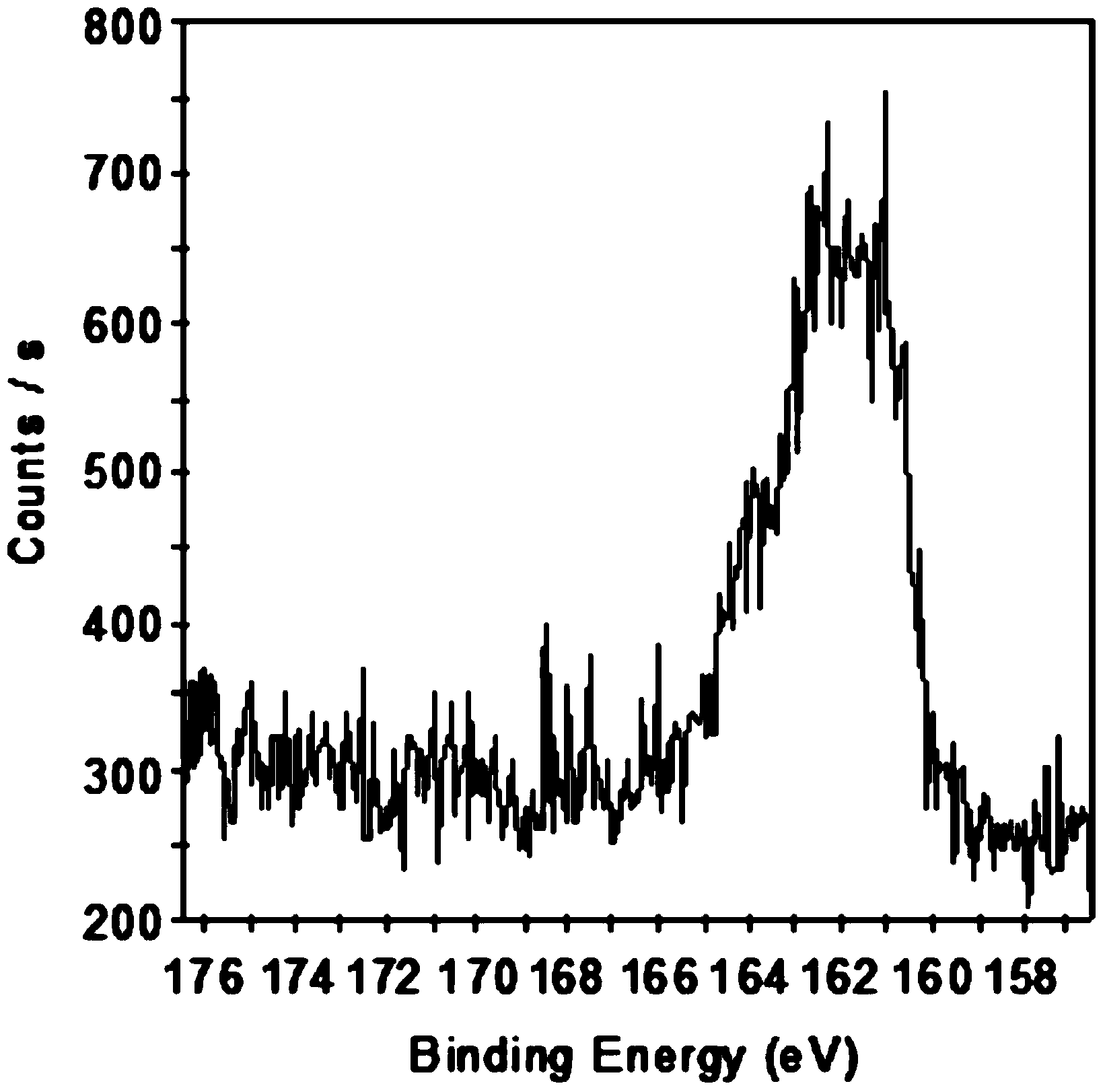

[0024] Example 1 A mercaptocellulose-based straw adsorbent

[0025] Its preparation method is as follows:

[0026] 1) Take the straw, wash it with deionized water, put it in a constant temperature drying box, dry it at 50°C, take it out and pulverize it into powder, then take 20g of straw powder, add 80mL of concentrated sulfuric acid, heat in a water bath, and control the temperature at At about 80°C, stir for 12 hours and filter, then use 0.1mol / L NaHCO 3 Washing, and then washing with deionized water until neutral, filtering again, and drying at 60°C for 24 hours to obtain product A, which was ground and sieved. Then add 30mL ammonia water and 100mL epichlorohydrin to a 500mL round bottom flask, react at a constant temperature of 60°C for 4h, then add product A, 1gNaOH, react at a constant temperature of 110°C for 8h, filter, wash with water until neutral, and dry at 55°C to obtain product B.

[0027] 2) Add 9.114g (0.1mol) thiosemicarbazide to a 500mL round bottom flask,...

Embodiment 2

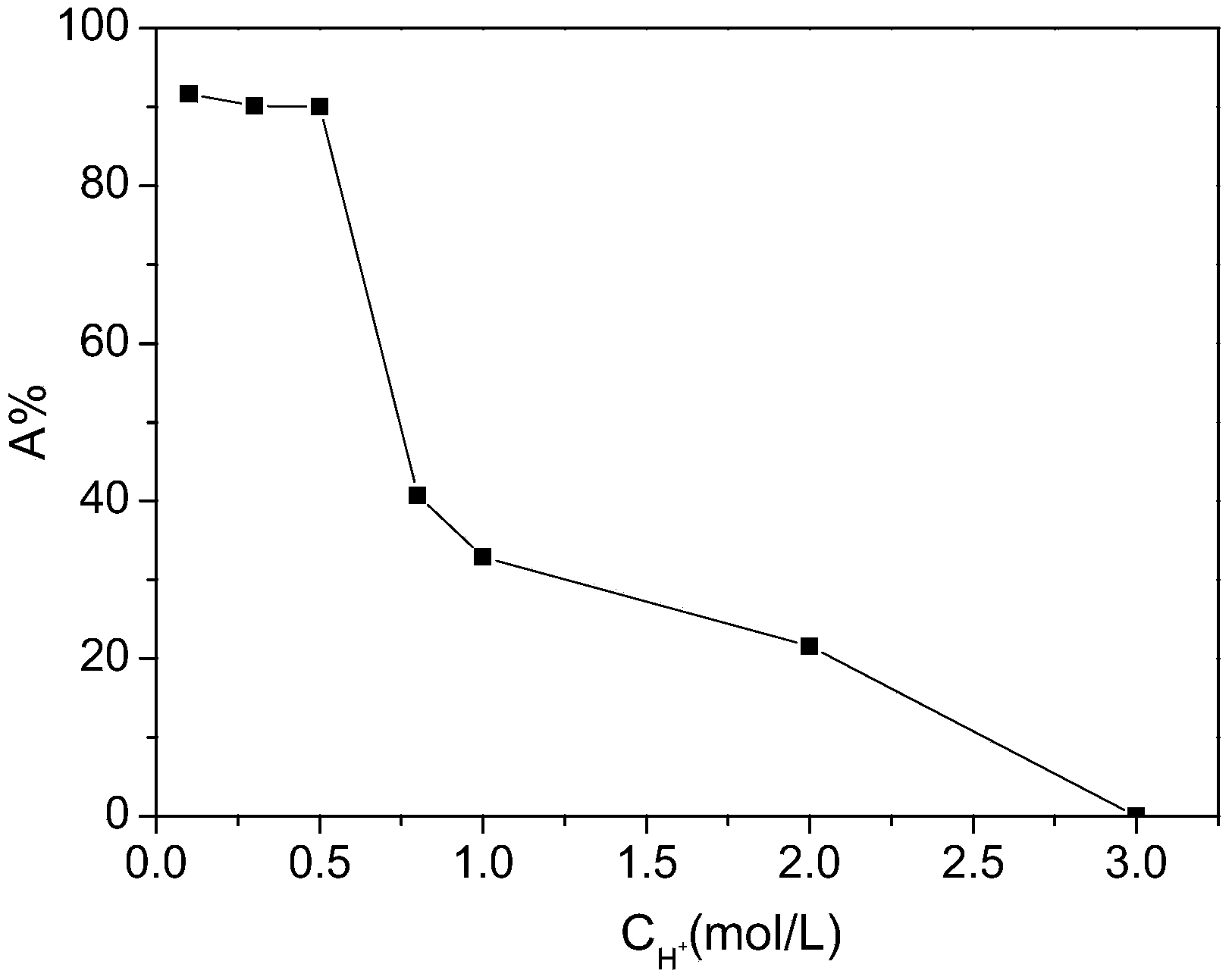

[0029] Example 2 The effect of a mercaptocellulose-based straw adsorbent on the separation of silver in high-concentration copper-nickel solutions at different acidities

[0030] Take Cu 10g·L -1 , Ni 10g L -1 , and Ag(I) 15mg / L solution 50mL, the acidity of hydrochloric acid in the solution is 0.1mol L -1 , 0.3mol·L -1 , 0.5mol·L -1 , 0.8mol·L -1 , 1mol L -1 , 2mol L -1 and 3mol L -1 , and then add 100 mg of mercaptocellulose-based straw adsorbent respectively, and measure the concentration of each ion in the solution after shaking for 2 hours. Such as figure 2 Shown, at 0.1mol·L -1 , 0.3mol·L -1 , 0.5mol·L -1 Under the condition of acidity, the adsorption rate of the adsorbent to the high-concentration copper-nickel solution is not much different, and the highest adsorption rate reaches 92%, indicating that the acidity is less than 0.5mol L -1 At high concentrations of Cu 2+ and Ni 2+ Under the influence of the sorbent, the adsorbent still has a high adsorptio...

Embodiment 3

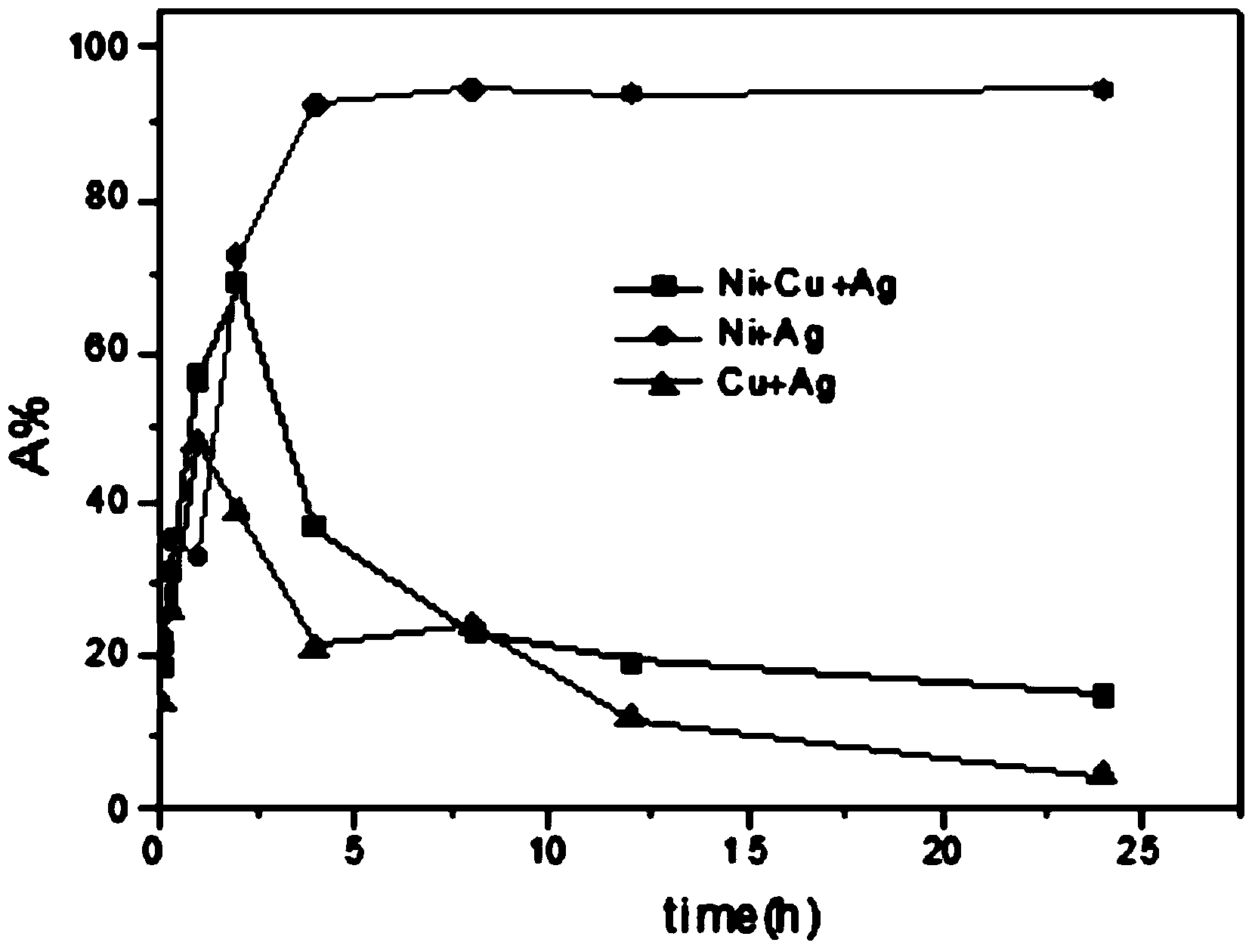

[0031] Example 3 Separation of silver by a mercaptocellulose-based straw adsorbent in different coexisting ion solutions

[0032] Prepare solution Cu 10g·L respectively -1 and Ag(I) 15mg / L; Ni 10g·L -1 And Ag(I) 15mg / L, Cu 10g·L -1 , Ni 10g L -1 and Ag(I) 15mg / L three solutions 50mL, the acidity of hydrochloric acid in the solution is 0.5mol L -1 , then add 100mg of mercaptocellulose straw adsorbent respectively, shake for 1h, 2h, 3h, 4h, 5h, 8h, 12h, 24h and track the concentration of silver ions in the solution as image 3 shown by image 3It can be seen that there is no competitive adsorption when there are only nickel and silver in the system, but when there is a high concentration of copper ions in the solution, copper ions will compete with silver ions for adsorption after 2 hours of reaction, resulting in a decrease in the adsorption rate of silver. Therefore, the preferred adsorption time of the mercaptocellulose straw adsorbent is 0.5-2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com