Creep-resistant polypropylene composite material with interpenetrating network structure and preparation method thereof

A technology of interpenetrating network structure and composite materials, which is applied in the field of polypropylene composite materials, creep-resistant polypropylene composite materials and their preparation, and can solve problems such as increased molecular chain entanglement, composite material performance degradation, and molecular chain shortening. To achieve the effect of improving creep resistance characteristics, improving creep resistance performance, and improving creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

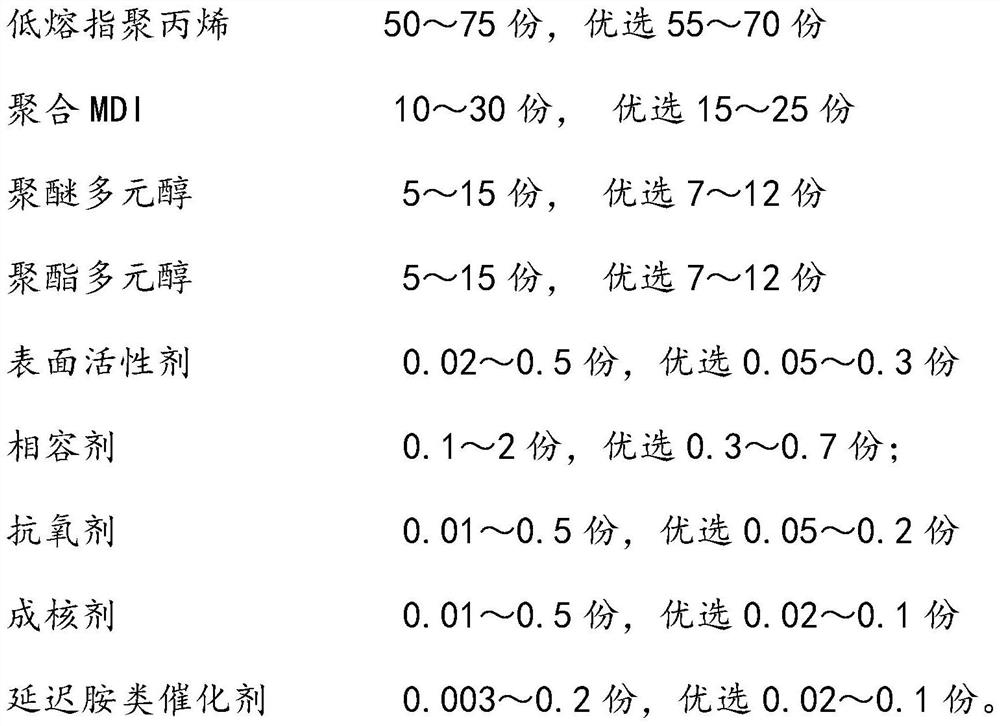

Method used

Image

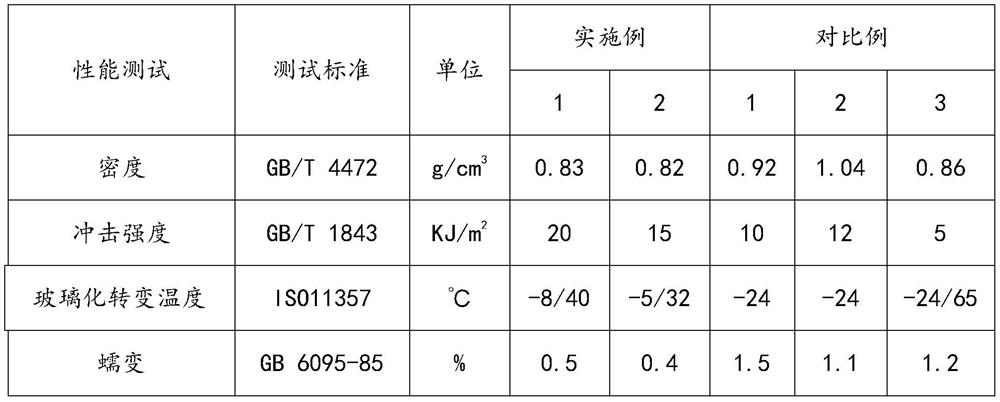

Examples

Embodiment 1

[0032] (1) Preparation of polyurethane composite material: Weigh 950g of polyether polyol respectively R2305, 800g polyester polyol Huada Chemical MX-806, 25g surfactant L6900, 6g delay catalyst Dabco 8154, poured into the reaction kettle, after the disperser stirred at high speed, transferred to No. 1 liquid weight loss scale; 1800g Aggregated MDI PM200 is introduced into the No. 2 liquid weight loss scale.

[0033] (2) Preparation of polypropylene mixture: Mix 6000g low melting index polypropylene particles BU510, 3g nucleating agent NA-11, 50g compatibilizer GPM200A, and 8g antioxidant (1010:168=1:1) evenly Then pour it into the weight loss scale of the main feeding port;

[0034] (3) Preparation of composite materials: set the extrusion temperature and process, the weight loss scale of the main feeding port starts to feed, and after stable extrusion, the No. 1 liquid weight loss scale and the No. 2 liquid weight loss scale start the same side feeding port according to ...

Embodiment 2

[0036] (1) Preparation of polyurethane composite material: Weigh 750g of polyether polyol respectively R2305, 1000g polyester polyol Huada Chemical MX-806, 27g surfactant L6900, 6g delay catalyst Dabco 8154, poured into the reaction kettle, after the disperser stirred at high speed, transferred to No. 1 liquid weight loss scale; 2400g Aggregated MDI PM200 is introduced into the No. 2 liquid weight loss scale.

[0037] (2) Preparation of polypropylene mixture: Mix 7500g of low-melting index polypropylene particles BU510, 5g of nucleating agent NA-11, 60g of compatibilizer CMG-5701, and 8g of antioxidant (1010:168=1:1) after mixing evenly Pour into the weight loss scale of the main feeding port;

[0038](3) Preparation of composite materials: set the extrusion temperature and process, the weight loss scale of the main feeding port starts to feed, and after stable extrusion, the No. 1 liquid weight loss scale and the No. 2 liquid weight loss scale start the same side feeding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com