Patents

Literature

53results about How to "Good binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-containing metal surface treatment agent and preparation method of anti-corrosion coating

InactiveCN104629603AIncrease penetration timeGood bindingLiquid surface applicatorsAnti-corrosive paintsCvd grapheneSurface finishing

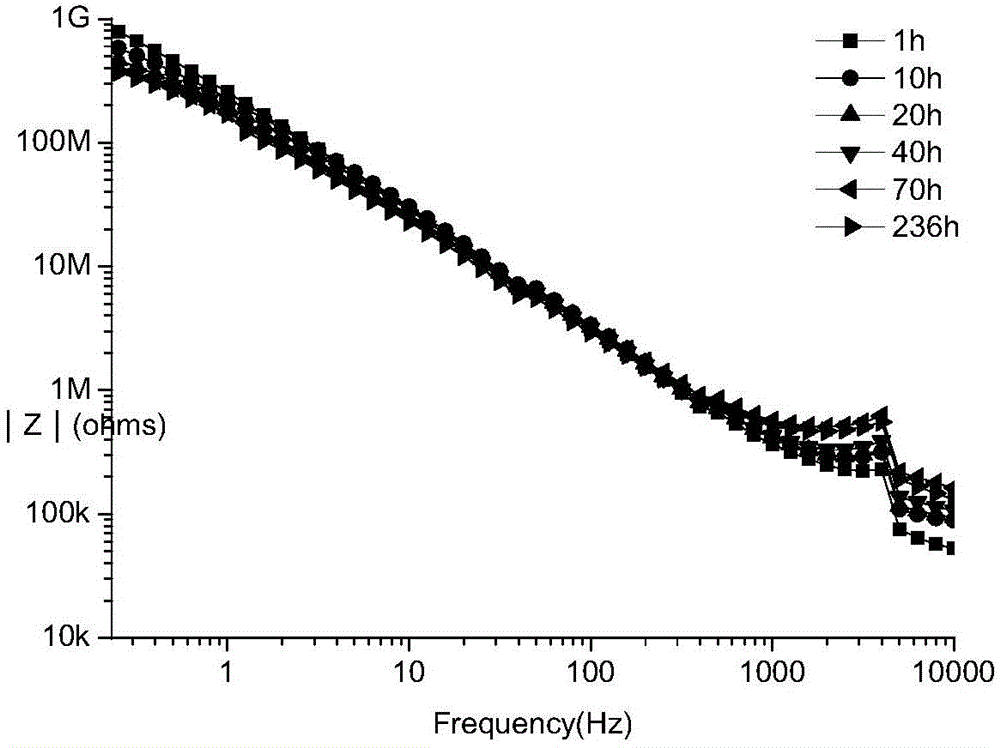

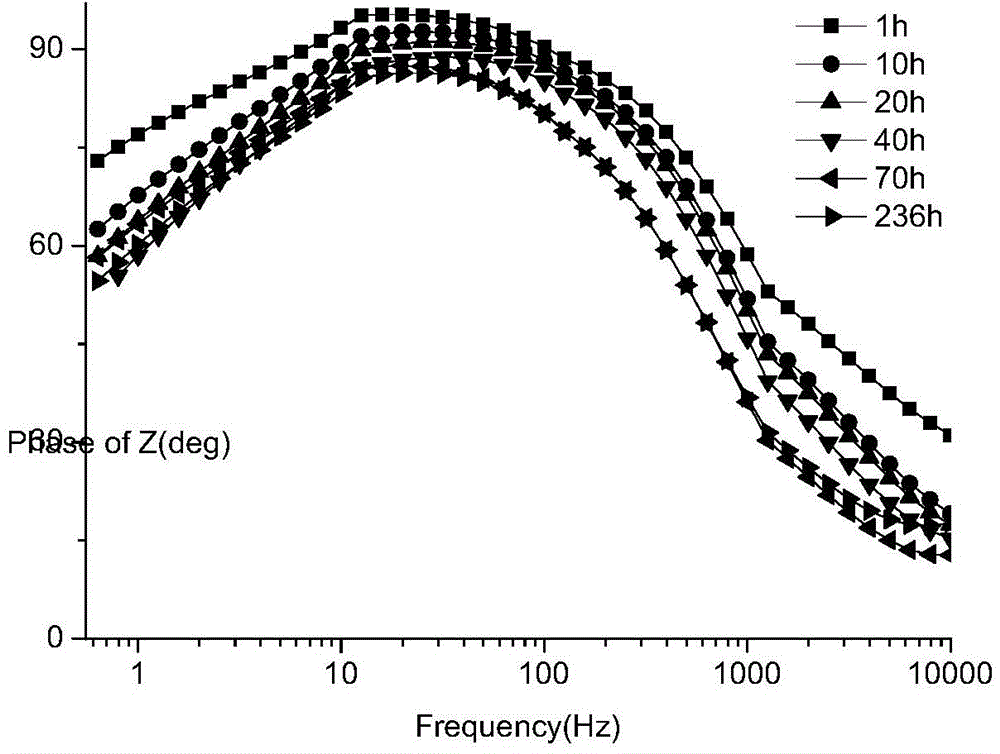

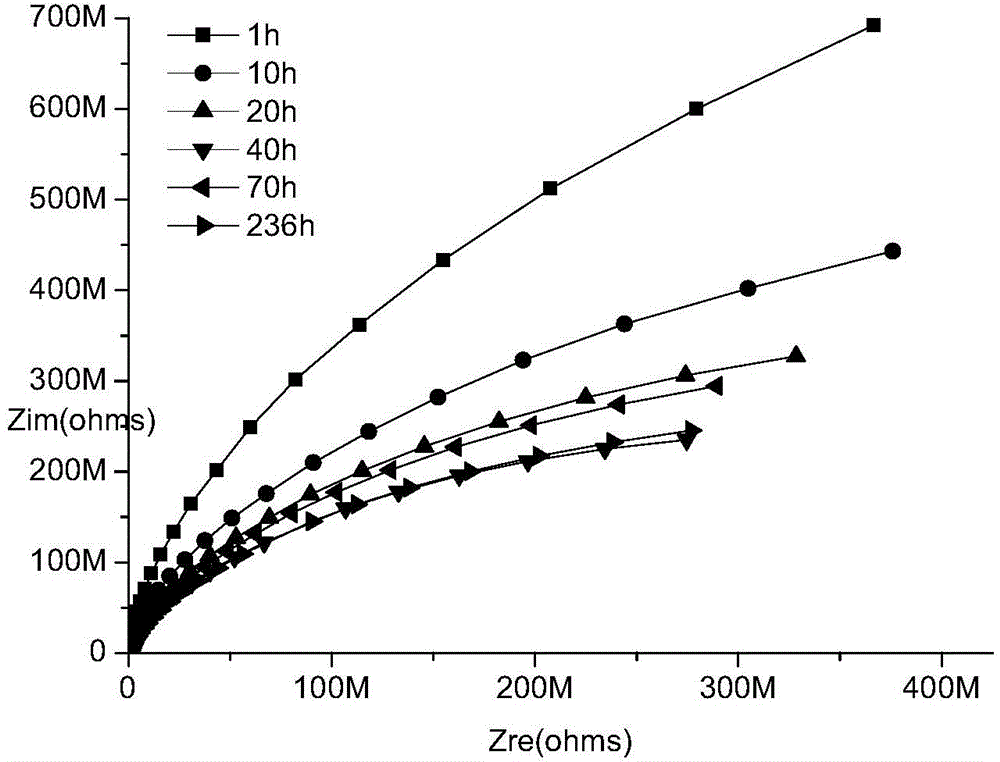

The invention relates to a graphene-containing metal surface treatment agent and a preparation method of an anti-corrosion coating thereof. Graphene oxide is prepared by a chemical oxidation method, and the graphene oxide is subjected to surface modification and reduction so as to obtain good compatibility with a metal surface treatment agent; and the graphene is added into the metal surface treatment agent according to a certain proportion. The treatment agent contains A) waterborne resin, for example, waterborne polyurethane and waterborne acrylic resin; B) a coupling agent, for example, a silane coupling agent and a titanate coupling agent; and C) graphene, wherein the surface state can be graphene oxide, reduced graphene oxide or graphene subjected to surface chemical modification. After the surface treatment agent containing uniformly dispersed graphene, a film is formed on the surface of a metal substrate by a rod coating method, and the film is dried at a certain temperature to obtain a graphene-reinforced composite coating. An electrochemical impedance test method proves that the composite coating has ultrahigh corrosion resistance.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Solar cell back sheet, preparation method thereof and solar cell

ActiveCN102956730AGood bindingIncrease surface and roughnessFinal product manufacturePhotovoltaic energy generationPolyvinylidene fluorideBinding force

The invention provides a solar cell back sheet. The back sheet comprises a metal aluminum alloy plate layer, an organic insulated layer and an anti-corrosion layer, wherein the organic insulated layer is arranged on one face of the metal aluminum alloy plate layer by virtue of electrostatic spraying, and the anti-corrosion layer is arranged on the other face of the metal aluminum alloy plate layer; and the metal aluminum alloy plate layer contains at least one of polyvinyl fluoride resin, polyvinylidene fluoride resin, polytrifluoroethylene resin, polytetrafluoroethylene resin or copolymers of monomers of the polyvinyl fluoride resin, the polyvinylidene fluoride resin, the polytrifluoroethylene resin and monomers of the other resins. The invention further provides a preparation method of the back sheet and a solar cell containing the back sheet. A well binding force exists between the organic insulated layer and the metal aluminum alloy plate layer of the back sheet provided by the invention.

Owner:BYD CO LTD

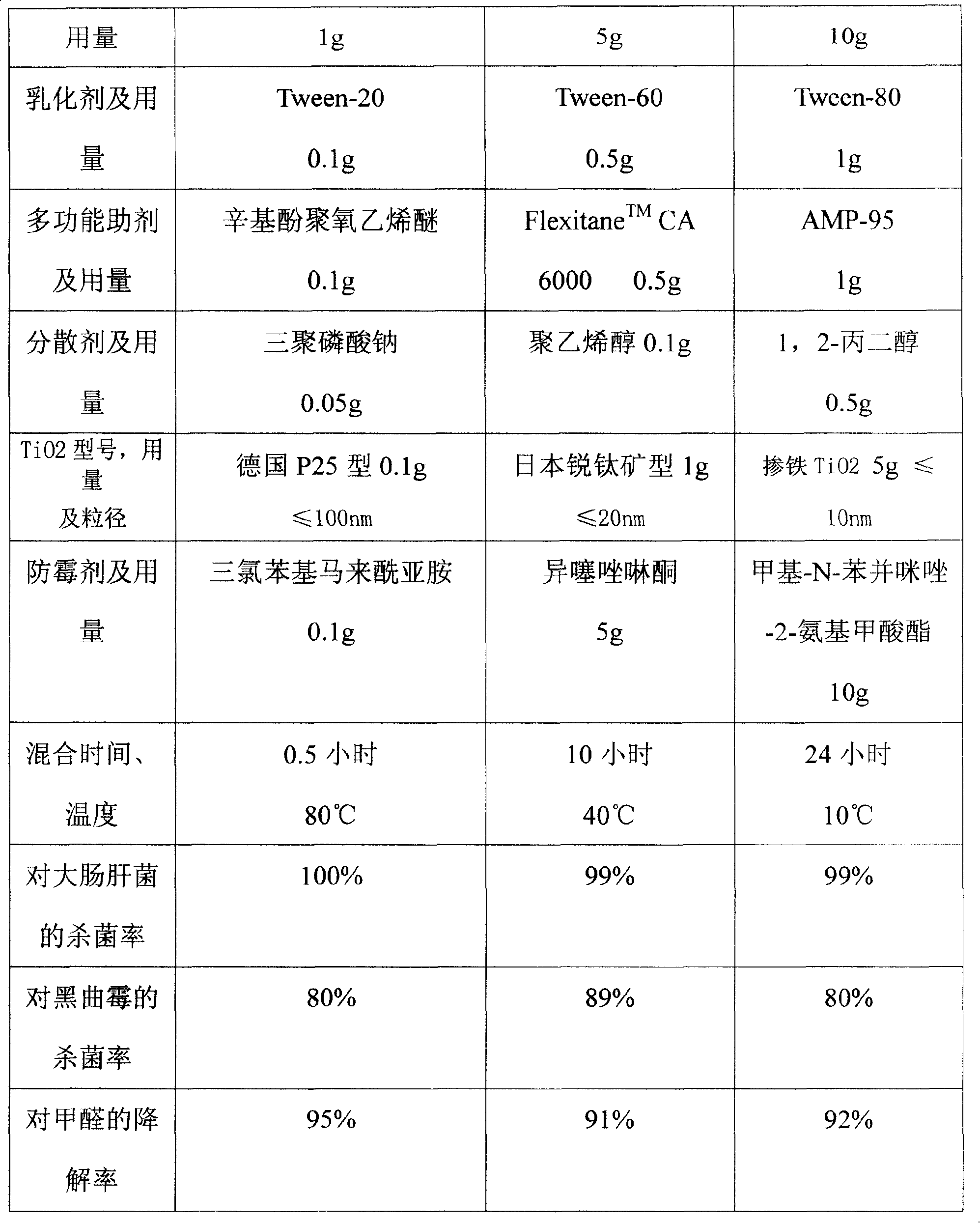

Preparation method of antibiotic anti-fungus agent for building surface

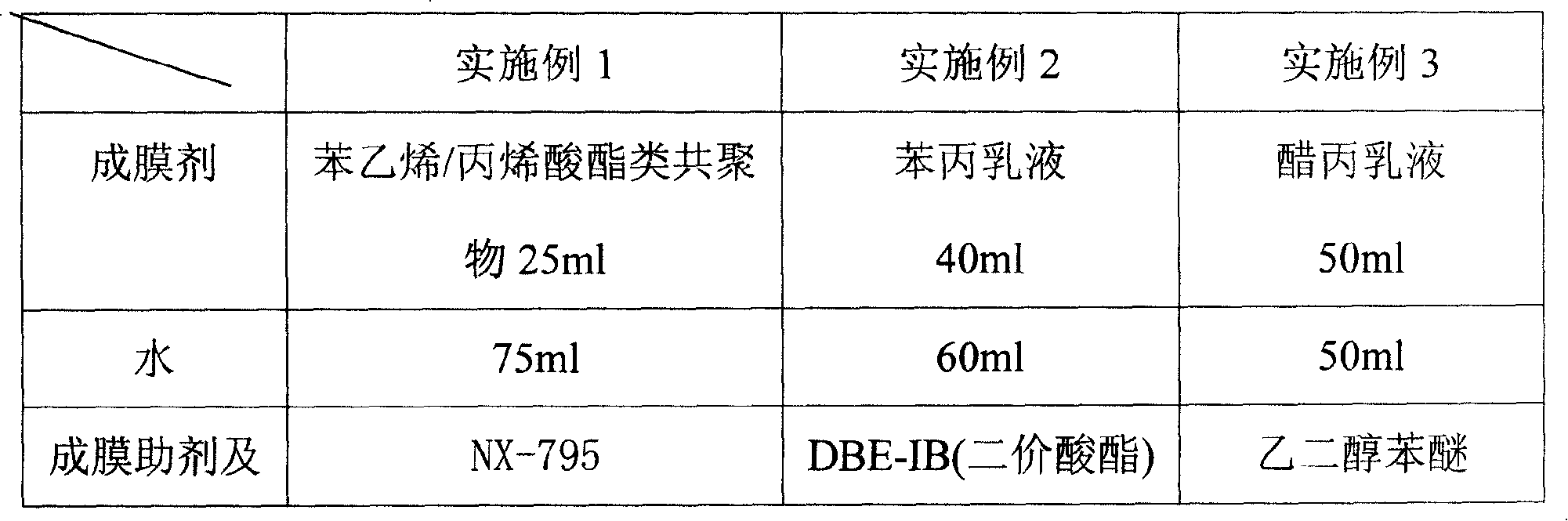

The invention relates to a method for preparing an antibacterial and antifungal agent on the surface of buildings, adding film-forming aids, nano-TiO2, dispersants, emulsifiers, multifunctional auxiliary agents and antifungal agents to coating emulsions for architectural coatings. The weight percentage of each component is controlled as follows: 20%-90% of coating emulsion, 0.1%-5% of nano-TiO2, 0.1%-10% of film-forming aid, and 0.05%-0.5% of dispersant , 0.1% to 1% emulsifier, 0.1% to 1% multifunctional additive, 0.1% to 10% anti-mold additive, and 5% to 70% water. The antibacterial and antifungal agent prepared by the present invention can be sprayed on the surface of buildings at any time to renew the catalytic antibacterial and antifungal coating. The catalysis and antifungal agent have synergistic bactericidal and antifungal effects, can remove volatile gases such as formaldehyde VOC, and have a simple preparation method, few additives, and low production cost.

Owner:BEIJING UNIV OF CHEM TECH

Neodymium iron boron magnet material phosphating treatment and organic coating double layers protection method

InactiveCN102732871AGood anti-corrosion abilityGood bindingLiquid surface applicatorsMetallic material coating processesCorrosion resistantPre treatment

The invention relates to a surface protection technology of a neodymium iron boron magnet material, concretely relates to a neodymium iron boron magnet material surface phosphating treatment and an organic coating double layers protection method. The method comprises the following steps: removing oil on neodymium iron boron, removing rust, and then immersing neodymium iron boron in a phosphating liquid for 5-15 minutes to generate a layer of phosphating coat, washing and drying, and then coating a layer of organic paint to form an organic coating. The method of the invention aims at the problems of complex, rigorous pre-treatment and poor anti-corrosive property in a surface protection method during electroplating and chemical plating. According to the invention, the surface treatment technology of phosphatization treatment and organic coating double layers protection can be used, the technology is simple without complex pre-treatment, under the prerequisite that the combination force of the coating and the matrix and the magnetic property are not be influenced, the neutral salt spray corrosion resistant performance of the coating can be largely enhanced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

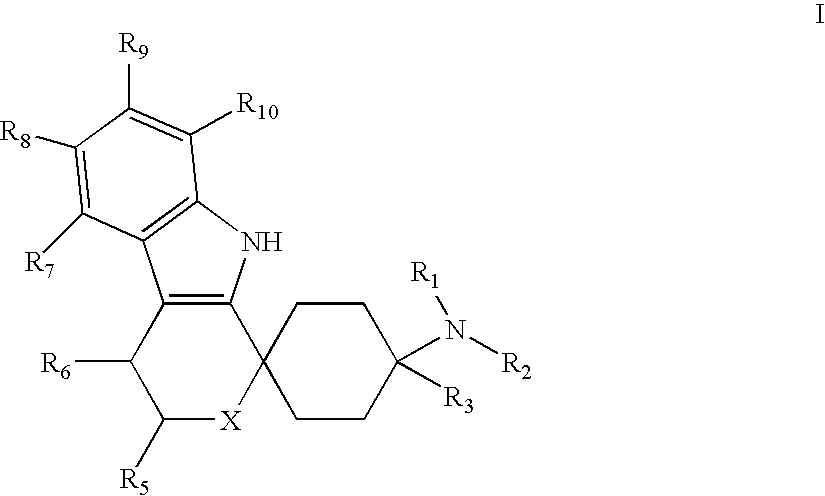

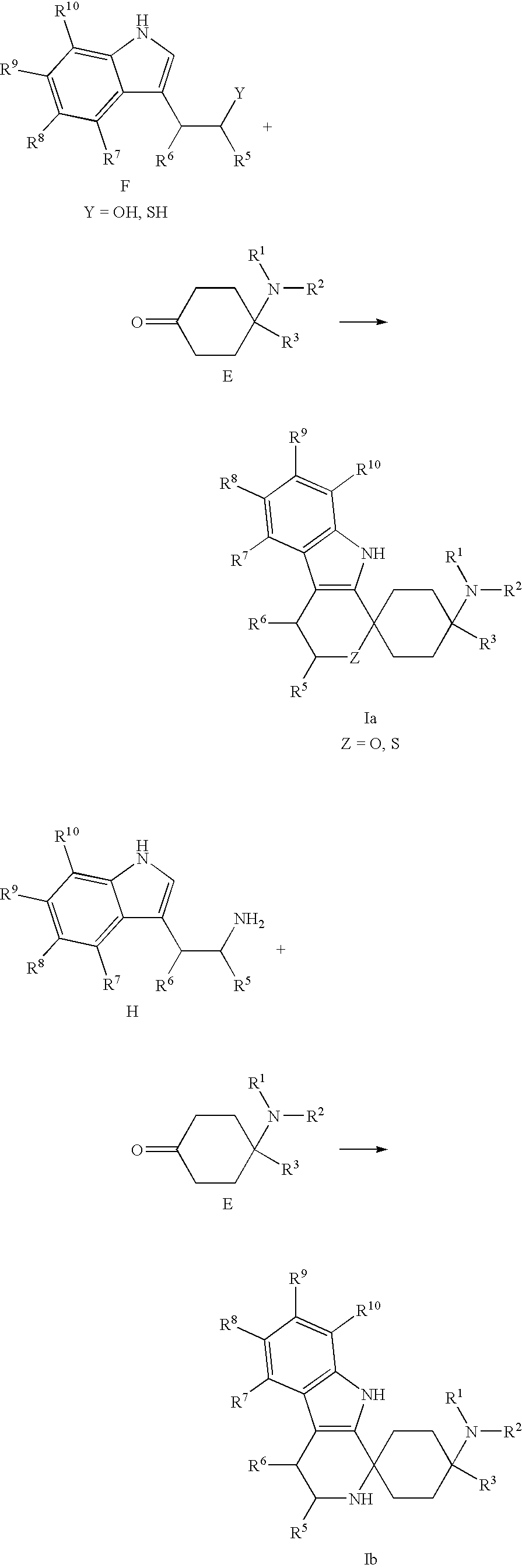

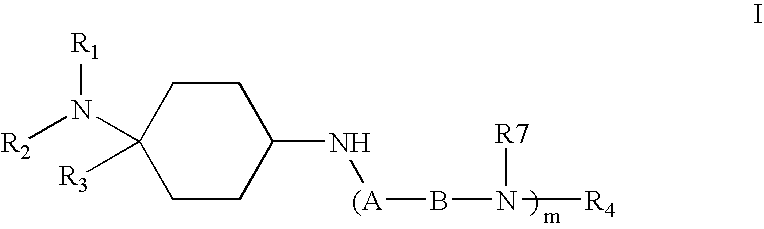

Spirocyclic Cyclohexane Compounds

Spirocyclic cyclohexane compounds corresponding to formula IIn which R1, R2, R3 and R5 through R10 and X have defined meanings, a process for their preparation, pharmaceutical compositions containing such compounds, and the use of such spirocyclic cyclohexane compounds in the treatment and / or inhibition of pain and other conditions mediated by the ORL-1 or the μ-opioid receptor.

Owner:GRUNENTHAL GMBH

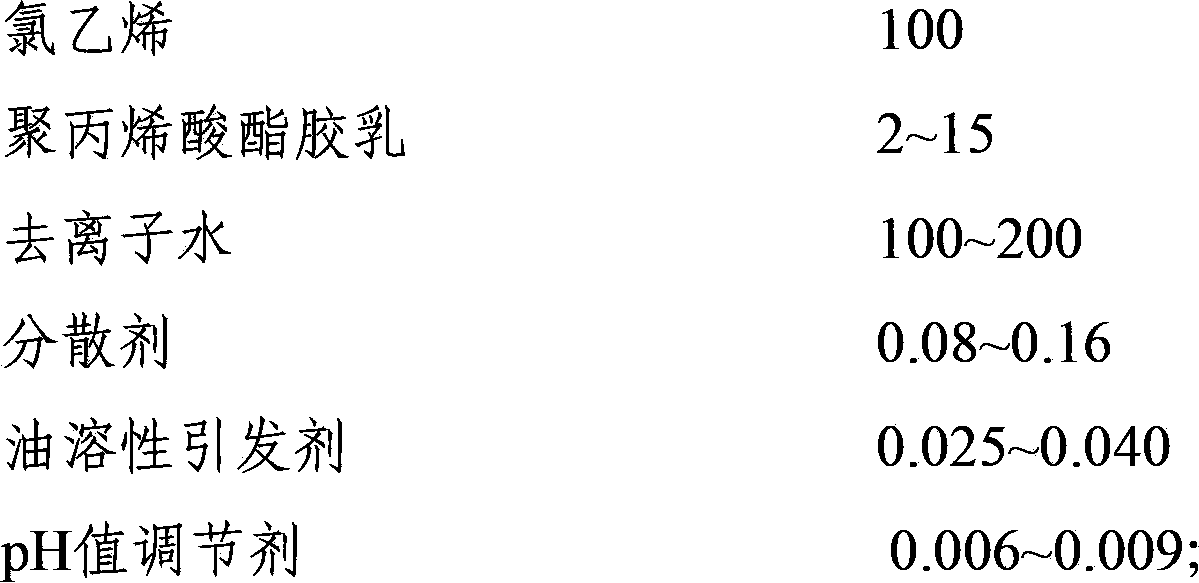

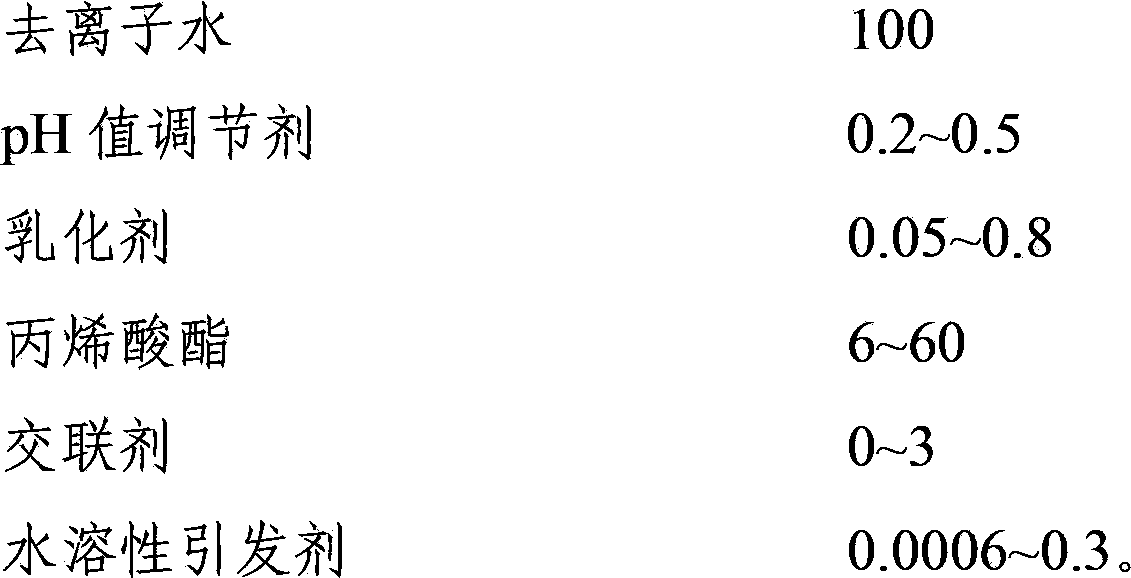

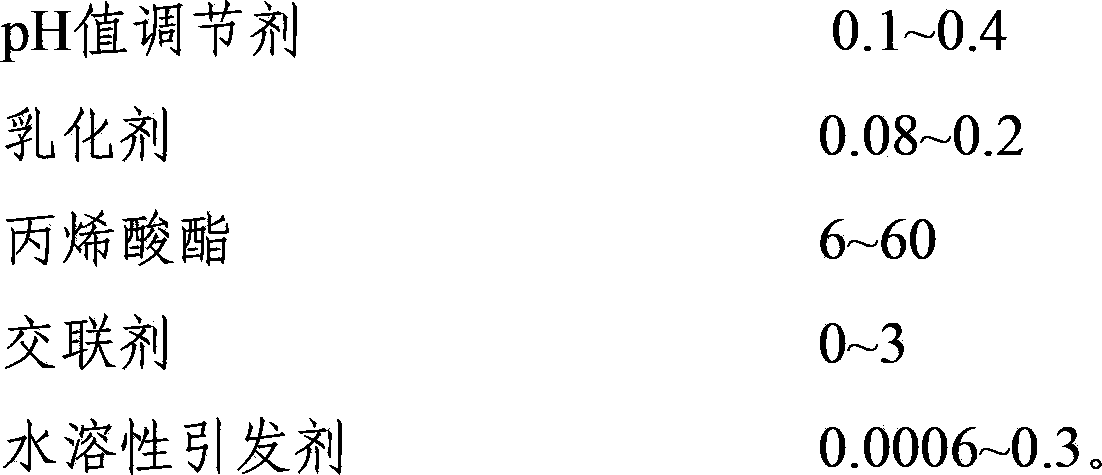

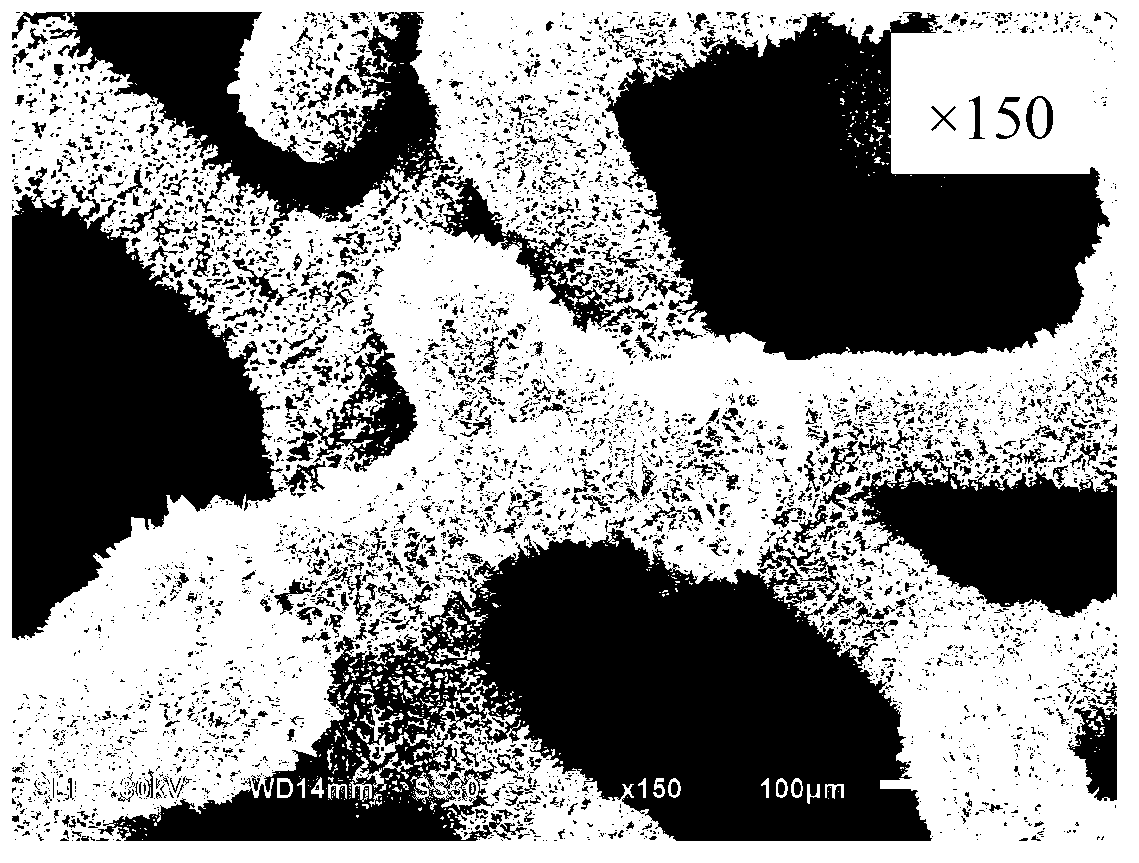

Polyacrylate grafted vinyl chloride composite resin and preparation method thereof

The invention relates to a polyacrylate grafted vinyl chloride composite resin and a preparation method thereof. The polyacrylate grafted vinyl chloride composite resin is prepared from the following components in parts by weight: 100 parts of vinyl chloride, 2-15 parts of polyacrylate latex (calculating by solid content), 100-200 parts of deionized water, 0.08-0.16 part of a dispersant, 0.025-0.040 part of an oil-soluble initiator and 0.006-0.009 part of a pH value adjusting agent. Polyacrylate latex is prepared by: continuing to dropwise add or not add acrylate into the system after acrylate is subjected to a polymerization reaction at 65-95 DEG C. The prepared polyacrylate grafted vinyl chloride composite resin is good in impact resistance, short in plasticizing time and excellent in processing fluidity.

Owner:河北盛华化工有限公司 +1

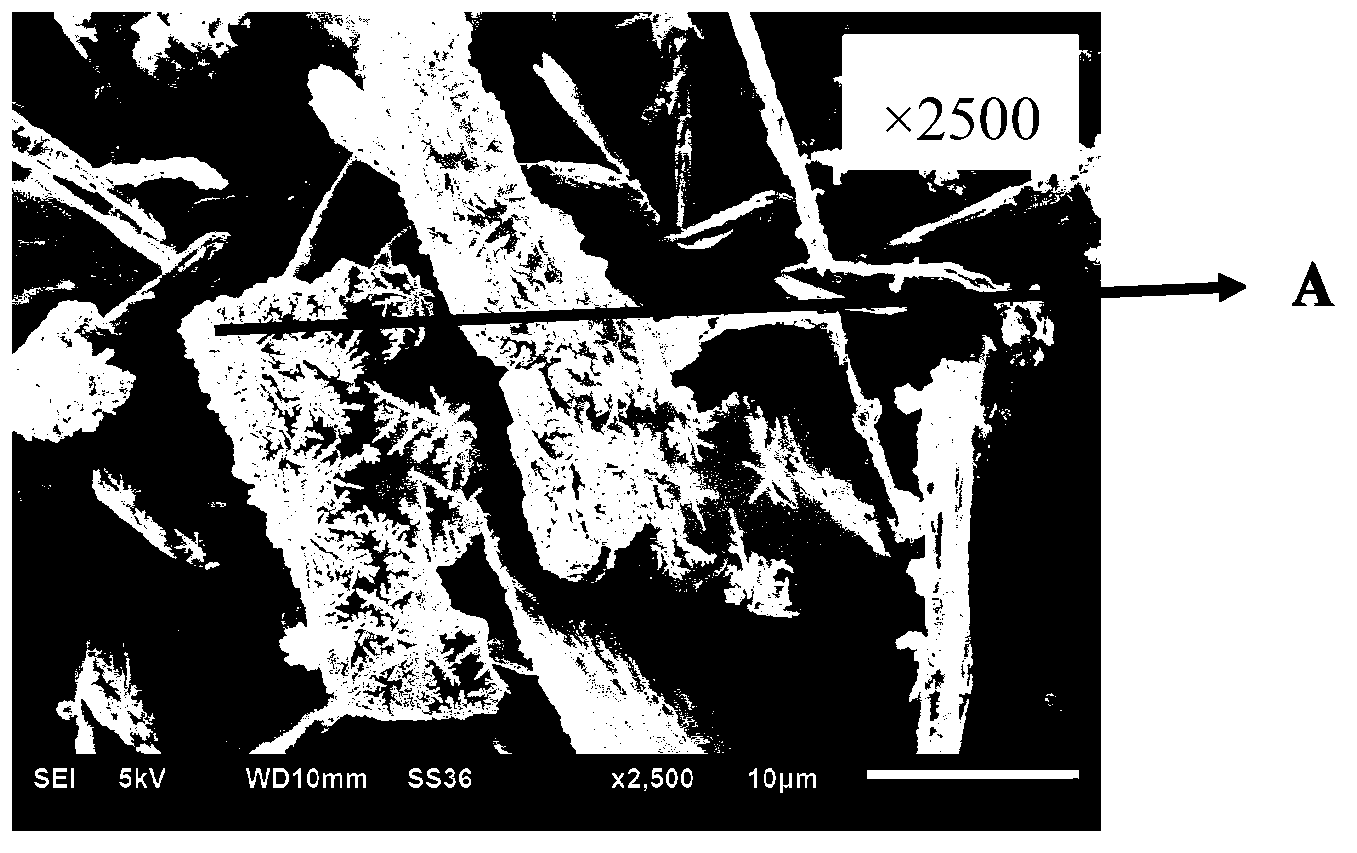

Copper sulfide anode and preparation method thereof

The invention provides a copper sulfide anode and a preparation method thereof, solving the problems of the conventional copper sulfide electrode that the bonding force of active substances and current collectors is poor and the anode conductivity is lowered because of a binder and also solving the problems of the integrated copper sulfide electrode which is synthesized in situ in a solution that the quantity of active substances is small and the preparation period is long. The copper sulfide anode is prepared by the following steps: uniformly spreading elemental sulfur which is prepared according to the sulfur carrying amount of foamy copper is 0.03-0.3g / cm<2> on the foamy copper, putting into a furnace, and carrying out in-situ reaction under a protection gas at a temperature of 155-350 DEG C so as to obtain the laminated copper sulphide which takes a foamy copper three-dimensional network structure as a framework, namely an integrated porous copper sulphide anode. By utilizing the copper sulfide anode, the application of the three-dimensional structured integrated porous anode in a lithium battery is widened, the energy density of a lithium battery anode is improved, and the performances of a lithium battery are improved. The copper sulfide anode is simple in preparation process, low in equipment requirement, low in cost and convenient for industrial production.

Owner:XIANGTAN UNIV

Fluoro polymer synergistic coating treatment process for iron and steel material

InactiveCN1616713AGood bindingGood wear resistanceHot-dipping/immersion processesMolten spray coatingNickel coatingHardness

The iron and steel material treating process with synergistic fluoropolymer coating features the first chemical nickel plating of iron and steel material to form the base layer of the synergistic coating, the subsequent pore creating treatment of the nickel coating, the introducing of fluoropolymer to the pores and surface and the heat treatment under vacuum state for the fluoropolymer to fuse with the chemical coating to form the synergistic coating. The said technological process has the advantages of high coating hardness, high wear resistance, the self-lubricating performance and increased wear resistance caused by the fluoropolymer as friction reducing matter, resistance to most harmful matters of the fluoropolymer, and self-lubricating function of the dry coating.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

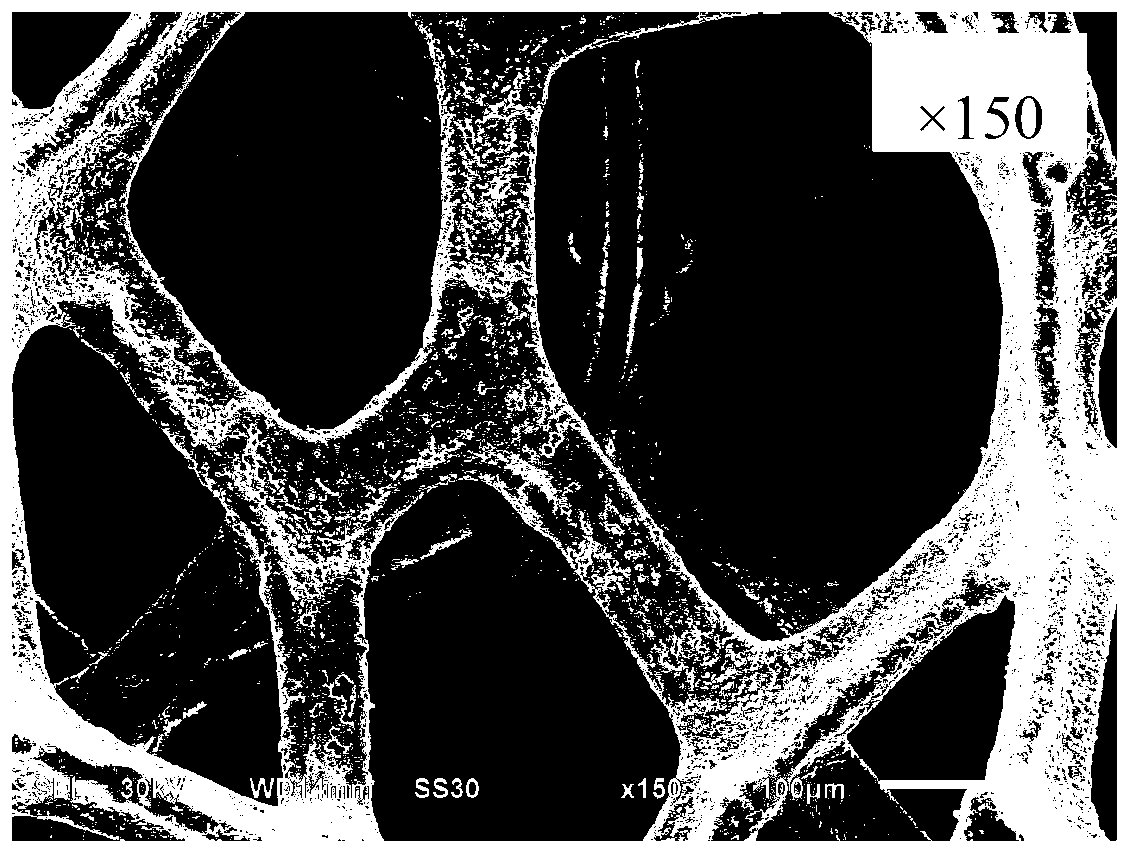

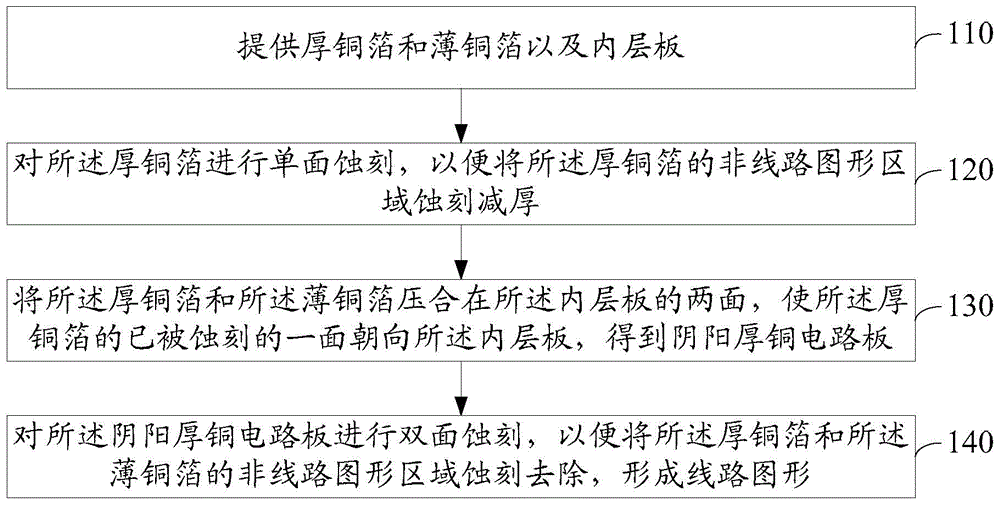

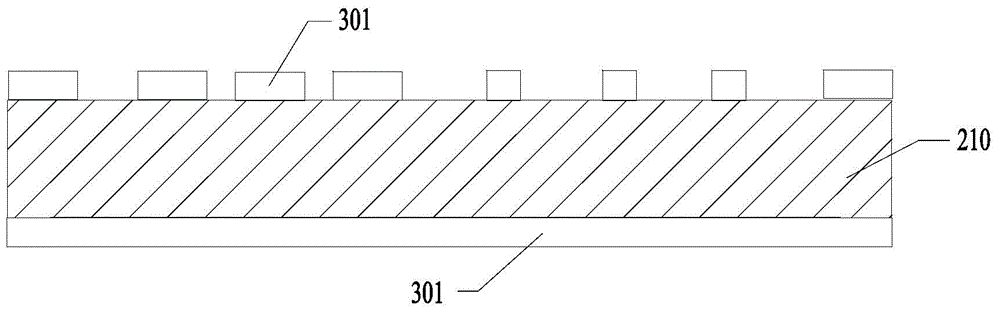

Processing method of female and male thick copper circuit board

ActiveCN104684263AGood bindingStrong anti-corrosion abilityConductive material chemical/electrolytical removalCopper foilEtching

The invention discloses a processing method of a female and male thick copper circuit board. The processing method comprises the following steps that a thick copper foil, a thin copper foil and an inner layer plate are provided; the thick copper foil is subjected to single-side etching, so that a non-circuit-pattern region of the thick copper foil is etched to reduce the thickness; the thick copper foil and the thin copper foil are pressed on the two sides of the inner layer plate, so that the etched side of the thick copper foil faces the inner layer plate, and the female and male thick copper circuit board is obtained; the female and male thick copper circuit board is subjected to double-side etching, so that the non-circuit-pattern regions of the thick copper foil and the thin copper foil are removed through being etched, and circuit patterns are formed. Through the technical scheme, the processing method solves the problems that in the existing single-side etching process, a dry film covers the circuit patterns, the bonding force is low, and the anti-corrosion capability is poor. The processing method also solves the problems that in the existing circuit compensation process, the compensation design needs to be added to one side of the thin copper coil, so that the problems that the circuit space is large, and fine and tight circuits cannot be processed are caused.

Owner:SHENNAN CIRCUITS

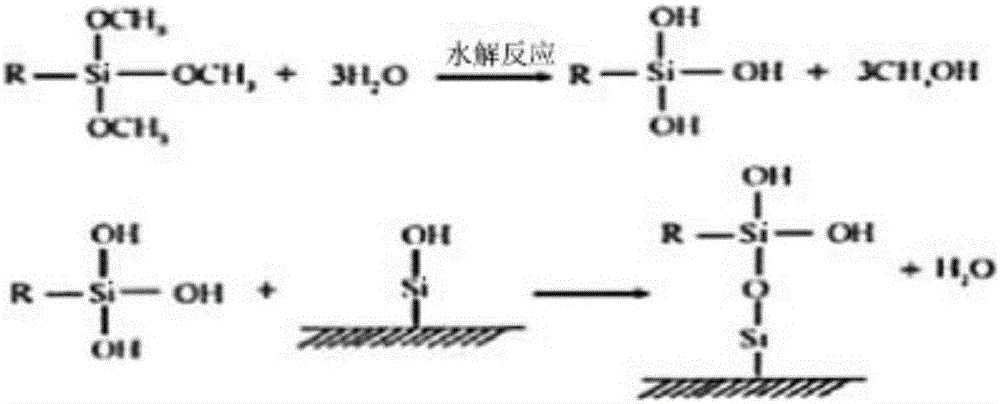

Method of preparing hydrophobic membrane through physical vapor deposition of fluoroalkyl silane

InactiveCN105779943AReduce manufacturing costGood bindingVacuum evaporation coatingSputtering coatingVoltageSilica membrane

The invention discloses a method of preparing a hydrophobic membrane through physical vapor deposition of fluoroalkyl silane. The method comprises the following steps of one, plasma glow processing: putting substrates into PVD vacuum equipment, vacuumizing, and implementing plasma glow processing on the substrates when the vacuum degree reaches 10<-2>Pa; two, medium frequency magnetron sputtering a transparent silica membrane, wherein a sputtering target material is a pure silicon target; and three, vacuum evaporation of fluoroalkyl silane hydrophobic membrane: adopting the vacuum evaporation technology, and beginning to evaporate the fluoroalkyl silane at the third minute in the process of sputtering a silicon dioxide membrane: preheating and cleaning a fluoroalkyl silane plating material for 10-30s at the voltage to be 2-3V; pre-evaporating for 20-50s at the voltage to be 3-4V; evaporating for 100-200s at the voltage to be 4-6V, depositing a layer of fluoroalkyl silane on the surface of a silicon dioxide membrane layer, and carrying out silane crosslinking reaction on the fluoroalkyl silane and silicon dioxide to obtain the transparent fluoroalkyl silane hydrophobic membrane. According to the method, a plating film with better binding force can be formed, and membrane formation does not need high-temperature braking, and the production cost is lowered.

Owner:XIAMEN RUNNER IND CORP

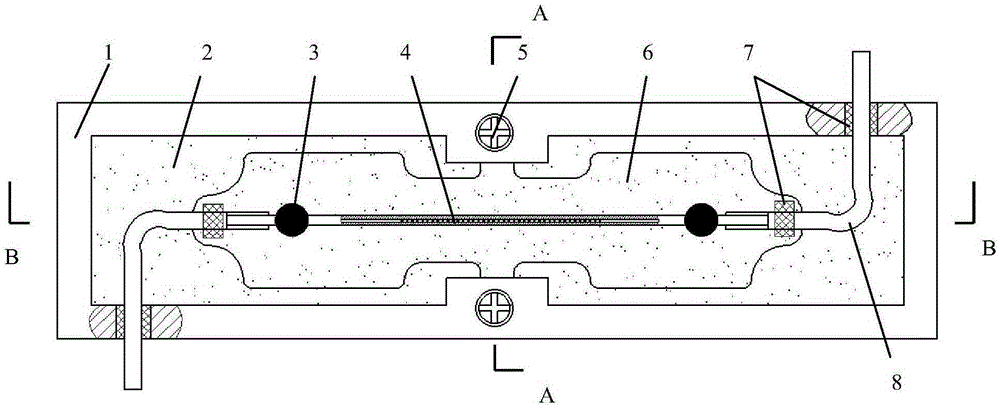

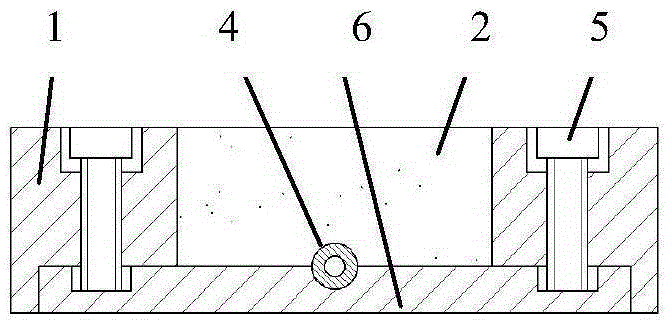

Laser-welding fiber grating surface temperature sensor and packaging method thereof

InactiveCN105241573AGood bindingOvercome Creep and AgingThermometers using physical/chemical changesTemperature measurementAdhesive

The invention provides a laser-welding fiber grating surface temperature sensor which comprises a fiber, a metal substrate and a bottomless nonmetal framework. The fiber comprises a fiber grating plated with a metal layer and signal transmission tail fibers at the two sides of the fiber grating. The two ends of the fiber grating are fixed to the metal substrate through laser welding; the signal transmission tail fibers are respectively sleeved by a fiber protection sleeve pipe; the bottom portion of the nonmetal framework is fixed to the metal substrate; the nonmetal framework is provided with through holes for allowing the fiber protection sleeve pipes to pass through; and the nonmetal framework is internally filled with paste-like heat-conduction silicone grease. The fiber grating is subjected to coating layer removing and metal film layer plating, and is then, fixed to the metal substrate through the laser welding method, thereby realizing full metal packaging of a temperature sensing portion of the whole sensor, and overcoming creep and aging of adhesives in a conventional adhesive substrate fiber grating temperature sensor; and compared with glass welding, the laser-welding fiber grating surface temperature sensor has higher mechanical strength, and can bear higher test temperature; and fiber grating object surface temperature measurement long-term reliability and stability are improved on the whole.

Owner:WUHAN UNIV OF TECH

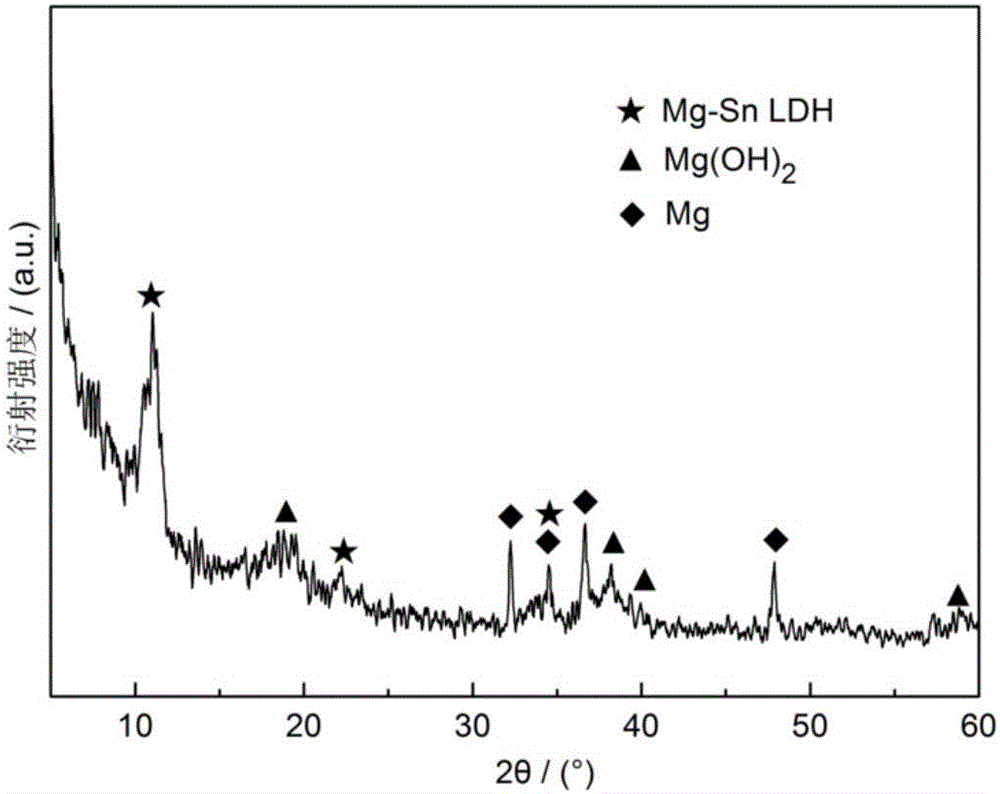

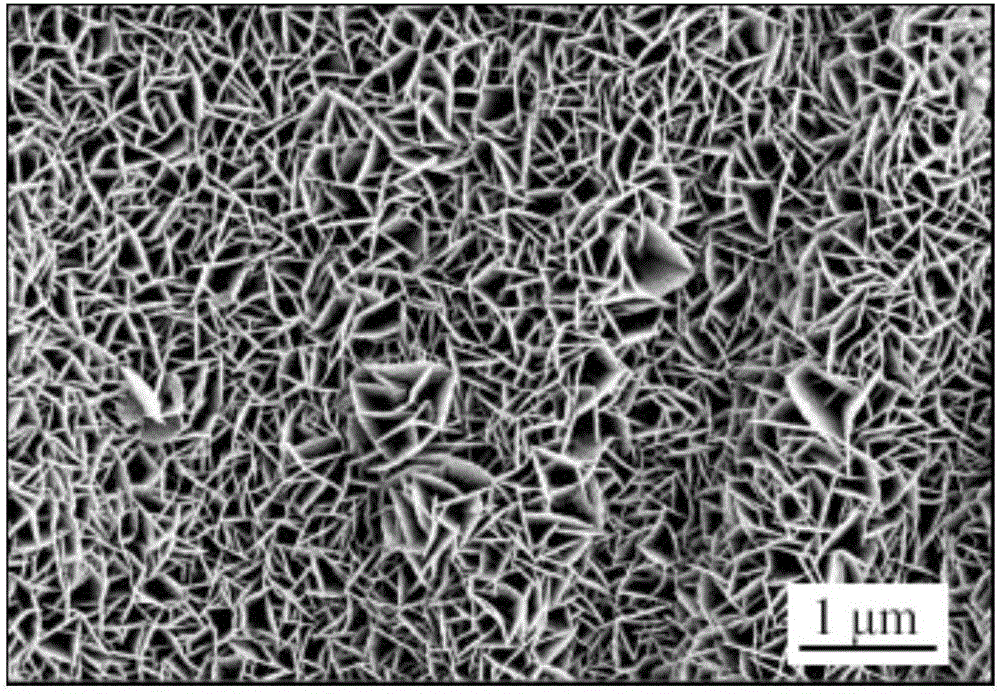

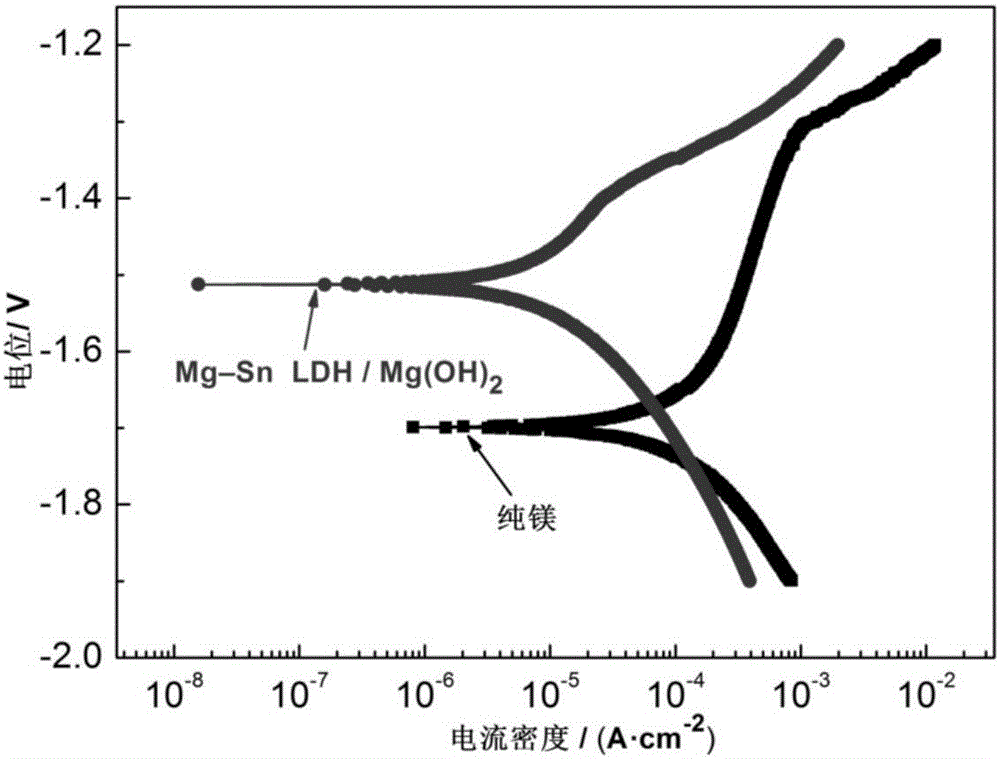

Mg(OH)2/Mg-Sn hydrotalcite composite film having intercalation structure on surface of magnesium and magnesium alloy and preparation method thereof

ActiveCN106283017AStable structureGood bindingMetallic material coating processesHydrotalciteCorrosion

The invention discloses a Mg(OH)2 / Mg-Sn hydrotalcite composite film having an intercalation structure on the surface of magnesium and magnesium alloy and a preparation method thereof, relates to the technical field of the surface of magnesium and magnesium alloy, and aims to improve the corrosion resistance of magnesium and magnesium alloy and widen the application prospects in the fields of biological medicine and the like. The preparation method comprises the following steps: S1, initial treatment of magnesium and magnesium alloy; S2, pretreatment: preparing a Sn4<+> salt solution, regulating the pH value to 4.0 to obtain a pretreatment solution, and putting the magnesium and magnesium alloy in the pretreatment solution with continuously introduced CO2 to obtain a precursor film; S3, posttreatment: soaking the magnesium and magnesium alloy coated with the precursor film in a Na2CO3 solution to grow a Mg(OH)2 / Mg-Sn hydrotalcite composite film on the surface of the magnesium and magnesium alloy; and S4, subsequent cleaning. According to the invention, the Mg(OH)2 / Mg-Sn hydrotalcite composite film containing no aluminum and having biosafety is grown on the surface of magnesium and magnesium alloy in an in-situ generation manner through a two-step method; the corrosion resistance of magnesium and magnesium alloy is improved; and the application of the hydrotalcite film in biological magnesium alloy surface protection is widened.

Owner:NANJING INST OF TECH

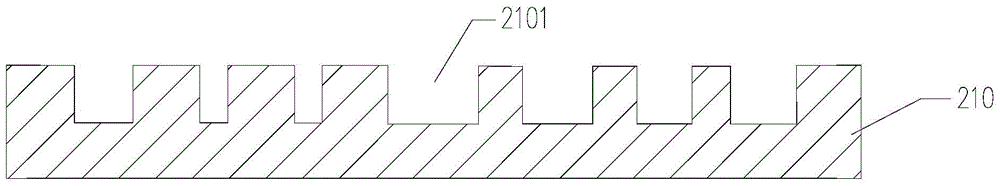

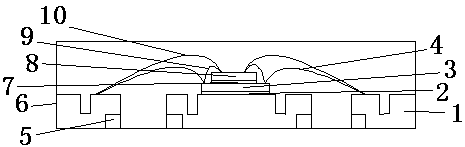

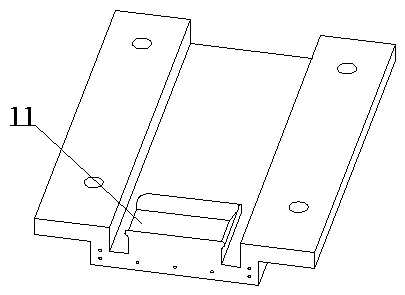

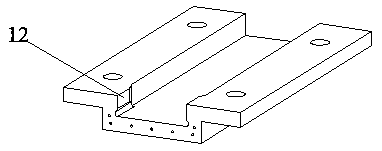

Flat multichip packaging piece with stamping frame with square groove and production method of flat multichip packaging piece

InactiveCN103021996AGood bindingReduce the likelihood of delaminationSemiconductor/solid-state device detailsSolid-state devicesChIP-on-chipAdhesive

The invention discloses a flat multichip packaging piece with a stamping frame with a square groove and a production method of the flat multichip packaging piece. The packaging piece mainly comprises a lead frame, the square groove, a lower chip, an upper chip, a lower surface mount adhesive, an upper surface mount adhesive, a lower bonding wire, a middle bonding wire, an upper bonding wire and a plastic package body, the square groove is reserved on the lead frame which is adhered with the lower chip through the lower surface mount adhesive, the lower chip is adhered with the upper chip via the upper surface mount adhesive, the lower bonding wire is connected with the lead frame and the lower chip, the middle bonding frame is connected with the upper surface mount adhesive and the upper surface mount adhesive, the upper bonding wire is connected with the upper surface mount adhesive and the lead frame, the plastic package body surrounds the lead frame, the lower chip, the upper chip, the lower surface mount adhesive, the upper surface mount adhesive, the lower bonding wire, the middle bonding wire and the upper bonding wire and particularly fills the square groove, and the lead frame, the lower chip, the upper chip, the lower bonding wire, the middle bonding wire and the upper bonding wire form a power source and a signal channel of a circuit. The plastic package body is combined with the lead frame more firmly, and delamination-resisting effect is better.

Owner:HUATIAN TECH XIAN

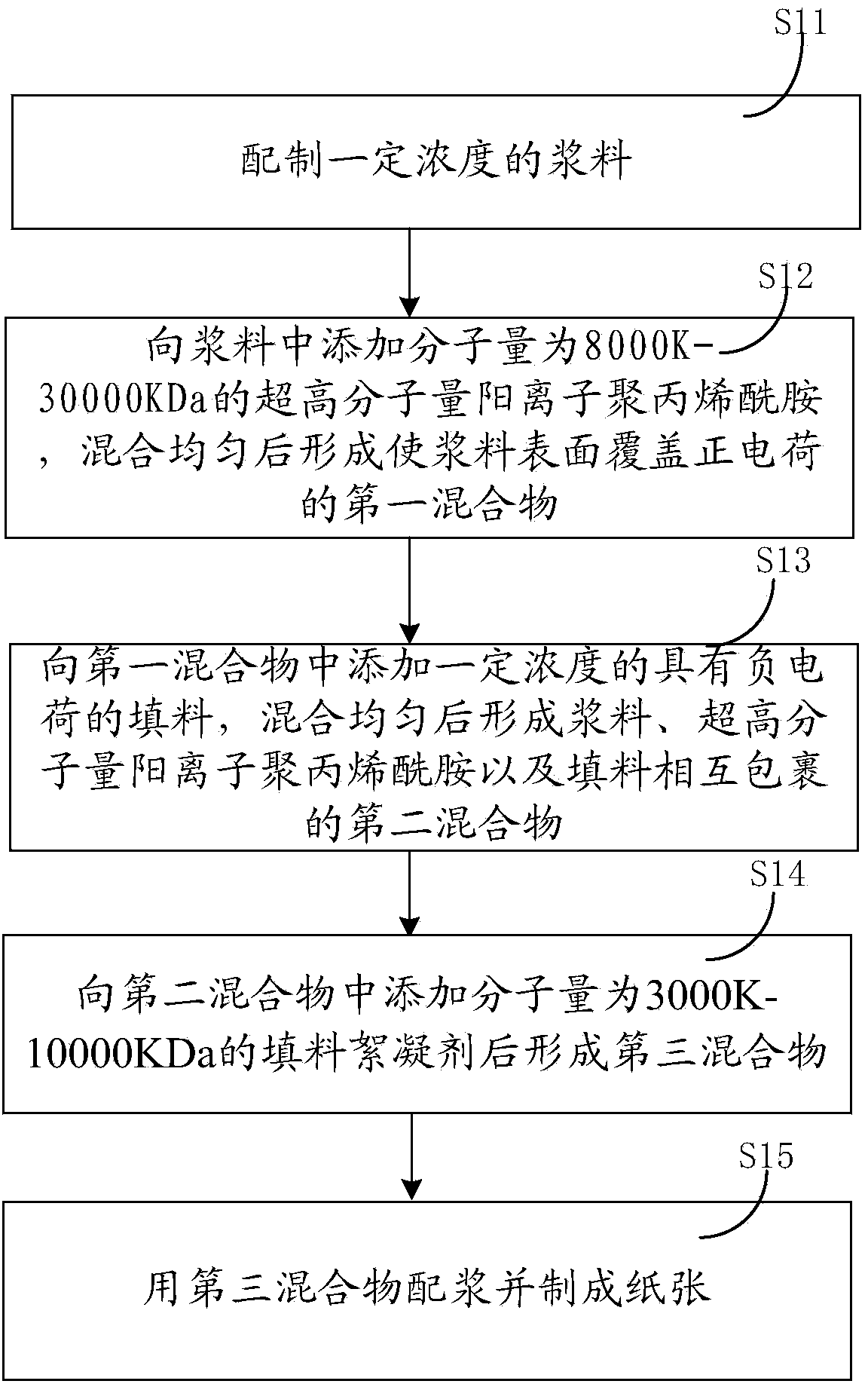

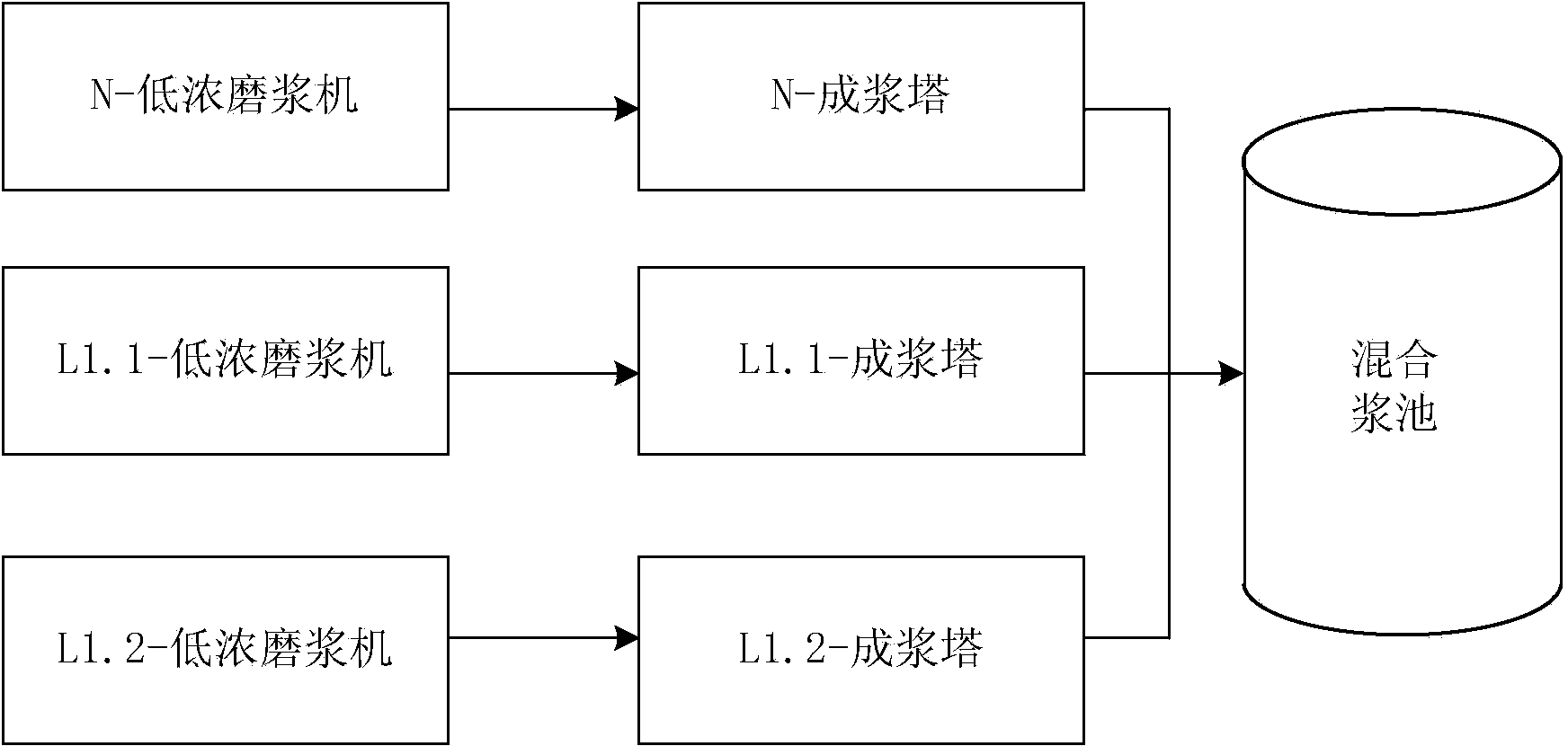

Method for making paper

ActiveCN103952940AStrong shear resistanceGood bindingNon-fibrous pulp additionNatural cellulose pulp/paperPhysical strengthChemistry

The invention discloses a method for making paper. The method comprises the following steps: preparing a sizing agent of certain concentration, adding ultra-high molecular weight cationic polyacrylamide of which the molecular weight is 8000K-30000KDa into the sizing agent, uniformly mixing to form a first mixture characterized in that positive charges covering the sizing agent, adding packing of certain concentration and with negative charges into the first mixture, uniformly mixing to form a second mixture characterized in that the sizing agent, the ultra-high molecular weight cationic polyacrylamide and the packing are wrapped with one another, adding a packing flocculating agent of which the molecular weight is 3000K-10000KDa into the second mixture so as to form a third mixture, dispensing pulp by using the third mixture and making into paper. In such a mode, the method improves the physical strength indexes such as internal aggregation and fracture resistance of the prepared paper.

Owner:GOLD EAST PAPER JIANGSU

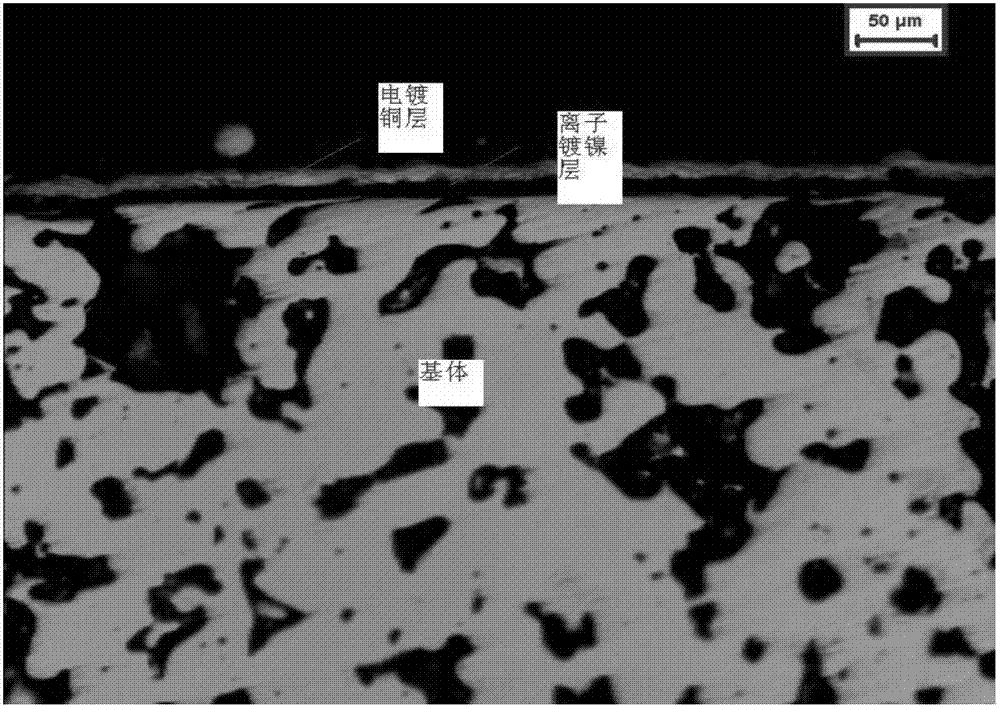

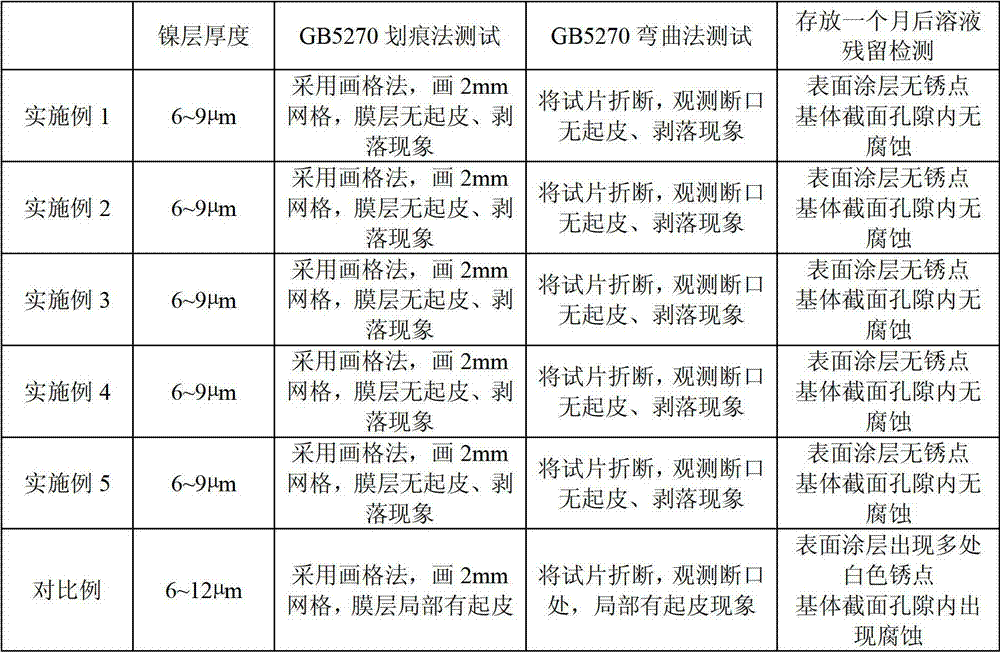

Nickel plating method of powder metallurgy porous material

ActiveCN102965626AGood bindingImprove film qualityVacuum evaporation coatingSputtering coatingIonSolvent

The invention provides a nickel plating method of a powder metallurgy porous material. The method comprises the following steps: A, utilizing a volatile organic solvent as a washing solvent to carry out ultrasonic washing on the powder metallurgy porous material; B, placing the powder metallurgy porous material into inert gas and applying an electric field to ionize the inert gas into inert gas ions; bombarding the surface of the powder metallurgy porous material by the inert gas ions; and C, adopting an electric arc ion plating method to plate nickel on the surface of the powder metallurgy porous material. According to the nickel plating method disclosed by the invention, the problems that the powder metallurgy porous material is contacted with corrosive liquid in the nickel plating process and the inner part is corroded due to that the liquid remains in pores of a base material are basically solved; and the problem that the inner part of the powder metallurgy porous material is corroded by that a washing solvent remains is further solved, the combining force of a plated nickel layer is good and the quality of a film layer is good.

Owner:CHINA HANGFA SOUTH IND CO LTD

Magnesium oxide annealing isolation agent for oriented silicon steel and coating process

The invention relates to a magnesium oxide coating process for oriented silicon steel, in particular to a magnesium oxide coating process for improving the quality of an oriented silicon steel coating. The magnesium oxide coating process comprises the following steps that firstly, magnesium oxide coating liquid is prepared according to the formula of 10-12 % of silicon steel grade MgO, 0.27-0.8% of TiO2, 0.18-0.33% of B, 0.03-0.08% of Re and the balance water; secondly, a steel strip obtained after secondary cold rolling is performed is coated with prepared magnesium oxide coating liquid through a coating machine; and thirdly, drying and coiling are performed through a drying furnace after coating. According to the magnesium oxide coating process, the rare earth elements are innovatively added to the magnesium oxide coating liquid, and through optimized configuration of different components, the rare earth elements and elements such as aluminum, magnesium and silicon in the silicon steel can well form composite oxides, and a pinning effect on the interface is played, so that the better bonding force between the bottom layer formed on the surface of the oriented silicon steel and asubstrate is improved, and the surface quality and adhesion of the oriented silicon steel are improved effectively.

Owner:新万鑫(福建)精密薄板有限公司

Preparation method for high-quality TiN thin film

InactiveCN106884142AGood uniformityGood bindingVacuum evaporation coatingSputtering coatingCorrosionTitanium

The invention discloses a method for preparing a high-quality TiN thin film, which comprises the following steps: selecting a Ti ingot to make a titanium strip through forging, rolling, heat treatment, leveling and machining; and then performing laser engraving on it, The engraved titanium strips are rolled into titanium rings with a rolling machine, and after cleaning and drying, the sputtered titanium rings are obtained; the steel sheet is used as the substrate, and the titanium ring and titanium palladium are bonded with conductive adhesive as the target material. TiN thin films were deposited on steel sheets. The invention rationally adjusts the sputtering process, so that the prepared TiN thin film is dense and uniform, has excellent wear resistance and corrosion resistance, smooth and flat surface, strong bonding force with the substrate, and good mechanical properties.

Owner:郭和谦

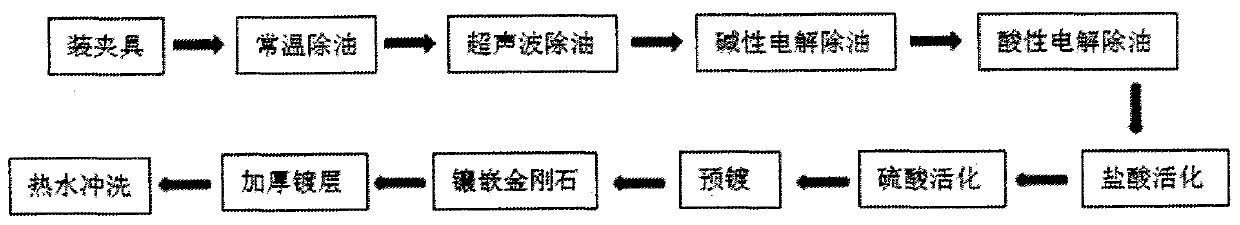

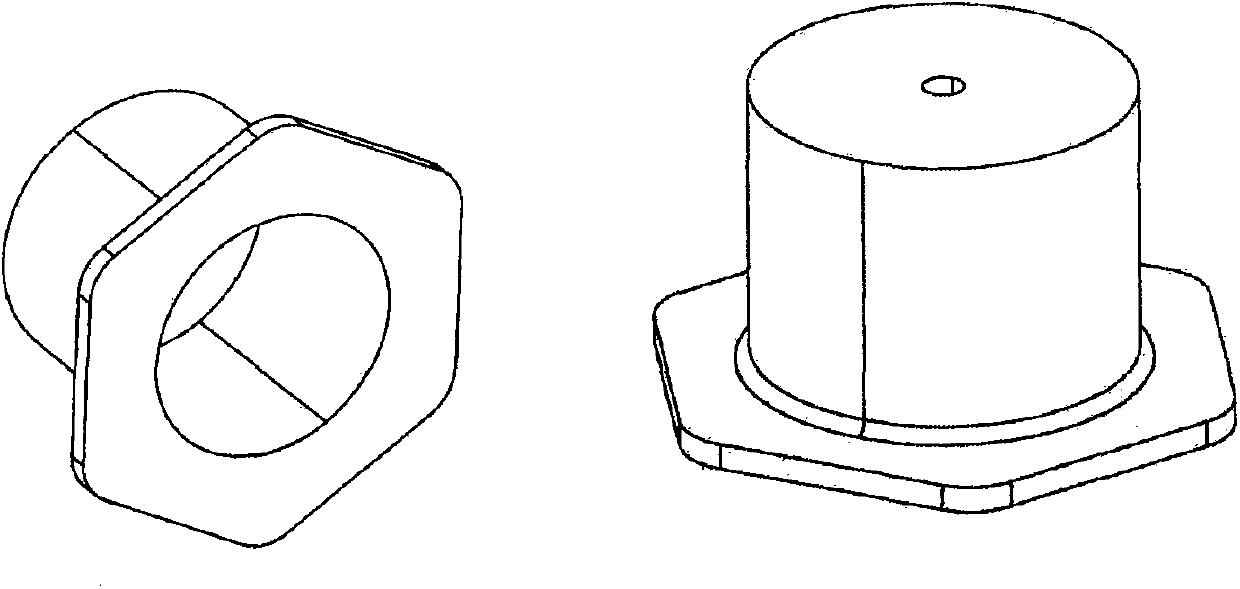

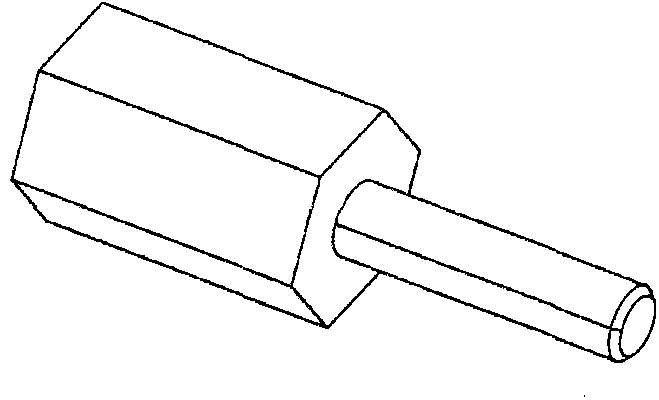

Method for manufacturing electroplating diamond grinding wheel

The invention discloses a method for manufacturing an electroplating diamond grinding wheel. The method comprises the steps of fixture assembly, normal-temperature degreasing, ultrasonic degreasing, alkaline electrolytic degreasing, acidic electrolytic degreasing, hydrochloric acid activation, sulfuric acid activation, pre-plating, diamond inlaying, coating thickening and hot water rinsing. The method disclosed by the invention improves a pre-treatment degreasing process and an activation process, and provides an optimum plating solution formula so as to improve the binding force between a coating and a matrix and increase the clamping force of the coating to a diamond, thus improving the grinding and cutting force and durability of the grinding wheel.

Owner:奚经龙

PCB plate-surface single-area local thickening copper plating production technology

InactiveCN106061127AReduce edge effectsGood bindingConductive pattern reinforcementWaxElectroless plating

The invention provides a PCB plate-surface single-area local thickening copper plating production technology. A technological process mainly comprises the following steps of (1) cleaning a copper material, wherein a cleaning fluid is a rosin oil stain cleaning fluid; (2) carrying out microetching and using NaPS to carry out microetching on bottom copper; (3) carrying out chemical electroless plating copper and immersing the PCB into a chemical plating liquid for one time so as to carry out copper plating; (4) carrying out pattern electroplating; (5) carrying out blindage, selecting a plating resistance material to be processed and then acquiring a blindage layer; (6) locally thickening the plated copper: using the blindage layer to locally thickening the plated copper; carrying out sand blast, carrying out sand blast on a copper surface so as to acquire a frosted surface; (8) spraying tin, after a sand-blast treatment, carrying out tin spraying; (9) washing, during washing, controlling a temperature and carrying out air stirring simultaneously; and (10) after plating, using boiled water to melt a blindage layer wax layer and recycling, and then using a water-soluble cleaning agent to clean. By using the technology of the invention, edge effect generation can be effectively reduced, simultaneously uniform and smooth copper layers and tin layers can be acquired, and good conductive performance of the PCB is guaranteed.

Owner:安徽广德威正光电科技有限公司

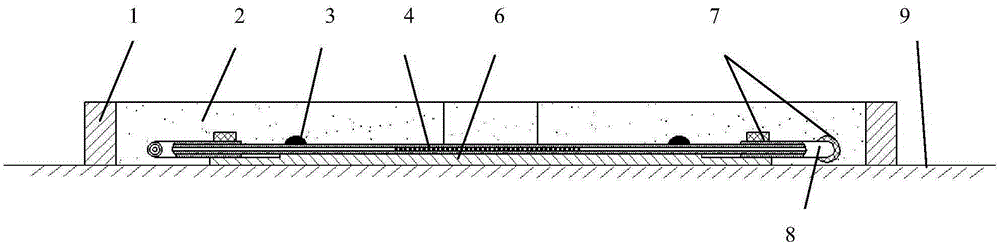

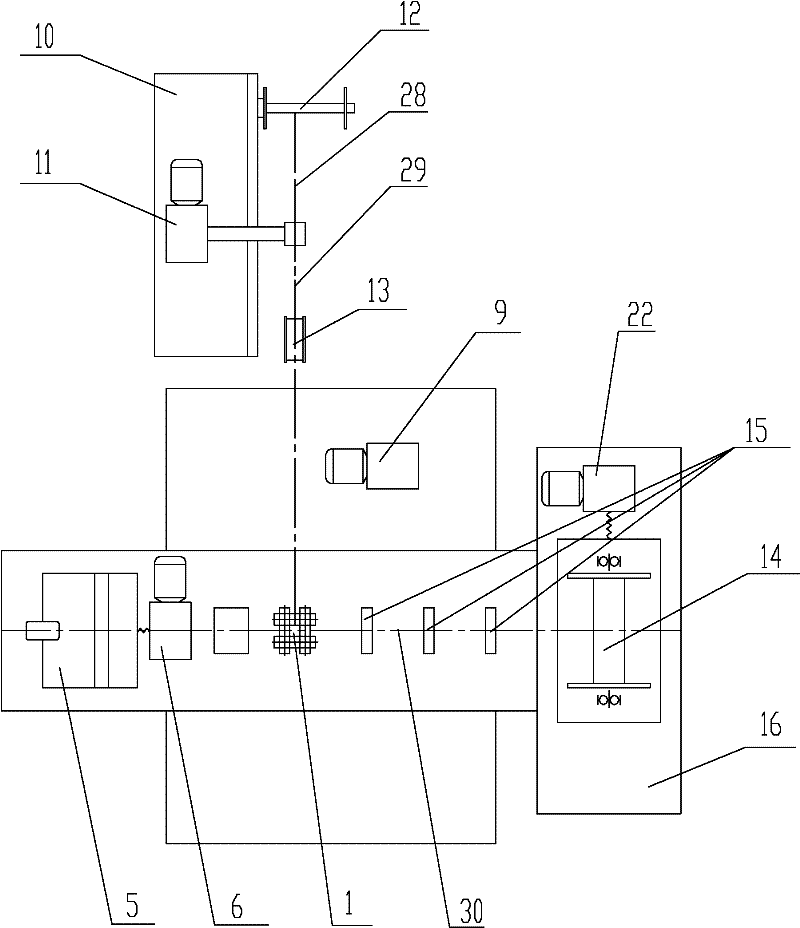

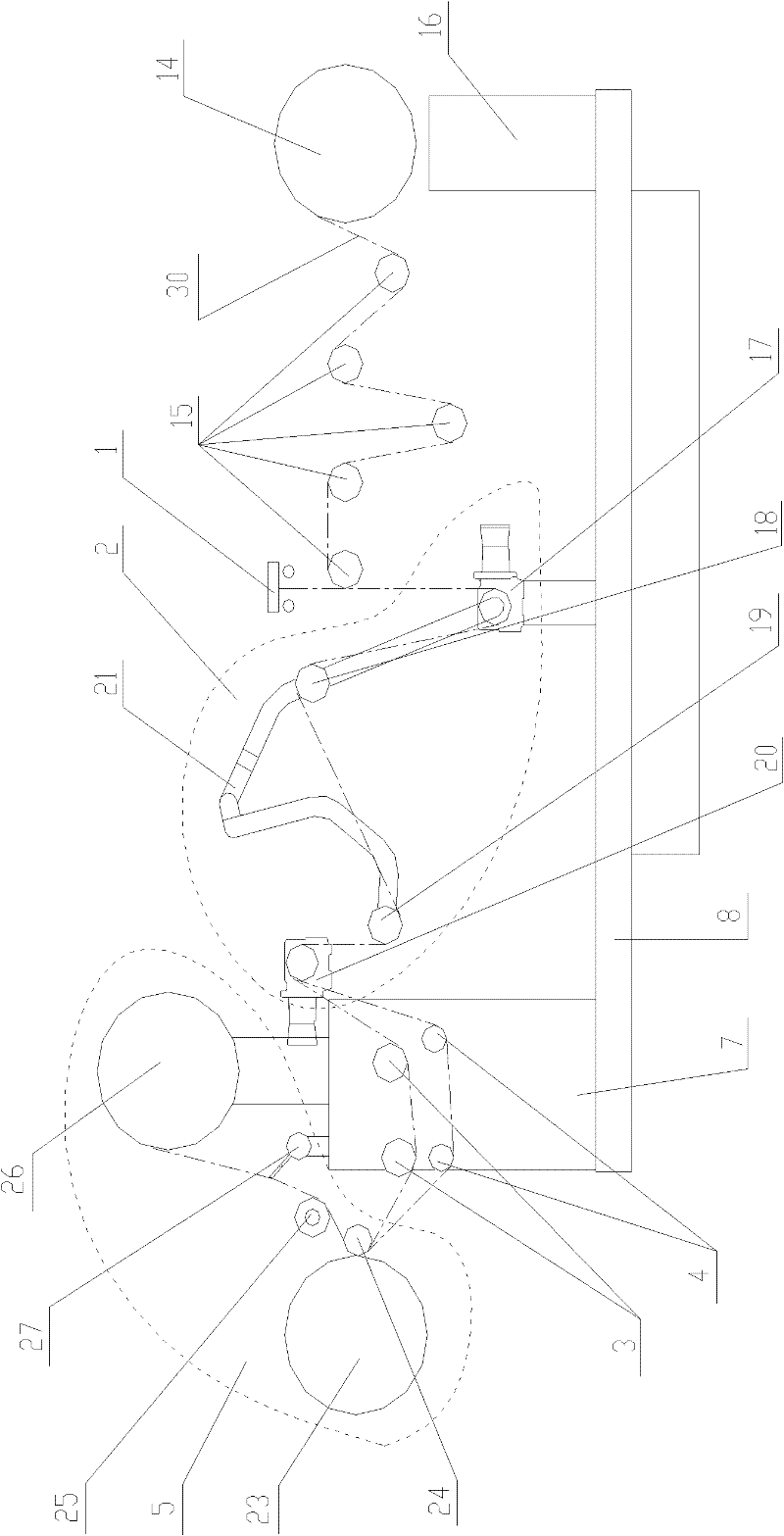

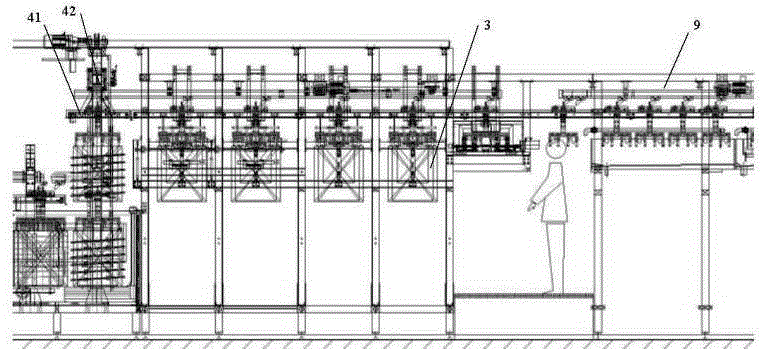

Device and method for winding belt layer of radial wire cord tire

The invention discloses a device and a method for winding a belt layer of a radial wire cord tire. The device comprises a steel wire gluing mechanism, a rubber sheet unwinding / rewinding mechanism and an attaching and winding mechanism; the steel wire gluing mechanism is arranged at the steel wire input end of the attaching and winding mechanism; the rubber sheet unwinding / rewinding mechanism is arranged at the rubber sheet input end of the attaching and winding mechanism; the method comprises the following steps of: releasing the glued steel wire by the steel wire gluing mechanism, simultaneously, releasing the rubber sheet by the rubber sheet unwinding / rewinding mechanism, conveying the glued steel wire and the rubber sheet at the same time to a winding head and winding the belt layer ona belt drum. According to the invention, one glued steel wire and one rubber sheet are attached and wound continuously in the attaching and winding process, so that the tensions of the rubber sheet and the steel wire is controlled, the belt layer is flat, the situation of concentrating the stress of the belt layer can be avoided effectively, and meanwhile, the method for continuously attaching and winding the belt layer can be realized; on the condition that the quality of the belt layer is guaranteed, the efficiency in producing the belt layer can be improved effectively and the mass production of the belt layers in industry is applicable.

Owner:桂林华工百川科技有限公司

Electroplating solution for electroplating decorative trivalent chromium on surface of electronic product

The invention discloses an electroplating solution for electroplating decorative trivalent chromium on the surface of an electronic product. The electroplating solution consists of the following components: 86-90g / L of chromium chloride, 74-78g / L of urea, 52-56g / L of ammonium bromide, 36-40g / L of sodium chloride, 12-14g / L of boric acid, 160-170ml / L of methanol, 80-100ml / L of formic acid, 0.03-0.04g / L of sodium dodecyl sulfate, 8-10g / L of iron chloride and the balance of water.

Owner:WUXI SANZHOU COLD ROLLED SILICON STEEL

Modification method for surface hydrophilization of PVC plastic

InactiveCN104073788AUniform coatingGood bindingLiquid/solution decomposition chemical coatingElectrically conductiveHydrophilization

A modification method for surface hydrophilization of PVC plastic relates to the technical field of PVC plastic preparation. The method comprises the following steps: conducting surface mucus membrane removing treatment on the PVC plastic with ethanol, soaking the treated PVC plastic in an alkali liquor to remove surface grease, carrying out surface polishing and coarsening, soaking the PVC plastic in ferric hydroxide colloid for modification treatment, and finally carrying out sensitization with a stannous chloride aqueous solution or a glucose aqueous solution. After modification, the PVC plastic has adsorptivity and can adsorb bibasic tin ions, so as to facilitate follow-up actification and copper plating. An obtained plating is uniform and is high in base body binding force. Moreover, environment-friendly requirements are met; through the adoption of the modification method, normal adhesion of a copper plating on the surface of the PVC plastic can be guaranteed, the surface is uniform, the electrical conductivity is high, and the adhesion capability is high.

Owner:YANGZHOU UNIV

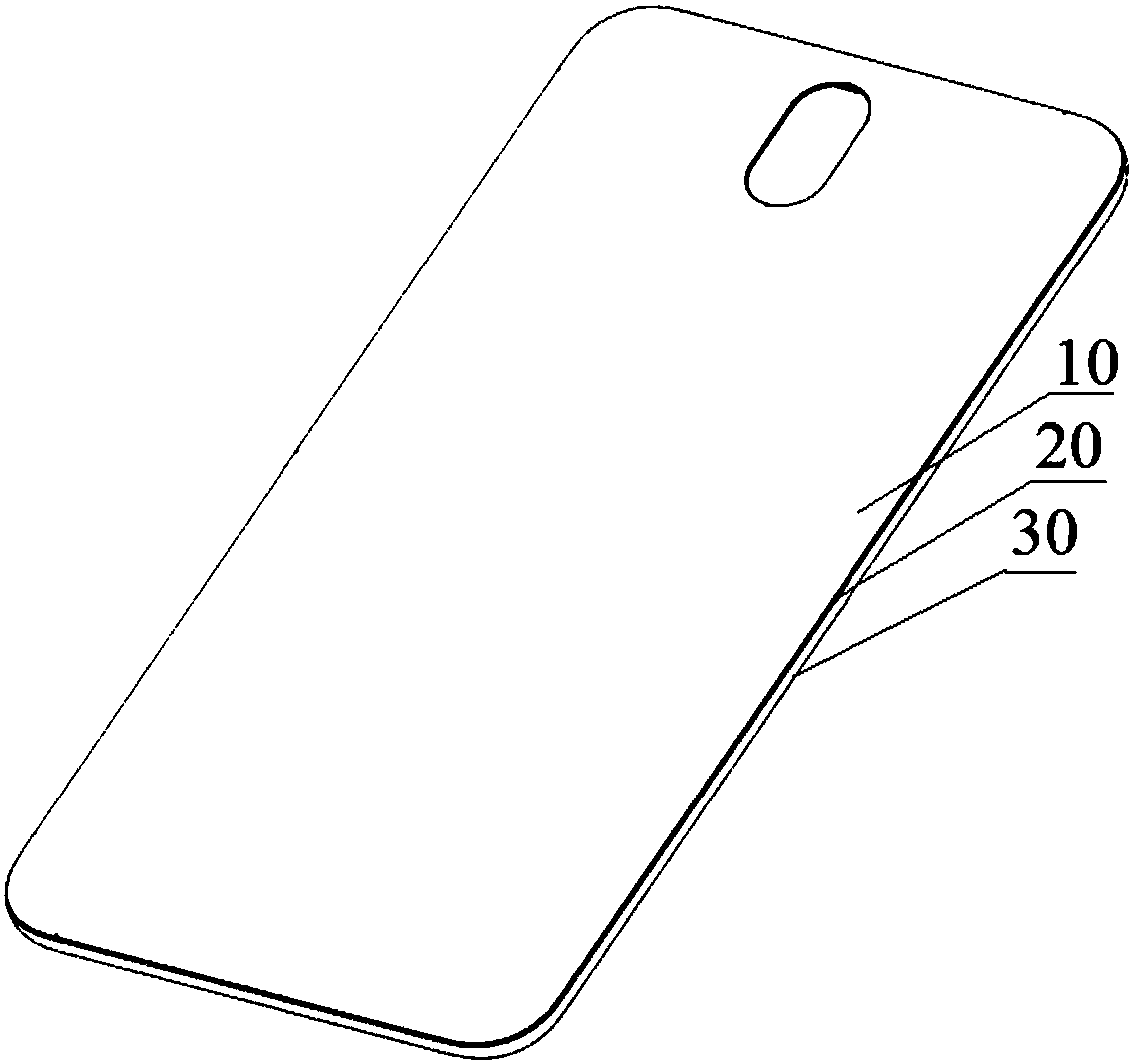

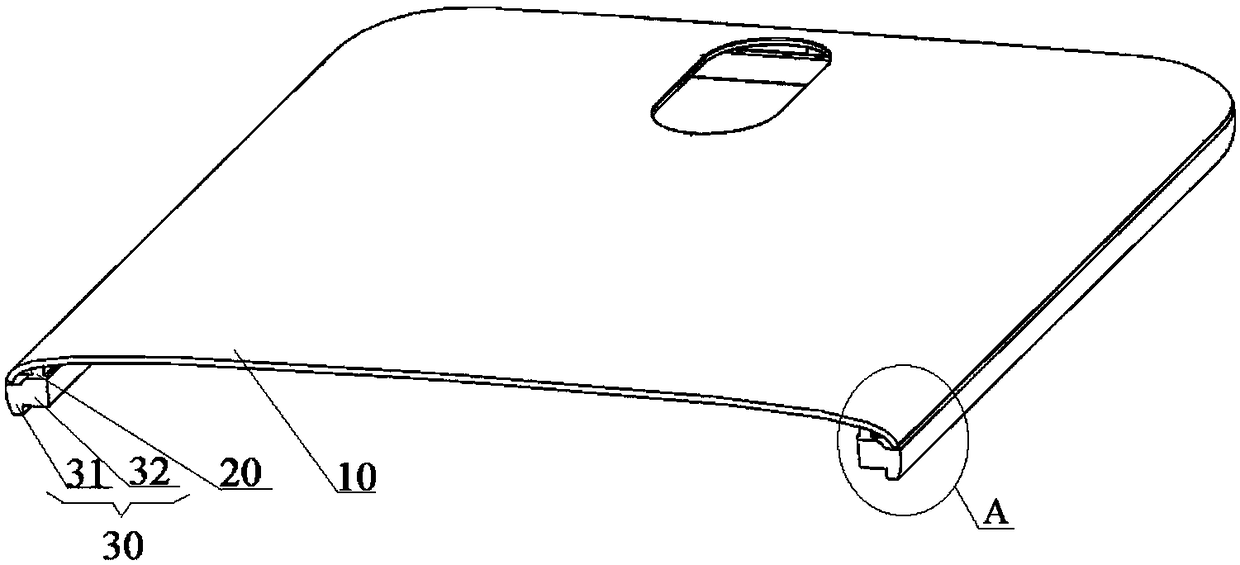

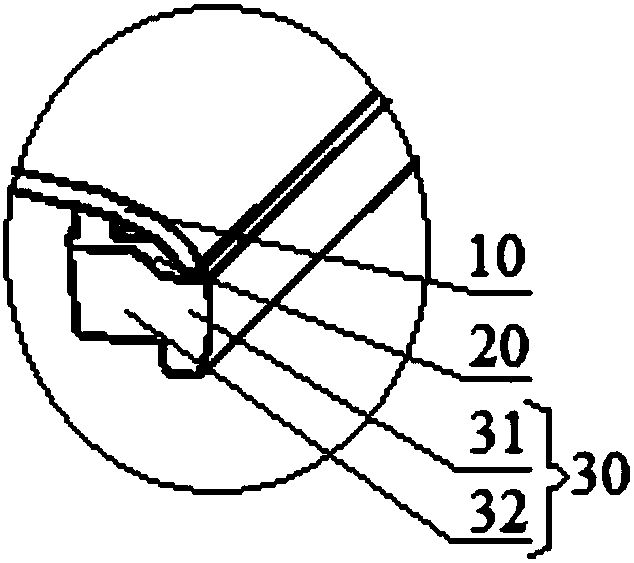

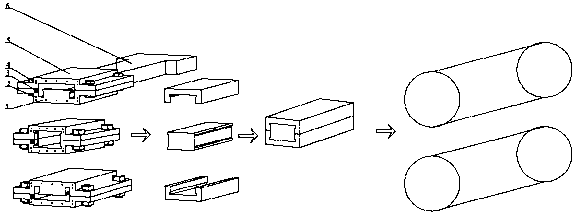

3D (Three-Dimensional) glass metal complex, preparation method thereof and electronic product

ActiveCN109429446AGood bindingReduce the risk of broken screenDigital data processing detailsCasings/cabinets/drawers detailsBinding forcePlastic cement

The invention discloses a 3D (Three-Dimensional) glass metal complex, a preparation method thereof and an electronic product. The 3D glass metal complex comprises a 3D glass cover plate, a plastic cement frame body and a metal border, wherein the upper surface of the metal border and the side surface of the 3D glass cover plate are correspondingly arranged; the plastic cement frame body is formedbetween the side surface of the 3D glass cover plate and the upper surface of the metal border; and in addition, the peripheries of the 3D glass cover plate, the plastic cement frame body and the metal border are in no-step smooth transition along the curvature of the 3D glass cover plate. The 3D glass metal complex has the advantages of good binding force, low screen breaking risk and high waterproof ability, is light and attractive and can be assembled as the cover plate with high practicality.

Owner:BYD CO LTD

Anti-mud polycarboxylate water reducer as well as preparation method and application thereof

The invention belongs to the technical field of building additives, and relates to an anti-mud polycarboxylate water reducer as well as a preparation method and application thereof. A synthetic product of an unsaturated polyether monomer and hydroxyl silicone oil is used for preparing a polycarboxylate water reducer, a siloxane structure is introduced into the end of the branched chain of the polycarboxylate water reducer molecule, the siloxane structure enables the polycarboxylate water reducer to have stronger resistance to clay, and the steric hindrance effect of the branched chains of themolecule is enhanced; secondly, an esterification product of polyethylene glycol and 4,4-stilbene dicarboxylic acid is introduced, the structure of the benzene ring enables the the branched chains ofthe molecule of the polycarboxylate water reducer to have a steric hindrance effect, and by slow condensation hydrolysis under an alkaline condition, the anti-mud and dispersing retention performancesof the obtained polycarboxylate water reducer are good.

Owner:詹烨

Preparing method and device for aluminum-magnesium-aluminum composite plate

PendingCN110842045AGood bindingReduction of Composite Interface DefectsExtrusion diesExtrusion control devicesAluminum compositesAluminium alloy

The invention discloses a preparing method and device for an aluminum-magnesium-aluminum composite plate. The preparation method includes the steps of homogenizing treatment of aluminum alloys and magnesium alloys, preparation of an I-shaped magnesium alloy blank, preparation of aluminum alloy blanks of a T-shaped cavity, stacking of the two aluminum alloy blanks to form the I-shaped cavity, extrusion of the I-shaped magnesium alloy blank into the two aluminum alloy blanks to obtain a composite blank and rolling treatment. The device is composed of a concave blank extrusion die and a convex blank extrusion die. The two sets of dies are each composed of an extrusion head, an upper die block, a lower die block, a heating device, a temperature measuring device and a fastening device; the lower die block of the concave blank extrusion die is provided with one T-shaped forming block, the convex blank extrusion die is provided with one I-shaped cavity, and the size of the I-shaped magnesiumalloy blank is slightly larger than that of the I-shaped cavity. The device is simple in structure, convenient to operate, capable of achieving three-dimensional compounding of composite materials through the aluminum alloy blanks and the magnesium alloy blank and capable of obtaining high-performance aluminum-clad magnesium composite materials.

Owner:HUNAN UNIV OF SCI & TECH

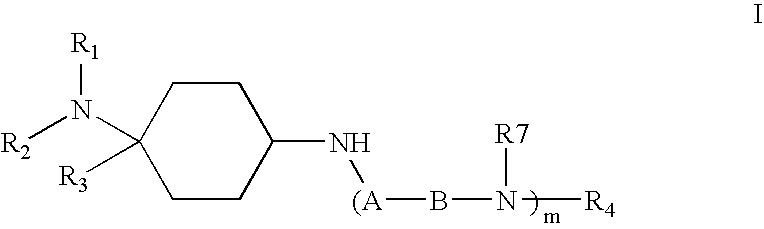

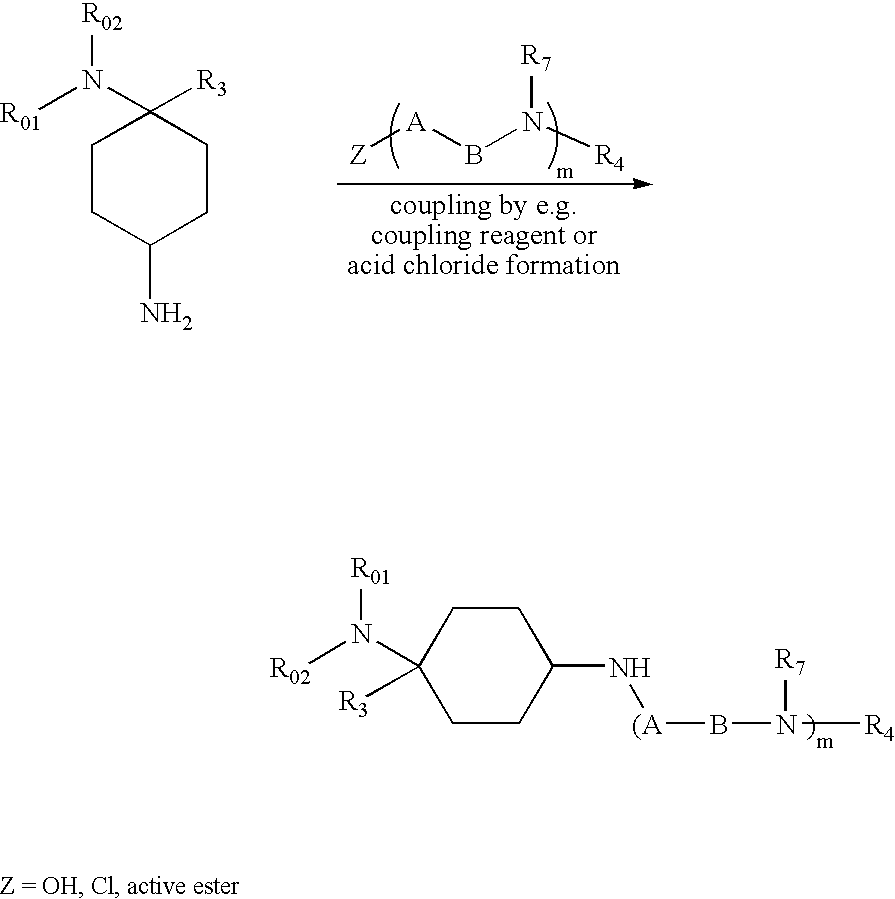

Cyclohexyl-1,4-diamine compounds

InactiveUS20070117803A1Increase vigilance and libidoGood bindingBiocideSenses disorderDiamineMedicinal chemistry

Novel cyclohexyl-1,4-diamine compounds corresponding to formula I, processes for the production thereof, pharmaceutical compositions containing these compounds, methods of producing pharmaceutical compositions including these compounds and related methods of treating or inhibiting certain diseases or conditions.

Owner:GRUNENTHAL GMBH

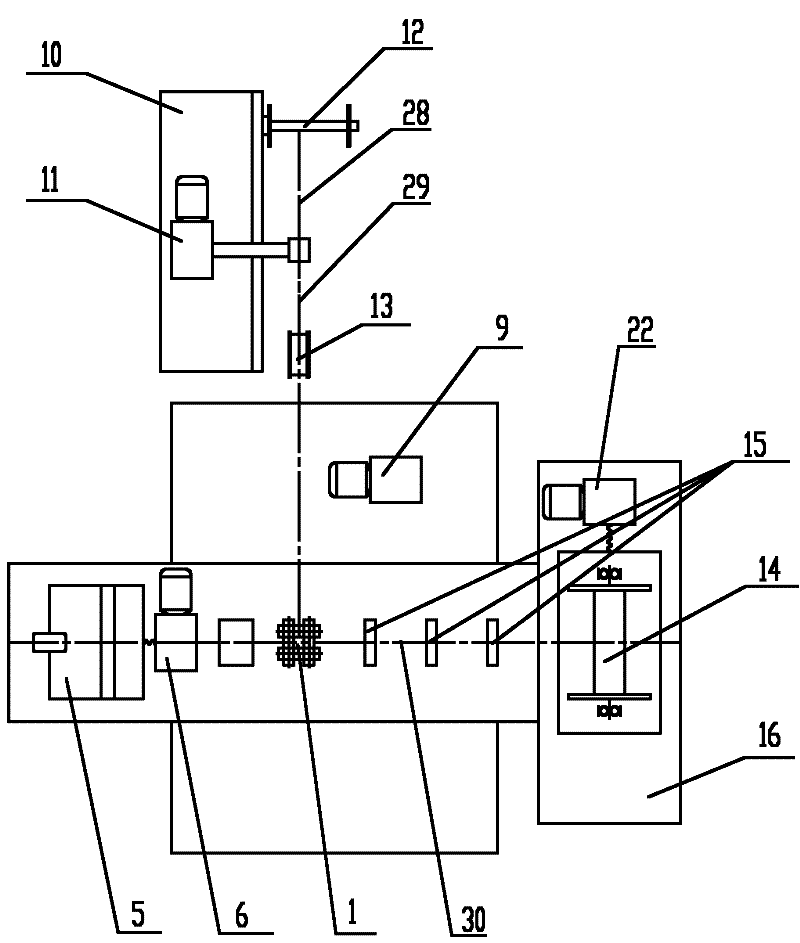

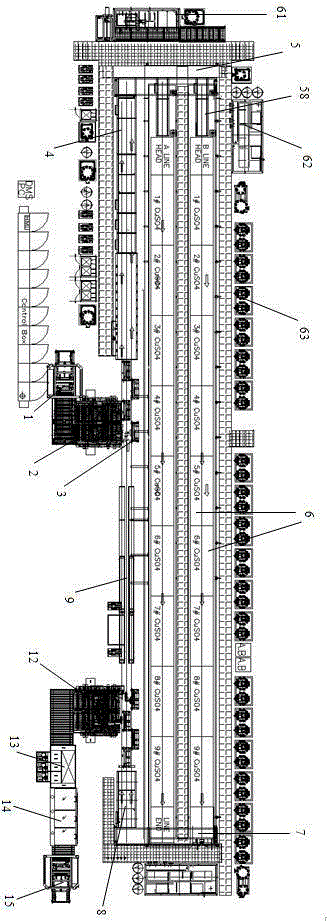

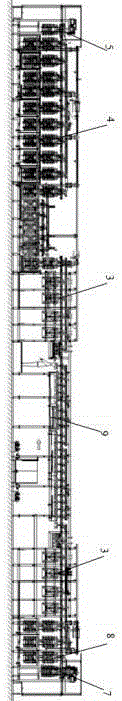

Vertical continuous electroplating hole filling line

PendingCN106637371AGood hole filling abilityGood bindingSemiconductor devicesPre treatmentEngineering

The present invention provides a vertical continuous electroplating hole filling line for PCB board processing. The vertical continuous electroplating hole filling line comprises a plurality of sub-lines arranged in a side-by-side manner, and is characterized in that each sub-line comprises a material feeding mechanism, a pretreatment device, a front shifting device, an electroplating pretreatment device, a multi-stage electroplating copper cylinder, a rear shifting device, a post-treatment device and a deplating device, wherein the material feeding mechanism, the pretreatment device, the front shifting device, the electroplating pretreatment device, the multi-stage electroplating copper cylinder, the rear shifting device, the post-treatment device and the deplating device are sequentially connected, the material inlet end of the material feeding mechanism is connected to an automatic plate feeding device, the material inlet end of the automatic plate feeding device is provided with a plate feeding conveying belt, and the material outlet end of the post-treatment device is sequentially connected to a central positioning machine, a corner turning machine, a horizontal plate drying machine and an automatic plate collection device. According to the present invention, with the vertical continuous electroplating hole filling line, the thickness uniformity of the plating layer at blind holes, buried holes and other hole filling positions of the high density circuit board, the deep plating ability, the hole filling ability and the bonding force are good, the shape is beautiful, the consistency of the hole wall plating layer and the plate surface plating layer is good, the operation, the maintenance and the repair are convenient, the structure is compact, the occupation space is small, the generated waste gas is less, and the environmental protection advantage is provided.

Owner:DONGGUAN CRAY AUTOMATION TECH

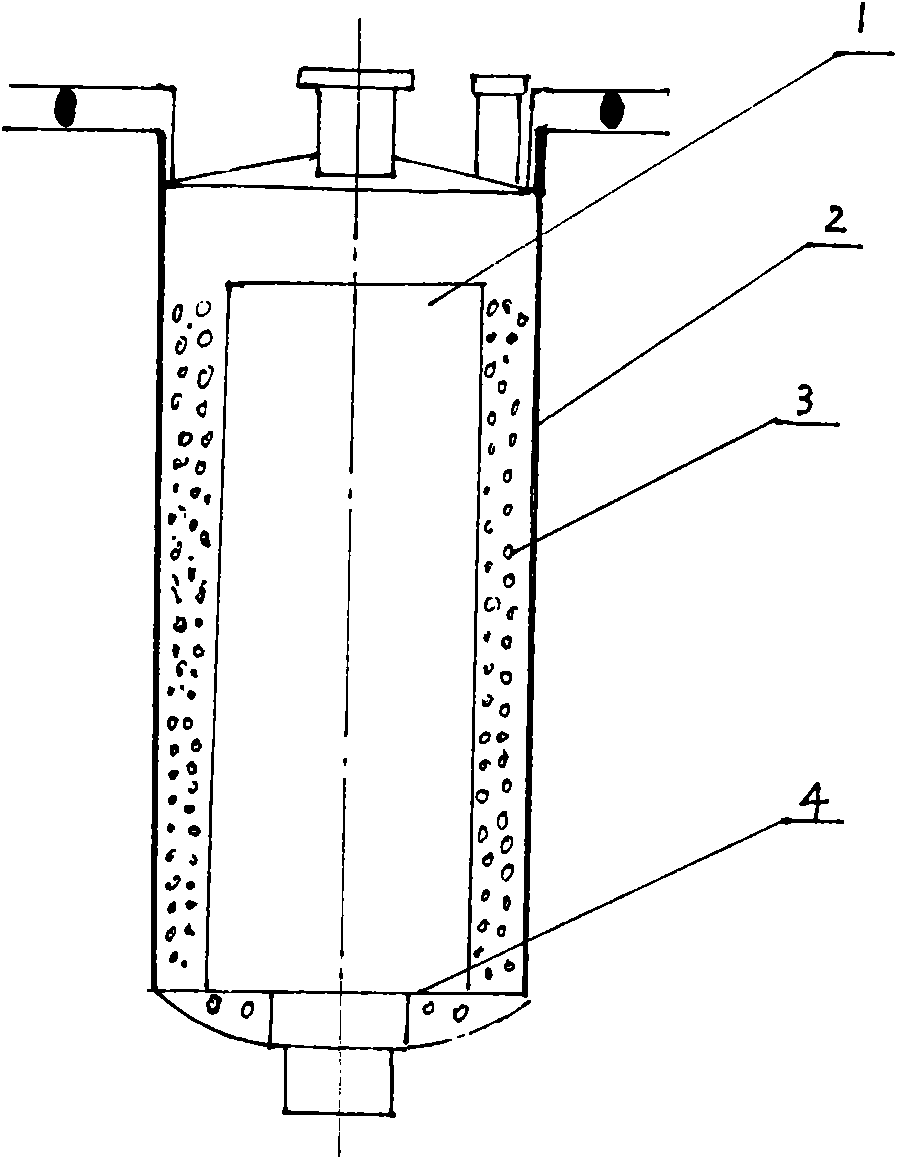

Method for titanizing inner wall of new reactor in production of titanium sponge

ActiveCN101676431ADense titanium coatingGood bindingVacuum evaporation coatingSputtering coatingCarbon steelBinding force

The invention provides a method for titanizing an inner wall of a new reactor in the production of titanium sponge, which is characterized in that the method comprising the following steps: (1) carrying out leakage detecting, acid pickling, washing and drying on the new reactor; (2) internally installing a stainless steel or carbon steel sleeve, leaving a space between the sleeve wall and the reactor wall, smashing the titanium sponge or the waste titanium until the granularity is greater than 0mm and less than or equal to 50mm, and filling the smashed titanium sponge or waste titanium into the space between the reaction wall and the sleeve; (3) configuring the reactor and a condenser, entering a furnace and pumping the vacuum; and (4) degassing for 2-5 hours at the temperature of 100-200DEG C, degassing for 2-5 hours at the pressure of less than 100Pa and the temperature of 300-400 DEG C, finally stopping heating at the temperature of 900-975 DEG C, the pressure of less than 30Pa andafter maintaining a constant temperature for 10-20 hours, reducing the temperature, cooling to room temperature and dismantling the furnace. The invention has the advantages that compared with the processing methods of the new reactors by utilizing the titanium powder water aqua method, titanium powder medicinal extract method or titanium hydride method, the titanizing layer obtained by the method in the invention is compact, has good binding force with the base body, and can completely block the pollution of the reactor iron on the titanium sponge. After adopting the invention, in the reduction-distillation process in the production of the titanium sponge, the average content of iron in the new reactor products is lowered to below 0.06% from 0.15%, and the invention also has the advantages of simple method, easy operation, low cost, high efficiency and wide application range.

Owner:CHAOYANG BAISHENG TITANIUM IND CO LTD +1

Method for preparing damping vibration attenuation composite coating on surface of rotary machine thin-shell component

InactiveCN103572221AGood bindingImprove dynamic stiffnessVacuum evaporation coatingSputtering coatingThin shellsRotary machine

The invention provides a method for preparing a damping vibration attenuation composite coating on the surface of a rotary machine thin-shell component, and belongs to the technical field of materials. The method comprises the following steps of (1) by utilizing the rotary machine thin-shell component as a base body, putting the base body in a vacuum chamber of a filtering electric arc ion plating machine; (2) preheating the base body after vacuumizing; (3) charging argon, starting the filtering electric arc ion plating machine, and depositing a titanium coating on the surface of the base body; (4) depositing a Ni60Cr33.7Al4.5Y1.8 alloy coating on the surface of the titanium coating; (5) depositing a magnesium aluminum alloy coating on the surface of the Ni60Cr33.7Al4.5Y1.8 alloy coating to prepare the damping vibration attenuation composite coating on the surface of the base body. The method for preparing the damping vibration attenuation composite coating further has the following characteristics that the pretreatment on the base body does not break the surface structure of a blade; the influence of the low preheating temperature on the structural characteristics of the material of the blade is small; the selected materials of the coating are common without being limited by conditions, such as purchase; the technique is simple, the stability is high, and no pollutants, such as dust and waste gas, in a cleaning process are generated.

Owner:NORTHEASTERN UNIV

Preparation method of chemical nickel-plating solution

InactiveCN105586579AFine electroless nickel platingGood bindingLiquid/solution decomposition chemical coatingChemistryCompound (substance)

The invention provides a preparation method of a chemical nickel-plating solution. The preparation method includes the steps of coursing, sensitizing, activating and nickel plating. The preparation method is simple in process. The chemical nickel-plating solution which is prepared through the method and is high in stability and long in service life has relatively stable chemical nickel plating performance and is long in service life, and meanwhile the crystallization of a product obtained through chemical nickel plating is more delicate.

Owner:CHANGDE LYRUN MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com