Patents

Literature

103results about How to "Good thickness consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

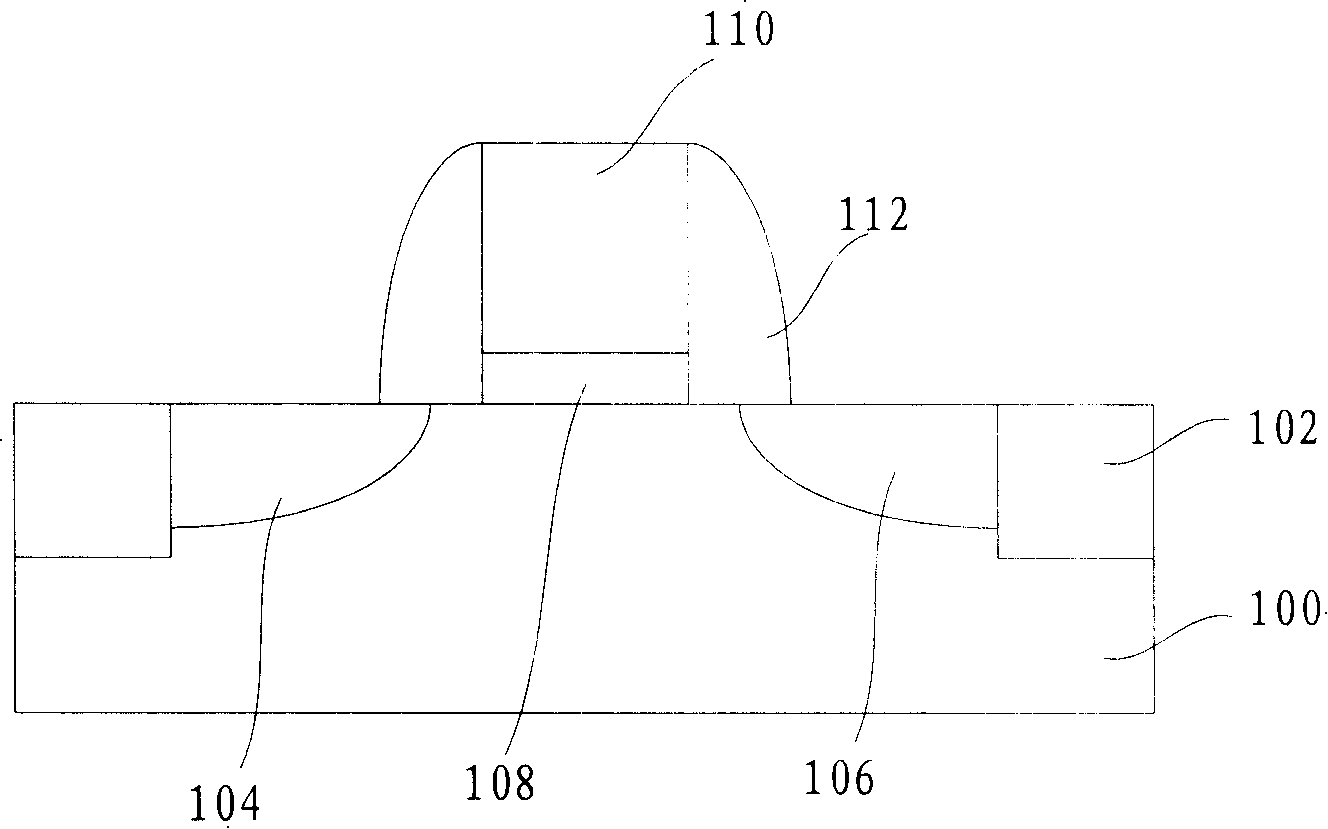

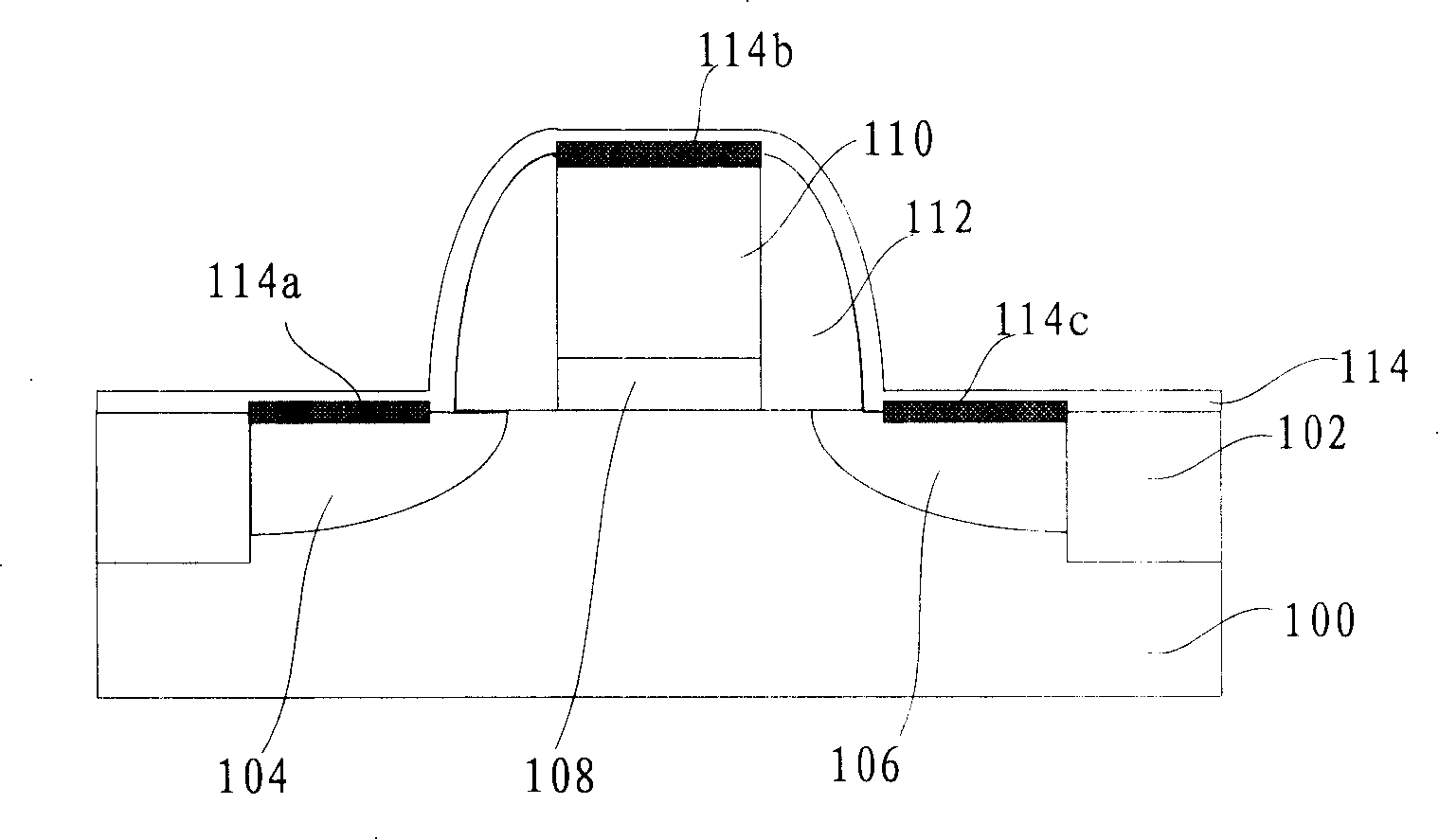

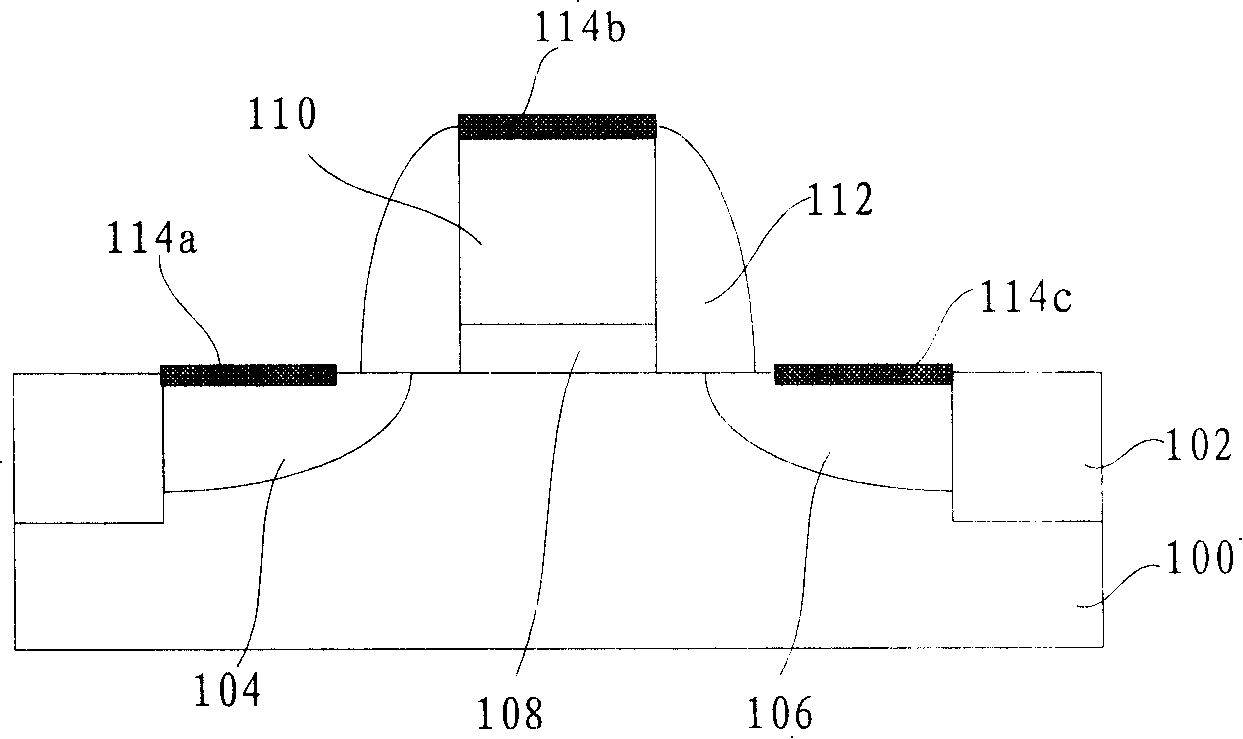

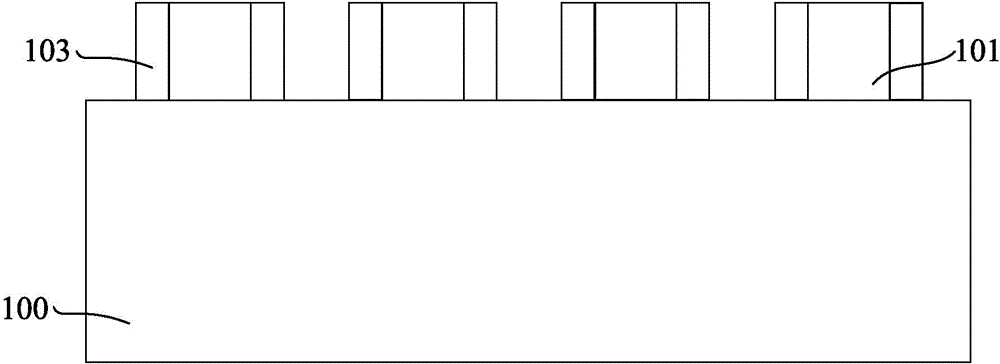

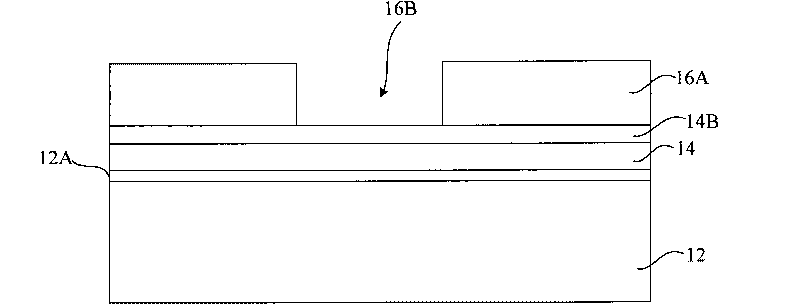

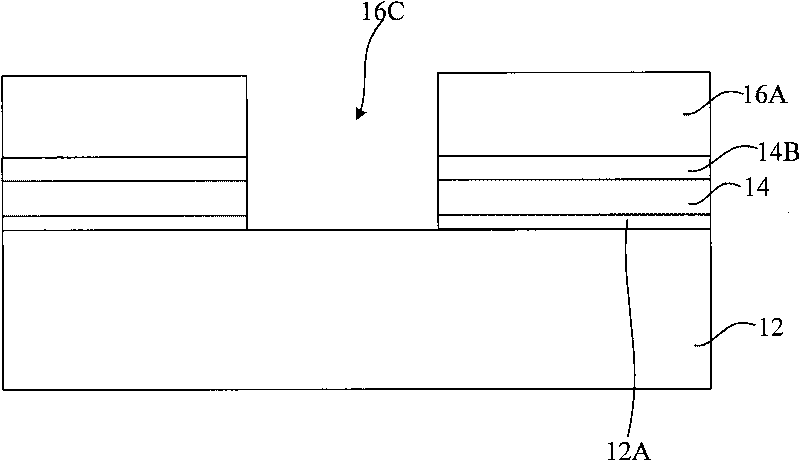

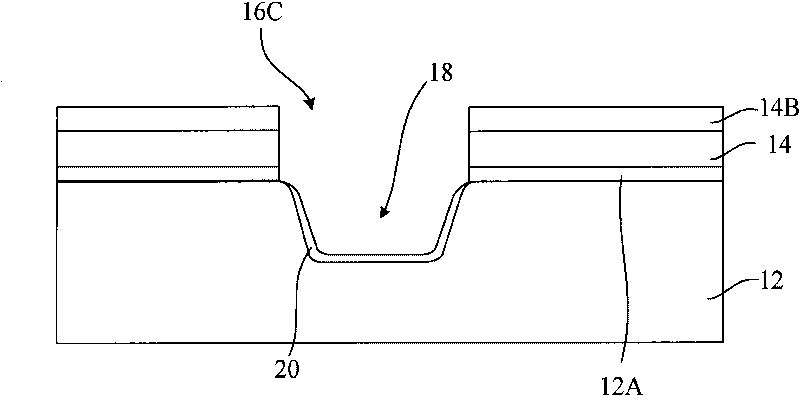

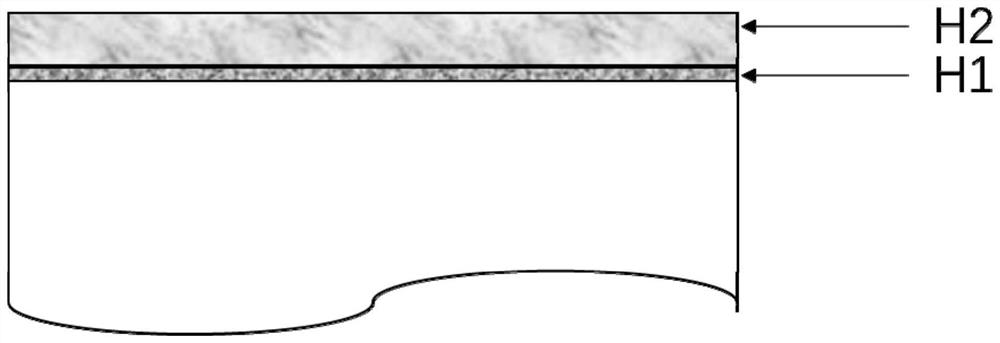

Shield gate trench MOSFET and manufacturing method thereof

InactiveCN108039369AElimination of sharp corner defectsEliminate leaksSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceTrench mosfet

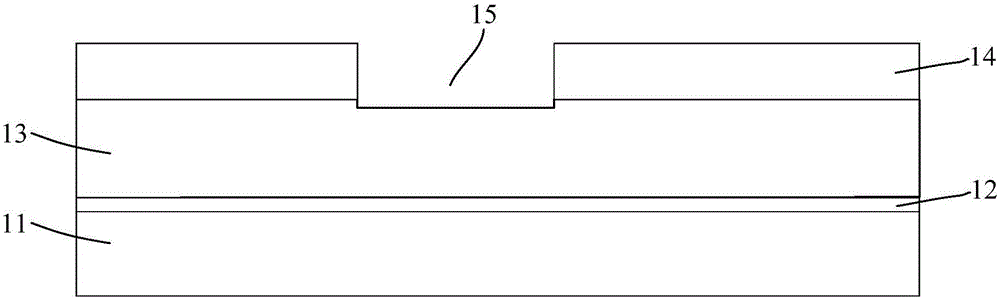

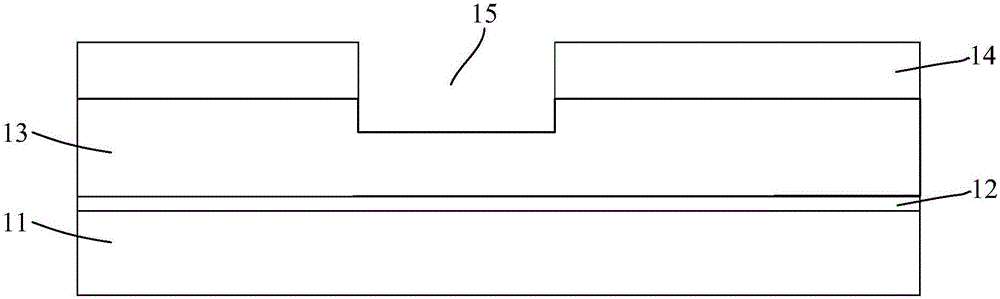

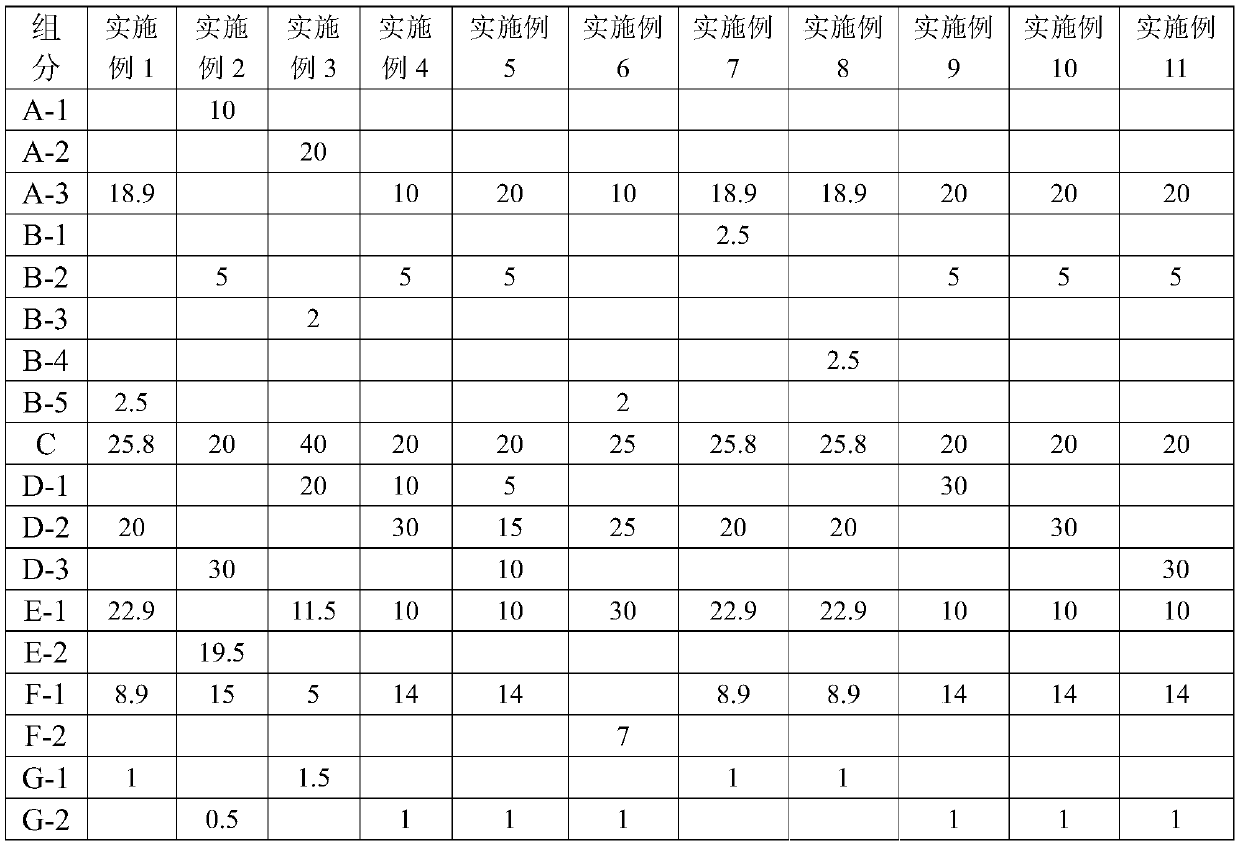

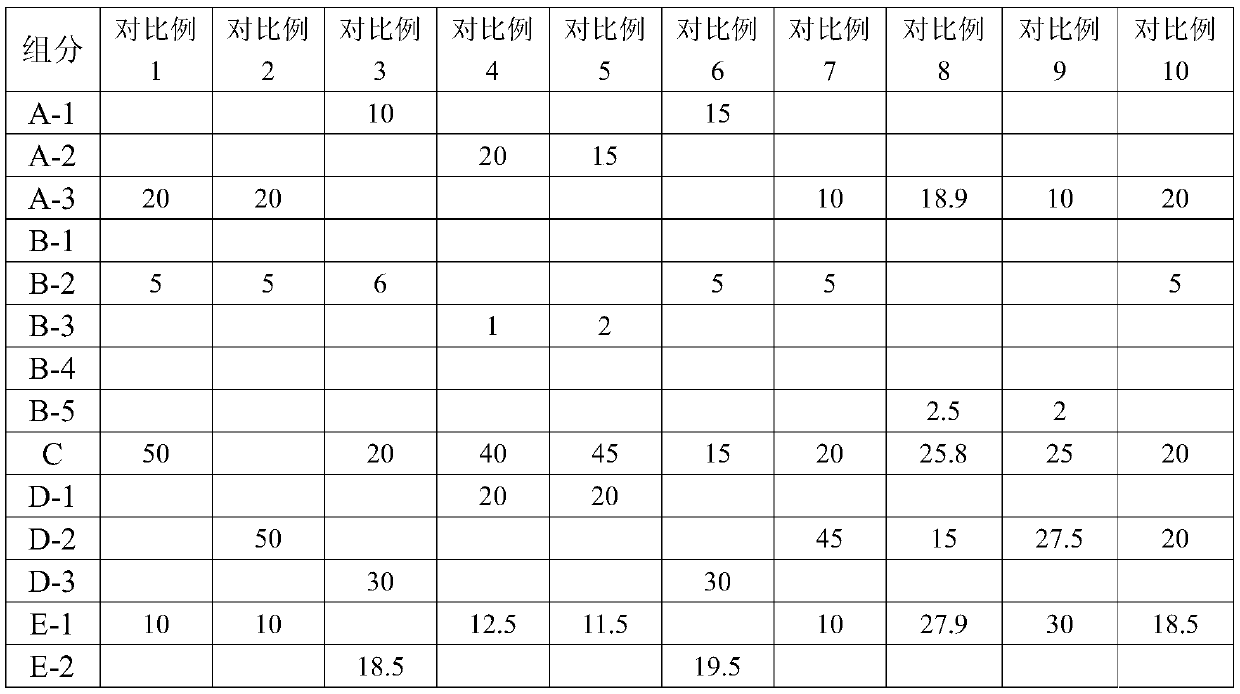

The invention discloses a shield gate trench MOSFET. A bottom oxide layer is formed on the side surface and the bottom surface of the trench of a gate structure, and shield polysilicon totally fills the trench; under self-alignment definition of the bottom oxide layer, the shield polysilicon is etched back to the bottom part of the trench in a self-alignment mode; the surface of the shield polysilicon after self-alignment etching back is oxidized to form an inter-polysilicon isolated oxide layer; after the inter-polysilicon isolated oxide layer is formed, the bottom oxide layer is etched backto the bottom part of the trench, the bottom oxide layer after etching back and the inter-polysilicon isolated oxide layer surround the shield polysilicon, and a top trench is formed at the top part of the trench; and the side surface of the top trench is provided with a gate oxide layer and is filled with polysilicon gate. The invention also discloses a manufacturing method for the shield gate trench MOSFET. Gate source electric leakage of the device can be reduced while the threshold voltage of the device is reduced, the thickness consistency of the inter-polysilicon isolated oxide layer canbe improved, and the capacitor corresponding to the inter-polysilicon isolated oxide layer is stable and controllable.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

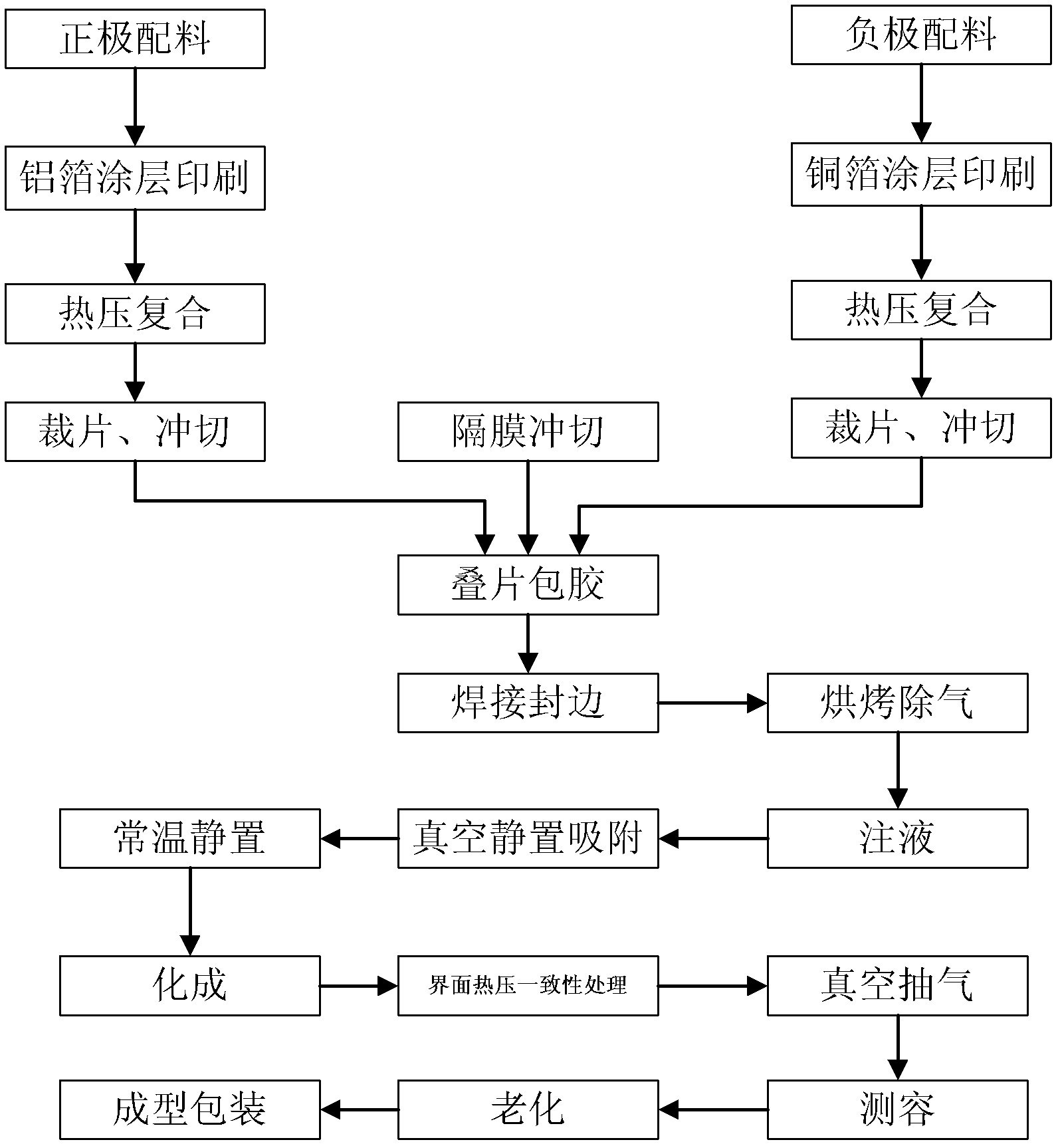

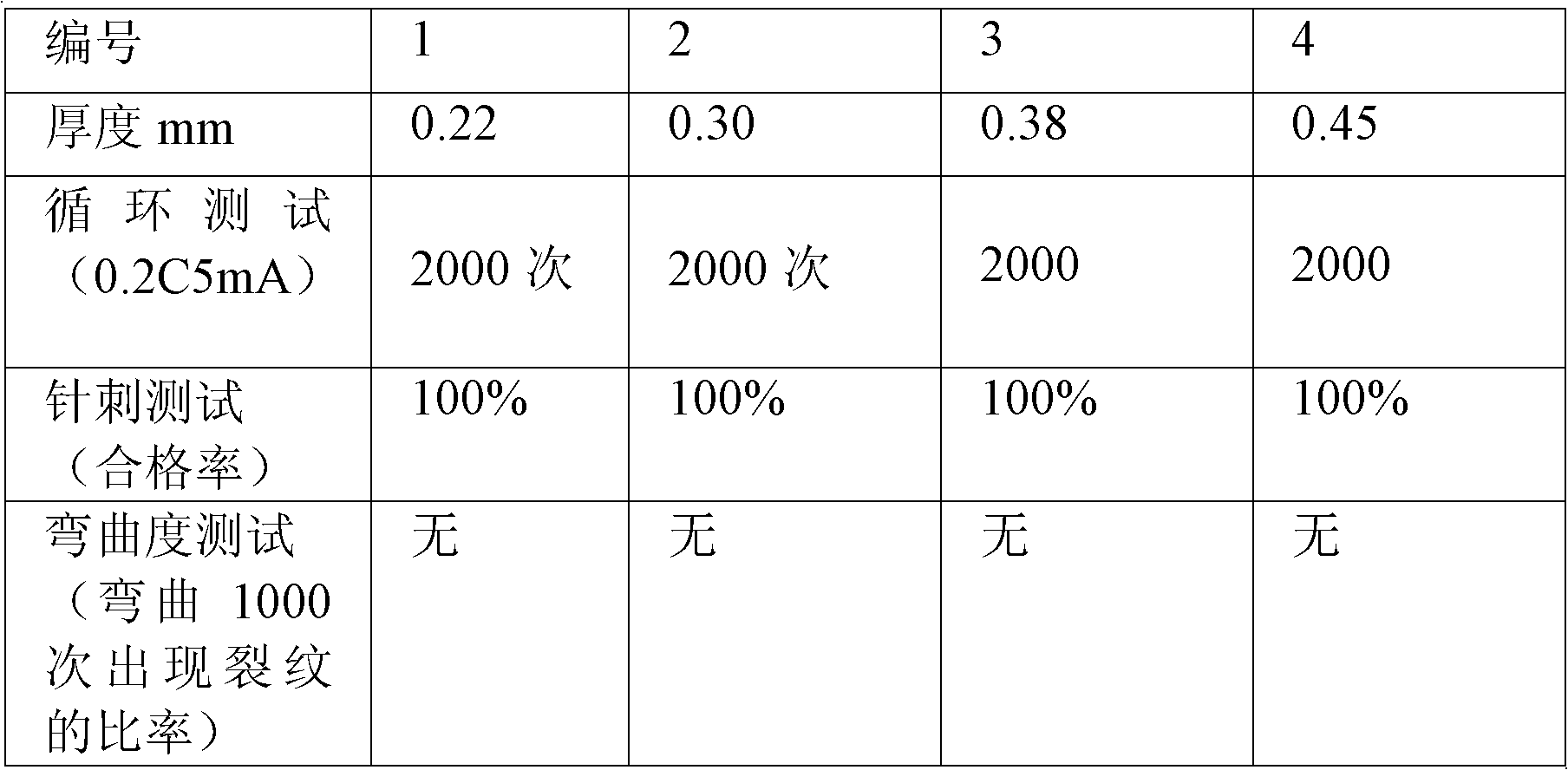

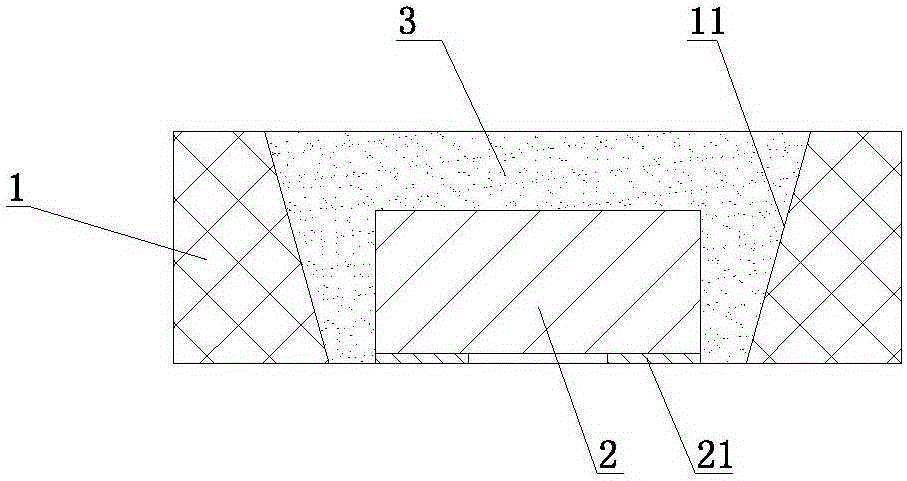

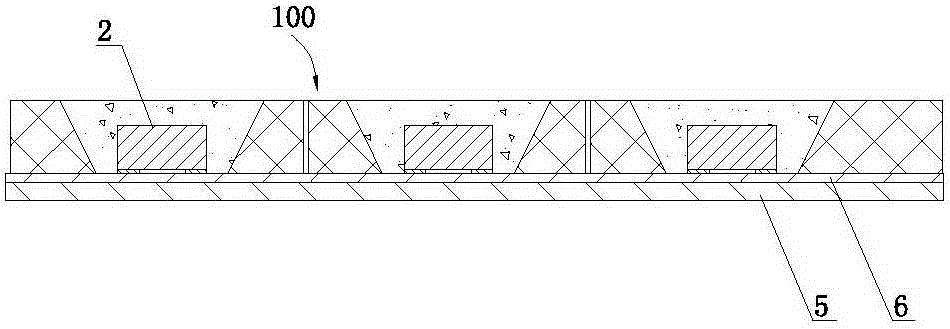

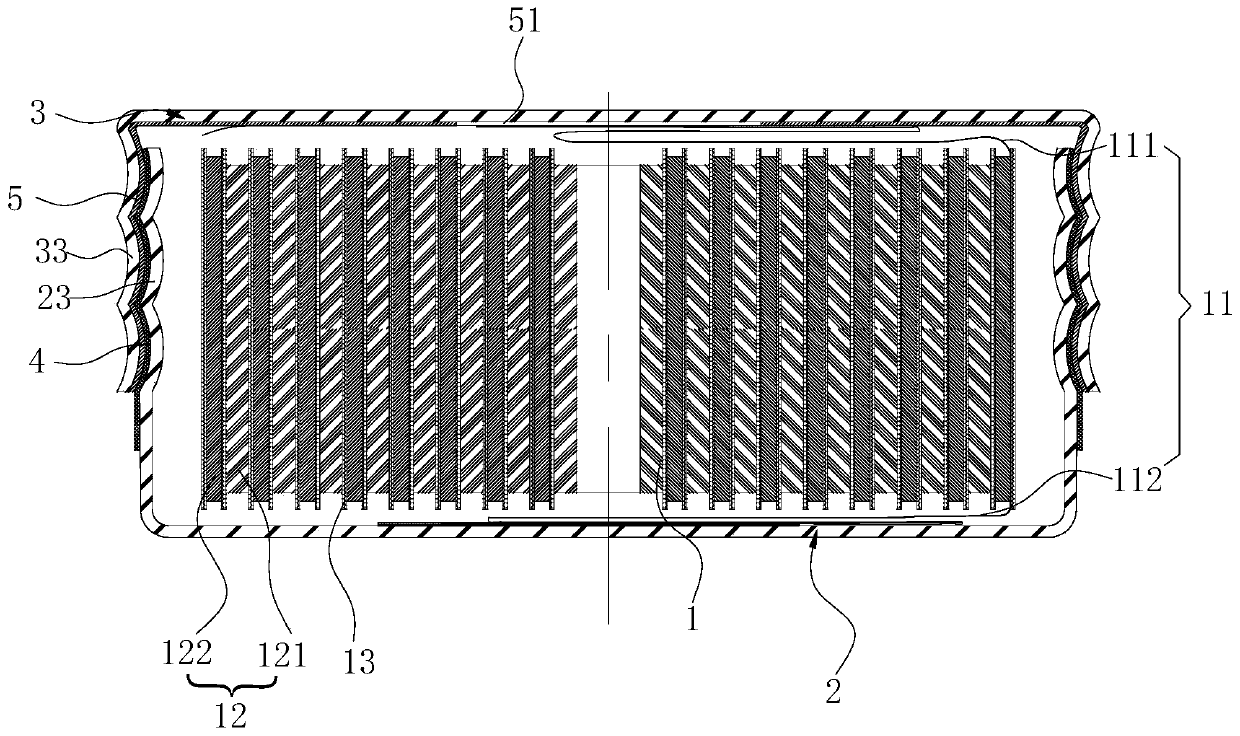

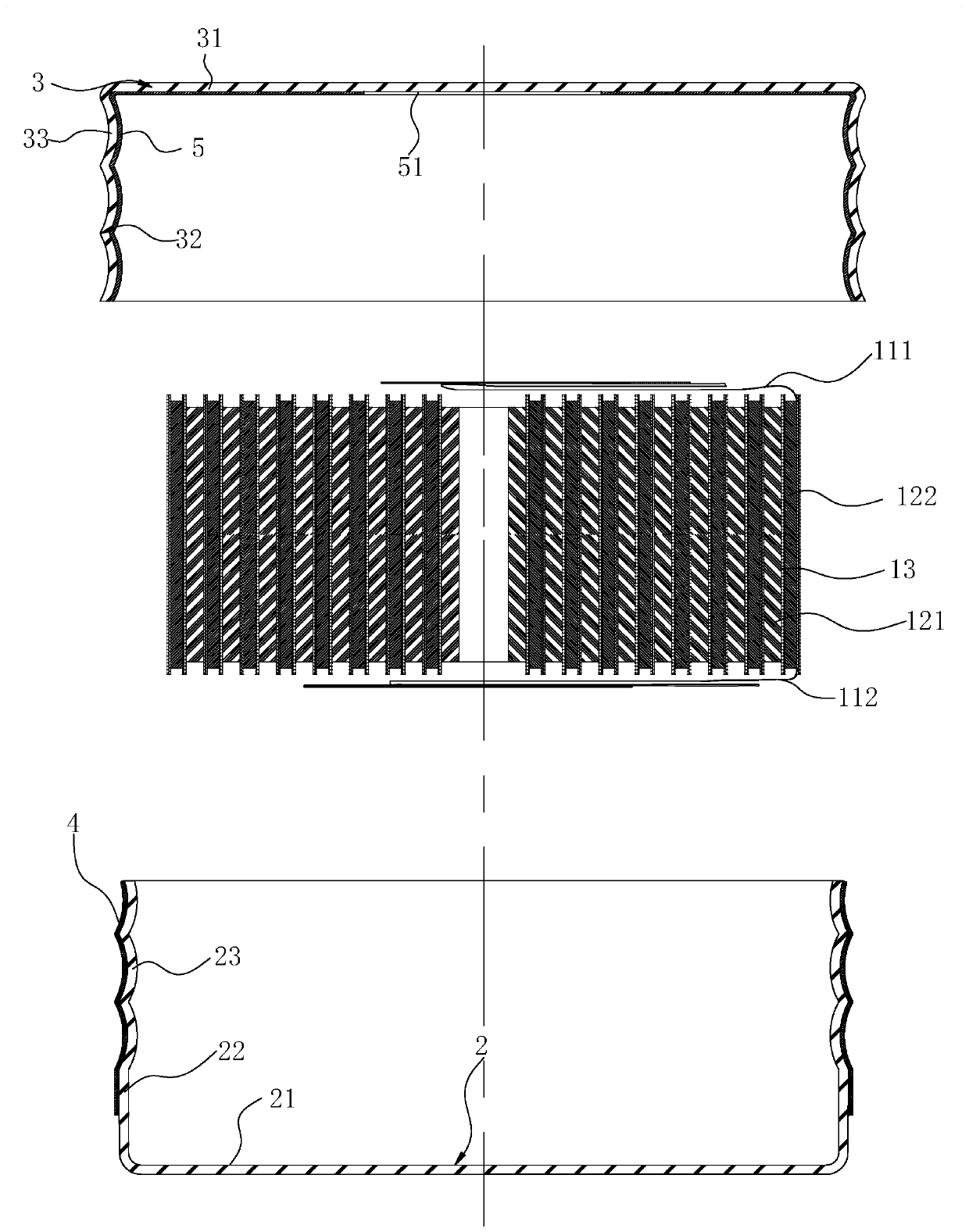

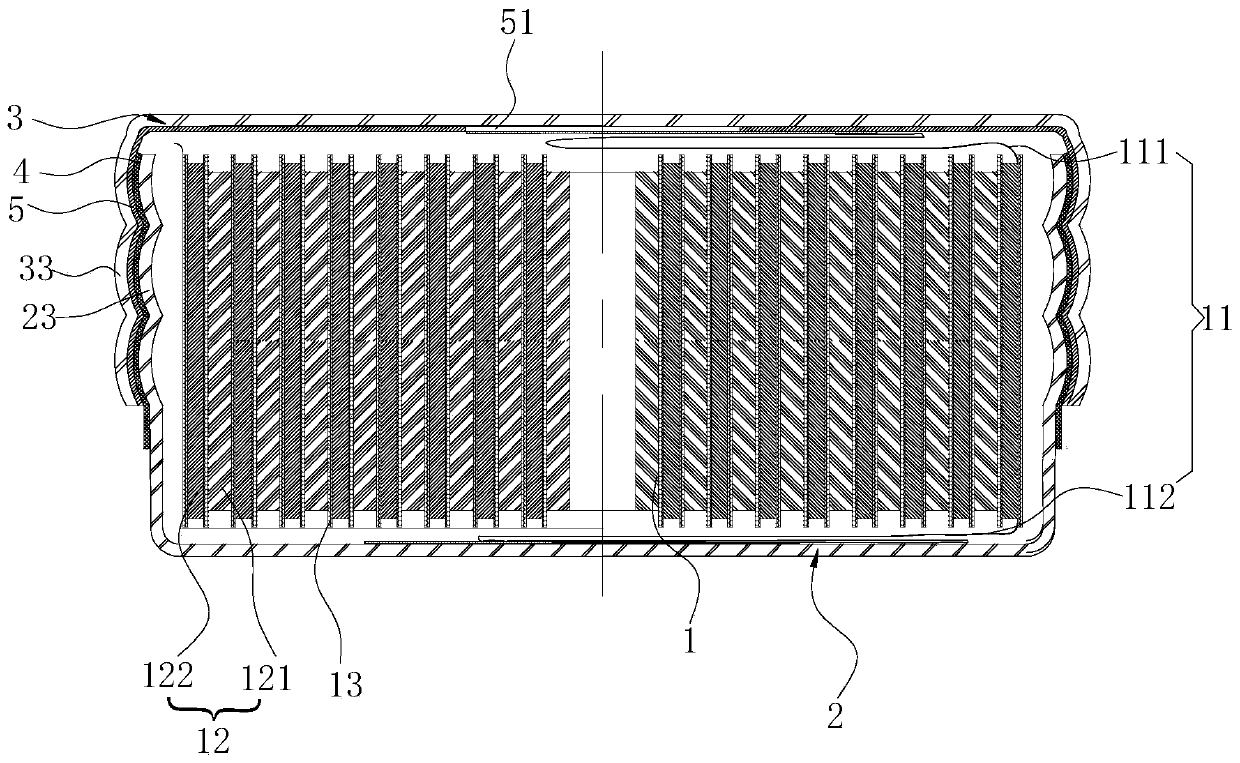

Flexible thin film lithium ion battery and manufacturing method thereof

ActiveCN102522595AImprove securityGood thickness consistencyCell electrodesFinal product manufactureFiberComposite film

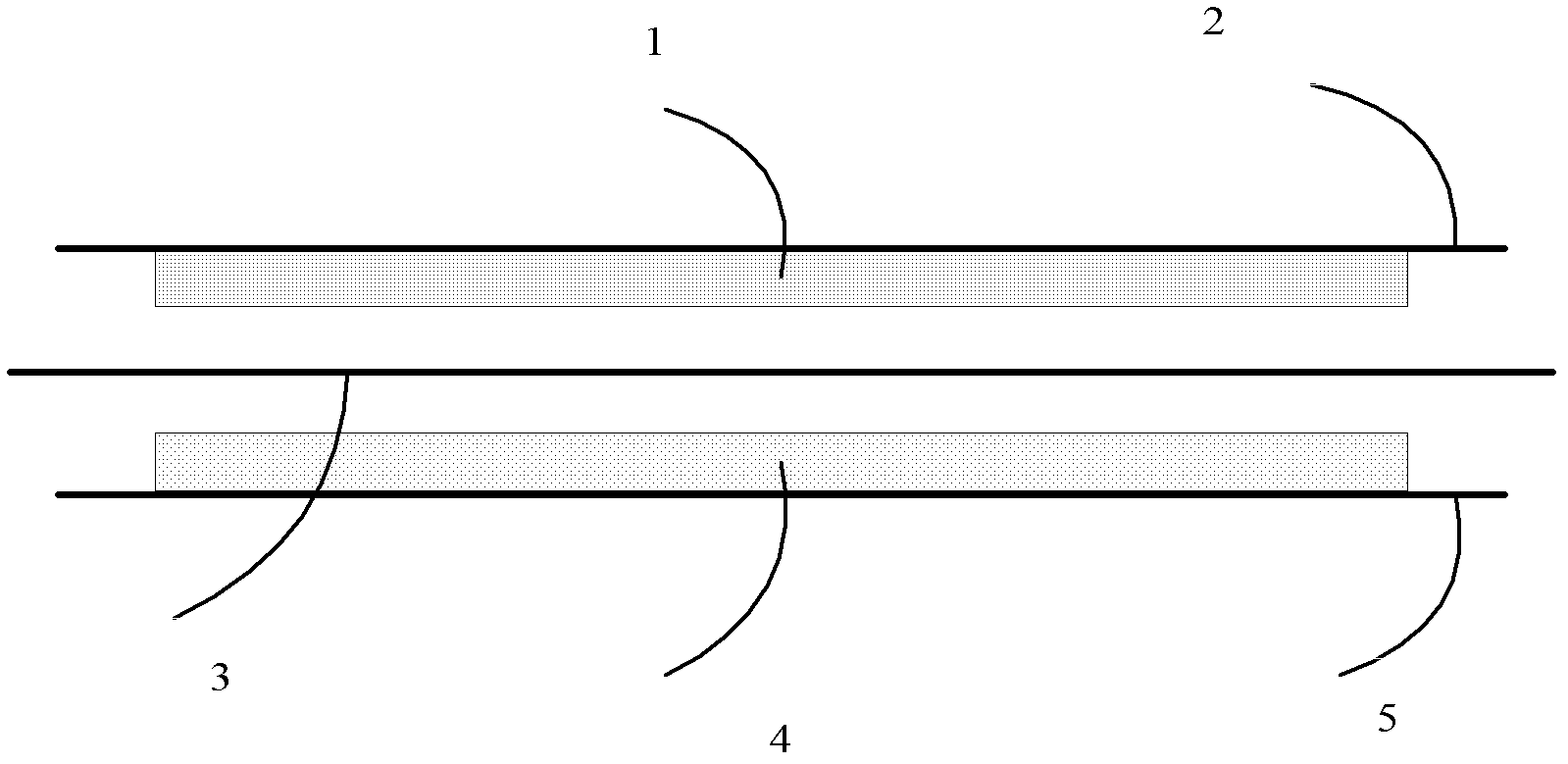

The utility model discloses a flexible thin film lithium ion battery and a manufacturing method thereof. The flexible thin film lithium ion battery is composed of a positive layer, a diaphragm, a negative layer and an external packing layer; the positive layer is composed of aluminum foil with a thickness of 16-30 microns and a positive material printed on one surface of the aluminum foil by adopting intaglio printing technology; the negative layer is composed of copper foil with a thickness of 10-30 microns and a negative material printed on one surface of the copper foil by adopting the intaglio printing technology; the external packing layer is an aluminum plastic composite film; the positive material of the battery comprises dispersant Hypermer KD-1; and the negative material of the battery comprises conductive agent vapor-grown carbon fiber. The flexible thin film lithium ion battery provided by the invention has the benefits that the safety is high, the thickness consistency is good, and the thickness of the battery can be controlled and lowered to 0.25MM, besides, the flexibility is good, the performance and the shape of the battery can not be affected even though the flexible thin film lithium ion battery is bent for several times.

Owner:江苏百特福新能源科技有限责任公司

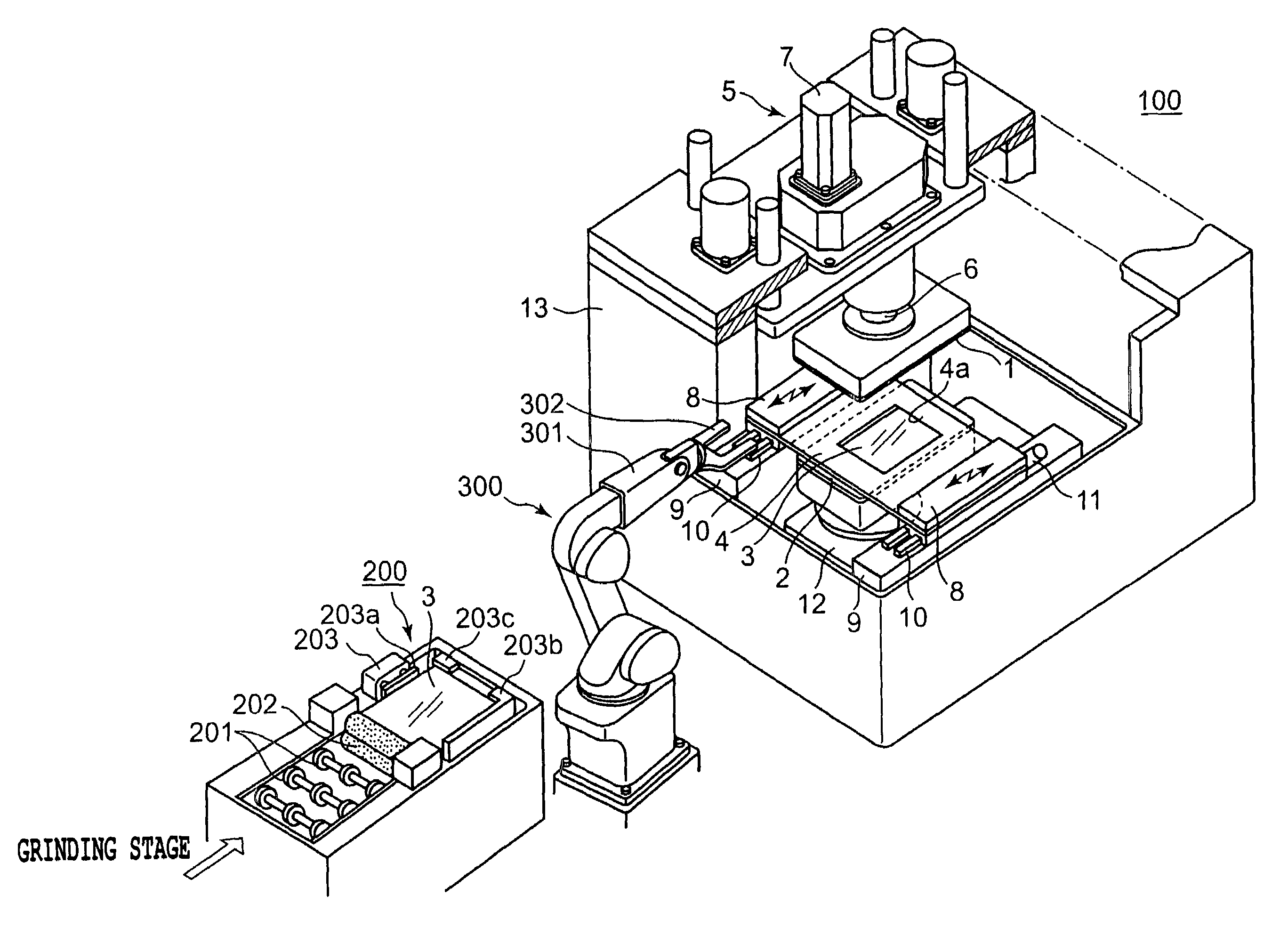

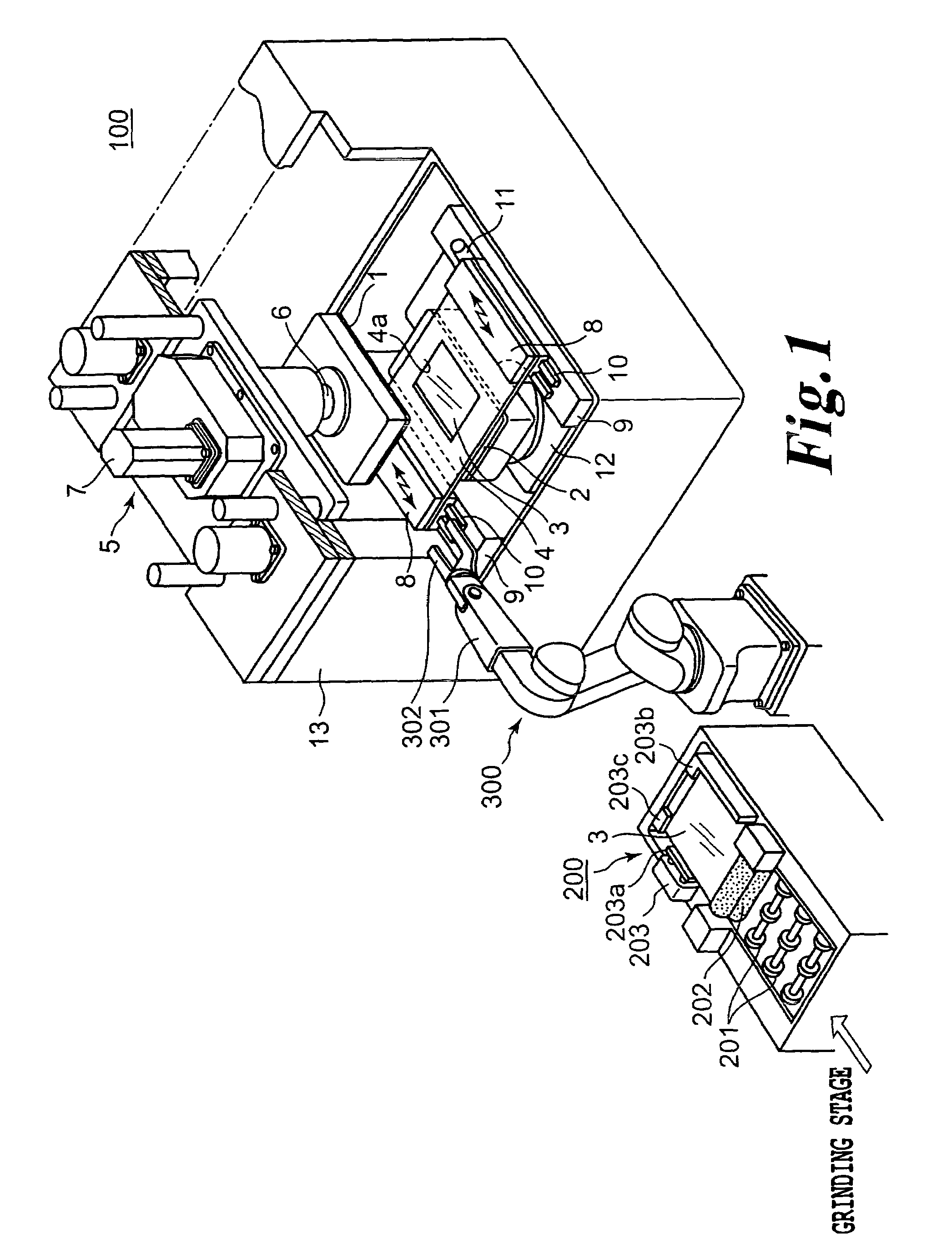

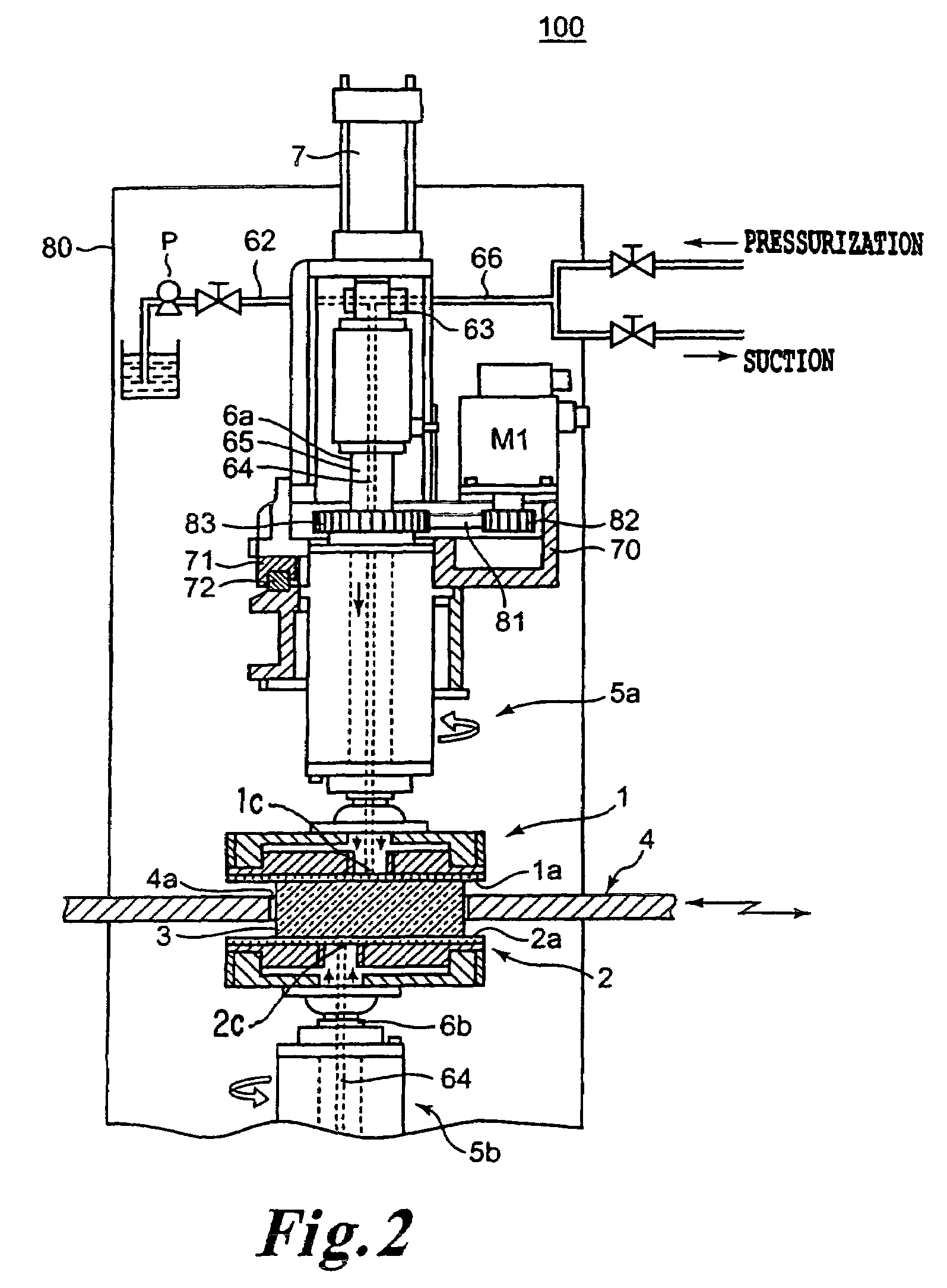

Equipment and method for polishing both sides of a rectangular substrate

InactiveUS7214124B2Good thickness consistencyDifference in thicknessEdge grinding machinesRevolution surface grinding machinesRotational axisElectrical and Electronics engineering

Double-sided polishing equipment configured to polish a rectangular substrate, comprising a carrier having a pocket configured to accommodate a rectangular substrate, a lateral linear moving mechanism configured to move the carrier, first and second polishing pads with first and second rotational axes, respectively, offset from centers of the pads, the polishing surfaces of the first and second polishing pads being parallel. The equipment further includes at least one elevating mechanism coupled to at least one of the polishing pads, first and second rotary drive mechanisms coupled to each of the first and second polishing pads, respectively; and configured to rotate the first and second pads about the first and second rotational axes. A polishing-agent supplying device is present and configured to supply polishing agent to a plane where a substrate that is accommodated in the pocket to accommodate the substrate comes into contact with the polishing pads.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

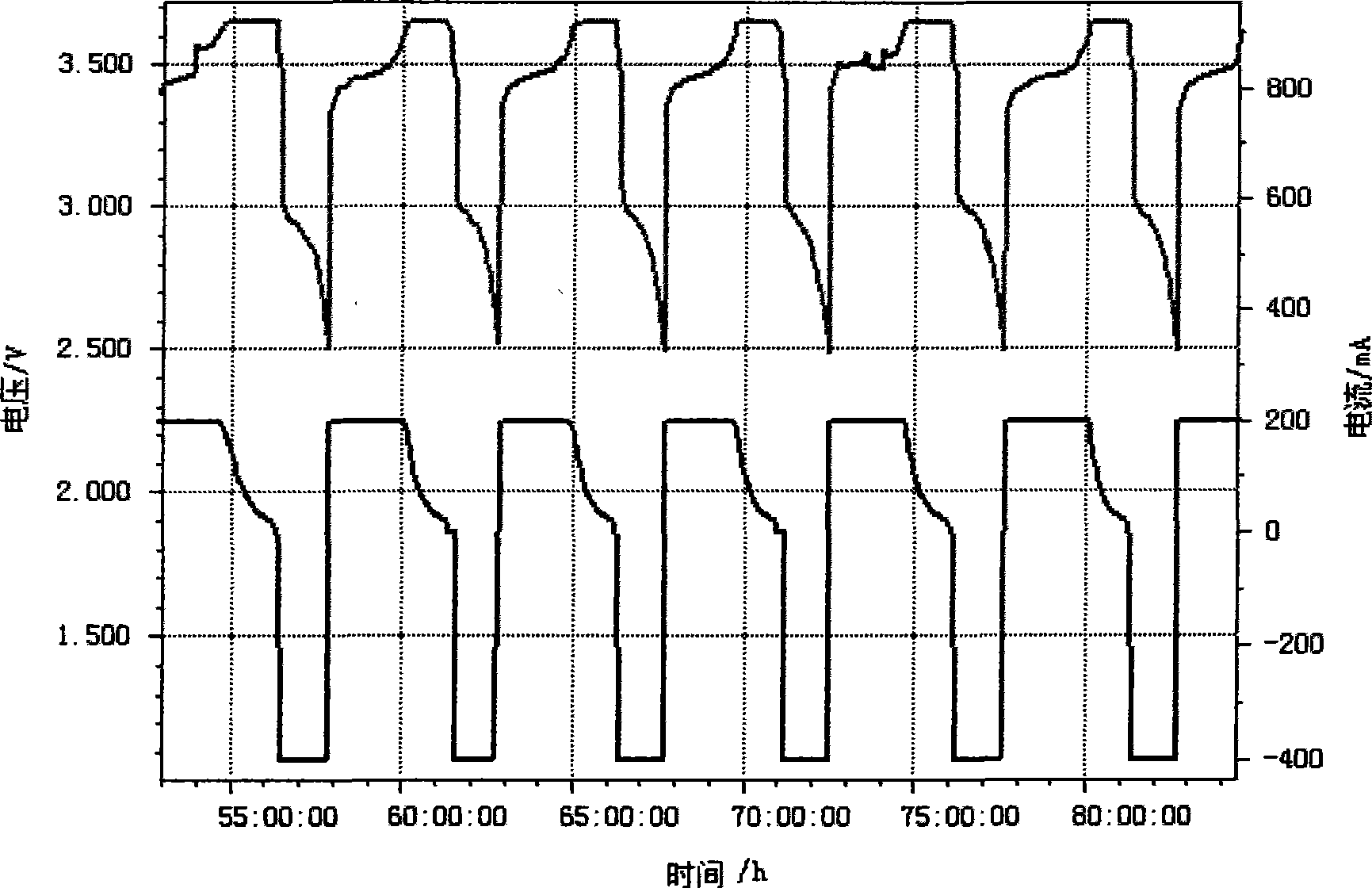

Preparation of lithium iron phosphate precursor and charging battery electrode thereof

InactiveCN101475156AImprove bindingHigh activityCell electrodesPhosphorus compoundsLithium iron phosphateAdhesive

The invention discloses a lithium iron phosphate precursor and a method for preparing a rechargeable battery electrode thereof. The method comprises the following steps: using a prepared active substance LiFePO4 precursor as a basic raw material, attaching the active substance to a conductive skeleton firmly by using intermolecular forces of the active substance precursor, and then pressing and sintering the active substance precursor to obtain the electrode. The method does not need adhesive to attach the active substance to the skeleton so as to simplify production technology; the electrode prepared by the method has the advantages of little internal resistance, high reaction speed and quick electrolyte absorption; and the method has the advantages of simple process, low energy consumption, low cost and better electric conductivity of the electrode. After the electrode prepared by the method is assembled into an actual battery with a cathode which is prepared by graphite, the internal resistance of the battery is less than or equal to 20 milliohms, the primary discharge capacity can reach 582 milliamperes, and the specific capacity can reach 102.1 milliamperes; and the discharge capacity still can reach 560 milliamperes after 50 times of cycle.

Owner:郑州市联合能源电子有限公司

Self-aligning metal silicide preparation method

InactiveCN101211781AImprove consistencyImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSalicideElectrical conductor

A method for manufacturing a self-aligned metal silicide comprises the steps that: a semiconductor substrate is provided and at least a silicon area is arranged on the surface of the semiconductor substrate; a metal layer is formed on the semiconductor substrate and the first step of annealing process is applied to the semiconductor substrate and the second step of annealing process is applied to the semiconductor substrate; the metal layer is removed by etching. The thickness and resistivity of the metal silicide formed through the method of the invention have better consistence.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Injection molding based CSP packaging structure and manufacturing process

ActiveCN105161598AEasy to shapeGood thickness consistencySemiconductor devicesFluorescenceEngineering

The invention discloses an injection molding based CSP packaging structure and a manufacturing process. The packaging structure comprises an injection molding body formed through injection molding, the injection molding body is provided with through holes, the through holes are internally provided with LED chips, the LED chips are provided with electrodes, and the lower surfaces of the electrodes are in flush with the lower surface of the injection molding body or project out of the lower surface of the injection molding body; and the through holes are filled up with fluorescent glue covering the side surfaces and the top surfaces of the LED chips. The manufacturing method is as follows: injection-molding an injection molding, arranging a fixation membrane on a support plate, arranging the injection molding on the fixation membrane, fixing the LED chips, filling the through holes with the fluorescent glue, cutting, and separating the support plate from an isolation membrane. According to the invention, the technical problems of difficult control of the shape and the application amount of the fluorescent glue, difficult control of thickness uniformity of the fluorescent glue at each position, and difficulty in ensuring the quality of a chip scale package LED are solved.

Owner:HONGLI ZHIHUI GRP CO LTD

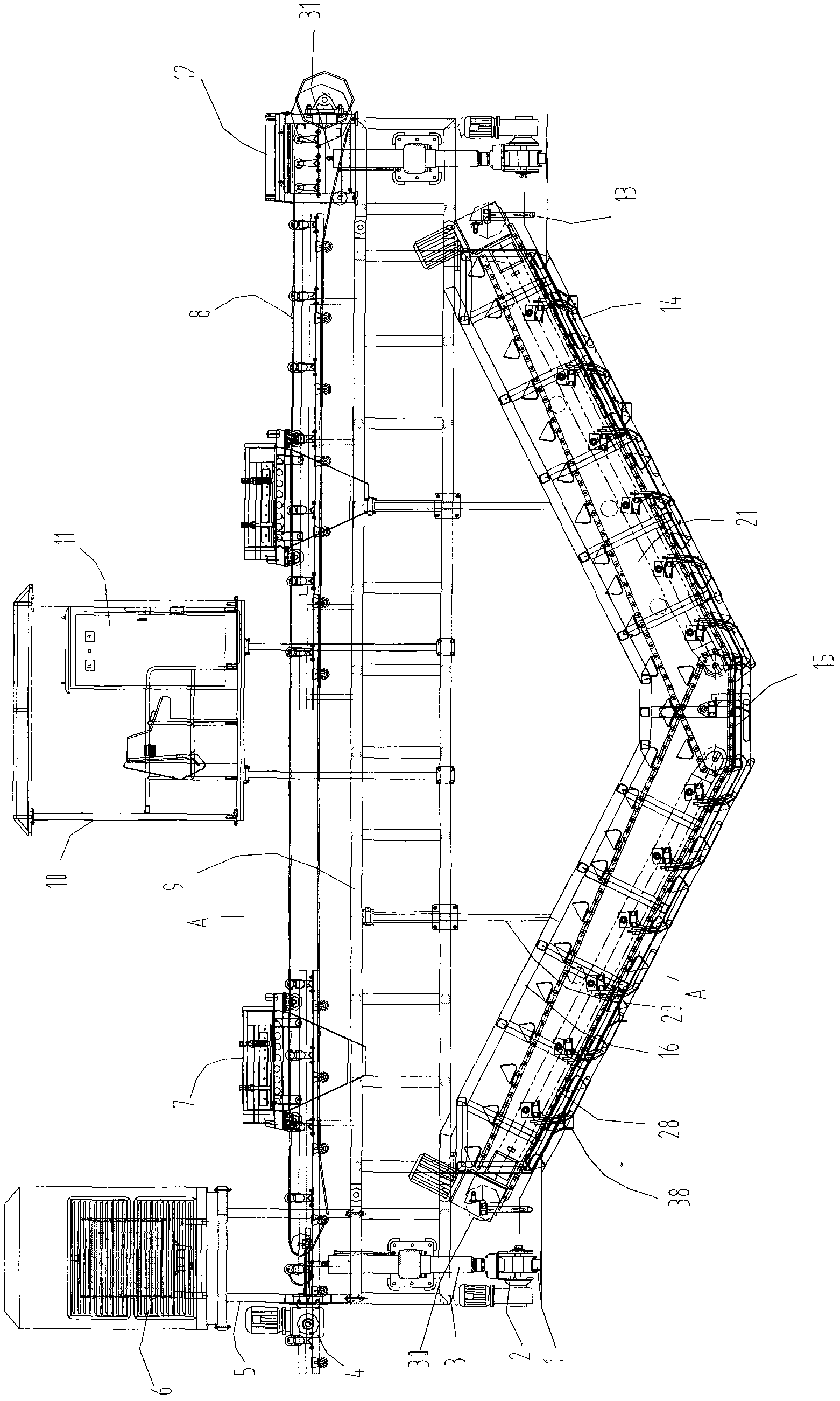

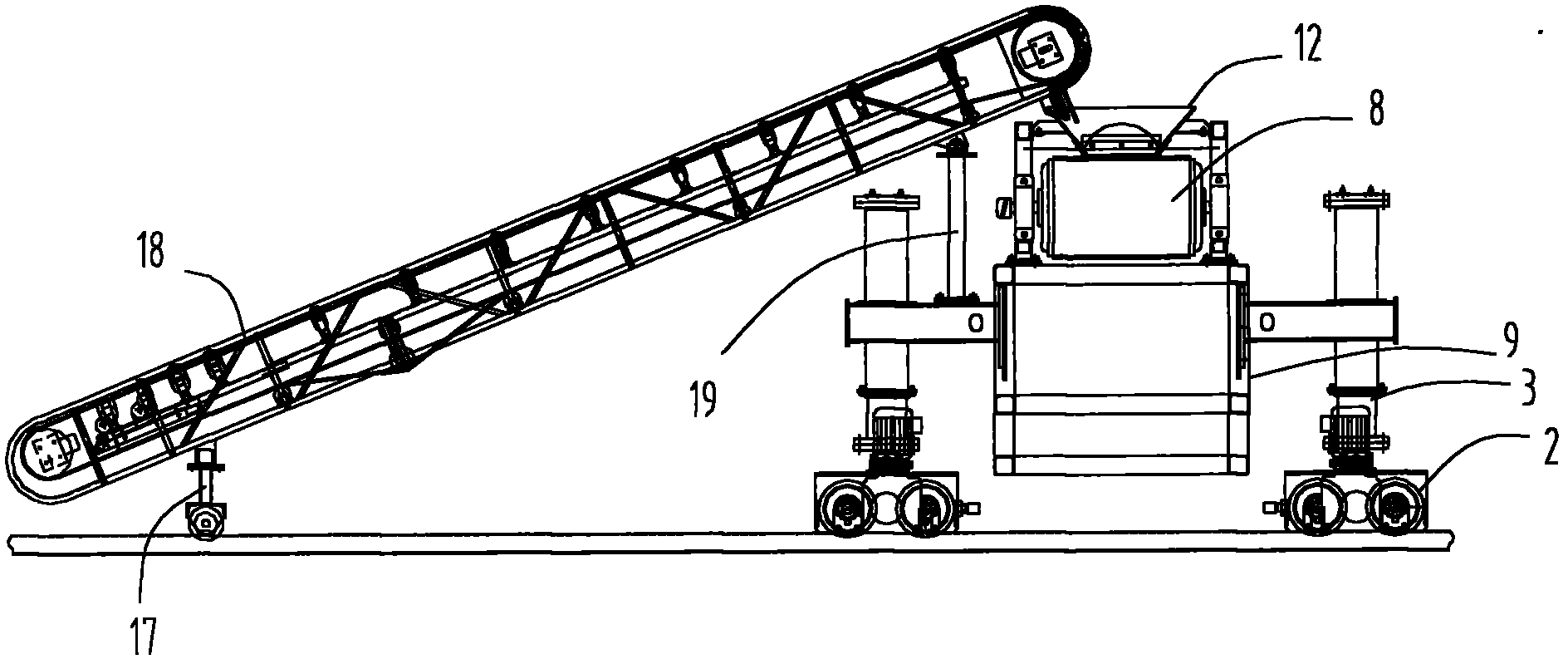

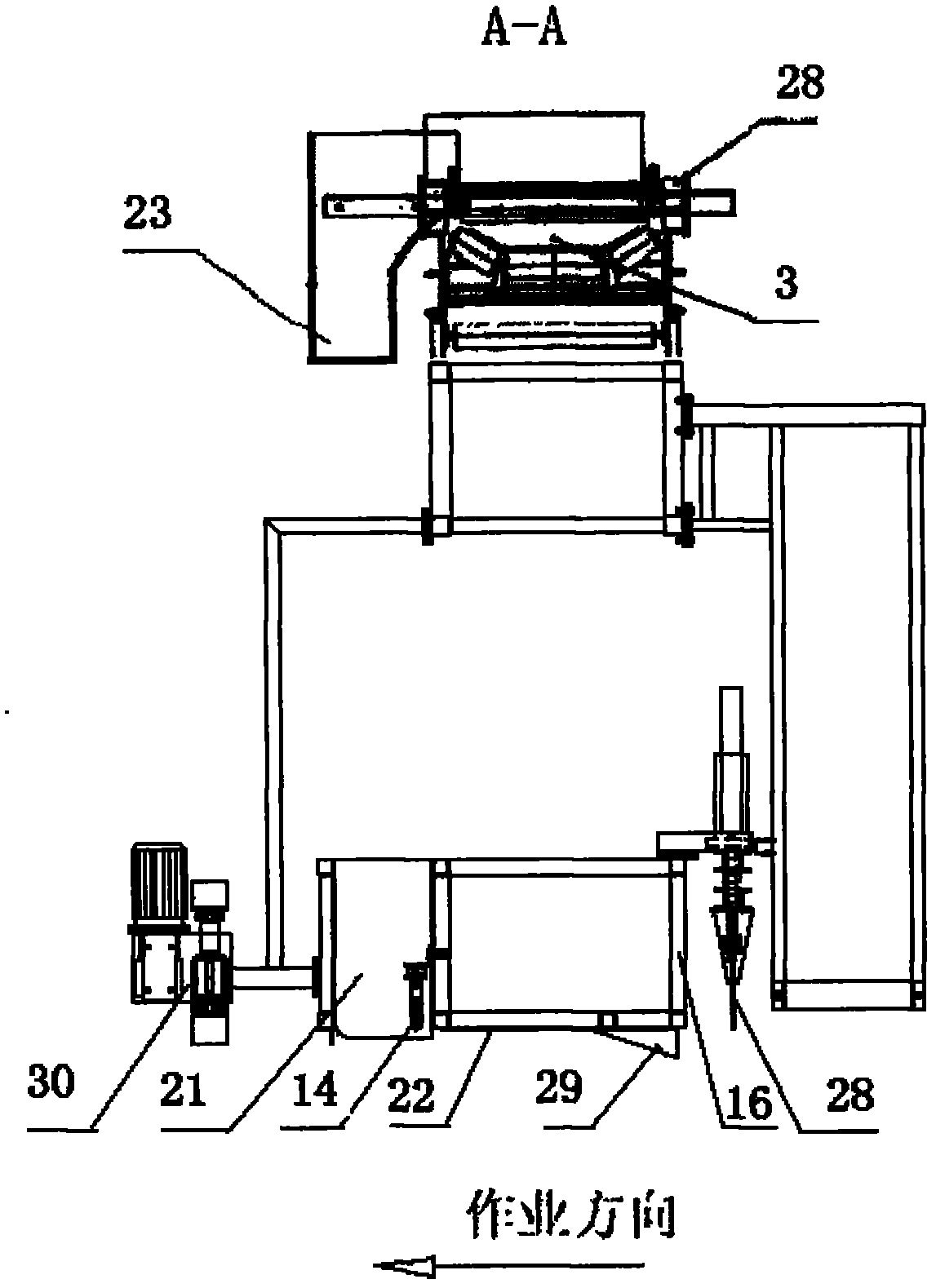

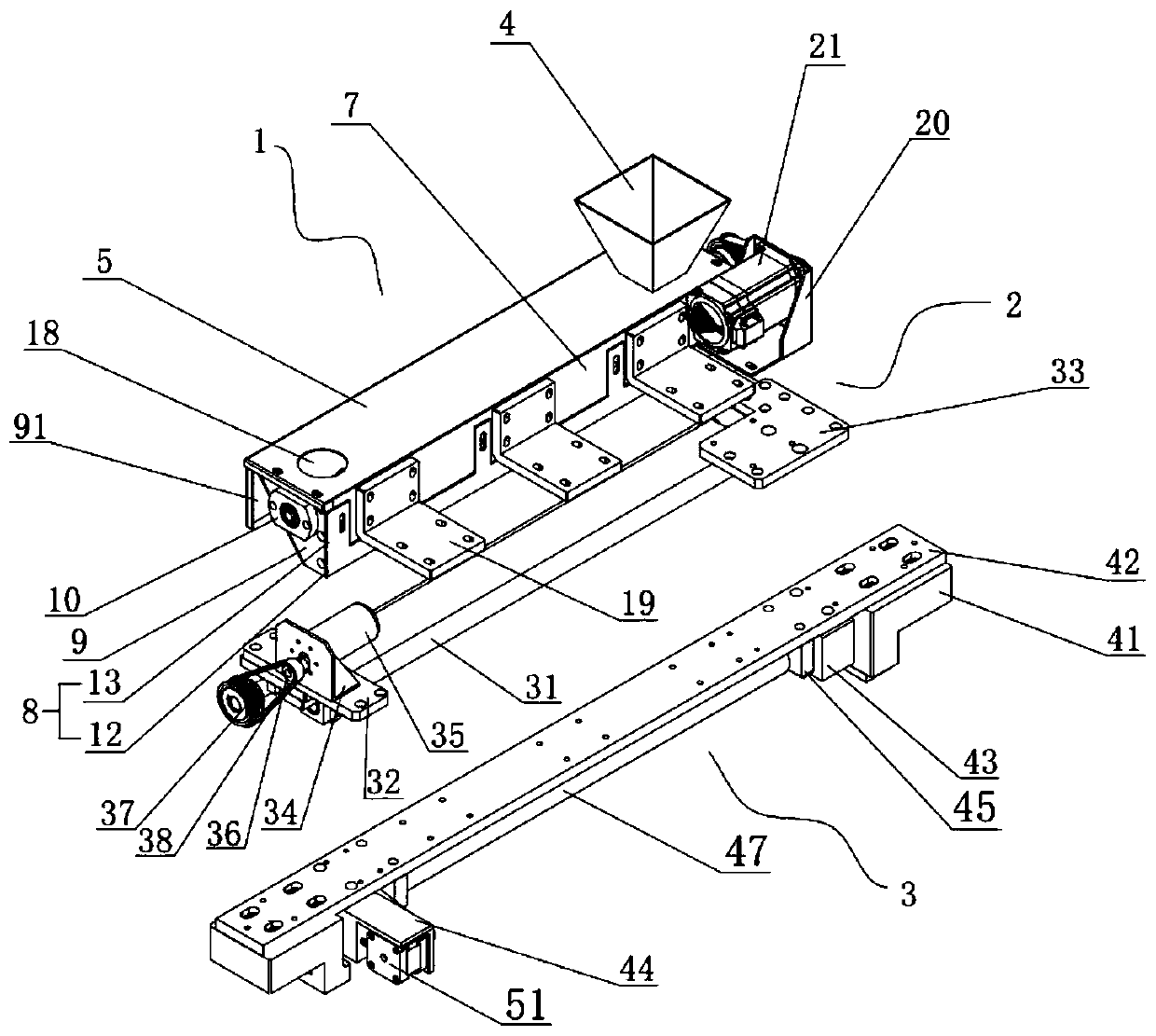

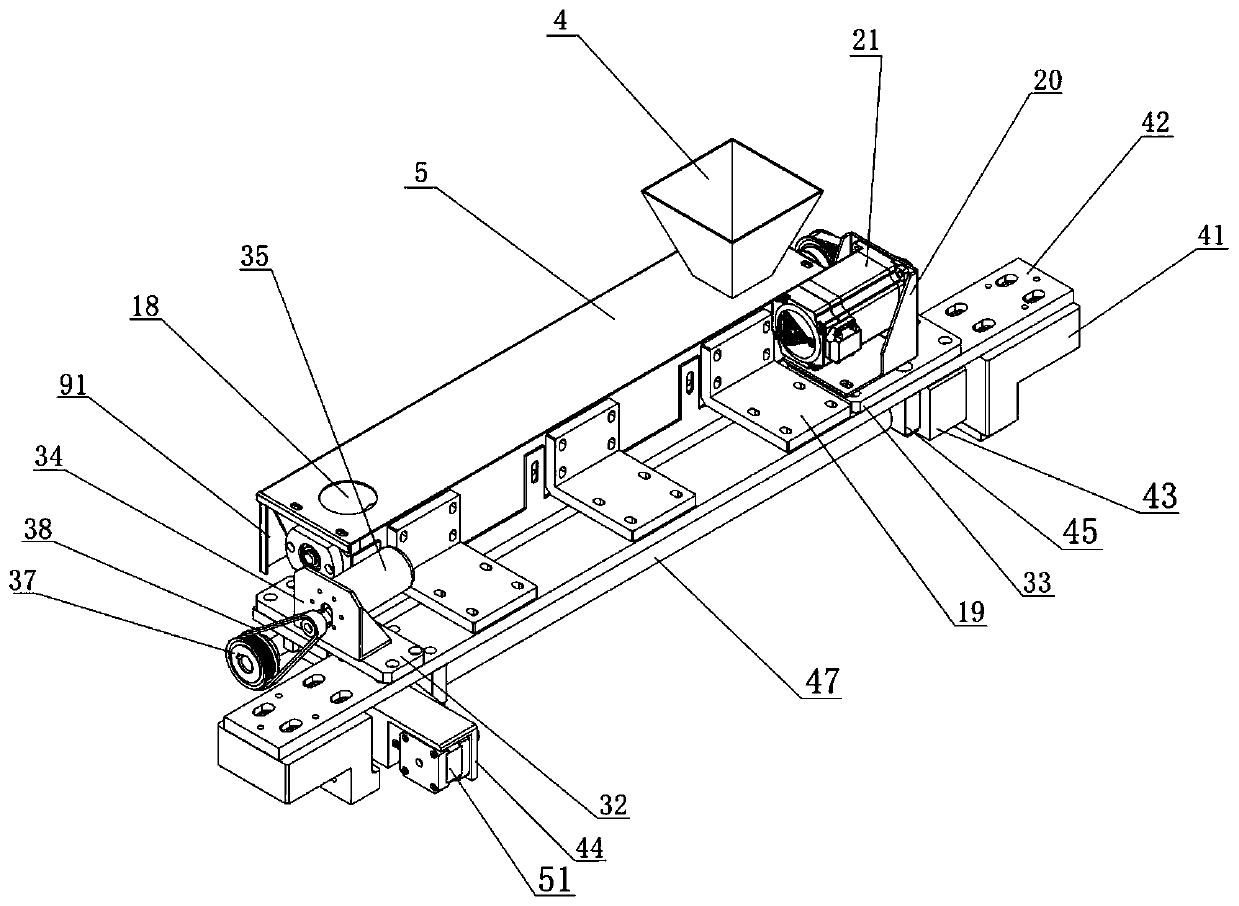

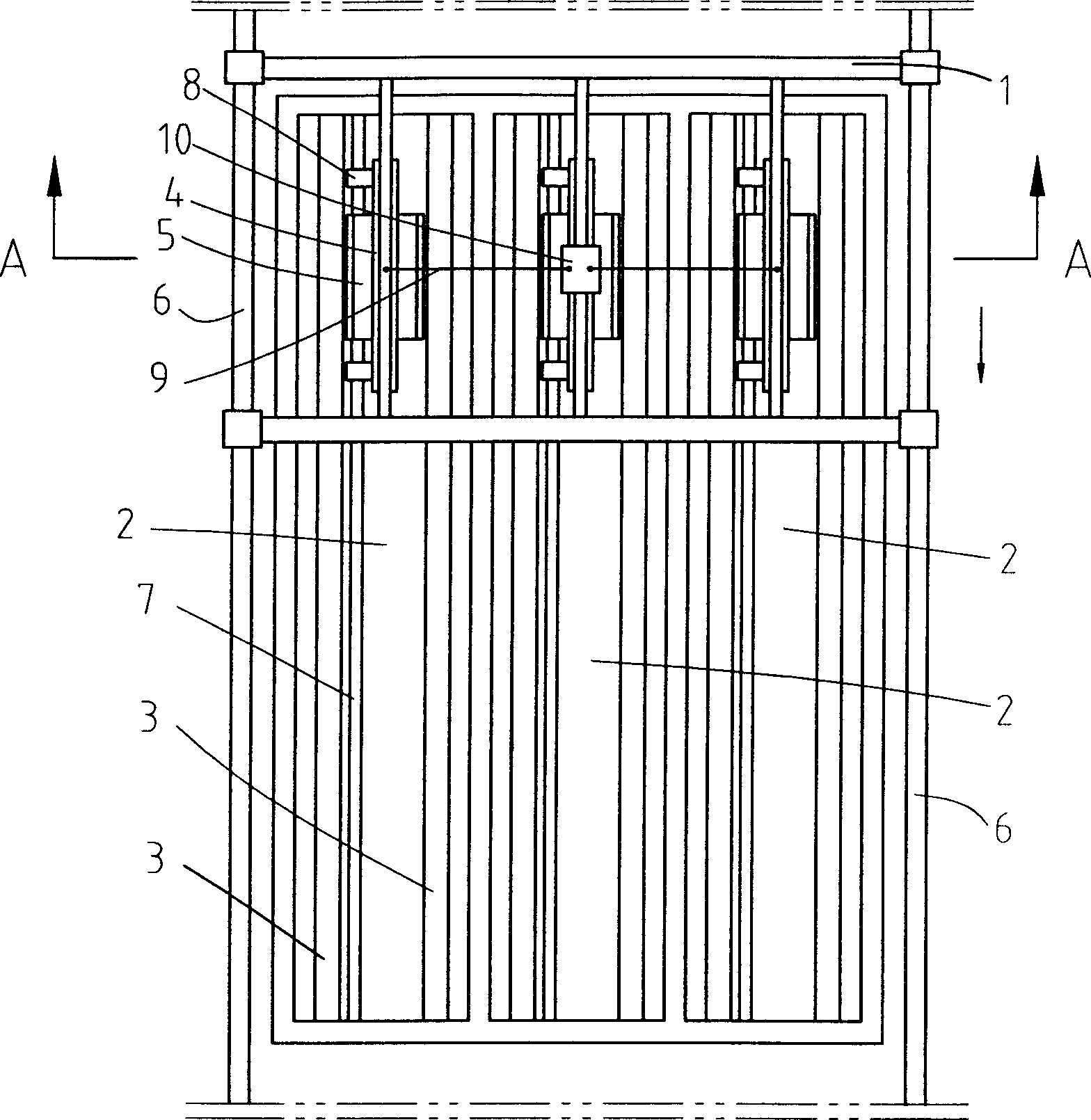

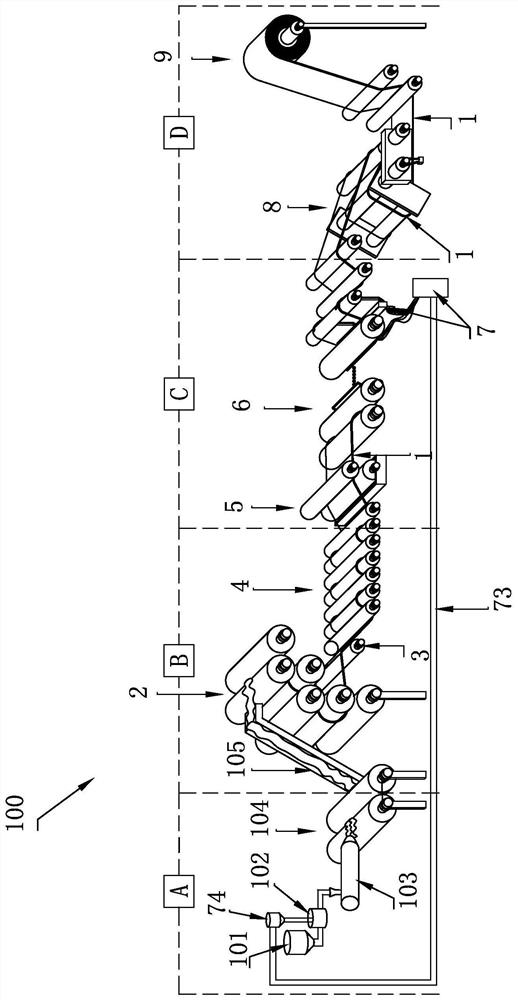

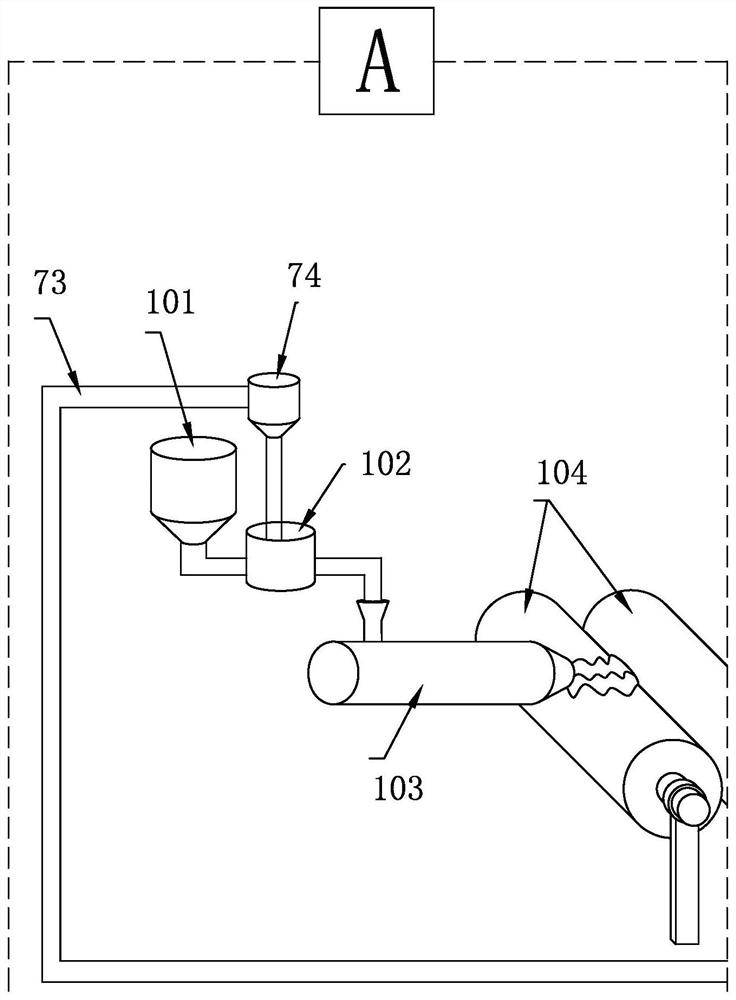

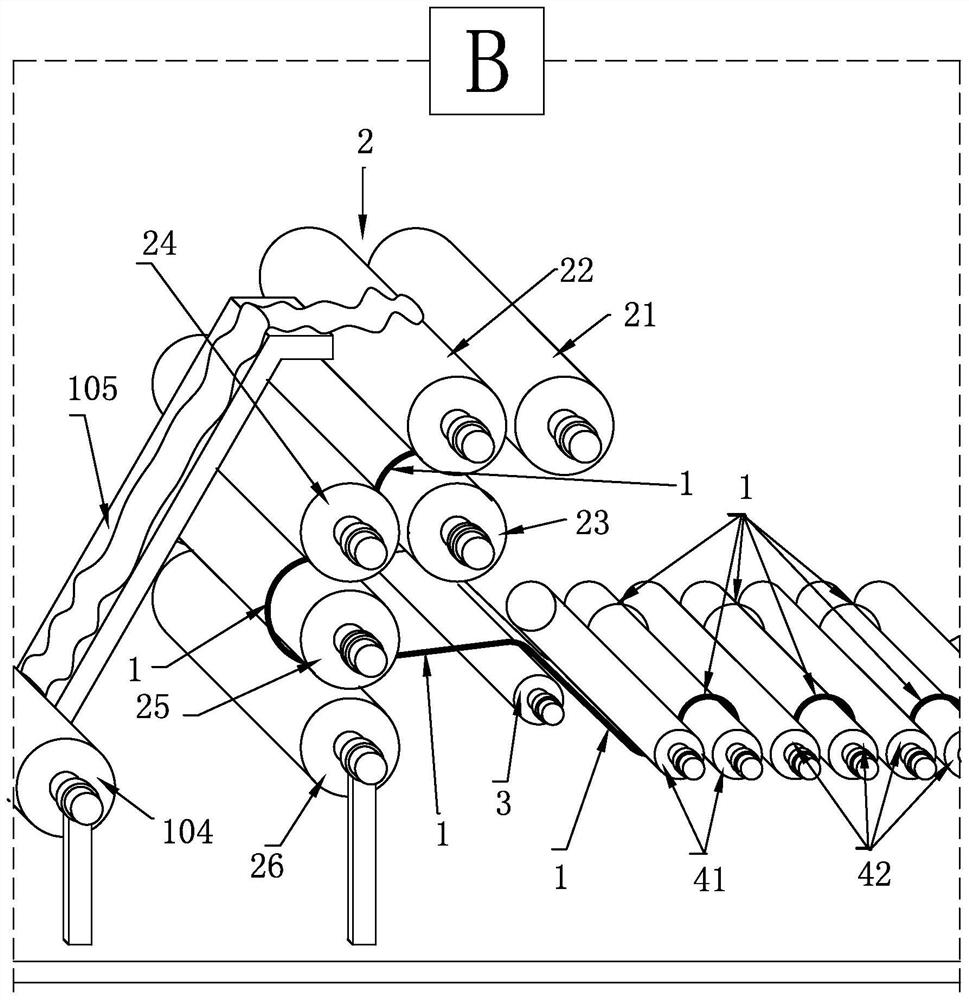

Full-section multi-functional channel concrete lining machine

InactiveCN102108693AGuaranteed flatnessMeet construction requirementsArtificial water canalsAutomatic controlEngineering

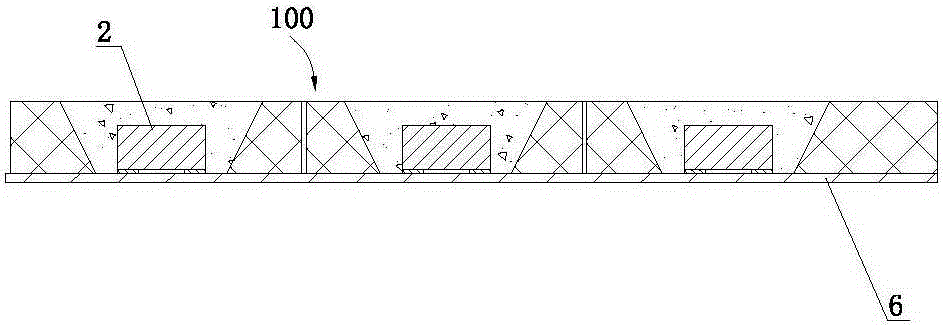

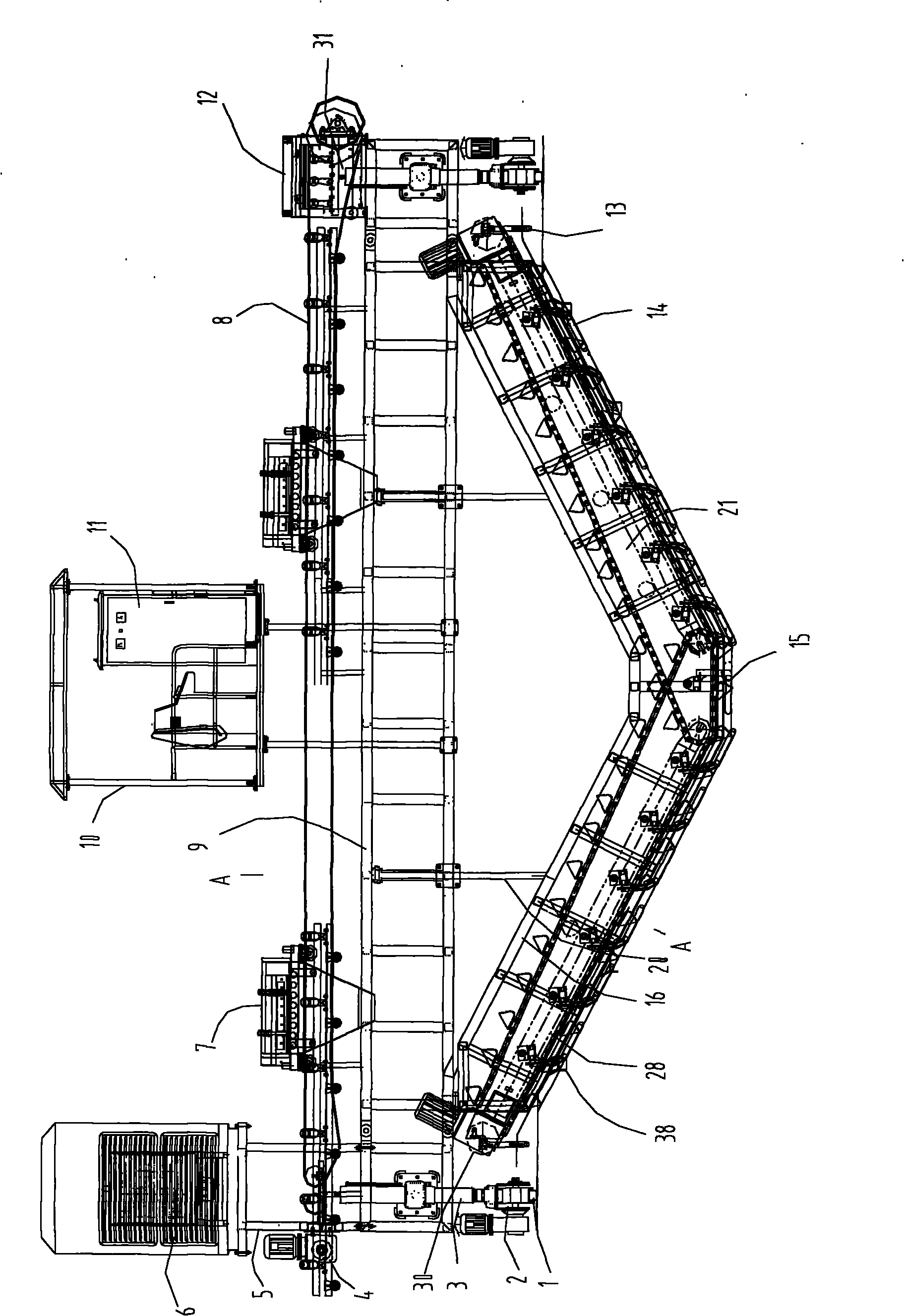

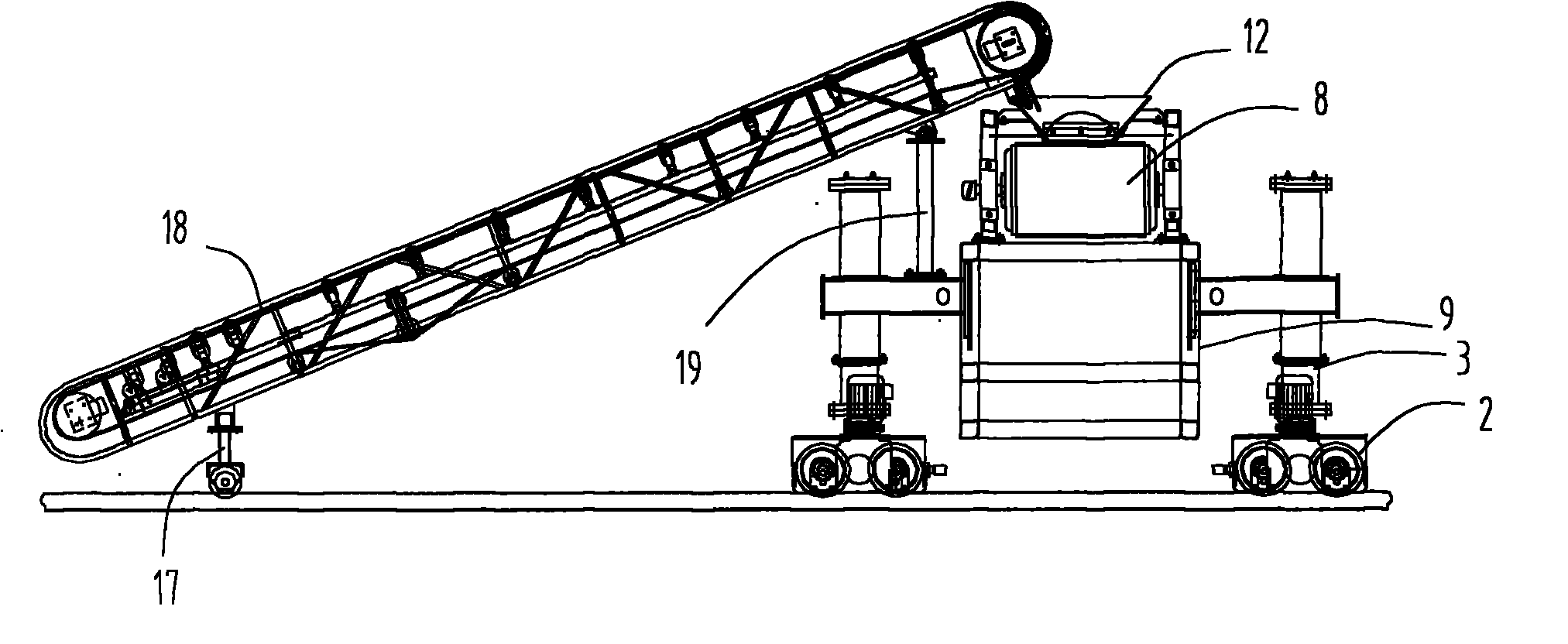

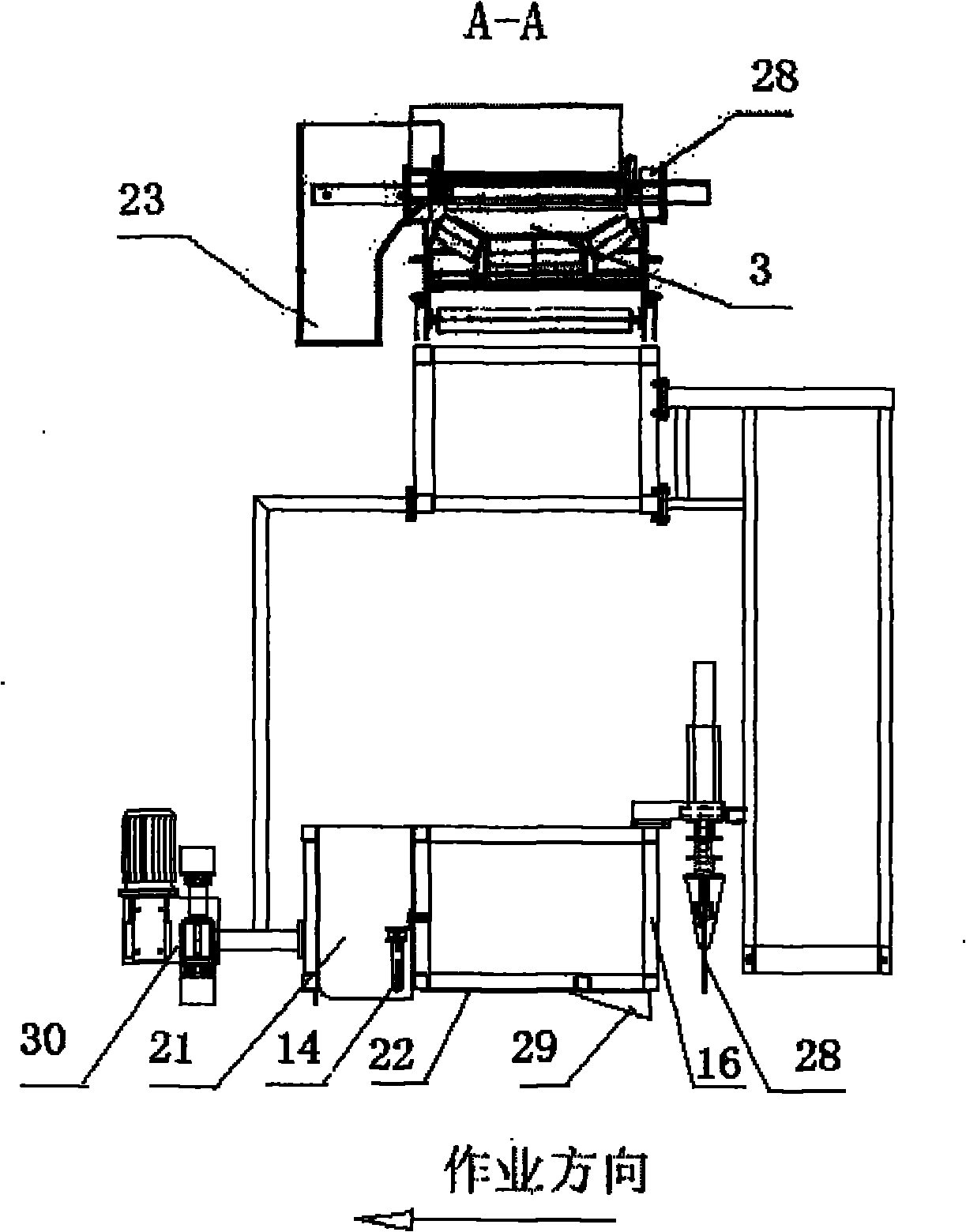

The invention discloses a full-section multi-functional channel concrete lining machine used in the construction of a channel, which comprises a main frame (9), a walking system, an operation table, an automatic control system and a power system, and is characterized by further comprising a full-section channel trimming system (30), a loading system, a material distribution system, a vibrating, striking-off and compacting system and a parting and molding system, wherein the loading system, the material distribution system and the vibrating, striking-off and compacting system are sequentially connected, and the full-section channel trimming system (30), the vibrating, striking-off and compacting system and the parting and molding system are sequentially connected. By adopting the full-section multi-functional channel concrete lining machine, trimming of the channel before the lining operation, automatic arrangement of slurry, overall operation of lining of the channel, integrated cutting of longitudinal and transverse parting and automatic alignment of the height of the whole machine can be realized, and the full-section multi-functional channel concrete lining machine can completevarious operations of the channel by walking along the channel once, thereby greatly improving the operation efficiency, simultaneously enabling the operation quality of the channel after lining to be good, and being good in thickness consistency.

Owner:韩其华

Full-section multi-functional canal concrete lining machine

InactiveCN102162228AGuaranteed flatnessMeet construction requirementsArtificial water canalsAutomatic controlEngineering

The invention discloses a full-section multi-functional canal concrete lining machine which is used in canal construction. The canal concrete lining machine comprises a main frame (9), a traveling system, an operating platform, an automatic control system and a dynamical system; and the canal concrete lining machine is characterized by further comprising a full-section canal trimming system (30), a charging system, a separating system, a vibrating-strickling-compacting system and a seam molding system, wherein, the charging system, the material distributing system and the vibrating-strickling-compacting system are sequentially connected, and the full-section canal trimming system (30), the vibrating-strickling-compacting system and the seam molding system are sequentially connected. By utilizing the full-section multi-functional canal concrete lining machine, canal trimming before lining operation, automatic slurry arrangement, integral canal lining operation, integrated cutting of longitudinal and horizontal seams and automatic alignment of height of the whole machine are realized so as to complete various canal operations by traveling along a canal at one time, thus greatly improving the operating efficiency; and meanwhile the lined canal has the advantages of good operating quality and good thickness consistency.

Owner:韩其华

Method for manufacturing flash memories

ActiveCN105679713AMeet process requirementsSmall difference in shapeTransistorSolid-state devicesElectrical and Electronics engineeringFlash memory

A method for manufacturing flash memories comprises the following steps: a graphical hard mask layer forms an opening penetrating a hard mask layer in a thickness direction; a floating gate layer with a first thickness below the opening is etched and removed with a first etching process, wherein etching time of the first etching process is determined based on the initial thickness of the floating gate layer below the opening before the first etching process, so that the thickness of the floating gate layer after the first etching process is completed is a fixed value; after the first etching process, a second etching process is adopted to etch and remove the floating gate layer with a second thickness, part of the floating gate layer below the hard mask layer is also etched and removed, and a floating gate tip region is formed below the hard mask layer, wherein the etching time of the second etching process is fixed. The method improves the morphological stability of formed floating gate tips, so that the yield of manufactured flash memories is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Preparation method of polytetrafluoroethylene heat-exchange tube

InactiveCN105522721AGood chemical stabilityImprove the lubrication effectTubular articlesPolymer scienceCrystallinity

The invention relates to a preparation method of a polytetrafluoroethylene heat-exchange tube and belongs to the technical field of fluoroplastic processing. The preparation method of the polytetrafluoroethylene heat-exchange tube comprises steps as follows: (1) mixing of raw materials: polytetrafluoroethylene dispersion resin and an extrusion aid are mixed by a mixer; (2) constant-temperature curing: constant-temperature curing is performed at the temperature of 30-50 DEG C; (3) pre-pressing of a blank: the raw materials are guided into a material cavity of a blank making machine, and a pressing block is added for pressurizing; (4) pushing extrusion: the blank is sent into a material cavity of an extruding machine for pushing extrusion; (5) oil removal and drying: the extrusion aid in an extruded tube is heated to be dried and cleaned; (6) high-temperature sintering: high-temperature sintering is performed in four intervals; (7) setting processing: the crystallinity of the inside of the tube is adjusted through quenching, the hardness and the flexibility of the tube are controlled, and the polytetrafluoroethylene heat-exchange tube is prepared. The preparation method has the advantages that the technology is simple, operation is convenient, the product has the over-length, the thin wall and the good consistency, the tube is high in heat exchange coefficient, corrosion-resistant, good in self-lubricating performance and long in service life, and the like.

Owner:TIANJIN TIANSU SCI & TECH GROUP

High-energy-density lithium iron phosphate battery

ActiveCN113078305ASignificant progressIncrease capacityMaterial nanotechnologyFinal product manufactureElectrolytic agentMagnesium doping

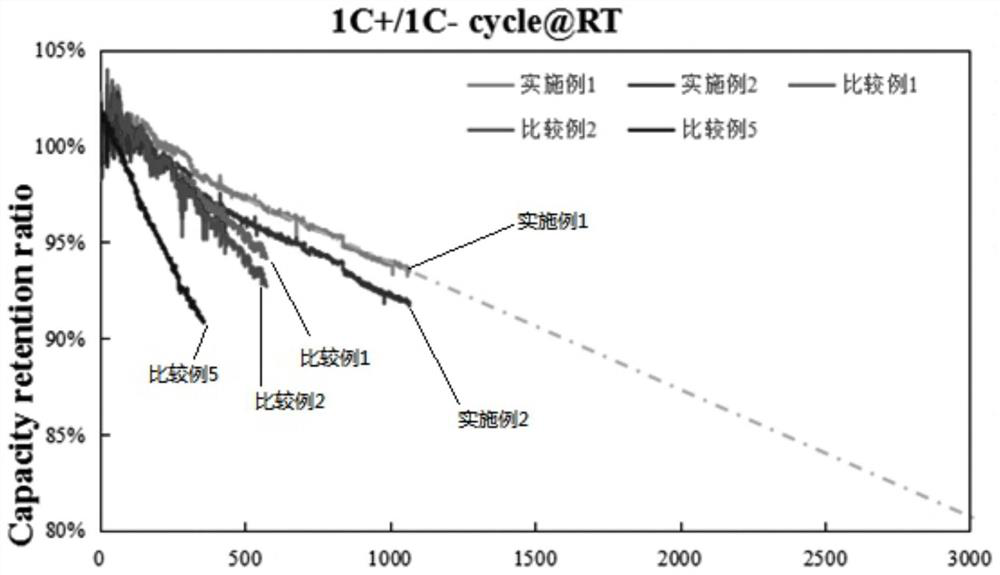

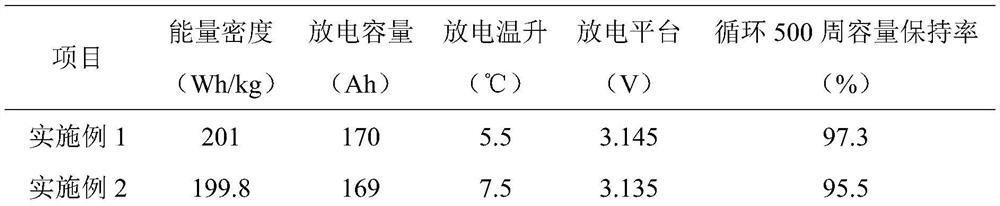

The invention belongs to the technical field of electrochemistry, and particularly relates to a high-energy-density lithium iron phosphate battery. A positive electrode active material is selected from titanium / magnesium-doped lithium iron phosphate, the surface density of a positive plate is 190-210 g / m<2>, the compaction density is greater than or equal to 2.60 g / cc, a negative electrode active material is carbon-coated single particle and secondary particle needle coke blend artificial graphite, and the compaction density of a negative plate is greater than or equal to 1.70 g / cc. The density of the electrolyte is equal to 1.15 g / cc, the wall thickness of the aluminum shell body is 0.40-0.50 mm, a positive electrode current collector is an aluminum foil with the diameter of 12-13 [mu]m, a negative electrode current collector is a copper foil with the diameter of 4.5 [mu]m, a diaphragm is a 7 + 2C + 2P ceramic gluing diaphragm, a conductive binder is used for replacing a positive electrode, the addition amount is 1.0-2.0%, and the weight ratio of a positive electrode active material to a positive electrode dressing is greater than or equal to 98%. According to the invention, the energy density of the battery is greatly improved and reaches 200Wh / kg.

Owner:江西安驰新能源科技有限公司

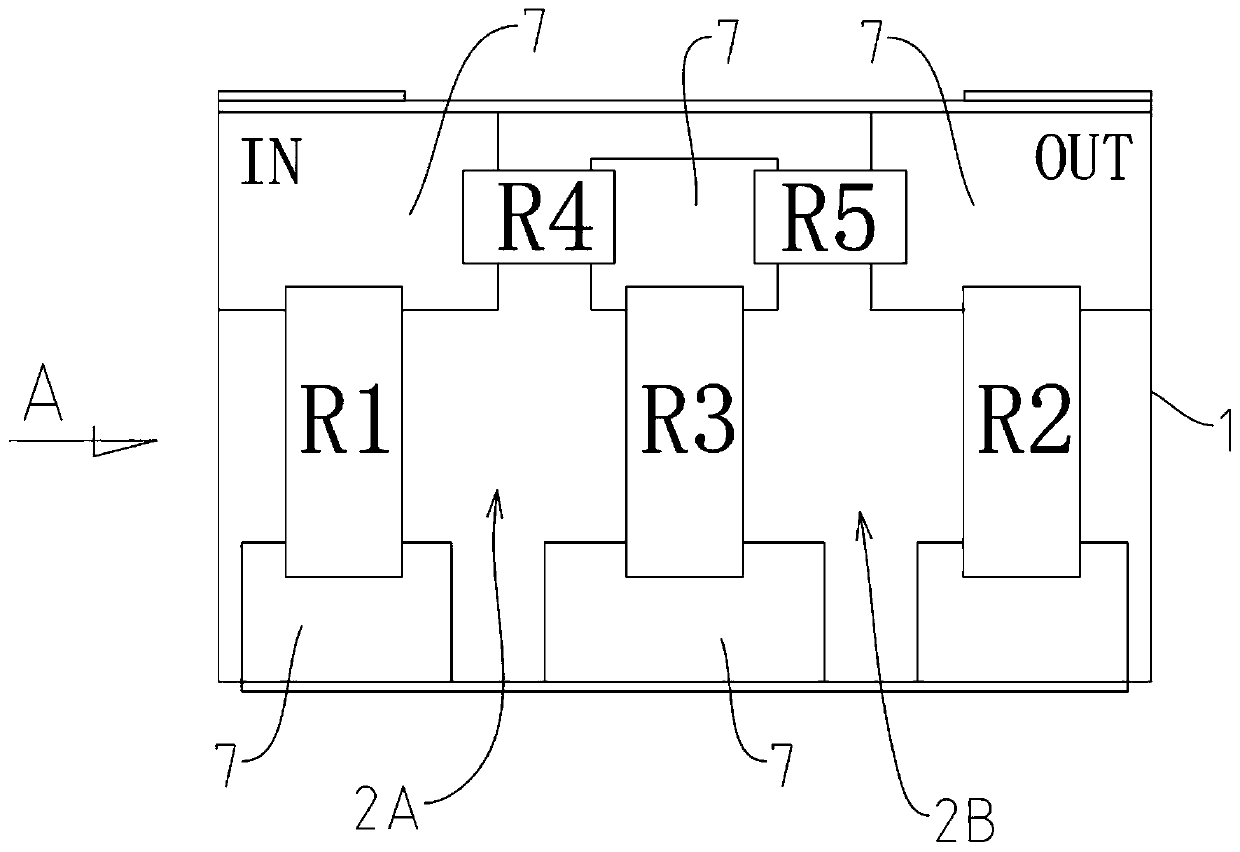

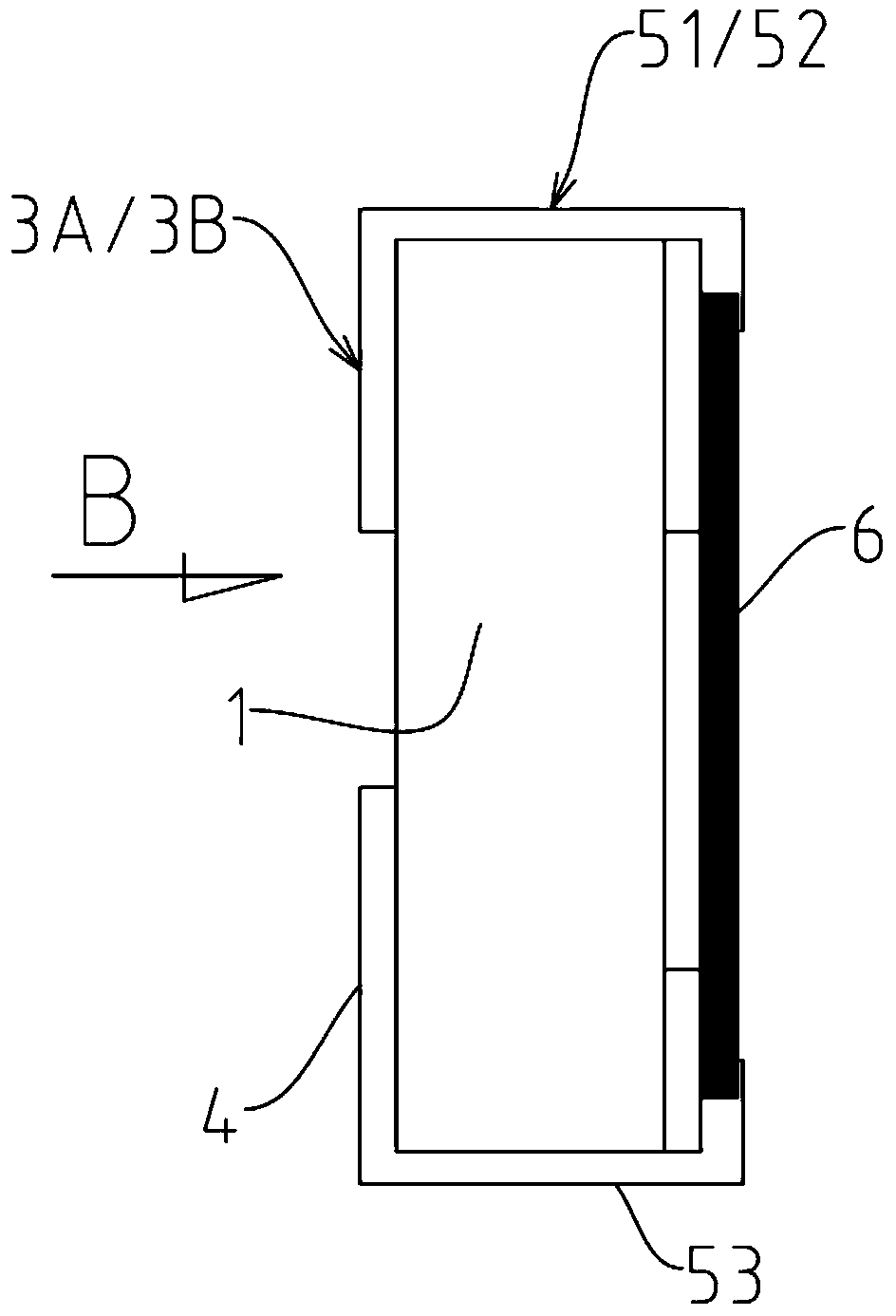

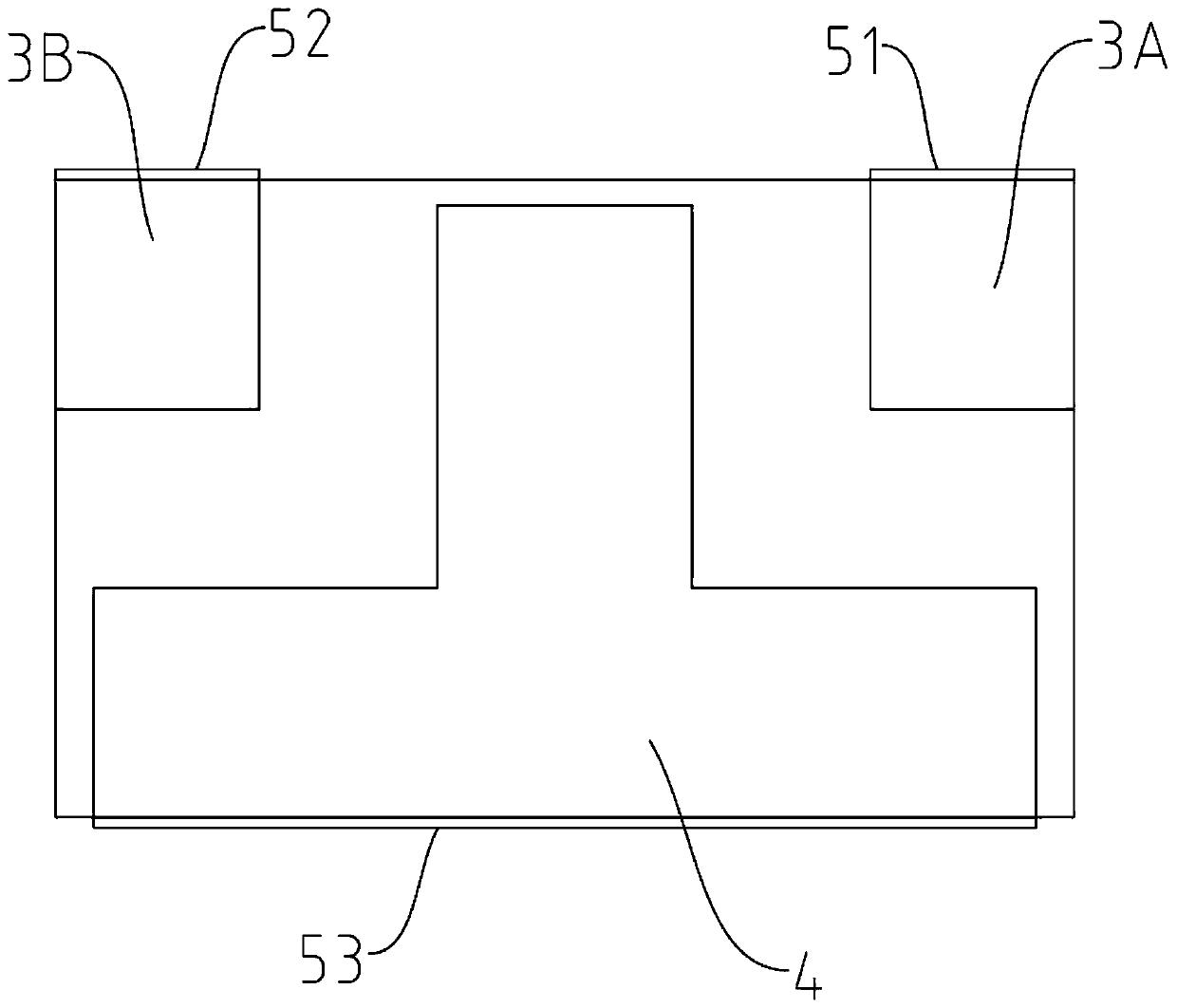

Surface-mounted miniature superimposed circuit attenuation sheet and preparation method thereof

ActiveCN111030640AImprove the attenuation effectReduce volumeFrequency-independant attenuatorsElectrical conductorHemt circuits

The invention discloses a surface-mounted miniature superimposed circuit attenuation sheet and a preparation method thereof. The size of the attenuation sheet is 2.5 mm * 4mm * 0.635 mm, the front surface of the attenuation sheet is provided with a first attenuation circuit and a second attenuation circuit, the first attenuation circuit and the second attenuation circuit are connected in series, and the first attenuation circuit and the second attenuation circuit share one resistor. The two attenuation circuits are connected in series to obtain the attenuation circuit with a higher attenuationvalue, and the relative resistance value is smaller, so that the precision requirement can be better met; and the first attenuation circuit and the second attenuation circuit creatively share one resistor to form respective attenuation circuits, so that the size of the attenuation sheet is effectively reduced, the attenuation sheet is easier to arrange in a high-frequency circuit, and an end conductor of the attenuation sheet is machined at one time, thereby further improving the precision and quality of the attenuation sheet.

Owner:苏州市新诚氏通讯电子股份有限公司

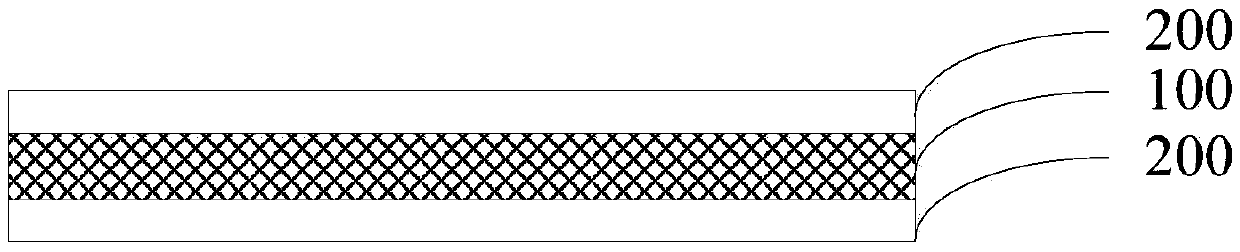

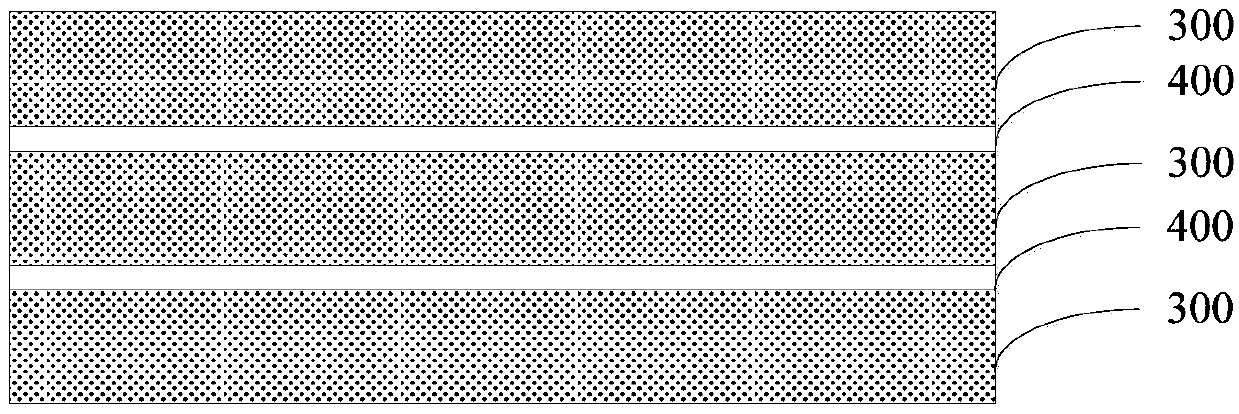

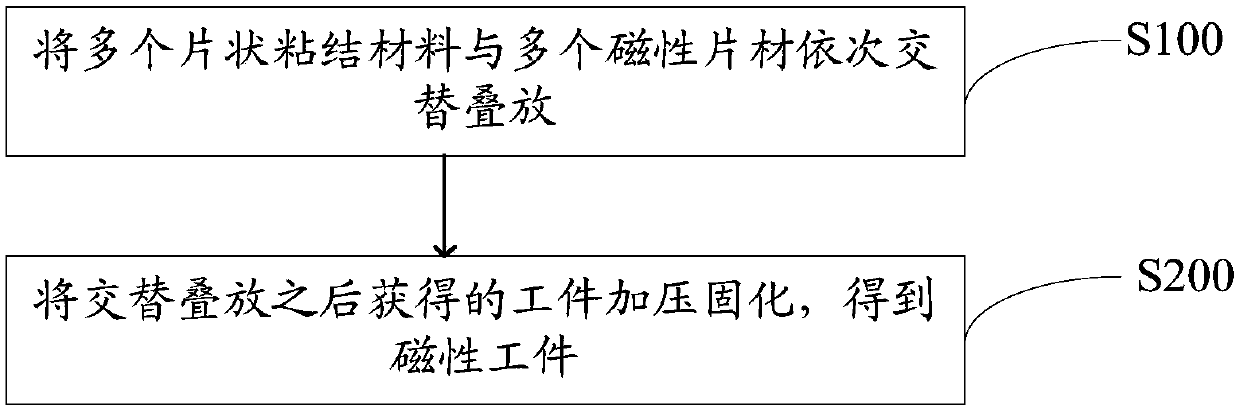

Sheet bonding material and magnetic workpiece and preparation method and application thereof

InactiveCN109686530ASimple structureUniform thicknessFilm/foil adhesivesPermanent magnetsNanotechnology

The invention provides a sheet bonding material and a magnetic workpiece and a preparation method and application thereof, and relates to the field of magnetic material bonding. The sheet bonding material comprises an insulating layer and glue layers disposed on the two opposite surfaces of the insulating layer. The inventor finds that the sheet bonding material has a simple structure, a uniform thickness, easy control of the thickness of the sheet bonding material, no bubbles and excellent bonding and insulating effects.

Owner:ZHEJIANG PANGOOD POWER TECH CO LTD

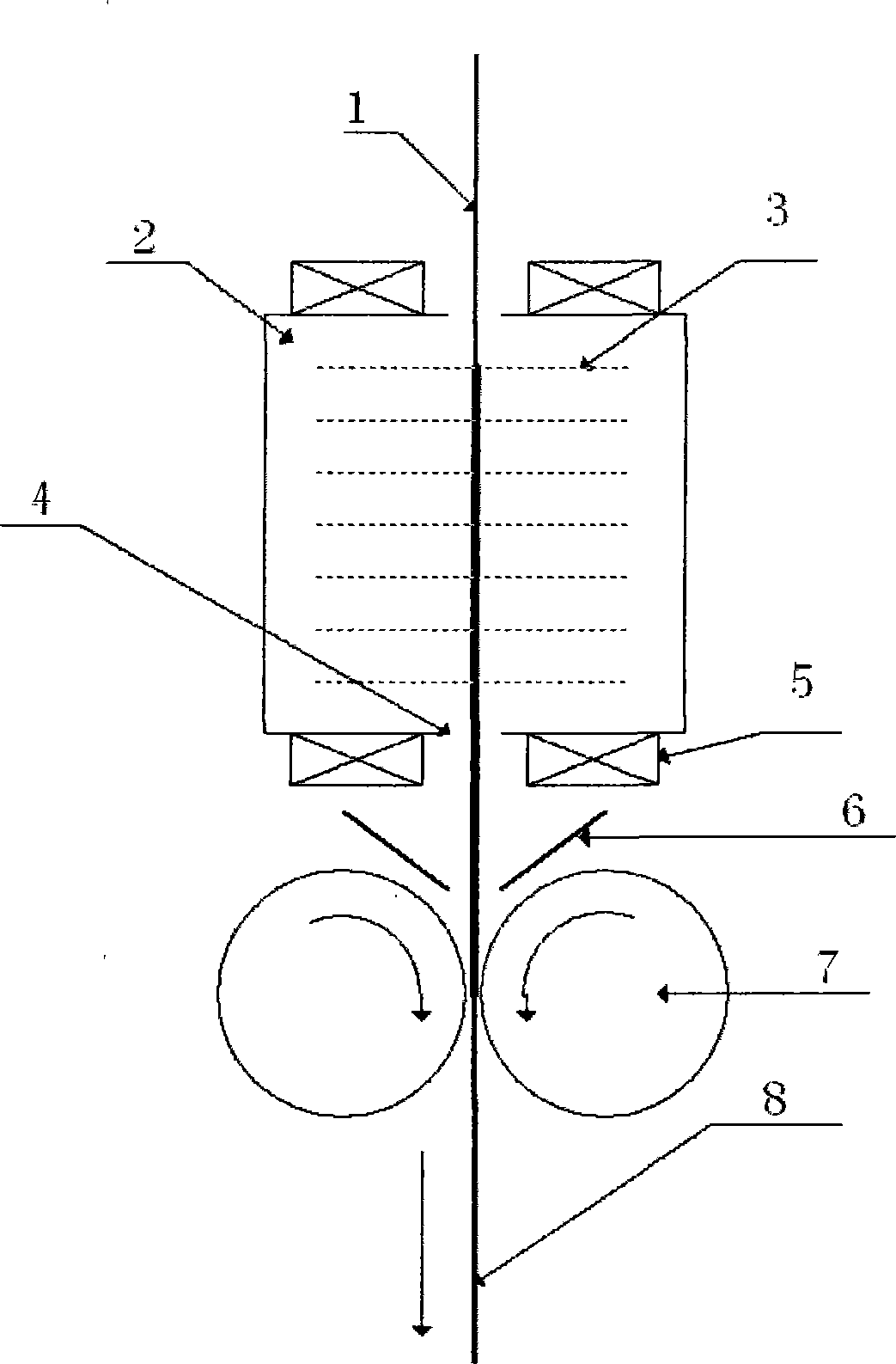

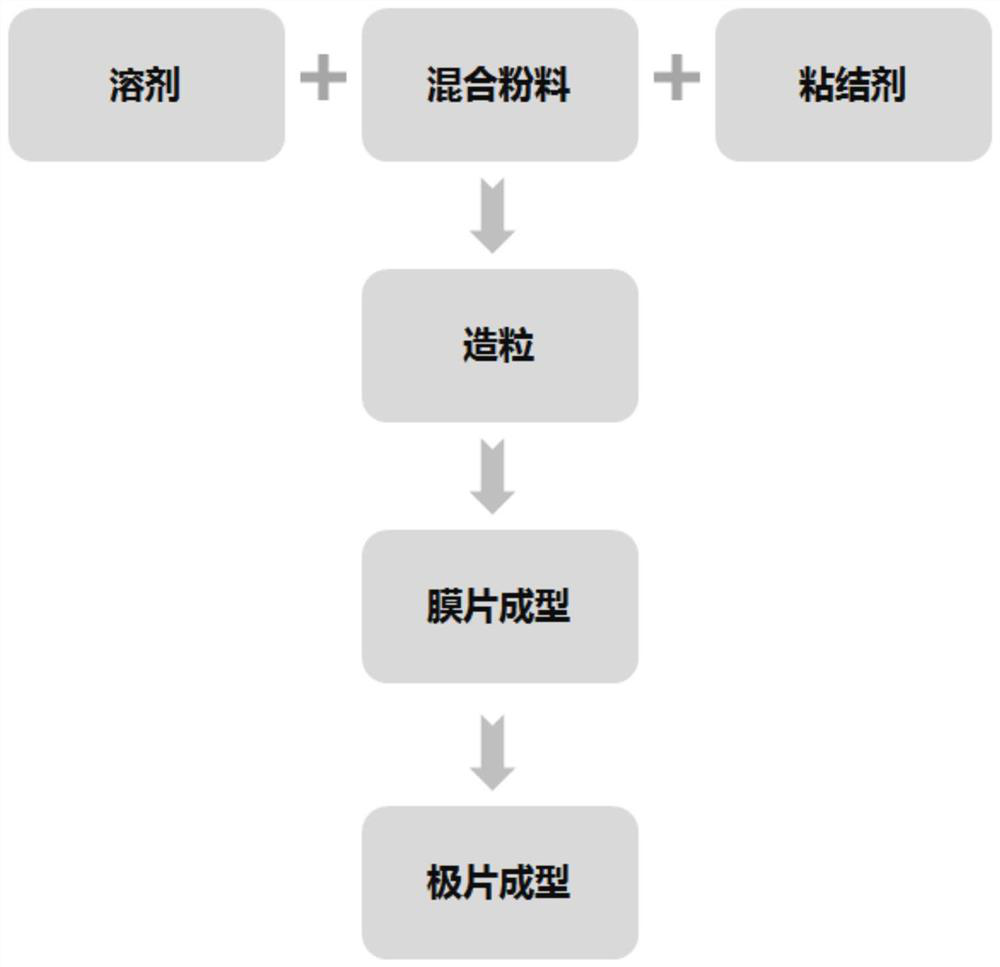

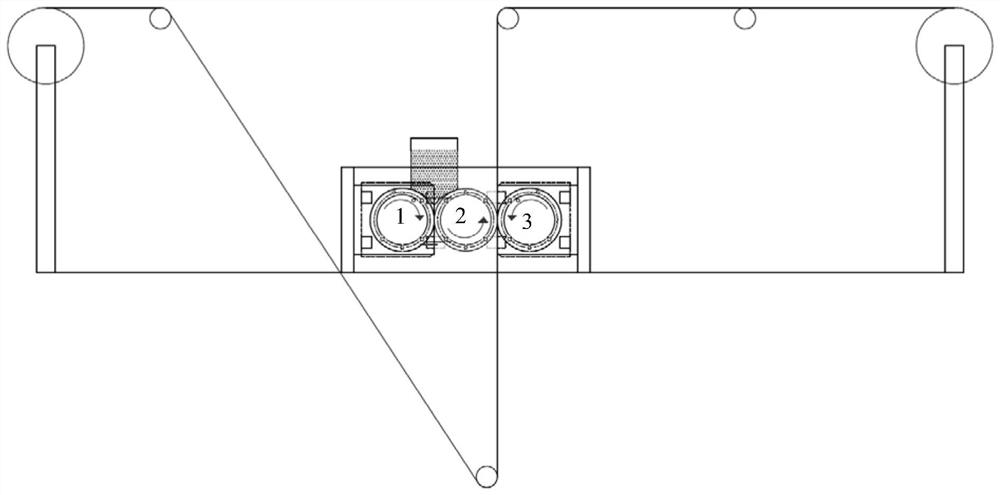

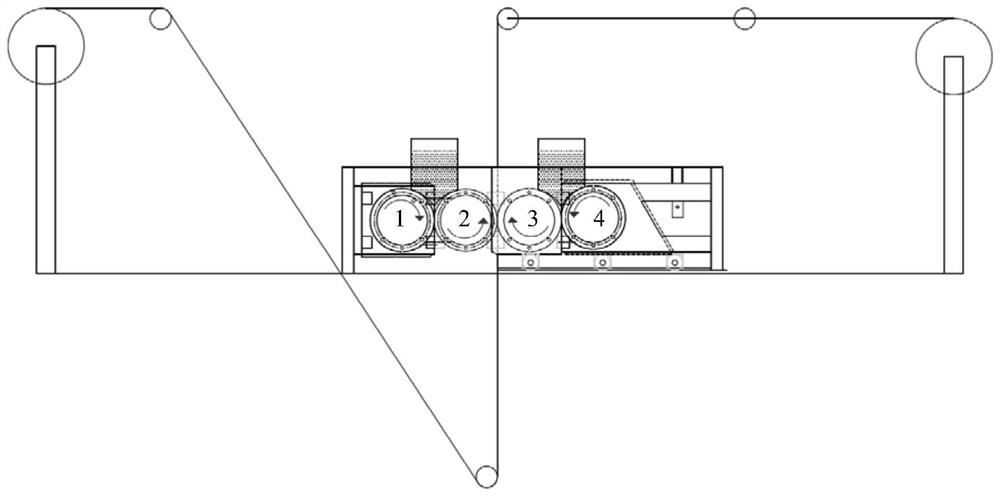

Pole piece, preparation method thereof and battery

InactiveCN112864346AHigh porosityGood thickness consistencyElectrode rolling/calenderingFinal product manufacturePole pieceElectric current flow

The invention provides a pole piece, a preparation method thereof and a battery. The preparation method comprises the following steps: (1) an active substance, a conductive agent, a solvent and a binder are mixed and granulatedto obtain mixed particles; and (2) the mixed particles obtained in the step (1) and a current collector are subjected to film combining in a film combining machine, the pole piece is obtained, and the number of rollers of the film combining machine is three or more than three. According to the preparation method provided by the invention, the pole piece can obtain relatively good porosity under the condition of keeping relatively high compaction density, so that the battery has relatively good discharge capacity, especially the discharge capacity under relatively high current and relatively low temperature conditions, and meanwhile, the thickness consistency of the pole piece is good. In addition, the method is simple in manufacturing process, high in automation level and capable of achieving one-process output from feeding to pole piece forming.

Owner:EVE ENERGY CO LTD

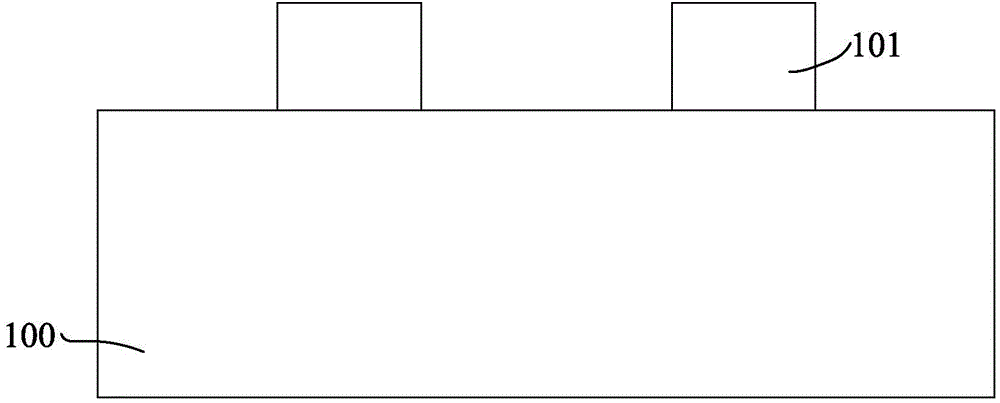

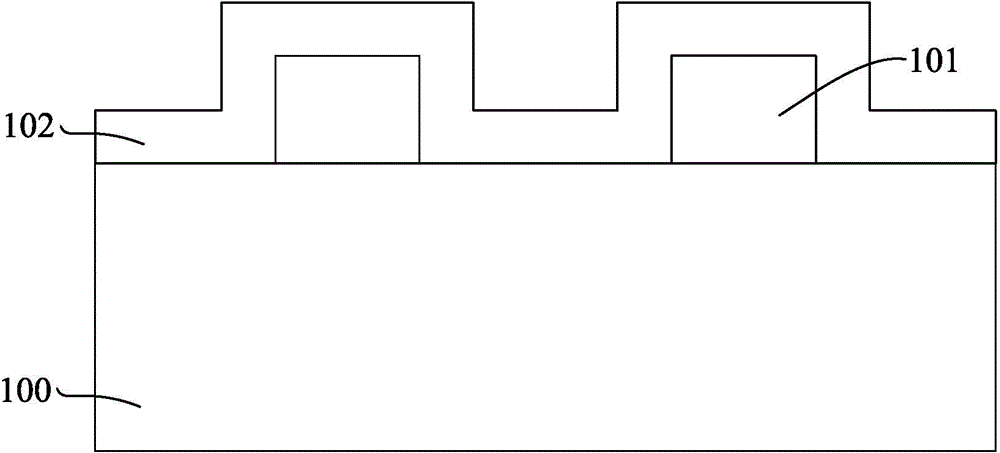

Fin type field effect transistor formation method

InactiveCN105097518AGood feature sizeReduce consumptionSemiconductor/solid-state device manufacturingEngineeringElectrical performance

The invention provides a fin type field effect transistor formation method comprising the steps that a substrate is provided, and multiple discrete fin parts are formed on the surface of the substrate; a shielding layer covering the surface of the fin parts is formed by adopting the deposition technology, and reactant gases of the deposition technology include a main source gas and an oxygen source gas, wherein the main source gas is gas including fin part material atoms; a photoresist film is formed on the surface of the shielding layer; exposure processing and development processing are performed on the photoresist film so that a patterned photoresist layer is formed; the patterned photoresist layer acts as a mask film, and the doping technology is performed on part of the fin parts; the patterned photoresist layer is removed; and the shielding layer is removed. In the technology process of formation of the shielding layer, consumption of the fin part material is low and even no fin part material is consumed so that the characteristic dimension of the fin parts is maintained to be unchanged. Besides, damage to the fin part material in the process of development processing can be prevented by the shielding layer so that the formed fin type field effect transistor is enabled to possess excellent electrical performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

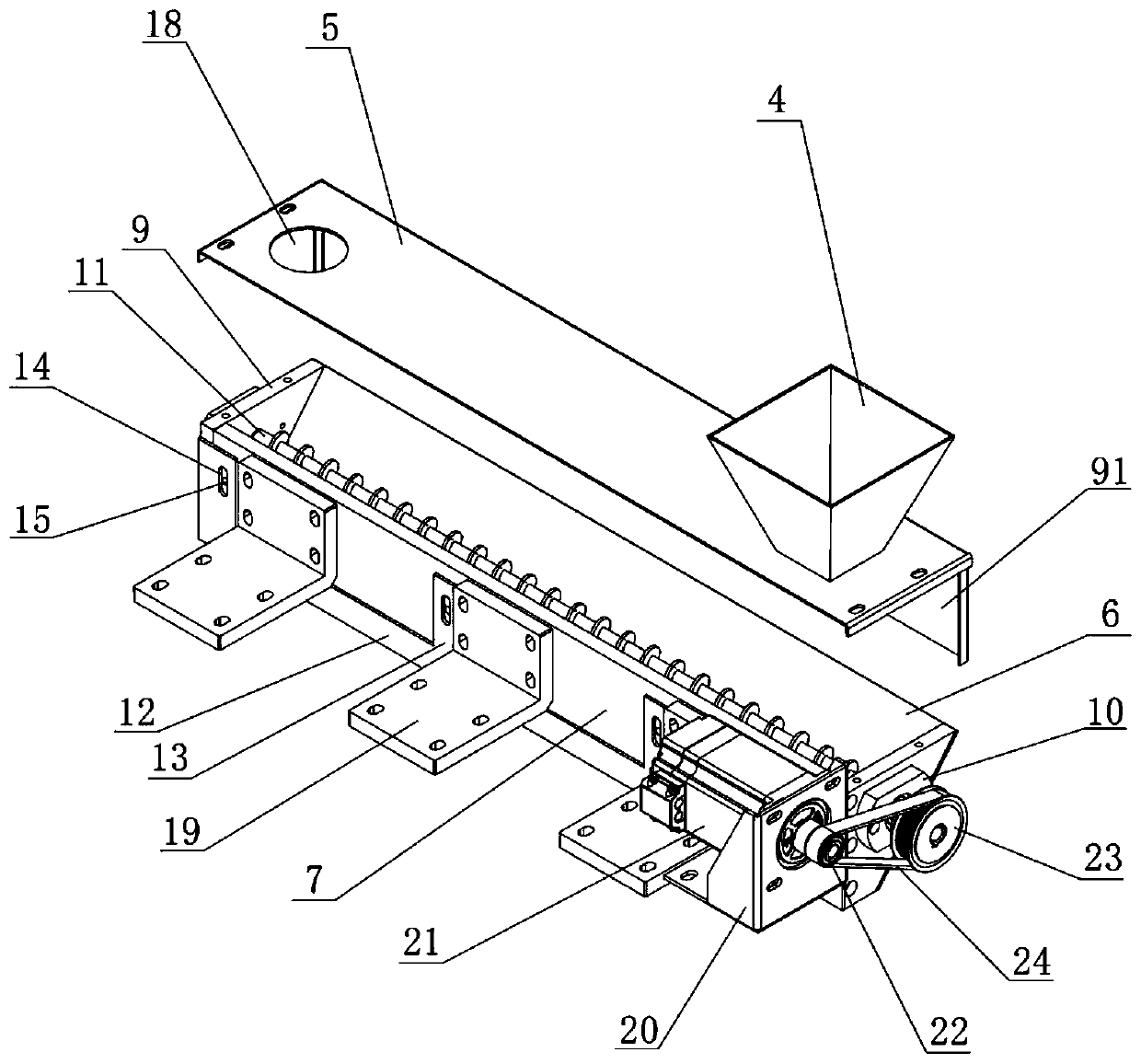

Powder spreading device of 3D printer

ActiveCN111231317ACompatible with compact spaceControl powder outputAdditive manufacturing apparatus3D object support structuresComputer printingElectric machinery

The invention discloses a powder spreading device of a 3D printer. The device comprises a powder falling part, a powder feeding part and a powder spreading part, the powder falling part comprises a powder falling hopper and a powder storage bin, the powder storage bin comprises an upper end plate, a side baffle, an adjusting plate after powder falling, a side plate, an adjusting plate before powder falling, a spiral shaft and a powder falling assembly fixed support, a powder falling motor is mounted at one end of the side plate, the powder feeding part comprises two powder feeding assembly fixed supports, a powder feeding driving shaft, a powder feeding driven shaft bearing pedestal, and a powder feeding driven shaft, a powder feeding conveying belt is mounted between the powder feeding driven shaft and the powder feeding driving shaft, a powder feeding motor is mounted beside the powder feeding assembly fixed supports, the powder spreading part comprises two powder spreading assemblyfixed supports, a powder spreading cross beam, a powder spreading roller bearing pedestal and a powder spreading motor base, a powder spreading roller is rotatably connected between the powder spreading roller bearing pedestal and the powder spreading motor base, and a powder spreading motor is fixedly mounted on the powder spreading base. Through the above arrangement, powder is not prone to blocking the powder falling opening, and the powder can be evenly spread on the whole powder spreading path at the same time.

Owner:武汉易制科技有限公司

Manufacturing method of shallow trench isolation structure

InactiveCN101740462AHigh activityQuick buildSemiconductor/solid-state device manufacturingOptoelectronicsSilicon oxide

The invention relates to a manufacturing method of a shallow trench isolation structure, which comprises the following steps of: providing a substrate and sequentially arranging a pad silicon oxide layer and a hard mask layer on the substrate; arranging a trench in the substrate and respectively arranging an opening at the positions in the pad silicon oxide layer and the hard mask layer corresponding to the trench; executing a wet-oxygen oxidation process and forming a pad silicon oxide layer at the bottom and the side wall of the trench; forming a dielectric layer on the pad silicon oxide layer and the hard mask layer in the trench; and removing the dielectric layer on the hard mask layer and the hard mask layer. The invention can improve the thickness consistency of the pad silicon oxide layer in the shallow trench isolation structure.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

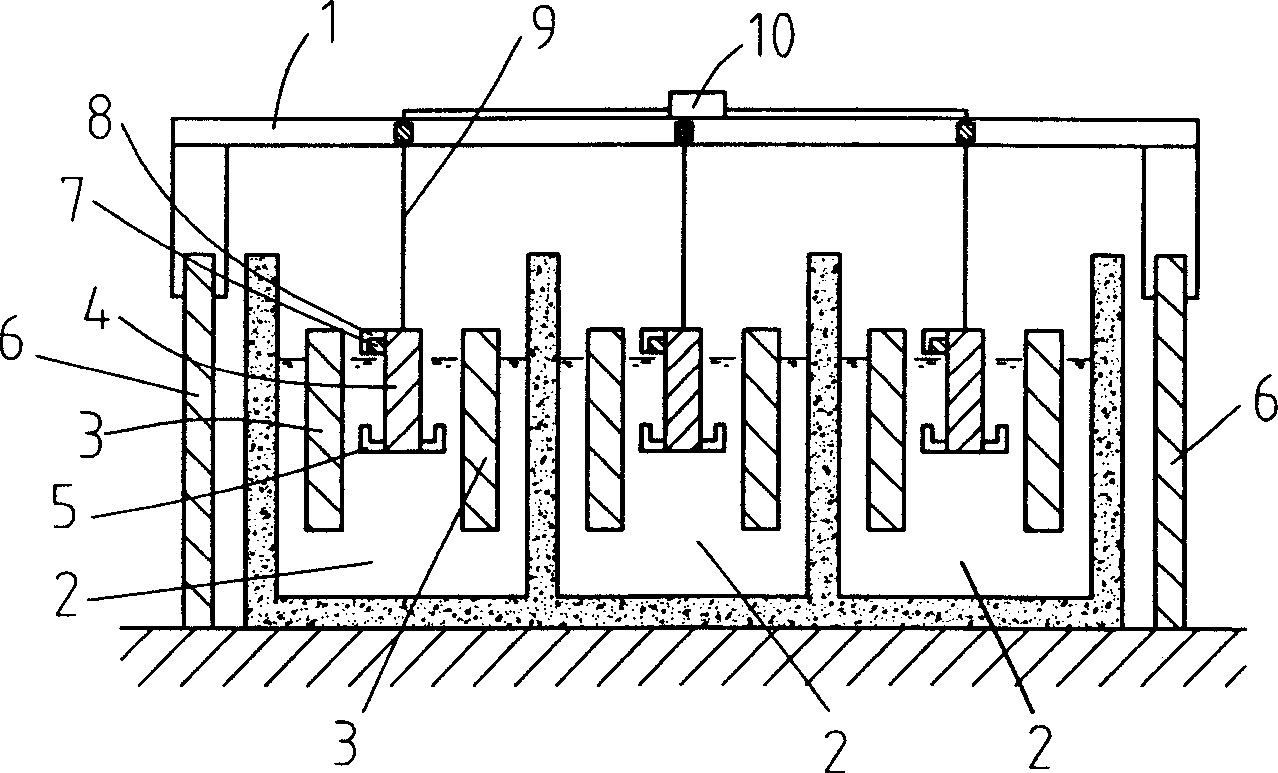

Electroplating apparatus

InactiveCN1888145AGood thickness consistencyQuality improvementElectrolysis componentsEngineeringElectroplating

The electroplating apparatus has one or several electroplating baths set between two tracks of traveling crane. Inside the electroplating bath, there are two parallel anode rods parallel to the tracks, one cathode rod with hung workpiece, two conducting slide rails between two anode rods, one conducting slide sleeve on the cathode rod for matching with the slide rails, one elevating mechanism for connecting the cathode rod via a hanging rope to the traveling crane. During electroplating, the cathode rod is driven with the traveling crane to move forward slowly and no corrosive electroplating solution drops from the workpiece to the anode rods. The present invention can obtain homogeneous coating thickness and stable product quality.

Owner:CHONGQING YUAN INNOVATION TECH GROUP

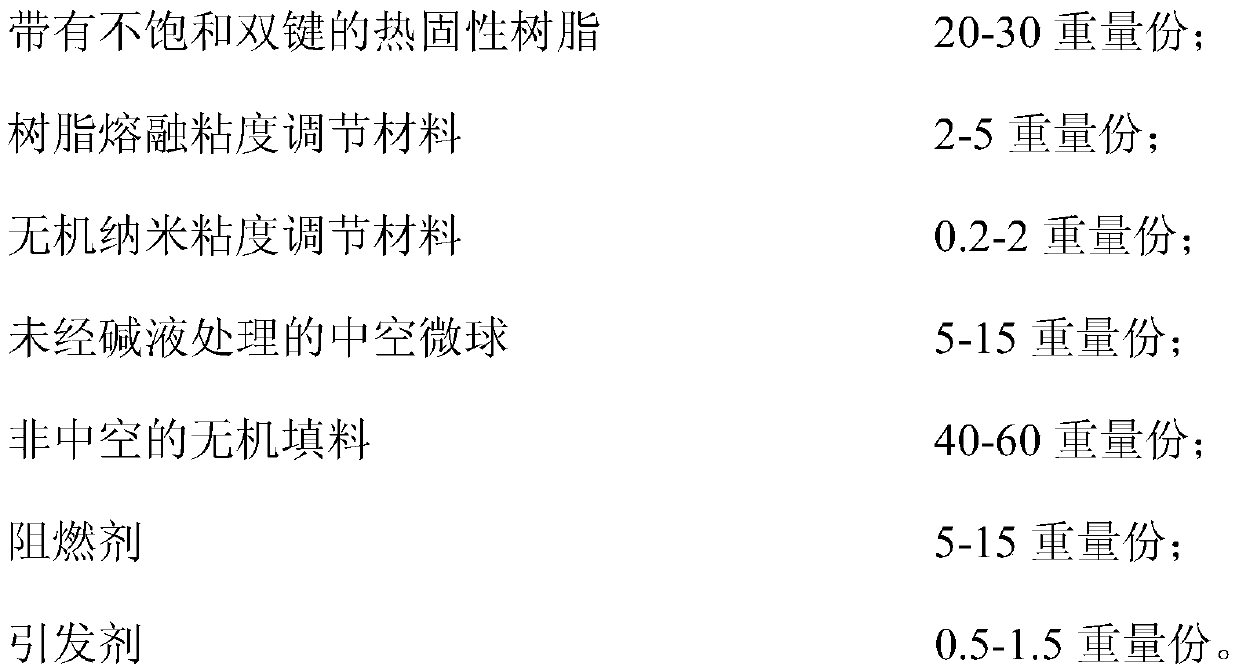

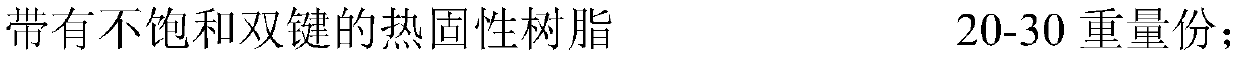

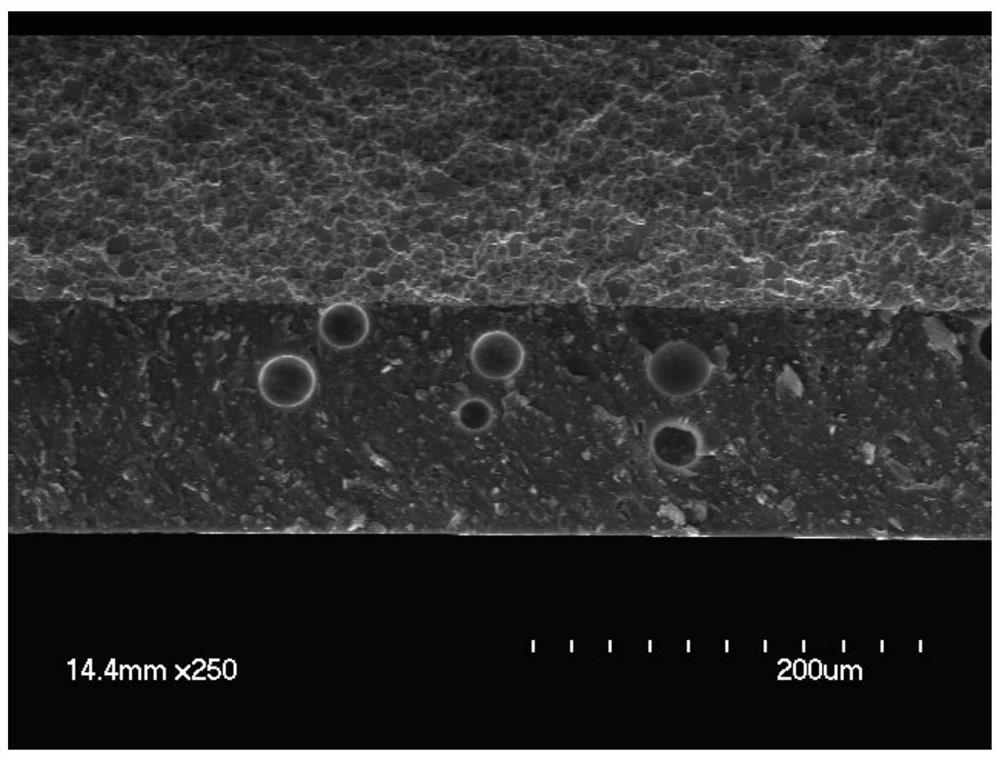

Resin composition, prepreg containing same and dielectric substrate for antenna

ActiveCN111378212AReduce outflowEvenly dispersedSynthetic resin layered productsMetal layered productsPolymer scienceMicrosphere

The invention provides a resin composition, a prepreg containing the resin composition and a dielectric substrate for an antenna. The resin composition is prepared from the following components: thermosetting resin with unsaturated double bonds, a resin melt viscosity adjusting material, an inorganic nano viscosity adjusting material, hollow microspheres which are not treated by alkali liquor, non-hollow inorganic filler, a flame retardant and an initiator, wherein the mass sum of the resin melt viscosity adjusting material and the inorganic nano viscosity adjusting material accounts for 3-6%of the total mass of the resin composition, and the mass ratio of the resin melt viscosity adjusting material to the inorganic nano viscosity adjusting material is (1-25): 1. The dielectric substrateobtained by adopting the resin composition provided by the invention has the advantages of low dielectric constant, low dielectric loss and excellent consistency of thickness and dielectric constant,and can meet the performance requirements of the dielectric substrate for the low-dielectric-constant antenna.

Owner:GUANGDONG SHENGYI SCI TECH

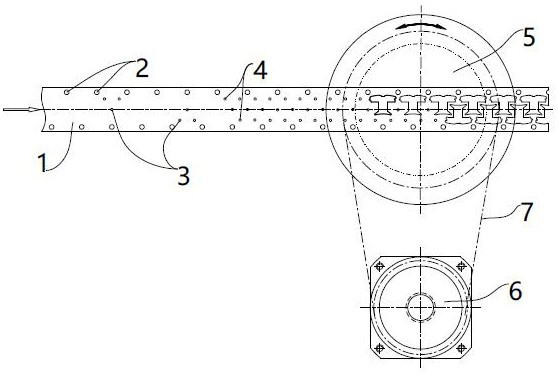

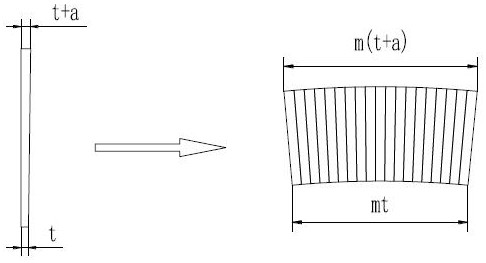

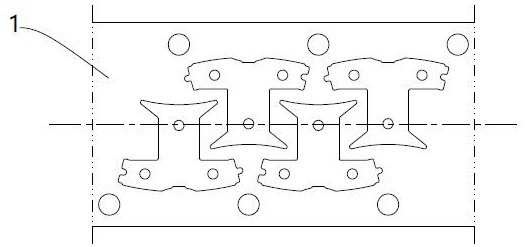

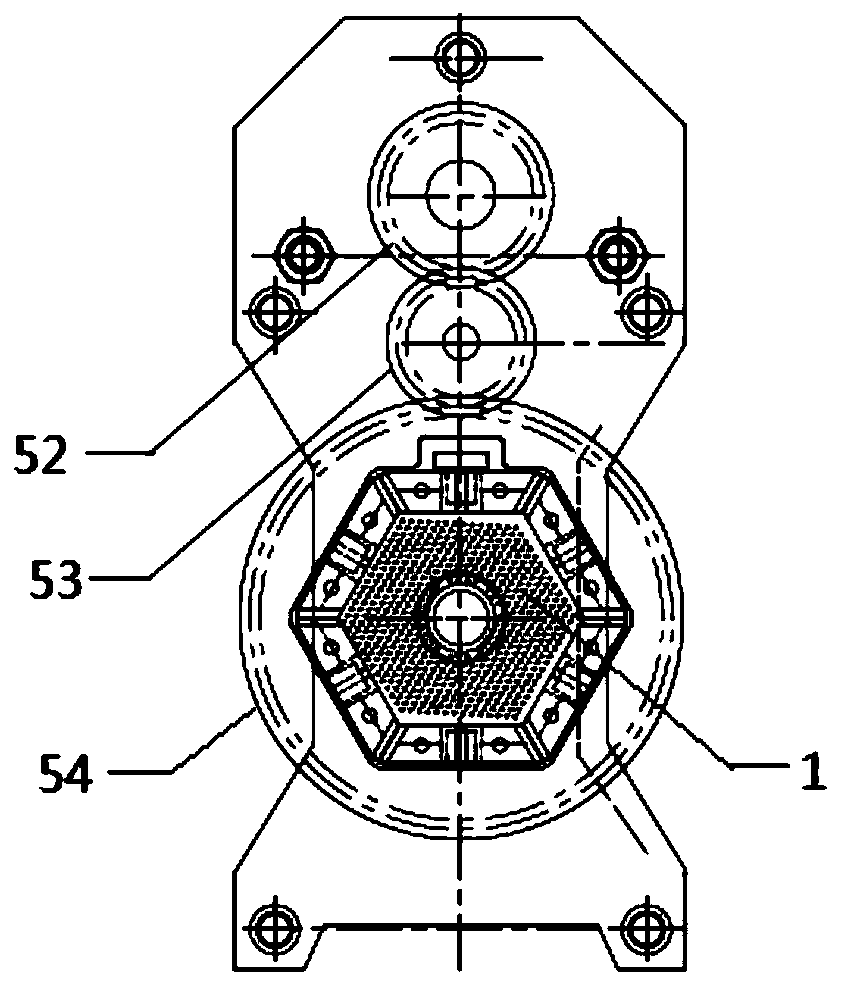

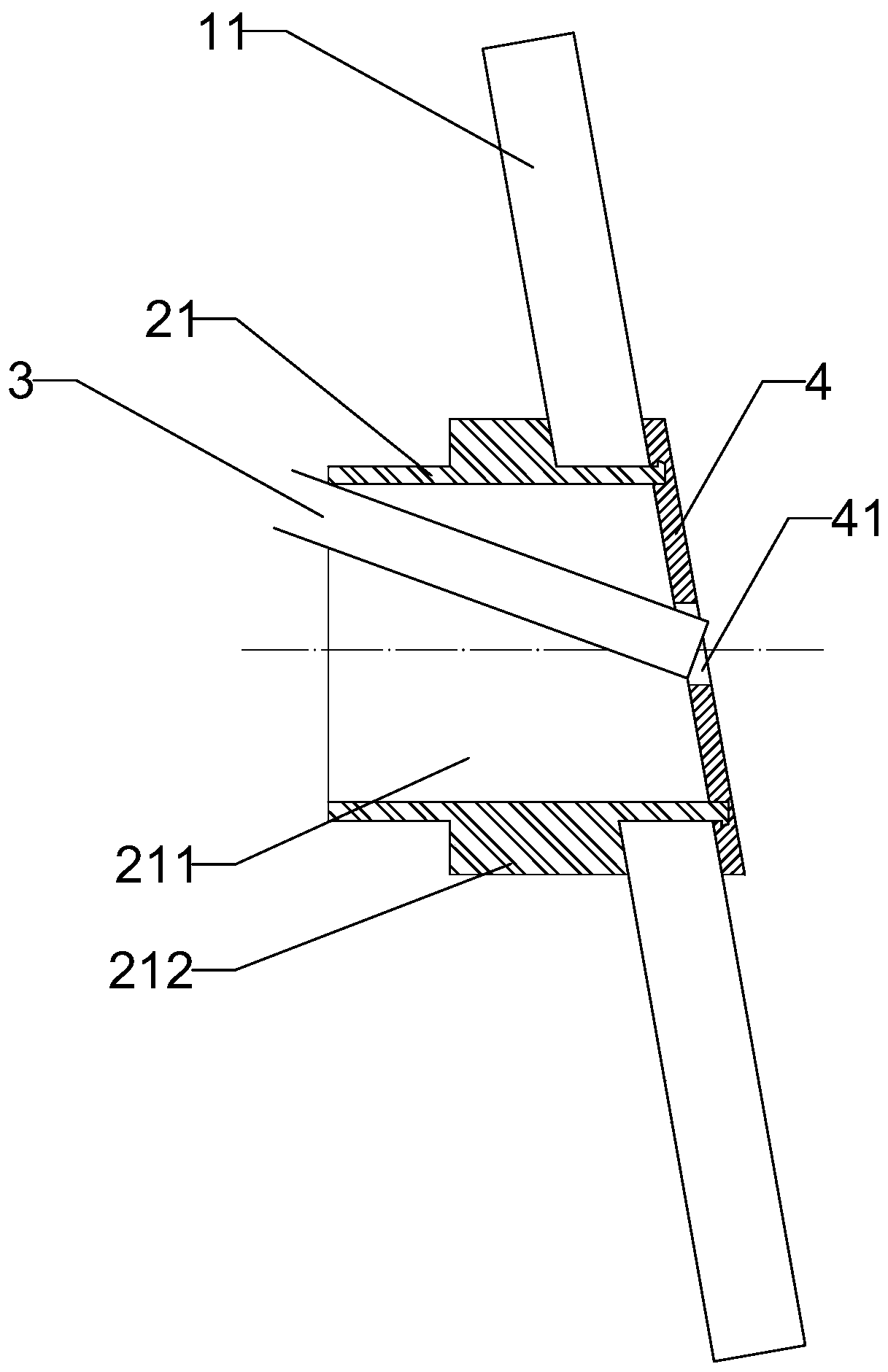

Manufacturing process of motor stator core

ActiveCN112260494AEliminate uneven thicknessGood thickness consistencyManufacturing stator/rotor bodiesStructural engineeringManufacturing engineering

The invention discloses a manufacturing process of a motor stator core. The manufacturing process comprises the following process steps of: step A, feeding; step B, punching a pilot hole; step C, punching metering points or buckling points, wherein each pair of metering points or buckling points are distributed in a central symmetry mode relative to the same point; and step D, blanking, namely carrying out stamping and blanking at the positions, punched with the metering points or the buckling points, of a strip material by utilizing a rotary stamping device with a rotatable female die to obtain a stator core monomer sheet temporarily stored in the rotary stamping device, and performing punching and blanking for multiple times repeatedly, rotating the female die by 180 degrees at least once after punching and blanking are finished each time, stacking the stator core single sheets obtained through punching and blanking for multiple times in the rotary punching device and finally enabling thestator core single sheets to fall off from the rotary punching device in the form of stator core single blocks; and step E, assembling, namely annularly splicing the plurality of stator core monomer blocks. The manufacturing process has the advantages that the produced stator iron core is good in thickness consistency, small in size difference and good in quality control.

Owner:NINGBO ZHENYU TECH

Coating, neodymium-iron-boron magnet and preparation method and application of neodymium-iron-boron magnet

PendingCN113881294AImprove corrosion resistanceImprove insulation performanceMagnetic circuit rotating partsPermanent magnetsBinding forceCorrosion resistant

The invention relates to a coating, a neodymium-iron-boron magnet and a preparation method and application of the neodymium-iron-boron magnet. The coating comprises a first coating layer and a second coating layer, the first coating layer is arranged on the magnet, and the second coating layer is arranged on the first coating layer. The second coating layer is prepared from a coating composition; and the coating composition contains a foaming body. When the foaming body is heated at the expansion temperature or at the temperature higher than the expansion temperature, the foaming body can expand, and expansion is irreversible. The surface of the magnet contains the coating layers, so that the disadvantage that the corrosion resistance is low due to large pores is improved, the overall corrosion resistance, insulativity and thickness consistency of the magnet are improved, and the magnet has good corrosion resistance and binding force with the magnet and a magnetic steel groove.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD +1

Resin composition, prepreg containing resin composition, dielectric substrate and printed circuit board

ActiveCN111378242AReduce the amount required for individual additionsImprove drilling processabilitySynthetic resin layered productsElectrical equipmentPolymer scienceHexagonal boron nitride

The invention provides a resin composition, a prepreg containing the resin composition, a dielectric substrate and a printed circuit board. The resin composition comprises the following components: (A) thermosetting resin with unsaturated double bonds; (B) a resin film-forming property improving material; (C) Hexagonal boron nitride; D, any one or a combination of at least two of aluminum nitride,silicon nitride or silicon carbide; (E) other inorganic fillers except the components (C) and (D); (F) a flame retardant and (G) an initiator, wherein the mass sum of the component (C), the component(D) and the component (E) accounts for 60-80% of the total mass of the resin composition, and the mass ratio of the component (C) to the component (D) is (1-4): 2. The dielectric substrate obtained by using the resin composition provided by the invention has the advantages of low dielectric constant, low dielectric loss, high thermal conductivity and stable thickness and dielectric constant, andcan fully meet the requirements of a high-frequency high-thermal-conductivity dielectric substrate.

Owner:GUANGDONG SHENGYI SCI TECH

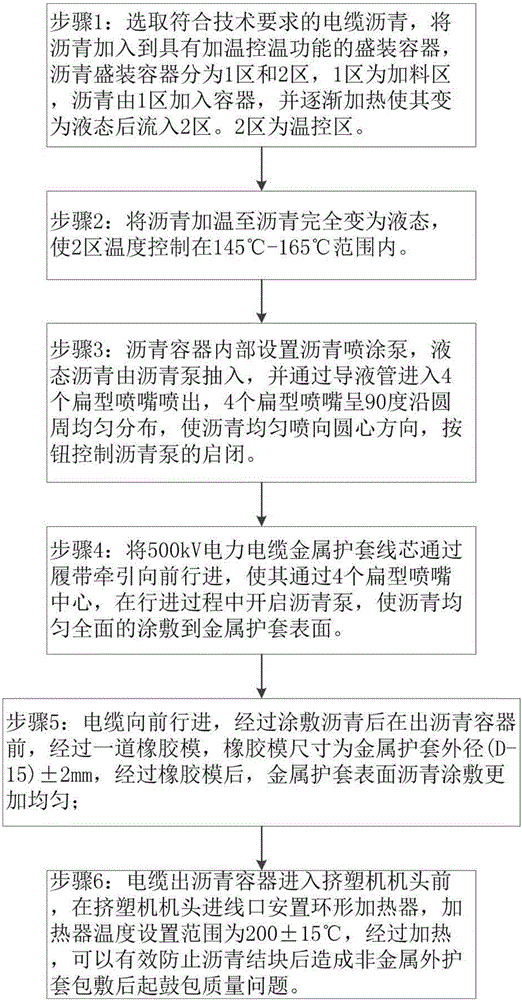

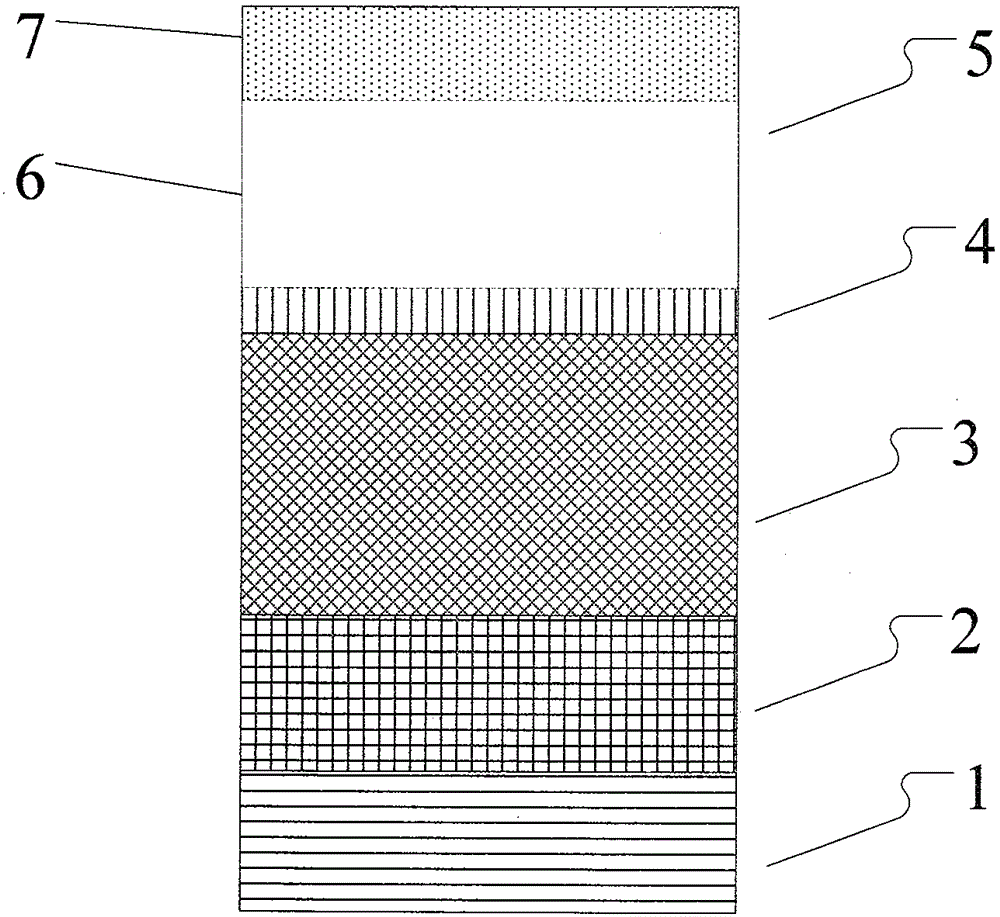

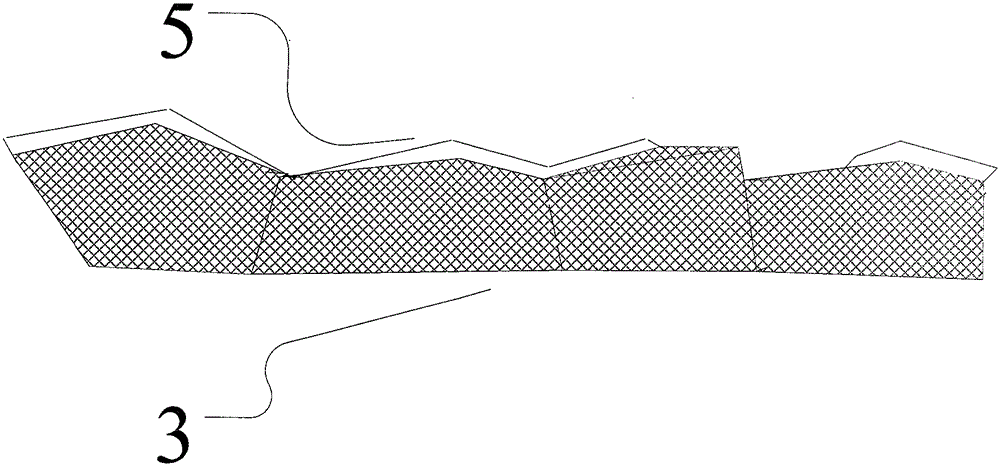

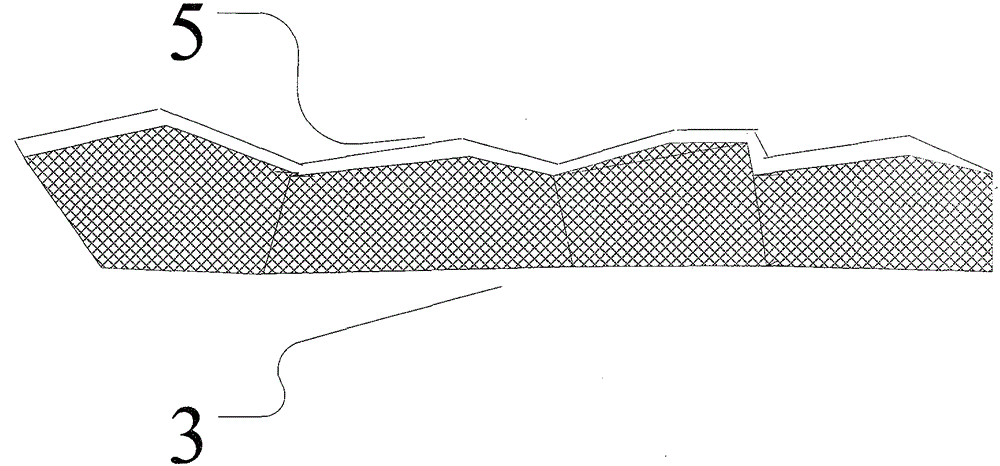

Application method of anti-corrosion pitch for 500kV power cable

InactiveCN106216195AGood corrosion resistanceUniform coatingPretreated surfacesCoatingsEngineeringMetal

The invention discloses an application method of anti-corrosion pitch for a 500kV power cable and aims to solve the problems that in the prior art, pitch for large-specification power cables is poor in application quality and is applied unevenly, and missing application is prone to occur. The method comprises the steps that the qualified cable pitch is selected and heated to the liquid state; the pitch in the liquid state is sprayed to the surface of a metal sheath in four radial directions of a cable core of the metal sheath of the cable; extruding application is conducted through a rubber mold; and then after being heated through a heater, the pitch enters a machine head of an extruding machine, so that the even pitch application process is completed. The method has the beneficial effects that a pitch anti-corrosion layer of the metal sheath is applied evenly; thickness consistency is good; the metal sheath is covered completely, and no missing application occurs; it is guaranteed that the metal protection layer of the cable is excellent in anti-corrosion property; and the surface of the outer sheath of the cable is god in quality.

Owner:HANGZHOU CABLE

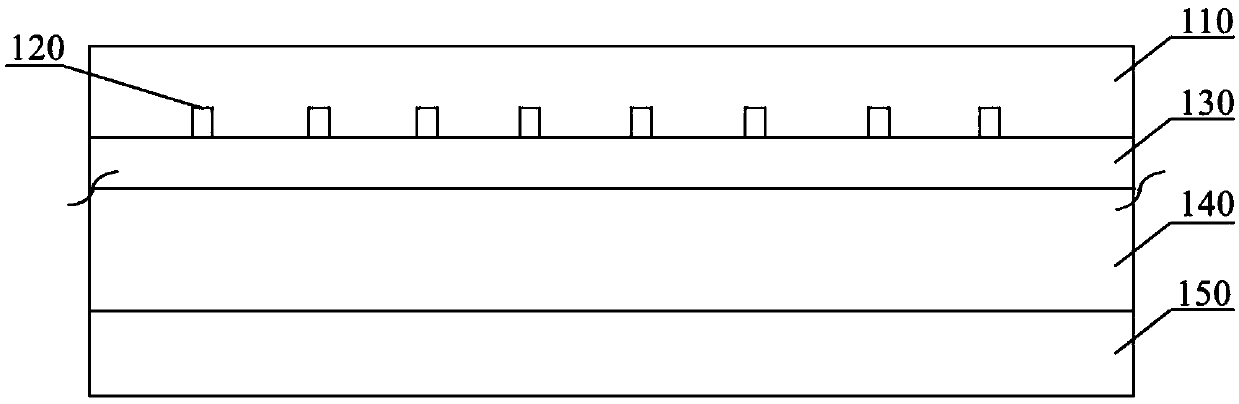

Method for increasing conversion efficiency of thin-film solar cell

InactiveCN105047750AImprove photoelectric conversion efficiencyImprove conversion efficiencyFinal product manufactureChemical vapor deposition coatingProcess equipmentChemical vapor deposition

The invention relates to the photovoltaic field of thin-film solar cells, and provides a method for increasing the conversion efficiency of a thin-film solar cell. The thin-film solar cell includes a substrate, a back electrode, a P-type light absorption layer, an N-type buffer layer and a window layer, wherein the back electrode, the P-type light absorption layer, the N-type buffer layer and the window layer are successively deposited on the substrate. The window layer includes an intrinsic layer and a doping conducting layer, the intrinsic layer is an intrinsic i-ZnO thin film, and the doping conducting laye ris aluminum-doping ZnO: AI thin film or a boron-doping ZnO:B thin film. The intrinsic layer and the doping conducting layer both have diethylzinc or dimethylzinc acting as zinc sources and are deposited to thin films by adopting a low pressure chemical vapor deposition method. The intrinsic layer and the doping conducting layer are successively deposited on the surface of the N-type buffer layer. The solar cell prepared by the method herein has the characteristics of high conversion efficiency, low requirements for technology and devices, easy mass-production and low cost.

Owner:GUANGDONG HANERGY THIN FILM SOLAR CO LTD

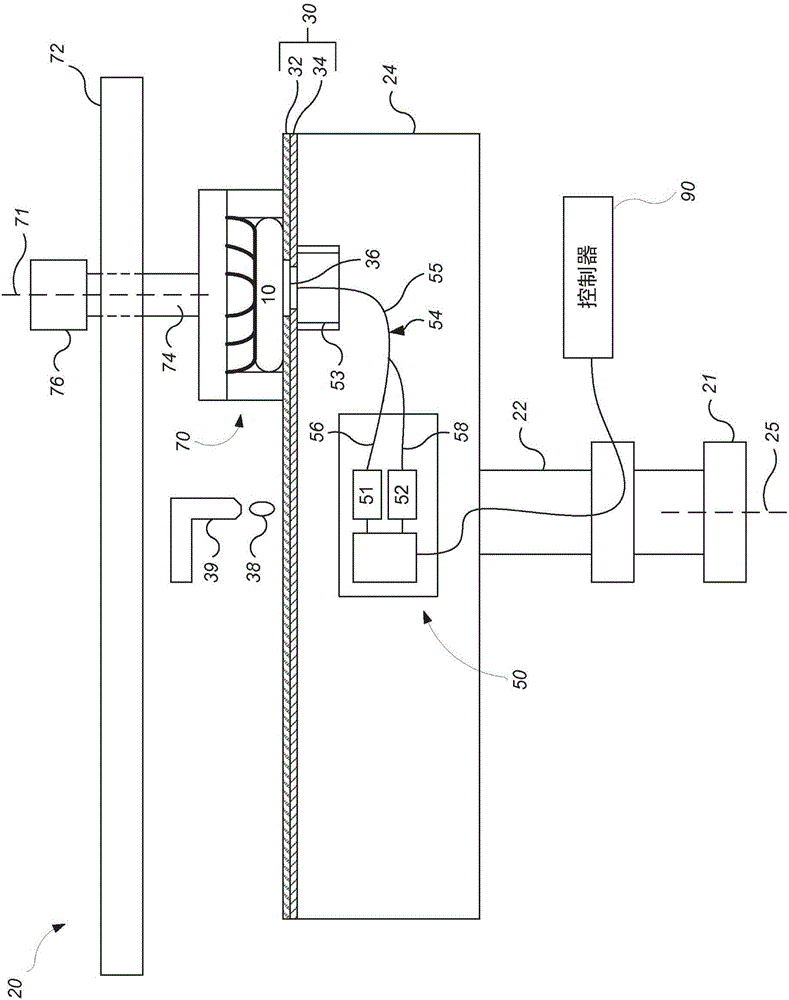

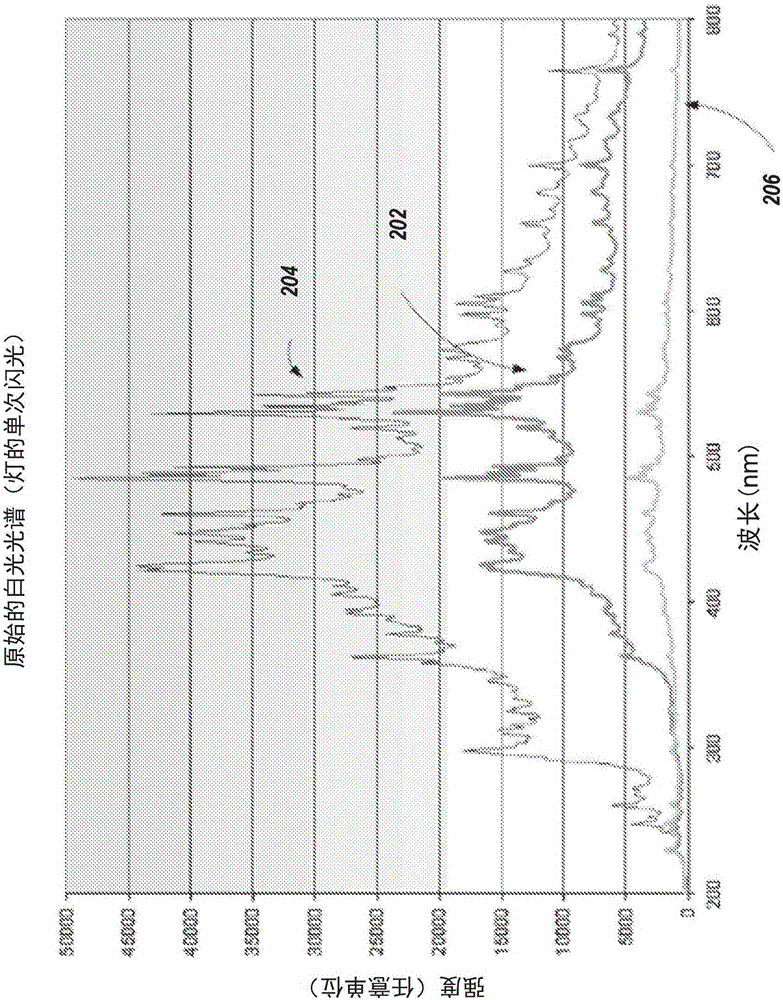

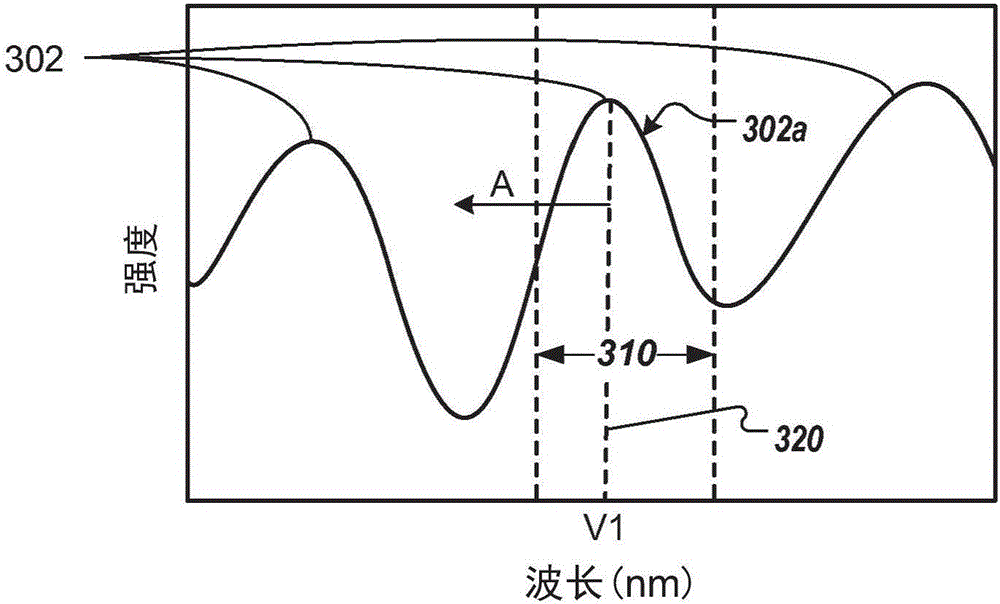

Serial feature tracking for endpoint detection

ActiveCN106463378AGood thickness consistencyImproved endpoint controlSemiconductor/solid-state device manufacturingLapping machinesFeature trackingMonitoring system

A method of controlling polishing includes polishing a substrate having a second layer overlying a first layer, detecting exposure of the first layer with an in-situ monitoring system, receiving an identification of a selected spectral feature and a characteristic of the selected spectral feature to monitor during polishing, measuring a sequence of spectra of light from the substrate while the substrate is being polished, determining a first value for the characteristic of the feature at the time that the first in-situ monitoring technique detects exposure of the first layer, adding an offset to the first value to generate a second value, and monitoring the characteristic of the feature and halting polishing when the characteristic of the feature is determined to reach the second value.

Owner:APPLIED MATERIALS INC

Semiconductor silicon-based optical waveguide device and preparation method thereof

ActiveCN109669237AFlexible designManufacturing flexibilityOptical waveguide light guideRefractive indexWaveguide

The invention provides a semiconductor silicon-based optical waveguide device and a preparation method thereof, and relates to the field of optical waveguide chip producing and manufacturing. The preparation method of the semiconductor silicon-based optical waveguide device comprises the following steps that (a) a bottom cladding layer is deposited on a non-polished surface of a single-surface-polished silicon wafer; (b) a lower cladding layer, a core layer and a mask layer are deposited in an overlapped mode in sequence on a polished surface of the single-surface-polished silicon wafer; (c) awaveguide channel is formed after the core layer is etched, and the mask layer is removed; and (d) an upper cladding layer is deposited on the etched core layer, and thus the semiconductor silicon-based optical waveguide device is obtained. Preferably, the mask layer is a metal mask layer, and the technical problems that quartz substrate slices are used in conventional waveguide devices, the dependency on the quality of the substrate slices is high and special quartz processing equipment needs to be ordered for manufacturing are solved. According to the preparation method of the semiconductorsilicon-based optical waveguide device, semiconductor silicon is adopted as a substrate slice, compatibility with silicon semiconductor manufacturing equipment is good, the influence of the substrateslice refractive index is avoided, and design and manufacturing are more flexible.

Owner:JILIN SINO MICROELECTRONICS CO LTD

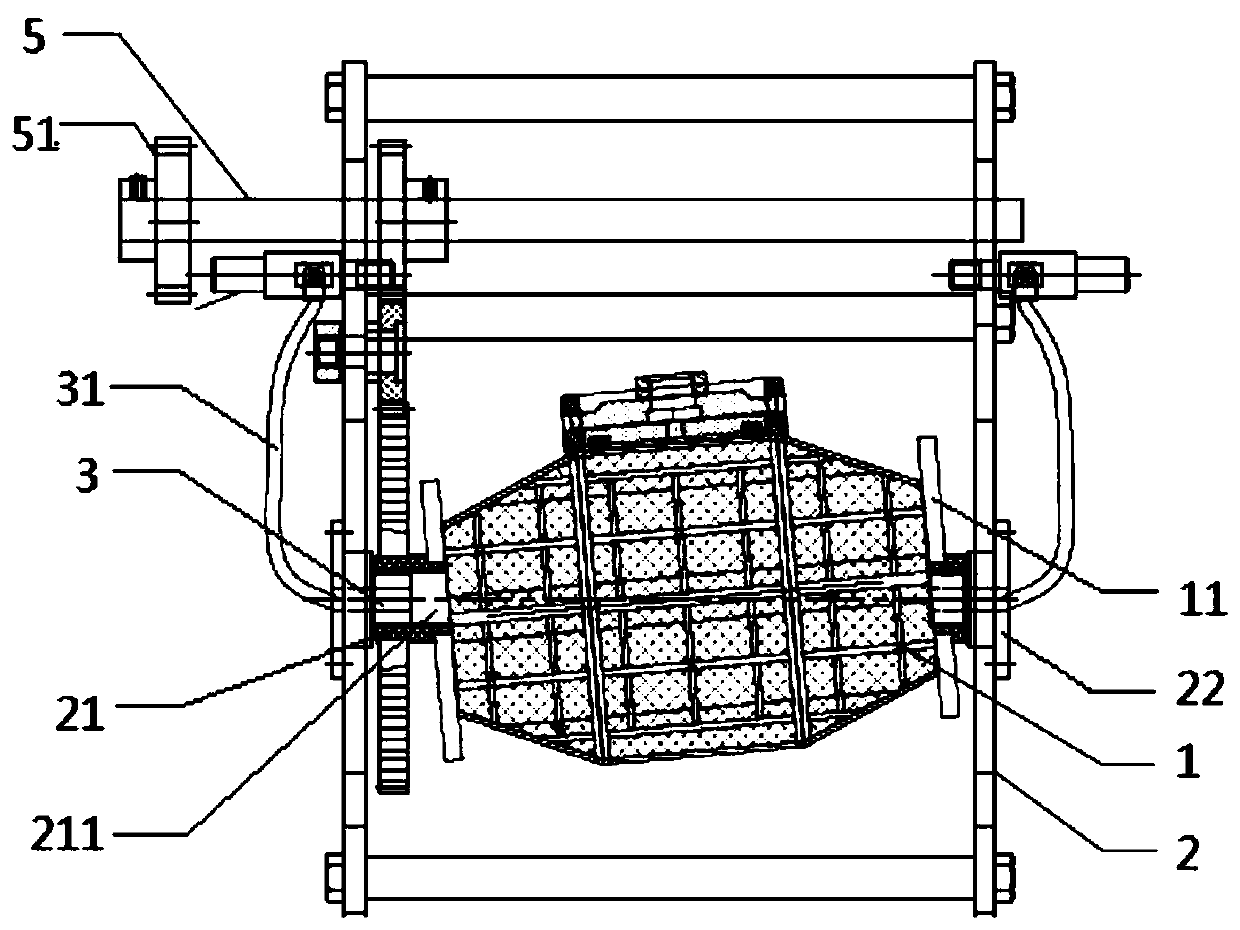

Assembly line equipment for producing hard PVC (polyvinyl chloride) sheets

The invention discloses assembly line equipment for producing hard PVC (polyvinyl chloride) sheets. The PVC sheets produced by the assembly line equipment are uniform in thickness and high in transverse shrinkage rate. A calender is composed of six calendering rollers, and the arrangement mode of the six calendering rollers is a combination of a positive Z-shaped arrangement structure and a positive I-shaped arrangement structure from top to bottom. According to the method, a six-roller calender is adopted for calendering a PVC sizing material into a thin sheet, then circulating ice water is adopted for cooling stripping rollers in an initial-section cooling area behind the calender, so that the temperatures of all positions of the surfaces of the stripping rollers are uniform and consistent, and after the PVC sheet which is output from a discharging hole of the calender and is in a high-temperature state passes through the stripping rollers, the temperature of the formed PVC sheet in the width direction is uniform, so that the thickness consistency of the PVC sheet in the width direction is improved. Through the rigidity improving section subjected to ice water cooling treatment, the PVC sheet penetrating through the initial section cooling area and the rigidity improving section is subjected to rapid cooling stimulation, and the transverse shrinkage rate is effectively increased.

Owner:深圳弘臻新材料科技有限公司

Special rotary drum for small-specification neodymium-iron-boron magnetic steel barrel plating

InactiveCN111364088AReduce the probability of pastingImprove bindingElectrolysis componentsEngineeringNeodymium iron boron

The invention discloses a special rotary drum for small-specification neodymium-iron-boron magnetic steel barrel plating. The special rotary drum comprises a support and a drum body rotatably connected to the support, wherein the drum body is in a shape with two smaller ends and a larger middle portion in the axial direction. According to the special rotary drum, the problems that in the prior art, a small-specification product is prone to attaching to an end wall or a dead angle is formed, so that the bonding force between a base body and a plating layer is reduced, the protective property ofthe plating layer is reduced, the magnetic decay rate of the product is increased, the qaulification rate of the product is reduced, the discharging time is increased, and the production efficiency is reduced are solved, piece sticking and wall attaching during the barrel plating of the product are prevented, the bonding force of the base body and the plating layer is improved, and the protectivecapability of the plating layer is improved; and during electroplating, power line distribution is concentrated, the deposition speed is increased, the magnetic decay rate of the product is reduced,the qualification rate of the product is increased, the discharging speed is high, and the production efficiency is improved.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

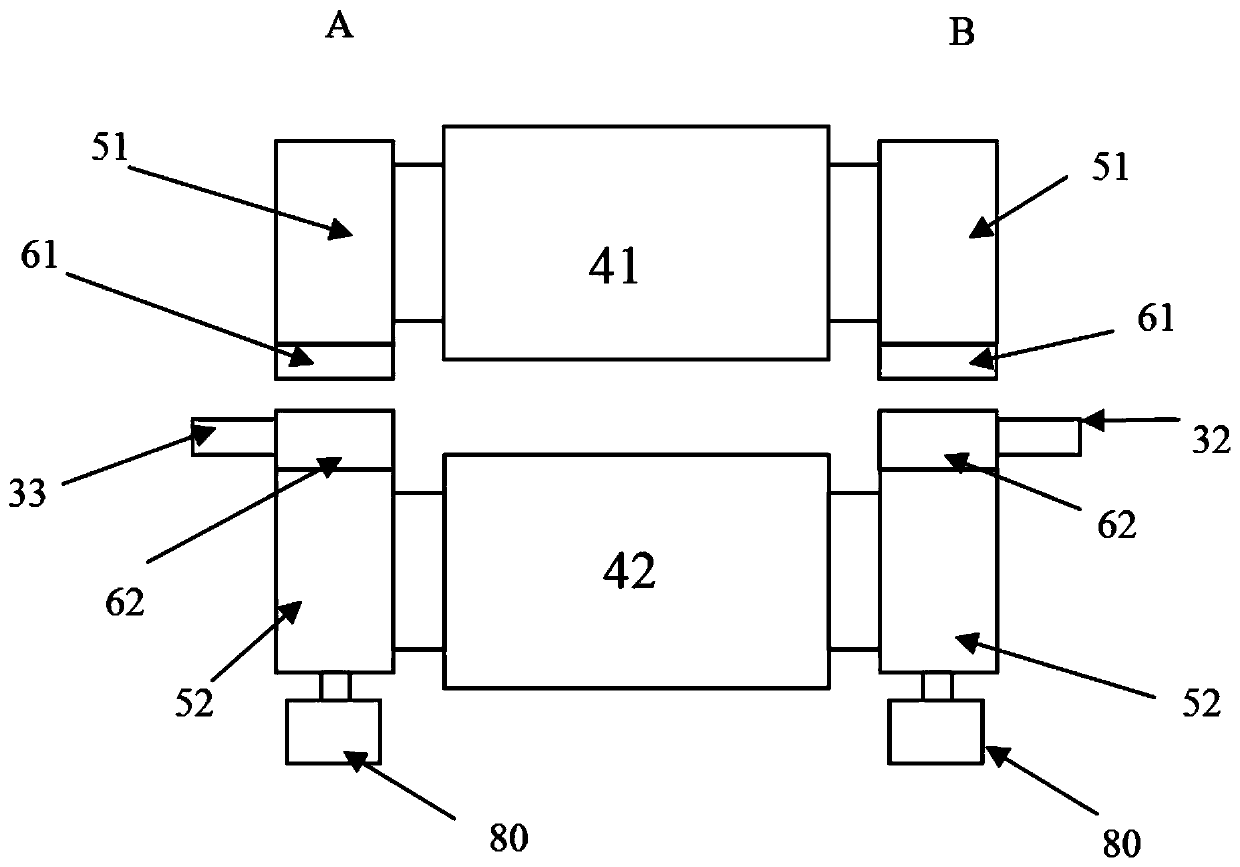

Bean type battery and manufacturing method thereof

InactiveCN111211260AGood thickness consistencyIncrease energy densityFinal product manufactureCylindrical casing cells/batteryWhole bodyStructural engineering

The invention discloses a bean type battery and a manufacturing method thereof. The bean type battery comprises a shell and a winding type battery cell. The shell comprises a bottom shell and a covercap; the bottom shell and the cover cap are both metal pieces; the bottom shell comprises a bottom plate and a first surrounding wall annularly arranged on one side surface of the bottom plate; the cover cap comprises a top plate and a second surrounding wall annularly arranged on one side surface of the top plate; the second surrounding wall sleeves the first surrounding wall; a first arc-shapedpart is arranged on the first surrounding wall; a second arc-shaped part matched with the first arc-shaped part is arranged on the second surrounding wall; a first insulating sealing film is adhered to an outer surface of the first surrounding wall; and a second insulating sealing film is adhered to an inner surface of the second surrounding wall, the first insulating sealing film and the second insulating sealing film abut against each other and then are cured into a whole body so as to form a sealing layer, a pole piece of the winding type battery cell is strip-shaped, and a tab is arrangedin a center of a length direction or at least two tabs are arranged on the pole piece. The bean type battery is simple in structure, good in sealing effect, high in space utilization rate and energy density and capable of achieving quick charging and high-rate discharging.

Owner:EVE ENERGY CO LTD

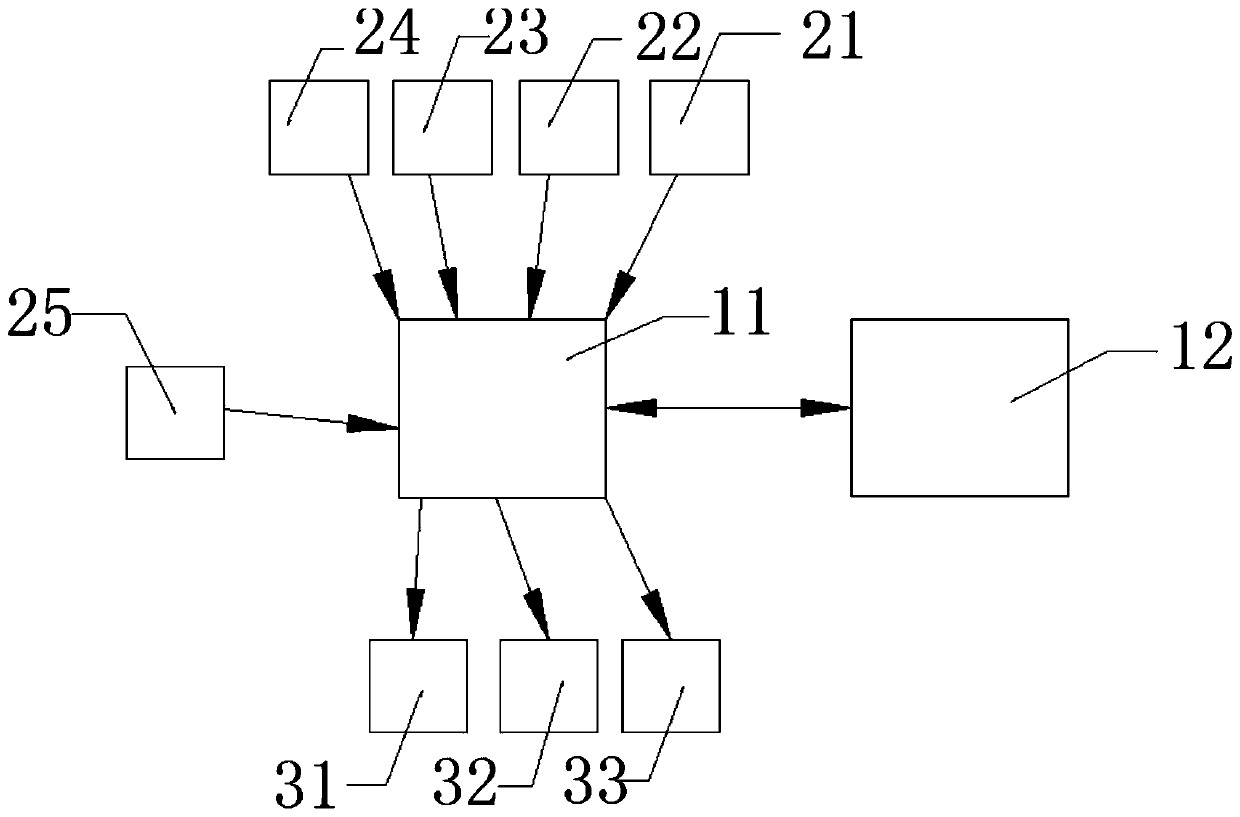

Online adjustment monitoring system for line pressure of rolling machine

ActiveCN111495969AGood thickness consistencyExtremely smallRoll force/gap control deviceMetal rolling arrangementsHuman–machine interfaceProgrammable logic controller

The invention discloses an online adjustment monitoring system for line pressure of a rolling machine. The online adjustment monitoring system comprises a Programmable Logic Controller (PLC) (11), a human-machine interface (HMI) (12), a first pressure transmitter (21), a second pressure transmitter (22), a third pressure transmitter (23), a fourth pressure transmitter (24), a hydraulic station total pressure transmitter (25), a hydraulic station proportional pressure reducing valve (31), an operation skew iron motor (32) and a driving skew iron motor (33). The Programmable Logic Controller (PLC) (11) is connected with the first pressure transmitter (21), the second pressure transmitter (22), the third pressure transmitter (23), the fourth pressure transmitter (24) and the hydraulic stationproportional pressure reducing valve (31) through signal lines. According to the online adjustment monitoring system for the line pressure of the rolling machine, the line pressure in the rolling process can be accurately controlled, the line pressure in the rolling process is constant, and therefore high-quality pole pieces with good thickness consistency and small range can be output.

Owner:TIANJIN LISHEN BATTERY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com