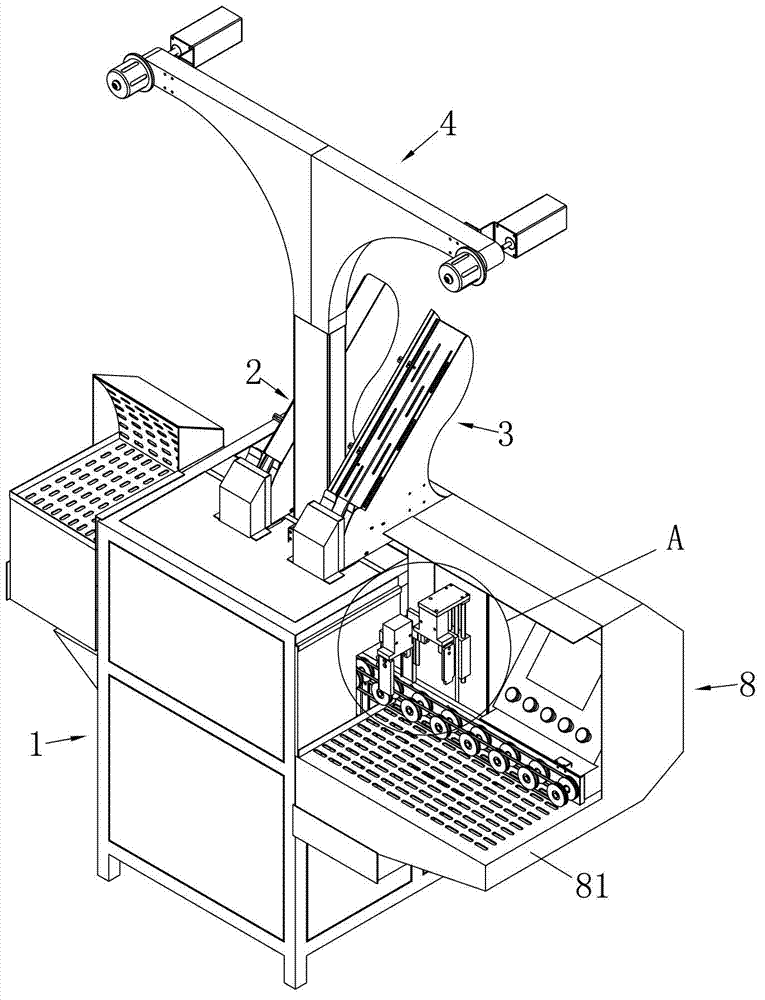

Full-automatic plate wrapping machine

A wrapping machine, fully automatic technology, applied in conveyor objects, transportation and packaging, sustainable manufacturing/processing, etc., can solve the problems of complex structure, health impact of operators, single production method, etc., to achieve high work efficiency, Improve work efficiency and use range, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

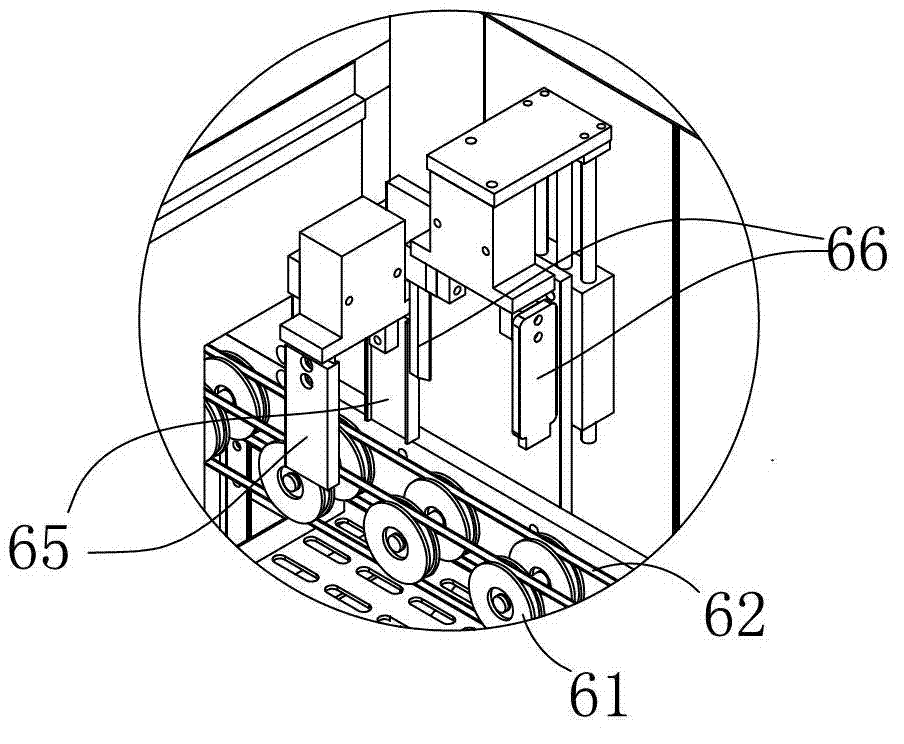

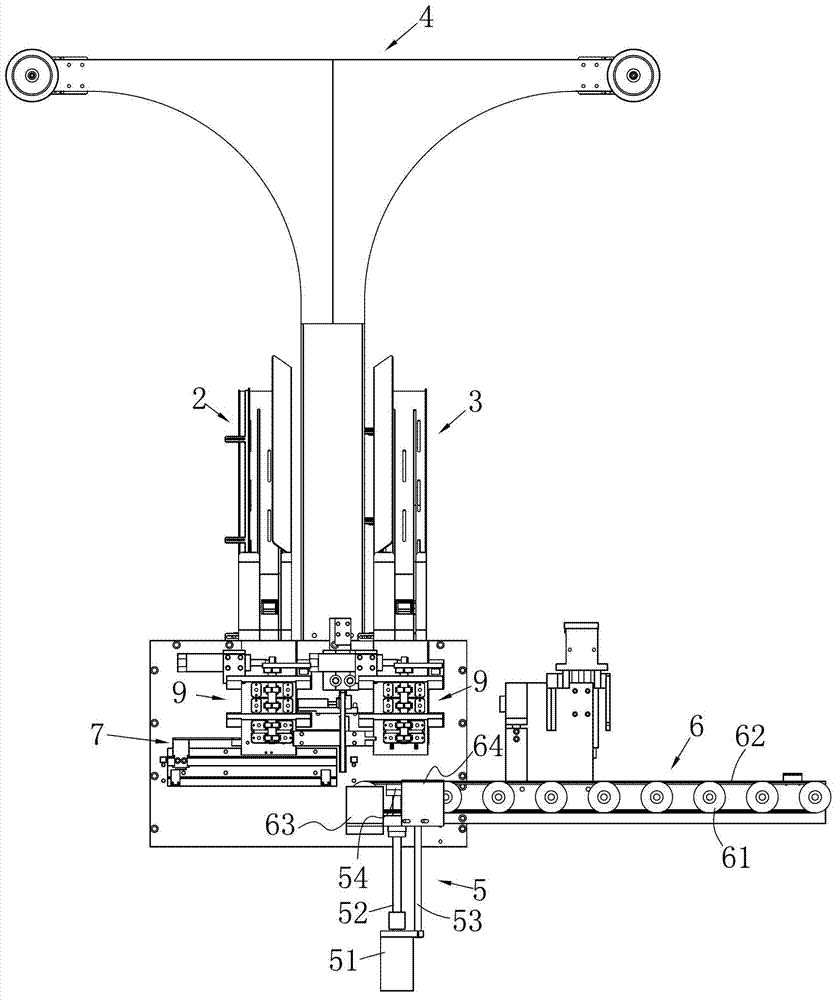

[0033] The invention provides a full-automatic bagging machine, which includes a machine body, which is provided with a push plate track, a push plate device, a paper feeding device, a film wrapping device, a first falling board frame, a second falling board frame and a lifting mechanism , the pushing plate device, the first falling plate frame, the paper feeding device, the wrapping device, and the second falling plate frame are arranged in sequence along the advancing direction of the pushing plate track, and the lifting mechanism is arranged on the second falling plate Just below the frame, the first falling board frame and the second falling board frame are provided with clamping parts, supporting plate parts and cam driving devices for driving the action of the clamping parts and supporting plate parts, and the supporting plate parts are The lowermost pole plate is released when the clamping member is in a clamped state, and the supporting plate supports the lowermost pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com