Full-automatic steel ball assembling machine

A fully automatic, steel ball technology, applied to engine components, engine lubrication, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

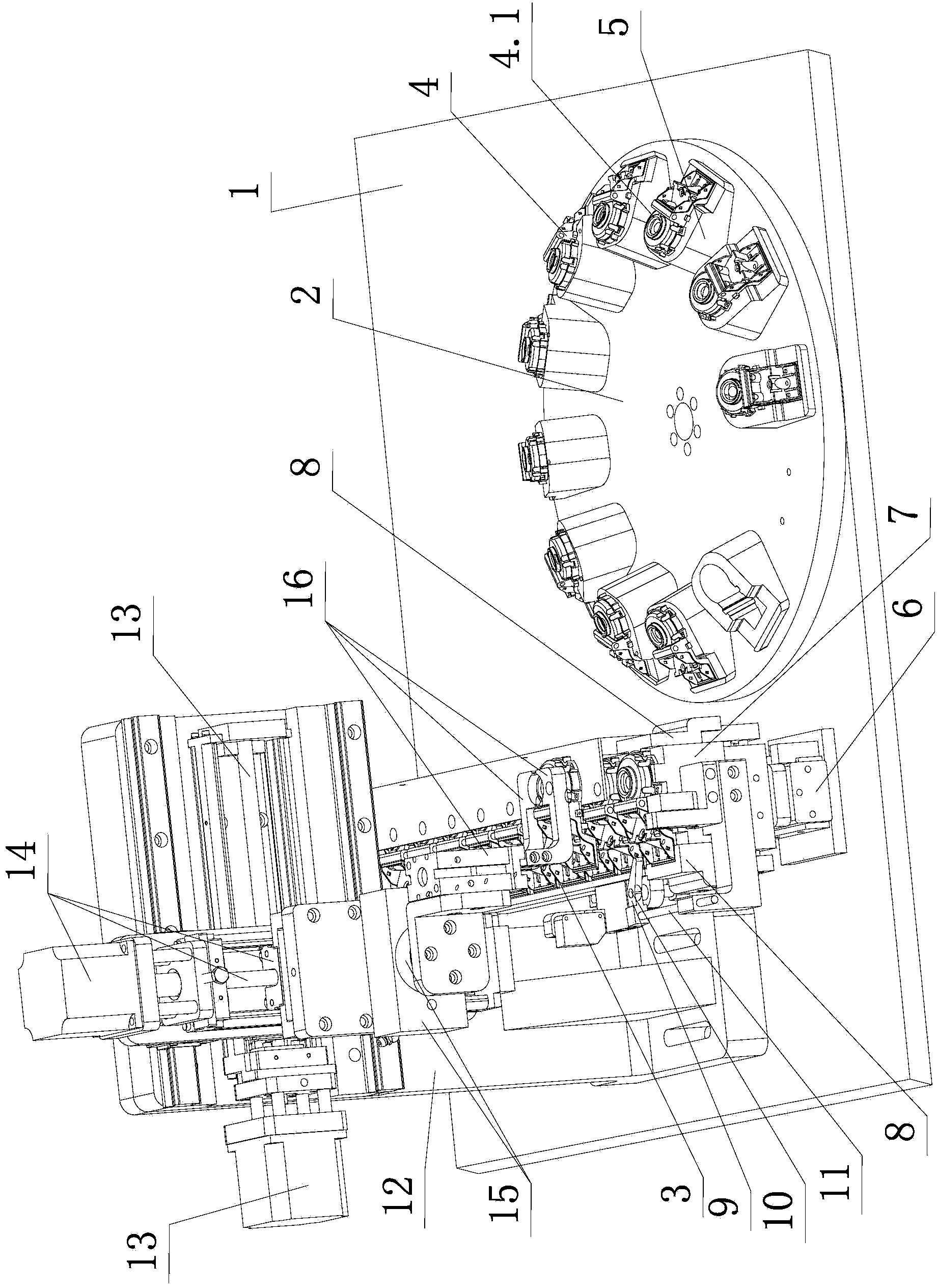

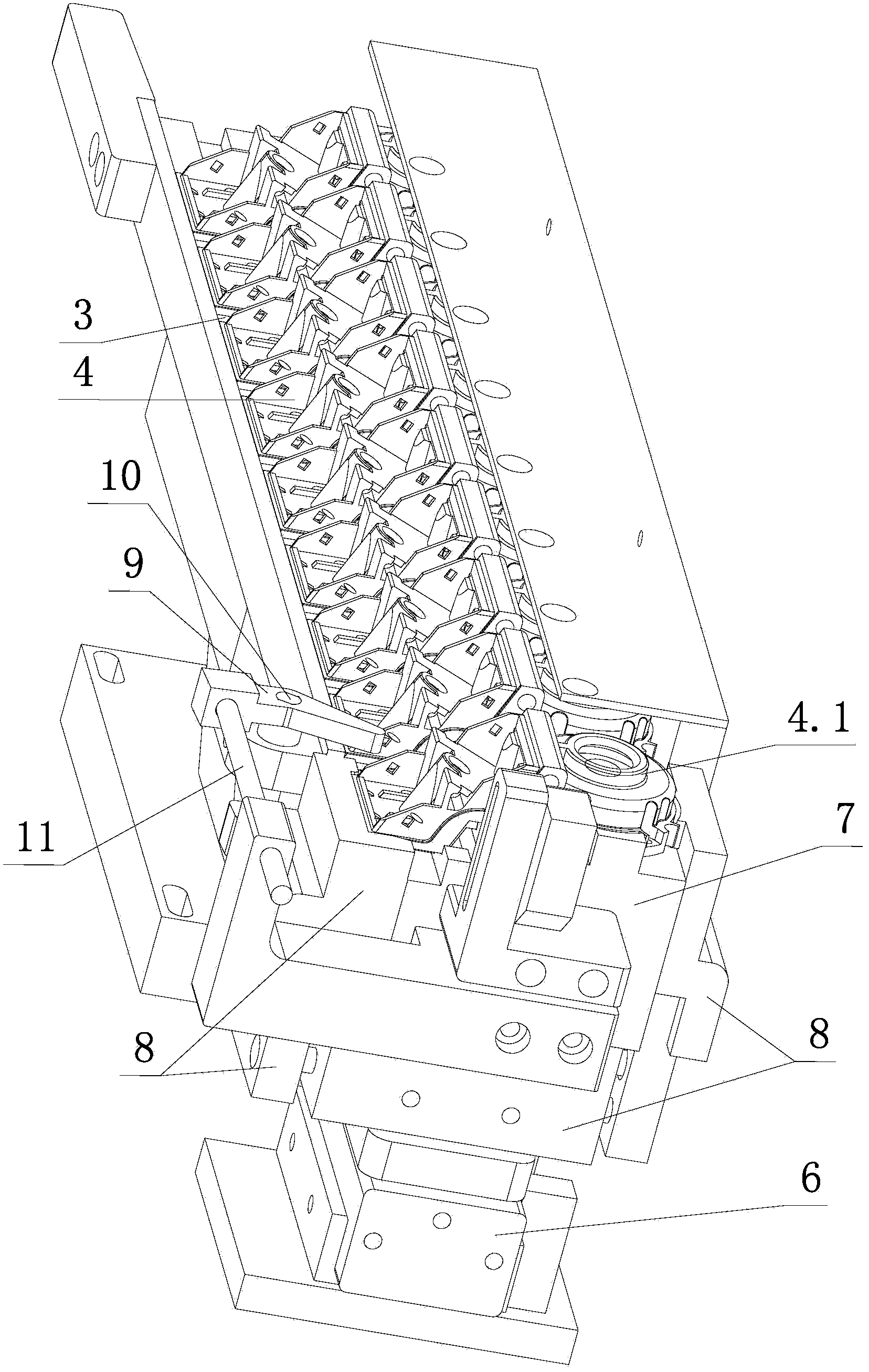

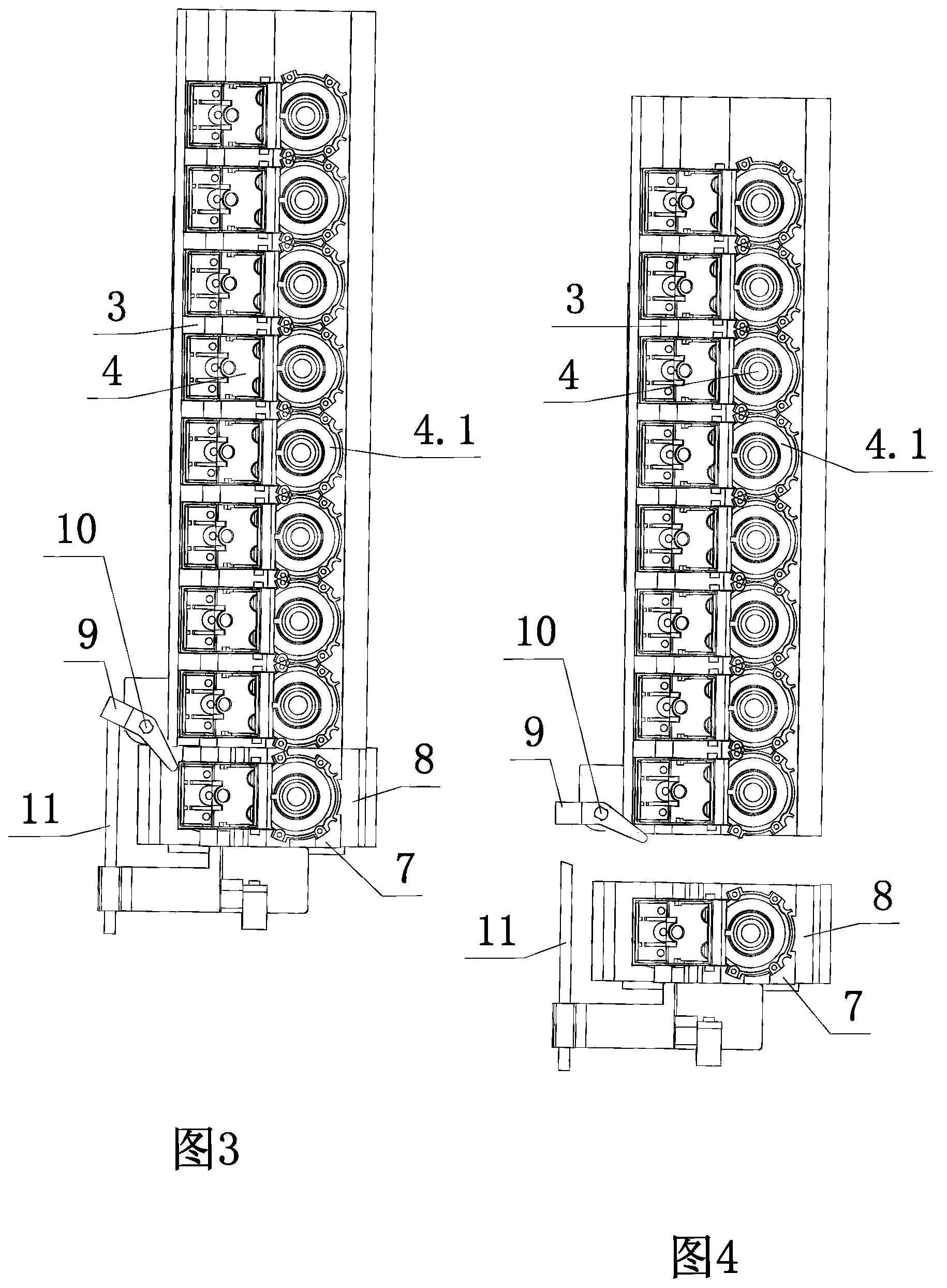

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 Shown, the automatic steel ball assembly machine of the present invention, it comprises frame 1. The frame 1 is provided with a station switching turntable 2 and an automatic feeding channel 3 driven by a driving mechanism. A plurality of bases 5 for clamping workpieces 4 are arranged on the station switching turntable 2 . The driving mechanism of the automatic feeding channel 3 is a conventional prior art vibrator, which is installed below the automatic feeding channel 3 to provide forward vibration for the automatic feeding channel 3 to push the workpiece 4 forward, of course in order to speed up The advancing speed of the workpiece 4 can also des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com