Patents

Literature

93results about How to "Realize discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

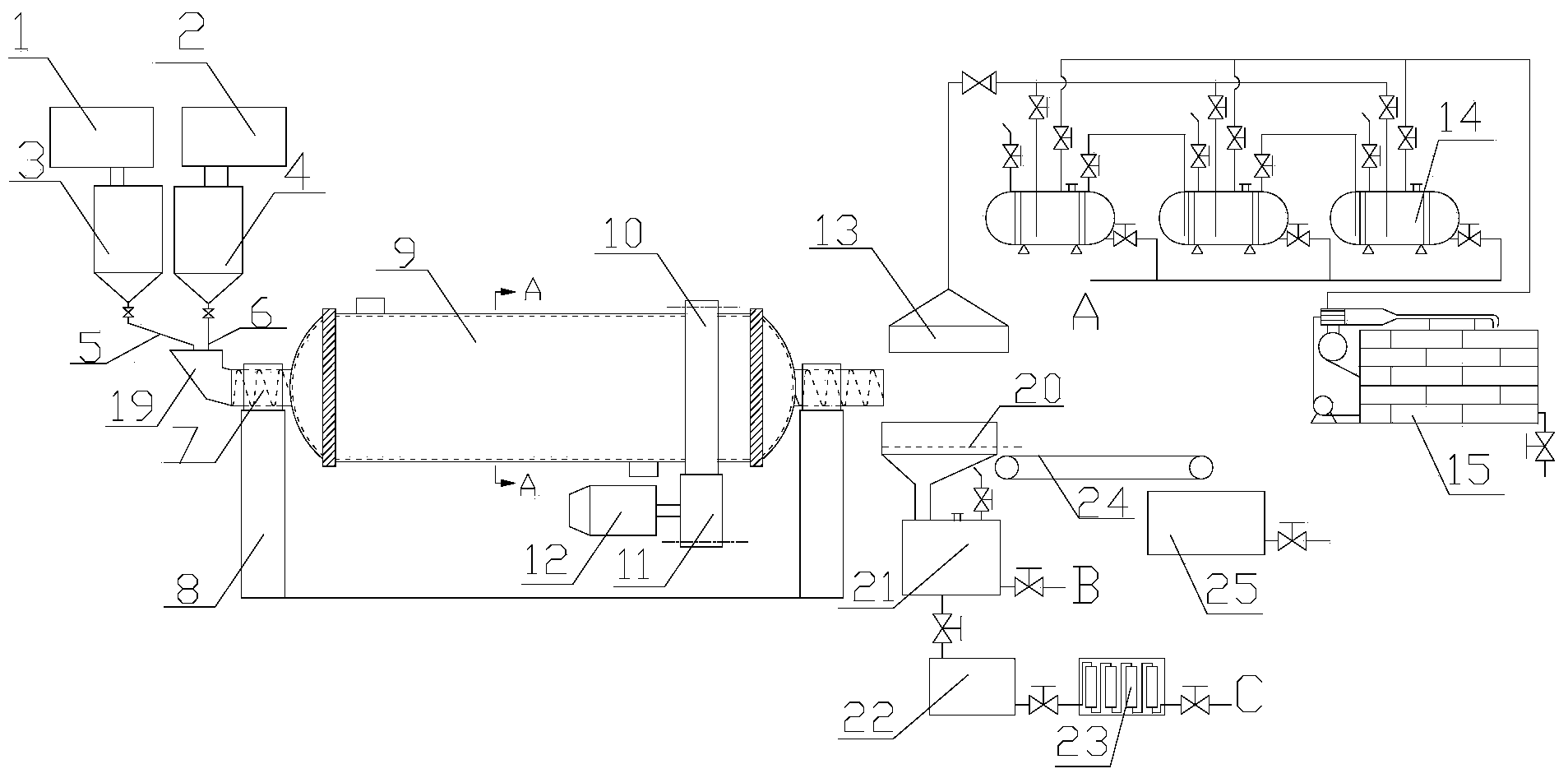

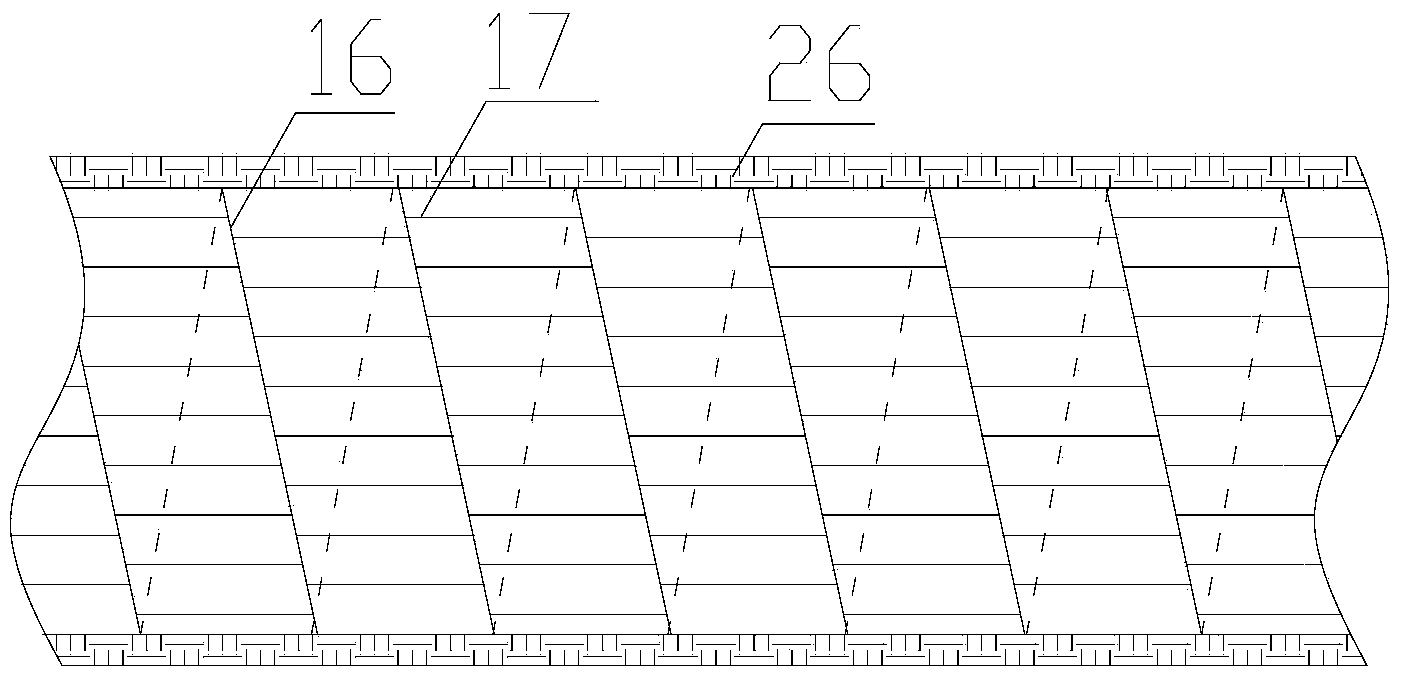

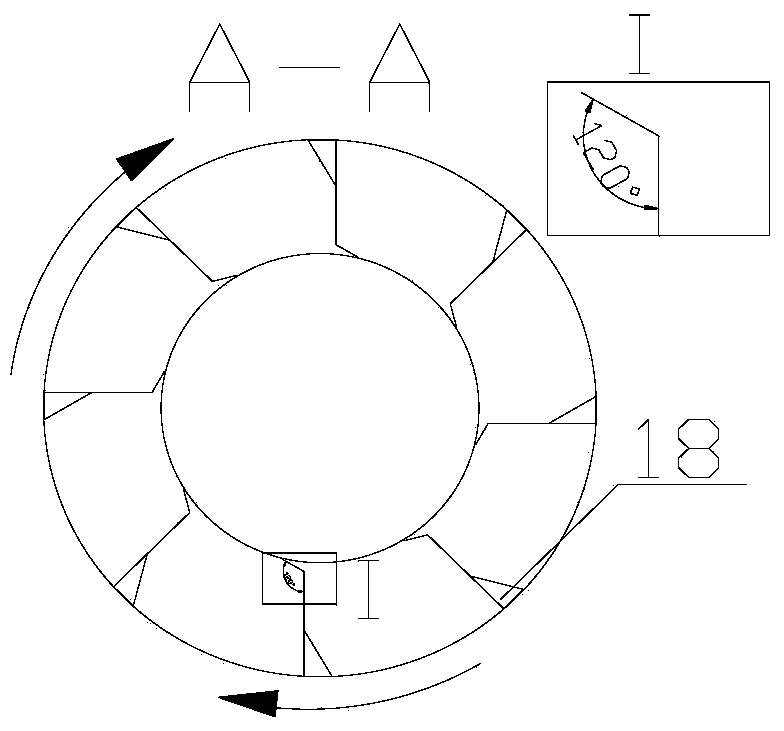

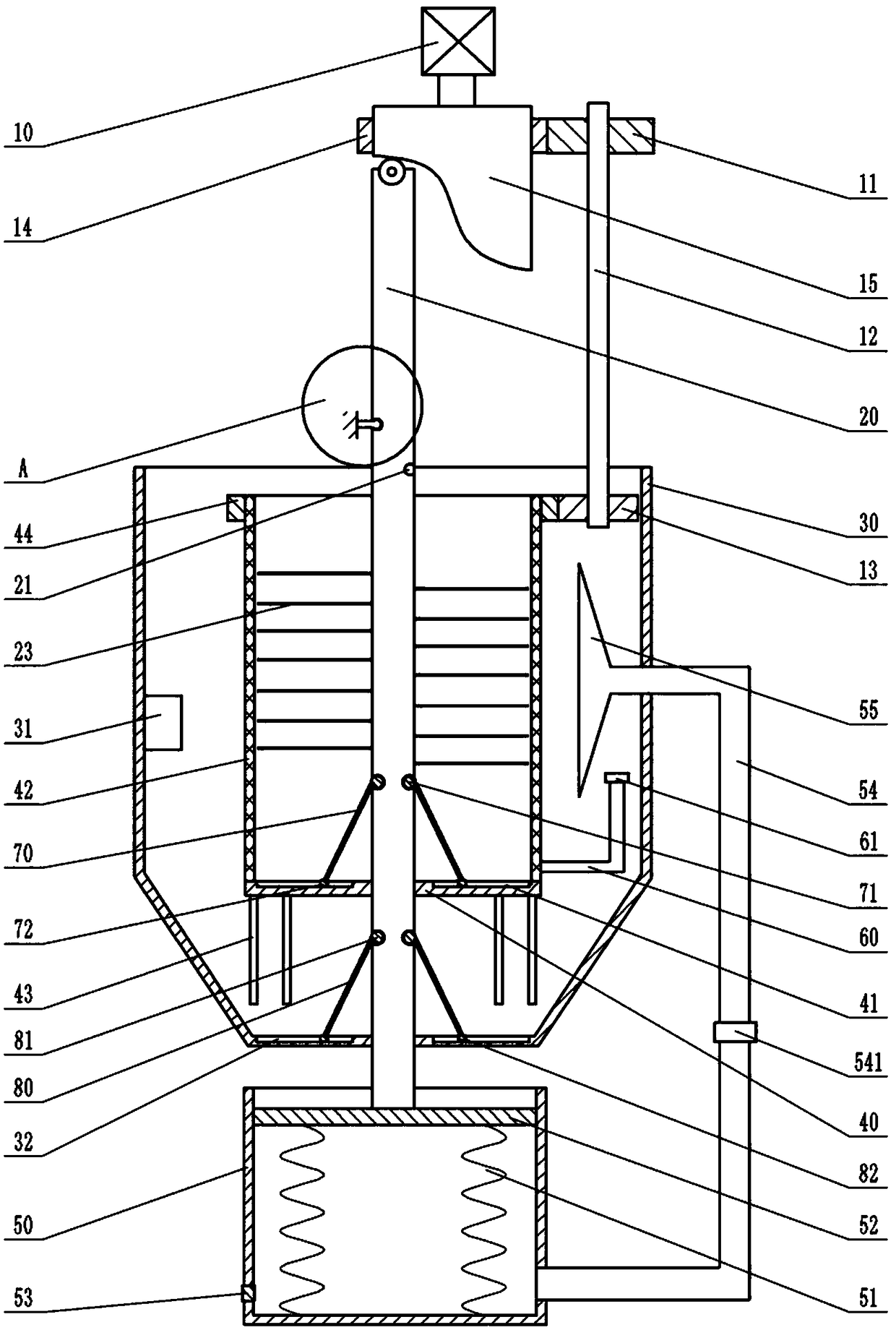

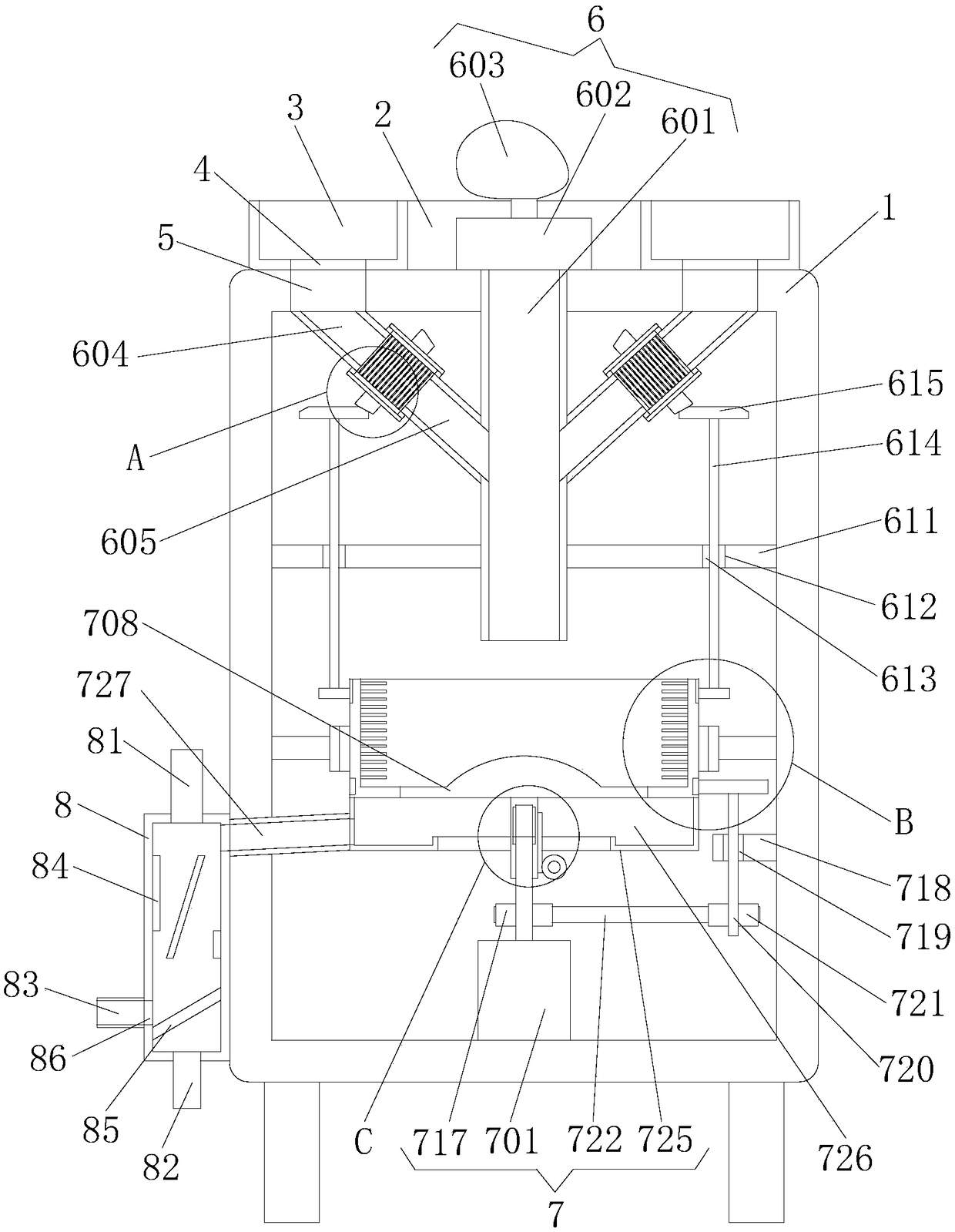

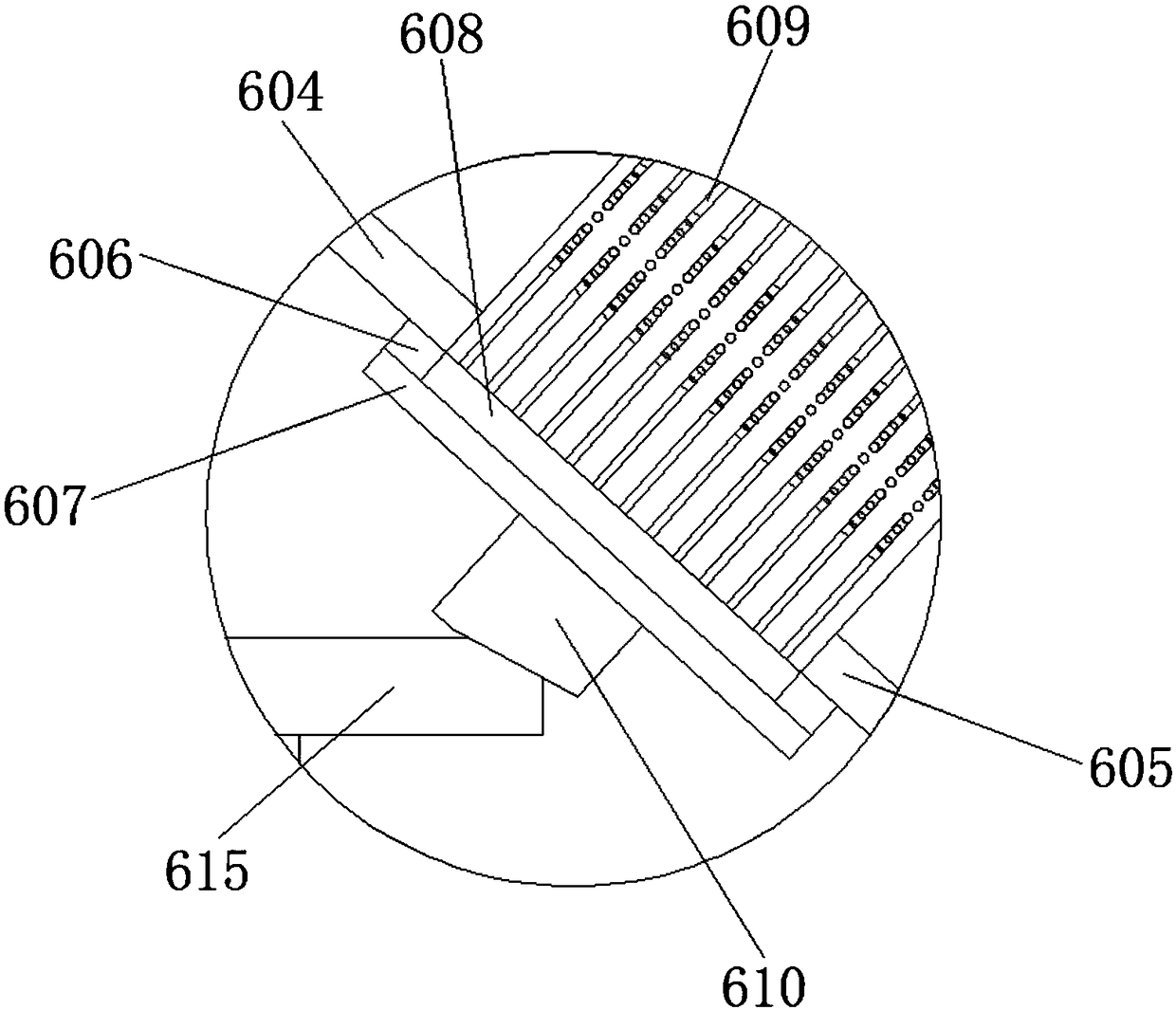

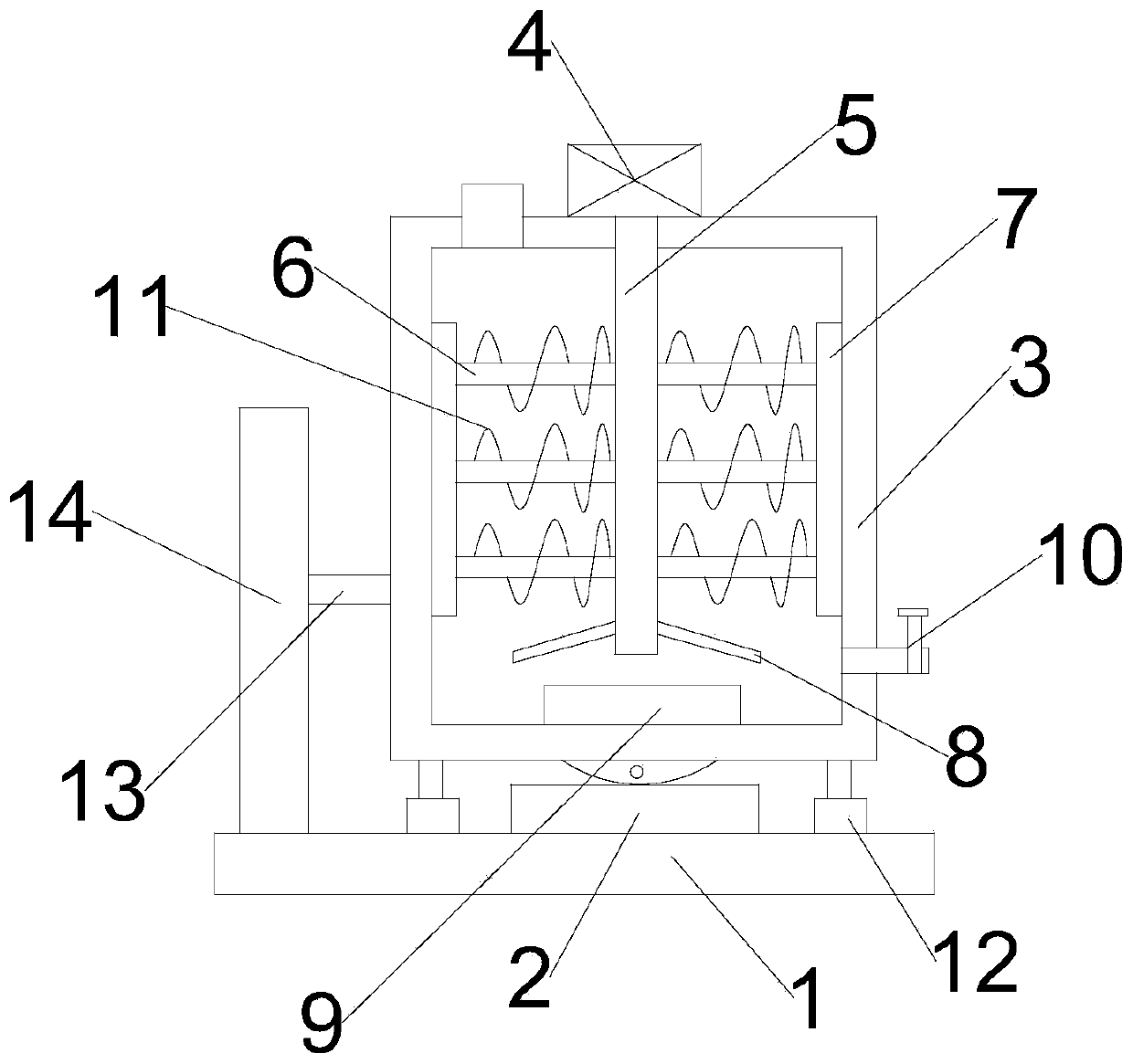

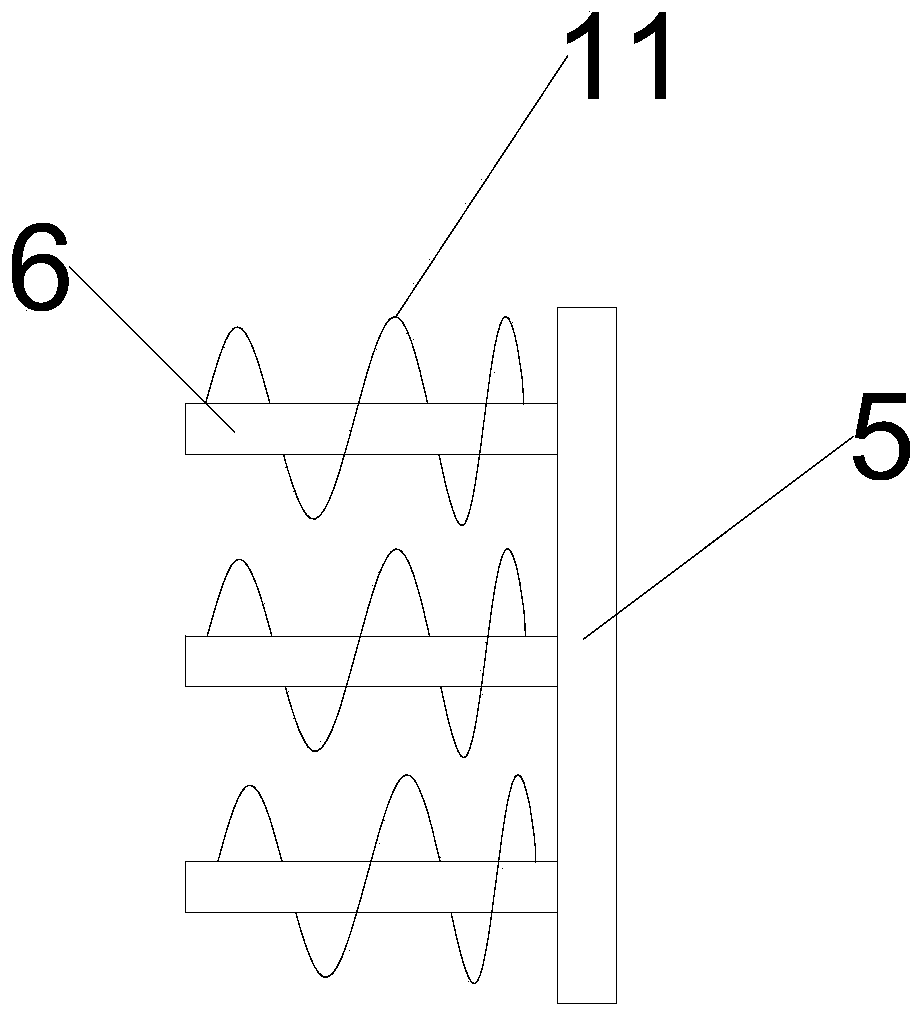

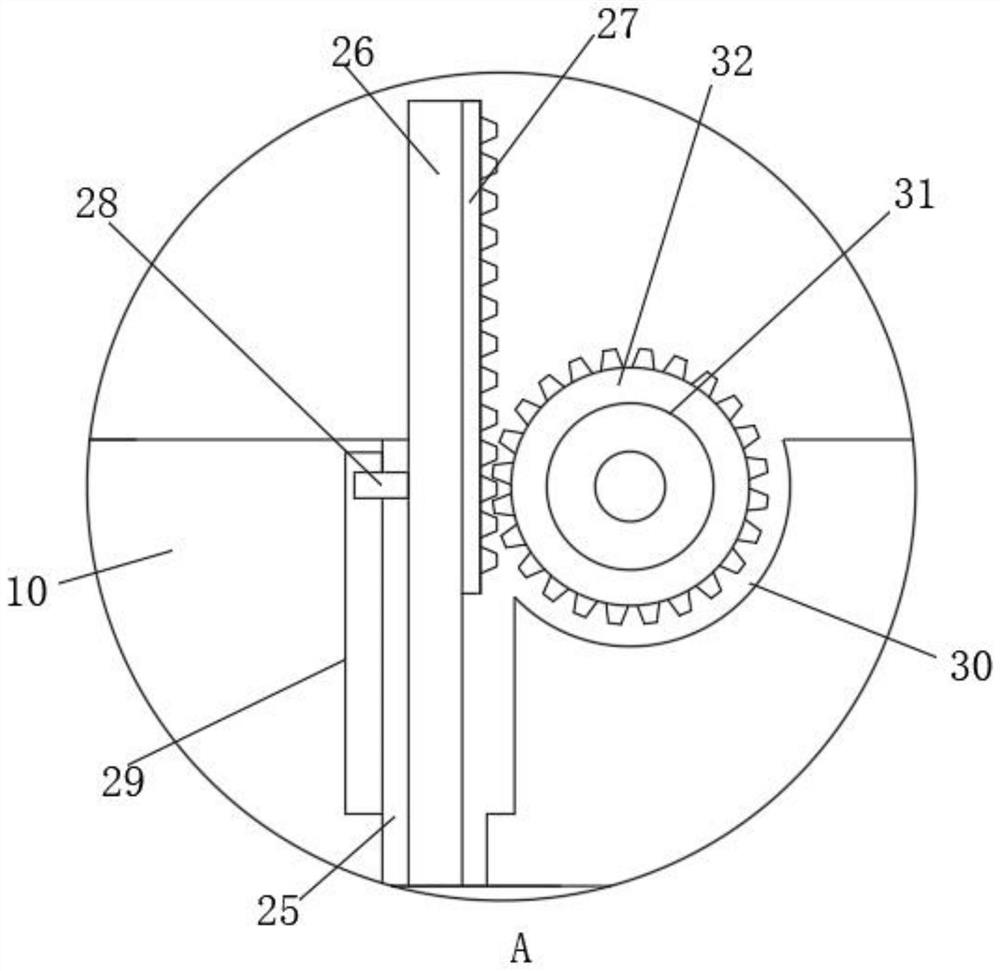

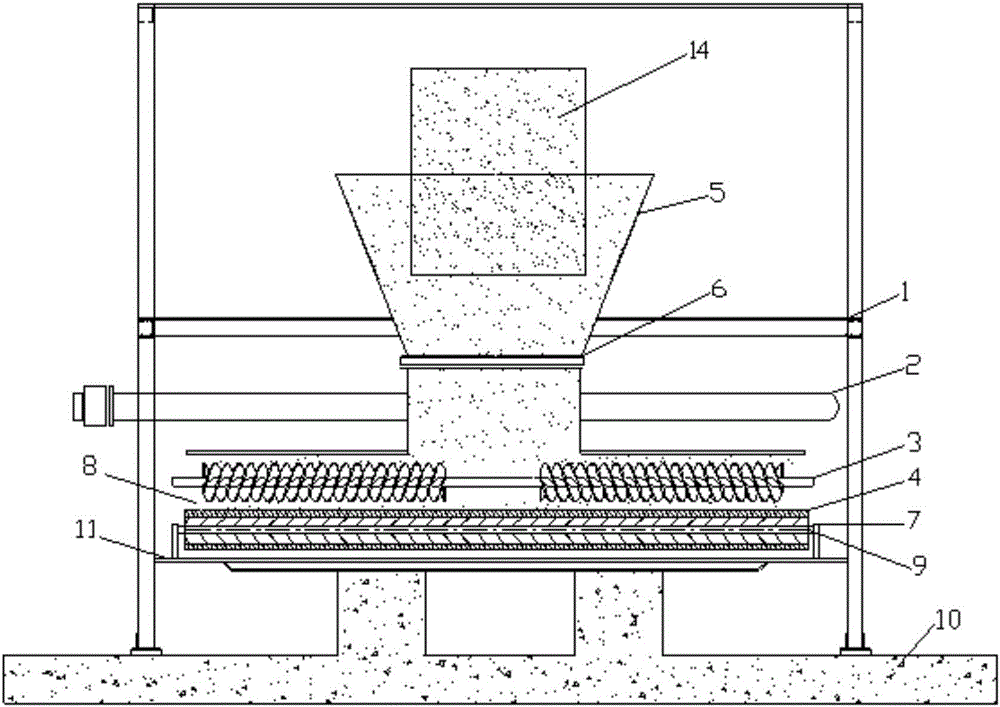

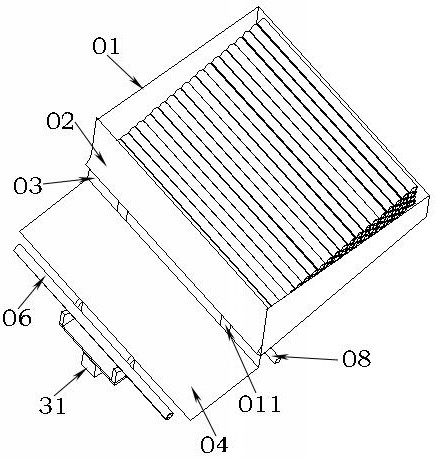

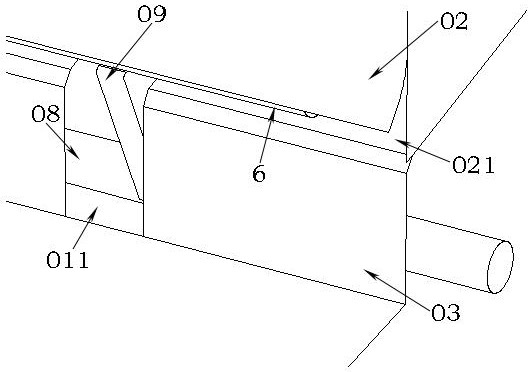

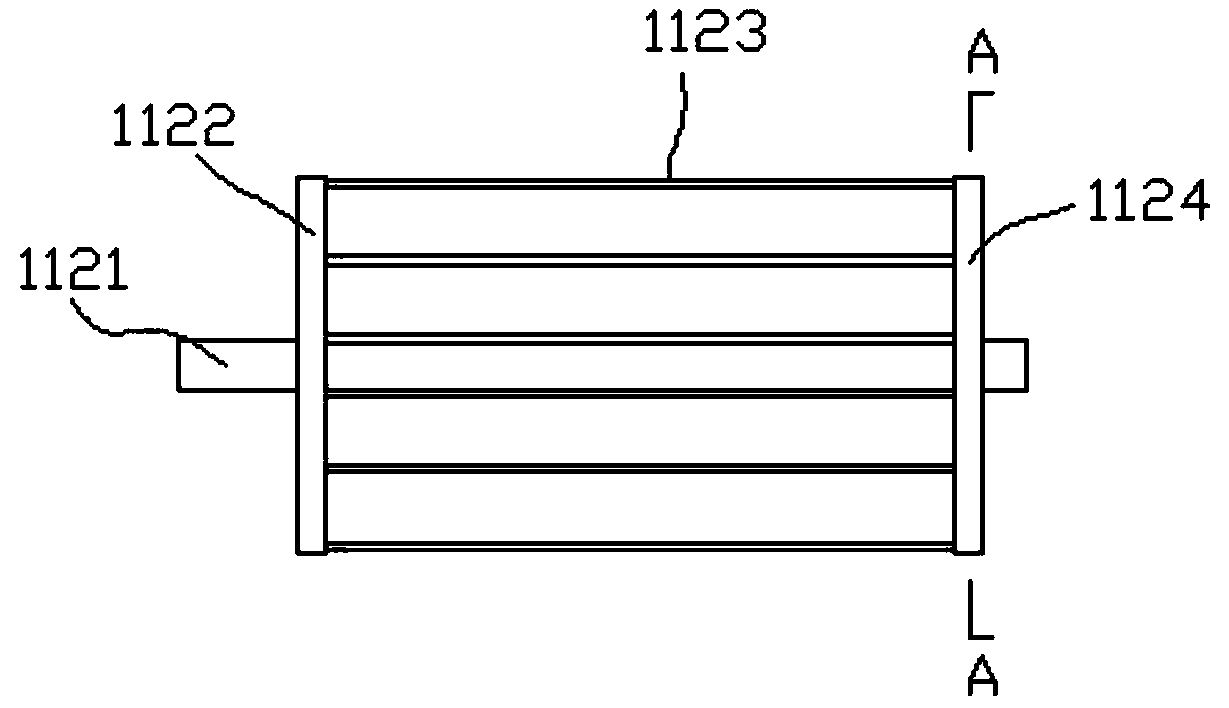

Method and device for continuous acid pickling purification of quartz sand

ActiveCN104058413ARealized by continuous pickling and purificationImproving the effect of pickling and impurity removalSilicaQuartzSpiral line

The invention provides a method for continuous acid pickling purification of quartz sand. The method comprises the steps of heating, material loading, acid pickling, deacidifying, water washing, acid recovering and tail gas treatment. The invention also provides a device for implementing the method to perform continuous acid pickling purification on quartz sand; the device comprises a heating unit, a storage unit, a drum mixer, a water washing unit, an acid recovery unit and a water-jet vacuum unit; spiral line plates are arranged on the inner wall of a drum of the drum mixer, 20-60 lifting plates are mounted between two adjacent spiral line plates, two adjacent lifting plates and the spiral line plates on the two sides thereof are combined to form a lifting bucket, a driven gear is arranged on the outer wall of the drum of the drum mixer in a sleeved manner, a charging opening and a discharging opening are formed in the two ends of the drum, and spiral line plates are mounted on the inner walls of both of the charging opening and the discharging opening. The method and the device are capable of realizing sufficient acid pickling purification of the quartz sand by virtue of continuous automatic feeding, turning over and discharging of the quartz sand and acid liquor; as a result, the production efficiency and the quality of product are improved, and the acid is recycled and absorbed by use of alkaline so that the production cost is reduced, and meanwhile, the environmental pollution is reduced.

Owner:田辉明

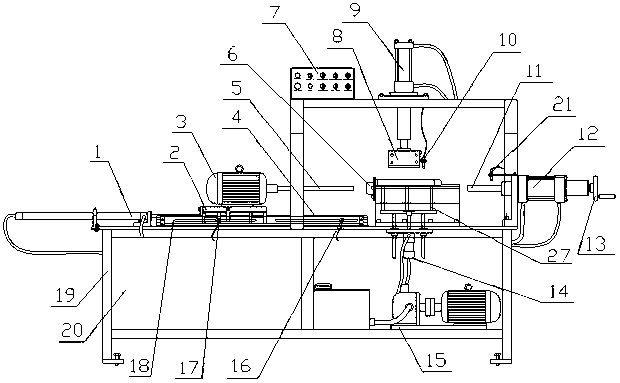

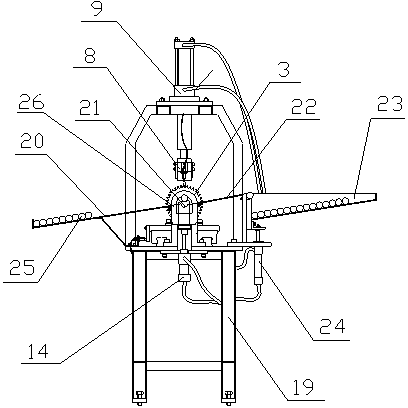

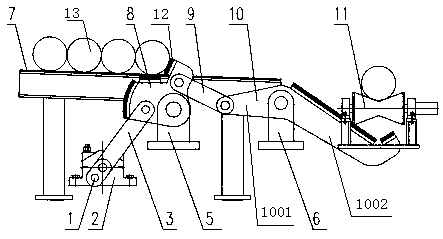

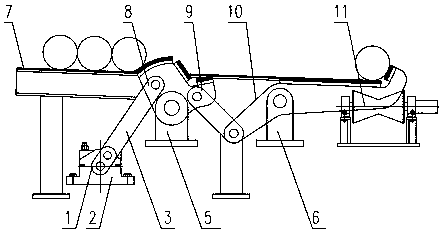

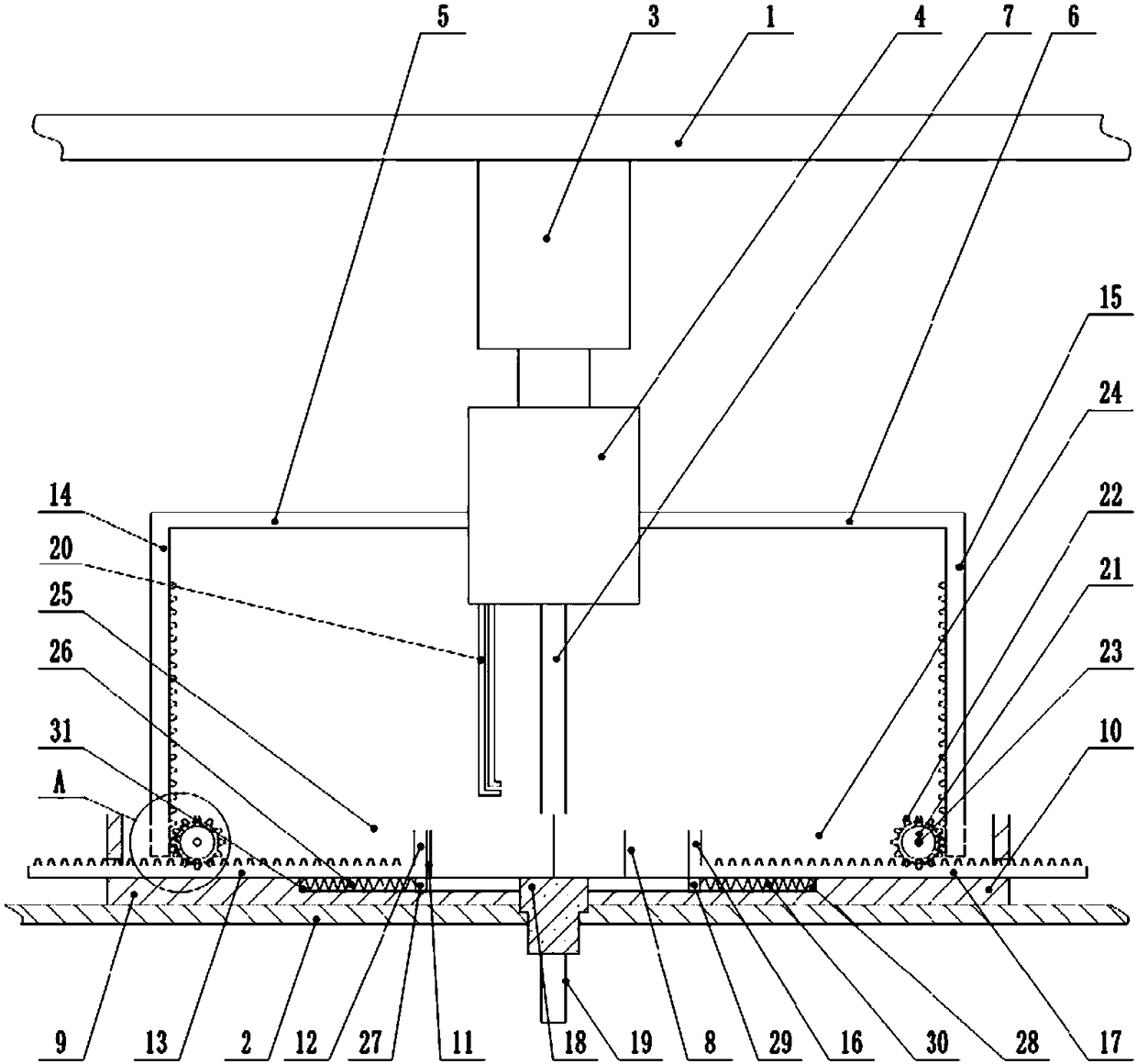

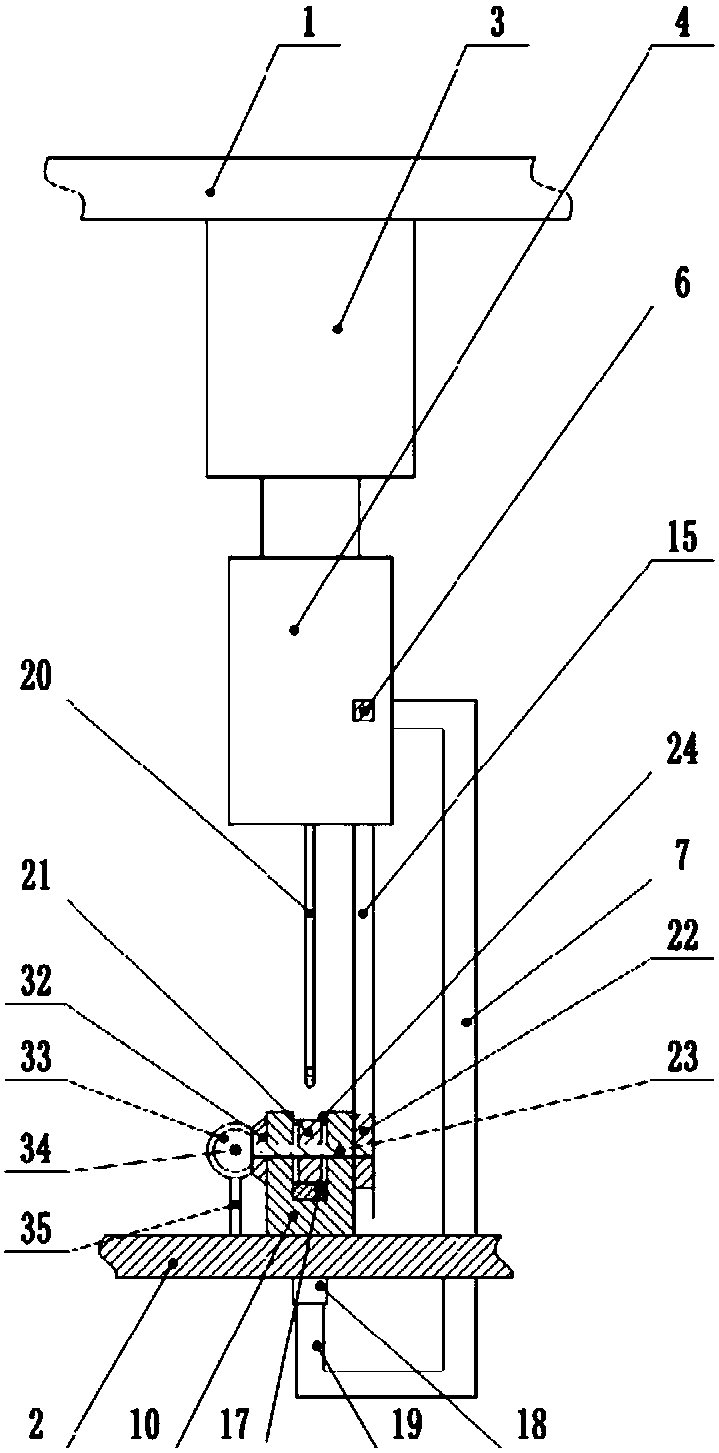

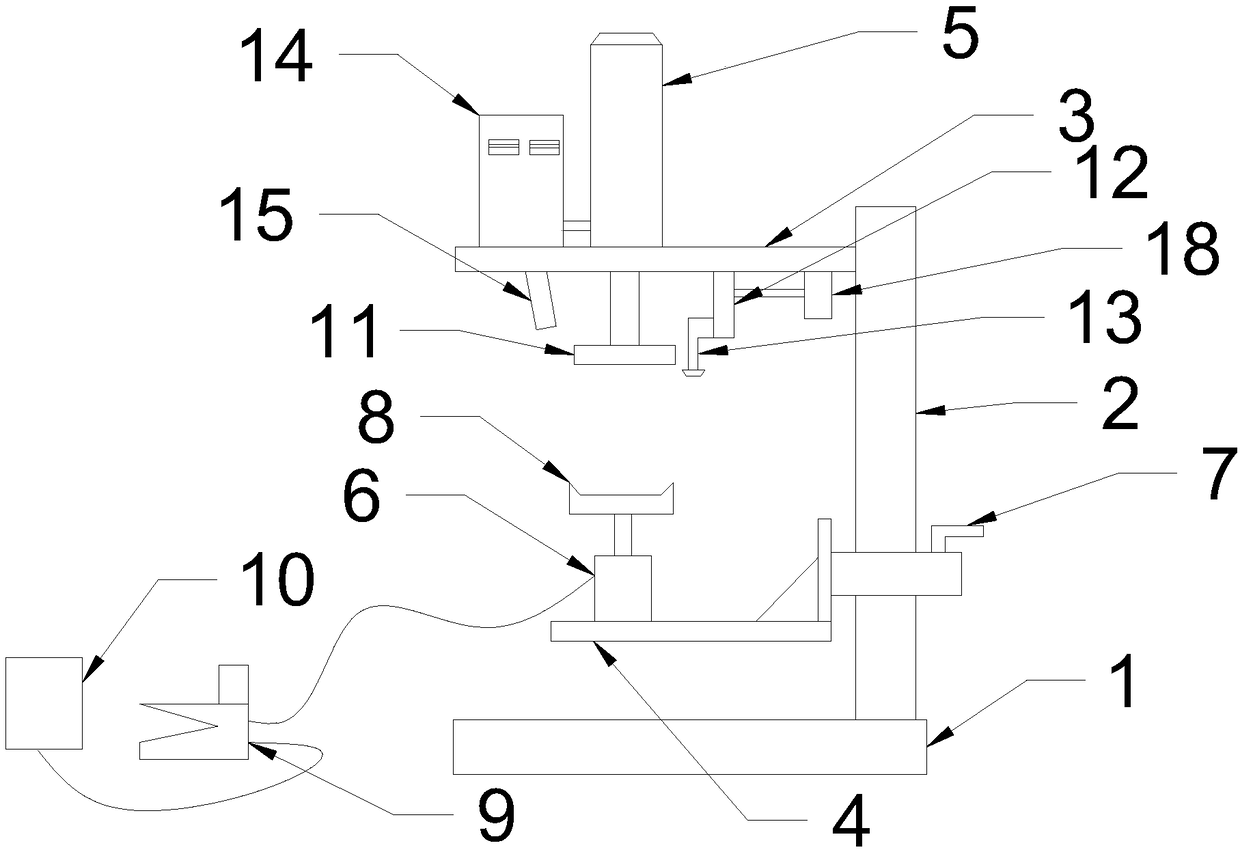

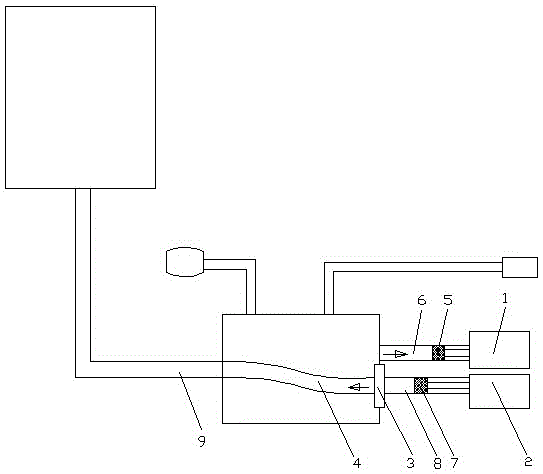

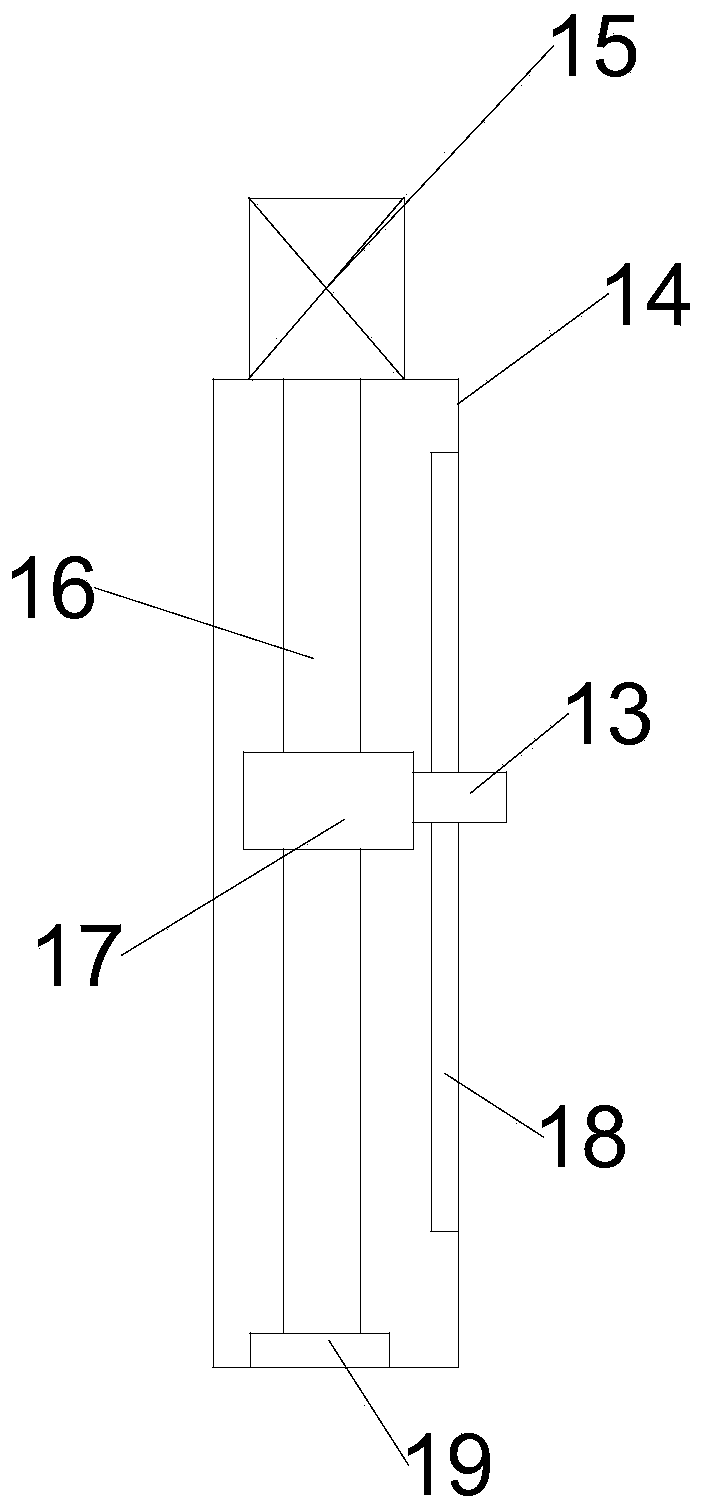

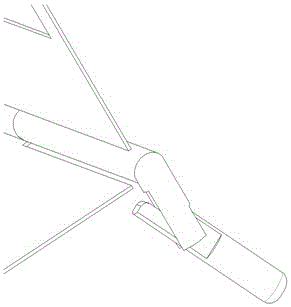

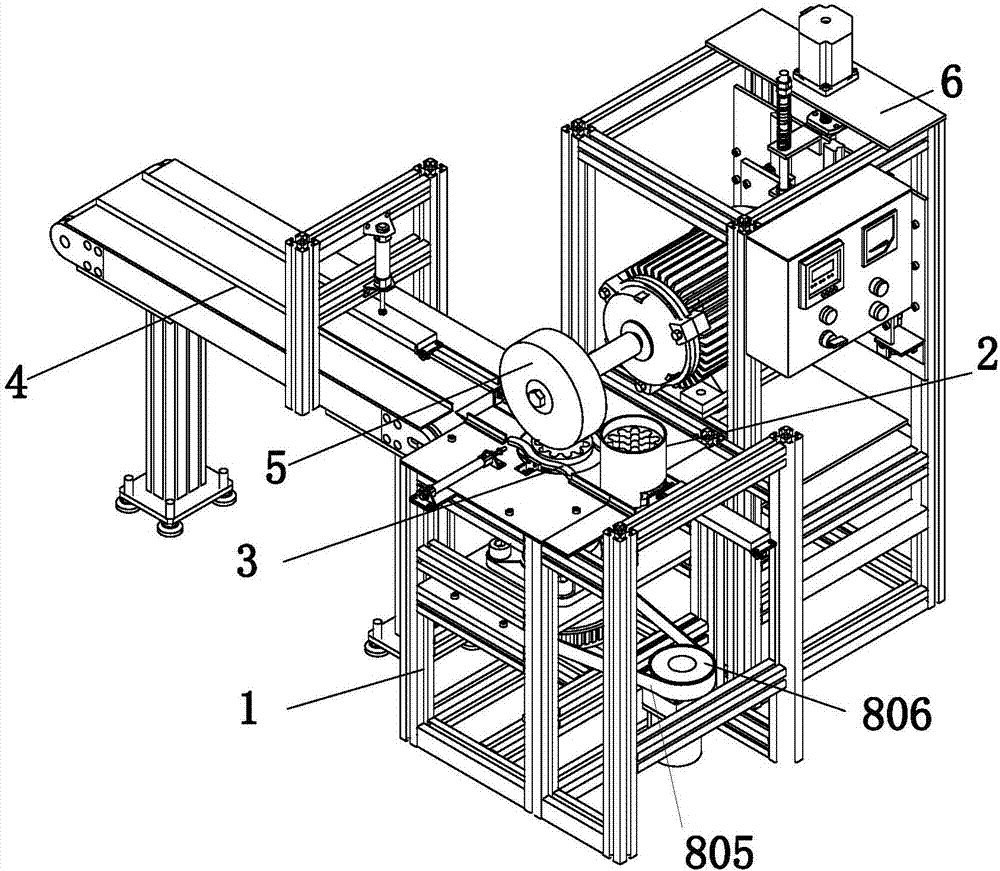

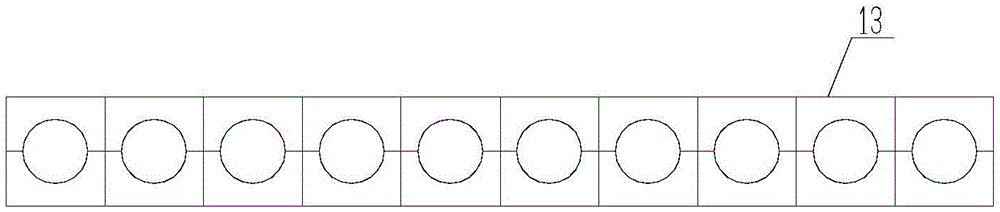

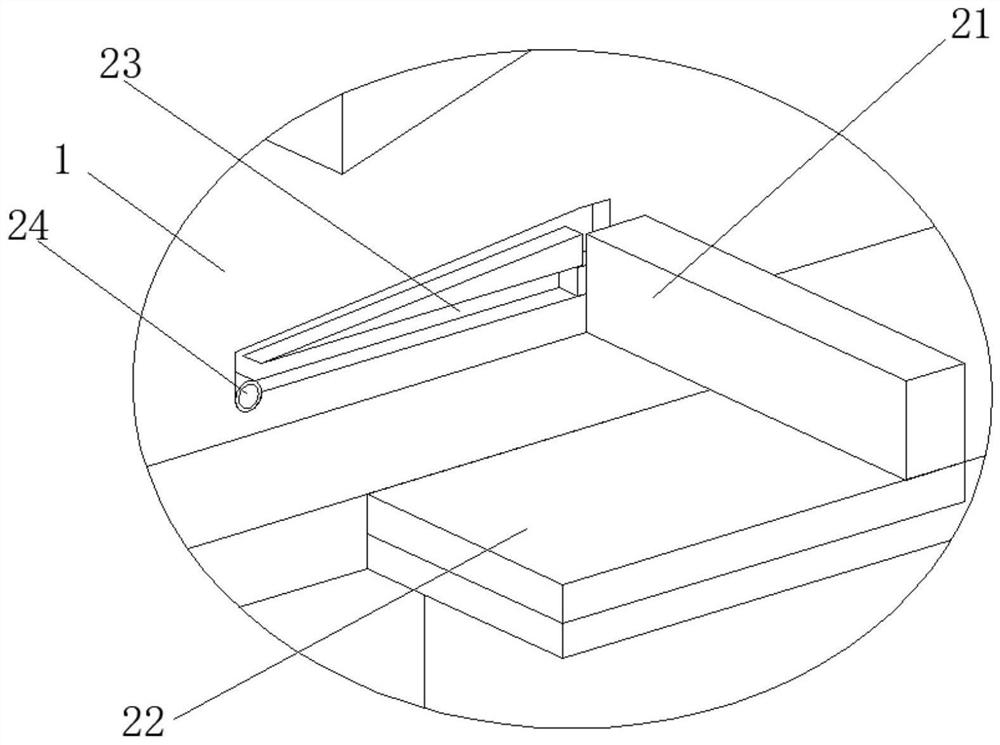

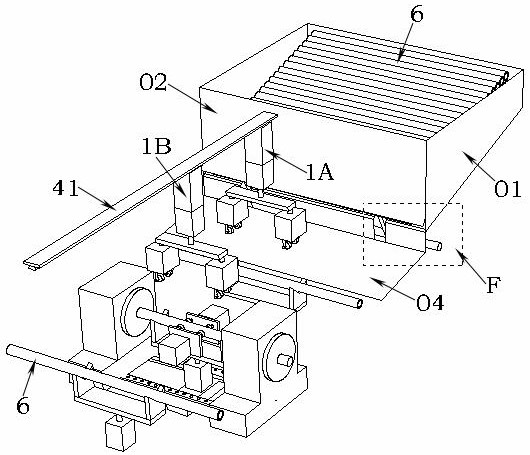

Automatic continuous inner hole polishing machine for steel tubes

InactiveCN103009225ARealize automatic feedingRealize dischargePolishing machinesSheet steelEngineering

The invention discloses an automatic continuous inner hole polishing machine for steel tubes. The automatic continuous inner hole polishing machine comprises a frame and a workbench arranged on the upper part of the frame, wherein an electric control device and a hydraulic device are arranged inside the frame; a fixing device, a sample conveying device and a polishing device are arranged on the workbench; the fixing device comprises an upper pressing die and a lower pressing die; a pressing oil cylinder is arranged above the upper pressing die; the sample conveying device comprises a feeding disk, a receiving disk and a connecting plate which is positioned between the feeding disk and the receiving disk; the polishing device comprises a polishing motor and a polishing shaft which is arranged at the front end of the polishing motor; the upper pressing die and the lower pressing die are positioned on the upper side and the lower side of the connecting plate respectively; the polishing motor is positioned in front of the connecting plate; the connecting plate is a steel plate with a certain inclination angle; and one end, which is close to the feeding disk, of the connecting plate is higher than the end, which is close to the receiving disk, of the connecting plate. The sample conveying device specific to the shapes of steel tubes is arranged, so that automatic feeding and discharging of steel tubes, and polishing of the inner walls of steel tubes under the condition of not turning round are realized.

Owner:QINGDAO ZHANGSHI MACHINERY

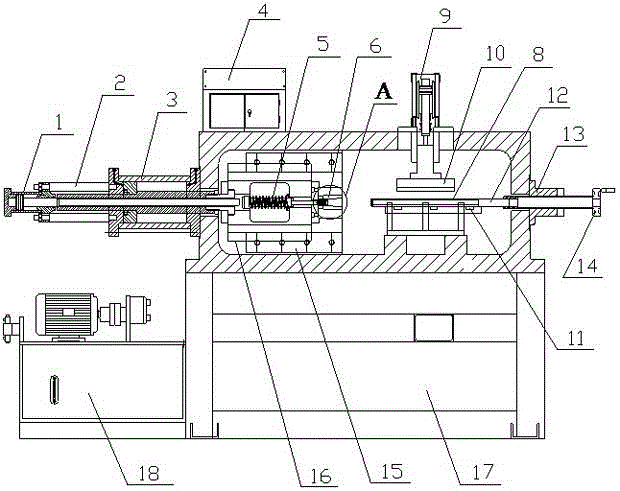

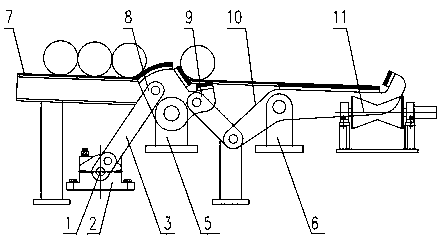

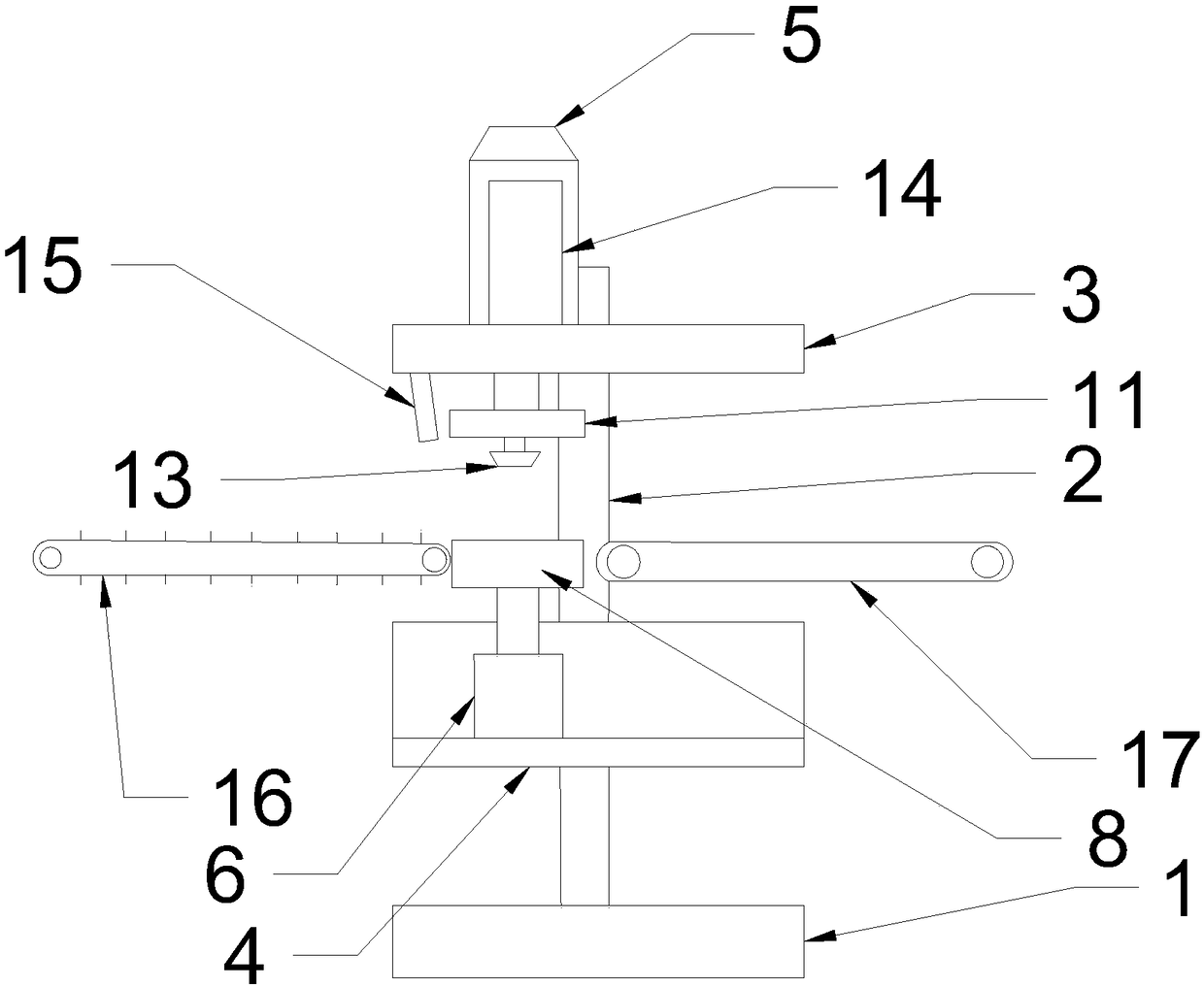

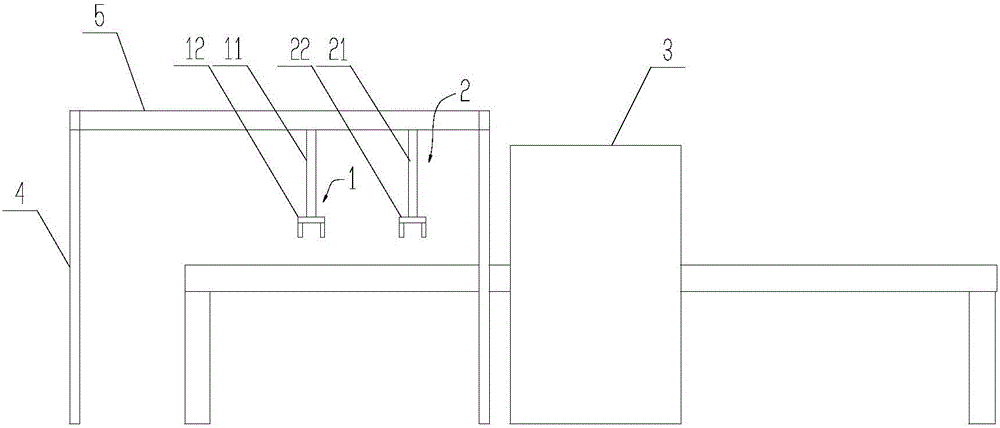

Automatic continuous horizontal-type punching machine for steel tube

ActiveCN103056210ARealize automatic feedingRealize dischargeShaping toolsMetal-working feeding devicesPunchingEngineering

An automatic continuous horizontal-type punching machine for a steel tube comprises a frame and a working platform on the upper portion of the frame. A hydraulic device and an electric control device are further arranged on the frame, and a stamping device, a fixing device and a sample conveying device are arranged on the working platform. The stamping device comprises a stamping oil cylinder, a stamping die and a discharge ejecting rod located between the stamping oil cylinder and the stamping die, a discharge oil cylinder is arranged at the front end of the stamping oil cylinder, and the stamping oil cylinder is connected with the discharge ejecting rod. The fixing device comprises an upper swaging die and a lower swaging die, and a swaging oil cylinder is arranged above the upper swaging die. The sample conveying device comprises a feeding hopper, a receiving hopper and a connecting plate located between the feeding hopper and the receiving hopper. The upper swaging die and the lower swaging die are respectively located on the upper side and the lower side of the connecting plate, and the stamping die is located on the front side of the connecting plate. The sample conveying device directing at shapes of the steel tube is arranged, one-time stamping of the steel tube is completed, and automatic feeding and discharging of the steel tube are achieved.

Owner:QINGDAO ZHANGSHI MACHINERY

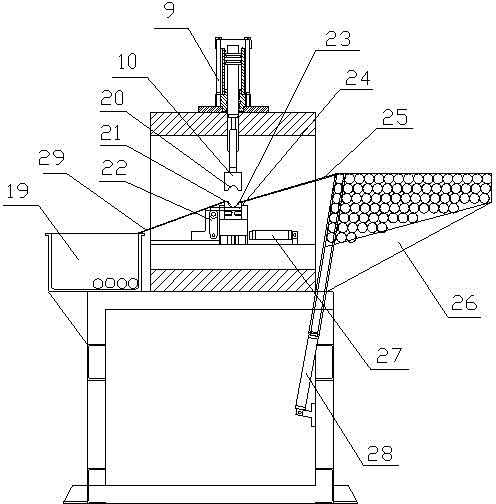

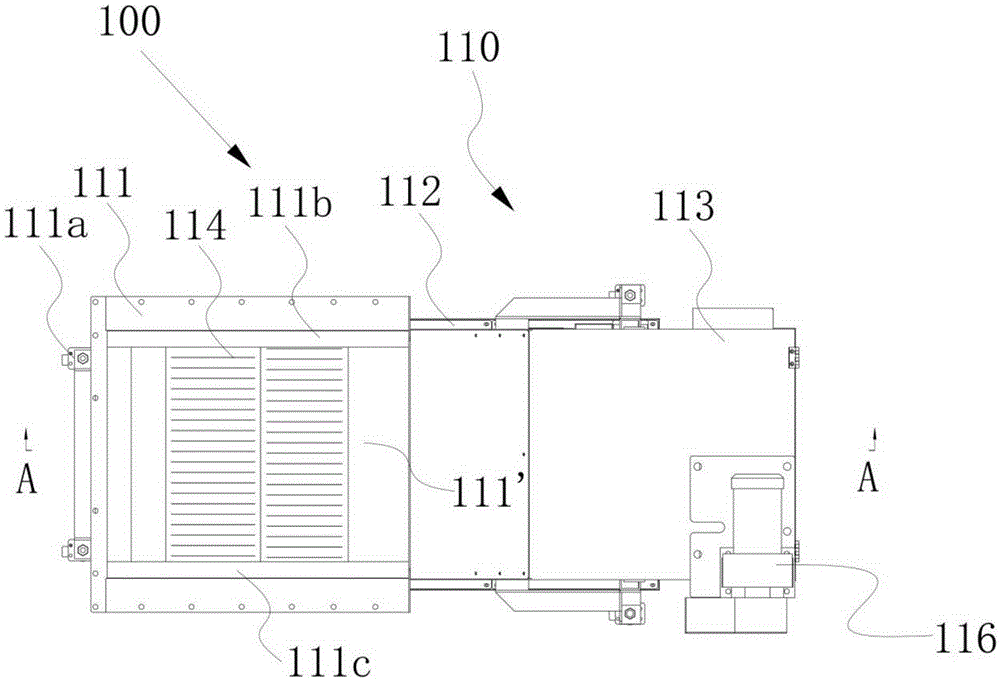

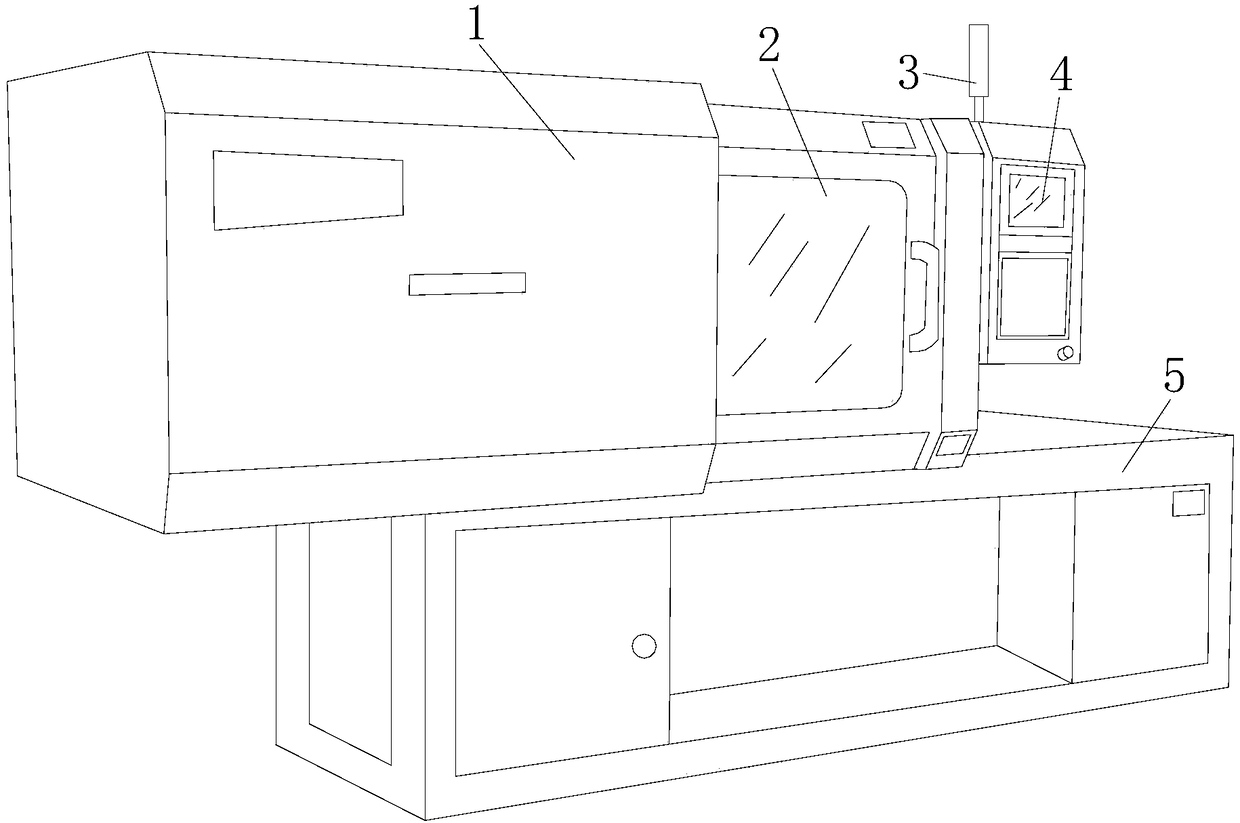

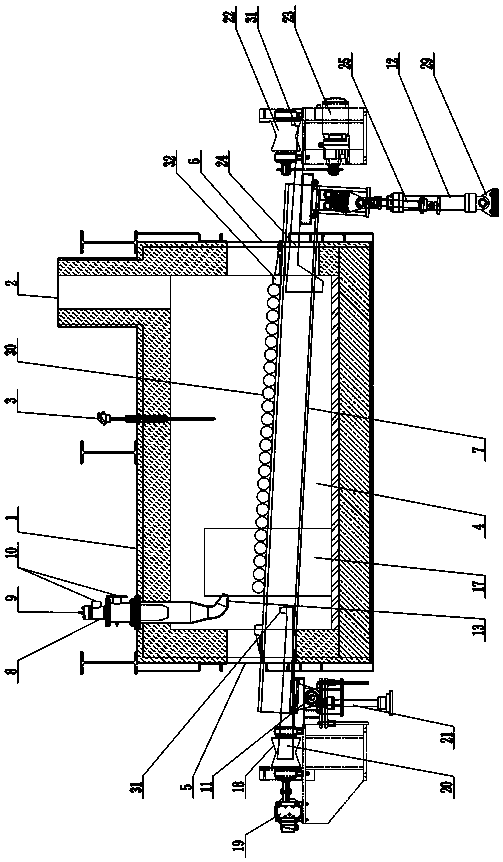

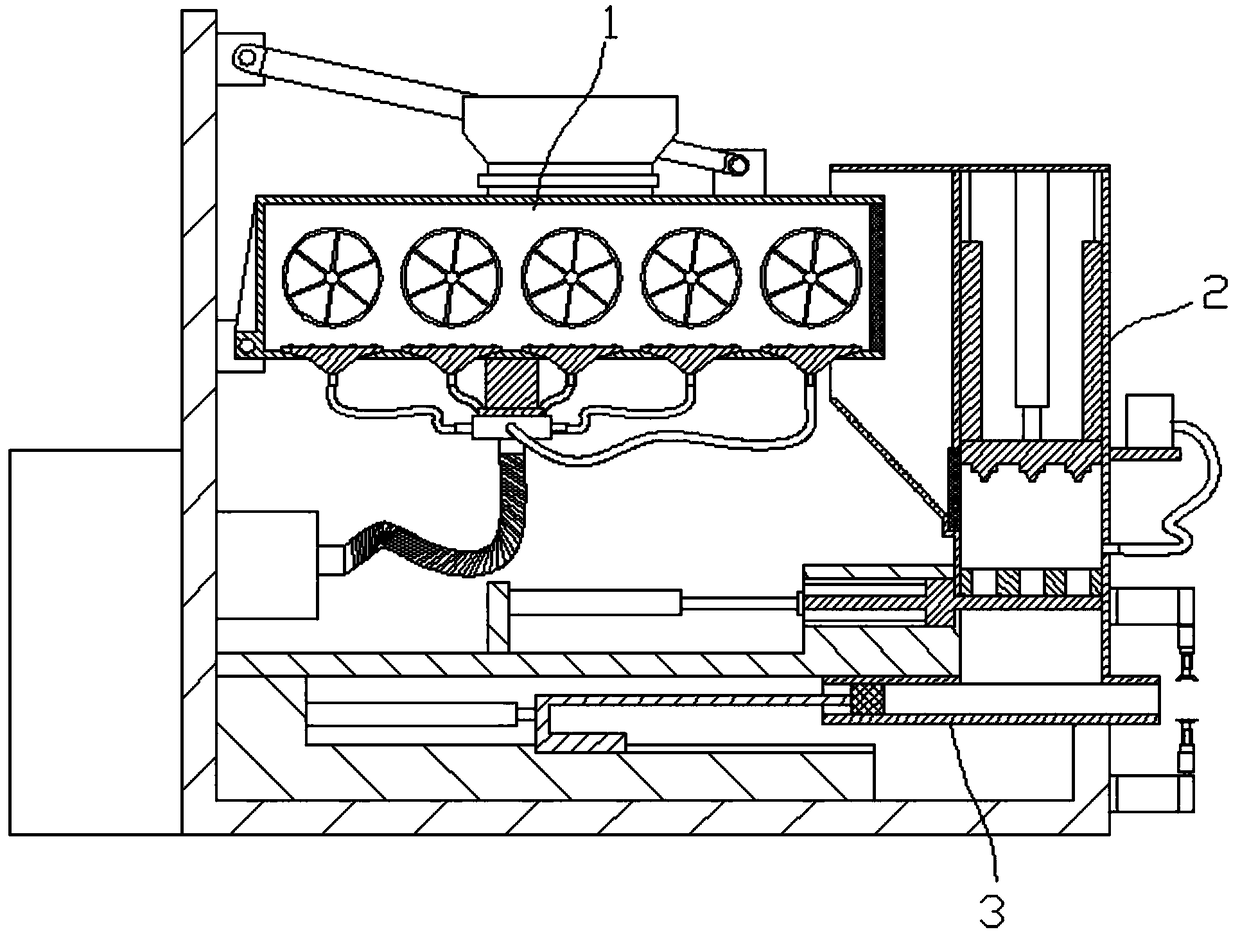

Cooling liquid recovery device integrating chip removal and circulation

InactiveCN105290876AScrape cleanRealize dischargeMaintainance and safety accessoriesCooling fluidCooling efficiency

The invention discloses a cooling liquid recovery device integrating chip removal and circulation. The cooling liquid recovery device comprises a cooling liquid recovery tank and a chip removal machine arranged over the cooling liquid recovery tank and used for removing cutting metal chips, wherein the chip removal machine comprises a hollow machine shell, a front conveying chain, a rear conveying chain and a chip removal driving motor, and the front conveying chain and the rear conveying chain are arranged on the front side and the rear side of the interior of the machine shell. The machine shell comprises a horizontal section, an ascending section, and a chip removal section, wherein the horizontal section is provided with an opening used for receiving foul cooling liquid, the ascending section is connected with the horizontal section and extends obliquely to the rear upper position, and the chip removal section is connected with the ascending section and extends horizontally and backwards. The chip removal driving motor is fixedly connected to the chip removal section, and a chip removal opening is formed in the lower surface of the tail end of the chip removal section. The cooling liquid recovery device has the beneficial effects that the filtering and cooling efficiency is improved as much as possible on the premise of guaranteeing the filtering precision, and meanwhile, the problem that the metal chip cleaning efficiency of an existing cooling liquid recovery device is low can be solved.

Owner:SUZHOU RS TECH

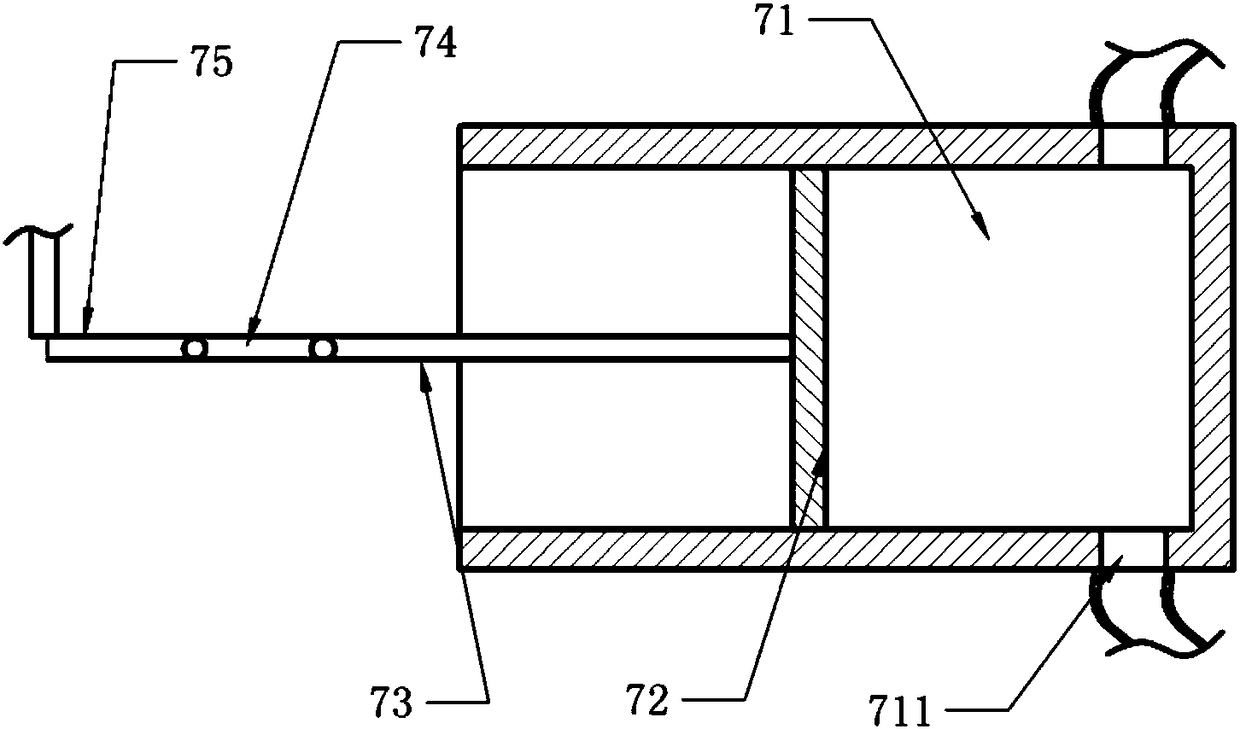

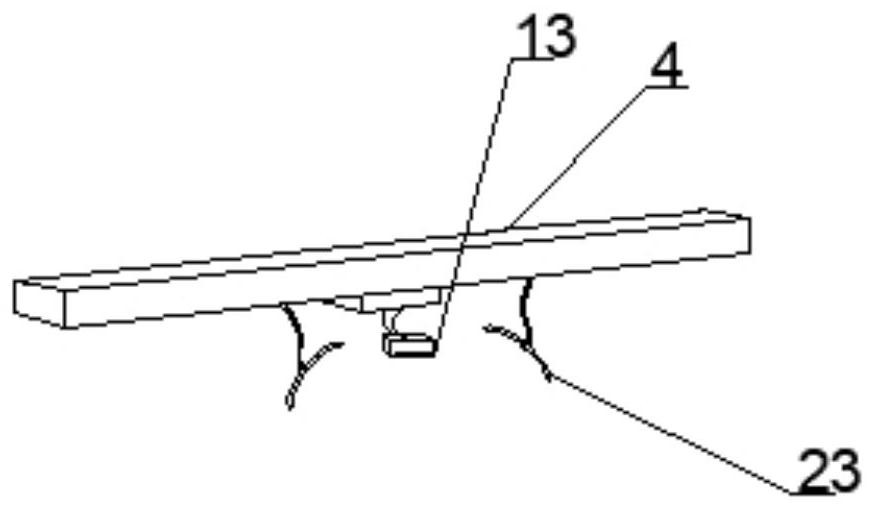

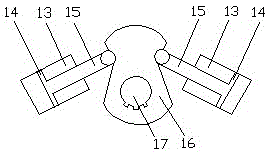

Single-drive separating and discharging device and method for steel pipes

PendingCN108100622ARealize material distributionRealize dischargeConveyorsConveyor partsEngineeringReducer

The invention provides a single-drive separating and discharging device and method for steel pipes. The single-drive separating and discharging device comprises a crankshaft, a bearing block, a motorreducer, a first support, a second support, a rack, a turning plate, a discharge arm and a roller way; the roller way is installed on a discharging side of the rack; the multiple steel pipes are placed on the rack; the first support and the second support are located between the rack and the roller way, and the first support and the second support are located on the same horizontal plane; the first support is connected with the turning plate, and the second support is connected with the discharge arm; the discharge arm is connected with the turning plate through a second connecting rod; and the crankshaft is arranged on the bearing block, the crankshaft is connected with the motor reducer, and the crankshaft is connected with the turning plate through a first connecting rod. According to the single-drive separating and discharging device, a separating device and a discharging device are integrated together so that the material separation and discharging functions of the steel pipes canbe realized through driving by one motor; and the separating and discharging device has the advantages that the number of driving devices is reduced, the structure is simple and reliable, cost is low, the efficiency is high, and the maintenance is convenient.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Daily necessity processing device

ActiveCN108187834AReduce outflowRealize current limitingGrain treatmentsPulp and paper industryRaw material

The invention belongs to the technical field of living goods processing, and discloses a daily necessity processing device. The daily necessity processing device comprises a smashing barrel, a material storing box, a rotating shaft and a motor. The lower end of the rotating shaft penetrates through the smashing barrel, and smashing cutter blades are arranged at the lower end of the rotating shaft.A feeding port and a discharging port are formed in the smashing barrel. An unloading port matched with the feeding port is formed in the material storing box. A tapered filter screen is slidably connected to the interior of the smashing barrel, a mounting piece is arranged on the filter screen, screening holes are formed in the smashing barrel, and supporting blocks and elastic pieces are arranged in the screening holes. A flow limiting mechanism and an air blowing mechanism are further arranged on the smashing barrel, the flow limiting mechanism comprises a supporting rod, a strut and a material blocking plate, the middle of the strut is hinged to the supporting rod, one end of the strut is connected with the bottom end of the material blocking plate, and a through hole matched with theunloading port is formed in the material blocking plate. The daily necessity processing device solves the problems that in the prior art, raw material grains in large grain sizes cannot be taken outtimely, thus a screen plate is blocked, the smashed raw material grains are accumulated on the screen plate, and accordingly smashing of following raw materials is affected.

Owner:江苏邦业护理用品有限公司

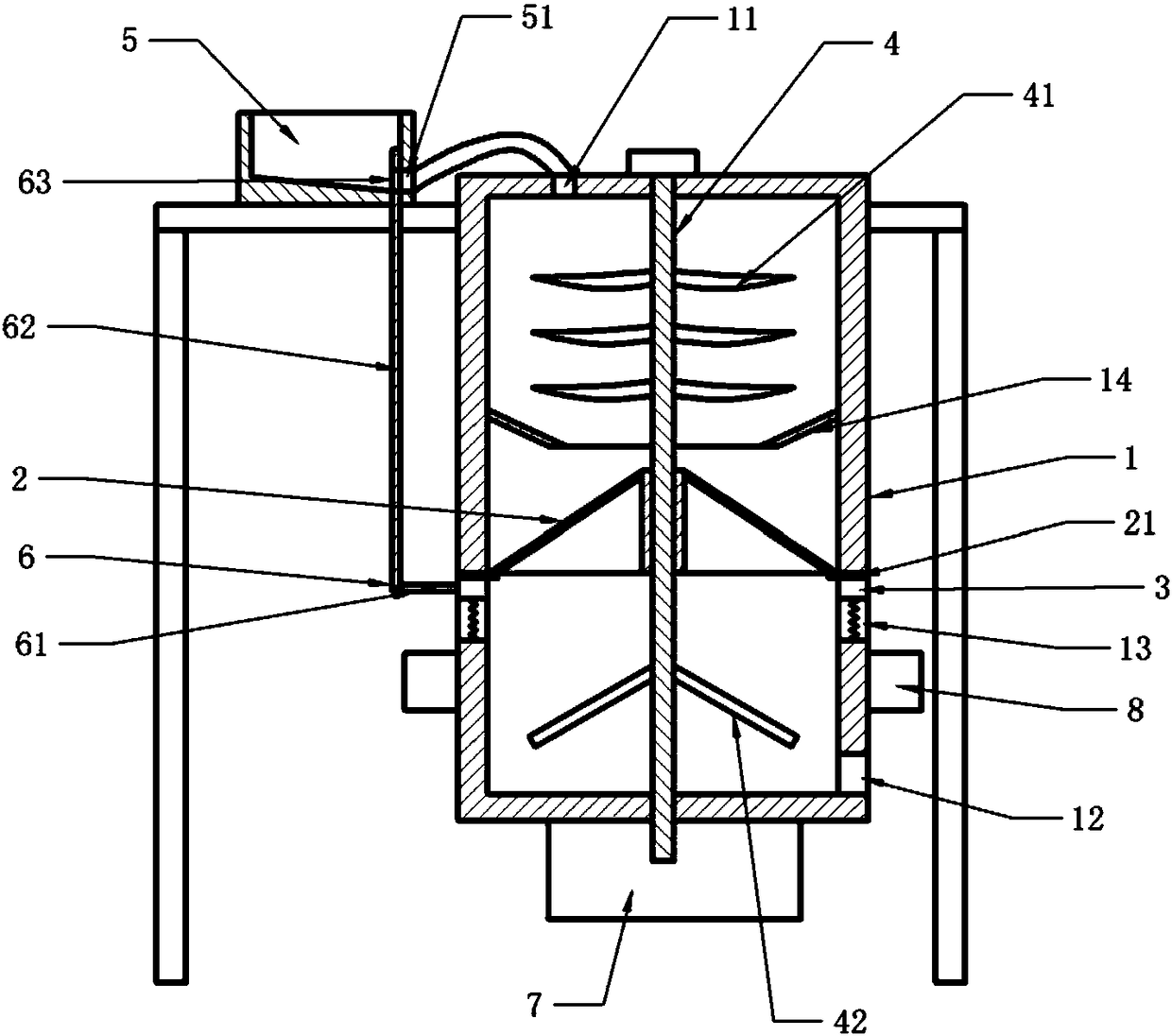

Efficient methane production device

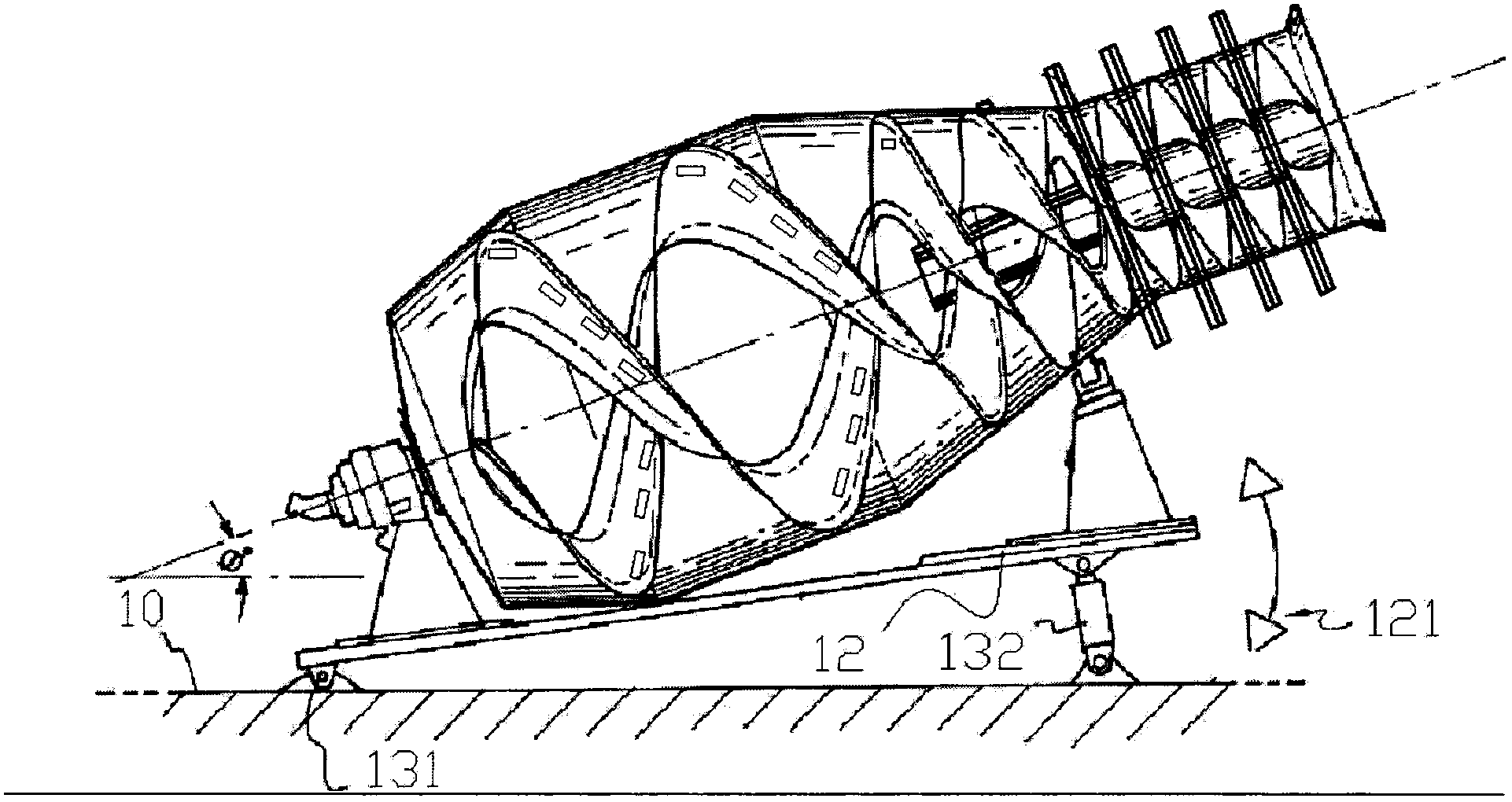

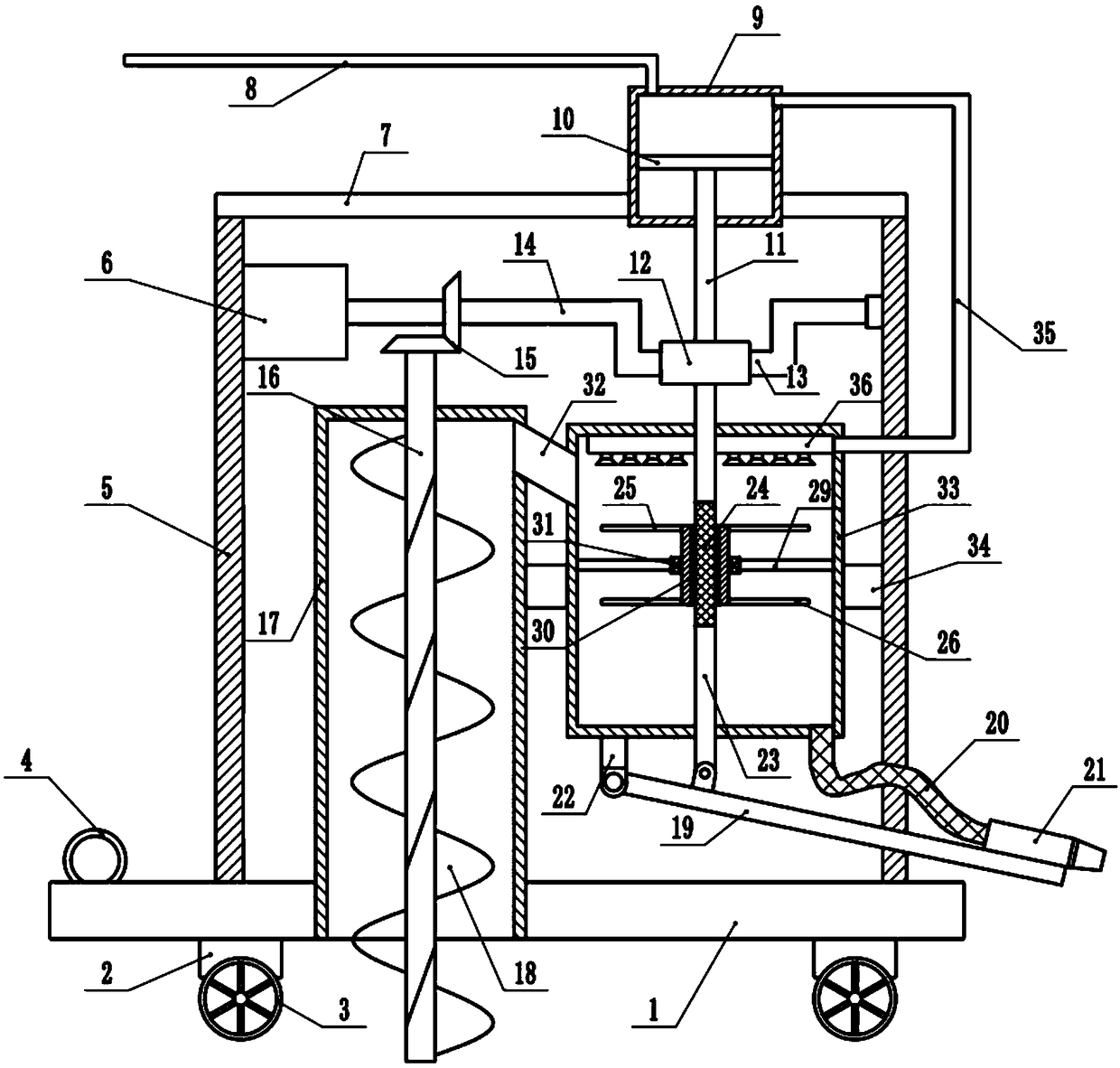

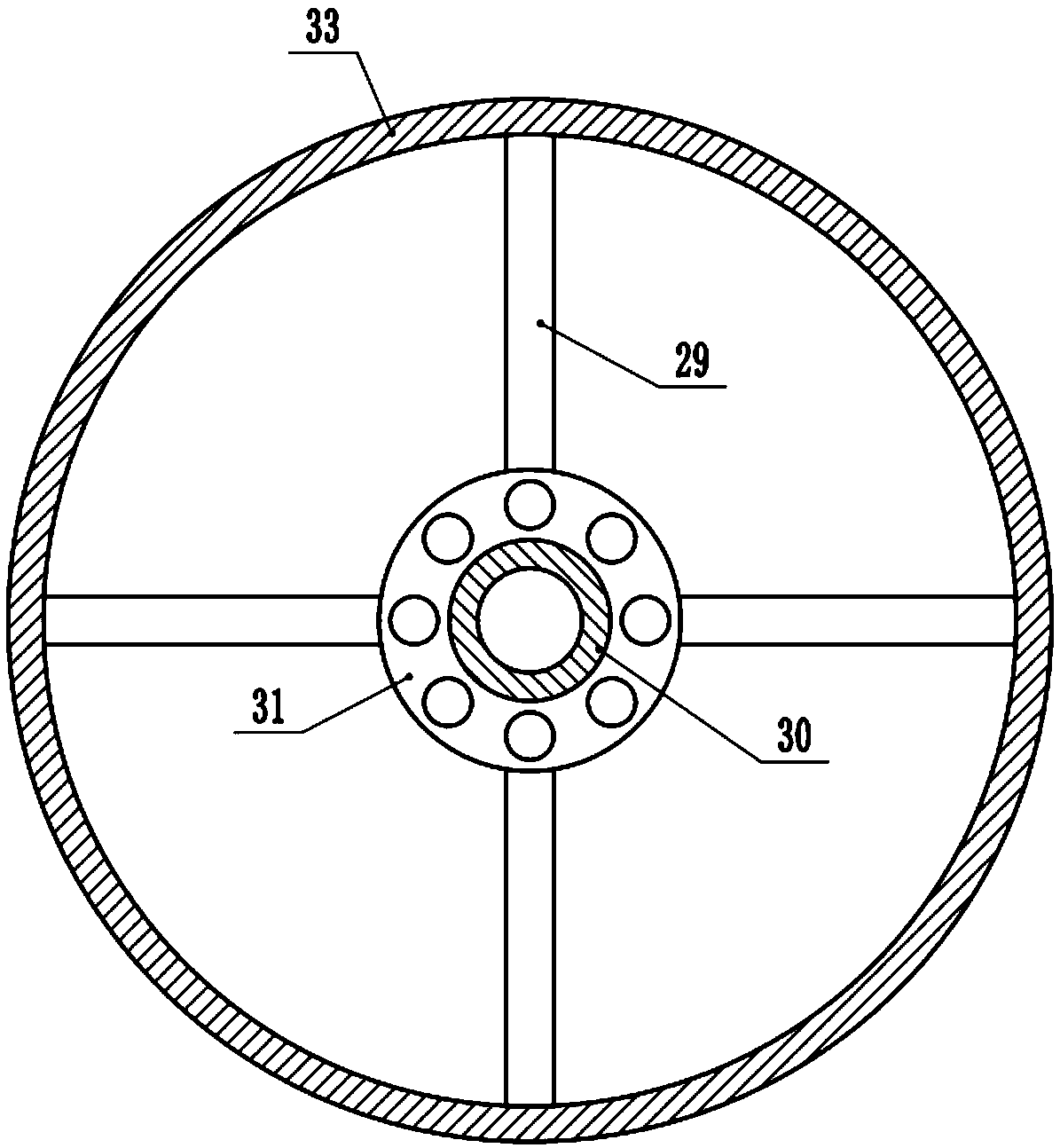

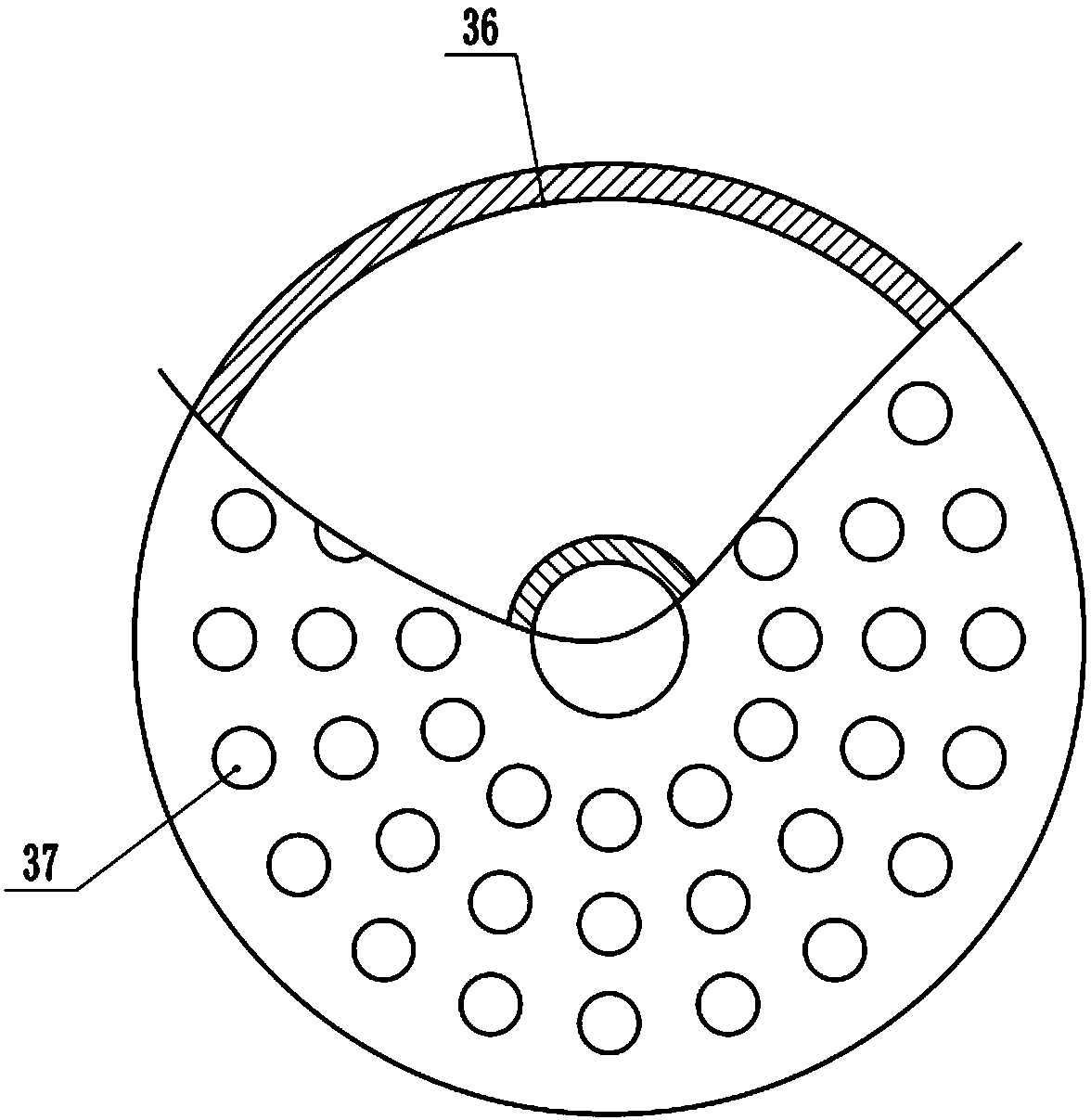

InactiveCN103468563ASolve the inability to achieve sustainabilitySolve productivityGas production bioreactorsWaste based fuelHelical bladeMethane production

The invention relates to an efficient methane production device which comprises a conveyable base seat and a rotatable methane production container which is placed on the base seat and provided with a rotary shaft and an opening, a methane chamber is formed by an inner cavity of the container, first double helical blades are disposed in the inner cavity and connected with an inner wall of the inner cavity, a helical revolving shaft of the first double helical blades is coaxial with the rotary shaft, the opening is connected with a blind flange which comprises a flange tube and an inner tube disposed in an inner cavity of the flange tube, second double helical blades naturally engaged with the first double helical blades are disposed between an inner wall surface of the flange tube and an outer wall surface of the inner tube in a connecting mode, a methane outlet tube which extends into the inner cavity is disposed in the inner tube in an inserted mode, a center shaft of the inner tube is coaxial with the rotary shaft, feed / discharge propellers which are coherent and lead to the opening from the bottom of the inner cavity are formed by the first double helical blades and the second double helical blades together, a lower portion of the inner tube extends into inner cavity biogas slurry, and flange plates are disposed at two ends of the flange tube. According to the efficient methane production device, clockwise rotation and anticlockwise rotation of the helical blades are adopted to achieve automatic feed and discharge, the device is conveyable, methane production is rapid, and efficiency is high.

Owner:杨华昌

Device for producing chopped chilli

The invention belongs to the technical field of chilli processing, and particularly discloses a device for producing chopped chilli, which comprises a chopping unit, a power unit, a frame and an outercylinder, wherein the chopping unit comprises a power shaft, an inner cylinder and an extension rod, wherein the power shaft passes through the upper and lower rotating centers of the inner cylinderand is rotatably connected with the inner cylinder; a cutter is arranged on the power shaft; the circumferential surface of the power shaft is provided with a first annular groove and a spiral groove,one end of the extension rod is clamped in the grooves; a side wall of the inner cylinder is configured to be a rigid screen; a turning over and mixing mechanism is arranged in the inner cylinder; the turning over and mixing mechanism comprises a turning over plate, a rotating block and a clamping groove; the clamping groove is arranged along the radial direction of the power shaft; the clampinggroove is slidably connected with a sliding block; one end of the turning over plate is hinged on the rotating block, and the other end of the turning over plate is hinged on the sliding block; the power unit comprises a cylindrical cam, a motor for driving the cylindrical cam to rotate and an intermittent mechanism for driving the inner cylinder to rotate intermittently. According to the invention, the device can shop the chilli and the problem of serious juice ejecting is avoided.

Owner:徐州千润高效农业发展有限公司

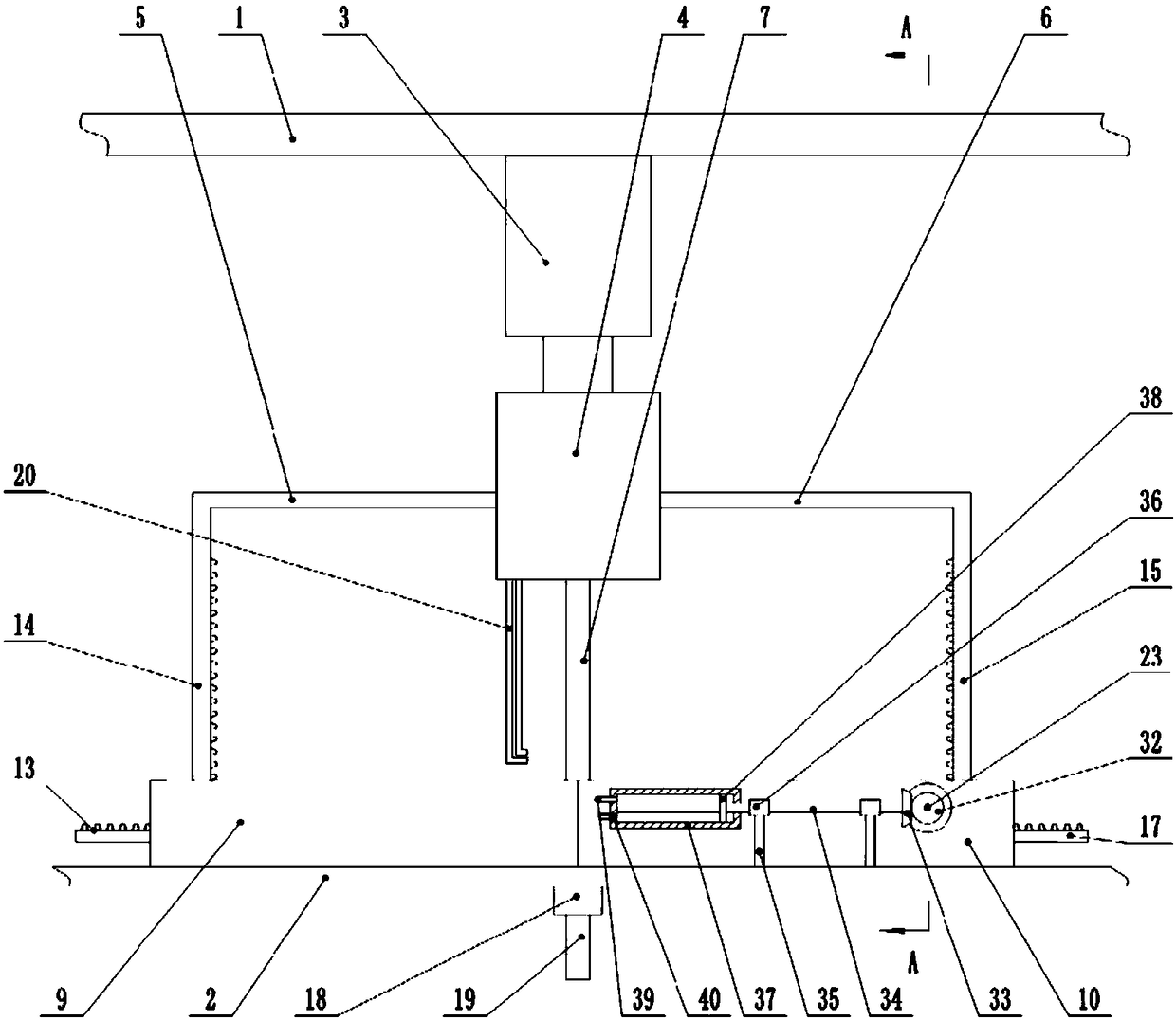

Online-repairing-type soil improvement treatment device

The invention discloses an online-repairing-type soil improvement treatment device, and belongs to the technical field of soil repairing equipment. The device comprises a moving base, supporting shelves are installed at the two sides of the upper end of the moving base, a top shelf is installed at the tops of the supporting shelves, a rotary shaft is installed between the upper ends of the supporting shelves, a transmission gear set is installed in the middle of the left end of the rotary shaft, a drilling shaft is installed at the lower end of the transmission gear set, and the lower end of the drilling shaft penetrates through a drilling cylinder which is arranged at the left side of the upper end of the moving base; a crank is installed in the middle of the right end of the rotary shaft, a slide sleeve is installed in the middle of the crank, a piston rod is installed at the upper end of the slide sleeve, a stirring rod is installed at the lower end of the slide sleeve, the lower end of the stirring rod penetrates through a stirring box arranged between the drilling cylinder and the supporting shelf at the right side, the bottom of the stirring rod is hinged to a swinging rod, apesticide spraying cavity is formed in the top inside the stirring box, a bearing is connected to the middle of the inner wall of the stirring box through a fixed shelf, and a threaded sleeve is installed in the middle of the bearing. According to the device, online digging of polluted soil and repairing of the dug soil are achieved, and the efficiency of repairing the polluted soil is improved.

Owner:霸州市辉月网络技术有限公司

Battery spot welding device

PendingCN108515293AImprove efficiencyImprove securityWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderSpot welding

The invention belongs to the technical field of coating or plating equipment by means of brazing or welding methods, and in particular discloses a battery spot welding device. The battery spot weldingdevice comprises a rack and a worktable, wherein the worktable is located below the rack; a hydraulic cylinder is fixedly mounted on the rack; the output end of the hydraulic cylinder is fixedly connected to a spot-welder; a spot-welding needle is fixedly mounted on the lower end surface of the spot-welder; a part feeding mechanism is fixedly mounted on the upper end surface of the worktable; thepart feeding mechanism is used for driving a protecting plate and a battery cell to move in opposite directions till the protecting plate and the battery cell are laminated; the part feeding mechanism is driven by the spot-welder; a glue spraying mechanism is arranged in the part feeding mechanism for spraying glue to the battery cell; and the glue spraying mechanism is driven by the part feedingmechanism. The battery spot welding device aims to solve the problems that the efficiency is low and the safety cannot be ensured as the battery cell and the protecting plate are manually held to weld in the prior art.

Owner:贵州鸿兴时代动力新能源科技有限公司

Kiwi fruit no-injury hair removing equipment

The invention belongs to the technical field of food processing mechanisms, and discloses kiwi fruit no-injury hair removing equipment. The kiwi fruit no-injury hair removing equipment comprises a machine housing, wherein the lower surface of a feeding ring is fixedly connected to the upper surface of the machine housing; an annular groove is formed in the upper surface of the feeding ring; inletsare respectively formed in the left side and the right side of the bottom wall of the annular groove; a material opening is formed in the position corresponding to each inlet, on the top wall of themachine housing; a fed material preprocessing mechanism is arranged on the upper side of the inner part of the machine housing; and a disk type brushing and removing mechanism is arranged on the lowerside of the inner part of the machine housing. According to the kiwi fruit no-injury hair removing equipment disclosed by the invention, the fed material preprocessing mechanism is arranged, so thatin the feeding process of kiwi fruits, preprocessing hair removing can be performed, quick hair removing is realized through the gravity and the rotation of a connecting ring, and the kiwi fruit no-injury hair removing equipment is simple in structure.

Owner:杨国宝

Can opening machine

ActiveCN109160470AEasy to operateSmooth cutHand-operated cutting devicesPower-operated cutting toolsEngineeringMechanical engineering

The invention relates to a can opening machine comprising a base frame, an air cylinder, a pressing head, a variable speed motor and a rotary tray. The base frame comprises a bottom base frame, an upper base frame, a cylinder base frame and an adjustable base frame. The cylinder base frame is fixed in the vertical direction of the bottom base frame. The upper base frame is fixed to the upper portion of the cylinder base frame. The adjustable base frame capable of sliding on the cylinder base frame is arranged between the bottom base frame and the upper base frame. The cylinder base frame is sleeved with the adjustable base frame provided with the air cylinder. A piston rod is arranged in the air cylinder. The rotary tray is fixed to the piston rod. The pressing head is fixed to the lower portion of the upper base frame. A cutter is arranged beside the pressing head. The variable speed motor is fixed to the upper portion of the upper base frame. The output end of the variable speed motor is connected with the pressing head.

Owner:NINGBO SHOWCO FOOD

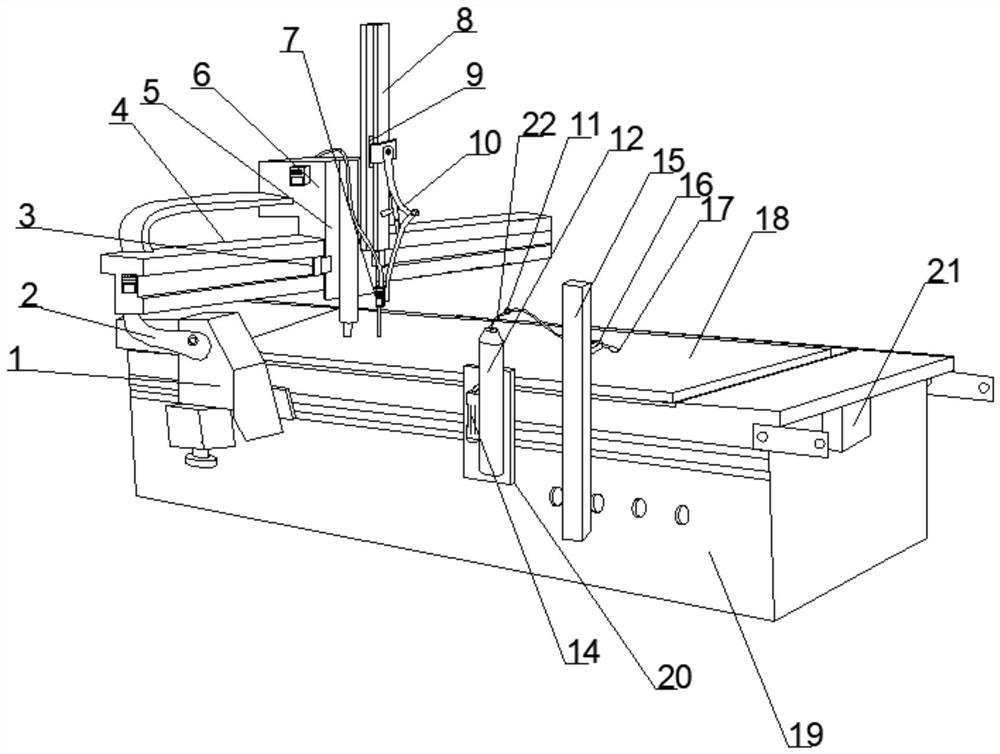

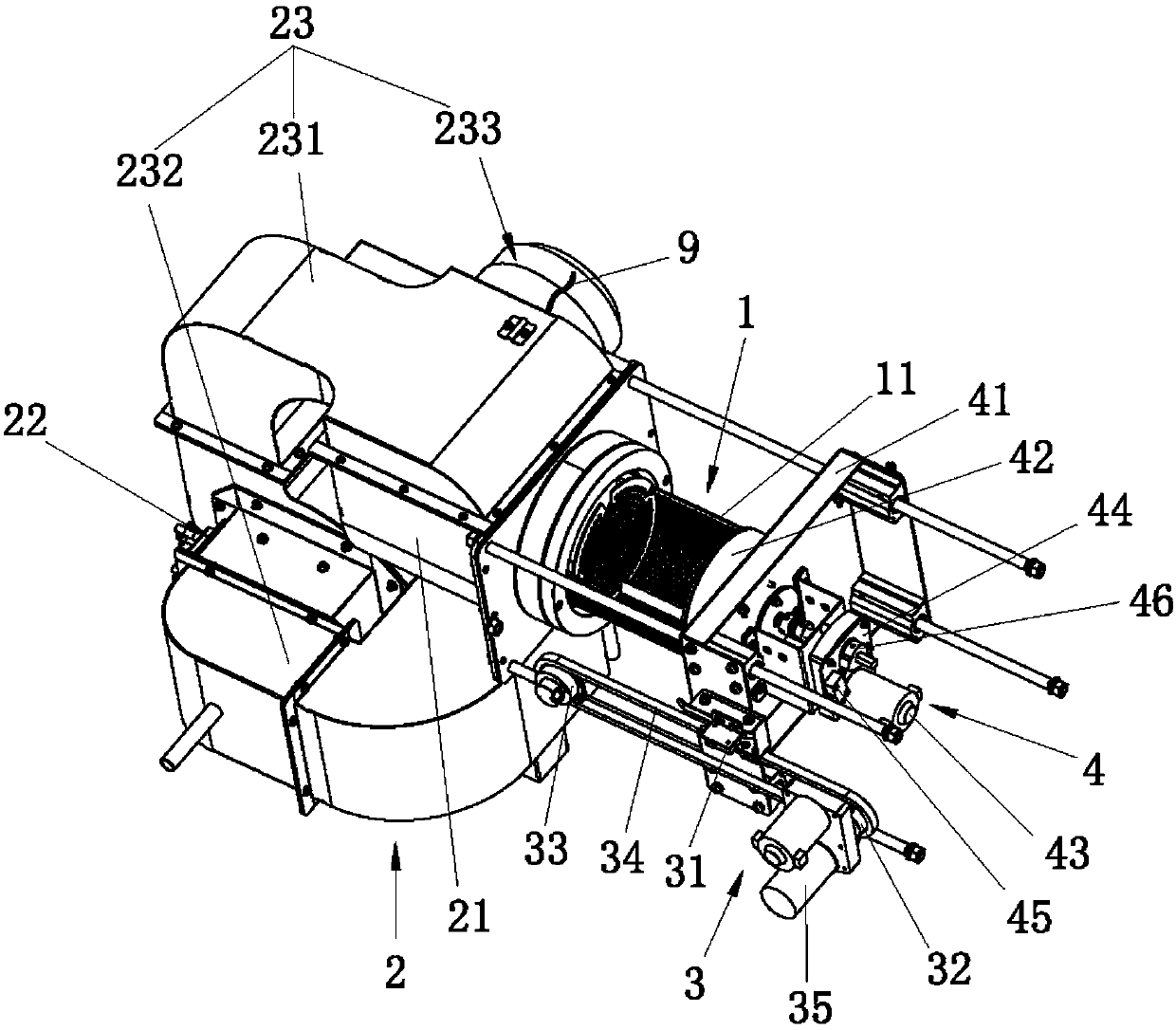

Electric arc welding automatic welding equipment and welding method thereof

InactiveCN113000997ALow failure rateImprove cleanlinessWelding accessoriesStructural engineeringWeld seam

The invention discloses electric arc welding automatic welding equipment and a welding method thereof. The electric arc welding automatic welding equipment comprises a cabinet body, a supporting block and an electric arc welder, wherein the supporting block is installed on one side of the cabinet body through a bolt; a horizontal sliding rail is installed at the top of the supporting block through an arc-shaped supporting rod and a bolt; a first electric sliding block is slidably connected into the horizontal sliding rail; a movable side plate is installed on one side of the first electric sliding block through a bolt; an electric arc welder is installed on one side of the movable side plate through a bolt; a vertical sliding rail is installed on the other side of the movable side plate through a bolt; a mechanical arm is arranged on one side of the vertical sliding rail; and a welding clamp is installed at the output end of the mechanical arm through a bolt. According to the electric arc welding automatic welding equipment and the welding method thereof, the welding seam appearance quality detection function is achieved, the welding seam quality can be improved, operation is convenient, the manufacturing cost is low, the intelligent degree is high, and manpower and material resources are effectively saved.

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

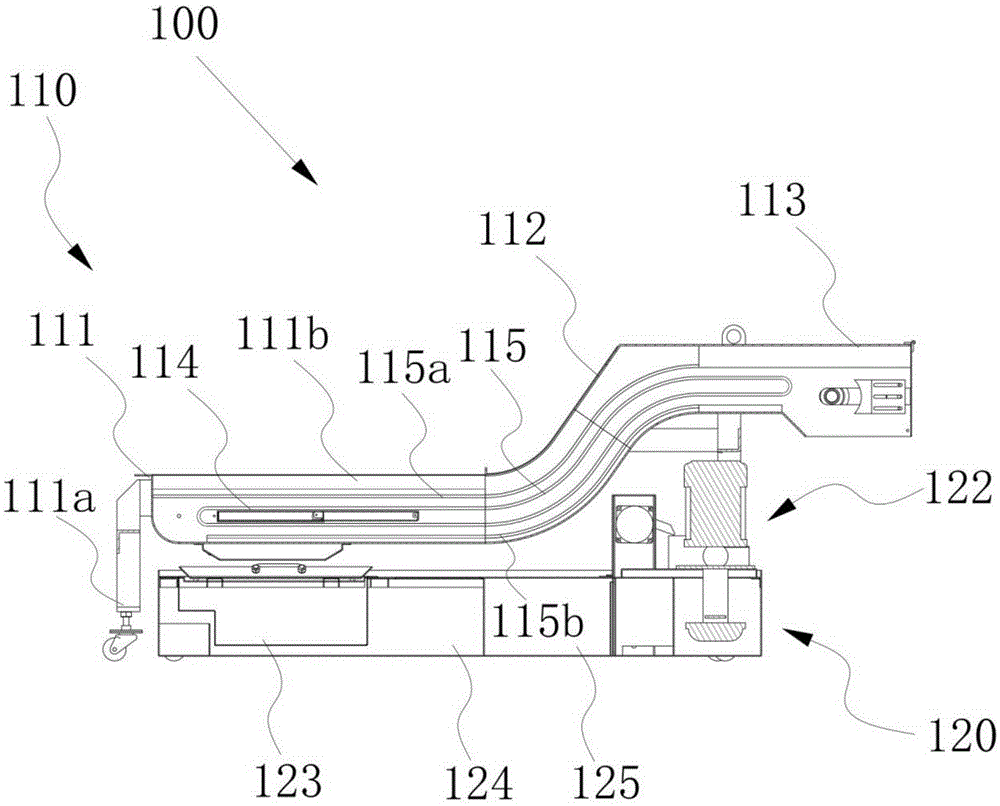

Baking equipment

PendingCN107595149ASimple structureReasonable designRoasting apparatusRoasters/grillsEnvironmentally friendlyProcess engineering

The invention relates to the technical field of baking electrical appliances, in particular to baking equipment. The equipment comprises a material storage mechanism which is used for storing materials, a baking device which is used for baking the materials in the material storage mechanism, a mobile driving mechanism which is used for driving the material storage mechanism to enter or move out ofthe baking device, and a rotation driving mechanism which is used for driving the material storage mechanism to rotate. The baking equipment is simple in structure and reasonable in design, is conveniently cleaned and maintained, achieves automatic baking of the materials, replaces a material baking mode with a deep frying mode, is hygienic and healthy, cannot generate hygienic, saves energy, andis environmentally friendly; the rotation driving mechanism drives the material storage mechanism to rotate, so that the materials are overturned in the material storage mechanism, the baking devicebakes the materials conveniently, the baking efficiency is improved, the baking time is shortened, the baking device bakes the materials evenly, and the quality of the baked materials is improved.

Owner:DONGGUAN JIAFENG MECHANICAL EQUIP

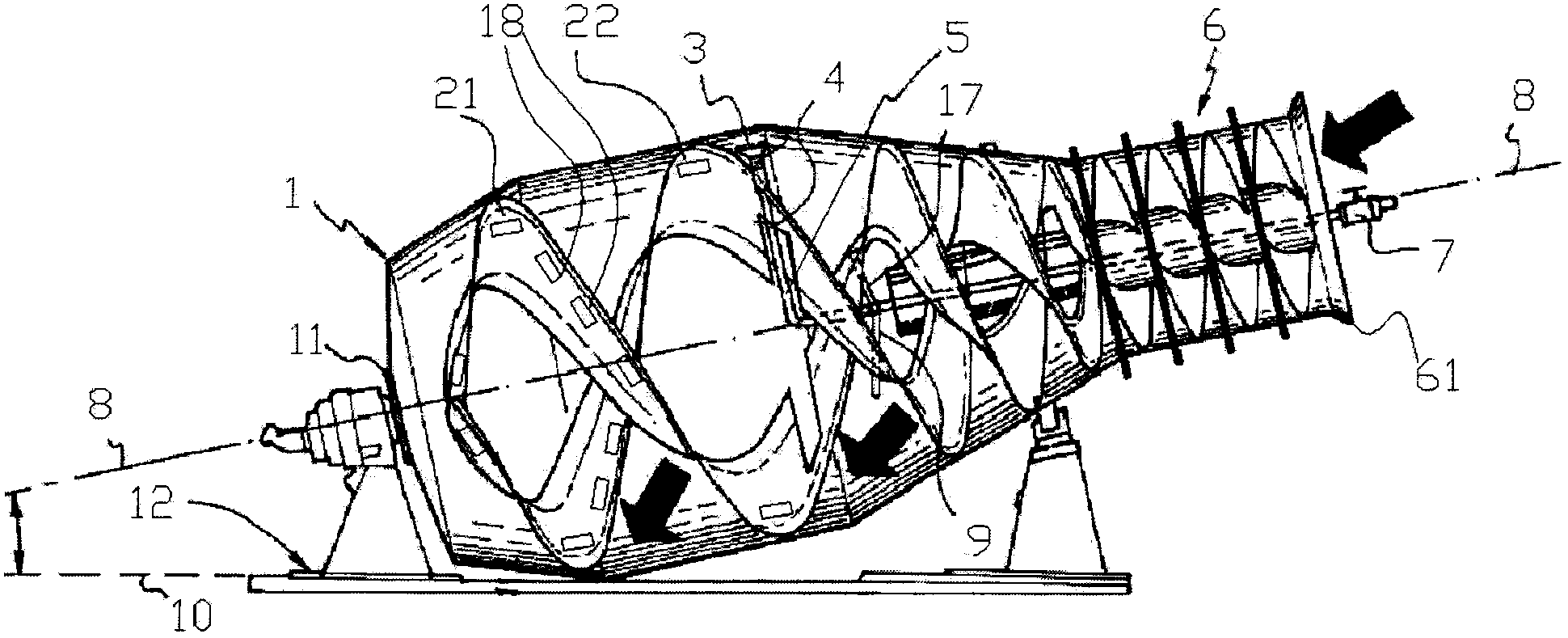

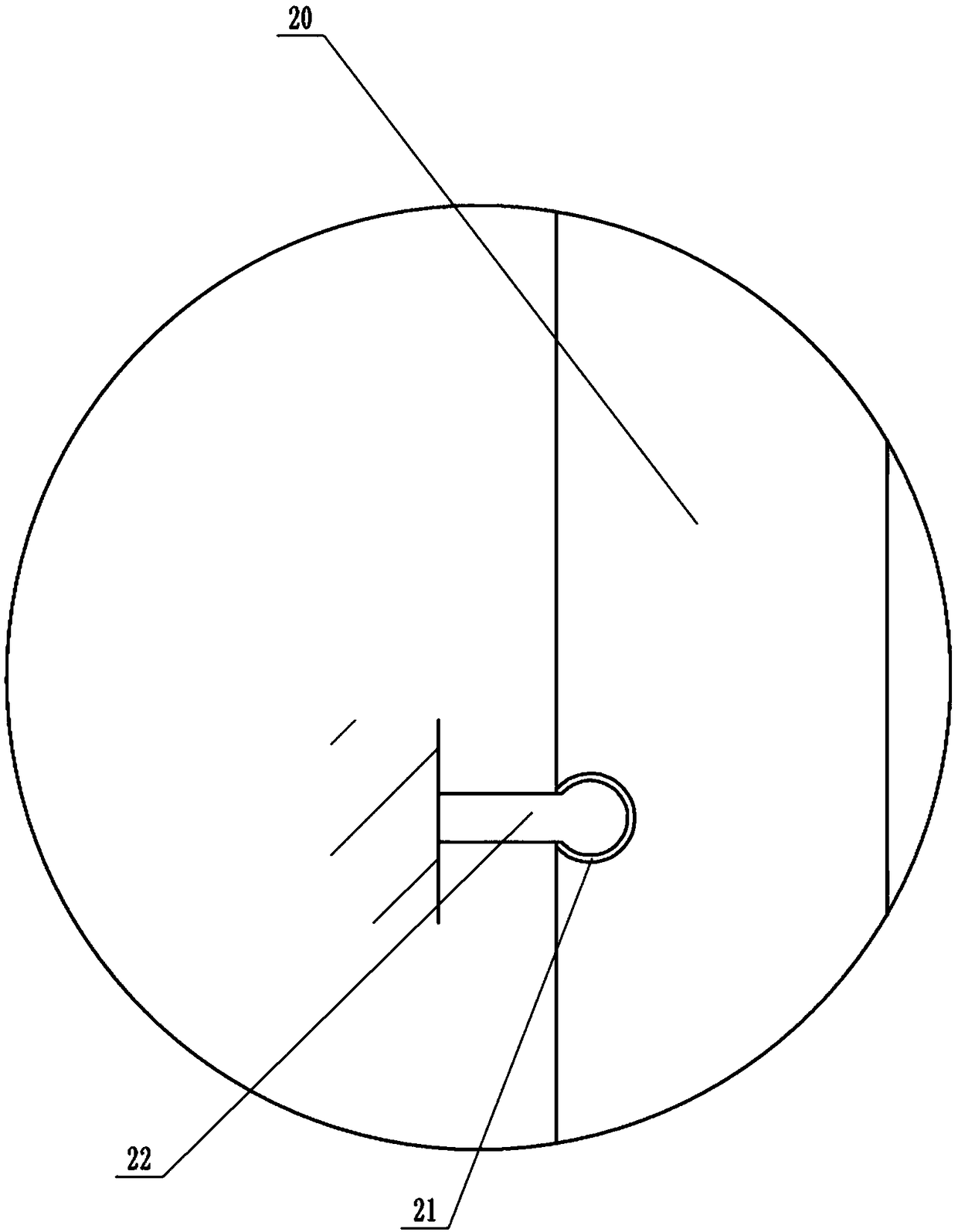

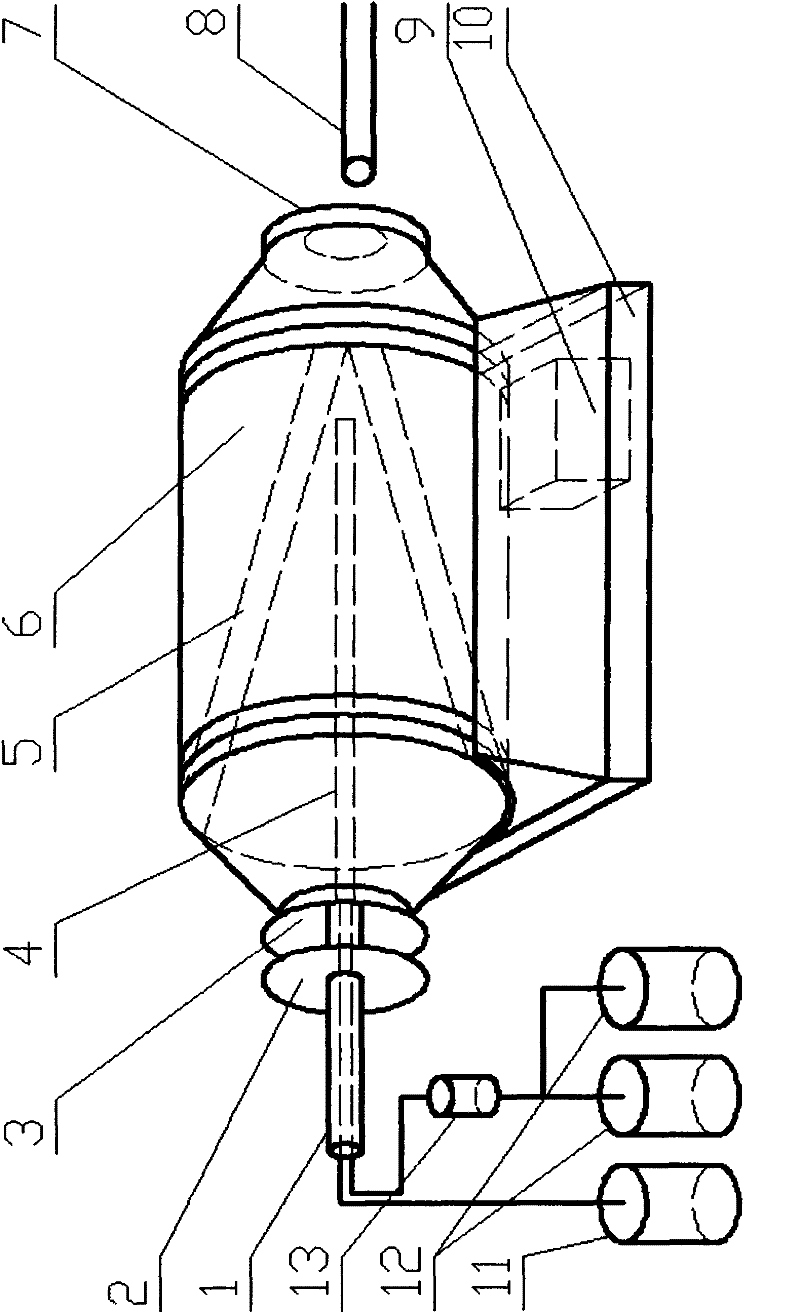

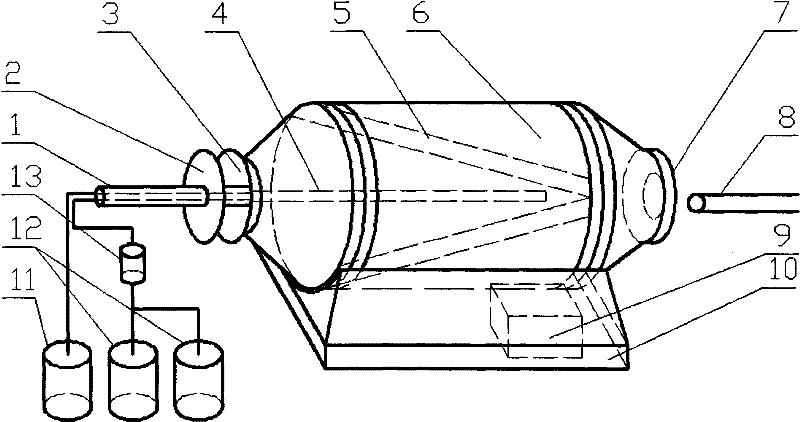

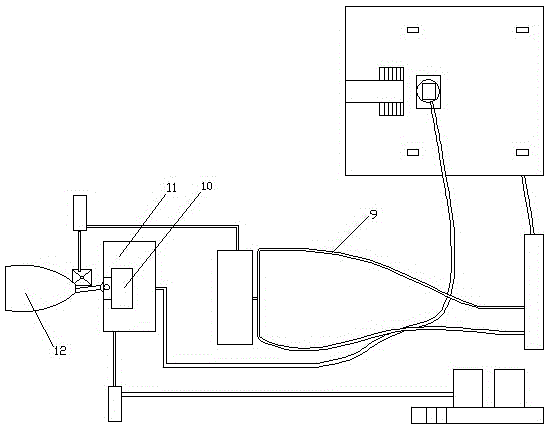

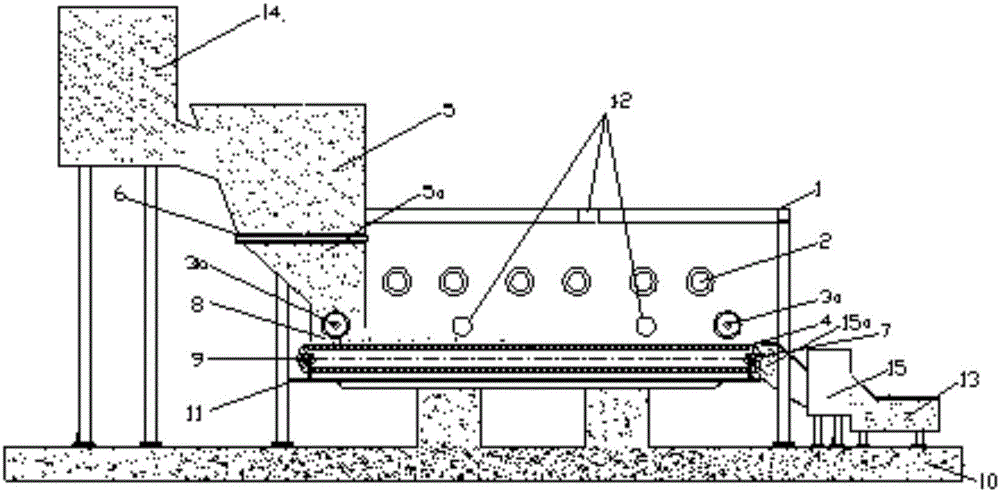

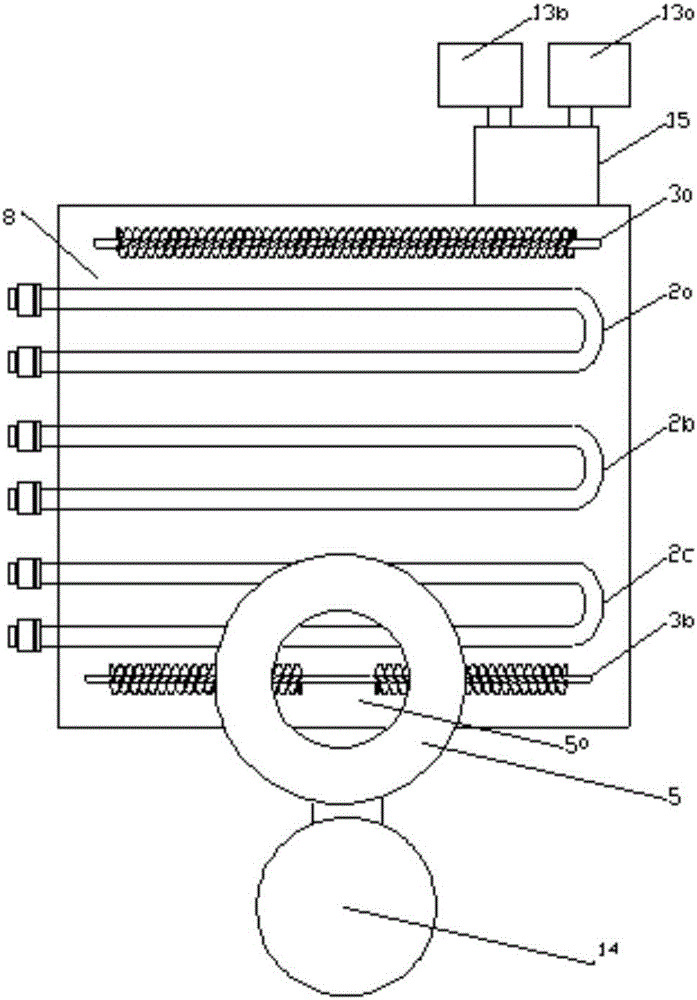

Rotary plant fruit soaking germination growth device

The invention belongs to the field of agriculture and agricultural product processing, and discloses an industrial cleaning, soaking, germination accelerating and growing device related to plants. The device is provided with a rotatable horizontal tubular plant soaking germination accelerating growth container 6 with a spiral rib plate 5 inside, a power system 9 that forcibly drives the rotatable horizontal tubular plant soaking germination accelerating growth container 6 rotations, auxiliary equipment (comprising Insert the liquid spraying device 4, ventilation device 11 inside the rotatable horizontal cylindrical plant soaking germination growth container 6, growth, disinfection, sterilizing preparation configuration device 12 and delivery device 13, frame 10), control system composition . The invention can solve the problems such as mutual extrusion of materials stacked, poor air permeability, temperature gradient inside the material piles, bacteria reproduction and the like during the germination growth process of plants. The device also realizes the cleaning and soaking of the plants to be germinated before the germination, automatic discharging and automatic cleaning of the germination growth container 6 .

Owner:南京远望富硒农产品有限责任公司 +1

Particle drilling method

InactiveCN105134080ASimplify the screening processImproving the efficiency of percussion drilling operationsDrilling machines and methodsWell drillingParticle injection

Owner:CCDC PETROLEUM CORING TECH

High-temperature furnace for producing ultra-wide continuous coiled graphene

The invention discloses a high-temperature furnace for producing ultra-wide continuous coiled graphene. The furnace includes a base, wherein an adjusting base is arranged at the top of the base, a furnace body is hinged to the adjusting base, a driving motor is arranged at the top of the furnace body, a disturbance shaft is connected to an output shaft of the driving motor, installation disturbance rods are symmetrically arranged on the two sides of the disturbance shaft, the three installation disturbance rods are jointly connected with a scraper, the scraper is attached to the inner wall ofthe furnace body, and an electric heating block is arranged on the bottom wall in the furnace body below the disturbance shaft. Materials are fed into the furnace body, the electric heating block is started, then the driving motor and the disturbance shaft are started to rotate so as to drive the installation disturbance rods to rotate and spiral blades rotate, and therefore the melting rate is increased, and meanwhile the material melting rate is further increased through arrangement of the disturbance inclined rods.

Owner:安徽碳华新材料科技有限公司

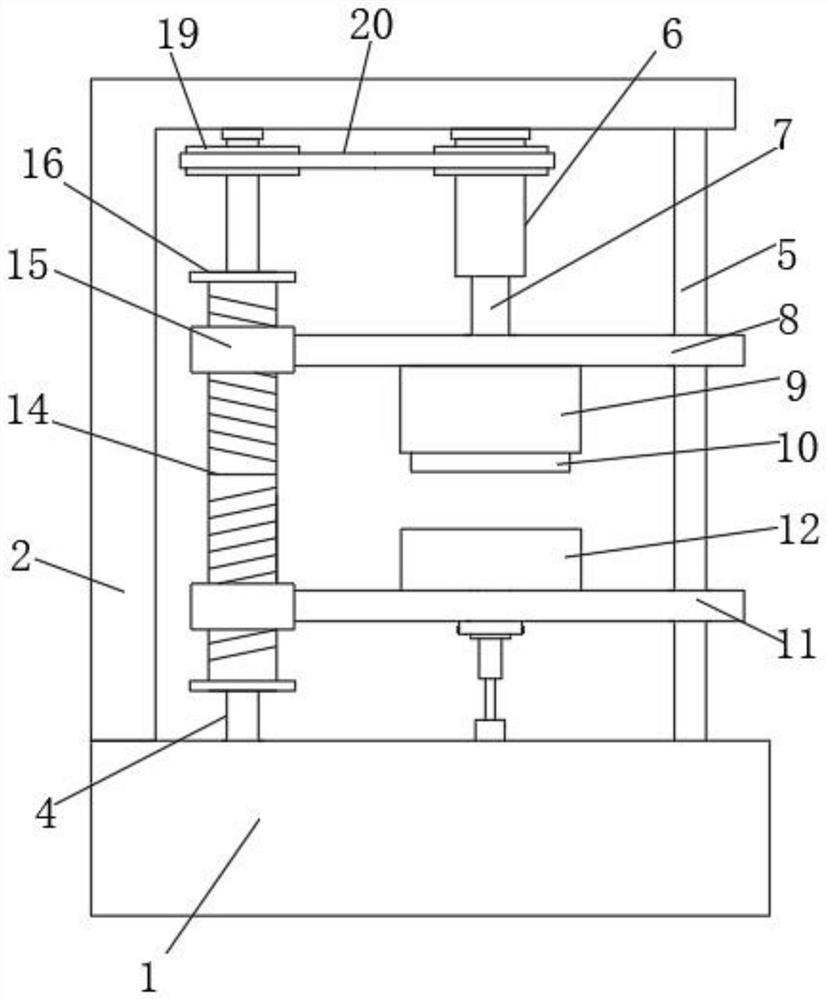

Method and equipment for making lightly pressed Fuzhuan tea

PendingCN114403249AEasy to drillImprove press molding efficiencyPre-extraction tea treatmentProcess engineeringFermentation

The invention relates to the technical field of Fuzhuan tea processing, discloses a making method and equipment of lightly pressed Fuzhuan tea, and solves the problems that during making of the Fuzhuan tea, the Fuzhuan tea needs to be manually taken for discharging, so that discharging is inconvenient, and the making speed of the Fuzhuan tea is slow. S2, the tender shoots in the step S1 are subjected to impurity removal and screening, the screened tender shoots are washed and cut up, the cut tender shoots are placed in a worm wheel fermentation machine to be steamed for 30 minutes, the tea leaves are softened for standby application, water is added into the tea leaves in the step S4, and the tea leaves are steamed again through the worm wheel fermentation machine for 1 minute; and through the design of the pushing mechanism and the pushing plate, the pushing plate can conveniently push the pressed and formed tea leaves to be discharged, manual discharging is effectively avoided, the discharging efficiency of the tea leaves is further improved, and the production efficiency of the tea leaves is further improved.

Owner:益阳冠隆誉黑茶发展有限公司

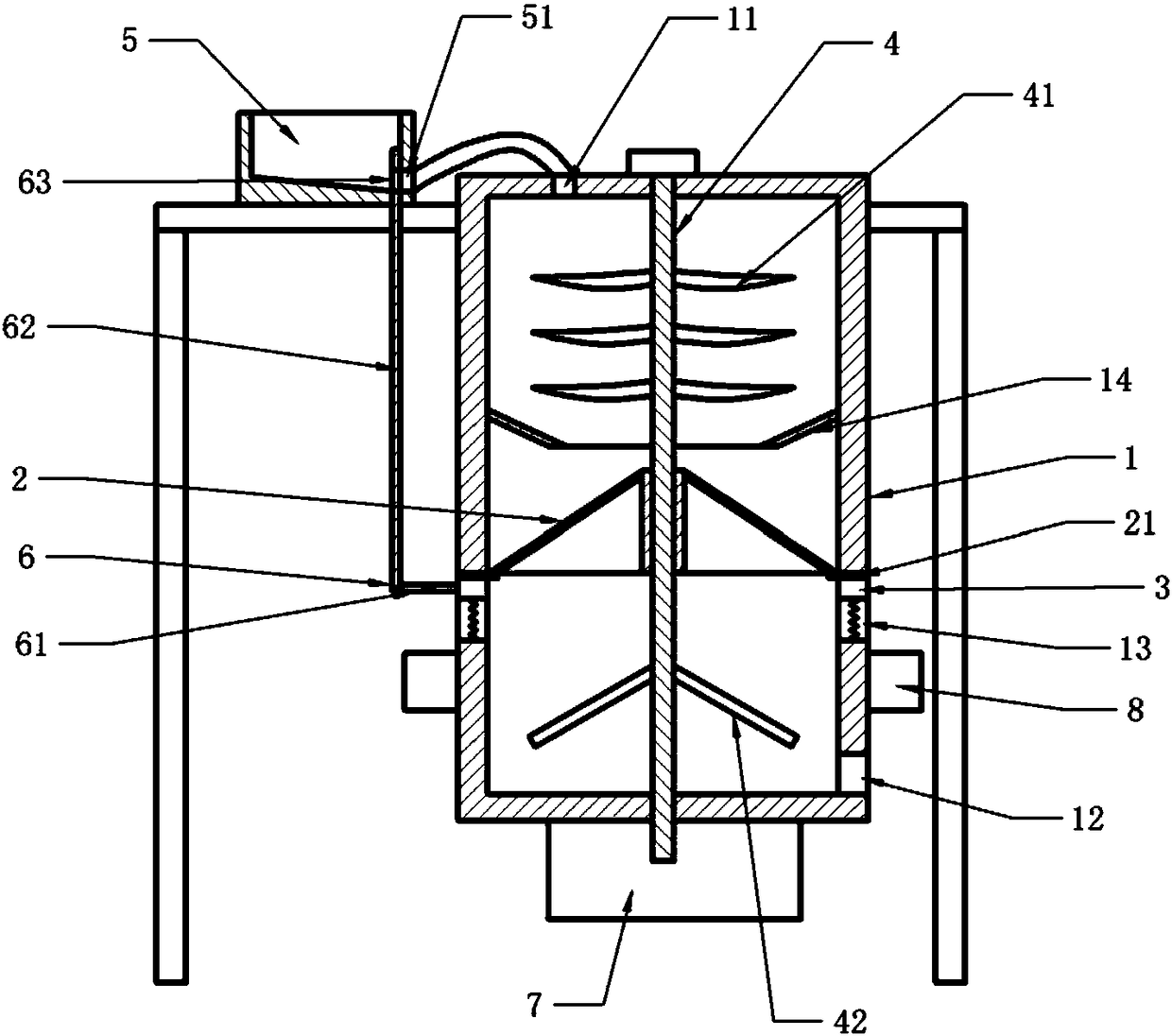

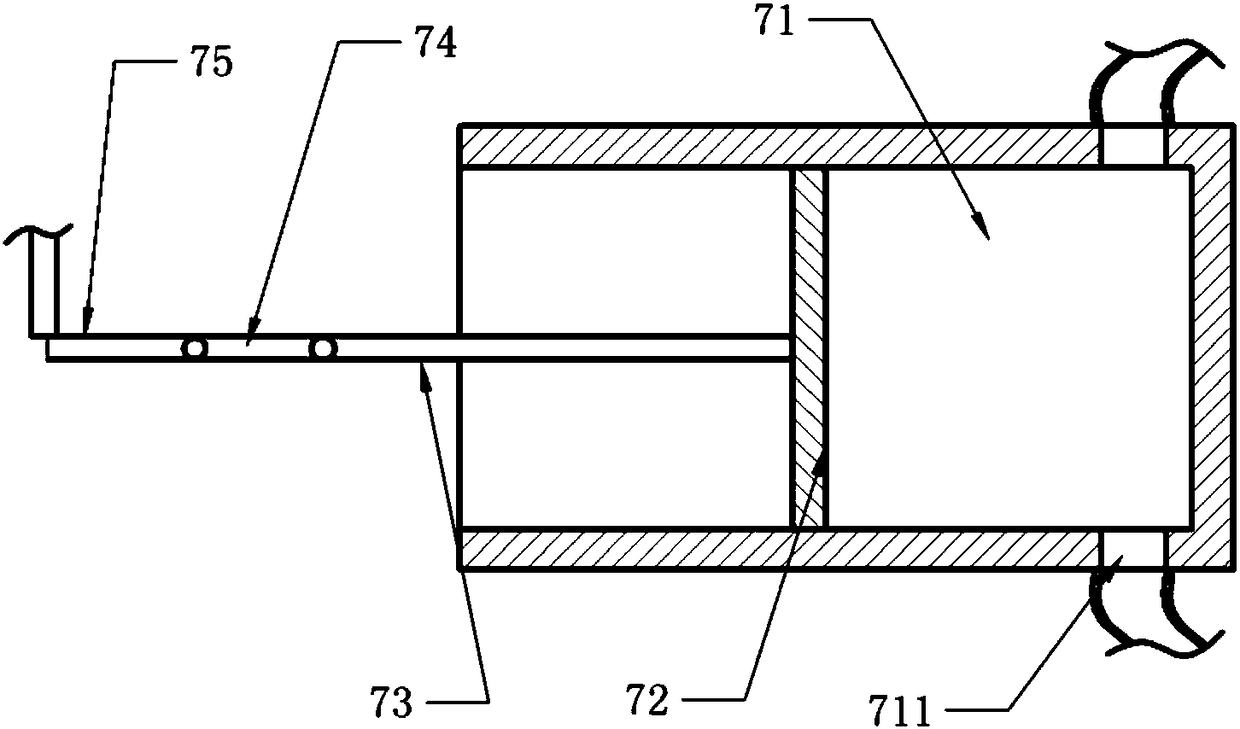

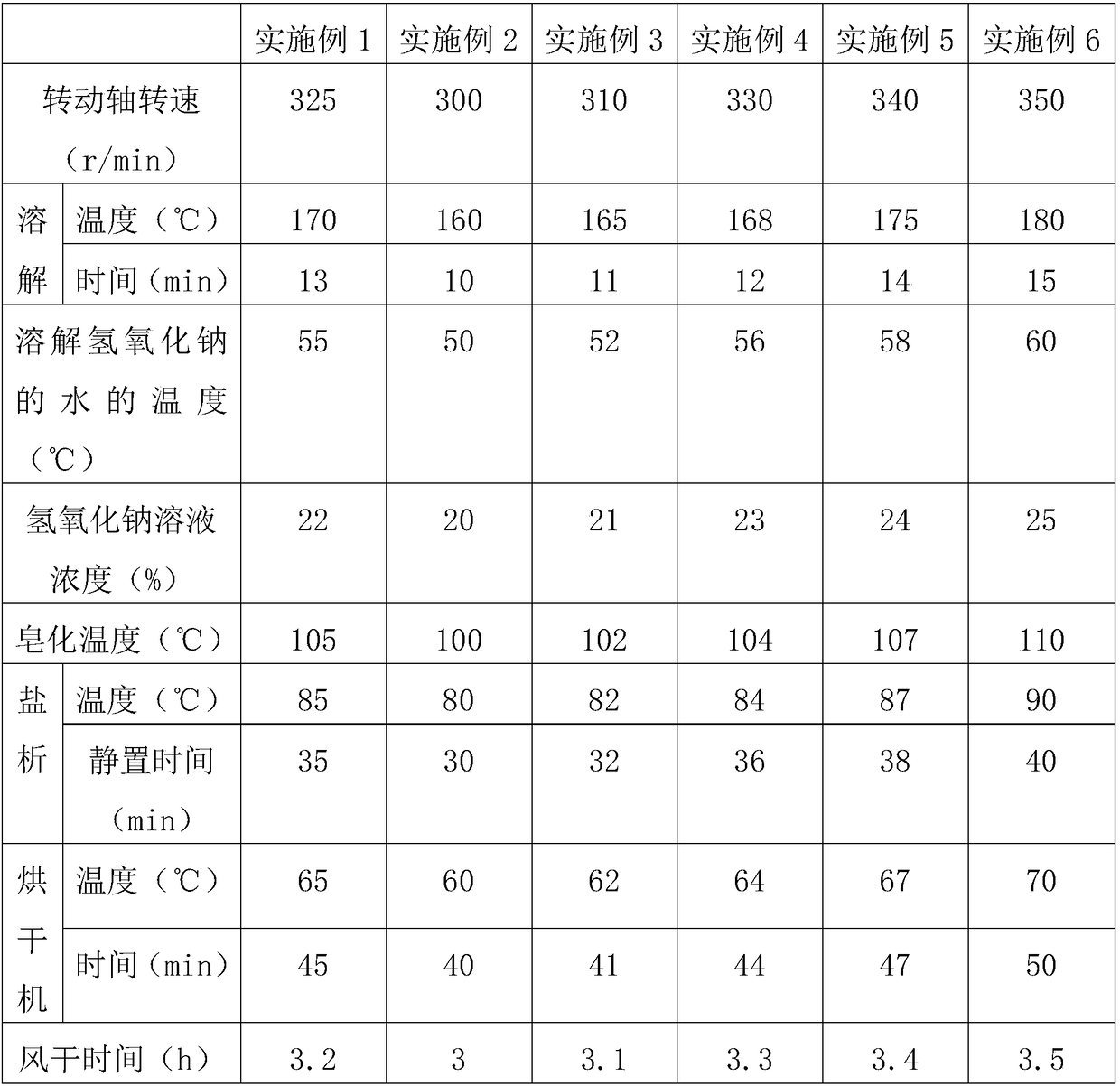

Processing method of soaps

ActiveCN108148694AReduce outflowRealize current limitingDrying soapCooling soapSalting outEngineering

Owner:XUZHOU XUANKE AGRI MASCH CO LTD

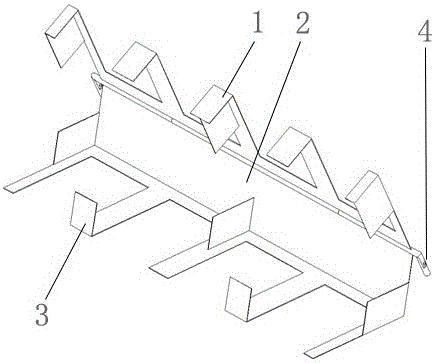

Koji block placing shelf

PendingCN105886189AImplement location changesRealize feedAlcoholic beverage preparationTransmission beltEngineering

The invention discloses a koji block placing shelf. The koji block placing shelf comprises a placing shelf free end and a placing shelf fixed end, wherein the placing shelf free end and the placing shelf fixed end are connected by a spring hinge and form a plurality of koji block containing cavities when being closed; and oscillating rods which extend toward the rear of the spring hinge and have elasticity are arranged at the sides of the placing shelf free end. The koji block placing shelf has the beneficial effects that the koji block placing shelf is installed on a koji block integral turning shelf and moves along with a transmission belt on the koji block integral turning shelf, so position change in fermentation room space can be achieved; the oscillating rods and fixed blocking rods on the koji block integral turning shelf are used cooperatively, so feeding and discharge of koji blocks can be achieved in the turning places at the two ends of the transmission belt of the koji block integral turning shelf; and the koji block placing shelf has a very simple structure and achieves automatic feeding and discharge by completely utilizing a mechanical structure, so the cost is low.

Owner:CHENGDU SHIWEI TECH CO LTD +1

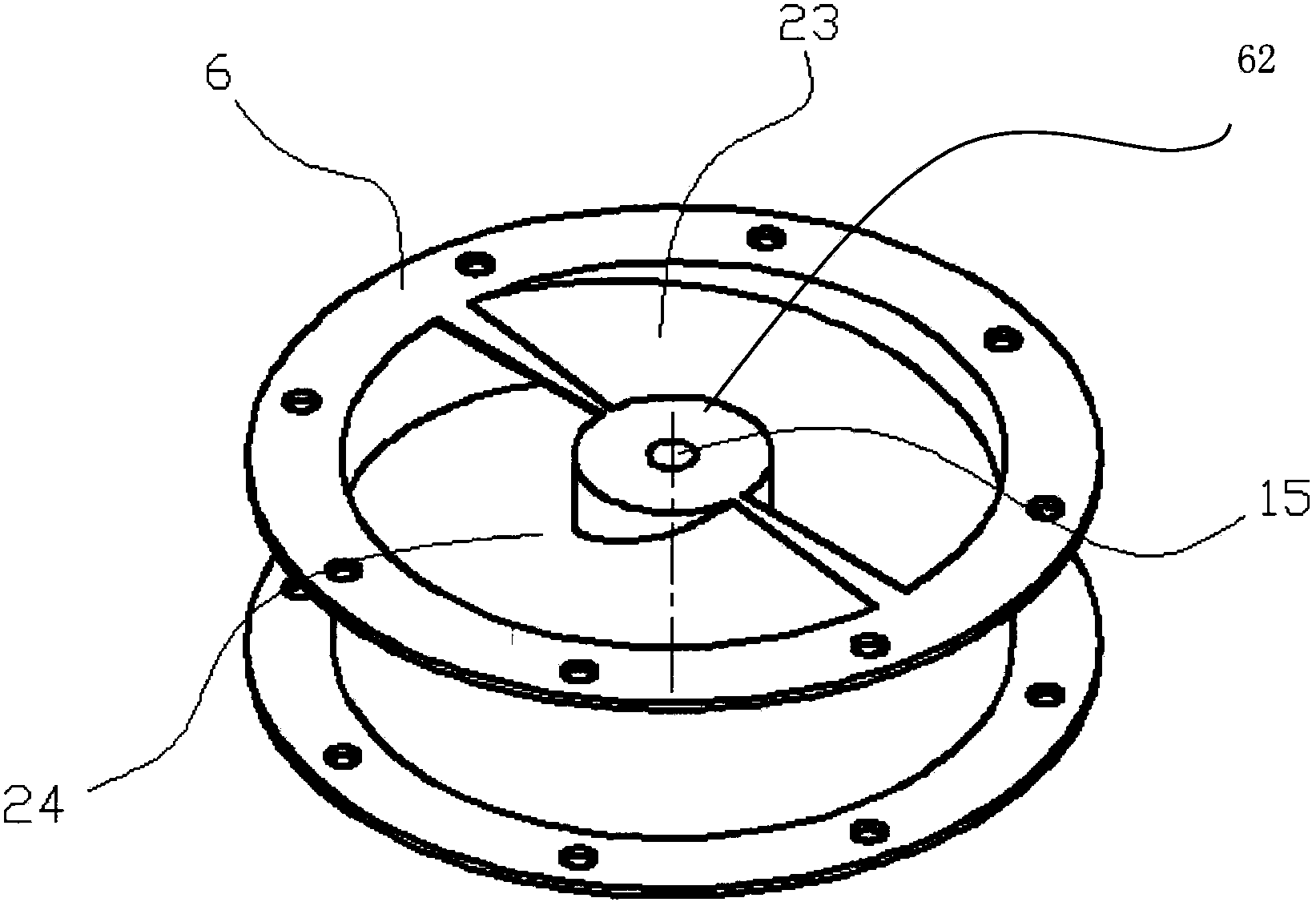

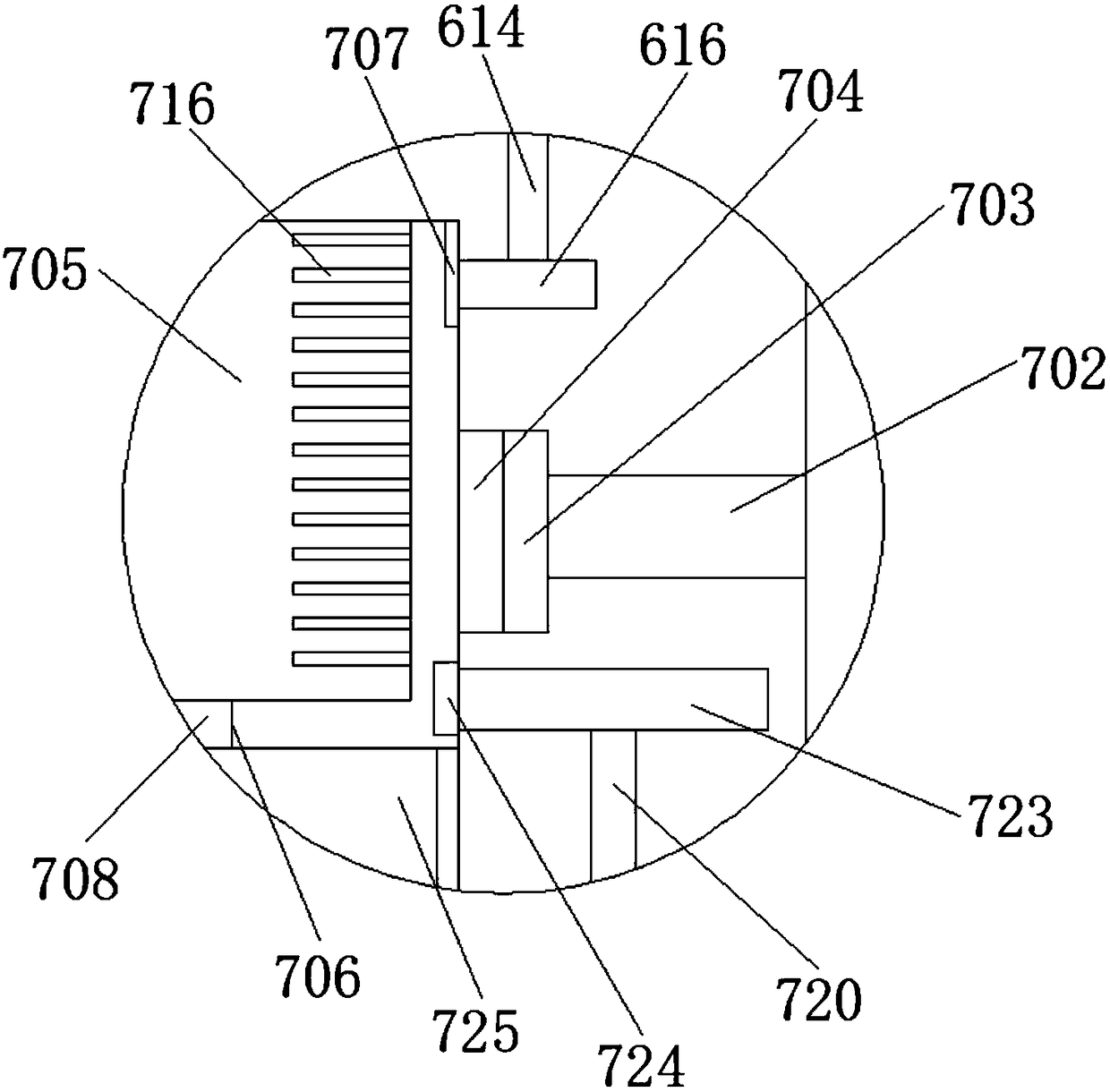

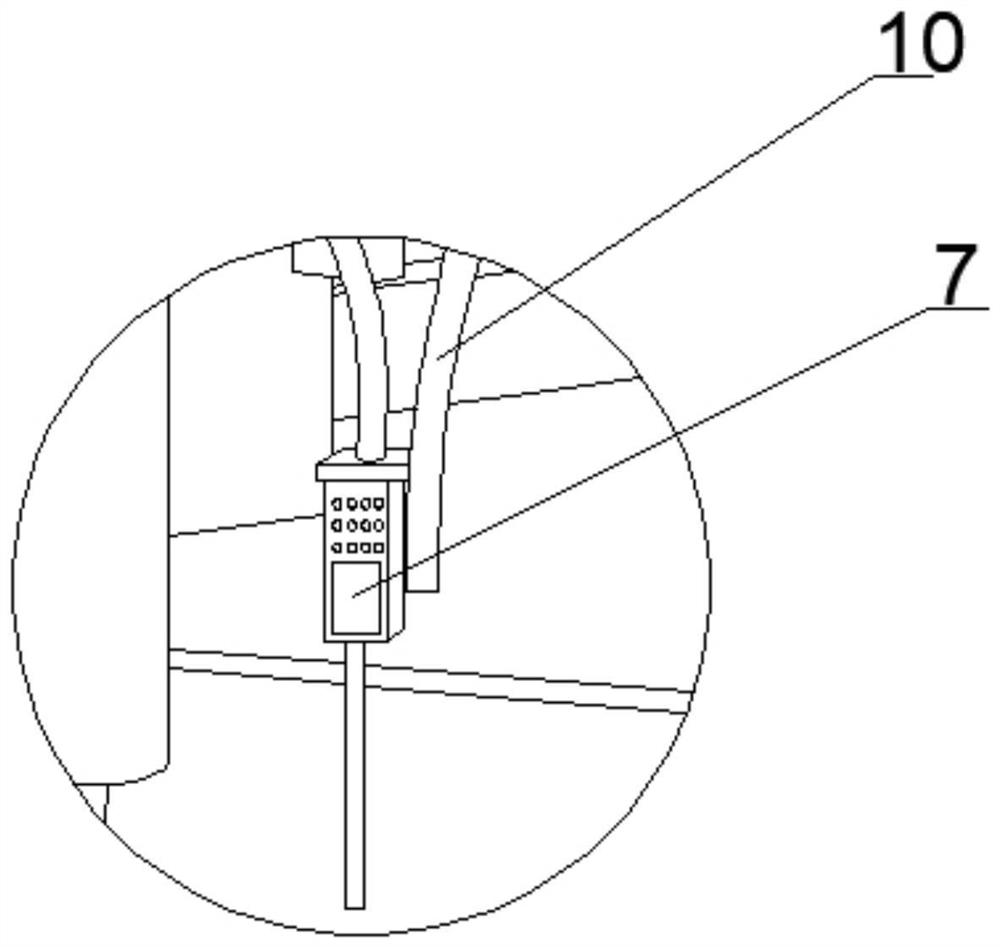

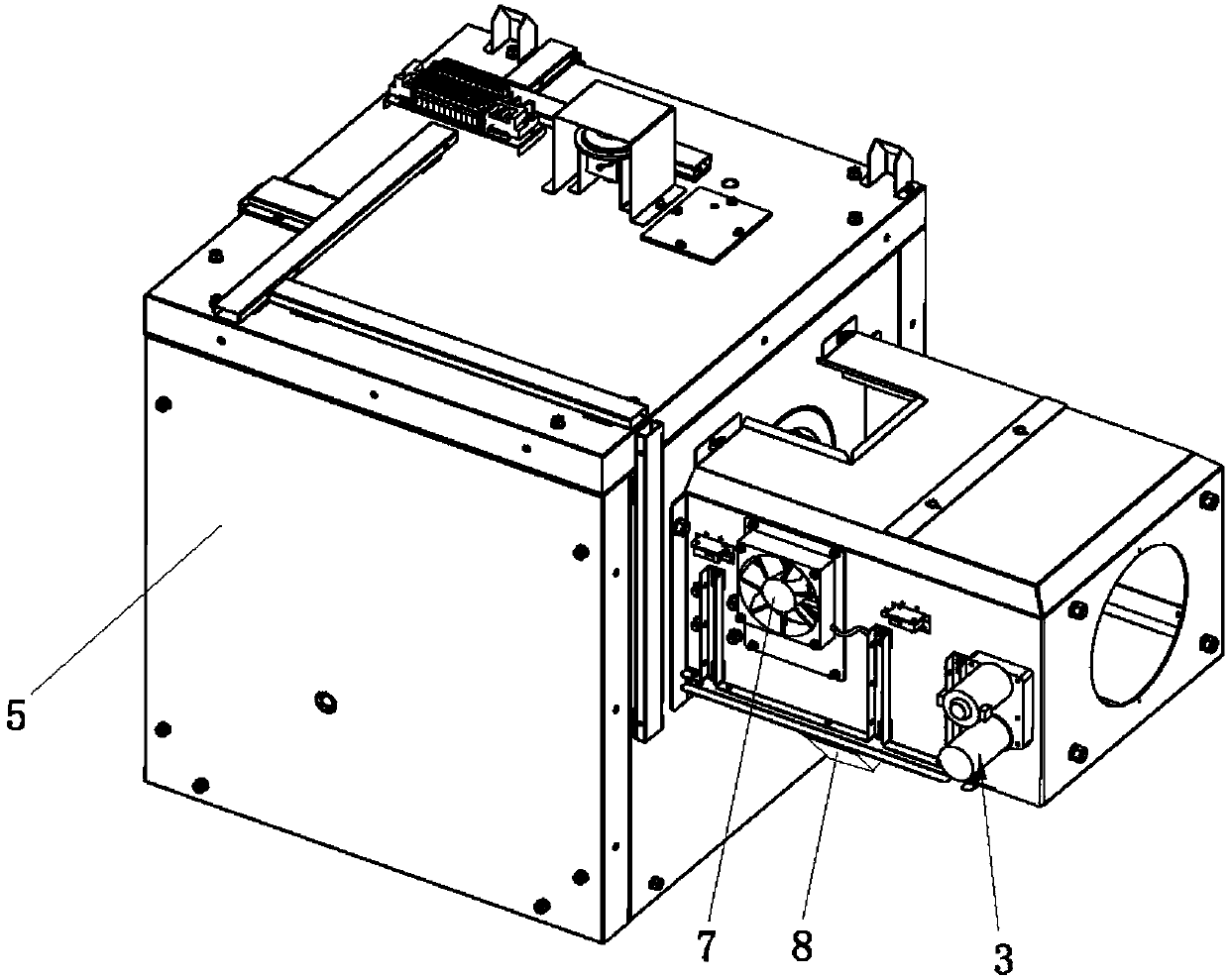

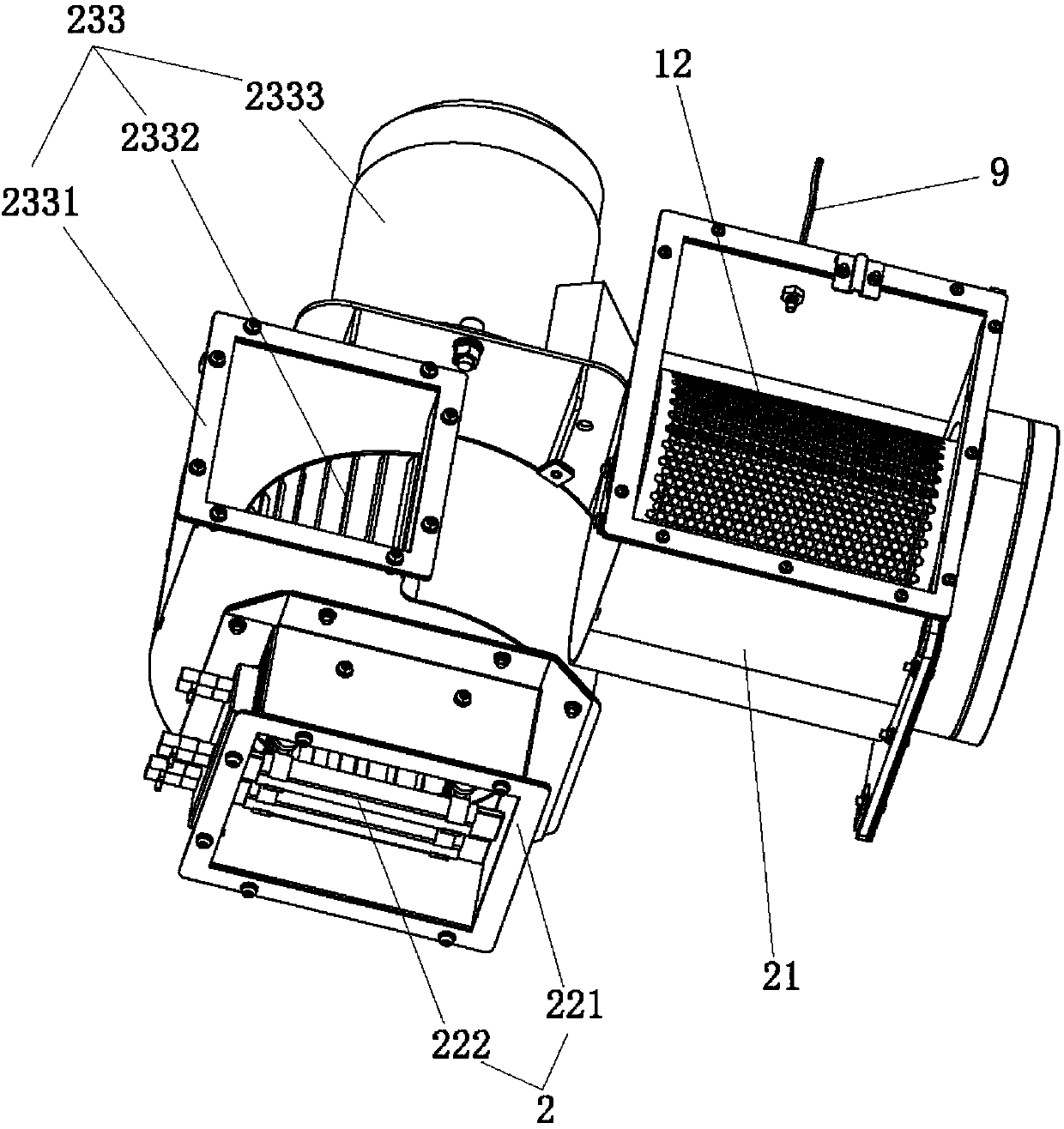

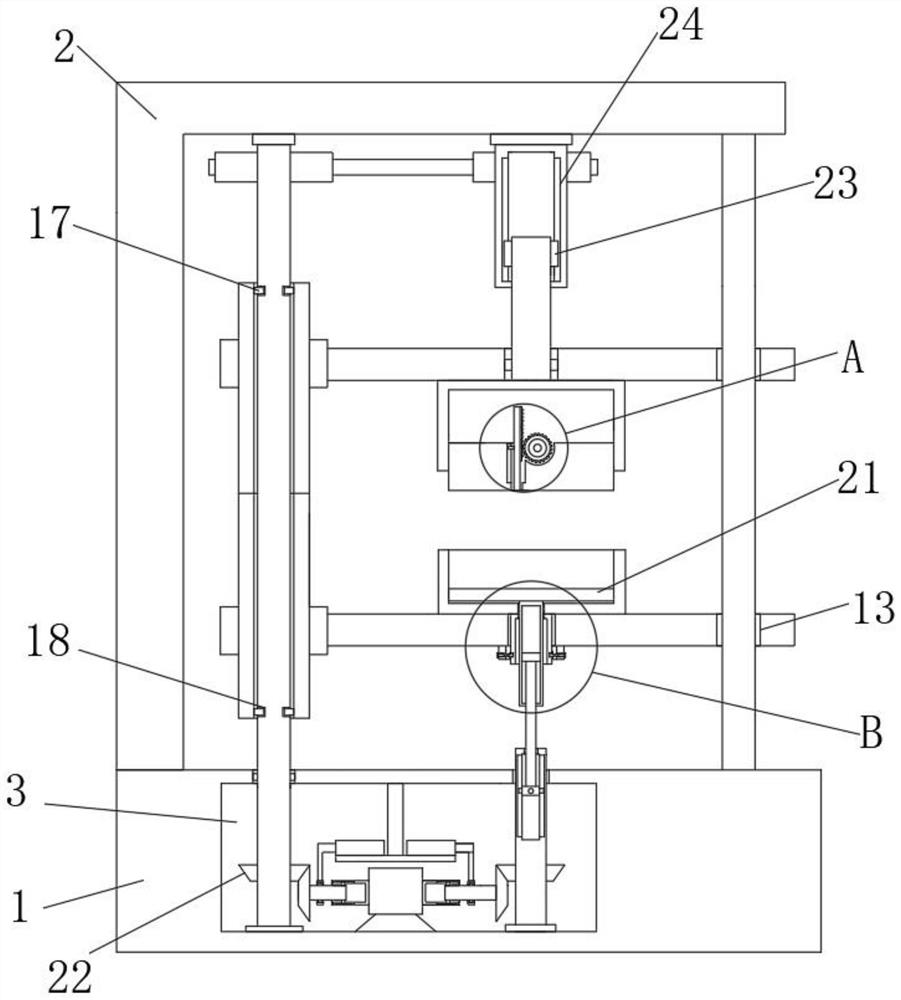

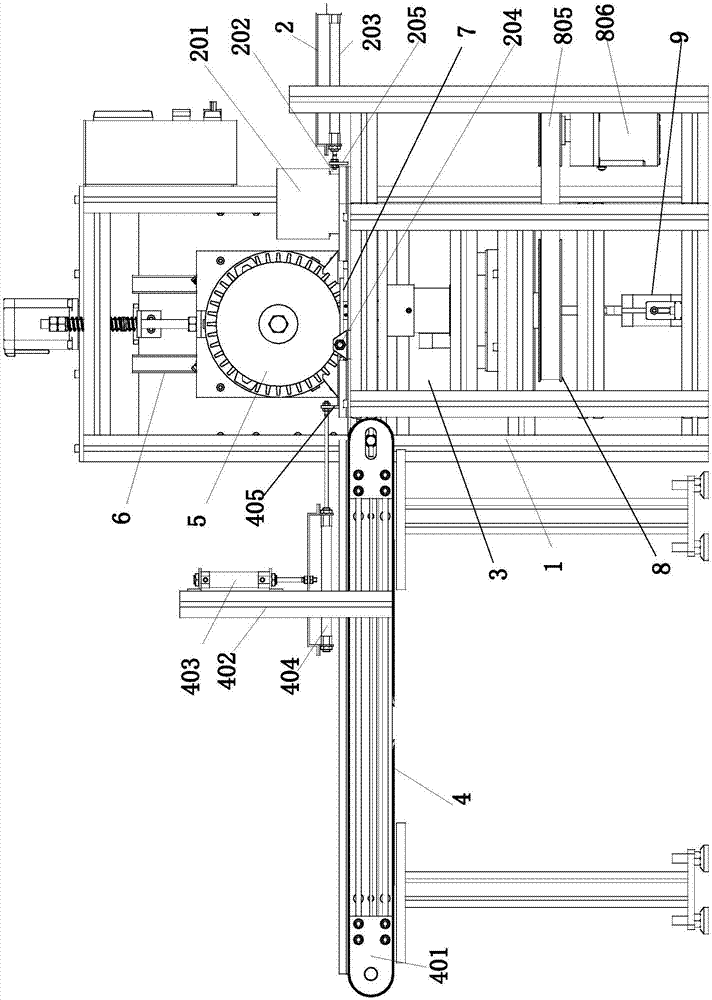

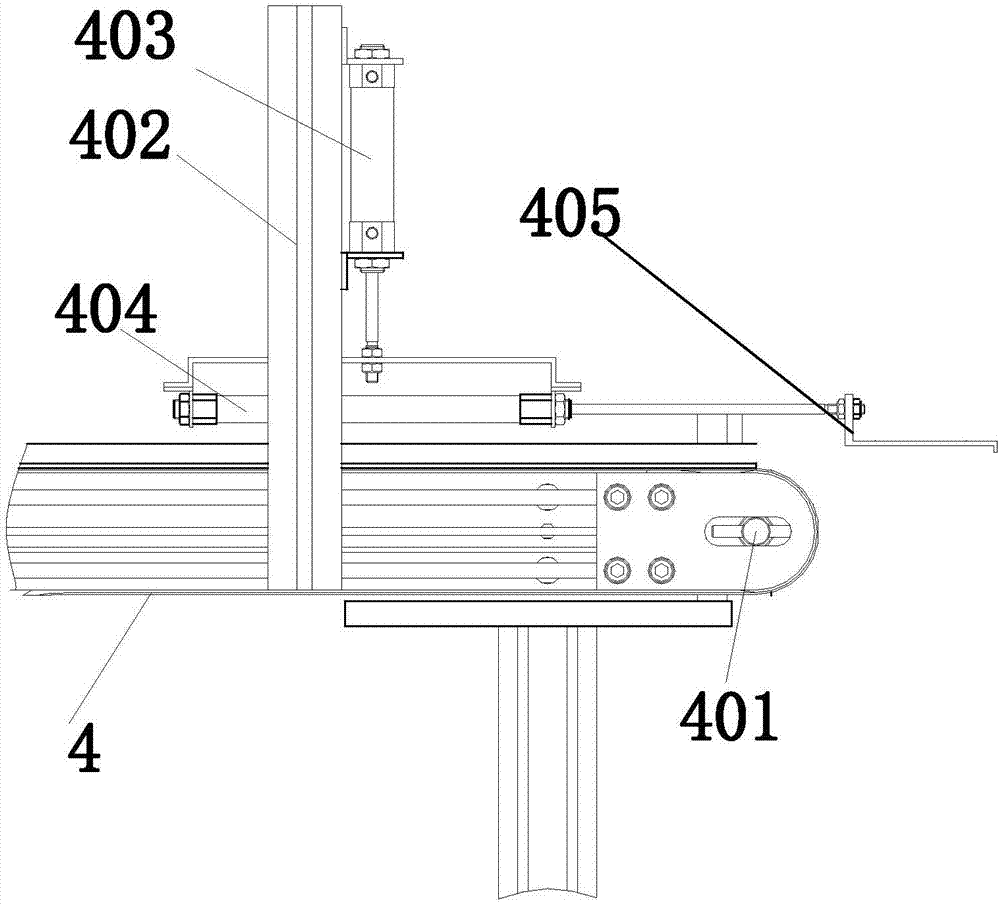

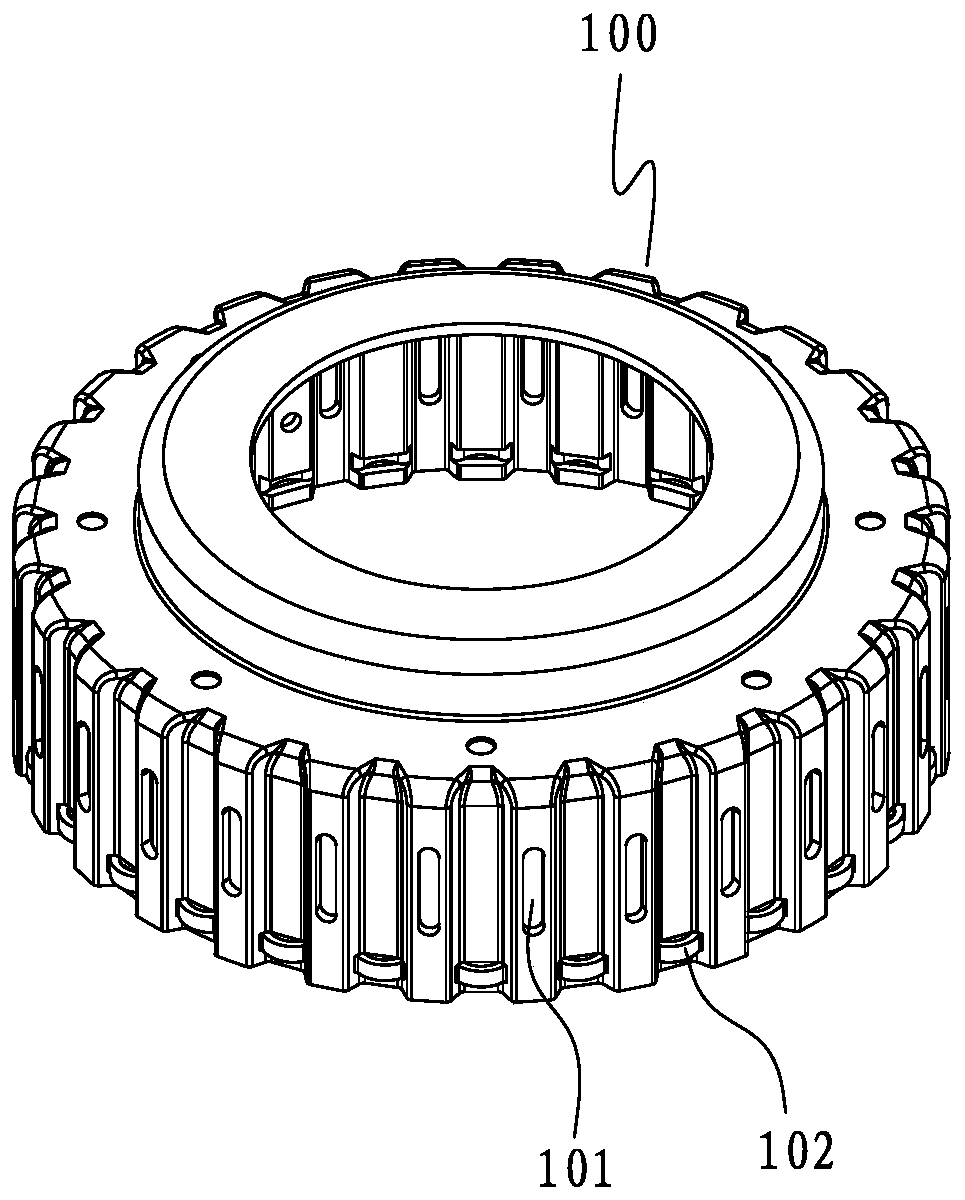

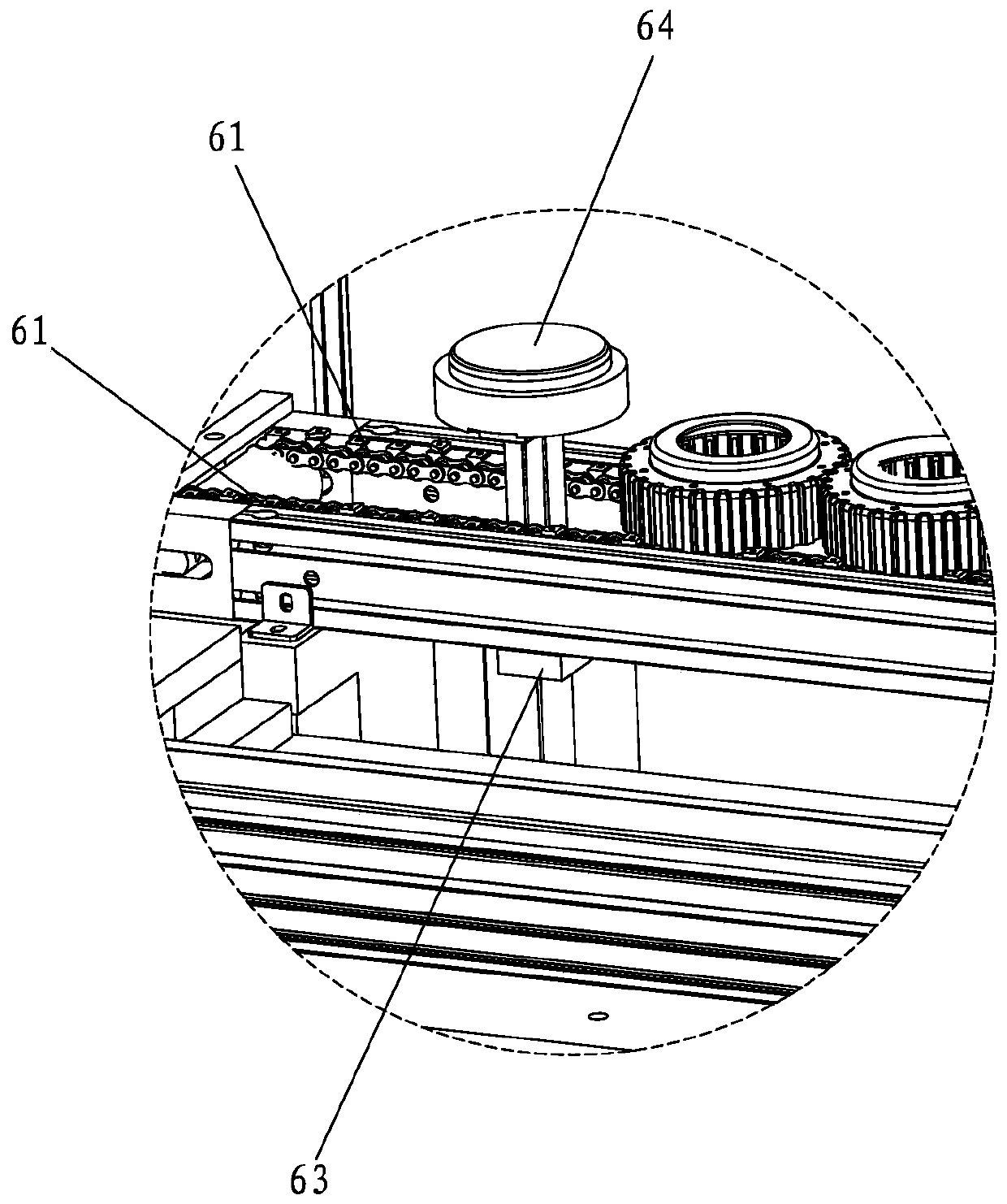

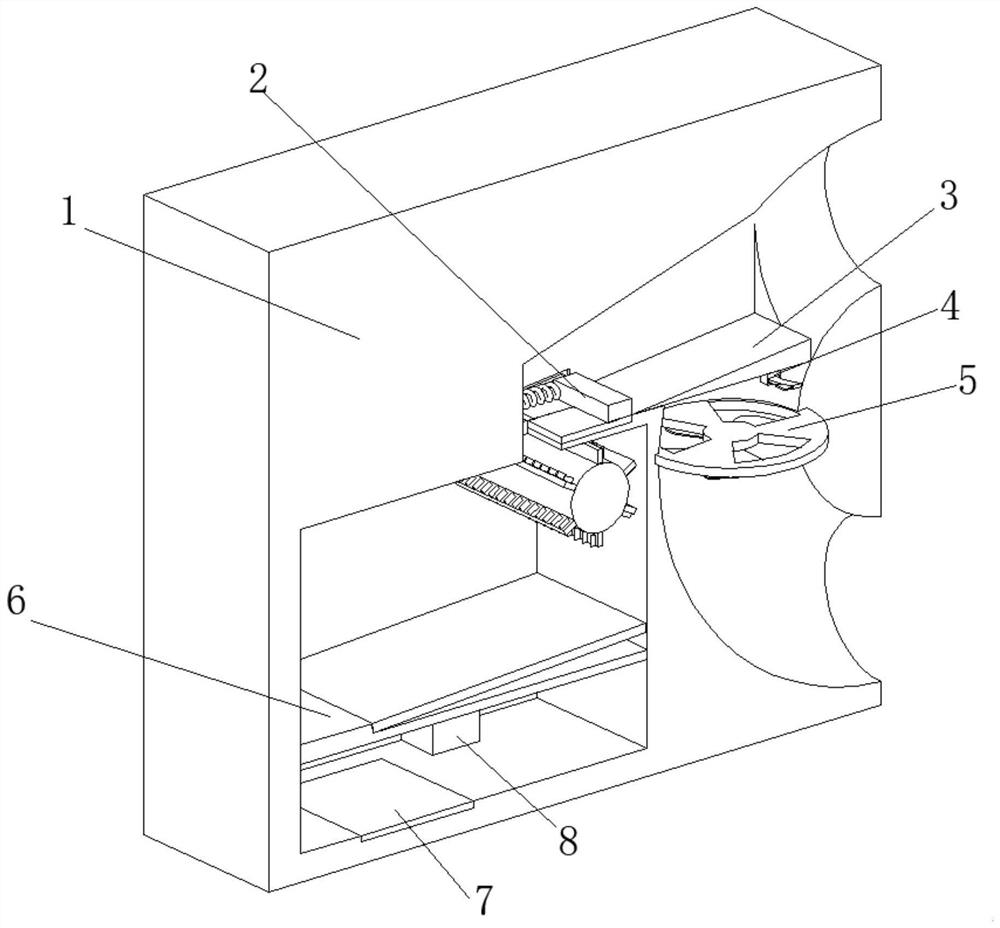

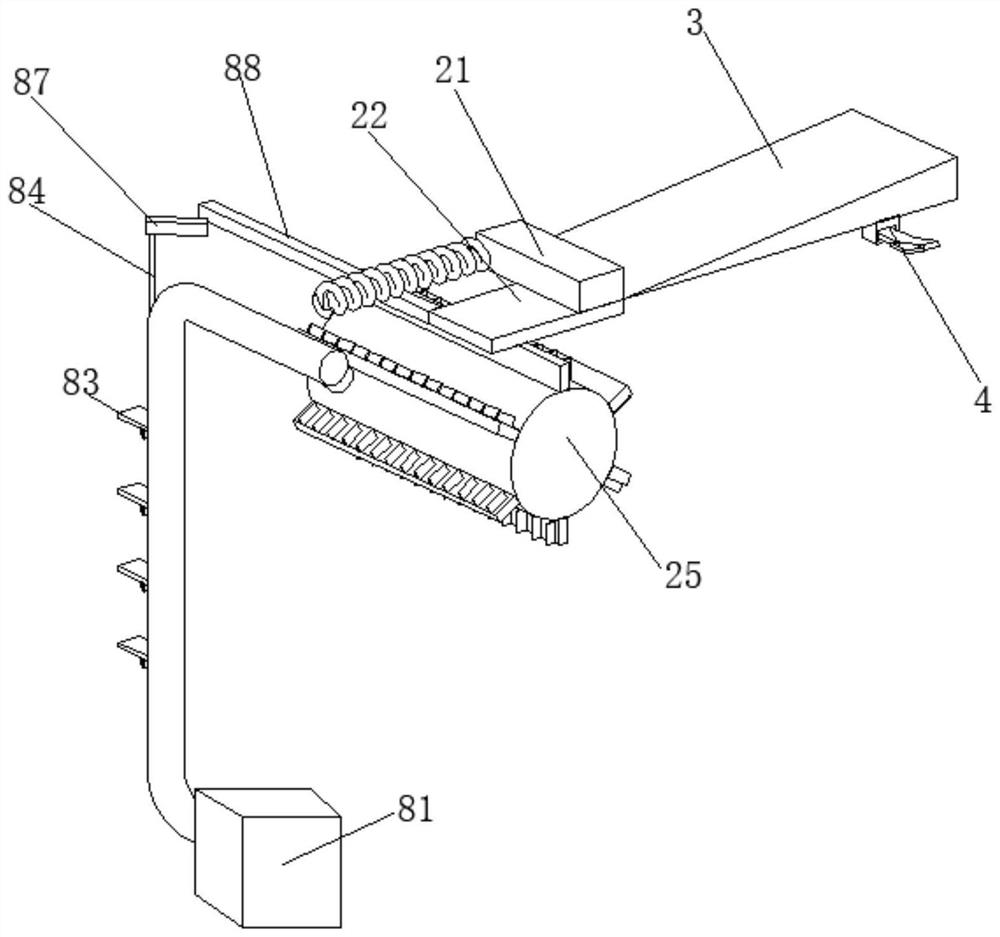

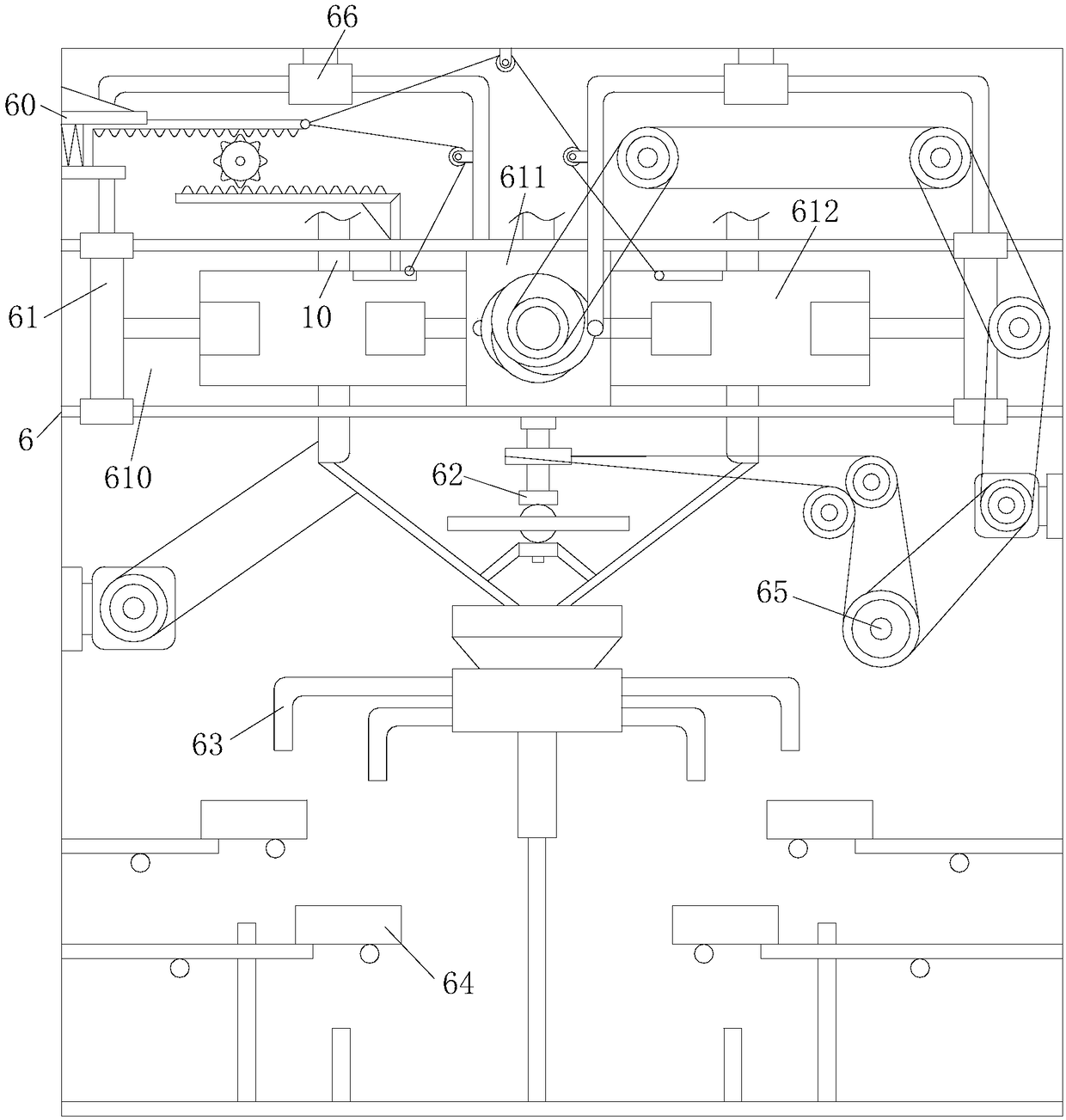

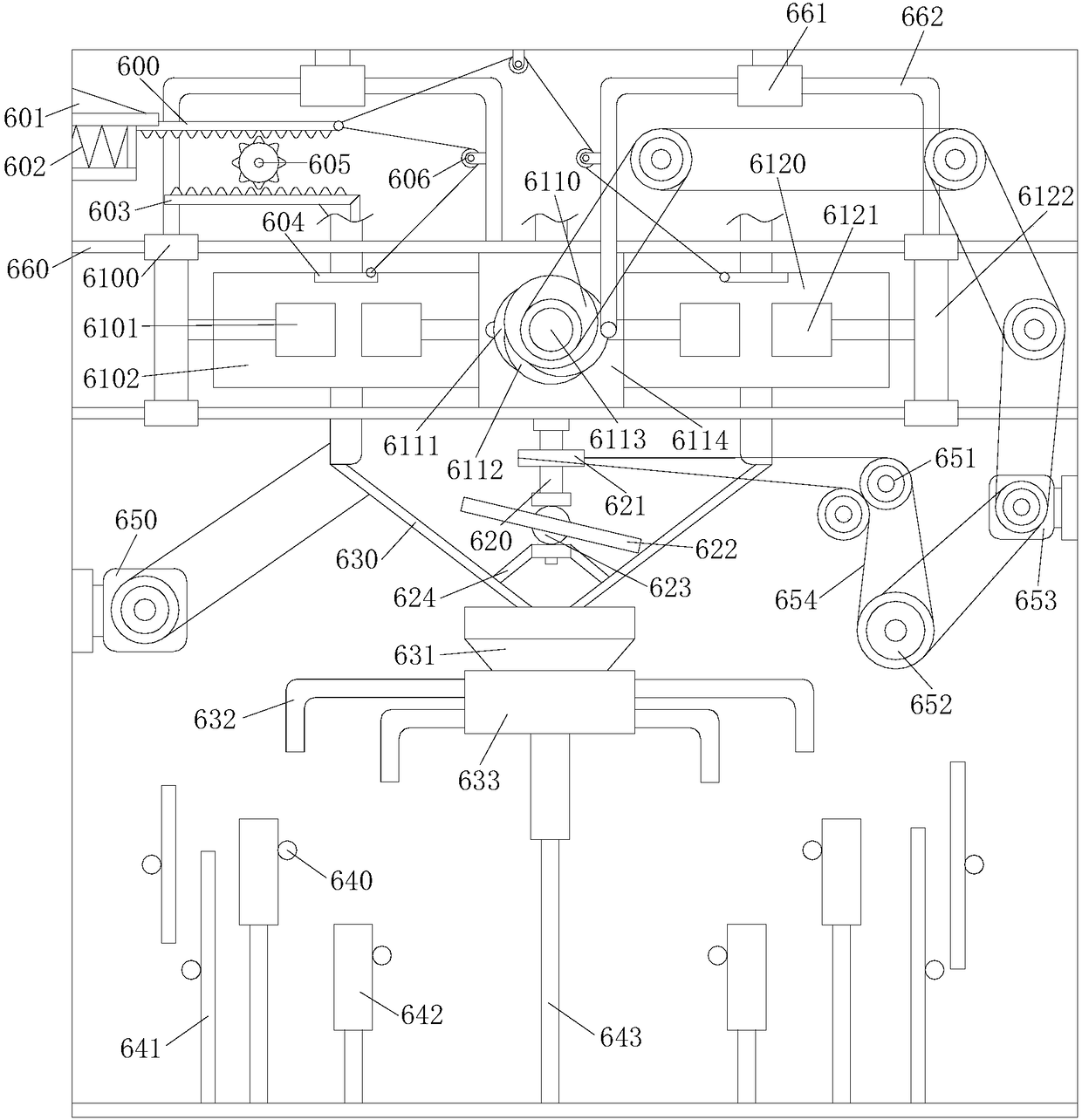

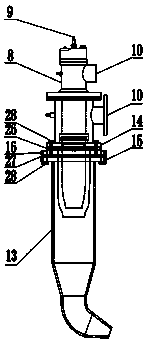

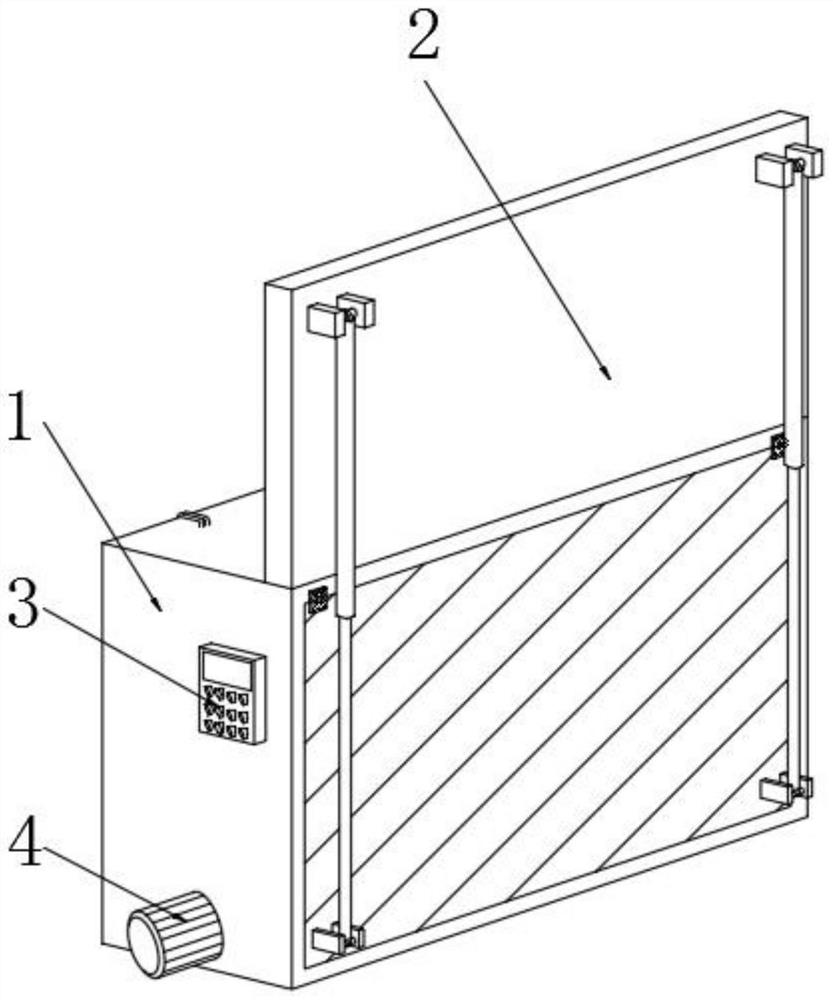

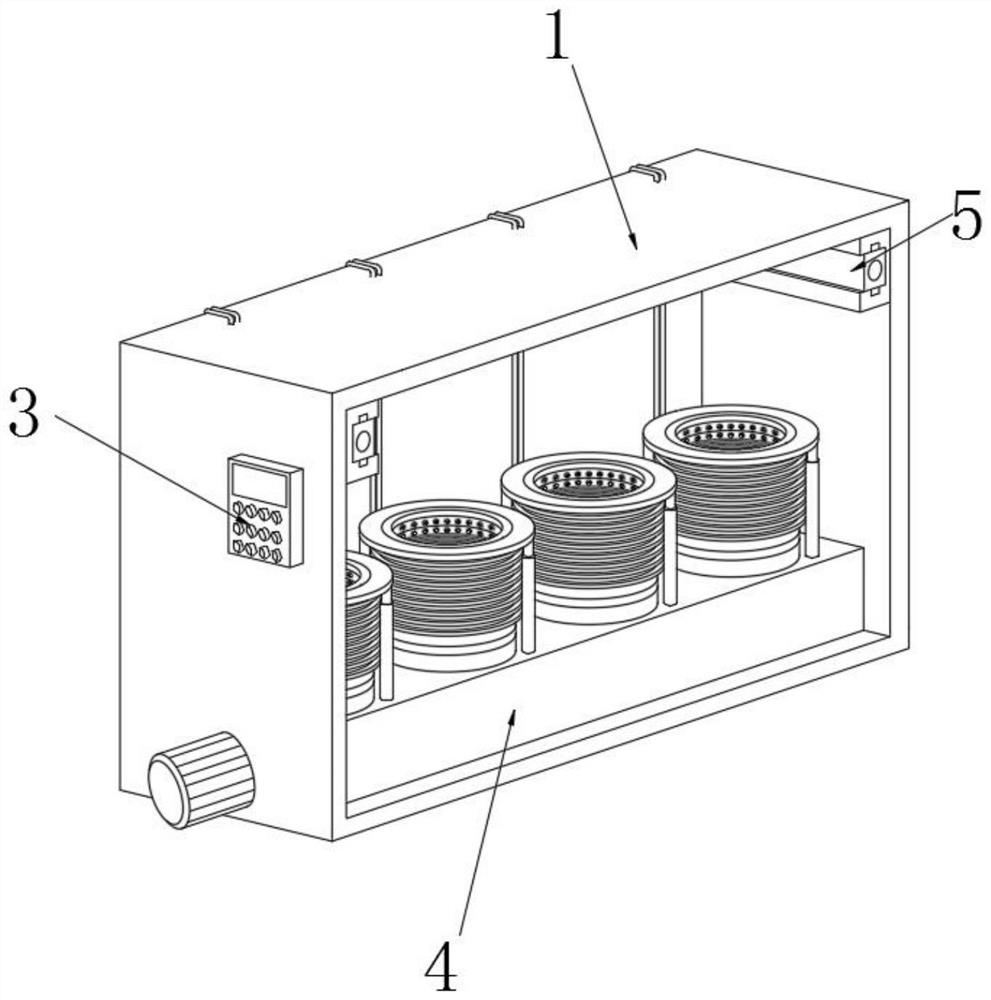

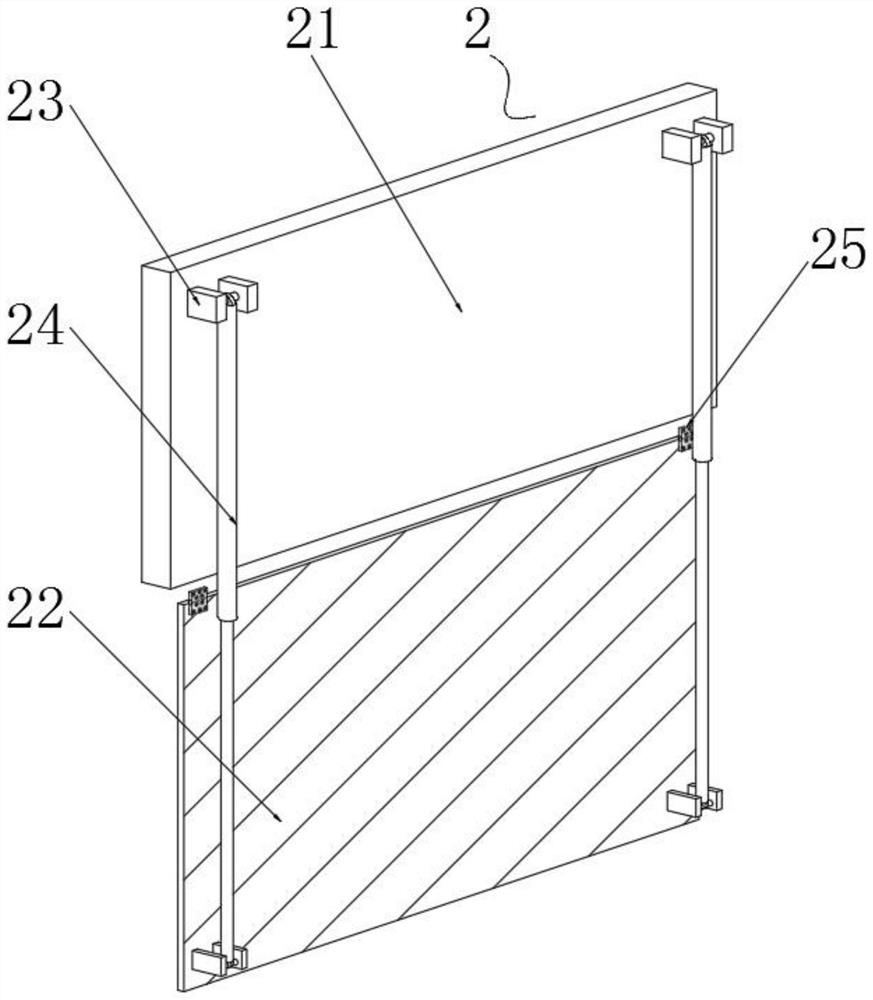

Oil pump rotor deburring device

ActiveCN108000278APrecise entryHigh positioning accuracyEdge grinding machinesGrinding feedersBiochemical engineering

The invention discloses an oil pump rotor deburring device which comprises a rack (1); a charging component (2), a clamping component (3) and a discharging component (4) are sequentially arranged on the rack (1); a grinding head (5) is arranged above the clamping component (3), and is connected with a grinding head component (6) located on the side surface of the clamping component (3); the charging component (2) comprises a charging bin (201) arranged at one end of the rack (1); a push-in port (202) is formed in the lower part of the charging bin (201); a push-in air cylinder (203) and a limiting air cylinder (204) are arranged on the two sides of the charging bin (201) correspondingly; a push plate (205) corresponding to the push-in port (202) is arranged at the protruding end of the push-in air cylinder (203); a limiting rod (206) is arranged at the protruding end of the limiting air cylinder (204); and the limiting rod (206) is located at the discharging end of the clamping component (3). The oil pump rotor deburring device has the characteristics that the burr treatment efficiency can be improved and the deburring effect can be improved.

Owner:ZHEJIANG UNIV CITY COLLEGE

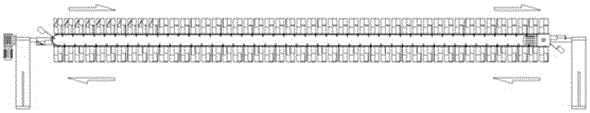

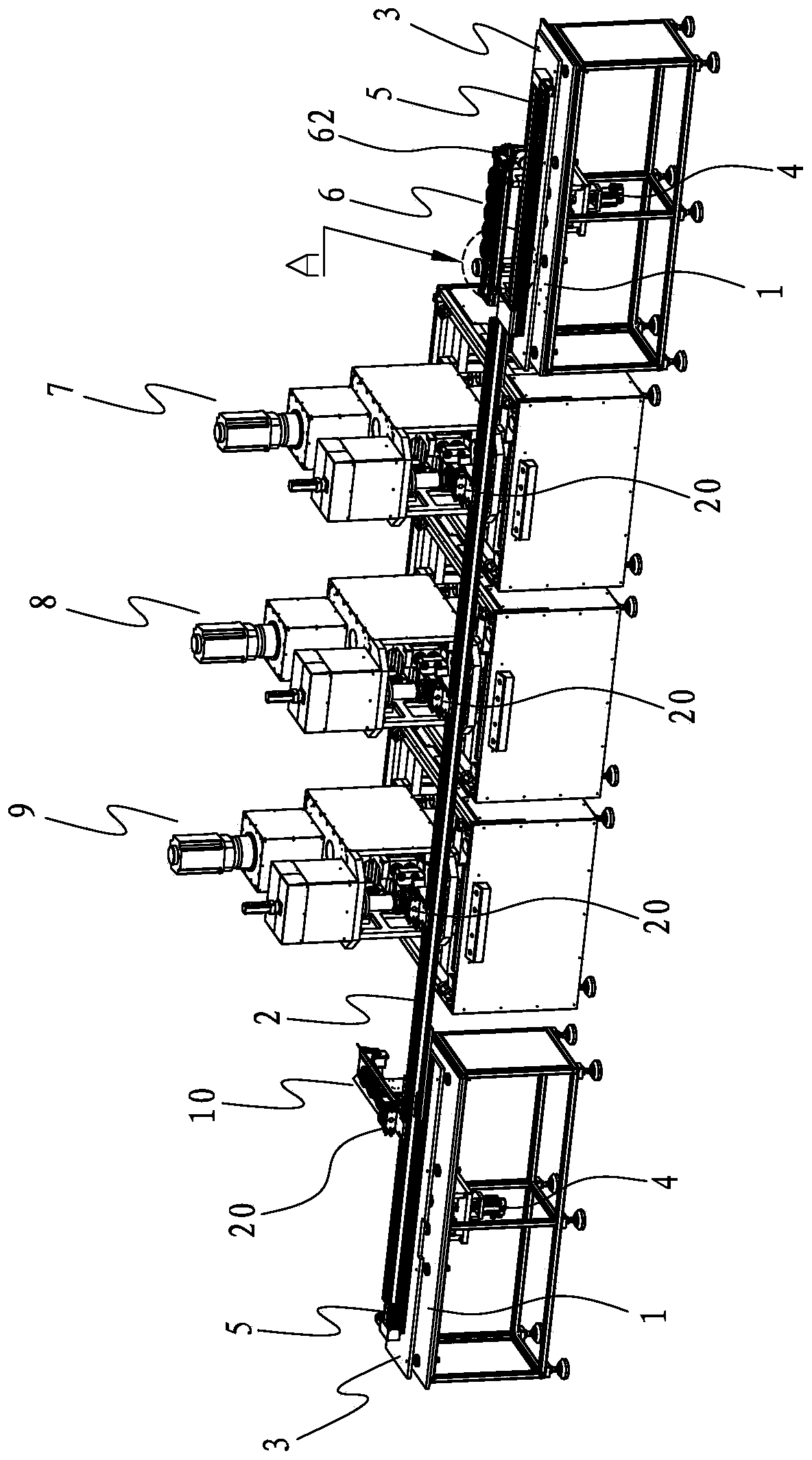

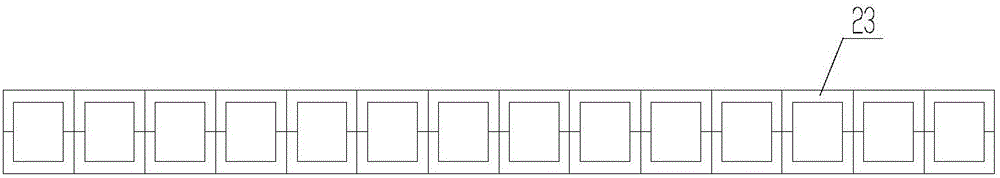

Clutch housing intelligent machining forming production line

PendingCN110202389ARealize automatic feeding processRealize dischargeOther manufacturing equipments/toolsMetal working apparatusProduction linePunching

The invention discloses a clutch housing intelligent machining forming production line. The clutch housing intelligent machining forming production line comprises a left working table and a right working table. Lifting plates capable of ascending and descending are slidably connected to the working tables. A feeding conveying line is arranged on the working table on the right side. A discharging conveying line is arranged on the working table on the left side. An edge cutting device, a punching device and a tongue punching device are arranged between the two working tables from right to left in sequence. A conveying rod is slidably connected between the two lifting plates. The conveying rod is driven to move left and right through linear sliding tables. The feeding conveying line, the edgecutting device, the punching device, the tongue punching device and the discharging conveying line are arranged on the same side and arranged equidistantly. Four clamping devices arranged equidistantly are fixed to the conveying rod. The clamping devices are used for clamping clutch housings and are driven by the linear sliding tables to transfer the clutch housings between the feeding conveyingline, the edge cutting device, the punching device, the tongue punching device and the discharging conveying line front and back. The clutch housing intelligent machining forming production line achieves the effects of automatic feeding, fixed-length cutting, punching, tongue punching and discharging.

Owner:ZHONGSHAN XINHUI PRECISION TECH CO LTD

Taking device for oven and glass cup production line adopting taking device

InactiveCN105967507AAchieve mechanical propertiesRealize dischargeDecorative surface effectsManipulatorDischarge efficiency

The invention relates to the technical field of glass cup production equipment, in particular to an oven retrieving device and a glass cup production line using the same. The oven retrieving device includes a manipulator for holding cups and a manipulator for holding tiles. Both the manipulator for holding cups and the manipulator for holding tiles are arranged on the feed conveyor belt and the discharge conveyor belt of the oven. At the same time, a glass production line using the above-mentioned oven retrieving device is also provided. The invention can realize the mechanized feeding and discharging of the oven through the setting of the manipulator for clamping cups and the manipulator for clamping tiles, thereby improving the efficiency of feeding and discharging of the oven and avoiding the problem of burns caused by manual operation .

Owner:KUNSHAN SHUGUANG LIGHTING EQUIP

Fixed bed reactor used for low-temperature continuous pyrolysis treatment of waste circuit boards, and method thereof

The invention relates to a fixed bed reactor used for low-temperature continuous pyrolysis treatment of waste circuit boards, and a method thereof. The reactor comprises a feeding opening, a reaction chamber, a discharging opening, an electrostatic separator, a solid carbon collecting bin and a metal collecting bin, the feeding opening is arranged above the discharging opening, the reaction chamber comprises a feeding screw, a discharging screw and a material plate, the material plate comprises a feeding end and a discharging end, the feeding screw is positioned under the feeding opening and at the upper portion of the feeding end, the discharging screw is positioned at the upper portion of the discharging end, the discharging end is arranged above the discharging opening, the feeding screw comprises a center screw rod, a left screw blade and a right screw blade, the center screw transversely traverses through the left screw blade and the right screw blade, the left screw blade and the right screw blade are vertical to the center line of the center screw and are axially symmetric, a distance between the left screw blade and the right screw blade is 1 / 3-1 / 2 of the caliber of the feeding opening; and the solid residue inlet of the electrostatic separator is connected with the discharging opening, the solid carbon outlet of the electrostatic separator is connected with the solid carbon collecting bin, and the metal outlet of the electrostatic separator is connected with the metal collecting bin. The reactor and the method have the advantages of realization of continuous treatment of the waste circuit boards, simplicity in operation, and high economic benefits.

Owner:SHENWU TECH GRP CO LTD

Dust cleaning equipment for constructional engineering

PendingCN113694671AGuaranteed cleaning effectImprove dust suppression efficiencyCombination devicesStructural engineeringWater spray

The invention relates to the technical field of constructional engineering, and discloses dust cleaning equipment for constructional engineering. The equipment comprises a box body, and a collecting mechanism is arranged in the box body; the inner wall of the box body is fixedly connected with a filter screen; a fixing block is welded to the bottom of the filter screen, and an arc-shaped plate is movably connected to the inner wall of the fixing block; an arc-shaped plate is arranged on the upper portion of the box body, a guide plate is welded to the surface of the arc-shaped plate, a fan set is fixedly connected to the inner wall of the box body, and a discharging mechanism is arranged on the inner wall of the box body. Air can be blown out from the lower portion of the box body through rotation of the fan set, the blown air can blow dust, and an opening in the upper portion can suck external air and the blown dust into the box body together; finally, the water in the box body is sprayed outwards through the water pump, so that most of dust can be sucked firstly, then a small part of dust is subjected to dust falling in a water spraying mode, the dust cleaning effect can be guaranteed, and meanwhile the dust falling efficiency is improved.

Owner:詹金斯

Novel rubber production equipment

The invention discloses novel rubber production equipment. The equipment comprises a production machine frame, an inspection machine frame, a prompter, a controlling machine, a discharge seat box andan internal mixing device, wherein the production machine frame and the inspection machine frame are connected with feeding pipes, an outer rail of the inspection machine frame is slidably connected with an inner rail of the production machine frame, the outer rail of the inspection machine frame and the inner rail of the production machine frame form an integrated structure, the prompter is arranged on the upper portion of the controlling machine, the controlling machine is arranged on the side face, away from the production machine frame, of the inspection machine frame, and the production machine frame and the inspection machine frame are connected to the upper portion of the discharge seat box; according to the novel rubber production equipment, after the material lays off, it is achieved that a material refining device carries out processing beating and stirring on the material through the operation of a motor, the material can be mixed more evenly, the material can be oscillated,stirred and mixed according to the falling inertia and gravity when being mixed, it is also achieved that the mixing quality of the material is effectively improved, the mixed material is delivered in a material separating mode, the discharge of multi-position rubber ports is achieved, and the production efficiency is effectively improved.

Owner:曾淑敏

Method and device for feeding and discharging polymer tubes and bars

InactiveCN112372711ARealize automatic feedingRealize dischargeMetal working apparatusConveyor partsMachining processMaterials science

The invention relates to a method and a device for feeding, discharging and mounting polymer tubes and bars. According to the method, an automatic feeding mechanism is used for conveying the tubes andbars to a supporting mechanism, a first clamping mechanism is used for clamping the tubes and bars on the supporting mechanism at the feeding position, the tubes and bars are moved to a product machining mechanism, and the product machining mechanism machines the tubes and bars; after the tubes and bars are machined, the first clamping mechanism is used for clamping the tubes and bars again, thetubes and bars are moved to a supporting mechanism at the discharging position, meanwhile a second clamping mechanism is used for clamping the tubes and bars on the supporting mechanism at the feedingposition, and the tubes and bars are moved to the product machining mechanism; and finally, the first clamping mechanism and the second clamping mechanism retreat together until the first clamping mechanism moves to the position above the supporting mechanism at the feeding position, and resetting of the first clamping mechanism and the second clamping mechanism is completed. By means of the method and the device, the machining efficiency of the polymer tubes and bars can be improved, the machining quality of products in the machining process is ensured, and safe machining is guaranteed.

Owner:ZHUZHOU HONGDA POLYMER MATERIALS

Uniform-temperature heating furnace

InactiveCN108826987ANo change in heating capacityChange the heating direction at willFurnace typesControl devices for furnacesHydraulic cylinderCombustion chamber

The invention discloses a uniform-temperature heating furnace. The uniform-temperature heating furnace comprises a furnace body. A flue is formed on the top of the furnace body, and a temperature detector and a burner device are installed on the top of the furnace body. A combustion chamber is formed in the furnace body, and a feeding inlet and a discharging outlet are formed in the left side andthe right side of the combustion chamber correspondingly. A feeding transmission mechanism is arranged on the feeding inlet side, and a discharging transmission mechanism is arranged on the discharging outlet side. Girders are installed in the combustion chamber and penetrate through the space between the feeding inlet and the discharging outlet. The burner device comprises a burner body, and a fuel gas inlet and air inlets are formed in the burner body. The head ends of the girders are installed on a fixing shaft in a sleeved mode, and a hydraulic cylinder is installed at the tail ends of thegirders. A flame guide pipe is installed at the outlet end of the burner body in a sleeving mode, an installation plate is arranged on the outer wall of the burner body, an edge opening is formed ina pipe opening of the flame guide pipe and connected with the installation plate through a transfer plate, and the outlet end of the flame guide pipe is of a hook-shaped structure. The uniform-temperature heating furnace is simple in structure. Due to the fact that the flame guide pipe is installed on the existing burner body, disassembly is convenient, the heating direction of the burner body canbe changed at will, the heating area of the burner is increased, and the uniform-temperature heating furnace has the high application and promotional value.

Owner:湖北中冶窑炉有限公司

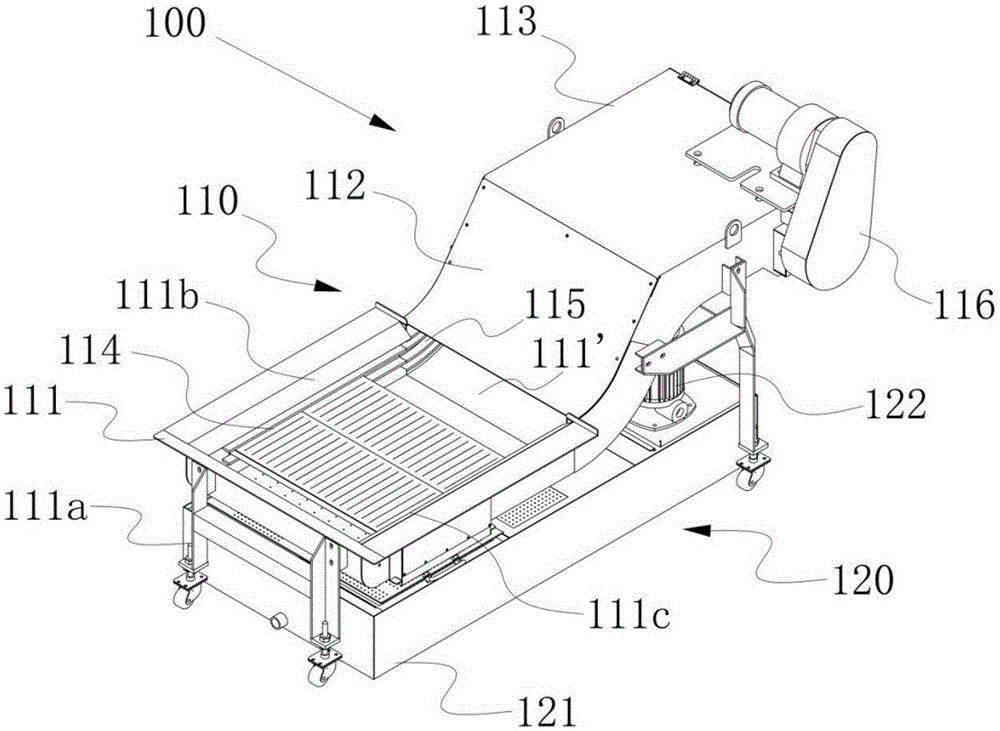

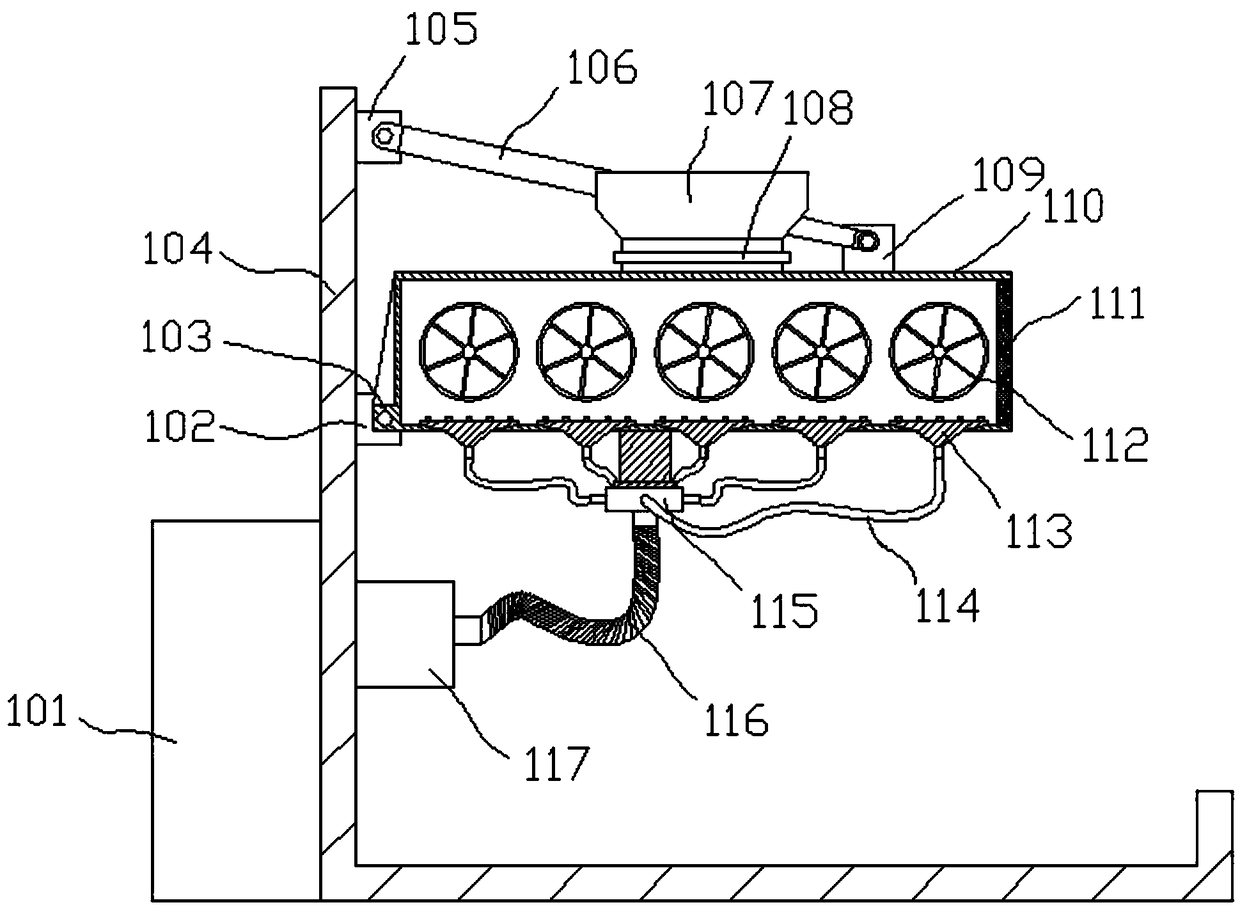

Equipment for tea leaf processing and shaping process

InactiveCN109315525AHigh degree of automationRealize automatic feedingPre-extraction tea treatmentPackagingEngineeringSoftening

The invention discloses equipment for a tea leaf processing and shaping process. The equipment comprises a tea leaf softening mechanism, a tea leaf shaping mechanism and a tea leaf bagging mechanism.The equipment is capable of softening, shaping and bagging tea leaves sequentially, the tea leaves can be turned evenly and can be heated evenly in the softening process, the tea leaves are preventedfrom cracking in the shaping process, the integrity of the leaves is maintained, and the quality of tea is improved; and quantitative filling can be achieved in the bagging process.

Owner:HUITONG RUICHUN TEA IND CO LTD

Production method of impeller for aero-engine

ActiveCN114749319APrevent splashRealize automatic opening and closing effectPretreated surfacesCoatingsImpellerEngineering

A spraying device comprises a box body, an automatic feeding device is arranged at the top of an inner cavity of the box body, an automatic opening and closing device is arranged at an end opening of the box body, a spraying and drying device is arranged at the bottom of the inner cavity of the box body, a control panel is fixedly connected to one side of the box body, and the control panel is fixedly connected to the other side of the box body. The invention relates to the technical field of aero-engines. According to the production method of the impeller for the aero-engine, the problems that when the impeller is sprayed through spraying equipment, the impeller needs to be turned over in the spraying process, comprehensive spraying on the impeller cannot be achieved under the non-stop condition, and in addition, spraying materials splash and remain on the inner wall of the equipment during spraying are solved; and secondly, after spraying is completed, the impeller needs to be taken out and dried through drying equipment, so that the drying effect cannot be achieved in the spraying process, the production process is reduced, and the production efficiency is improved.

Owner:YANGZHOU YIXING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com