Coating, neodymium-iron-boron magnet and preparation method and application of neodymium-iron-boron magnet

A neodymium iron boron and coating technology is applied in the field of magnet surface protection treatment to achieve the effects of high assembly precision, saving assembly cost and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

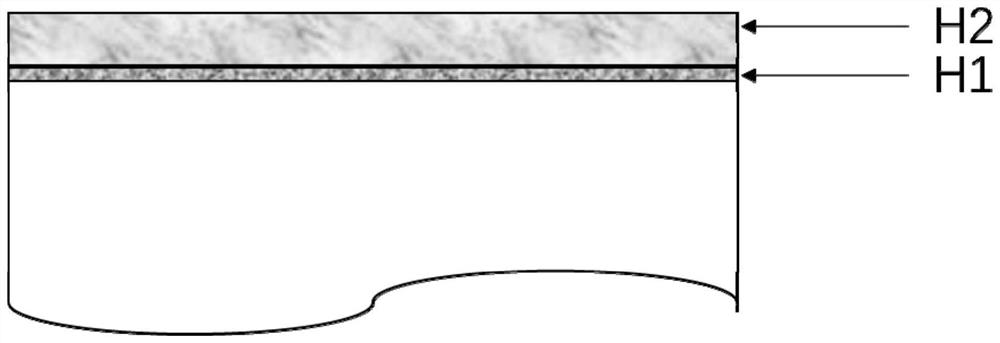

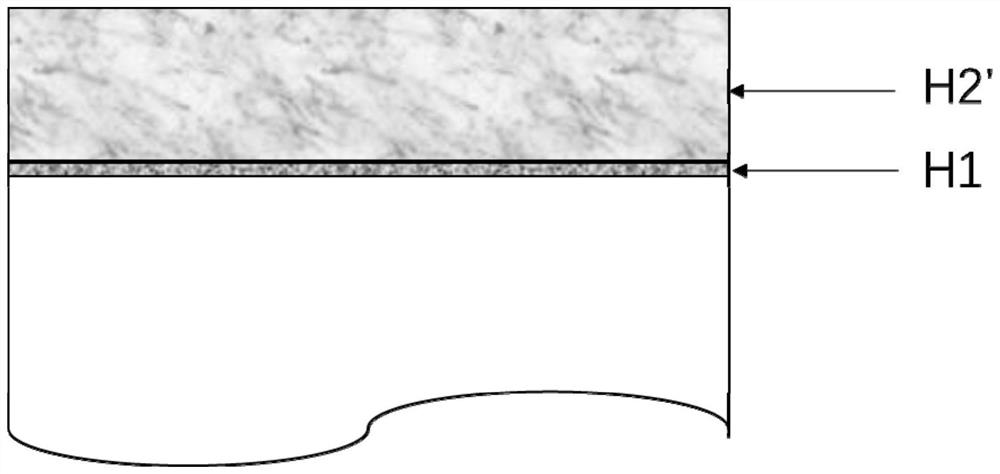

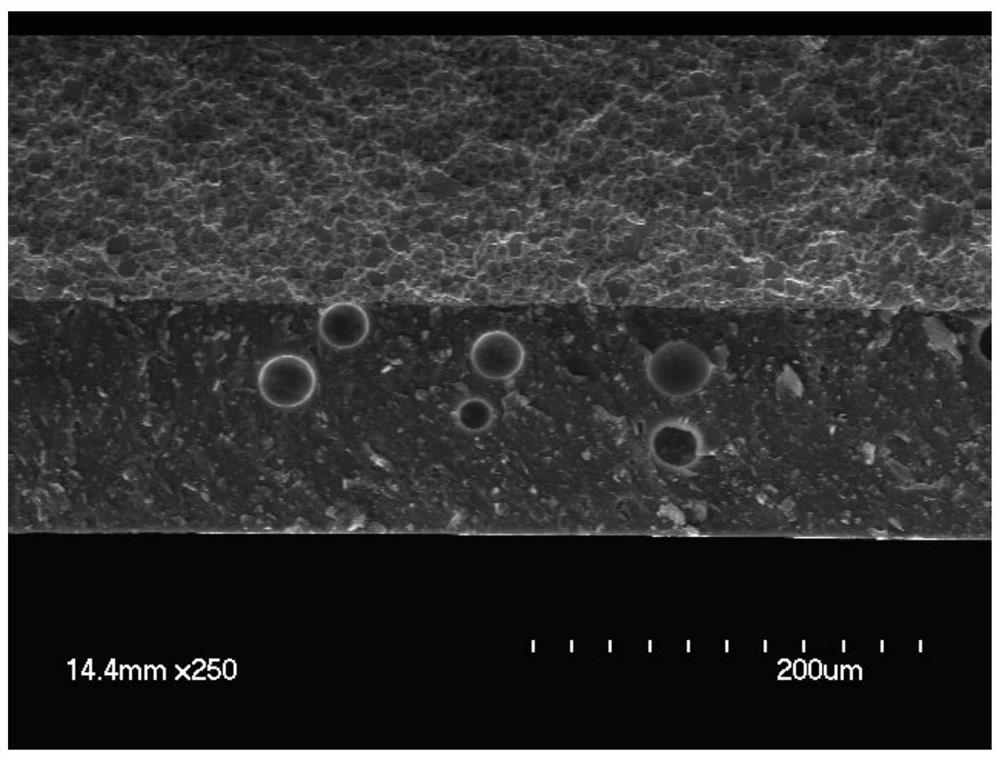

Image

Examples

Embodiment 1

[0108] To prepare NdFeB magnets, choose square NdFeB products with specifications of 20mm×10mm×3.5mm as the magnet matrix, and the steps are as follows:

[0109] 1. Surface pretreatment of magnet substrate:

[0110] 1) Degreasing: Degreasing NdFeB products with non-foaming, phosphorus-free, normal-temperature degreasing solution for 120s;

[0111] 2) wash twice;

[0112] 3) Rust removal: use dilute nitric acid with a volume concentration of 5% to carry out rust removal treatment on the degreased product, and the treatment time is 40s;

[0113] 4) After the rust removal is completed, the product is subjected to ultrasonic water washing-water washing;

[0114] 5) Activation: Use an activation solution to activate the derusted NdFeB products. The activation solution is composed of 3.5wt% citric acid, 1g / L thiourea and 1g / L sodium dodecylbenzenesulfonate. The activation time is 12s;

[0115] 6) washing twice with water to obtain a pretreated NdFeB product.

[0116] 2. Arrange...

Embodiment 2

[0122] This embodiment adopts the magnet same as embodiment 1 to prepare NdFeB magnet, the method of pretreatment is the same, the first coating and the second coating are all the same as embodiment 1, and its difference is:

[0123] The powder of the coating composition was arranged on the surface of the magnet substrate by brushing, pre-cured, and dried in an oven at 75° C. for 35 minutes. The thickness of the cured second coating was 110 μm, and an NdFeB magnet was obtained. Heating expansion conditions: oven at 190°C for 20 minutes to obtain an expanded NdFeB magnet, wherein the second coating expands after heating, which is designated as sample 2.

Embodiment 3

[0125] This embodiment adopts the same magnet as in Embodiment 1 to prepare NdFeB magnets, and the pretreatment method is the same, the difference is:

[0126] Without applying the first coating, the same second coating as in Example 1 was directly applied.

[0127] The powder of the coating composition was arranged on the surface of the magnet substrate by brushing, pre-cured, and dried in an oven at 75° C. for 35 minutes. The thickness of the cured second coating was 110 μm, and an NdFeB magnet was obtained. Heating expansion conditions: oven at 190°C for 20 minutes to obtain an expanded NdFeB magnet, wherein the second coating expands after heating, which is designated as sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com