Method and device for feeding and discharging polymer tubes and bars

A technology of polymer tubes, material in and out, applied in the direction of transportation and packaging, metal processing, conveyor objects, etc., can solve problems such as safety hazards, low work efficiency, error-prone, etc., to ensure safety, improve efficiency, and ensure processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

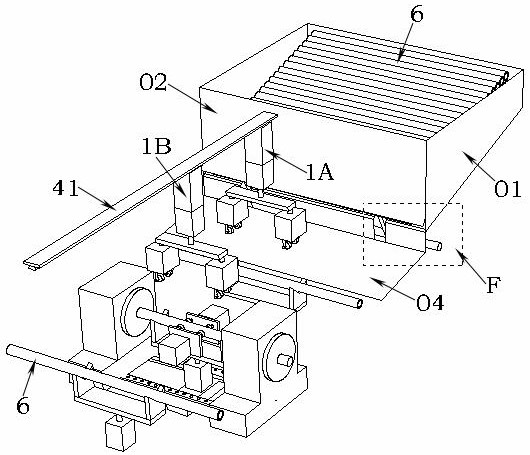

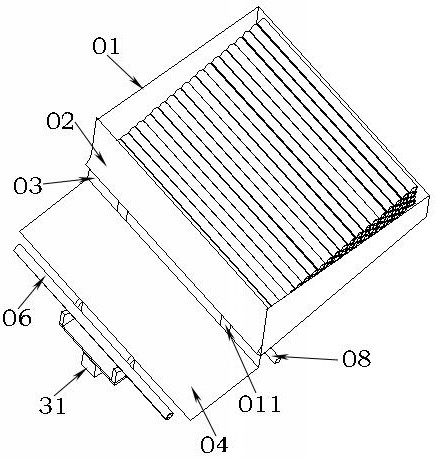

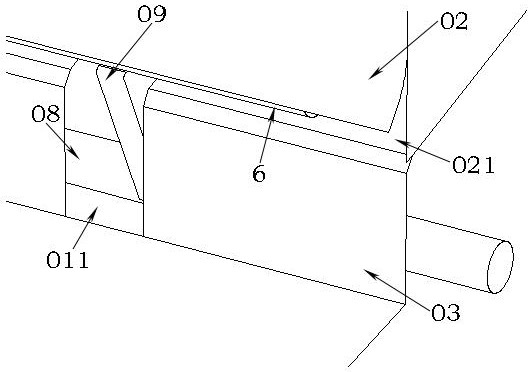

[0039] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the automatic feeding mechanism includes a box body, a curling door, a receiving plate, a transmission plate and a pushing mechanism. The bottom of the box body is an inclined plane, and multiple pipes and rods to be processed are neatly placed in the box body. The rear end of the box body is provided with a rolling door, the lower end of the rolling door is rolled up, and a transmission hole is opened between the lower end of the rolling door and the bottom of the box body. When the tube and bar closest to the transmission hole in the casing were not jacked up, the tube and bar could roll out from the transmission hole. In order to allow the tubes and rods in the box to roll out one by one at regular intervals, a plate hole is opened at the bottom of the box and a pushing mechanism is arranged below the box. The upper surface of the transmission plate is also an inclined slope, the upper end of the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com