Single-drive separating and discharging device and method for steel pipes

A technology of discharging device and steel pipe, which is applied in transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of troublesome maintenance, complex structure and high cost, and achieve the effect of convenient maintenance, few driving devices and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

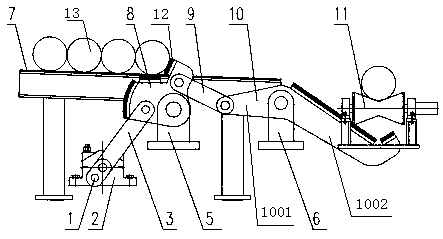

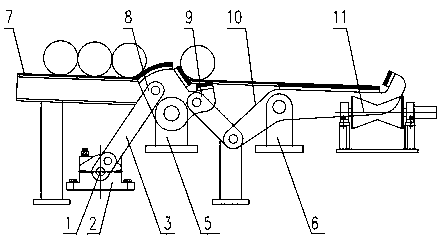

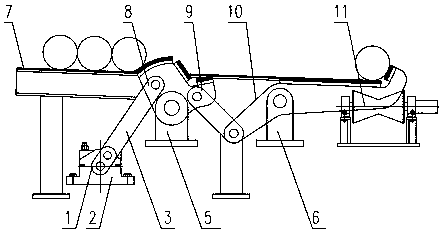

[0023] In order to overcome the problems that the traditional steel pipe distribution device and discharge device are two independent parts, each with its own drive and control, complex structure, high cost and troublesome maintenance, the present invention provides such Figure 1-3 A single-driven steel pipe material distribution and discharge device and method, the invention integrates the material distribution device and the material discharge device, driven by a motor can realize the steel pipe material distribution and discharge functions. The invention reduces the number of driving devices, has simple and reliable structure, low cost, high efficiency and convenient maintenance.

[0024] A single-drive steel pipe distributing and discharging device, including a crankshaft 1, a bearing seat 2, a motor reducer 4, a first support 5, a second support 6, a stand 7, a turning plate 8, and a discharge arm 10 and the roller table 11; the roller table 11 is installed on the discha...

Embodiment 2

[0027] Based on the above embodiments, in this embodiment, the crankshaft 1 is an eccentric shaft.

[0028] The turning plate 8 is hingedly mounted on the first bracket 5; one end of the second connecting rod 9 is hingedly connected to the turning plate 8, and the other end is hingedly connected to the discharging arm 10.

[0029] The upper surface of the stand 7 extending from the discharge side to the roller table 11 is higher than the horizontal highest point of the roller table 11 .

[0030] The feed side of the platform 7 is higher than the discharge side; and the inclination angle with the ground is 2-10°.

[0031] The upper surface of the stand 7 is provided with a polyurethane plate with a thickness of 10-30mm.

[0032] The inclined surface of the stand 7 extends to the upper surface of the roller table 11 must be higher than the highest level of the roller table 11, otherwise the steel pipe 13 cannot be put into the roller table 11 after passing through the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com