Vertical continuous electroplating hole filling line

A vertical continuous electroplating and hole line technology, applied in the direction of circuits, semiconductor devices, etc., can solve the problems of weak bonding between the coating and the substrate, uneven coating thickness, uneven appearance of filling holes, etc., and achieve compact structure and good thickness consistency , beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

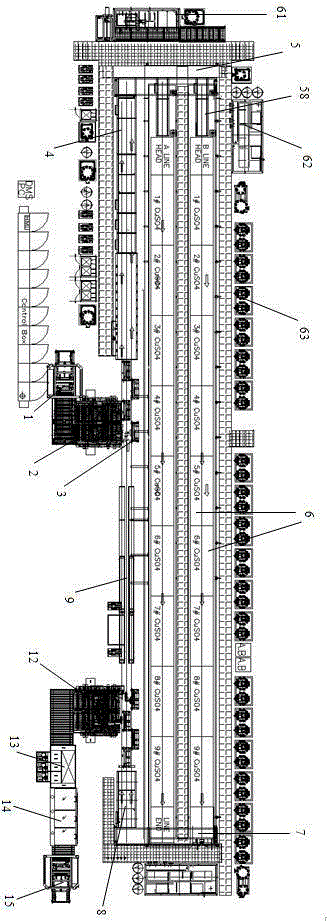

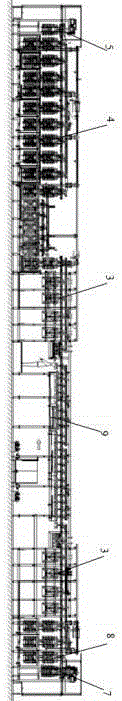

[0030] Such as figure 1 with figure 2 As shown, the vertical continuous electroplating filling line provided by the present invention includes several sub-lines arranged side by side. 5. Electroplating pretreatment device 58, several stages of electroplating copper cylinders 6, post-transfer device 7, post-processing device 8 and deplating device 9, this embodiment adopts two sub-lines of A line and B line arranged in parallel and the above-mentioned The devices are sequentially connected in a ring, obviously, the filling line can also be distributed in a linear or other form to the devices.

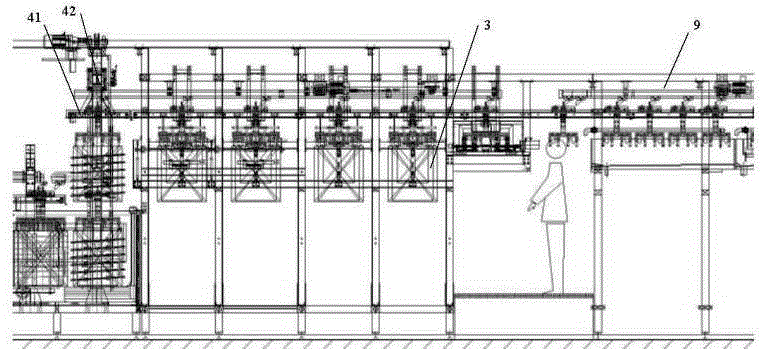

[0031] Such as image 3 with Figure 5 As shown, the pre-processing device 4 includes a feeding mechanism, an oil removal mechanism and a grading pre-processing mechanism. Synchronous operation, the feeding mechanism includes a guide post A2 and a guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com