Preparation method of surface modified nano palladium/iron catalytic reducing agent

A surface modifier and surface modification technology, which is applied in the field of nano-environmental functional materials and water treatment, can solve the problems of reduced reactivity and easy oxidation, and achieve the effect of low energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

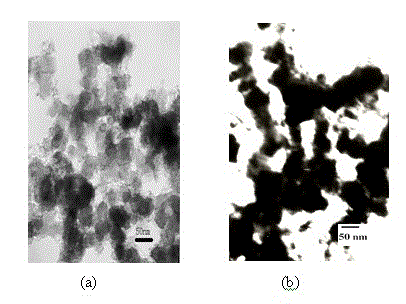

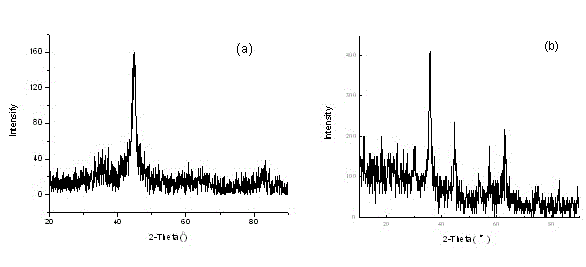

Image

Examples

Embodiment 1

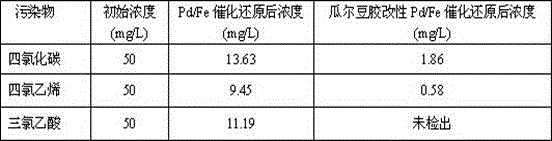

[0026] Embodiment 1: the preparation method of guar gum modified nano-palladium / iron catalytic reducing agent and its removal effect to various chlorinated organics, the specific contents are as follows:

[0027] (1) Prepare FeCl with a concentration of 1.0mol / L 3 solution, add guar gum to the solution, and stir evenly, wherein the amount of guar gum added is FeCl 3 0.01% of the mass of the solution.

[0028] (2) Under a nitrogen atmosphere, a concentration of 3.1mol / L sodium borohydride solution was added dropwise to FeCl containing guar gum 3 solution (to ensure FeCl 3 completely with NaBH 4 Reaction, add excess NaBH according to the reaction equation 4 solution), stirring while dripping, until the sodium borohydride solution was added dropwise and continued to stir for 15 min, and the completely reacted solution was filtered through a Bush funnel equipped with a 0.22 μm microporous membrane, rinsed twice with deionized water and then drained , place the dried nano-iron...

Embodiment 2

[0034] Embodiment 2: the preparation method of soluble starch modified nano-palladium / iron catalytic reducing agent and its effect on the removal of various chlorinated organics, the specific contents are as follows:

[0035] (1) Prepare FeCl with a concentration of 0.8mol / L 3 solution, add soluble starch to the solution, and stir evenly, wherein the amount of soluble starch added is FeCl 3 0.15% of the mass of the solution.

[0036] (2) Under a nitrogen atmosphere, a concentration of 2.5mol / L sodium borohydride solution was added dropwise to FeCl containing soluble starch 3 solution (to ensure FeCl 3 completely with NaBH 4 Reaction, add excess NaBH according to the reaction equation 4 solution), stirring while dripping, until the sodium borohydride solution was added dropwise and continued to stir for 20 minutes, the solution that was completely reacted was filtered through a Bush funnel equipped with a 0.22 μm microporous membrane, rinsed with deionized water for 3 times...

Embodiment 3

[0042] Embodiment 3: the preparation method of polyethylene glycol modified nano-palladium / iron catalytic reducing agent and its effect on the removal of various chlorinated organics, the specific contents are as follows:

[0043] (1) Prepare FeCl with a concentration of 0.9mol / L 3 solution, add polyethylene glycol to the solution, and stir evenly, wherein the amount of polyethylene glycol added is FeCl 3 1.5% of the mass of the solution.

[0044] (2) Under a nitrogen atmosphere, a concentration of 3.5mol / L sodium borohydride solution was added dropwise to FeCl containing polyethylene glycol 3 solution (to ensure FeCl 3 completely with NaBH 4 Reaction, add excess NaBH according to the reaction equation 4 solution), stirring while dripping, until the sodium borohydride solution was added dropwise and continued to stir for 10 min, and the completely reacted solution was filtered through a Bush funnel equipped with a 0.22 μm microporous membrane, rinsed twice with deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com