Patents

Literature

38results about How to "Carrying out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

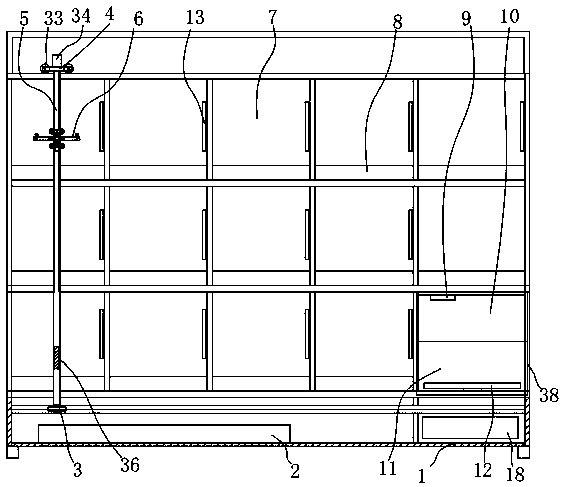

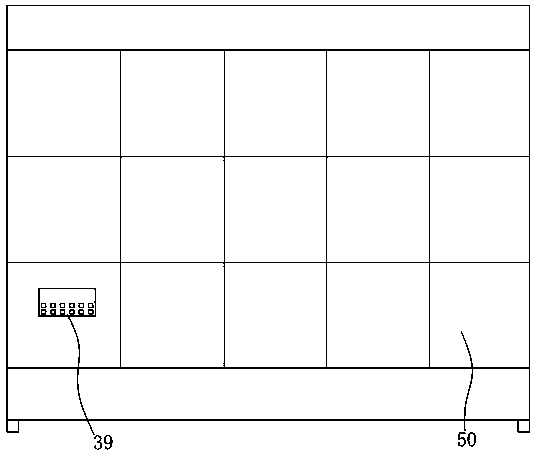

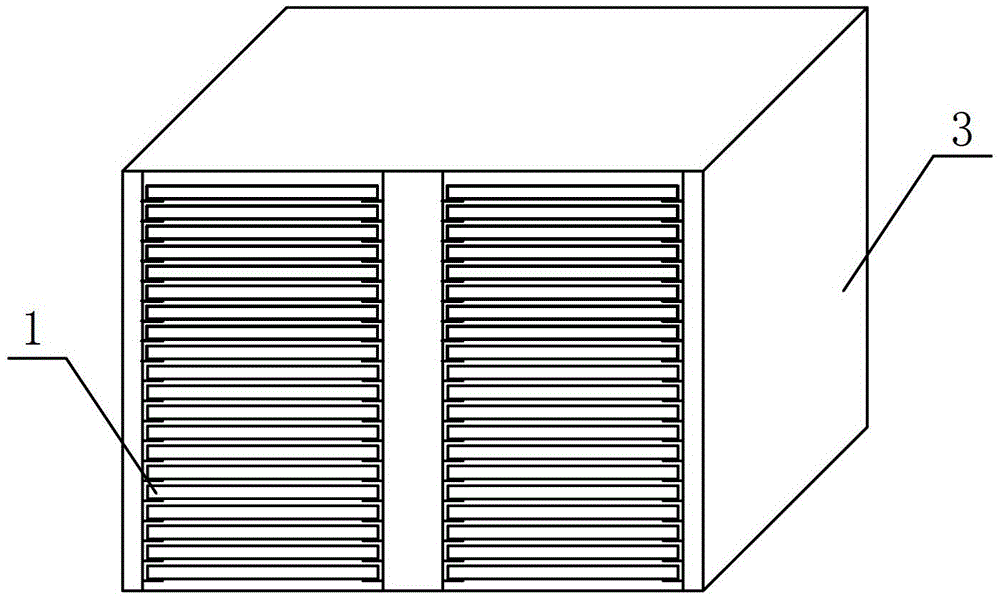

Automatic catering vending system

PendingCN107798784AAchieve heatingCarrying outApparatus for meter-controlled dispensingControl theoryRefrigeration

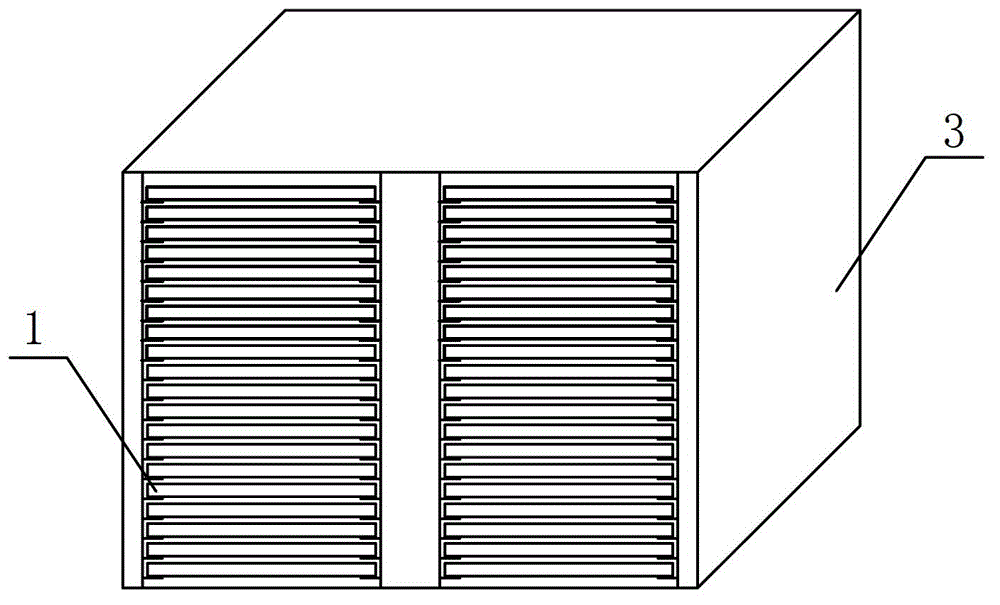

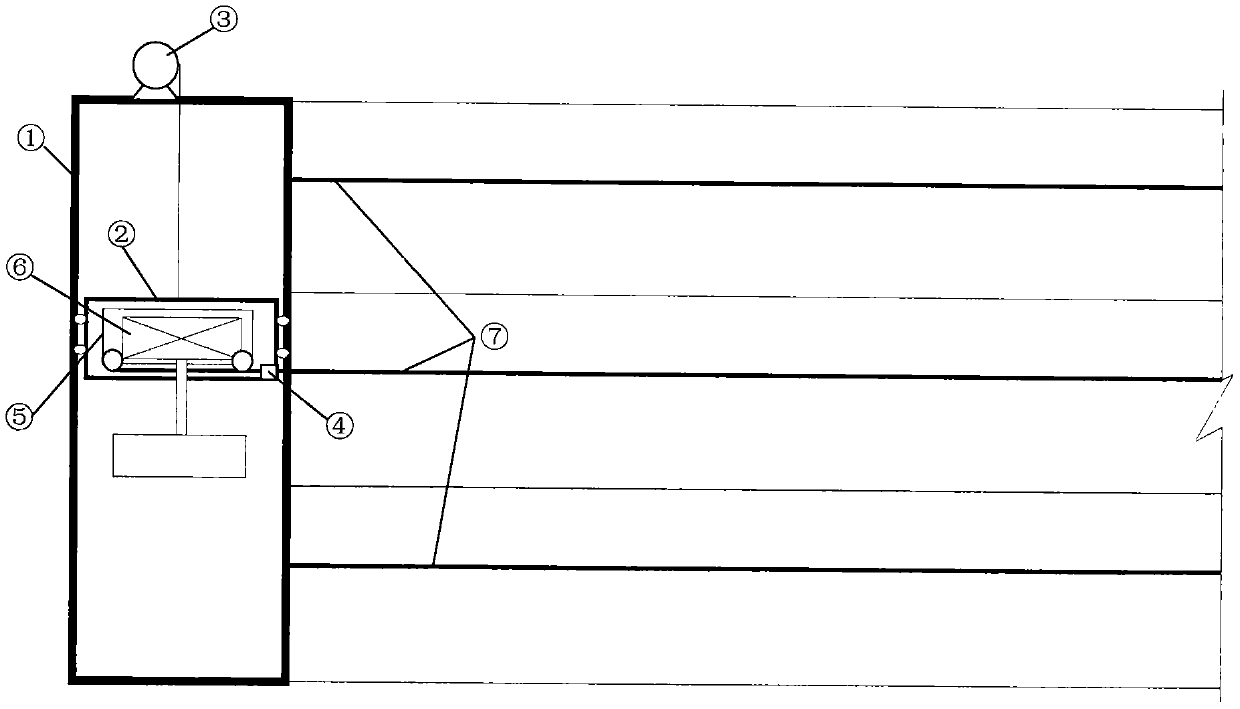

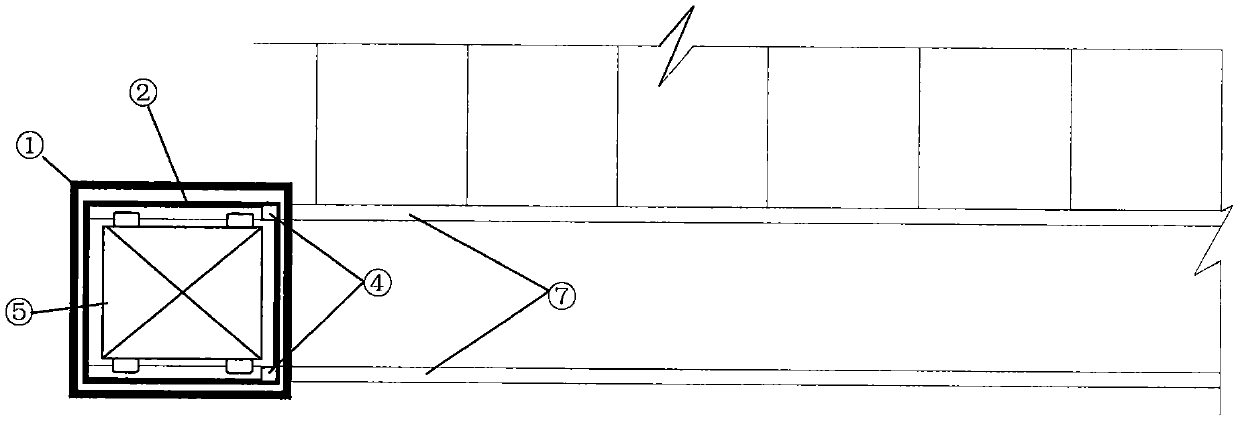

The invention relates to an automatic catering vending system. The automatic catering vending system comprises a cabinet body, a computer, input equipment, a refrigerating bin and a heating bin, wherein a carrying bin is arranged on the rear side of the refrigerating bin; a transverse sliding track is arranged on the top of the carrying bin; a carrying trolley is arranged on the transverse slidingtrack and is provided with a longitudinal sliding track; the longitudinal sliding track is provided with a lifting trolley; a rear sealing door is arranged on the rear side of the heating bin; a microwave heater is arranged in the heating bin; and refrigeration equipment is arranged at the bottom of the cabinet body. Different kinds of fast food are refrigerated by the separated refrigerating bin, workers can supplement goods in idle time favorably, supply of fast food of a vending place can be ensured for a long time, owing to an integrated structure, use and mounting of equipment are facilitated, the heating bin is integrated in the cabinet body, heat of the fast food is realized, left-right movement of the lifting trolley is realized by the carrying trolley in the carrying bin, liftingcontrol over a clamping seat is realized by lifting of the lifting trolley, and fast movement of the clamping seat is realized favorably to carry the fast food.

Owner:苏州卓膳餐饮管理有限公司

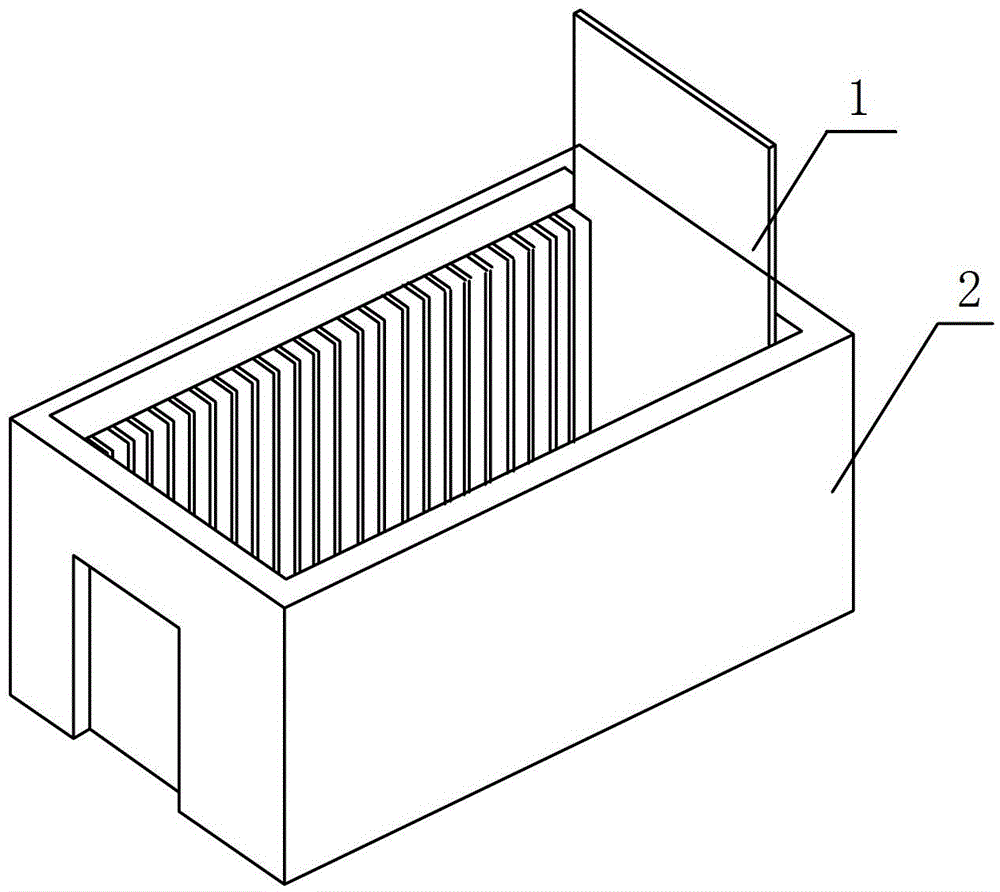

Carrier device and carrier method

ActiveCN103332459ACarrying outSemiconductor/solid-state device manufacturingCharge manipulationEngineeringMechanical engineering

Owner:BOE TECH GRP CO LTD +1

Construction method of nutrient carrying system based on nano-food

ActiveCN102228239ACarrying outImprove stabilityFood preparationTemperature controlBiological availability

The invention discloses a construction method of a nutrient carrying system based on nano-food. The construction method is characterized in that (1) one or more nutrients and a nano-food are mixed uniformly to form a mixture, wherein a mass ratio of the one or more nutrients and the nano-food is 1: (4 to 200); a lipid content of the nano-food is less than 12%; and a peak value of a particle size distribution curve of the nano-food is less than 400 nm; (2) if the above mixture is in a solution system, a solution concentration is adjusted to a concentration of 0.5 to 55% by nano-food weight; a solution pH is adjusted to a pH of 2.2 to 13; an ion strength converted into a sodium ion concentration is in a range of 0.001 to 5 mol / L; and at a temperature of 0 to 85 DEG C, an ultrasonic vibration process adopting a power density of 0 to 65 W / cm <2> is carried out and nano-food clusters are obtained after a gathering process for 1 to 48 hours; or if the above mixture is in a solid state, nano-food clusters are obtained through a gathering process lasting for 2 to 80 hours under the conditions of a pressure intensity controlled in a range of 0.05 to 4 MPa, a temperature controlled in a range of 0 to 230 DEG C and a relative humidity controlled in a range of 0 to 100%; and (3) the nano-food clusters are packaged in a vacuum and then are stored at normal temperature or low temperature. Through the construction method, nutrients are wrapped in nano-food clusters thus nutrient carrying is realized; a stability of carried nutrients is improved and nutrients carried by nano-food clusters can be stored in liquid form or solid form thus the degradation of nutrients can be reduced or even avoided and conditions of after processing are relaxed; and a bioavailability of nutrients carried by nano-food clusters is improved greatly.

Owner:杭州纳福载运科技有限责任公司

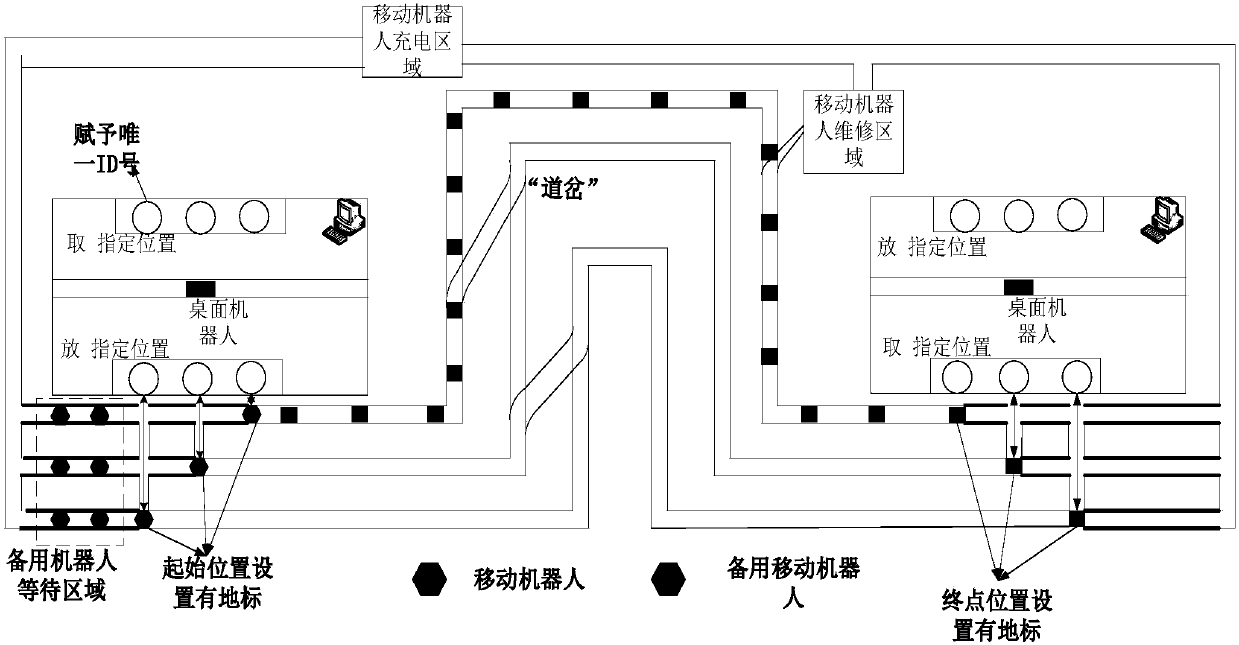

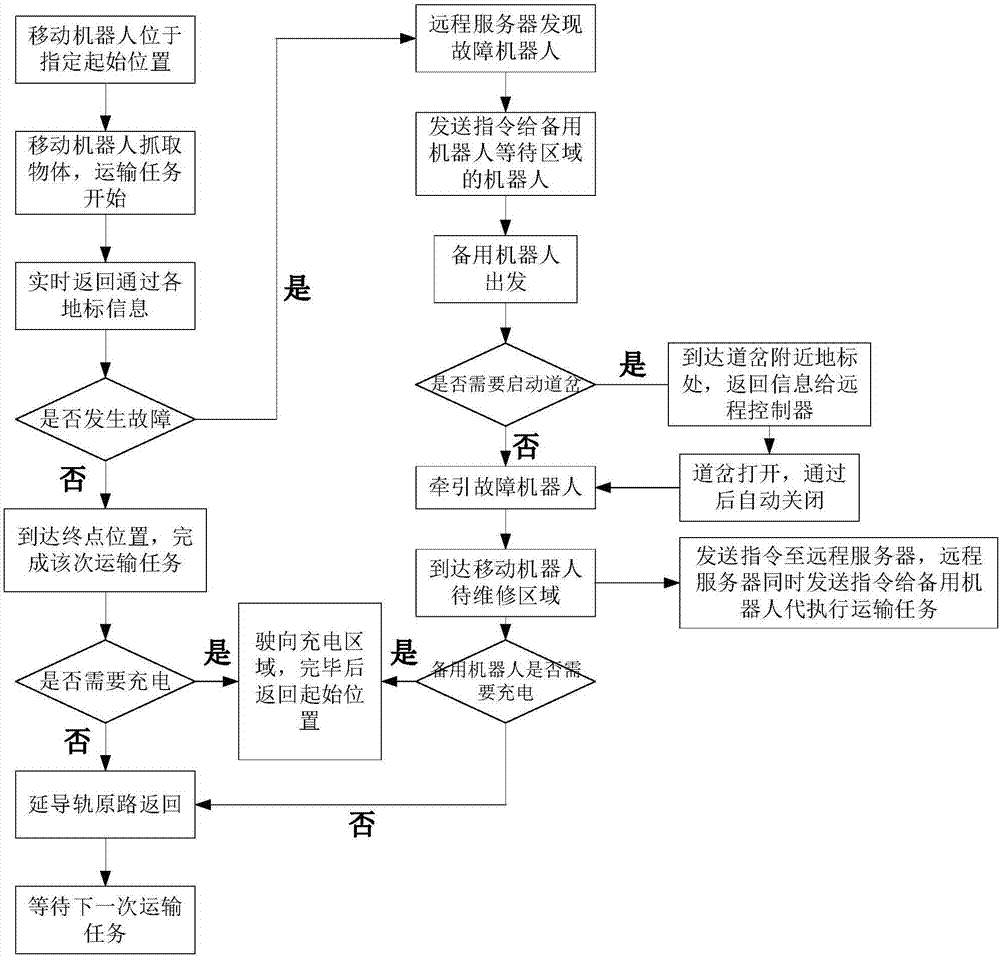

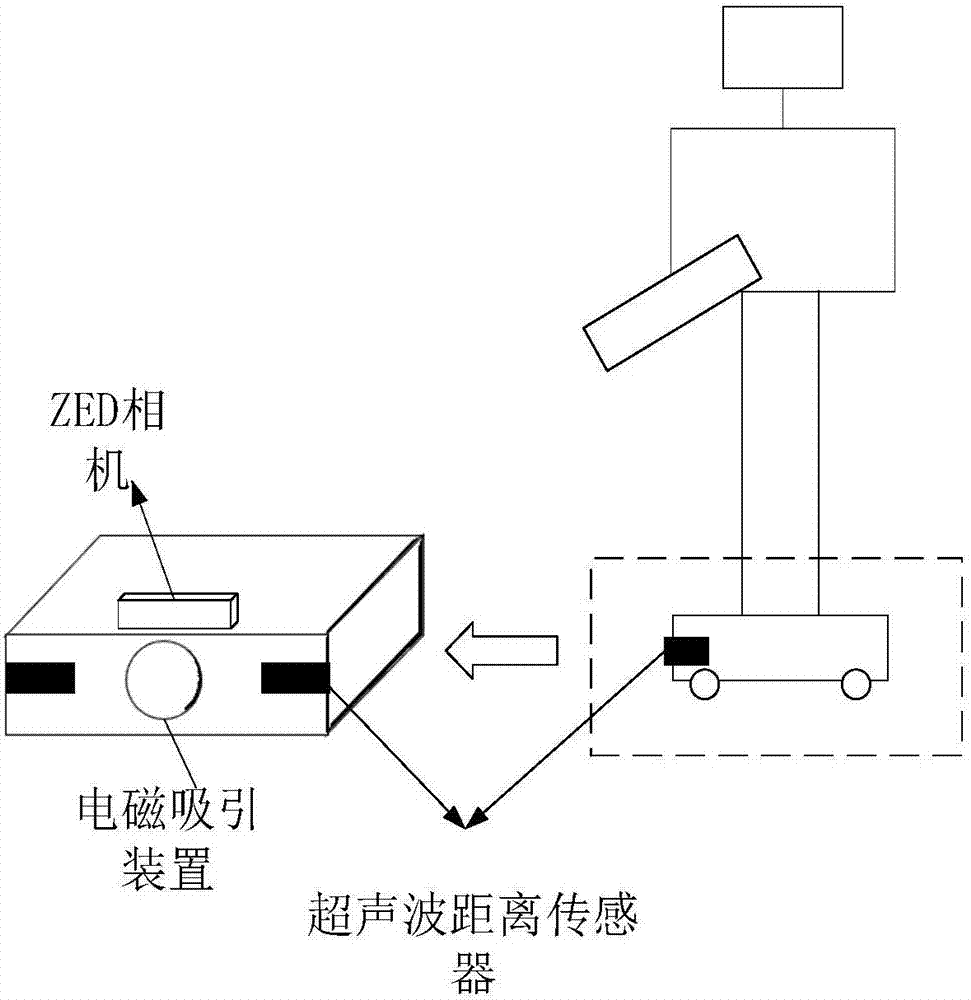

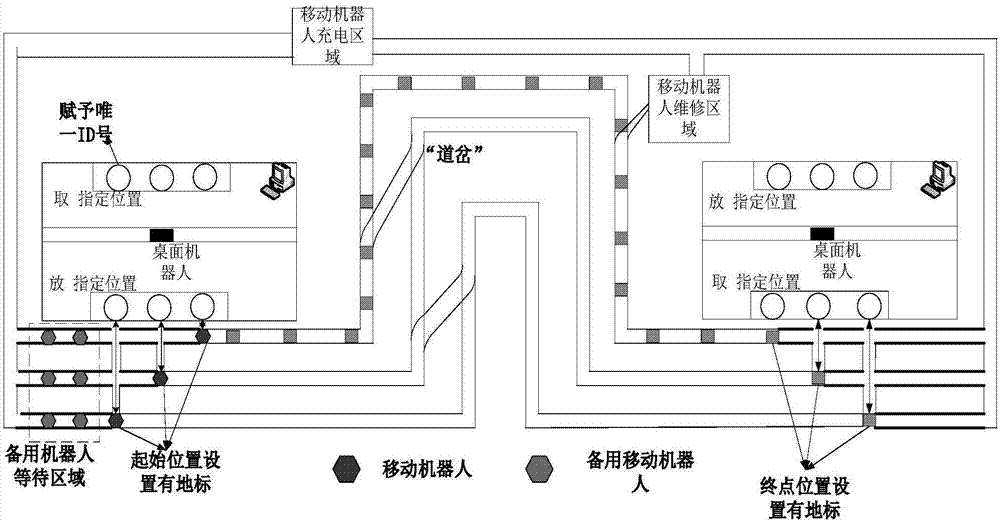

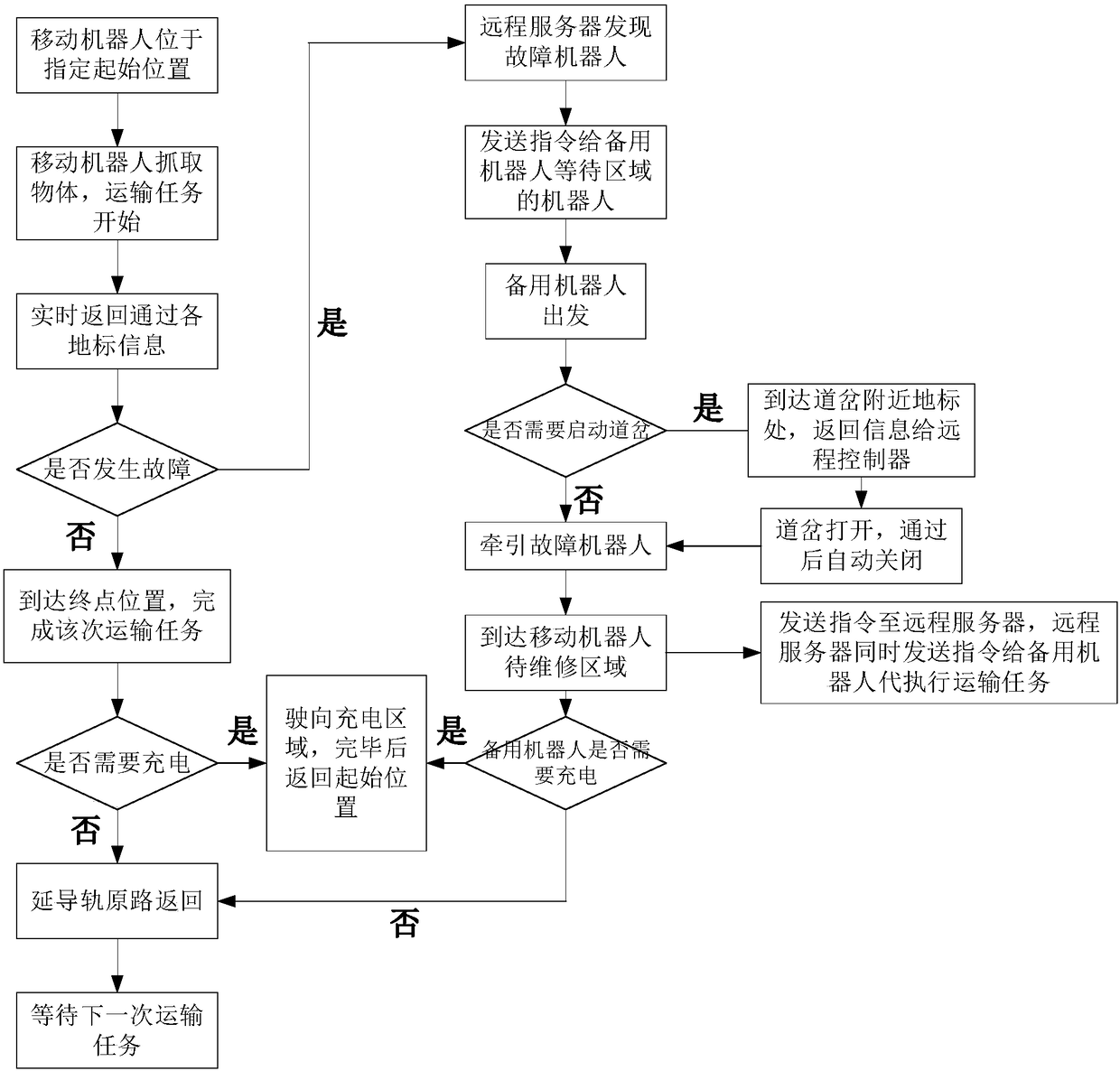

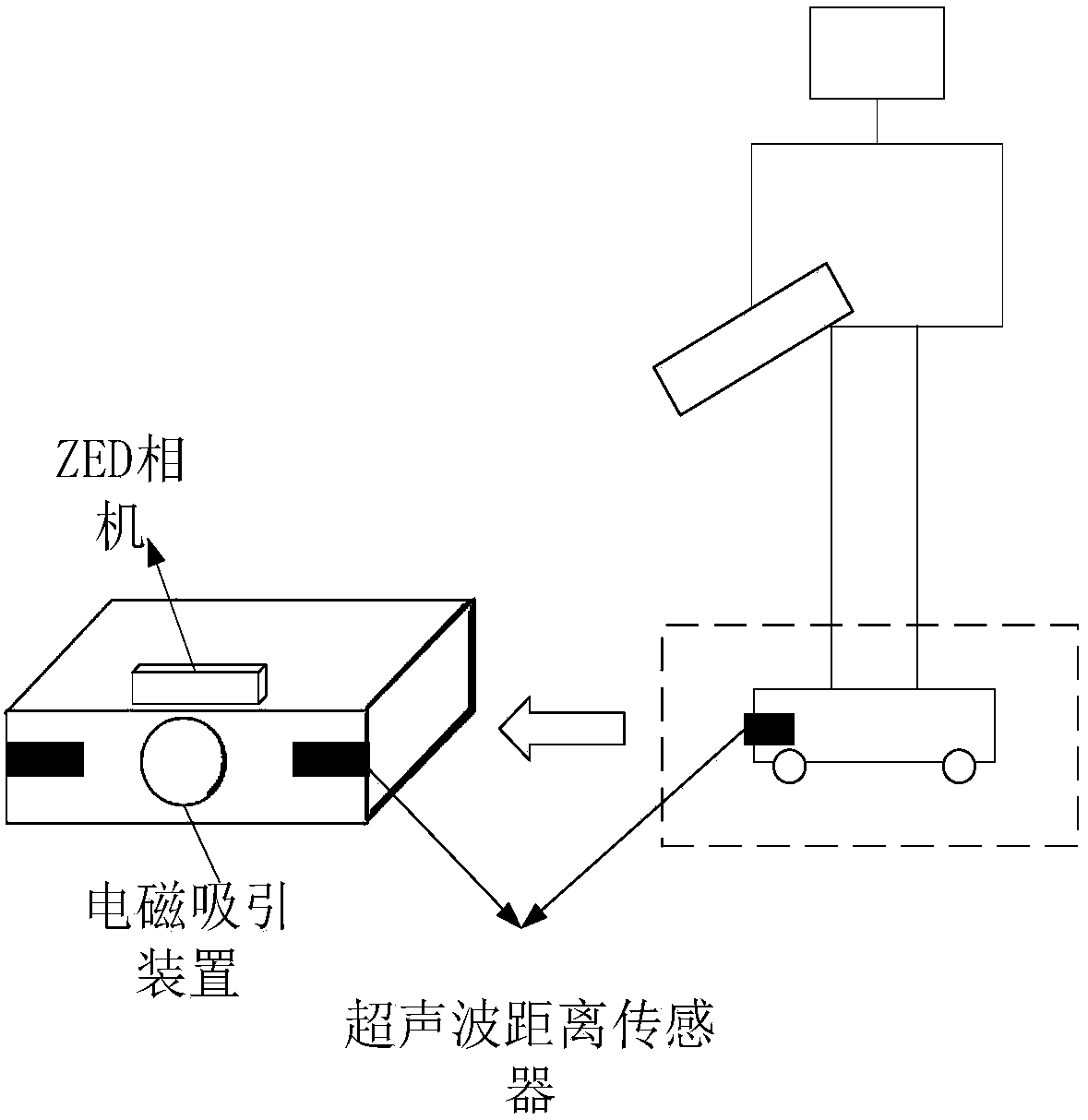

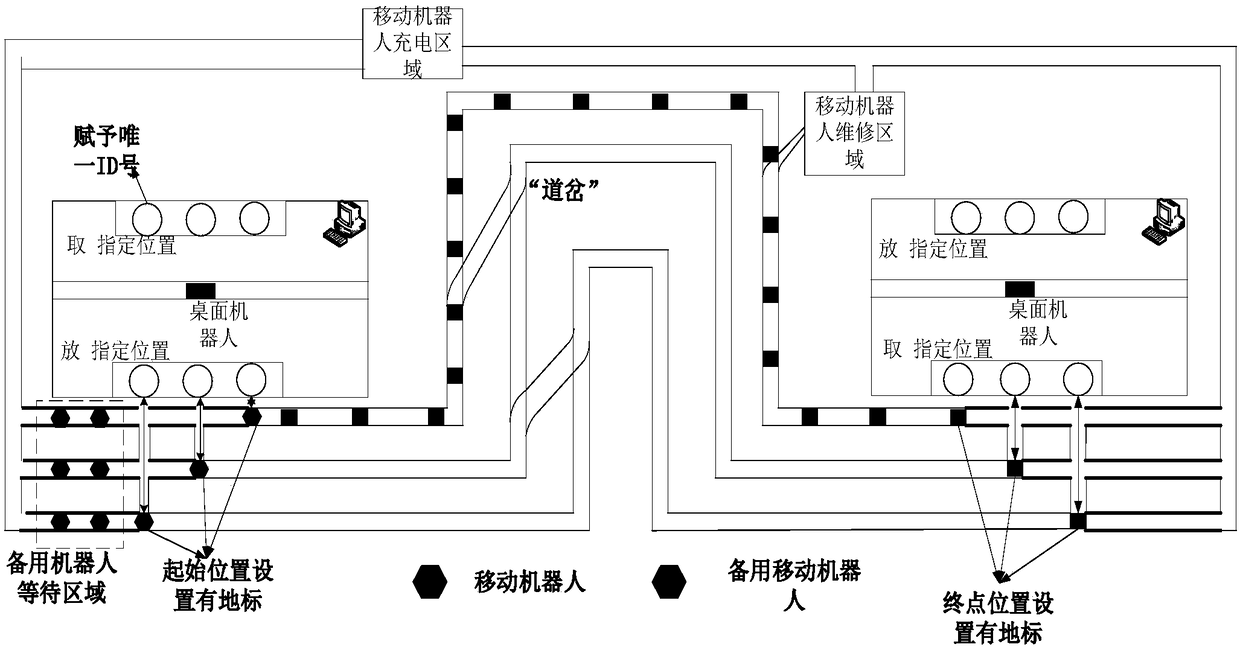

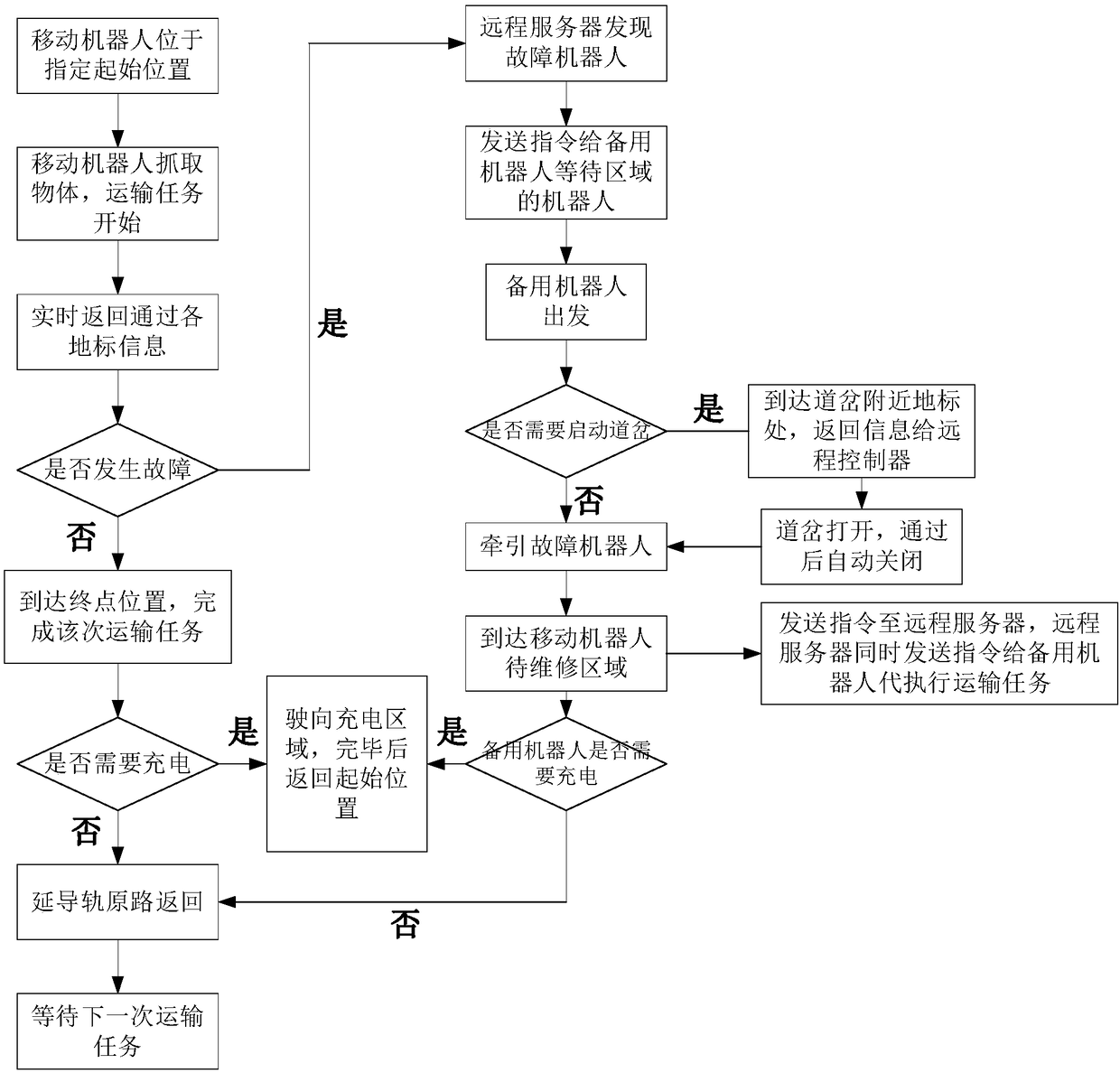

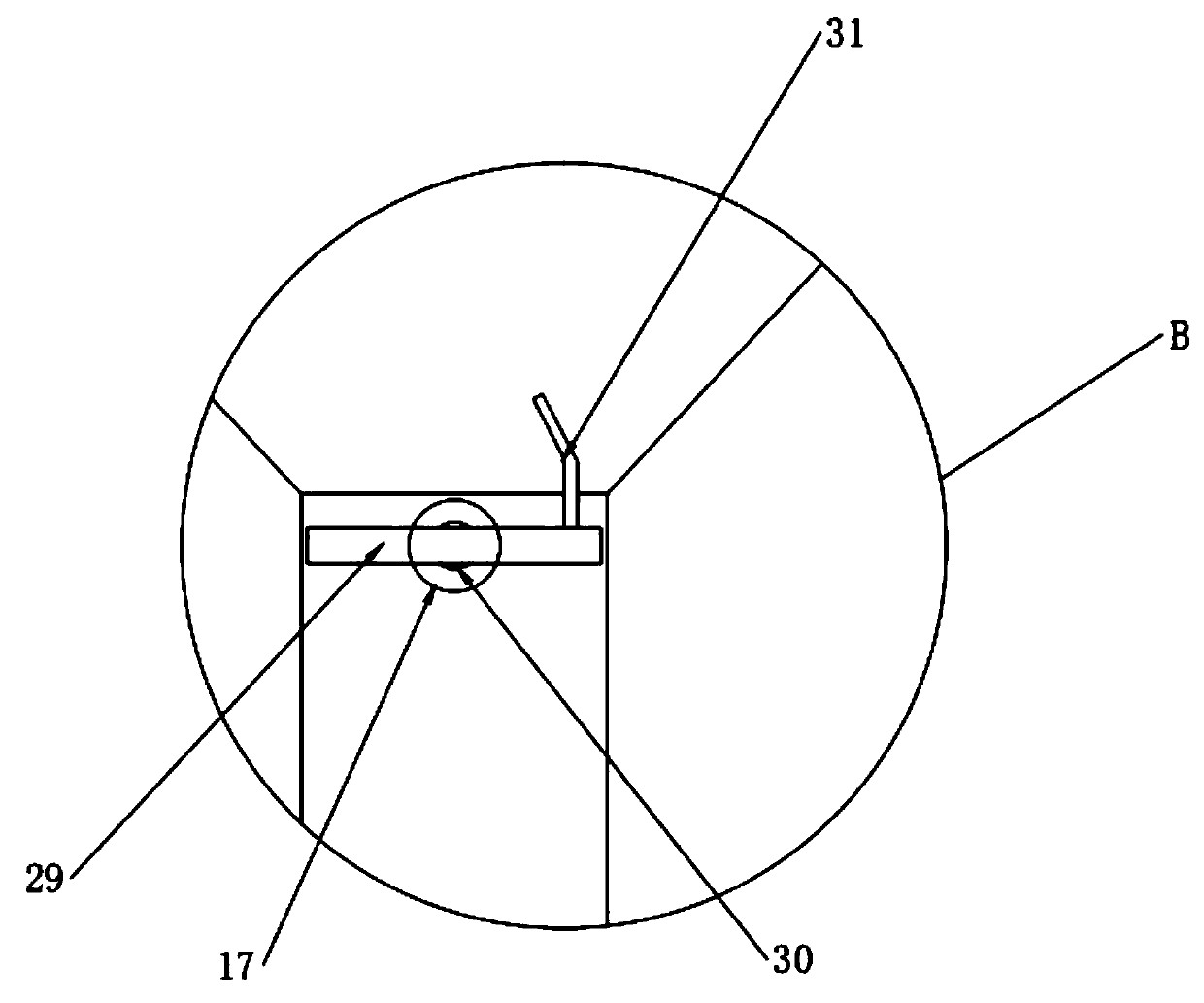

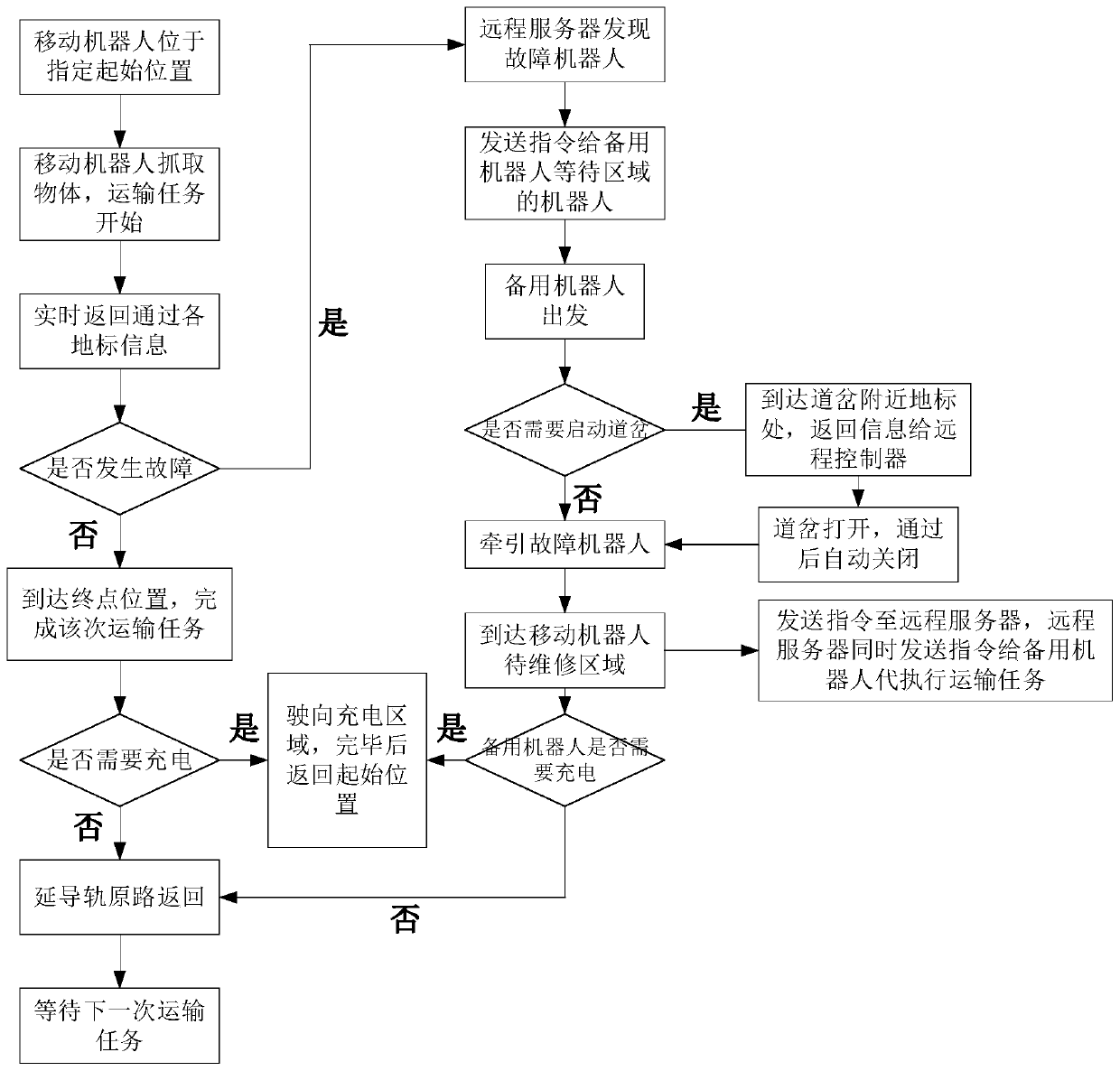

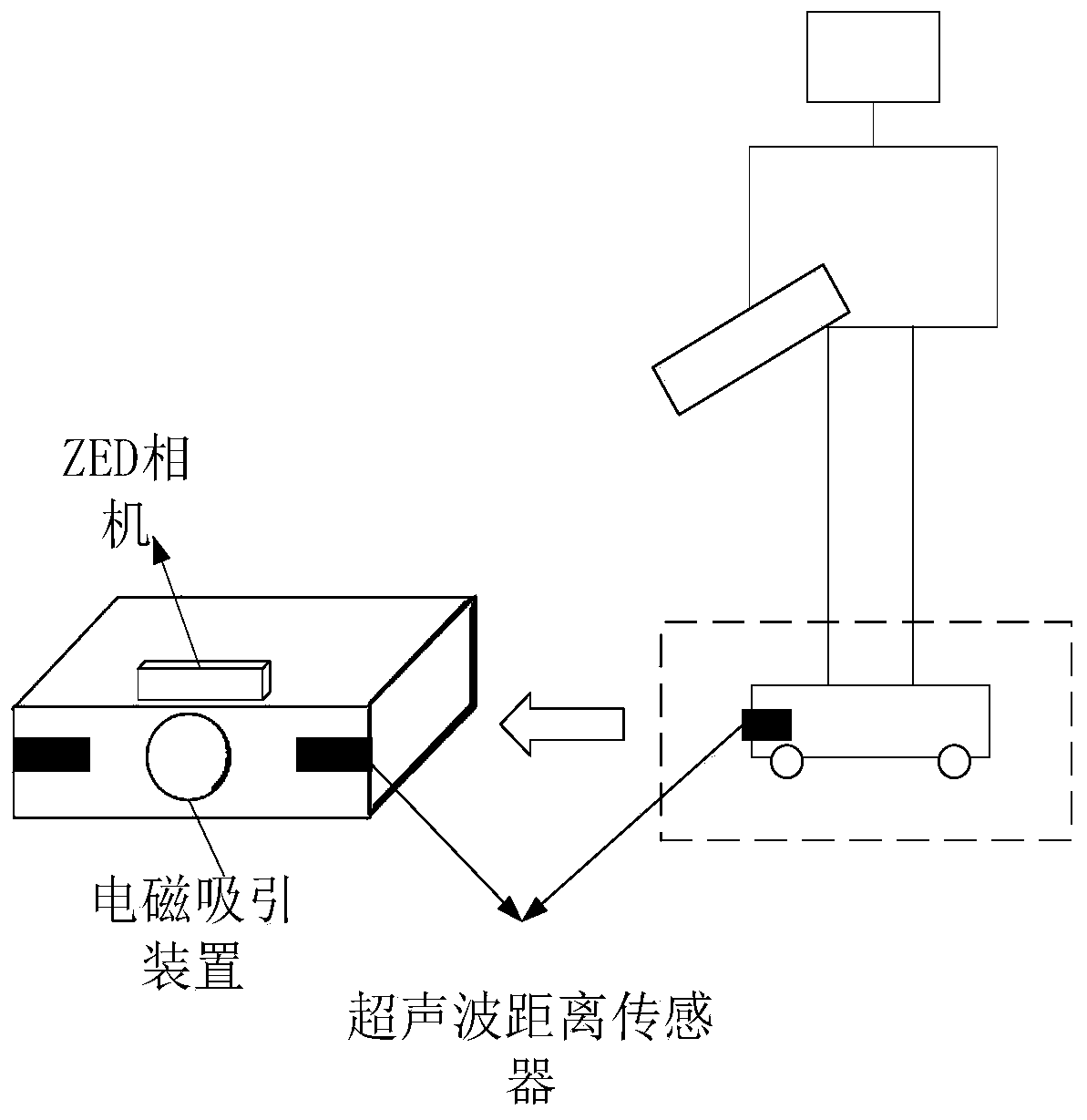

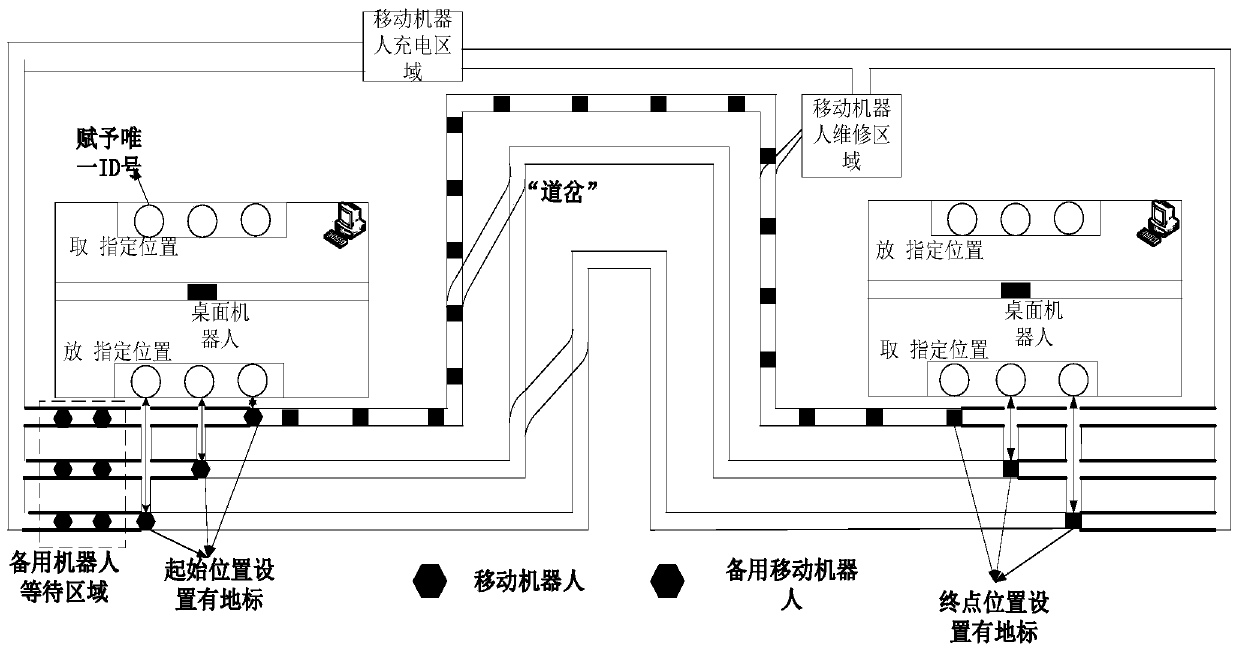

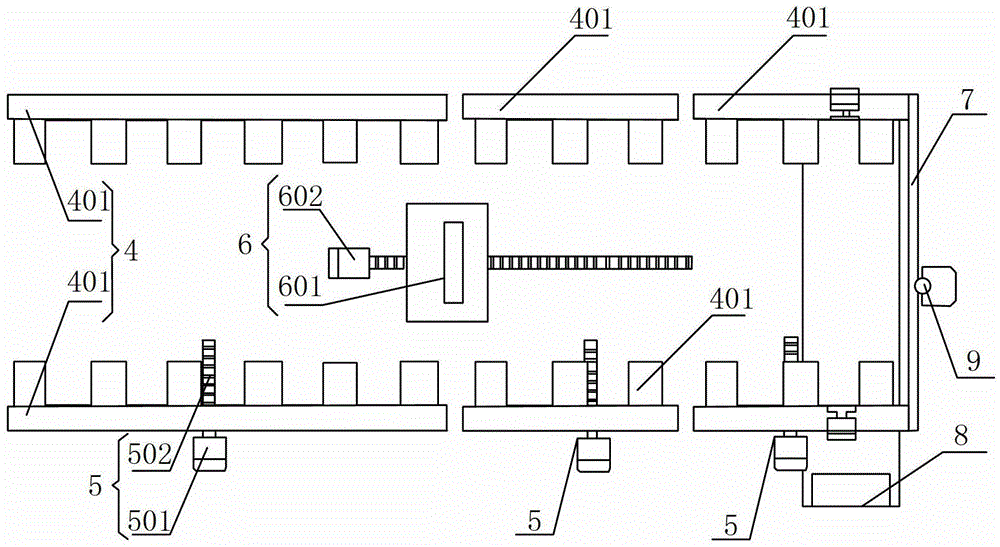

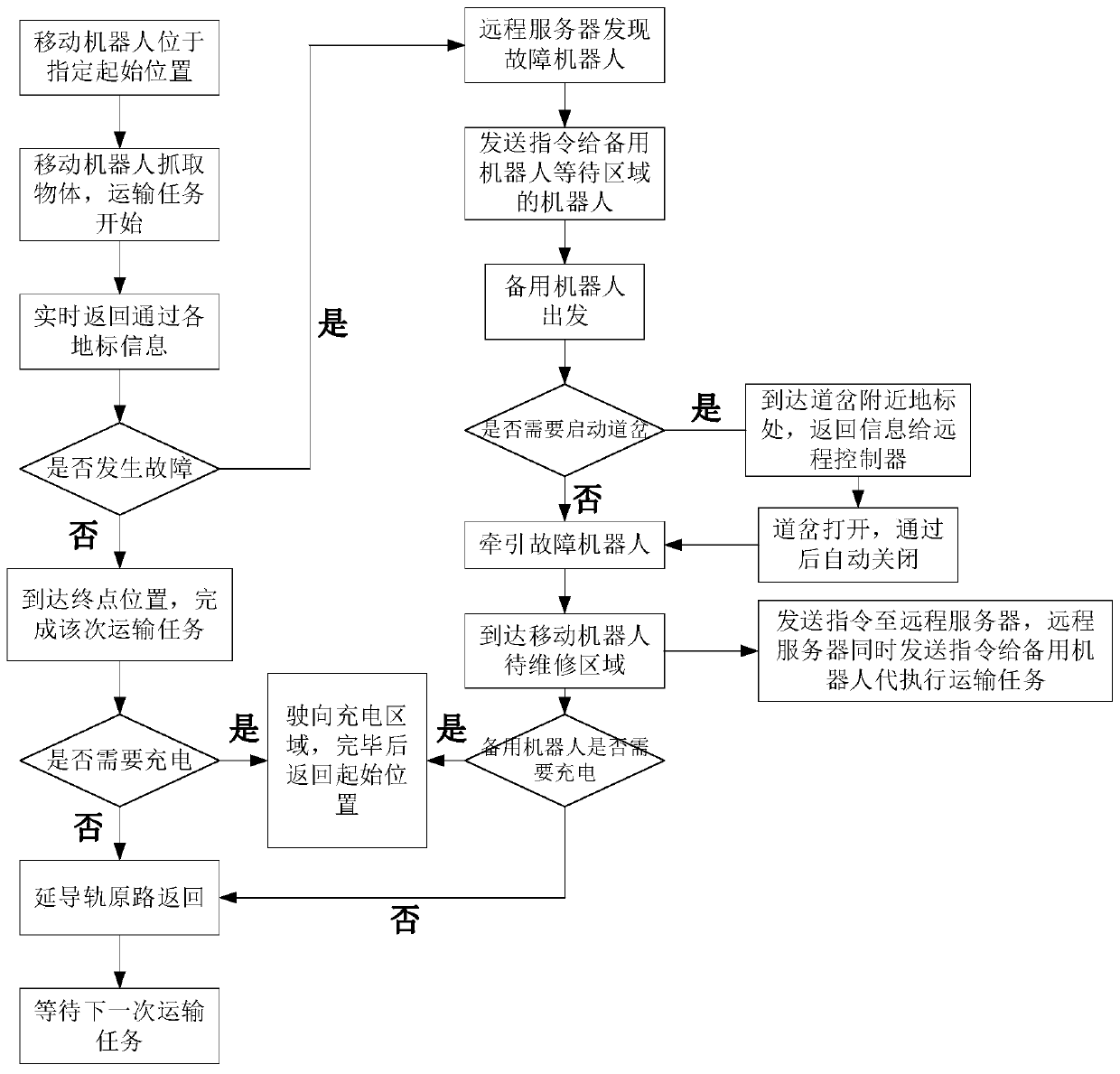

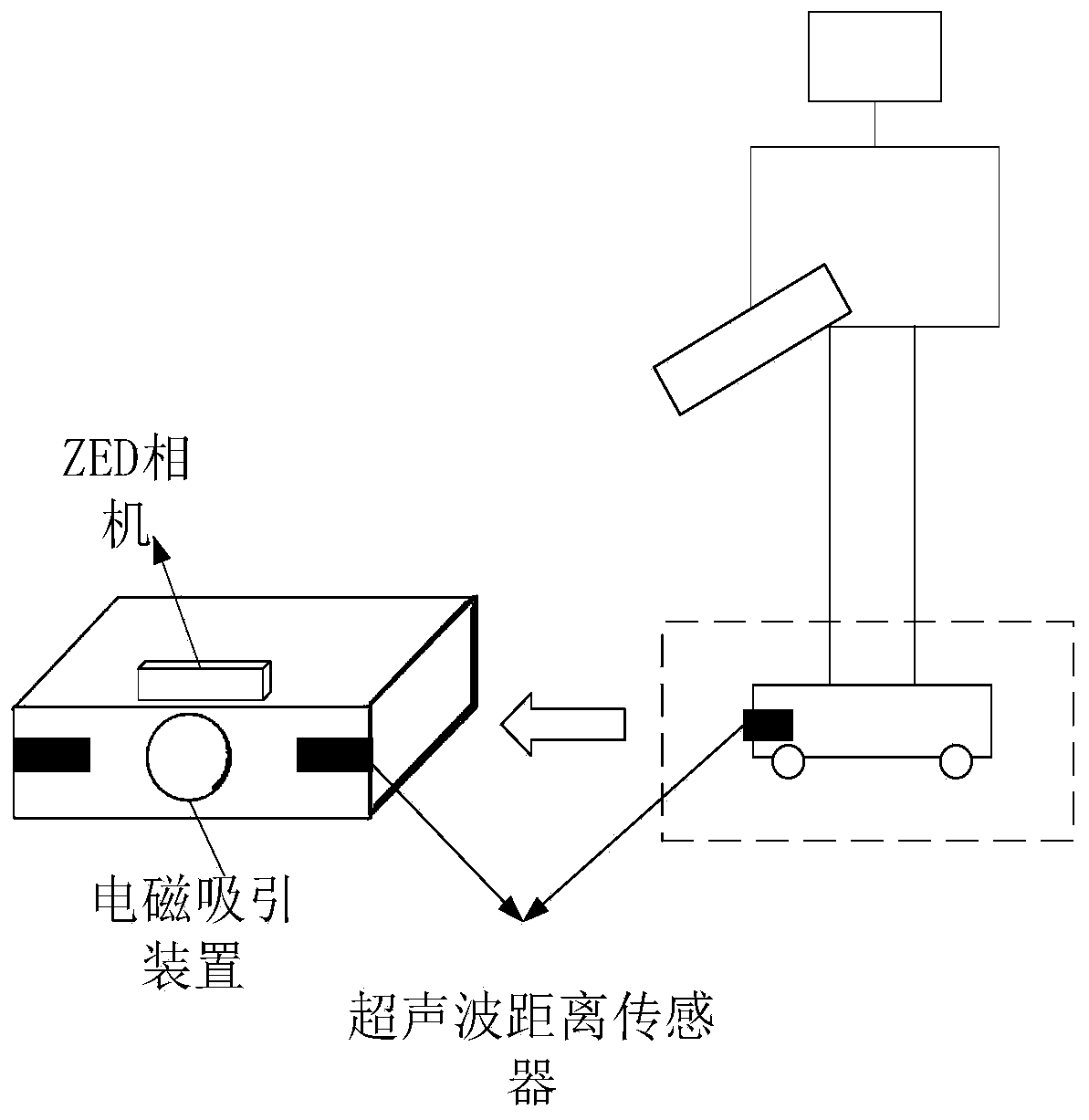

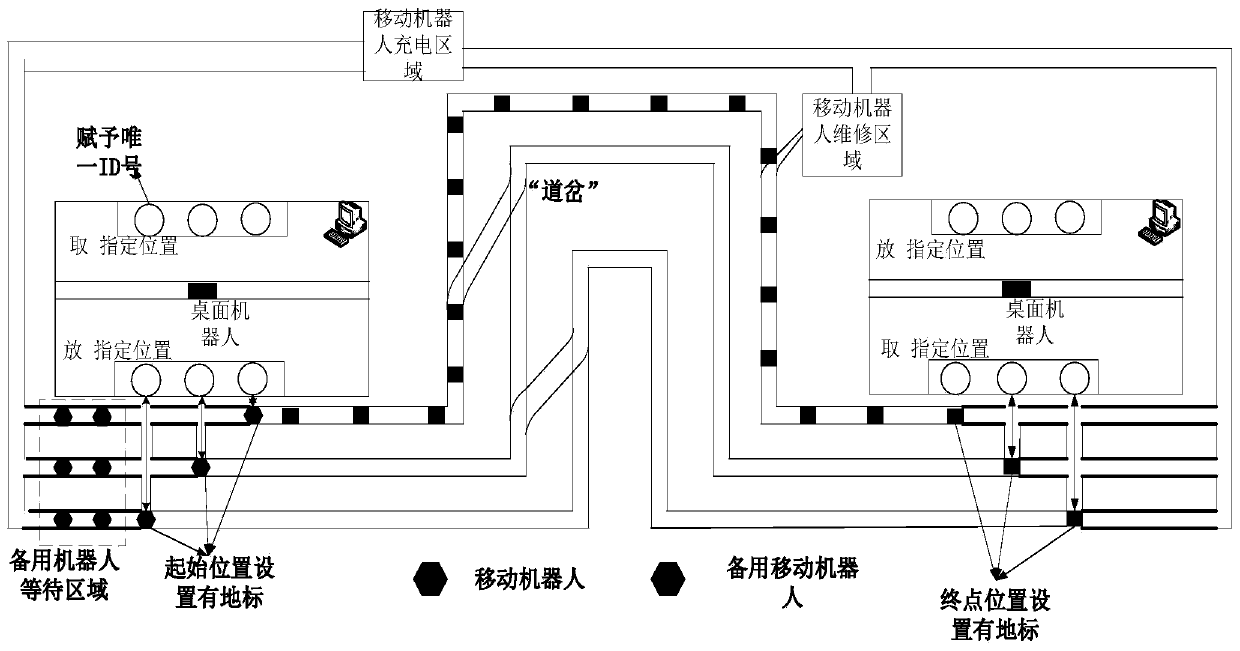

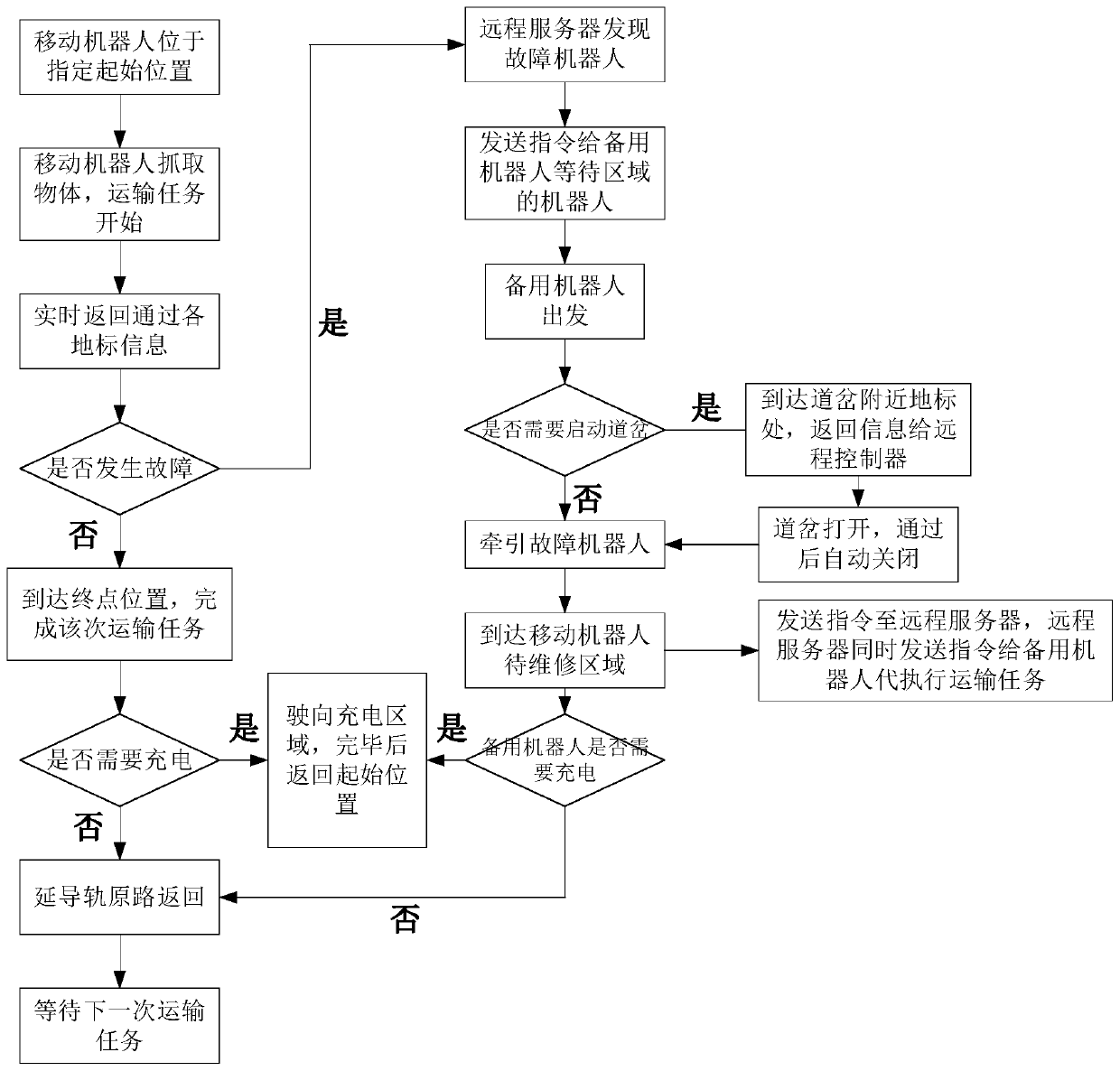

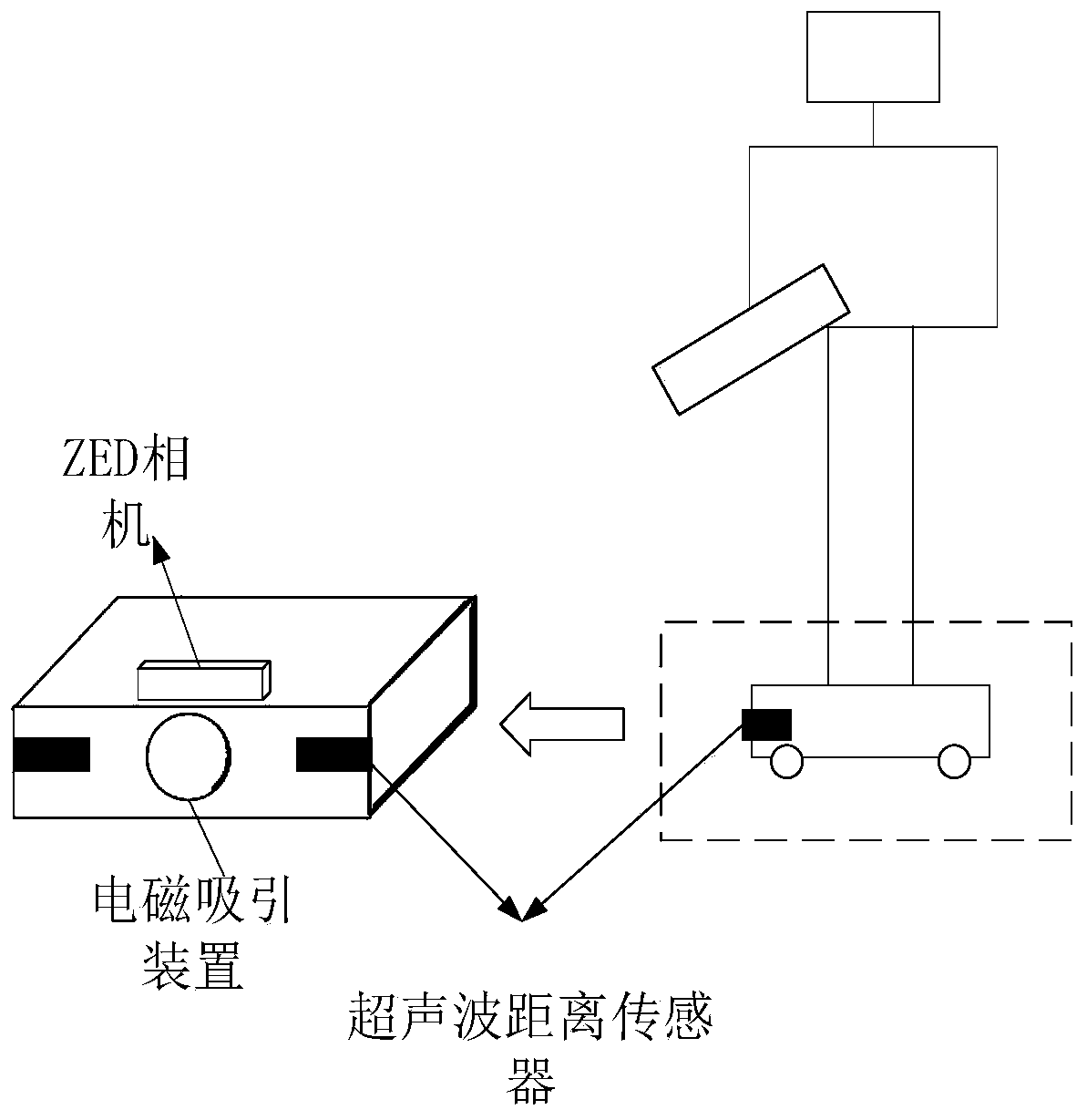

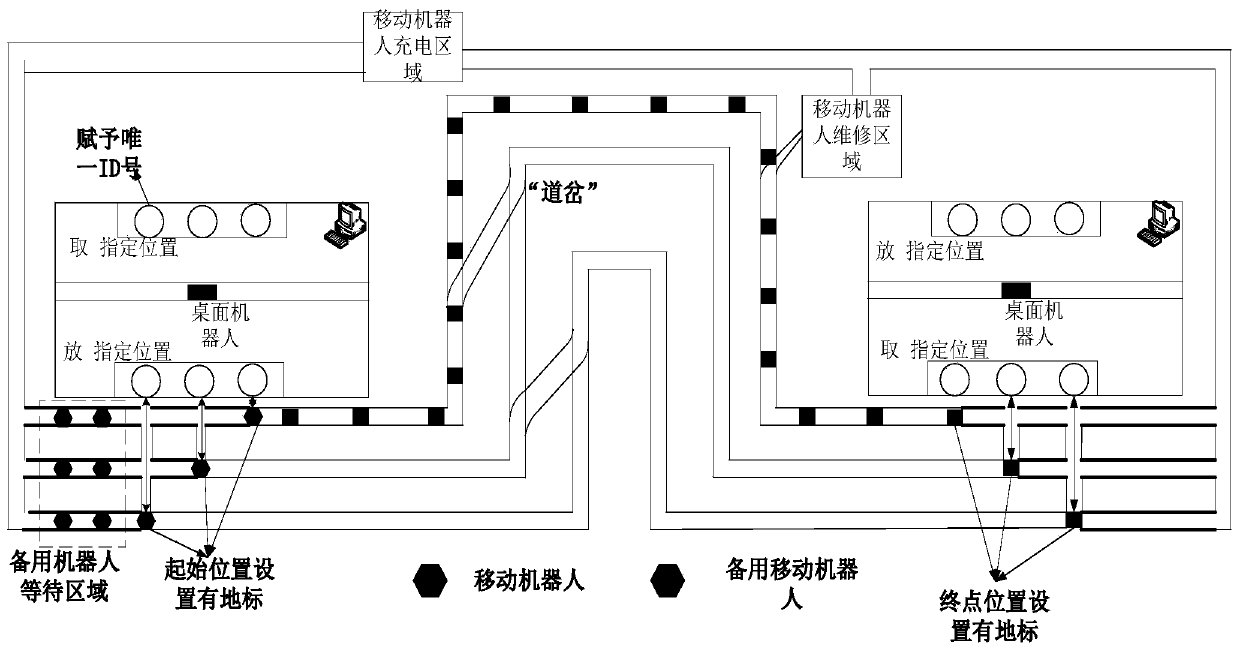

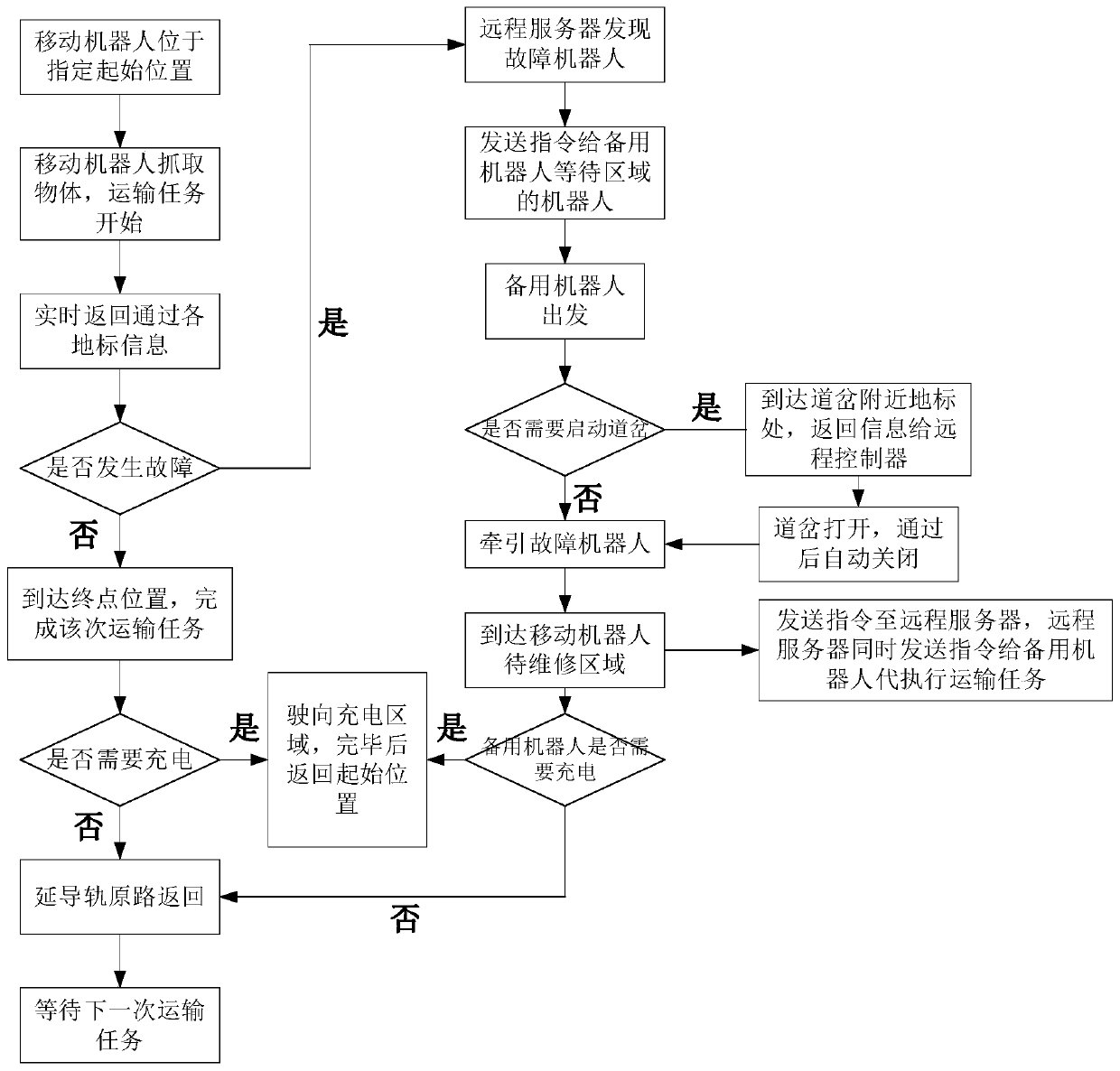

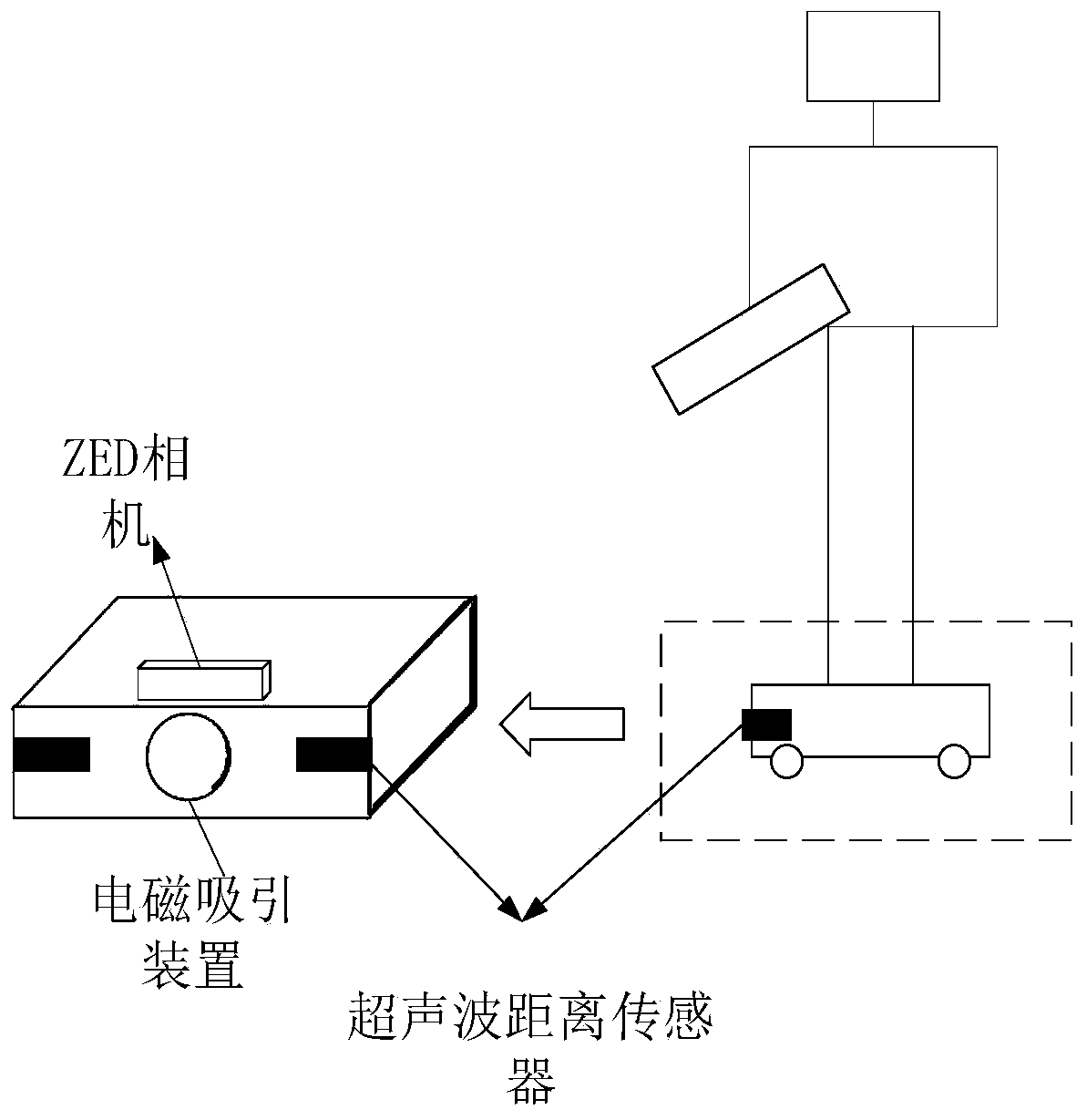

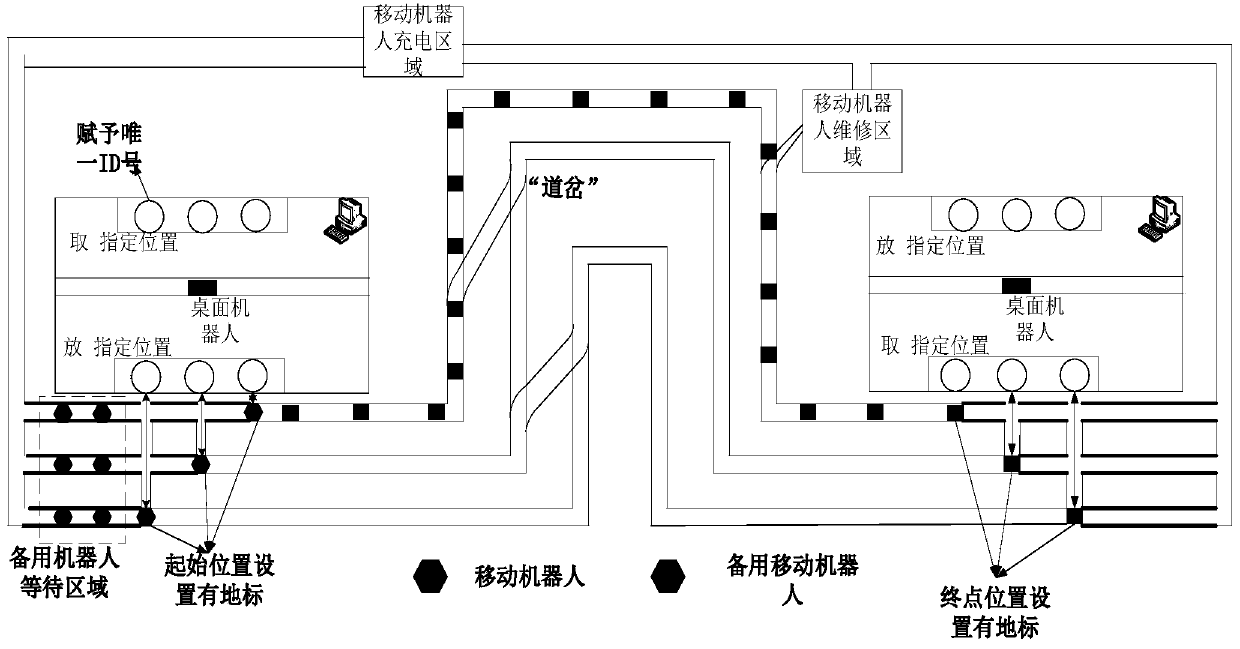

Automatic guide rail carrying device and robot cooperative carrying method and system

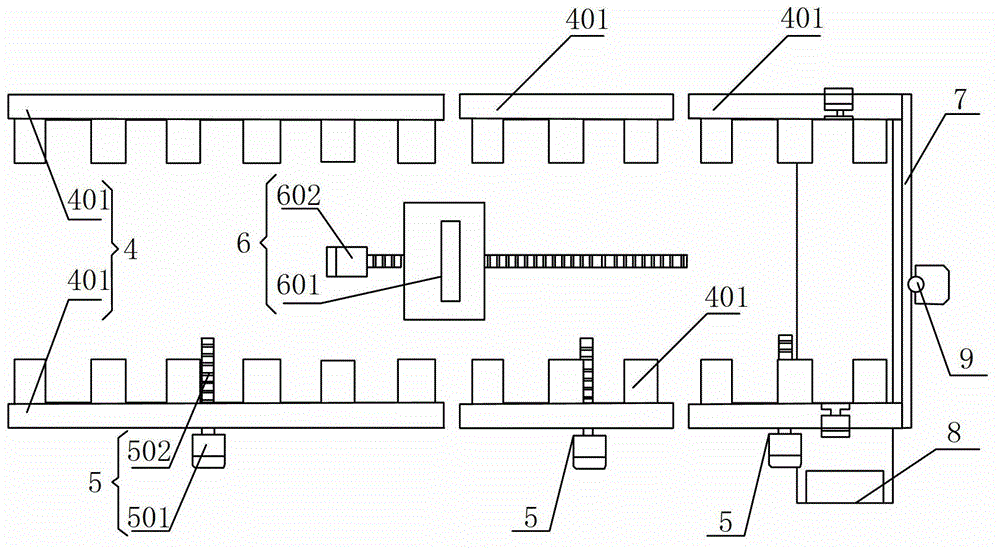

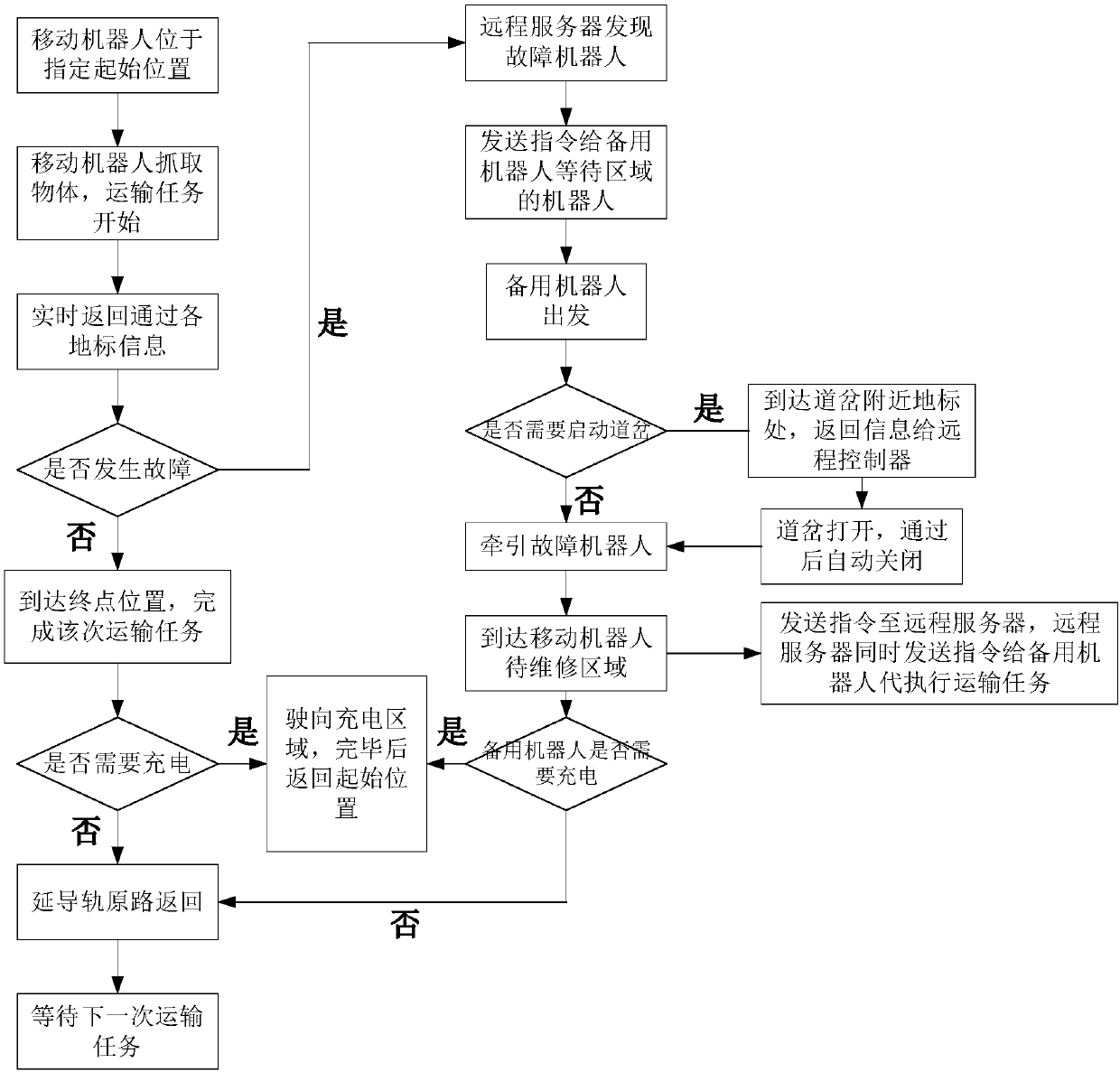

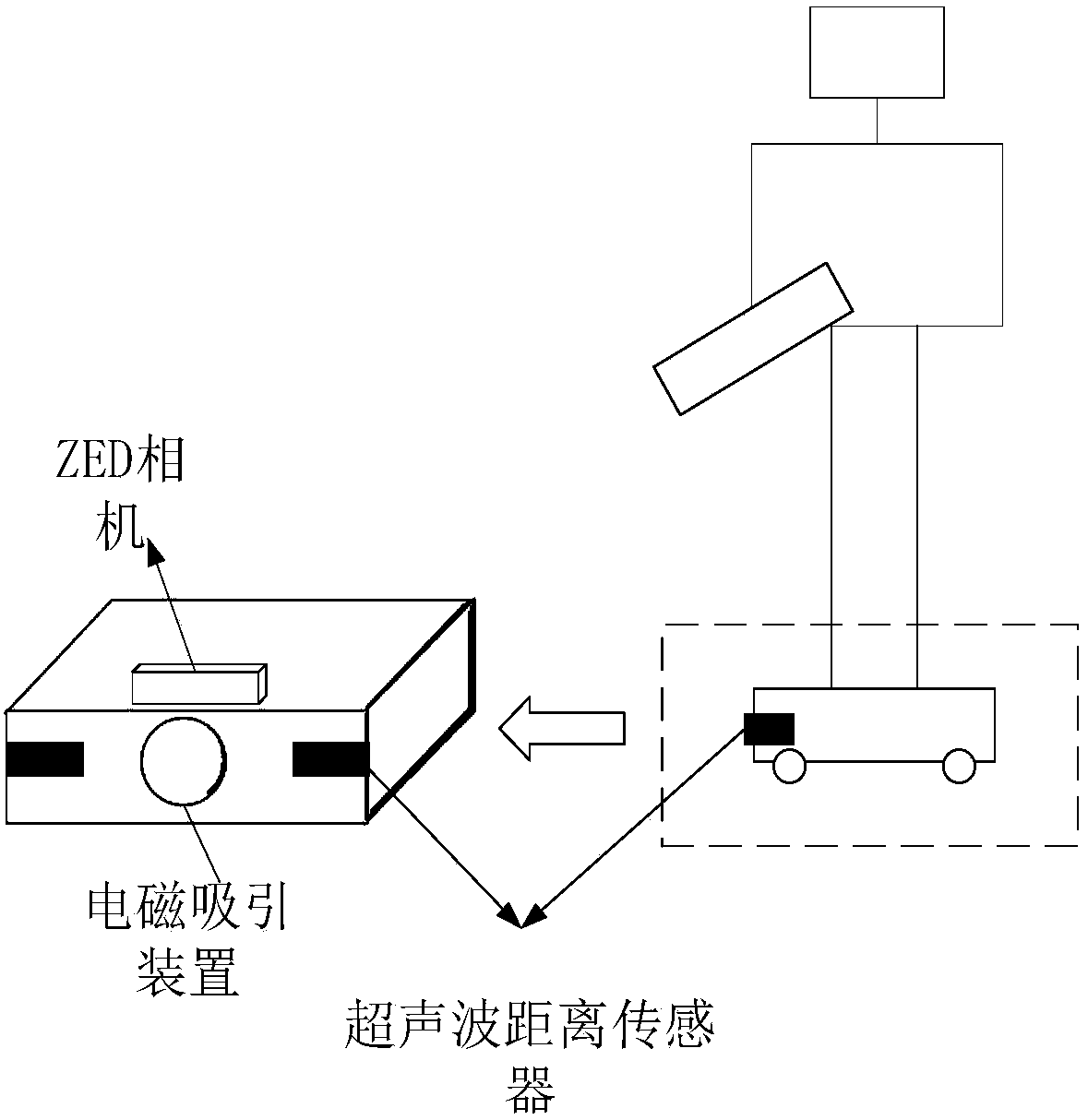

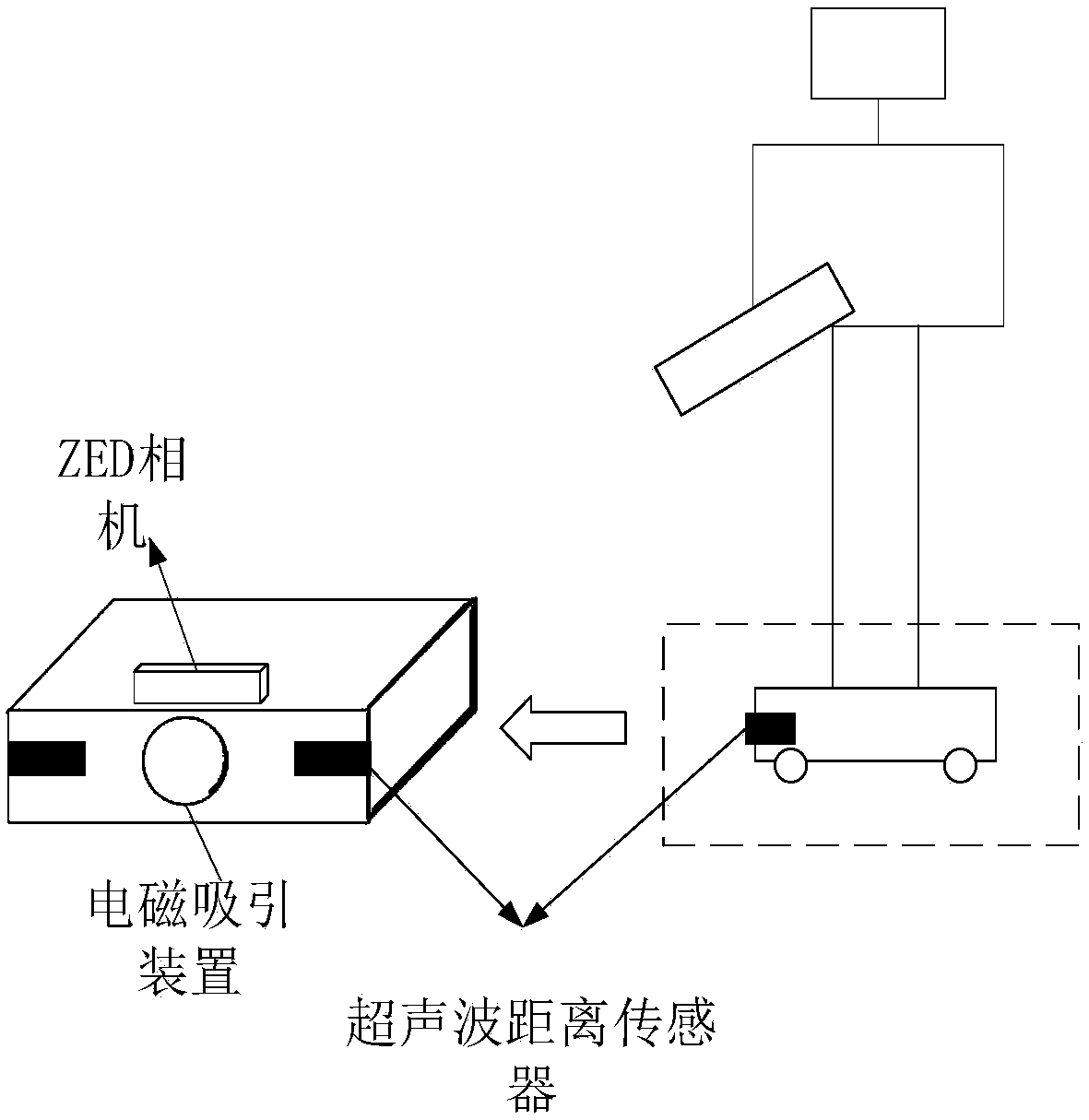

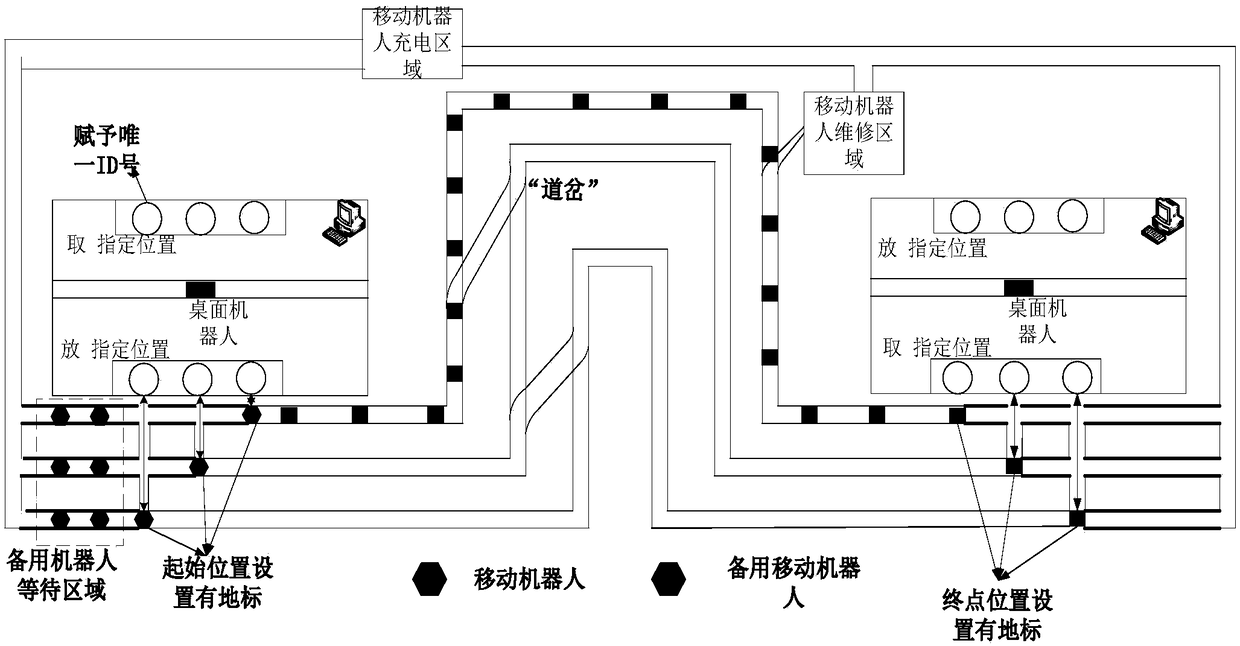

ActiveCN108287548ACarrying outLow failure rateBiological neural network modelsMachine learningControl theoryLandmark

The present invention discloses an automatic guide rail carrying device and robot cooperative carrying method and system. The method comprises the following steps of: the step 1: arranging a ground guide rail arranged between workbenches from a transportation starting point and a transportation end point and guide rails arranged on the workbenches, and arranging a landmark on the ground guide rail; the step 2: grabbing an object from an object-fetching assigned position by a desktop robot located on an object-fetching workbench; the step 3: allowing a mobile robot to move through the ground guide rail and grab an object to the other workbench; the step 4: after a desktop robot located on an object-put workbench grabs the object, moving the desktop robot to an object-put assigned position of the object-put workbench; and the step 5: combining an extreme learning machine and a wavelet neural network to establish an electric quantity prediction model to perform decision of the next motionof the mobile robot. The automatic guide rail carrying device and robot cooperative carrying method and system complete timing and fixed-point transportation of industrial laboratory objects throughcooperation of the desktop robot and the mobile robot so as to achieve round-the-clock transportation of the industrial laboratory.

Owner:CENT SOUTH UNIV

Intelligent lab robot delivery method and system

ActiveCN107992061ACarrying outEfficient and accurate deliveryPosition/course control in two dimensionsMobile robotFixed time

The invention discloses an intelligent lab robot delivery method and system. The method comprises the following steps: step 1, arranging a ground guiding rail between workbenches where transportationstarting point and end point are located and arranging a table board guiding rail on the work bench; step 2, making a table board robot of an article taking workbench grab an article from the appointed article taking position of the article taking workbench; step 3, making a movable robot move along the ground guiding rail and grab the article to transport the article to the other workbench; step4, after the table board robot on an article accommodating workbench grabs the article, moving the article to the appointed accommodating position of the article accommodating workbench and finishingtransporting the article among the workbenches. By means of cooperation between the table board robot and a movable robot, fixed-time fixed-point transportation of the lab articles can be automatically finished; the table board robot is in charge of taking and putting the articles in a short distance, and the movable robot can utilize the guiding rail and a landmark to finish long-distance transportation of the articles; by means of arranging a matched charging area, automatic round-the-clock transportation of a lab is achieved.

Owner:CENT SOUTH UNIV

Distributed environment robot and vehicle moving interconnection carrying method and system

ActiveCN108280518ACarrying outRealize transportationNeural learning methodsVehiclesProportion integration differentiationInterconnection

The invention discloses a distributed environment robot and vehicle moving interconnection carrying method and system. The method includes the steps: firstly, arranging guide rails between a worktableof a transportation start point and a worktable of a transportation end point and on the worktables, and arranging landmarks on ground guide rails; secondly, grabbing objects from an object taking designated position by a table top robot positioned on an a object taking worktable; thirdly; enabling a moving robot to move along the ground guide rails and grab and transport the object to the otherworktable; fourthly, enabling a tabletop robot positioned on an object placing worktable to grab and move the an object to an object placing designated position of the object placing worktable; fifthly, building an electric quantity prediction model to decide next action of the moving robot by combining an extreme learning machine with a PID (proportion integration differentiation) neural network.The table top robot and the moving robot are cooperated, transportation of objects in an industrial laboratory is achieved at regular time and place, and all-weather transportation in the industriallaboratory is achieved.

Owner:CENT SOUTH UNIV

AGV logistics carrying system and control method thereof

PendingCN109782761AAchieve deliveryImprove stabilityPosition/course control in two dimensionsLogistics managementEngineering

The invention discloses an AGV logistics carrying system and a control method thereof. The AGV logistics carrying system comprises a carrying trolley and a guiding unit. A control unit, a driving unit, a magnetic navigation signal sensor and an RFID reader are installed on the carrying trolley, the control unit is connected with the driving unit, the magnetic navigation signal sensor and the RFIDreader, and the guiding unit comprises a guiding magnetic stripe and an RFID tag. The magnetic navigation sensor acquires a magnetic field signal of the guide magnetic stripe, and the magnetic field signal is processed by the control unit to control the driving unit to drive the carrying trolley to track and run along the guide magnetic stripe; the RFID reader transmits read RFID label data to thecontrol unit, and the control unit controls the speed and direction of the carrying trolley according to the data, so that the carrying trolley accurately reaches an appointed position, and materialtransportation is realized.

Owner:北京华晟经世信息技术股份有限公司

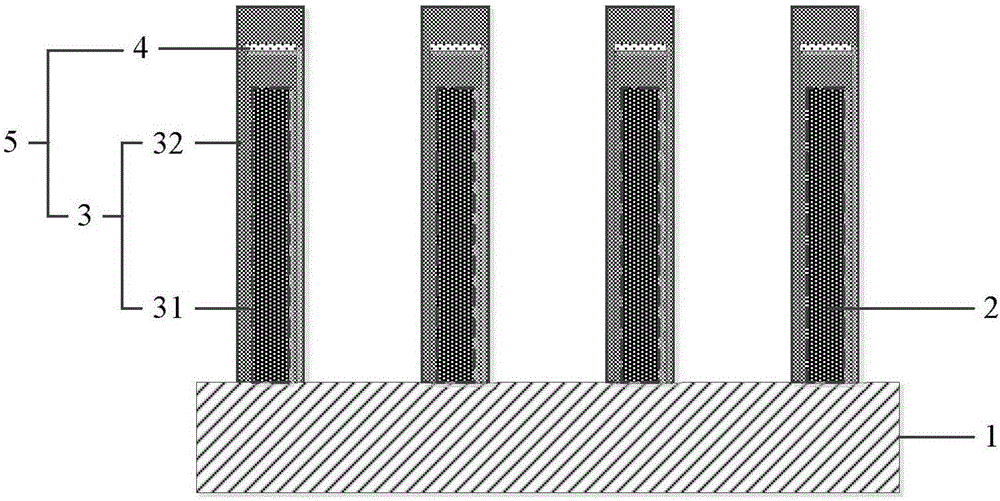

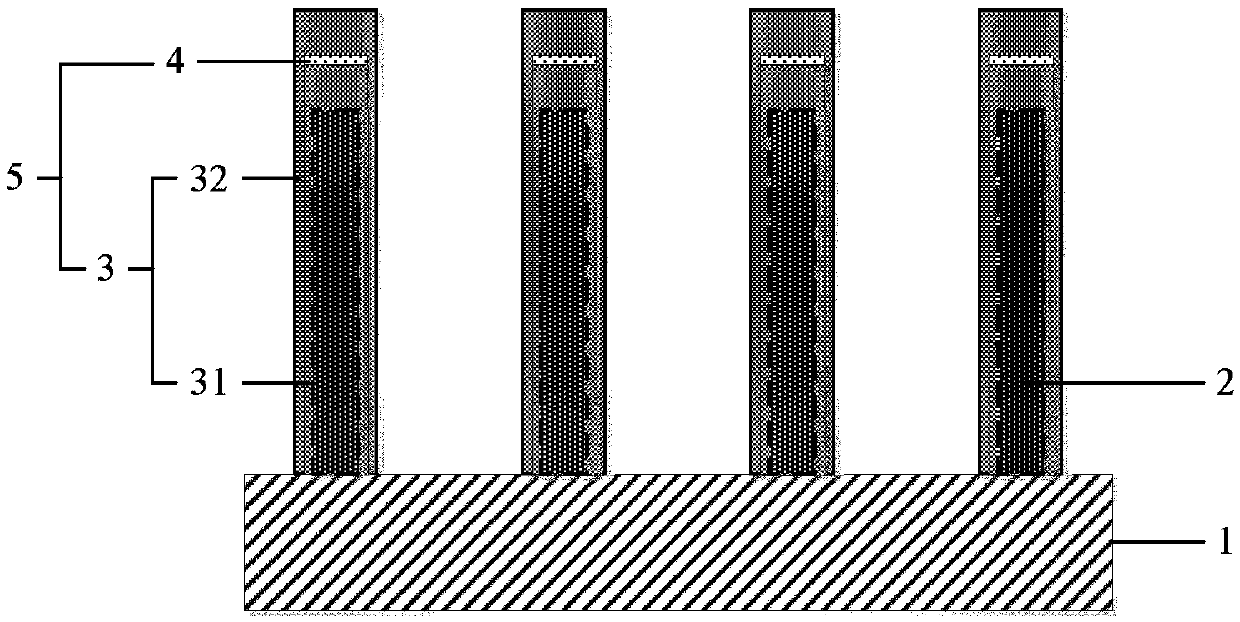

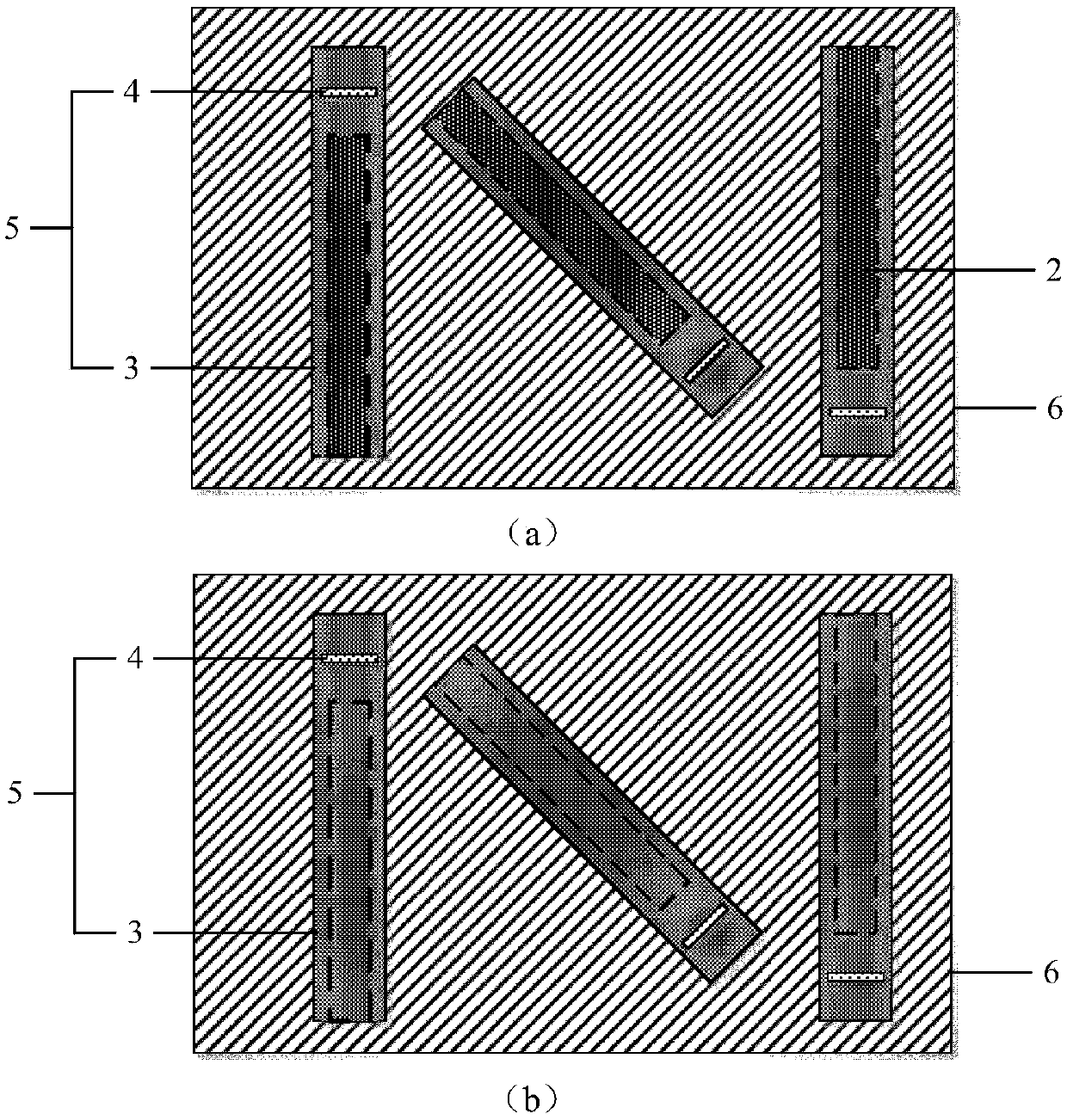

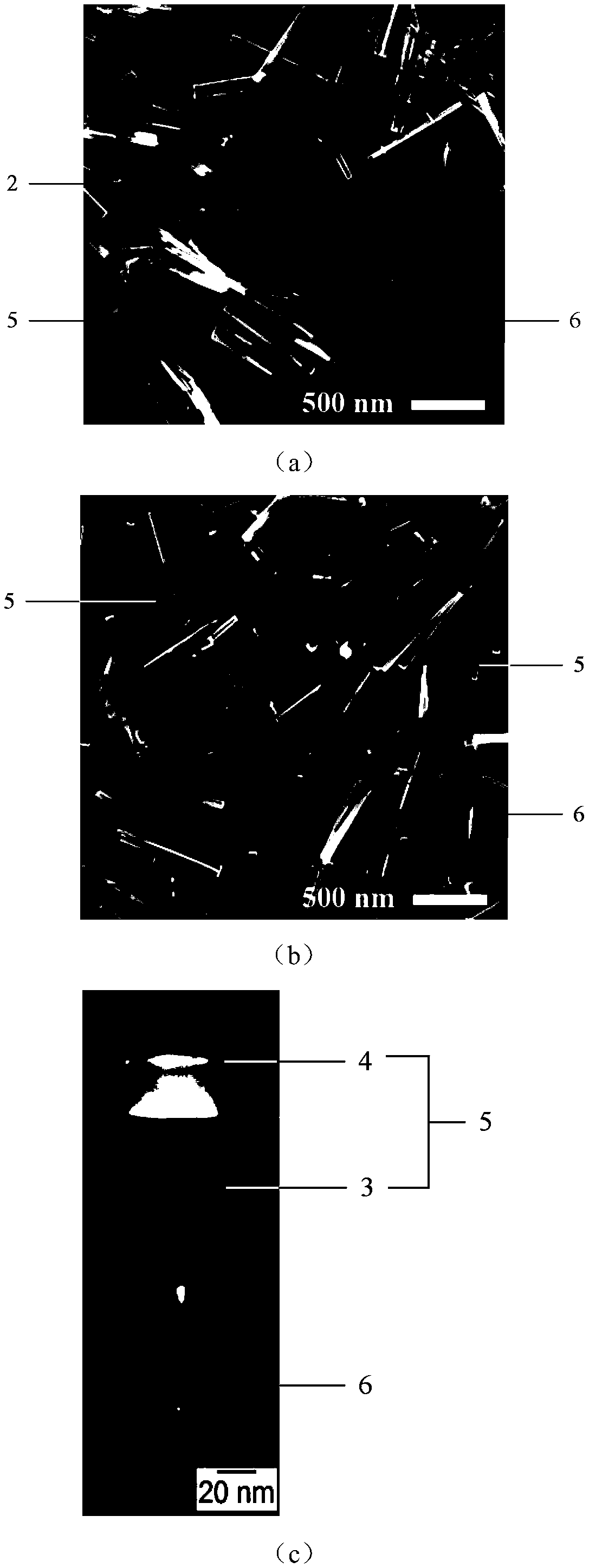

Nanotube-based fluorescence marked carrier and preparation method thereof

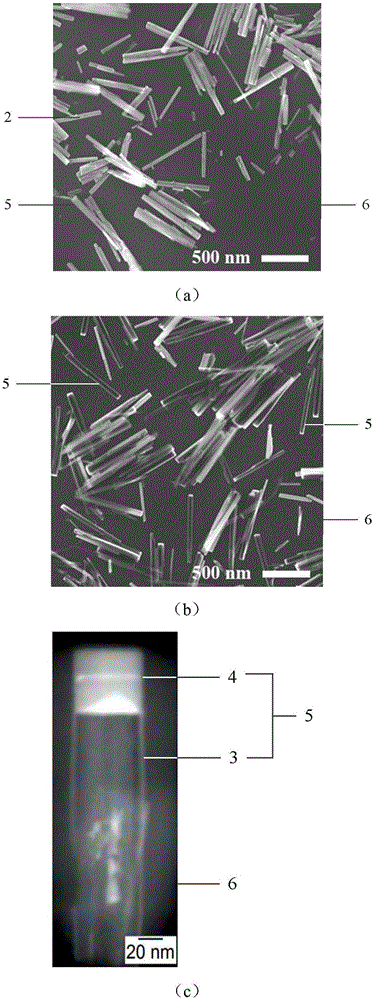

ActiveCN106680252AImprove alloy orderEnsuring efficient radiative recombinationFluorescence/phosphorescenceBroad spectrumSemiconductor

The invention discloses a nanotube-based fluorescence marked carrier and a preparation method thereof. The fluorescence marked carrier comprises a nanotube inner wall, a quantum structure and a nanotube outer wall. The size of the nanotube structure is designed according to the characteristics of a simulated carrying object, and the size of the nanotube structure is regulated and controlled accurately by controlling the growth condition; in the fixed-temperature annealing process, a nanowire in a core-shell structure is guaranteed to be decomposed completely and the quantum structure limited between the nanotube inner wall and the nanotube outer wall is not damaged; the fluorescence marked part of the nanotube adopts a semiconductor quantum structure, has high fluorescence intensity, long duration time and stable photochemical property, is insusceptible to photobleaching and realizes high-efficiency radiative recombination; furthermore, continuous broad spectrum excitation can be adopted, the absorption coefficient is big, fluorescence emission peak is narrow, wavelength trailing is avoided, and the distinguishing degree is high; the nanotube structure can realize fluorescence marked carrying of the carrying object in the tube and also can perform the traditional wrapping or combined type fluorescence marked carrying.

Owner:PEKING UNIV

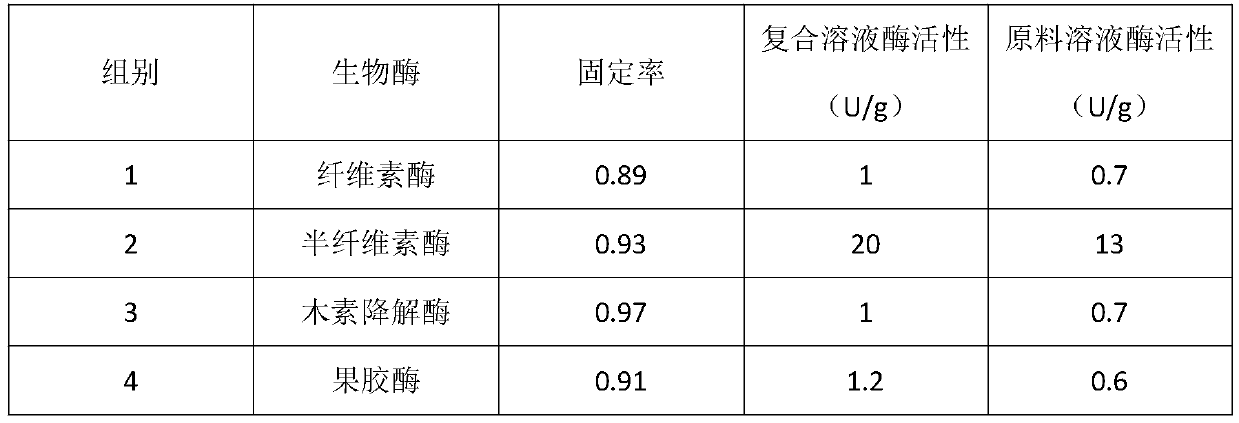

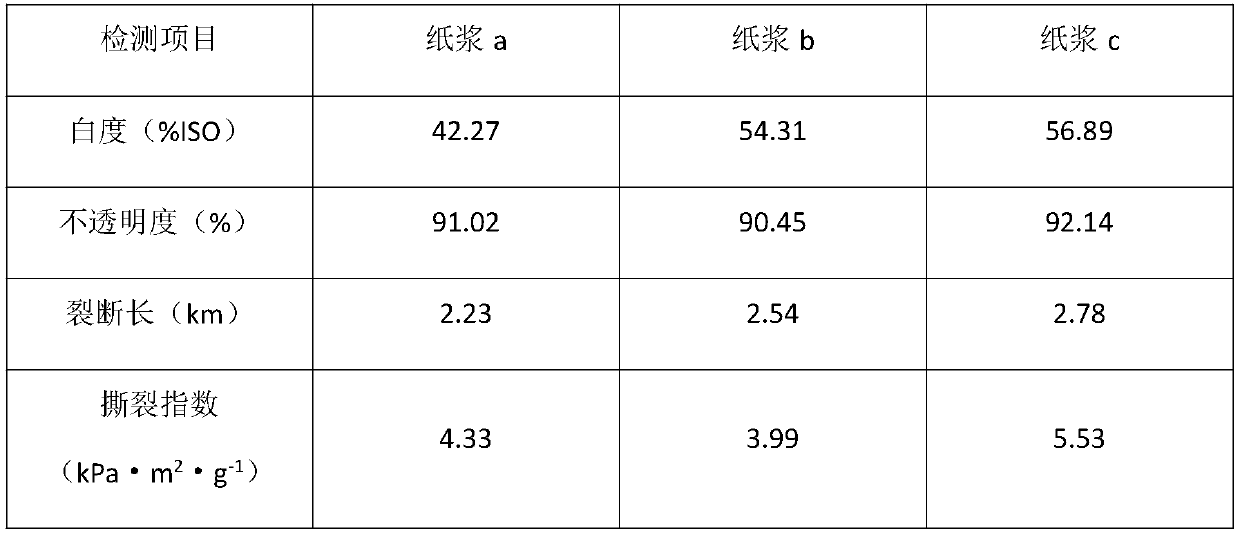

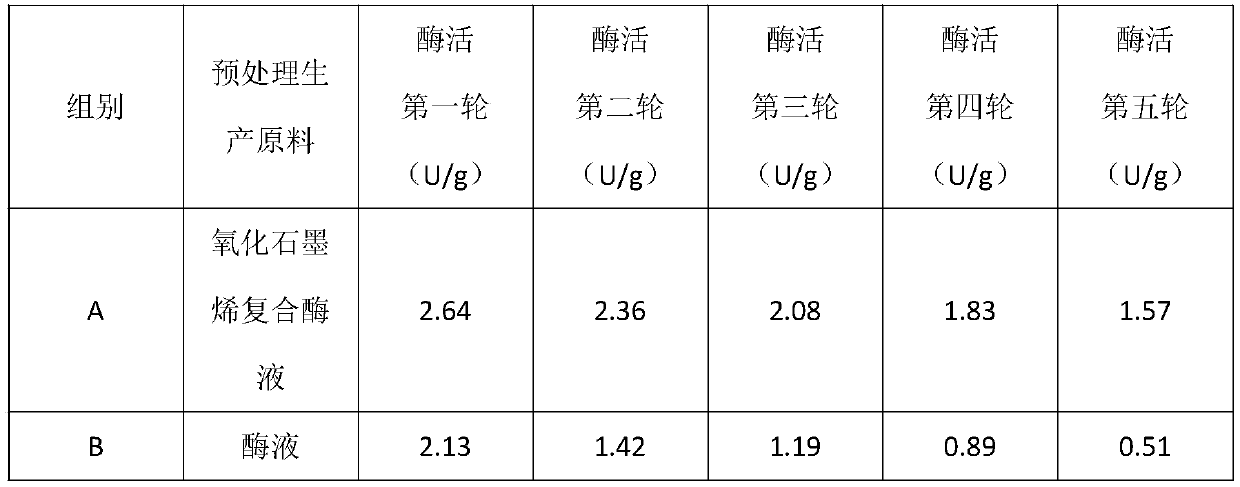

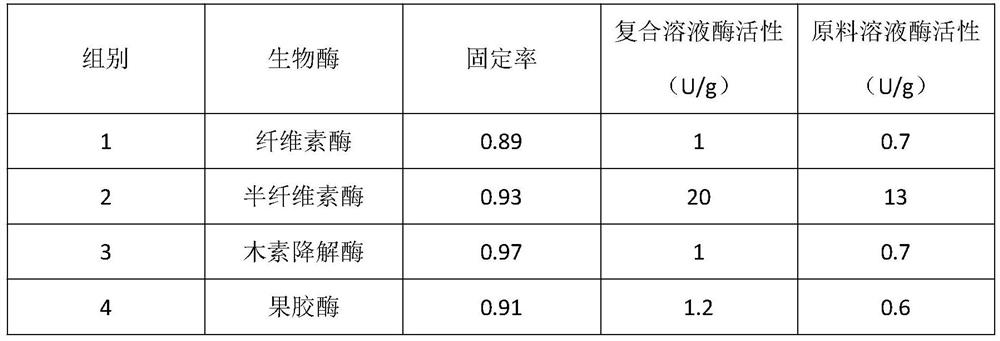

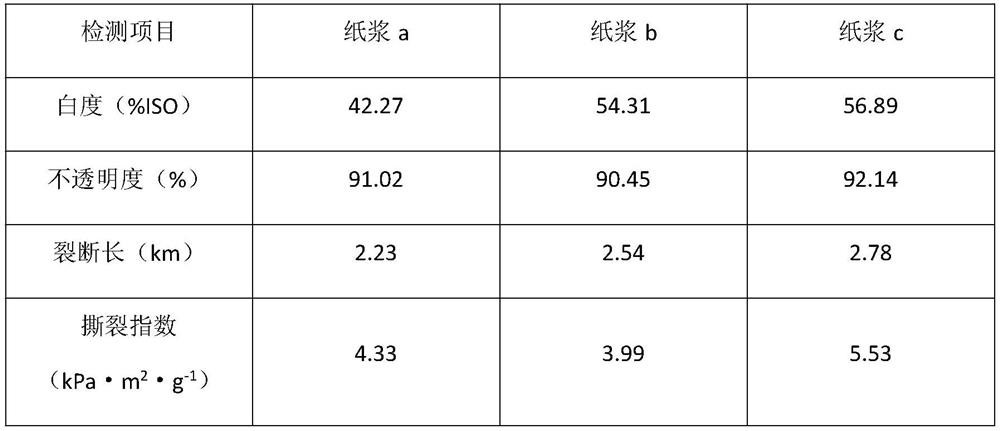

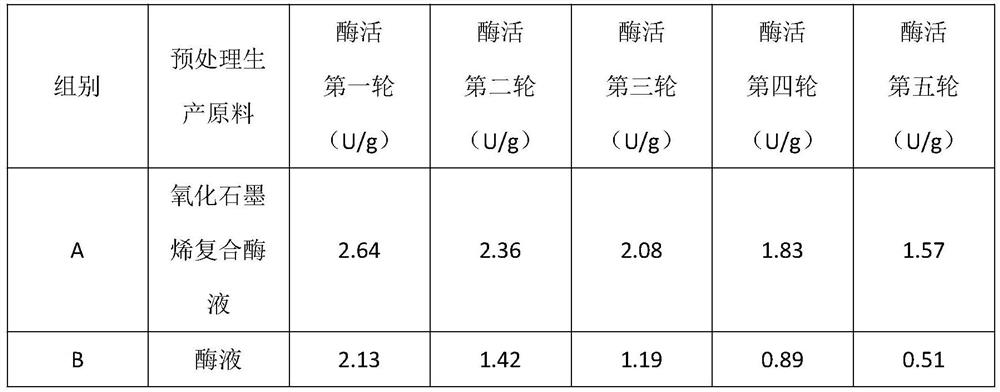

Compound enzyme for preparing pulp, and preparation method and use method of compound enzyme

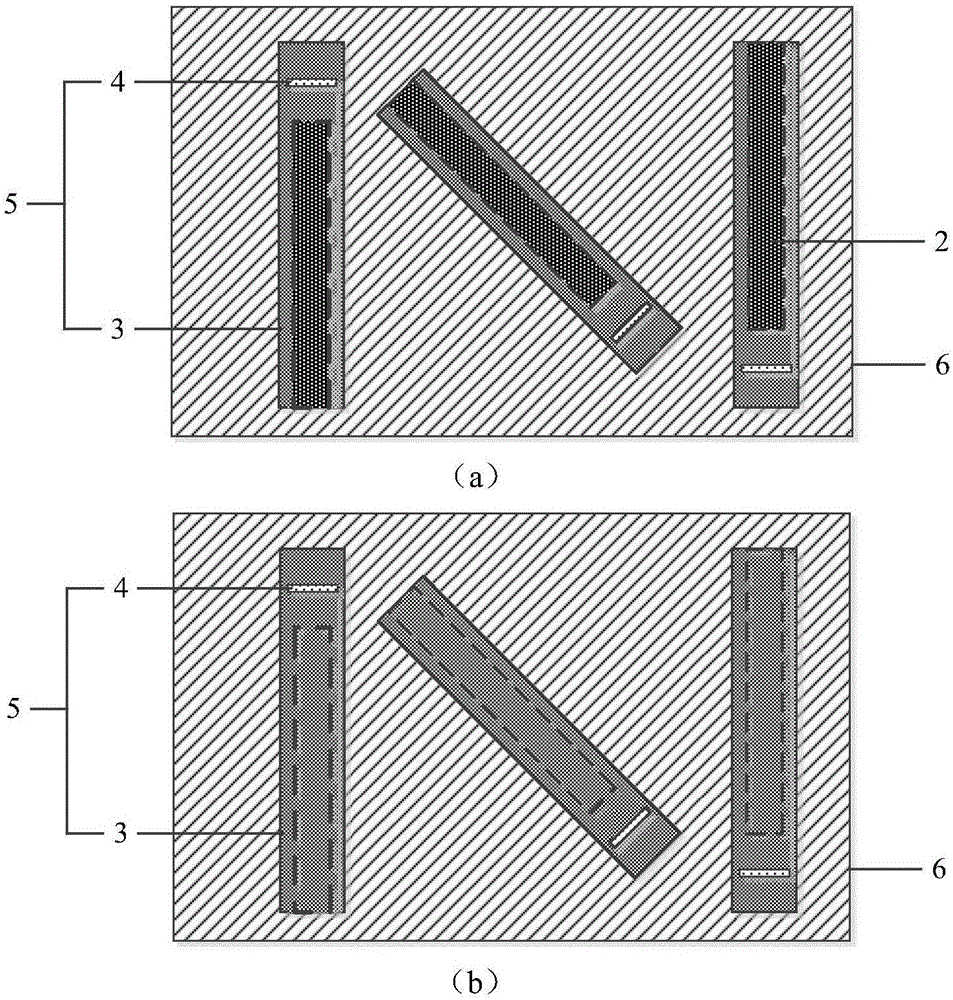

ActiveCN109881520AEffectively fixedHigh activityPaper material treatmentPectinaseBiocompatibility Testing

The invention provides a compound enzyme for preparing pulp. The compound enzyme comprises an enzyme carrier and a bio-enzyme, the enzyme carrier is graphene oxide, the bio-enzyme is one or more of cellulase, hemicellulase, ligninase and pectinase, and the bio-enzyme is fixed to the enzyme carrier in an adhering mode. By adopting a method, the bio-enzyme can be effectively fixed to the graphene oxide carrier, the high-proportion surface area and good biocompatibility of the graphene oxide are fully utilized, functional groups rich on the surface of the graphene oxide also have the acidic chemical property, and the action of neutralizing alkaline ions in a solution can be achieved, so that the pH value of the local part around the graphene oxide is decreased, thus the bio-enzyme adhering to the surface of the graphene oxide exerts activity advantageously, the bio-enzyme is fixed by the graphene oxide, most of the bio-enzyme remains in a liquid environment so as to be secondarily utilized, the utilization efficiency of the bio-enzyme is improved, and production waste is reduced.

Owner:秾源科技(北京)有限公司

Method for Constructing Nutrient Nano-carrying System Directly Using Ordinary Food

ActiveCN102266059ACarrying outImprove stabilityDough treatmentFood preparationSolid-state storageMass ratio

The method of directly using ordinary food to construct a nutrient nano-carrying system is characterized by: (1) mixing food raw materials with a lipid content of less than 12% and nutrients at a mass ratio of 4-200:1, and then performing nano-processing, so that the particle diameter The distribution peak is below 600nm; (2) In the solution system, the concentration of the solution is adjusted to 0.5%-55% based on the quality of nano-food, and then the pH is adjusted to 2.2-13, and the ionic strength is converted to a sodium ion concentration of 0.001mol / L to 5mol / L, adopt ultrasonic oscillation of 0-65W / cm2, the temperature is 0-85°C, after 1-48 hours of aggregation process; or, in the solid state, control the temperature at 0-230°C and the pressure at 0.05-4MPa, The relative humidity is 0-100%, after 2-80 hours of accumulation; (3) Vacuum packaging, storage at room temperature or low temperature. The present invention wraps nutrients in nano-food clusters to realize the delivery of nutrients, improves stability, can be stored in liquid or solid state, can reduce or even avoid the degradation of nutrients, and has loose post-processing conditions; Greater improvement.

Owner:杭州纳福载运科技有限责任公司

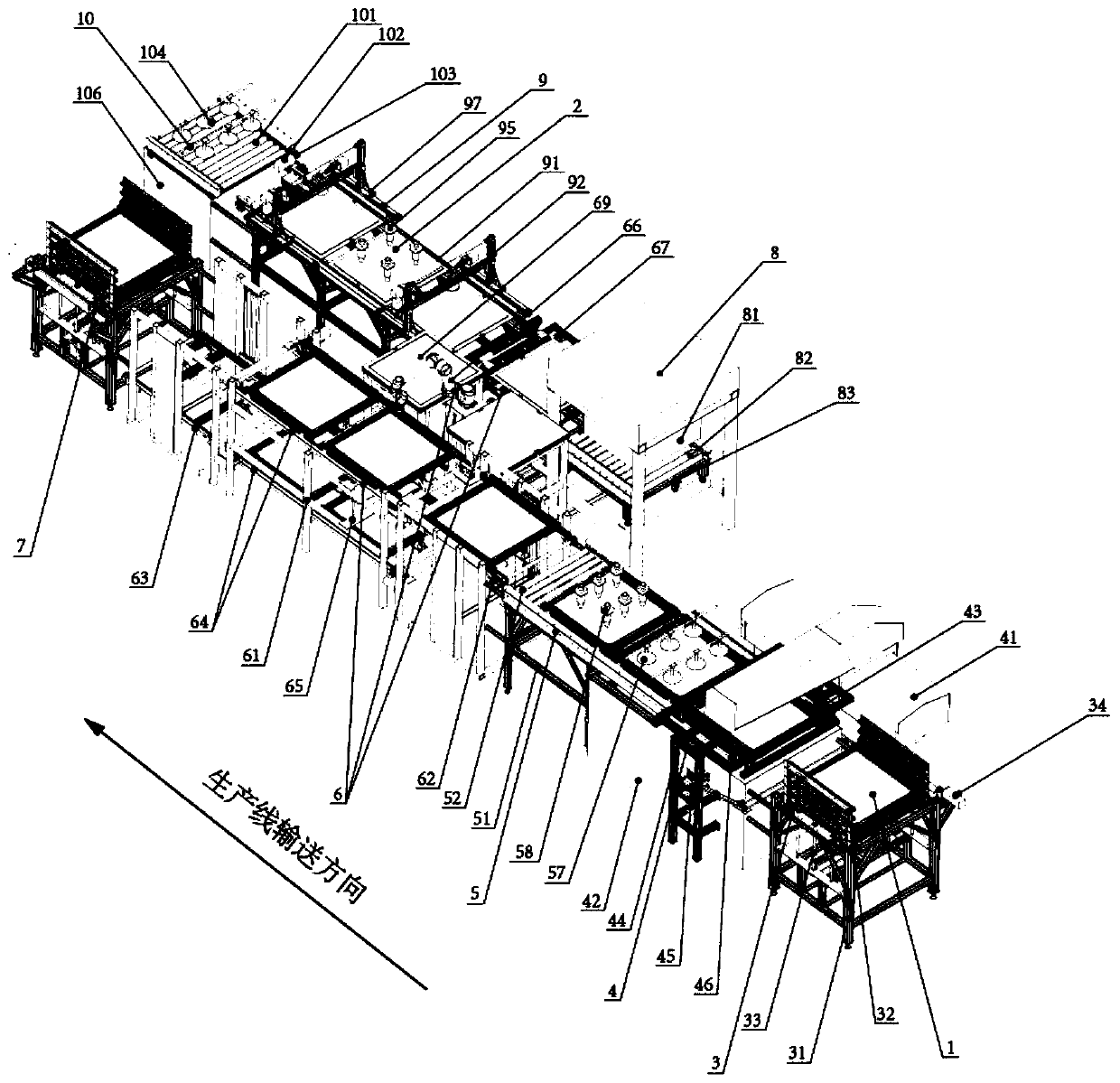

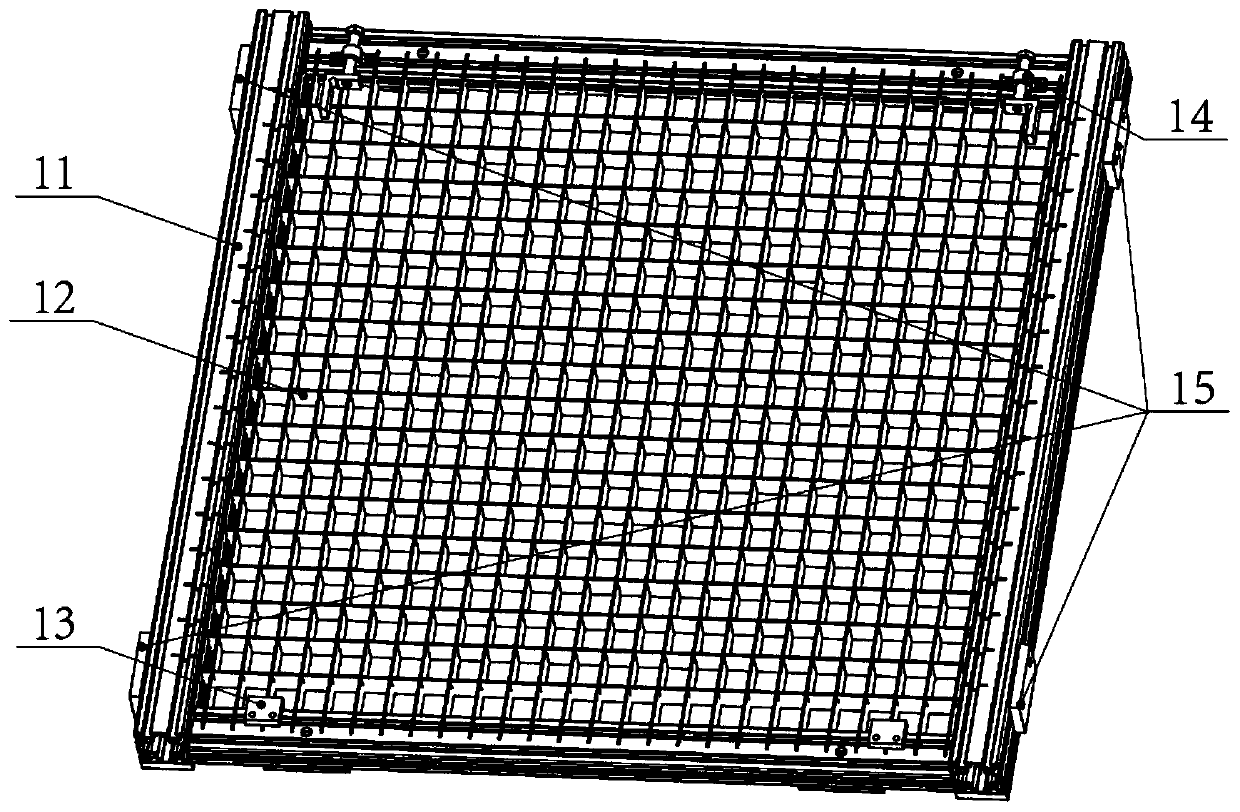

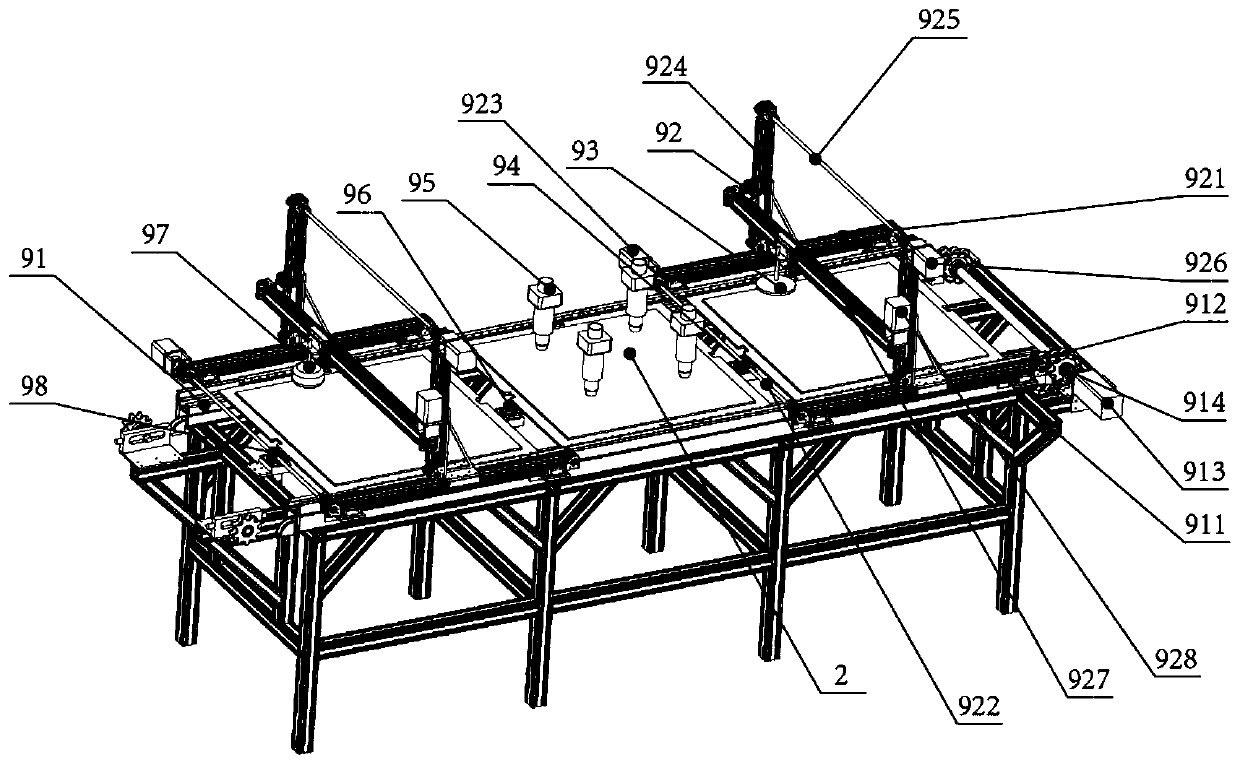

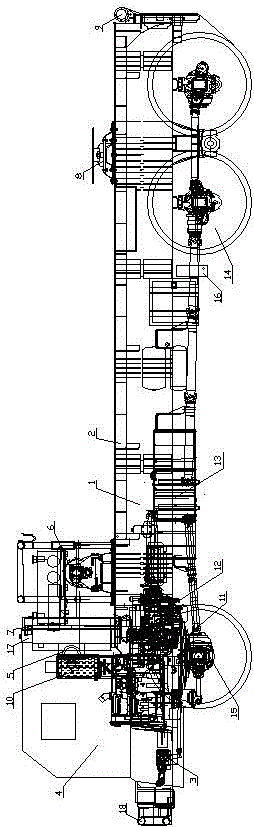

A water jet mosaic automatic production line

ActiveCN107627219BCarrying outAchieve fixationDecorative surface effectsAbrasive machine appurtenancesProduction lineAutomatic control

The invention relates to an automatic production line for water-jet patterning. According to the automatic production line for water-jet patterning, multiple procedures including feeding, cutting, cleaning, drying, patterning, turning, primer coating, flattening and thermo-setting, seam beautifying, polishing and temporary storage of plate spare parts are integrated, and the water-jet patterning process can be achieved automatically. The automatic production line for water-jet patterning comprises an automatic feeding station, a water-jet machining station, a cleaning station before patterning, a drying station before patterning, a patterning gluing station, a seam beautifying station, a drying station after patterning, a polishing station, a cleaning station after patterning, a tool traytemporary storage station, and a flattening and thermo-setting station, wherein the automatic feeding station, the water-jet machining station, the cleaning station before patterning, the drying station before patterning, the patterning gluing station, the seam beautifying station, the drying station after patterning, the polishing station and the cleaning station after patterning are connected insequence, and the tool tray temporary storage station is connected with the patterning gluing station. According to the automatic production line for water-jet patterning, the requirement for automatic control is taken into consideration, the water-jet patterning process can be achieved automatically by additionally arranging an automatic control module and by additionally executing an automaticcontrol procedure, most manual work in the field of traditional water-jet patterning can be replaced, and the automatic production line has a good effect on improving the working efficiency and improving the working environment.

Owner:GUANGDONG UNIV OF TECH +1

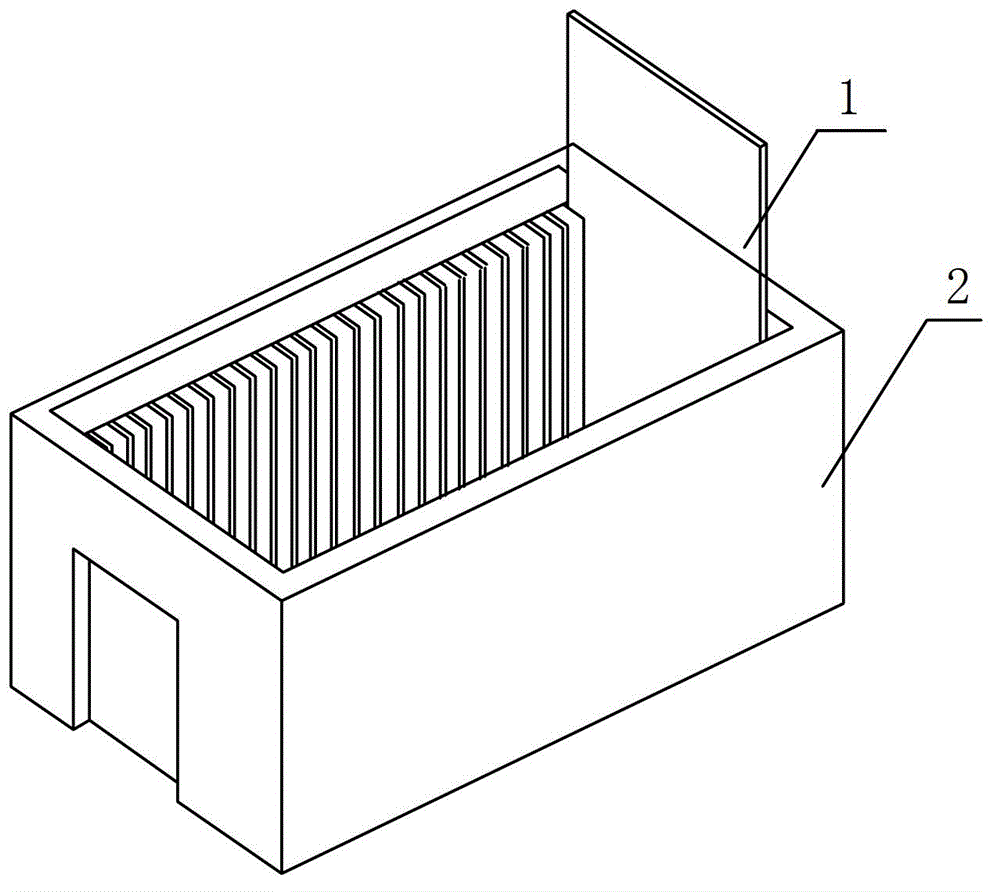

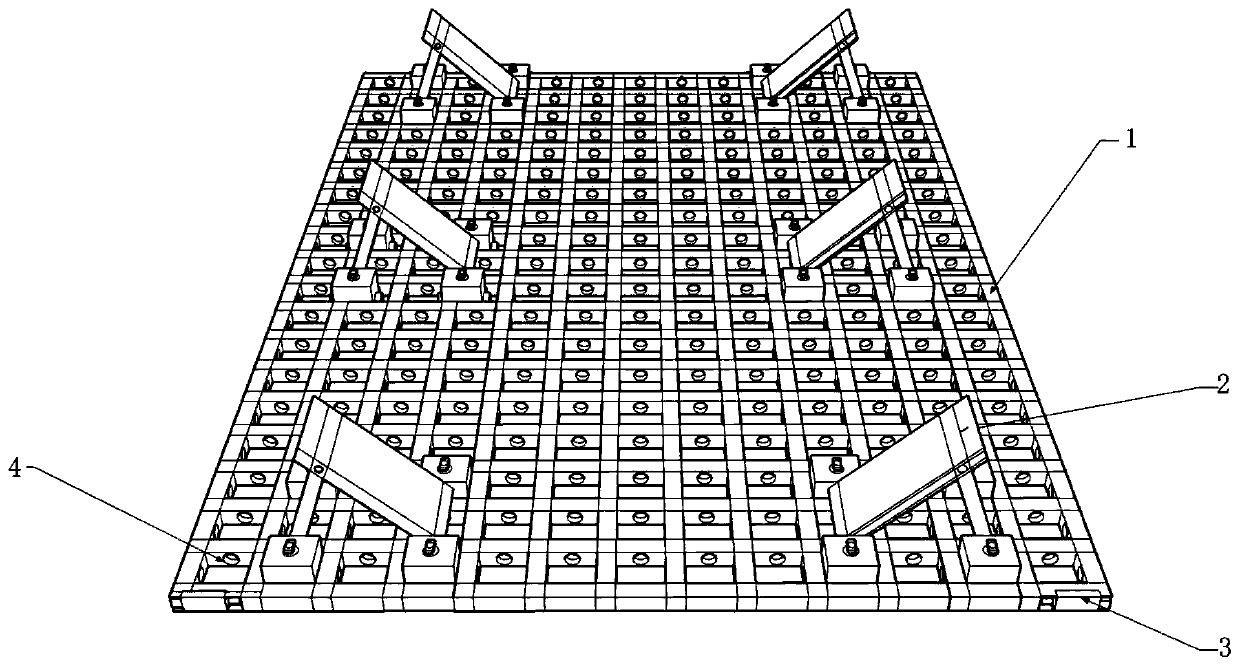

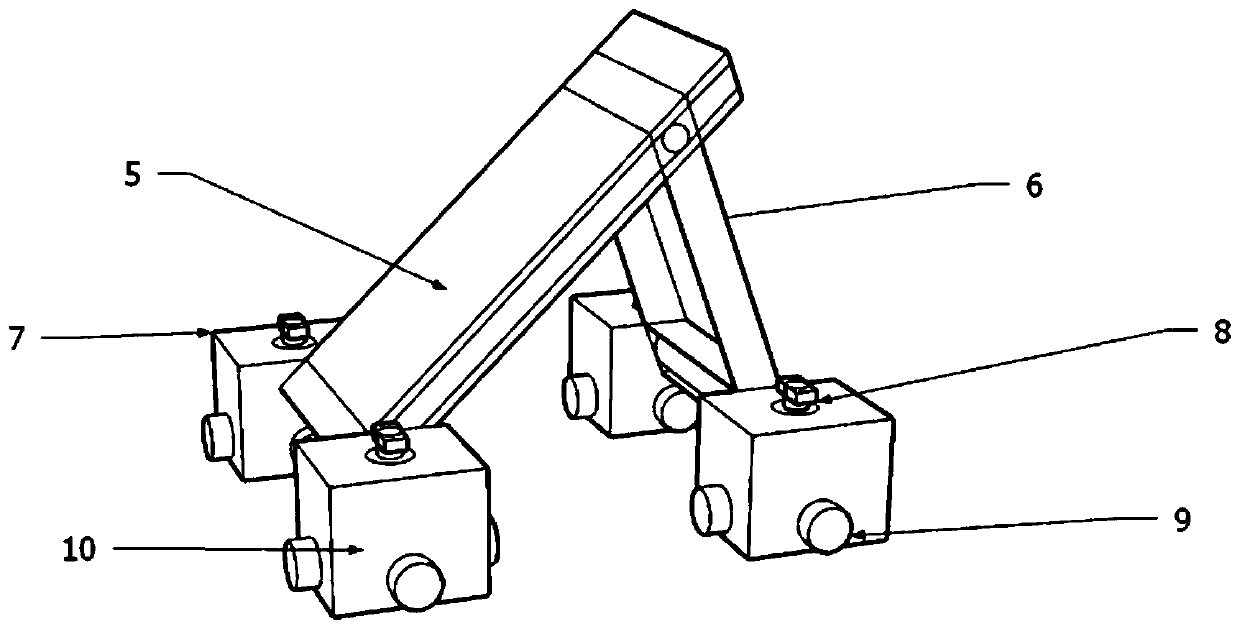

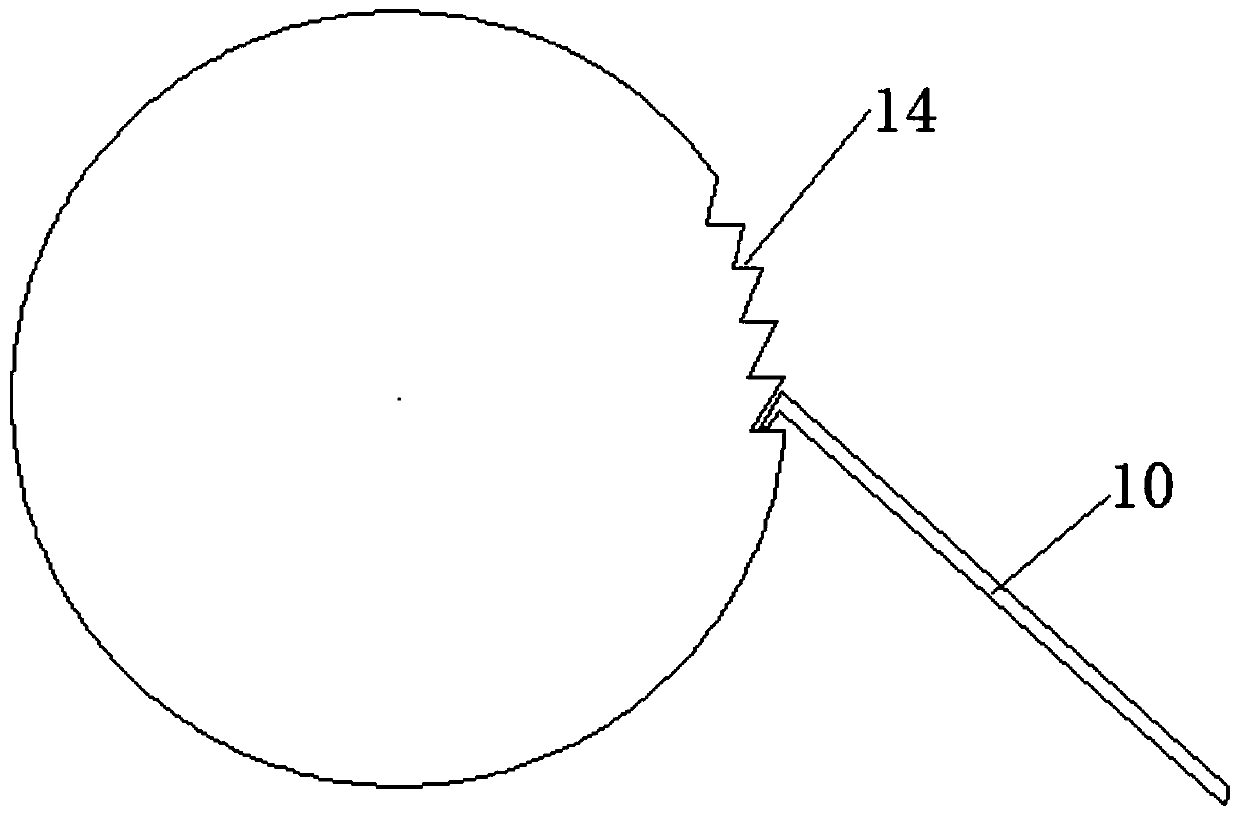

Tray, steel carrying box and steel carrying method

ActiveCN110539952ACarrying outExtended payload rangeLarge containersLoading/unloadingEngineeringMechanical engineering

Owner:SHANDONG JIAOTONG UNIV

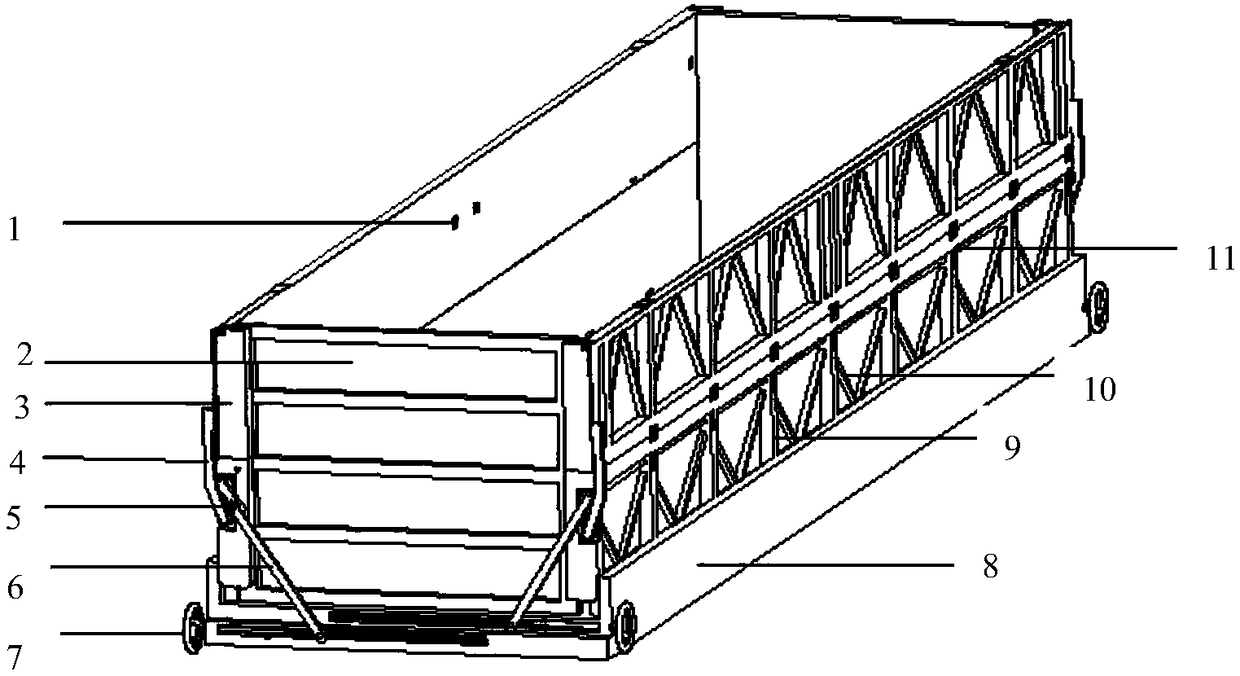

Universal rail flat-open wagon

ActiveCN108238057AImprove substitutionImprove transportation efficiencyAxle-box lubricationWagons/vansEngineeringMechanical engineering

A universal rail flat-open wagon mainly comprises a container lock hole, an end wall, an upper side wall, an upper side wall ejector rod, a gear A, a gear B, a gear C, a lower side wall ejector rod, aball screw, a bottom frame, a lower side wall, diagonal bracings, side columns, a locking device, lock pins, lock rods, a cam, a rotating shaft hole, an end wall lock hole, an end wall rotating shaft, an end wall lock, a handle and a rotary handlebar. The functions of an open wagon and a flat wagon are shared, and granular goods can be transported when the flat-open wagon is used as an open wagon(such as coal transportation, and the work condition of a car dumper can be adapted); and when used as a flat wagon, the flat-open wagon can complete transportation of container flat cars. Vehicle type substitution is enhanced, the empty-wagon walking rate is lowered, and the universal rail flat-open wagon has important significance for improving railway transporting efficiency.

Owner:YANSHAN UNIV

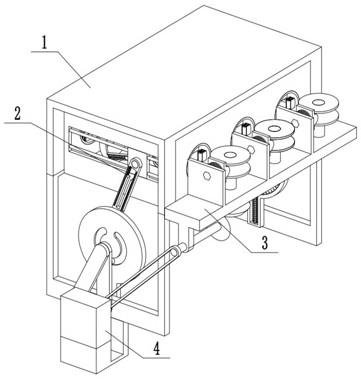

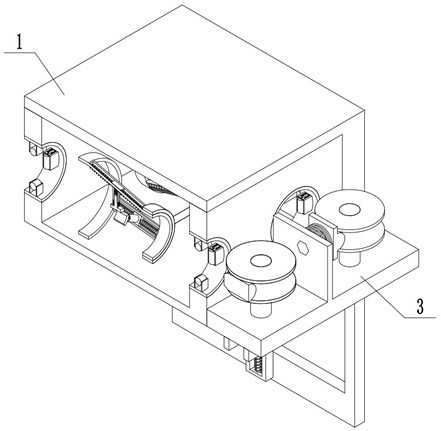

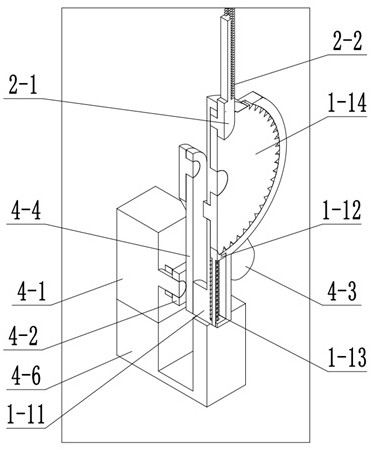

Straightening machine

The invention relates to the field of straightening machines, in particular to a straightening machine which can change the straightening speed. The straightening machine comprises a carrying assembly, a transmission assembly, a straightening assembly and a power assembly, and when an inner end connecting rod moves from left to right, an inner end sliding rod and a steel bar needing to be straightened are in a non-contact state, therefore, the steel bar needing to be straightened is conveyed in one direction from the right side to the left side, and meanwhile, the steel bar needing to be straightened is carried. A turntable is rotated, then the turntable rotates around the swing rod, the relative positions of the connecting positions of the swing rod and the rotated turntable and a transmission sliding rod I are changed, and then the amplitude of the reciprocating motion of a side wall slider driven by a transmission sliding rod II along a side wall sliding column is changed through the disclosed transmission relation, and the carrying speed of the steel bar needing to be straightened is changed through inner end sliding rods, and then the straightening speed of the steel bar needing to be straightened is adjusted.

Owner:河北中重冷轧材料有限公司

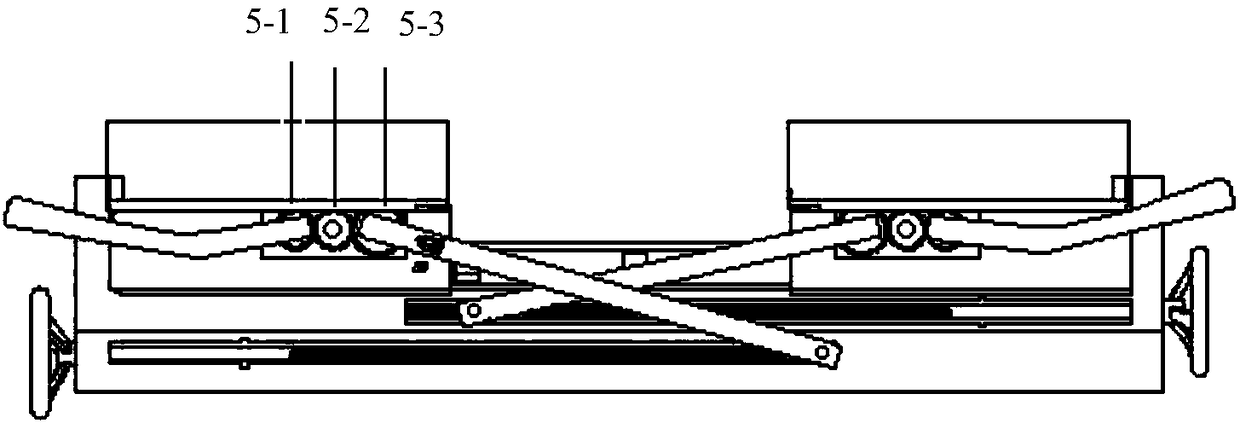

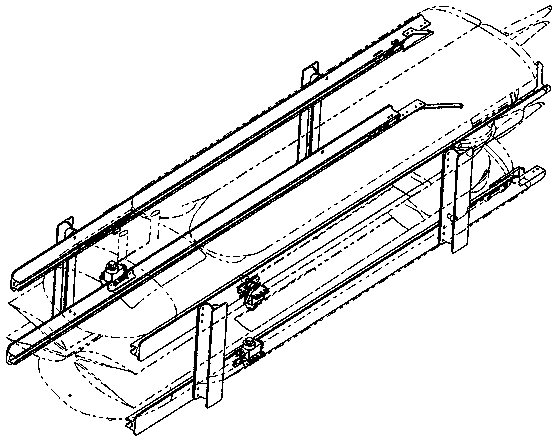

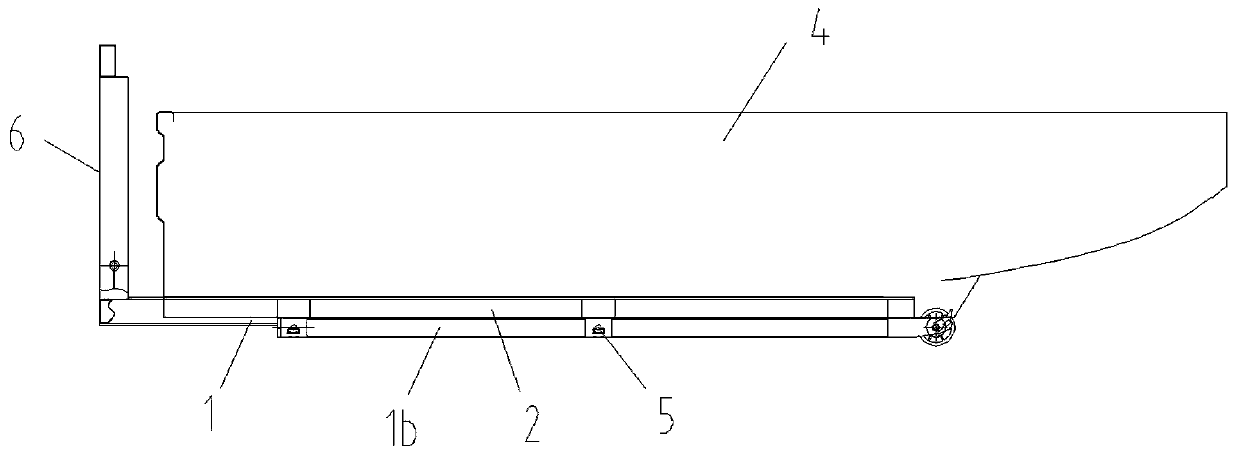

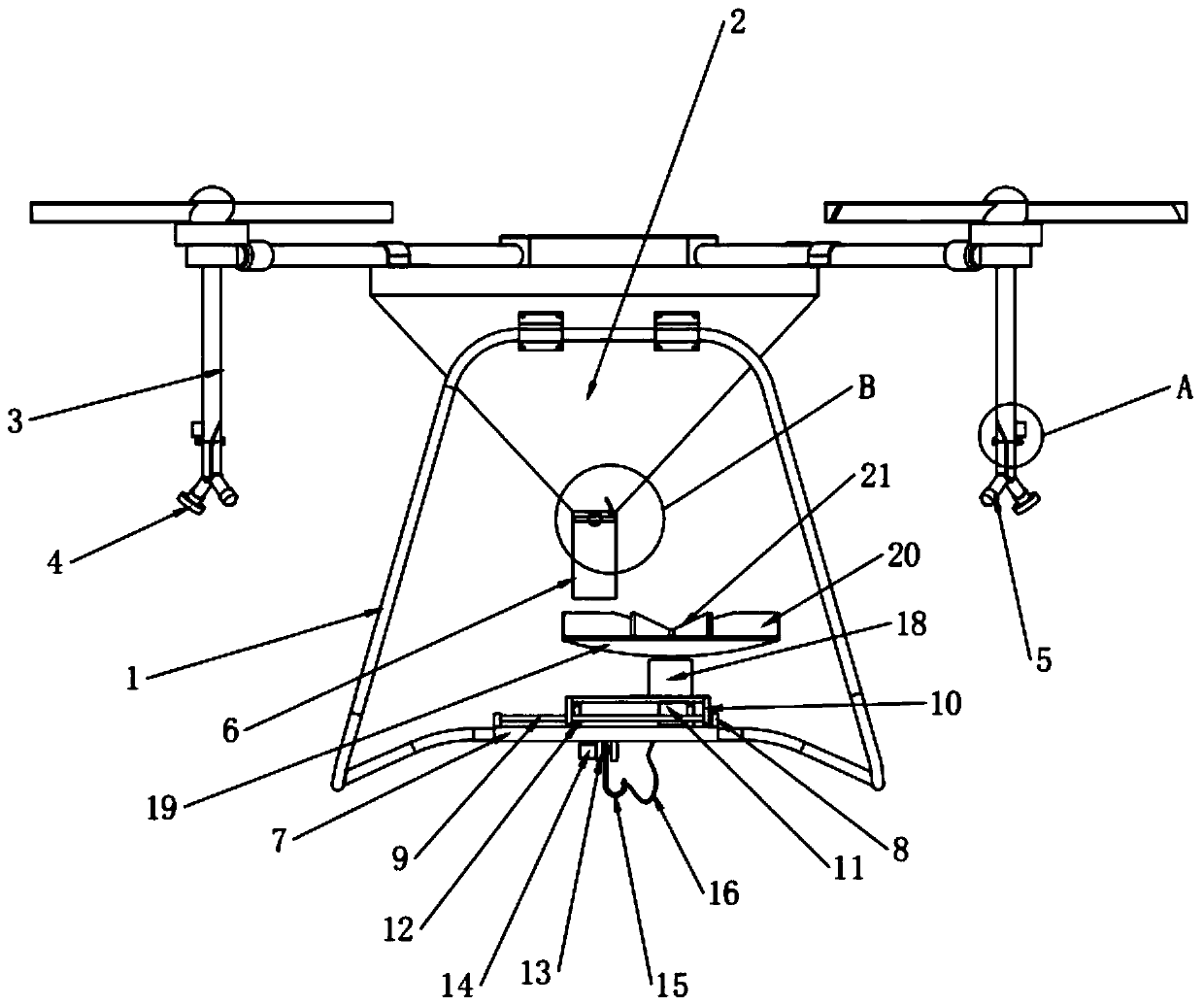

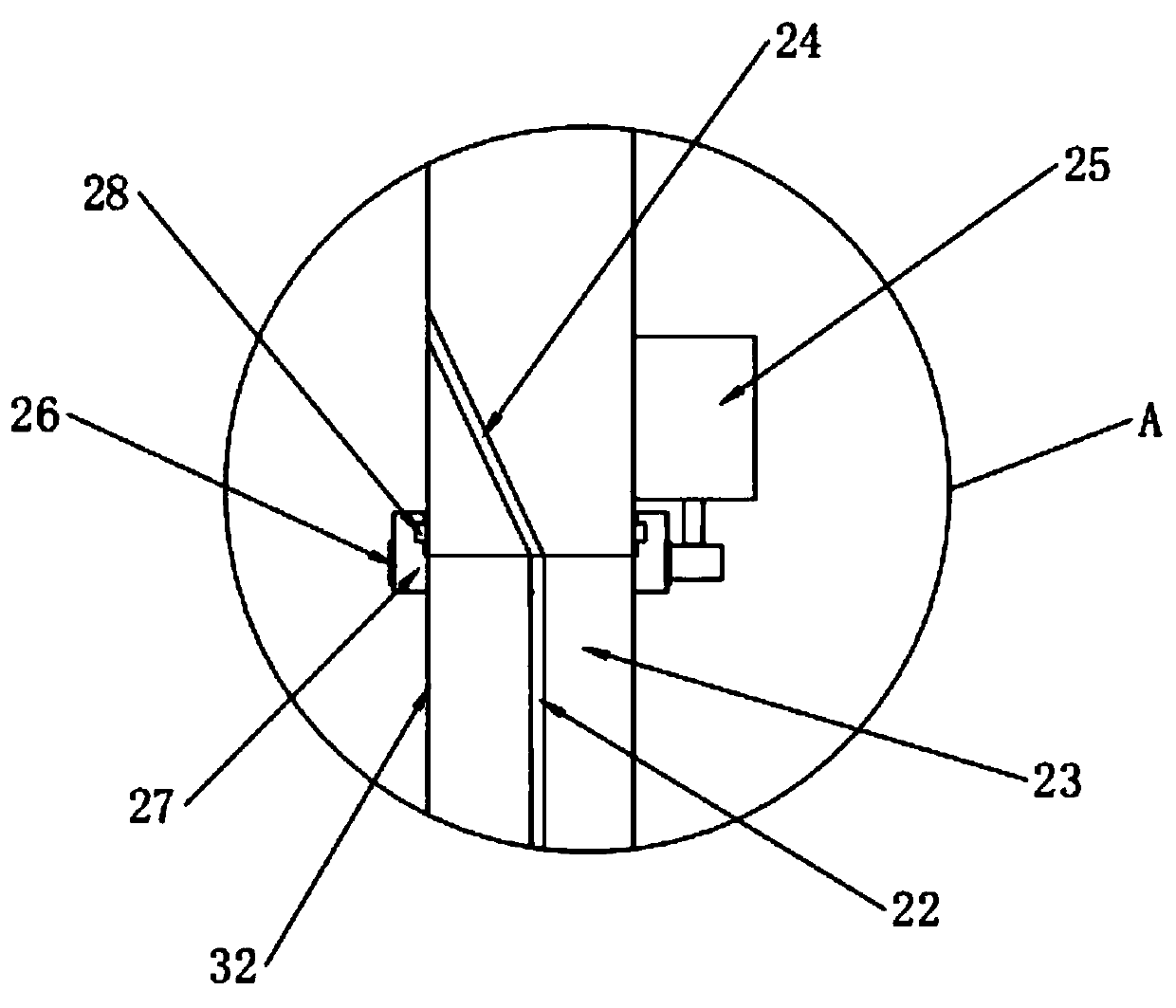

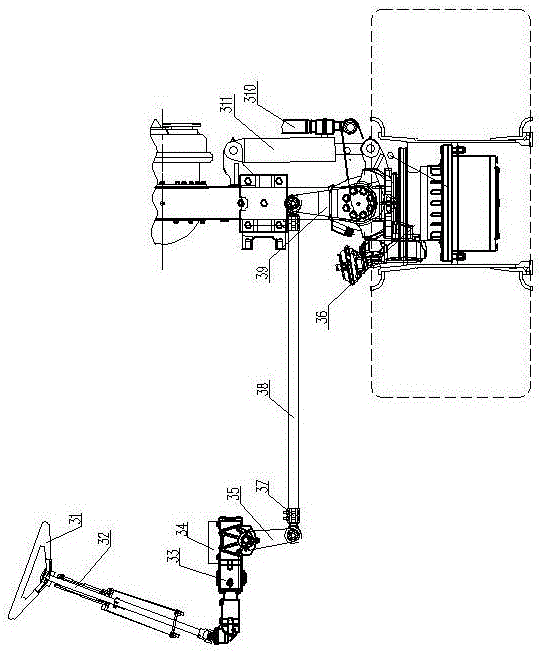

Pod system capable of hoisting two unmanned aerial vehicles simultaneously

The invention belongs to the technical field of aerospace application and relates to a mechanism capable of carrying, locking, automatically unlocking and releasing two small unmanned aerial vehiclesin a pod, in particular to a pod system capable of hoisting the two unmanned aerial vehicles simultaneously. The pod system is characterized by comprising an unmanned aerial vehicle carrying, locking,automatic unlocking and releasing sliding rail mechanism. By applying the unmanned aerial vehicle carrying, locking, automatic unlocking and releasing sliding rail mechanism, pin pullers do not needto be demounted in the maintenance process of the unmanned aerial vehicles during mounting and demounting, and maintenance is convenient and rapid through the manual pin pulling function and front blocking compression springs; the individual difference of the interval of front and rear roller shafts of each unmanned aerial vehicle can be eliminated through an adjustable rear blocking assembly, andreliable fixing can be achieved; front blocking plug pins adopts bevel locking through the weight component, and electric initiation pin pullers are applied, so that the mechanism achieves the function of reliably locking, automatically unlocking and releasing the unmanned aerial vehicles; and the unmanned aerial vehicles are limited, supported and carried by sliding rail assemblies, strength issufficient, and the structure and space arrangement is reasonable.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

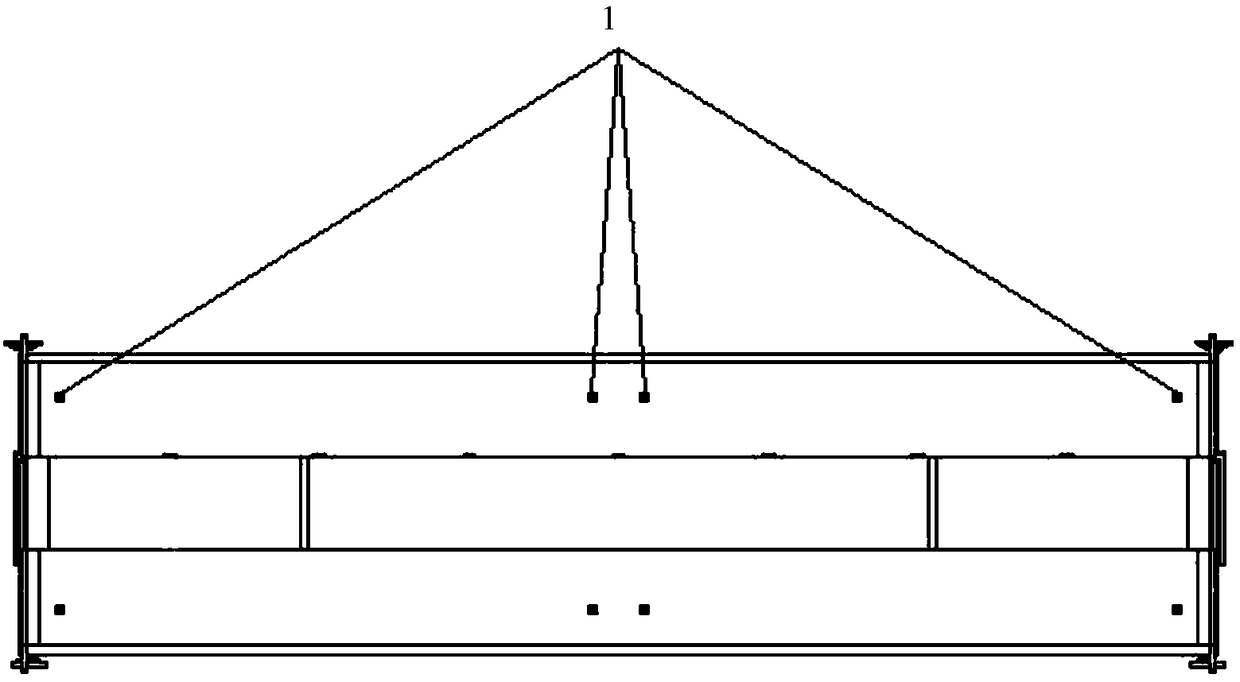

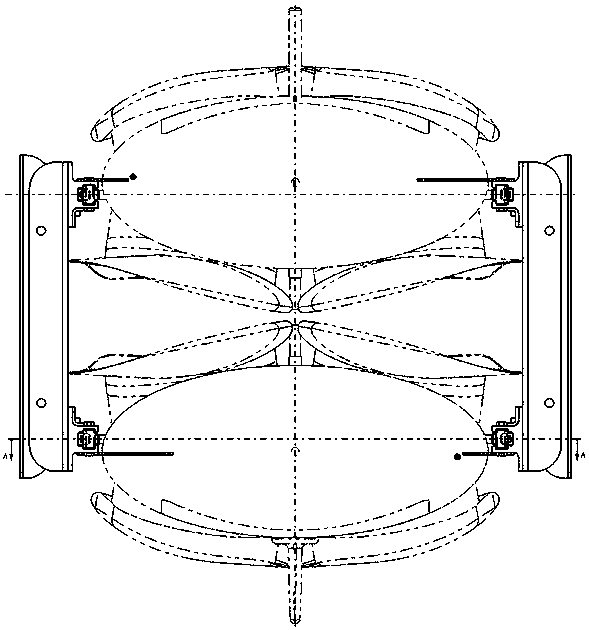

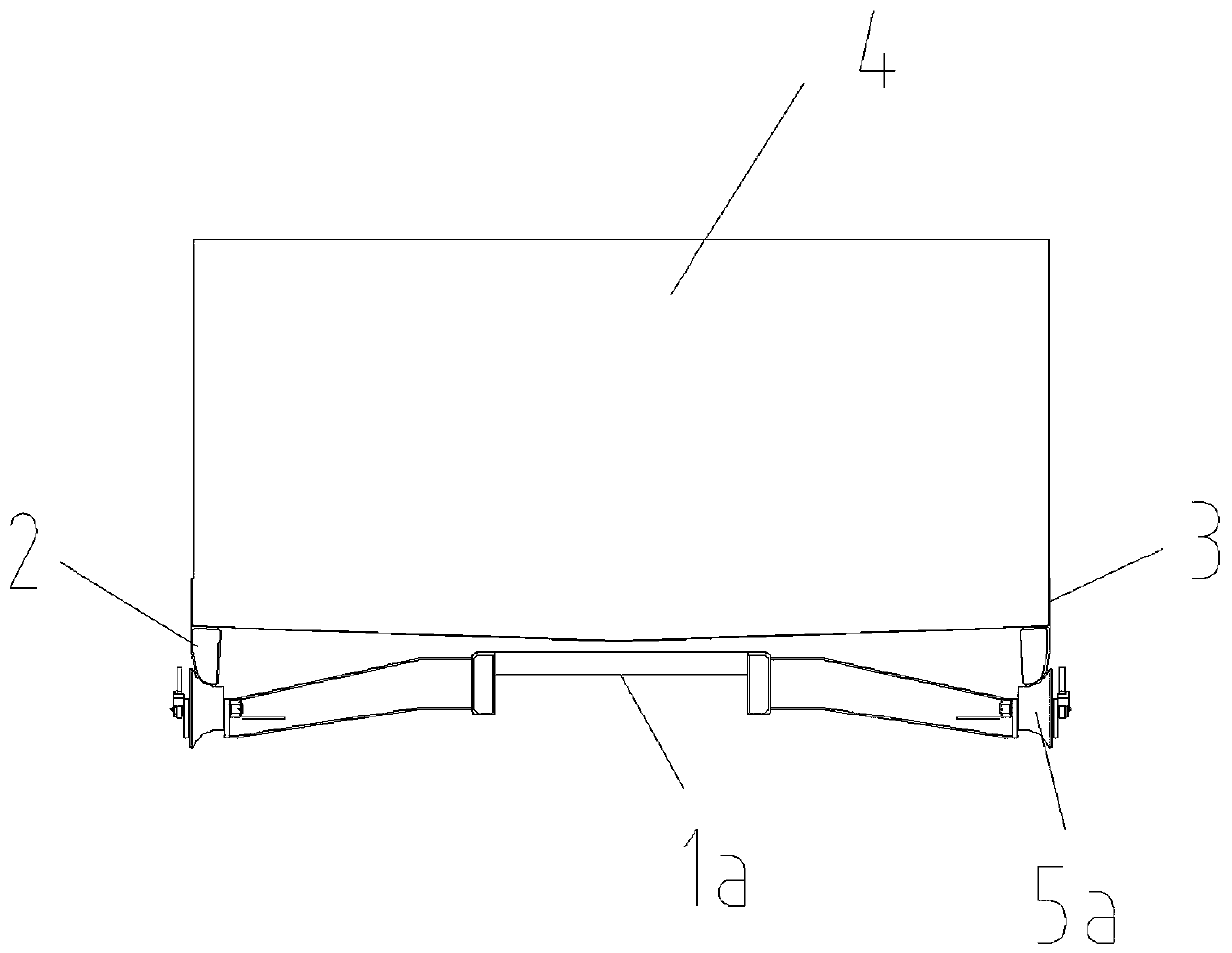

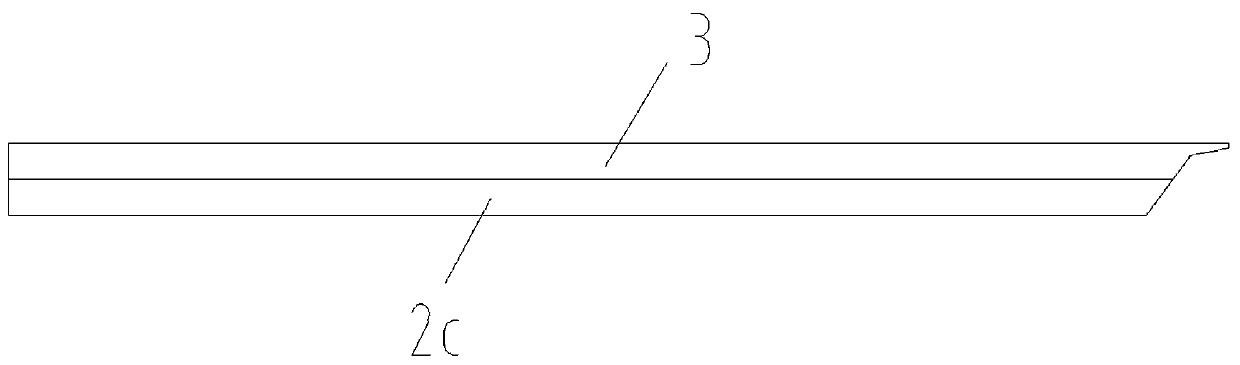

Ship rail carrying device

PendingCN110282104ACarrying outNo adverse consequencesWaterborne vesselsLoading/unloadingMarine engineering

The invention discloses a ship rail carrying device comprising a carrying platform and two rails. Each roller bed comprises a hollow strip-shaped rail body, the cross section of the rail body is in a right-angled fan shape, the top of each rail body is provided with a vertical connecting plate in the axial direction, and the two roller beds are fixed to the two sides of the bottom of a ship through the connecting plates; the two sides of a carrying platform are provided with roller sets; cambered surfaces of the rail bodies can be in fit with the wheel faces of the roller sets; the rails are fixed to the two sides of the bottom of the ship and are matched with the roller sets of the carrying platform, and ship carrying is achieved; and the hollow roller bed only needs increase of the small amount of weight of the ship, and adverse consequences caused after launching can be avoided.

Owner:BENGBU SHENZHOU MACHINERY

Intelligence-driven conveying method and system for calculation of intelligent environment making robots and vehicles

ActiveCN108255180ACarrying outRealize transportationPosition/course control in two dimensionsVehiclesIntelligent environmentComputational intelligence

The invention discloses an intelligence-driven conveying method and system for calculation of intelligent environment making robots and vehicles. The method includes the steps of 1, arranging a groundguide rail between different worktables, and arranging one tabletop guide rail on each worktable; 2, adopting a tabletop robot positioned on the object taking worktable for grabbing objects on an assigned object taking position of the object taking worktable; 3, moving the robot along the ground guide rail and conveying the grabbed objects to the other worktable; 4, after a tabletop robot positioned on the object placing worktable grabs the objects, moving the objects to an assigned object placing position of the object placing worktable to complete transportation of the objects between the worktables; 5, combining with a grayscale neural network and a PID neural network to create an electric quantity prediction model to decide the next move of a moving robot. Through cooperative work ofthe tabletop robots and the moving robot, fixed-time fixed-position transportation of the objects in an automated lab is completed, and under cooperation with the arrangement of a charging area of themoving robot, all-weather transportation of the automated lab is achieved.

Owner:CENT SOUTH UNIV

Agricultural unmanned aerial vehicle

InactiveCN110979683AIncrease the throwing radiusIncrease running speedAircraft componentsSeed depositing seeder partsMaterial typeAutomotive engineering

Owner:WEIFANG ENG VOCATIONAL COLLEGE

A Distributed Environmental Robot and Vehicle Mobile Interconnection Carrying Method and System

ActiveCN108280518BCarrying outRealize transportationNeural learning methodsVehiclesLearning machineProportion integration differentiation

The invention discloses a distributed environment robot and vehicle moving interconnection carrying method and system. The method includes the steps: firstly, arranging guide rails between a worktableof a transportation start point and a worktable of a transportation end point and on the worktables, and arranging landmarks on ground guide rails; secondly, grabbing objects from an object taking designated position by a table top robot positioned on an a object taking worktable; thirdly; enabling a moving robot to move along the ground guide rails and grab and transport the object to the otherworktable; fourthly, enabling a tabletop robot positioned on an object placing worktable to grab and move the an object to an object placing designated position of the object placing worktable; fifthly, building an electric quantity prediction model to decide next action of the moving robot by combining an extreme learning machine with a PID (proportion integration differentiation) neural network.The table top robot and the moving robot are cooperated, transportation of objects in an industrial laboratory is achieved at regular time and place, and all-weather transportation in the industriallaboratory is achieved.

Owner:CENT SOUTH UNIV

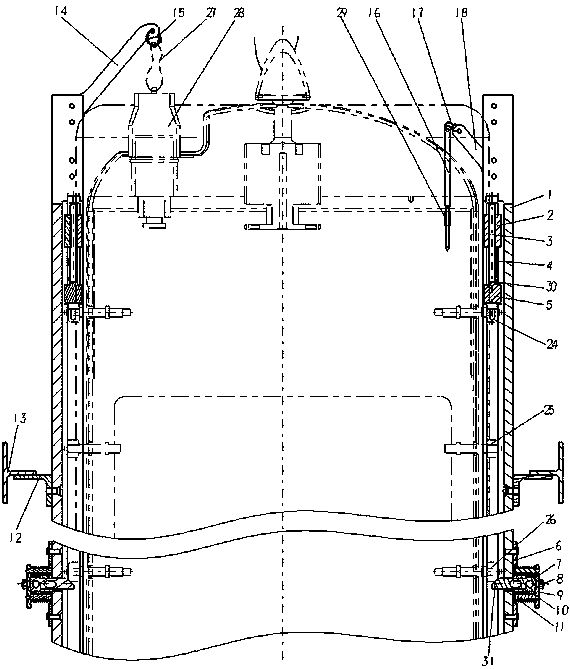

Vertical bin transfer device

PendingCN111533593ACarrying outMeet the use requirementsBio-organic fraction processingOrganic fertiliser apparatusStructural engineeringElectric control

A vertical bin transfer device is disclosed. The device structurally comprises a fixed structure frame, a movable structure frame, a lifting mechanism, a connection mechanism and an electric control system, wherein the fixed structure frame is located on one side of a multi-layer composting system, and is provided with a vertical direction limiting rail inside; the movable structure frame is located in the fixed structure frame; the lifting mechanism is located at the top of the fixed structure frame and connected with the movable structure frame to achieve vertical movement of the movable structure frame in the fixed structure frame. Horizontal bin transfer equipment carries pile turning equipment into the movable structure frame; the connection mechanism is located in the movable structure frame, and a channel is formed by a telescopic assembly of the connection mechanism and a workshop track or a walking tread. The electric control system controls the device to implement operation.The device has the advantages of being simple in structure, convenient to operate and not prone to failure.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

Composite enzyme for pulp making and its preparation method and use method

The invention provides a composite enzyme for pulp making, the composite enzyme includes an enzyme carrier and a biological enzyme, the enzyme carrier is graphene oxide, and the biological enzyme is cellulase, hemicellulase, and lignin degrading enzyme and one or more of the pectinases, the biological enzymes are attached and fixed on the enzyme carrier. The present invention adopts the above method, which can effectively immobilize biological enzymes on the graphene oxide carrier, fully utilizes the high proportion surface area and good biocompatibility of graphene oxide, and secondly, the functional groups rich in its surface are also acidic. The chemical properties of the graphene oxide can neutralize the alkaline ions in the solution, reduce the local pH value around the graphene oxide, and facilitate the activity of the biological enzymes attached to its surface. The use of graphene oxide to immobilize the biological enzymes makes the biological Most of the enzymes are kept in the liquid environment for secondary use, which improves the utilization efficiency of biological enzymes and reduces production waste.

Owner:秾源科技(北京)有限公司

A nanotube-based fluorescent labeling carrier and its preparation method

ActiveCN106680252BPrecise size controlGuaranteed decompositionFluorescence/phosphorescenceNanowireLength wave

The invention discloses a nanotube-based fluorescence marked carrier and a preparation method thereof. The fluorescence marked carrier comprises a nanotube inner wall, a quantum structure and a nanotube outer wall. The size of the nanotube structure is designed according to the characteristics of a simulated carrying object, and the size of the nanotube structure is regulated and controlled accurately by controlling the growth condition; in the fixed-temperature annealing process, a nanowire in a core-shell structure is guaranteed to be decomposed completely and the quantum structure limited between the nanotube inner wall and the nanotube outer wall is not damaged; the fluorescence marked part of the nanotube adopts a semiconductor quantum structure, has high fluorescence intensity, long duration time and stable photochemical property, is insusceptible to photobleaching and realizes high-efficiency radiative recombination; furthermore, continuous broad spectrum excitation can be adopted, the absorption coefficient is big, fluorescence emission peak is narrow, wavelength trailing is avoided, and the distinguishing degree is high; the nanotube structure can realize fluorescence marked carrying of the carrying object in the tube and also can perform the traditional wrapping or combined type fluorescence marked carrying.

Owner:PEKING UNIV

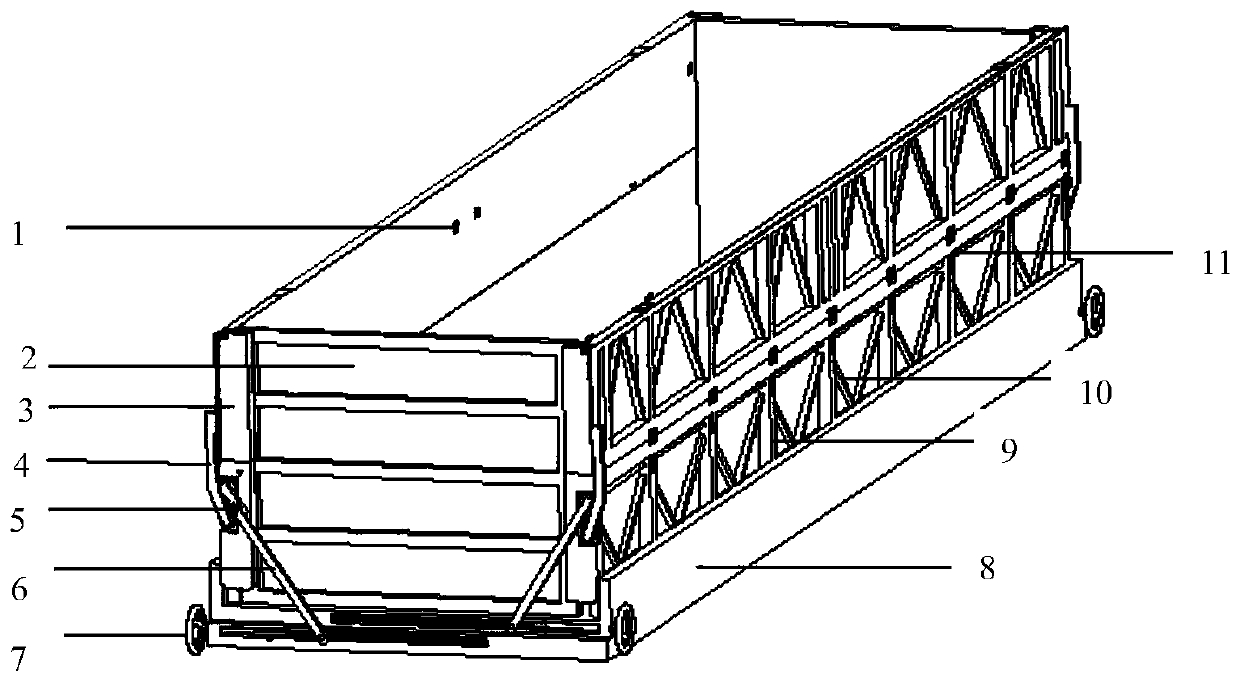

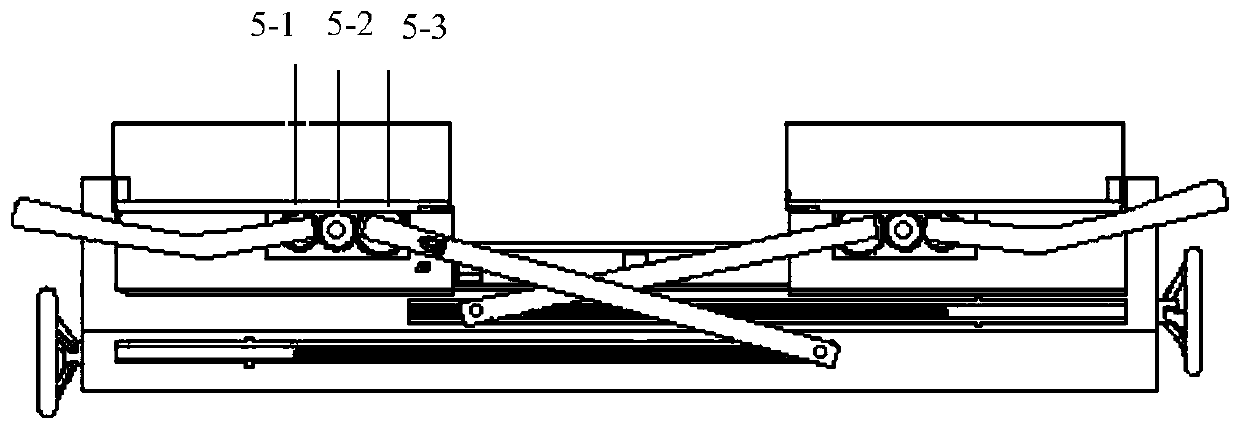

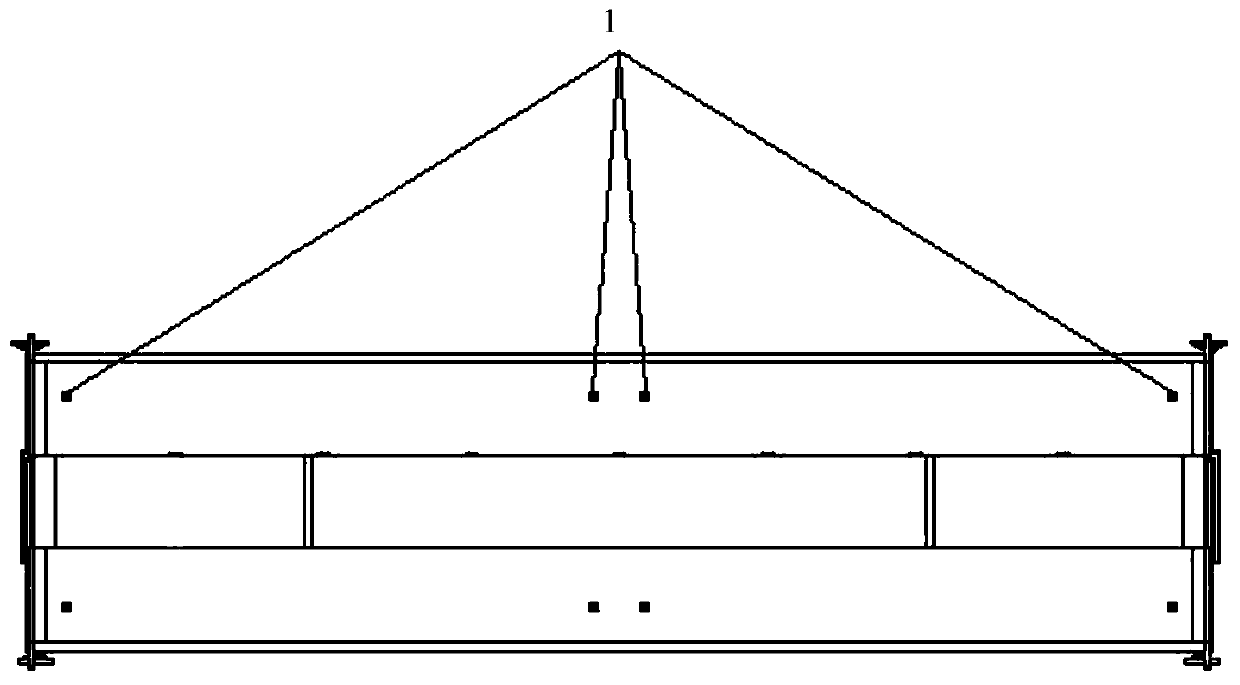

Chassis device based on loads and traction

InactiveCN106394709ACarrying outMeet the needs of different delivery formsTractor-trailer combinationsFluid steeringRolling chassisAutomotive engineering

A chassis device based on loads and traction comprises a running chassis with a machine frame (1) and an automobile traction saddle (8) which is arranged to be connected with the machine frame (1) in an overturning mode and used for being connected with other devices through a traction pin. The automobile traction saddle (8) is placed into an accommodating window of the running chassis, so that the machine frame (1) and the automobile traction saddle (8) form a plane, and cargoes are transported. The automobile traction saddle (8) is installed on the machine frame (1) and connected with the other devices through the traction pin, so that the other devices are pulled. The running chassis is not directly used any more, so that the requirements for different transport modes are met, and the transport efficiency is improved.

Owner:CHINA NAT HEAVY DUTY TRUCK GRP TAIAN WUYUESPECIAL VEHICLE

Carrier and method of delivery

ActiveCN103332459BCarrying outSemiconductor/solid-state device manufacturingCharge manipulationEngineeringMechanical engineering

Owner:BOE TECH GRP CO LTD +1

An intelligent manufacturing environment robot and vehicle computing intelligent drive delivery method and system

ActiveCN108255180BCarrying outRealize transportationPosition/course control in two dimensionsVehiclesIntelligent environmentComputational intelligence

The invention discloses an intelligent manufacturing environment robot and vehicle computing intelligent drive transportation method and system. The method includes the following steps: Step 1: Set ground guide rails between different workbenches, and set a desktop guide rail on the workbench; Step 2 : The desktop robot located on the fetching workbench grabs the object from the designated position on the fetching workbench; Step 3: The mobile robot moves along the ground guide rail and grabs the object and transports it to another workbench; Step 4: Located on the object placing workbench After the desktop robot on the workbench grabs the object, it moves to the designated position on the workbench to complete the transportation of the object between workbench; Step 5: Combine the grayscale neural network and the PID neural network to establish a power prediction model. The mobile robot makes decisions about its next move. Through the collaborative work of desktop robots and mobile robots, the scheduled and fixed-point transportation of objects in the automated laboratory is completed, and with the setting of the mobile robot charging area, all-weather transportation in the automated laboratory is realized.

Owner:CENT SOUTH UNIV

A smart laboratory robot carrying method and system

ActiveCN107992061BCarrying outEfficient and accurate deliveryPosition/course control in two dimensionsShortest distanceShort distance

The invention discloses a smart laboratory robot transportation method and system. The method includes the following steps: Step 1: Set a ground guide rail between the workbench where the starting point and end point of transportation are located, and set a desktop guide rail on the workbench; Step 2 : The desktop robot located on the fetching workbench grabs the object from the designated position on the fetching workbench; Step 3: The mobile robot moves along the ground guide rail and grabs the object and transports it to another workbench; Step 4: Located on the object placing workbench After the desktop robot on the workbench grabs the object, it moves to the designated position on the workbench to complete the transportation of the object between workbench. Through the collaboration of desktop robots and mobile robots, the scheduled and fixed-point transportation of objects in the automated laboratory is completed. The desktop robot is responsible for short-distance pickup and placement of objects, and the mobile robot uses guide rails and landmarks to complete long-distance transportation of objects, and cooperates with the setting of charging areas to achieve Round-the-clock transportation for automated laboratories.

Owner:CENT SOUTH UNIV

A kind of track open general vehicle

ActiveCN108238057BCarrying outImprove substitutionAxle-box lubricationWagons/vansCamMechanical engineering

A universal rail flat-open wagon mainly comprises a container lock hole, an end wall, an upper side wall, an upper side wall ejector rod, a gear A, a gear B, a gear C, a lower side wall ejector rod, aball screw, a bottom frame, a lower side wall, diagonal bracings, side columns, a locking device, lock pins, lock rods, a cam, a rotating shaft hole, an end wall lock hole, an end wall rotating shaft, an end wall lock, a handle and a rotary handlebar. The functions of an open wagon and a flat wagon are shared, and granular goods can be transported when the flat-open wagon is used as an open wagon(such as coal transportation, and the work condition of a car dumper can be adapted); and when used as a flat wagon, the flat-open wagon can complete transportation of container flat cars. Vehicle type substitution is enhanced, the empty-wagon walking rate is lowered, and the universal rail flat-open wagon has important significance for improving railway transporting efficiency.

Owner:YANSHAN UNIV

A kind of automatic guide rail carrying device and robot cooperative carrying method and system

ActiveCN108287548BCarrying outLow failure rateBiological neural network modelsMachine learningControl theoryLaboratory facility

The present invention discloses an automatic guide rail carrying device and robot cooperative carrying method and system. The method comprises the following steps of: the step 1: arranging a ground guide rail arranged between workbenches from a transportation starting point and a transportation end point and guide rails arranged on the workbenches, and arranging a landmark on the ground guide rail; the step 2: grabbing an object from an object-fetching assigned position by a desktop robot located on an object-fetching workbench; the step 3: allowing a mobile robot to move through the ground guide rail and grab an object to the other workbench; the step 4: after a desktop robot located on an object-put workbench grabs the object, moving the desktop robot to an object-put assigned position of the object-put workbench; and the step 5: combining an extreme learning machine and a wavelet neural network to establish an electric quantity prediction model to perform decision of the next motionof the mobile robot. The automatic guide rail carrying device and robot cooperative carrying method and system complete timing and fixed-point transportation of industrial laboratory objects throughcooperation of the desktop robot and the mobile robot so as to achieve round-the-clock transportation of the industrial laboratory.

Owner:CENT SOUTH UNIV

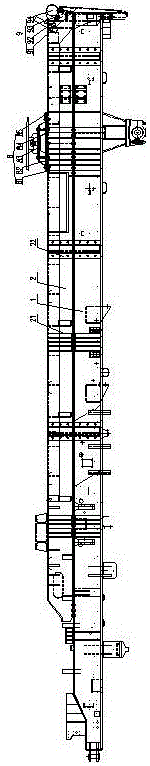

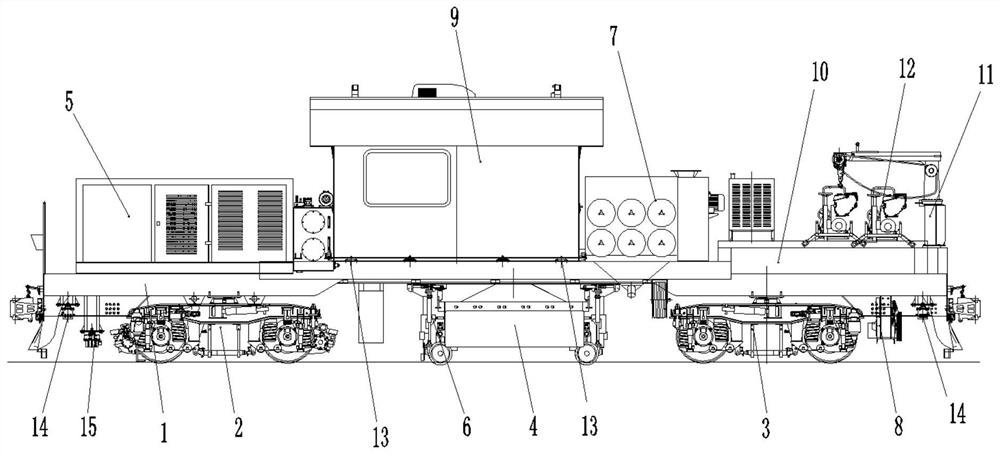

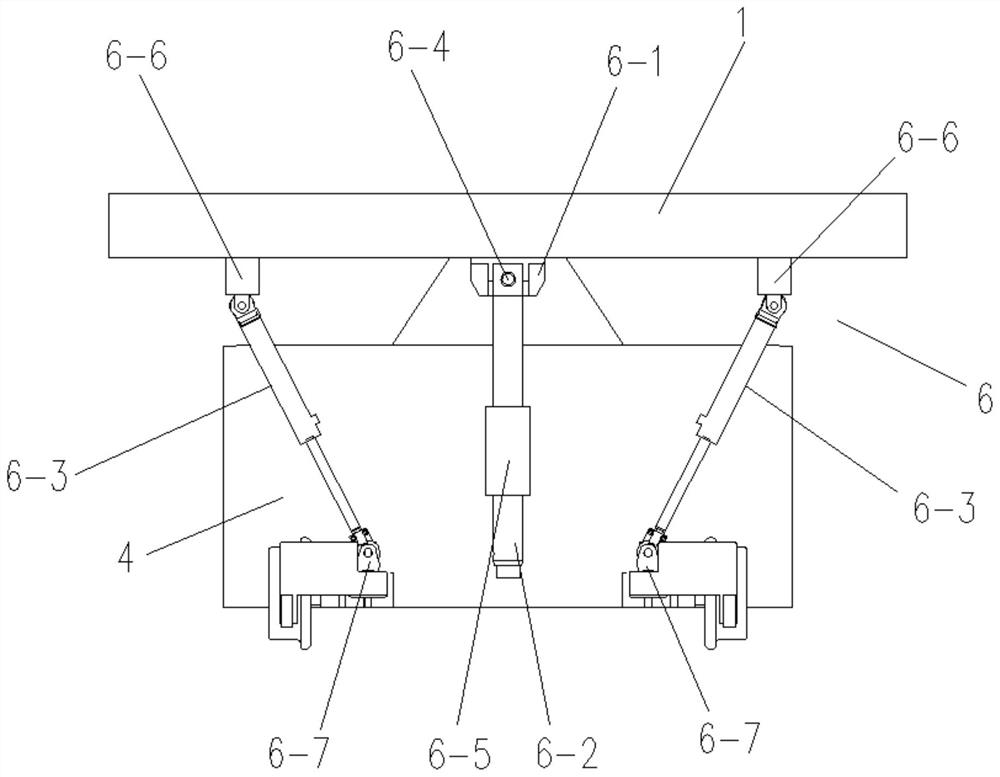

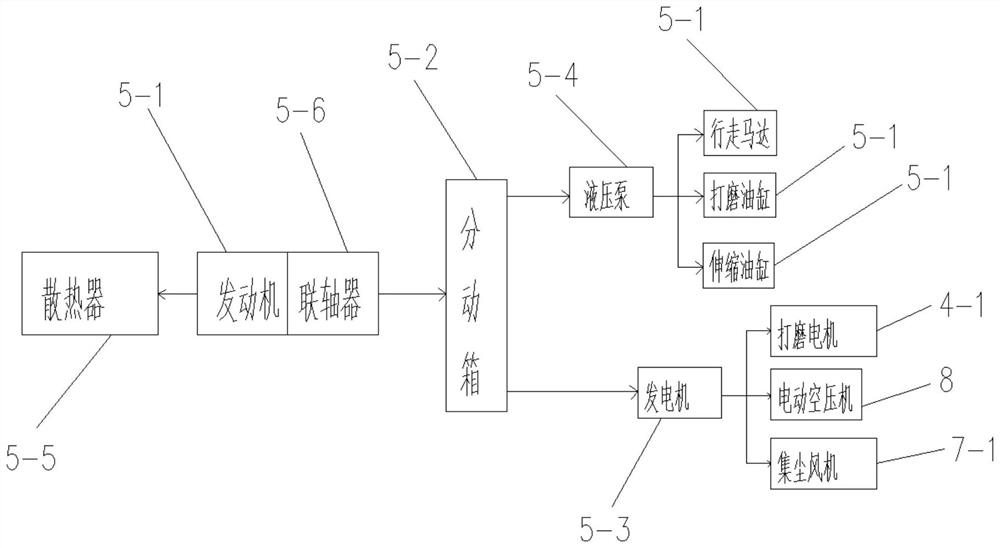

Medium-sized grinding wagon for railway work section

PendingCN111959536AImproved sanding capacity and sanding qualityReduce the difficulty of grindingNon-rotating vibration suppressionRailway track constructionGrindingVehicle frame

The invention provides a medium-sized grinding wagon for a railway work section. A power bogie and a non-power bogie are arranged on the lower end surface of a frame; a grinding trolley used for grinding the surface of a steel rail is arranged between the power bogie and the non-power bogie. The grinding trolley is connected with a grinding position adjusting mechanism which is arranged on the lower end face of the frame and used for adjusting the height and the grinding direction of the grinding trolley, and a power system arranged on the upper end face of the frame provides power for the grinding position adjusting mechanism, the power bogie and the grinding trolley. The grinding position adjusting mechanism connected with the grinding trolley and used for adjusting the height and the grinding direction of the grinding trolley is arranged on the lower end face of the frame; the grinding trolley has the up-down freedom degree and the grinding trolley has good operation performance ona curve, short-distance operation points and turnout related areas, so that the grinding capacity and the grinding quality of the grinding trolley are improved, the steel rail grinding difficulty is lowered, limitation is small, and the application range is wide.

Owner:BAOJI CSR TIMES ENG MACHINERY +1

Construction method of nutrient carrying system based on nano-food

The invention discloses a construction method of a nutrient carrying system based on nano-food. The construction method is characterized in that (1) one or more nutrients and a nano-food are mixed uniformly to form a mixture, wherein a mass ratio of the one or more nutrients and the nano-food is 1: (4 to 200); a lipid content of the nano-food is less than 12%; and a peak value of a particle size distribution curve of the nano-food is less than 400 nm; (2) if the above mixture is in a solution system, a solution concentration is adjusted to a concentration of 0.5 to 55% by nano-food weight; a solution pH is adjusted to a pH of 2.2 to 13; an ion strength converted into a sodium ion concentration is in a range of 0.001 to 5 mol / L; and at a temperature of 0 to 85 DEG C, an ultrasonic vibration process adopting a power density of 0 to 65 W / cm <2> is carried out and nano-food clusters are obtained after a gathering process for 1 to 48 hours; or if the above mixture is in a solid state, nano-food clusters are obtained through a gathering process lasting for 2 to 80 hours under the conditions of a pressure intensity controlled in a range of 0.05 to 4 MPa, a temperature controlled in a range of 0 to 230 DEG C and a relative humidity controlled in a range of 0 to 100%; and (3) the nano-food clusters are packaged in a vacuum and then are stored at normal temperature or low temperature. Through the construction method, nutrients are wrapped in nano-food clusters thus nutrient carrying is realized; a stability of carried nutrients is improved and nutrients carried by nano-food clusters can be stored in liquid form or solid form thus the degradation of nutrients can be reduced or even avoided and conditions of after processing are relaxed; and a bioavailability of nutrients carried by nano-food clusters is improved greatly.

Owner:杭州纳福载运科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com