Application method of anti-corrosion pitch for 500kV power cable

A power cable and bitumen technology, applied in the field of 500kV power cable metal sheath bitumen anti-corrosion coating, can solve the problems of poor bitumen coating quality, uneven coating, easy to leak coating, etc., to achieve excellent anti-corrosion performance, Improve product quality and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

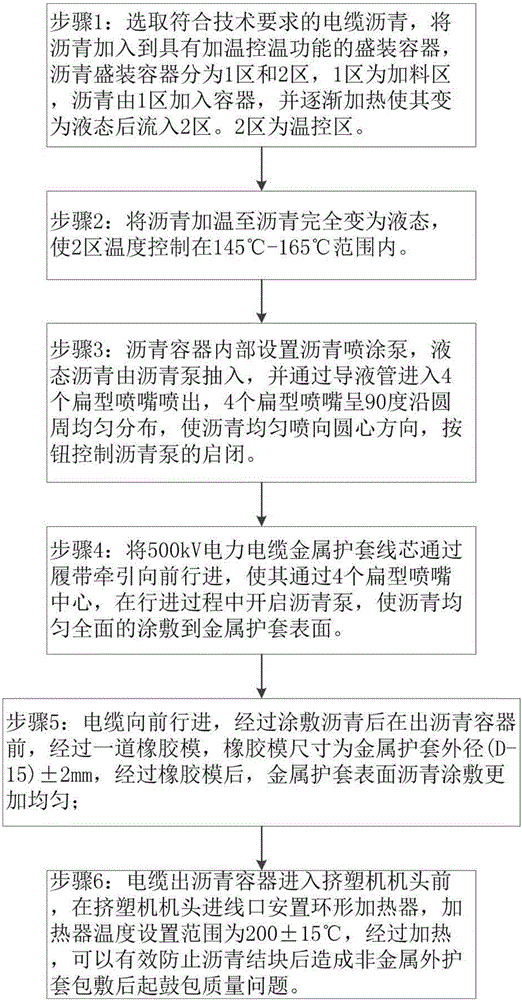

[0015] A method for coating a 500kV power cable asphalt anticorrosion layer, comprising the steps of:

[0016] Step 1: Select the cable asphalt that meets the technical requirements, add the asphalt to the container with temperature control function, the asphalt container is divided into zone 1 and zone 2, zone 1 is the feeding zone, and the asphalt is added to the container from zone 1, and Gradually heat to make it into a liquid and flow into Zone 2. Zone 2 is the temperature control zone.

[0017] Preferably, this step specifically includes: Step 1-1: Select qualified cable bitumen with a softening point of 85°C to 100°C and a flash point of not less than 260°C; Step 1-2: The bitumen container has two temperature control zones, one zone It is the feeding area, and the container wall is surrounded by high-power heating tiles, which can quic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com