Zirconium-tin-niobium corrosion-resistant zirconium-base alloy for nuclear fuel cans

A technology for zirconium-based alloys and nuclear fuels, which is applied in the field of corrosion-resistant zirconium-based alloys and zirconium-tin-niobium-based corrosion-resistant zirconium-based alloys for nuclear fuel cladding, can solve the problems of corrosion performance decline, grain boundary segregation, etc. The effect of corrosion resistance, excellent comprehensive performance and excellent creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

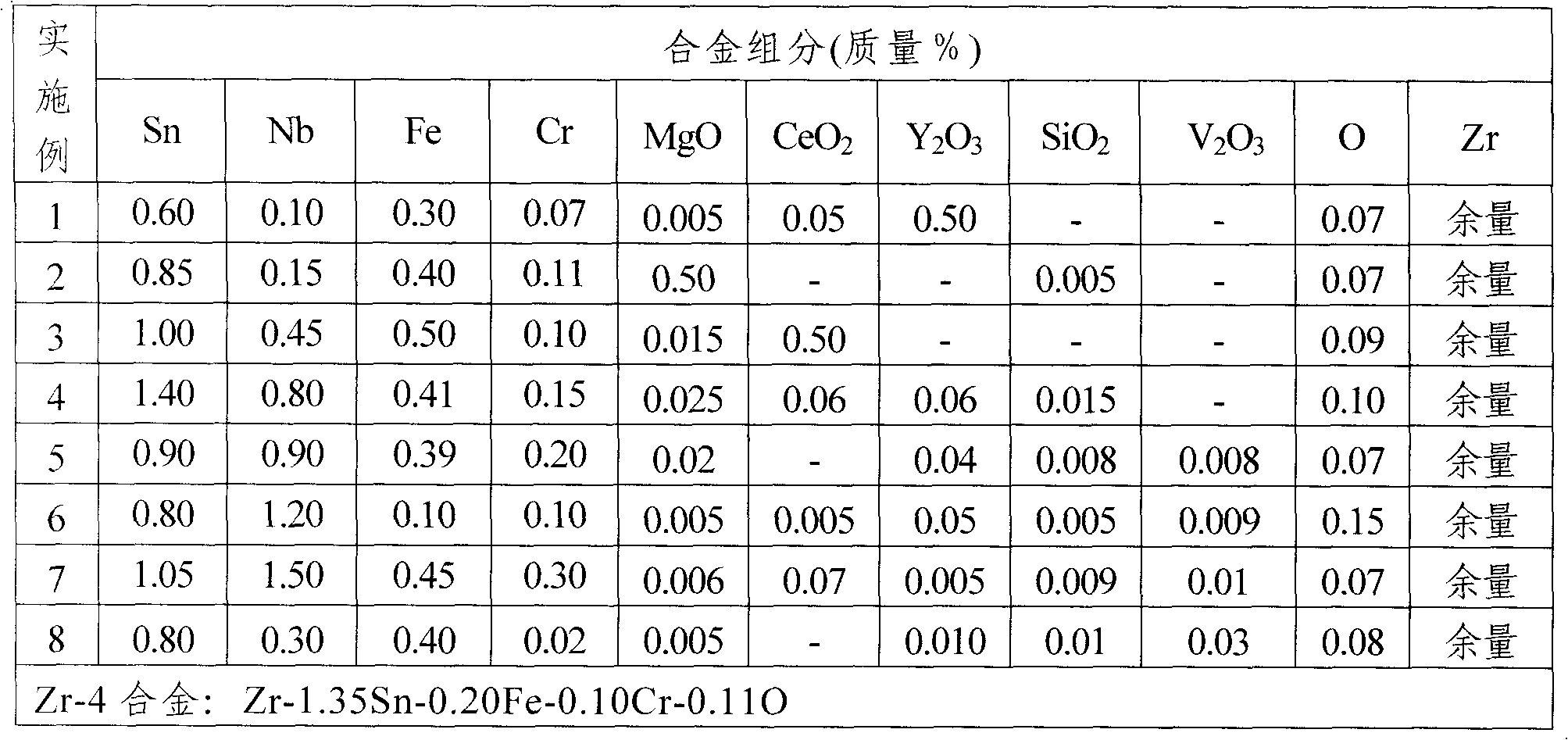

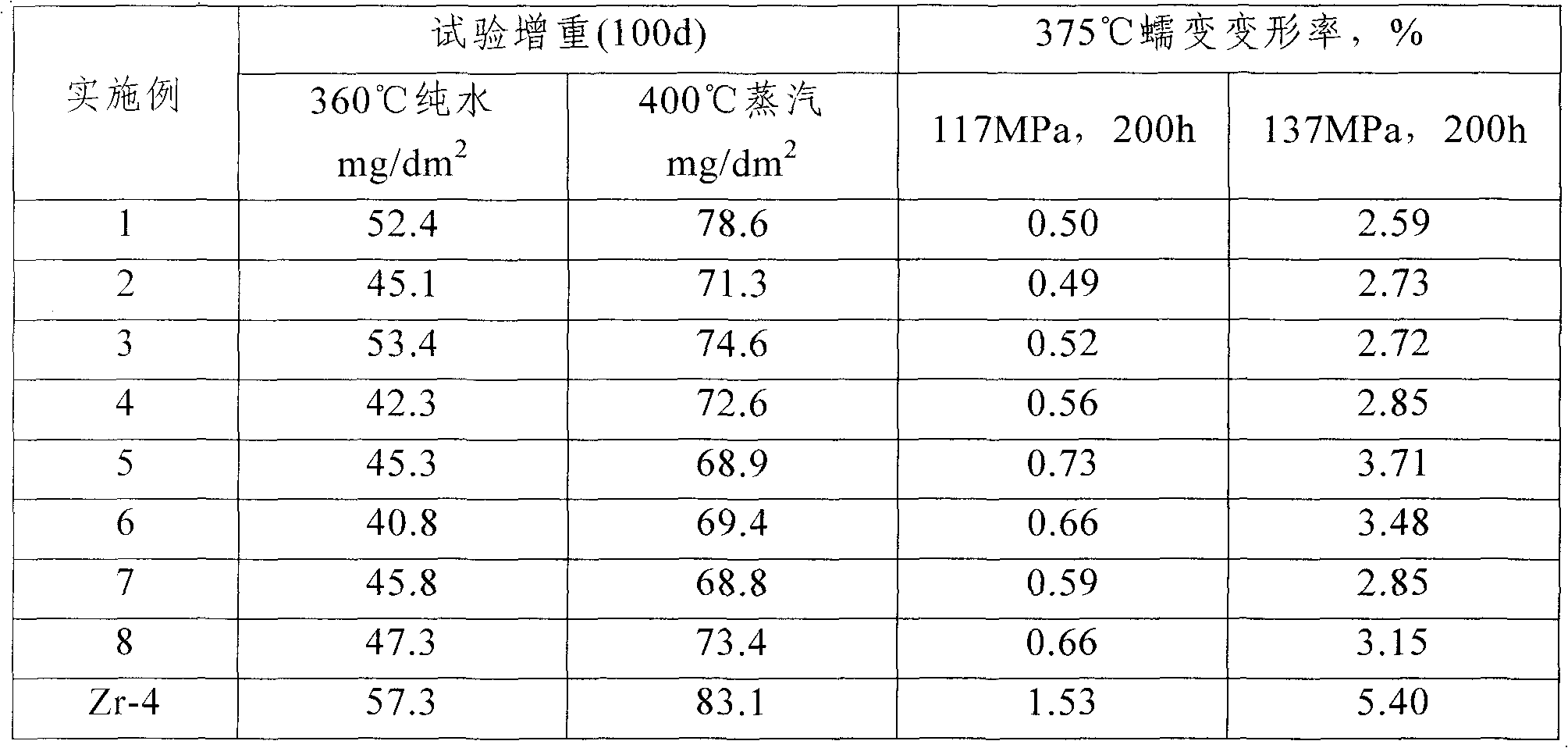

[0045] Use nuclear grade sponge zirconium, Nb, MgO, CeO 2 , Y 2 o 3 , SiO 2 , V 2 o 3 , O and other elements in the form of an intermediate alloy according to the formulation and pressed into electrodes, using a vacuum consumable electric arc furnace for three times melting to produce 3 kg alloy ingots with 6 alloy components; chemical composition analysis of the ingot samples, alloy composition see Table 1. The alloy ingot is forged at 980°C to 1050°C to make a billet; it is then heated in the β phase zone at 1015°C to 1075°C and quenched in water; the billet is hot rolled below 620°C, and the deformation is greater than 60%. Perform intermediate annealing at 600°C, and then undergo multiple times of cold rolling, and the heat deformation is greater than 50%. Use the same annealing temperature as after hot rolling for intermediate annealing to make a plate, and the final product is recrystallized and annealed at 580°C. Obtain the zirconium alloy plate.

[0046] The cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com