Patents

Literature

66results about How to "Improve the output effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image feature extraction method and saliency prediction method using the same

InactiveUS20190355126A1Reduce distortion problemsImprove image feature map extraction qualityImage enhancementImage analysisFeature extractionImaging Feature

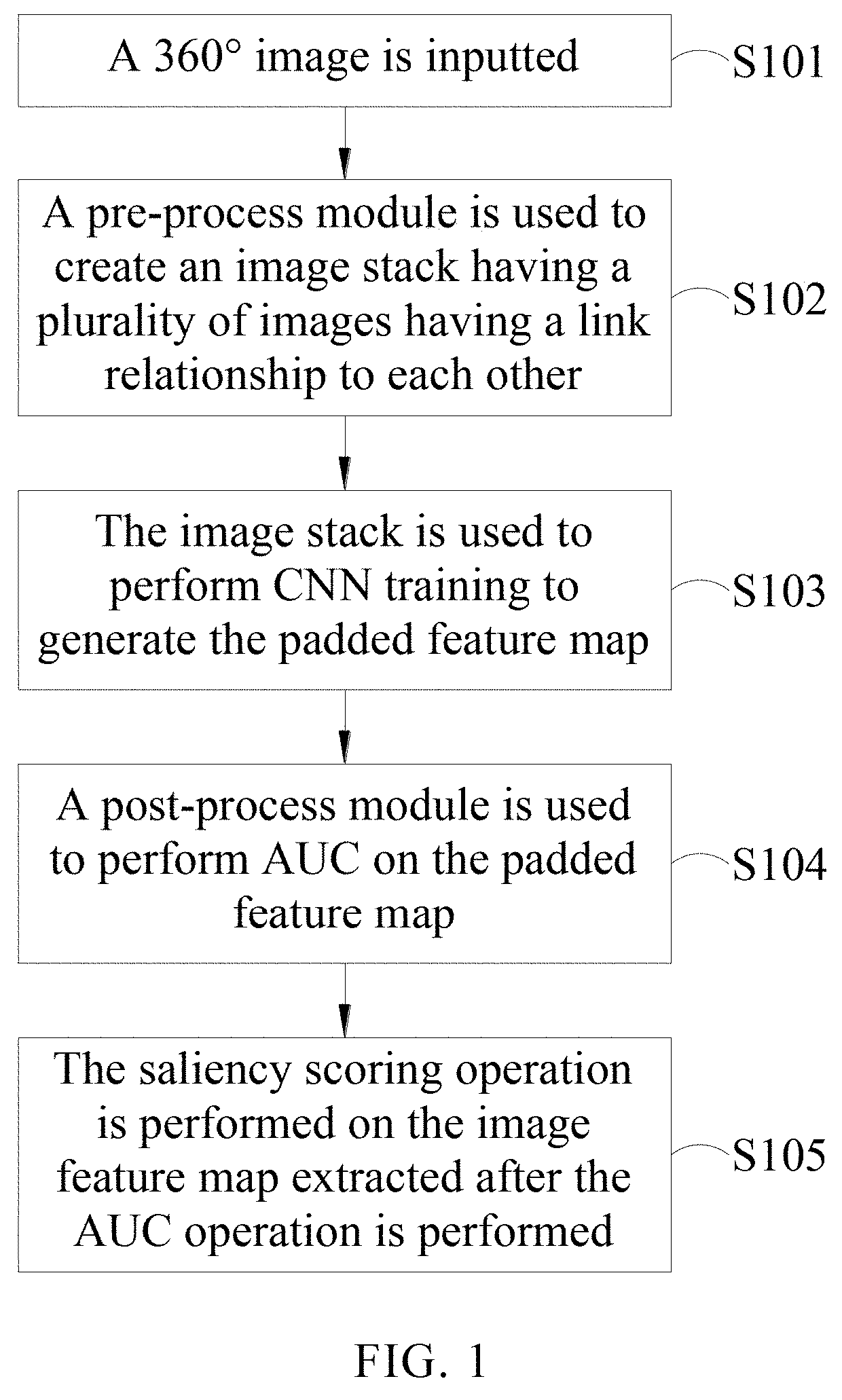

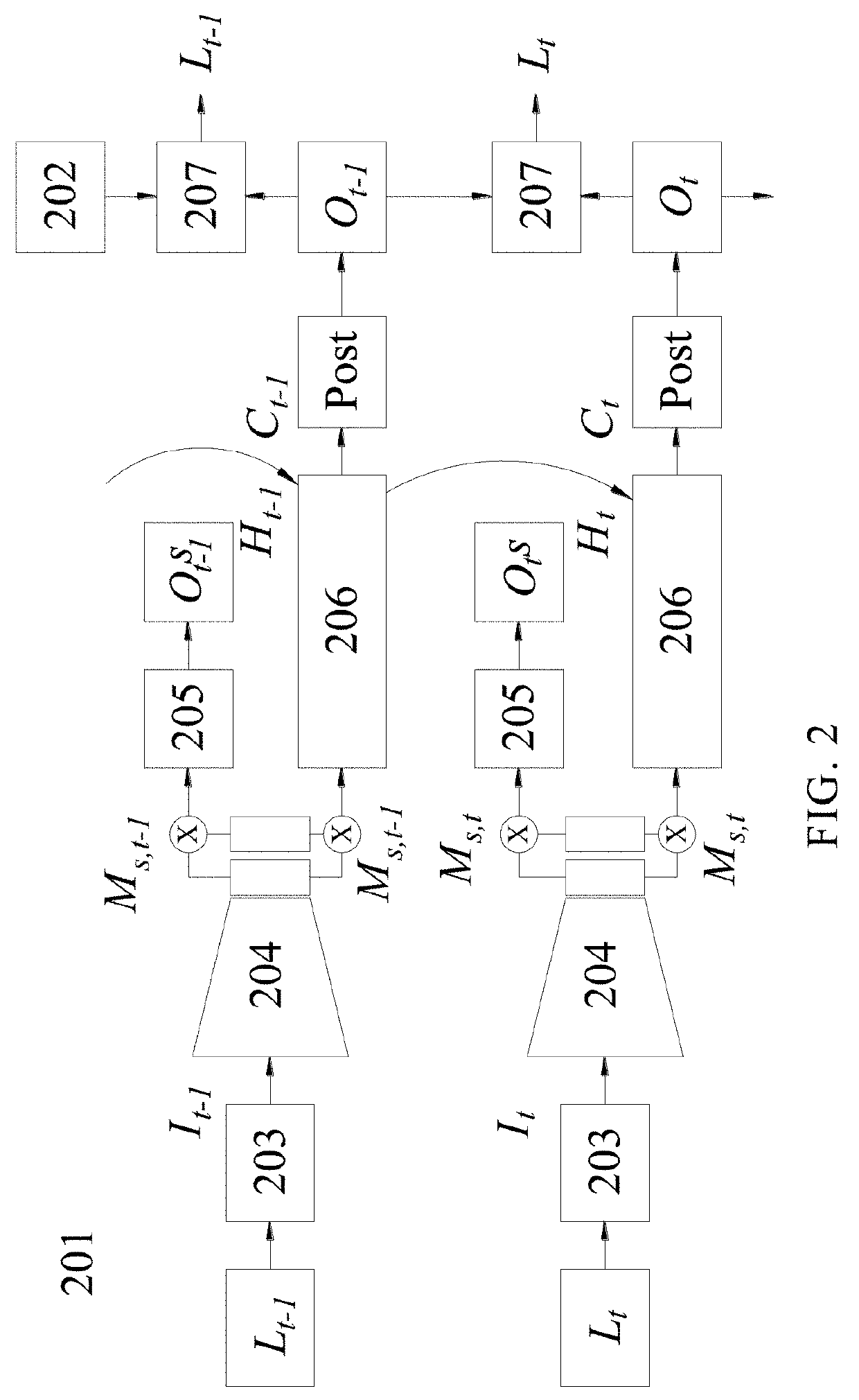

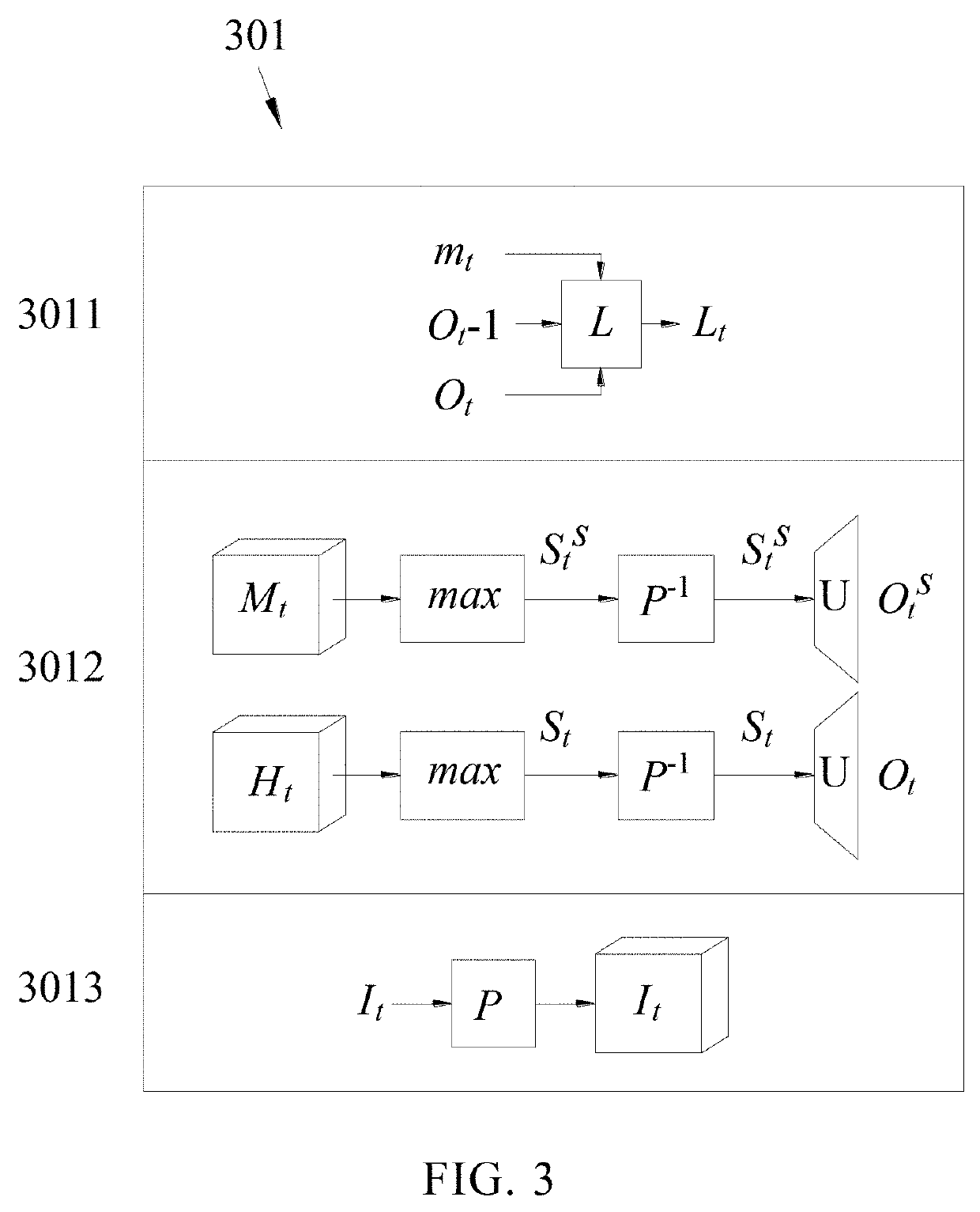

An image feature extraction method for a 360° image includes the following steps: projecting the 360° image onto a cube model to generate an image stack including a plurality of images having a link relationship; using the image stack as an input of a neural network, wherein when operation layers of the neural network performs padding operation on one of the plurality of images, the link relationship between the plurality of adjacent images is used such that the padded portion at the image boundary is filled with the data of neighboring images in order to retain the characteristics of the boundary portion of the image; and by the arithmetic operation of the neural network of such layers with the padded feature map, an image feature map is generated.

Owner:NATIONAL TSING HUA UNIVERSITY

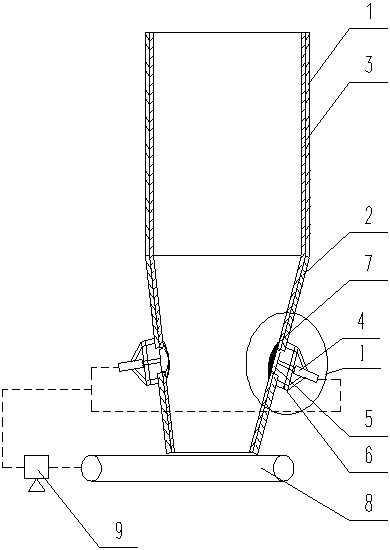

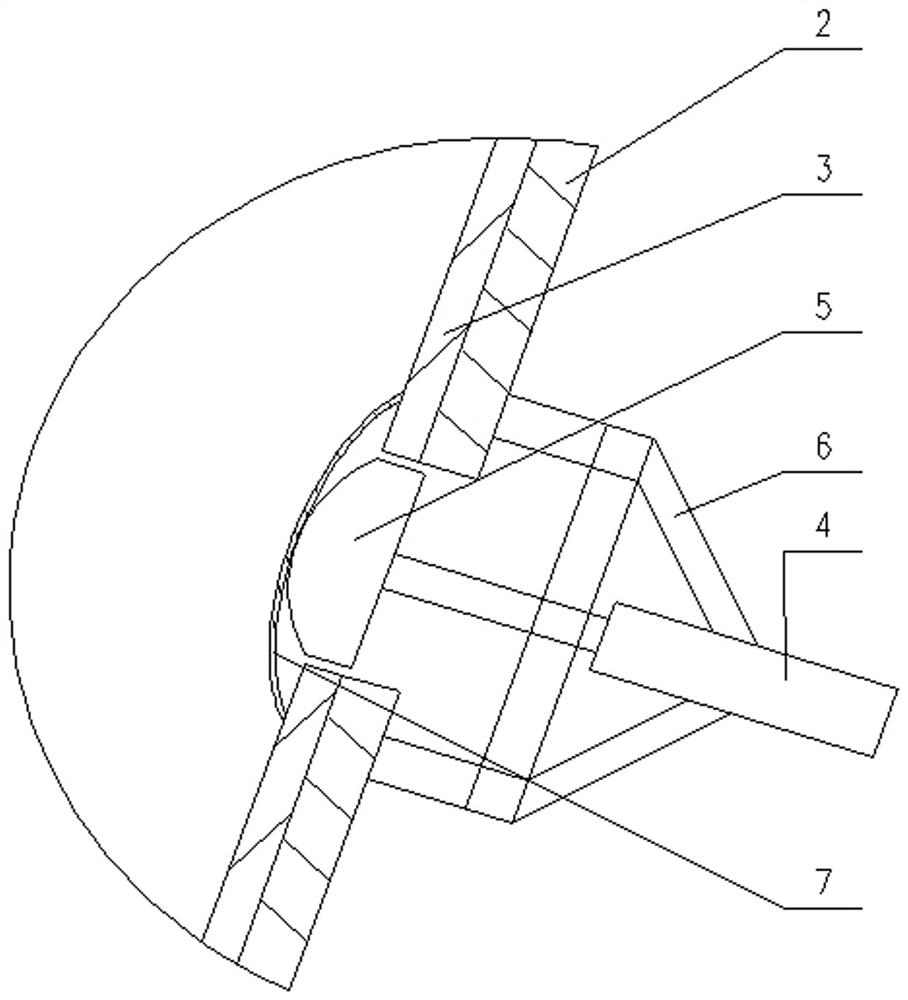

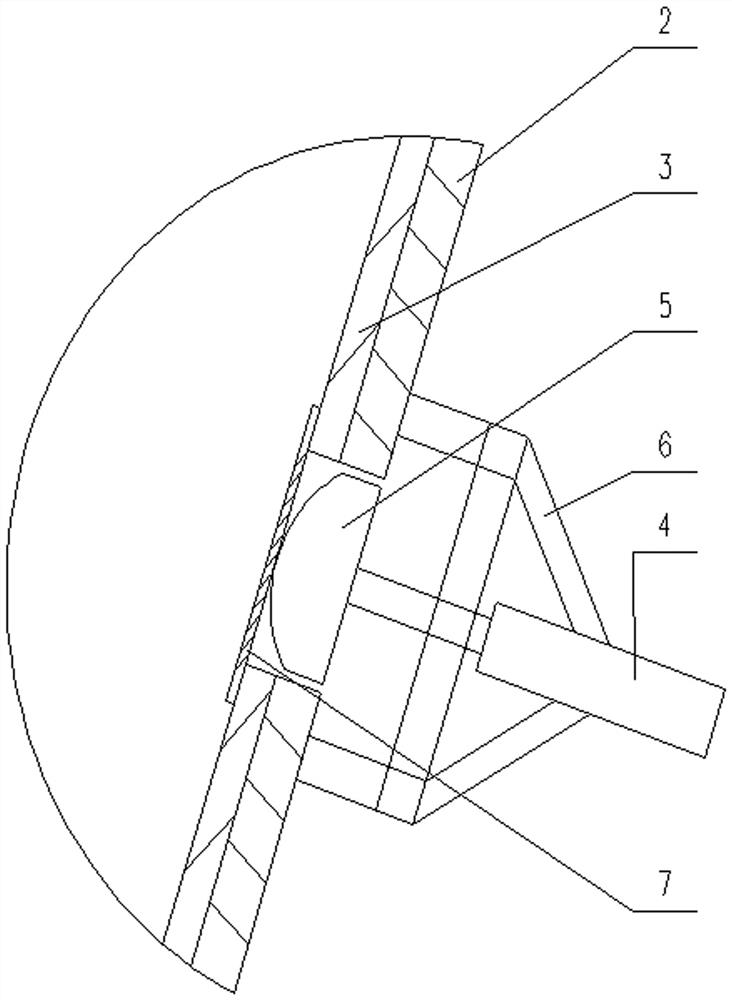

Assembly welding fixture and welding process for tank body and stirring blades of concrete mixer

ActiveCN102672374AAvoid transitional ledgesImprove the mixing effectWelding/cutting auxillary devicesArc welding apparatusButt weldingSpiral blade

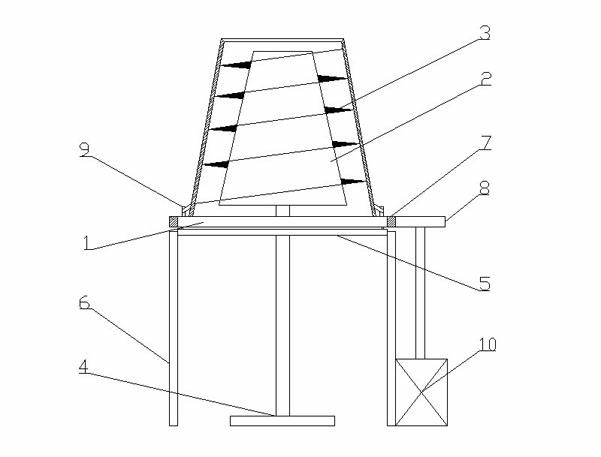

The invention relates to an assembly welding fixture for a tank body and stirring blades of a concrete mixer and a process for welding by utilizing the welding fixture. According to the welding process, the moulded large partitioned stirring blades are attached to a blade parent plate on an inner cone male die correspondingly one by one and are subjected to butt welding to form an integral spiral blade in the partitioned tank body; the inner cone male die is pushed into the partitioned tank body by a lifting device, so that the spiral blade is in bonded with the tank body to weld quickly and fill gaps, and after bonding, the bonding part of the spiral blade and the partitioned tank body is subjected to spot welding; and a tank body rotating substrate which is put into the partitioned tank body is rotated and contracted by matching with the lifting device, so that the blade parent plate on the inner cone male die is separated from the large partitioned spiral blades, and the inner cone male die withdraws from the partitioned tank body. By the welding fixture and the welding process, the influence of harmful gas and dust on the health condition of operators due to small operation space during the welding in the tank body is avoided.

Owner:LUOYANG CIMC LINYU AUTOMOBILE

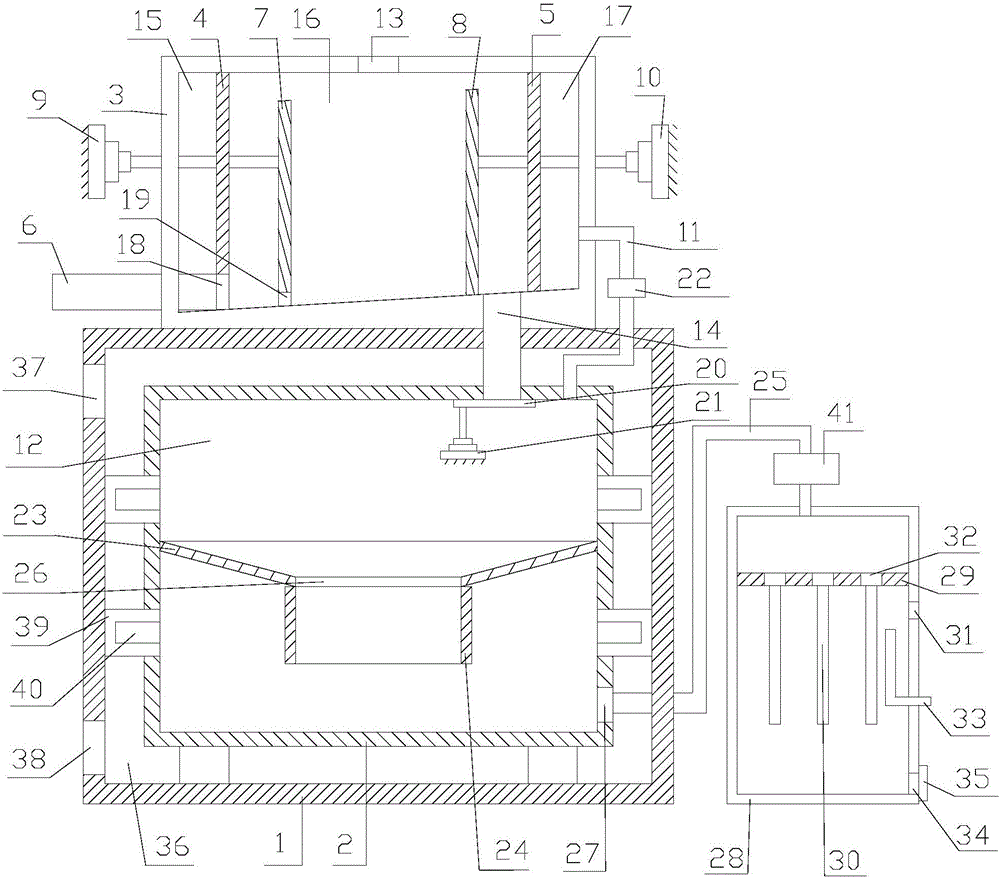

3D (Three-dimensional) printer waste recovery system and recovery method thereof

InactiveCN107756805AReasonable designRealize detachable functionAdditive manufacturing apparatusPlastic recyclingRecovery methodInjection moulding

The invention relates to the technical field of 3D (Three-dimensional) printing, concretely relates to a 3D printer waste recovery system, and discloses a recovery method utilizing the recovery system. The recovery system comprises a waste storage device, a waste recovery device, a waste cooling device, a waste smashing device, a smashed waste conveying device and a re-injection molding device; and the recovery method comprises a waste storage process, a waste recovery process, a waste cooling process, a waste smashing process, a waste conveying process and an injection molding process. According to the 3D printer waste recovery system and the recovery method thereof provided by the invention, through the reasonable setting and the coordination and distribution of responsibilities of the processes, the 3D wastes are recovered through the system, and the cyclic utilization of the 3D printer wastes is realized.

Owner:HUNAN KUANGCHU TECH CO LTD

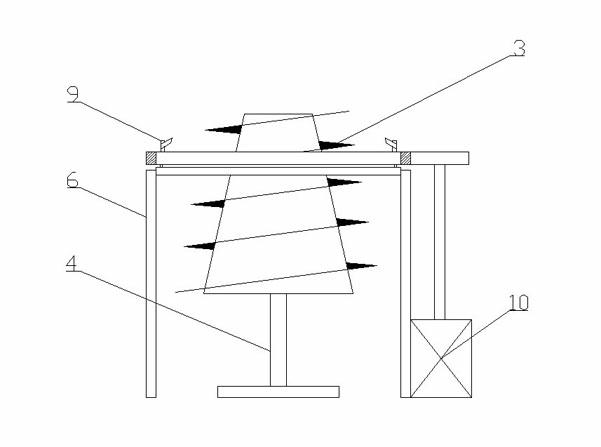

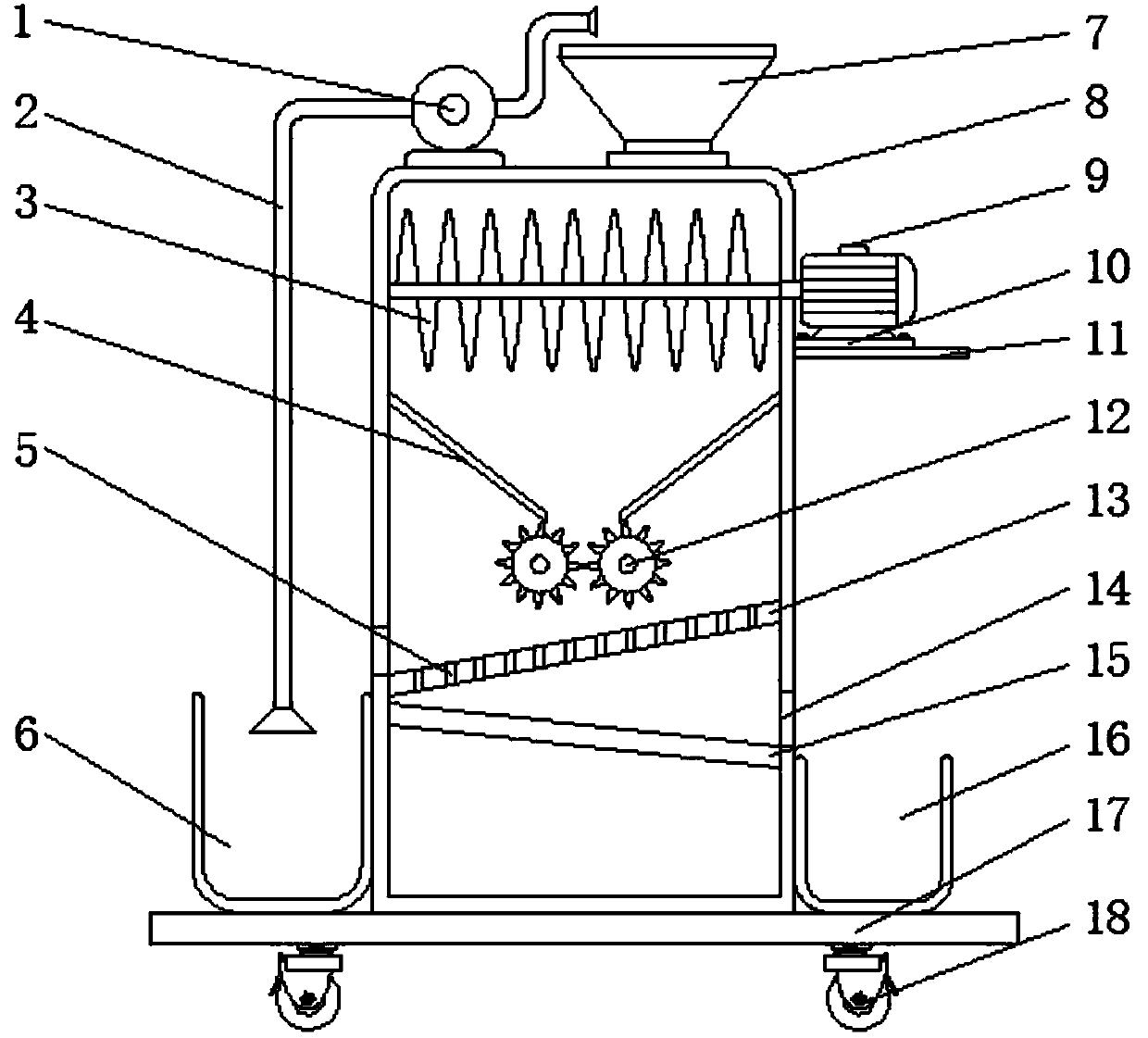

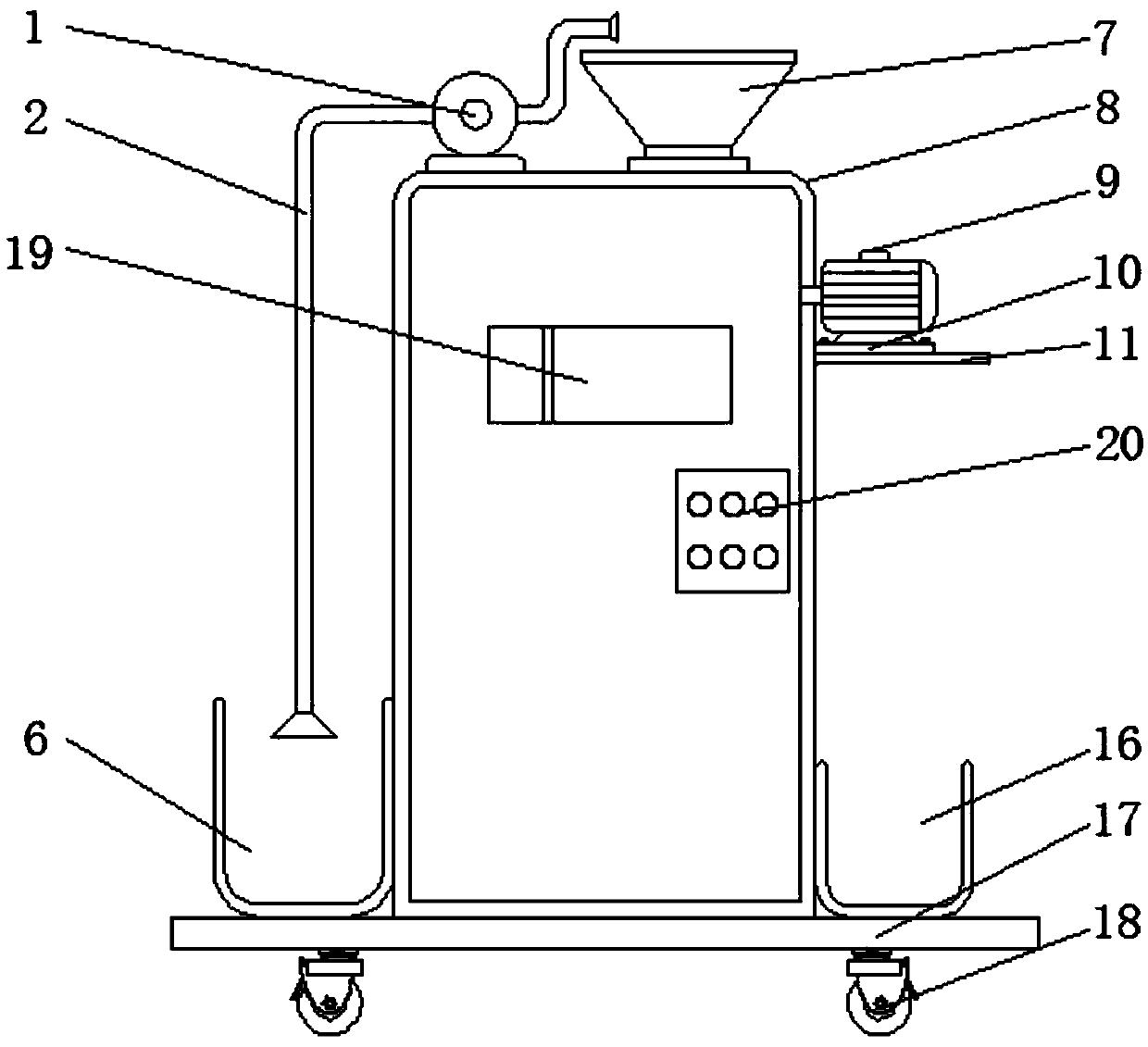

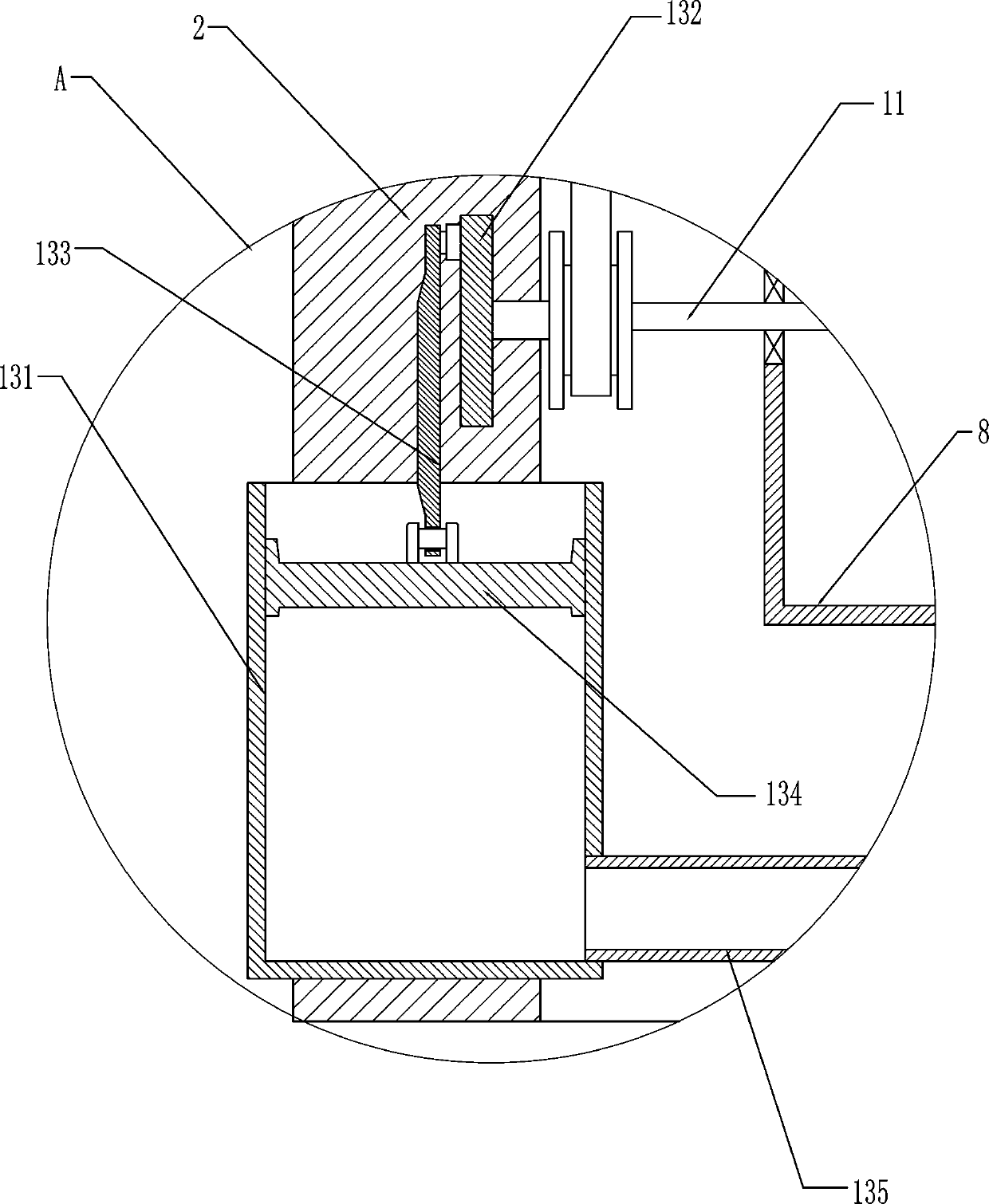

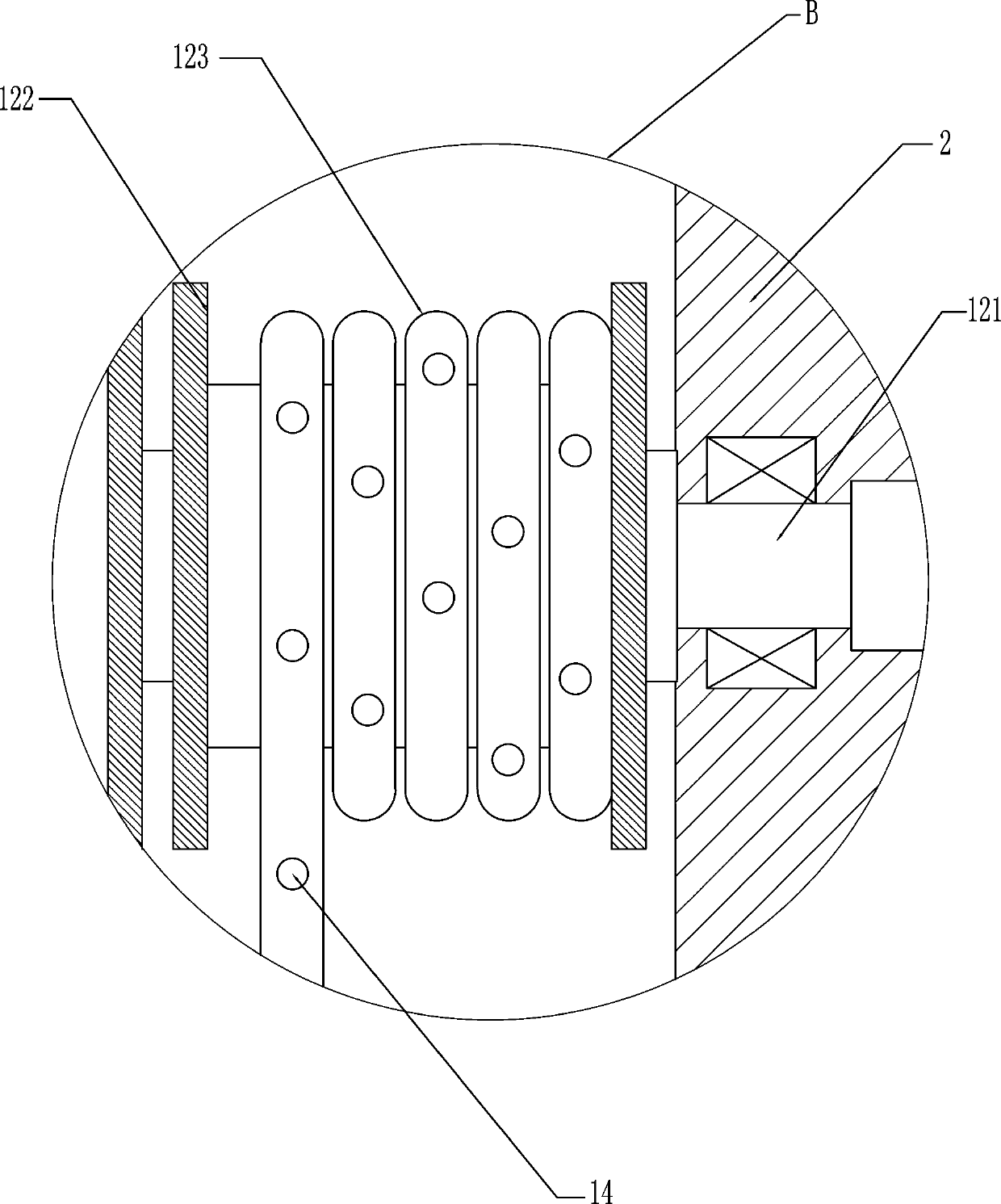

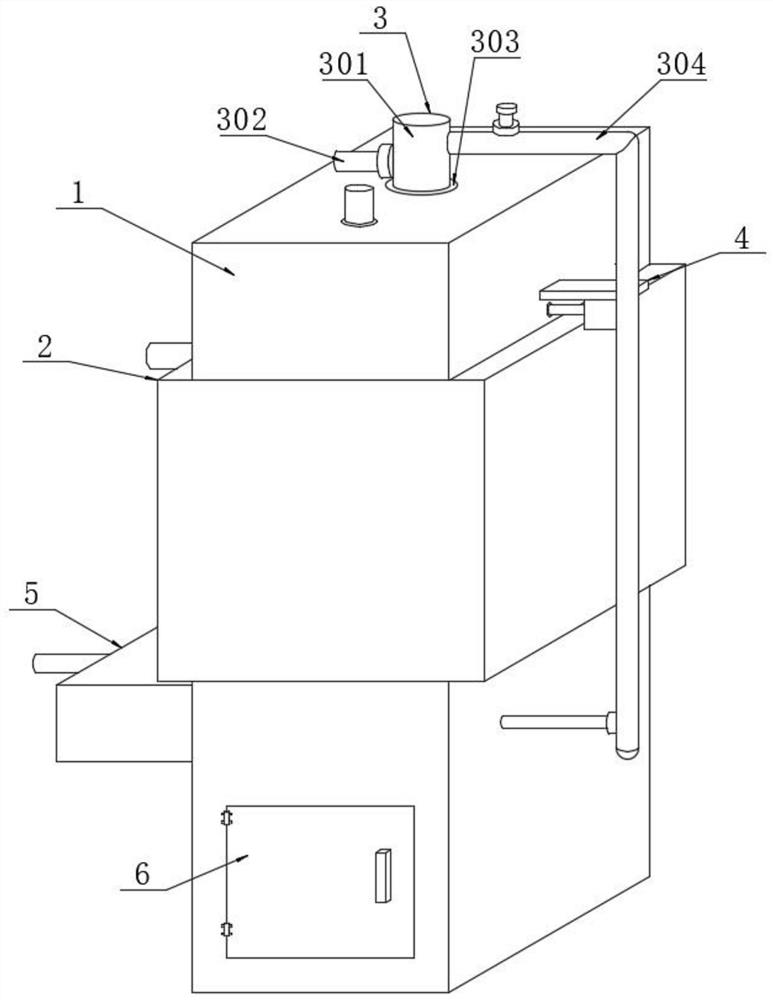

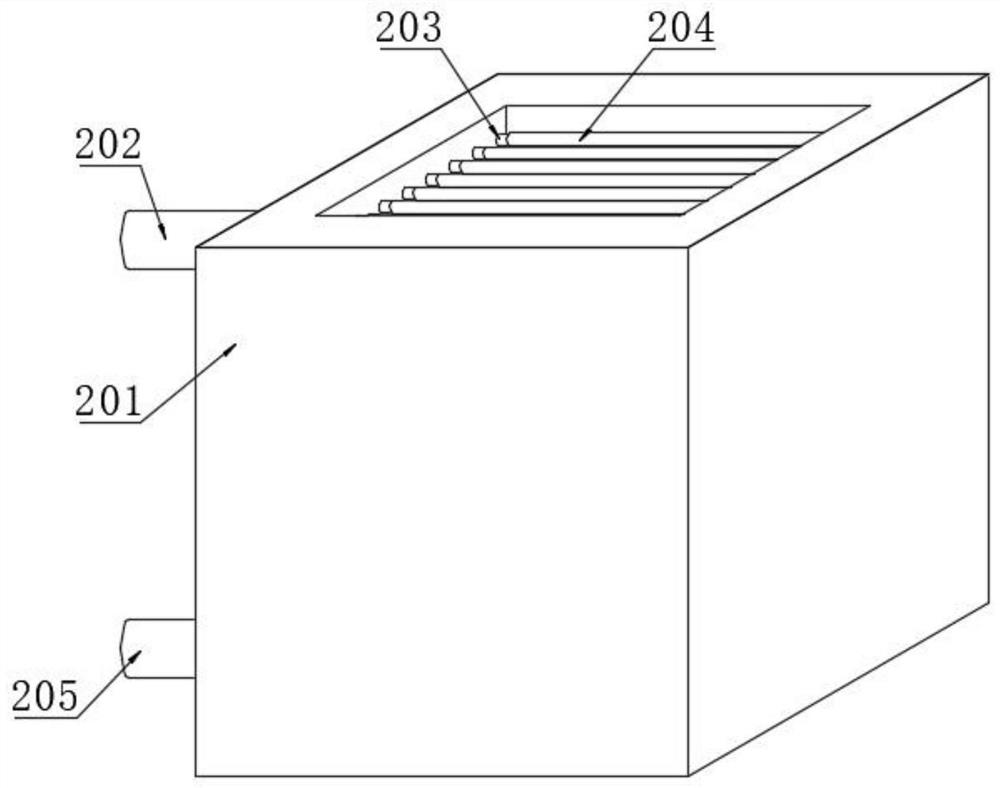

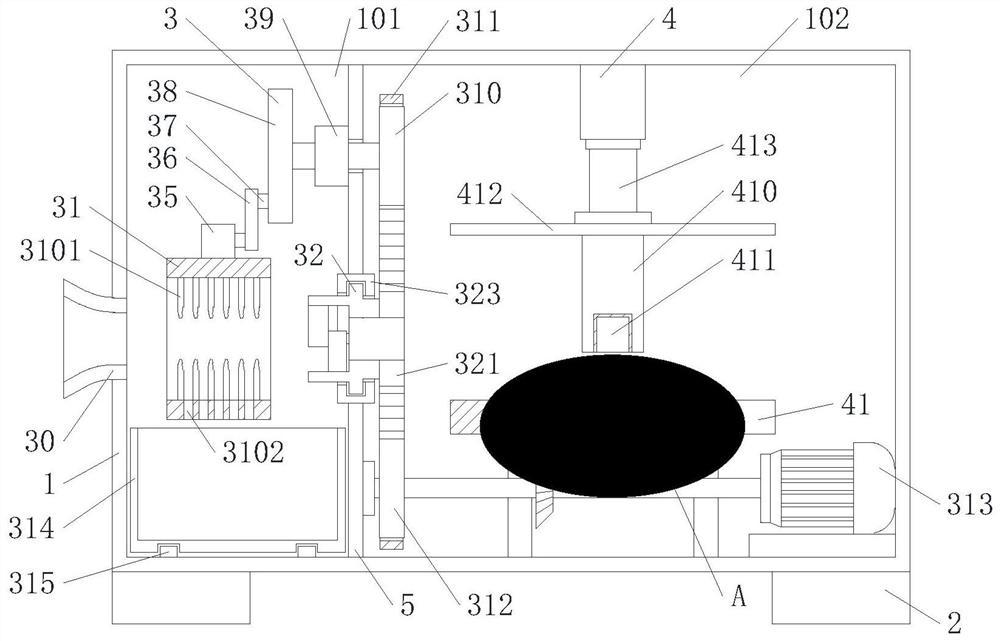

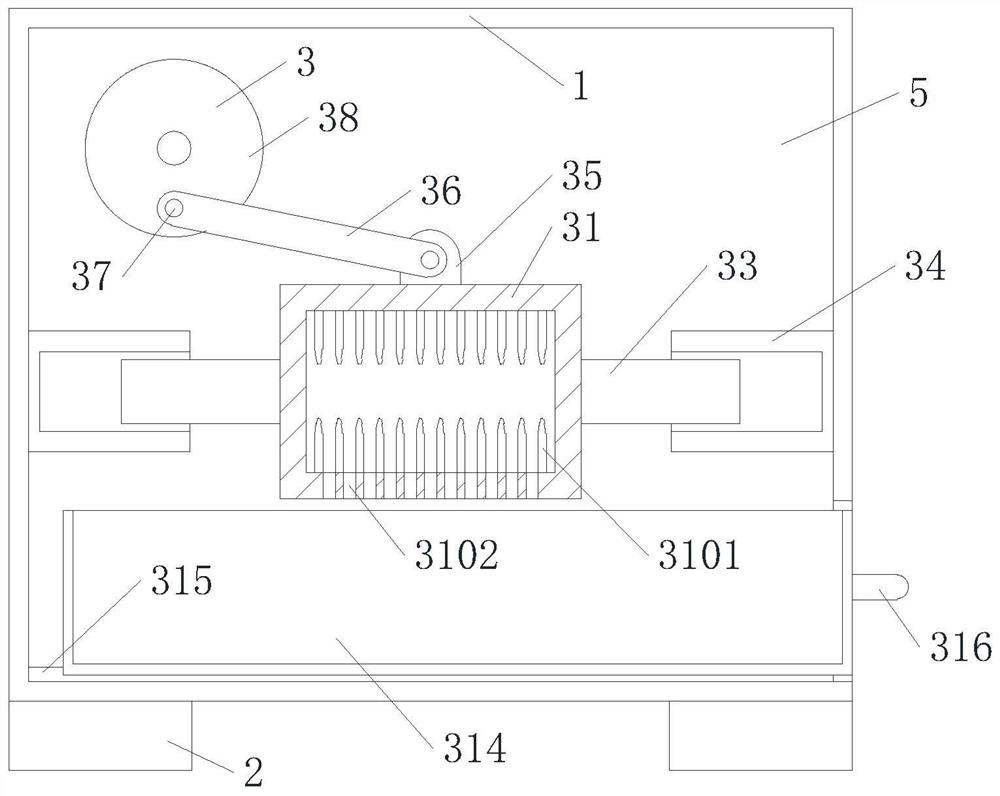

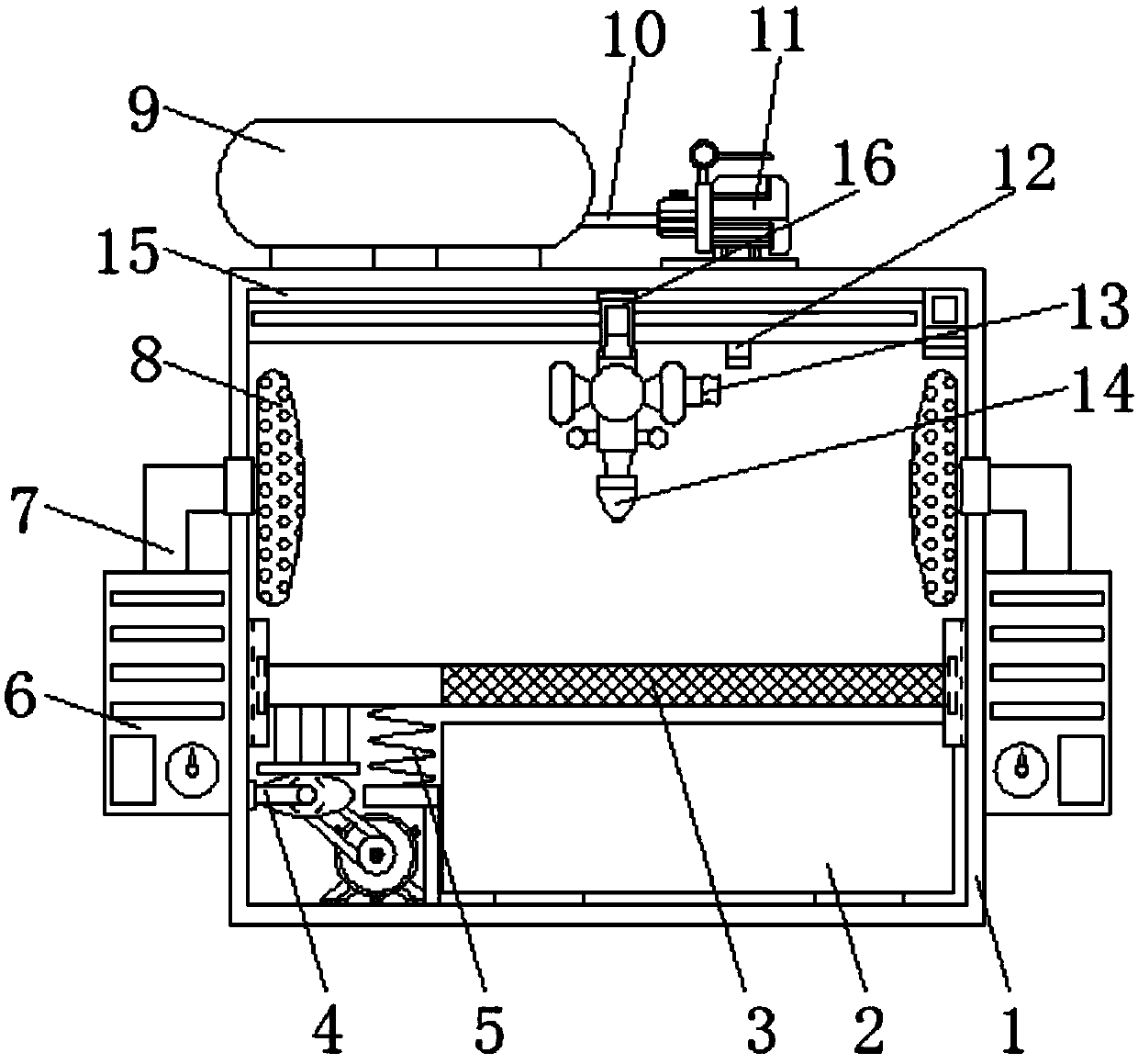

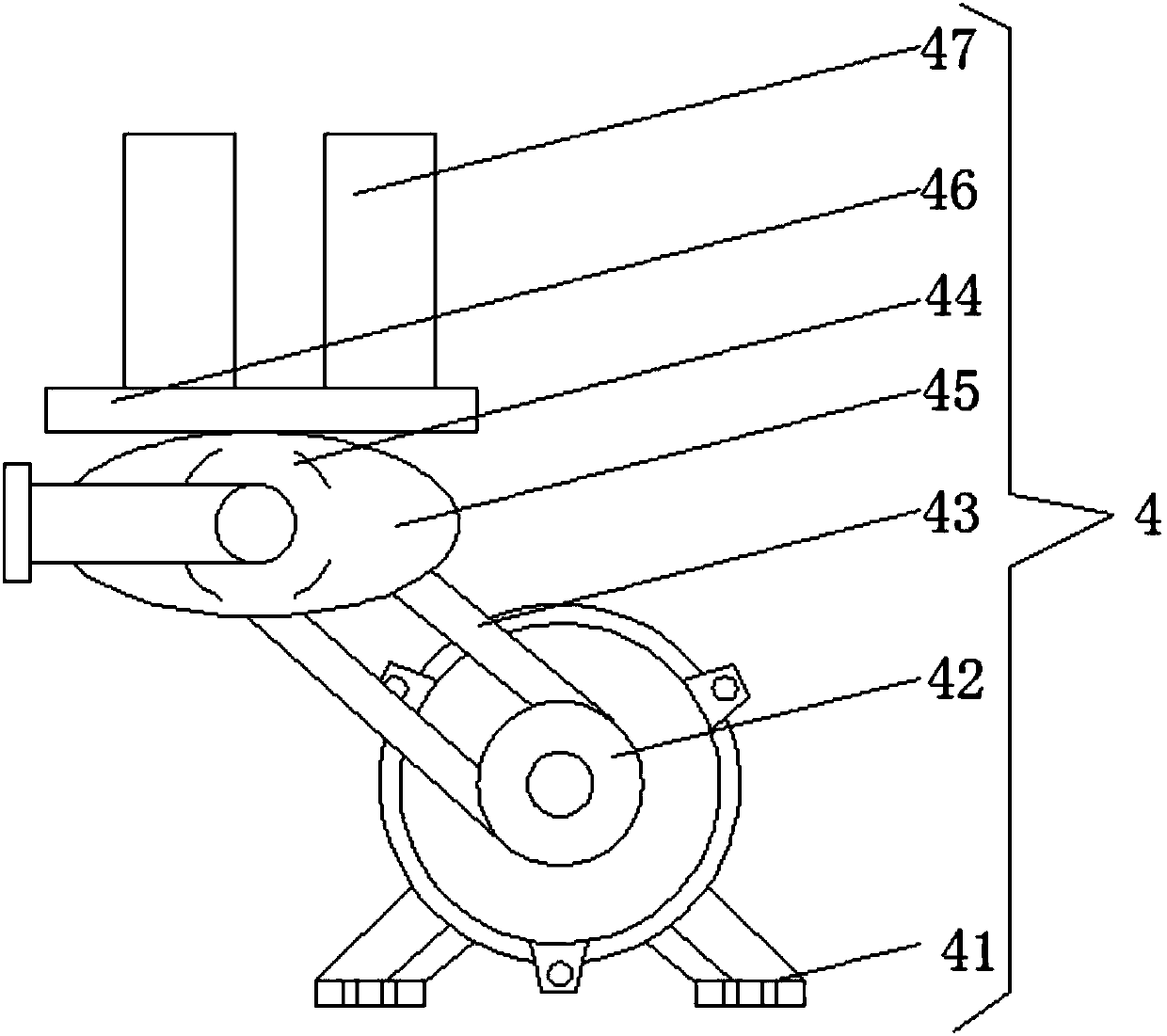

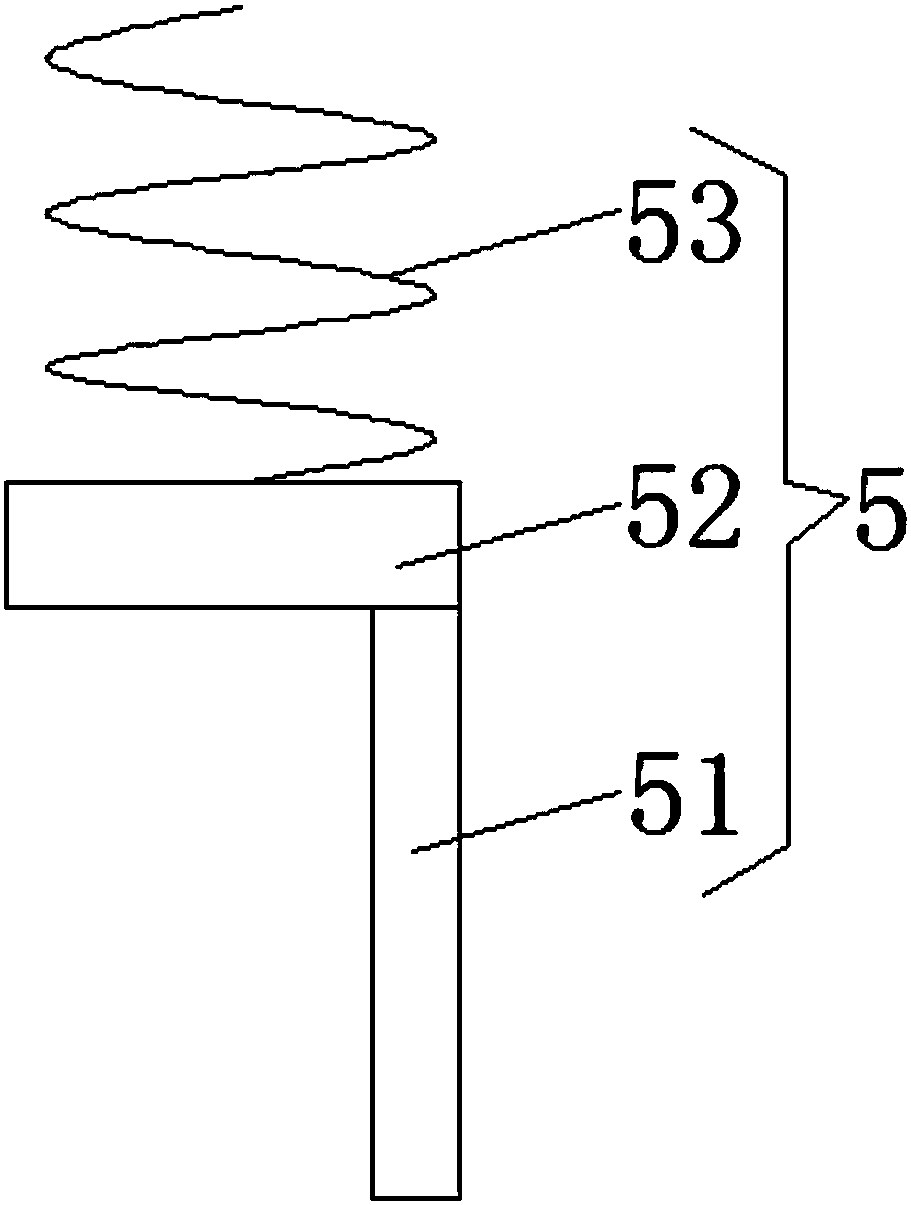

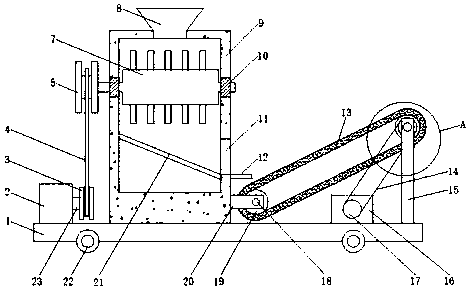

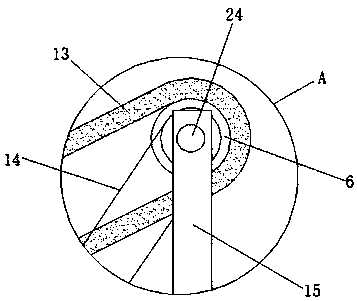

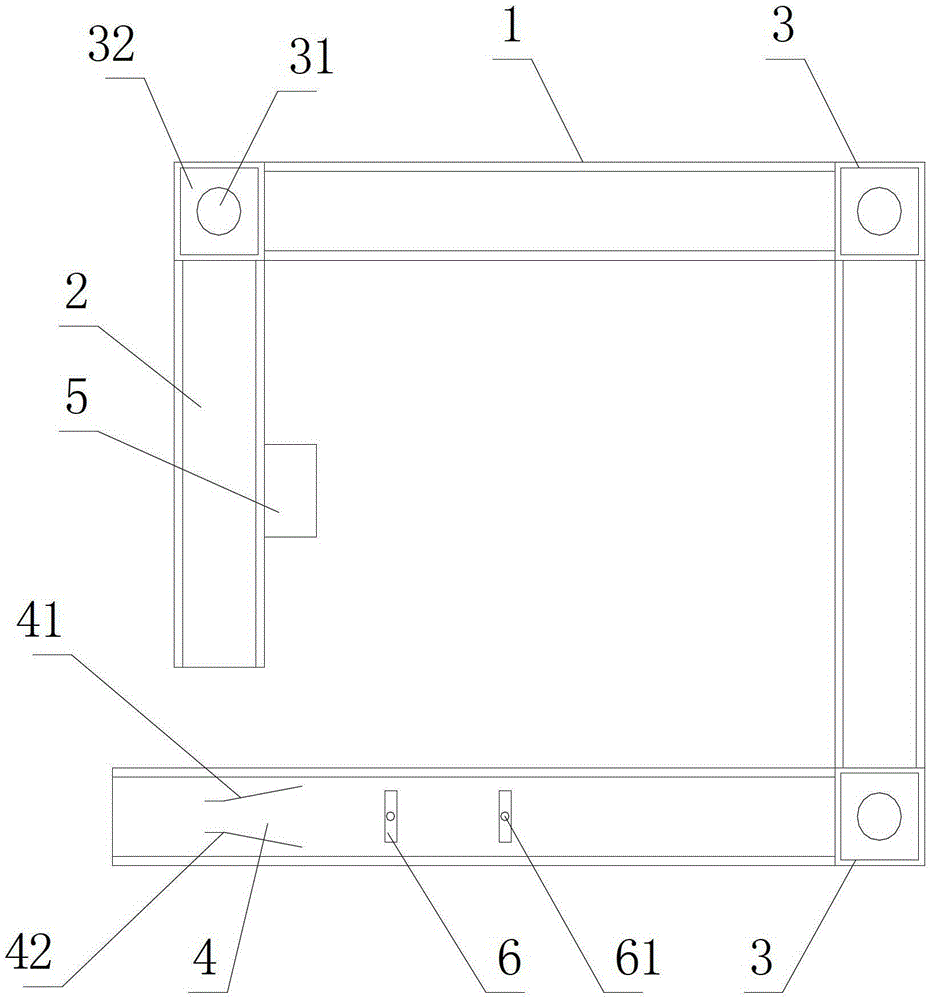

Waste crushing device of 3D printer

InactiveCN107716083AImproved uniformity of particle sizeImprove the output effectAdditive manufacturing apparatusManufacturing recyclingComputer printingProcess engineering

The invention discloses a waste crushing device of a 3D printer. The waste crushing device comprises a working platform and a crusher box body, wherein four uniformly distributed universal wheels arearranged at the bottom of the working platform; the crusher box body is arranged above the working platform; one side of the crusher box body is provided with a recovery tank; and the other side of the crusher box body is provided with a storage tank. The waste crushing device provided by the invention has the following beneficial effects: waste materials can be broken into finer particles throughone-time cutting and one-time rolling, and large particles are removed through screening for recycling treatment again, so that the uniformity of particle sizes is improved, the discharging effect ofequipment is improved, and great help is provided for subsequent heating and melting treatment; and only one feeding is needed manually, the equipment can automatically and orderly break raw materials into refined particles, the automation degree of the equipment is extremely high, the production and processing efficiency is high, the use is convenient, and the manpower is liberated.

Owner:HUNAN KUANGCHU TECH CO LTD

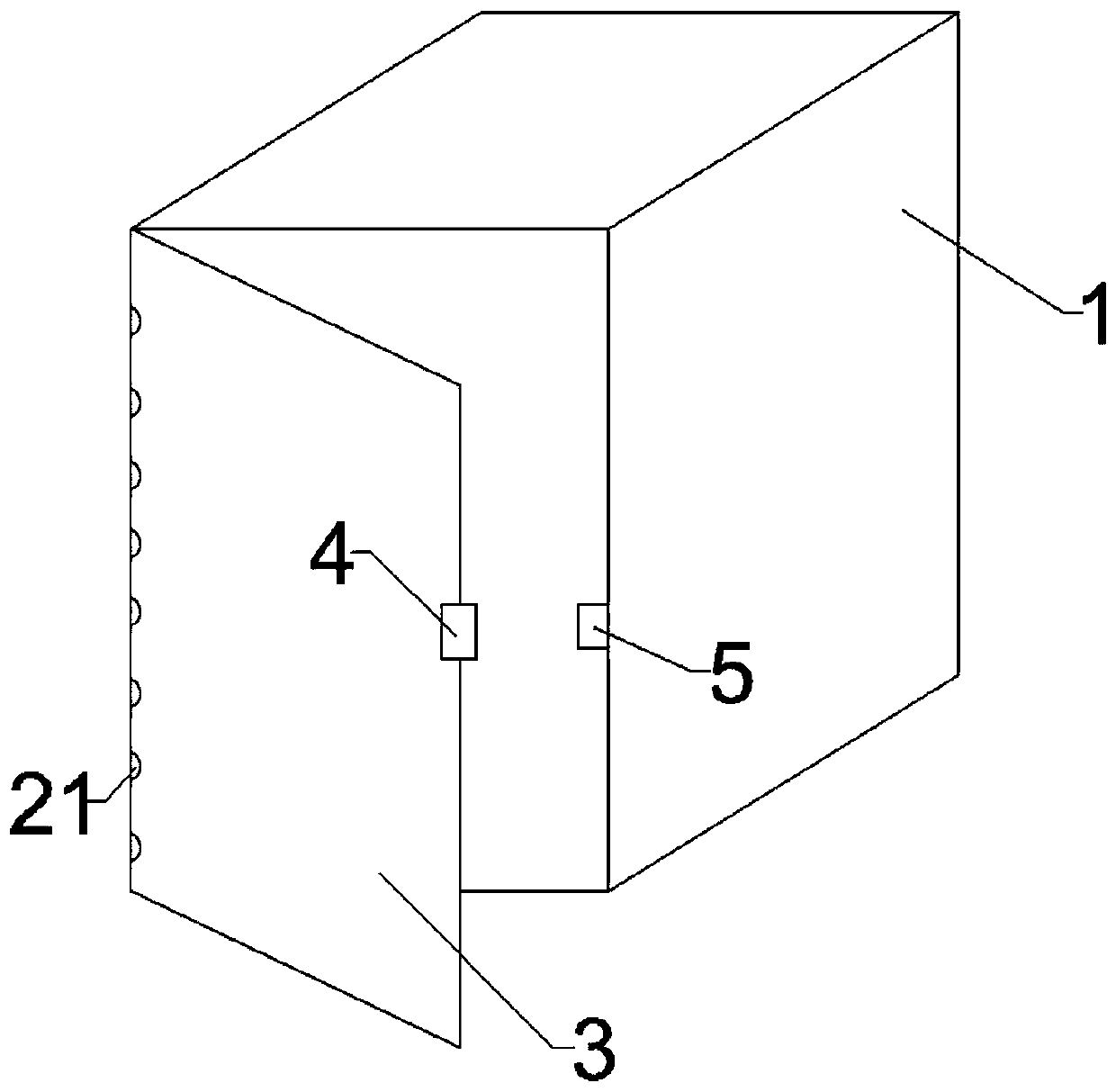

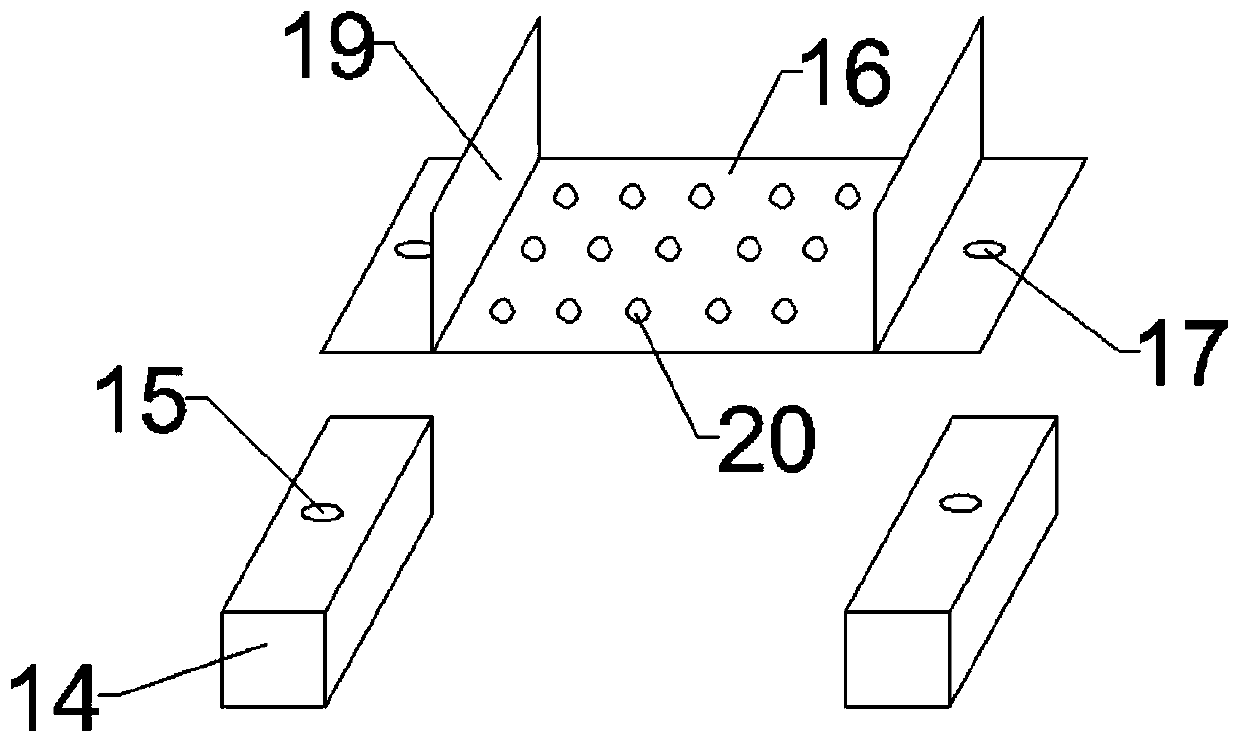

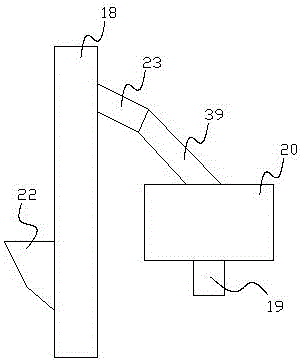

Efficient screening device for quartz sand production

PendingCN110152998AEasy to install and disassembleImprove screening efficiencySievingScreeningEngineeringQuartz

The invention discloses an efficient screening device for quartz sand production. The efficient screening device comprises a box body and a mounting seat. The box body is connected with a closing doorthrough a movable shaft, the closing door is provided with a locking block, the locking block is matched with a lock groove formed in the box body, the front and rear sides of the mounting seat are provided with electric telescopic rods, the two electric telescopic rods are jointly connected with the bottom of the box body, the top of the box body is provided with a feeding port, and the bottom of the box body is provided with a discharging port. The size of mesh holes in a sieve plate of the device can be selected according to the required quartz sand particle size, so that the screened quartz sand meets the requirements of enterprises, and the screening efficiency is high; and the selected sieve plate is in threaded connection with a first screw hole and a second screw hole through bolts to be fixed, and the sieve plate is easy to install and disassemble.

Owner:XINYI ZHONGXIN OPTOELECTRONICS TECH CO LTD

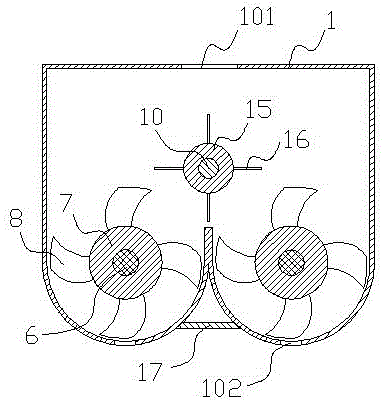

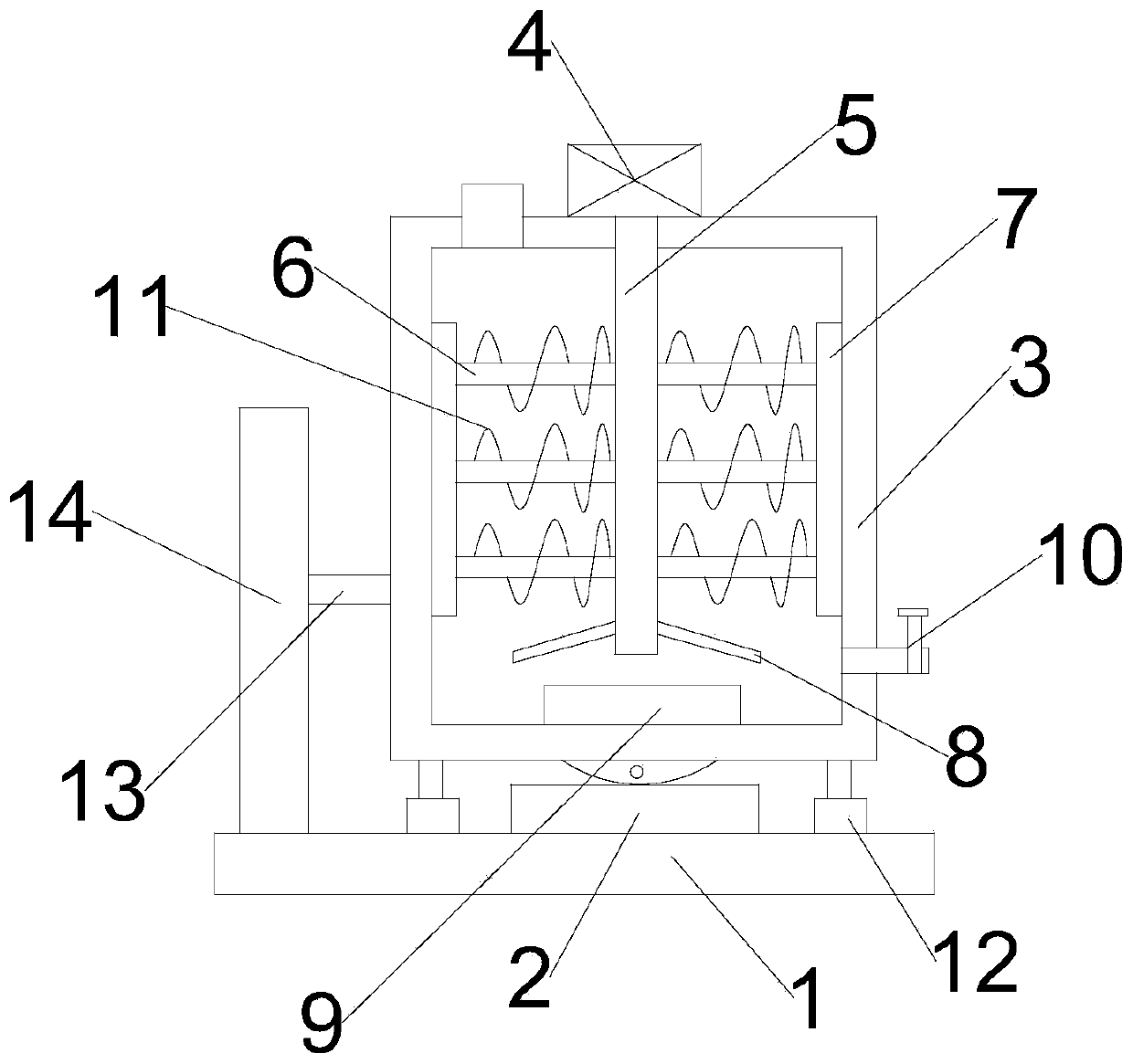

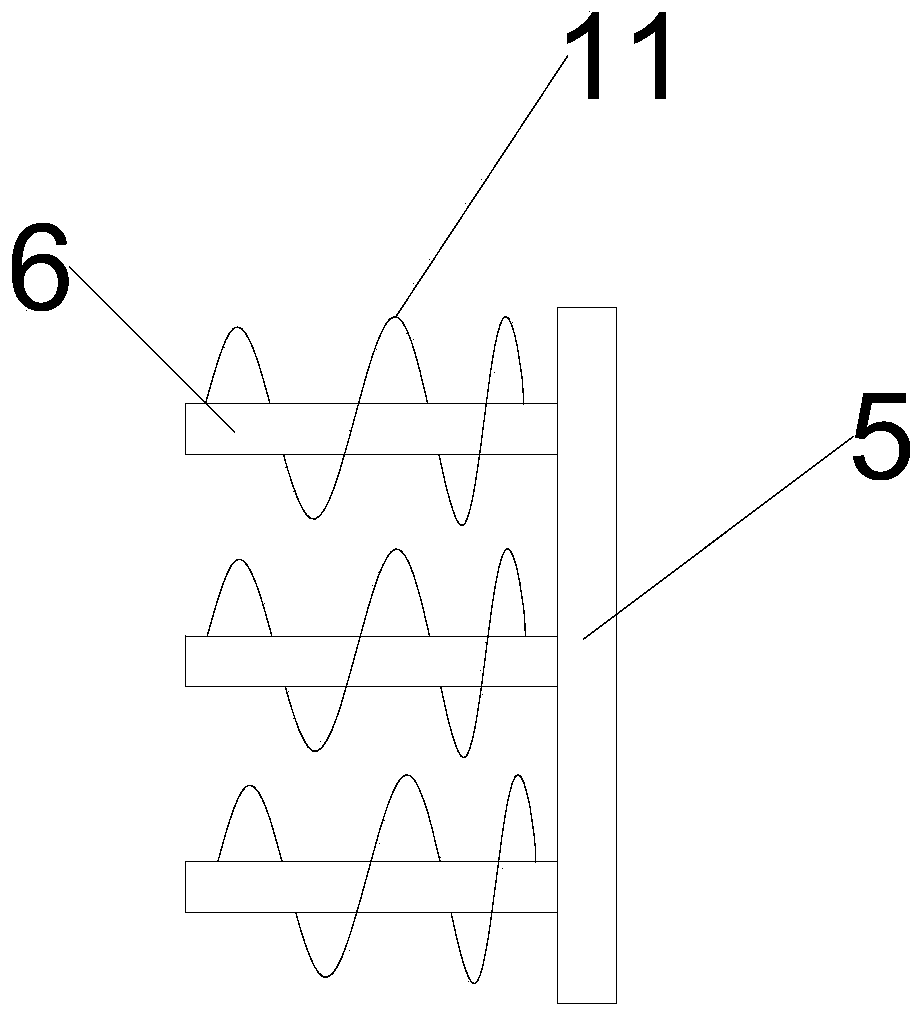

Mixing all-in-one machine used for processing synthetic mica

ActiveCN105126663AImprove the mixing effectQuality improvementRotary stirring mixersMixer accessoriesButt jointEngineering

The invention relates to a mixing all-in-one machine used for processing synthetic mica. A material lifting inlet and a material lifting outlet are formed in a material lifting device; the material lifting outlet is connected to a feeding hole of a material mixing device through a butt joint pipe; a discharging hole of the material mixing device is connected with a discharging device; a second rotary shaft is arranged at the upper part of a material mixing box body of the material mixing device, and two first rotary shafts are arranged at the lower part of the material mixing box body; the central line of the second rotary shaft is located on front and back symmetrical planes of the material mixing box body; the first rotary shafts are symmetrical about the front and back symmetrical planes of the material mixing box body; the first rotary shafts and the second rotary shaft are located in the material mixing box body and are in sleeving joint with first rotary barrels and a second rotary barrel respectively; stirring blades are arrayed on the first rotary barrel in a staggered manner and stirring rods are arrayed on the second rotary barrel in the staggered manner. According to the mixing all-in-one machine, the three rotary shafts are distributed in a triangular shape for mixing materials, so that the material mixing efficiency is extremely improved and the material mixing time is shortened; meanwhile, the material mixing quality can also be improved; the material lifting device is arranged, so that the materials can be fed to a high-efficiency material mixing device very well.

Owner:PINGJIANG XINGKE MICA PRODS

Wood crusher

PendingCN110302866AUniform sizePracticalWood working apparatusGrain treatmentsDischarge efficiencyEngineering

The invention discloses a wood crusher comprising a shell, a crushing device, a feeding device and a discharging device. The crushing device is installed in an inner cavity of the shell; the shell isprovided with a feeding guiding port and a discharging port, and the feeding device and the discharging device are installed correspondingly. According to the wood crusher, the crushing device is provided with a fixed speed motor, the discharging speed can be adjusted according to the rotating speed, and the same discharging size is ensured; a plurality of groups of air holes are formed, so that the vacuum state is prevented from happening, the discharging efficiency is enhanced, and blockage is prevented; a feeding barrel of the feeding device can be adjusted with a certain scope to adapt towood within a certain size range; the discharging device having the multi-directional adjustment function can adapt to more complicated environments, and the adaptability is higher; a safety protection device is arranged so that safety of maintenance personnel can be ensured; and the problems that a traditional wood crusher is large in size, the wood is prone to happening blockage, the dischargingdirection is single, and the maintenance risk is high are solved effectively.

Owner:福建省鑫港路通车辆制造有限责任公司

Concrete mixing equipment for airport construction

InactiveCN113103434AImprove practicalityImprove sealingDischarging apparatusMixing operation control apparatusElectric machineryStructural engineering

The invention relates to concrete mixing equipment for airport construction. The concrete mixing equipment comprises a main body, a motor, a first bearing, a rotating shaft, two supporting legs and a plurality of mixing plates, and further comprises a cleaning mechanism and a discharging mechanism. The cleaning mechanism comprises a plurality of cleaning assemblies, and the discharging mechanism comprises a rotating rod, two vibration assemblies, a plurality of convex blocks and a plurality of connecting rods. According to the concrete stirring equipment for airport construction, the function of cleaning the inner wall of the main body is achieved through the cleaning mechanism, concrete waste caused by the fact that concrete adheres to the inner wall of the main body is prevented, and therefore the practicability of the equipment is improved, the function of vibration of a discharging pipe is achieved through the discharging mechanism, concrete in the discharging pipe can be shaken off, the moving speed of the concrete in the discharging pipe is increased, so that the discharging effect can be improved, and the discharging efficiency is improved.

Owner:南京秋杰通讯科技有限公司

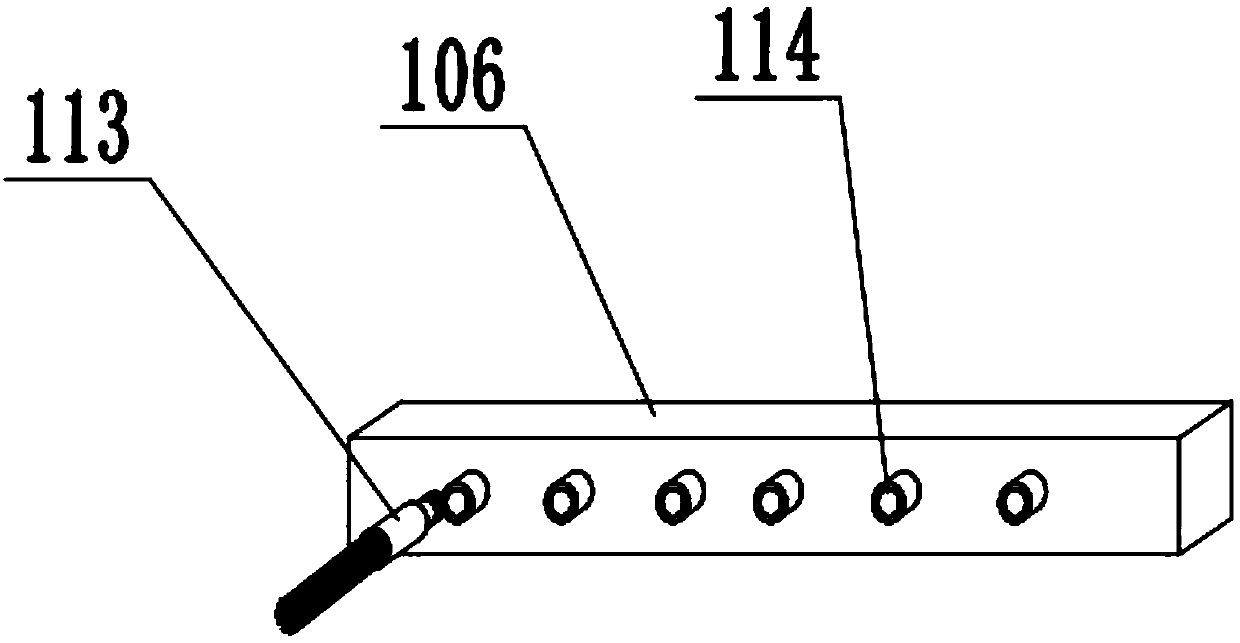

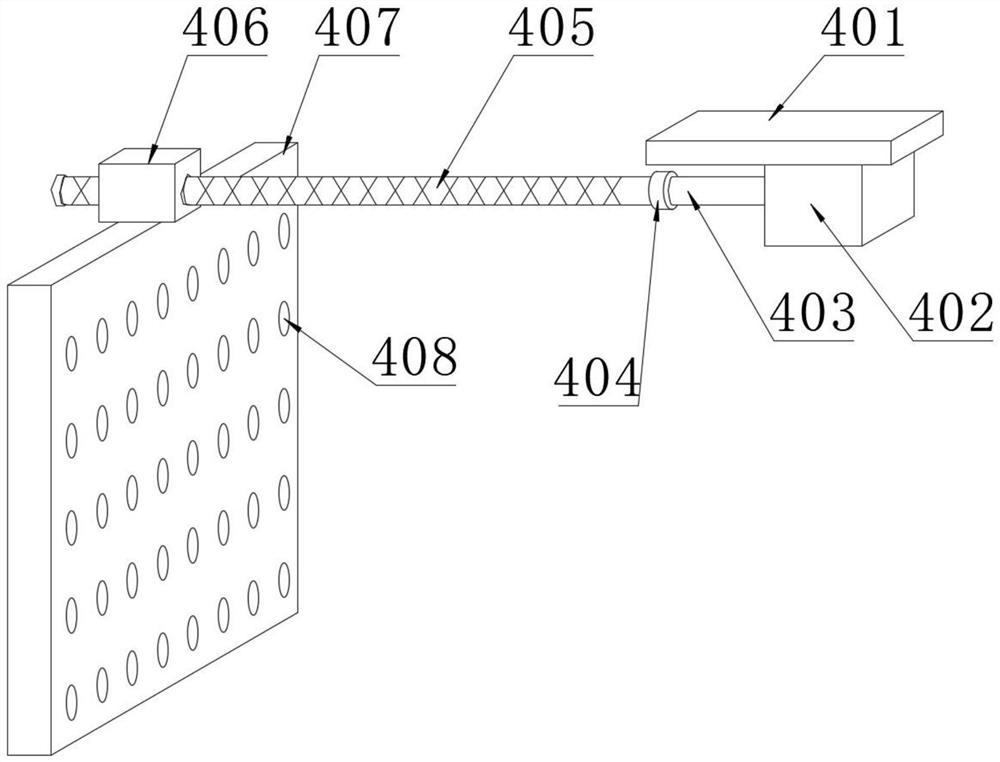

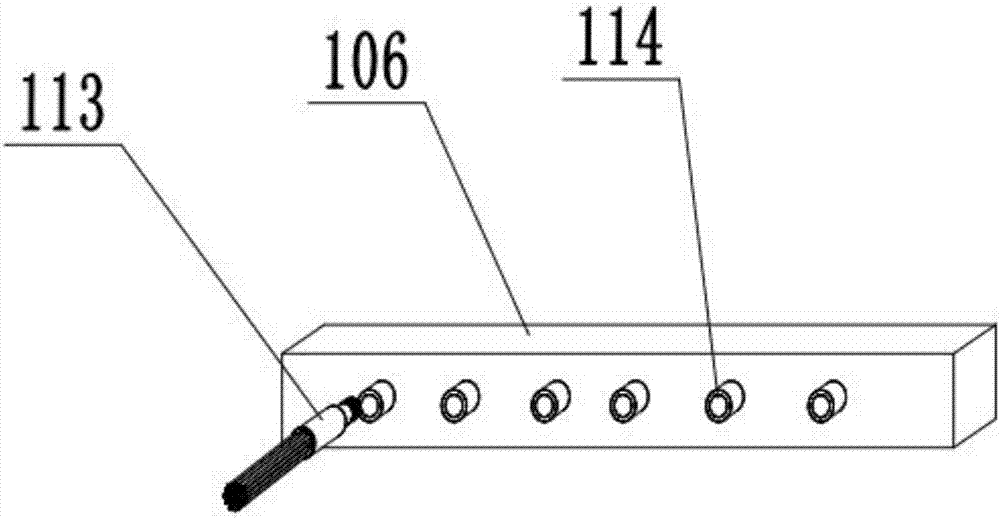

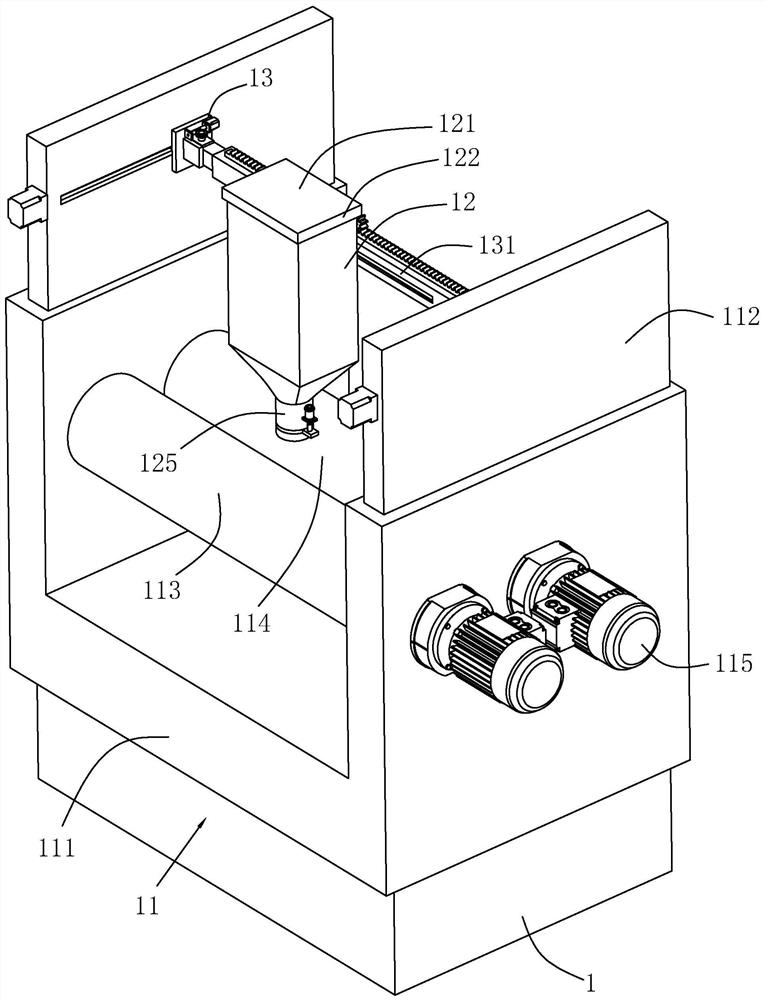

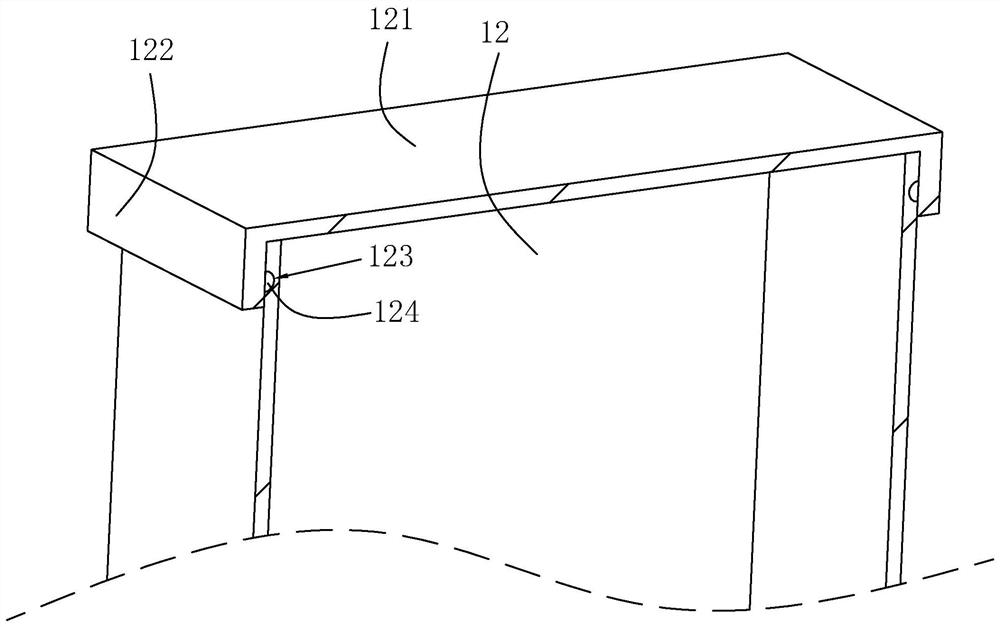

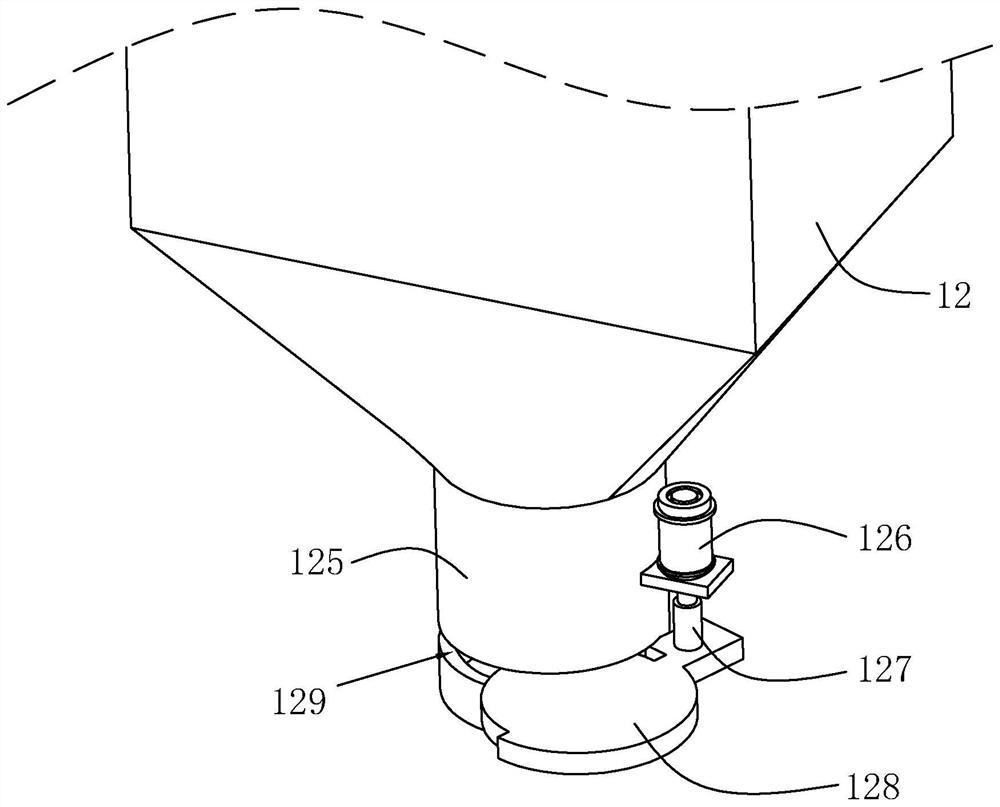

Flocculant uniform-dosing equipment capable of extending into water body

ActiveCN111056608AUniform dischargeImprove spray distanceSustainable biological treatmentWater/sewage treatment by flocculation/precipitationSewage treatmentMechanical engineering

The invention relates to dosing equipment, and especially relates to flocculant uniform-dosing equipment capable of extending into a water body. The technical problem to be solved is how to design theflocculant uniform-dosing equipment capable of extending into the water body, which can feed a flocculant into the water body, improves the sewage treatment effect and saves materials. The flocculantuniform-dosing equipment capable of extending into the water body comprises a base, a lower supporting frame, an upper supporting frame, a hopper, a material guide cylinder, a bidirectional spiral shaft and the like; the lower supporting frame is arranged at the top of the base, the upper supporting frame is arranged at the top of the lower supporting frame, the hopper is arranged on the upper supporting frame, a guide cylinder is arranged on the upper portion of the inner side of the lower supporting frame and communicated with the hopper, and the bidirectional spiral shaft is rotatably arranged in the material guide cylinder and makes contact with the inner wall of the material guide cylinder. The dosing equipment fixed on a ship body, when the ship moves on the water surface, a liquidoutlet hose moves in the water body, and discharging holes in the liquid outlet hose can achieve the effect of uniform discharging.

Owner:山东万盛电气有限公司

Daily chemical production device with distillation function and rapid discharging function and daily chemical production method

InactiveCN112675565AImprove discharge efficiencyAvoid condensation and scalingDistillation regulation/controlVapor condensationThermodynamicsDistillation

The invention discloses a daily chemical production device with a distillation function and a rapid discharging function and a daily chemical production method, belonging to the technical field of chemical production. The daily chemical production device comprises a distillation tower body, wherein a condensation mechanism with a fractional condensation function is installed at the middle portion of the distillation tower body; a scraping mechanism used for scraping a discharged material is arranged in and connected with the condensation mechanism; a reflux mechanism for reflux processing of vaporous distillate is arranged at the top of the distillation tower body; a spraying mechanism is further connected to the lower part of the reflux mechanism; a cover plate is arranged on one side of the lower part of the distillation tower body; a heating kettle is in transmission connection with the bottom of the distillation tower body; the cover plate is used for accommodating the heating kettle to feed and discharge materials; and a discharging mechanism is arranged on one side of the distillation tower body and is positioned at the bottom of the condensation mechanism. According to the daily chemical production device disclosed by the invention, the heating kettle is arranged in the distillation tower body, a heat exchange pipe is used for cooling and condensing internal steam, and the condensed distillate is scraped to fall into a discharge box, so distillate discharge efficiency can be remarkably improved, and discharge difficulty is reduced.

Owner:涡阳县华腾日用化学品有限公司

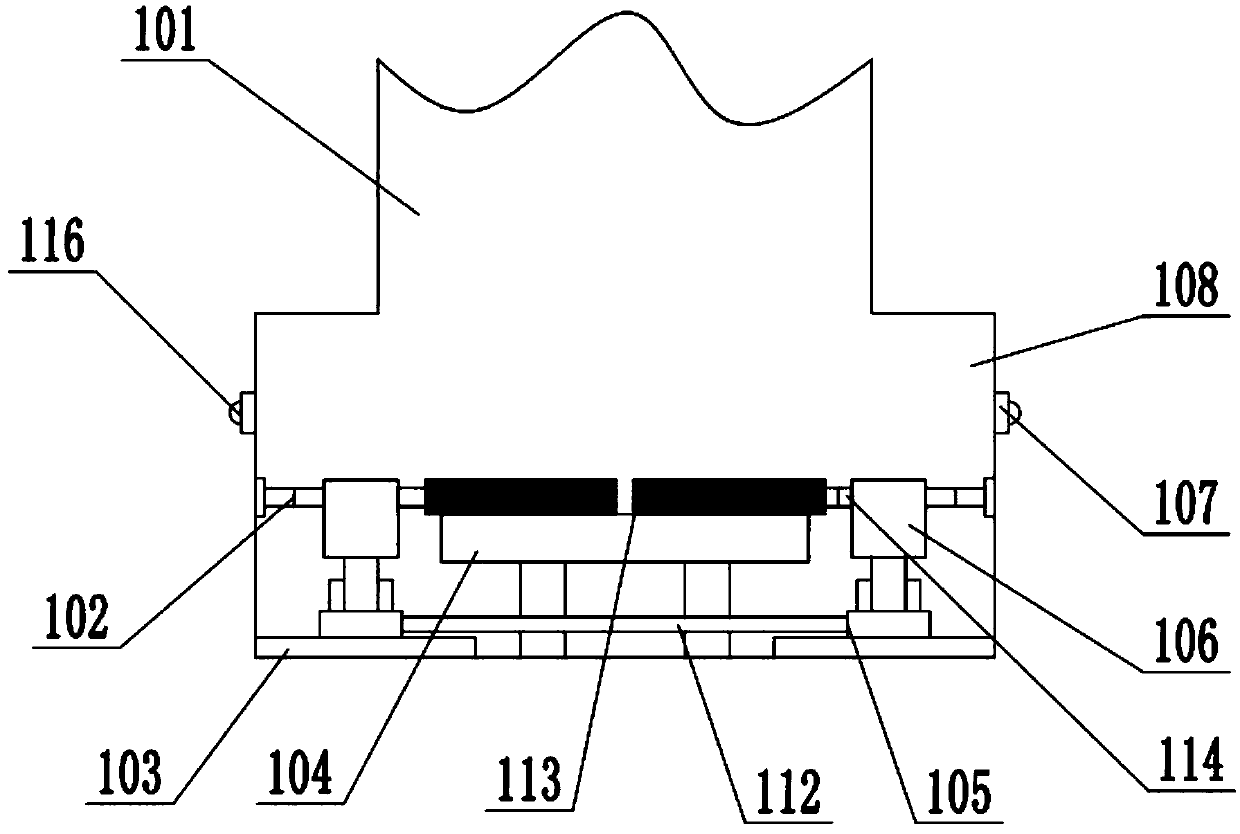

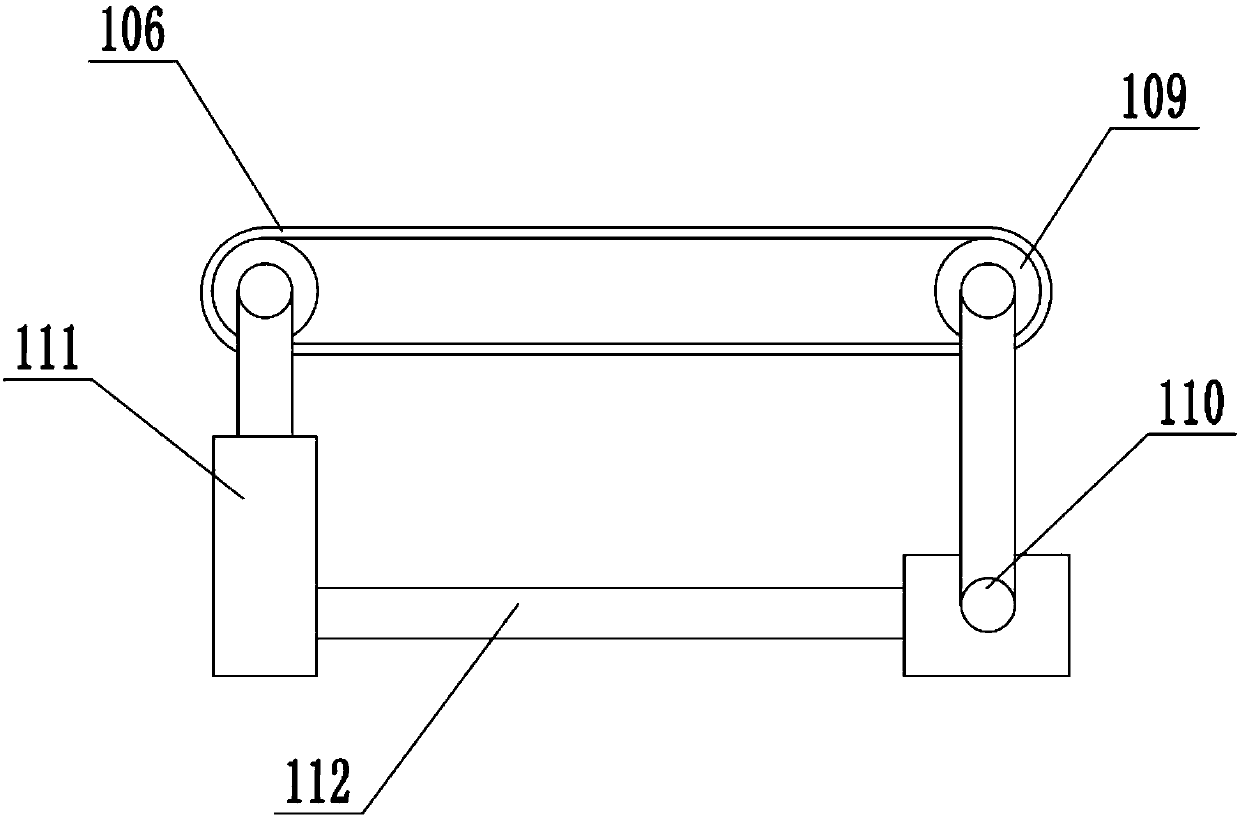

Culture device and method for perches

InactiveCN110226538AHelps growImprove survival rateClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The invention provides a culture device and method for perches. The device comprises a motor I, a screw, a nut seat, a moving plate, a connecting rod, a feed hopper, a rotating column, rotating blades, a discharge pipe, a delivery pipe and high-pressure nozzles, wherein the motor I is mounted on the upper surface of a mounting plate, the screw is arranged on the left side of the motor I, the nut seat is arranged on the annular side surface of the screw, the connecting rod is connected with the front end surface of the nut seat, and the moving plate is connected with the front end surface of the connecting rod. By means of the design, the problem of poor moving feeding effect of the original perch culture device is solved, the feed hopper is arranged on the upper end surface of a charging barrel, the rotating column is arranged on the lower side of a motor II, the rotating blades are arranged on the annular side surface of the rotating column, the discharge pipe is arranged on the lowerend surface of the charging barrel, the delivery pipe is connected to the lower side of the discharge pipe, and the high-pressure nozzles are arranged on the front side of the delivery pipe. The problem of uneven feeding of the original perch culture device is solved by the design; the device has reasonable structure, good feeding effect and even discharging.

Owner:NANJING SHUAIFENG FEED

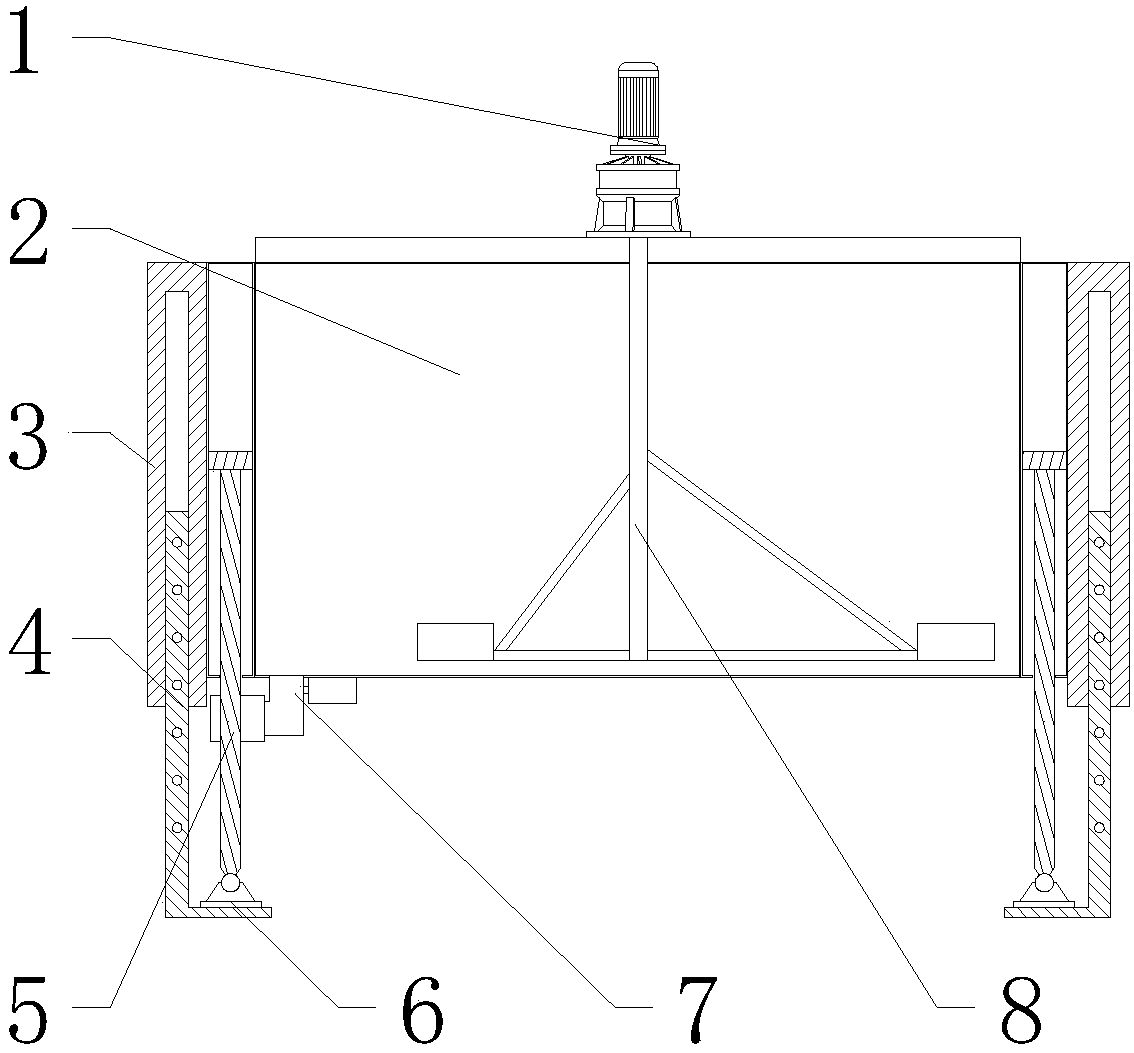

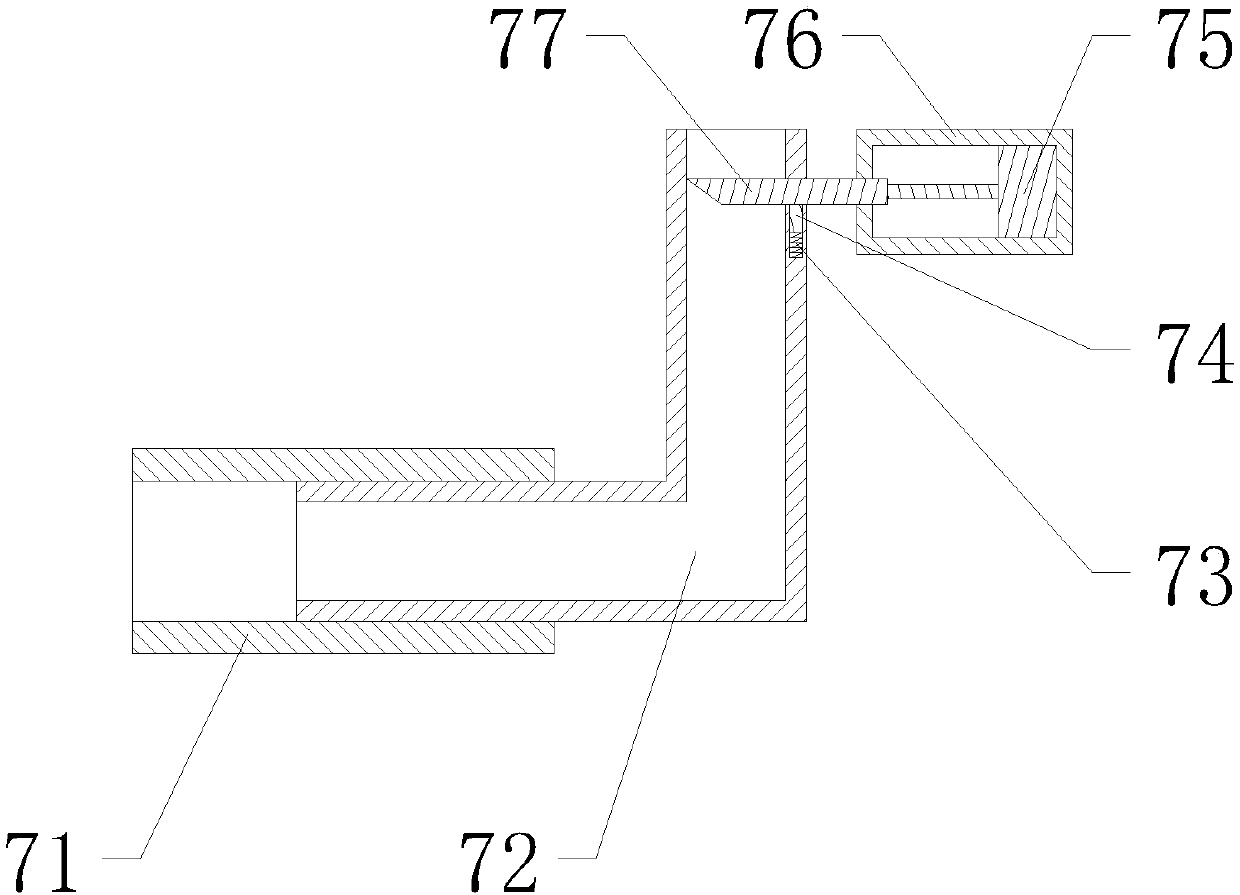

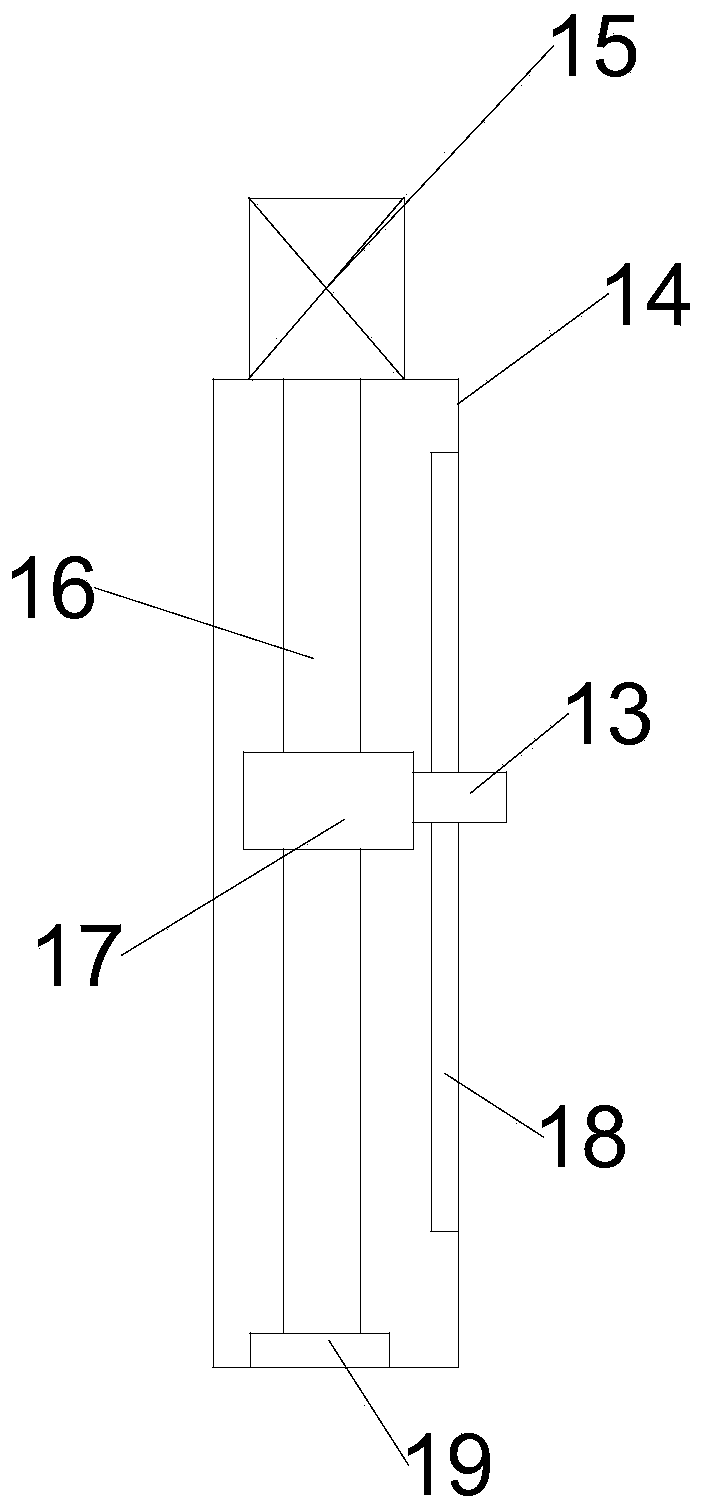

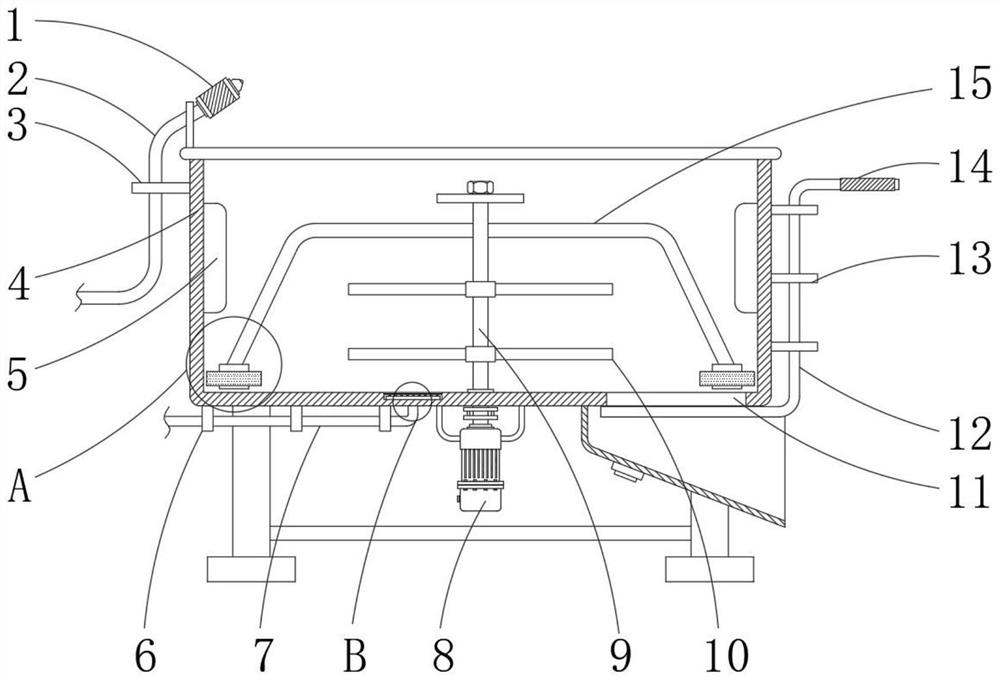

Hydraulic lift type mortar transfer equipment

InactiveCN108016769AImprove lifting stabilityEasy to collectLarge containersHydraulic cylinderEngineering

The invention provides hydraulic lift type mortar transfer equipment. The hydraulic lift type mortar transfer equipment comprises a transfer tank, sleeves, mechanical supporting legs, hydraulic oil cylinders, supporting leg base plates, a hollow pipeline, an L-shaped discharging pipeline, an electric push rod, a fixed tank body and a telescopic plate, wherein the hydraulic oil cylinders are separately installed at the outer ends of the transfer tank; each supporting leg base plate is arranged at the lower end of the corresponding hydraulic oil cylinder and is arranged at the internal bottom end of the corresponding mechanical supporting leg; and each sleeve is installed at the upper end of the corresponding mechanical supporting leg and is fixed to the outer end of the corresponding hydraulic oil cylinder. The hydraulic lift type mortar transfer equipment provided by the invention can implement a lifting action; the electric push rod is arranged at the right wall inside the tank body;the telescopic plate is arranged at the left end of the electric push rod and is installed on the L-shaped discharging pipeline; the hollow pipeline is installed at the left end of the L-shaped discharging pipeline; so the hydraulic lift type mortar transfer equipment can stretch and retract. The hydraulic lift type mortar transfer equipment provided by the invention is convenient to use and operate, can implement the lifting action, can stretch and retract, and is good in stability and high in reliability.

Owner:HUNAN MAINHORN TECH DEV CO LTD

Trash burning treatment device

ActiveCN105698181ABurn completelyEffective early dischargeCombustion technology mitigationIncinerator apparatusBurn treatmentExhaust fumes

The invention discloses a trash burning treatment device. The trash burning treatment device comprises an outer shell, an inner shell, a box, a first separating plate, a second separating plate, a blow-off pipe, a first movement plate, a second movement plate, a first power unit, a second power unit and a connecting pipe; the inner shell is arranged on the inner side of the outer shell, and a burning cavity is arranged inside the inner shell; the box is arranged on the outer shell, a cavity is formed in the box, a feeding opening is formed in the top wall of the box, and a discharging opening is formed in the bottom wall of the box and communicated with the burning cavity; the first separating plate and the second separating plate are both arranged in the cavity and sequentially divide the cavity into a first containing cavity, a second containing cavity and a third containing cavity; the first containing cavity is communicated with the third containing cavity, and the feeding opening and the discharging opening are both communicated with the second containing cavity; a blow-off opening is formed in the first separating plate; and the first end of the blow-off pipe is arranged on the outer side of the box, and the second end of the blow-off pipe penetrates the box to be connected with the blow-off opening. The trash burning treatment device is good in trash treatment effect and waste gas treatment effect.

Owner:湖南未名环保科技有限公司

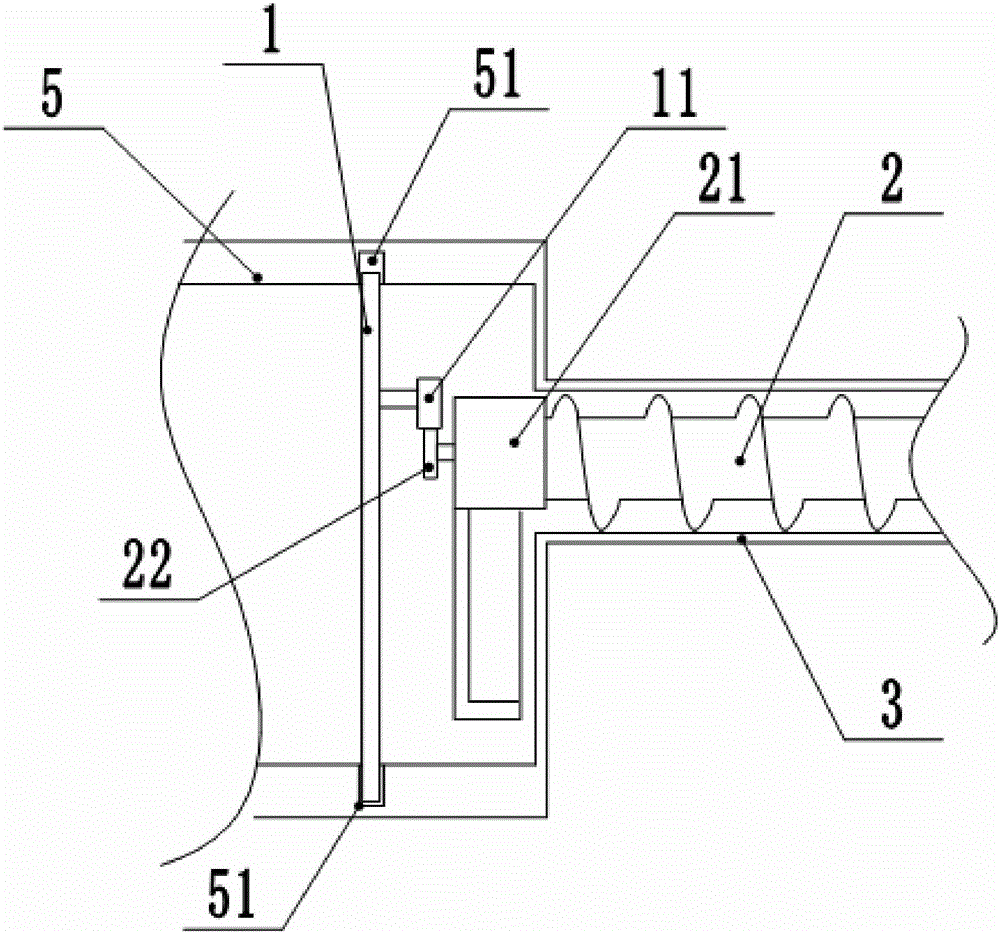

Anti-blocking discharging device of discharging hole of cement grinding mill

InactiveCN105750028AAvoid cloggingOptimize the discharge methodGrain treatmentsEngineeringCement grinding

The invention discloses an anti-blocking discharging device of a discharging hole of a cement grinding mill. The anti-blocking discharging device comprises a filter screen, a discharging hole and a spiral shaft mounted at the discharging hole, wherein the spiral shaft is provided with a feeding hopper; a first cam is mounted at one end, close to the filter screen, of the feeding hopper; a second cam is mounted on one face, close to the feeding hopper, of the filter screen; grooves, which are matched with the end parts of the filter screen and are used for the upward and downward movement of the filter screen, are formed in parts, corresponding to the two ends of the filter screen, of an inner wall of the cement grinding mill; the spiral shaft drives the feeding hopper and the first cam to rotate; the first cam rotates to drive the second cam to rotate; and the filter screen moves up and down along the rotation of the second cam. The invention aims at providing the anti-blocking discharging device of the discharging hole of the cement grinding mill, which can prevent the filter screen from being blocked and has a rapid discharging function.

Owner:广西建筑材料科学研究设计院有限公司

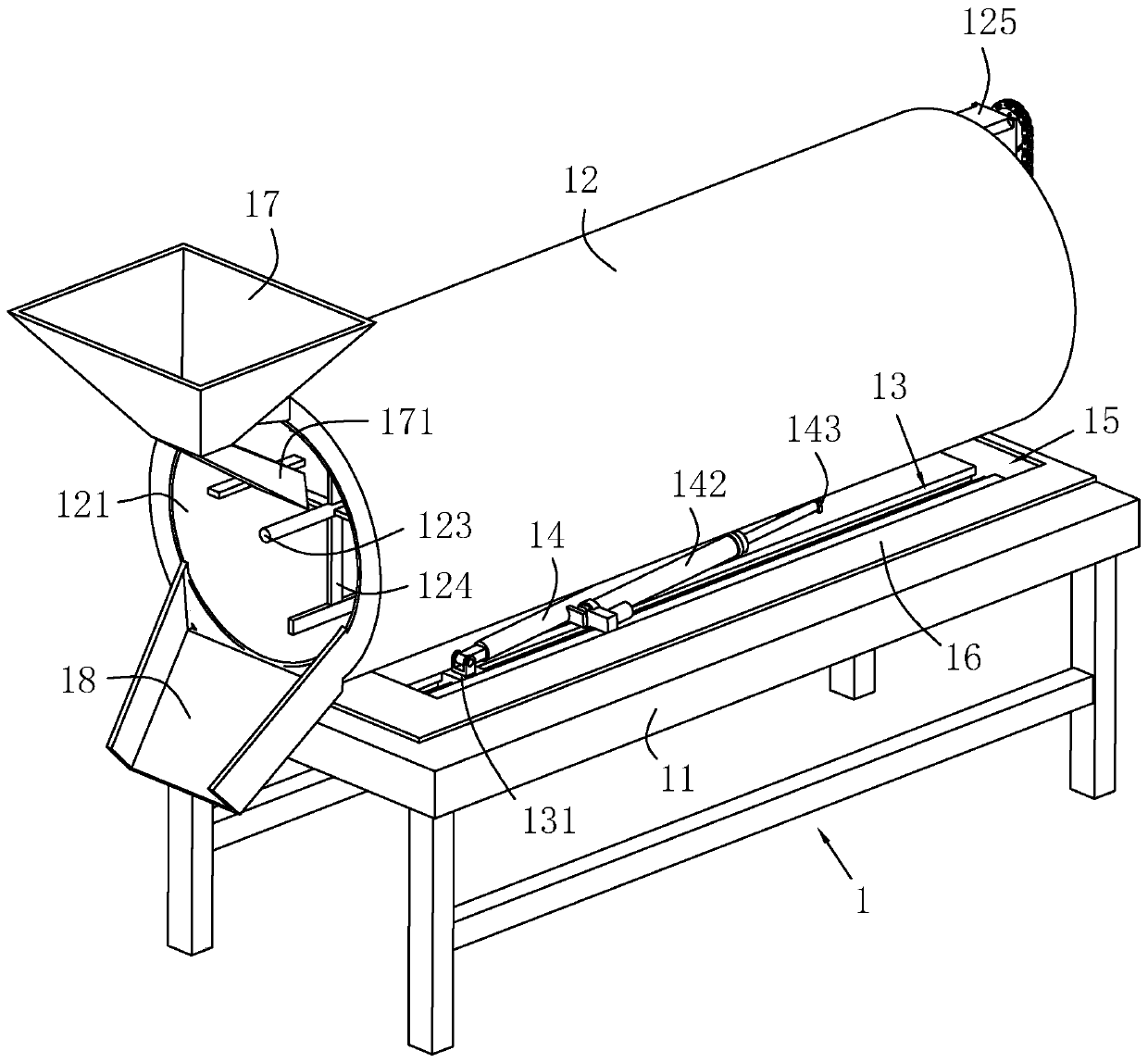

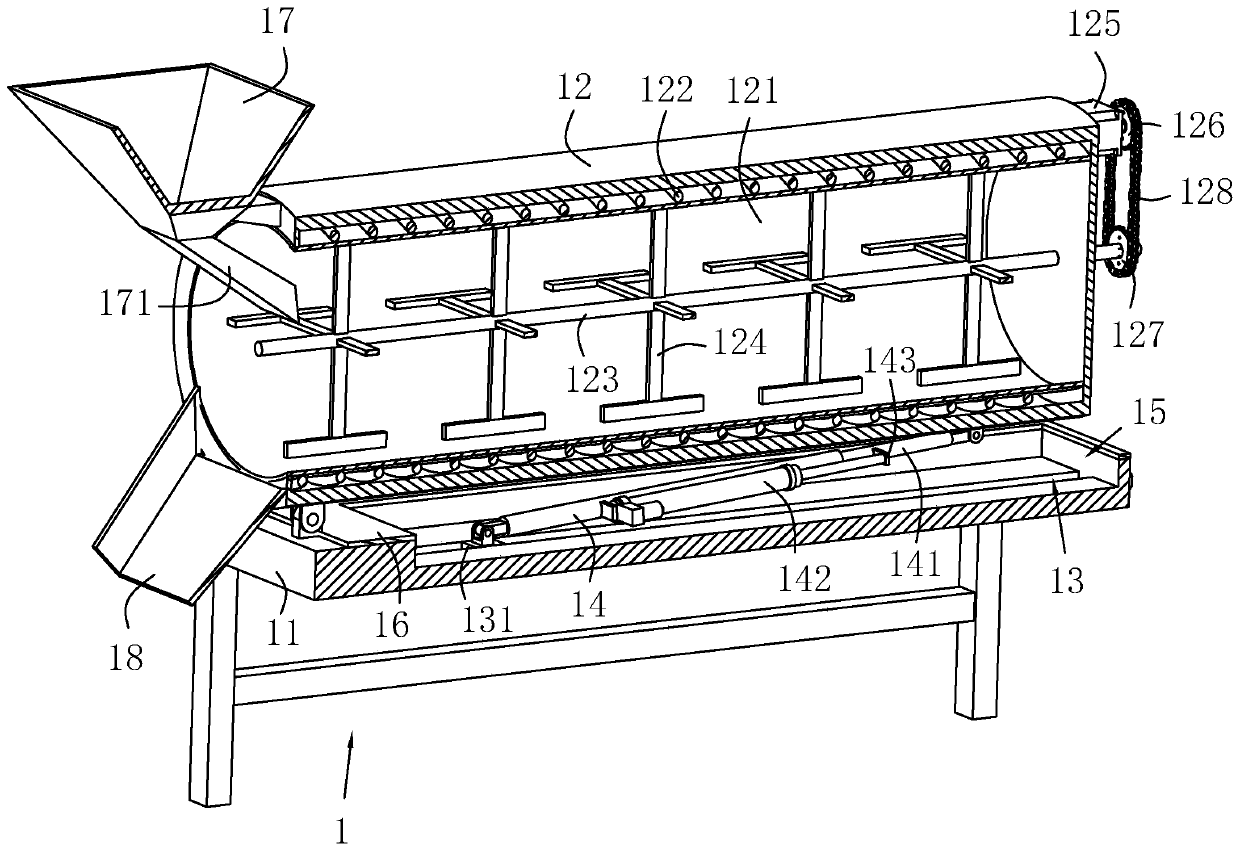

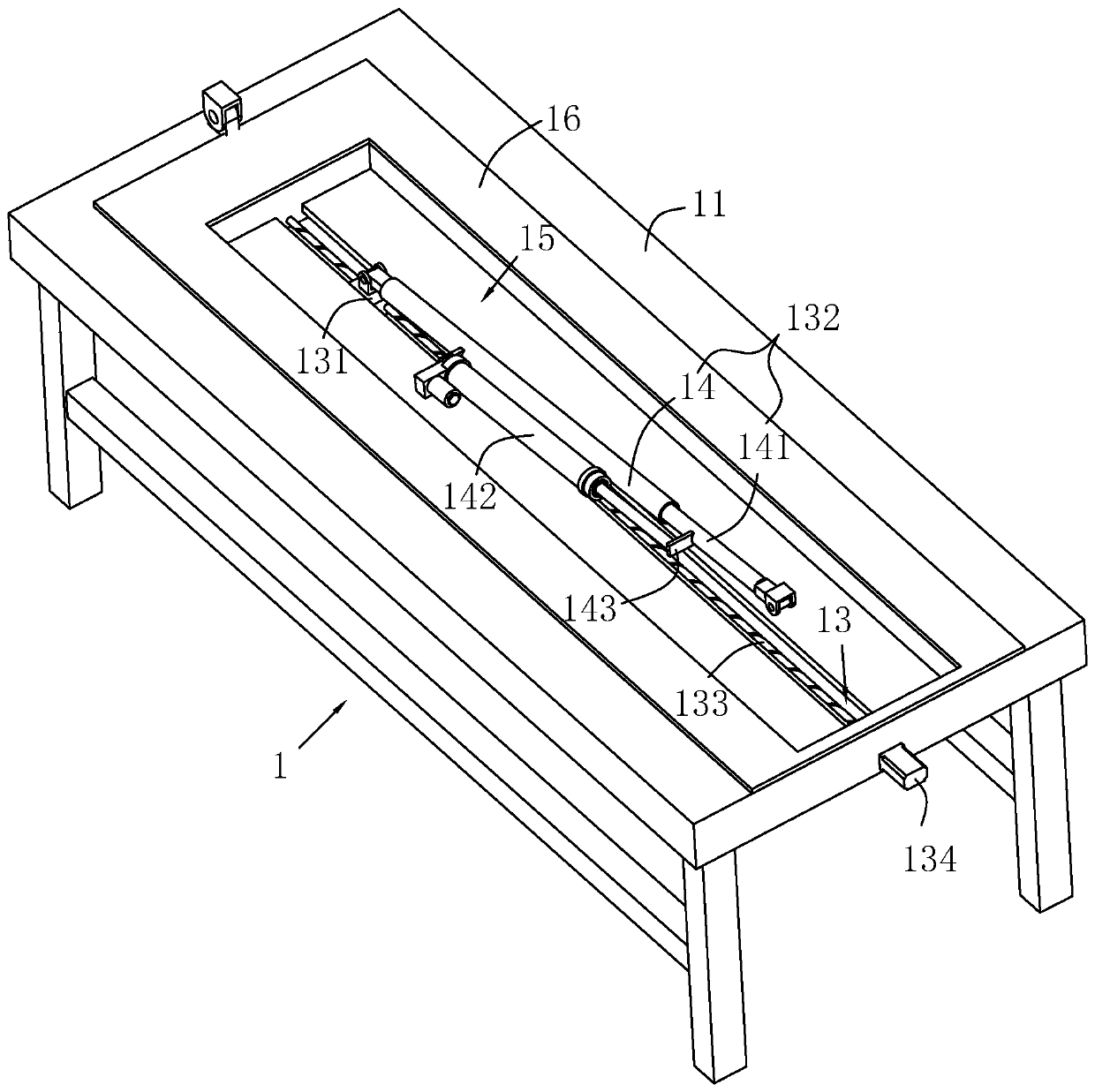

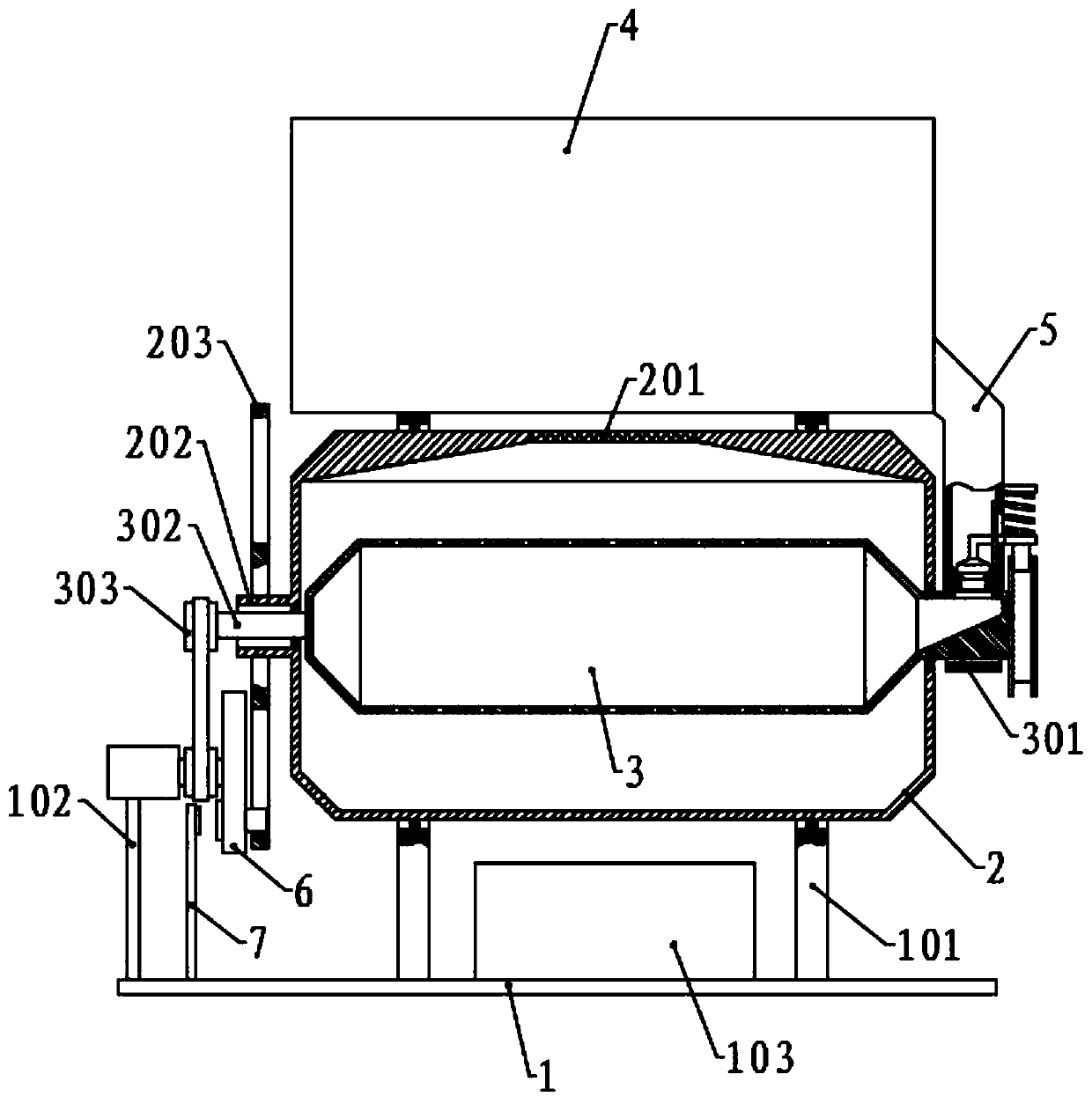

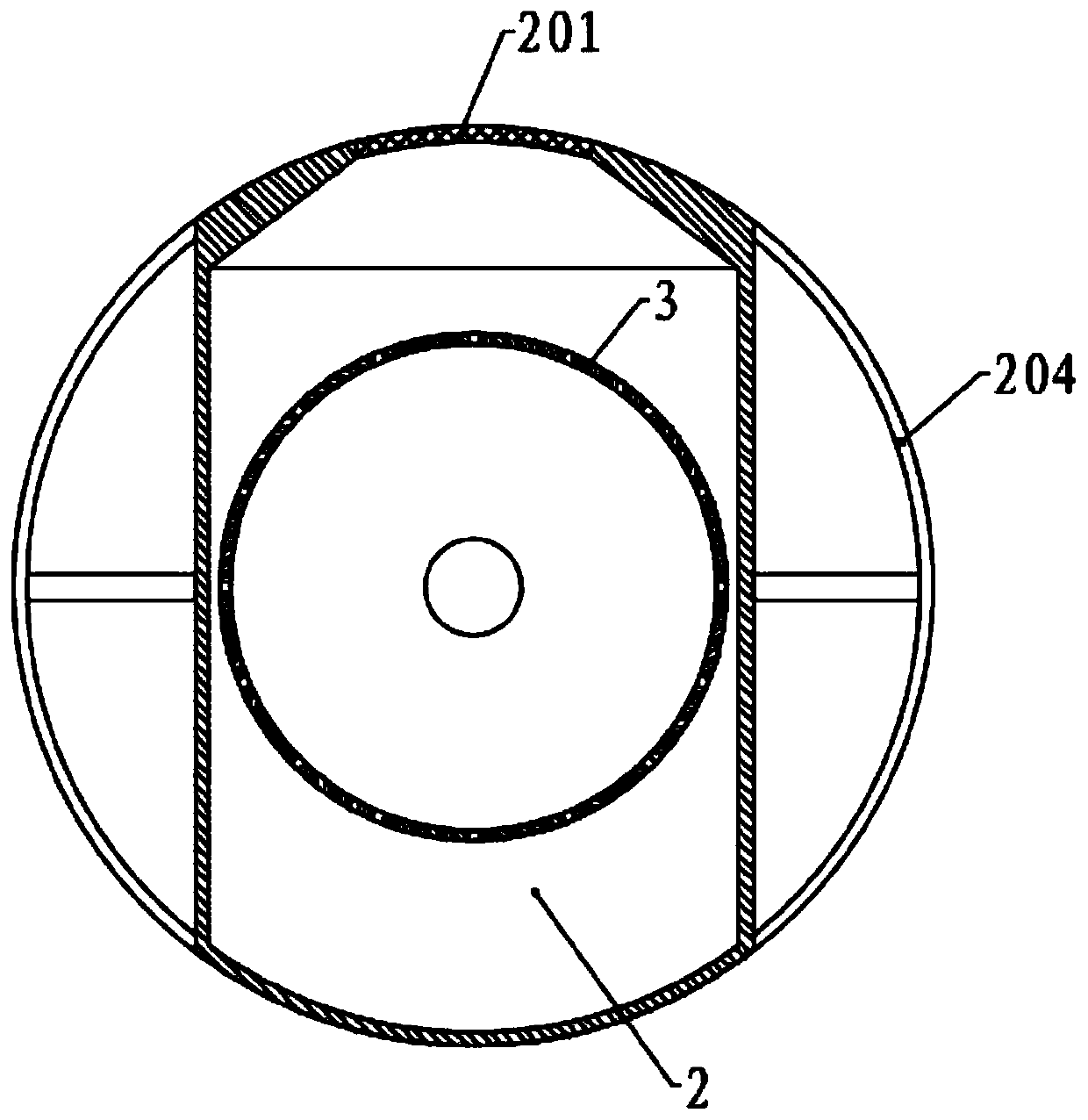

Raw material stir-frying equipment for sesame oil production

PendingCN111234915AImprove the output effectIncrease the tilt angleFatty-oils/fats productionFood treatmentEngineeringSesame Oils

The invention relates to raw material stir-frying equipment for sesame oil production. The invention belongs to the technical field of sesame oil production equipment. The equipment comprises a framebody, wherein a base is arranged on the frame body; a heating cylinder is arranged on the base; a stir-frying cylinder coaxial with the heating cylinder is arranged in the heating cylinder; a heatingmechanism is arranged between the heating cylinder and the stir-frying cylinder; the same ends of the stir-frying cylinder and the heating cylinder are opened; a stirring mechanism is arranged in thestir-frying cylinder; one end of the heating cylinder is hinged to the base; the hinged point of the heating cylinder and the base is arranged at a position close to the openings of the stir-frying cylinder and the heating cylinder; the base is provided with a driving piece for driving the heating cylinder to rotate at the hinge point so as to drive stir-fried materials to be poured out along theopening of the stir-frying cylinder; the driving piece can drive the heating cylinder to rotate at the hinge point, so that the heating cylinder rotates from the horizontal direction to the inclined direction, sesame in the stir-frying cylinder can be poured out along the opening of the stir-frying cylinder, the sesame in the stir-frying cylinder can be completely poured out along the opening of the stir-frying cylinder, and the discharging effect of the stir-frying equipment is improved.

Owner:成都新润油脂有限责任公司

Efficient cleaning and winding equipment for cable production

The invention discloses efficient cleaning and winding equipment for cable production. The efficient cleaning and winding equipment comprises a hollow machine box and a plurality of supporting legs mounted at the lower end of the machine box, a partition plate is vertically arranged in an inner cavity of the machine box and divides the inner cavity of the machine box into a cleaning chamber and a winding chamber in sequence, a cleaning mechanism is arranged in the cleaning chamber, a winding mechanism is arranged in the winding chamber, the cleaning mechanism comprises a wire inlet penetrating through the side wall of the cleaning chamber in an inserted mode, a cleaning box is arranged in an inner cavity, corresponding to the horizontal position of the wire inlet, of the cleaning chamber in a sliding mode, the two sides of the cleaning box are not closed, banister brush wires are densely distributed in the cleaning box, sliding rods horizontally extend on the front side wall and the rear side wall of the cleaning box, the sliding rods are sleeved with sliding sleeves in a sliding mode, the sliding sleeves are horizontally and fixedly installed on the inner walls of the front side and the rear side of the cleaning chamber correspondingly, and a linkage rod is connected to the top wall of the cleaning box in a rotating mode through a linkage base. The efficient cleaning and winding equipment solves the problems that in the prior art, the cable winding efficiency is low, cable discharging is inconvenient, and the wound cables cannot be cleaned.

Owner:皖缆集团股份有限公司

High-temperature furnace for producing ultra-wide continuous coiled graphene

The invention discloses a high-temperature furnace for producing ultra-wide continuous coiled graphene. The furnace includes a base, wherein an adjusting base is arranged at the top of the base, a furnace body is hinged to the adjusting base, a driving motor is arranged at the top of the furnace body, a disturbance shaft is connected to an output shaft of the driving motor, installation disturbance rods are symmetrically arranged on the two sides of the disturbance shaft, the three installation disturbance rods are jointly connected with a scraper, the scraper is attached to the inner wall ofthe furnace body, and an electric heating block is arranged on the bottom wall in the furnace body below the disturbance shaft. Materials are fed into the furnace body, the electric heating block is started, then the driving motor and the disturbance shaft are started to rotate so as to drive the installation disturbance rods to rotate and spiral blades rotate, and therefore the melting rate is increased, and meanwhile the material melting rate is further increased through arrangement of the disturbance inclined rods.

Owner:安徽碳华新材料科技有限公司

Double-layer ball milling device for high-purity quartz sand processing

ActiveCN111589533AAvoid affecting the ball milling effectRealize intermittent feedingGrain treatmentsEngineeringQuartz

The invention discloses a double-layer ball milling device for high-purity quartz sand processing in the technical field of high-purity quartz sand processing. The double-layer ball milling device comprises a base, an outer cylinder, an inner cylinder and a storage box, wherein a driving assembly is arranged on the base, and the base is connected with the inner cylinder and the outer cylinder through the driving assembly; the storage box is connected with a feeding pipe, and a sealing assembly is arranged in the feeding pipe; and the sealing assembly is correspondingly connected with a rotating wheel on the inner cylinder. According to the double-layer ball milling device, the inner cylinder is rotated through the driving assembly, so that quartz sand is subjected to primary ball milling through a ball milling ball, and enters the outer cylinder through sieve holes, and meanwhile, intermittent discharging is realized through the rotating wheel and the sealing assembly; the outer cylinder is enabled to swing in a reciprocating mode through a rotating disc and rotating rods, and the quartz sand is subjected to secondary grinding; and a connecting shaft is separated from the rotatingrods through an electromagnet, the outer cylinder is turned over until a screen is downward, so that discharging is facilitated, the connecting shaft is connected with the corresponding rotating rod again, and as a result, the outer cylinder swings and drives the quartz sand to move at the screen, and the screening and discharging effect is improved.

Owner:连云港原舜光伏材料有限公司

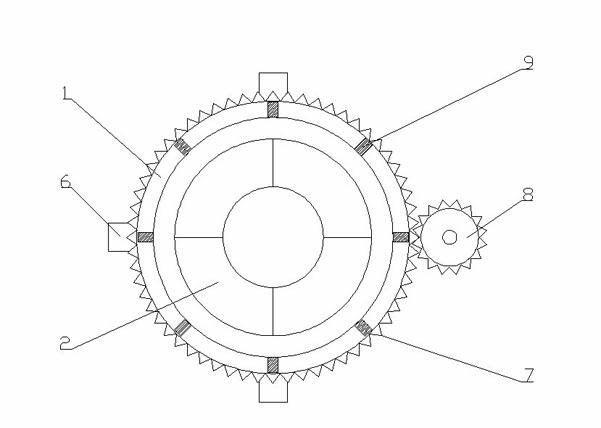

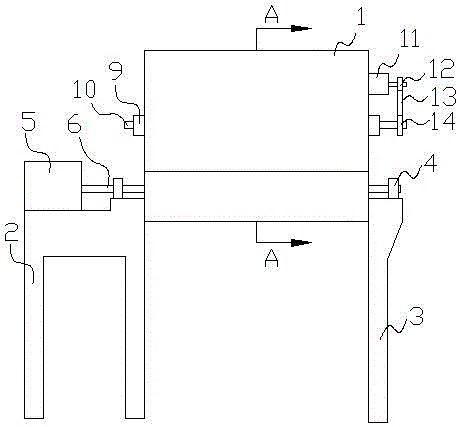

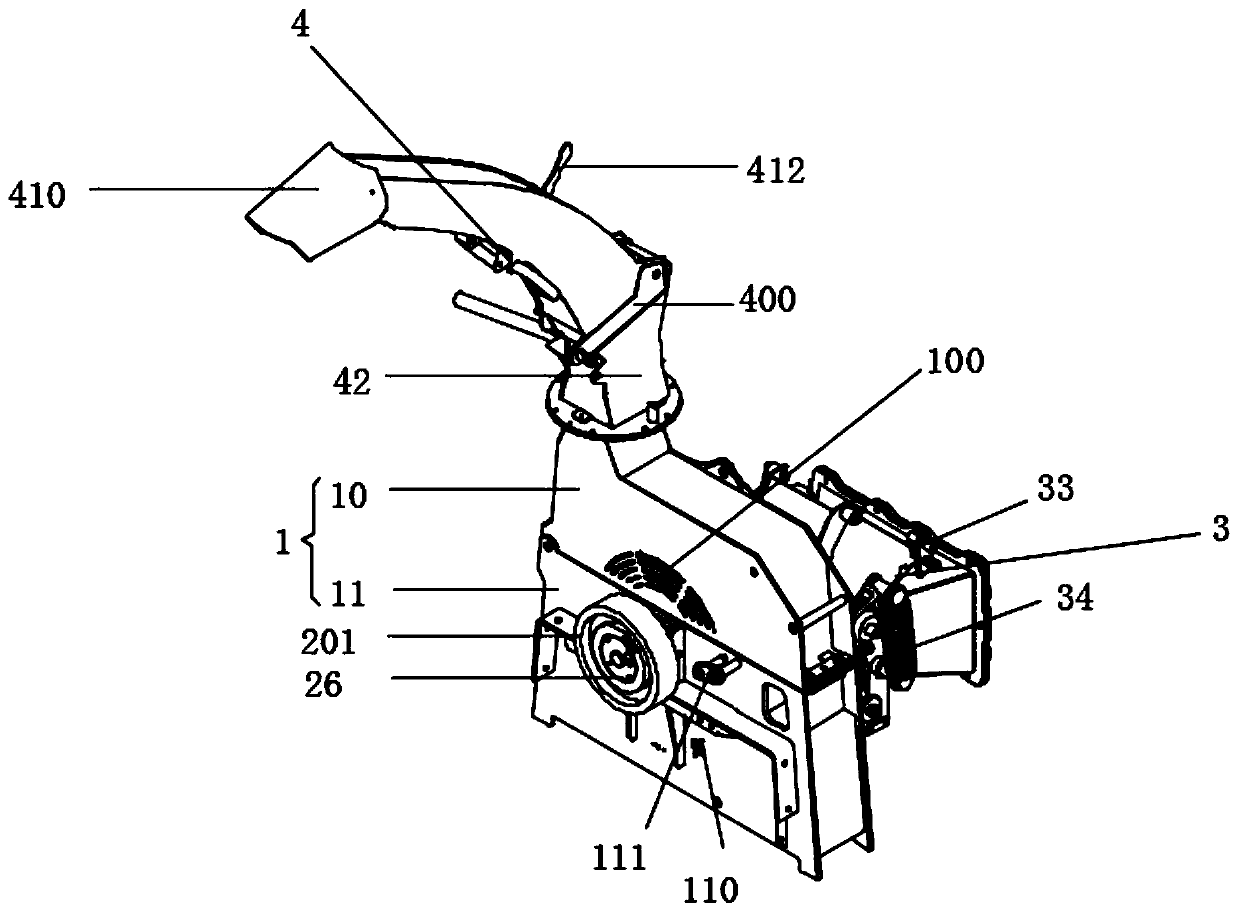

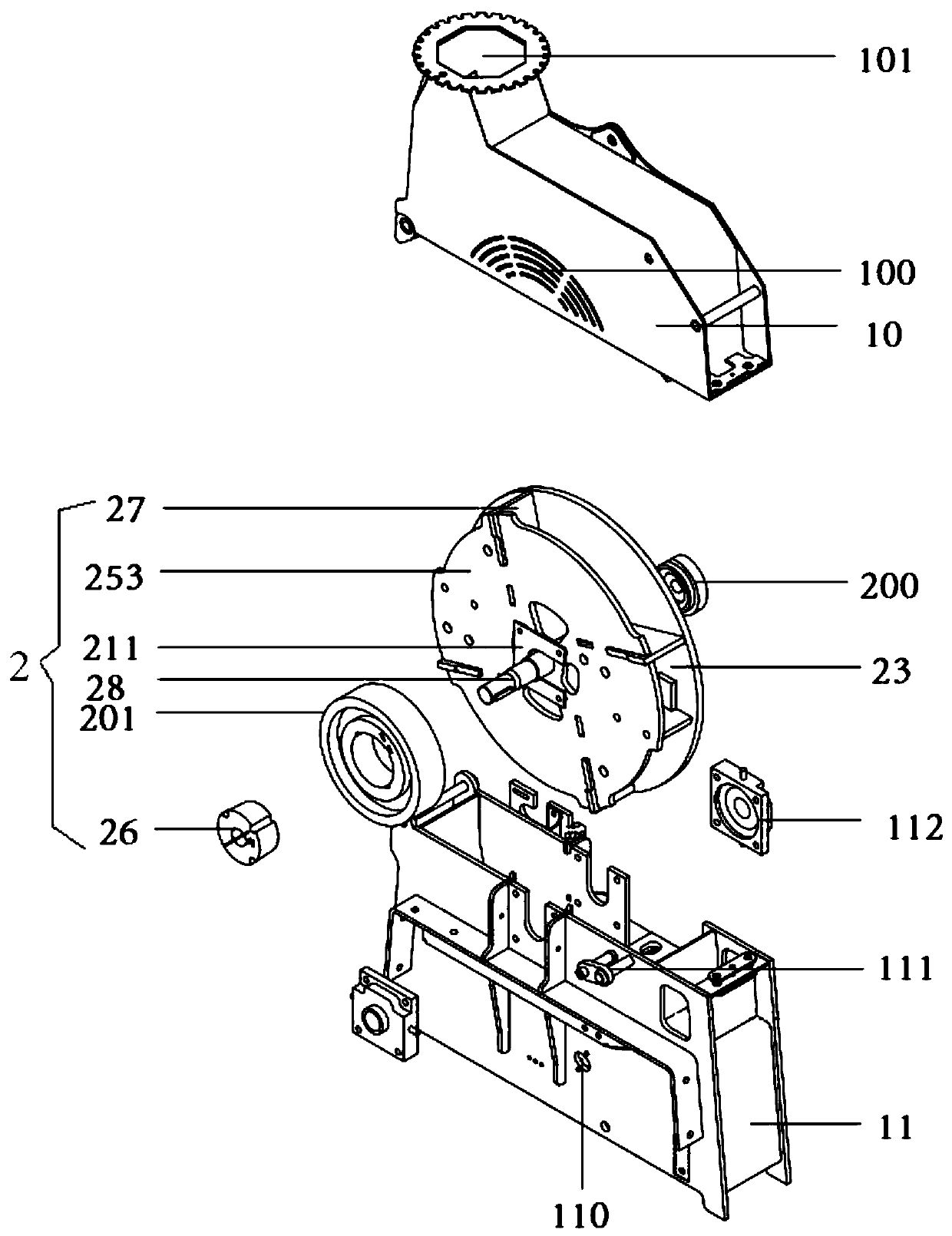

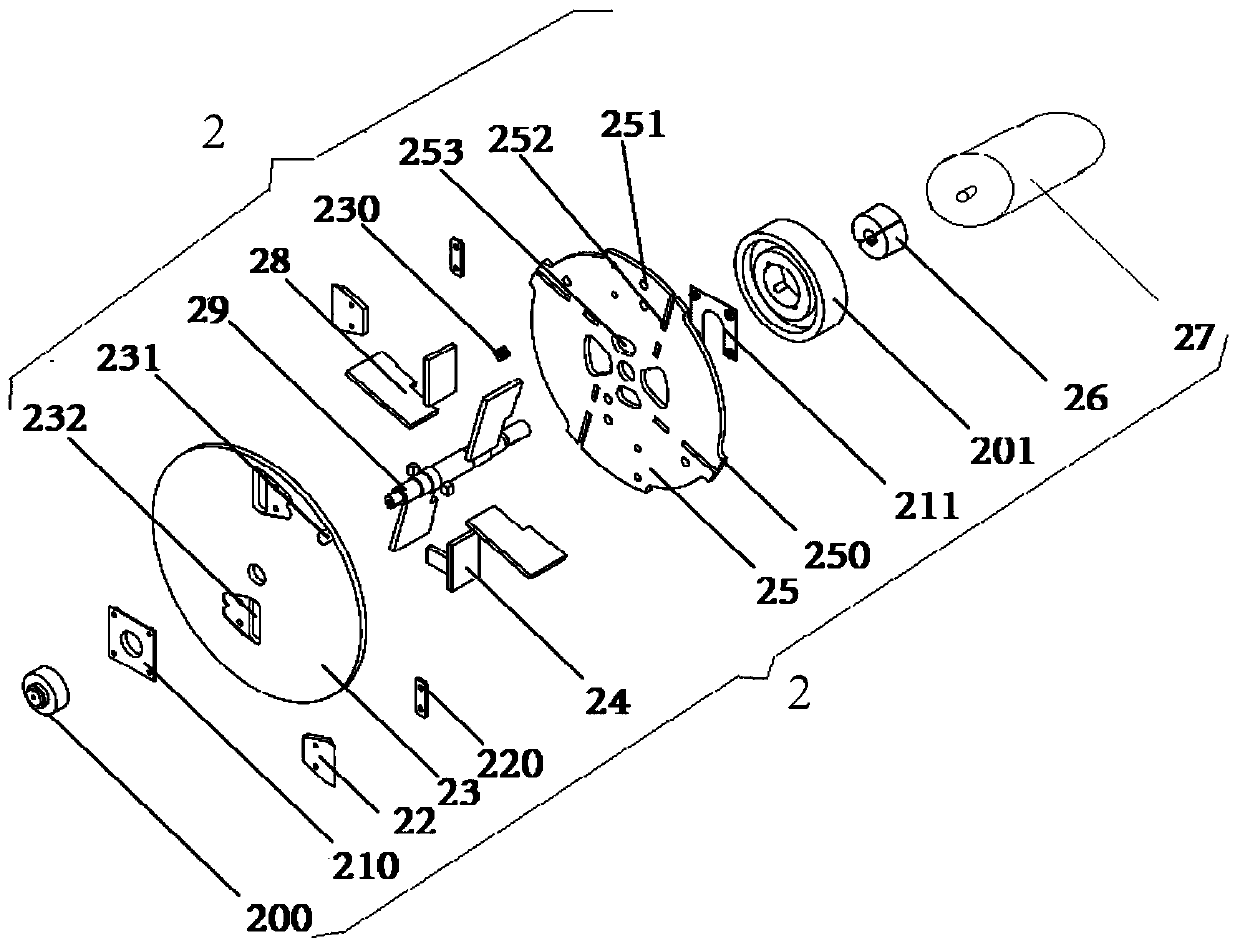

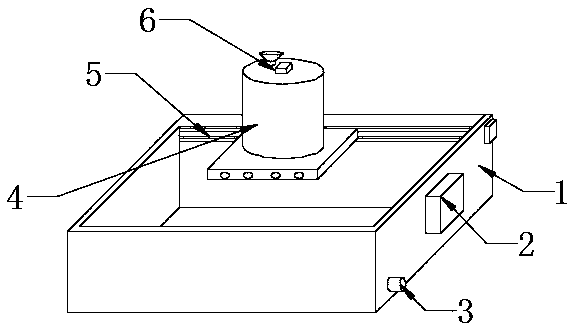

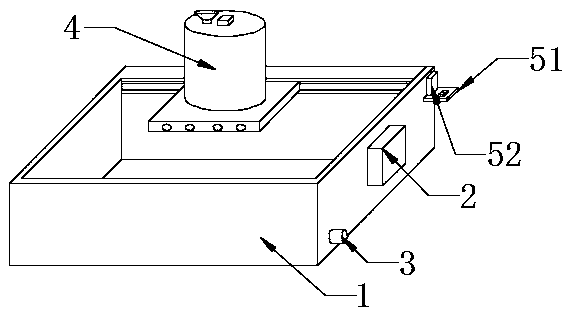

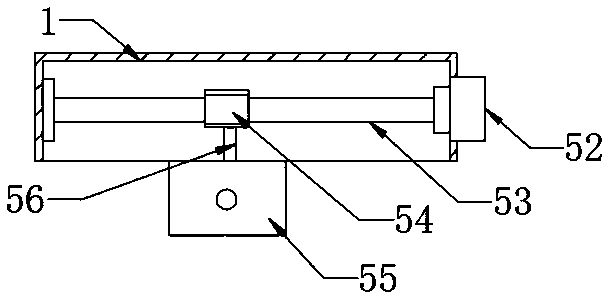

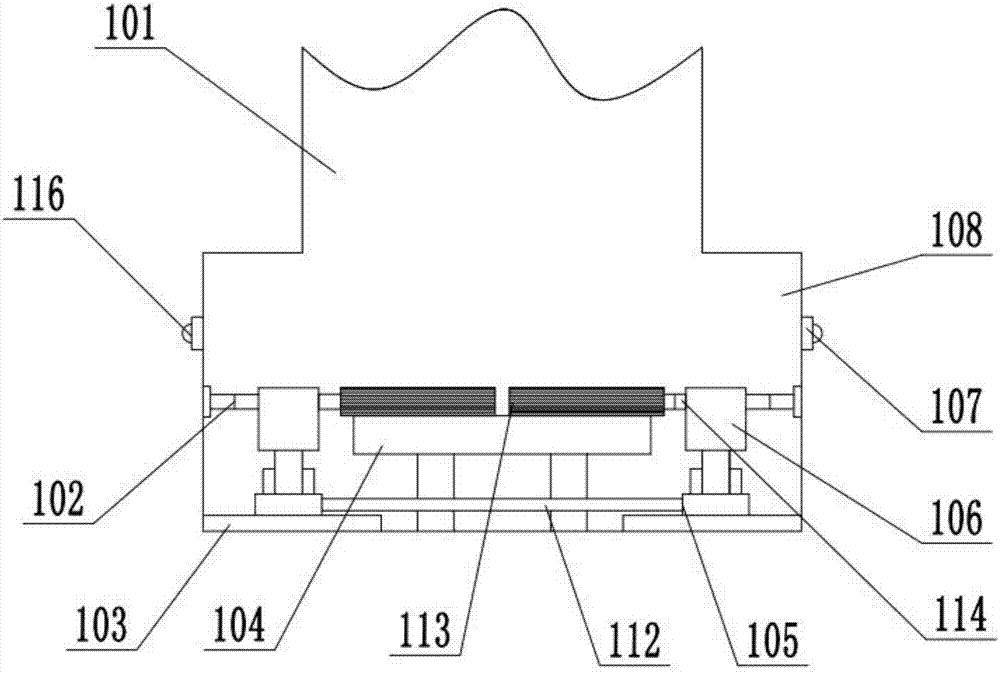

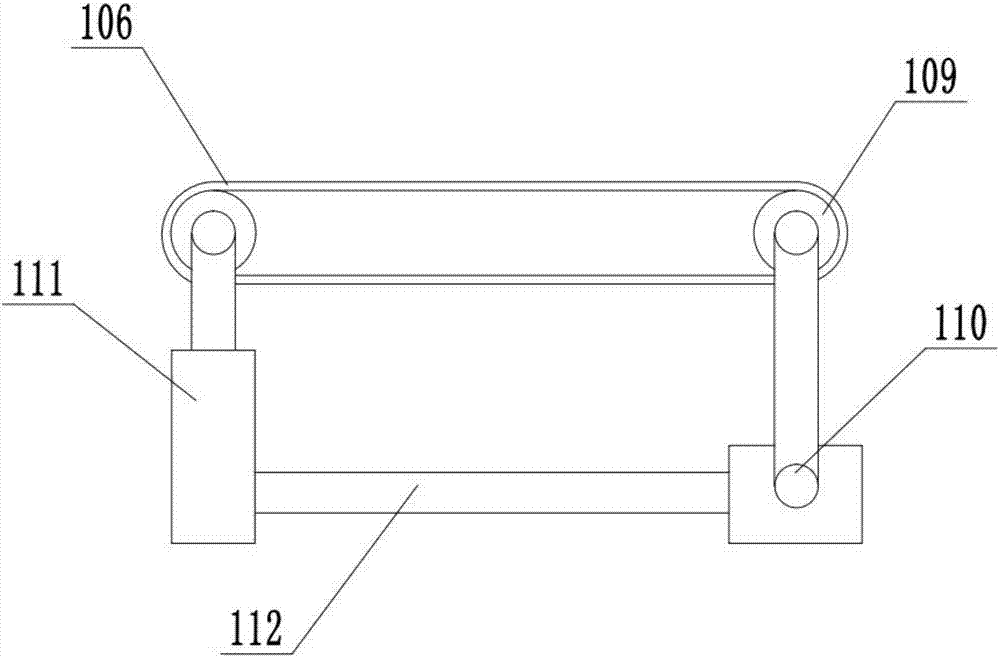

Transmission device for production line of outdoor unit of air conditioner

ActiveCN103274166AReduce manual conversionImprove the output effectConveyorsControl devices for conveyorsProduction lineEngineering

The invention relates to a transmission device for a production line of an outdoor unit of an air conditioner. The transmission device comprises a machine frame and a transmission chain, wherein the cross section of the machine frame is rectangular, the transmission chain is arranged on the machine frame, steering devices facilitating steering of the air conditioner on the production line are arranged on corners of the machine frame, and a guide device is arranged on a position, on the discharging side of the transmission chain, of the machine frame. The machine frame is further provided with a control device used for controlling the steering devise to rotate. The transmission device has the advantages that due to the fact that the steering devices are disposed on the corners of the machine frame, the outdoor unit of the air conditioner is steered, and accordingly the outdoor unit of the air conditioner is automatically steered to the next installation position where a part needs to be installed; manual changes are reduced; due to the fact that the guide device is arranged on the discharging side for discharging, discharging effects are improved and use effects are good.

Owner:海信(浙江)空调有限公司

Spray drying machine for ceramic tile production

InactiveCN107823899ALarge contact rangeEasy to spray dryEvaporator accessoriesEvaporation by sprayingProcess engineeringSpray dried

The invention discloses a spray drying machine for ceramic tile production and relates to the technical field of ceramic tiles. The spray drying machine comprises an outer frame and is characterized in that a material receiving case is slidably connected to the bottom of the inner wall of the outer frame, a discharging plate located at the top of material receiving case is slidably connected between two sides of the inner wall of outer frame, a moving device is fixedly connected to the left side of the bottom of the inner wall of the outer frame, and a stabilizing device located on the right side of the moving device is connected to the bottom of the inner wall of the outer frame. The spray drying machine has the advantages that spray drying is facilitated, hot air forms reflux inside theouter frame through two air outlet plates to increase a drying effect, an atomizing sprayer is driven to move to expand the contact range between materials and the air so as to facilitate drying, thedischarging plate is conveniently driven to vibrate to allow the materials to enter the material receiving case conveniently so as to increase a discharging effect, time waste is reduced, the stability of the spray drying machine is increased, the service life of the spray drying machine is prolonged, and use convenience is brought to people.

Owner:WUXI HUIOU CERAMIC CO LTD

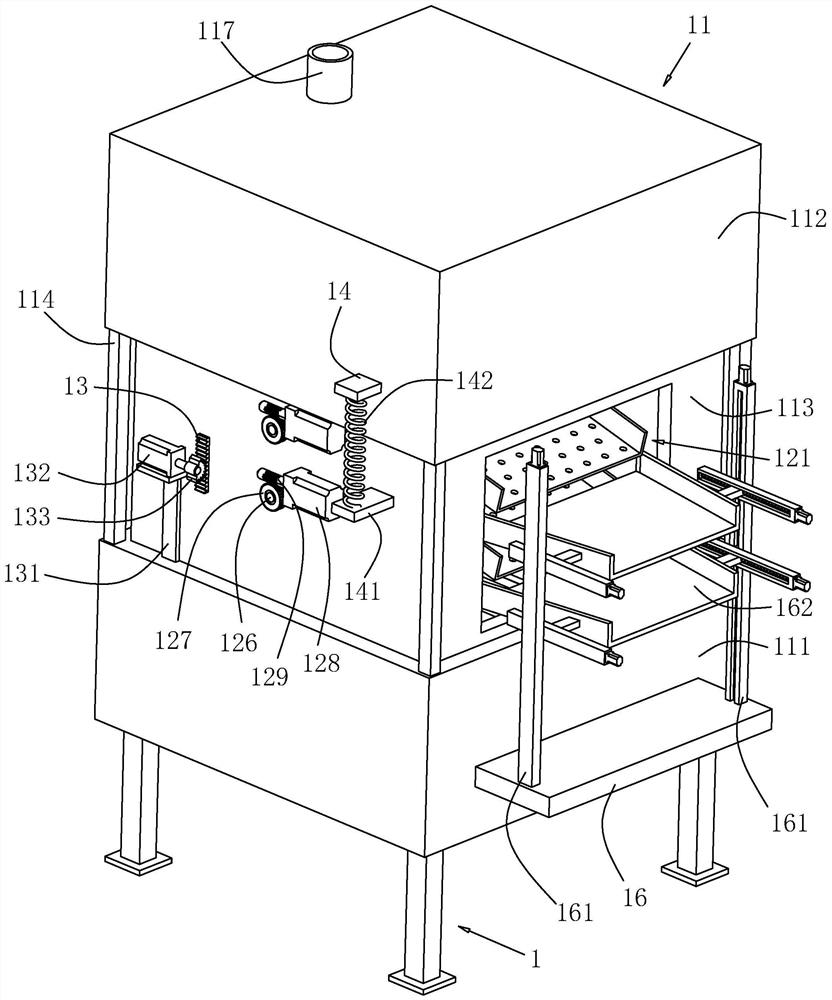

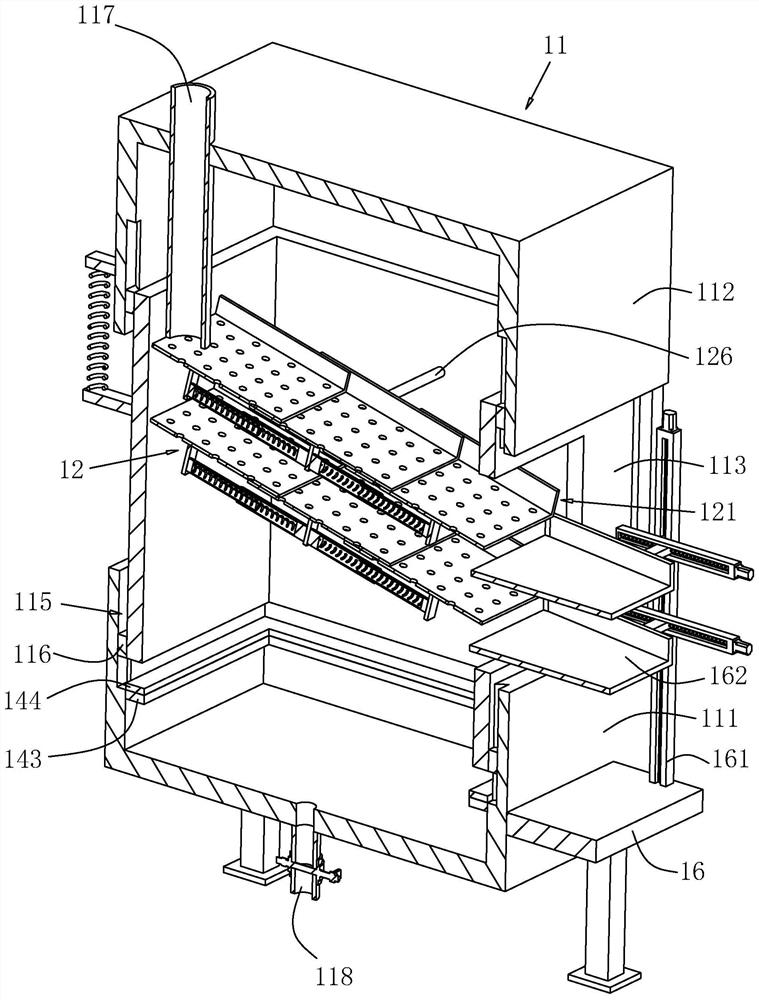

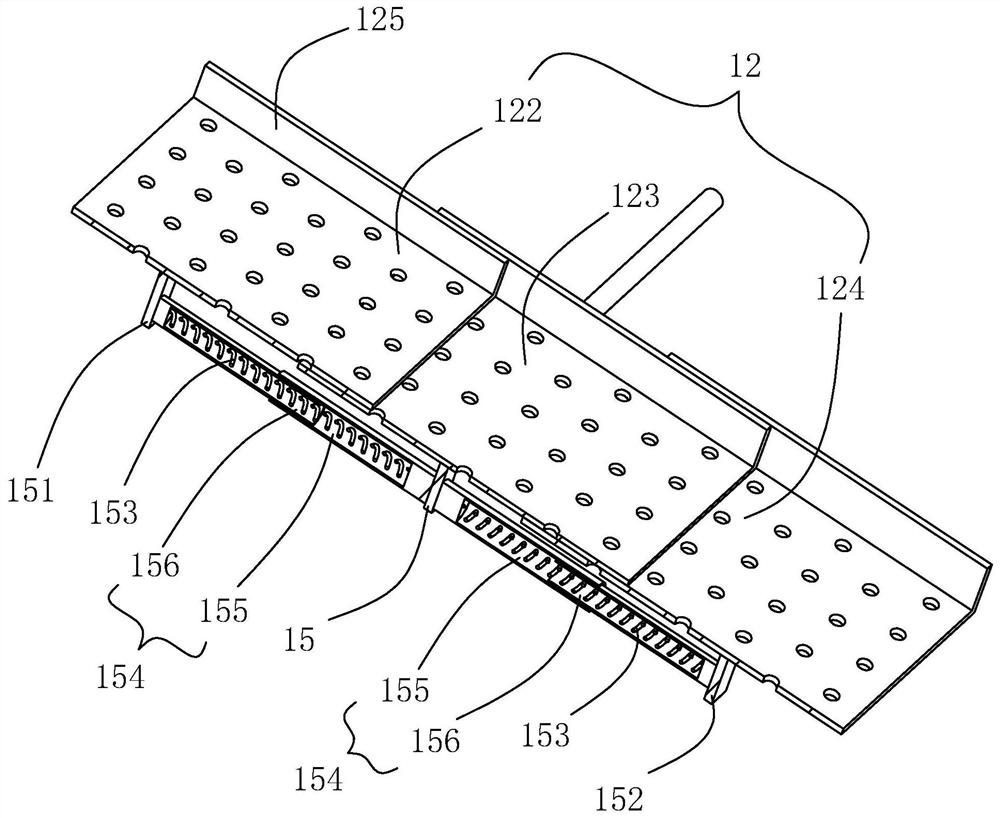

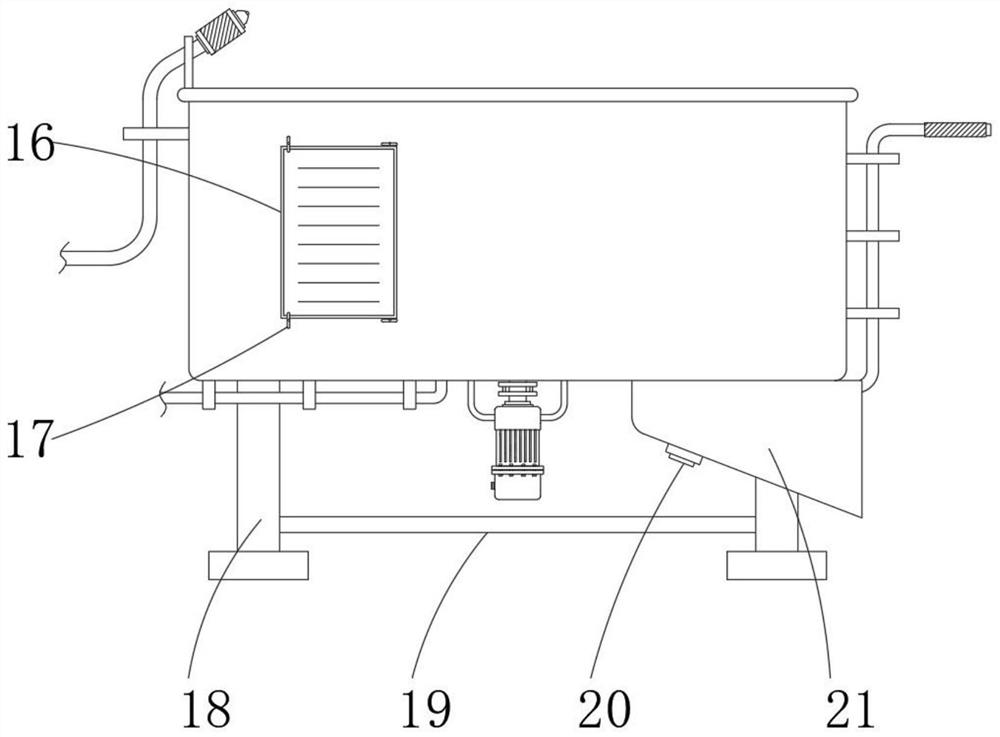

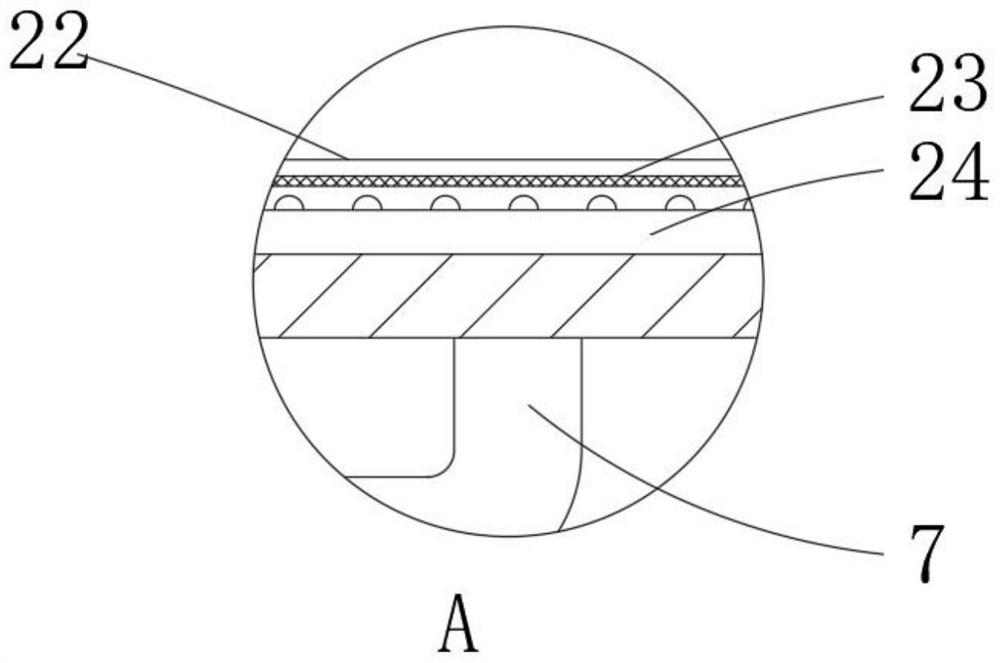

Concrete sewage sand and gravel separation equipment

ActiveCN112169425BImprove separation efficiencyImprove the output effectMoving filtering element filtersEngineeringSewage

The application relates to a concrete sewage sand and gravel separation equipment, which includes a frame body, on which a box body is arranged, and the box body includes a first fixed box, a second fixed box and a sliding box, and the top wall of the second fixed box is provided with a Feed pipe, the bottom wall of the first fixed box is provided with an outlet pipe, and the first fixed box is provided with a driving member for driving the sliding box to reciprocate in the first fixed box and the second fixed box, and the sliding box slides along the The height direction of the box is provided with a plurality of filter screens, and the diameters of the filter holes on the multiple filter screens decrease from top to bottom along the height direction of the box body, and each filter screen is arranged in the sliding box in an inclined state. There are openings on the side wall and at the edge of the same side of multiple filter screens. The concrete sewage sand and gravel separation equipment also includes a bearing mechanism for receiving the filtered materials on each filter screen; Advantages of stone separation efficiency.

Owner:仁寿县鑫路达混凝土有限公司

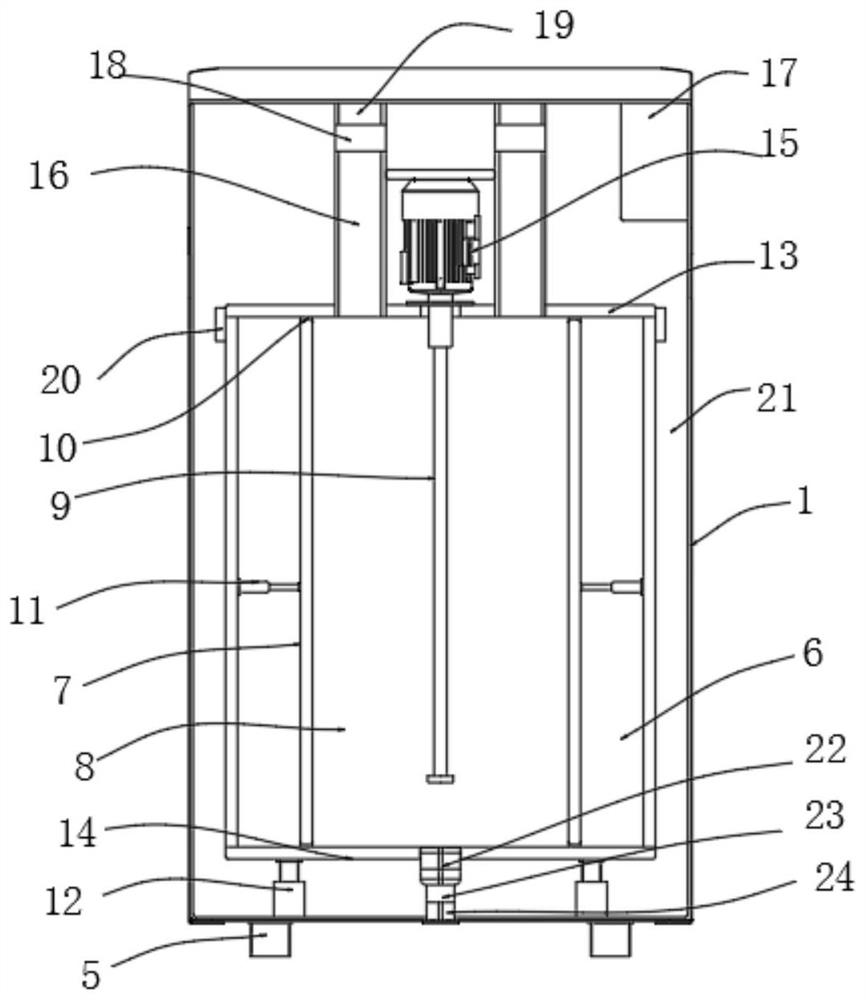

Efficient stirring device for production raw materials of aerated concrete bricks

InactiveCN112372835AProtect health and safetyReduce adhesionDischarging apparatusUsing liquid separation agentBrickWater flow

The invention discloses an efficient stirring device for production raw materials of aerated concrete bricks, and relates to the technical field of aerated concrete brick production. The efficient stirring device comprises a shell, a vertically-arranged stirring shaft is rotatably connected to the center of the lower inner wall of the shell, multiple uniformly-distributed stirring rods are fixedlyconnected to the outer side of the stirring shaft, and two symmetrically-distributed stirring paddles are fixedly connected to the top end of the stirring shaft. According to the device, water flow is introduced through a dust falling pipe, water mist is continuously sprayed out under the action of an atomizing spray head, and therefore the dust falling effect is achieved on raised dust, and thehealth and safety of operators are protected; and during stirring, under work of a driving motor, the stirring shaft can drive the stirring paddles to rotate, the rotating stirring paddles can drive rotating rings at the bottom ends of the stirring paddles to rotate, the rotating rings can drive a sweeping brush to continuously brush the edge of the inner wall of the shell, and therefore attachment of raw materials is reduced, and the overall mixing and stirring effect of the raw materials is improved.

Owner:ANHUI LYUFENG ENVIRONMENTAL PROTECTION & ENERGY SAVING MATERIAL CO LTD

Recovery method for waste of 3D printer

InactiveCN107972277AReasonable designRealize detachable functionAdditive manufacturing apparatusPlastic recyclingRecovery methodInjection moulding

The invention relates to the technical field of 3D printing, in particular to a recovery system for waste of a 3D printer, and discloses a recovery method using the recovery system. The recovery system comprises a waste storage device, a waste recovery device, a waste cooling device, a waste crushing device, a crushed waste conveying device and a second-time injection molding device. The recoverymethod comprises the processes of waste storage, waste recovery, waste cooling, waste crushing, waste conveying, and injection molding. Through reasonable arrangement and cooperation division of the processes, the 3D waste is systematically recovered, and recycling of the waste of the 3D is achieved.

Owner:HUNAN KUANGCHU TECH CO LTD

Conductive rubber roller producing and manufacturing device

ActiveCN112959537AImprove uniformityImprove the mixing effectStructural engineeringMechanical engineering

The invention relates to a conductive rubber roller producing and manufacturing device which comprises a base, and a frame body is arranged on the base and comprises a bottom plate and side plates which are perpendicular to the bottom plate and located on the two sides of the bottom plate. A first roller and a second roller are rotationally arranged between the side plates on the two sides, and driving mechanisms used for driving the first roller and the second roller to rotate are arranged on the side plates. A conveying device used for conveying powder to the rubber between the first roller and the second roller is arranged between the side plates on the two sides and comprises a storage hopper and a driving device used for driving the storage hopper to move in the length direction of the first roller and the second roller, and the face, back on to the base, of the storage hopper is opened. The storage hopper is detachably connected with a cover plate used for sealing the opening of the storage hopper, a discharging pipe communicated with the storage hopper is arranged on the face, facing the base, of the storage hopper, and a discharging switch used for controlling the discharging pipe to be opened or closed is arranged on the discharging pipe. The conductive rubber roller producing and manufacturing device has the advantage that manpower for manually conveying the powder can be saved.

Owner:明治橡胶化成(深圳)有限公司

Wet iron ore powder bin device capable of preventing arching and arch breaking and application method

ActiveCN112978108AOptimize the appearance structureCamber restraintLarge containersStructural engineeringMechanical engineering

The invention relates to a wet iron ore powder bin device capable of preventing arching and arch breaking and an application method. The wet iron ore powder bin device comprises a bin straight barrel, a bin cone, lining plates, driving devices, drum hammers, supports, drum membranes and a weighing belt weigher, wherein the lower end of the bin straight barrel is connected with the upper end of the bin cone; the lower end of the bin cone is a discharging port; the bin cone is of an asymmetric structure with inconsistent side tapers; the lining plates are fixed on the inner surfaces of the bin straight barrel and the bin cone; holes are formed in the bin cone and the lining plates in the bin cone in the circumferential direction; the drum hammers are arranged in the holes, and are arranged at the holes in the inner sides of the lining plates. the drum hammers are connected with push rods of the driving devices; the driving devices are installed on the supports; the supports are fixed onto the bin cone; and the weighing belt weigher is installed below the discharging port. The device further comprises a computer, wherein the driving devices and the weighing belt weigher are electrically connected with the computer. According to the wet iron ore powder bin device capable of preventing arching and arch breaking and the application method provided by the invention, the arching prevention measures are taken from three aspects, and arching prevention and arch breaking can be achieved for wet iron ore powder.

Owner:SHENYANG XINBO IND TECH

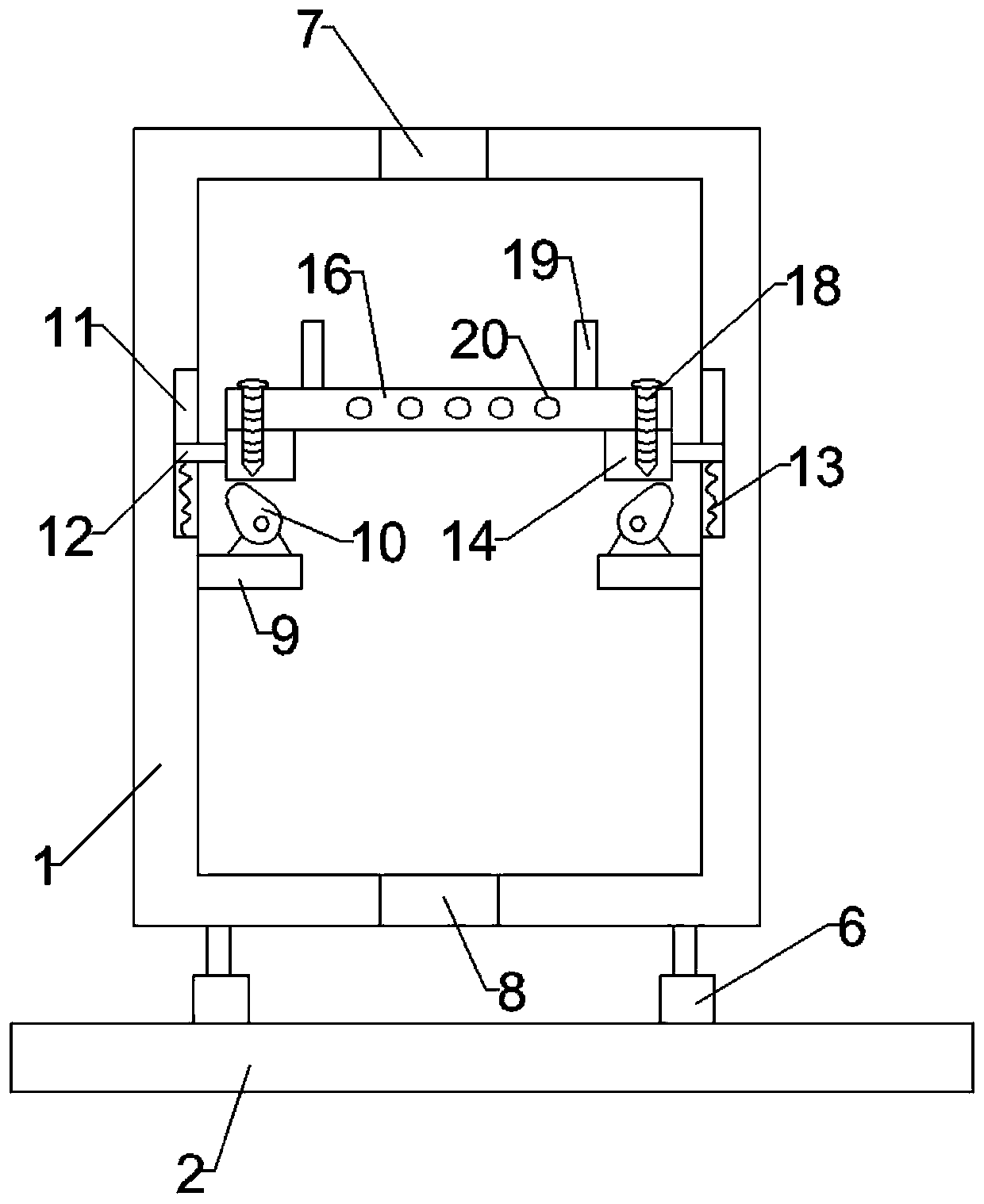

Production apparatus and method of concrete additive

InactiveCN112808198AEasy to useEasy dischargeChemical/physical/physico-chemical stationary reactorsFeed devicesProcess engineeringMechanical engineering

The invention relates to a production apparatus and method of a concrete additive. The production apparatus of the concrete additive comprises a device main body; a control panel is connected to the outer surface of the device main body; a feeding device is connected to the upper end face of the device main body; a discharging device and supporting leg pieces are arranged on the lower end face of the device main body; a stirring device and a control machine are arranged in the device main body; the input end of the control machine is connected with the output end of the control panel; the output end of the control machine is connected with the feeding device, the discharging device and the stirring device; the stirring device comprises a material mixing cavity; the material mixing cavity is formed in the device main body; the size of the material mixing cavity is variable; the production apparatus for the concrete additive is simple in structure, convenient to operate and flexible to use, has higher stirring efficiency and discharging capacity, facilitates production and preparation of the concrete additive, and is convenient to popularize and use in the industry.

Owner:庐江县新创新型材料有限公司

Boiler fuel feeding device

InactiveCN107906552AEase of workEasy to useFuel feeding arrangementsSolid fuel pretreatmentCombustion chamberConveyor belt

The invention discloses a fuel feeding device for a boiler, which comprises a base. A crushing box is fixedly connected to the upper surface of the base. A crushing shaft is placed inside the crushing box. Two symmetrical bearings are fixedly inlaid on the inner side wall of the crushing box. The left end of the shaft and the right end of the crushing shaft respectively pass through two bearings and extend to the outside of the crushing box, and the outer surfaces of the left end of the crushing shaft and the right end of the crushing shaft are respectively fixedly connected with the inner rings of the two bearings. The boiler fuel feeding device can crush the fuel, make the fuel burn better, improve the efficiency of the boiler, improve the discharge effect of the device and the crushing effect of the fuel, and can pass the crushed fuel through the conveyor belt Imported into the combustion chamber of the boiler, it effectively reduces the difficulty of the user's work, allows the user to move to the corresponding position according to their own needs, can use the device more efficiently, and feeds materials more conveniently.

Owner:WUXI HENGDA MINE MACHINERY

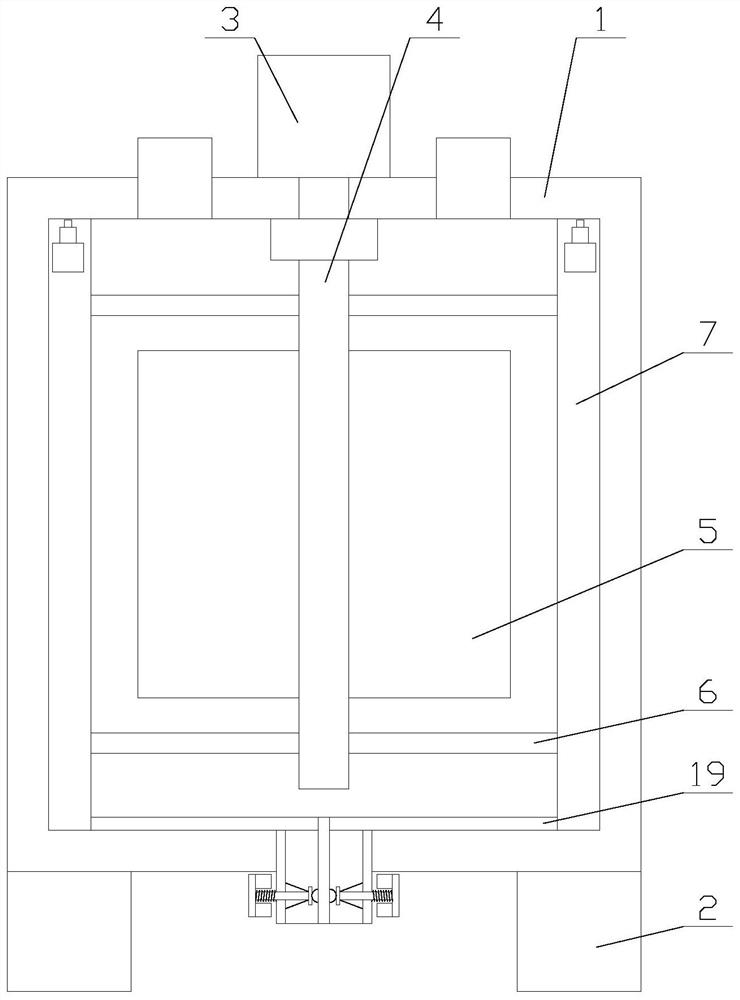

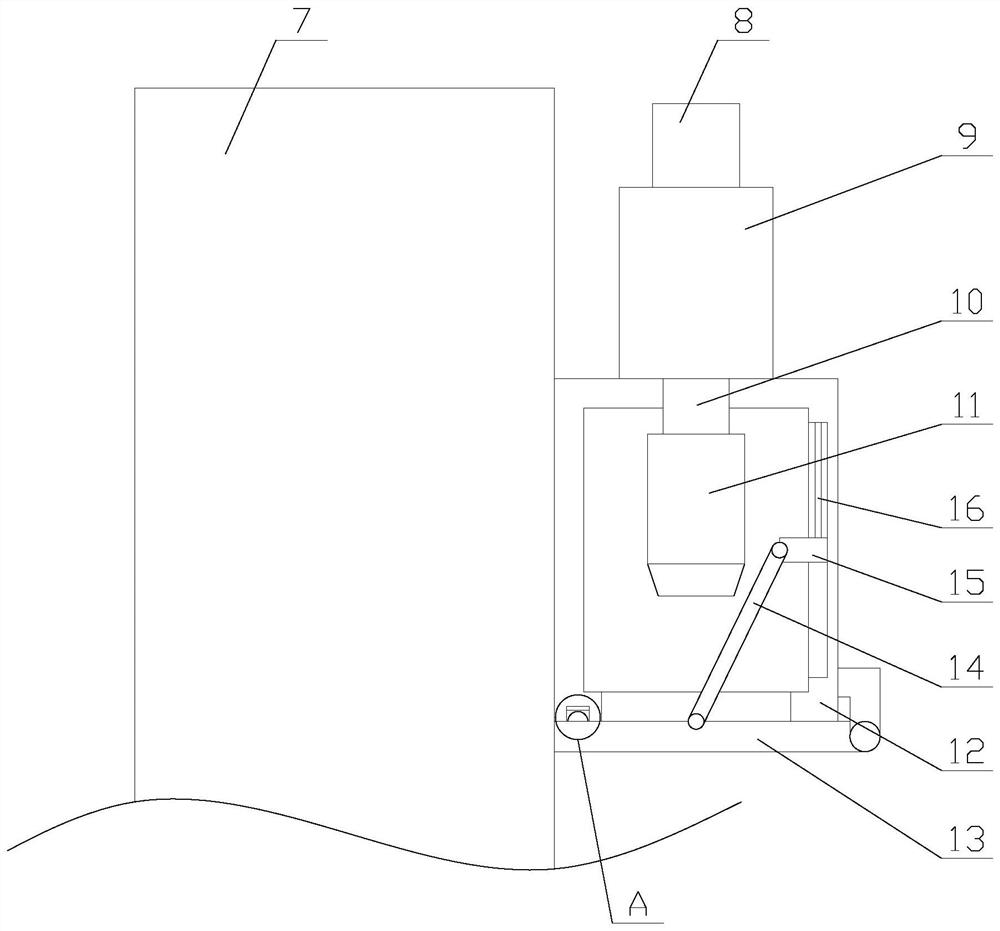

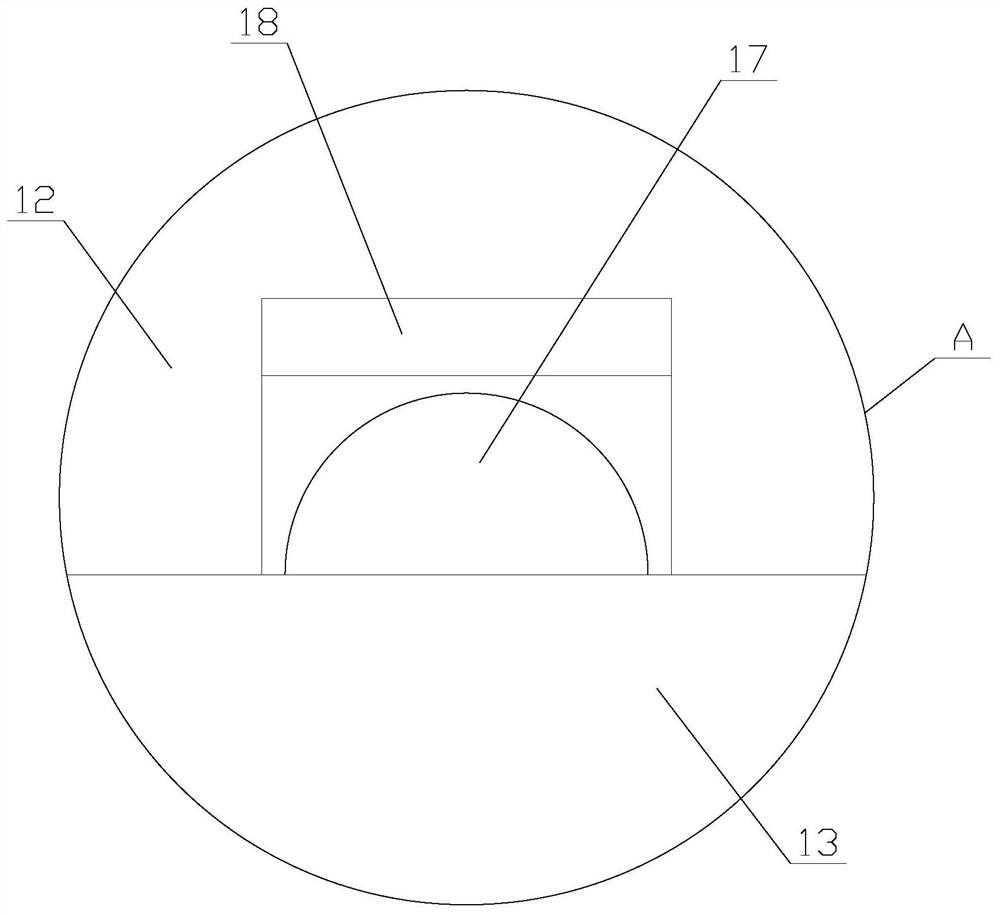

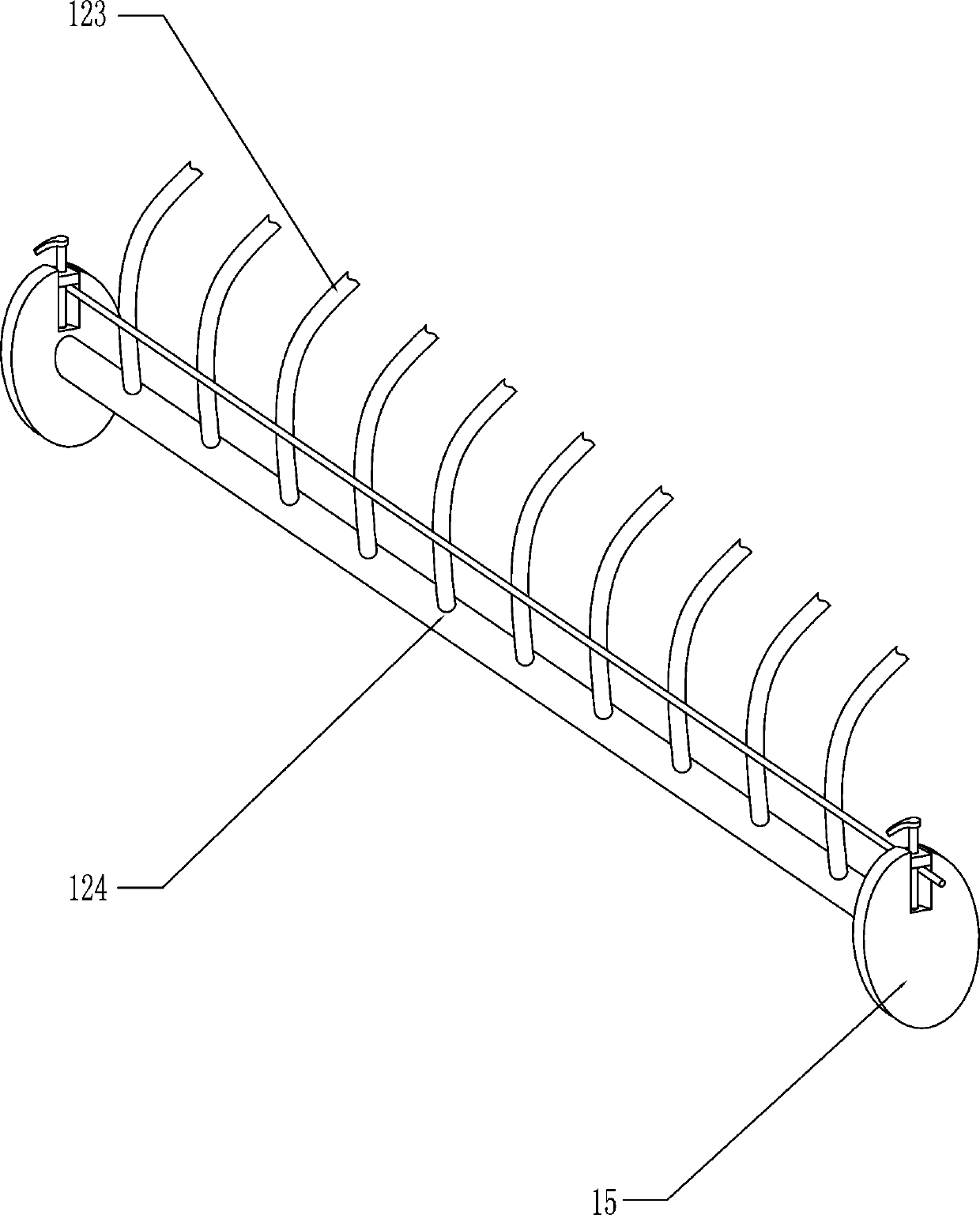

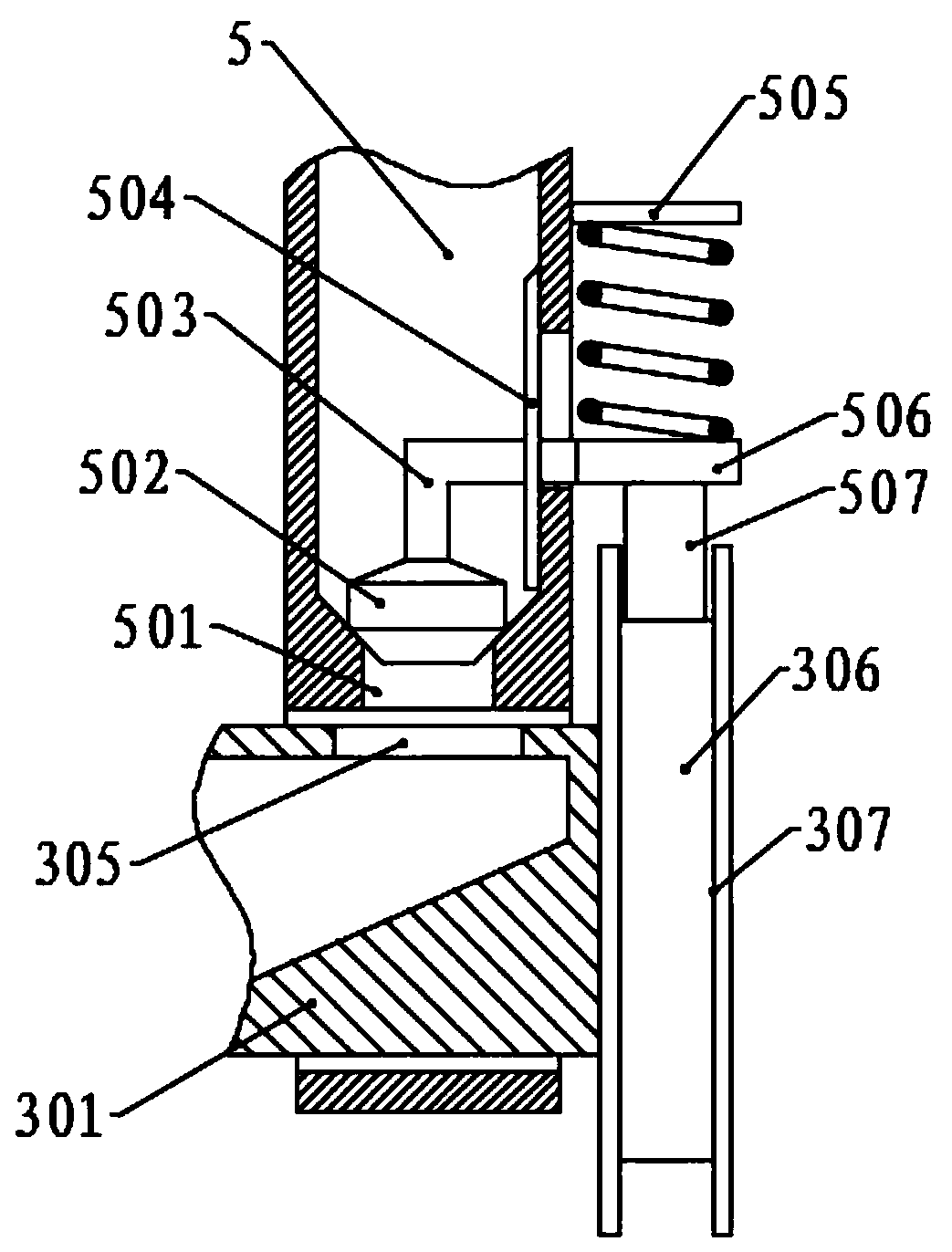

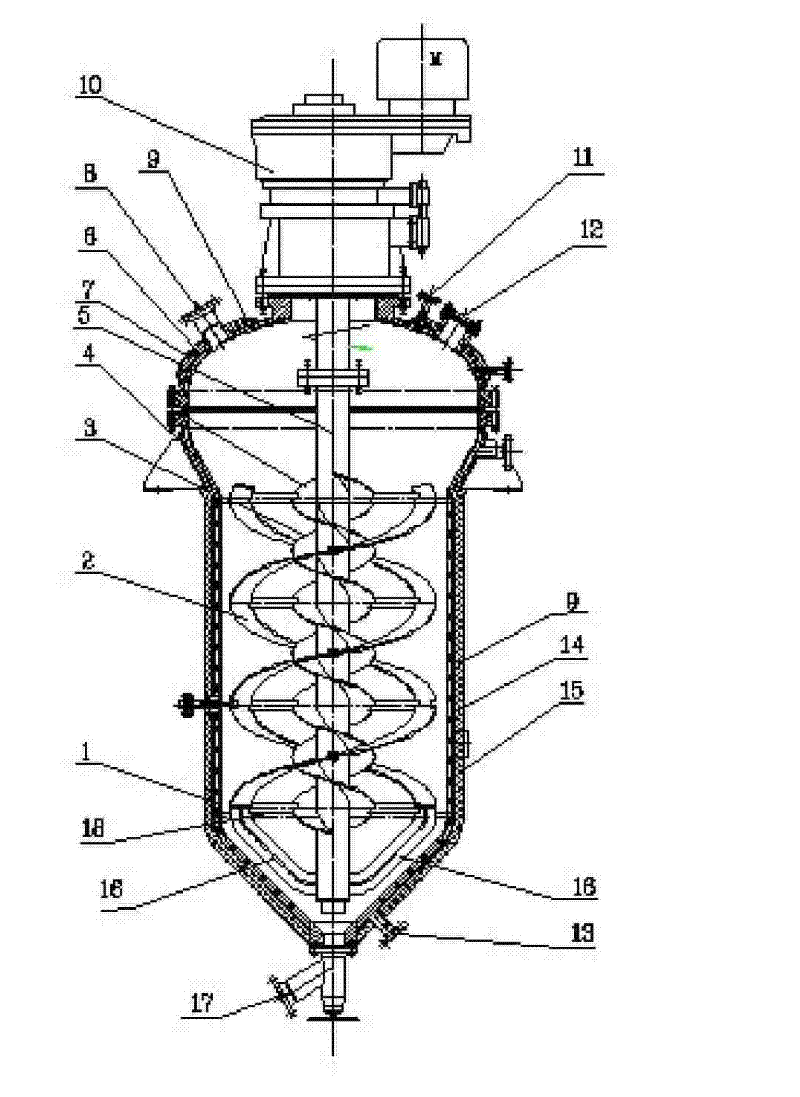

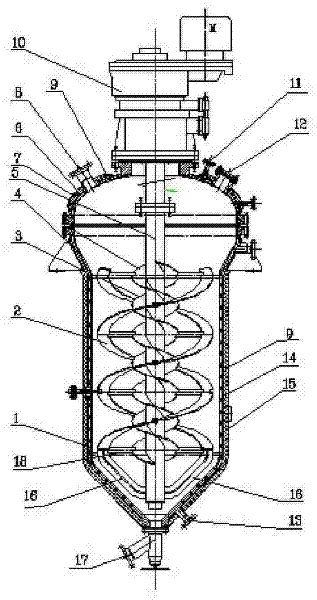

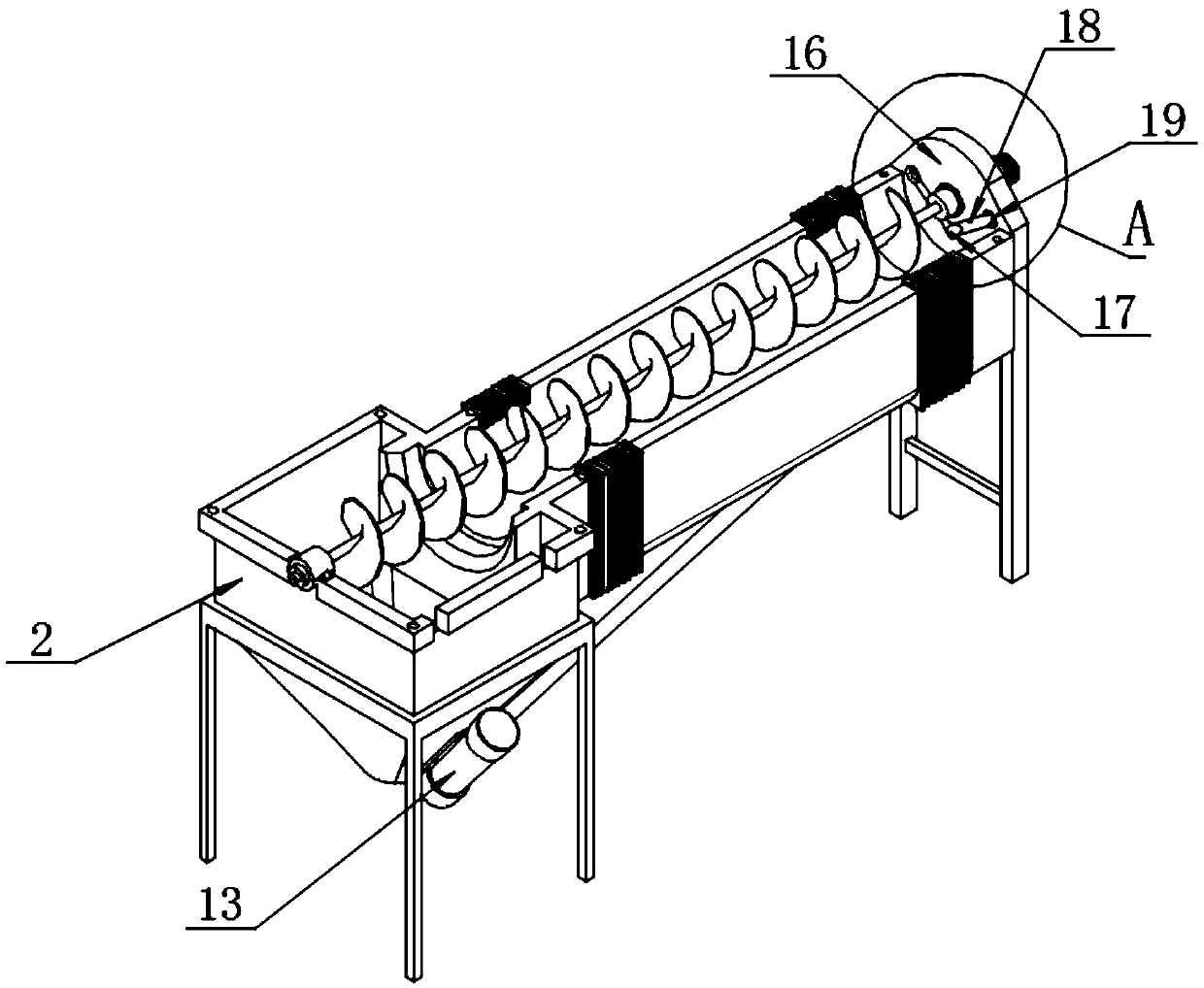

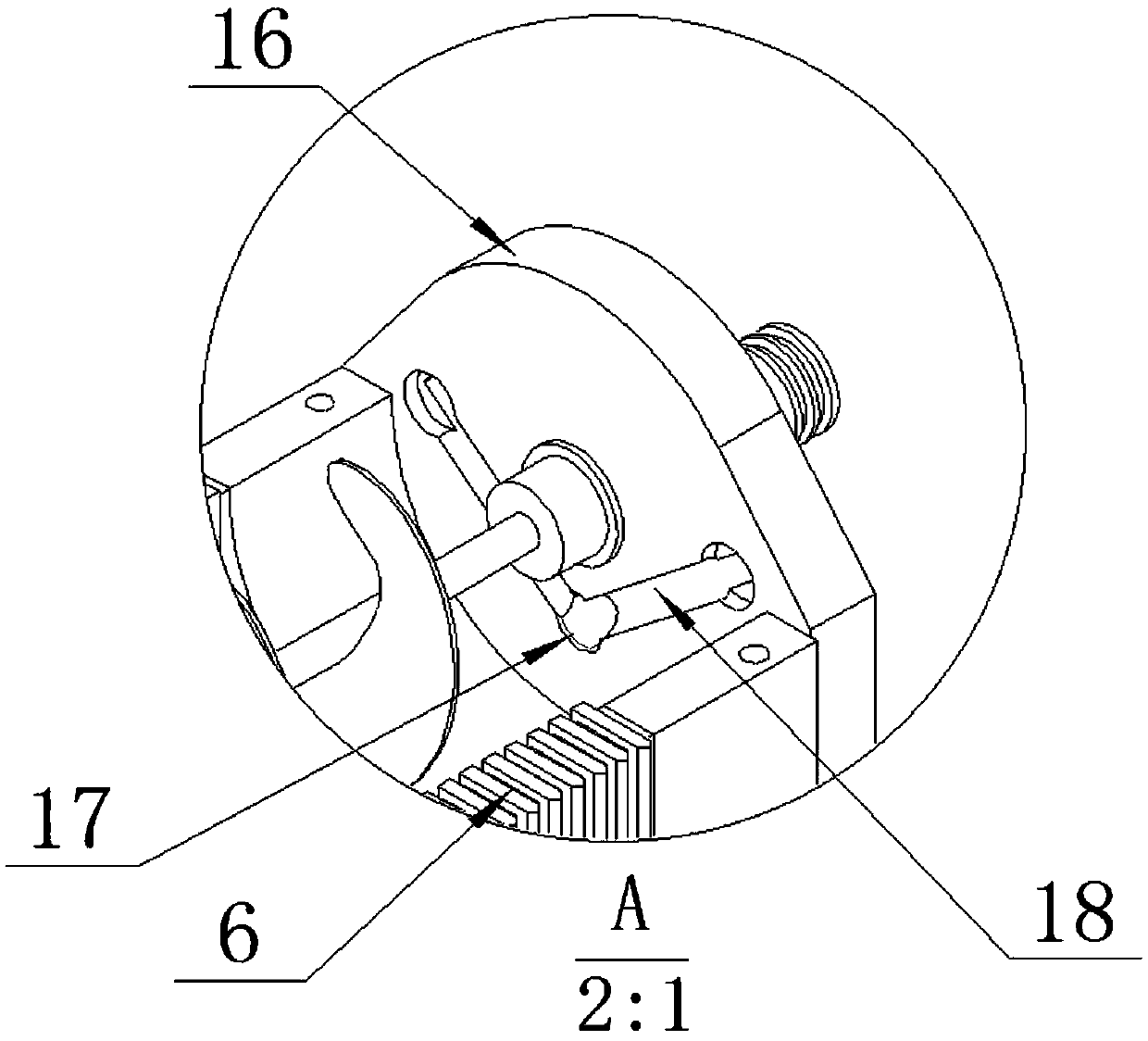

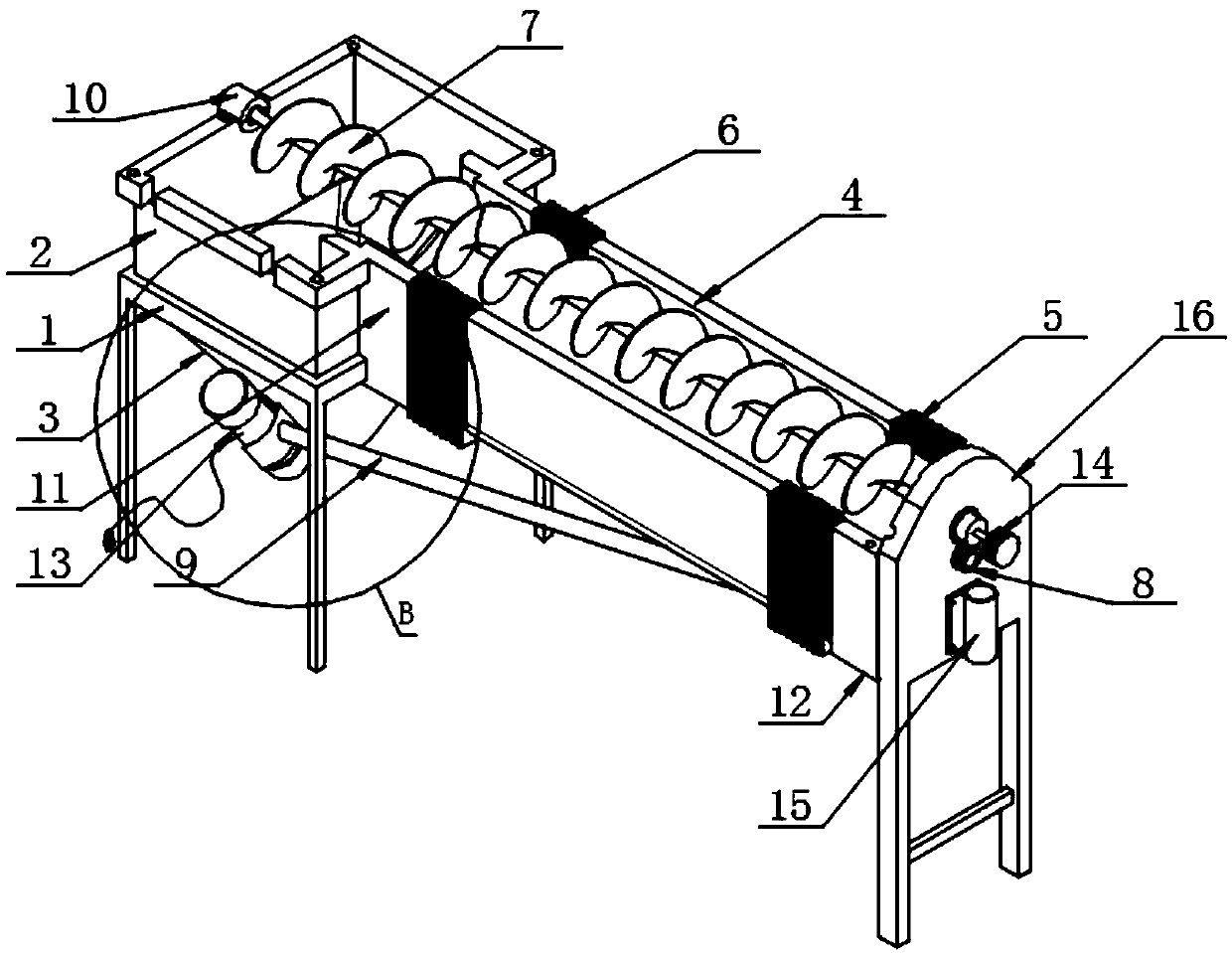

Macromolecular material polymerization reaction kettle

ActiveCN101596440BImprove the output effectReduce inventoryRotary stirring mixersChemical/physical/physico-chemical stationary reactorsInsulation layerWide mouth

The invention discloses a macromolecular material polymerization reaction kettle. The kettle comprises a kettle body, an upper closed cover, a drive sealing device, a stirring device, a feed and discharge port, wherein the upper part of the kettle body is an inverted cone-shaped wide mouth; the middle part of the kettle body is of a bucket shape; the lower part of the kettle body is cone; the kettle body is provided with a heating jacket 14 with a spiral flow channel and a heat insulation layer 9; the upper closed cover 6 is provided with a heating jacket 7, a heat insulation layer 9, a vacuum port 8 and a feed port 12; the stirring device consists of a stirring shaft 5, an inner strip-shaped spiral stirring paddle 3, an outer strip-shaped spiral stirring paddle 2, a scraping blade 16 anda supporting oar 18; the drive sealing device consists of a motor, a retarder and a sealing machine; and the upper part of the stirring shaft is connected with the drive sealing device. The macromolecular material polymerization reaction kettle has good stirring effect and high heat and mass transferring efficiency, can solve the difficult problems of pole climbing and devolatilization of high-viscosity fusant and is in particular suitable for the polymerization reaction of a high-viscosity macromolecular material.

Owner:SICHUAN KEXIN MECHANICAL & ELECTRICAL EQUIPCO

Discharging mechanism with air-jet dual-vibration effect for mechanical equipment

The invention provides a discharging mechanism with an air-jet dual-vibration effect for mechanical equipment. The discharging mechanism comprises a supporting base and an external joint pipe. The topsurface of a left supporting frame is provided with a filling port, the bottom surface of the left supporting frame is provided with a discharging hopper of a funnel-cavity-shaped structure, and oneouter wall of the discharging hopper is provided with a vibrating motor electrically connected with an external power source. The two ends of a hopper cavity are connected to left and right frames ofthe hopper cavity through corrugated flexible sections to achieve contact connection between the hopper cavity and the original vibrating motor on the outer wall of a discharging port, so that a vibration effect generated by the vibrating motor is synchronously transmitted to a receiving hopper, the discharging speed of the receiving hopper can be increased, materials received by the receiving hopper can flow leftwards to the discharging port more smoothly, and in cooperation with an auger on the top side, discharging can be better completed. The right frame of the receiving hopper cavity is provided with a flange connector for achieving connection with an external air inlet pipeline to make an external pressure air source enter the hopper, so that after the device is used, some retainingdust-like materials are blown away leftwards, and air-source cleaning of the retaining dust-like materials is achieved.

Owner:新昌县凌智机械有限公司

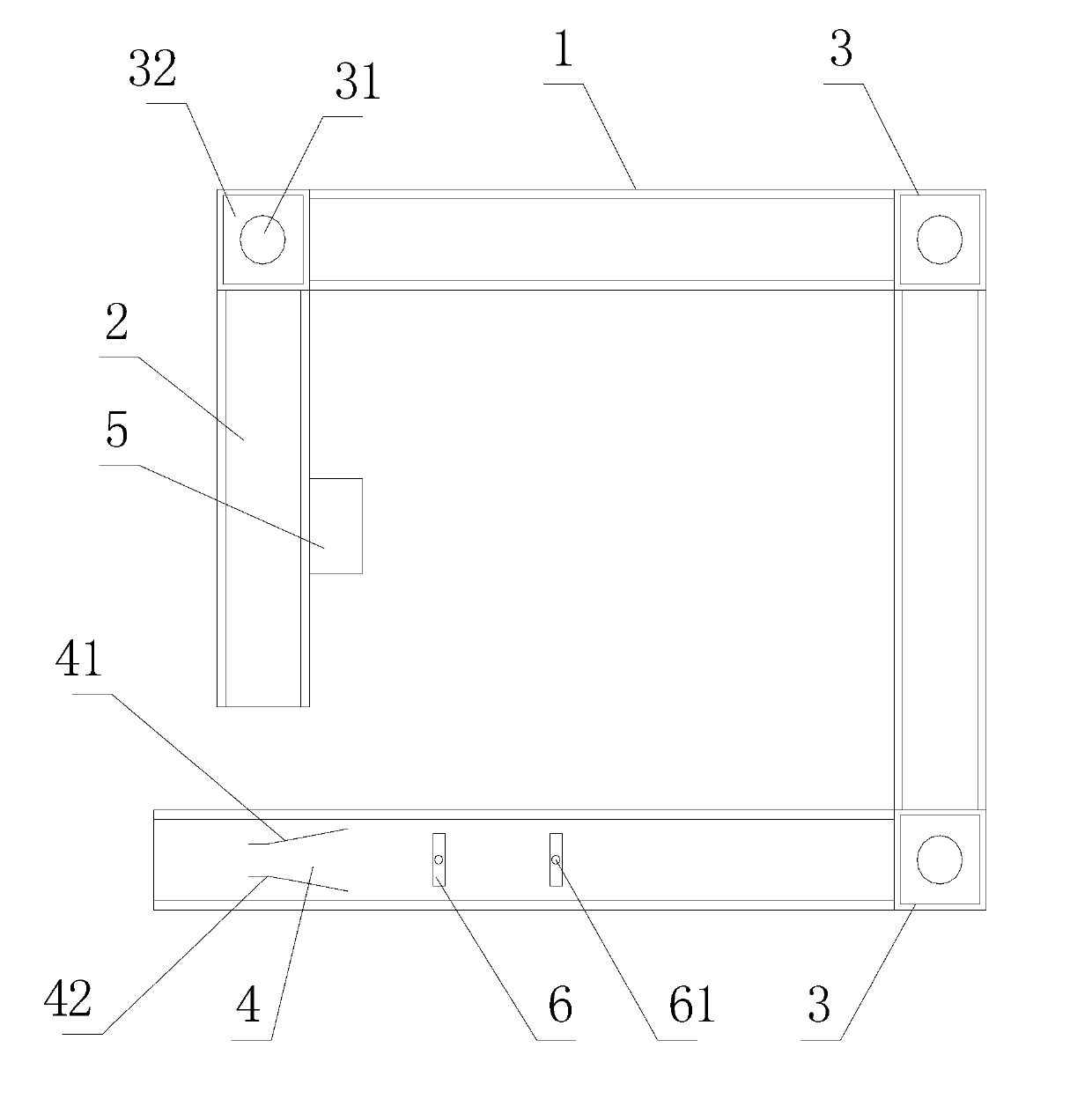

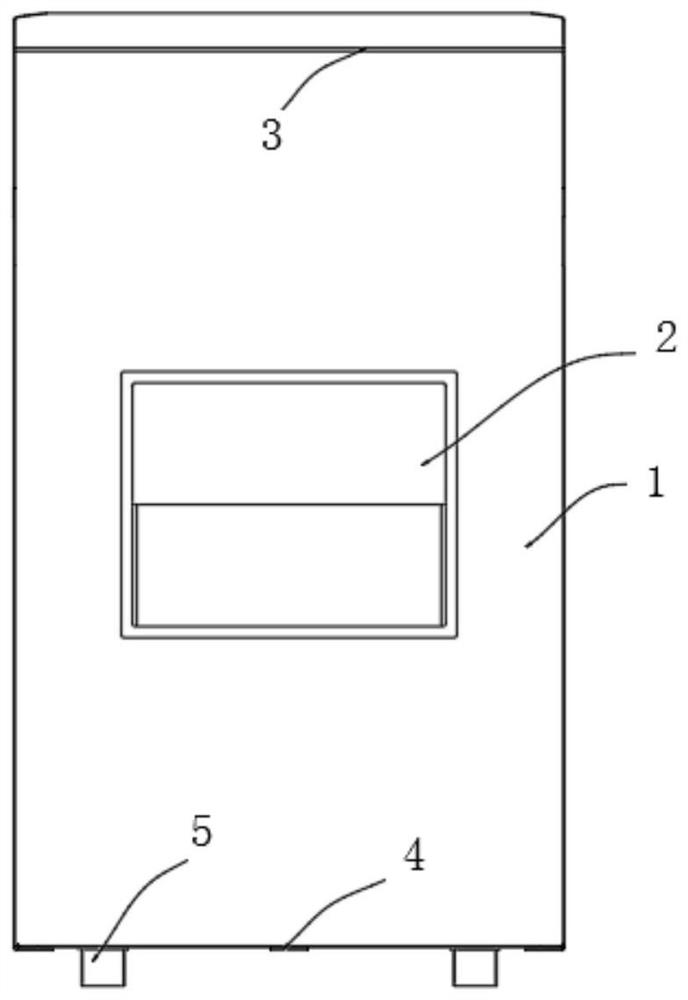

A transmission device for an air conditioner outdoor unit production line

ActiveCN103274166BReduce manual conversionImprove the output effectConveyorsControl devices for conveyorsProduction lineElectrical and Electronics engineering

The invention relates to a transmission device for a production line of an outdoor unit of an air conditioner. The transmission device comprises a machine frame and a transmission chain, wherein the cross section of the machine frame is rectangular, the transmission chain is arranged on the machine frame, steering devices facilitating steering of the air conditioner on the production line are arranged on corners of the machine frame, and a guide device is arranged on a position, on the discharging side of the transmission chain, of the machine frame. The machine frame is further provided with a control device used for controlling the steering devise to rotate. The transmission device has the advantages that due to the fact that the steering devices are disposed on the corners of the machine frame, the outdoor unit of the air conditioner is steered, and accordingly the outdoor unit of the air conditioner is automatically steered to the next installation position where a part needs to be installed; manual changes are reduced; due to the fact that the guide device is arranged on the discharging side for discharging, discharging effects are improved and use effects are good.

Owner:海信(浙江)空调有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com