Patents

Literature

390results about How to "Enhanced binding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

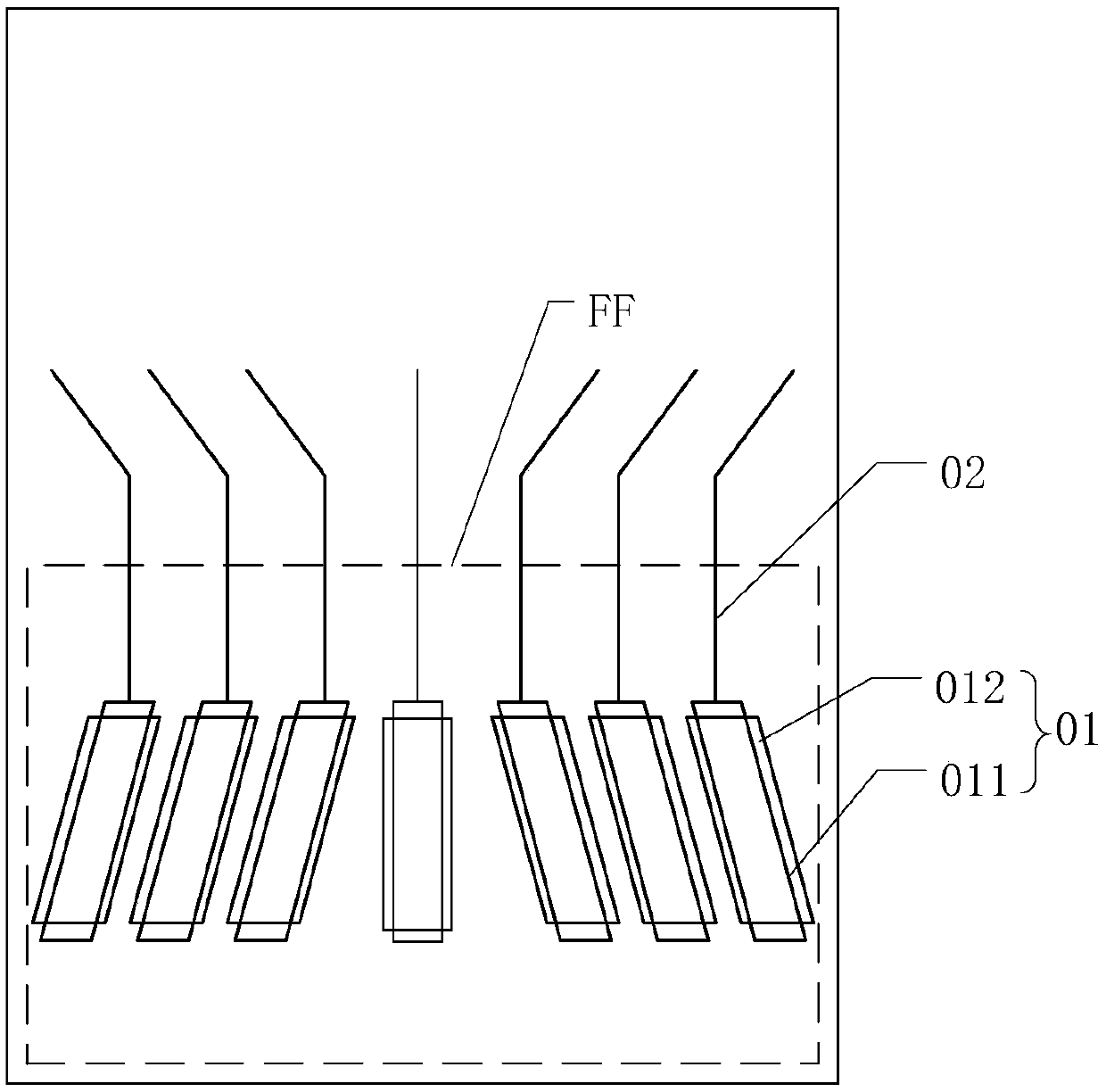

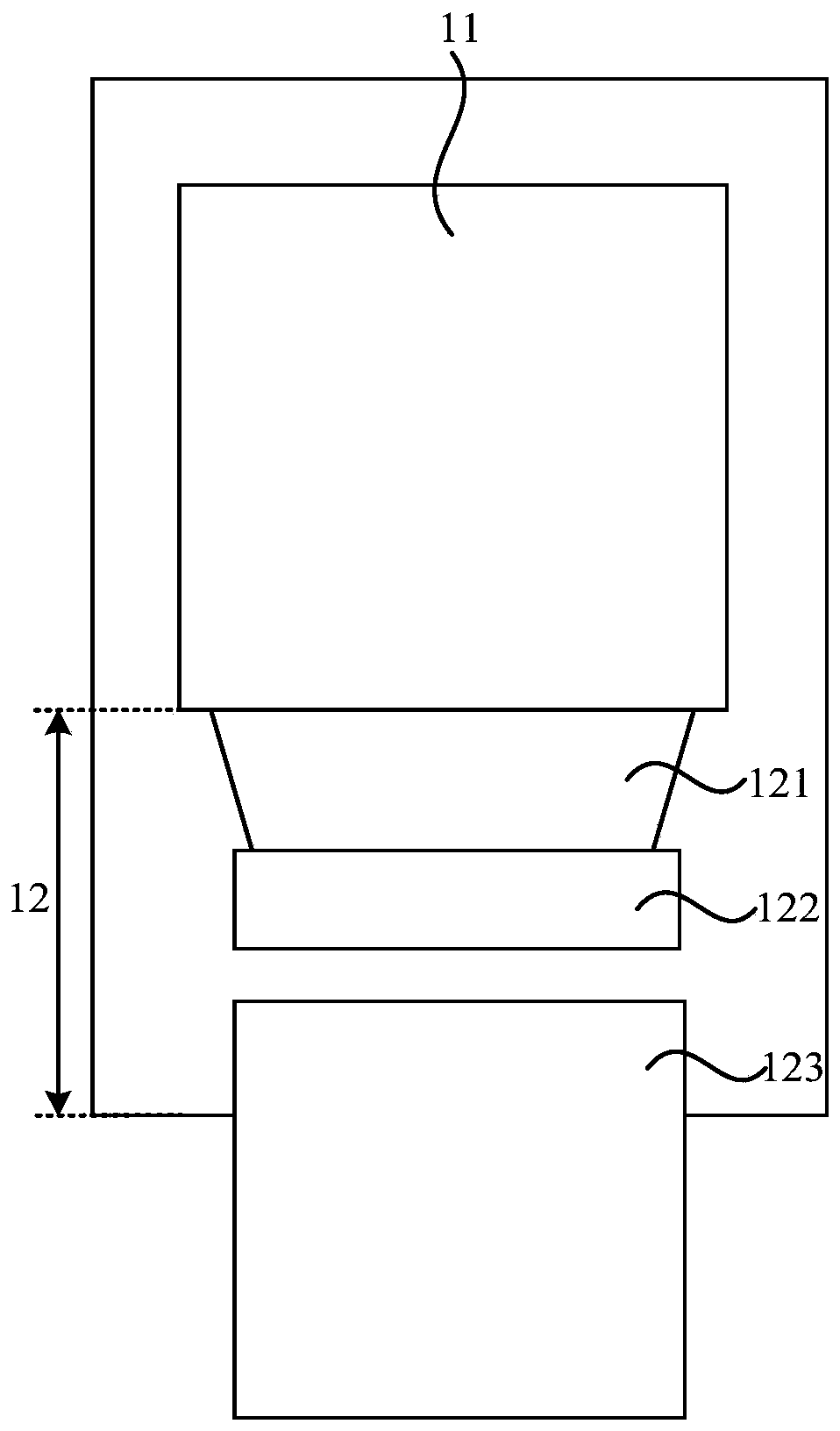

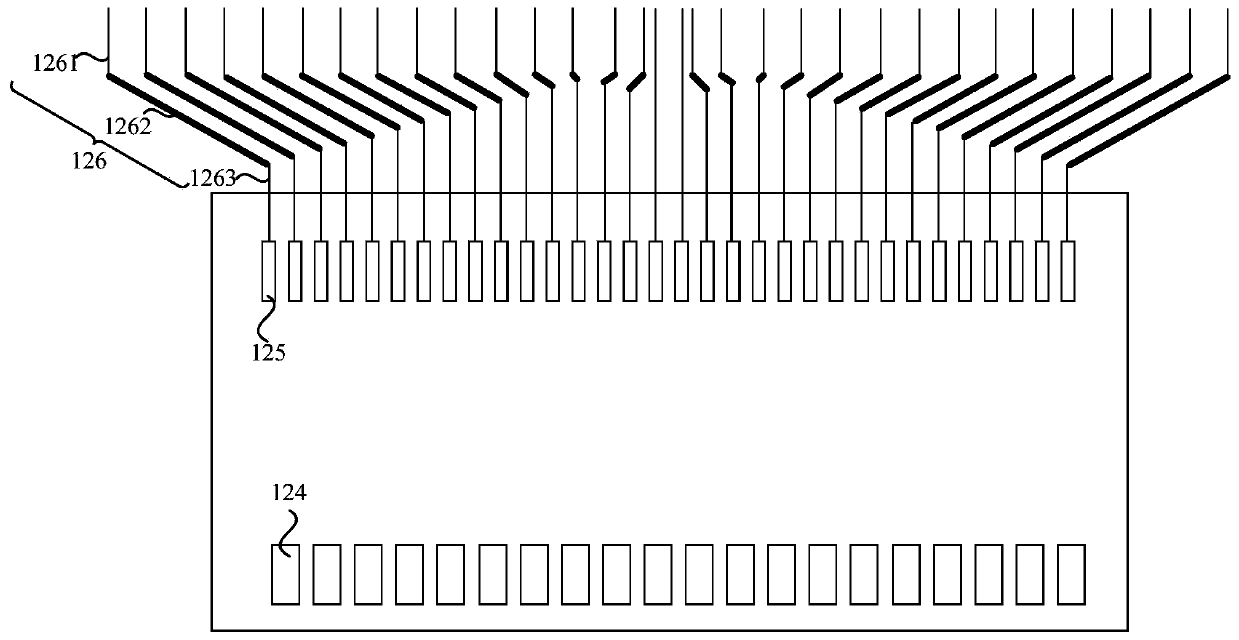

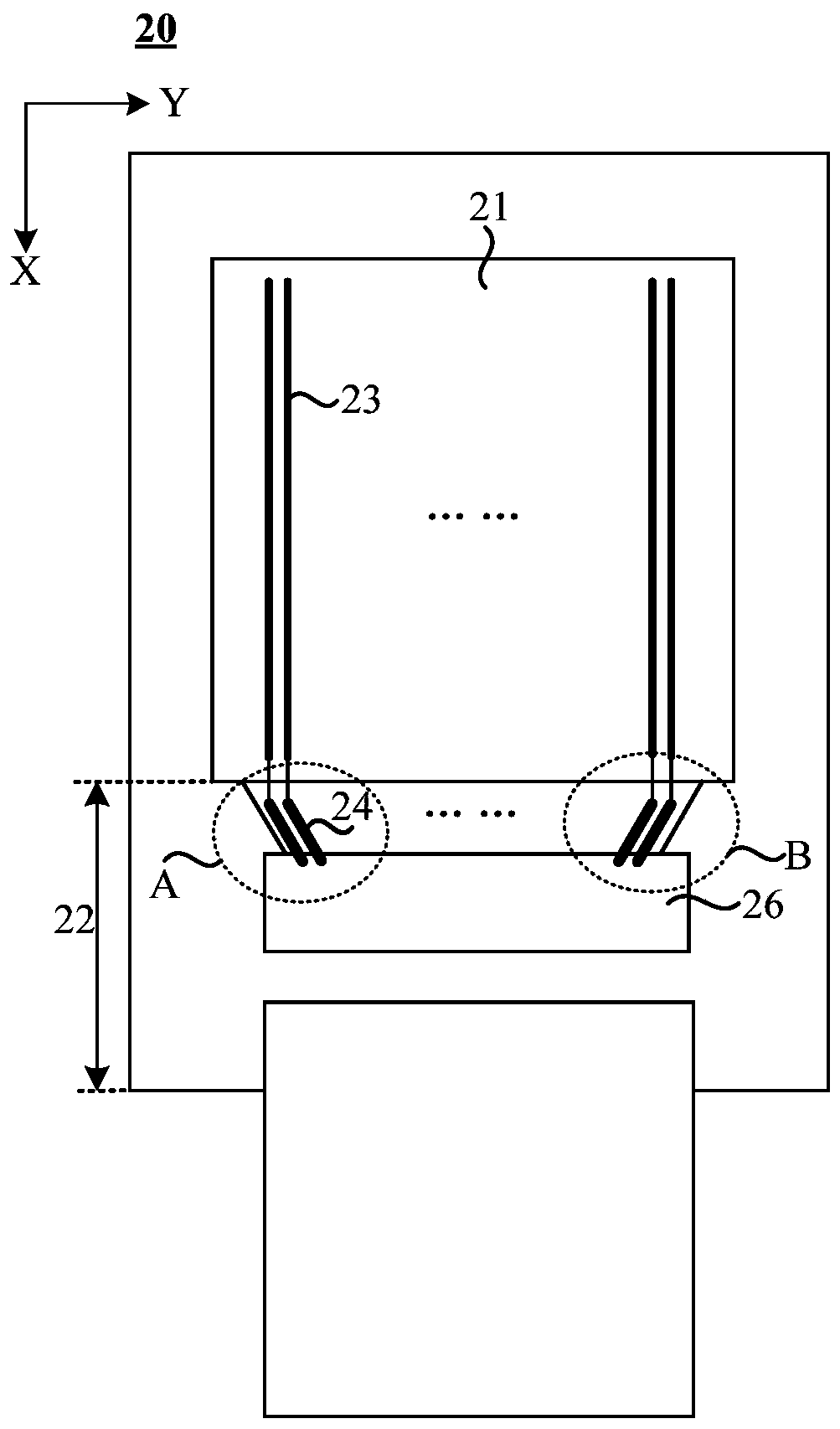

Array substrate, display panel and display device

ActiveCN107884994AEnhanced binding effectImprove the display effectNon-linear opticsBlock structureDisplay device

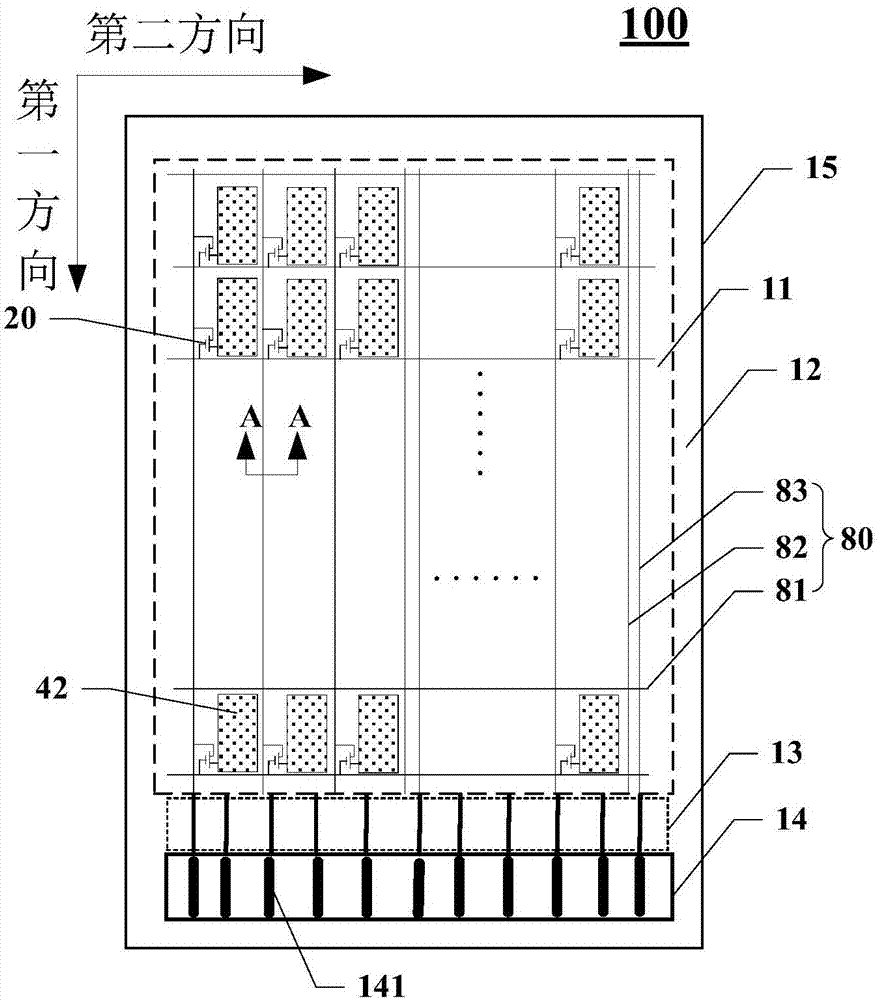

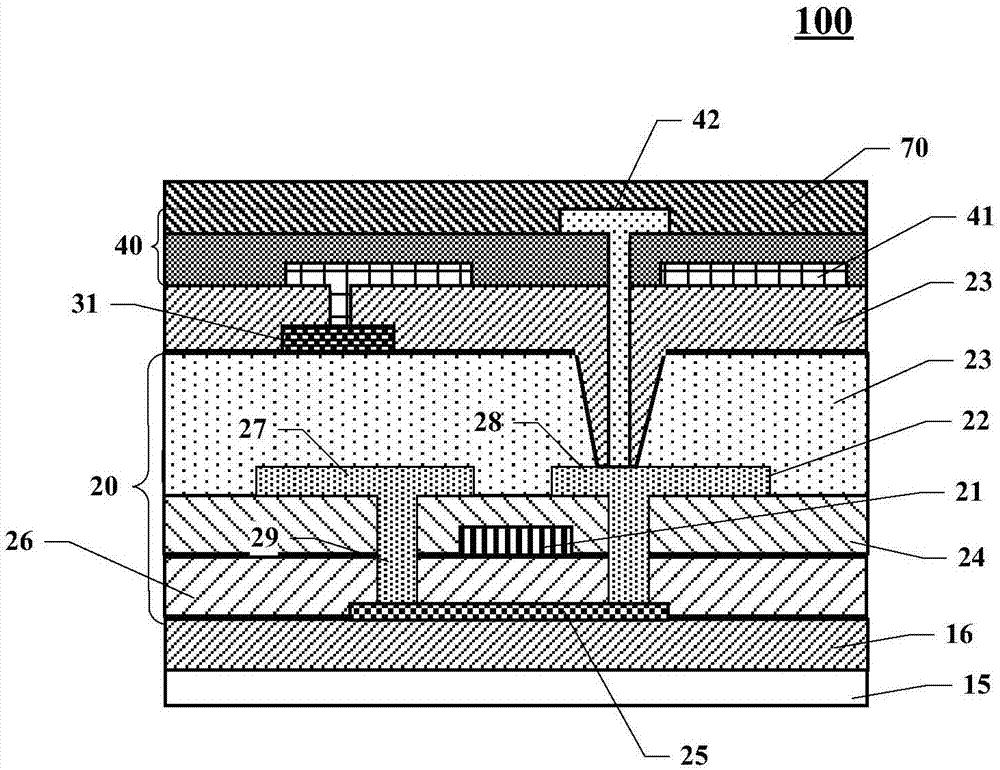

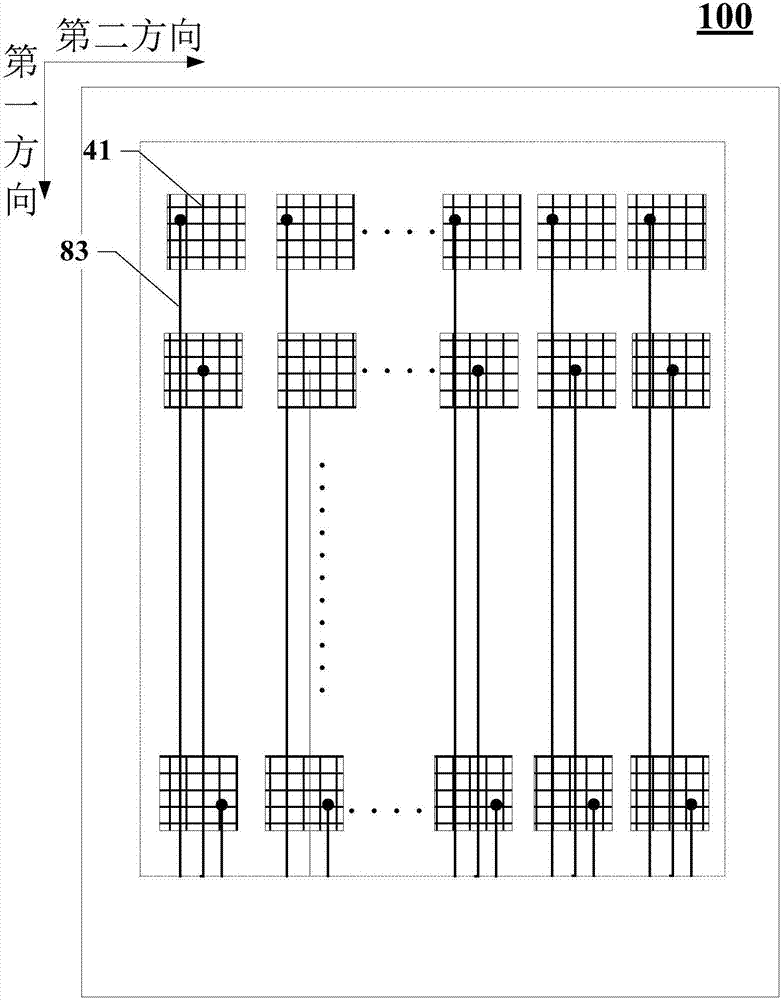

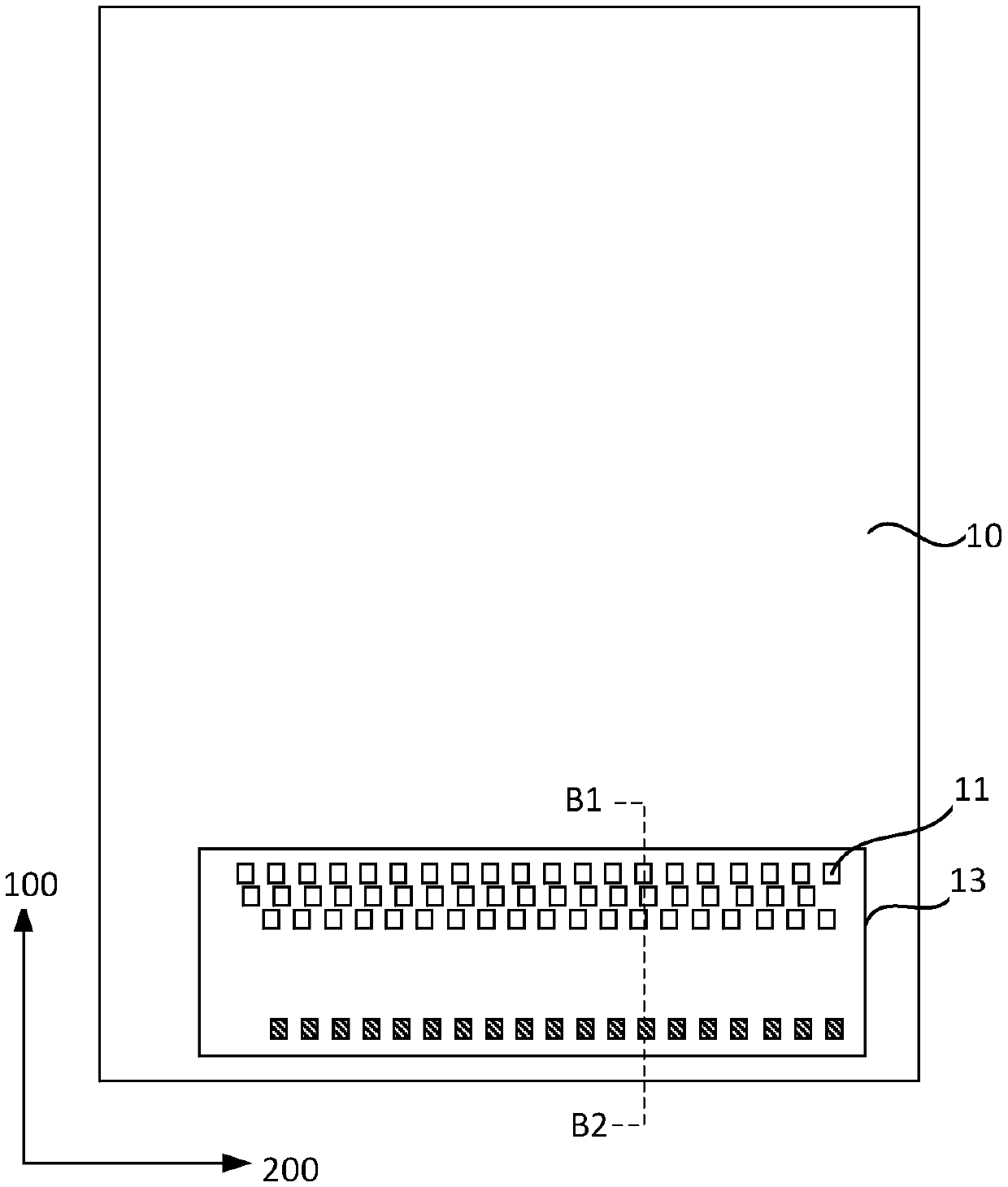

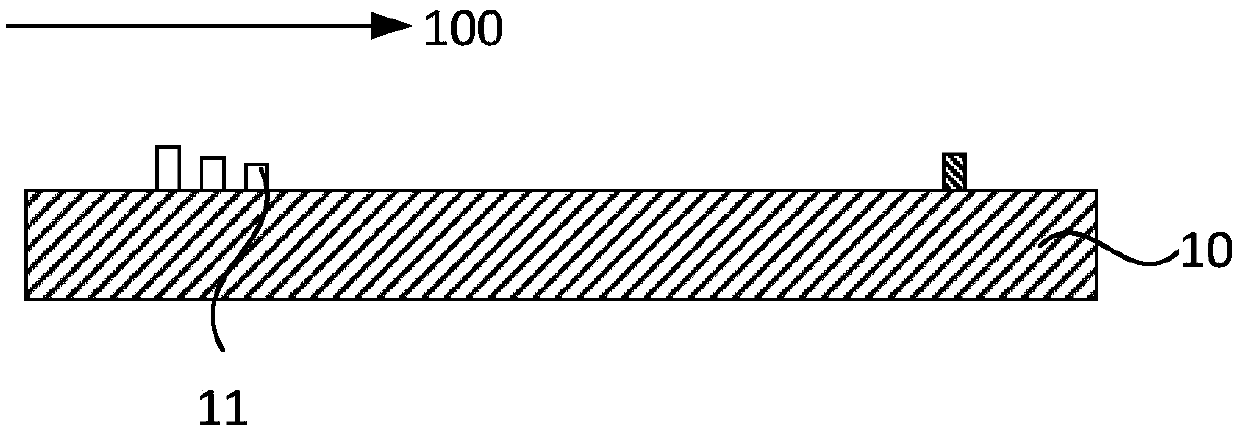

The present application discloses an array substrate, a display panel and a display device, and relates to the technical field of display. The array substrate includes a display area, a non-display area, a binding area, a fanout trace area and alignment film blocking structures, wherein the non-display area is disposed around the display area, the binding area is arranged in the non-display area and includes a plurality of conductive pads, the fanout trace area is arranged between the display area and the binding area and includes a plurality of first fanout traces, second fanout traces and third fanout traces, the first fanout traces and the second fanout traces extend in a first direction and are arranged in a second direction, the first fanout traces, the second fanout traces and the third fanout traces are located in different film layers, signal leads in the display area are electrically connected with the conductive pads via the fanout traces, the alignment film blocking structures are disposed in the fanout trace area and are arranged in the same layer as the third fanout traces, and in the second direction, vertical projections of adjacent two alignment film blocking structures toward the first direction are continuous. In this way, the diffusion of an alignment film to the binding area can be effectively blocked.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

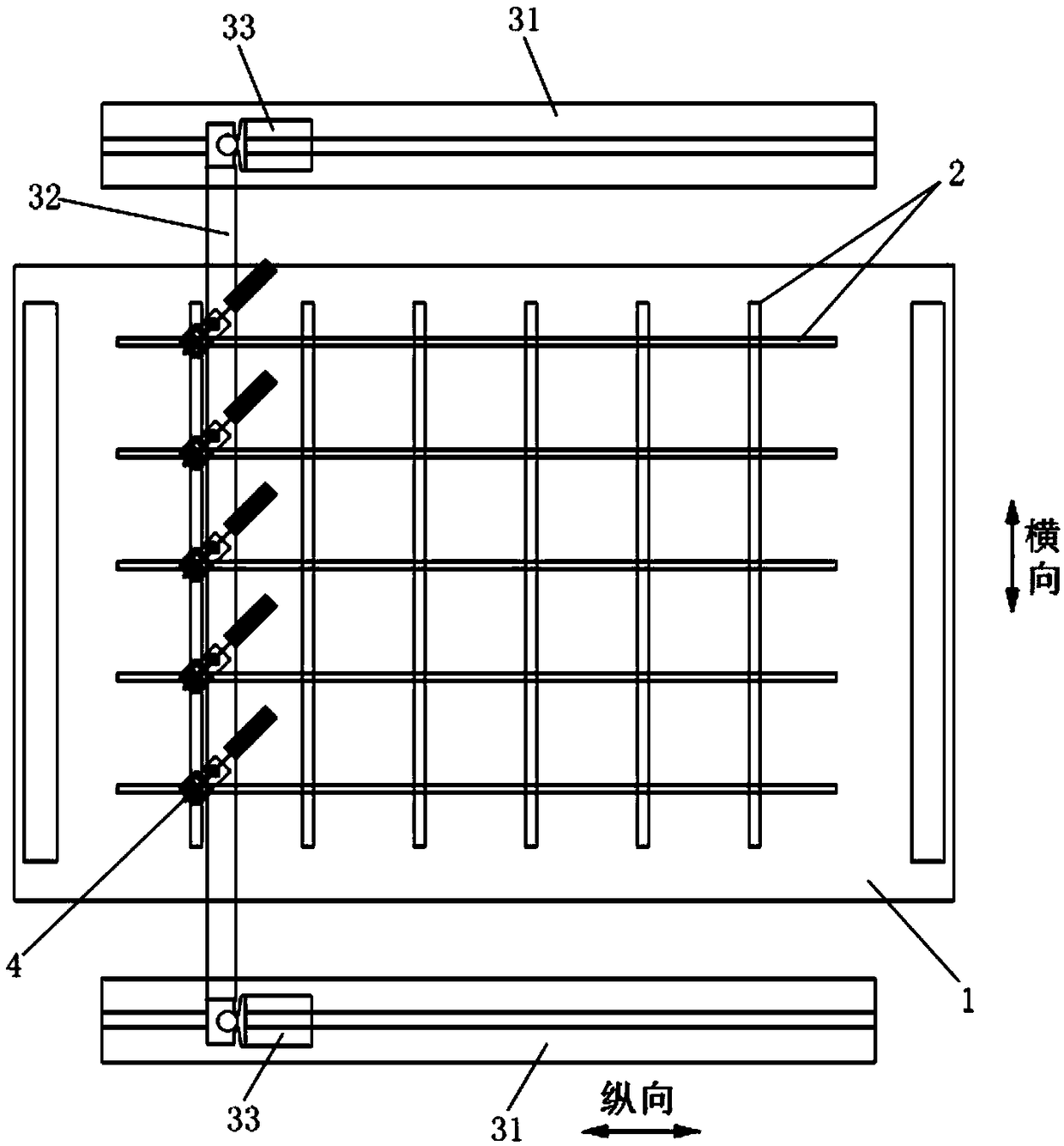

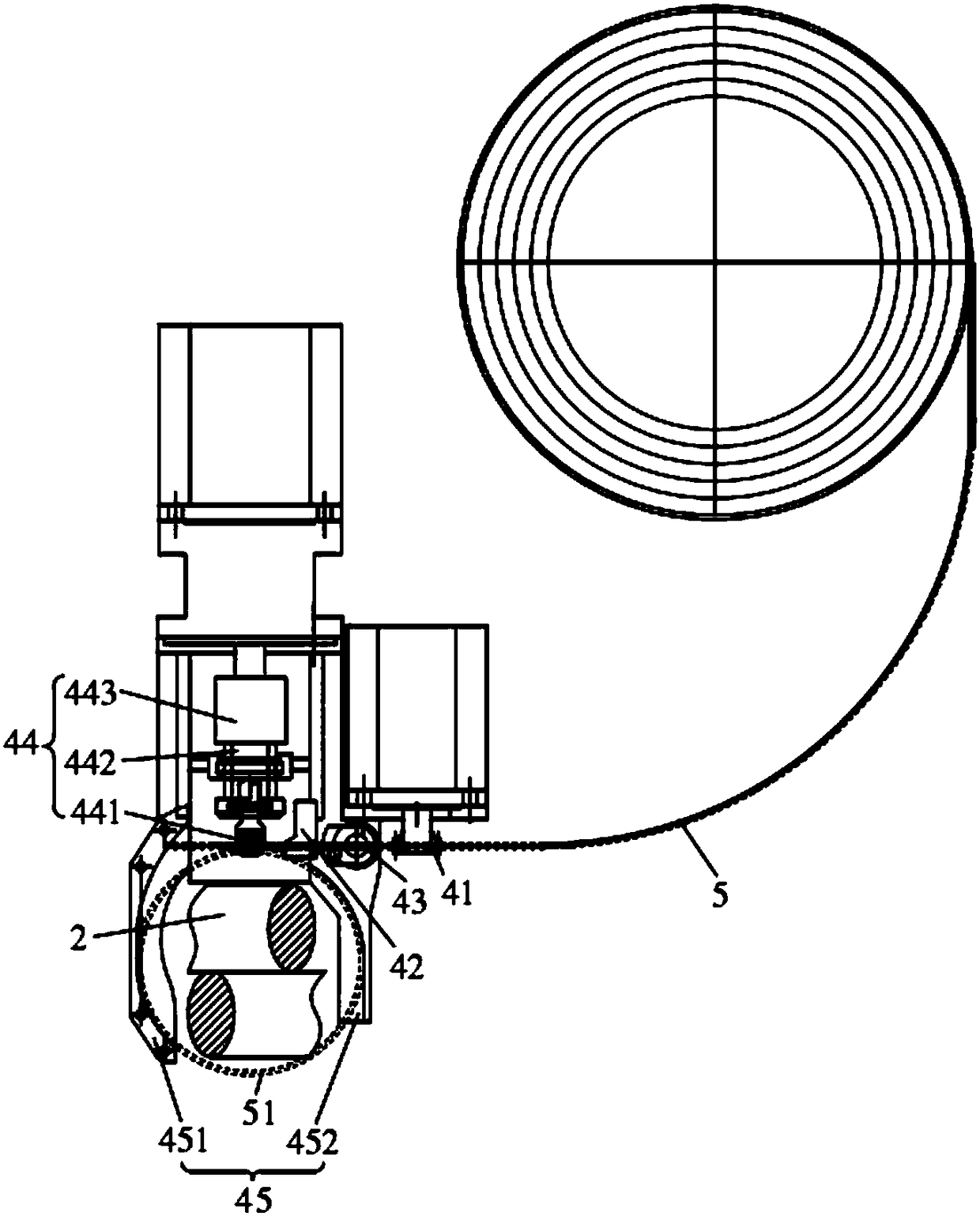

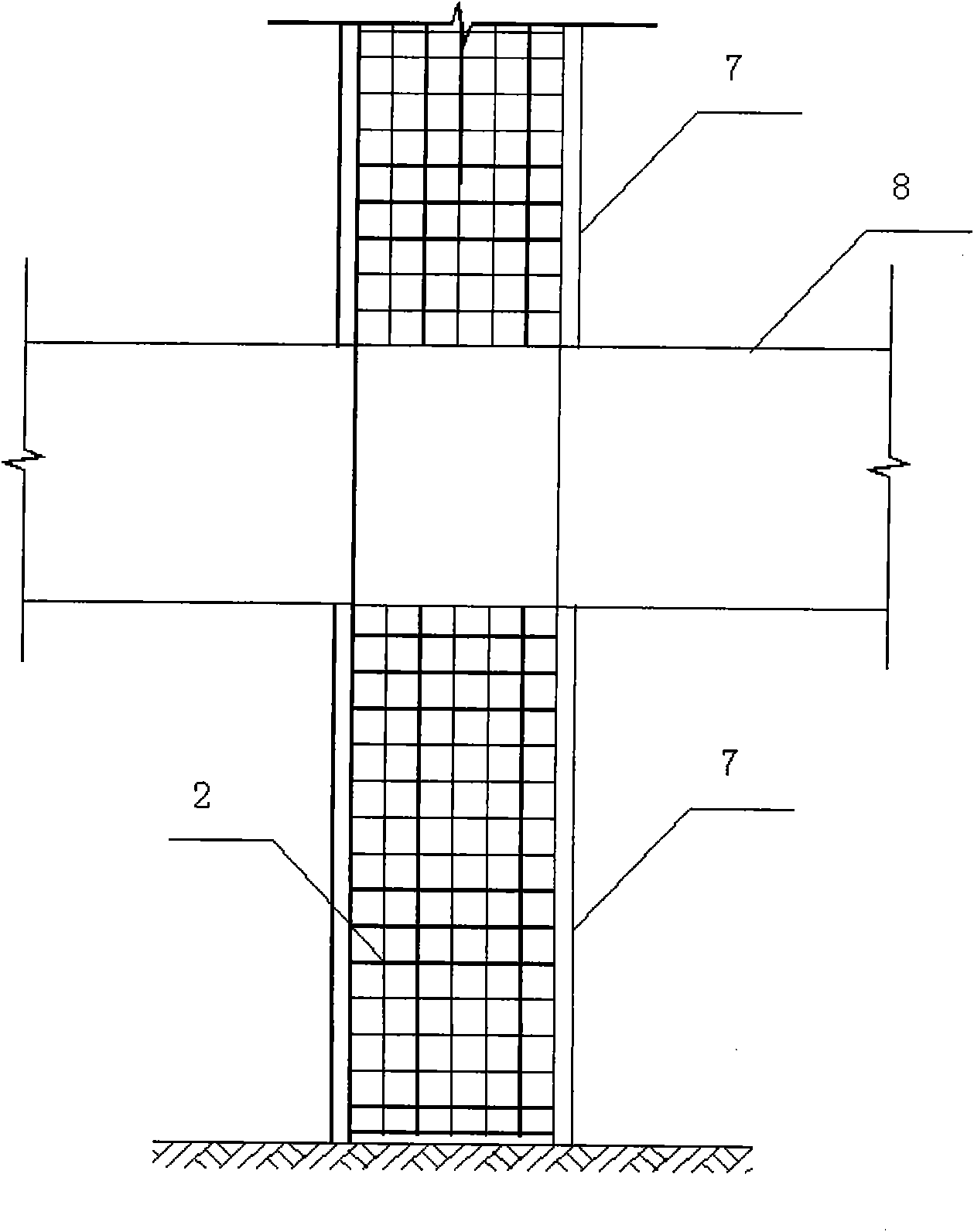

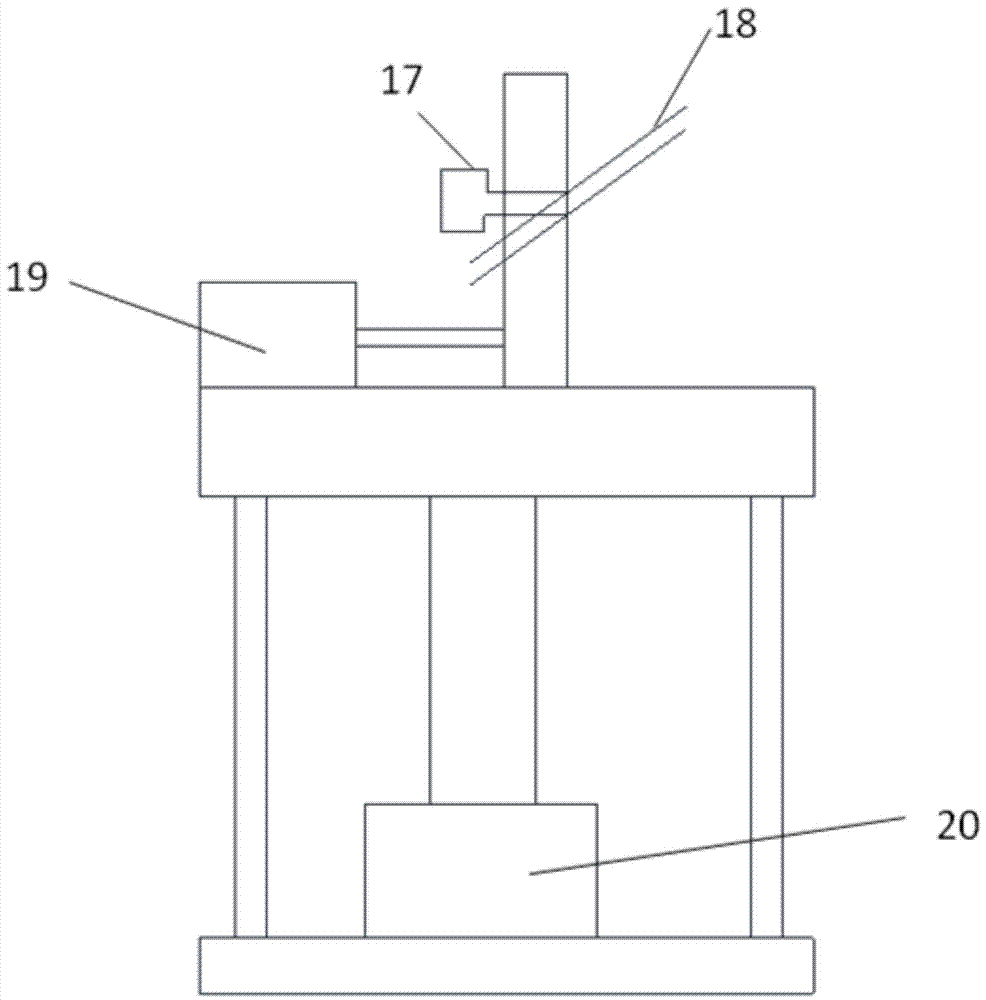

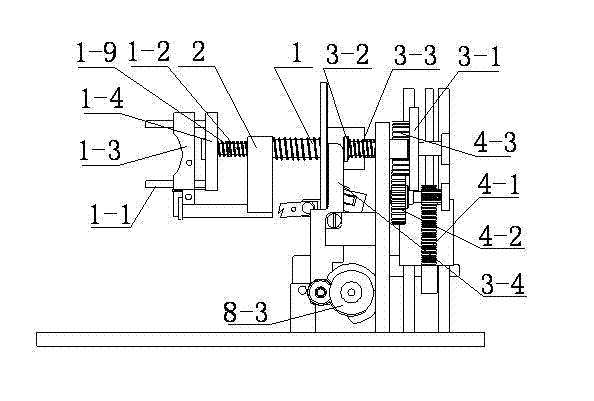

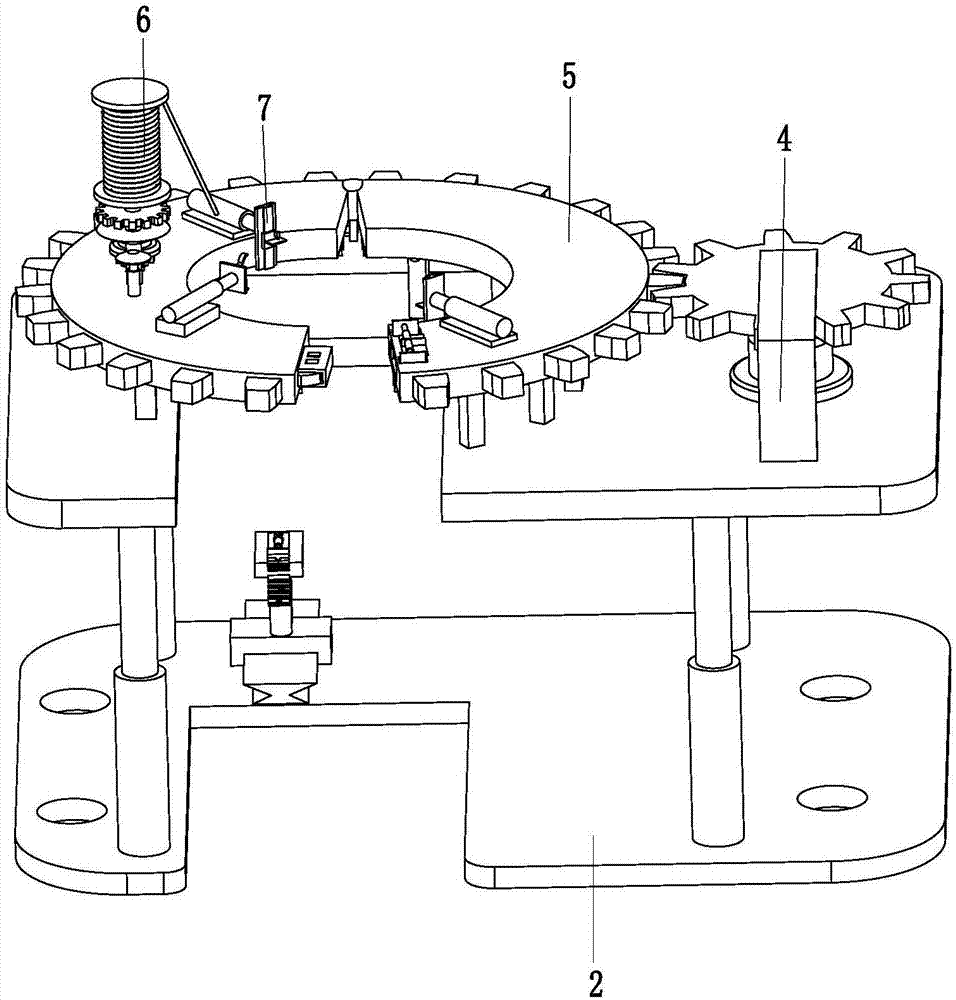

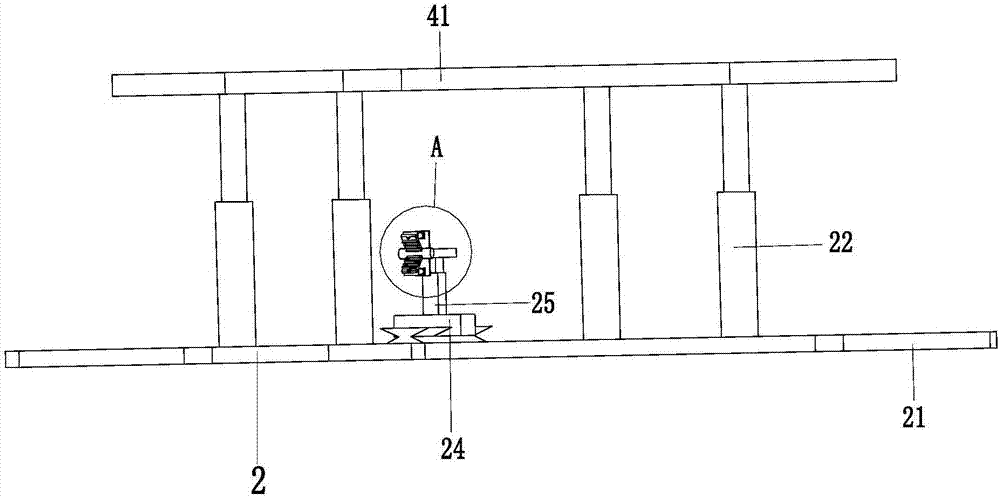

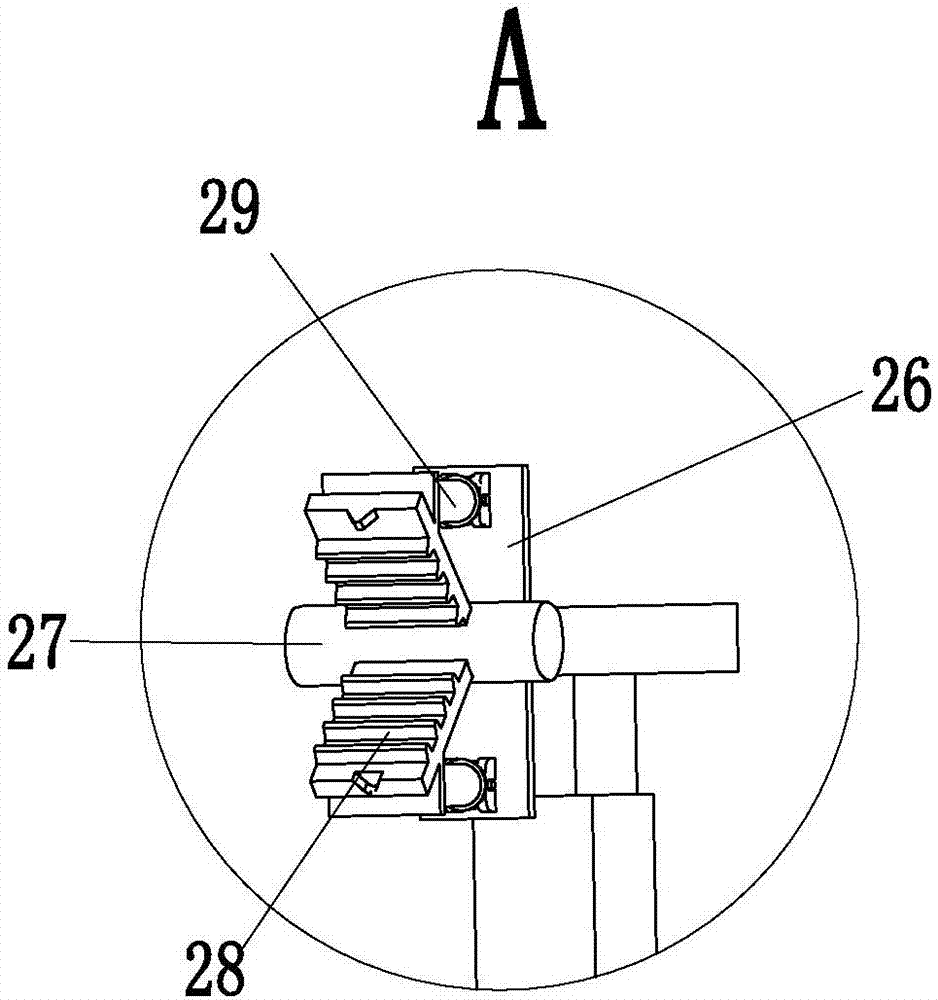

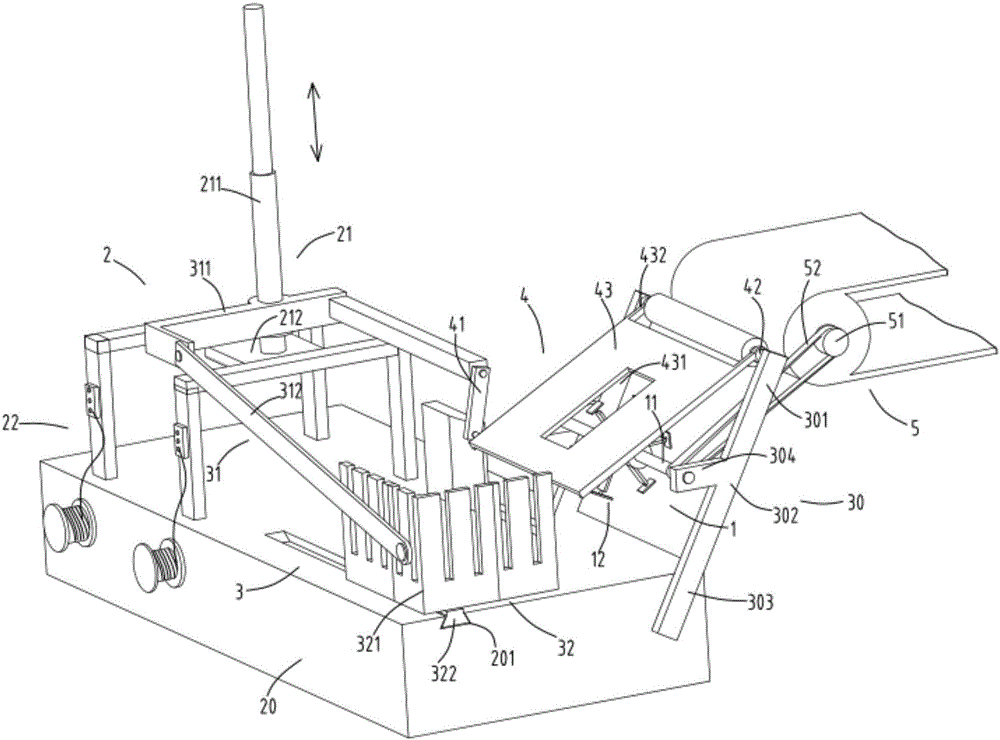

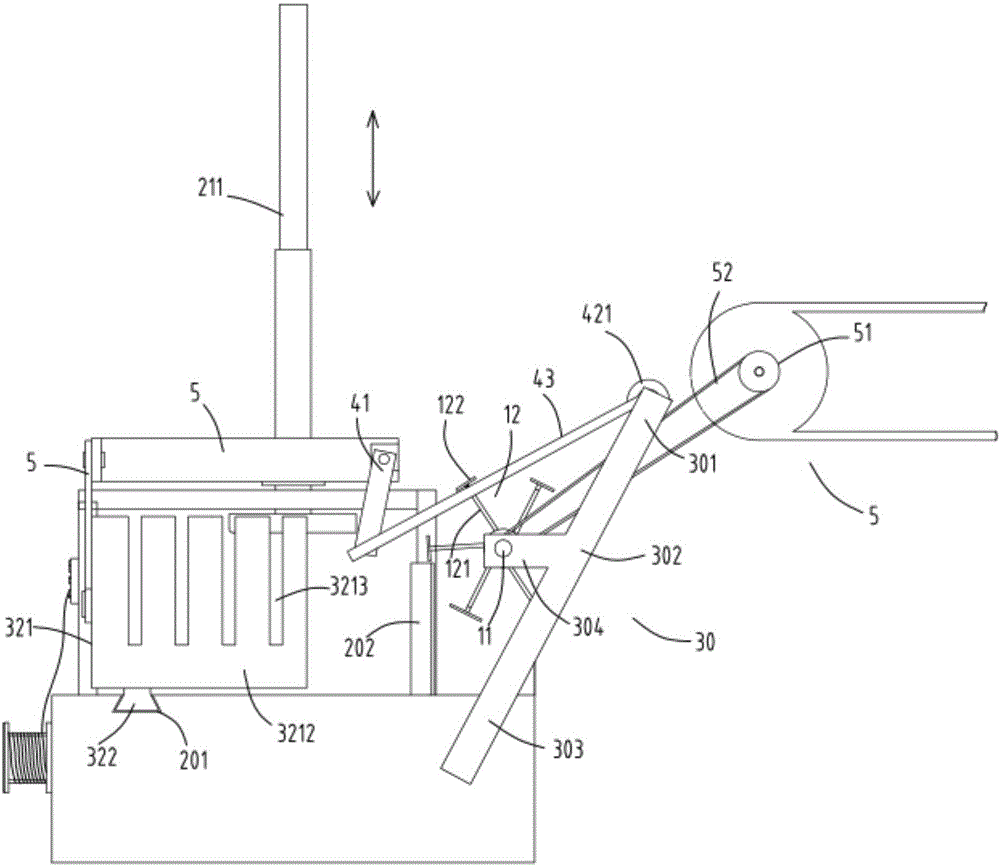

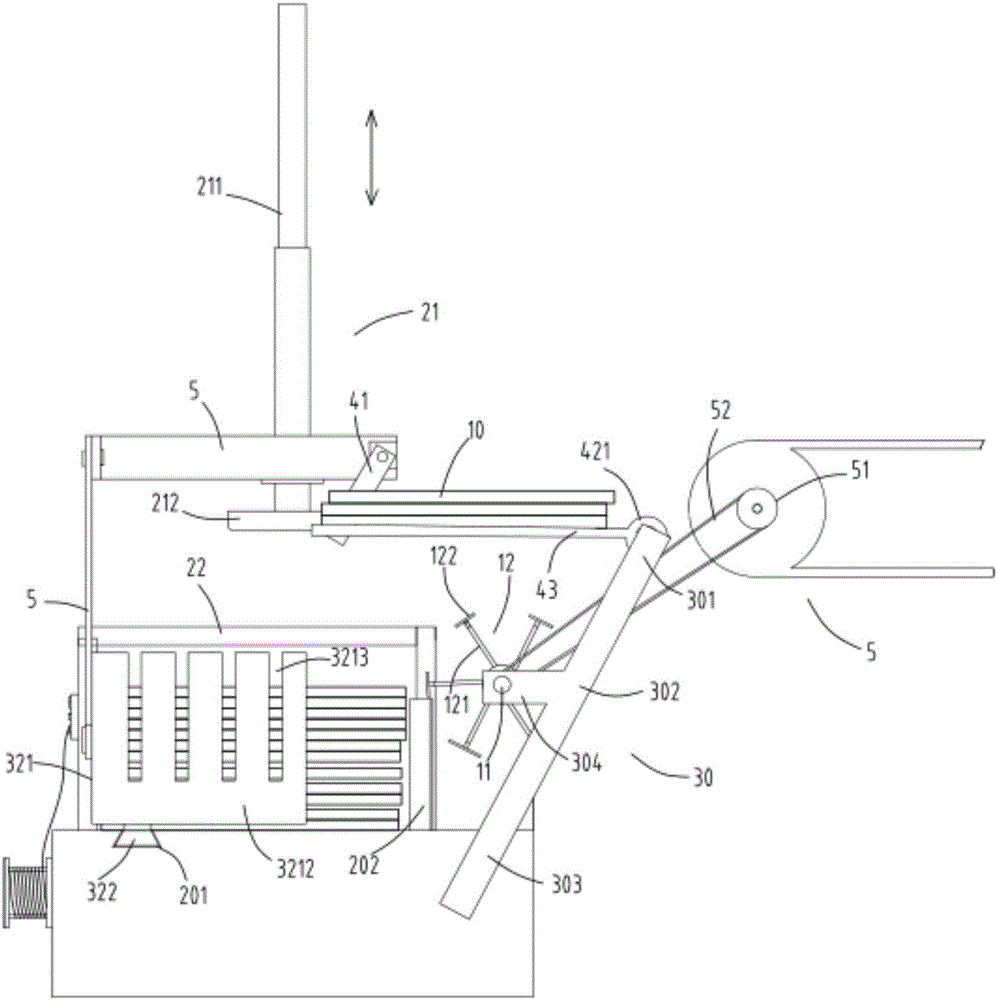

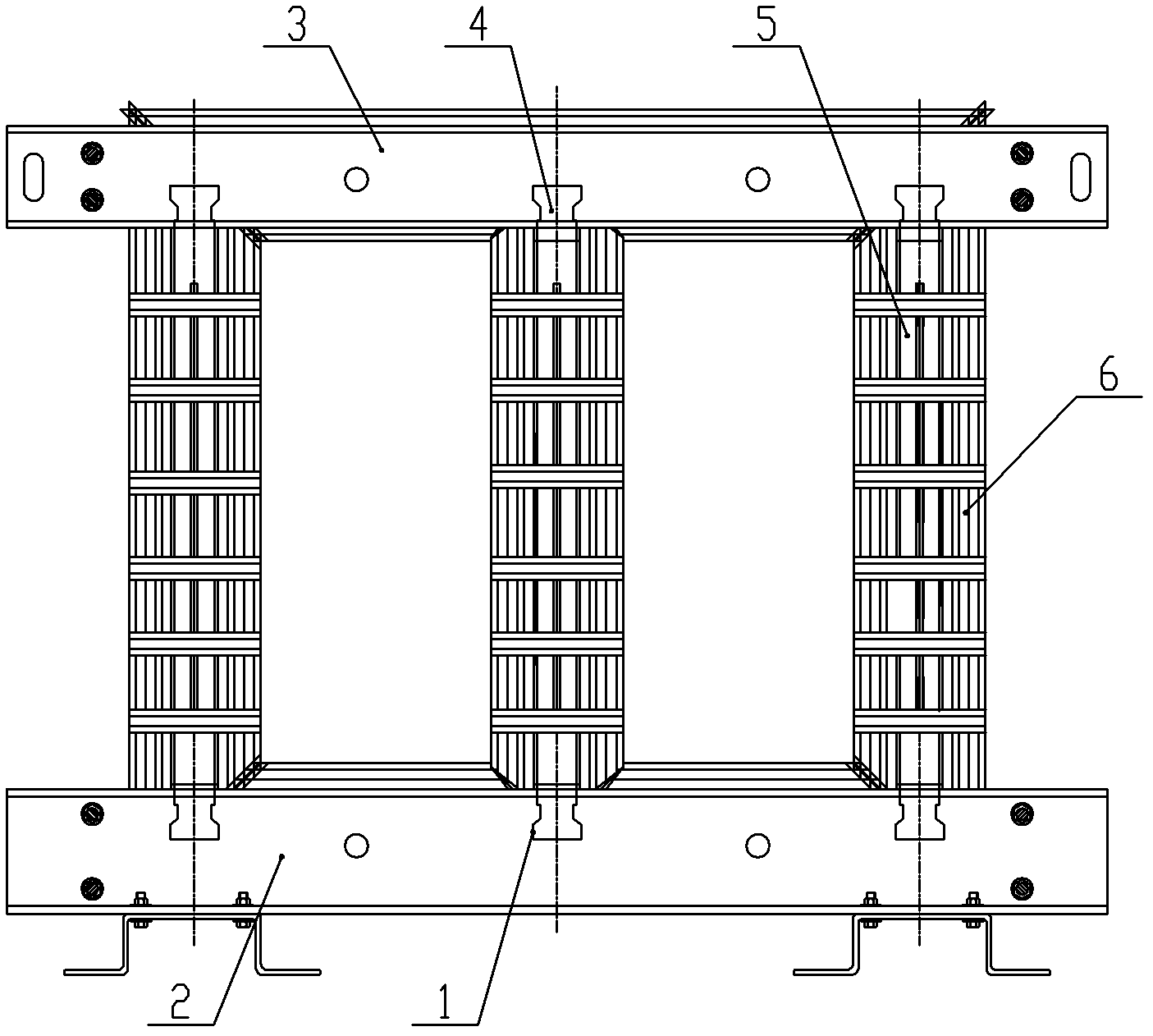

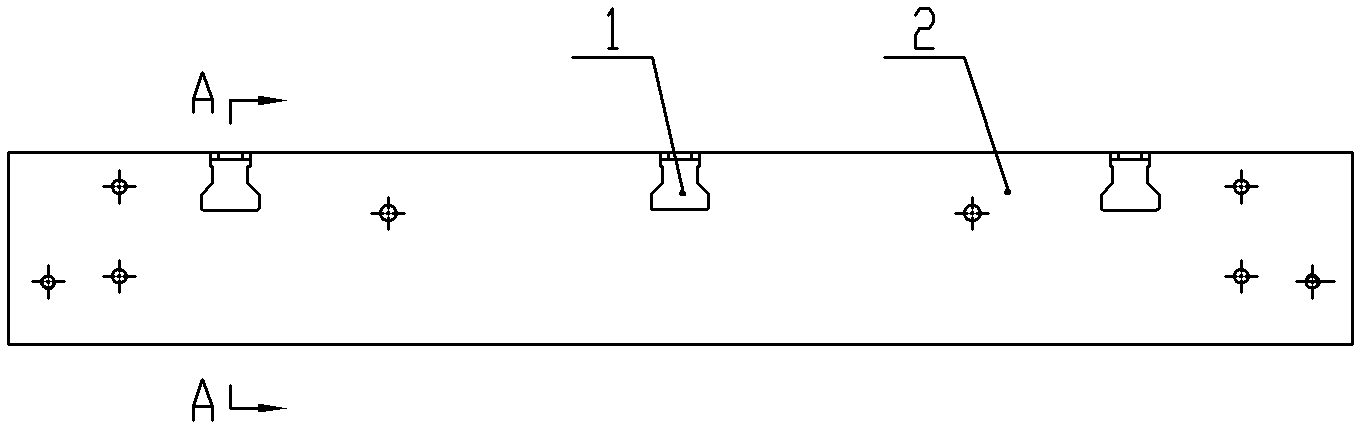

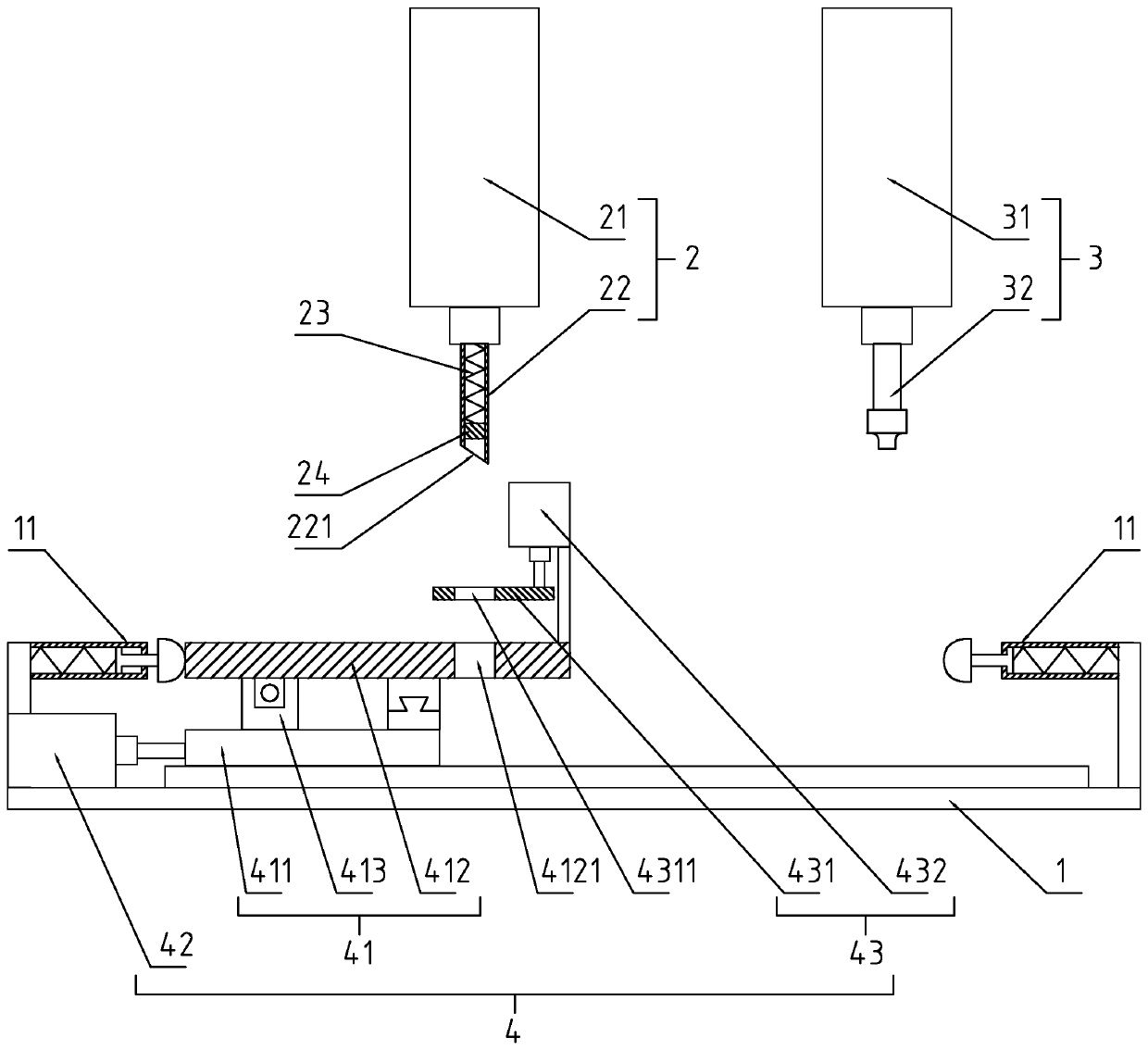

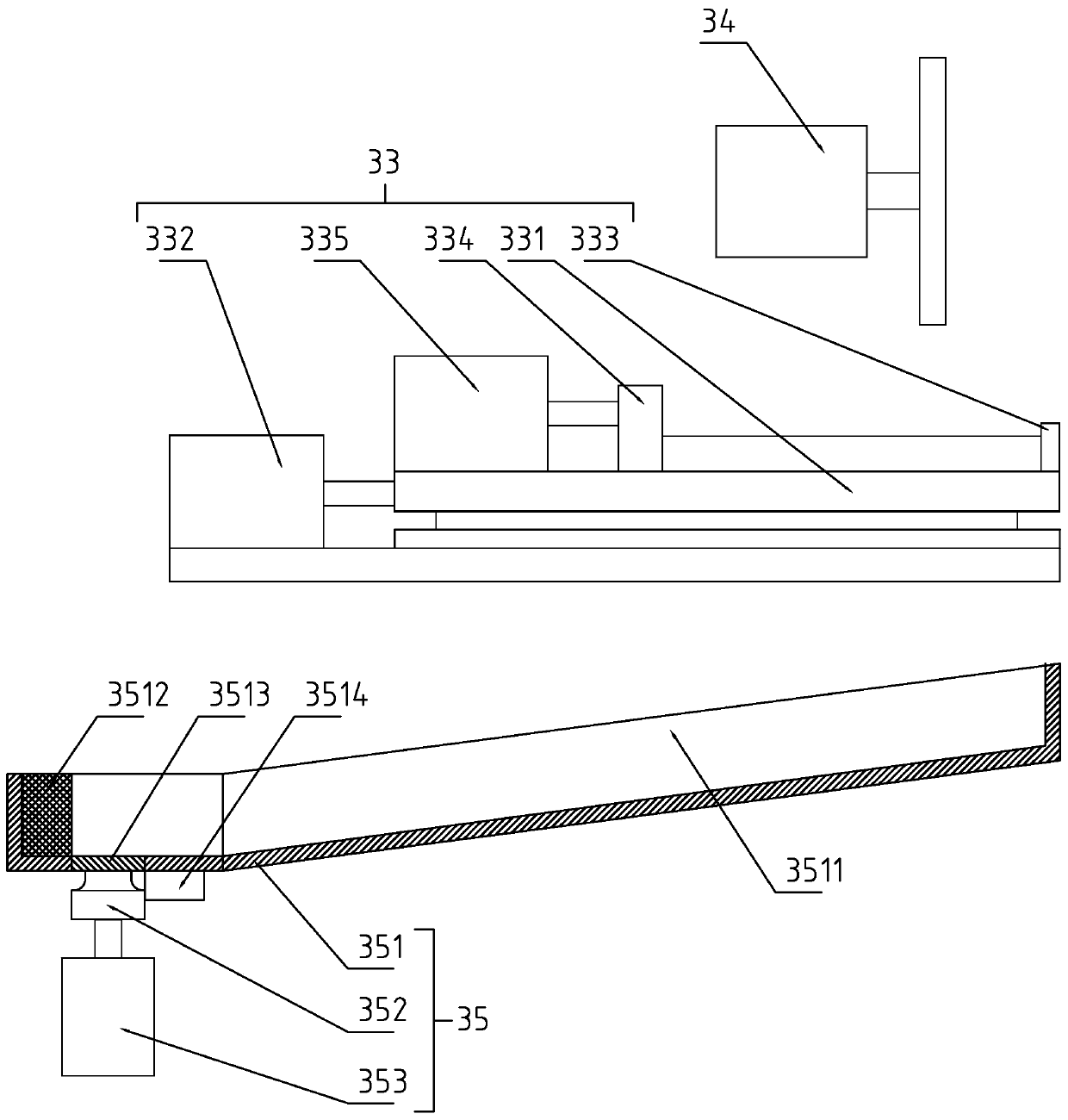

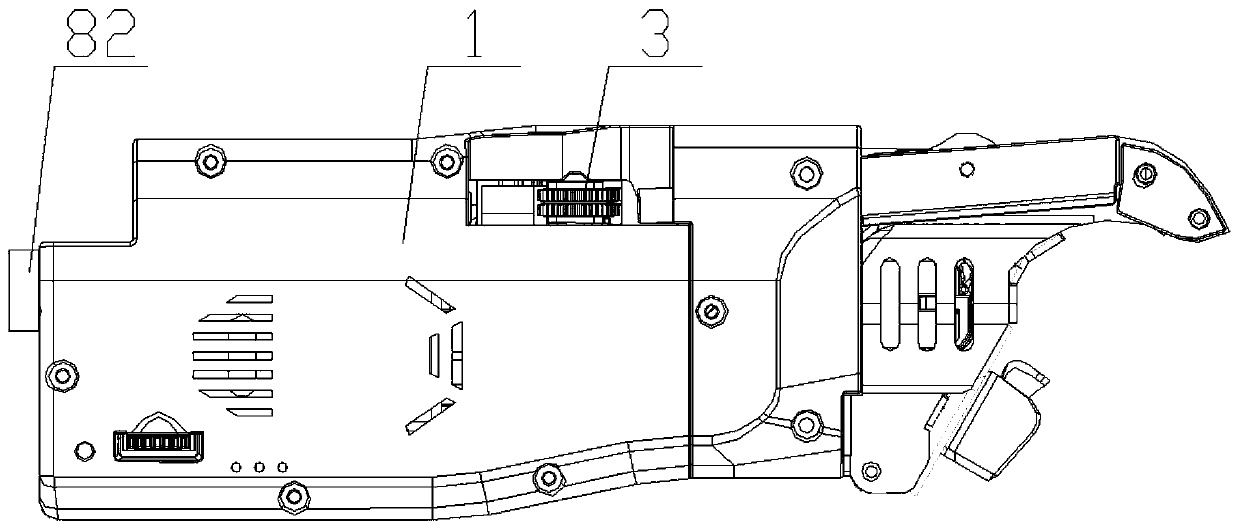

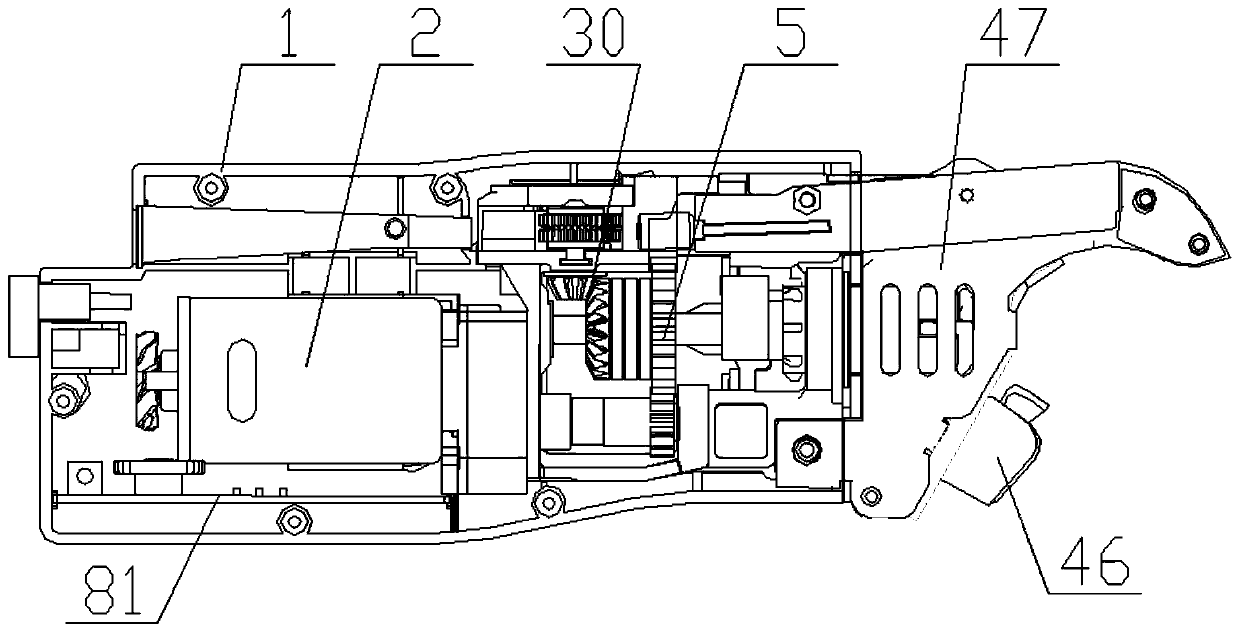

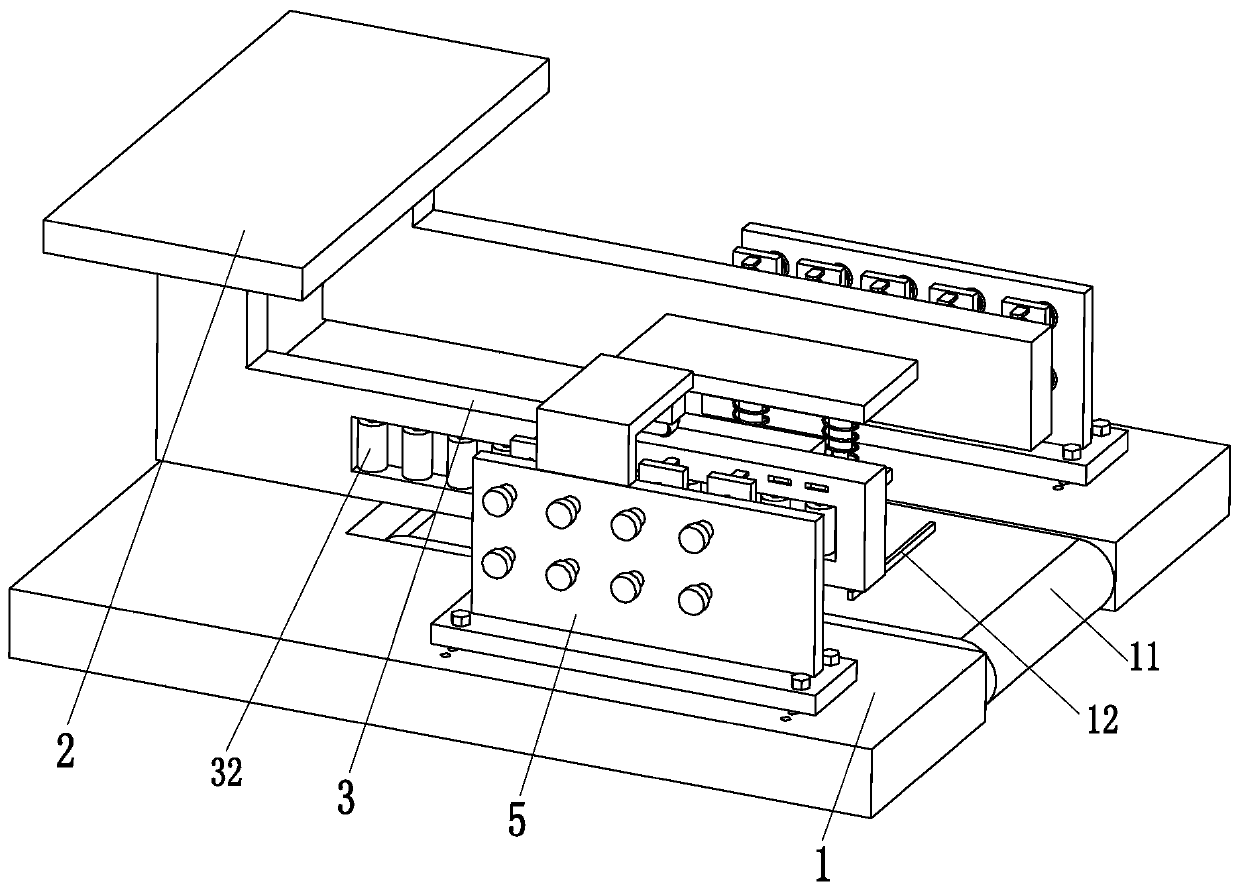

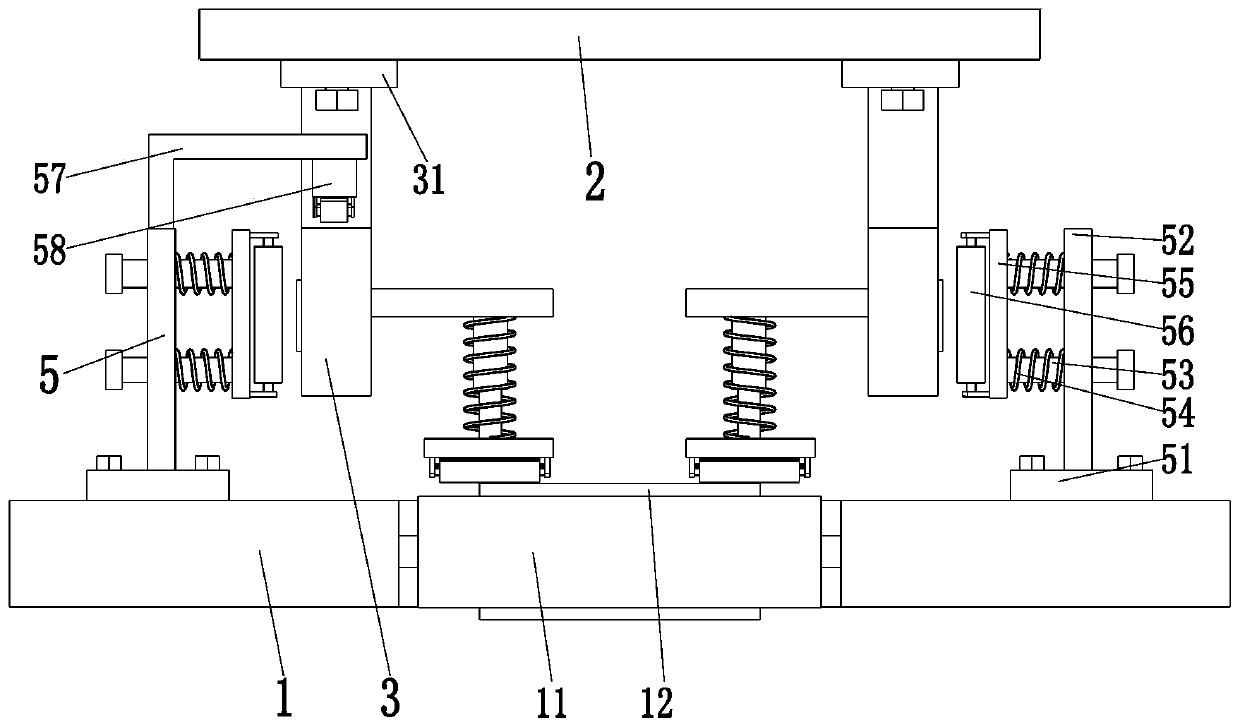

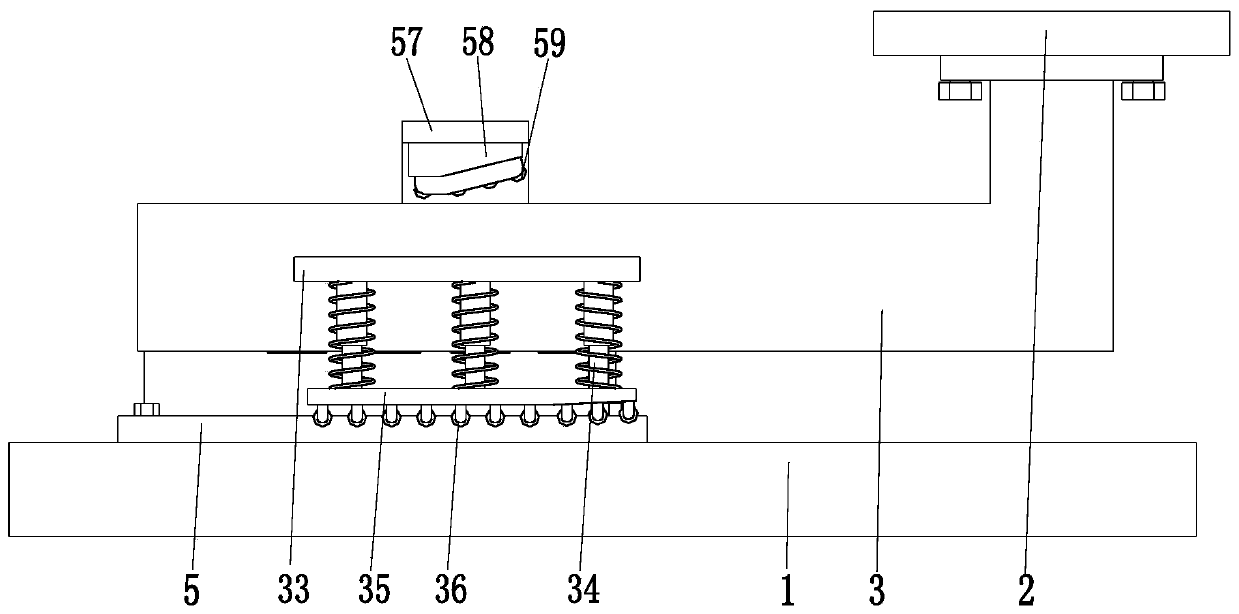

Reinforcing mesh sheet binding machine

PendingCN108756251AEnhanced binding effectImprove work efficiencyBuilding material handlingRebarEngineering

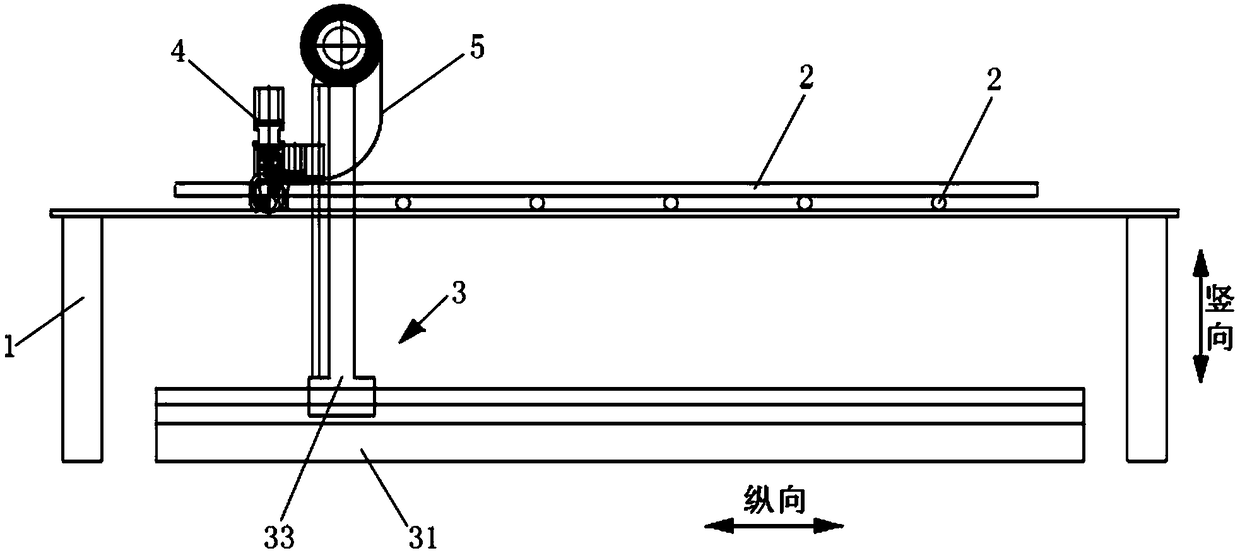

The invention discloses a reinforcing mesh sheet binding machine, and belongs to the technical field of construction equipment. The reinforcing mesh sheet binding machine comprises a material bearingframe, a rack and one or more automatic binding mechanisms. A plurality of steel bars arranged crosswise are borne on the material bearing frame. The rack comprises longitudinal brackets, a transversebracket and vertical brackets. The longitudinal brackets are arranged on the two sides of the material bearing frame. The vertical brackets are slidably arranged on the longitudinal brackets. The transverse bracket is slidably arranged on the vertical brackets and located on the steel bars. The automatic binding mechanisms are slidably arranged on the transverse bracket and can bind binding wiresat the crossing joints of the steel bars. According to the reinforcing mesh sheet binding machine, automatic binding forming of large-diameter reinforcing mesh sheets is achieved, the reinforcing mesh sheet binding machine is high in automation degree, simple and practical in structure, easy to operate, safe and efficient, high-intensity manual labor can be replaced, meanwhile, the reinforcing mesh sheet binding machine is good in binding effect and high in operation efficiency, and steel wires are saved advantageously.

Owner:TJK MACHINERY TIANJIN

Heavy oil reservoir artificial bubble oil throughput exploiting method

ActiveCN104213886AImprove stabilityImprove liquidityFluid removalDrilling compositionFoaming agentGas oil ratio

The invention provides a heavy oil reservoir artificial bubble oil throughput exploiting method. The method comprises the following steps of step 1, injecting solvent type foam liquid into an oil well; step 2, after the well is covered for proper time, opening the well to produce oil; step 3, when the daily oil yield is 1m<3> / d to 2 m<3> / d, stopping throughput production of the period, and repeating the step 1 to step 3, and when the gas yield is gradually reduced and the cycle produced gas-oil ratio is smaller than 5, performing step 4; step 4, injecting an oil-soluble viscosity reducer into the oil well; step 5, injecting a solvent type foaming agent into the oil well; step 6, after the well is covered for proper time, opening the well to produce oil; step 7, when the daily oil yield is 1m<3> / d to 2 m<3> / d, stopping throughput production of the period, and repeating the step 4 to step 6; step 8, when the cycle oil yield is smaller than 100 to 200m<3>, stopping production. By the exploiting method provided by the invention, the viscosity of crude oil can be greatly reduced, and the aim of greatly improving the primary gas-containing heavy oil reservoir recovery ratio is fulfilled due to the fact that bubble oil flow is artificially produced.

Owner:PETROCHINA CO LTD

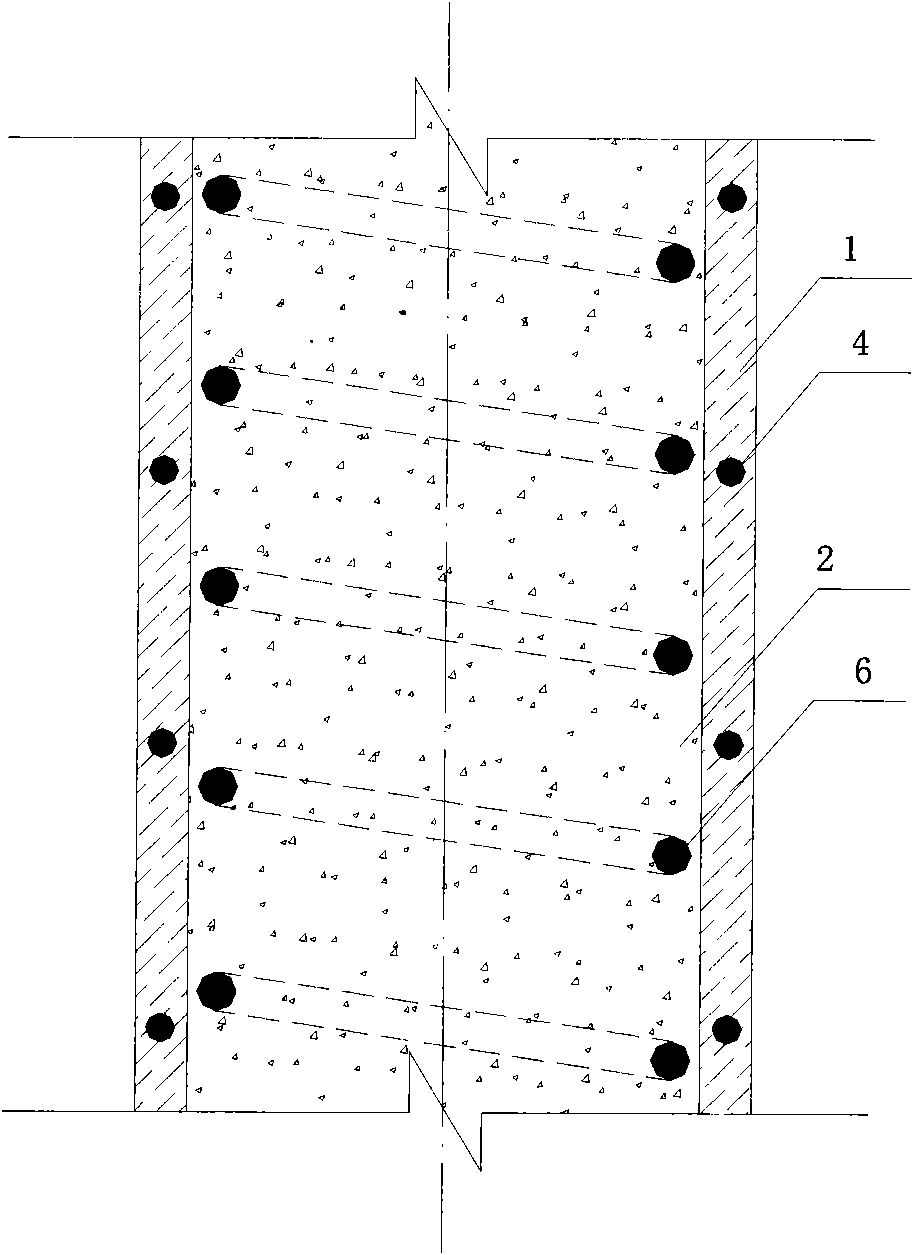

Sleeve reinforced concrete column

InactiveCN102102423AGive full play to the material performanceEasy constructionStrutsPillarsReinforced concrete columnShock resistance

The invention discloses a sleeve reinforced concrete column. The sleeve reinforced concrete column is characterized in that: a sleeve (1) of a reinforced concrete column (2) is a prefabricated active powder concrete sleeve. The sleeve reinforced concrete column has the advantages of convenience for construction, low cost, high axial bearing capacity, good shock resistance, predominant fireproof performance, excellent durability and the like, meanwhile, saves more resources and energy, and accords with the requirements of sustainable development.

Owner:HUNAN UNIV

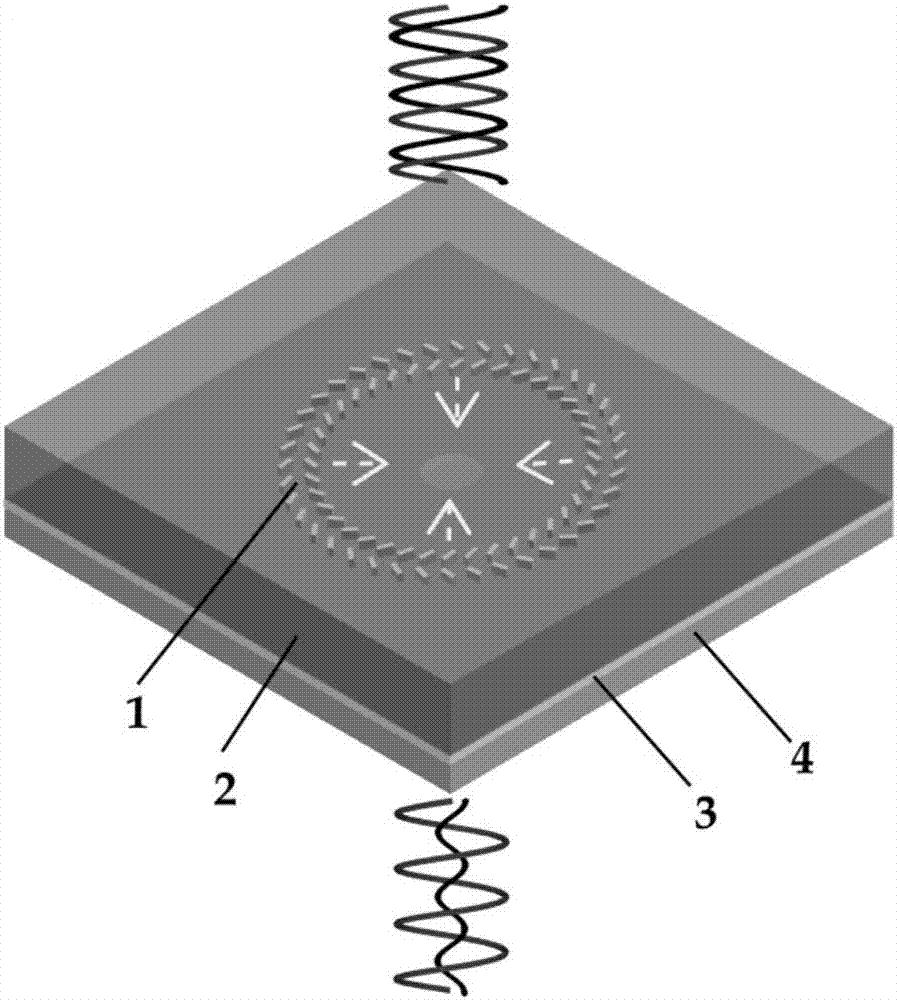

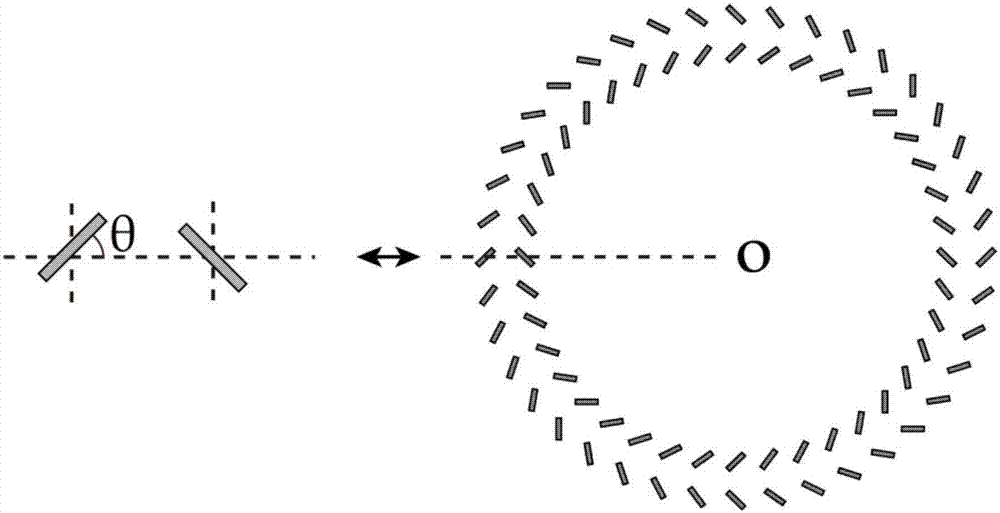

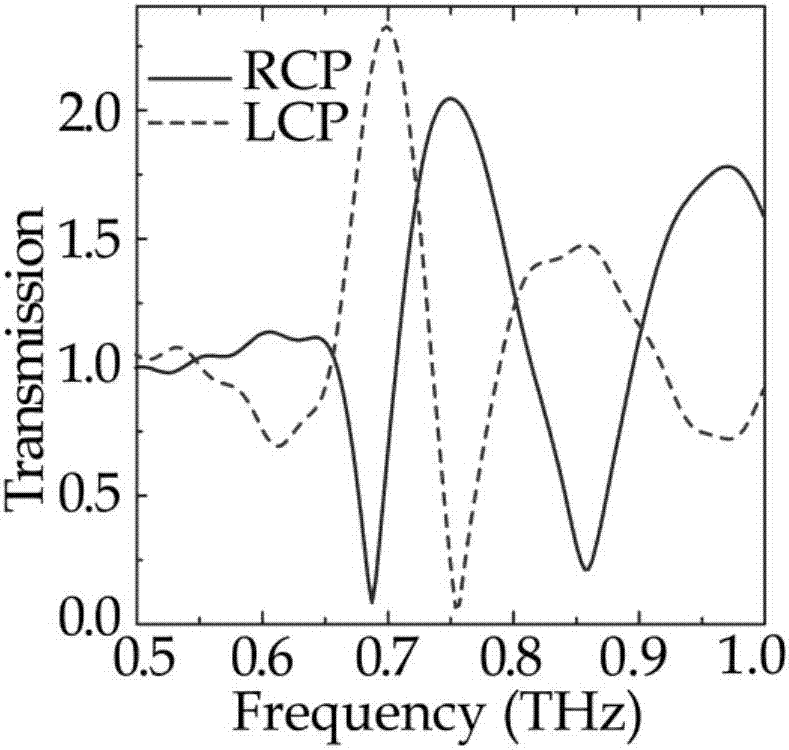

Terahertz chiral modulator based on superstructure hole structure

InactiveCN107957604APreserve the polarization stateReduce the numberPolarising elementsSurface plasmon excitationMetal strips

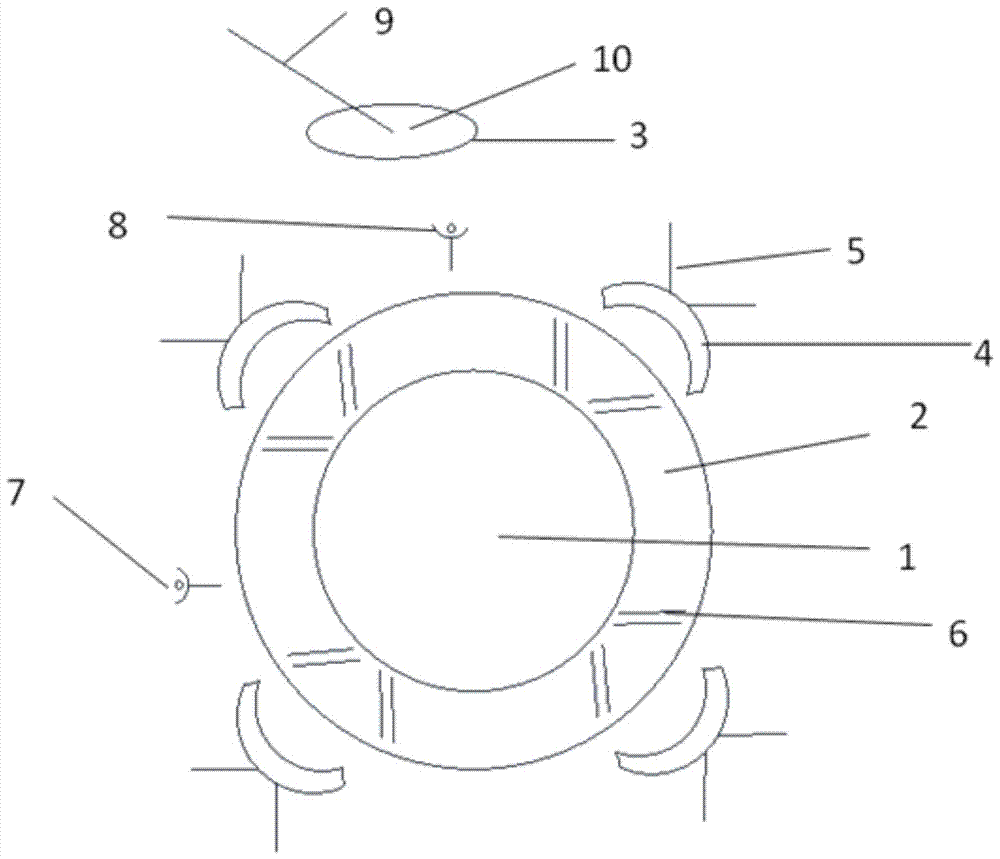

The invention relates to the chiral modulator technology and provides a multi-functional chiral modulator which works in a terahertz band and has a simple structure, and chiral dependent transmission,chiral dependent surface plasmon excitation, chiral polarization state control and the like can be achieved. Therefore, the terahertz chiral modulator based on a superstructure hole structure is disclosed, the superstructure hole structure is formed by four layers which are a metasurface metal ring, a dielectric layer, a metal plate hollowed out in the middle and a dielectric layer from the top to bottom, metal strip pair resonators are employed by basic units of the metasurface metal ring of the top layer, each of the metal strip pair resonators is formed by two same metal strips which are perpendicular to each other, the metal strip pair resonators are uniformly and rotatingly arranged around a center point O to form the metal ring, the center of the metal ring is opposite to the centerof a metal hole made in the metal plate. A strong magnetic effect can be generated by the design of the metal ring, the dielectric layer and the metal plate. The terahertz chiral modulator is mainlyapplied to the design and manufacture of chiral modulators.

Owner:TIANJIN UNIV

Fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column

ActiveCN103899040AEnhanced binding effectDelayed bucklingStrutsBuilding reinforcementsFiberReinforced concrete

The invention aims at providing a fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column which comprises a steel tube, a hoop rib, an FRP reinforced rib and a longitudinal reinforcement, wherein the hoop rib and the FRP reinforced rib are arranged in the steel tube; the inner wall of the steel tube is provided with fixed angle iron; the end part of the FRP reinforced rib is fixed on the angle iron; the FRP reinforced rib is provided with a hole, and the hoop rib passes through the hole in the FRP reinforced rib; the longitudinal reinforcement is fixed on the hoop rib; the steel tube is filled with concrete. An FRP reinforced rib plate internally provided with the hoop rib and the longitudinal reinforcement is arranged in the FRP reinforced concrete-filled steel tube combination column, and the concrete can be separated again, so that the restraint effect of the concrete is improved, the bearing capacity of the concrete is improved, and the tube wall on the stressed side is effectively prevented from being bended. By adopting a structure of enabling reinforced concrete, the FRP reinforced rib and the steel tube to cooperative work, the FRP reinforced concrete-filled steel tube combination column is simple in structure and convenient to construct, and has the characteristics of being light in weight, high in carrying capacity and good in ductility and shock resistance.

Owner:HARBIN ENG UNIV

Display panel, display device and manufacturing method of display panel

ActiveCN107749239AEnhanced binding effectEliminate signal crosstalkIdentification meansDisplay deviceComputer module

The embodiment of the invention discloses a display panel, a display device and a manufacturing method of the display panel. The display panel comprises a substrate base plate, the substrate base plate comprises a driving chip binding region, at least two rows of first connection pins are arranged in the driving chip binding area, and each row of first connection pins comprises at least two firstconnection pins; the thicknesses of the first connecting pins arranged in the same row are the same, and the thicknesses of the first connecting pins arranged in the different rows are different; thedriving chip binding area is rectangular, and the extension direction of the rows is parallel to the long-edge direction of the driving chip binding area. Compared with the existing display panel, forthe display panel provided by the embodiment of the invention, the binding effect of the display panel and a control module can be improved, so that the phenomena of signal crosstalk and uneven display of the display panel are eliminated, and the display effect of the display panel is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Crab bundling device and method

ActiveCN107499556AIt is good for control and will not move casuallyConducive to the problem of running outBinding material applicationBundling machine detailsEngineeringFlange

The invention relates to a crab bundling device which comprises a multifunctional crab receiving pan, a flexible crab pressing device, C-type crab hooping supports, a crab hooping support holding flange plate, a symmetric rotating platform, a rope head clamping and exchanging mechanism, a rope body guide mechanism, a rope head and rope tail closing and rope tightening mechanism, a rope tying mechanism and a rope shearing mechanism. According to the crab bundling device provided by the invention, crabs can be automatically bundled, and the bundling effect is quite good. The invention further relates to a crab bundling method.

Owner:上海异复材料科技有限公司

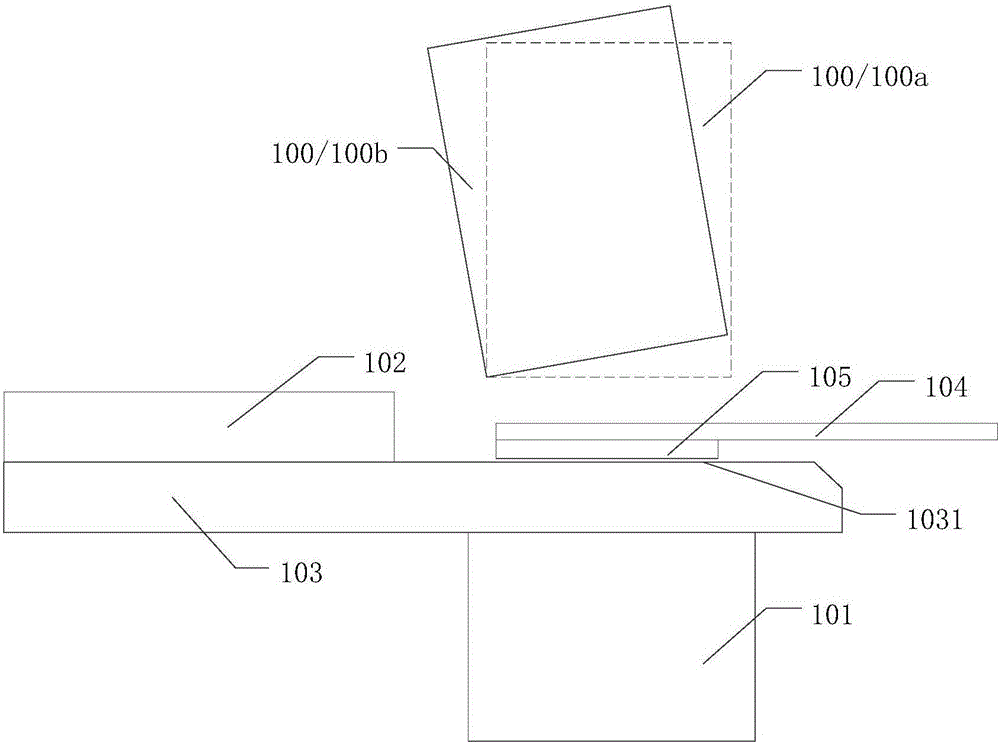

Binding device, display panel, binding system and operation method thereof

InactiveCN106707573AHigh precisionOptimize the binding effectSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringBinding effect

The invention provides a binding device, a display panel, a binding system and an operation method thereof. The binding system comprises the binding device and the display panel, wherein the binding device comprises a binding pressing head, a supporting platform, a light transmitter and a light receiver. According to the binding system, a first alignment hole is formed in the binding pressing head, the display panel is provided with an alignment marker, and a second alignment hole is formed in the supporting platform; a position and / or a posture of the binding pressing head, the position and / or the flatness of a binding region of the display panel, and an alignment degree between the binding pressing head and the display panel are monitored in real time by utilizing the light transmitter and the light receiver, so that the binding pressing head, the display panel, and the alignment degree between the binding pressing head and the display panel can be adjusted in real time; and the binding alignment accuracy is improved, the binding effect is optimized, the binding efficiency is improved, the rejection rate is reduced, and the yield of products is improved.

Owner:FUZHOU BOE OPTOELECTRONICS TECH CO LTD +1

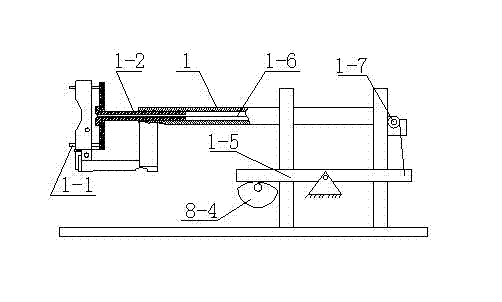

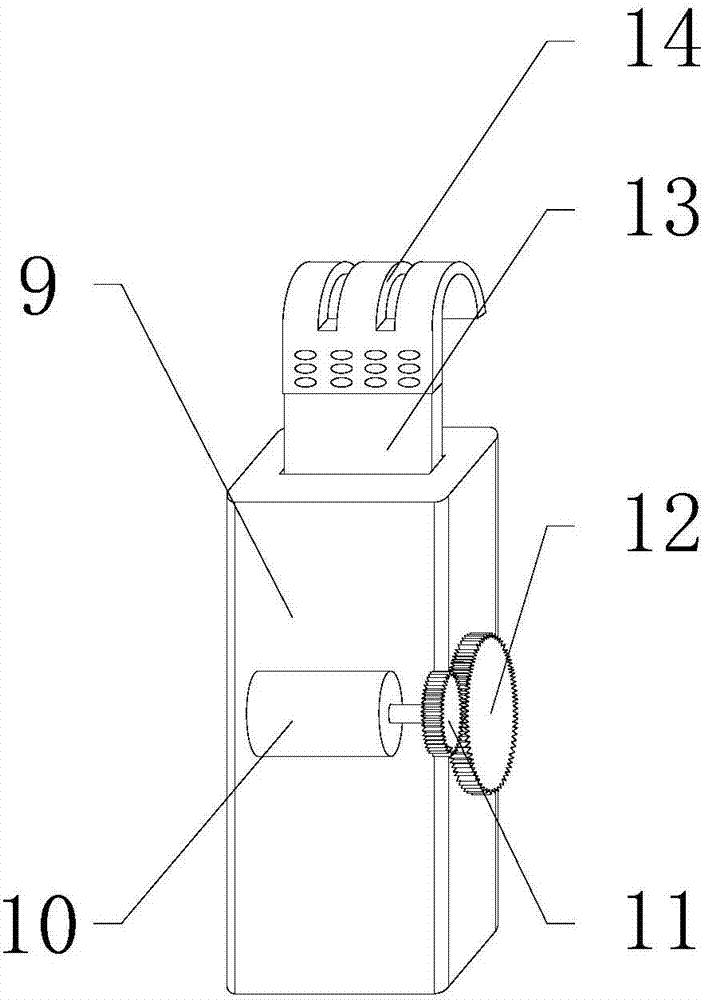

Multifunctional bundler

ActiveCN102514749AReduce labor intensityFill the technical gapBinding material applicationBundling machine detailsEngineeringCam

The invention discloses a multifunctional bundler. The structure comprises a cam drive mechanism assembly, a belt feeding / drawing mechanism assembly, a belt wrapping mechanism assembly and a cut-off bonding mechanism arranged on a bracket. The multifunctional bundler has the beneficial effects that the labor intensity is effectively reduced by using the multifunctional bundler, and the bundling effect on small-scale and irregular objects also can be realized, such as the bundling of the Zongzi (glutinous rice dumpling), besides the regular objects, such as the bundling of cashes. The multifunctional bundler makes up for the technology defect of the traditional bundler, and the work efficiency is effectively improved.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

Display panel and display device

ActiveCN109523912AIncrease contact areaIncrease binding areaPrinted circuit assemblingIdentification meansEngineeringSurface plate

The invention discloses a display panel and a display device. Multiple welding discs are included, the welding discs comprise first secondary parts and second secondary parts which are electrically connected, the first secondary parts have first length, the second secondary parts have second length, the second length is greater than the first length, the edges, close to a fastening area, of the display panel is first edges, the ends, close to the first edges, of the first secondary parts are first end parts, the distance from the first end parts to the first edges is first range, the ends, close to the first edges, of the second secondary parts are second end parts, the distance from the second end parts to the first edges is second range, and the second range is smaller than the first range. By lengthening the second secondary parts of the welding discs to increase the fastening area, the fastening effect is better, the signal transmission accuracy and stability of the fastening areaare improved, better compatibility is achieved when the electronic assembly is fastened, and the influence on the fastening of an electronic assembly caused by expansion caused by heat and contractioncaused by cold is reduced.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

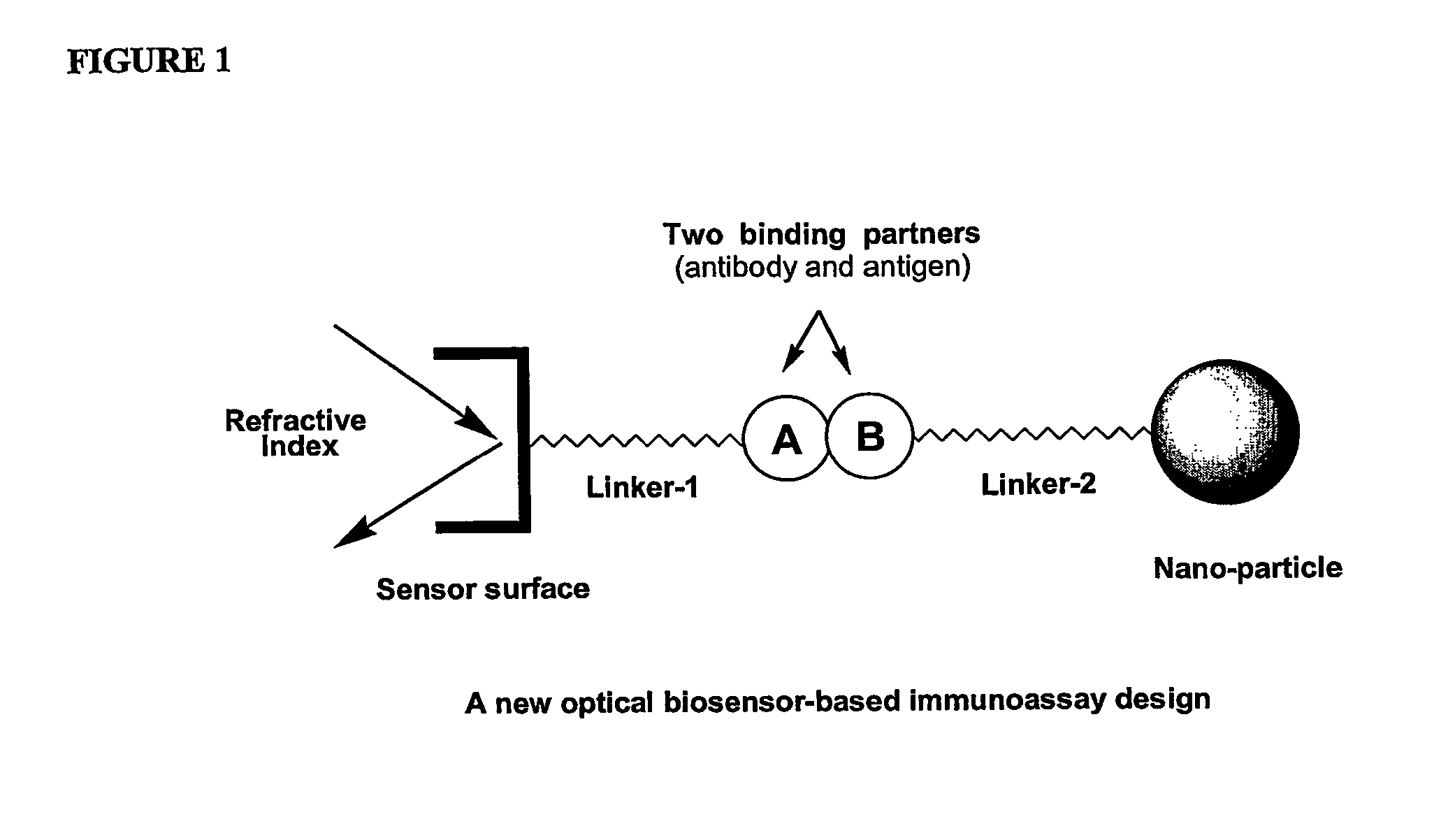

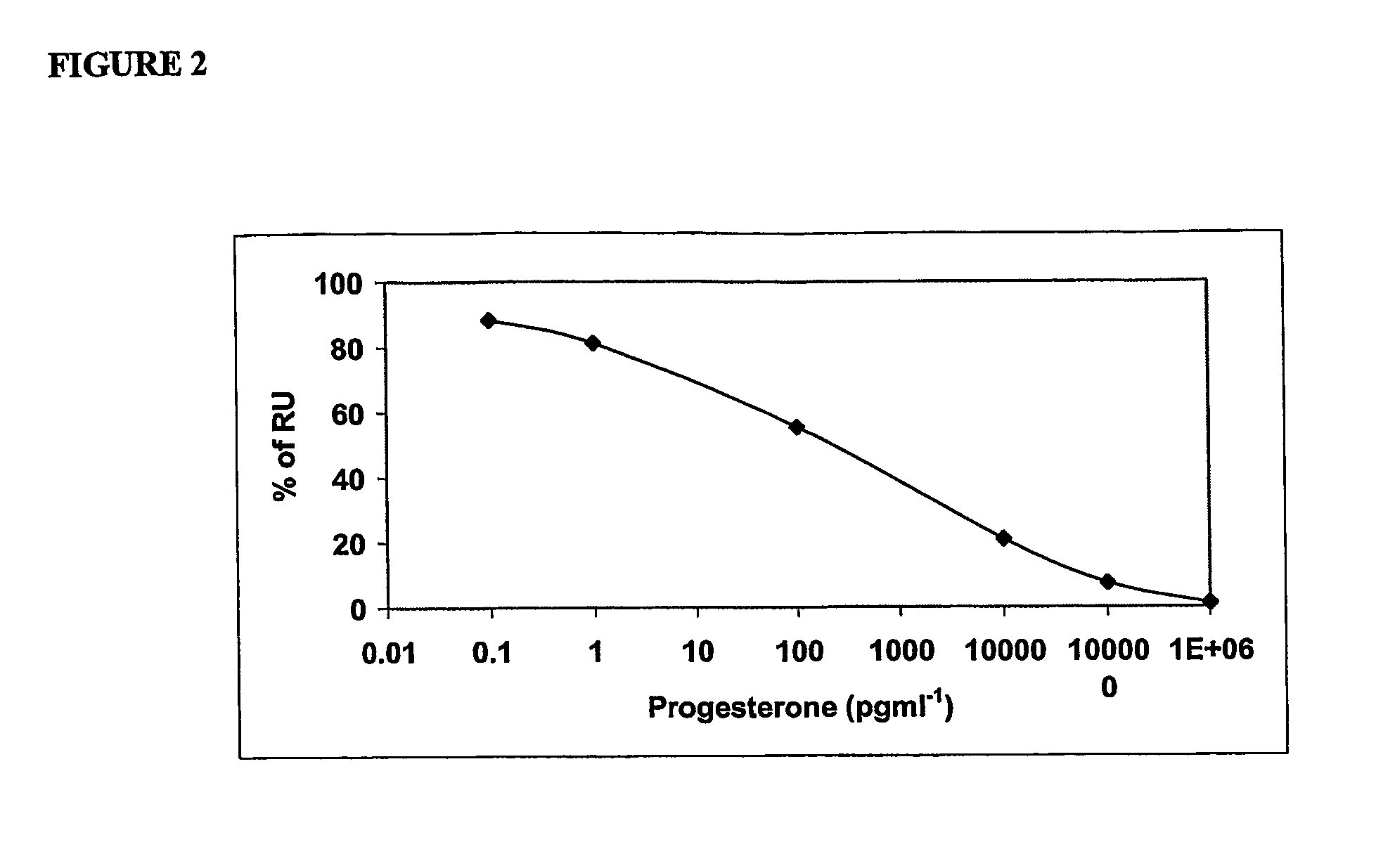

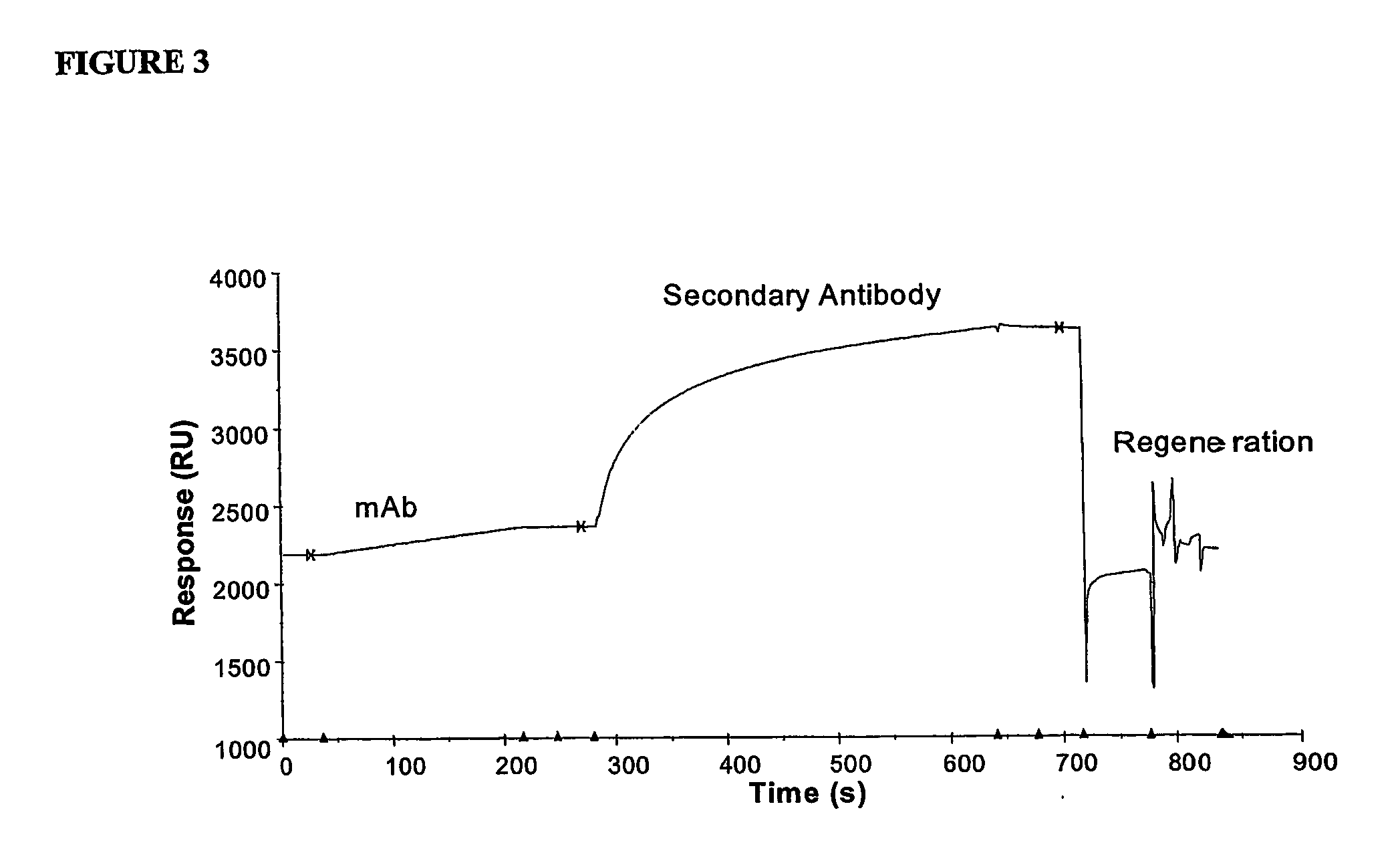

Immunoassay

InactiveUS20070087383A1Increase binding partner binding performanceHigh detection sensitivityBiological material analysisMaterial analysis by optical meansNanoparticleHapten

The invention provides a method for detecting a hapten in a sample comprising the steps of: a) providing a sample potentially containing the hapten; b) providing a pre-determined amount of a first moiety, said first moiety being bound to a signaller and separated therefrom by a first linker, which first moiety is either: i) a binding partner that specifically binds to the hapten of interest, or ii) the hapten of interest or an analogue thereof; wherein said signaller is a macromolecule or a nanoparticle providing high mass signal; c) providing a flow of a) and b) separately or together to an immobilised second moiety, said second moiety being bound to the surface of a sensor and separated therefrom by a second linker, which second moiety is either: i) a binding partner that specifically binds to the hapten of interest, or ii) is the hapten of interest or an analogue thereof, providing that when the first moiety is a binding partner, the second moiety is a hapten or hapten analogue and when the first moiety is a hapten or hapten analogue, the second moiety is a binding partner; and d) detecting the amount of first moiety bound to second moiety.

Owner:THE NEW ZEALAND INST FOR PLANT & FOOD RES LTD

Curing agent for treatment of electroplating sludge, and preparation method and application method thereof

The invention relates to a curing agent for treatment of electroplating sludge. The curing agent comprises the following raw materials in percentage by weight: 75%-79% of cement, 10%-15% of sands, 5%-8% of sodium silicate and 6%-10% of activated aluminium oxide; the invention further discloses a preparation method and an application method of the curing agent. The curing agent has a wide application range, and overcomes potential hazards due to secondary environmental pollution of electroplating heavy metal sludge.

Owner:湖南中车环境工程有限公司

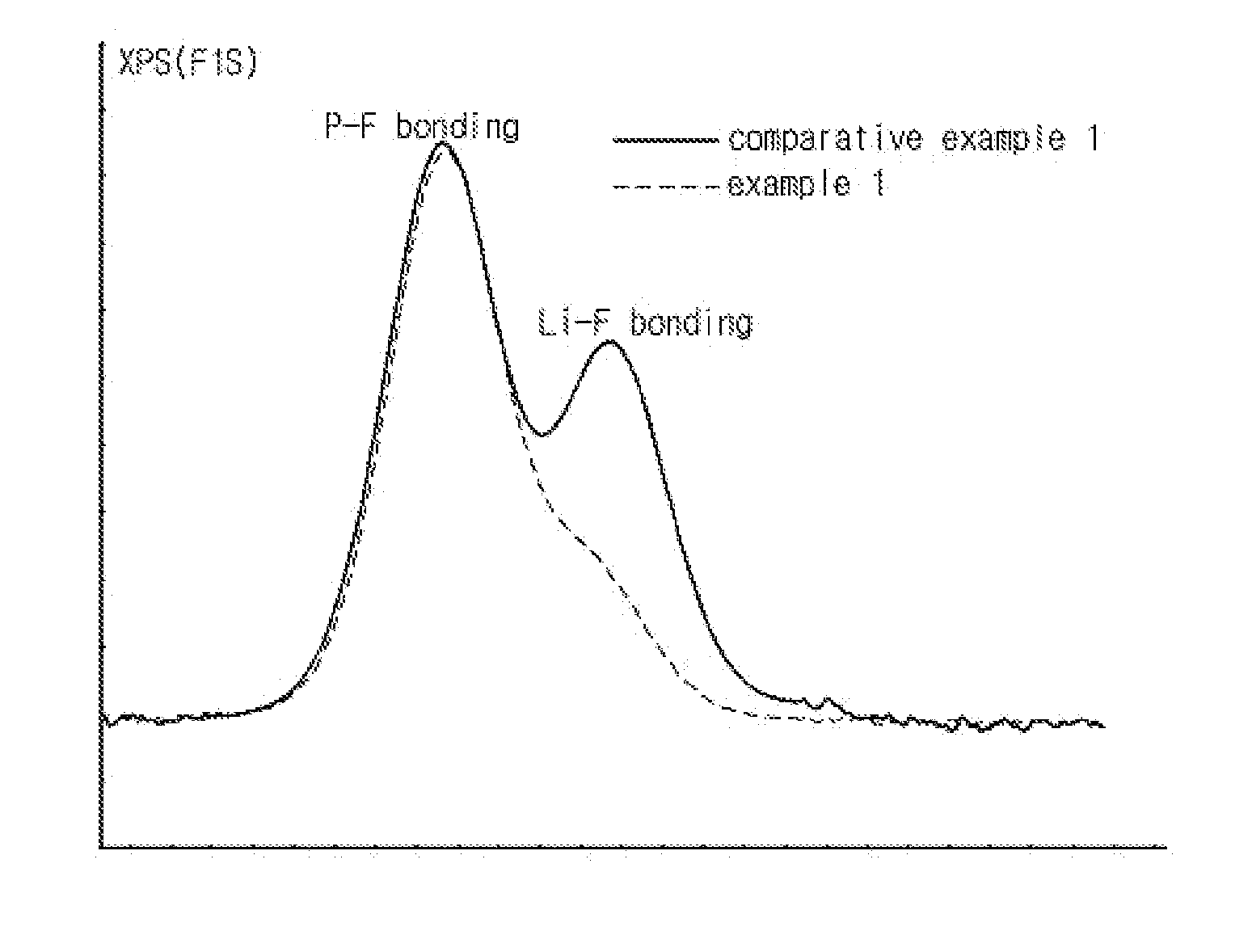

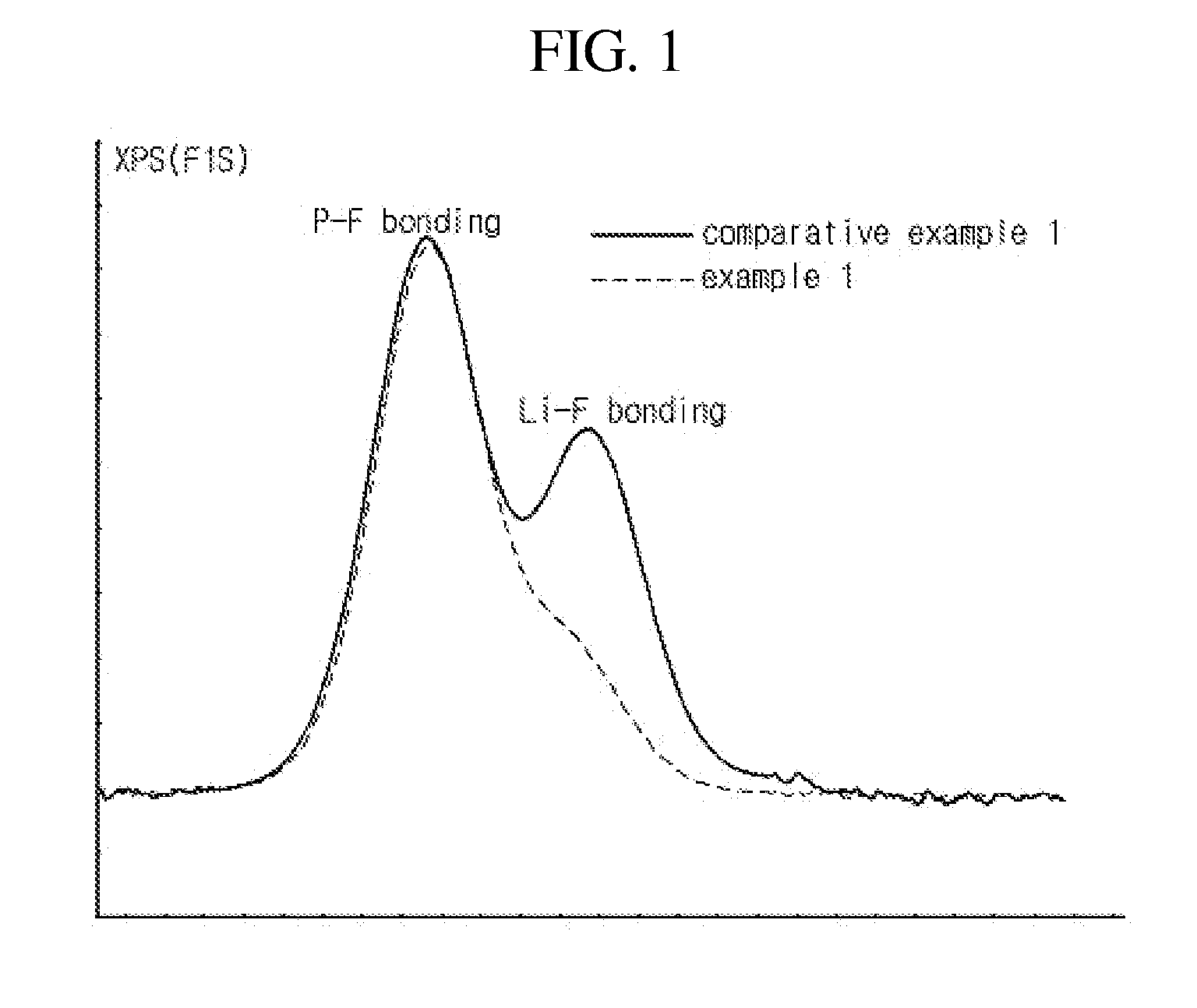

Non-aqueous electrolyte solution for lithium secondary battery and lithium secondary battery including the same

ActiveUS20120088161A1Improve cycle life characteristicEfficiently solveCell electrodesOrganic electrolyte cellsElectrical batteryLithium electrode

Disclosed is a non-aqueous electrolyte solution for a lithium secondary battery. The non-aqueous electrolyte solution includes an electrolyte salt and an organic solvent. The non-aqueous electrolyte solution further includes (a) a polyfunctional compound including two or more functional groups, at least one of which is an acryl group, and (b) an anion receptor selected from the group consisting of a borane compound, a borate compound and a mixture thereof. Further disclosed is a lithium secondary battery including the non-aqueous electrolyte solution. A stable solid electrolyte interface (SEI) film is formed on an anode of the lithium secondary battery. The amount of LiF in the SEI film is controlled, achieving improved cycle life characteristics of the battery.

Owner:LG ENERGY SOLUTION LTD

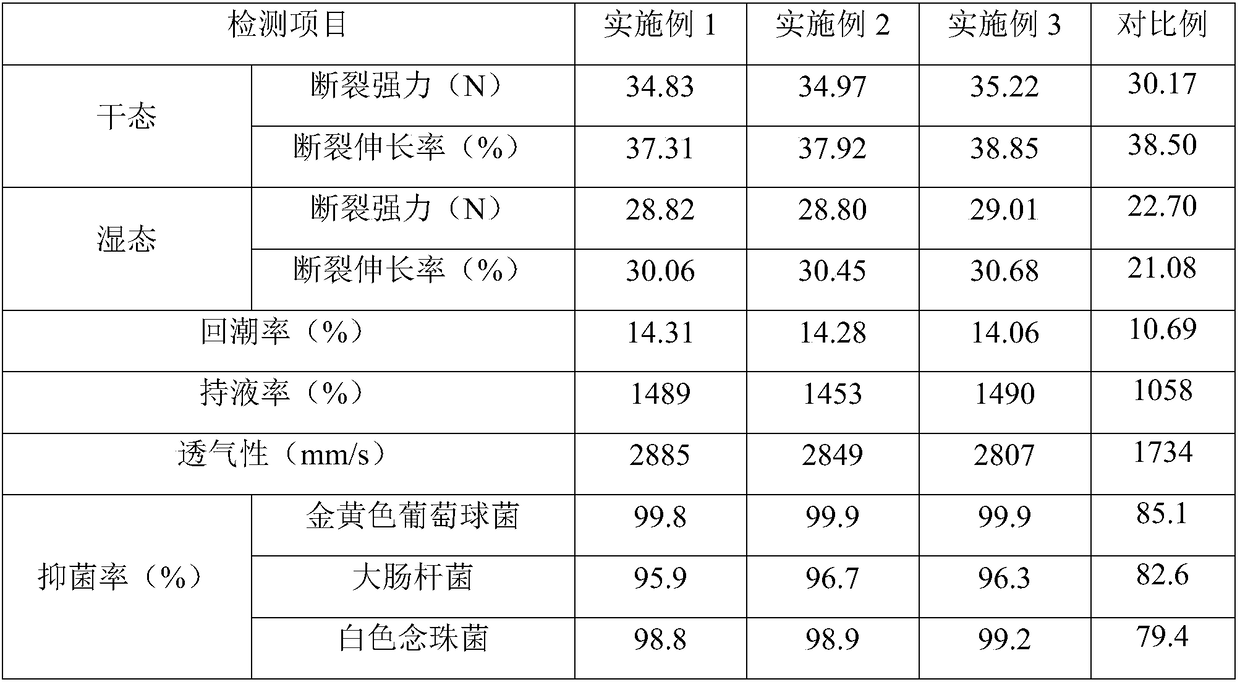

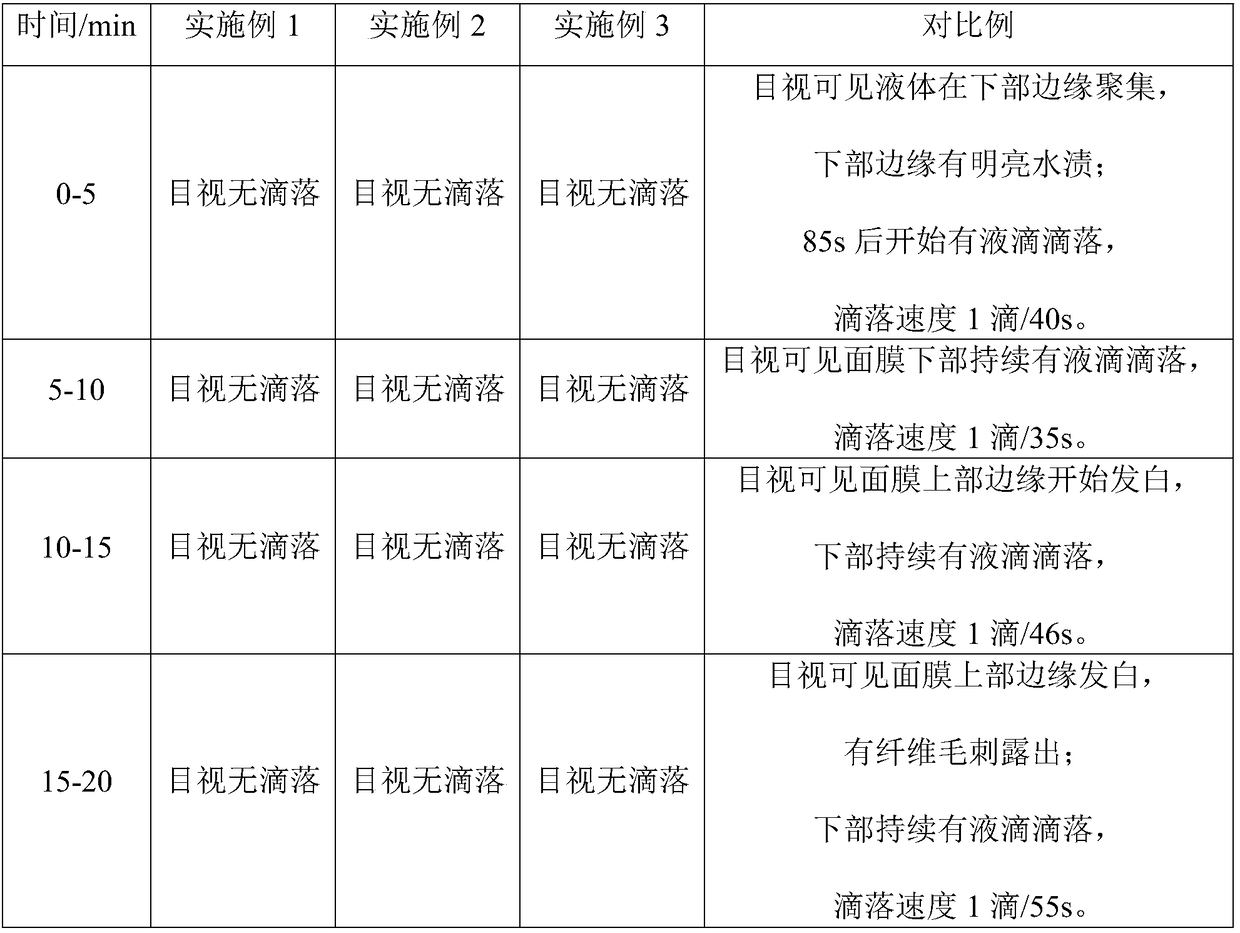

Bamboo charcoal viscose facial mask base cloth and high moisture retention and moisturizing facial mask

ActiveCN108403446AMeet physiological requirementsEliminates allergy riskCosmetic preparationsToilet preparationsCardingSlurry

The invention relates to a bamboo charcoal viscose facial mask base cloth and a high moisture retention and moisturizing facial mask. The bamboo charcoal viscose facial mask base cloth is prepared with the following method: 1) adding nanometer bamboo charcoal powder and sodium alga acid into dispersion solution to be dispersed evenly in bamboo charcoal serous fluid; 2) adding the bamboo charcoal serous fluid into viscose spinning solution to be dispersed evenly, and filtering and deforming to obtain mixed spinning solution; 3) carrying out wet method spinning on the mixed spinning solution toobtain the bamboo charcoal viscose, and carrying out opening, mixing, carding and lapping to obtain a bamboo charcoal viscose felt; 4) dissolving chitosan in acetic acid aqueous solution, adding gelatin to be dissolved to obtain finishing liquor, and dipping the bamboo charcoal viscose felt into the finishing liquor to carry out impregnation modification to obtain a compound fiber felt; 5) carrying out spunlace reinforcement on the compound fiber felt. The bamboo charcoal viscose facial mask base cloth has high constraint ability on serum and good water retention and moisture liberation performance; after the facial mask serum is loaded through a liquid hanging step, the high moisture retention and moisturizing facial mask is obtained, situation that serum loss due to dripping and droppingcan be avoided, and waste is avoided.

Owner:魏科峰

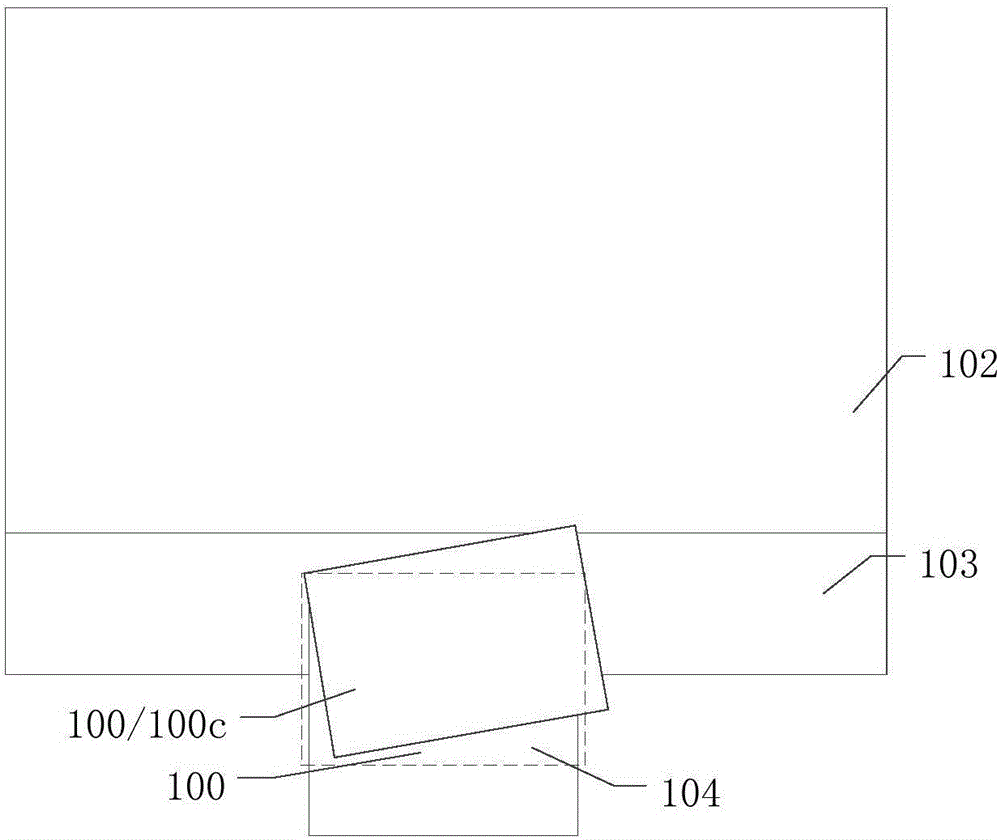

Display panel and display device

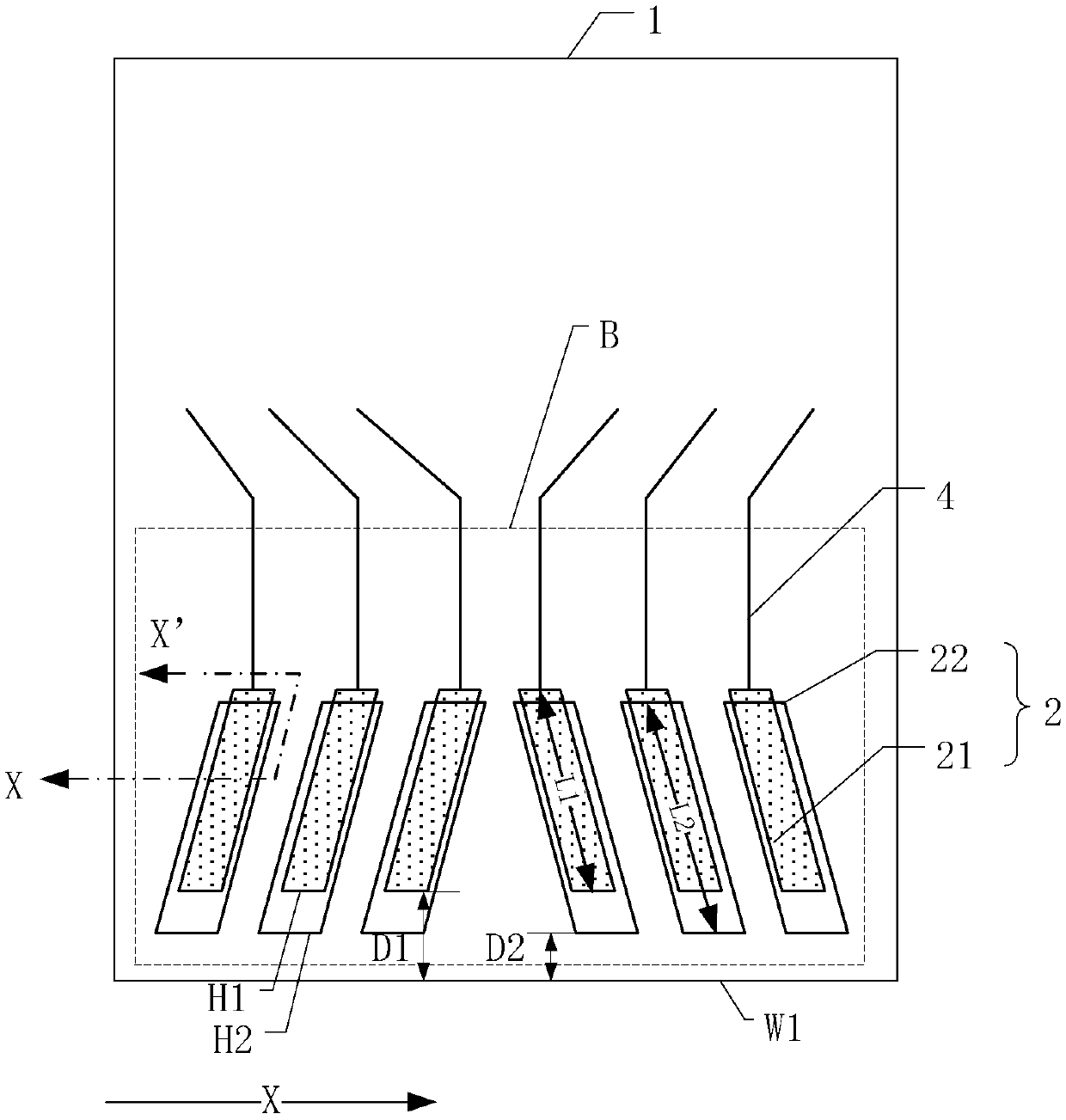

ActiveCN111564111AEnhanced binding effectRealize the designIdentification meansAcute angleDisplay device

The embodiment of the invention discloses a display panel and a display device, the display panel comprises a display area and a non-display area, and the display area comprises a plurality of signallines. The non-display area is provided with a first bonding pad binding area and a plurality of fan-out wires. The first bonding pad binding area is provided with a plurality of first bonding pads, the included angle between the extending direction of the first long edge of each first bonding pad and the first direction is an acute angle, and the included angle between the extending direction ofthe first short edge away from the display area and the second direction is an acute angle. The fan-out wire at least comprises a first sub fan-out wire, a first wiring part of the first sub fan-out wire is electrically connected with a signal line, and a second wiring part of the first sub fan-out wire is electrically connected with the first bonding pad. The included angle between the extendingdirection of the second wiring part and the first direction is an acute angle and is smaller than a preset included angle with the extending direction of the first long side. The oblique line part inthe first sub fan-out wire is directly connected with the first bonding pad, so that the fan-out wire can be translated towards the bonding pad side, and the lower frame of the display panel can be compressed.

Owner:SHANGHAI AVIC OPTOELECTRONICS

Automatic rope bundling machine for transplanting of trees of various diameters with high survival rate for municipal garden maintenance

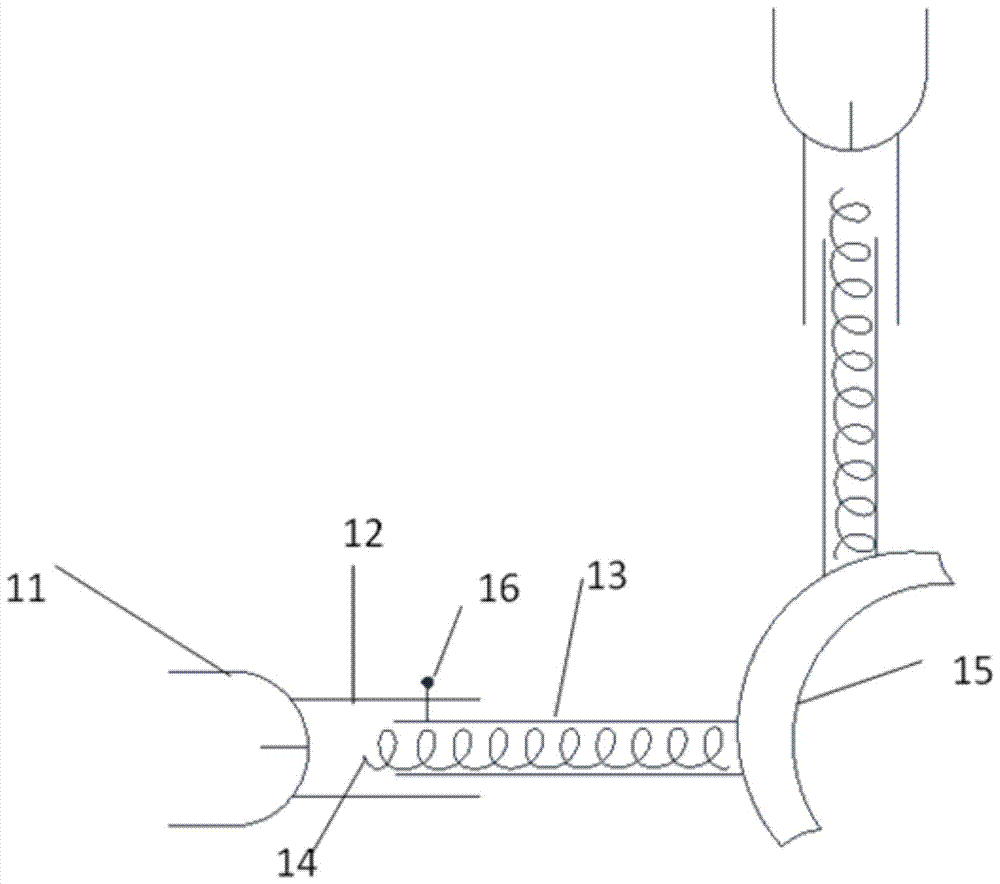

The invention relates to an automatic rope-tying machine for transplanting trees of various diameters with a high survival rate for municipal garden maintenance, which includes a lifting device, a supporting rotating device, a rotating device, a retracting device and a correcting device. The supporting rotating device is installed on the lifting device On the top, the rotating device is connected with the supporting rotating device, and the retracting device and the correcting device are installed on the rotating device. The present invention can solve the problems of low work efficiency, high labor intensity, inability to tie ropes at higher positions of trees, inability to tighten ropes when tying trees, and poor effect on tree tying ropes when tying trees manually. Good, it is troublesome to arrange the ropes after tying the trees; it can realize the function of adjusting the winding distance when tying the trees with different diameters, and has high work efficiency and low labor intensity. It has the advantages of adjusting the tension of the rope when tying the rope to the trees, having a good effect on tying the rope to the trees, and automatically rewinding the rope after tying the rope to the trees.

Owner:潘军

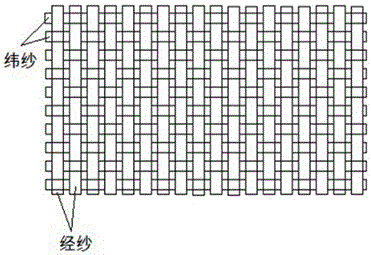

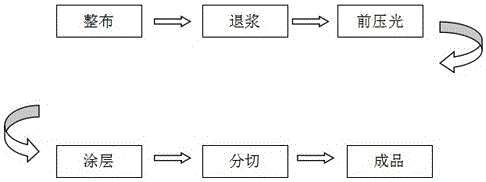

Pure-cotton trademark tape and manufacturing method thereof

Owner:湖州倍亨纺织有限公司

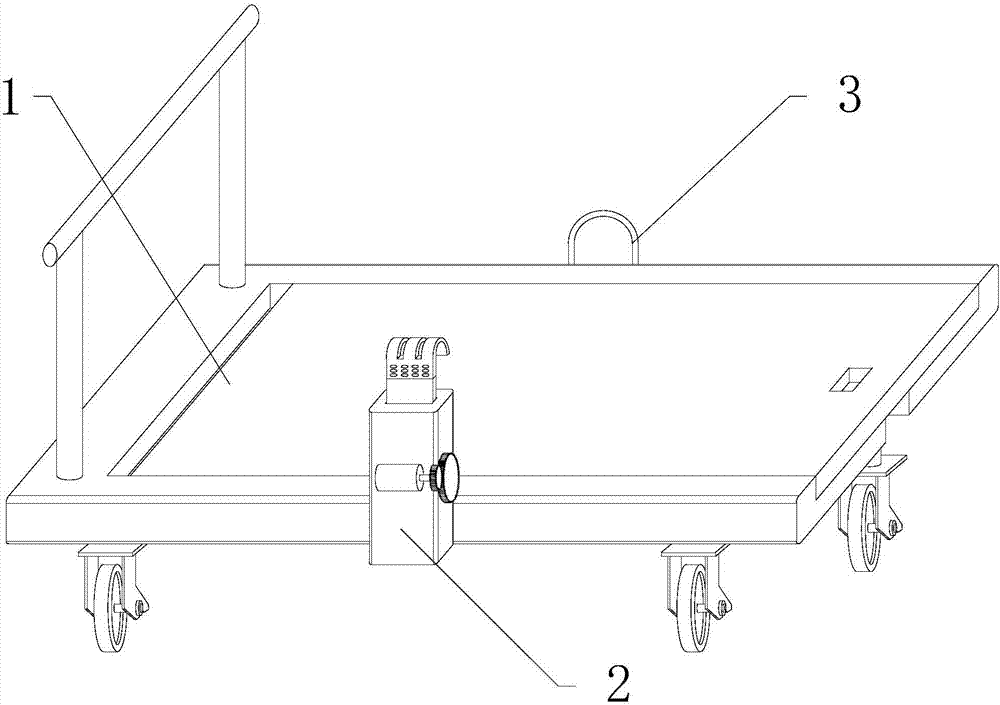

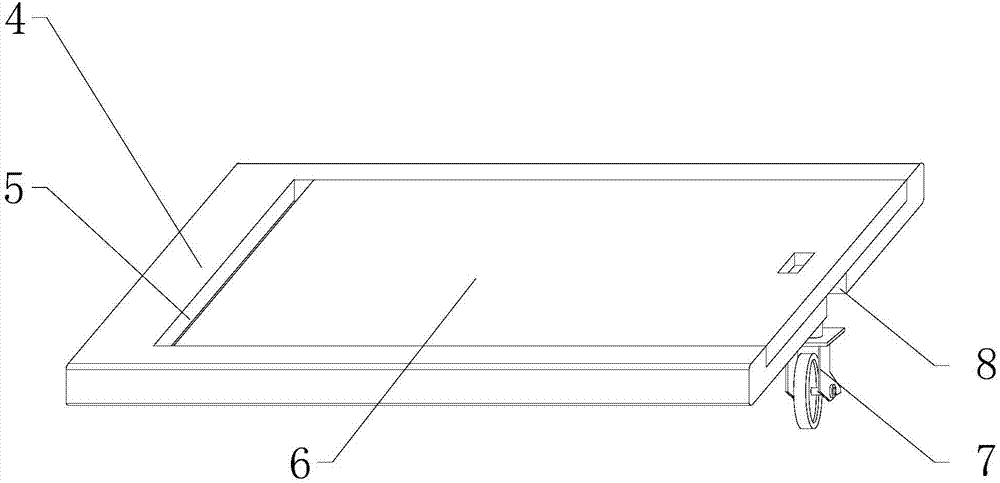

Space adjustable transport vehicle for logistics transportation system

InactiveCN107161191AMeet transportationEasy to moveHand carts with multiple axesHand cart accessoriesLogistics managementControl theory

The invention provides a space-adjustable transport vehicle for a logistics transportation system, which includes a base plate, a groove, a movable plate, a moving wheel, a card slot, a casing, a servo motor, a transmission gear, an auxiliary gear, a binding rope, and a three-headed hook As well as the rotating shaft, a groove is processed on the upper end of the base plate, a movable plate is installed inside the groove, the groove is processed at the right end of the base plate, and the upper end of the moving wheel passes through the groove to connect with the movable plate. The length of the base can be adjusted to meet the transportation of different items. The front end of the housing is provided with a servo motor, the right end of the servo motor is provided with a transmission gear, the rear end of the transmission gear is equipped with an auxiliary gear, and the shaft is wound with a binding rope. The above-mentioned binding rope passes through the shell and is connected with the three-headed hook. This design can automatically shrink the binding rope, thereby realizing the tightening of the articles and reducing the labor intensity. The invention is easy to use, expands the scope of use, improves the binding effect, and has high reliability .

Owner:安徽海之纳科技有限公司

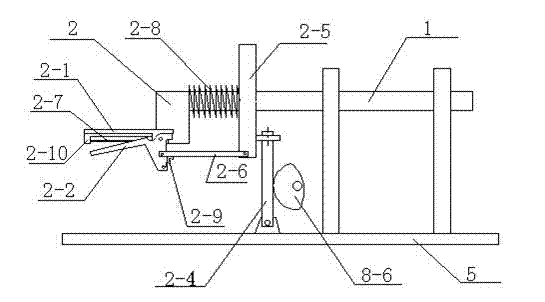

Arrangement equipment for packaging with supporting and sending device

ActiveCN106672288AEnhanced binding effectWork well togetherBundling machine detailsInstabilityCarton

The invention relates to arrangement equipment for packaging with a supporting and sending device. The arrangement equipment comprises the supporting and sending device, a pressing and packaging part, a pushing and arranging part and a bearing part; the supporting and sending device is composed of a rotary shaft and a plurality of supporting units fixedly arranged in the circumferential direction of the rotary shaft; each supporting unit is composed of a supporting rod and a supporting plate fixed at the end part of the supporting rod; the pressing and packaging part is composed of a pressing device and a packaging device; the pressing device is composed of a lifting rod and a pressure plate fixed at the end part of the lifting rod; the pushing and arranging part is composed of a transmission part driven by the lifting rod and a baffle part which slides along a workbench driven by the transmission part; the bearing part is composed of moving rod driven by the lifting rod and a bearing plate which rotates around a fixing shaft arranged at the upper section part of a bracket driven by the moving rod; and a through groove through which the supporting and sending device rotates is formed in the bearing plate. According to the arrangement equipment, the problems of untidy piling of paper boxes before packaging, infirmness in loose packaging, large equipment operation noise, instability in whole transmission of cached and piled paper boxes and up and down irregularity are overcome

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

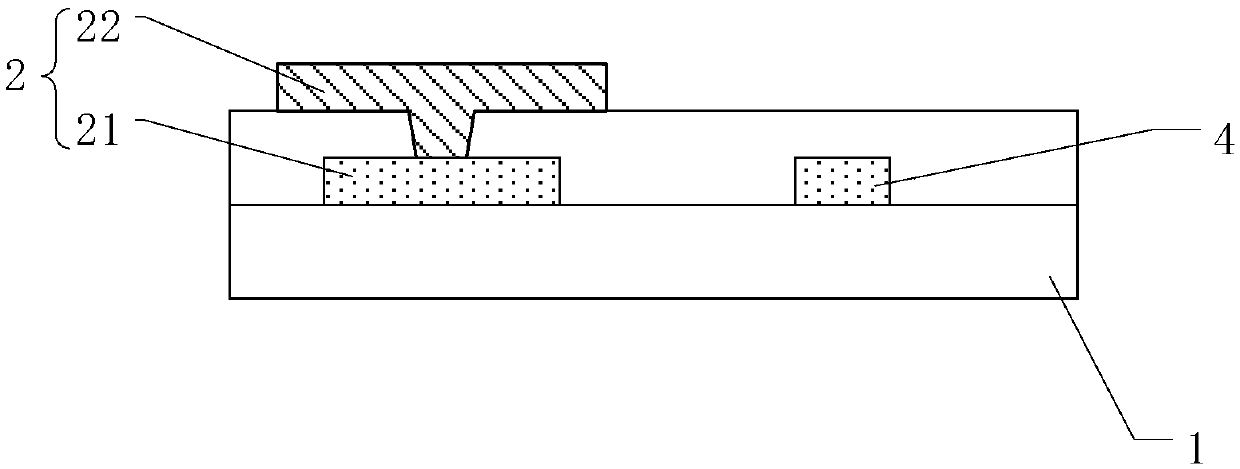

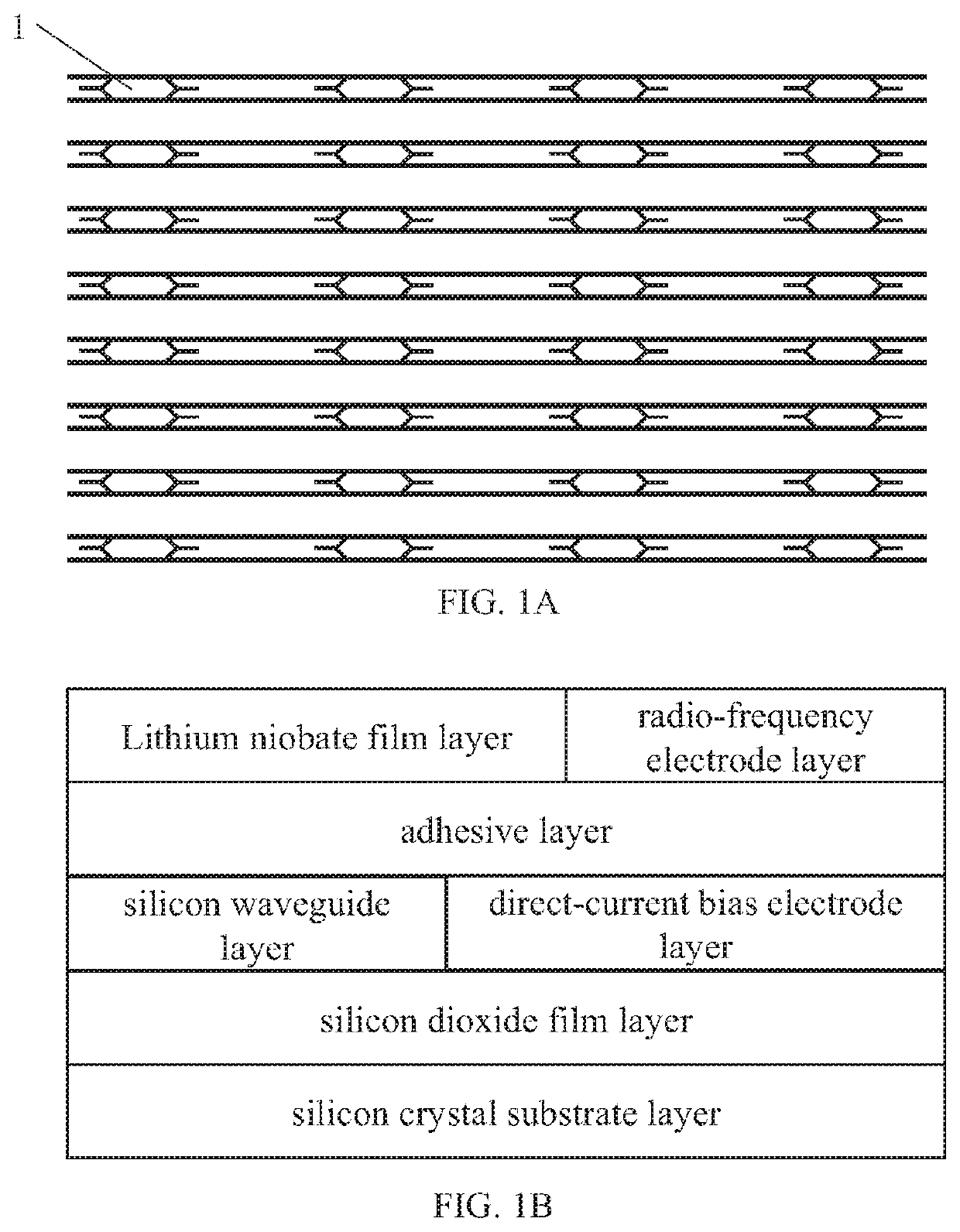

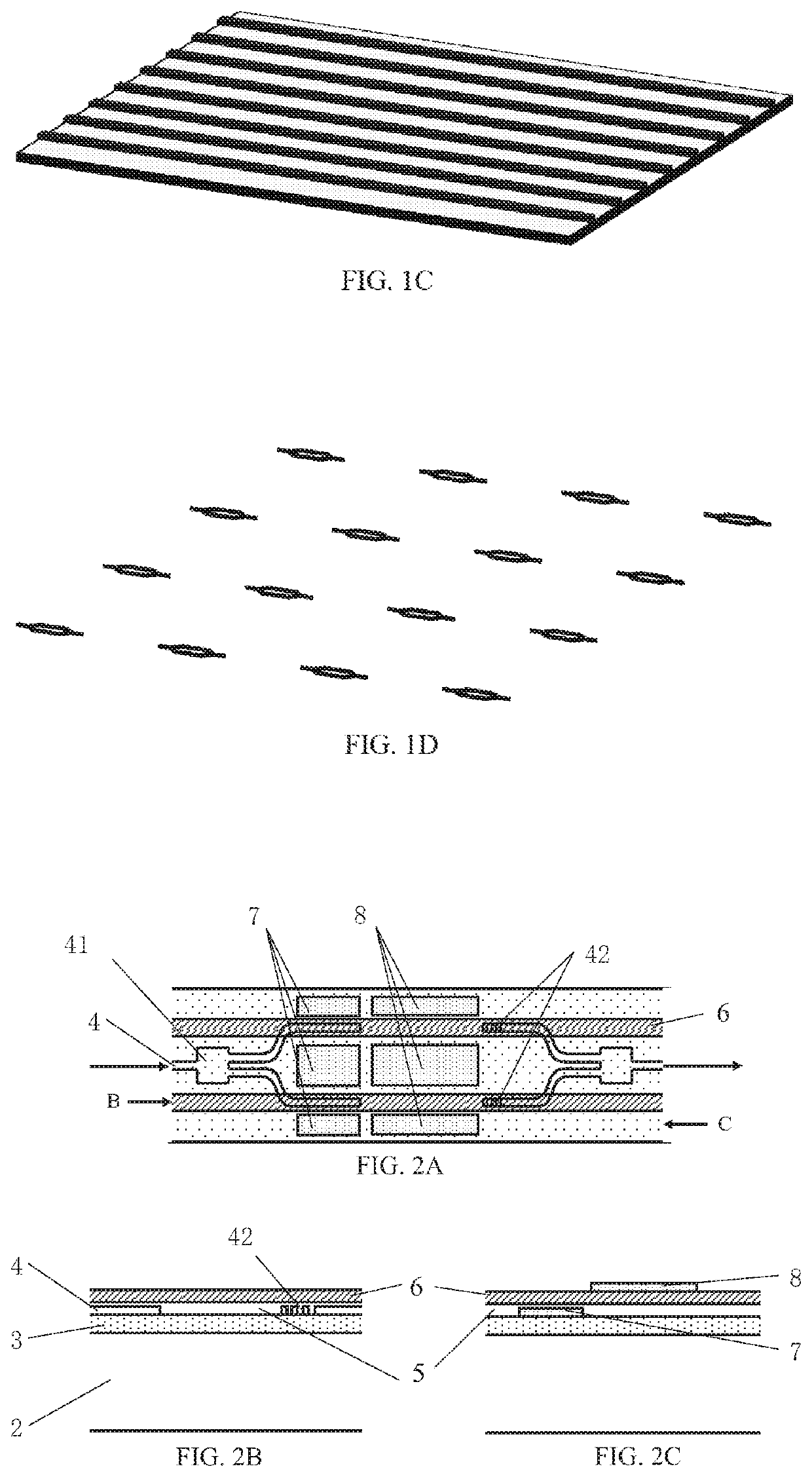

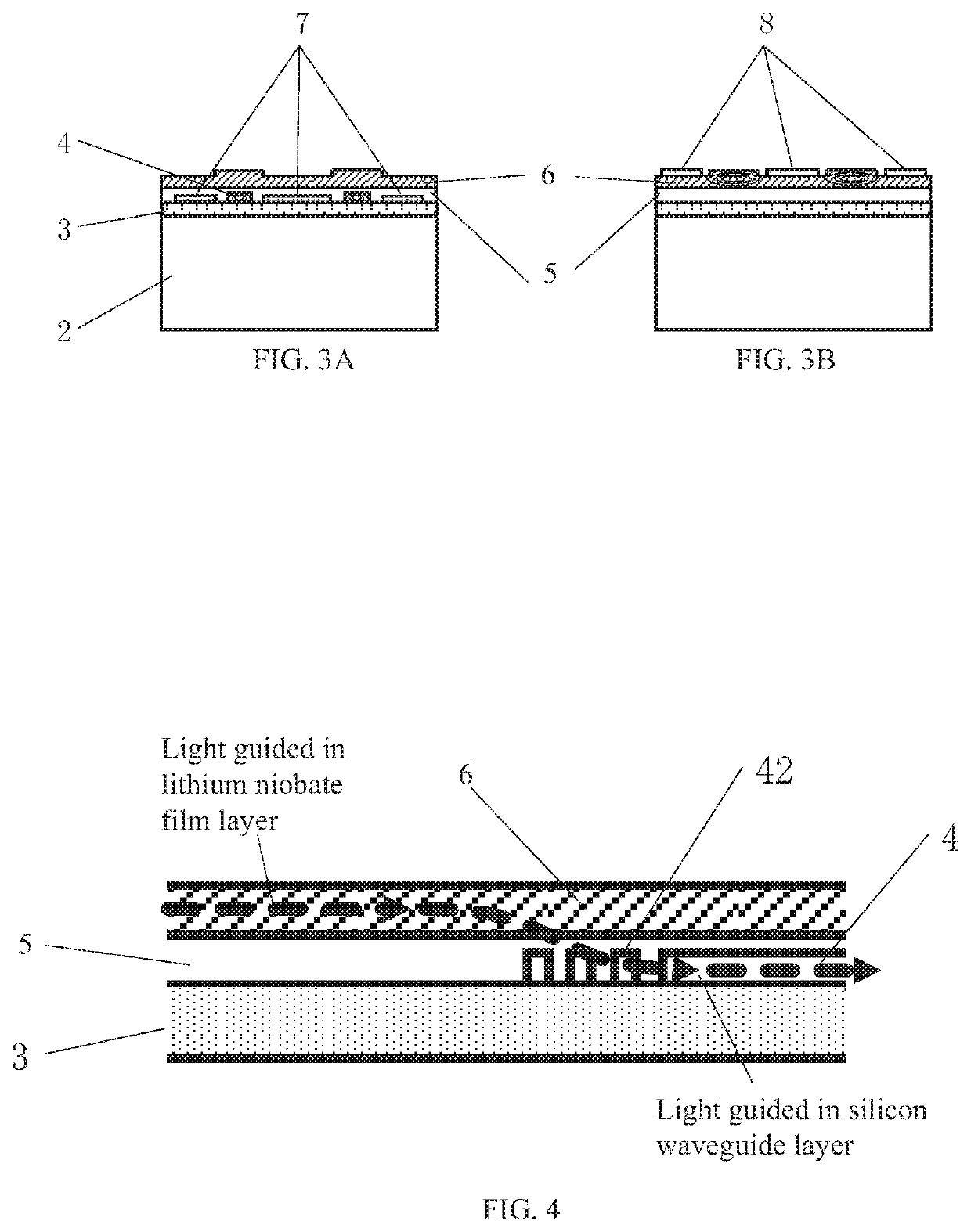

Silicon-based lithium niobate film electro-optic modulator array and integration method thereof

ActiveUS20200363693A1Added fabricationStable supportCoupling light guidesNon-linear opticsEngineeringLithium niobate crystal

Integration method of a large-scale silicon-based lithium niobate film electro-optic modulator array. By using the method, the difficulty of a fabrication process of a lithium niobate crystal layer is reduced, requirements on precision of bonding lithium niobate and silicon is reduced, and fabrication and bonding of the large-scale array lithium niobate crystal layer can be completed at one time, so that production efficiency of the silicon-based lithium niobate film electro-optic modulator array is greatly improved; through design and optimization of the structure of the silicon crystal layers, light can be naturally alternated and mutually transmitted in silicon waveguides and lithium niobate waveguides, and a high-performance electro-optic modulation effect of the lithium niobate film is achieved.

Owner:SHANGHAI JIAO TONG UNIV

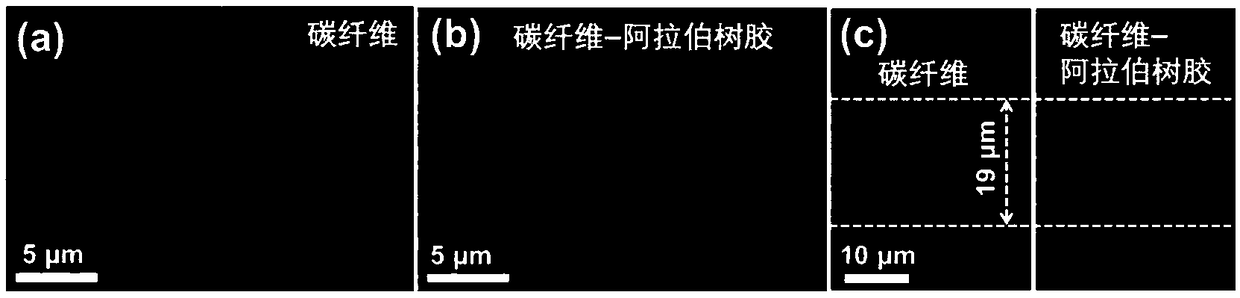

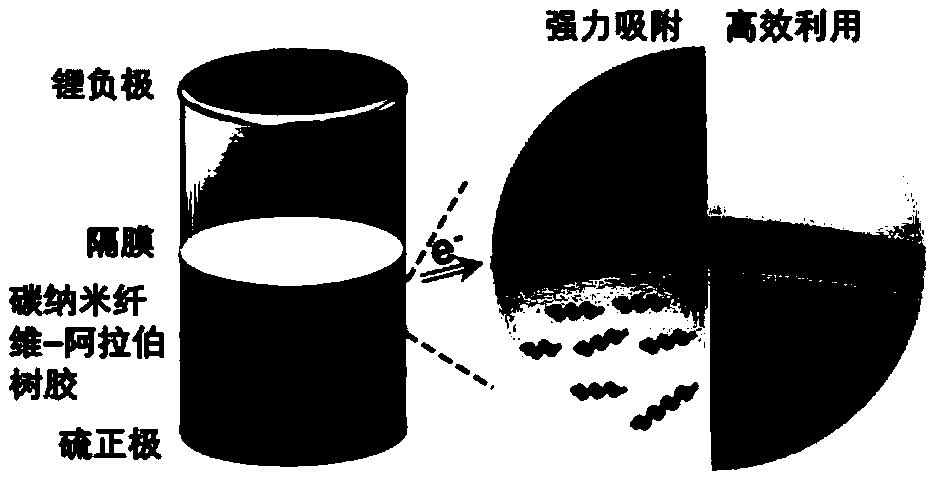

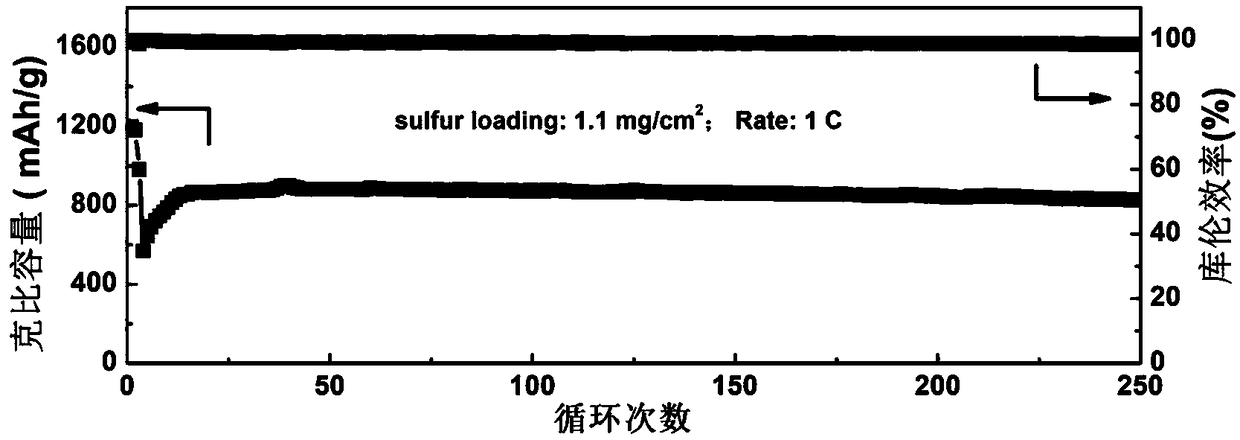

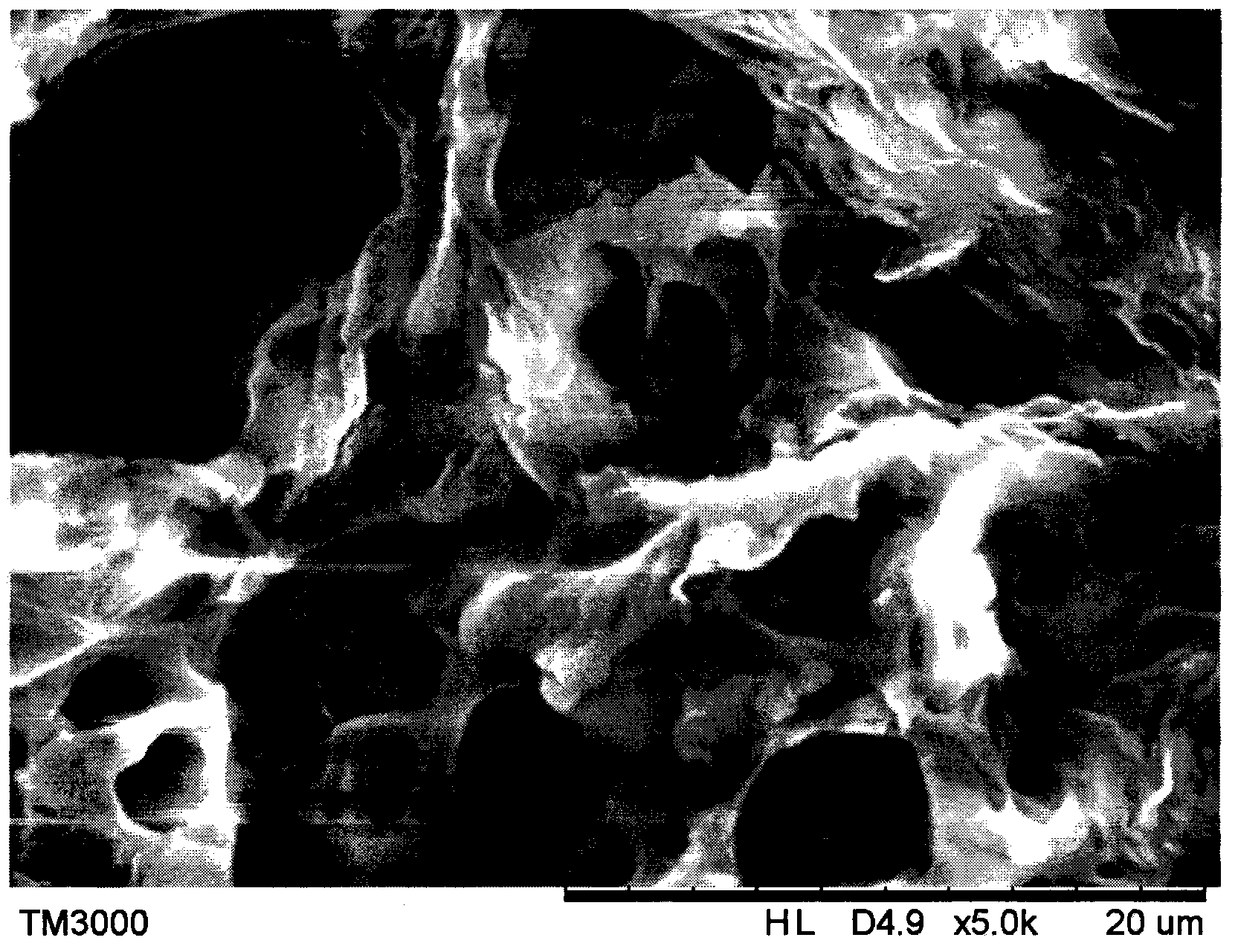

Polymer blocked layer material for lithium-sulfur battery and preparation method thereof

ActiveCN109378430AExcellent anti-self-discharge abilityAlleviate the "shuttle effect" problemLi-accumulatorsCell component detailsCarbon nanofiberNitrogen gas

The invention relates to a polymer blocked layer material for a lithium-sulfur battery and a preparation method thereof. The preparation method comprises the following steps: preparing 1-3mg / ml of N,N-dimethyl formamide of polyacrylonitrile, and preparing a nano-fiber precursor membrane by adopting an electrostatic spinning method; carbonizing the precursor membrane in nitrogen at 800-1000 DEG C to form a carbon nano-fiber membrane; dissolving natural polymer acacia gum in water to prepare a solution; directly dropwise adding the acacia gum onto the carbon nano-fiber membrane to form a carbonnano-fiber-acacia gum composite membrane; drying the composite membrane in vacuum at 60-80 DEG C for 16-24 hours to enable the composite membrane to have a thickness of 17-25mu m and mass of 0.18-0.36mg / cm<2>. By adopting the method, the excellent circulating performance that a lithium-sulfur battery has 94 percent volume after circulating for 250 times is realized, the 'shuttle effect' problem oflithium polysulfide can be relieved, and the battery shows excellent self-discharge resistance.

Owner:TIANJIN UNIV

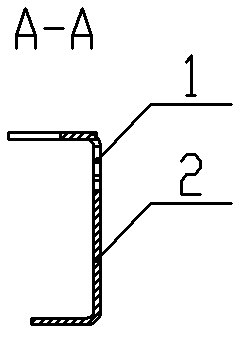

Full face type pulling plate and clamping piece structure

ActiveCN102360793AContact surface stabilityEnhanced binding effectTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

The invention relates to a full face type pulling plate and clamping piece structure for a transformer iron core. The full face type pulling plate and clamping piece structure comprises an upper clamping piece, a lower clamping piece and a pulling plate, wherein cross sections of the upper clamping piece and the lower clamping piece have a groove shape; both ends of the pulling plate are providedwith chucks; the webs of the upper clamping piece and the lower clamping piece are provided with troughs of which the shapes are matched with those of the chucks; the chucks are clamped on the rear side of the troughs; and the pulling plate, the upper clamping piece and the lower clamping piece are stuck on the same plane of the iron core. In the full face type pulling plate and clamping piece structure, both ends of the pulling plate are provided with the chucks, both ends of the pulling plate are clamped in the troughs of the upper clamping piece and the lower clamping piece in an inlaying way, and the pulling plate, the upper clamping piece and the lower clamping piece are stuck on the same plane of the iron core, so that the contact surface of the clamping pieces and the iron core is more smooth, and a bundling effect on the iron core is relatively good, and the difficulty in processing an insulating material filled in the center of the iron core is reduced. The full face type pulling plate and clamping piece structure is easy to assemble and has high iron core assembly efficiency.

Owner:WUXI PUTIAN IRON CORE CO LTD

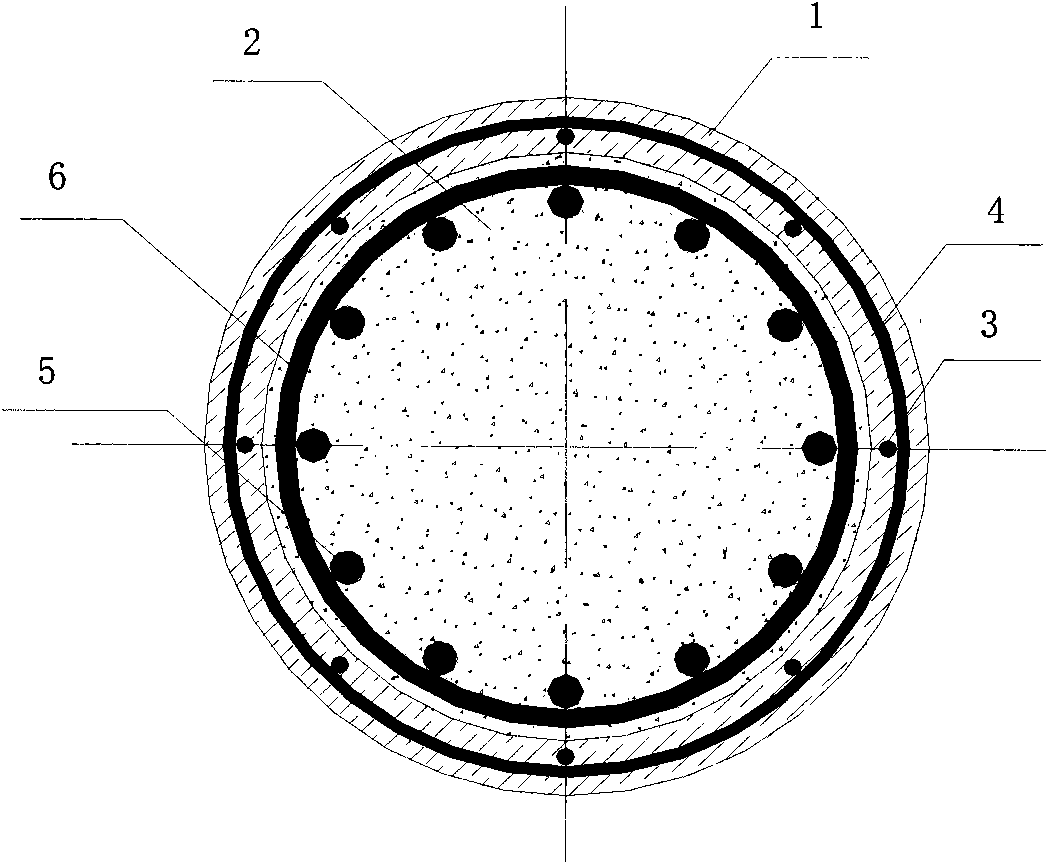

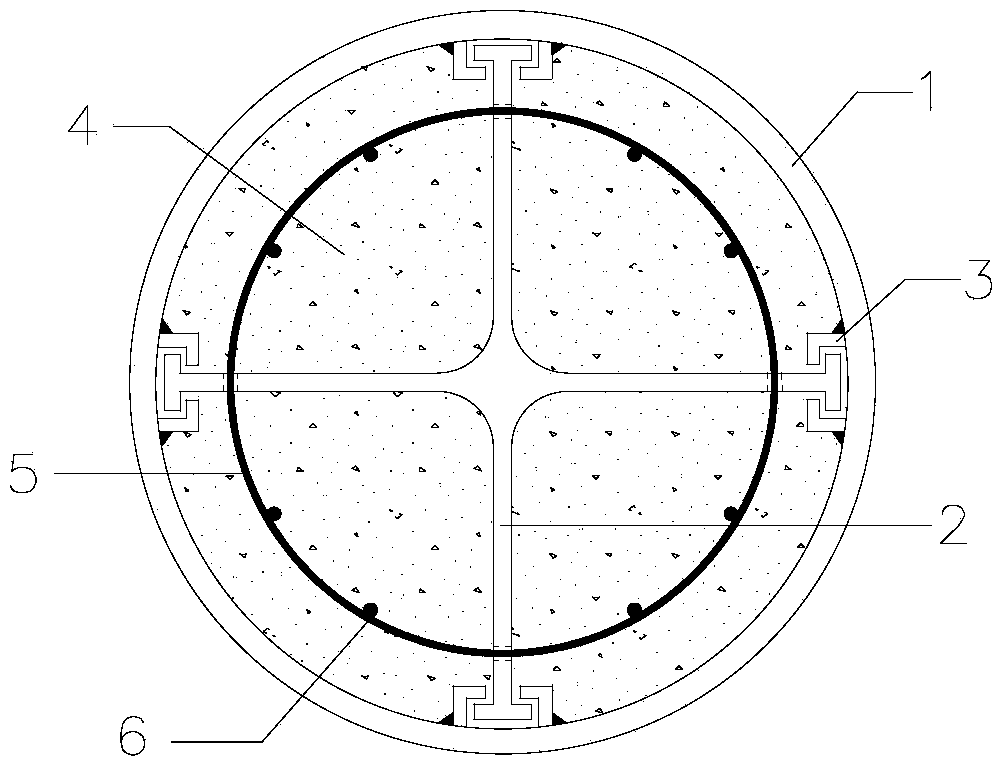

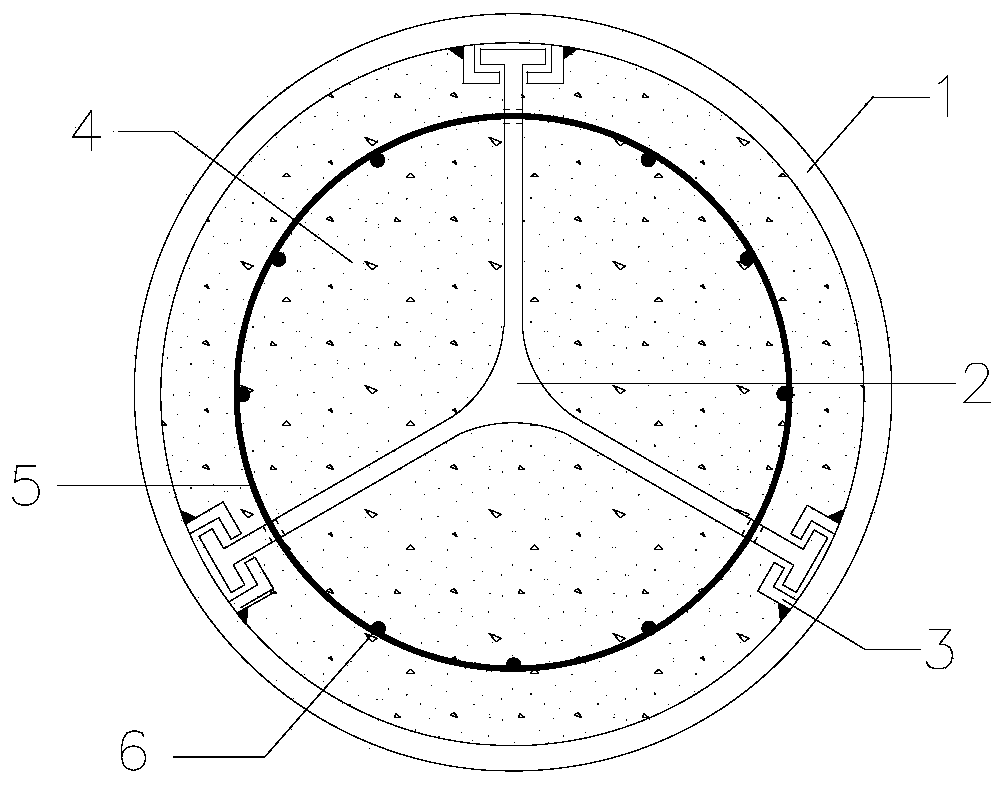

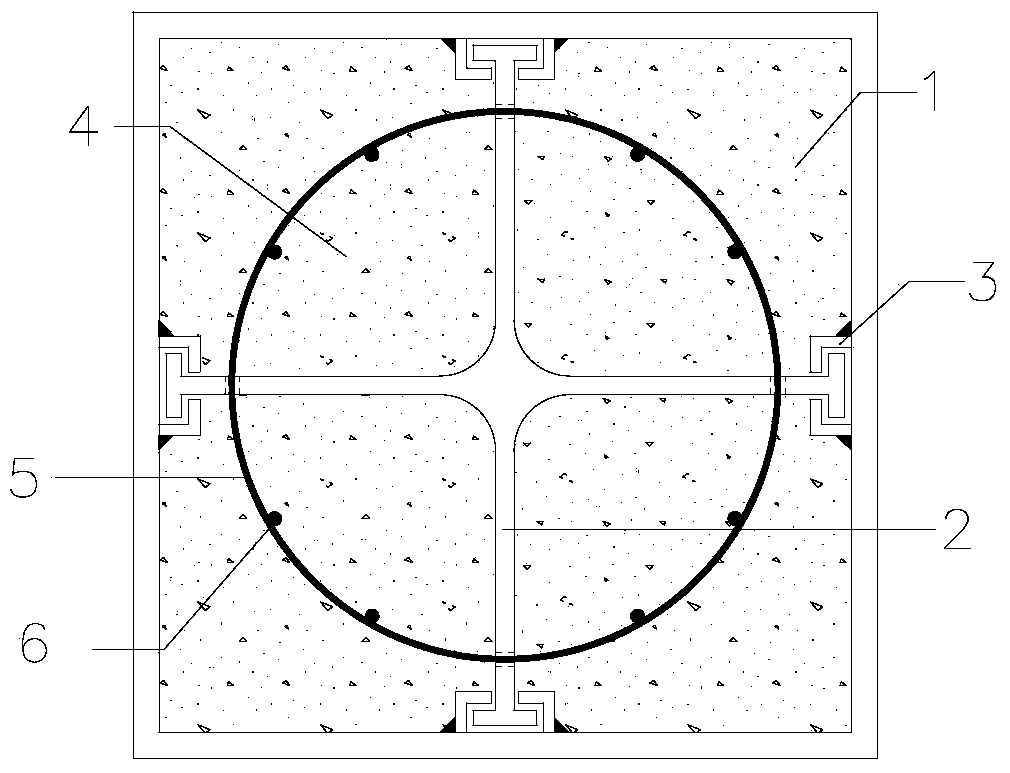

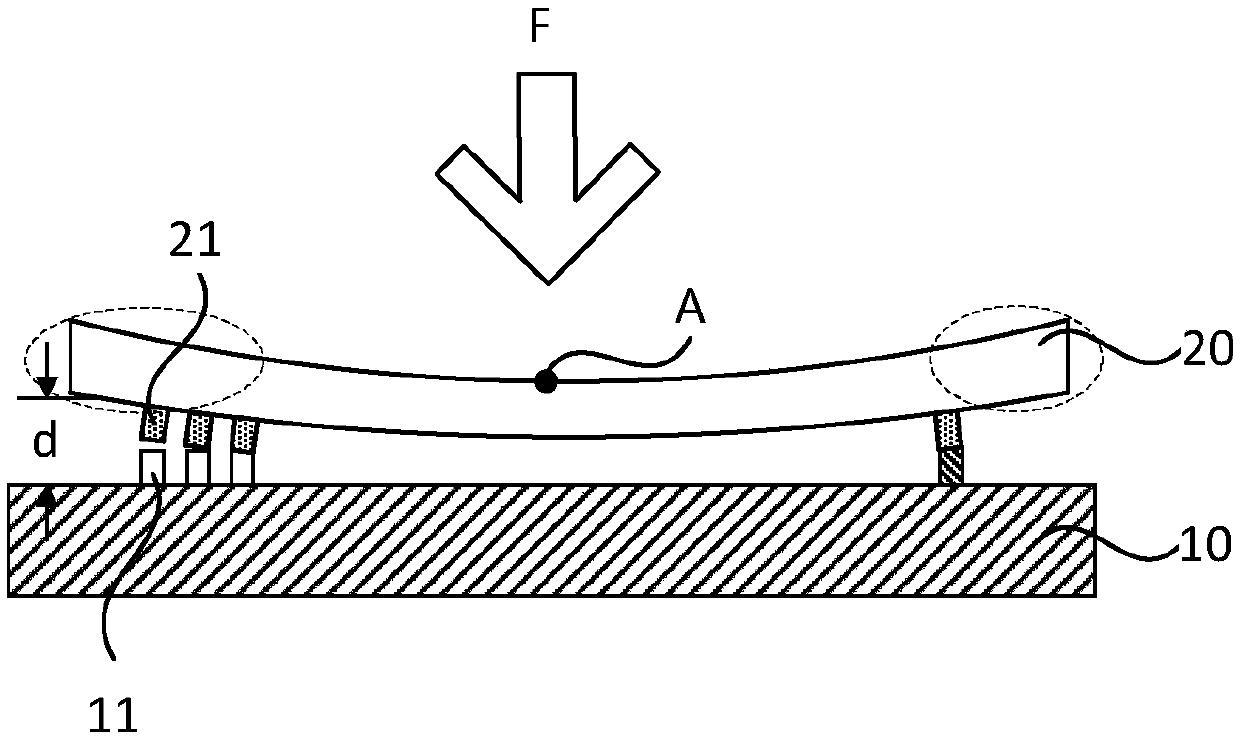

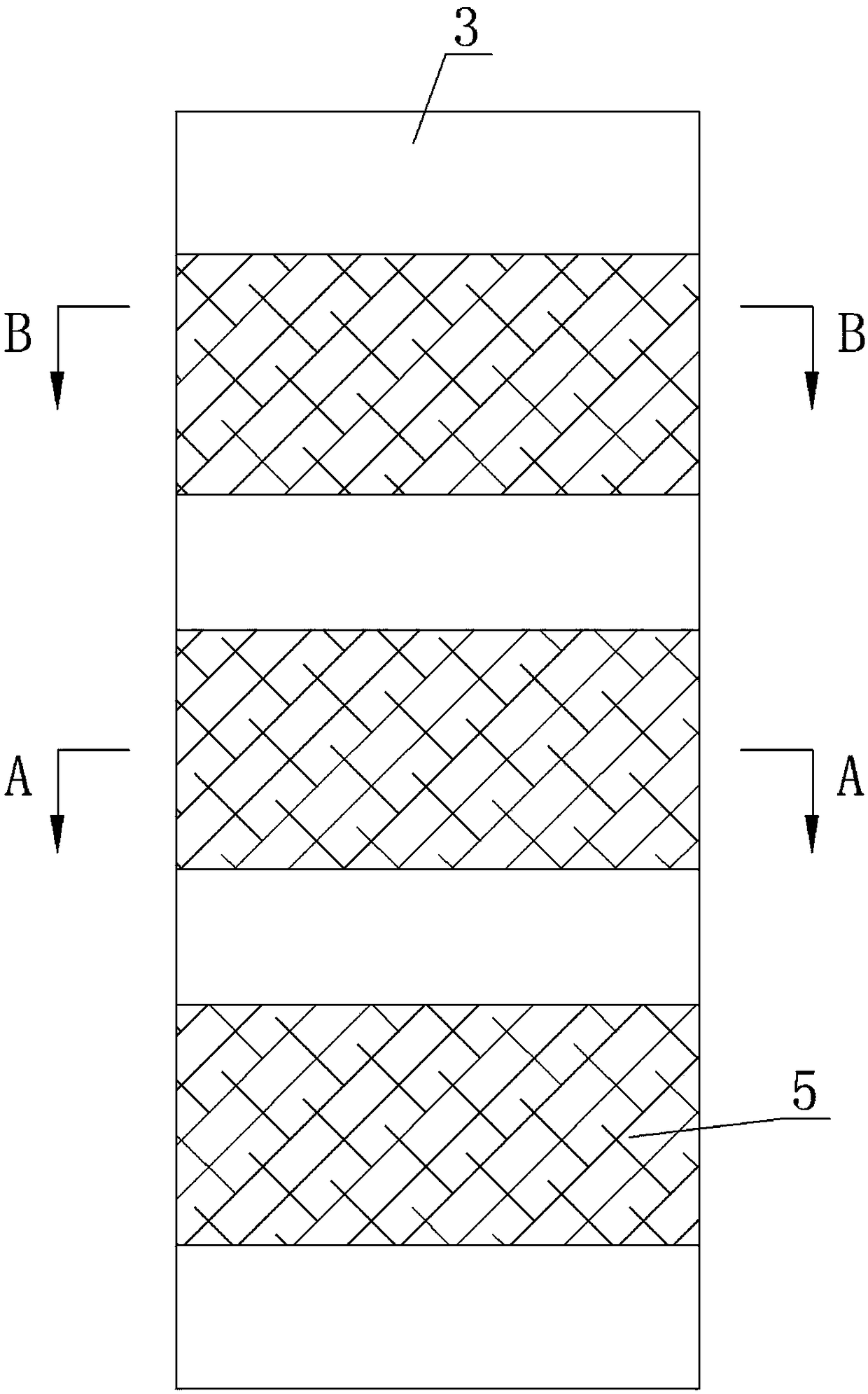

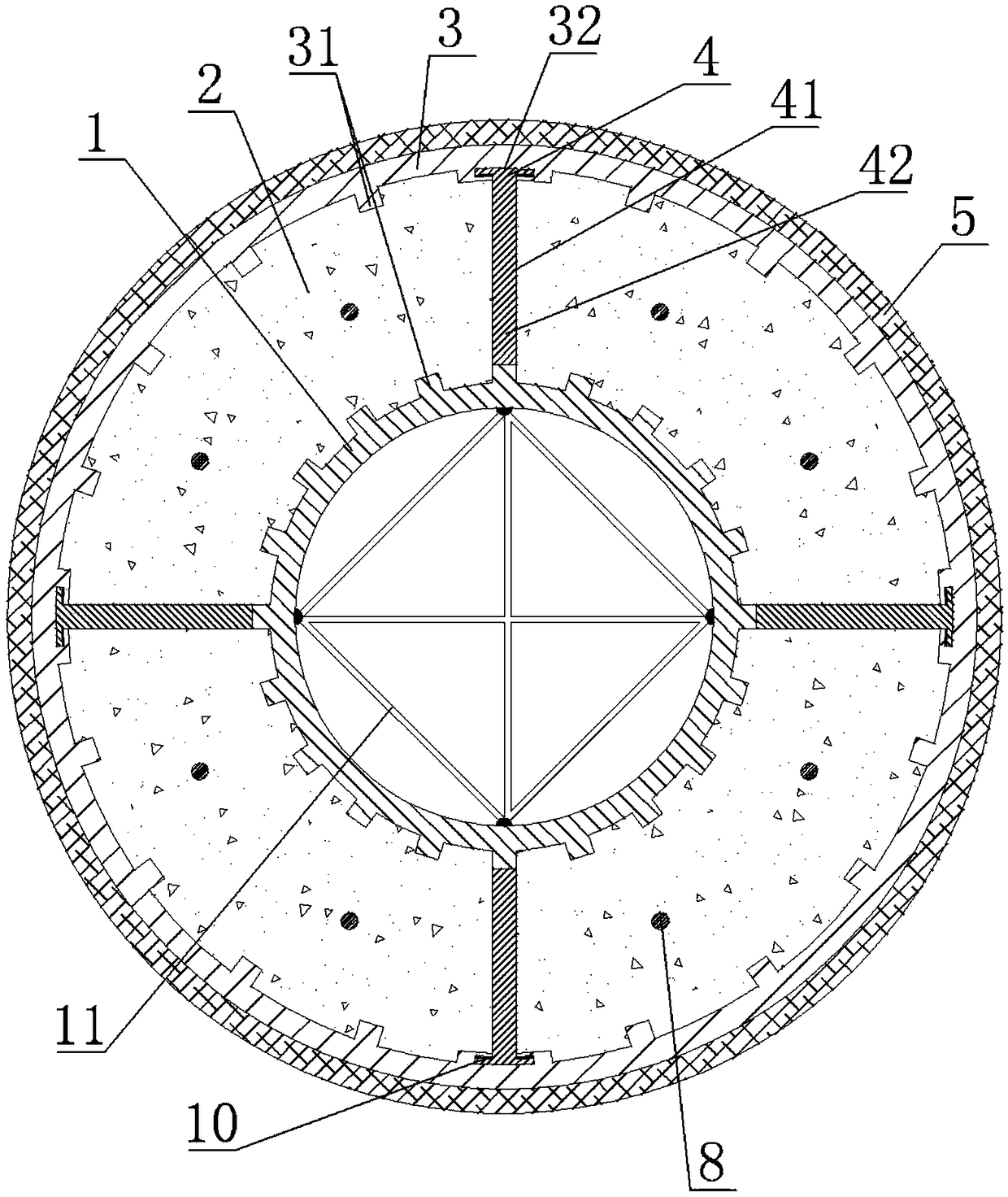

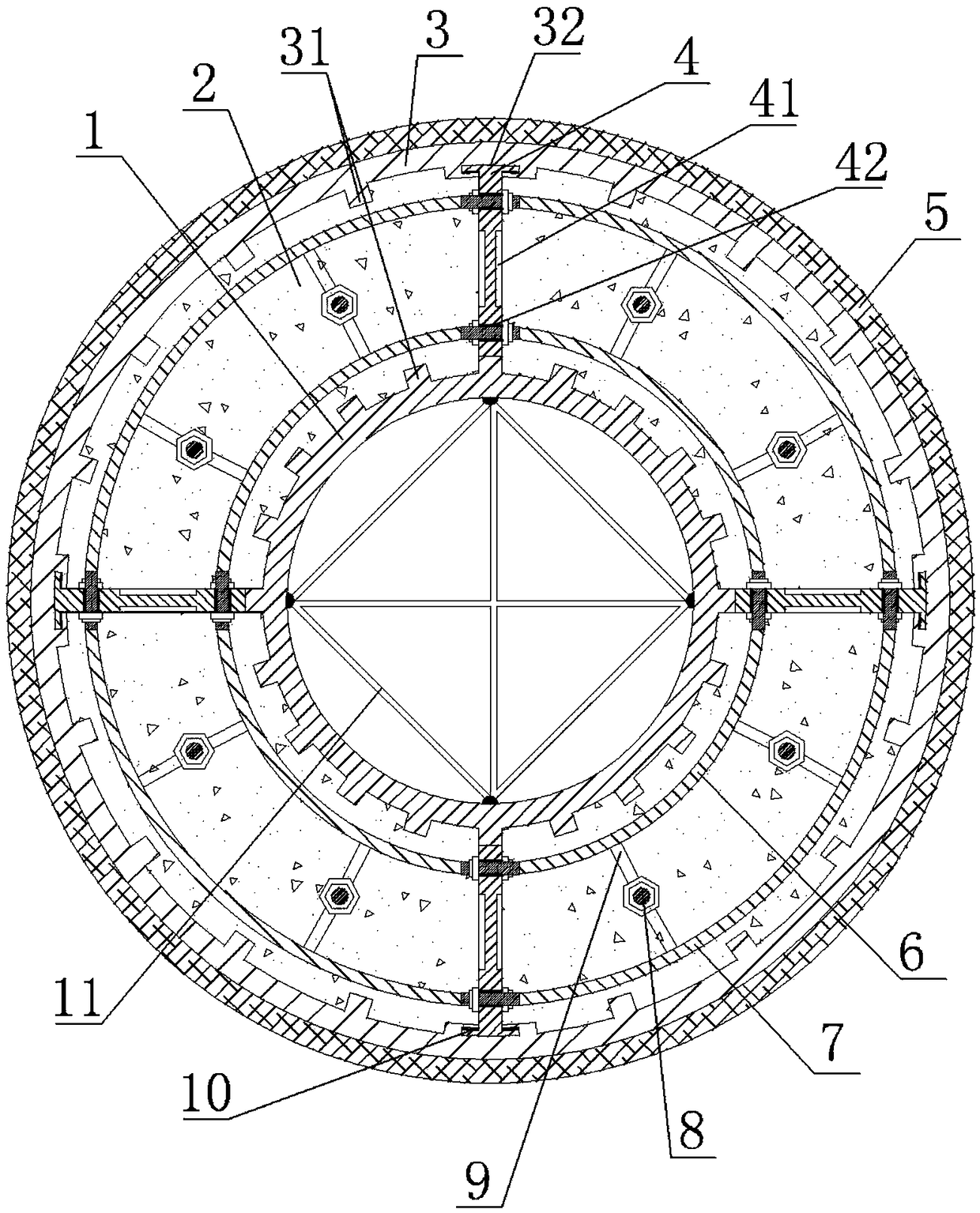

Hollow-sandwich multi-cavity steel pipe concrete member and preparation method thereof

PendingCN109403205ASolve the rustLow maintenanceStrutsBridge structural detailsClamp connectionStressed state

The invention discloses a hollow-sandwich multi-cavity steel pipe concrete member and a preparation method thereof. The hollow-sandwich multi-cavity steel pipe concrete member comprises an internal steel pipe and an external steel pipe which are concentrically placed; a space between the internal steel pipe and the external steel pipe is filled with concrete; a plurality of transverse diaphragms are uniformly distributed on the external wall of the internal steel pipe around the axis of the internal steel pipe; each transverse diaphragm is placed along the full length of the internal steel pipe in the axial direction; the external end part of each transverse diaphragm is in clamping connection with a groove formed in the internal wall of the external steel pipe; convex teeth are arranged on the internal wall of the external steel pipe and the external wall of the internal steel pipe; a plurality of shear grooves are uniformly formed in the side surfaces of the transverse diaphragms inthe axial direction; a plurality of external cylinders made of carbon fiber composite materials are bonded outside the external steel pipe in the annular direction; and the external cylinders are notconnected with the end part of the external steel pipe. According to the hollow-sandwich multi-cavity steel pipe concrete member, the corrosion resistance is high, less separation phenomena between the steel pipe walls and the concrete are less, the steel pipes are unlikely to generate local buckling, and the stressed states of the concrete in three directions are uniform.

Owner:CENT SOUTH UNIV

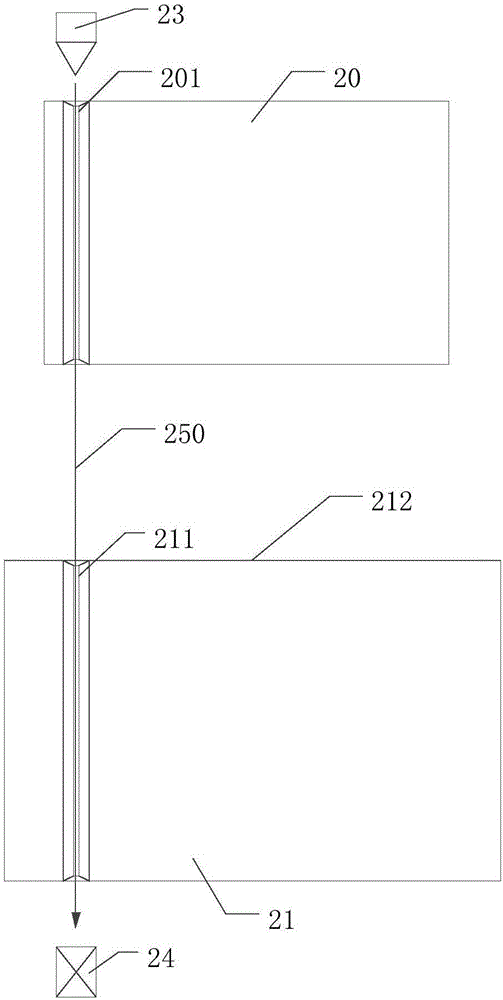

Air cylinder type perforating and bookbinding device for accountants

ActiveCN110341342AAvoid clutterHigh degree of automationSheet bindingLaser rangingMechanical engineering

The invention discloses an air cylinder type perforating and bookbinding device for accountants. According to the key points of the technical scheme, the air cylinder type perforating and bookbindingdevice comprises a rack, a perforating mechanism, a bookbinding mechanism and a moving mechanism. The perforating mechanism comprises a perforating drive air cylinder and a perforating knife. The moving mechanism comprises an operation table and a conveying drive air cylinder. The operation table is provided with an operation hole and a pressing assembly. The pressing assembly comprises a pressingblock, a pressing drive air cylinder and a laser range finder. The bookbinding mechanism comprises a bookbinding drive air cylinder, a bookbinding pressing head, a bar locating assembly, a cutter anda conveying assembly. The bar locating assembly comprises a bar locating base, a locating drive structure, a locating block, a clamping claw and a bar drive structure. The locating drive structure can adjust the distance from the locating block to the cutter according to the sheet thickness detected by the laser distance finder. The conveying assembly comprises a conveying track, a lifting tableand a lifting air cylinder. The head end of the conveying track is located below a discharging opening of the cutter. The height of the head end of the conveying track is higher than that of the tailend.

Owner:诸暨市晨足针织有限公司

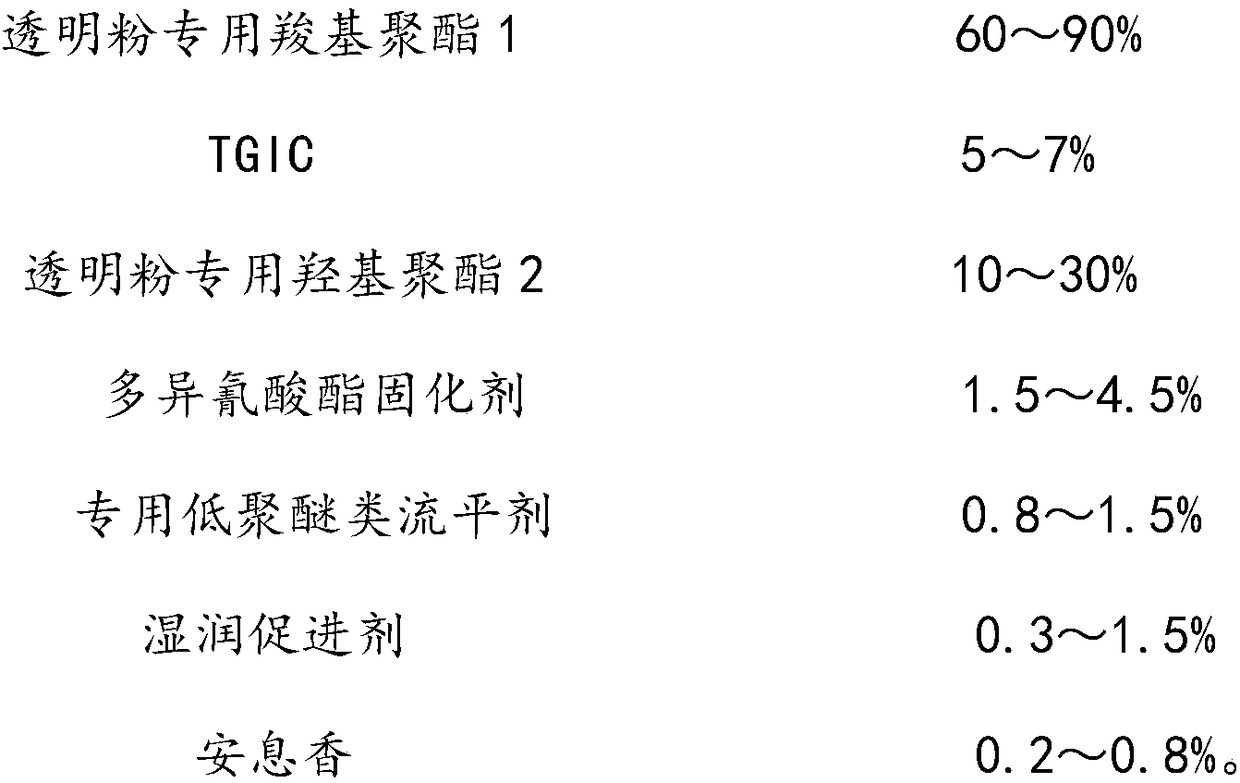

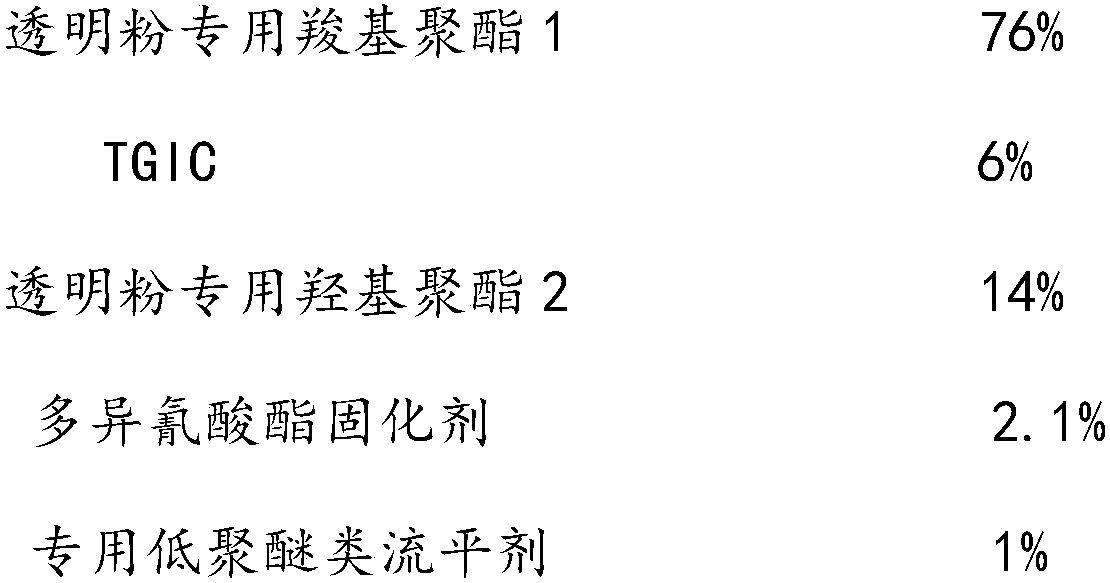

Powder coating with bonding metal effect

InactiveCN108373765ATo promote floatingGood binding effectPolyester coatingsPolyesterMaterials science

The invention discloses a powder coating with a bonding metal effect. The powder coating with the bonding metal effect comprises 80-99% of transparent base powder and 1-20% of effect pigment. The transparent base powder comprises the following raw material components in percentages by weight: 60-90% of special carboxyl polyester 1 for transparent powder, 5-7% of TGIC, 10-30% of special hydroxyl polyester 2 for transparent powder, 1.5-4.5% of a polyisocyanates curing agent, 0.8-1.5% of a special low polyether flatting agent, 0.3-1.5% of a wetting accelerator and 0.2-0.8% of benzoin. By cooperation of two polyesters and two curing agents, the comprehensive physical property of the coating is adjusted, large surface tension is obtained during fusion of the coating, floating of the effect pigment is facilitated, and thus, a metal surface effect can be shown; and moreover, by cooperative adjustment through the carboxyl polyester and the hydroxyl polyester, good floating effect and excellentleveling property and plumpness are achieved.

Owner:佛山市南海嘉多彩粉末涂料有限公司

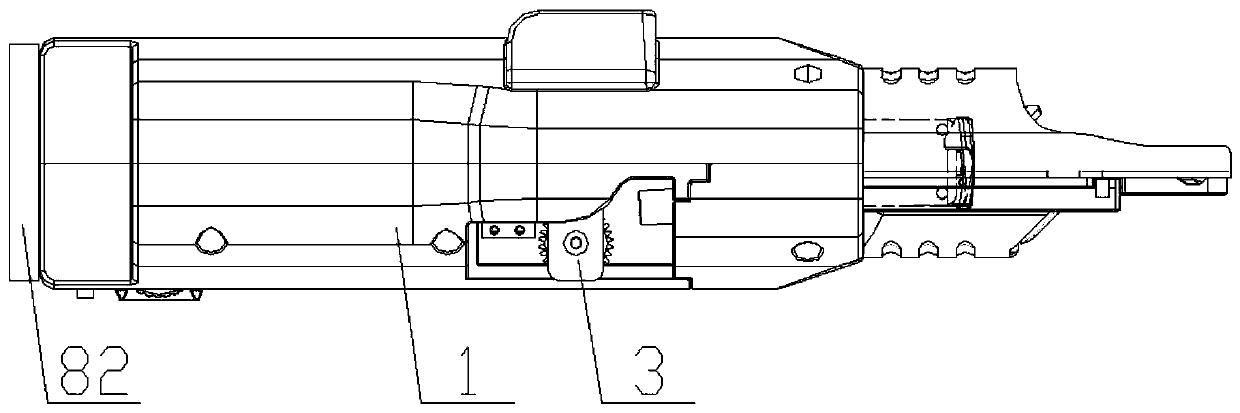

Communication type no-handheld steel bar strapping machine and steel bar strapping automation equipment

PendingCN111576888AQuality assuranceReduce volumeClosed circuit television systemsBuilding material handlingStrappingElectric machinery

The invention discloses a communication type no-handheld steel bar strapping machine and steel bar strapping automation equipment. The communication type no-handheld steel bar strapping machine comprises a machine shell, a main control unit, a motor, a wire feeding mechanism, a wire twisting mechanism and a cutting-off mechanism, wherein the machine shell is in a long strip type shape without a handheld portion, the motor is arranged inside the machine shell, and the wire feeding mechanism, the wire twisting mechanism and the cutting-off mechanism are all arranged inside the machine shell in the length direction of the machine shell to make the steel bar strapping machine be long in size only in the length direction. The communication type no-handheld steel bar strapping machine is small in structural volume and is suitable for performing steel bar strapping work in some relatively narrow areas in which plate face steel bars and vertical face steel bars intersect and steel bar combination sites where inner layer and outer layer steel bar nets exist, and the quality of steel bar strapping in these special sites is guaranteed; and meanwhile, the steel bar strapping automation equipment realized on account of the communication type no-handheld steel bar strapping machine can be suitable for automation strapping of various steel bar combinations and has the advantage of being highin steel bar strapping efficiency and quality.

Owner:GUANGDONG SHUNDE HUAYAN ELECTRONICS TECH CO LTD

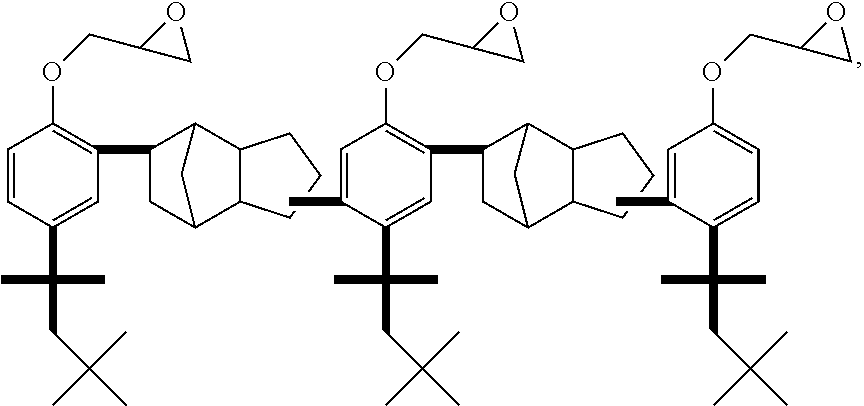

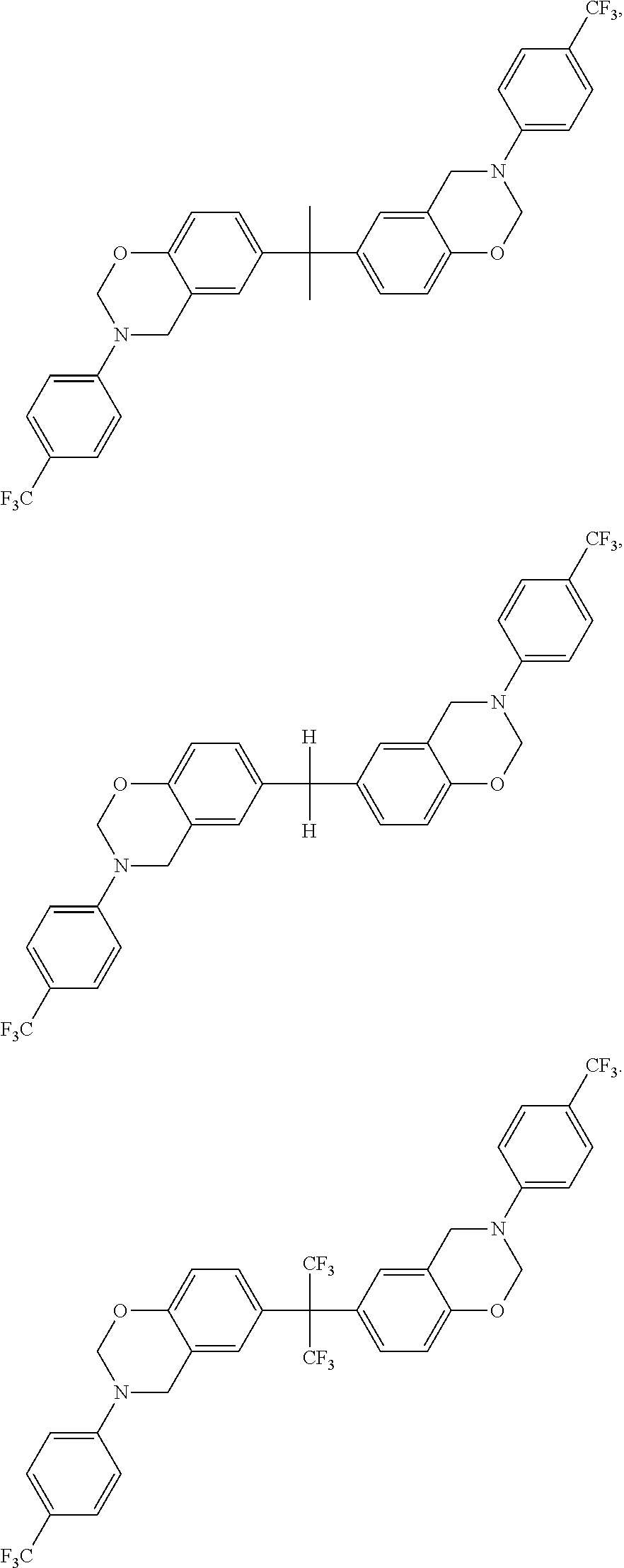

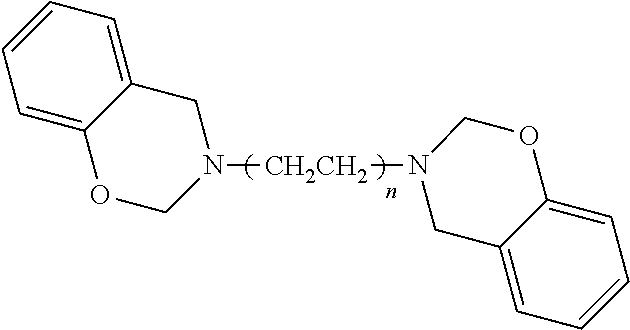

Halogen-free resin composition and prepreg and laminate prepared therefrom

InactiveUS20180327558A1Enhanced binding effectGood adhesionSynthetic resin layered productsPrinted circuit aspectsDielectric lossHeat resistance

A halogen-free resin composition and a prepreg and a laminate prepared therefrom. The halogen-free resin composition comprises the following ingredients in parts by weight: 50-100 parts of an epoxy resin, 20-70 parts of benzoxazine, 5-40 parts of polyphenyl ether, 5-30 parts of styrene-maleic anhydride, 5-40 parts of a halogen-free flame retardant, 0.2-5 parts of a curing accelerator, and 20-100 parts of a filler. The prepreg and the laminate, which are manufactured from the halogen-free resin composition, have the comprehensive properties of low dielectric constant, low dielectric loss, excellent heat resistance, adhesive property and wet resistance and the like, and are suitable for being applied to halogen-free high-frequency multilayer circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

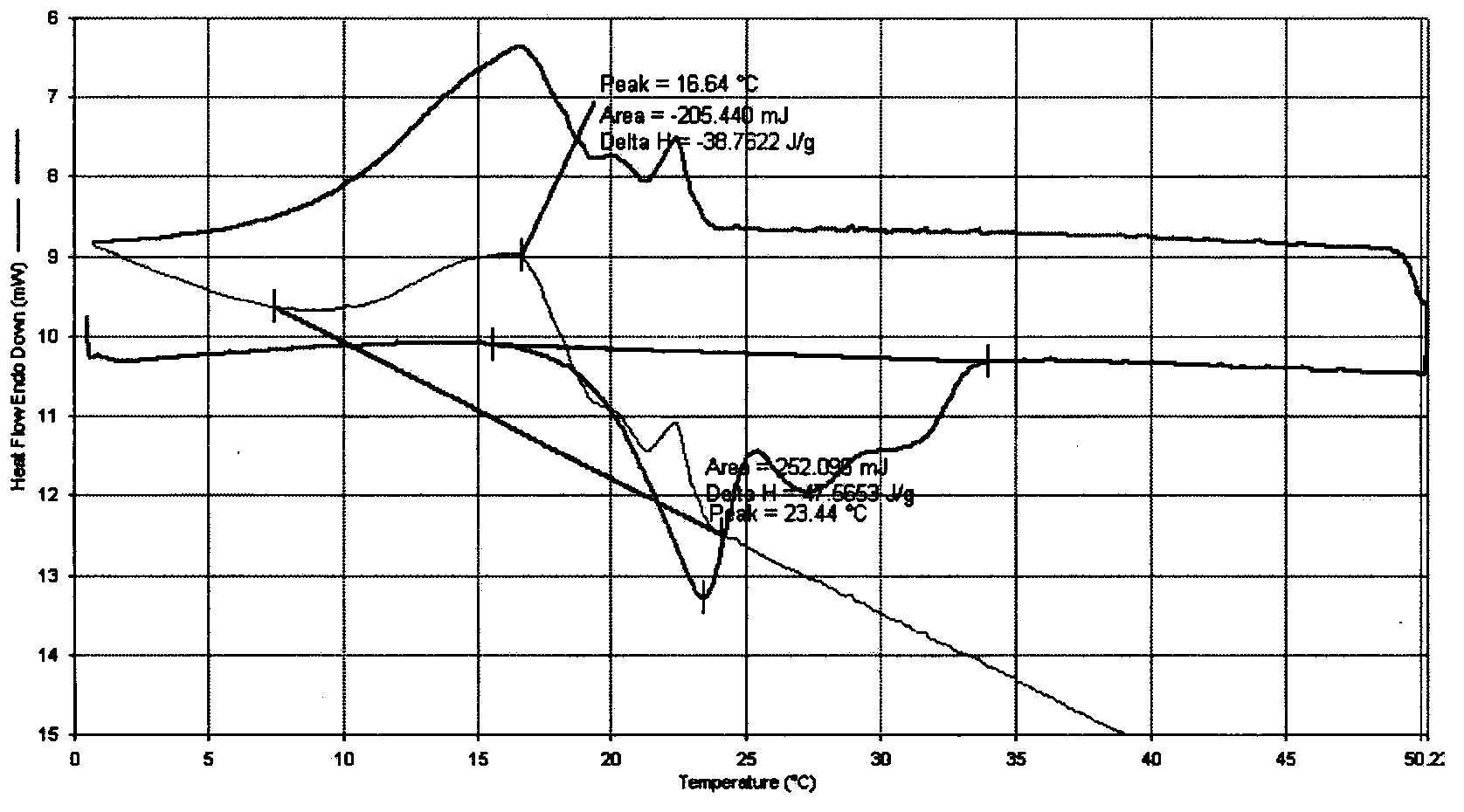

Preparation method of binary aliphatic acid/PMMA shape-stabilized phase change material

InactiveCN104059615AImprove corrosion resistanceGood chemical stabilityHeat-exchange elementsWater bathsThermal stability

The invention provides a binary aliphatic acid / PMMA shape-stabilized phase change material and a preparation method thereof. The shape-stabilized phase change material is prepared from the following raw materials: 30 wt%-70 wt% of a binary aliphatic acid eutectic mixture, 30 wt%-70 wt% of MMA (methyl methacrylate), and 0.3 wt%-0.7 wt% of AIBN (azodiisobutyronitrile). The preparation method comprises adding MMA and AIBN in a water bath of 80 DEG C, stirring for 25 min, then adding molten binary aliphatic acid, intensely stirring for 5 min; pouring the mixture into a die, sealing the die, putting the die in a water bath of 60 DEG C for 2 hours, and then putting the die in a water bath of 90 DEG C for 1 hour to obtain the binary aliphatic acid / PMMA shape-stabilized phase change material. The shape-stabilized phase change material has an appropriate phase change temperature and large phase change latent heat, is good in heat stability, and has good application prospects.

Owner:NANJING UNIV OF TECH

Corrugated box processing method

ActiveCN110421895AEnhanced binding effectImprove fluencyPaper-makingBox making operationsCardboardLeveling mechanism

The invention relates to a corrugated box processing method. The corrugated box processing method comprises the following steps that S1, corrugated board is machined; S2, corrugated board is subjectedto die cutting, especially, the corrugated board is cut and creased by using a cutting creasing machine so that the corrugated board can be folded to form a box body; S3, the corrugated board is folded, especially, the corrugated board is folded to form a corrugated box, the corrugated box is put between a bottom plate and the inner supporting plate mounted on a top plate, and the side edge of the corrugated box is flattened through a leveling mechanism; S4, the corrugated box is bound, especially, the corrugated box in the step S3 is conveyed to a proper position, and the corrugated box is bound by a box nailing machine; S5, the corrugated box is detected; and S6, the corrugated box is stacked up. According to the corrugated box processing method, the problems that a folding position ofthe corrugated box deviates when the corrugated box is bound, so that the corrugated box binding is inclined, a binding position of the corrugated box can be warped when the corrugated paper box is bound, multi-person cooperation operation is needed, the labor amount of workers is increased, and the processing efficiency of the corrugated box is low are solved.

Owner:厦门竣扬包装制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com