Nickel plating method of powder metallurgy porous material

A porous material, powder metallurgy technology, applied in the field of PVD surface treatment, can solve the problems of poor adhesion between the nickel layer and the substrate, corrosion of parts, etc., to improve adhesion and film quality, increase cleanliness, and high film quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

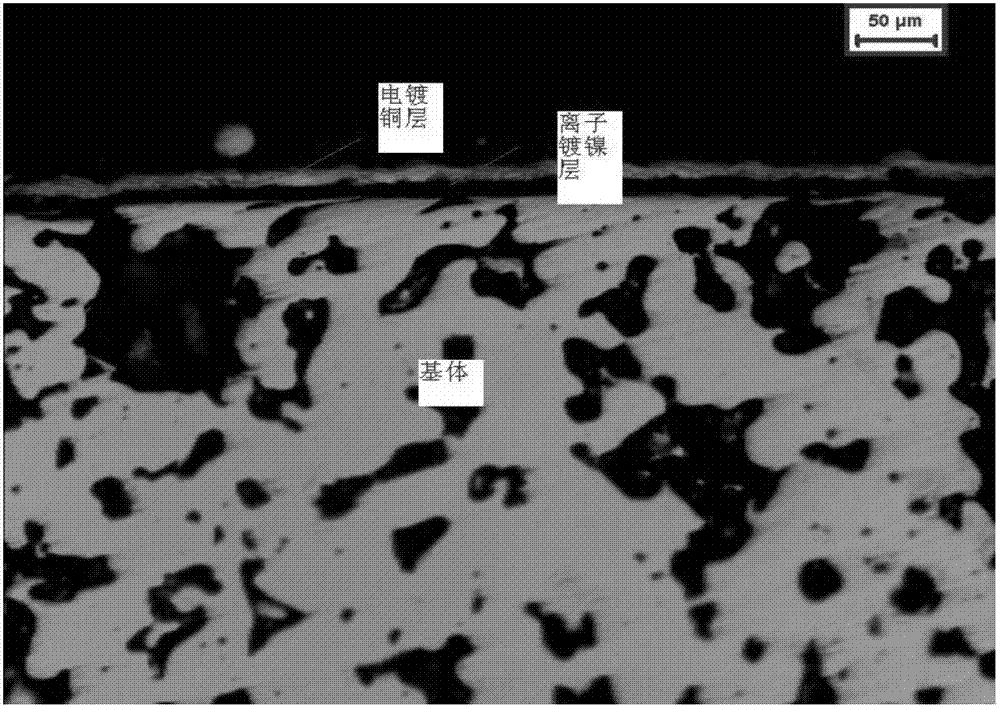

Image

Examples

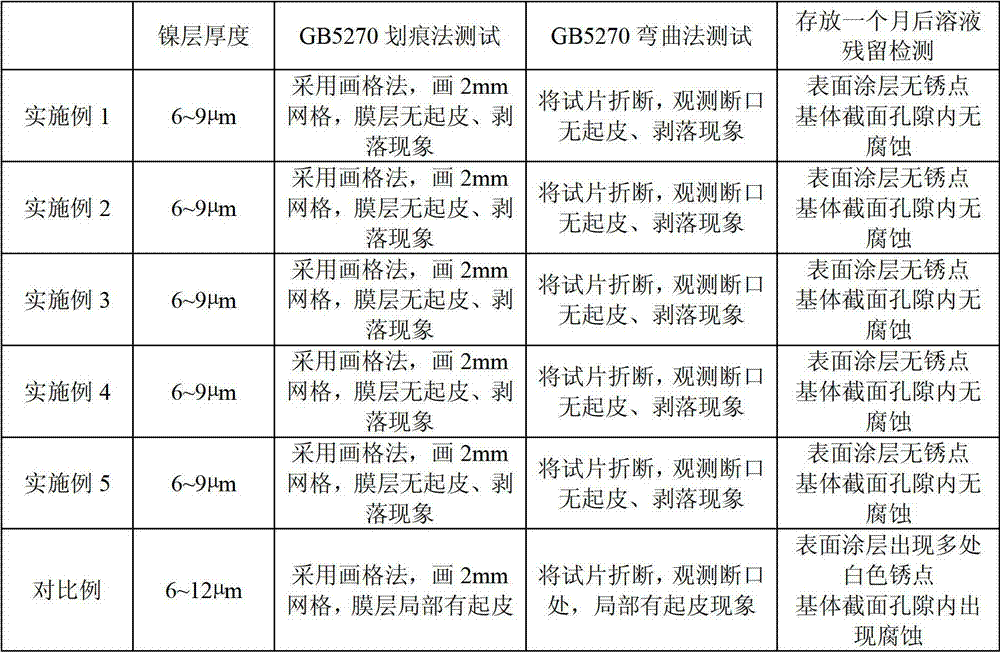

Embodiment 1

[0033] Select the powder metallurgy porous material part as the part to be plated.

[0034] Absolute ethanol was used as the cleaning solvent, and the parts to be plated were cleaned ultrasonically, the ultrasonic power was 1.5kW, and the ultrasonic frequency was 10kHz. Dry after ultrasonic cleaning.

[0035] Put the parts to be plated into the furnace, evacuate the furnace, fill the argon gas to make the pressure of the argon gas reach 2Pa, apply an electric field with a bias voltage of 1000V to ionize the argon gas into argon ions, and the argon ions bombard the surface of the parts to be plated, Perform ion cleaning.

[0036] Use the arc ion plating method to plate nickel on the surface of the parts to be plated. The arc current used is 80A. First, the voltage is set to 800-1000V. The pressure of the inert gas in the furnace is controlled at 0.1-0.2Pa, and nickel is plated on the surface of the powder metallurgy porous material. Bottom layer; then set the voltage to 50-80...

Embodiment 2

[0038] Select the powder metallurgy porous material part as the part to be plated.

[0039] Absolute ethanol was used as the cleaning solvent, and the parts to be plated were cleaned ultrasonically, with an ultrasonic power of 2.0kW and an ultrasonic frequency of 10kHz. Dry after ultrasonic cleaning.

[0040] Put the parts to be plated into the furnace, evacuate the furnace, fill the argon gas to make the pressure of the argon gas reach 1Pa, apply an electric field with a bias voltage of 900V to ionize the argon gas into argon ions, and the argon ions bombard the surface of the parts to be plated, Perform ion cleaning.

[0041] Use the arc ion plating method to plate nickel on the surface of the parts to be plated, set the arc current to 70A, first set the voltage to 800-1000V, control the pressure of the inert gas in the furnace at 0.1-0.2Pa, and plate nickel on the surface of the powder metallurgy porous material Bottom layer; then set the voltage to 50-800V, control the pre...

Embodiment 3

[0043] Select the powder metallurgy porous material part as the part to be plated.

[0044] Absolute ethanol was used as the cleaning solvent, and the parts to be plated were cleaned ultrasonically. The ultrasonic power was 1.8kW, and the ultrasonic frequency was 15kHz.

[0045] Put the parts to be plated into the furnace, evacuate the furnace, fill the argon gas to make the pressure of the argon gas reach 3Pa, apply an electric field with a bias voltage of 1100V to ionize the argon gas into argon ions, and the argon ions bombard the surface of the parts to be plated, Perform ion cleaning.

[0046] Use the arc ion plating method to plate nickel on the surface of the parts to be plated. The arc current used is 100A. First, the voltage is set to 800-1000V. The pressure of the inert gas in the furnace is controlled at 0.1-0.2Pa, and nickel is plated on the surface of the powder metallurgy porous material. Bottom layer; then set the voltage to 50-800V, control the pressure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com