Creep-resistant sheath material for automobile tail wire harness and preparation method thereof

A sheath material and creep resistance technology, applied in the field of polymer materials, can solve the problems of poor creep resistance and achieve excellent creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

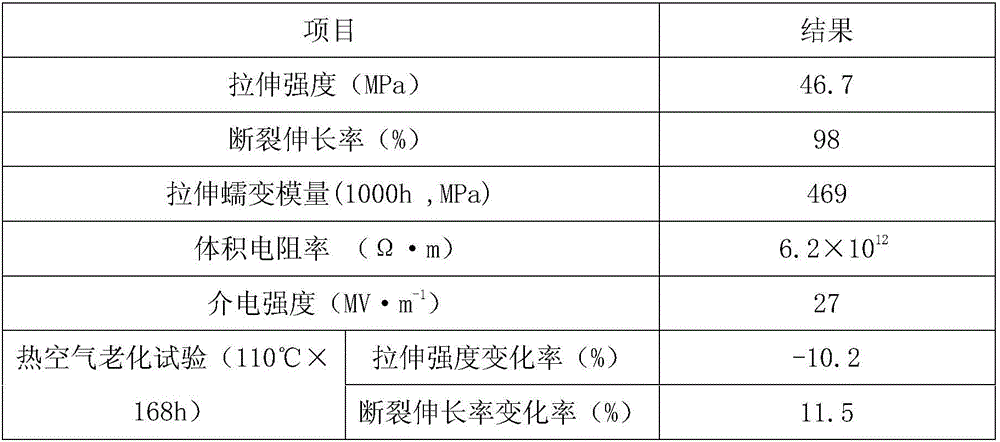

Examples

Embodiment Construction

[0012] A kind of anti-creep sheath material for automobile tail harness, made of the following raw materials in weight (kg): polyphenylene ether 43, high-magnesium phosphorus tailings 8, polyphenol oxygen resin 20, poly-1-butene 16, Polyamide imide 12, ethylene bislauric acid amide 4.5, waste bone china 10, epoxy linseed oil 12, carbon whisker 8, lithium china stone 7, low molecular weight polypropylene 6, dimethoxyethylene phthalate Ester 12, zinc oleate 5, calcium zirconate 8.

[0013] A preparation method for a creep-resistant sheath material for an automobile tail harness as claimed in claim 1, comprising the following steps:

[0014] (1) Mix bone china waste, high-magnesium phosphorus tailings, and lithium china stone evenly, pulverize, sieve, then add 30% hydrochloric acid solution equivalent to 7 times the weight of the powder, heat in a water bath to 65°C, and oscillate ultrasonically for 28 minutes. Centrifuge at high speed for 35 minutes, let stand for 23 hours, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com