Patents

Literature

42results about How to "Adapt to automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

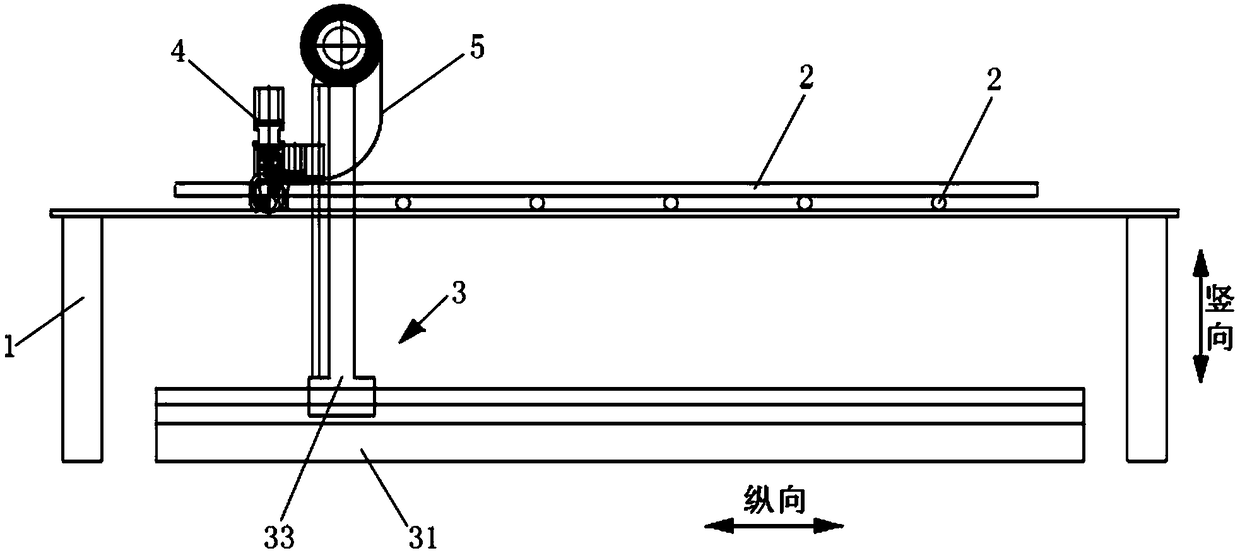

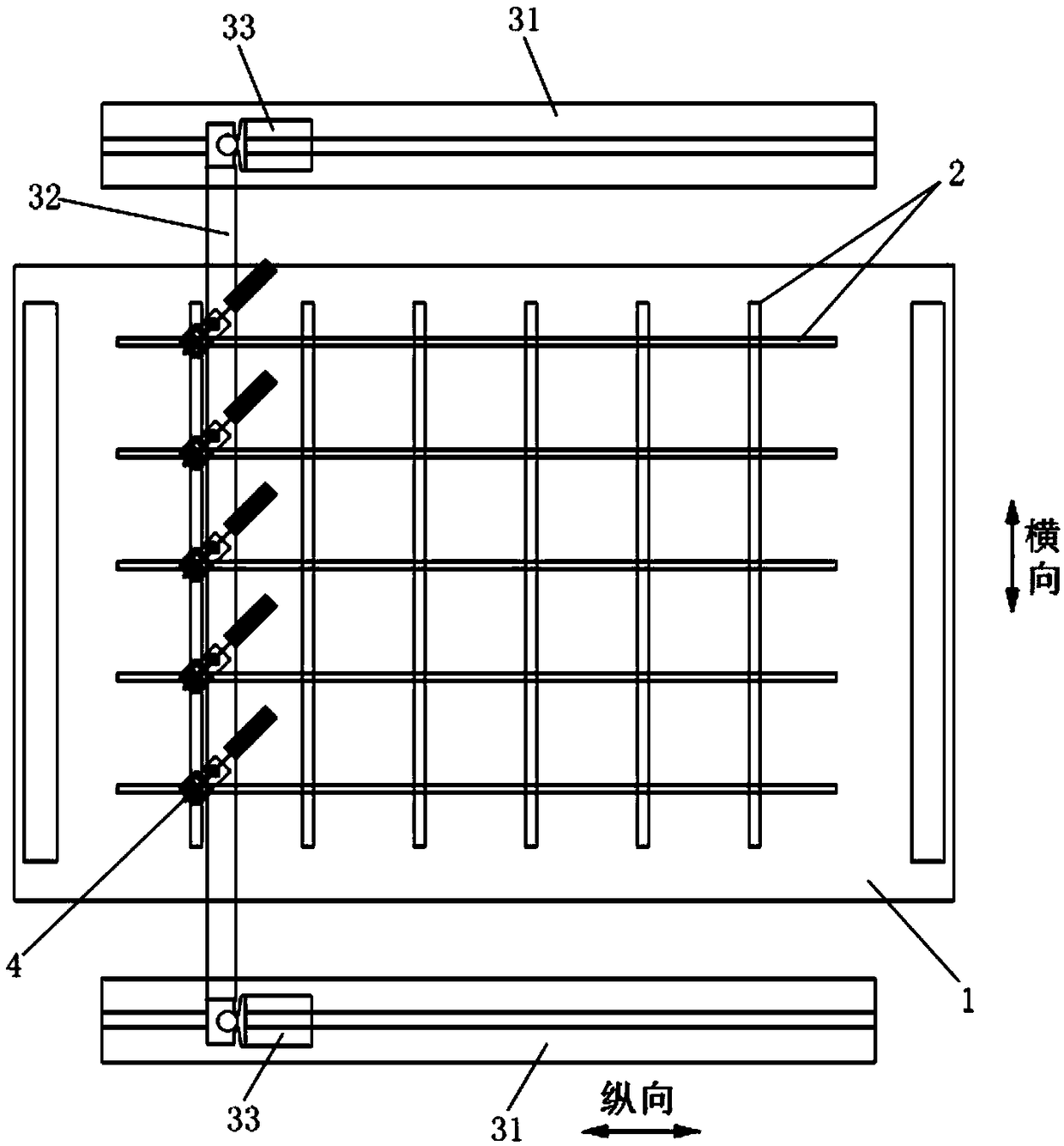

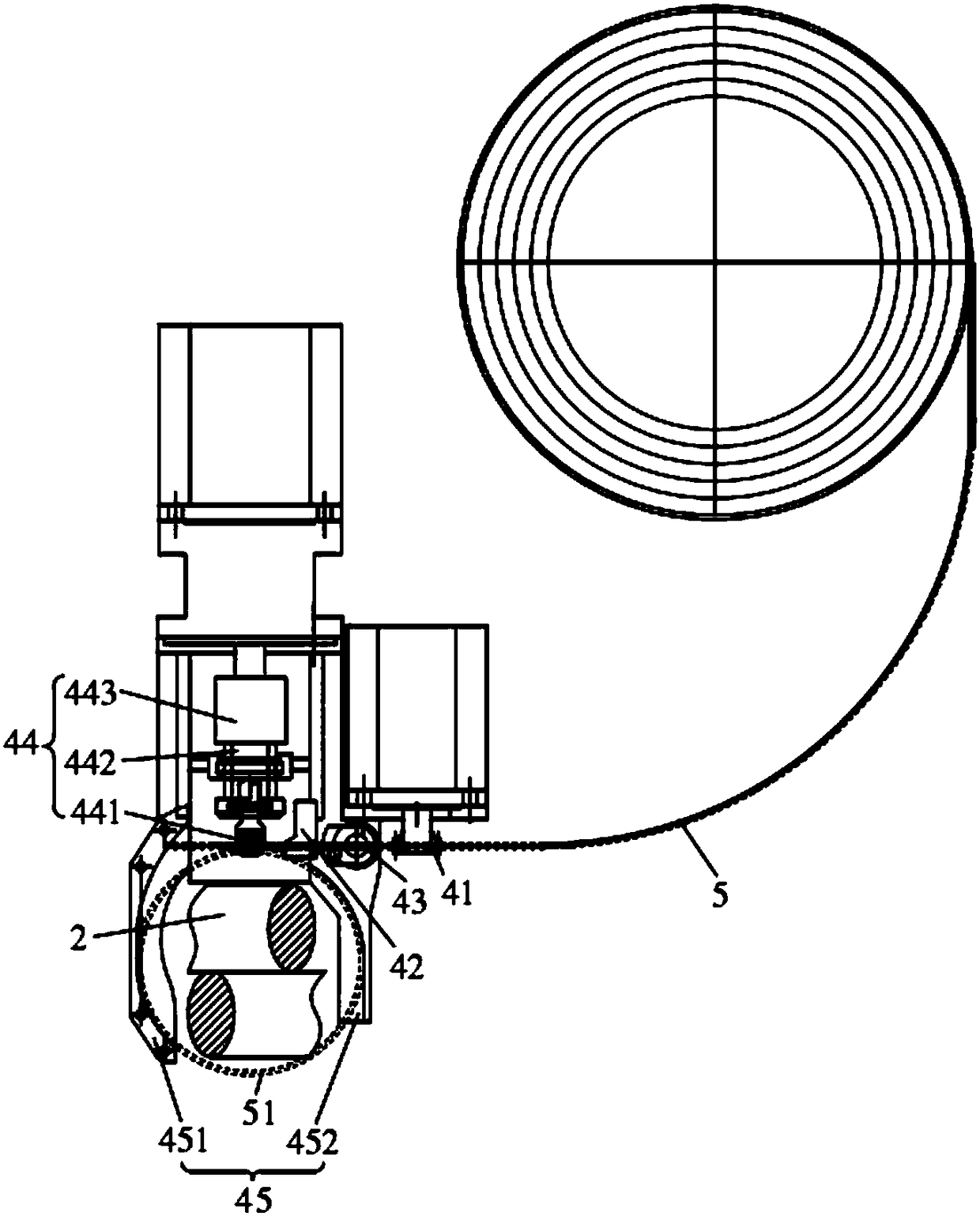

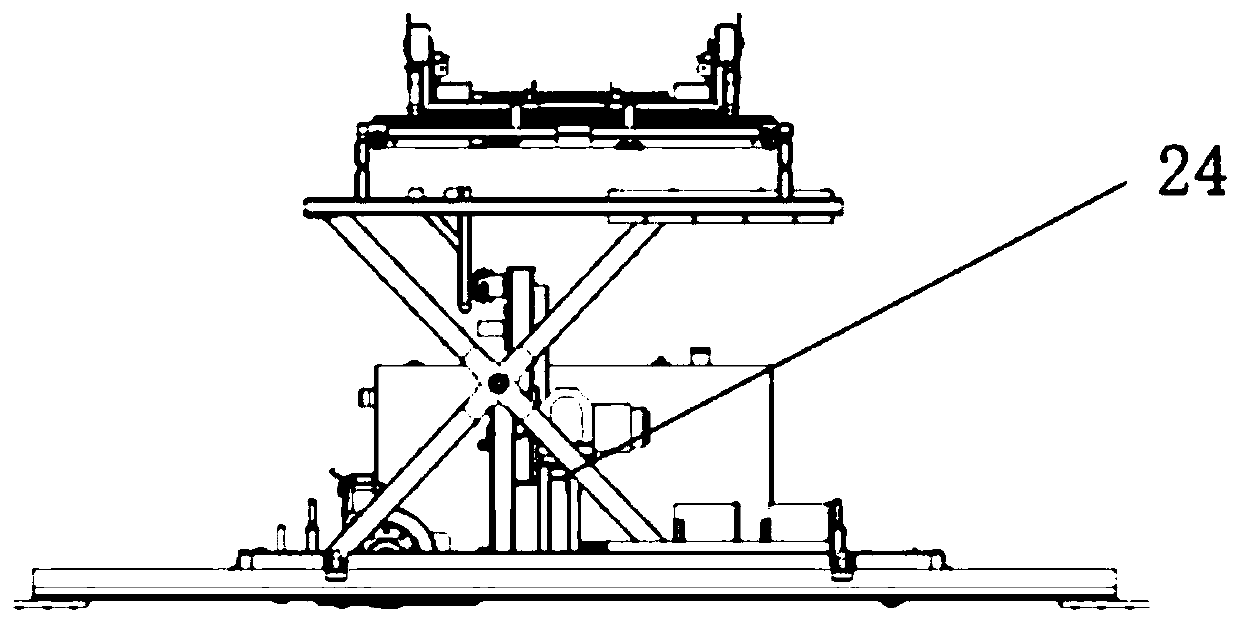

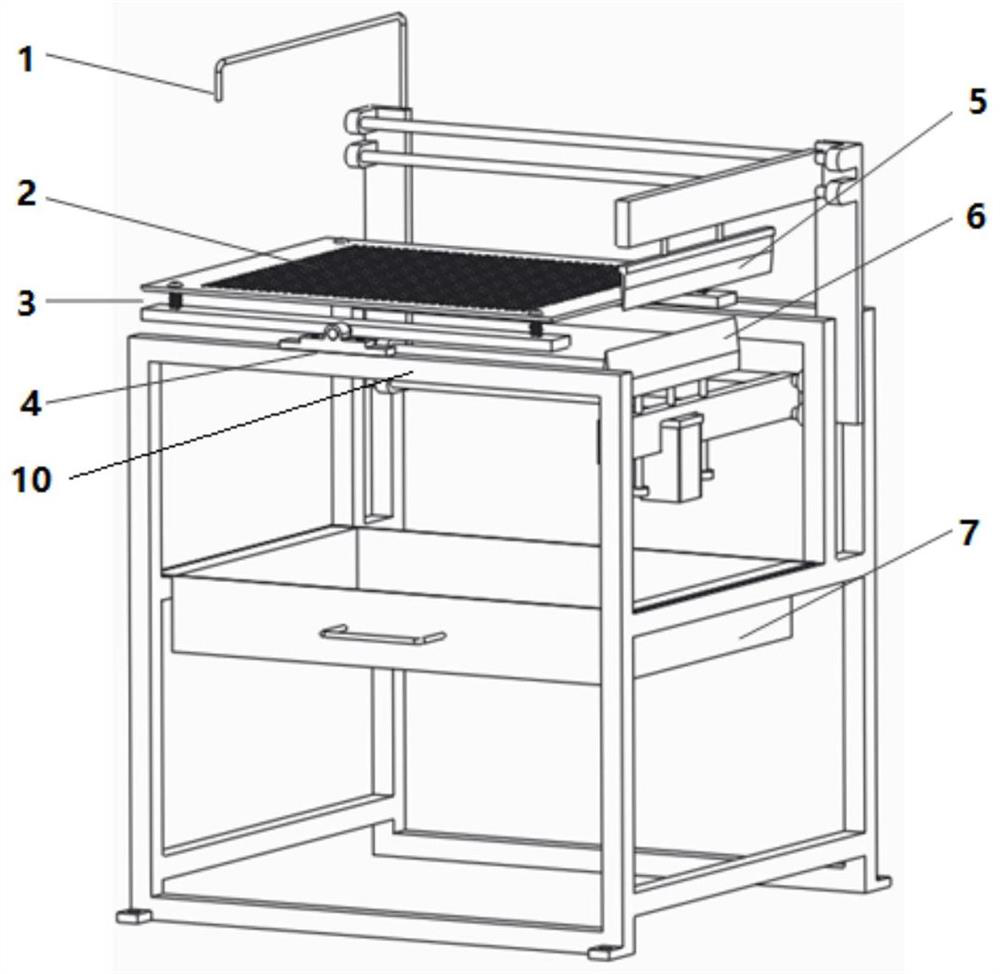

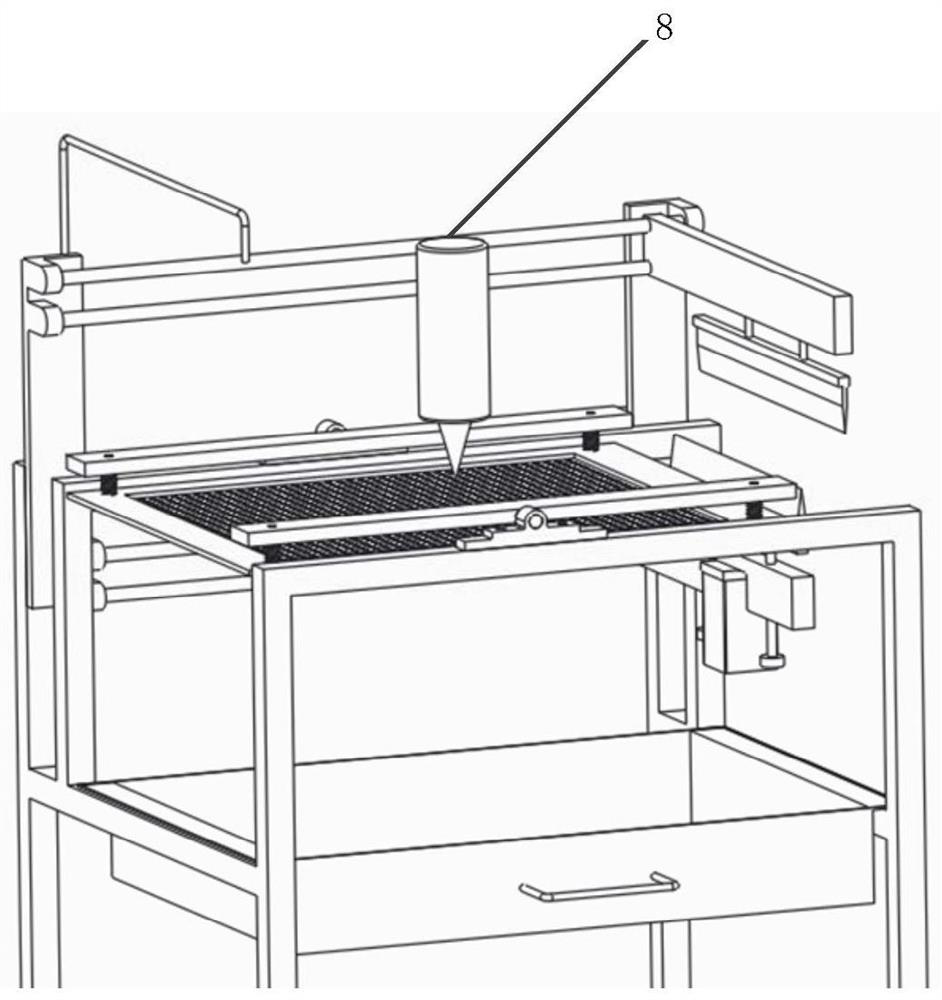

Reinforcing mesh sheet binding machine

PendingCN108756251AEnhanced binding effectImprove work efficiencyBuilding material handlingRebarEngineering

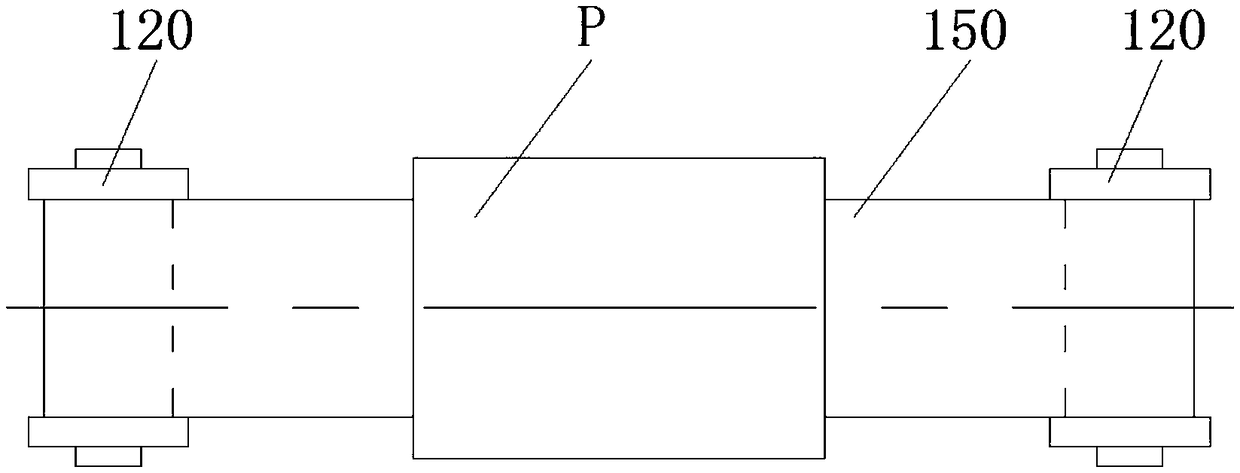

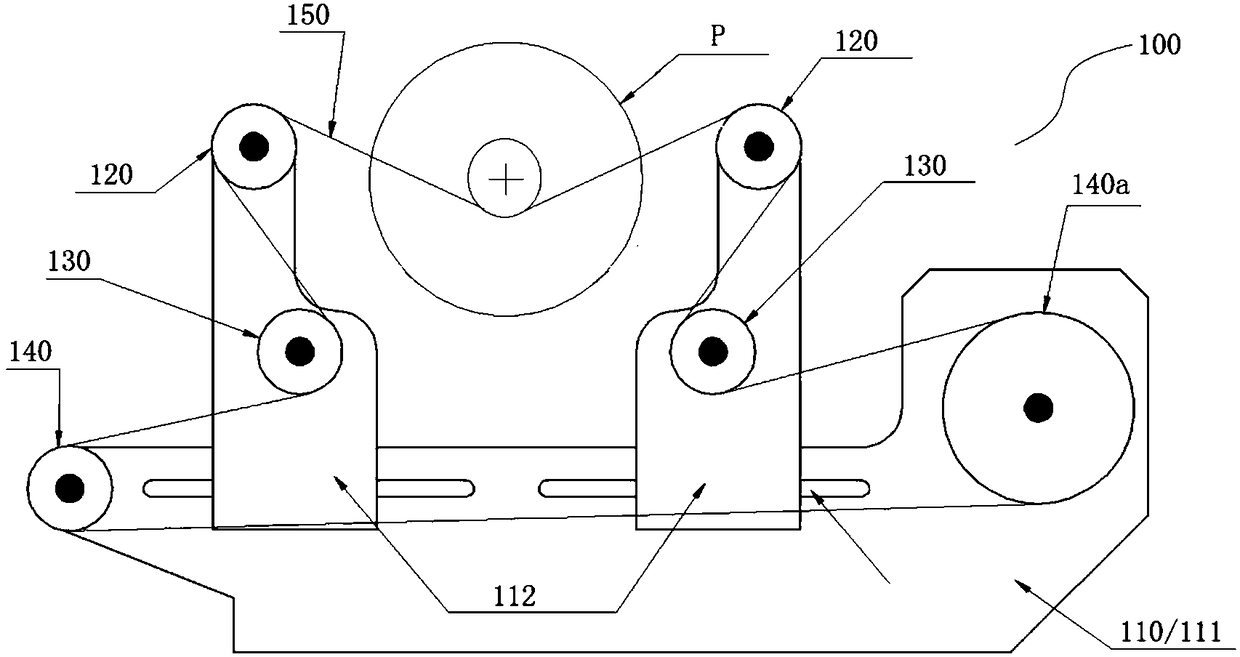

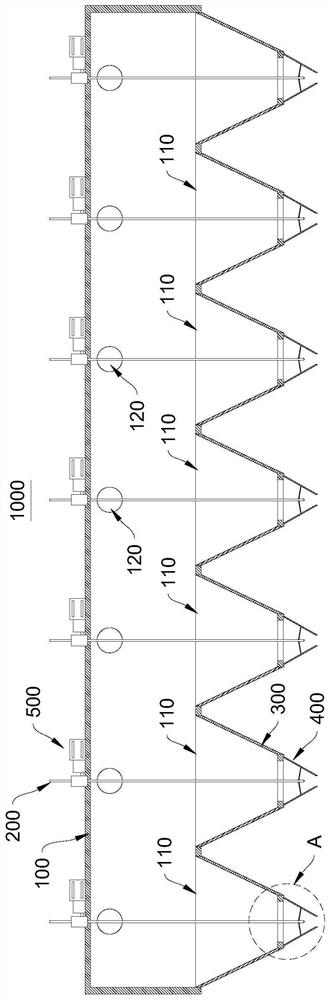

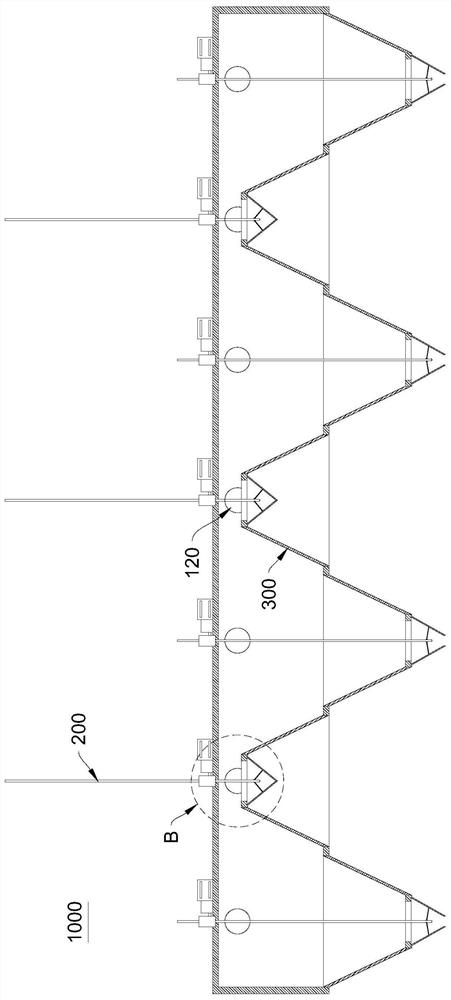

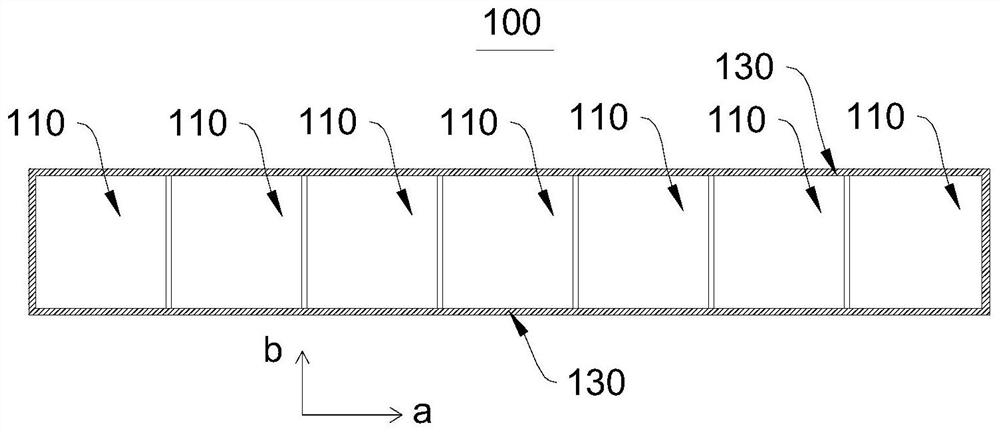

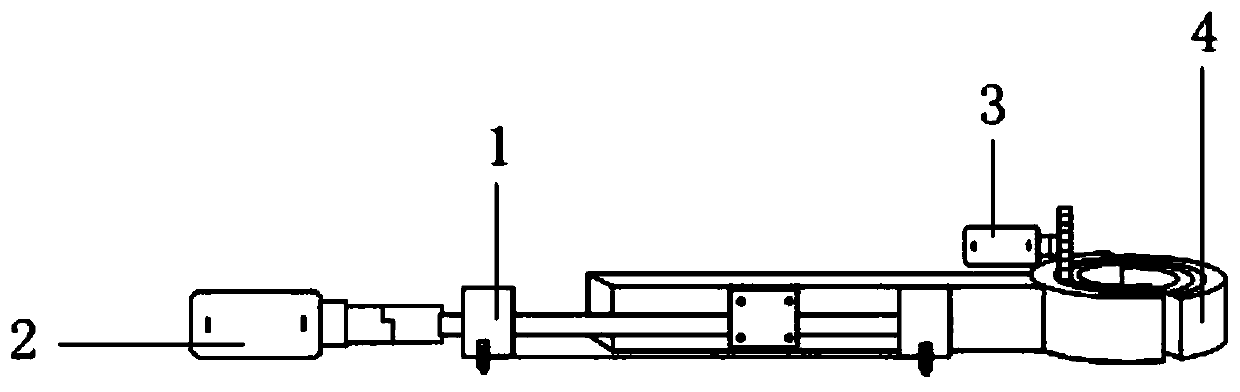

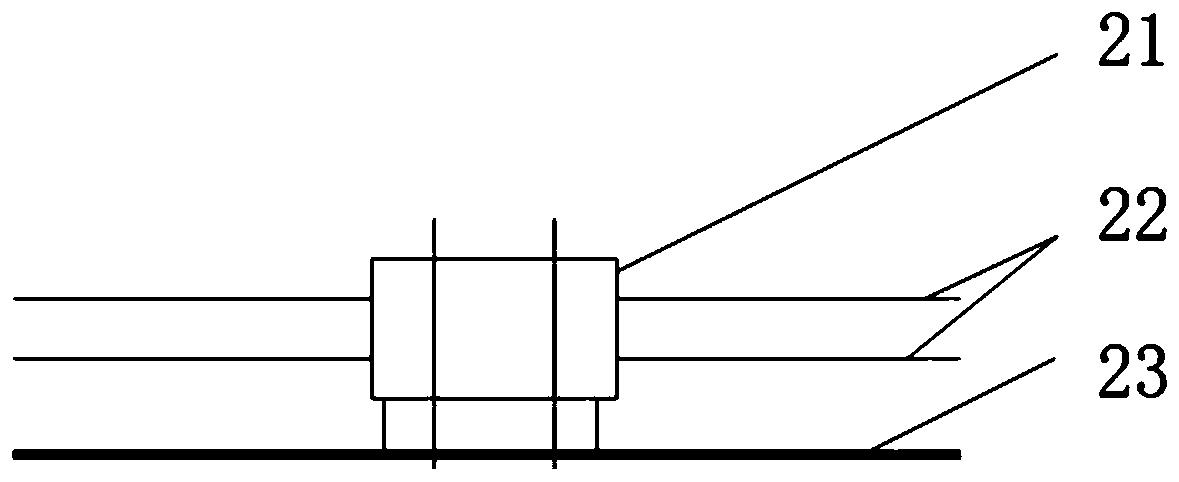

The invention discloses a reinforcing mesh sheet binding machine, and belongs to the technical field of construction equipment. The reinforcing mesh sheet binding machine comprises a material bearingframe, a rack and one or more automatic binding mechanisms. A plurality of steel bars arranged crosswise are borne on the material bearing frame. The rack comprises longitudinal brackets, a transversebracket and vertical brackets. The longitudinal brackets are arranged on the two sides of the material bearing frame. The vertical brackets are slidably arranged on the longitudinal brackets. The transverse bracket is slidably arranged on the vertical brackets and located on the steel bars. The automatic binding mechanisms are slidably arranged on the transverse bracket and can bind binding wiresat the crossing joints of the steel bars. According to the reinforcing mesh sheet binding machine, automatic binding forming of large-diameter reinforcing mesh sheets is achieved, the reinforcing mesh sheet binding machine is high in automation degree, simple and practical in structure, easy to operate, safe and efficient, high-intensity manual labor can be replaced, meanwhile, the reinforcing mesh sheet binding machine is good in binding effect and high in operation efficiency, and steel wires are saved advantageously.

Owner:TJK MACHINERY TIANJIN

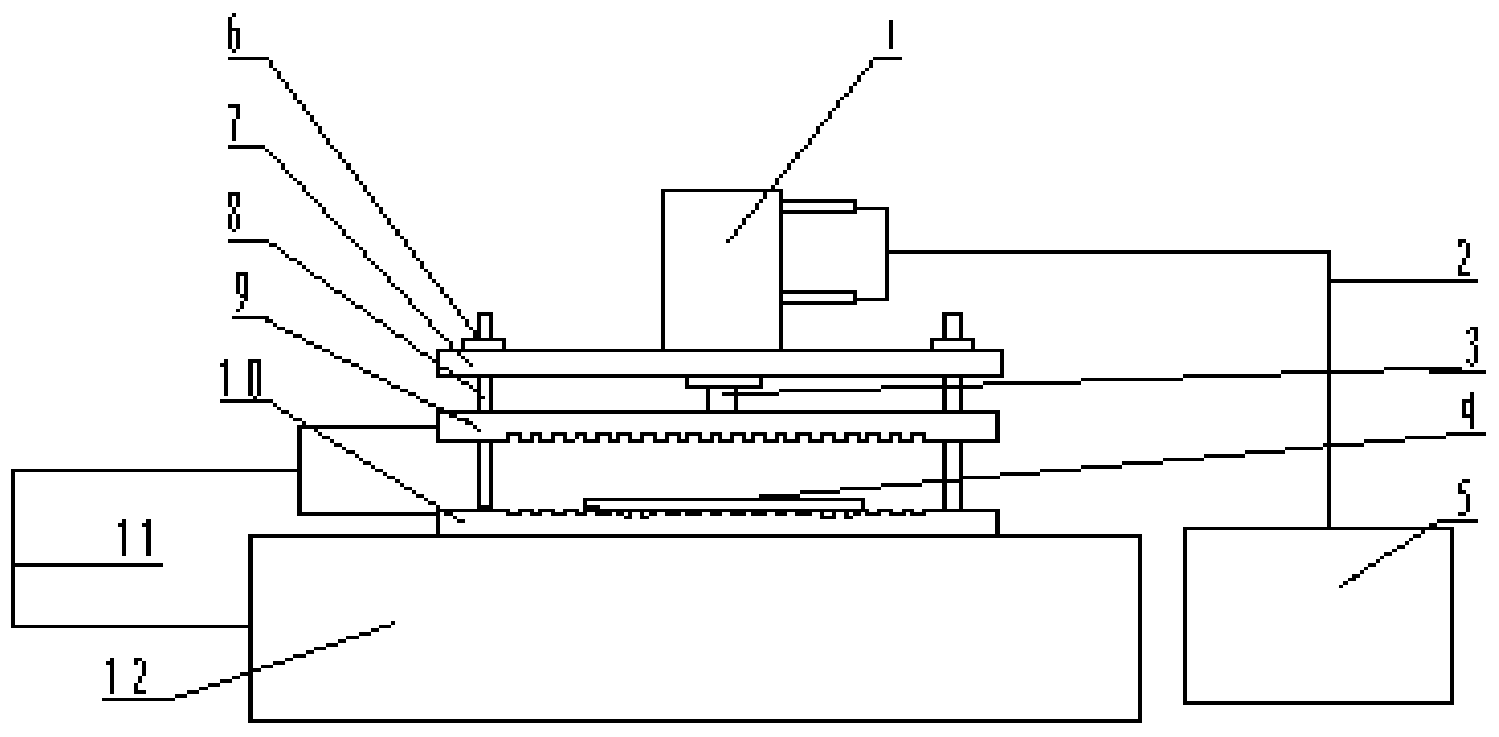

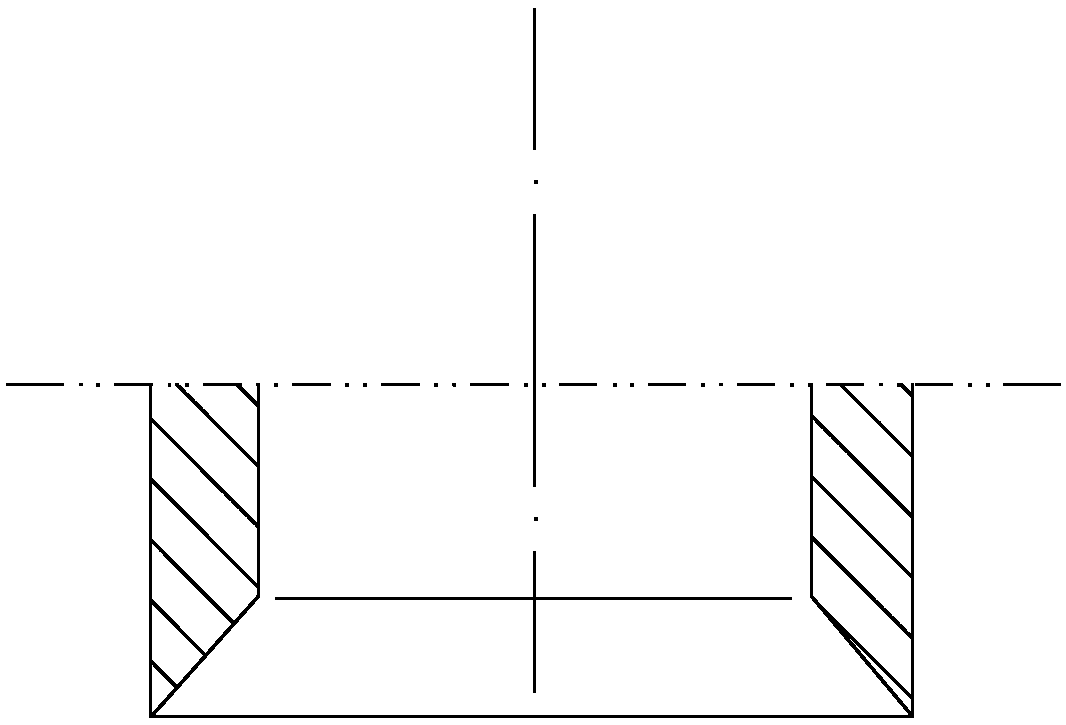

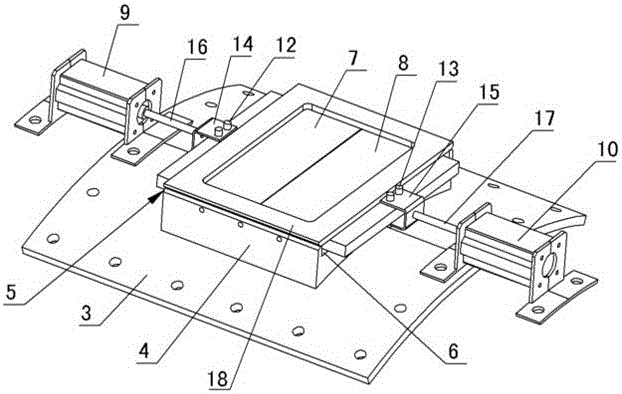

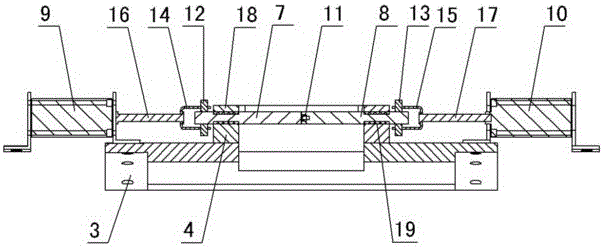

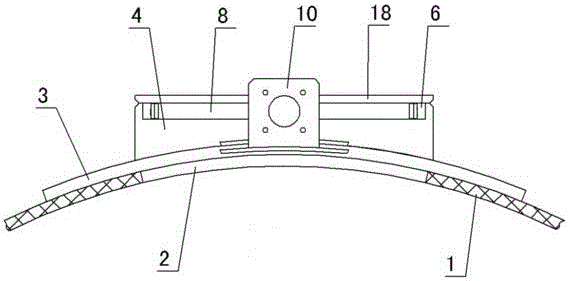

Saw blade matrix pressure quenching device and quenching process thereof

ActiveCN103320599ACool evenlyEliminate deformationFurnace typesHeat treatment furnacesMovable typeFuel tank

The invention relates to the field of manufacturing of diamond saw blade matrixes and in particular relates to a saw blade matrix pressure quenching device and a quenching process thereof. The device comprises a hydraulic oil cylinder, a hydraulic control loop system, a hydraulic oil cylinder and upper pressing plate connecting device, a saw blade matrix, a hydraulic oil tank, an upper fixing rack, a guide post, an upper pressing plate, a lower pressing plate, a quenching oil control loop system and a quenching oil tank, wherein the upper pressing plate is in a vertical movable type and can move up and down under driving of the hydraulic oil cylinder; during quenching, the saw blade matrix is arranged on the lower pressing plate, the upper pressing plate is pressed downwards and presses the matrix in the up-down manner by means of a correction pressure block, the spread oil cooling is performed, and the press tempering is performed after the cooling. When the saw blade matrix is subjected to quenching treatment, so that the hardness can be guaranteed, the deformation of the saw blade matrix can be controlled, the production cost is controlled, the production efficiency is improved, and the saw blade matrix pressure quenching device is suitable for quenching various sheets of the saw blade matrix and suitable for large-scale automatic production.

Owner:BOSUN TOOLS CO LTD

Injection molding technology of composite panel

InactiveCN101879770AIncreased complexitySimplify production stepsFlat articlesEngineeringSurface plate

The invention relates to an injection molding technology of a composite panel, which comprises the following steps: selecting a film; printing patterns on the film; printing adhesion ink on the film; punching and heating to mold the film; punching the film until the size and the shape of the film are identical to those of the panel when the film is punched to be molded; arranging the film into an injection mould and positioning; and injecting to make resin base materials adhered with the film so as to process the composite panel. The lower die of a heating molding mould used for arranging the film is a silica gel mould. The silica gel mould can smooth the drawing process, and effectively protects the ink, and the molded film has small rebound and better shaping effect and is easier to operate.

Owner:ZHEJIANG DAAN MOLDING TECH

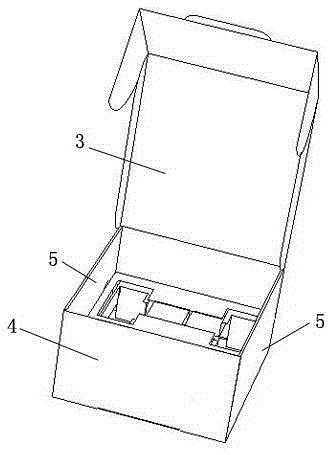

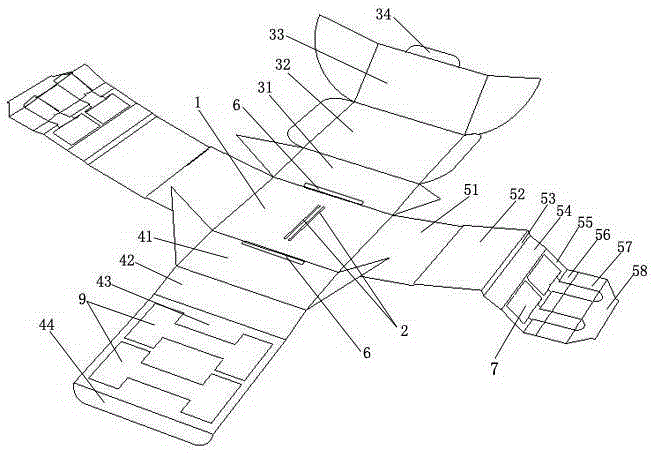

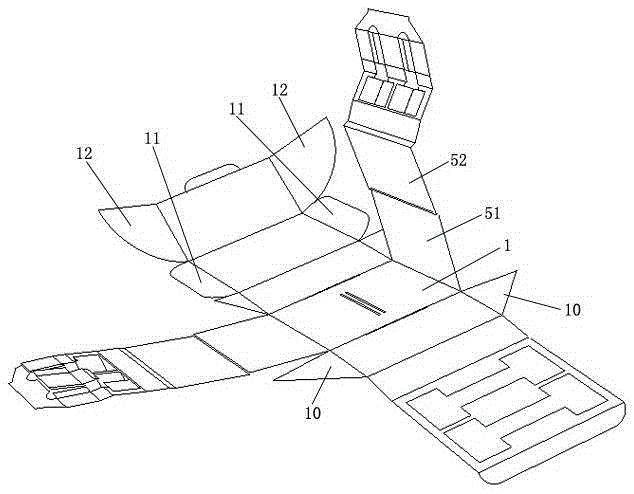

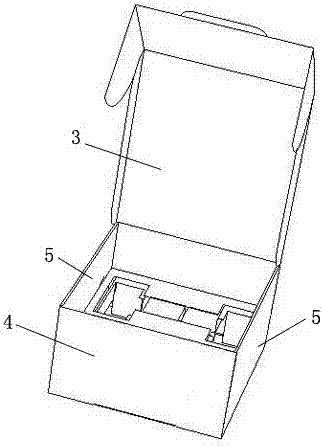

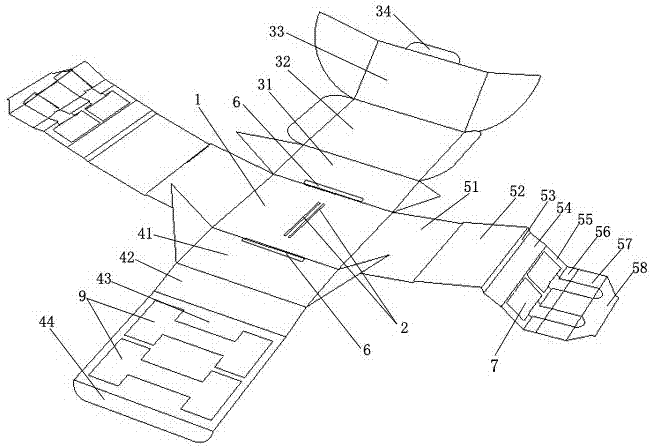

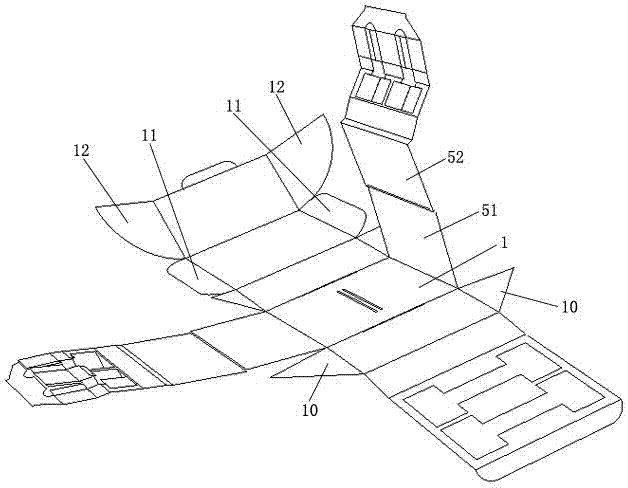

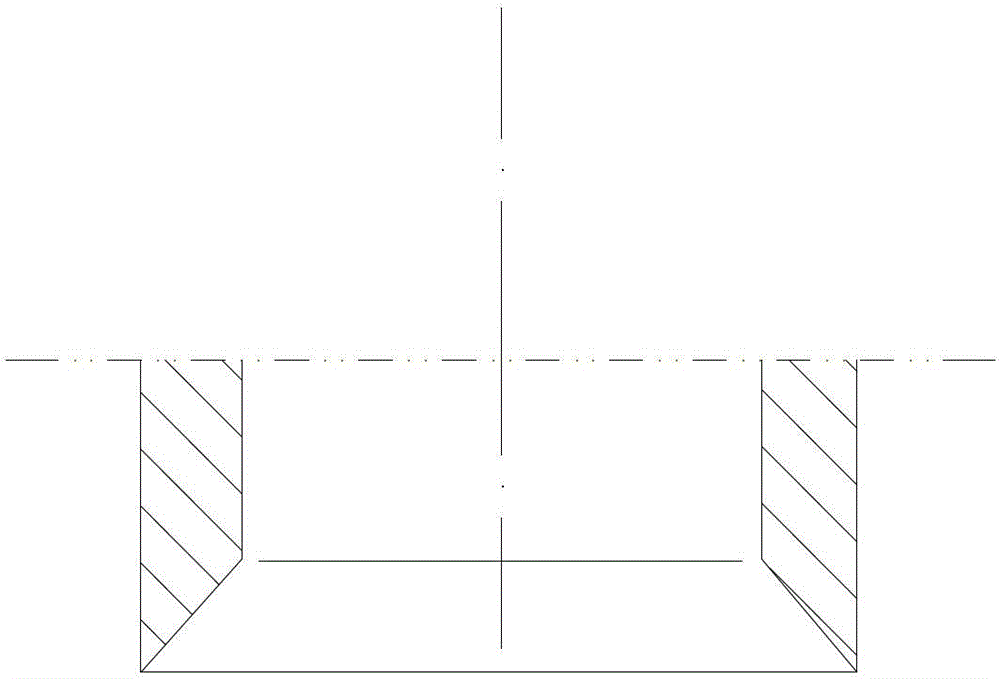

Corrugated paper package box used for displaying H-shaped product

The invention provides a corrugated paper package box used for displaying an H-shaped product. The package box is formed by folding integrated corrugated paper and comprises a square plate, an outer connection part, a protection part and two supporting parts symmetrically arranged on the two opposite lateral sides of the square plate. The outer connection part and the protection part are connected to the other two lateral sides of the square plate. The protection part is composed of a first protection plate, a second protection plate, a third protection plate and a fourth protection plate. The second protection plate is attached to the inner wall of the first protection plate. The outer connection part is composed of a first connection plate, a second connection plate, a third connection plate and a fourth connection plate which are sequentially and perpendicularly folded. An insertion groove for the fourth connection plate to pass is formed in the joint of the square plate and the first protection plate. In the corrugated paper package box, a box body part and the supporting parts are integrated, the product is placed and fixed in the manner that grooves are formed in the supporting parts, and therefore the structural body containing stability is increased, and collisions between objects in the transportation process are avoided.

Owner:XUCHANG UNIV

Multicomponent polymer for rigid polyvinyl chloride and preparation method of multicomponent polymer

ActiveCN103351562AGood plasticizing performanceIncrease extrusion speedFunctional monomerMethyl methacrylate

The invention aims at providing a multicomponent polymer for rigid polyvinyl chloride and a preparation method of the multicomponent polymer. The multicomponent polymer is prepared by a polymer emulsion intermediate A and a polymer emulsion intermediate B at a mass ratio of 9:1-8:2, wherein the polymer emulsion intermediate A is prepared by a monomer A (comprising a functional monomer and vinyl acetate), water, a dispersing agent, an emolsifier, an initiator and a separant; and the polymer emulsion intermediate B is prepared by a monomer B (comprising alkyl acrylate and methyl methacrylate), water, an emolsifier and an initiator. The polymer is excellent in plastification performance and self-lubricating property, can increase extrusion velocity, improves production efficiency, greatly improves melt strength greatly, and increases a balancing torque greatly on the premise of ensuring a plasticification degree. The water resistance, alkali resistance and heat resistance of a copolymer are improved. The invention further provides a preparation method of the polymer, which is simple and easy to operate.

Owner:SHANDONG SHITUO HIGH MOLECULAR WEIGHT MATERIAL

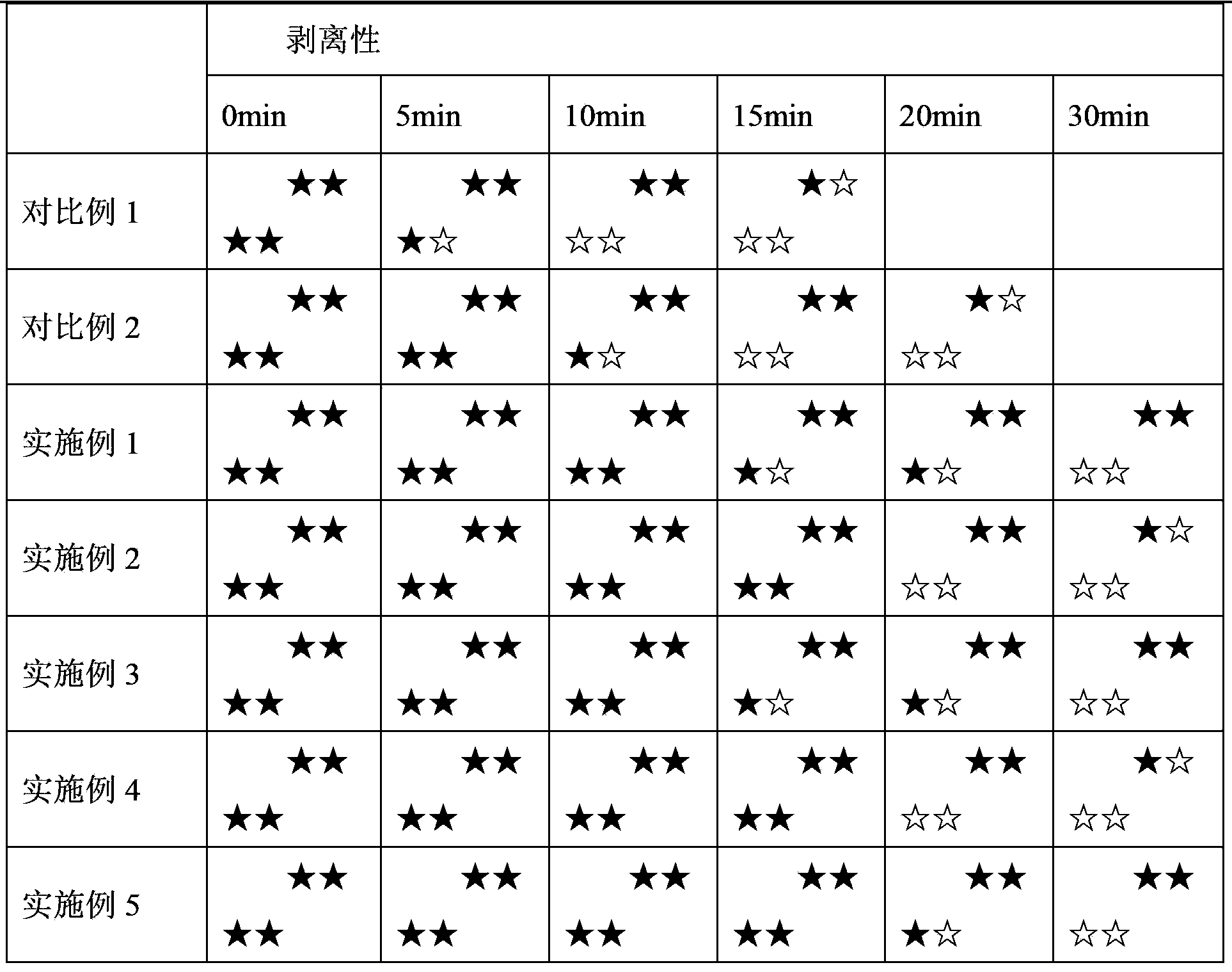

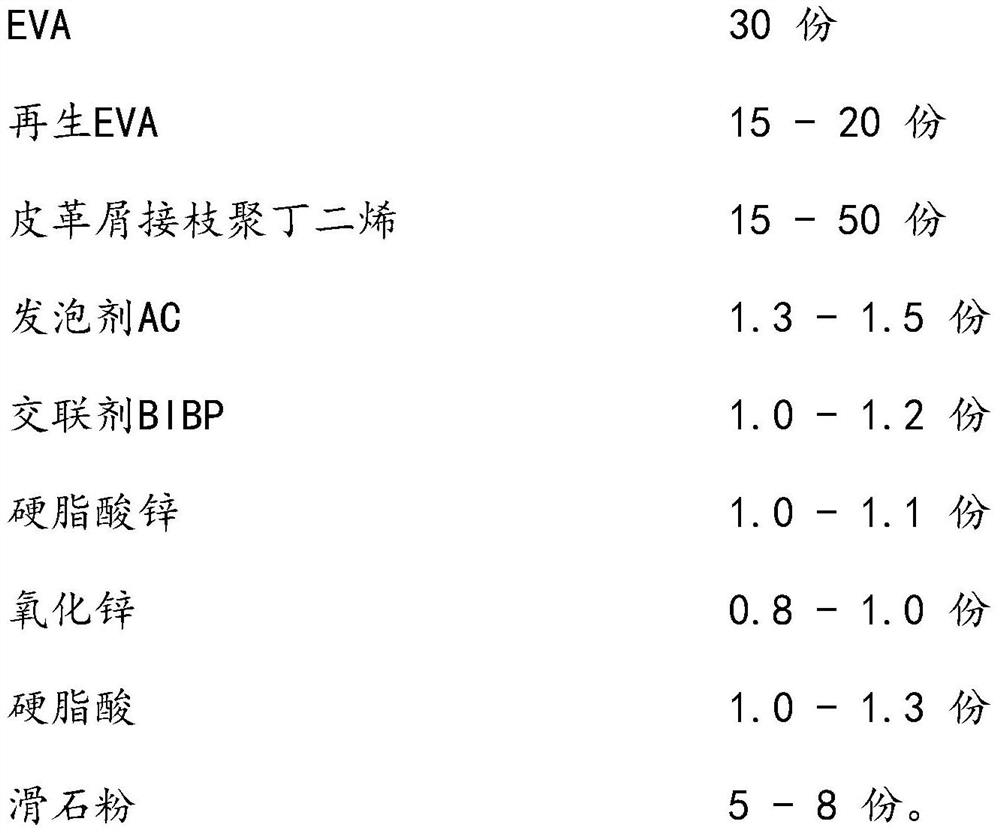

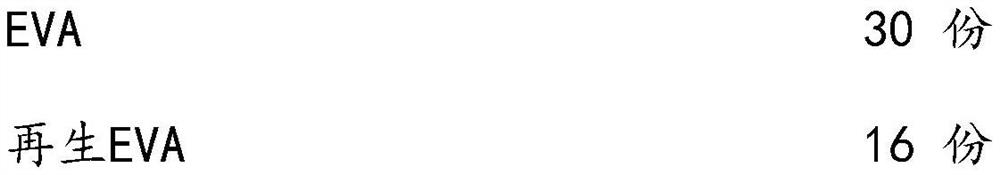

Leather scrap modified foamed shoe insole and preparation method thereof

The leather scrap modified foamed shoe insole comprises, by weight, 30 parts of EVA, 15-20 parts of regenerated EVA, 15-50 parts of leather scrap grafted polybutadiene, 1.3-1.5 parts of a foaming agent AC, 1.0-1.2 parts of a cross-linking agent BIBP, 1.0-1.1 parts of zinc stearate, 0.8-1.0 part of zinc oxide, 1.0-1.3 parts of stearic acid and 5-8 parts of talcum powder. According to the invention,carboxyl groups in maleic anhydride grafted polybutadiene and amido groups of leather scraps are subjected to amidation crosslinking by utilizing a melt grafting modification technology, so that thecompatibility of leather wastes and EVA shoe materials is improved; a macromolecular protein is introduced into EVA, so that the problem of environmental pollution caused by difficult biodegradation of EVA can be solved; and through amidation crosslinking, the environment-friendly performance of the EVA shoe materials is improved, the crosslinking degree between molecular chains can be increased,the leather scrap modified foaming material with excellent performance is obtained, high-value utilization of leather waste is achieved, resource recycling is achieved, environmental pollution is reduced, and the production cost of shoe materials is reduced.

Owner:MAOTAI FUJIAN SOLES CO LTD

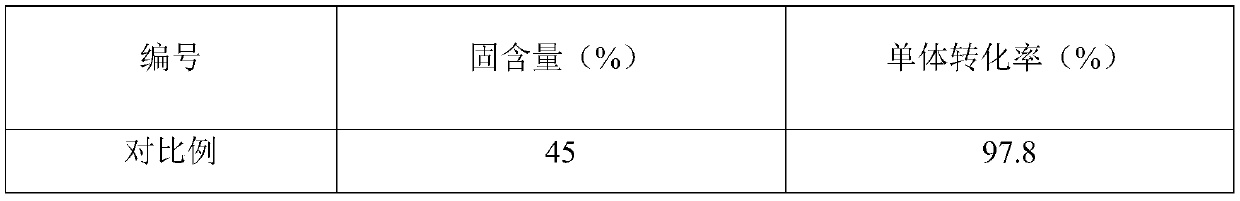

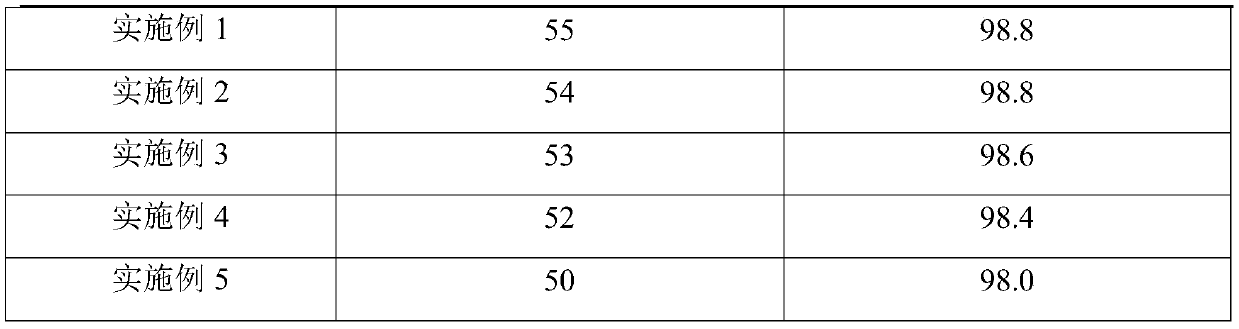

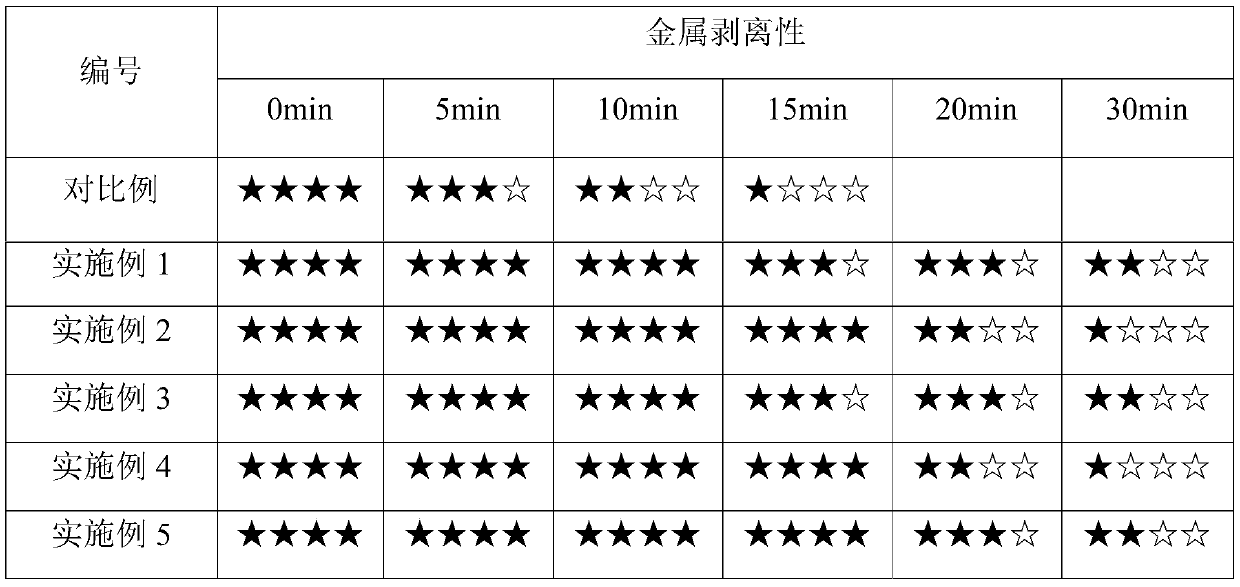

Production method of high-solid-content ultra-high-molecular-weight acrylic ester copolymer emulsion

The invention relates to a production method of an acrylic ester copolymer emulsion, in particular to a production method of a high-solid-content ultra-high-molecular-weight acrylic ester copolymer emulsion. According to the production method, an emulgator, a wetting agent, an emulsification dispersing agent, a pH conditioning agent and an oxidation-reduction initiator system are introduced into acrylic ester mixed monomer emulsion polymerization, by adopting one-time feeding, the oxidation-reduction system and an ultra-low temperature emulsion polymerization technology, an acrylic ester copolymer with high solid content (50-55%) and ultra-high molecular weight (the Mw range is 9.5 million-10.50 million, and the intrinsic viscosity eta range is 16-20) is prepared, a traditional old technology for producing a foaming conditioning agent is successfully replaced, and the adverse factors are overcome that the traditional foaming conditioning agent is generally low in molecular weight, widein distribution range, poor in flowability and low in melt strength, and the density of the finished product is difficultly lowered. The prepared emulsion is high in solid content, spray drying is easily achieved, the product moisture is easy to control, the energy is saved, and the consumption is lowered.

Owner:山东源邦新材料股份有限公司

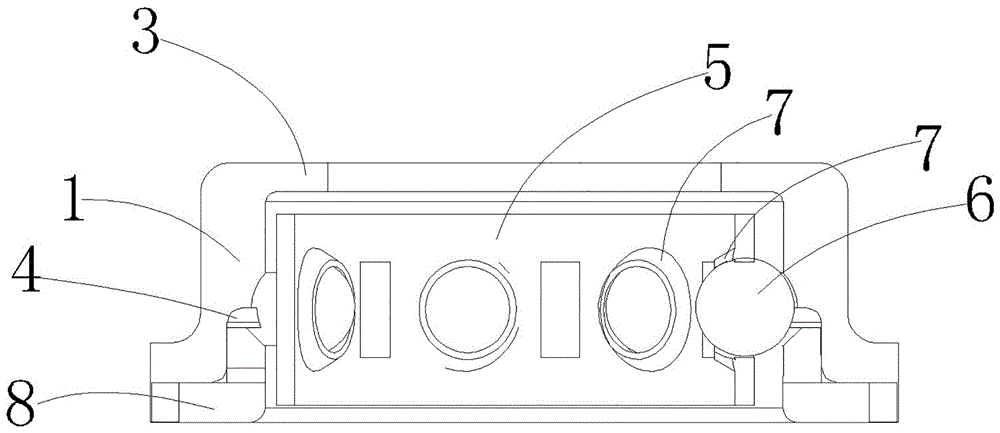

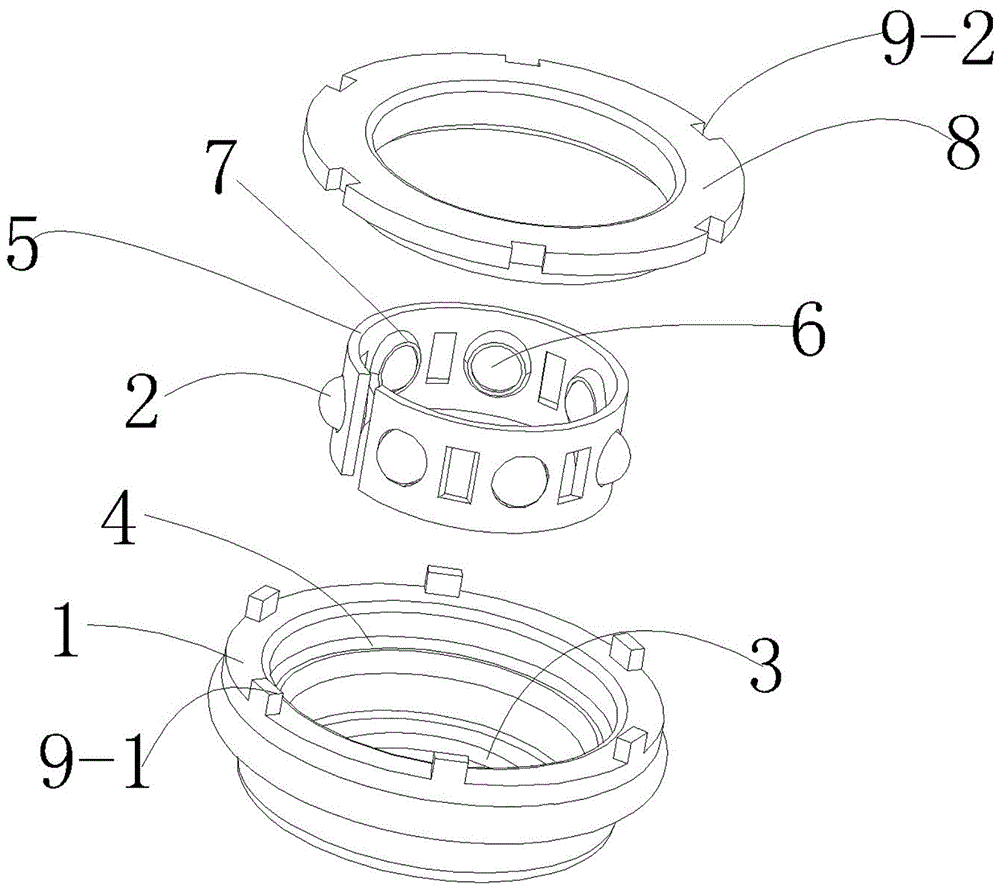

Micro high-speed inner-ring-free ball bearing and assembling device thereof

The invention discloses a micro high-speed inner-ring-free ball bearing. The micro high-speed inner-ring-free ball bearing comprises a bearing outer ring and balls. A folded edge is inwards arranged on one side of the bearing outer ring, and a ring groove is formed in the upper half portion of the bearing outer ring. The micro high-speed inner-ring-free ball bearing further comprises a ball frame. The ball frame is arranged in the ring groove of the bearing outer ring. The ball frame is formed by bending a metal sheet, and multiple ball holes are formed in the metal sheet. One side of each ball hole is pressed to form a limiting face, wherein the limiting face is located on the inner side of the ball frame, and the hole diameter of the limiting face is smaller than the diameter of the balls. The micro high-speed inner-ring-free ball bearing is convenient to produce and low in cost, the structure is simple so that the bearing can adapt to automatic production, operation is simple and fast, and the production cost is greatly reduced.

Owner:NINGBO HEPINGGE ORAL MEDICAL EQUIP

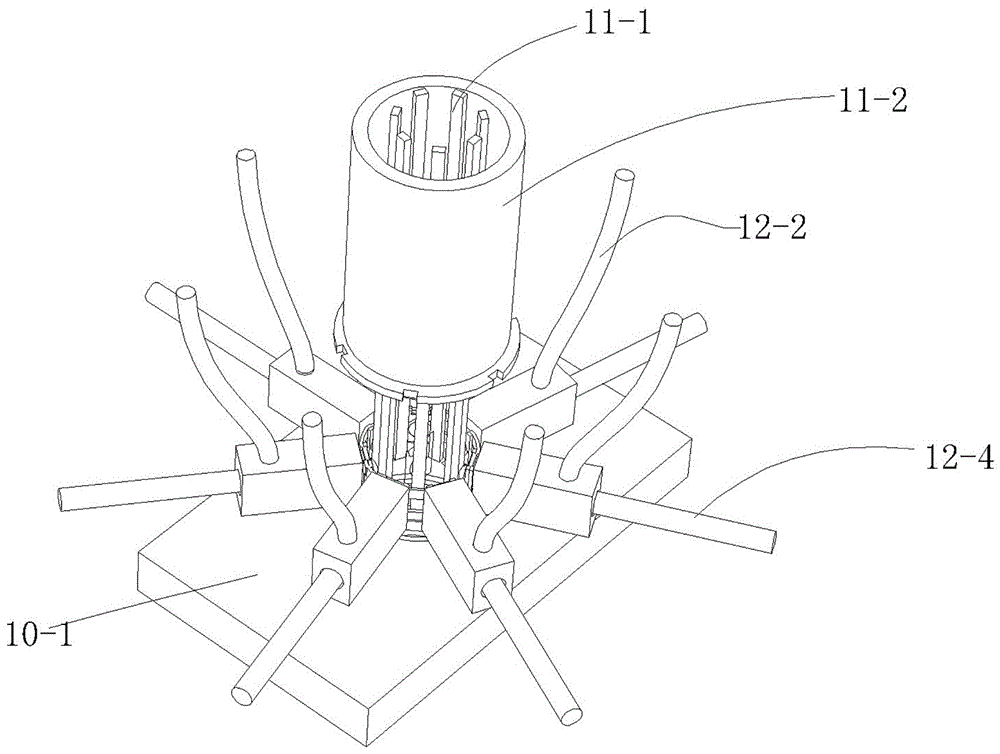

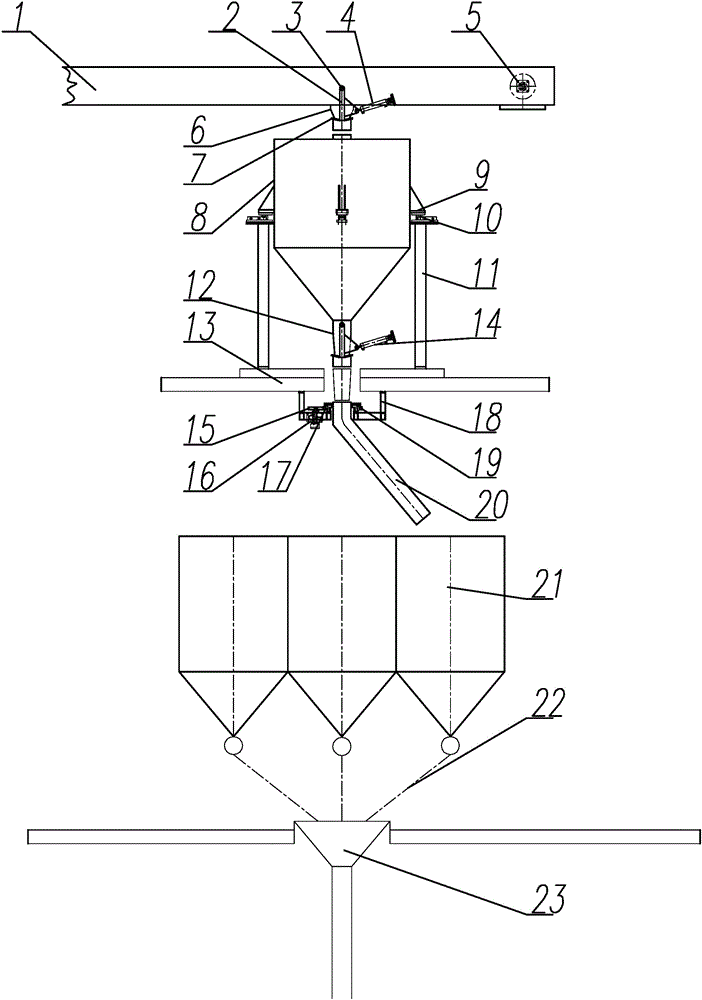

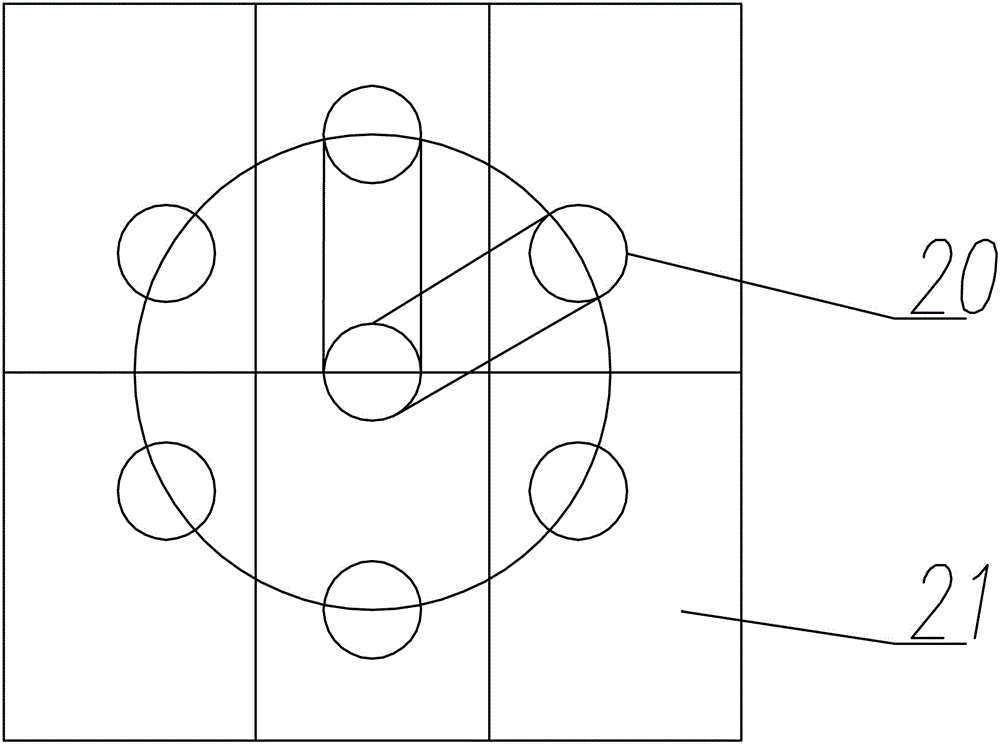

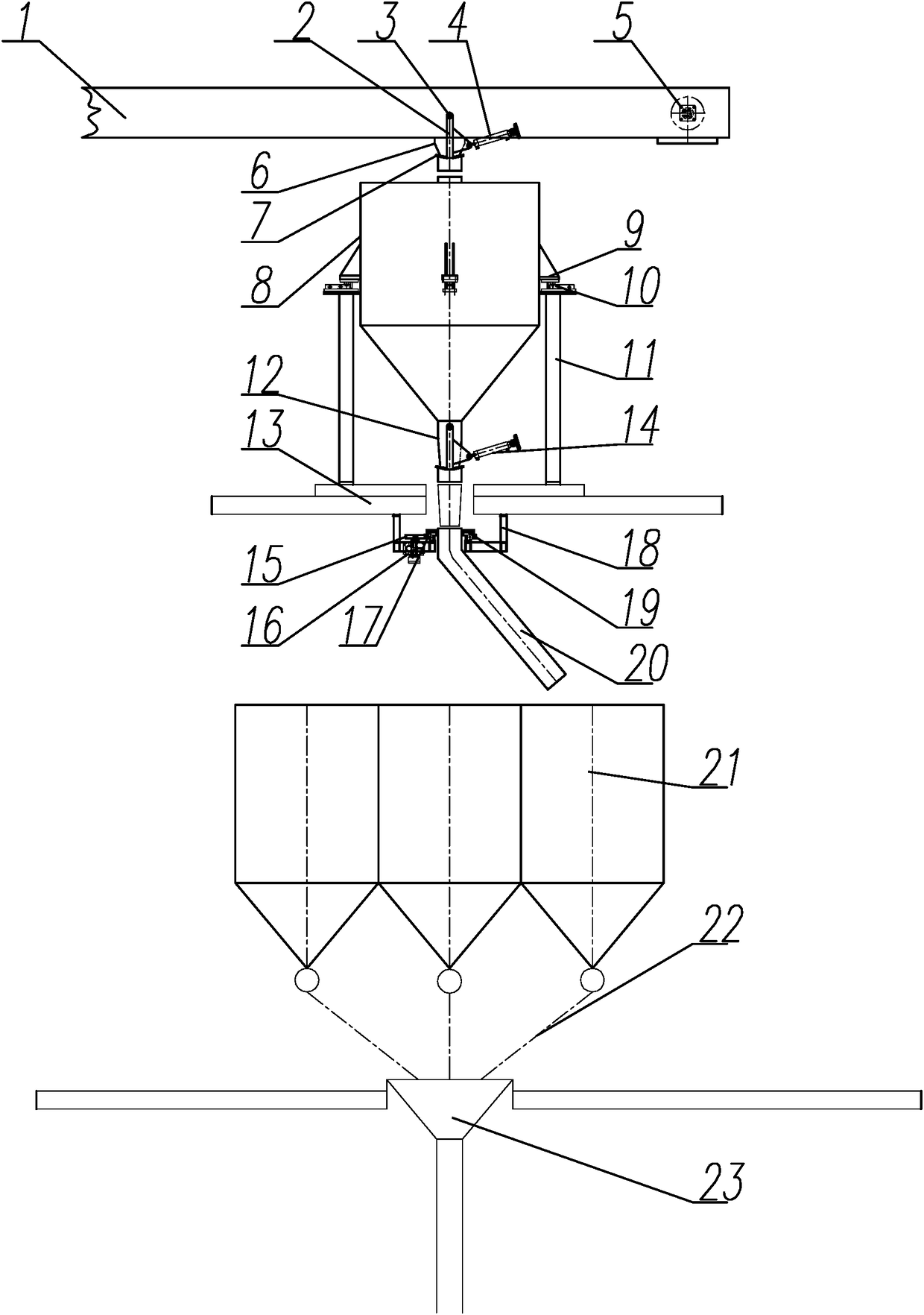

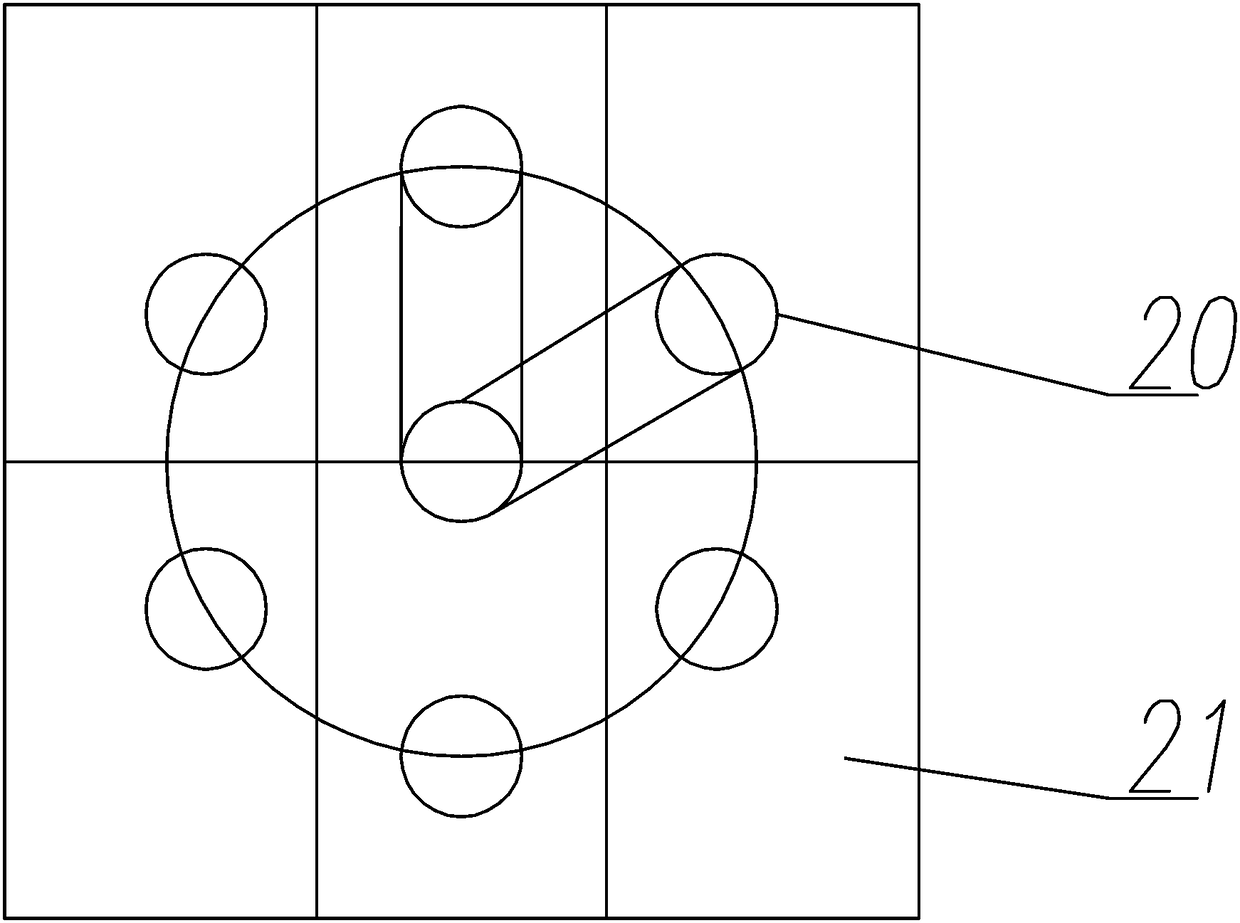

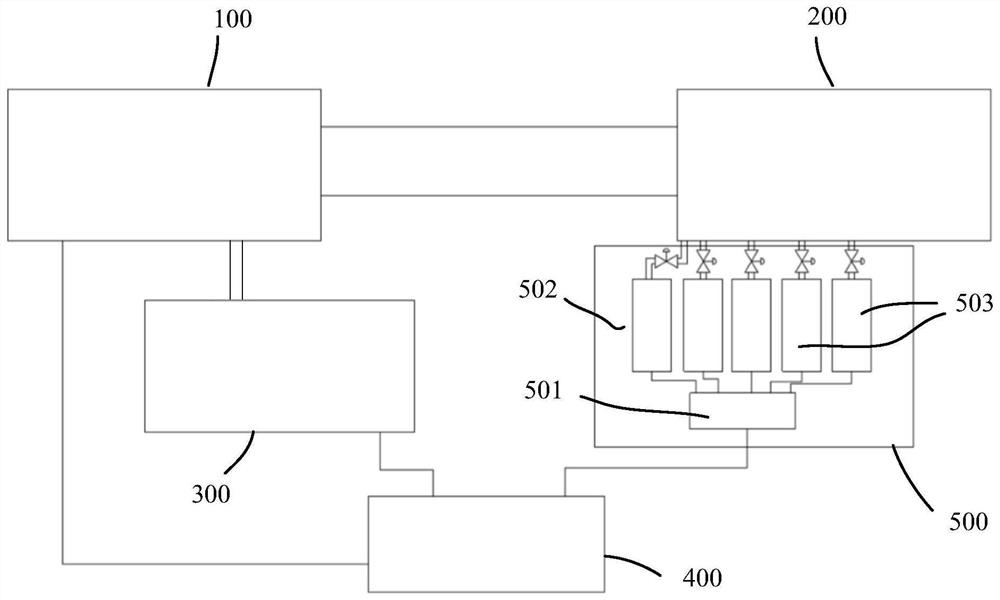

Quantitative and point-fixed multi-station grain automatic unloading device and method

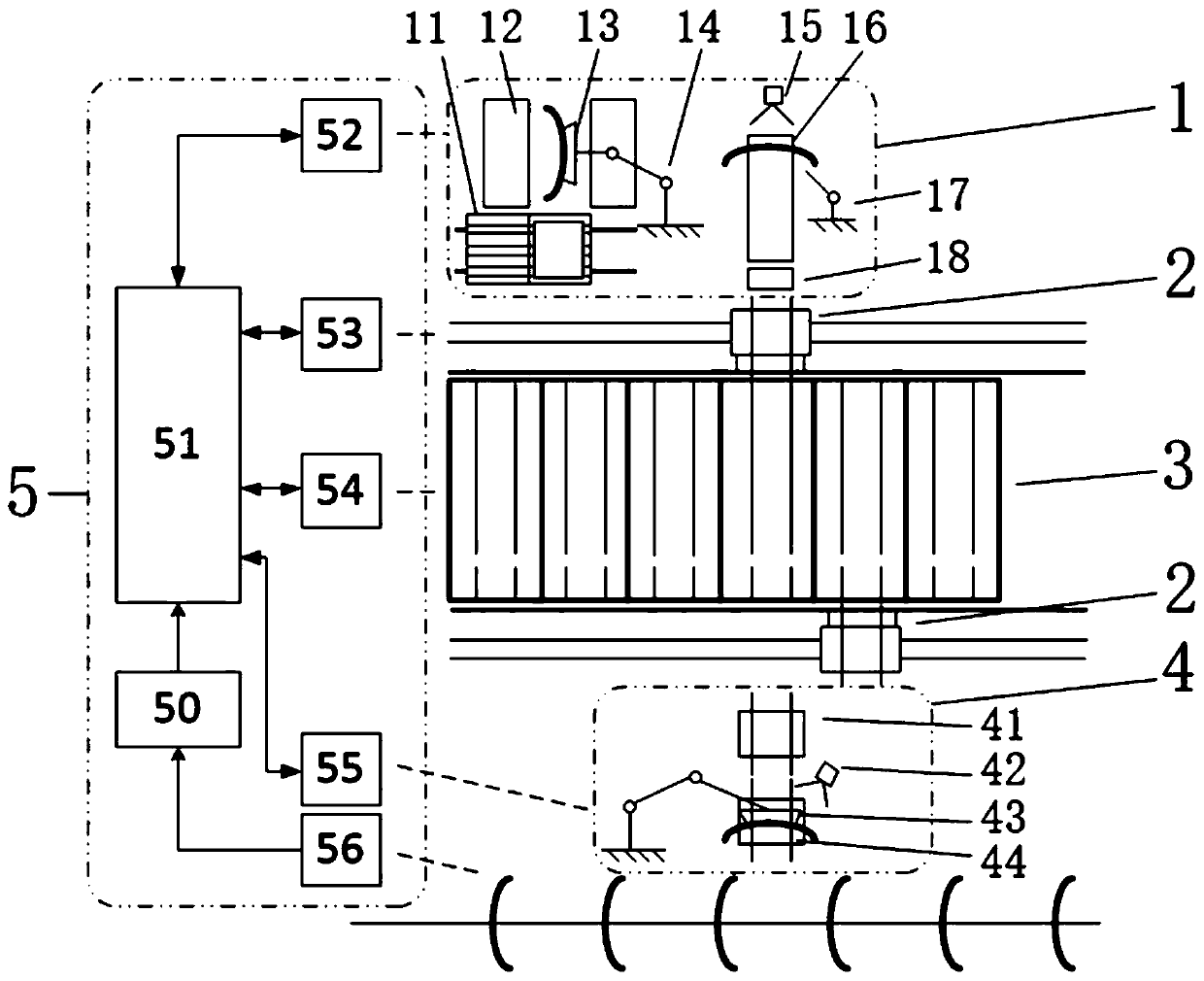

ActiveCN106219260ARealize automatic blanking operationAutomatic dropConveyorsLoading/unloadingAutomatic controlEngineering

The invention discloses a quantitative and point-fixed multi-station grain automatic unloading device and a method. The device comprises an embedded scrapper conveyor; an automatic unloading device is mounted at the bottom of a conveying belt of the embedded scraper conveyor; a cache barrel is mounted at the bottom of the automatic unloading device; support angle steel is fixed at the outer wall periphery of the cache barrel; a static weighing balance is arranged at the bottom of the support angle steel, and is supported and mounted on a stand column; the stand column is supported on a baseplate; an unloading cylinder is mounted at the bottom of the cache barrel; a pneumatic discharge mechanism is mounted on the unloading cylinder; a fixed-point rotary unloading device is mounted rightly below the unloading cylinder; and multiple dipping cylinders are correspondingly arranged below the fixed-point rotary unloading device. The device can realize automatic grain weighing operation, can realize automatic unloading, can realize fixed-point unloading through automatic control in the unloading process, and can perform the feeding operation of multiple dipping boxes in sequence to improve the dipping efficiency.

Owner:HUBEI DAOHUAXIANG WINE IND +1

An H-shaped corrugated paper box for product display

The invention provides a corrugated paper package box used for displaying an H-shaped product. The package box is formed by folding integrated corrugated paper and comprises a square plate, an outer connection part, a protection part and two supporting parts symmetrically arranged on the two opposite lateral sides of the square plate. The outer connection part and the protection part are connected to the other two lateral sides of the square plate. The protection part is composed of a first protection plate, a second protection plate, a third protection plate and a fourth protection plate. The second protection plate is attached to the inner wall of the first protection plate. The outer connection part is composed of a first connection plate, a second connection plate, a third connection plate and a fourth connection plate which are sequentially and perpendicularly folded. An insertion groove for the fourth connection plate to pass is formed in the joint of the square plate and the first protection plate. In the corrugated paper package box, a box body part and the supporting parts are integrated, the product is placed and fixed in the manner that grooves are formed in the supporting parts, and therefore the structural body containing stability is increased, and collisions between objects in the transportation process are avoided.

Owner:XUCHANG UNIV

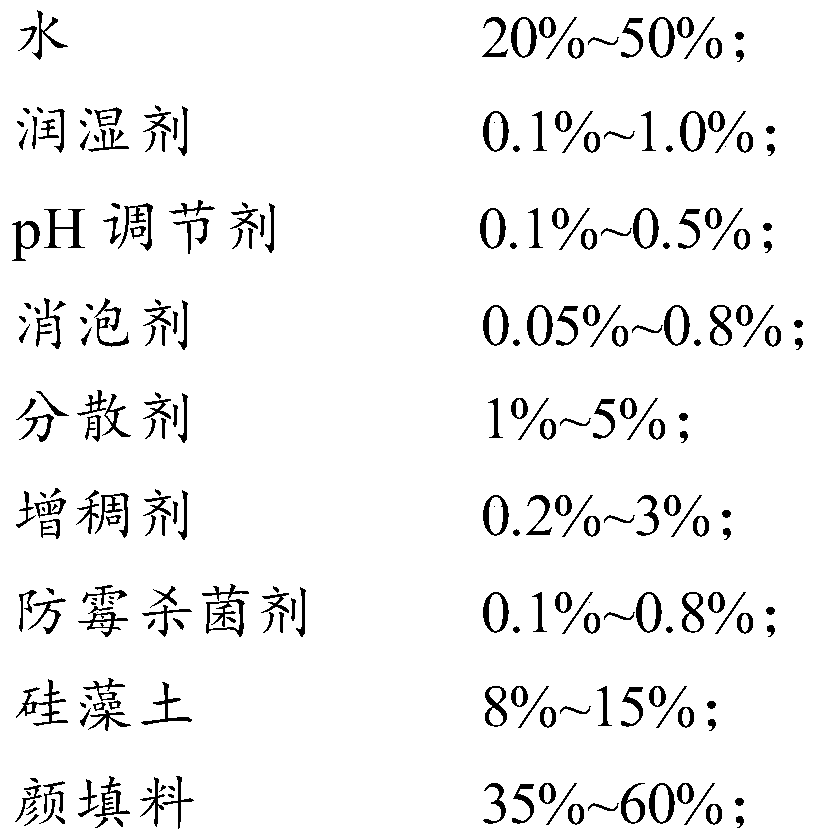

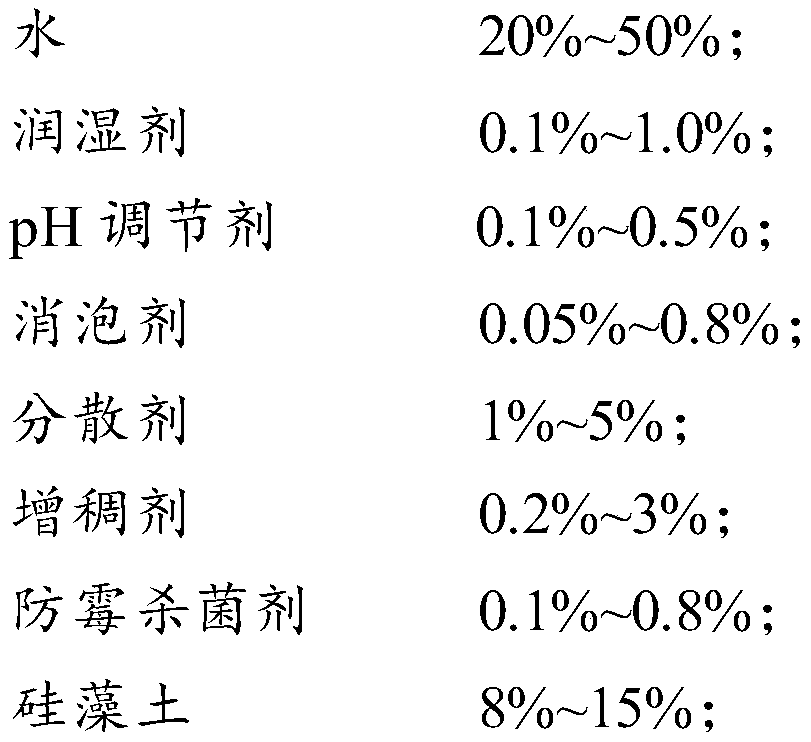

Water-based composite slurry and preparation method thereof

ActiveCN111154341AOvercoming the problem of high thixotropyImprove transportation efficiencyAntifouling/underwater paintsSolid waste managementPhysical chemistrySlurry

The invention provides water-based composite slurry and a preparation method thereof. The water-based composite slurry provided by the invention is composed of the following components in percentage by mass: 20-50% of water, 0.1%-1.0% of a wetting agent, 0.1%-0.5% of a pH adjusting agent, 0.05%-0.8% of a defoaming agent, 1%-5% of a dispersant, 0.2%-3% of a thickening agent, 0.1%-0.8% of a mildew-proof bactericide, 8%-15% of diatomite, 35%-60% of a pigment filler. The pigment filler is selected from one or more of titanium dioxide, calcium carbonate, barium sulfate, quartz powder and xiashi powder; the diatomite is calcined diatomite, and the particle size of the diatomite is 20-40 [mu]m; the pH value of the composite slurry is 8 or more. The diatomite is compounded with the pigment filler,and the wetting agent, the dispersing agent, the pH regulator, the defoamer, the thickener and the mildew-proof bactericide are matched, so that the slurry has excellent stability and flowability.

Owner:MEICHAO GROUP

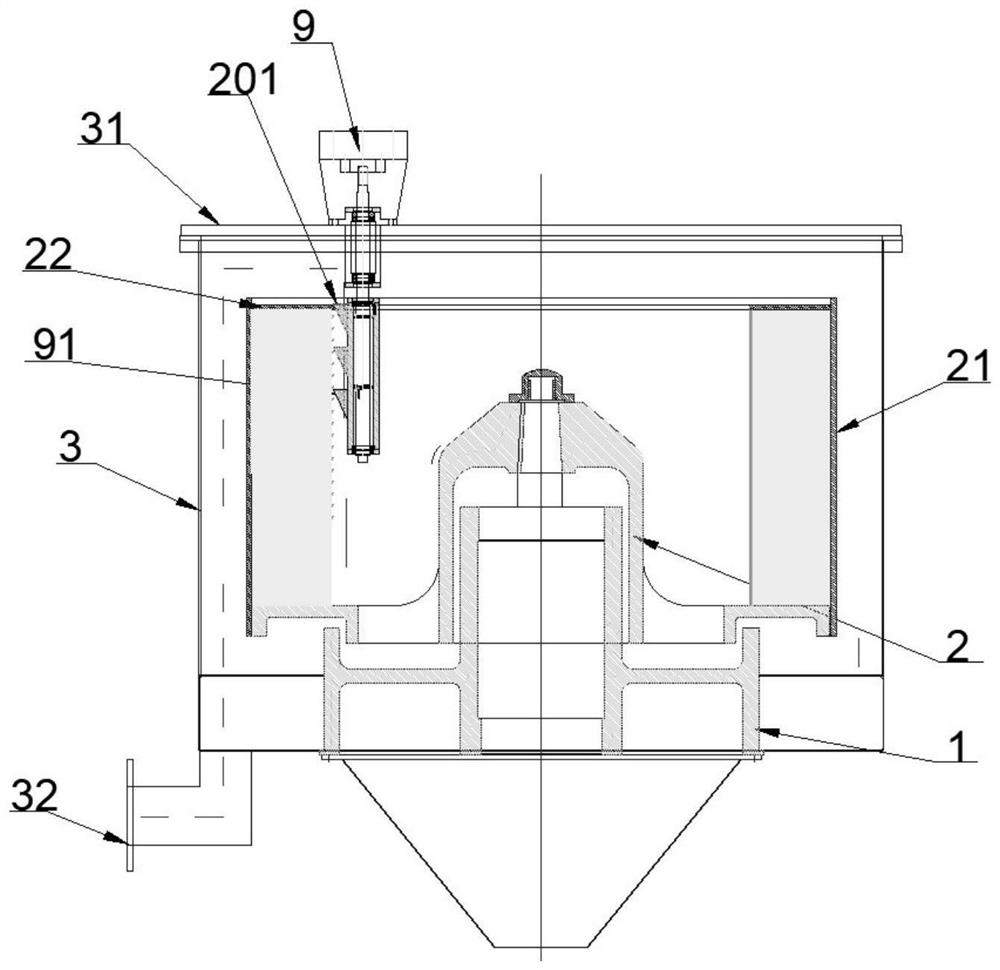

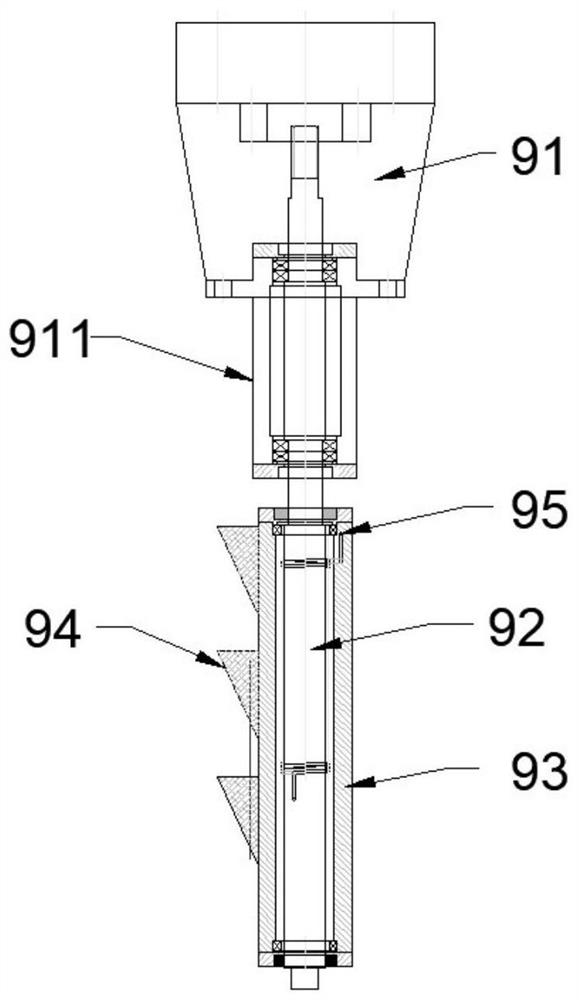

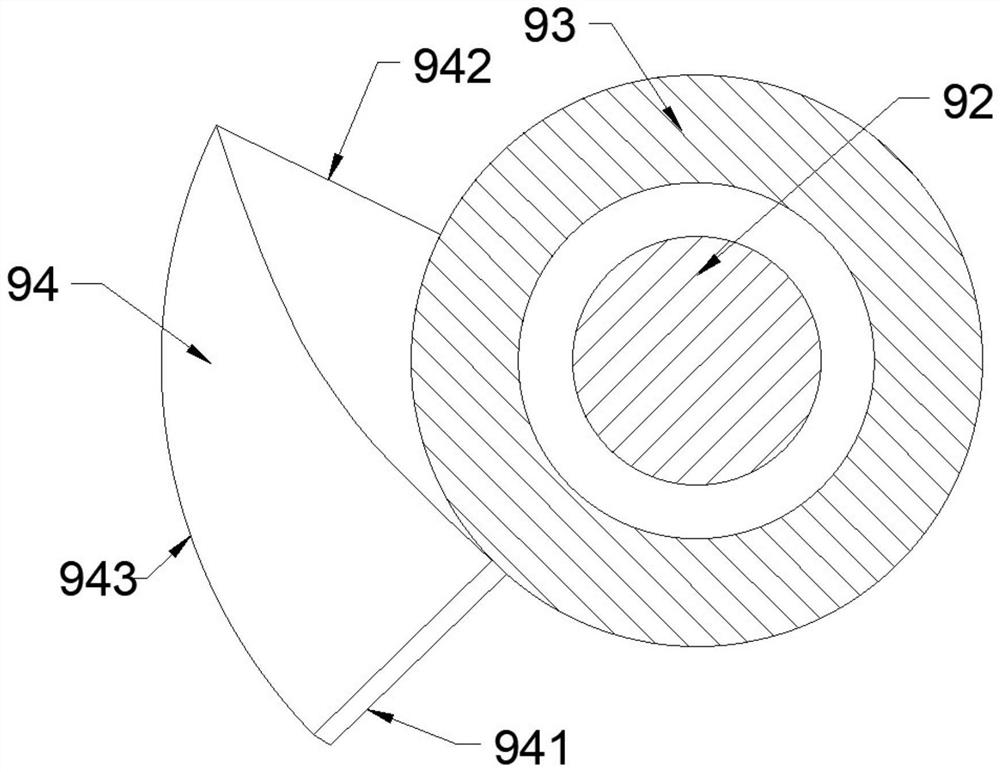

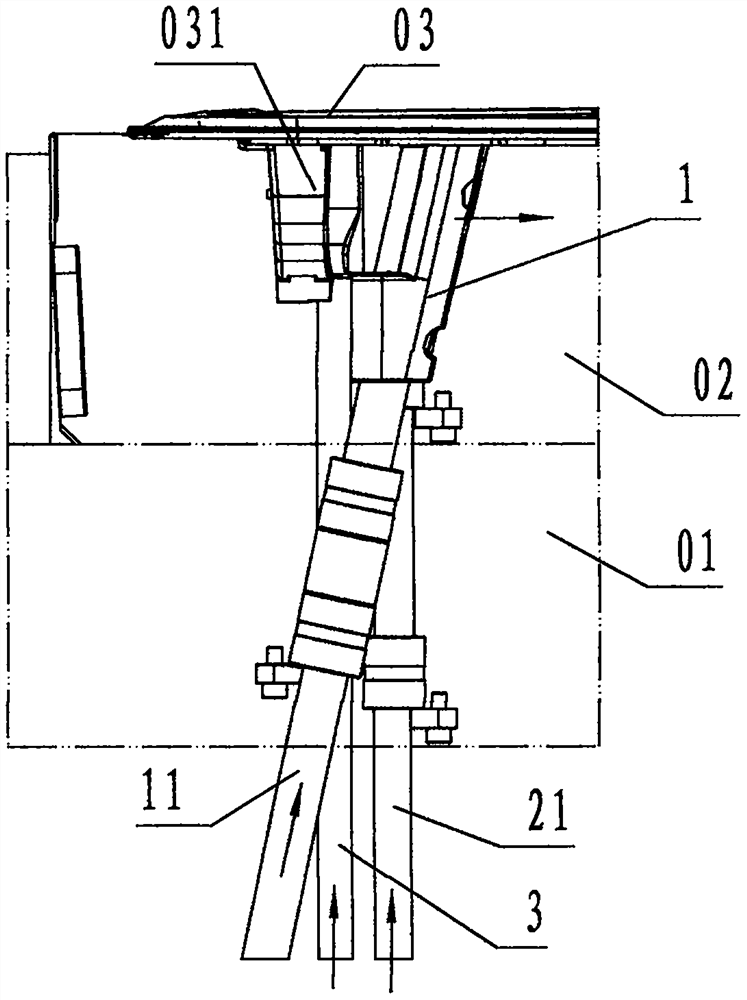

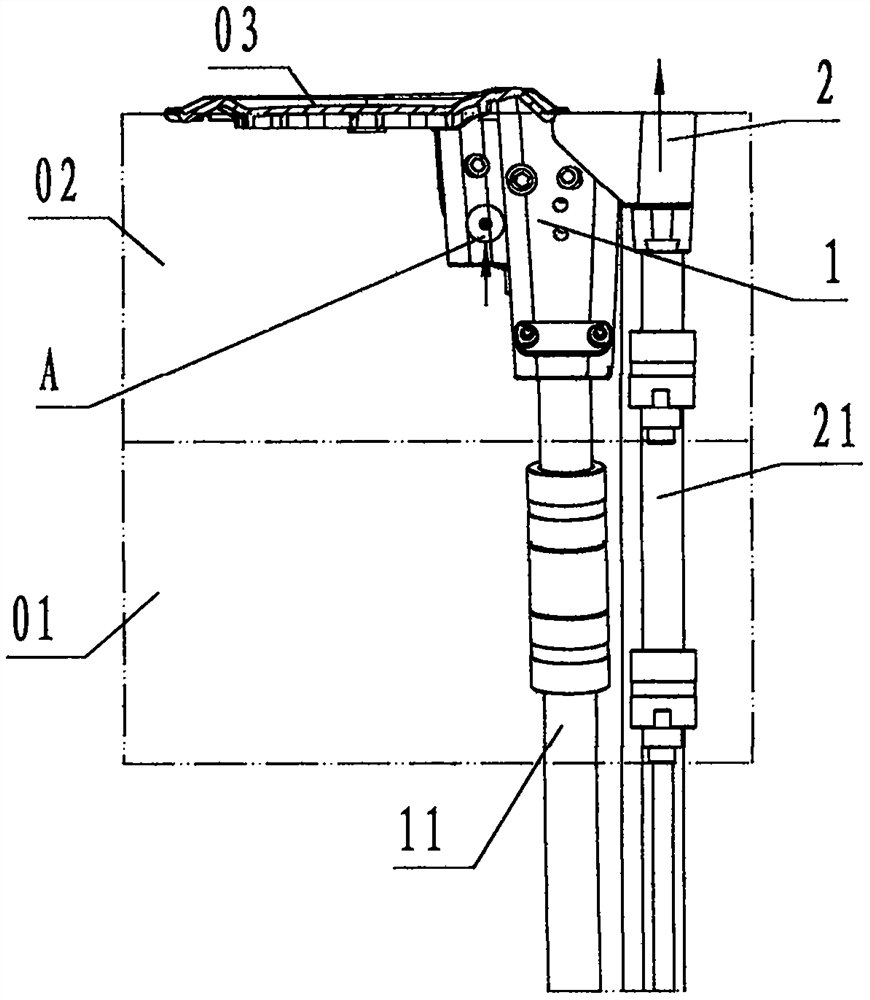

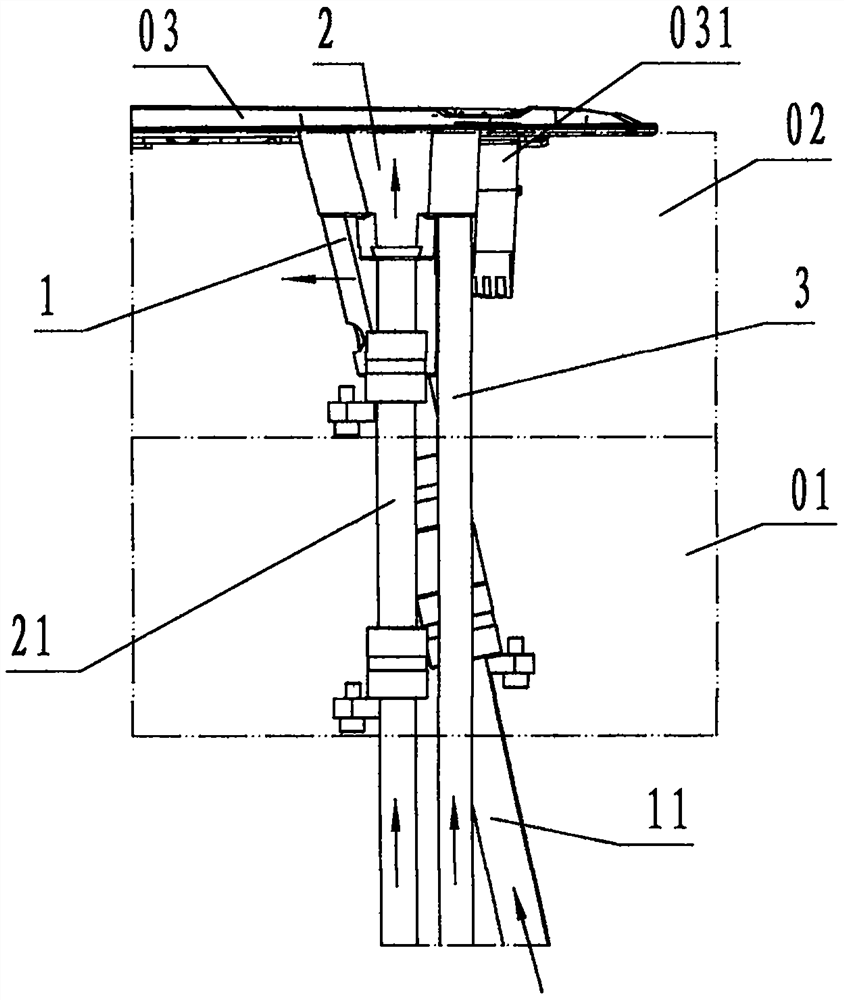

Liquid skimming device, liquid skimming method and centrifugal machine

The invention relates to the technical field of wheat deep processing, in particular to a liquid skimming device, a liquid skimming method and a centrifugal machine. The skimming device comprises a mounting seat, a rotating shaft and a driving part. The mounting seat is arranged on the machine cover of the centrifugal machine. The rotating shaft is rotatably connected to the inner wall of the mounting seat; and the driving part is arranged on the mounting seat and can drive the rotating shaft to rotate. According to the liquid skimming device, the liquid skimming method and the centrifugal machine, a scraper is elastically attached to the surface of a solid-phase material in a rotating mode, when the scraper rotates to be gradually close to the surface of the solid-phase material, the side face of the scraper makes contact with the solid-phase material, and the reasonable contact area is set, so that the pressure of the solid-phase material on the side face of the scraper is larger than the torsion of a spring; the pressure of a viscous material on the side surface of the scraper is smaller than the torsion of the spring, so that the scraper just intrudes into a viscous material layer to scrape the material, the scraper plays a role in automatically limiting and also plays a role in scraping and throwing away the viscous material, and automatic material skimming is realized.

Owner:张家港市金麦穗离心机有限公司

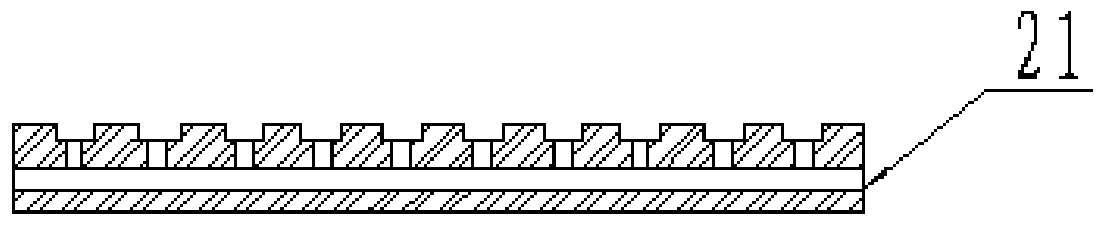

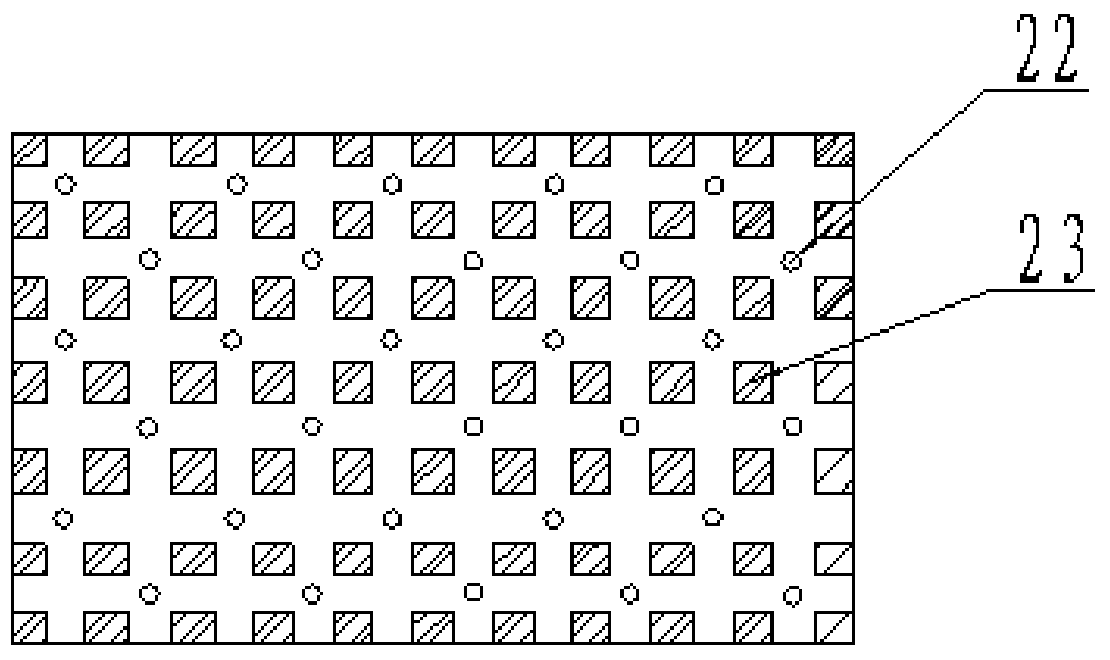

Multi-circle QFN package lead frame manufacturing method

InactiveCN103474358AHigh preparation precisionGuaranteed accuracySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPlastic packaging

The invention relates to a multi-circle QFN package lead frame manufacturing method, and belongs to the technical field of semi-conductor packaging. According to the technical scheme, the multi-circle QFN package lead frame manufacturing method comprises the following steps that 1 a substrate is provided and needed lead foot graphs are formed on the front face of the substrate; 2 multiple circles of needed outer lead feet are formed on the substrate by the utilization of the lead foot graphs on the substrate; 3 a needed packaging chip is arranged on the substrate and the packaging chip is electrically connected with the outer lead feet on the substrate through connecting lines; 4 plastic packaging is conducted on the packaging chip on the substrate to obtain a plastic packaging body, and the plastic packaging body enables the packaging chip, the connecting lines and the outer lead feet to be pressed on the substrate in a covering mode; 5 etching is conducted on the back face of the substrate so as to separate the packaging chip from the outer lead feet. According to the multi-circle QFN package lead frame manufacturing method, the structure is compact, the technology is simple and convenient to implement, the compatibility is good, the cost is low, and the machining precision and the machining efficiency are high.

Owner:NAT CENT FOR ADVANCED PACKAGING

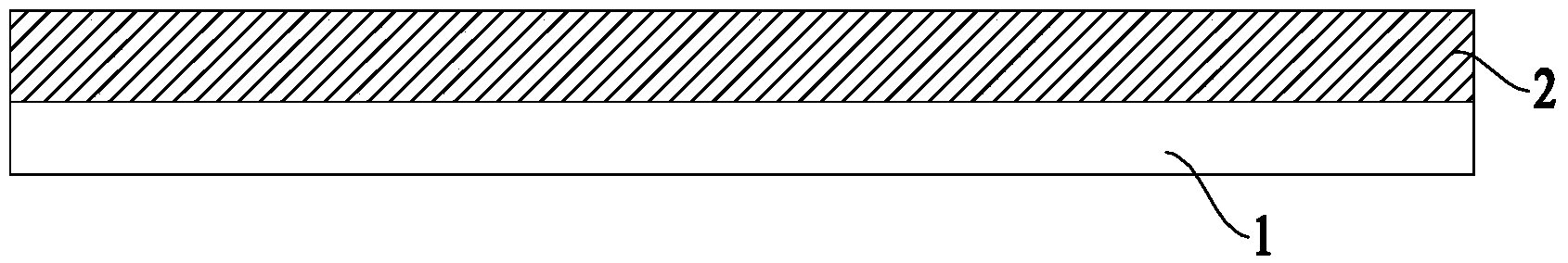

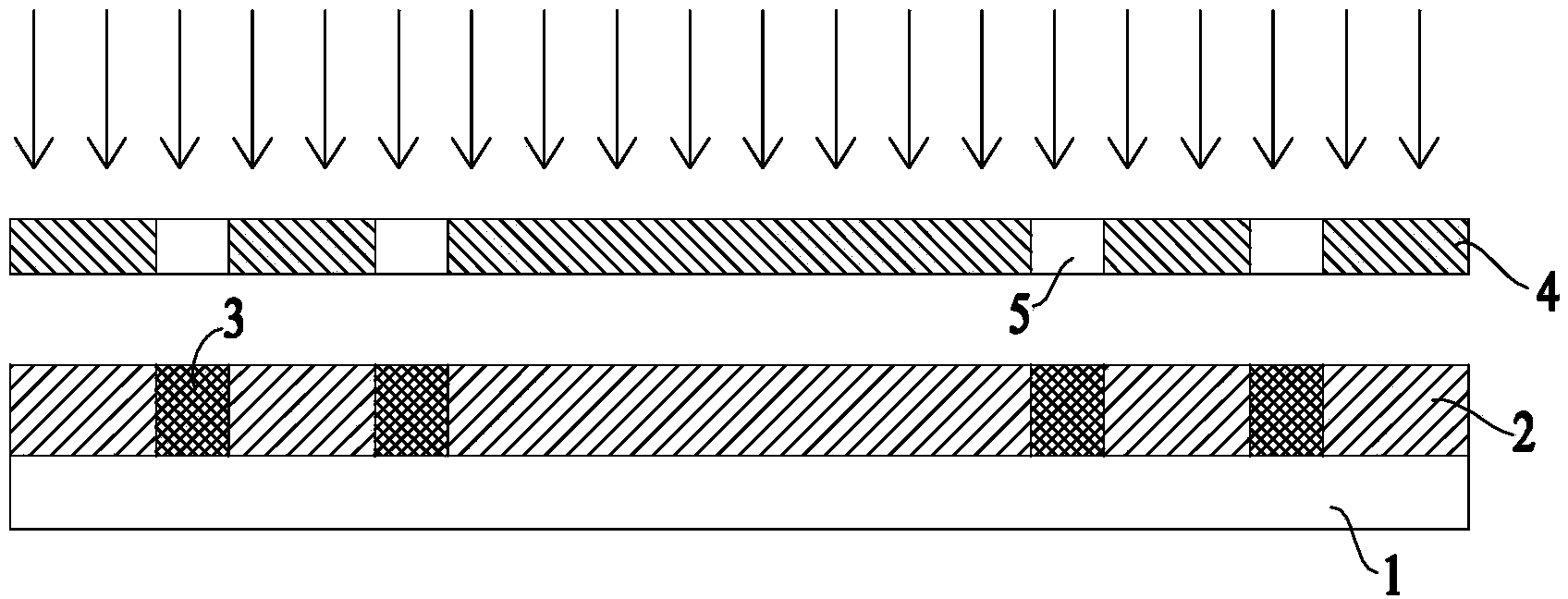

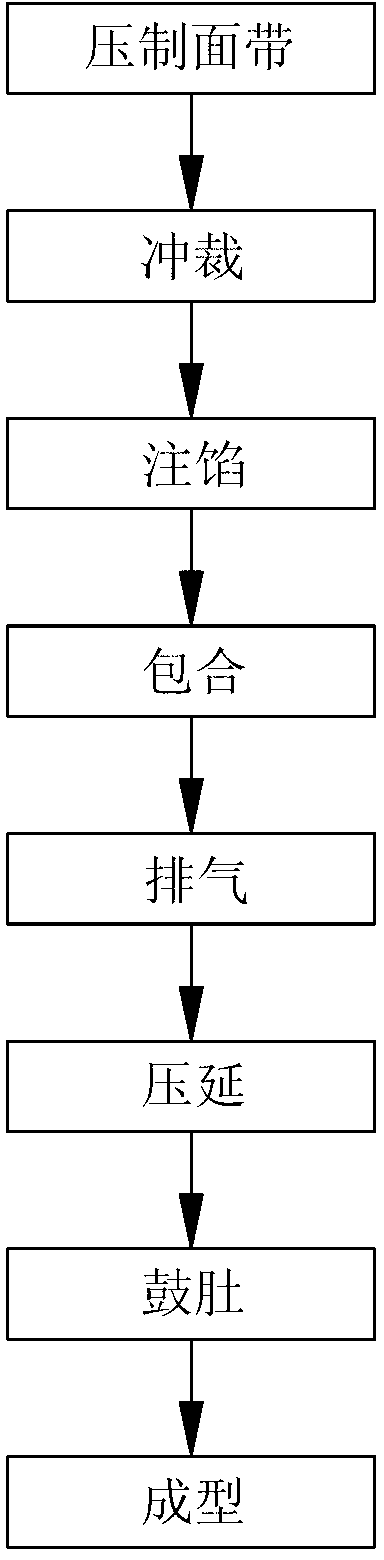

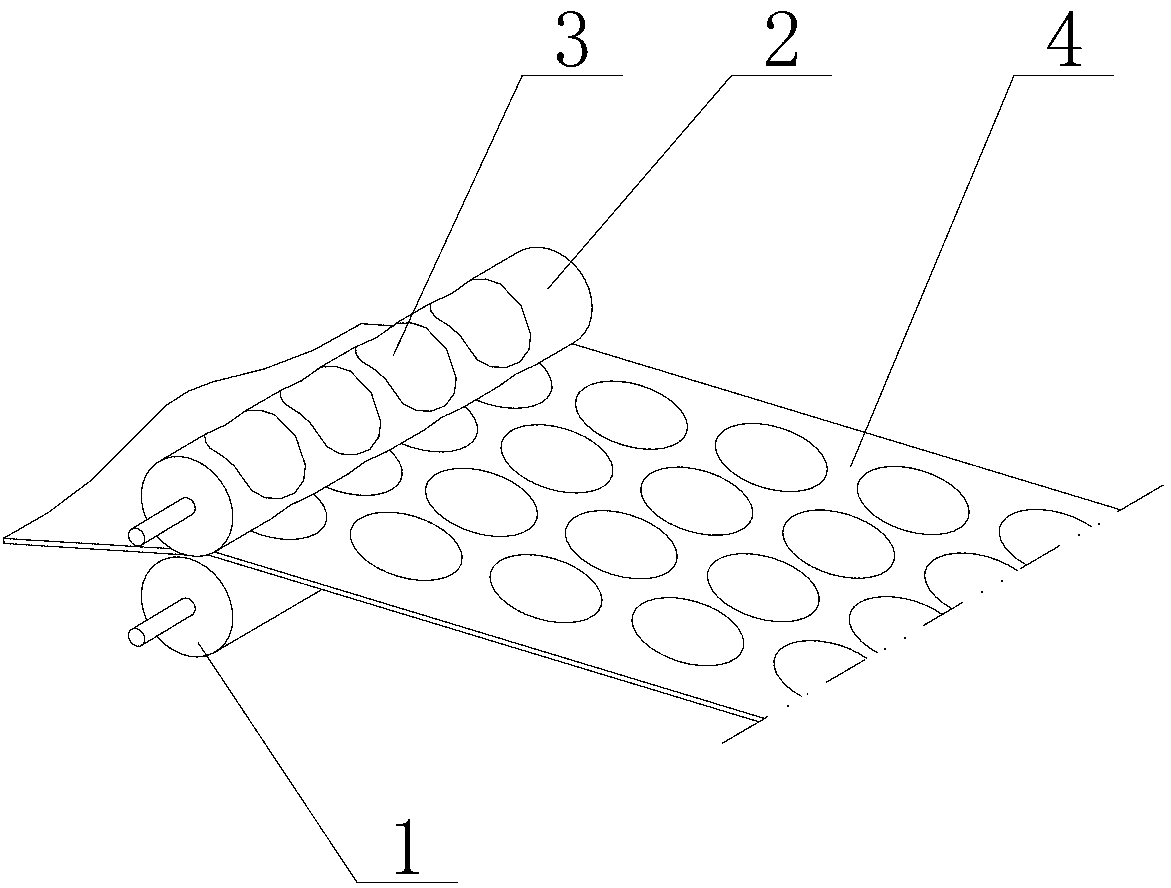

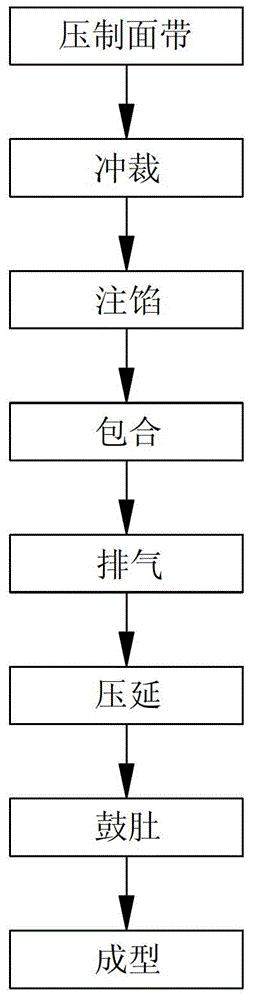

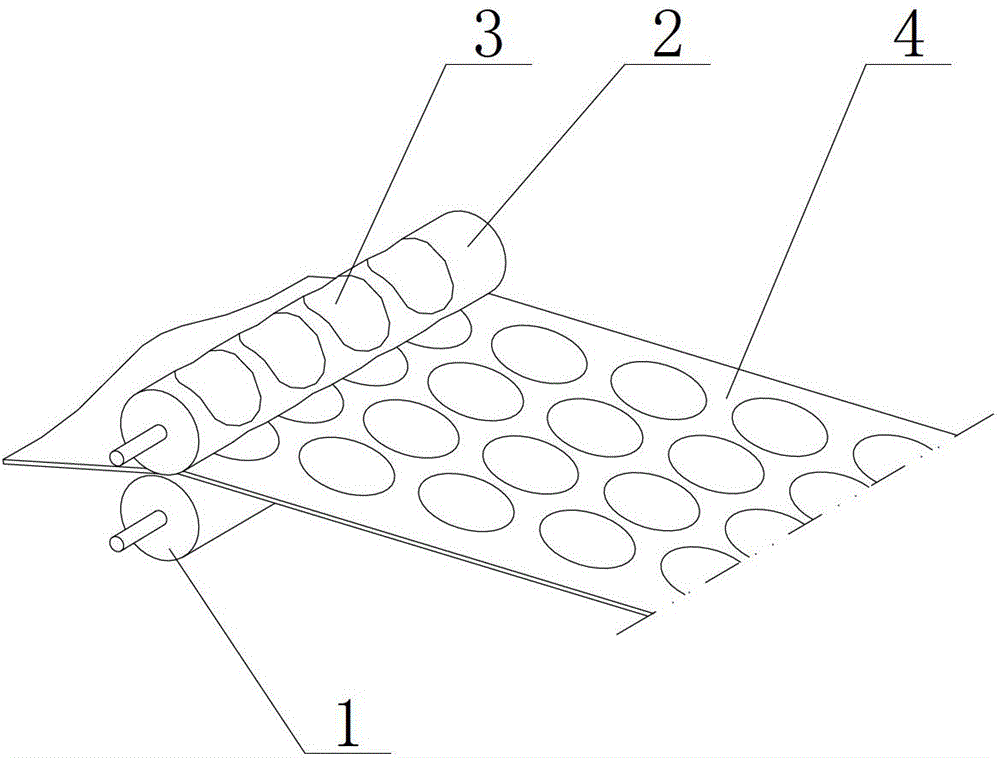

Automatic imitation handmade dumpling making process

The invention discloses an automatic imitation handmade dumpling making process comprising the following steps of: adopting a molding surface pressing roller to prepare a molded flour belt of an island-shaped wrapper with a thick middle part and a thin periphery; adopting a punching die to punch and cut the molded flour belt into a dumpling wrapper with the thick middle part and the thin periphery, which is made in an imitation handmade manner; quantitatively adding dumpling stuffing on the prepared dumpling wrapper; covering the dumpling stuffing by the dumpling wrapper through adopting an edge sealing die; pressing one part of a skirt edge and virtually pressing the other part of the skirt edge to be used as an air gap; discharging air in a closed dumpling cavity by adopting an air discharging die; utilizing an edge pressing die to roll a skirt edge wrapper; adopting a belly extruding die to squeeze a dumpling stuffing part and stretching the wrapper of a dumpling belly part so that a dumpling stuffing part is downward convex; and utilizing a molding die to correct the appearance of a dumpling with the convex belly, so as to mould. The automatic imitation handmade dumpling making process is simple and feasible; the appearance and the mouth feel of the dumpling produced by the process are similar with the levels of a handmade dumpling, and manual shape correction is not needed; and the requirements on the high-grade dumpling by a market can be met.

Owner:无锡孚德机械制造有限公司

Pneumatic ram fully sealed feeding and discharging port of plastic powder mixing drum

The invention discloses a full-sealed feeding and discharging hole of a pneumatic shutter of a plastic powder mixing cylinder. The full-sealed feeding and discharging hole comprises a cylinder body of the mixing cylinder, wherein a feeding and discharging hole is formed in the cylinder body. The full-sealed feeding and discharging hole is characterized in that a cover plate is arranged around the feeding and discharging hole, a shutter base is arranged on the cover plate, a left shutter groove and a right shutter groove are respectively formed in the left side and the right side of the shutter base, pressing plates are arranged on the left shutter groove and the right shutter groove, a left shutter and a right shutter are respectively arranged between the left shutter groove and the corresponding pressing plate and between the right shutter groove and the corresponding pressing plate, the inner end faces of the left shutter and the right shutter are in contact and are provided with sealing devices, the outer side end of the left shutter is connected with a left cylinder, the outer side end of the right shutter is connected with a right cylinder, and the left cylinder and the right cylinder respectively drive the left shutter and the right shutter to be opened or closed. The cylinders automatically drive the shutters to be opened or closed, and thus the full-sealed feeding and discharging hole is suitable for automatic production, and is high in speed, good in sealing property and high in production efficiency.

Owner:ZHEJIANG CHENTAI DECORATION MATERIAL

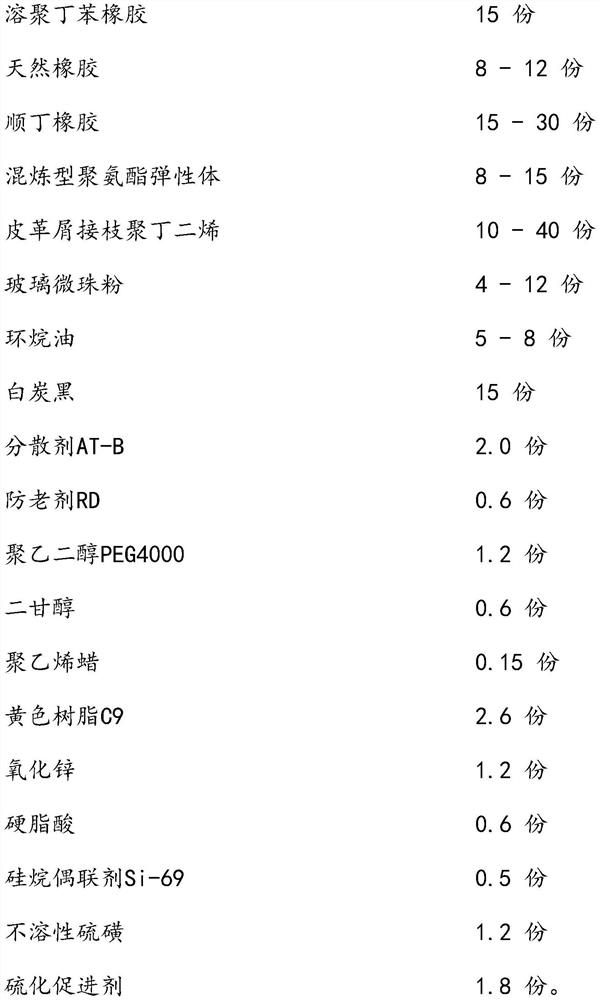

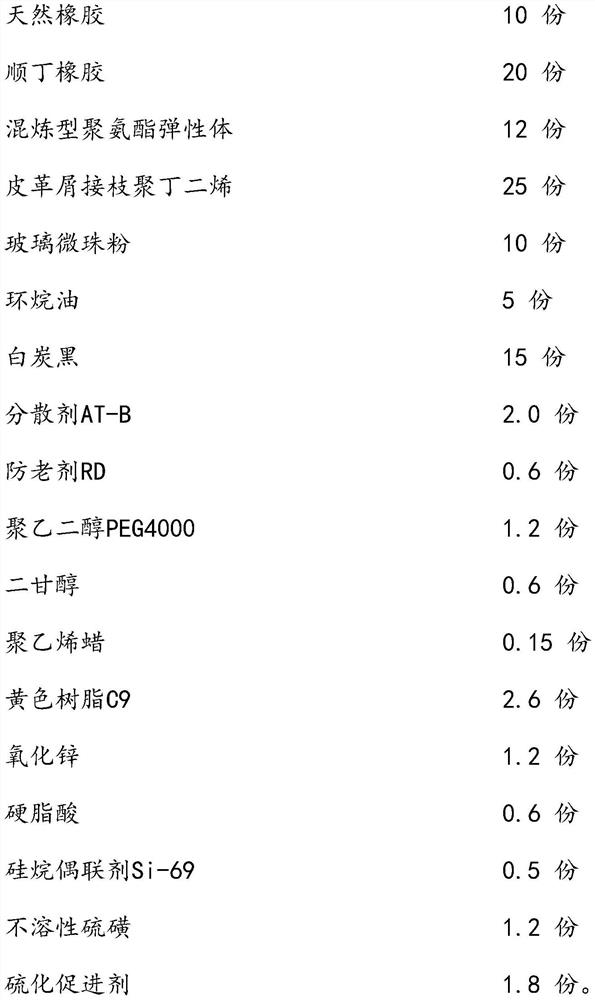

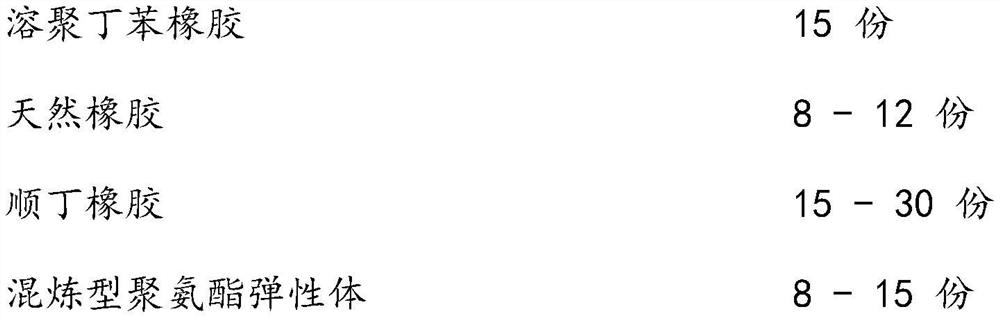

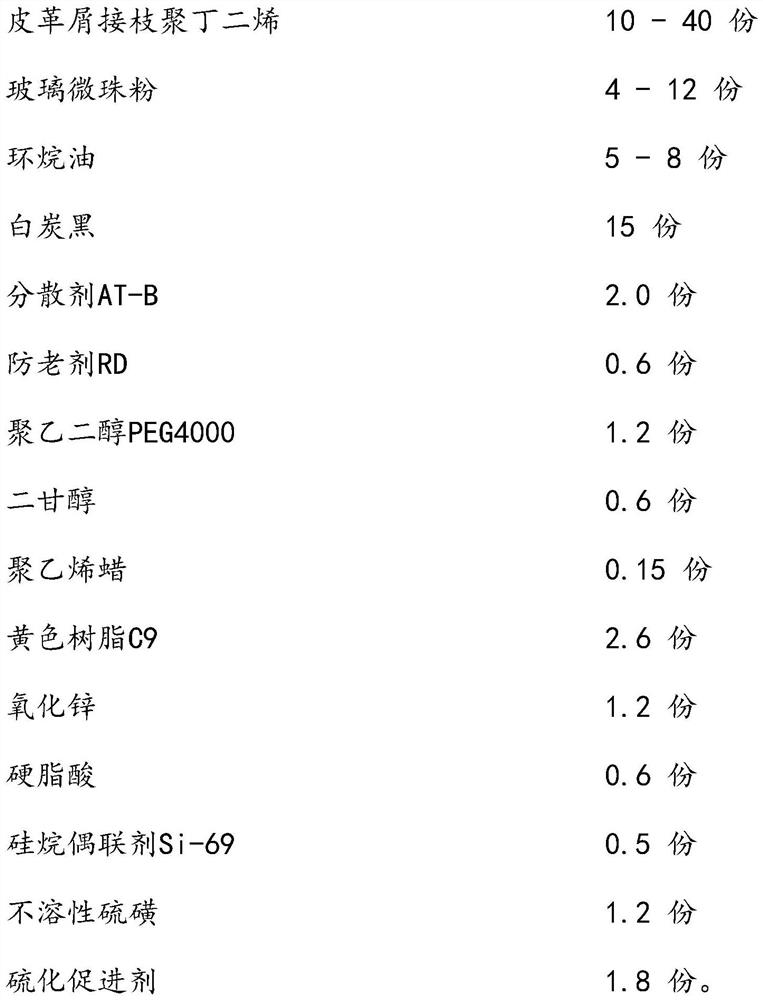

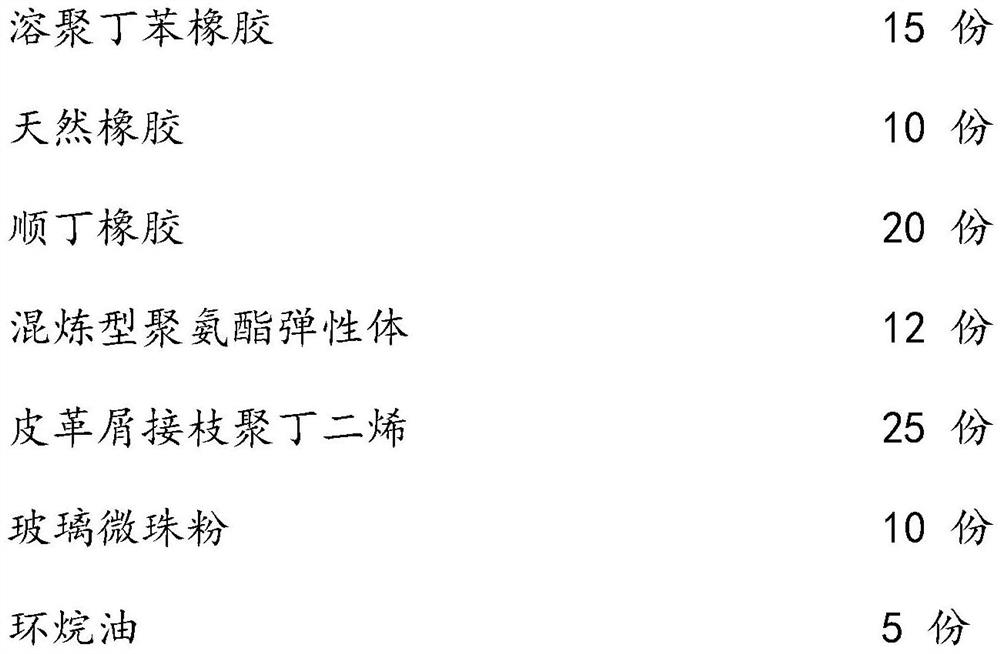

Leather scrap modified rubber outsole and preparation method thereof

The invention discloses a leather scrap modified rubber outsole and a preparation method thereof. The leather scrap modified rubber outsole comprises, by weight, 15 parts of solution polymerized styrene-butadiene rubber, 8-12 parts of natural rubber, 15-30 parts of butadiene rubber, 8-15 parts of a mixed polyurethane elastomer, 10-40 parts of leather scrap grafted polybutadiene, 4-12 parts of glass beads, 5-8 parts of naphthenic oil, 15 parts of white carbon black, 2.0 parts of a dispersing agent ATB, 0.6 part of an anti-aging agent RD, 1.2 parts of polyethylene glycol PEG4000, 0.6 part of diethylene glycol, 0.15 part of polyethylene wax, 2.6 parts of yellow resin C9, 1.2 parts of zinc oxide, 0.6 part of stearic acid, 0.5 part of a silane coupling agent Si-69, 1.2 parts of insoluble sulfurand 1.8 parts of a vulcanization accelerator. The rubber modified outsole with excellent performance is obtained on the basis of fully utilizing leather wastes.

Owner:MAOTAI FUJIAN SOLES CO LTD

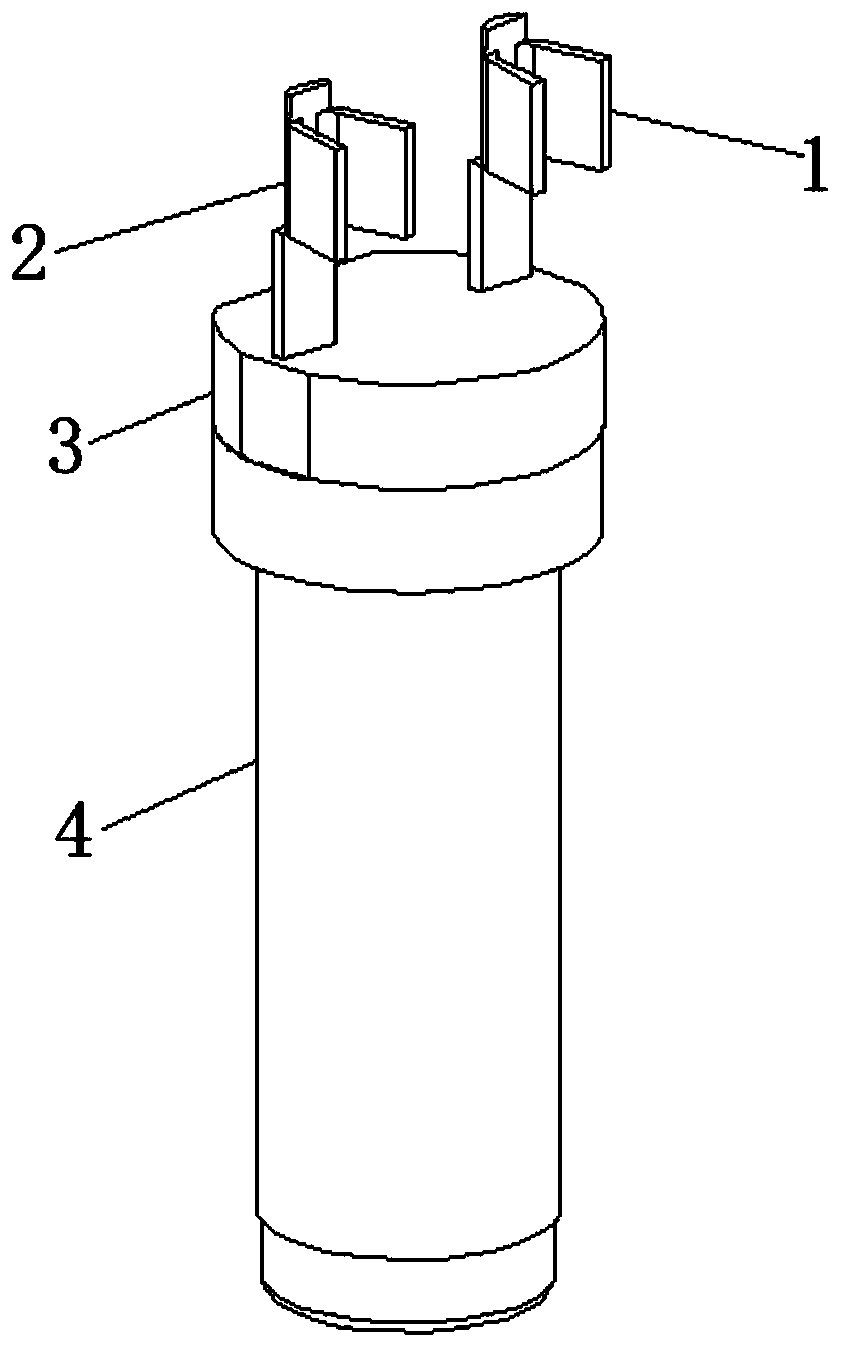

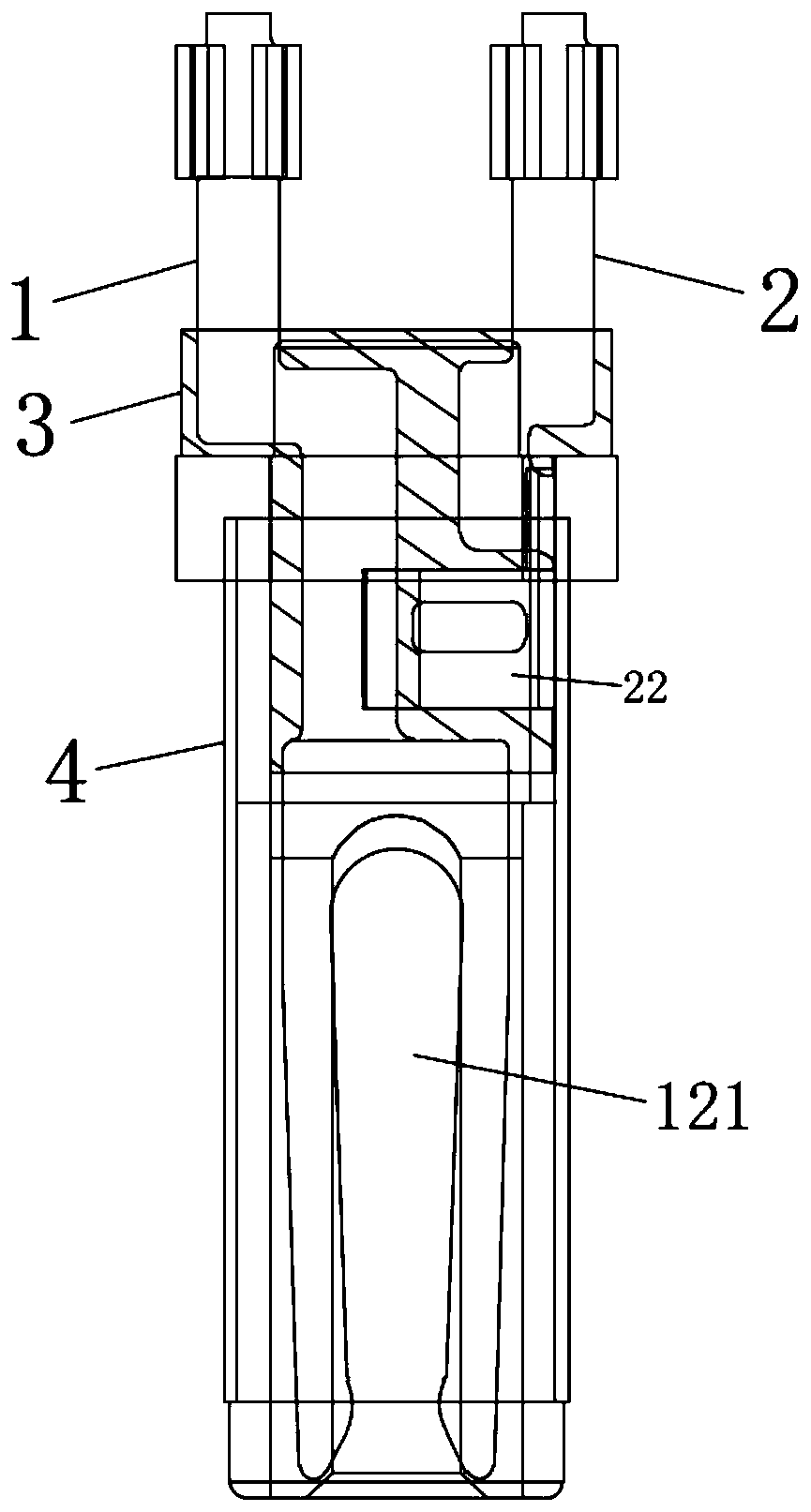

Integrated wire-wound DC tuning fork, plug and method for manufacturing the same

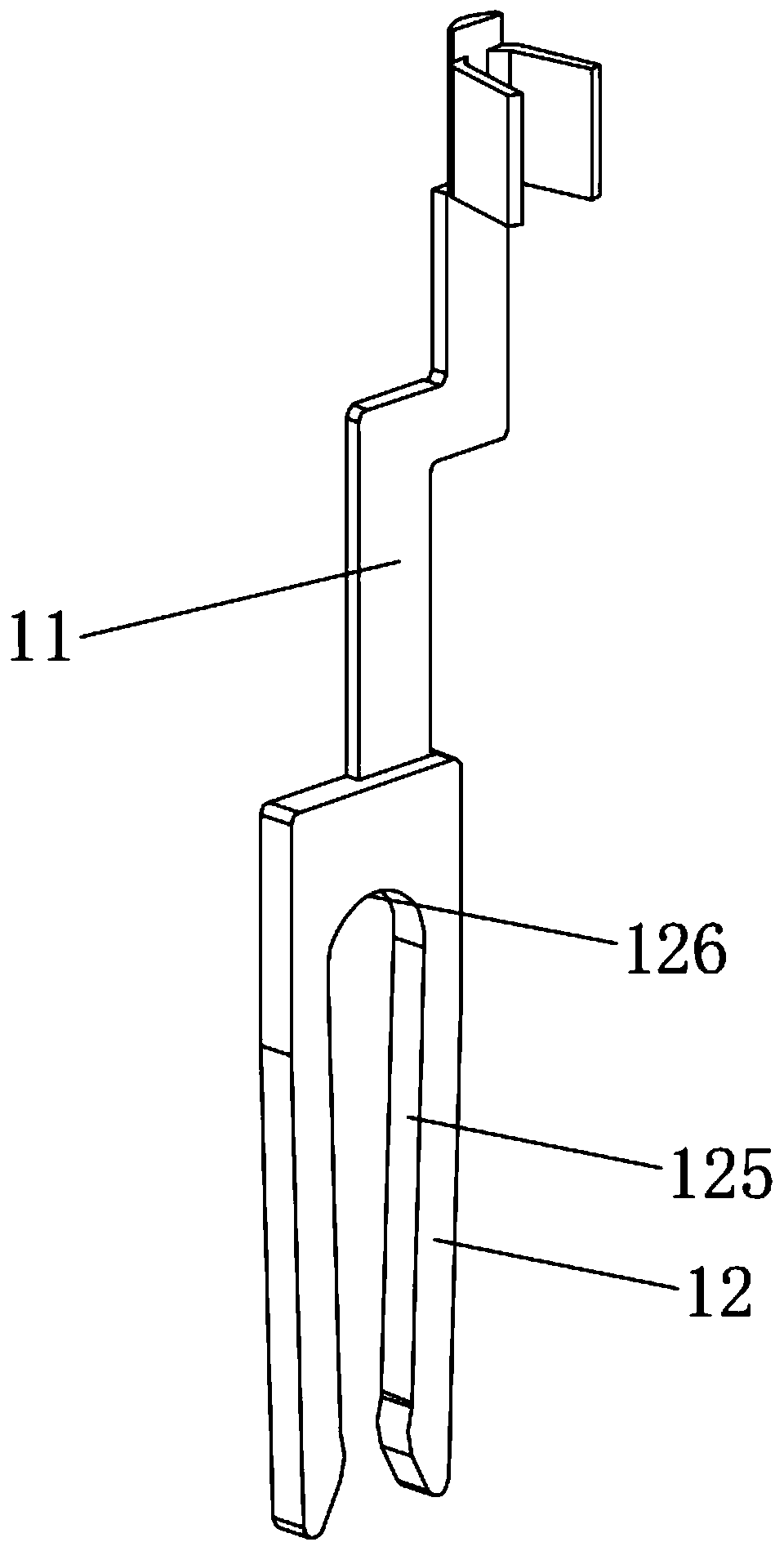

PendingCN109830827AImprove reliabilityIncrease productivityContact member manufacturingContact member assembly/disassemblyTuning forkEngineering

The invention relates to an integrated wire-wound DC tuning fork and a method for manufacturing the same. The integrated wire-wound DC tuning fork comprises a first electrode, wherein the first electrode comprises a conductive connecting piece and a contact elastic piece; the conductive connecting piece has a thickness less than that of the contact elastic piece; the conductive connecting piece and the contact elastic piece are integrally formed by blanking; the contact elastic piece comprises a fixing piece, a first elastic tuning fork arm and a second elastic tuning fork arm; the first elastic tuning fork arm and the second elastic tuning fork arm are vertically and fixedly disposed on both sides of the fixing piece in the longitudinal direction respectively. The integrated wire-wound DCtuning fork improves the structure of a lead terminal, avoids soldering, and is simpler and faster in process than a conventional tuning fork. In addition, the integrated structure provides no soldering point for the conductive connecting piece and the contact elastic piece, thereby avoiding quality problems caused by soldering.

Owner:余志林

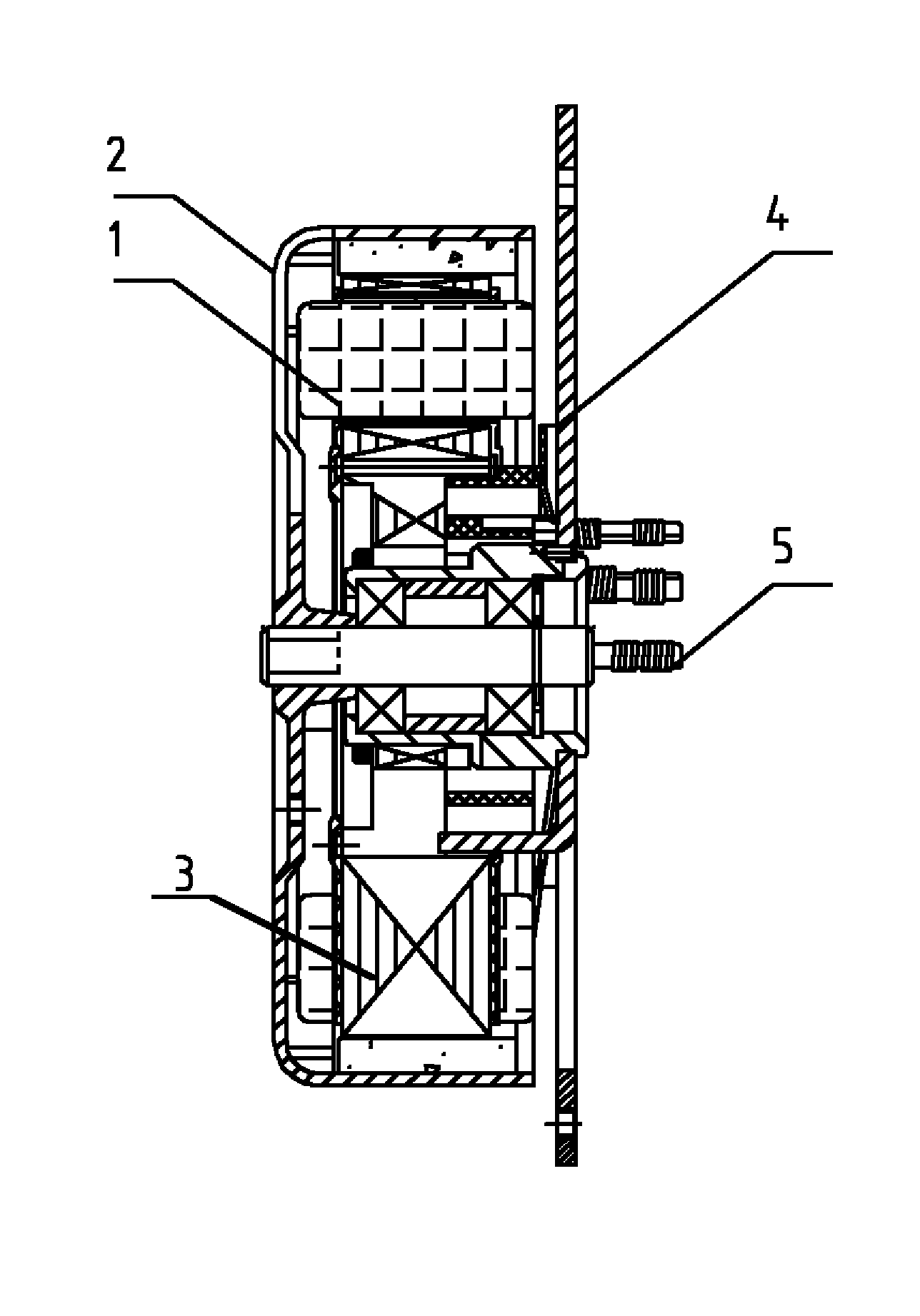

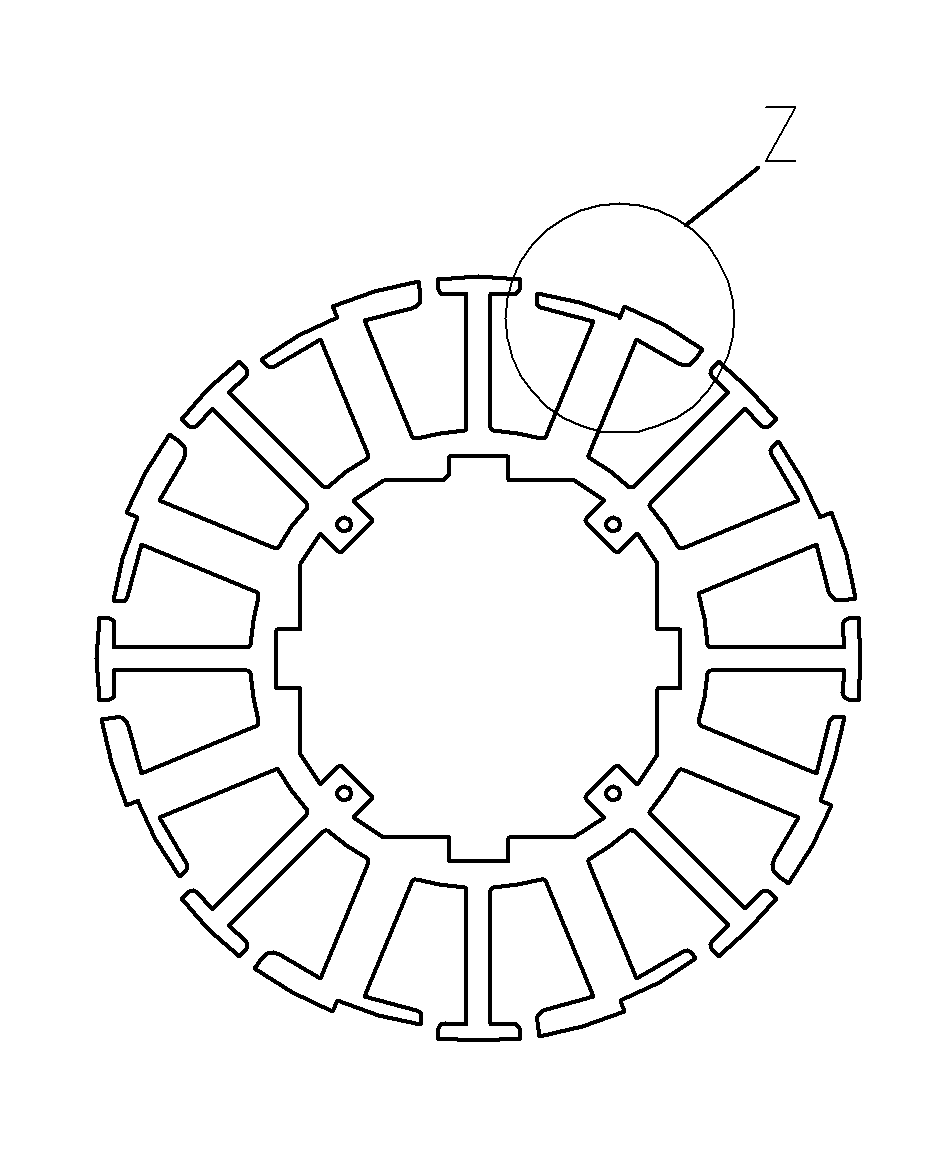

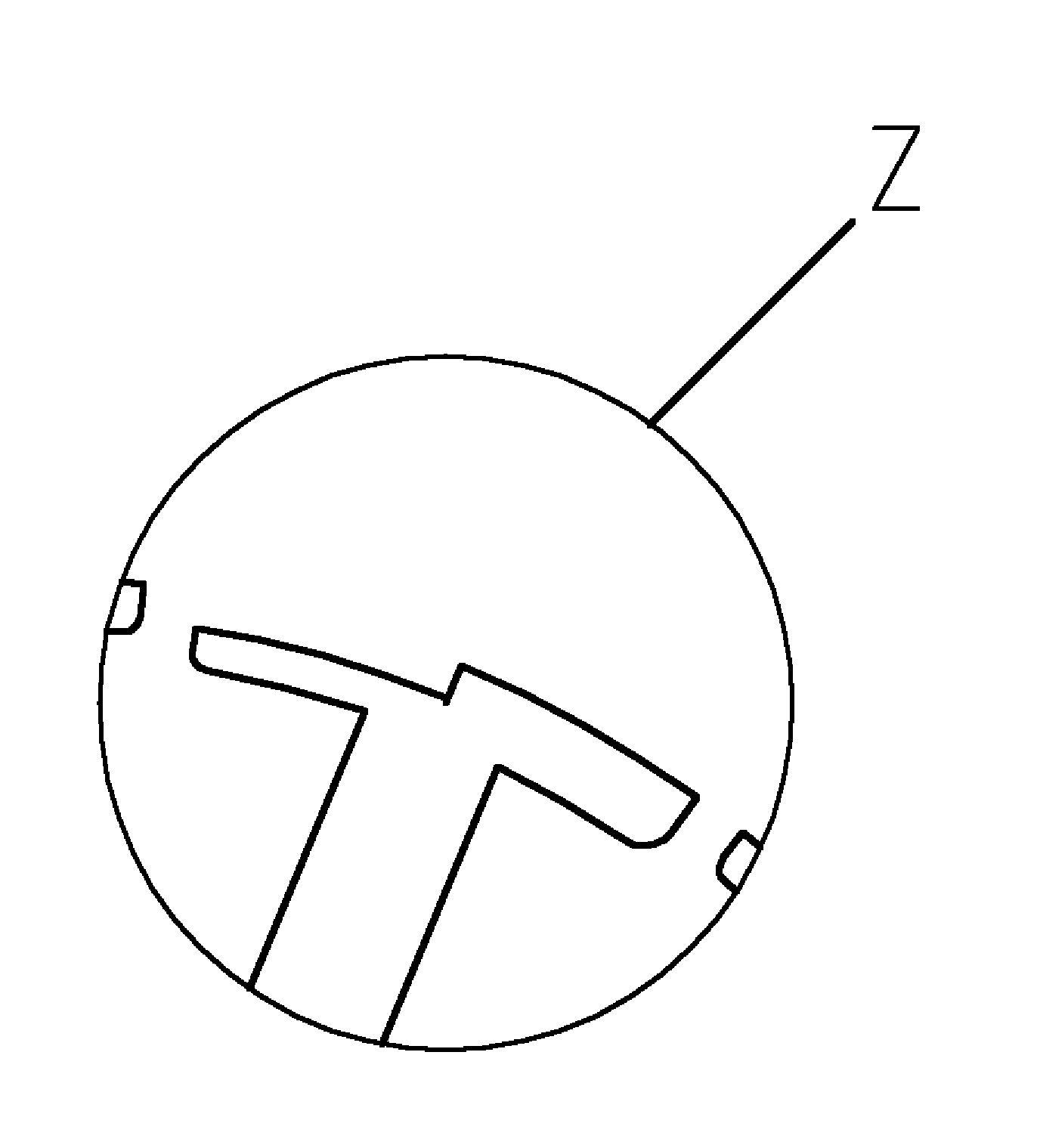

Brushless permanent magnet direct current motor for automobile

InactiveCN102255465AImprove reliabilityAdapt to automated productionWindings insulation shape/form/constructionMagnetic circuit stationary partsInsulation systemPermanent magnet direct current

The invention provides a brushless permanent magnet direct current motor for an automobile. The brushless permanent magnet direct current motor has a compact and reasonable structure. A controller has a good controlling effect, a rotor rotates in a predetermined direction, and high reliability is achieved. The brushless permanent magnet direct current motor comprises a stator, an outer rotor and an insulating system, and is characterized in that: the circular-arc top surface of a T-shaped toothed part of the stator is provided with a gap according to a magnetic path; and a rotating magnetic field is formed around the gap.

Owner:WUXI SOUTHEAST VEHICLE TECH

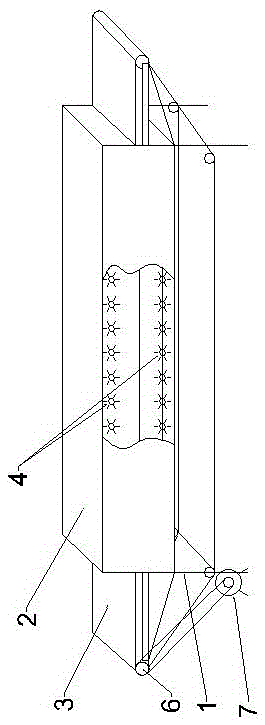

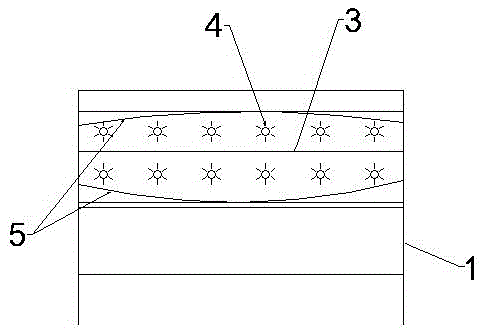

A light decolorization device for producing white pepper

InactiveCN104431983BImprove luminous efficiencyLow calorific valueSolid materialFood ingredient functionsProduction lineEngineering

The invention provides an illuminating and decolorizing device for producing white peppers; the illuminating and decolorizing device comprises a frame, a decolorizing tunnel and a conveying belt; the belt is installed on the frame; the decolorizing tunnel is installed at the upper part of the frame and covers the upper, lower and two sides of the top of the frame; two layers of light sources are arranged in the decolorizing tunnel and are respectively located above or below the belt surface of the conveyor belt at the top of the frame; an upper arc light collecting plate with a downward internal arc surface is arranged above the light source at the upper layer and a lower arc light collecting plate with an upward internal arc surface is arranged below the light source at the lower layer. The traditional drying process in the Sun is replaced by an illuminating tunnel in favor of photoxidation for chlorophylls of peppers. The transportation with a net belt and the variable-frequency control are utilized to facilitate the controlling of illumination time and are applicable to automatic production of production lines.

Owner:湖南瑞莱斯卡科技有限公司

Quantitative, fixed-point multi-station grain automatic feeding device and method

ActiveCN106219260BRealize automatic blanking operationAutomatic dropConveyorsLoading/unloadingAutomatic controlEngineering

The invention discloses a quantitative and point-fixed multi-station grain automatic unloading device and a method. The device comprises an embedded scrapper conveyor; an automatic unloading device is mounted at the bottom of a conveying belt of the embedded scraper conveyor; a cache barrel is mounted at the bottom of the automatic unloading device; support angle steel is fixed at the outer wall periphery of the cache barrel; a static weighing balance is arranged at the bottom of the support angle steel, and is supported and mounted on a stand column; the stand column is supported on a baseplate; an unloading cylinder is mounted at the bottom of the cache barrel; a pneumatic discharge mechanism is mounted on the unloading cylinder; a fixed-point rotary unloading device is mounted rightly below the unloading cylinder; and multiple dipping cylinders are correspondingly arranged below the fixed-point rotary unloading device. The device can realize automatic grain weighing operation, can realize automatic unloading, can realize fixed-point unloading through automatic control in the unloading process, and can perform the feeding operation of multiple dipping boxes in sequence to improve the dipping efficiency.

Owner:HUBEI DAOHUAXIANG WINE IND +1

An automatic imitation hand-made dumpling process

The invention discloses an automatic imitation handmade dumpling making process comprising the following steps of: adopting a molding surface pressing roller to prepare a molded flour belt of an island-shaped wrapper with a thick middle part and a thin periphery; adopting a punching die to punch and cut the molded flour belt into a dumpling wrapper with the thick middle part and the thin periphery, which is made in an imitation handmade manner; quantitatively adding dumpling stuffing on the prepared dumpling wrapper; covering the dumpling stuffing by the dumpling wrapper through adopting an edge sealing die; pressing one part of a skirt edge and virtually pressing the other part of the skirt edge to be used as an air gap; discharging air in a closed dumpling cavity by adopting an air discharging die; utilizing an edge pressing die to roll a skirt edge wrapper; adopting a belly extruding die to squeeze a dumpling stuffing part and stretching the wrapper of a dumpling belly part so that a dumpling stuffing part is downward convex; and utilizing a molding die to correct the appearance of a dumpling with the convex belly, so as to mould. The automatic imitation handmade dumpling making process is simple and feasible; the appearance and the mouth feel of the dumpling produced by the process are similar with the levels of a handmade dumpling, and manual shape correction is not needed; and the requirements on the high-grade dumpling by a market can be met.

Owner:无锡孚德机械制造有限公司

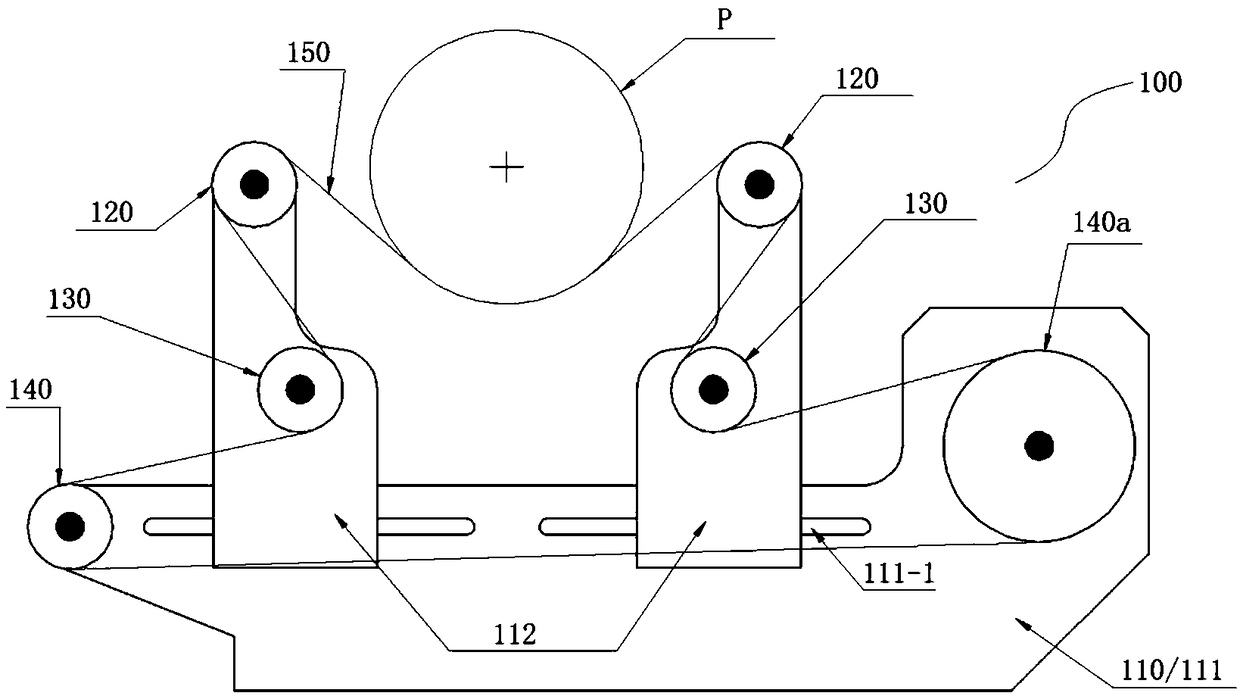

Balance machine drive device

The invention provides a balance machine drive device. The balance machine drive device comprises at least one drive assembly. The drive assembly comprises a drive frame, two positioning wheels and atransmission belt, wherein the positioning wheels are arranged on the drive frame, the transmission belt sleeves the positioning wheels, the two positioning wheels are the same in size and are locatedat the same height position, the circumference of a workpiece is placed on the part, located between the positioning wheels, of the transmission belt, and the transmission belt rotates and drives thesurface of the workpiece to rotate. The balance machine drive device has the beneficial effects that dependence on the actions of the gravity and the friction force of the workpiece, the workpiece isplaced on the transmission belt and directly driven to rotate, a locking and loosening structure and operation steps are not needed, the labor intensity of operators is relieved, and the work efficiency is improved.

Owner:上海剑平动平衡机制造有限公司

Discharging device for nylon heat insulation strip master batch production

ActiveCN113895982AImprove the output effectResidue reductionConveyorsLoading/unloadingNylon materialThermodynamics

The invention discloses a discharging device for nylon heat insulation strip master batch production, and relates to the field of nylon material production equipment. The discharging device comprises a shunting box, an adjusting rod, an elastic sealing film and a discharging switch, wherein a plurality of discharging ports are formed in the shunting box; the elastic sealing film seals the discharging ports, a through hole is formed in the elastic sealing film, and the discharging switch is fixedly connected with the through hole; the adjusting rod is in sliding fit with the shunting box, and the bottom end of the adjusting rod is matched with the discharging switch; and the adjusting rod is provided with a first sliding stop point and a second sliding stop point. When the adjusting rod is located at the first sliding stop point, the discharging switch is pressed by the adjusting rod to the side, away from the top wall, of the bottom wall of the shunting box and is in an on state. When the adjusting rod is located at the second sliding stop point, the discharging switch is pulled by the adjusting rod to the side, close to the top wall, of the bottom wall of the shunting box and is in a closed state. The discharging device is convenient to open and close, easy and convenient to control and operate, not prone to material blocking, capable of better adapting to automatic production, simple in structure and capable of being used for constructing a high-coordination automatic production line.

Owner:赣州能之光新材料有限公司

Screw taking structure

InactiveCN110587262AThe process of picking and receiving goods is controllableAdapt to automated productionMetal working apparatusProduction lineCoupling

The invention discloses a screw taking structure, and in particular, relates to a screw fastening operation automatic mechanical structure, particularly a screw taking structure for collection at thetail end of a production line. The screw taking structure comprises a lead screw mechanism, a lead screw motor, a taking motor and a taking jaw head; the lead screw motor is connected with the lead screw mechanism through a coupling; a lead screw is driven to rotate; a thread is arranged on the lead screw of the lead screw mechanism; through rotation of the lead screw, a slide block is driven to move left and right; the taking jaw head is connected with the slide block on the lead screw mechanism through a screw; the taking jaw head forms a whole circle by two fixed and rotary arcs; a tooth belt is arranged on the rotary arc; and a gear is mounted on a motor shaft of the taking motor through a structural part, and is engaged with the tooth belt on the taking jaw head to drive the taking jaw head to close or open. The screw taking structure has the beneficial effects of controllable taking and collecting process and adaption to automatic production.

Owner:南京北凌网络科技有限公司

An intelligent production system for the whole process of automobile bumper from injection molding to spraying

ActiveCN110948778BEfficient crawlingAvoid misproductionDomestic articlesSmart factoryIndustrial robotics

The invention discloses an intelligent production system for an automobile bumper in a whole course from injection molding to spraying. The system comprises an injection molding system, a carrying system, a caching system, a hanging system and a master control system. The injection molding system comprises an injection molding machine, a mold replacing table, an adjustable grasper, an industrial robot, a bar type confirming camera, a long segment conveyor belt, a material shearing unit and a short segment adjusting belt. The carrying system comprises a carrying RGV, a wireless power supply system and a guide rail. The intelligent production system can achieve functions of visual recognition, adaptive grasping, excessive material trimming, carrying, intelligent warehouse selection, precisehanging, automatic mold replacing reverse control and the like for different bar types. The intelligent production system can achieve totally unmanned and intelligent production of the automobile bumps of various models from mold injection to hanging process of a coating line, a lot of manual participation is replaced, production and manufacturing with zero stock are achieved, and a local production function of an intelligent plant is achieved.

Owner:柯慕自动化装备(天津)有限公司 +2

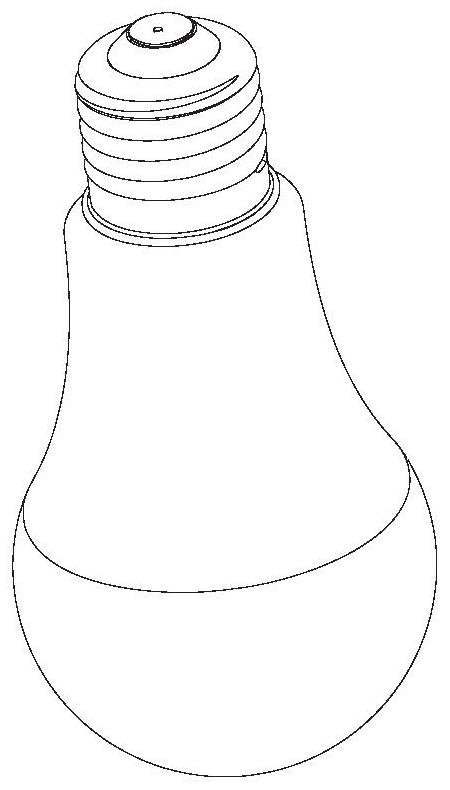

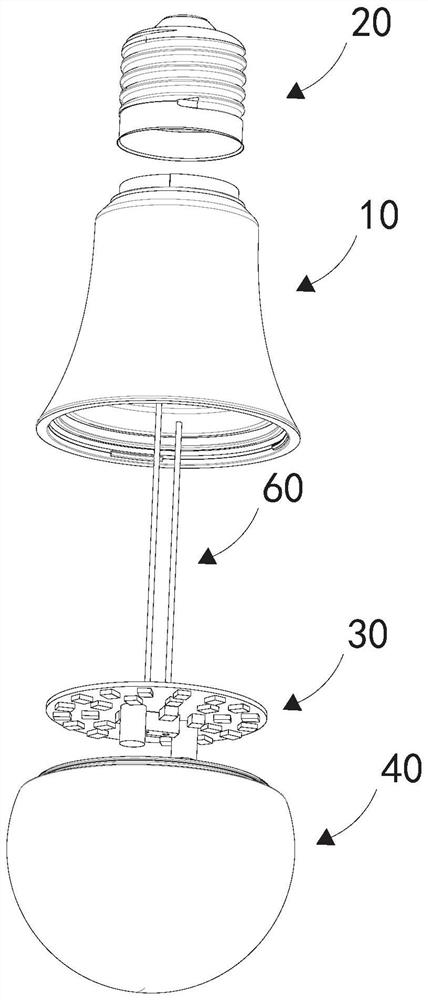

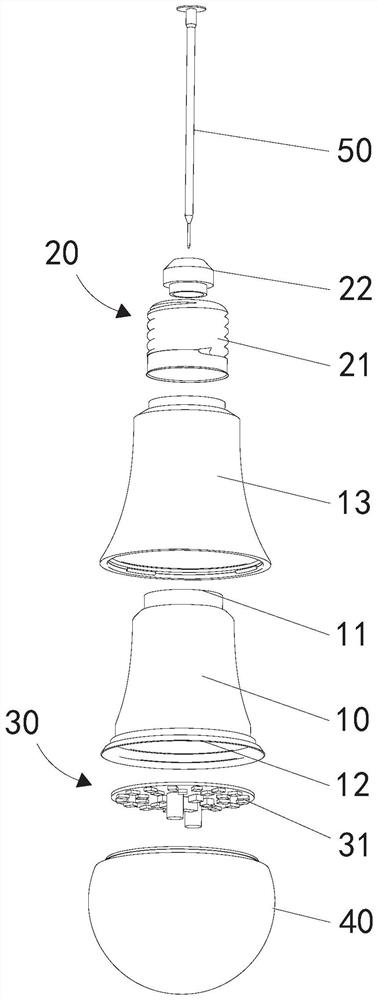

LED lamp without power line

PendingCN114383061ASimplify the assembly processGuaranteed StrengthLighting support devicesElectric circuit arrangementsEngineeringLight head

The LED lamp without the power line comprises a lamp cup, a lamp holder, a lamp panel and a lampshade, and the lamp cup is in a horn shape and is provided with a large head end and a small head end; the lamp cap is connected to the small end and used for being inserted into and / or screwed into the lamp holder. The lamp panel is arranged close to the large head end, and LED lamp beads used for emitting light are arranged on the lamp panel. The lampshade is connected to the large head end and covers the lamp panel. The lamp cup is made of the metal material, the conducting rod is arranged between the lamp holder and the lamp panel, and the conducting rod and the lamp cup are arranged at intervals, so that the strength of the lamp cup can be ensured, the lamp cup and the conducting rod can be utilized to lead the two electrodes of a power supply provided by the lamp holder to the lamp panel from the lamp holder, the LED lamp beads are lightened, the design of a power line is abandoned, the material cost is reduced, and the service life of the LED lamp is prolonged. And the lamp cup and the conducting rod can be conveniently conducted with the lamp holder and the lamp panel through traditional press-fitting operation, the assembly process of the LED lamp is simplified, time and labor are saved, efficiency is high, and the LED lamp can well adapt to automatic production.

Owner:RED100 LIGHTING CO LTD

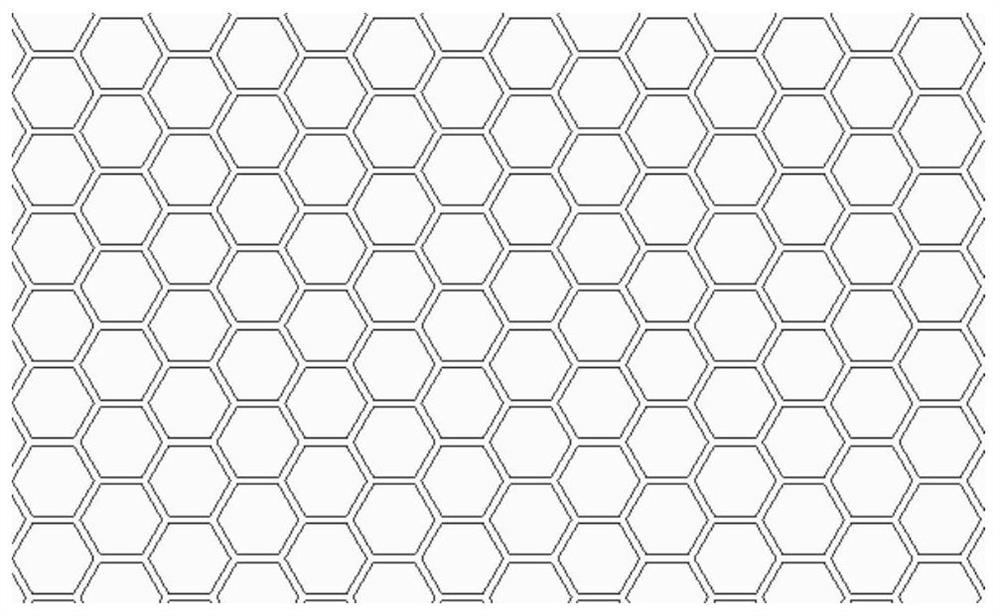

Coating device and coating method

ActiveCN112264246ASimple structureEnsure consistencyLiquid surface applicatorsCoatingsComposite materialCoating

The invention provides a coating device and a coating method. The coating device comprises a fixed table, a coating net and a coating assembly, wherein the coating net is located on the fixed table, the coating net comprises a plurality of hole channels penetrating through the upper surface and the lower surface of the coating net, and a product to be coated is located on the surface of one side of the coating net; the coating assembly is located on the surface of the other side of the coating net; and the coating assembly coats the coating net with a coating medium, so that the coating mediumpermeates into the hole channels and makes contact with the surface of the product to be coated. The coating device is simple in structure and easy to implement and apply, uniform coating of the coating medium on the surface of the product to be coated can be completed through the coating device, meanwhile, the coating thickness is controllable, especially, the consistency of the surface coatingquality and the coating process of the product to be coated can be guaranteed in batch production, then the covering amount of each batch of coating media is the same, thus the service life of the product is prolonged, in addition, the production efficiency is high, and the method is suitable for batch and automatic production.

Owner:航天科工空间工程发展有限公司

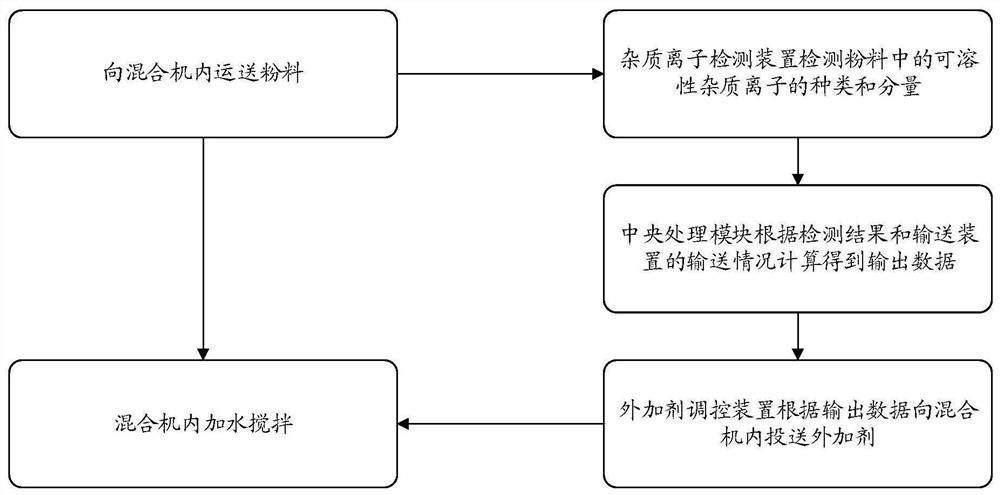

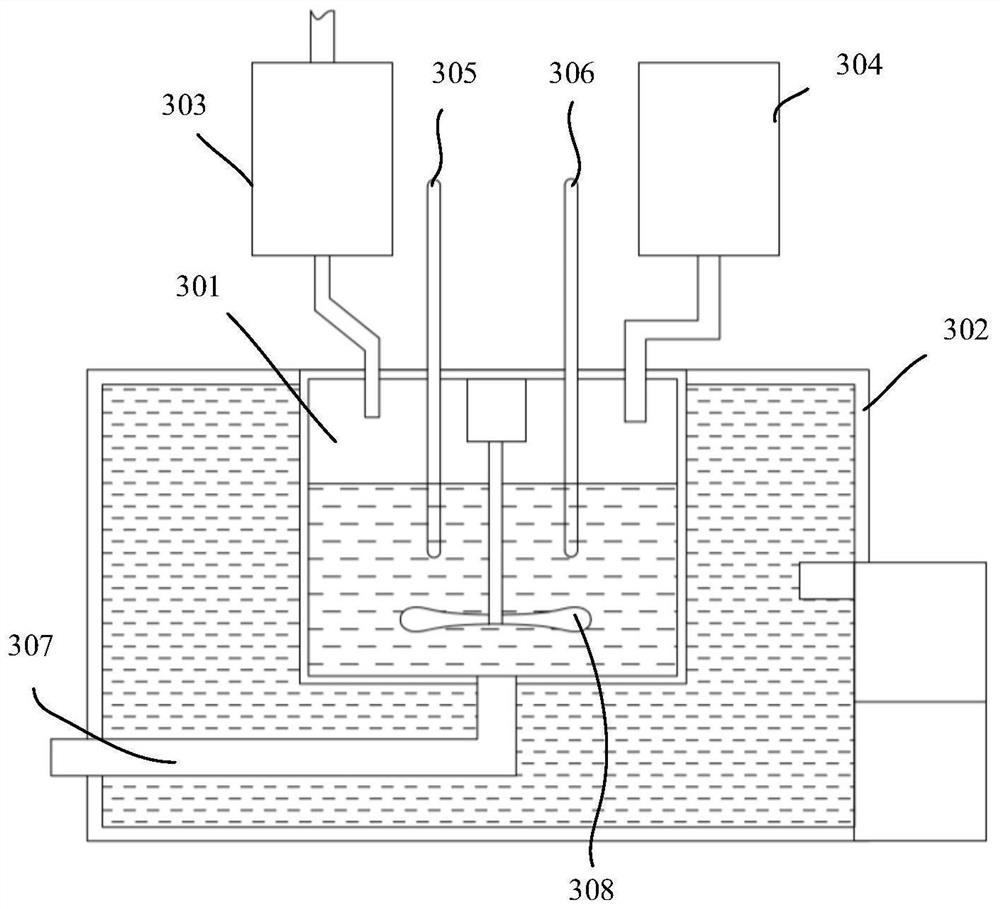

A gypsum board production system

ActiveCN111672355BReduce quality problemsReduce production capacityRotary stirring mixersTransportation and packagingPhysical chemistryImpurity ions

The invention discloses a gypsum board production system, which includes a mixer and a conveying device for providing powder, and includes an impurity ion detection device, and the impurity ion detection device is set corresponding to the conveying device to detect The type and amount of impurity ions provide a basis for the subsequent addition of admixtures. The invention relates to the field of gypsum board production, and provides a gypsum board production system, which can quickly match the admixtures for solidifying soluble impurity ions according to the types and contents of impurity ions in raw materials, so as to achieve the purpose of removing soluble impurity ions in raw materials, reduce The influence of soluble impurity ions on the quality and production process of gypsum board was studied, and the gypsum board was further optimized.

Owner:BEIJING NEW BUILDING MATERIALS PLC +1

A leather shavings modified rubber outsole and preparation method thereof

The invention discloses a leather scrap modified rubber outsole and a preparation method thereof, comprising the following components in parts by weight: 15 parts of solution-polymerized styrene-butadiene rubber, 8-12 parts of natural rubber, 15-30 parts of butadiene rubber, mixing Type polyurethane elastomer 8‑15 parts, leather shavings grafted polybutadiene 10‑40 parts, glass microspheres 4‑12 parts, naphthenic oil 5‑8 parts, white carbon black 15 parts, dispersant AT‑B 2.0 0.6 parts of anti-aging agent RD, 1.2 parts of polyethylene glycol PEG4000, 0.6 parts of diethylene glycol, 0.15 parts of polyethylene wax, 2.6 parts of yellow resin C9, 1.2 parts of zinc oxide, 0.6 parts of stearic acid, silane coupling agent Si ‑69 0.5 parts, insoluble sulfur 1.2 parts, vulcanization accelerator 1.8 parts; the invention realizes a rubber modified outsole with excellent performance on the basis of fully utilizing leather waste.

Owner:MAOTAI FUJIAN SOLES CO LTD

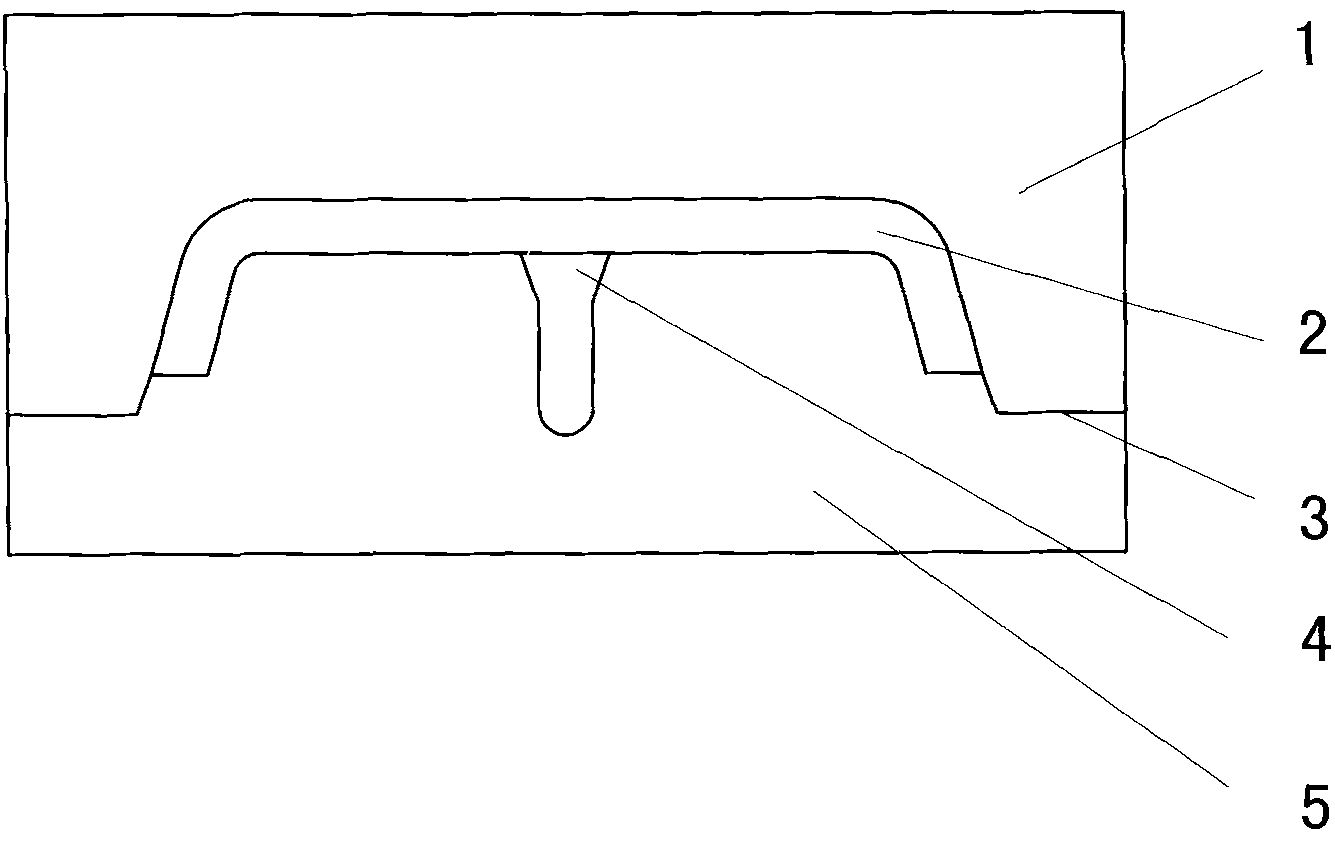

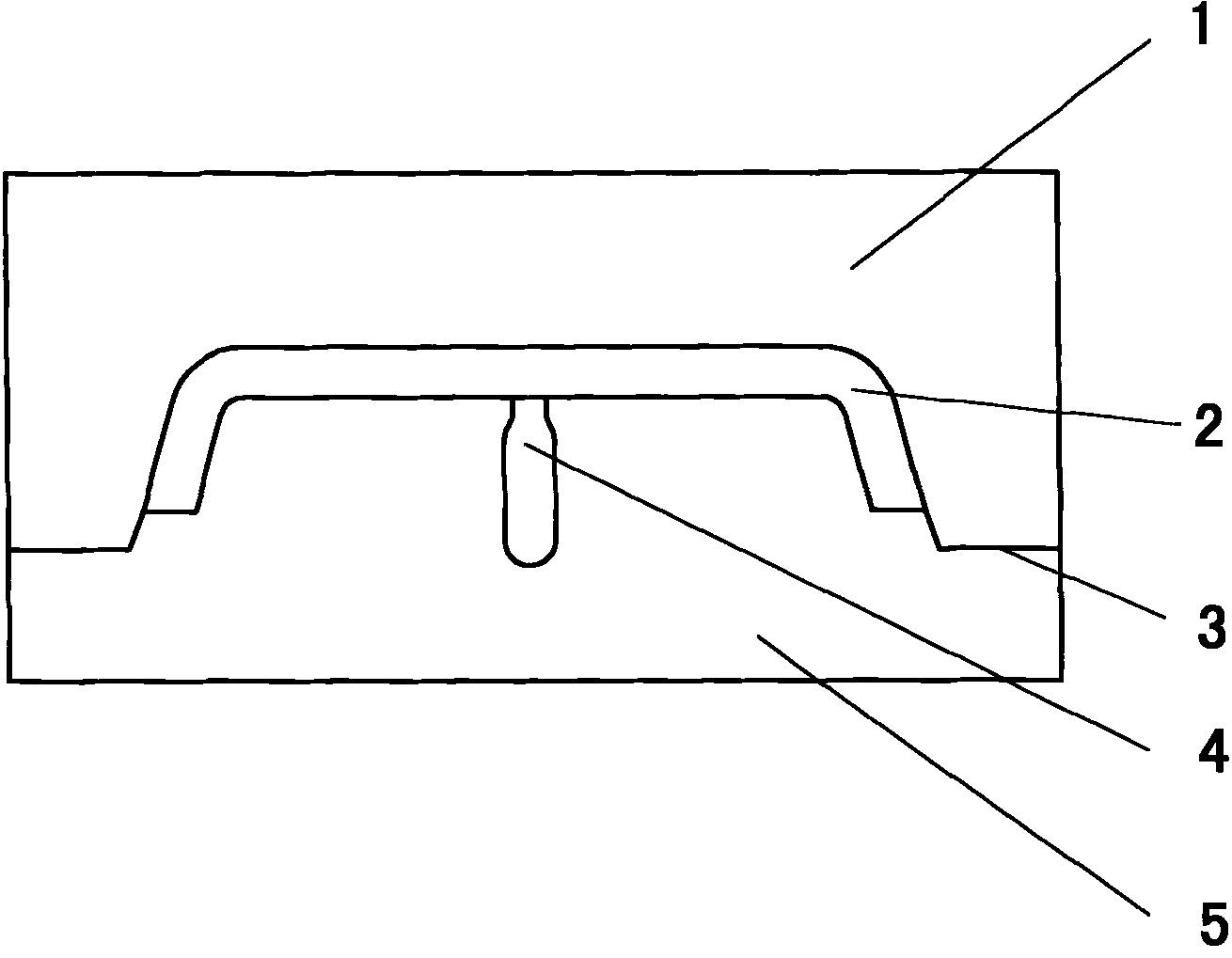

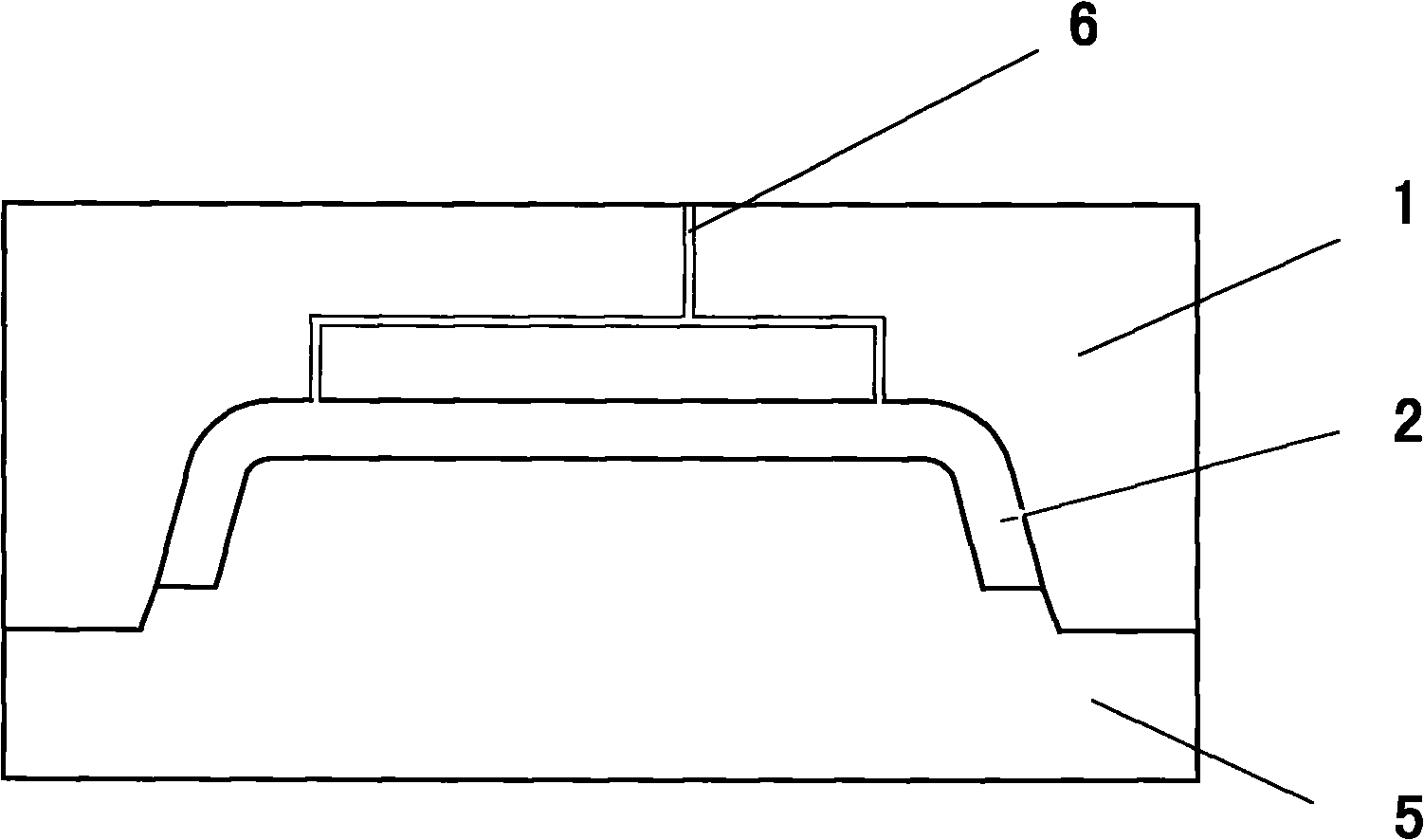

Combined ramp-roof core pulling stripping device for injection mold deep coating dense undercut

PendingCN111976101ASmooth disengagementAvoid twisting damageInjection productUltimate tensile strength

The invention discloses a combined ramp-roof core pulling stripping device for an injection mold deep coating dense undercut. The combined ramp-roof core pulling stripping device comprises a ramp-roofcore pulling block (1), a follow-up stopping ejection block (2) and a distortion stopping ejection rod (3). The ramp-roof core pulling block adopted by the combined ramp-roof core-pulling stripping device is a block-shaped steel component provided with a profile of the deep coating dense undercut, and the ramp-roof core-pulling block is provided with a ramp-roof rod; the follow-up stopping ejection block is a blocky steel component provided with a profile corresponding to an injection product, and the follow-up stopping ejection block is provided with a follow-up stopping ejection rod; the distortion stopping ejection rod is a cylindrical rod-shaped steel component; and during working, the technical scheme that the follow-up stopping ejection block stops the deep coating dense undercut from undercut following, and the follow-up stopping ejection rod and the distortion stopping ejection rod are combined to powerfully stabilize the follow-up stopping ejection block to eliminate distortion damage of the injection product is carried out, and the deep coating dense undercut is stripped through double-rod combined ramp-roof core pulling, so that injection molding production of the injection product with the deep coating dense undercut achieves the purposes of reducing the working intensity, improving the efficiency, reducing the cost and adapting to automatic production.

Owner:宁海县第一注塑模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com