Discharging device for nylon heat insulation strip master batch production

A technology of nylon heat insulation strips and discharge devices, which is applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., and can solve problems such as material jams, obstructions in automated production lines, and inconvenient control of masterbatch discharge equipment switches. Prevent material jamming, improve discharge effect and reduce residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

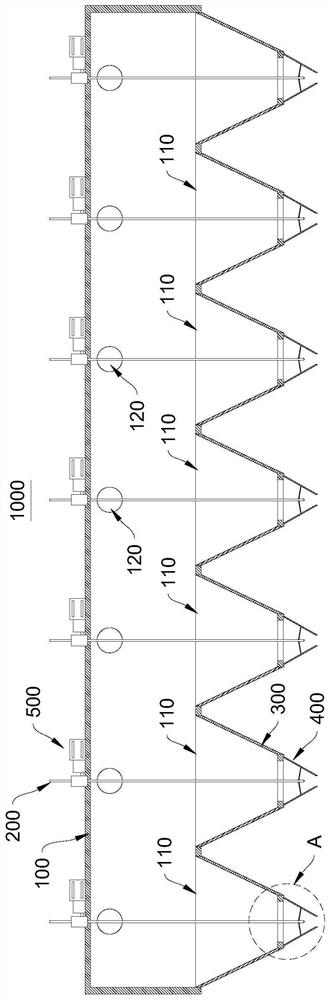

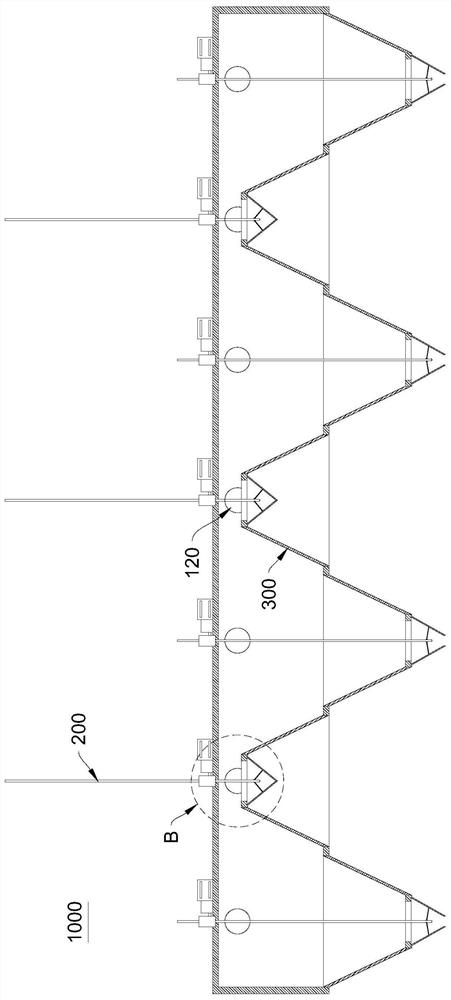

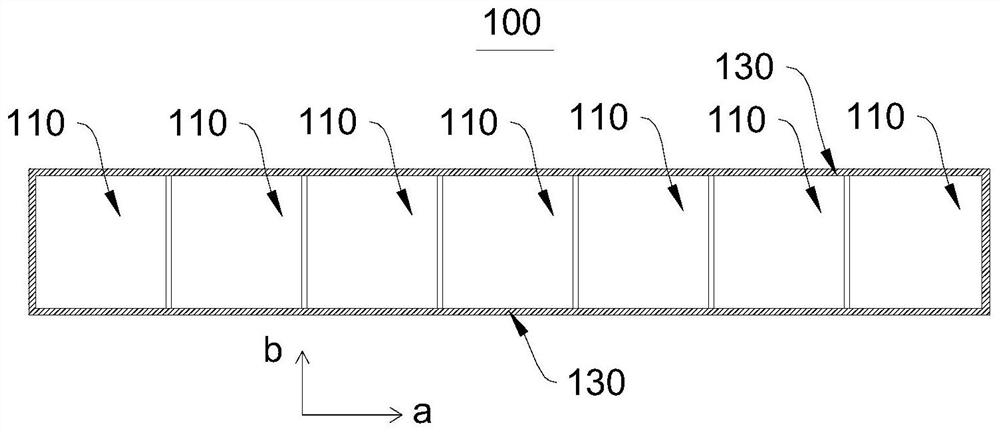

[0046] Please refer to figure 1 and figure 2, this embodiment provides a discharge device 1000 for the production of nylon heat-insulation strip masterbatch. The discharge device 1000 for the production of nylon heat-insulation strip masterbatch includes: a splitter box 100, an adjustment rod 200, an elastic sealing film 300 and a discharge switch 400.

[0047] The bottom wall of the distribution box 100 is provided with a plurality of outlets 110, and the outlets 110 are arranged at intervals, and the distance between two adjacent outlets 110 is less than or equal to 15 mm.

[0048] The edge of the elastic sealing film 300 is connected to the edge of the discharge port 110 and closes the discharge port 110, the middle part of the elastic sealing film 300 is provided with a through hole 310, and the discharge switch 400 is accommodated in the through hole 310 and connected to the Edge fixed connection.

[0049] The adjusting rod 200 is arranged along the height direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com